Preliminary

RT9913A/B

Integrated Multi-Channel DC-DC Converter for

TFT LCD Panels

General Description

The RT9913A/B includes a high-performance boost

regulator, one linear-regulator controller for VGL, one low

dropout linear regulator, a gate pulse modulator (GPM), a

voltage detector and a V

active-matrix thin-film transistor (TFT) liquid-crystal displays

(LCDs).

The boost converter provides the regulated supply voltage

for the panel source driver ICs. With integrated 16V

N-Channel 0.2Ω MOSFET it allows the use of ultra-small

inductors and ceramic capacitors and provides fast transient

response to pulsed loads. The VGL linear-regulator

controller provides regulated TFT Gate-Off . The low-dropout

linear regulator (LDO) using an internal PMOS as the pass

device can supply up to 350mA current is suitable for the

supply voltage to the T-CON ASIC. And the GPM is

controlled by frame signals from timing controller to

modulate the Gate-On voltage. Voltage detector monitors

the supply voltage to issue a reset signal while the

detected voltage is too low. The V

high-performance operation amplifier) can drive the LCD

backplane (V

) and features high short-circuit current

COM

(140mA), fast slew rate (12V/μs), wide bandwidth (12MHz)

and rail-to-rail input and output.

Buffer (Unity- gain OPA) for

COM

Buffer (Unity-gain)

COM

Features

zz

2.5V to 5.5V Input Supply Voltage

z

zz

zz

z 640kHz/1.2MHz (A/B version) Current-Mode Step-Up

zz

Boost Regulator

Fast Transient Response to Pulsed Load

High Accuracy Output Voltage (

Built-In 16V, 2.0A, 0.2

ΩΩ

Ω N-Channel MOSFET

ΩΩ

High Efficiency Up to 90%

Programmable Soft-Start

Programmable Over-Current Protection

zz

z Linear-Regulator Controller for VGL

zz

zz

z Low Drop-Out Voltage Linear Regulator

zz

Adjustable Output Voltage (2.5V to 3.3V)

350mA Maximum Output Current

zz

z On-Chip GPM Controller with Adjustable Falling

zz

Time

Flicker Compensator

Power-On Sequence Control

zz

z Low Voltage Detector

zz

Programmable Detecting Voltage and Delay Time

zz

z Unity-Gain Operation Amplifier for V

zz

zz

z Over-Temperature Protection

zz

zz

z Thin 24-Lead VQFN Package

zz

zz

z RoHS Compliant and 100% Lead (Pb)-Free

zz

±±

±2%)

±±

COM

Buffer

Marking Information

Ordering Information

RT9913A/B

Package Type

QV : VQFN-24L 4x4 (V-Type)

Operating Temperature Range

P : Pb Free with Commercial Standard

Switching Frequency

A : 640kHz

B : 1.2MHz

Note :

RichTek Pb-free products are :

`RoHS compliant and compatible with the current require-

ments of IPC/JEDEC J-STD-020.

`Suitable for use in SnPb or Pb-free soldering processes.

`100% matte tin (Sn) plating.

DS9913A/B-00 February 2006 www.richtek.com

For marking information, contact our sales representative

directly or through a RichTek distributor located in your

area, otherwise visit our website for detail.

1

RT9913A/B

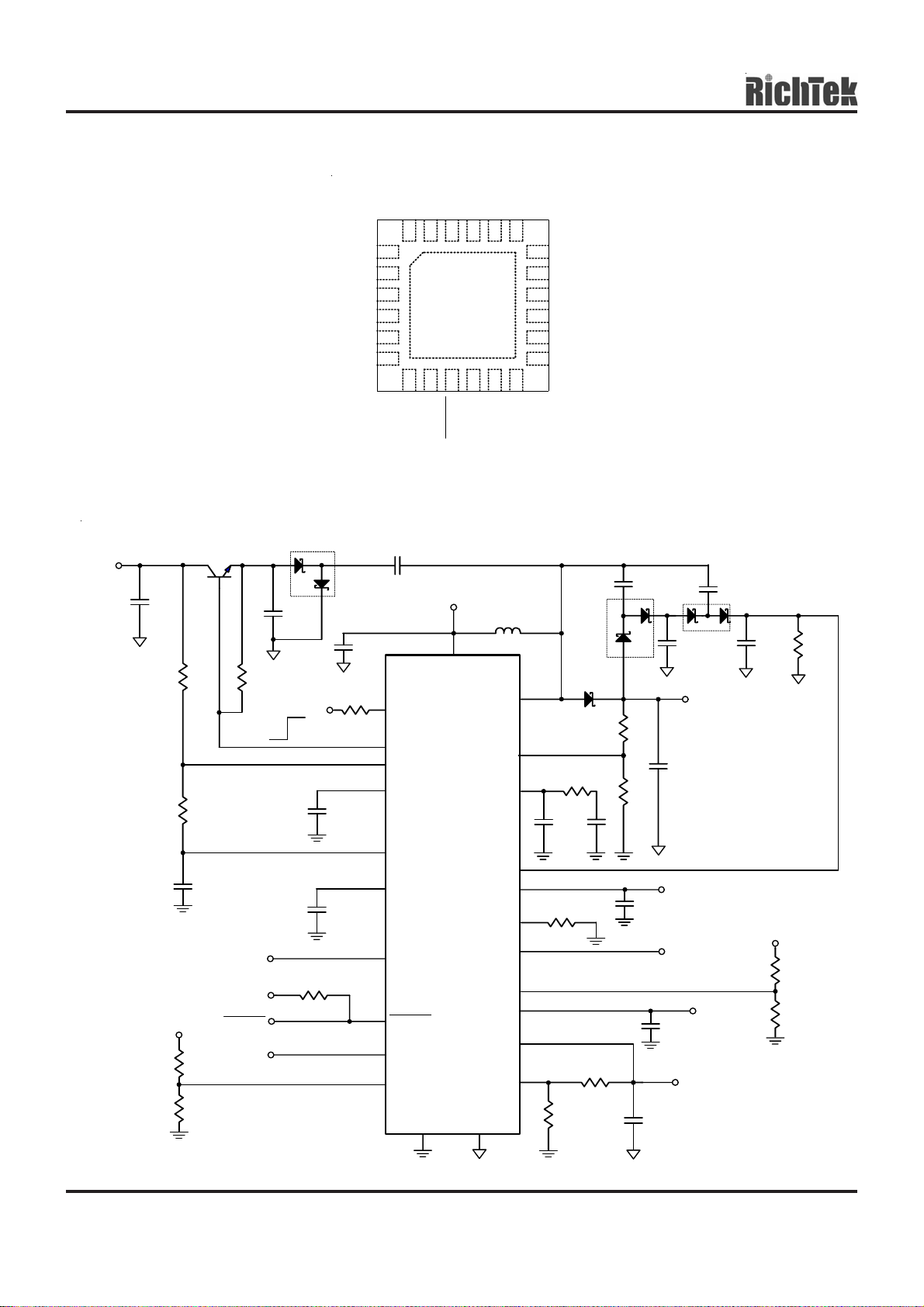

Pin Configurations

VFLK

VGH

VGHM

RE

VREF

FBN

Preliminary

(TOP VIEW)

OPAI

OPAO

AVDD

24 2223

1

2

3

4

5

6

7

21 20 19

GND

8 9 10 12

PGND

EN

FB

18

LX

17

VIN

16

COMP

15

SS

14

LDOI

13

LDOO

11

Typical Application Circuit

V

GL

-6V

C13

0.22uF

V

Q1

MMBT3904

R9

240k

R10

50k

C14

0.22uF

DIN

R6

65k

R7

110k

R8

6.8k

V

FLK

V

LDO

RESET

V

AVDD

Chip Enable

BAT54S

C12

0.1uF

D4

R14

100k

C4

27nF

C10

0.1uF

R

C1

10uF

SET

19

7

6

15

5

8

1

9

22

10

DRVN

VQFN-24L 4x4

C11

0.1uF

EN

DRVN

FBN

SS

VREF

CD

VFLK

RESET

AVDD

VDIV

AGND

CD

RESET

V

IN

3.3V

17

VIN

RT9913

11

VDIV

COMP

VGHM

OPAO

OPAI

LDOI

LDOO

PGND

21

AGND

4.7uH

LX

FB

VGH

RE

ADJ

L1

ADJ

C7

0.1uF

V

AVDD

8.5V

C2

4.7uF x 3

C6

0.1uF

D3

BAT54S

C8

0.1uF

R

30k

GH

18

20

16

C

COMP

NC

D2

BAT54S

SS12

D1

R3

56k

C3

1nF

C5

0.1uF

R1

330k

R2

56k

2

C15

1.5nF

C9

1uF

V

GHM

25V

V

COM_OUT

C16

1uF

V

LDO

2.5V

V

IN

3.3V

V

COM_IN

V

AVDD

R12

56k

R13

56k

3

4

23

24

14

13

12

R11

1.2k

R5

56k

R4

56k

DS9913A/B-00 February 2006www.richtek.com

2

Preliminary

RT9913A/B

Functional Pin Description

Pin Number Pin Name Pin Function

1 VFLK VFLK is produced by timing controller for charging or discharging VGHM.

2 VGH Switch input for charge VGHM

3 VGHM VGHM is the supply voltage for the gate driver ICs.

4 RE Switch input for discharge VGHM

5 VREF

6 FBN

7 DRVN

8 CD Pin for external capacitor setting the delay time for voltage detector reset delay time.

9 RESET Voltage Detector open-drain Output for Reset.

10 VDIV

11 AGND Analog Ground.

12 ADJ

13 LDOO Voltage Output of the LDO.

14 LDOI Voltage Input of the LDO.

15 SS

16 COMP Compensation Error Amplifier Pin. Connect a compensation network to ground.

17 VIN

18 LX Switching pin. Drain of the internal power NMOS for the main step-up regulator.

19 EN Active-High Enable Control Input and OCP level setting.

20 FB

21 PGND Power Ground. PGND is the source of the power NMOS.

22 AVDD VDD for Source Driver Power. It also supplies OP power and GPM level shift voltage.

23 OPAO Unit-Gain OPA Output Pin.

24 OPAI Unit-Gain OPA Input Pin.

Exposed Pad GND Exposed pad should be soldered to PCB board and connected to GND.

Internal Reference Bypass Terminal. Connect a 0.22uF ceramic capacitor from the VREF

to analog ground (AGND). The source capability is 100uA.

Negative Linear-Regulator Feedback Input. Connect FBN to the center of a resistive

voltage-divider between the negative output voltage VGL and the VREF to set the

negative linear-regulator output voltage. Place the resistive voltage-divider close to the

pin.

Negative Linear-Regulator Base Drive. Open drain of an internal PMOS. Connect DRVN

to the base of the external linear-regulator NPN pass transistor.

Voltage Detector Divider Input. Connect VDIV to the center of a resistive voltage-divider

between the detected voltage input (VDIN) and analog ground (AGND).

Low-Dropout Linear Regulator (LDO) Feedback Input. ADJ regulates to 1.24V nominal.

Connect ADJ to the center of a resistive voltage-divider between the LDO output voltage

LDOO and the analog ground (AGND) the LDO output voltage. Place the resistive

voltage-divider close to the pin.

Soft-Start Control Pin. Connect a soft-start capacitor (C

capacitor is charged with a constant current 4uA.

Supply Input. The supply voltage powers all the control circuits including the boost

converter, negative linear-regulator, gate pulse regulator and voltage detector.

Main Boost Regulator Feedback Input. FB regulates to 1.24V nominal. Connect FB to the

center of a resistive voltage-divider between the main output AVDD and the analog

ground (AGND) the boost regulator output voltage. Place the resistive voltage-divider

close to the pin.

) to this pin. The soft-start

SS

DS9913A/B-00 February 2006 www.richtek.com

3

RT9913A/B

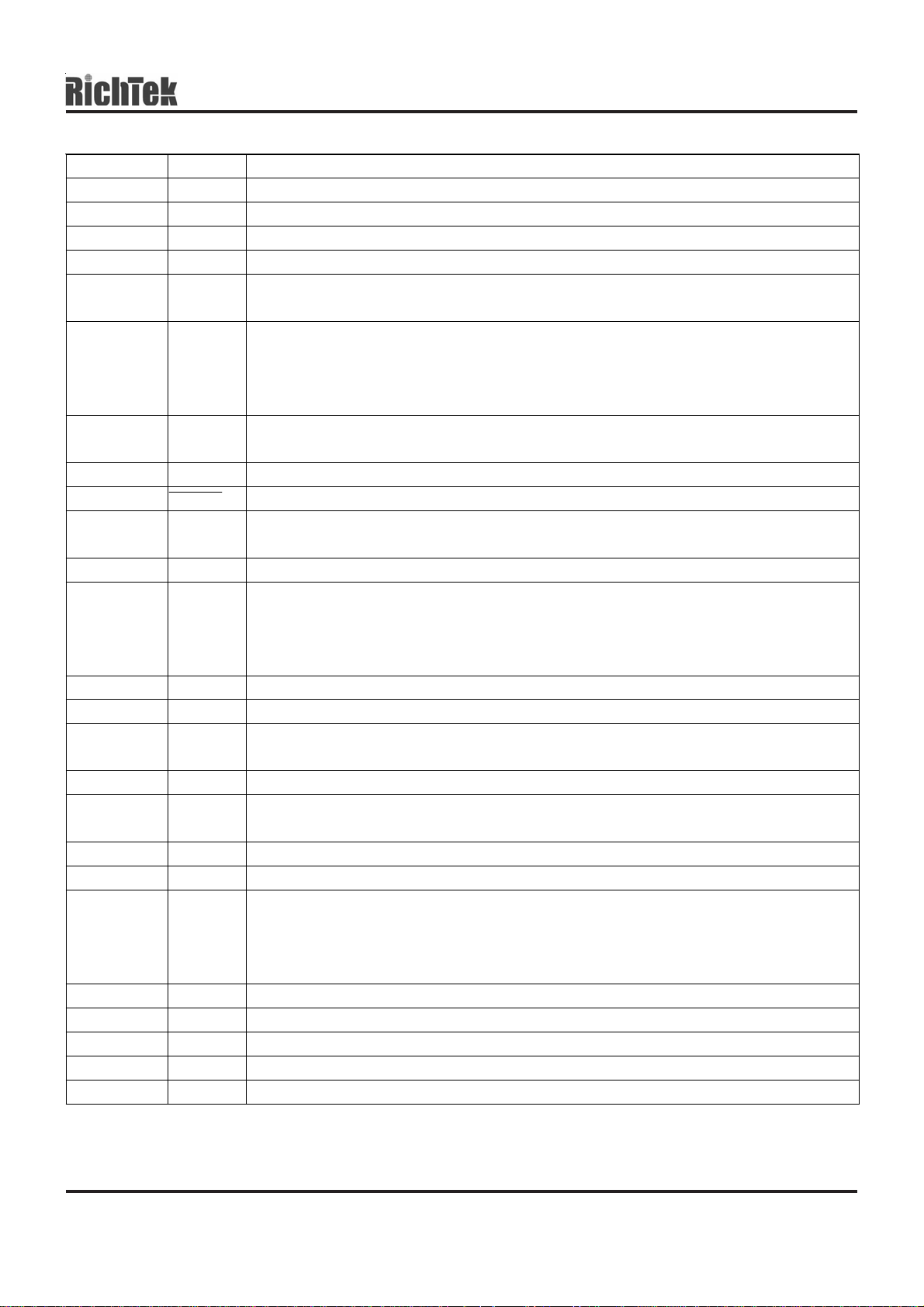

Function Block Diagram

Preliminary

EN

SS

V

IN

VIN

VDIV

RESET

LDOI

LDOO

ADJ

VREF

FBN

AGND

Boost Regulator Block Diagram

CD

Voltage

Detector

LDO

1.24V

Voltage

Reference

+

-

DRVN

Boost

Regulator

GPM

LX

PGND

FB

COMP

V

IN

VGHM

RE

AVDD

VGH

VFLK

OPAO

+

-

OPAI

VIN

4uA

EN

COMP

FB

Oscillator

1.24V

Protection

+

Error

Amplifier

Slope

Compensation

Summing

Comparator

+

-

Clock

SoftStart

Control

and

Driver

Logic

Current

Sense

SS

LX

PGND

DS9913A/B-00 February 2006www.richtek.com

4

Preliminary

Absolute Maximum Ratings (Note 1)

RT9913A/B

z Supply Input Voltage, V

z VGH-AVDD, VGHM-AVDD ---------------------------------------------------------------------------------- 18V

z LX ---------------------------------------------------------------------------------------------------------------- −0.3V to 16V

z VGH, VGHM RE ---------------------------------------------------------------------------------------------- −0.3V to 30V

z AVDD ------------------------------------------------------------------------------------------------------------ −0.3V to 16V

z OPAI, OPAO --------------------------------------------------------------------------------------------------- −0.3V to (AVDD + 0.3V)

z DRVN ------------------------------------------------------------------------------------------------------------ (V

z VFLK, VREF, FBN, CD, RESET_, VDIV, SS, COMP, EN, FB ------------------------------------ −0.3V to (V

z LDOI ------------------------------------------------------------------------------------------------------------- −0.3V to 7V

z ADJ, LDOO ---------------------------------------------------------------------------------------------------- −0.3V to (LDOI + 0.3V)

z Power Dissipation, P

----------------------------------------------------------------------------------- −0.3V to 7V

IN

@ T

D

= 25°C

A

− 16V) to (VIN + 0.3V)

IN

+ 0.3V)

IN

VQFN-24L 4x4 ------------------------------------------------------------------------------------------------ 1.786W

z Package Thermal Resistance (Note 4)

VQFN-24L 4x4, θJA------------------------------------------------------------------------------------------- 56°C/W

z Lead Temperature (Soldering, 10 sec.) ------------------------------------------------------------------ 260°C

z Storage Temperature Range ------------------------------------------------------------------------------- −65°C to 150°C

z Junction Temperature ---------------------------------------------------------------------------------------- 150°C

z ESD Susceptibility (Note 2)

HBM (Human Body Mode) --------------------------------------------------------------------------------- 2kV

MM (Machine Mode) ----------------------------------------------------------------------------------------- 200V

Recommended Operating Conditions (Note 3)

z Ambient Temperature Range ------------------------------------------------------------------------------- −40°C to 85°C

z Junction Temperature Range ------------------------------------------------------------------------------- −40°C to 125°C

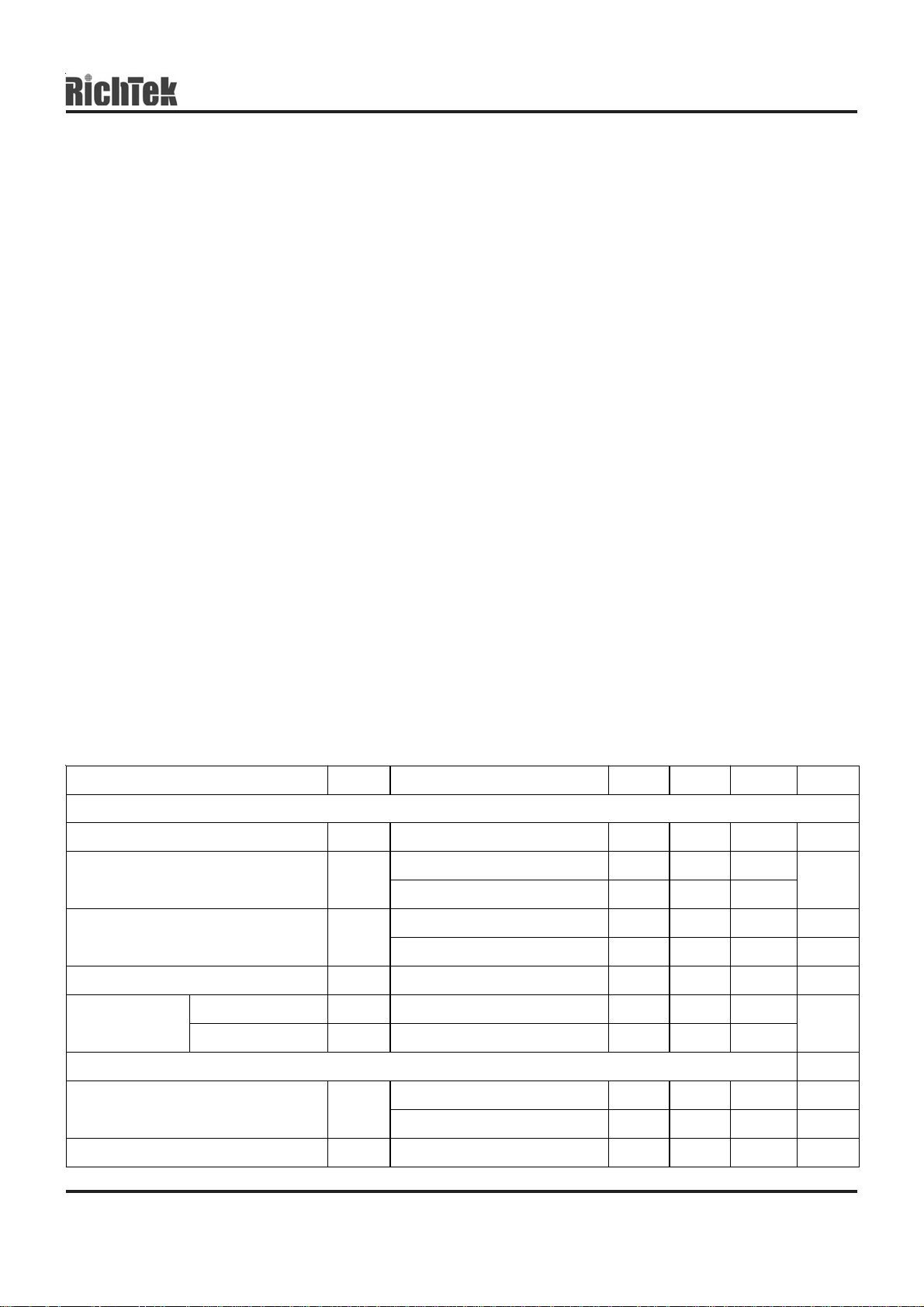

Electrical Characteristics

(VIN = 3.3V, V

System Supply

Input Supply Voltage

VIN Under Voltage Lockout Threshold V

VIN Quiescent Current IQ

Shut Down Current

EN Threshold

Main Boost Regulator

Operation Frequency

= 8.5V, TA = 25°C, unless otherwise specification)

OUT

Parameter Symbol Test Condition Min Typ Max Units

2.5 -- 5.5 V

V

rising

IN

1.8 2.0 2.2

Hysteresis 0.05 0.1 0.15

V

= 1.3V, LX no switching

FB

= 1.1V, LX switching

V

FB

VIN = 3.3V

-- -- 1.5

0.8 -- --

0.15 0.4 1 mA

1 2 3.5 mA

-- 1 5

Logic-High Voltage

Logic-Low Voltage

V

I

IN

V

V

IN

UVLO

IH

IL

RT9913 A -- 640 -- kHz

F

OSC

RT9913 B 0.9 1.2 1.4 MHz

V

μA

V

Maximum Duty Cycle 86 90 94 %

To be continued

DS9913A/B-00 February 2006 www.richtek.com

5

RT9913A/B

Parameter Symbol Test Condition Min Typ Max Units

Preliminary

Feedback Voltage

V

FB

FB Input Bias Current

Transconductance of Error Amplifier Gm

Voltage Gain of Error Amplifier

A

V

Feedback Voltage Line Regulation

Output Voltage Load Regulation

LX ON-Resistance

R

LX(ON)

No load, TA = 25°C

V

= 1.5V

FB

I

= 5μA

COMP

-- 700 -- V/V

V

= 2.5V to 5.5V

IN

V

= 3.3V,

IN

I

= 20 to 200mA

LOAD

50 200 500

1.22 1.24 1.26 V

-40 -- +40 nA

-- 160 --

μA/V

-- 0.1 0.15 %/V

−1

-- 0 %

mΩ

Current Sense Transresistance -- 0.5 -- A/V

Soft-Start Charge Current

Thermal Shutdown Temperature

Thermal Shutdown Hysteresis

Current Limit

I

SS

T

ΔT

I

LIM

SD

2 4 6

-- 170 --

-- 20 --

SD

-- 2 -- A

μA

°C

°C

Gate-Off Regulation Controller

V

source current capability I

REF

FBN Regulation Voltage

FBN Effective Load Regulation Error

FBN Line Regulation Error

DRVN Source Current

Power-On-Delay Time

REF

V

FBN

I

DRVN

T

Refer to V

VGL

-- 100 1000

V

= −10V,

DRVN

I

= 50uA to 1mA

DRVN

I

= 0.1mA, 2.5V<VIN<5.5V

DRVN

−20

−30 −5

-- 1 6 mV

0 20 mV

0 mV

1 4 6 mA

FB

> 1V

25 32 39 ms

μA

Low Drop-Out Linear Regulator (LDO)

Input Voltage

Dropout Voltage

Feedback Voltage

Current Limit

Quiescent Current

Line Regulation

Load Regulation

Gate Pulse Modulator

VFLK Input High Voltage

VFLK Input Low Voltage

Power-On-Delay Time (Note 5)

6

V

LDOI

V

DROP

V

ADJ

I

LIM

I

LDO

V

IH_FLK

V

IL FLK

T

VGHM

2.5 -- 5.5 V

V

= 3.3V, I

IN

1.22 1.24 1.26 V

OUT

= 350mA

200 300 500 mV

350 500 650 mA

-- 60 100

V

= 2.8V to 5.5V,

IN

I

= 100mA, V

OUT

I

= 1mA to 300mA

OUT

1.5 -- -- V

-- -- 0.6 V

Refer to V

FB

> 1V

LDO

= 2.5V

-- 0.1 0.3 %/V

0 0.2 0.5 %

50 64 78 ms

μA

To be continued

DS9913A/B-00 February 2006www.richtek.com

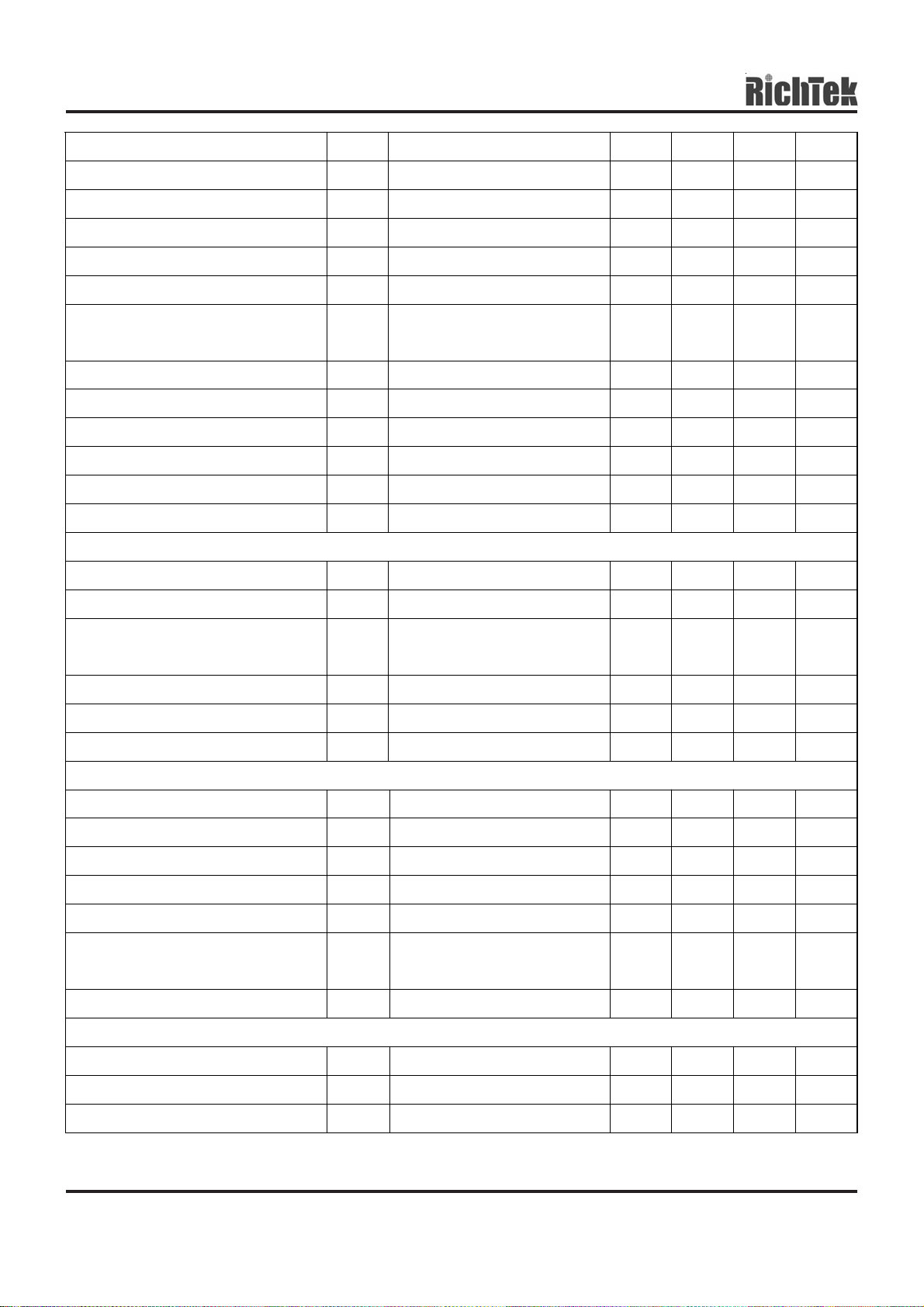

Parameter Symbol Test Condition Min Typ Max Units

Gate Pulse Modulator

Preliminary

RT9913A/B

VGH Switch On-Resistance RP1 10 30 50

RE Switch On-Resistance RN2 10 25 50

Ω

Ω

Voltage Detector

Minimum Operating Voltage 1.6 -- -- V

Detecting voltage adjustment

V

DIV

Detecting voltage accuracy

Adjustable delay time-constant k

V

Buffer

COM

Supply Voltage Range

Supply Current

Input Offset Voltage

Input Bias Current

Output Voltage Swing High

Output Voltage Swing Low

V

SUP

I

OP

V

V

OS

I

BIAS

V

OH

V

OL

-- 1.1 -- V

−2%

= k(Ω)*C10(F)

t

D

AVDD -- 15 V

80k 120k 160k

-- 2% %

Ω

-- 0.5 0.9 mA

= AVDD/2, TA = 25°C

COM

-- 1 50 nA

I

= 100μA

OUT

= 75mA

I

OUT

I

= −100μA

OUT

= −75mA

I

OUT

−15

AVDD-20 AVDD-5 -- mV

AVDD-1.5 AVDD-1.3 -- V

-- 2 20 mV

-- 1.5 1.8 V

0 15 mV

Source 100 140 180 mA

Short-Circuit Current To AVDD/2

Sink 100 140 180 mA

-3dB Bandwidth

F

3db

-- 12 -- MHz

Gain Bandwidth Product GBW -- 8 -- MHz

Slew Rate SR 8 12 16

Note 1. Stresses listed as the above “Absolute Maximum Ratings” may cause permanent damage to the device. These are for

stress ratings. Functional operation of the device at these or any other conditions beyond those indicated in the

operational sections of the specifications is not implied. Exposure to absolute maximum rating conditions for extended

periods may remain possibility to affect device reliability.

Note 2. Devices are ESD sensitive. Handling precaution recommended.

Note 3. The device is not guaranteed to function outside its operating conditions.

Note 4. θ

Note 5. It is guaranteed by design.

is measured in the natural convection at TA = 25°C on a low effective thermal conductivity test board of

JA

JEDEC 51-3 thermal measurement standard.

V/μs

DS9913A/B-00 February 2006 www.richtek.com

7

RT9913A/B

Typical Application Circuit

Preliminary

Boost Efficiency vs. Output Current

95

90

85

80

75

70

65

Efficiency (%)

60

55

50

0 20 40 60 80 100 120 140 160 180 200

V

= 8.5V, f = 1.2MHz

AVDD

Output Current (mA)

Boost Efficiency vs. Outpu t Curren t

95

90

85

80

75

70

65

Efficiency(%)

60

55

50

0 20 40 60 80 100 120 140 160 180 200

Output Current (mA)

V

= 12V, f = 1.2MHz

AVDD

V

= 3.3V

IN

V

= 3.0V

IN

V

= 2.7V

IN

VIN = 3.3V

VIN = 3.0V

Boost Output Voltage vs. Output Current

8.62

8.6

8.58

8.56

8.54

8.52

Output Voltage (V)

8.5

V

= 8.5V, f = 1.2MHz

8.48

0 20 40 60 80 100 120 140 160 180 200

AVDD

Output Current (mA)

Boost Output Voltage vs. Output Current

12.04

12

11.96

11.92

Output Voltage (V)

11.88

11.84

11.8

11.76

0 20 40 60 80 100 120 140 160 180 200

VIN = 3.0V

VIN = 3.3V

V

= 12V, f = 1.2MHz

AVDD

Output Current (mA)

V

V

V

= 2.7V

IN

= 3.0V

IN

= 3.3V

IN

Boost Efficiency vs. Output Current

90

88

V

AVDD

86

84

82

Efficiency (%)

80

78

76

0 20 40 60 80 100 120 140 160 180 200

V

C1 = 6.9μF, C2 = 30μF

Output Current (mA)

= 7.5V

= 8V

= 8.5V

= 3V, f = 1.2MHz

IN

= 7V

Boost Output Voltage v s. Output Current

8.6

8.4

V

= 8.5V

AVDD

8.2

8

V

= 8V

AVDD

7.8

7.6

7.4

V

= 7.5V

AVDD

7.2

Output Voltage (V)

7

V

= 7V

AVDD

6.8

6.6

0 20 40 60 80 100 120 140 160 180 200

V

= 3V, f = 1.2MHz, C1 = 6.9μF, C2 = 30μF

IN

Output Current (mA)

DS9913A/B-00 February 2006www.richtek.com

8

Boost Feedback (V)

Boost Feedback vs. Temperature

1.255

1.250

1.245

1.240

1.235

1.230

1.225

1.220

1.215

1.210

1.205

-40-30-20-100 102030405060708090

Temperature

(°C)

Preliminary

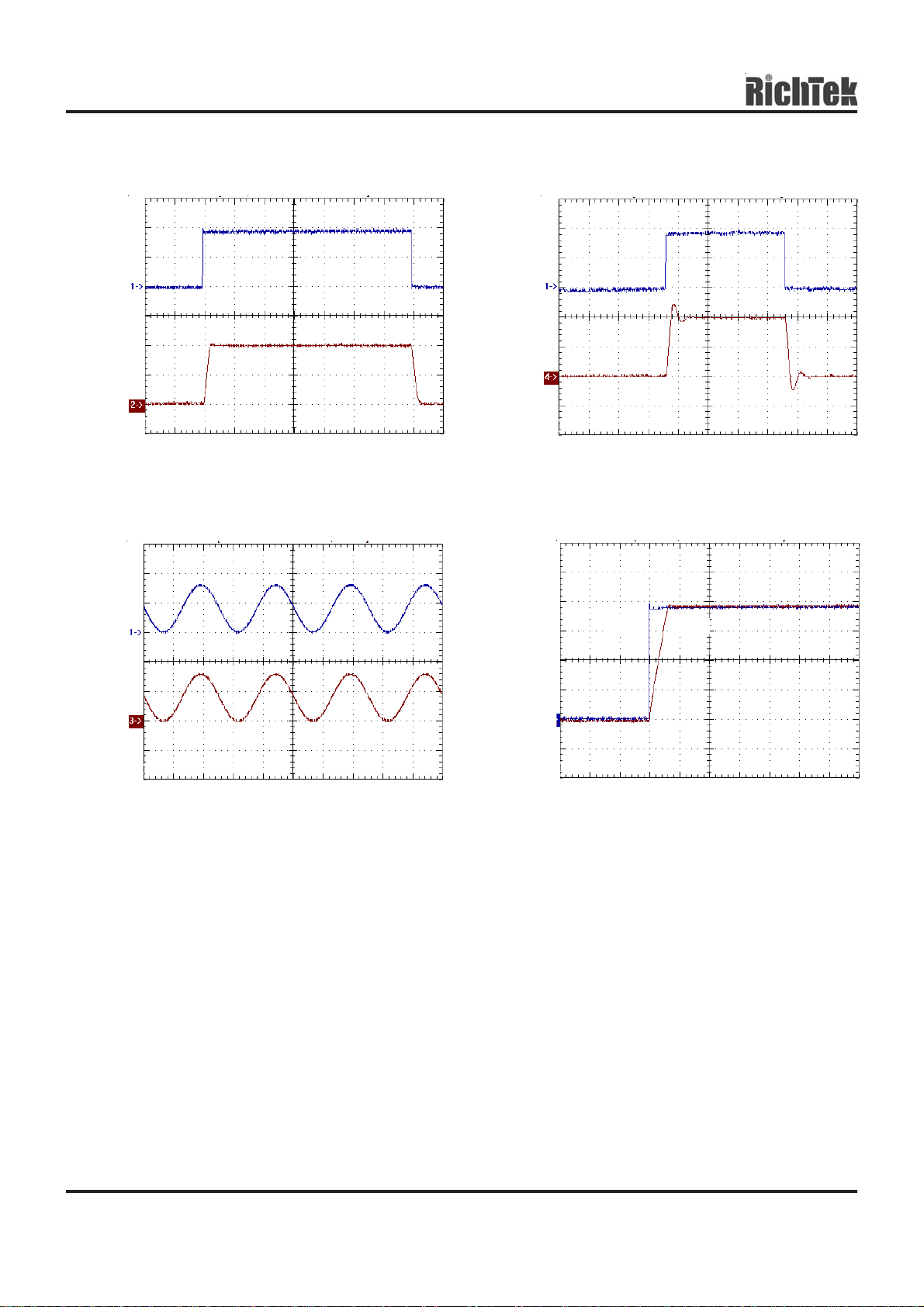

V

AVDD

ac coupled

(500mV/Div)

I

LOAD

(100mA/Div)

I

L

(500mA/Div)

RT9913A/B

Boost Regulator Load

Transient Response

I

= 10mA to 200mA

LOAD

Time (200μs/Div)

V

AVDD

(5V/Div)

V

IN

(5V/Div)

EN

(2V/Div)

I

IN

(500mA/Div)

V

LX

(5V/Div)

V

ripple

AVDD

ac coupled

(50mV/Div)

I

L

(200mA/Div)

Boost Regulator Soft-Start

I

= 200mA

LOAD

Time (2.5ms/Div)

Boost Regulator Stability

Time (400ns/Div)

f = 1.2MHz

I

LOAD

= 100mA

V

LX

(5V/Div)

V

ripple

AVDD

ac coupled

(50mV/Div)

I

L

(200mA/Div)

-5.75

-5.77

-5.79

-5.81

-5.83

VGL Voltage (V)

-5.85

-5.87

Boost Regulator Stability

I

= 10mA, f = 1.2MHz

LOAD

Time (400ns/Div)

VGL Regulator Load Regulation

0 102030405060708090100

Load Current (mA)

DS9913A/B-00 February 2006 www.richtek.com

9

RT9913A/B

Preliminary

-5.75

-5.77

-5.79

-5.81

-5.83

VGL Output Voltage (V)

-5.85

(5V/Div)

(5V/Div)

(10V/Div)

(10V/Div)

VGL Regulator Line Regulation

IGL = 50mA

-14 -13 -12 -11 -10 -9 -8 -7

Input Voltage(V)

Power Off Sequence

with GPM Function

V

AVDD

VGH

VGL

VGHM

FLK = 50kHz/50%

V

AVDD

(5V/Div)

VGH

(10V/Div)

VGHM

(10V/Div)

VGL

(5V/Div)

(5V/Div)

(5V/Div)

(10V/Div)

(10V/Div)

Power On Sequence

Time (25ms/Div)

Power Off Sequence

V

VGHM

FLK = V

AVDD

VGL

VGH

IN

VFLK

(1V/Div)

VGHM

(10V/Div)

10

Time (2.5ms/Div)

VGHM

R11 = 670Ω, C15 = 1.5nF

Time (10μs/Div)

Time (25ms/Div)

VGHM

VFLK

(1V/Div)

VGHM

(10V/Div)

R11 = 1.2kΩ, C15 = 680pF

Time (10μs/Div)

DS9913A/B-00 February 2006www.richtek.com

Preliminary

RT9913A/B

VFLK

(1V/Div)

VGHM

(10V/Div)

V

LDOO

ac coupled

(100mV/Div)

VGHM

R11 = 1.2kΩ, C15 = 2.2nF

Time (10μs/Div)

LDO Line Transient

V

LDOO

ac coupled

(50mV/Div)

I

LDOO

(200mA/Div)

2.59

2.585

LDO Load Transient

I

= 10mA to 350mA

LDOO

Time (100μs/Div)

LDO Load Regulation

V

LDOI

(1V/Div)

Dropout Voltage (mV)

4

3

V

LDOO

= 2.5V, V

= 3V to 4V, I

LDOI

LDOO

Time (100μs/Div)

LDO Dropout Voltage

500

450

400

350

300

250

200

150

100

50

0

0 0.05 0.1 0.15 0.2 0.25 0.3 0.35 0.4

Load Current (A)

85°C

= 50mA

25°C

-40°C

2.58

2.575

LDO Output Voltage (V)

2.57

I

LDO

(200mA/Div)

V

LDO

(1V/Div)

V

= 2.5V, V

LDOO

0 50 100 150 200 250 300 350

LDOI

= 3.3V

LDO Loading Current (mA)

LDO OCP

I

= 100mA to 600mA

OUT

Time (100μs/Div)

DS9913A/B-00 February 2006 www.richtek.com

11

RT9913A/B

Preliminary

V

OPAI

(1V/Div)

V

OPAO

(1V/Div)

V

OPAI

(5V/Div)

OPA Large-Signal Step Response

Time (1μs/Div)

OPA Rail-to-Rail Input/Output

V

OPAI

(100mV/Div)

V

OPAO

(100mV/Div)

OPA Small-Signal Step Response

Time (500ns/Div)

OPA Slew Rate

V

OPAI

V

OPAO

V

OPAO

(5V/Div)

Time (400μs/Div)

(2V/Div)

Time (1μs/Div)

12

DS9913A/B-00 February 2006www.richtek.com

Application Information

Preliminary

RT9913A/B

The RT9913 contains a high performance boost regulator

to generate voltage for output voltage, gate-on driver and

negative voltage regulated by linear regulator controller

for gate-off driver. It also includes of a high-current rail-to-

rail operation amplifier, a gate pulse modulator (GPM), a

programmable timing control voltage detector, and a low

dropout linear regulator. The following content contains

the detailed description and the information of component

selection.

Boost Regulator

The boost regulator is a high efficiency current-mode PWM

architecture with 1.2MHz or 640kHz operation frequency.

It performs fast transient responses to generate gate driver

supplies for TFT LCD display. The high operation frequency

allows smaller components used to minimize the

thickness of LCD panel. To regulate the output voltage is

to set resistive voltage-divider sensing at FB pin. The error

amplifier varies the COMP voltage by sensing FB pin to

regulate the output voltage. For better stability, the slope

compensation signal summed with the current-sense

signal will be compared with the COMP voltage to

determine the current trip point and duty cycle.

Soft-Start

The RT9913 provides soft-start function to minimize the

inrush current. When EN pin is connected to high, an

internal constant current charges an external capacitor.

The rising voltage rate on COMP pin is limited during the

charging period and the inductor peak current also limited

at the same time. In the meanwhile, the frequency

increases slowly at the beginning. When the EN pin is

connected to GND, the external capacitor will be

discharged for next soft start time.

The soft-start function is implemented by the external

capacitor with a 4μA constant current charging to the soft-

start capacitor. Therefore, the capacitor should be large

enough for output voltage regulation. Typical value for soft-

start capacitor range is 27nF. The available soft start

capacitor range is from 10nF to 200nF.

Inductor Selection & Maximum output current

capability

The minimum inductance value, peak current rating and

series resistance are factors to consider when selecting

the inductor. These factors influence the converter's

efficiency, maximum output load capability, transient-

response time and output voltage ripple. Physical size

and cost are also important factors to be considered. The

maximum output current, input voltage, output voltage and

switching frequency determine the inductor value. Very

high inductance values minimize the current ripple and

therefore reduce the peak current, which decreases core

losses in the inductor and I2R losses in the entire power

path. However, large inductor values also require more

energy storage and more turns of wire, which increase

physical size and can increase I2R losses in the inductor.

Low inductance values decrease the physical size but

increase the current ripple and peak current.

Finding the best inductor involves choosing the best

compromise between circuit efficiency, inductor size and

cost.

Choose an available inductor value from an appropriate

inductor family. Calculate the maximum DC input current

at the minimum input voltage V

using the following

IN(MIN)

equation.

VI

×

I

=

MAX) IN(DC,

V

The expected efficiency at that operating point (η

AVDDAVDD(MAX)

η

×

(MIN)IN(MIN)

) can

MIN

be taken from an appropriate curve in the Typical Operating

Characteristics. Calculate the ripple current at that

operating point and the peak current required for the

inductor :

I

RIPPLE

I

RIPPLE

2

−×

fVL

××

OSCAVDD

=

I I

+=

MAX) IN(DC,PEAK

)V(VV

IN(MIN)AVDDIN(MIN)

The inductor's saturation current rating and the LX over-

current protection (I

inductor DC current rating should exceed I

) should exceed I

OCP

and the

PEAK

IN(DC,MAX)

. For

good efficiency, choosing an inductor with less than 0.1Ω

series resistance is suggested.

DS9913A/B-00 February 2006 www.richtek.com

13

RT9913A/B

Preliminary

Diode Selection

To achieve high efficiency, Schottky diode is the

recommended diode for lower forward drop voltage and

faster switching time. The output diode rating should be

large enough for maximum output voltage, average power

dissipation and the pulsating diode peak current.

Output Capacitor Selection

For lower output voltage ripple, low-ESR ceramic capacitor

is recommended. The output voltage ripple consists of

two components: one is the pulsating output ripple current

flowing through the ESR, and the other is the capacitive

ripple caused by charging and discharging.

+=

VVV

RIPPLE_CRIPPLE_ESRRIPPLE

−

AVDD

VV

⎞

INAVDD

⎟

×

fV

⎠

RI

ESRPEAK

C

OUT

⎜

⎝

I

⎛

PEAK

+×≅

Input Capacitor Selection

For better input bypassing, low-ESR ceramic capacitor is

recommended for better performance. A 10μF input

capacitor is sufficient and it is flexible to reduce the value

for a lower output power requirement.

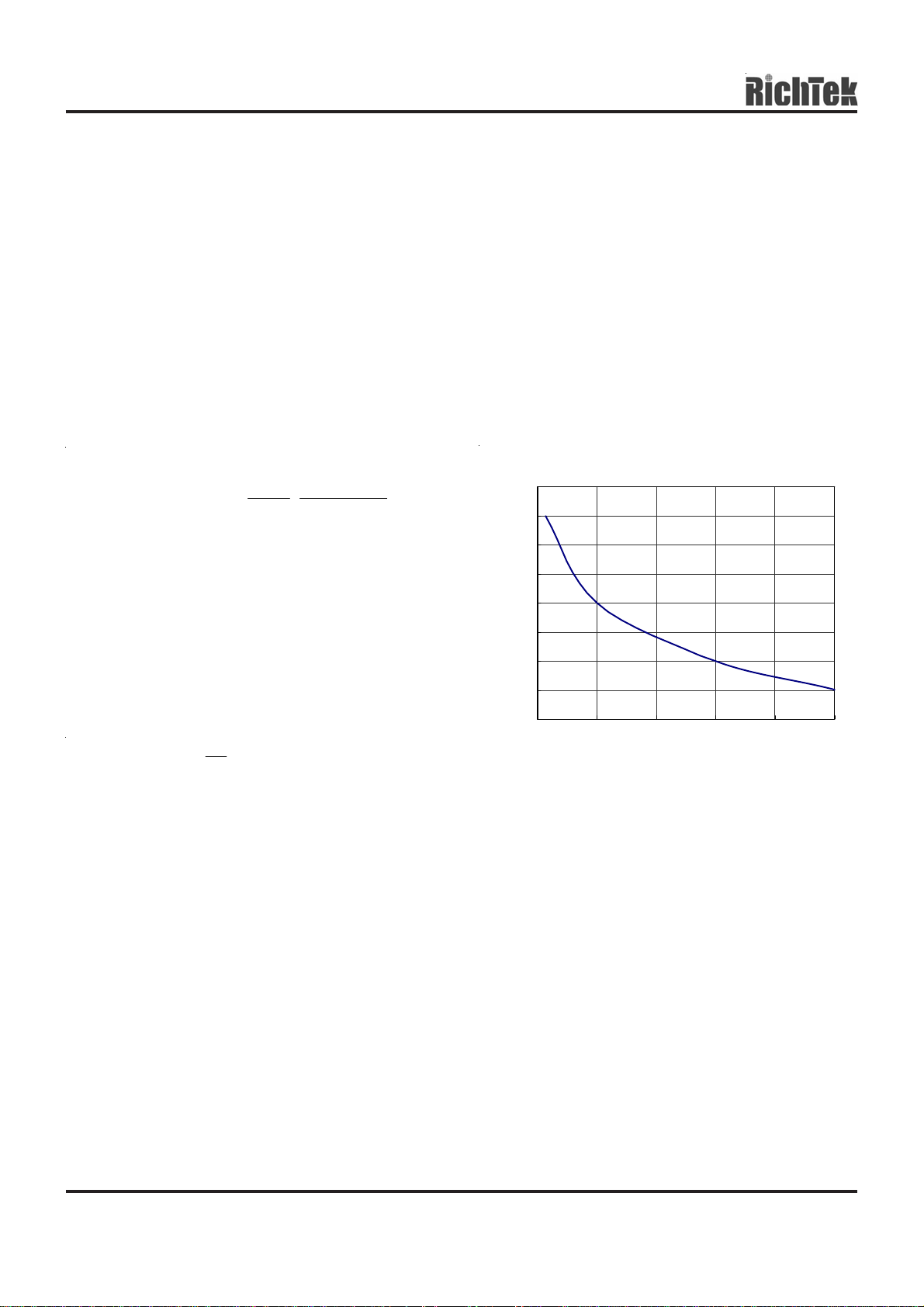

Over Current Protection

The RT9913 main boost converter has over-current

protection to limit peak inductor current. It prevents large

current damaging the inductor and diode. During the

ON-time, once the inductor current exceeds the current

limit, the internal LX switch turns off immediately and

shortens the duty cycle. Therefore, the output voltage

drops if the over-current condition occurs. Actual current

limit is always larger than nominal value because of the

internal circuit delay. Current limit is also affected by the

input voltage, duty cycle, and inductor value. The following

figure shows the different over-current settings and the

corresponding R

and V

AVDD

2.2

2

1.8

1.6

1.4

1.2

OCP Current (A)

1

falls to 90%.

resistance while OCP function works

SET

OCP Current vs. R

SET

Output Voltage

The regulated output voltage is the following formula :

R1

OUT

⎛

⎜

⎝

⎞

+×=

11.24VV

⎟

R2

⎠

The recommended value for R2 should be up to 100kΩ

without some sacrificing. To place the resistor-divider as

close as possible to the chip can reduce noise sensitivity.

Loop Compensation

The voltage feedback loop can be compensated with an

external compensation network consisted of R3, C3 and

C

(As Figure 1). Choose R3 to set high frequency

COMP

integrator gain for fast transient response and C3 to set

the integrator zero to maintain loop stability.

Place C

between COMP and GND to add an additional

COMP

high-frequecncy pole. The value is between 10pF and

47pF. For typical application VIN = 3.3V , V

,C

= 4.7μF x 3 , L = 4.7μH, the recommened value

OUT

OUT

= 8.5V

for compensation is as below:

0.8

0.6

50 100 150 200 250 300

(kΩ)

R

SET

Figure 1. OCP settings versus R

SET

@ V

= 2.5V

EN

Over Temperature Protection

The RT9913 main boost converter has thermal protection

function to prevent the excessive power dissipation from

overheating. When the junction temperature exceeds

170°C, it will shut down the device. Once the device cools

down by approximately 20°C, it will start to operate

normally. For continuous operation, do not operate over

the maximum junction temperature rating around 150°C.

R3 = 56kΩ , C3 = 1nF , Ccomp=NC

14

DS9913A/B-00 February 2006www.richtek.com

Preliminary

RT9913A/B

Gate-Low Linear Regulator Controller

The gate-low linear regulator controller is to provide the

TFT-LCD gate off voltage. One stage charge pump can

provide a negative voltage. Using the gate-low regulator

after the produced negative voltage can regulate the

exceeded voltage. With a 6.8kΩ base to emitter resistor

it can drive an extra NPN pass transistor and at least 4mA

source current. VGL can be regulated by the voltage-divider

resistor and 0.22μF ceramic output capacitor. The output

load current (I

(β), drive current (I

drop (VBE) and base-to-emitter resistor (R8) as the following

equation :

β

=

DRVNLOAD

C14

C13

The VGL regulator controls the intermediate charge-pump

stage and regulates the final charge-pump's output voltage

as the following equation :

) can be decided by the current gain

LOAD

), base-to-emitter forward voltage

DRVN

V

BE

)

-(I I

R8

VGL Regulation Circuit

VREF

1.24V

R10

R9

VGL

FBN

RL

+

-

DRVN

Q1

PWM

R8

C12

Figure 2

LX

C11

VGL

ZD1

V

IN

VIN

LX

Boost

Regulator

FB

RT9913A/B

V

AVDD

Figure 3

GPM

The GPM function is controlled by frame signals from

timing controller to modulate the Gate-On voltage (VGHM).

According to the different loading capacitor (C16), the

falling slope of the Gate-On voltage is programmable by

an external resistor (R11) .The VGL lags 32ms (typ.) behind

AVDD and the VGHM lags 64ms (typ.) behind AVDD while

power on.

VGH

VFLK

PGOOD

Pos-edge

64ms delay

PGOOD

Delay

Gate Pulse Modulator

VGHM

P1

N2

RE

C15

R11

Gate

Driver IC

VGL = −V

Zener Diode for the Negative Regulator

Instead of the gate-low linear regulator controller,

bypassing a zener diode(ZD1) after the charge-pump satge

can also stable the negative voltage. However, for better

efficiency, using the gate-low linear regulator controller is

recommended.

VGL = −(V

(R9/R10)

REF

AVDD

− VD)

Figure 4

The GPM operation sequence is shown in Figure 5.

PGOOD is the logic signal detecting the feedback voltage

(VFB). If V

is below 1V, PGOOD becomes low ;

FB

otherwise, PGOOD is high while VFB is above 1V. When

PGOOD is high lasting more than 64ms, PGOOD Delay

signal is built and then VGHM is controled by V

FLK

signal.

VD : forward voltage drop of the charge pump diode

DS9913A/B-00 February 2006 www.richtek.com

15

RT9913A/B

Preliminary

VIN

AVDD

VGH

PGOOD

PGOOD Delay

VFLK

64ms

VGHM

adjustable falling slope

V

GH

Figure 5

GPM for Power Sequence

The GPM function also achieves the power-on sequence

control. The GPM internal delay time (64ms) can be used

for VGH built-up delay. The application circuit is shown in

Figure 6 connecting input voltage to V

a 1uF to VGHM .VGH will lag 64ms after V

and bypassing

FLK

built.

AVDD

Charge Pumps

The charge pump stages can be achieved by the flying

capacitors and the Schottky diodes. According to the

application circuit, the positive and negative charge-pump

output voltages can be determined by the following

equations :

VGH = 3V

V

: the forward voltage drop of the charge pump diodes

D

AVDD

− 2V

D

The flying capacitor requires the voltage rating larger than

16V and 0.1uF ceramic capacitors are enough for the low-

current applications (10mA) . Besides, Schottky diodes

with a current rating should equal to or greater than two

times the average charge-pump input current. Note that

the voltage difference between VGH (VGHM) and AVDD

should not exceed 18V.

Operational Amplifier

The operational amplifier to drive the LCD backplane V

The operational amplifier features +/- 140mA output short-

circuit current, 12V/μs slew rate, and 12MHz bandwidth.

COM

.

VGH

VIN

VIN

AVDD

VGH

VGL

VGHM

VGH

VFLK

RT9913A/B

32ms

GPM

64ms

Figure 6

VGHM

RE

1uF

V

GHM

An internal short-circuit protection circuit is implemented

to protect the device from output short circuit. The

operational amplifier limits the short circuit current while

the output is directly shorted.

LDO

The low-dropout linear regulator (LDO) can supply up to

350mA current while input voltage is 3.3V. It uses an

internal PMOS as the pass device. The output current

limitation is 500mA. It is suitable for the supply voltage

for the T-CON ASIC.

LDOI

+

Current

Limit

LDOO

R4

ADJ

R5

AGND

16

Figure 7

DS9913A/B-00 February 2006www.richtek.com

Preliminary

RT9913A/B

Voltage Detector

The voltage detector monitors the VDIN voltage to generate

a reset signal while VDIN is lower than the detecting level.

The detecting level is decided by an external resistor divider.

V

= V

DET

V

= 50mV (1+R6/R7)

HYS

The delay time is programmable by an external capacitor

(C10) as equation. For example, setting C10 = 100nF can

generate 12ms delay for reset signal.

tD = 120k x C10

VDIN

R6

R7

(1+R6/R7) = 1.1V x (1+R6/R7)

REF2

VDIV

V

REF2

= 1.1V

+

-

Delay

Circuit

CD

C10

VIN

RESET

VLDO

R14

Layout Guideline

For high frequency switching power supplies, the PCB

layout is important to get good regulation, high efficiency

and stability. The following descriptions are the guidelines

for better PCB layout.

z For good regulation place the power components as

close as possible. The traces should be wide and short

especially for the high-current output loop.

z The current limit setting resistor R

EN pin, The trace must be shorter and avoid the trace

near any switching nodes.

z The feedback voltage-divider resistors must be near the

feedback pin. The divider center trace must be shorter

and avoid the trace near any switching nodes.

z The compensation circuit should be kept away from

the power loops and be shielded with a ground trace to

prevent any noise coupling.

z Minimize the size of the Lx node and keep it wide and

shorter. Keep the Lx node away from the FB and analog

ground.

must be near the

SET

VDI

V

HYS

GND

t

D

Figure 8

V

DET+VHYS

V

DET

Min Operating Voltage

GND

RESET

Release Voltage

Detecting Voltage

z The power ground (PGND) consists input and output

capacitor grounds, the components' ground of charge

pump and GPM. The PGND should be wide and short

connected to a ground plane.

z The analog ground (AGND) consists the grounds of

compensation, soft-stat capacitor, FB divider, and OP

divider. The AGND should be separated from PGND and

connected to the ground of the input capacitor.

z The exposed pad of the chip should be connected to

ground plane for thermal consideration.

DS9913A/B-00 February 2006 www.richtek.com

17

RT9913A/B

Outline Dimension

Preliminary

D

E

A

A3

A1

D2

SEE DETAIL A

1

be

E2

L

1

2

1

2

DETAIL A

Pin #1 ID and Tie Bar Mark Options

Note : The configuration of the Pin #1 identifier is optional,

but must be located within the zone indicated.

Dimensions In Millimeters Dimension s In Inches

Symbol

Min Max Min Max

A 0.800 1.000 0.031 0.039

A1 0.000 0.050 0.000 0.002

A3 0.175 0.250 0.007 0.010

b 0.180 0.300 0.007 0.012

D 3.950 4.050 0.156 0.159

D2 2.300 2.750 0.091 0.108

E 3.950 4.050 0.156 0.159

E2 2.300 2.750 0.091 0.108

e 0.500 0.020

L 0.350 0.450

RICHTEK TECHNOLOGY CORP .

Headquarter

5F, No. 20, Taiyuen Street, Chupei City

Hsinchu, Taiwan, R.O.C.

Tel: (8863)5526789 Fax: (8863)5526611

0.014 0.018

V-Type 24L QFN 4x4 Package

RICHTEK TECHNOLOGY CORP .

Taipei Office (Marketing)

8F-1, No. 137, Lane 235, Paochiao Road, Hsintien City

Taipei County, Taiwan, R.O.C.

Tel: (8862)89191466 Fax: (8862)89191465

Email: marketing@richtek.com

18

DS9913A/B-00 February 2006www.richtek.com

Loading...

Loading...