Page 1

7 CH Power Management IC

RT9971

General Description

The RT9971 is a complete power supply solution for digital

still cameras and other hand held devices. The RT9971 is

a multi-channel power management IC including two stepup DC/DC converters, two step-down DC/DC converters,

one selectable step-up/step-down DC/DC converter, one

inverting DC/DC converter and one WLED driver.

The RT9971 is designed to fulfill the applications for DSC

just as follows :

CH1 is a synchronous step-up output for motor or DSC

system I/O power

CH2 is a selectable synchronous step-up/step-down

output for motor or DSC system I/O power

CH3 and CH4 are synchronous step-down outputs for DSP

core and memory power supply

CH5 is a high voltage step-up output for CCD bias power

supply

CH6 is an inverting output for negative CCD bias power

supply

CH7 is a high voltage step-up output for driving WLED

Features

l One Synchronous Step-Up or Step-Down

Selectable Convertor

l Support 2AA or Li-ion Battery Applications

l Preset On/Off Sequence

l 5 CHs with Internal Compensation

l All Power Switches Integrated

l Up to 95% Efficiency

l 100% (max) Duty Cycle for Step-Down Converter

l Adjustable Output Voltage

l LED PWM Dimming Control

l LED Open Protection

l Transformerless Inverting Converter for CCD

l Fixed 1MHz Switching Frequency at CH1 to CH7

l RTC_LDO/SW1 Selectable by CN Pin

l 40-Lead WQFN Package

l RoHS Compliant and Halogen Free

Applications

l Digital Still Camera

l PDA

l Portable Device

For the CH2, the step-up or step-down converter, operation

mode can be selected by the SEL pin. Among all CHs,

there are 5 CHs with the built-in internal compensation.

The RT9971 also provides a transformerless inverting

converter for supplying the CCD power. For the

synchronous step-up and step down converters, the

efficiency can be up to 95%. The IC provides load

disconnection for CH 1 and CH 5. The IC has selectable

RTC_LDO/SW1 that can be determined by the CN pin.

The RT9971 is able to support Li-ion and 2AA battery

applications. The RT9971 provides WLED open protection,

current limit, thermal shutdown protection, over voltage

and under voltage protection to achieve complete

protection. The RT9971 is available in WQFN-40L 5x5

package.

Ordering Information

RT9971

Package Type

QW : WQFN-40L 5x5 (W-Type)

Lead Plating System

G : Green (Halogen Free and Pb Free)

Note :

Richtek products are :

} RoHS compliant and compatible with the current require-

ments of IPC/JEDEC J-STD-020.

} Suitable for use in SnPb or Pb-free soldering processes.

DS9971-01 April 2011 www.richtek.com

1

Page 2

RT9971

Pin Configurations

PVDD1

LX6

PVDD6

CP

CN

PNEG

FB6

FB4

EN6

LX4

(TOP VIEW)

EN2

COMP1

LX1

40

1

2

3

4

5

6

7

8

9

10

11

PVDD4

FB1OKVOUT1

39

EN5

SW5I

SW5O

GND

FB5

FB2

COMP2

EN134

LX2

35363738

34

VREF

313233

30

PVDD2

29

VDDM

28

CFB7

27

GND

26

LX7

25

LX5

24

VOUT7

FB3

23

41

22

EN7

21

LX3

201918171615141312

SEL

RTC_R

PVDD3

RTC_PWR

WQFN-40L 5x5

DS9971-01 April 2011www.richtek.com

2

Page 3

Typical Application Circuit

→

→→→→→

For 2AA

V

V

OUT_SW1

V

3.3V

OUT_CH2

3V3

3V3

BAT

V

OUT_CH1

C5

10µFx2

V

OUT_CH3

2.5V

V

OUT_CH4

1.8V

R19

50k

10µF

C12

10µF

V

C9

BAT

3V3

470k

R4

470k

R5

88.7k

Q1

C1

10µF

5V

C8

10uF

C11

10uF

R1

R2

150k

10µF

R7

768k

R8

360k

R9

470k

R10

374k

C2

4.7pF

C4

C6

4.7pF

C22

10µF

C3

560pF

C7

560pF

OFF

L22.2µH

C10

C13

33pF

ON

V

L1

2.2µH

10µF x 2

R3

39k

R6

39k

4.7µH

22pF

4.7µH

BAT

C27

L3

L4

40

37

38

36

35

31

30

34

33

20

21

23

11

10

39

32

12

17

22

1

8

9

LX1

PVDD1

FB1

COMP1

OK

VOUT1

LX2

PVDD2

FB2

COMP2

PVDD3

LX3

FB3

PVDD4

LX4

FB4

EN2

EN134

EN5

EN6

SEL

EN7

3V3

29

VDDM

RT9971

C23

1µF

SW5O

SW5I

PVDD6

VREF

VOUT7

CFB7

RTC_R

RTC_PWR

PNEG

GND

V

BAT

25

LX5

13

14

15

FB5

3

C25

1µF

2

LX6

7

FB6

16

26

LX7

24

28

18

19

4

CP

5

CN

6

27, Exposed Pad (41)

L5

10µH

D3

D4

R16

10k

C29

1µF

L6

10µH

10µH

C28

0.1µF

D5

C24

1µF

C14

10µF/25V

C15

1nF

V

BAT

R13

63.4k

R14

11.3k

L7

RTC Reset

RTC 3.25V

C26

1µF

15V

R11

1000k

R12

90.9k

RT9971

C16

10µF/25V

V

-7V

C18

C17

10µF/16V x 2

1nF

C19

0.1µF

D1

C20

D2

1µF/16V

R15

10

V

OUT_CH5

15V

OUT_CH6

V

BAT

WLED

Note :

(1) SEL = High, CH2 is Step -Up, CN Connect to CAP

(2) V

= 1.8V to 3.2V

BAT

Timing Diagram

Power On Sequence : CH1 Step -Up 3.3V CH3 Step -Down 2.5V CH4 Step -Down 1.8V (CH2 Step -Up 5V and

SW1 3.3V)

Power Off Sequence : (CH2 Step -Up 5V and SW1 3.3V) CH4 Step -Down 1.8V CH3 Step -Down 2.5V CH1

Step -Up 3.3V

VDDM

EN2, EN134

V

V

V

V

OUT_CH1

OUT_CH3

OUT_CH4

OUT_SW1

V

OUT_CH2

3.3V

2.5V

1.8V

3.3V

5V

DS9971-01 April 2011 www.richtek.com

User define

3.5ms

3.5ms

3.5ms

3.5ms

3.5ms

IC shutdown

Wait until FB3 < 0.1V

Wait until FB4 < 0.1V

Wait until V

OUT1

< 0.4V

Depends on loading

3

Page 4

RT9971

→→→→→

→

For Li-ion

V

OUT_CH1

5V

RTC 3.25V

V

BAT

or 5V

V

BAT

V

BAT

C1

10µF x 2

V

C4

10µF

C8

10µF

C11

10µF

OUT_CH2

3.3V

C5

10µF

V

OUT_CH3

2.5V

10µF

V

OUT_CH4

1.8V

10µF

C9

C12

V

R1

470k

R2

88.7k

BAT

R4

470k

R5

150k

R7

768k

R8

360k

R9

470k

R10

374k

C2

4.7pF

560pF

C3

OFF

C22

10µF

C21

0.22F

C6

10pF

2200pF

C7

C10

22pF

C13

33pF

ON

L1

2.2µH

R3

39k

V

BAT

L2

4.7µH

4.7µH

4.7µH

L3

L4

R6

15k

40

37

38

36

35

30

31

34

33

20

21

23

11

10

39

32

12

17

22

1

8

9

LX1

PVDD1

FB1

COMP1

OK

VOUT1

PVDD2

LX2

FB2

COMP2

PVDD3

LX3

FB3

PVDD4

LX4

FB4

EN2

EN134

EN5

EN6

SEL

EN7

V

BAT

29

VDDM

RT9971

C23

1µF

SW5O

SW5I

PVDD6

VREF

VOUT7

CFB7

RTC_R

RTC_PWR

PNEG

V

25

LX5

13

14

15

FB5

3

2

LX6

7

FB6

16

26

LX7

24

28

18

19

4

CP

5

CN

6

27, Exposed Pad (41)

GND

BAT

C25

1µF

L5

10µH

D3

D4

R16

10k

10µH

R18

10k

V

L6

10µH

C24

1µF

C14

10µF/25V

C15

1nF

BAT

L7

D5

RTC Reset

RTC 3.25V

R13

63.4k

R14

11.3k

V

BAT

C26

1µF

15V

R11

1000k

R12

90.9k

C17

1nF

10

D1

D2

R15

C19

0.1µF

C16

10uF/25V

C18

10µF/16V x 2

C20

1µF/16V

V

OUT_CH5

15V

V

OUT_CH6

-7V

V

BAT

WLED

Note :

(1) SEL = Low, CH2 is Step -Down, CN Pull High

(2) V

= 2.7V to 4.2V

BAT

Timing Diagram

Power On Sequence : CH1 Step -Up 5V CH3 Step -Down 2.5V CH4 Step -Down 1.8V CH2 Step -Down 3.3V

Power Off Sequence : CH2 Step -Down 3.3V CH4 Step -Down 1.8V CH3 Step -Down 2.5V CH1 Step -Up 5V

VDDM

EN2, EN134

V

V

OUT_CH3

V

OUT_CH4

V

OUT_CH2

OUT_CH1

5V

2.5V

1.8V

3.3V

4

User define

3.5ms

3.5ms

3.5ms

3.5ms

IC shutdown

Wait until FB3 < 0.1V

Wait until FB4 < 0.1V

Wait until FB2 < 0.1V

DS9971-01 April 2011www.richtek.com

Page 5

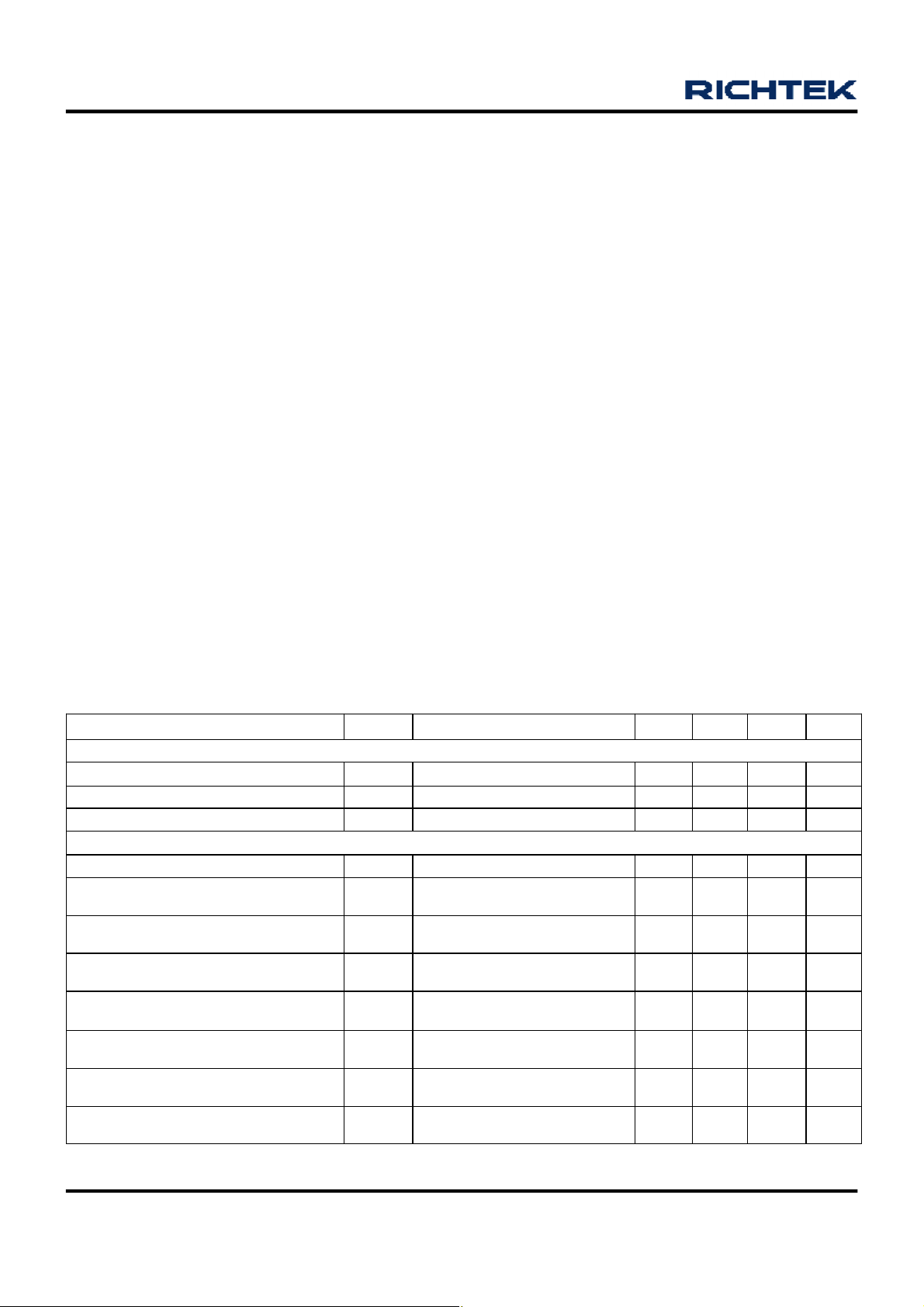

Table 1. Recommended Components for the Typical Application Circuit

Channel CH3

RT9971

Formula V

V

OUT_CH3

(V) 2.5 1.8 1.5 1.3 1.2 1

OUT_CH3

= (1+R7/R8) x 0.8

L3 (µH) 4.7 4.7 4.7 4.7 4.7 4.7

R7 (kΩ) 768 470 330 237 187 23.2

R8 (kΩ) 360 374 374 374 374 93.1

C10 (pF) 22 33 47 68 82 47

C9 (µF) 10 10 10 10 10 10

Channel CH4

Application V

V

OUT_CH4

(V) 2.5 1.8 1.5 1.3 1.2 1

OUT_CH4

= (1+R9/R10) x 0.8

L4 (µH) 4.7 4.7 4.7 4.7 4.7 4.7

R9 (kΩ) 768 470 330 237 187 23.2

R10 (kΩ) 360 374 374 374 374 93.1

C13 (pF) 22 33 47 68 82 47

C12 (µF) 10 10 10 10 10 10

Channel CH5

Formula V

V

OUT_CH5

(V) 12 13 14 15 15.5 16

OUT_CH5

= (1+R11/R12) x 1.25

L5 (µH) 10 10 10 10 10 10

R11 (kΩ) 820 820 953 1000 820 886

R12 (kΩ) 95.3 86.6 93.1 90.9 71.5 75

C15 (pF) 1000 1000 1000 1000 1000 1000

C16 (µF) 10/16V 10/16V 10/25V 10/25V 10/25V 10/25V

Channel CH6

Formula V

V

OUT_CH6

(V) -6 -6.3 -7 -7.5 -8

OUT_CH6

= (R13/R14) x (-1.25) * R13+R14 <90k

L6 (µH) 10 10 10 10 10

R13 (kΩ) 57.6 69.8 63.4 68 68

R14 (kΩ) 12 13.7 11.3 11.3 10.5

C17 (pF) 1000 1000 1000 1000 1000

C18 (µF) 10 x 2pcs. 10 x 2pcs. 10 x 2pcs. 10 x 2pcs. 10 x 2pcs.

DS9971-01 April 2011 www.richtek.com

5

Page 6

RT9971

oltage. High impedance

. High impedance in

Functional Pin Description

Pin No. Pin Name Pin Function

1 PVDD1 Power Output of CH1.

2 LX6 Switch Node of CH6. High impedance in shutdown mode.

3 PVDD6 Power Input of CH6.

4 CP Charge Pump External Driver.

5 CN Charge Pump External Driver.

6 PNEG Negative Output of Charge Pump.

7 FB6 Feedback Input of CH6. High impedance in shutdown mode.

8 FB4 Feedback Input of CH4. High impedance in shutdown mode.

9 EN6 Enable Control Input of CH6.

10 LX4 Switch Node of CH4. High impedance in shutdown mode.

11 PVDD4 Power Input of CH4.

12 EN5 Enable Control Input of CH5.

13 SW5O Output of CH5 Load Disconnect.

14 SW5I Input of CH5 Load Disconnect.

15 FB5 Feedback Input of CH5. High impedance in shutdown mode.

16 VREF 1.25V Reference Output.

17 SEL Li-ion or 2AA Select. Logic state can not be changed during operation.

18 RTC_R RTC_Reset Output.

19 RTC_PWR Power Input of RTC_Reset.

20 PVDD3 Power Input of CH3.

21 LX3 Switch Node of CH3. High impedance in shutdown mode.

22 EN7 Enable Control Input of CH7.

23 FB3 Feedback Input of CH3. High impedance in shutdown mode.

24 VOUT7 Sense Input for CH7 Output Voltage.

25 LX5 Switch Node of CH5. High impedance in shutdown mode.

26 LX7 Switch Node of CH7. High impedance in shutdown mode.

27,

41 (Exposed Pad)

28 CFB7 Feedback Input of CH7.

29 VDDM IC Analog Power Input.

30 PVDD2

31 LX2 Switch Node of CH2. High impedance in shutdown mode.

32 EN134 Enable Control Input of CH1, CH3 and CH4.

33 COMP2 Compensation of CH2. Pull to GND in shutdown mode.

34 FB2 Feedback input of CH2. High impedance in shutdown mode.

35 VOUT1

36 OK

37 FB1 Feedback Input of CH1. High impedance in shutdown mode.

38 COMP1 Compensation of CH1. Pull to GND in shutdown mode.

39 EN2 Enable Control Input of CH2.

40 LX1 Switch Node of CH1. High impedance in shutdown mode.

6

GND

Ground. The exposed pad must be soldered to a large PCB and connected to

GND for maximum thermal dissipation.

Power Input of CH2 step-down converter, or power output of CH2 step-up

converter.

CN is set to low or floating : Sense Pin for CH1 Output V

in shutdown. CN is set to High: Output pin of RTC_LDO.

CN is set to low or floating : External Switch Control

shutdown. CN is set to High : Power input pin of RTC_LDO.

DS9971-01 April 2011www.richtek.com

Page 7

Function Block Diagram

RT9971

VDDM

LX5

FB5

SW5I

SW5O

PVDD6

LX6

FB6

LX7

VOUT7

EN7

CFB7

VREF

EN2

EN134

EN5

EN6

SEL

CP

CN

PNEG

OK

VOUT1

1.25V

REF

0.25V

REF

1.25V

REF

SW1

+

+

-

-

+

CH5

C-Mode

Step-Up

PWM

CH6

C-Mode

Inverting

CH7

C-Mode

Step-Up

PWM

Sequence

Negative

Charge

Pump

RTC

LDO

SW5

VDDM

Enable

Mode

CH1

C-Mode

Step-Up

CH2

C-Mode

Step-Up or

Step-Down

CH3

C-Mode

Step-Down

CH4

C-Mode

Step-Down

PVDD1

LX1

+

0.8V

REF

+

0.8V

REF

+

0.8V

REF

COMP1

FB1

PVDD2

LX2

COMP2

FB2

PVDD3

LX3

FB3

PVDD4

LX4

RTC_PWR

RTC_R

RTC

Reset

GND

+

0.8V

REF

FB4

Timing Diagram

CH5 and CH6 Timing Diagram

DS9971-01 April 2011 www.richtek.com

EN5

SW5I

SW5O

(to CCD +)

EN6

V

OUT_CH6

(to CCD -)

10ms

10ms

Depends on loading

Depends on loading

Depends on loading

7

Page 8

RT9971

Absolute Maximum Ratings (Note 1)

l Supply Voltage, V

l Power Switch :

------------------------------------------------------------------------------ −0.3V to 7V

DDM

LX1, LX2, LX3, LX4---------------------------------------------------------------------------------- −0.3V to 6.5V

LX5, LX7, SW5I, SW5O, VOUT7---------------------------------------------------------------- −0.3V to 21V

LX6-----------------------------------------------------------------------------------------------------(PVDD6 − 14V) to (PVDD6 + 0.3V)

l The Other Pins-------------------------------------------------------------------------------------- −0.3V to 6.5V

l Power Dissipation, P

@ T

D

= 25°C

A

WQFN 40L 5x5--------------------------------------------------------------------------------------2.778W

l Package Thermal Resistance (Note 2)

WQFN 40L 5x5, θJA---------------------------------------------------------------------------------36°C/W

WQFN 40L 5x5, θJC--------------------------------------------------------------------------------7°C/W

l Junction Temperature------------------------------------------------------------------------------150°C

l Lead Temperature (Soldering, 10 sec.)---------------------------------------------------------260°C

l Storage Temperature Range---------------------------------------------------------------------- −65°C to 150°C

l ESD Susceptibility (Note 3)

HBM (Human Body Mode)------------------------------------------------------------------------2kV

MM (Machine Mode)-------------------------------------------------------------------------------200V

Recommended Operating Conditions (Note 4)

l Junction Temperature Range--------------------------------------------------------------------- −40°C to 125°C

l Ambient Temperature Range--------------------------------------------------------------------- −40°C to 85°C

Electrical Characteristics

(V

= 3.3V, T

DDM

Supply Voltage

VDDM Operating Voltage V

VDDM Startup Voltage VST 1.5 -- -- V

VDDM Over Voltage Protection 6 6.25

Supply Current

Shutdown Supply Current into VDDM I

CH1 (Syn-Step-Up) : Supply Current

into VDDM

CH2 (Syn-Step-Up or Syn-Step-Down)

: Supply Current into VDDM

CH3 (Syn-Step-Down) :

Supply Current into VDDM

CH4 (Syn-Step-Down) :

Supply Current into VDDM

CH5 (Asyn-Step-Up) :

Supply Current into VDDM

CH6 (Inverting) + Charge pump :

Supply Current into VDDM

CH7 (WLED):

Supply Current into VDDM

= 25°C, unless otherwise specified)

A

Parameter Symbol

2.7 -- 5.5 V

DDM

All EN = 0, CN = 3.3V -- 5 10 µA

OFF

IQ1 Non Switching, EN134 = 3.3V

IQ2 Non Switching, EN2 = 3.3V -- -- 800 µA

IQ3 Non Switching, EN134 = 3.3V

IQ4 Non Switching, EN134 = 3.3V

IQ5 Non Switching, EN5 = 3.3V -- -- 800 µA

IQ6

IQ7 Non Switching, EN7 = 3.3V -- -- 800 µA

Test Condition Min Typ Max Unit

Non Switching, EN6 = 3.3V

PVDD6 = 3.3V

6.5 V

-- -- 800 µ A

-- -- 800 µ A

-- -- 800 µ A

-- -- 800 µ A

To be continued

DS9971-01 April 2011www.richtek.com

8

Page 9

RT9971

Parameter Symbol

Test Condition Min Typ Max Unit

Oscillator

CH1,2,3,4, 5, 6, 7 Operating Frequency f

CH1 Maximum Duty Cycle (Step-Up) V

CH2 Maximum Duty Cycle (Step-Up) V

CH2 Maximum Duty Cycle (Step-Down) V

CH3 Maximum Duty Cycle (Step-Down) V

CH4 Maximum Duty Cycle (Step-Down) V

CH5 Maximum Duty Cycle (Step-Up) V

CH6 Maximum Duty Cycle (Inverting) V

CH7 Maximum Duty Cycle (WLED) V

900 1000 1100 kHz

OSC

= 0.7V 80 83 86 %

FB1

= 0.7V 80 83 86 %

FB2

= 0.7V -- -- 100

FB2

= 0.7V -- -- 100

FB3

= 0.7V -- -- 100

FB4

= 1.15V 91 94 97 %

FB5

= 0.1V 91 94 97 %

FB6

= 0.15V 91 94 97 %

FB7

%

%

%

Feedback Regulation Voltage

Feedback Regulation Voltage @ FB1,

FB2, FB3, FB4

0.788 0.8 0.812 V

Feedback Regulation Voltage @ FB5 1.237 1.25 1.263 V

Feedback Regulation Voltage @ FB6

(Inverting)

Feedback Regulation Voltage @ CFB7

-15 0 15 mV

0.237 0.25 0.263 V

OK Sink Current OK = 1V 50 -- -- µA

Reference

VREF Output Voltage V

VREF Load Regulation 0µA < I

1.237 1.25 1.263 V

REF

< 200µA -- -- 10 mV

REF

Negative Charge Pump

PVDD6 Low Threshold to Start Pump 3.4 3.6 3.8 V

PVDD6 Hysteresis Gap to Stop Pump 0.1 0.3 0.5 V

(PVDD6 − PNEG) Clamped Voltage PVDD6 = 3.3V 4.1 4.5 4.9 V

Power Switch

CH1 On Resistance of MOSFET R

DS(ON)

P-MOSFET, PVDD1 = 3.3V

N-MOSFET, PVDD1 = 3.3V

-- 150 --

-- 150 --

mΩ

CH1 Current Limitation (Step-Up) -- 3 -- A

CH2 On Resistance of MOSFET R

DS(ON)

P-MOSFET, PVDD2 = 3.3V

N-MOSFET, PVDD2 = 3.3V

-- 150 --

-- 150 --

mΩ

CH2 Current Limitation (Step-Down) -- 1.5 -- A

CH2 Current Limitation (Step-Up) -- 3 -- A

CH3 On Resistance of MOSFET R

DS(ON)

P-MOSFET, PVDD3 = 3.3V

N-MOSFET, PVDD3 = 3.3V

-- 200 --

-- 200 --

mΩ

CH3 Current Limitation (Step-Down) -- 1.5 -- A

CH4 On Resistance of MOSFET R

DS(ON)

P-MOSFET, PVDD4 = 3.3V

N-MOSFET, PVDD4 = 3.3V

-- 200 --

-- 200 --

mΩ

CH4 Current Limitation (Step-Down) -- 1.5 -- A

CH5 Load Disconnect MOSFET P-MOSFET, SW5I = 3.3V -- 0.5 -- Ω

CH5 On Resistance of MOSFET

N-MOSFET -- 0.5 -- Ω

CH5 Current Limitation N-MOSFET -- 1.2 -- A

To be continued

DS9971-01 April 2011 www.richtek.com

9

Page 10

RT9971

Parameter Symbol

CH6 On Resistance of MOSFET P-MOSFET, PVDD6 = 3.3V

CH6 Current Limitation P-MOSFET -- 1.5 -- A

CH7 On Resistance of MOSFET N-MOSFET -- 1 -- Ω

CH7 Current Limitation N-MOSFET -- 0.8 -- A

Protection

Over Voltage Protection of PVDD1

and PVDD2

Under Voltage Protection of VOUT1 -- 1.75

Over Voltage Protection of SW5I 18 -- 21 V

Over Voltage Protection of VOUT7 12 -- 16 V

CH5 Load Disconnect UVP of SW5O 0.35 0.4 0.45 V

Under Voltage Protection of FB2

(Step-Down)

Under Voltage Protection of FB3 -- 0.4 -- V

Under Voltage Protection of FB4 -- 0.4 -- V

Under Voltage Protection of FB5 -- 0.8 -- V

Under Voltage Protection of FB6 -- 0.4 -- V

Protection Fault Delay -- 100 -- ms

Control

EN134, EN2, EN5, EN6, EN7 Input

High Level Threshold

EN134, EN2, EN5, EN6, EN7 Input

Low Level Threshold

EN134, EN2, EN5, EN6, EN7 Sink

Current

SEL Input High Level Threshold 1.3 -- -- V

6 6.25

-- 0.4 -- V

1.3 -- -- V

-- -- 0.4 V

-- 2 6 µA

Test Condition Min Typ Max Unit

-- 0.5 -- Ω

6.5 V

-- V

SEL Input Low Level Threshold -- -- 0.4 V

SEL Sink Current SEL = 3.3V -- 2 6 µA

Thermal Protection

Thermal Shutdown TSD 125 160 -- °C

Thermal Shutdown Hysteresis ΔTSD -- 20 -- °C

RTC Reset

RTC_PWR Reset Threshold 1.57 1.6 1.63 V

Hysteresis -- 16 -- mV

Standby Current RTC_PWR = 3V -- 2 4 µA

RTC_R Rising Delay Time 35 55 75 ms

RTC_R Sink Capability

10

RTC_R = 0.5V,

RTC_PWR = 1.5V

4 -- -- mA

To be continued

DS9971-01 April 2011www.richtek.com

Page 11

RT9971

Parameter Symbol

Test Condition Min Typ Max Unit

RTC LDO, CN = High

Input Voltage Range VIN -- -- 5.5 V

Standby Current V

Output Voltage V

OUT

I

= 4.2V -- 5 8 µA

IN

= 0mA -- 3.25 3.3 V

OUT

Maximum Output Current VIN = 4.2V 60 -- -- mA

Dropout Voltage V

DROP

I

OUT

= 20mA -- -- 200 mV

Note 1. Stresses listed as the above “ Absolute Maximum Ratings” may cause permanent damage to the device. These

are for stress ratings. Functional operation of the device at these or any other conditions beyond those indicated

in the operational sections of the specifications is not implied. Exposure to absolute maximum rating conditions

for extended periods may remain possibility to affect device reliability.

Note 2. θJA is measured in the natural convection at T

= 25°C on a high effective four layers thermal conductivity test

A

board of JEDEC 51-7 thermal measurement standard. The case point of θJC is on the exposed pad for the WQFN

package.

Note 3. Devices are ESD sensitive. Handling precaution is recommended.

Note 4. The device is not guaranteed to function outside its operating conditions.

DS9971-01 April 2011 www.richtek.com

11

Page 12

RT9971

Typical Operating Characteristics

CH1 Step-Up Efficiency vs. Output Current

100

90

80

V

= 3V

V

V

V

V

V

BAT

BAT

BAT

BAT

BAT

BAT

= 2.7V

= 2.5V

= 2.2V

= 2V

= 1.8V

Efficiency (%)

70

60

50

40

30

20

10

= 3V, V

DDM

L1 = 2.2µH, C1 = 10µFx2

OUT_CH1

= 3.3V,

V

0

10 100 1000

Output Current (mA)

CH2 Step-Up Efficiency vs. Output Current

100

90

80

70

60

50

40

Efficiency (%)

30

20

10

0

10 100 1000

Output Current (mA)

V

= 3.4V

BAT

V

= 3V

BAT

V

= 2.7V

BAT

V

= 2.5V

BAT

V

= 2.2V

BAT

V

= 1.8V

BAT

V

= 3V, V

DDM

OUT_CH2

L2 = 2.2µH, C5 = 10µFx2

= 5V,

CH1 Step-Up Efficiency vs. Output Current

100

90

V

= 4.5V

80

70

60

50

V

V

V

V

V

BAT

BAT

BAT

BAT

BAT

BAT

= 4.2V

= 3.9V

= 3.6V

= 3.3V

= 3V

40

Efficiency (%)

30

20

10

= 5V, V

DDM

L1 = 2.2µH, C1 = 10µFx2

OUT_CH1

= 5V,

V

0

10 100 1000

Output Current (mA)

CH2 Step-Down Efficiency vs. Output Current

100

90

Efficiency (%)

80

70

60

50

40

30

20

10

0

V

= 3.4V

BAT

V

= 3.6V

BAT

V

= 3.9V

BAT

V

= 4.2V

BAT

V

= 4.5V

BAT

V

= 5V

BAT

V

DDM

= 5V, V

OUT_CH2

= 3.3V,

L2 = 4.7µH, C5 = 10µF

10 100 1000

Output Current (mA)

CH3 Step-Down Efficiency vs. Output Current

100

90

Efficiency (%)

80

70

60

50

40

30

20

10

0

V

= 2.7V

BAT

V

= 3V

BAT

V

= 3.3V

BAT

V

= 3.6V

BAT

V

= 3.9V

BAT

V

= 4.2V

BAT

V

= 4.5V

BAT

V

DDM

= 5V, V

OUT_CH3

= 2.5V,

L3 = 4.7µH, C9 = 10µF

10 100 1000

Output Current (mA)

CH4 Step-Down Efficiency vs. Output Current

100

90

80

Efficiency (%)

70

60

50

40

30

20

10

0

V

= 1.8V

BAT

V

= 2.5V

BAT

V

= 3V

BAT

V

= 3.3V

BAT

V

= 3.6V

BAT

V

= 4.5V

BAT

V

DDM

= 3V, V

OUT_CH4

= 1V,

L4 = 4.7µH, C12 = 10µF

10 100 1000

Output Current (mA)

DS9971-01 April 2011www.richtek.com

12

Page 13

RT9971

CH5 Step-Up Efficiency vs. Output Current

100

90

80

V

= 4.5V

BAT

V

= 4.2V

BAT

V

= 3.9V

BAT

V

= 3.6V

BAT

V

= 3.4V

BAT

V

= 5V, V

DDM

OUT_CH5

L5 = 10µH, C16 = 10µF

0

1 10 100

Efficiency (%)

70

60

50

40

30

20

10

Output Current (mA)

CH7 Efficiency vs. Input Voltage

100

90

80

70

60

50

40

Efficiency (%)

30

20

10

V

= 5V, L7 = 10µH, C20 = 1µF, I

0

DDM

3.4 3.53.6 3.7 3.83.9 4 4.1 4.2 4.34.4 4.5

OUT

= 25mA

Input Voltage (V)

= 16V,

CH6 Inverting Efficiency vs. Output Current

100

90

80

70

60

50

40

30

20

Inverting Efficiency (%)

10

0

1 10 100

V

= 3.4V

BAT

V

= 3.6V

BAT

V

= 3.9V

BAT

V

= 4.2V

BAT

V

= 4.5V

BAT

V

DDM

= 5V, V

OUT_CH6

= -8V,

L6 = 10µH, C18 = 10µFx2

Output Current (mA)

CH1 Step-Up Output Voltage vs. Output Current

5.080

5.075

V

= 3V

V

V

BAT

BAT

DDM

= 4.5V

= 5V

5.070

5.065

5.060

Output Voltage (V)

5.055

5.050

0 100 200 300 400 500 600

Output Current (mA)

CH1 Step-Up Output Voltage vs. Output Current

3.35

3.33

3.31

3.29

Output Voltage (V)

3.27

3.25

0 100 200 300 400 500 600

Output Current (mA)

V

V

V

BAT

BAT

DDM

= 1.8V

= 4.5V

= 3V

CH2 Step-Down Output Voltage vs. Output Current

3.340

3.335

3.330

3.325

3.320

V

= 4.5V

BAT

V

= 5V

BAT

V

= 5V

DDM

Output Voltage (V)

3.315

3.310

3.305

3.300

0 100 200 300 400 500 600

Output Current (mA)

DS9971-01 April 2011 www.richtek.com

13

Page 14

RT9971

CH2 Step-Up Output Voltage vs. Output Current

5.07

5.06

5.05

V

= 3.4V

BAT

5.04

Output Voltage (V)

5.03

V

= 3V

5.02

0 100 200 300 400 500 600

DDM

Output Current (mA)

CH4 Step-Down Output Voltage vs. Output Current

1.015

1.013

1.011

1.009

1.007

1.005

Output Voltage ( V)

1.003

1.001

0.999

0.997

0.995

0 100 200 300 400 500 600

Output Current (mA)

V

V

V

V

BAT

BAT

BAT

DDM

= 3V

= 1.8V

= 4.5V

= 3V

CH3 Step-Down Output Voltage vs. Output Current

2.520

2.515

2.510

V

= 3V

BAT

2.505

2.500

V

BAT

= 4.5V

Output Voltage (V)

2.495

V

= 5V

2.490

0 100 200 300 400 500 600

DDM

Output Current (mA)

CH5 Step-Up Output Voltage vs. Output Current

16.3

16.2

16.1

16.0

V

= 4.5V

BAT

= 3.4V

V

15.9

Output Voltage (V)

15.8

15.7

BAT

V

= 2.7V

BAT

V

= 5V

DDM

020406080100

Output Current (mA)

CH6 Inverting Output Voltage vs. Output Current

-8

-8.05

-8.1

14

-8.15

-8.2

-8.25

Inver ting Output Voltage (V)

-8.3

020406080100

Output Current (mA)

V

V

V

V

BAT

BAT

BAT

DDM

= 4.5V

= 3.4V

= 2.7V

= 5V

V

OUT_CH1

(5V/Div)

V

OUT_CH2

(5V/Div)

V

OUT_CH3

(2V/Div)

V

OUT_CH4

(1V/Div)

Power On

V

= 5V, V

DDM

Time (5ms/Div)

DS9971-01 April 2011www.richtek.com

= 3.7V, SEL = Low

BAT

Page 15

RT9971

V

OUT_CH1

(5V/Div)

V

OUT_CH2

(5V/Div)

V

OUT_CH3

(2V/Div)

V

OUT_CH4

(1V/Div)

LX2

(2V/Div)

Power Off

V

DDM

= 5V, V

= 3.7V, SEL = Low

BAT

Time (1ms/Div)

CH2 Output Voltage Ripple

LX1

(2V/Div)

V

OUT_CH1_ac

(20mV/Div)

LX3

(2V/Div)

CH1 Output Voltage Ripple

V

= 5V, V

DDM

= 400mA, L1 = 2.2μH, C1 = 10μFx2

I

OUT

= 3.7V, V

BAT

OUT_CH1

Time (1μs/Div)

CH3 Output Voltage Ripple

= 5V,

V

OUT_CH2_ac

(10mV/Div)

LX5

(10V/Div)

V

OUT_CH5_ac

(10mV/Div)

V

= 5V, V

DDM

= 400mA, L2 = 4.7μH, C5 = 10μF

I

OUT

= 3.7V, V

BAT

OUT_CH2

Time (1μs/Div)

CH5 Output Voltage Ripple

V

= 5V, V

DDM

I

= 30mA, L5 = 10μH, C16 = 10μF

OUT

Time (1μs/Div)

= 3.7V, V

BAT

OUT_CH5

= 3.3V,

= 16V,

V

OUT_CH3_ac

(10mV/Div)

LX6

(10V/Div)

V

OUT_CH6_ac

(10mV/Div)

V

= 5V, V

DDM

I

= 300mA, L3 = 4.7μH, C9 = 10μF

OUT

= 3.7V, V

BAT

OUT_CH3

Time (1μs/Div)

CH6 Output Voltage Ripple

V

= 5V, V

DDM

= 50mA, L6 = 10μH, C18 = 10μFx2

I

OUT

Time (1μs/Div)

= 3.7V, V

BAT

OUT_CH6

= 2.5V,

= -8V,

DS9971-01 April 2011 www.richtek.com

15

Page 16

RT9971

I

OUT

(200mA/Div)

V

OUT_CH1_ac

(100mV/Div)

I

OUT

(200mA/Div)

CH1 Load Transient Response

V

= 3V, V

DDM

I

= 50mA to 250mA, L1 = 2.2μH, C1 = 10μFx2

OUT

= 1.8V, V

BAT

OUT_CH1

= 3.3V,

Time (1ms/Div)

CH3 Load Transient Response

I

OUT

(200mA/Div)

V

OUT_CH2_ac

(100mV/Div)

I

OUT

(200mA/Div)

CH2 Load Transient Response

V

= 5V, V

DDM

= 0 to 300mA, L2 = 4.7μH, C5 = 10μF

I

OUT

= 3.7V, V

BAT

OUT_CH2

= 3.3V,

Time (1ms/Div)

CH4 Load Transient Response

V

OUT_CH3_ac

(50mV/Div)

I

OUT

(20mA/Div)

V

OUT_CH5_ac

(50mV/Div)

V

= 5V, V

DDM

= 100mA to 300mA, L3 = 2.2μH, C9 = 10μF

I

OUT

BAT

= 3V, V

OUT_CH3

= 2.5V,

Time (1ms/Div)

CH5 Load Transient Response

V

= 5V, V

DDM

I

= 10mA to 30mA, L5 = 10μH, C16 = 10μF

OUT

= 3.7V, V

BAT

OUT_CH5

Time (1ms/Div)

= 16V,

V

OUT_CH4_ac

(50mV/Div)

I

OUT

(20mA/Div)

V

OUT_CH6_ac

(50mV/Div)

V

= 3V, V

DDM

I

= 100mA to 300mA, L4 = 4.7μH, C12 = 10μF

OUT

= 1.8V, V

BAT

OUT_CH4

= 1V,

Time (1ms/Div)

CH6 Load Transient Response

V

= 5V, V

DDM

I

= 15mA to 50mA, L6 = 10μH, C18 = 10μFx2

OUT

= 3.7V, V

BAT

OUT_CH6

Time (1ms/Div)

= -8V,

16

DS9971-01 April 2011www.richtek.com

Page 17

Application information

RT9971

The RT9971 includes the following seven DC/DC converter

CHs to build a multiple-output power-supply system.

CH1 : Step-up synchronous current mode DC/DC converter

with internal power MOSFETs. The output voltage could

be load disconnected by a switch controller and an

external P-MOSFET.

CH2 : Selectable step-up or step-down synchronous

current mode DC/DC converter with internal power

MOSFETs.

CH3 : Step-down synchronous current mode DC/DC

converter with internal power MOSFETs and internal

compensation network.

CH4 : Step-down synchronous current mode DC/DC

converter with internal power MOSFETs and internal

compensation network.

CH5 : Step-up asynchronous current mode DC/DC

converter with internal power MOSFET and internal

compensation network. The output voltage could be load

disconnected by an internal P-MOSFET.

CH6 : Inverting current mode DC/DC converter with internal

power P-MOSFET and internal compensation network.

CH7 : Current mode WLED driver with internal power

N-MOSFET and internal compensation network. This CH

also provides open LED protection.

SW1 : Load disconnect controller.

SW5 : Load disconnect switch for CH5

CH1 to CH7 operate in PWM mode with 1MHz constant

frequency under moderate to heavy loading.

The output voltage can be set by the following equation :

V

OUT_CH1

Where V

= (1+R1/R2) x V

is 0.8V typically.

FB1

FB1

SW1

SW1 is an open drain controller to drive an external

P-MOSFET and then functions as a load disconnect

switch for CH1. This switch features soft-start, Power On/

Off Sequence and under voltage protection functions. OK

is an open drain control pin. Once CH1, CH3, and CH4's

soft-start are finished, SW1 will be turned on. The OK pin

is slowly pulled low and controlled with soft-start to

suppress the inrush current. VOUT1 is used for SW1 softstart and under voltage protection.

CH2 : Synchronous Step-Up or Step-Down

Selectable DC/DC Converter

The CH2 is a synchronous step-up or step-down

selectable converter for motor or DSC system I/O power.

Mode setting

The CH2 of the RT9971 features flexible Step-up or Stepdown topology setting for either 1 x Li-ion or 2 x AA

application by the SEL pin. Please refer to “Electrical

Characteristics” for level of Logic-High or Logic-Low. When

the CH2 operates as a Step-up converter, the SEL must

be set at Logic-High. If the CH2 operates at Step-down

mode, the SEL must be set at Logic-Low. In addition,

please note that the logic state can not be changed during

operation.

Table 2. CH2 Mode Setting

RTC_LDO : Low quiescent current, high output voltage

accuracy LDO for Real Time Clock.

RTC_Reset : Accurate voltage detector for RTC LDO.

CH2 Operating Mode

Step-up Logic-High

Step-down Logic-Low

SEL

CH1: Synchronous Step-Up DC/DC Converter

The CH1 is a synchronous step-up converter for motor or

DSC system I/O power. The converter operates at fixed

frequency and PWM Current Mode. The CH1 converter

integrates internal MOSFETs, compensation network and

synchronous rectifier for up to 95% efficiency.

DS9971-01 April 2011 www.richtek.com

Step-Up :

The converter operates at fixed frequency PWM Mode,

continuous current mode (CCM), and discontinuous current

mode (DCM) with internal MOSFETs, compensation

network and synchronous rectifier for up to 95% efficiency.

17

Page 18

RT9971

Step-Down :

The converter operates at fixed frequency PWM mode

and continuous current mode (CCM) with internal

MOSFETs, compensation network and synchronous

rectifier for up to 95% efficiency. The CH2 step-down

converter can be operated at 100% maximum duty cycle

to extend the input operating voltage range. While the

input voltage is close to the output voltage, the converter

enters low dropout mode.

The output voltage can be set by the following equation :

V

OUT_CH2

Where V

= (1+R4/R5) x V

is 0.8V typically.

FB2

FB2

CH3 : Synchronous Step-Down DC/DC Converter

The converter operates at fixed frequency PWM mode,

CCM, integrated internal MOSFETs and compensation

network. The CH3 step-down converter can be operated

at 100% maximum duty cycle to extend the battery

operating voltage range. When the input voltage is close

to the output voltage, the converter could enter low dropout

mode with low output ripple.

The output voltage can be set by the following equation :

V

OUT_CH3

Where V

= (1+R7/R8) x V

is 0.8V typically.

FB3

FB3

CH4 : Synchronous Step-Down DC/DC Converter

The converter operates at fixed frequency PWM mode,

CCM, integrated internal MOSFETs and compensation

network. The CH4 step-down converter can be operated

at 100% maximum duty cycle to extend battery operating

voltage range. When the input voltage is close to the output

voltage, the converter could enter low dropout mode with

low output ripple.

The output voltage can be set by the following equation :

V

OUT_CH4

Where V

= (1+R9/R10) x V

is 0.8V typically.

FB4

FB4

CH5 : Step-Up DC/DC Converter

It integrates asynchronous step-up converter with an

internal N-MOSFET, internal compensation and an external

schottky diode to provide CCD positive power supply. The

converter is inactive until the SW5 soft-start procedure is

finished. This feature provides load disconnect function

and effectively limits inrush current at start up.

The output voltage can be set by the following equation :

V

OUT_CH5

Where V

= (1+R11/R12) x V

is 1.25V typically.

FB5

FB5

SW5

SW5 is an internal switch enabled by EN5 and functions

as a load disconnection for CH5. This switch features softstart, Powe On Sequence, over voltage (for SW5I) and

under voltage (for SW5O) protection functions.

CH6 : INV DC/DC Converter

This converter integrates an internal P-MOSFET and an

external schottky diode to provide CCD negative power

supply.

The output voltage can be set by the following equation :

V

OUT_CH6

= (R13/R14) x (-V

REF

)

Where R13 and R14 are the feedback resisters connected

to FB6, V

equals to 1.25V in typical.

REF

Charge Pumps

The charge pump will be enabled while the PVDD6 voltage

is lower than 3.6V. This CH provides pump voltage to

enhance P-MOSFET gate driving capability. This function

is not necessary while battery is Li-ion type.

Reference Voltage

The RT9971 provides a precise 1.25V reference voltage

with souring capability of 100µA. Connect a 0.1µF ceramic

capacitor from the VREF pin to GND. Reference voltage

is enabled by connecting EN6 to logic high. Furthermore,

this reference voltage is internally pulled to GND at

shutdown.

CH7 : WLED Driver

It is an asynchronous step-up converter with an internal

MOSFET, internal compensation and an external schottky

diode to drive up to 3 WLED. This CH also features PWM

dimming control from EN7 pin and open diode protection.

In addition, CH7 will be turned on until the CH4 soft-start

is finished.

18

DS9971-01 April 2011www.richtek.com

Page 19

RT9971

The current flows through WLED can be set by the following

equation :

I (mA) = [250mV/R(Ω)] x Duty (%)

R : Current sense resistor from CFB7 to GND.

Duty: PWM dimming by EN7 pin. Dimming frequency

range is from 30kHz to 100kHz.

Hold EN7 low for more than 64µs will turn off CH7.

RTC_Reset

The RT9971 provides an accurate voltage detector for

RTC_LDO voltage detection. It is used to detect whether

RTC_LDO output voltage is ready or not. Its power pin is

RTC_PWR and output pin is RTC_R. The output pin is an

open drain N-MOSFET and the sink capability is above

4mA. Once the RTC_PWR pin reaches 1.6V, it will count

for about 55ms, then the RTC_R will go high.

RTC_LDO

The RT9971 provides a LDO for real time clock. The LDO

function has features of low quiescent current (5µA) and

high output voltage accuracy since this LDO is running all

the time, even when the system is shutdown. In addition,

LDO share “OK” and “VOUT1” pin with SW1 and the

function is decided by “CN” pin. Following table is used

to select LDO or SW1.

Table 3. RTC_LDO and SW1 Setting

Function CN

RTC_LDO Logic-High

SW1 Logic-Low

Power On/Off Sequence

The Power On Sequence is :

While EN134 goes high, CH1 will be turned on to wait for

the completion of CH1's soft-start. After that, CH3 will be

turned on to wait for the completion of CH3's soft-start.

And then, CH4 will be turned on to wait for the completion

of CH4's soft-start. Then,SW1 will be turn on and CH2 is

allowed to be turn on by EN2 at any time. Finally, SW1

soft-start will be completed.

The Power-Off Sequence is :

and CH2 (Note A) will be shutdown. After that, CH4 will be

turned off and internally pulled low to wait for the completion

of CH4's shutdown. And then, CH3 will be turned off and

internally pulled low to wait for CH3's shutdown completion.

Then, CH1 will be turned off and internally pulled low

(Note B) to wait for CH1's shutdown completion. Finally,

the whole IC will be shutdown (if EN2, EN5, EN6 and EN7

already go low).

Note A : If CH2 is configured as a step -up, then the CH2

will not be internally pulled low and the completion of

shutdown will not be checked.

Note B : CH1 is configured as a step -up, so the CH1 will

not be internally pulled low and the completion of shutdown

will not be checked.

Table 4. Power On/Off Sequence

Power On

Sequence

Power Off

Sequence

CH1 -> CH3 -> CH4 -> (SW1 and CH2)

(SW1 and CH2) -> CH4 -> CH3 -> CH1

Thermal Considerations

For continuous operation, do not exceed absolute

maximum operation junction temperature. The maximum

power dissipation depends on the thermal resistance of

IC package, PCB layout, the rate of surroundings airflow

and temperature difference between junction to ambient.

The maximum power dissipation can be calculated by

following formula :

P

Where T

temperature, T

D(MAX)

= (T

− TA ) / θ

J(MAX)

is the maximum operation junction

J(MAX)

is the ambient temperature and the θ

A

JA

JA

the junction to ambient thermal resistance.

For recommended operating conditions specification of

RT9971, The maximum junction temperature is 125°C.

The junction to ambient thermal resistance θJA is layout

dependent. For WQFN-40L 5x5 packages, the thermal

resistance θJA is 36°C/W on the standard JEDEC 51-7

four layers thermal test board. The maximum power

dissipation at TA = 25°C can be calculated by following

formula :

is

P

= (125°C − 25°C) / (36°C/W) = 2.778W for

At first, while EN134 goes low, (SW1 is shutdown and

internally pull low, CH2 must be turned off by EN2) SW1

DS9971-01 April 2011 www.richtek.com

D(MAX

WQFN-40L 5x5 packages

19

Page 20

RT9971

The maximum power dissipation depends on operating

ambient temperature for fixed T

and thermal

J(MAX)

resistance θJA. For RT9971 packages, the Figure 1 of

derating curves allows the designer to see the effect of

rising ambient temperature on the maximum power

allowed.

3.0

2.8

2.6

2.4

2.2

2.0

WQFN-40L 5x5

1.8

1.6

1.4

1.2

1.0

0.8

0.6

0.4

0.2

Maximum Power Dissipation (W)

0.0

0 25 50 75 100 125

Ambient Temperature (°C)

Four Layers PCB

Figure 1. Derating Curves for RT9971 Packages

Layout Considerations

For the best performance of the RT9971, the following

PCB layout guidelines must be strictly followed.

} Place the input and output capacitors as close as

possible to the input and output pins respectively for

good filtering.

} Keep the main power traces as wide and short as

possible.

} The switching node area connected to LX and inductor

should be minimized for lower EMI.

} Place the feedback components as close as possible

to the FB pin and keep these components away from

the noisy devices.

} Place the compensative components as close as

possible to the COMP pin and keep these components

away from the noisy devices.

} Connect the GND and Exposed Pad to a strong ground

plane for maximum thermal dissipation and noise

protection.

Input/Output

capacitors must

be placed as close

as possible to the

Input/Output pins.

V

LX should be connected to inductor by

wide and short trace, keep sensitive

components away from this trace.

V

OUT_CH1

V

C19

OUT_CH4

OUT_CH6

C13

R10

GND

L6

C18

R9

D4

C25

C17

R13

R14

V

GND

V

BAT

BAT

L1

C22

C1

PVDD1

LX6

PVDD6

CP

CN

PNEG

FB6

FB4

EN6

LX4

L4

C12

GND

Figure 2. PCB Layout Guide

GND

1

2

3

4

5

6

7

8

9

10

BAT

V

Place the feedback and compensation

components as close as possible to the FB and

COMP pin and keep away from noisy devices.

V

35363738

C15

OUT_CH2

R4C6

C7

R5

R6

L2

FB2

COMP2

EN1234

LX2

313233

34

SEL

VREF

R16

R11

30

29

28

27

26

25

24

23

41

22

21

201918171615141312

RTC_R

PVDD3

RTC_PWR

C8

BAT

V

GND

C11

R1C2

C3

C21

R2

R3

SYS_R

COMP1

FB1OKVOUT1

LX1

40

39

GND

11

FB5

EN5

SW5I

SW5O

PVDD4

C16

R12

OUT_CH5

V

GND

C5

C4

PVDD2

VDDM

CFB7

GND

LX7

LX5

VOUT7

FB3

EN7

LX3

L3

Connect the Exposed Pad

to a ground plane.

V

BAT

C23

D5

L7

L5

D3

R7R8

C9

R15

WLED+

V

BAT

C26

C24

V

BAT

C10

V

OUT_CH3

WLED-

D2

D1

C20

GND

C14

GND

GND

20

DS9971-01 April 2011www.richtek.com

Page 21

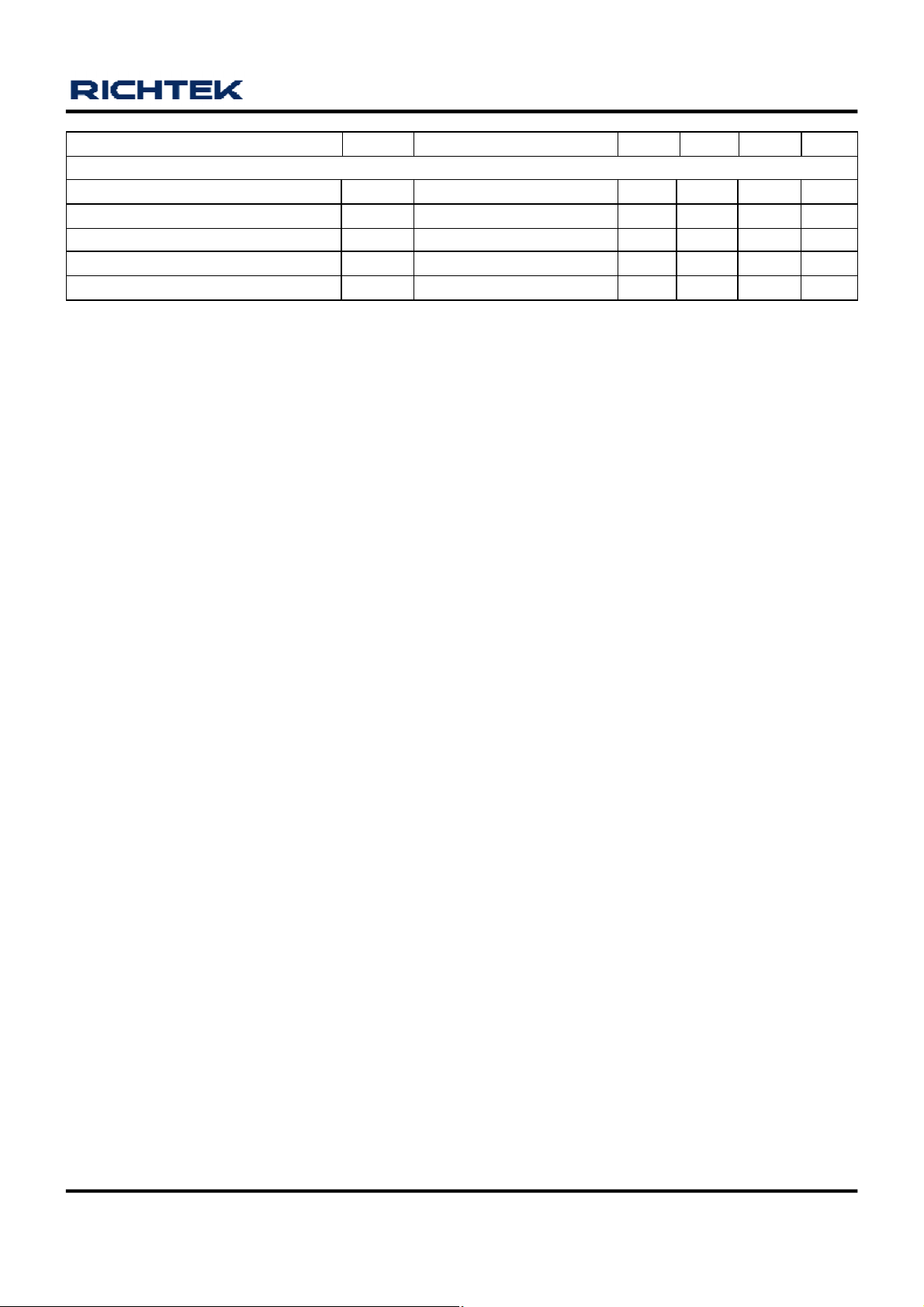

Table 5. Protection Items

Protection

Threshold (typical)

spec

.

IC

Delay time

cycle

.

Automatic reset

tic reset

Automatic reset

Applicable

EN7

RT9971

V

OVP V

DDM

Current

CH1

Step-Up

Limit

PVDD1

OVP

Current

CH2

Step-Up

Limit

PVDD2

OVP

CH2

Step-Down

CH3

Step-Down

CH4

Step-Down

CH5

Asyn

Step-Up

CH6

Inverting

Current

Limit

Current

Limit

Current

Limit

Current

Limit

Current

Limit

Current

CH7

Limit

WLED

OVP VOUT7 > 14V Shutdown CH7

type

Refer to Electrical

> 6.25V Automatic reset at V

DDM

N-MOSFET current >

3A

Protection methods

< 6V 100ms

DDM

N-MOSFET off, P-MOSFET off.

Automatic reset at next clock

cycle

Shutdown

100ms

PVDD1 > 6.25V N-MOSFET off, P-MOSFET off. No-delay

N-MOSFET current >

3A

N-MOSFET off, P-MOSFET off.

Automatic reset at next clock

cycle

100ms

PVDD2 > 6.25V N-MOSFET off, P-MOSFET off. No-delay

P-MOSFET current >

1.5A

P-MOSFET current >

1.5A

P-MOSFET current >

1.5A

N-MOSFET current >

1.2A

P-MOSFET current >

1.5A

N-MOSFET current >

0.8A

N-MOSFET off, P-MOSFET off.

Automatic reset at next clock

cycle

N-MOSFET off, P-MOSFET off.

Automatic reset at next clock

N-MOSFET off, P-MOSFET off

Automatic reset at next clock

cycle

N-MOSFET off.

at next clock cycle

P-MOSFET off. Automa

at next clock cycle

N-MOSFET off.

at next clock cycle

100ms

100ms V

100ms

100ms

100ms

Not

Applicable

Not

Reset method

V

power

DDM

reset

V

power

DDM

reset

V

power

DDM

reset

V

power

DDM

reset

V

power

DDM

reset

V

power

DDM

reset

power reset

DDM

V

power

DDM

reset

V

power

DDM

reset

V

power

DDM

reset

Automatic reset

at next clock

cycle

Reset by toggling

SW1 UVP

VOUT1 < 1.75V after

SW1 soft start end

OVP SW5I > 18V N-MOSFET off No-delay

SW5

UVP

Thermal

CH2

Step-Down

CH3

Step-Down

CH4

Step-Down

Thermal

shutdown

UVP

UVP

UVP

CH5 UVP

SW5O < 0.4V after

SW5 soft start end

Temperature > 160°C All channels stop switching No-delay

FB2 < 0.4V after CH2

soft start end

FB3 < 0.4V after CH3

soft start end

FB4 < 0.4V after CH4

soft start end

FB5 < 0.8V after CH5

soft start end

CH6 UVP FB6 > 0.4V P-MOSFET off. No-delay

Automatic reset at

VOUT1 > 1.75V

Automatic reset at

SW5O > 0.4V

N-MOSFET off, P-MOSFET off.

Automatic reset at FB2 > 0.4V

N-MOSFET off, P-MOSFET off.

Automatic reset at FB3 > 0.4V

N-MOSFET off, P-MOSFET off.

Automatic reset at FB4 > 0.4V

100ms

100ms

100ms

100ms

100ms

N-MOSFET off. No-delay

V

power

DDM

reset

V

power

DDM

reset

V

power

DDM

reset

Temperature <

140°C

V

power

DDM

reset

V

power

DDM

reset

V

power

DDM

reset

V

power

DDM

reset

V

power

DDM

reset

DS9971-01 April 2011 www.richtek.com

21

Page 22

RT9971

Outline Dimension

D

E

e

A

A3

A1

D2

SEE DETAIL A

1

b

L

E2

1

2

1

2

DETAIL A

Pin #1 ID and Tie Bar Mark Options

Note : The configuration of the Pin #1 identifier is optional,

but must be located within the zone indicated.

Dimensions In Millimeters

Dimensions In Inches

Symbol

Min Max Min Max

A 0.700 0.800 0.028 0.031

A1 0.000 0.050 0.000 0.002

A3 0.175 0.250 0.007 0.010

b 0.150 0.250 0.006 0.010

D 4.950 5.050 0.195 0.199

D2 3.250 3.500 0.128 0.138

E 4.950 5.050 0.195 0.199

E2 3.250 3.500 0.128 0.138

e 0.400 0.016

L 0.350 0.450

Richtek Technology Corporation

Headquarter

5F, No. 20, Taiyuen Street, Chupei City

Hsinchu, Taiwan, R.O.C.

Tel: (8863)5526789 Fax: (8863)5526611

0.014 0.018

W-Type 40L QFN 5x5 Package

Richtek Technology Corporation

Taipei Office (Marketing)

5F, No. 95, Minchiuan Road, Hsintien City

Taipei County, Taiwan, R.O.C.

Tel: (8862)86672399 Fax: (8862)86672377

Email: marketing@richtek.com

Information that is provided by Richtek Technology Corporation is believed to be accurate and reliable. Richtek reserves the right to make any change in circuit

design, specification or other related things if necessary without notice at any time. No third party intellectual property infringement of the applications should be

guaranteed by users when integrating Richtek products into any application. No legal responsibility for any said applications is assumed by Richtek.

DS9971-01 April 2011www.richtek.com

22

Loading...

Loading...