Page 1

RT9912A

Multi-Channel Power Management IC for Portable Device

General Description

The RT9912A is a multi-channel power management IC

providing power conversion and system power ma nagement functions for one or two alkaline battery powered

portable handheld device.

The RT9912A integrates one high efficiency synchronous

buck regulator, one high efficiency boost regulator, one

linear regulator and one adjustable voltage detector for

reset function.

Ordering Information

RT9912A

Package Type

QW : WQFN-24L 4x4 (W-Type)

Lead Plating System

G : Green (Halogen Free and Pb Free)

Note :

Richtek products are :

` RoHS compliant and compatible with the current require-

ments of IPC/JEDEC J-STD-020.

` Suitable for use in SnPb or Pb-free soldering processes.

Marking Information

For marking information, contact our sales re presentative

directly or through a Richtek distributor located in your

area.

Features

zz

300mA Sync. Step Down Converter for V

z

zz

zz

z 300mA Sync. Step Up Converter for IO and Memory

zz

zz

z High Efficiency Up to 92%

zz

zz

z Low Dropout Linear Regulator

zz

zz

z Adjustable Voltage Detector for Reset Function

zz

zz

z Current Limit Protection

zz

zz

z Thermal Shutdown Protection

zz

zz

z Low Operation Current Consumption

zz

zz

z Small 24-Lead WQFN Package

zz

zz

z RoHS Compliant and Halogen Free

zz

CORE

Applications

z DSC

z Portable Multimedia Player

z GPS

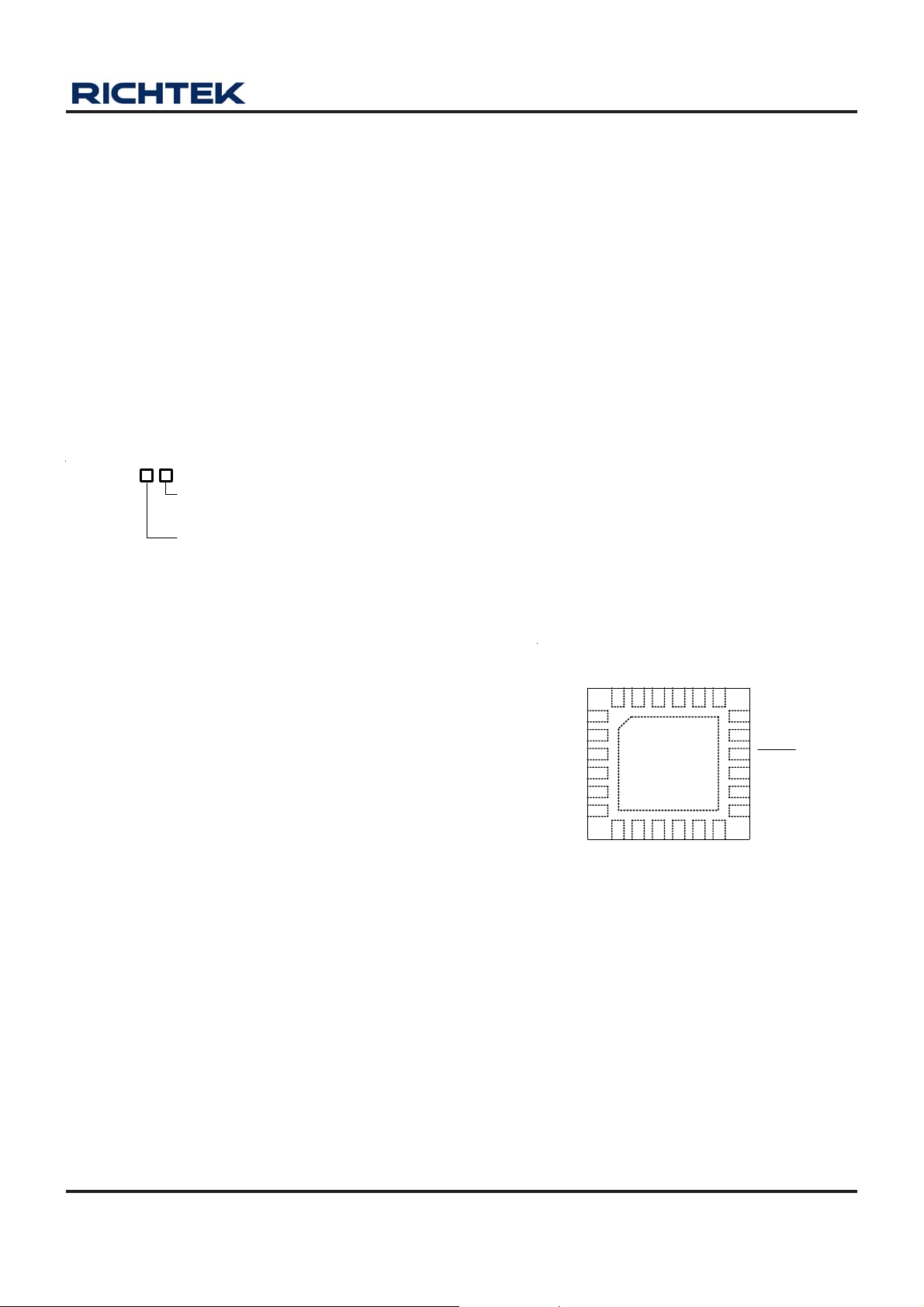

Pin Configurations

(TOP VIEW)

GND

CT

18

FB4

17

VDD4

16

RESET

15

ENBUK

14

25

11

VDD3

13

FB3

VDD1

FB1

ENSW

PSW

NC

ENBST

VOUT1

24 2223

1

2

3

4

5

6

7

LX1

VBAT

21 20 19

GND

8 9 10 12

LX2

FB2

PGND2

PVDD2 PGND1

VDD2

VOUT3

WQFN-24L 4x4

DS9912A-01 April 2011 www.richtek.com

1

Page 2

RT9912A

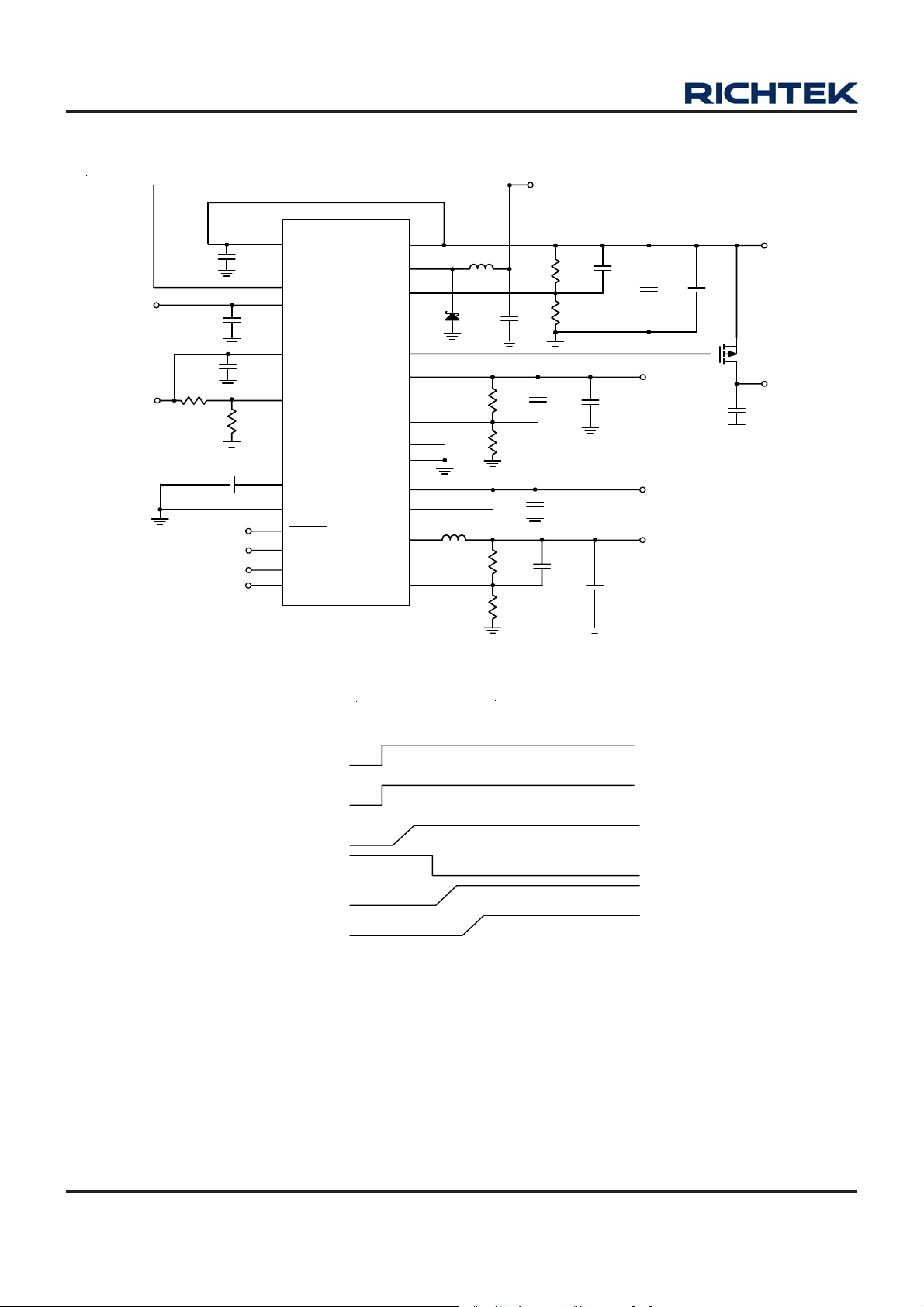

Typical Application Circuit

V

BAT

VDD3

VDD3V3_IO

C1

1uF

22

14

C3

1uF

17

C2

V

C4

1nF

OUT2

1uF

R4

120k

18

20

16

15

R3

1M

19, Exposed Pad (25)

1

3

6

VDD1

VBAT

VDD3

VDD4

FB4

CT

GND

RESET

ENSW

ENBUK

ENBST

RT9912A

VOUT1

LX1

FB1

PSW

VOUT3

FB3

PGND1

PGND2

PVDD2

VDD2

LX2

FB2

24

23

2

4

12

13

21

8

10

11

9

7

L1

D1

L2 4.7uH

4.7uH

10uF

R5

590k

R6

390k

R7

1.6M

R8

330k

C5

120k

C8

1nF

C12

1uF

C10

100pF

R1

1.2M

R2

C6

2.2pF

C9

4.7uF

C11

10uF

C13

22nF

V

OUT3

3V

VDD2

V

OUT2

1.8V

C7

22uF

Q1

C16

22uF

V

OUT1

3.3V

VDD3V3_IO

Power ON Sequence : V

VDD3V3_IO

→

VDD3V3_IO V

OUT2

ENBUK

ENBST

V

OUT2

PSW

V

OUT3

→

OUT3

DS9912A-01 April 2011www.richtek.com

2

Page 3

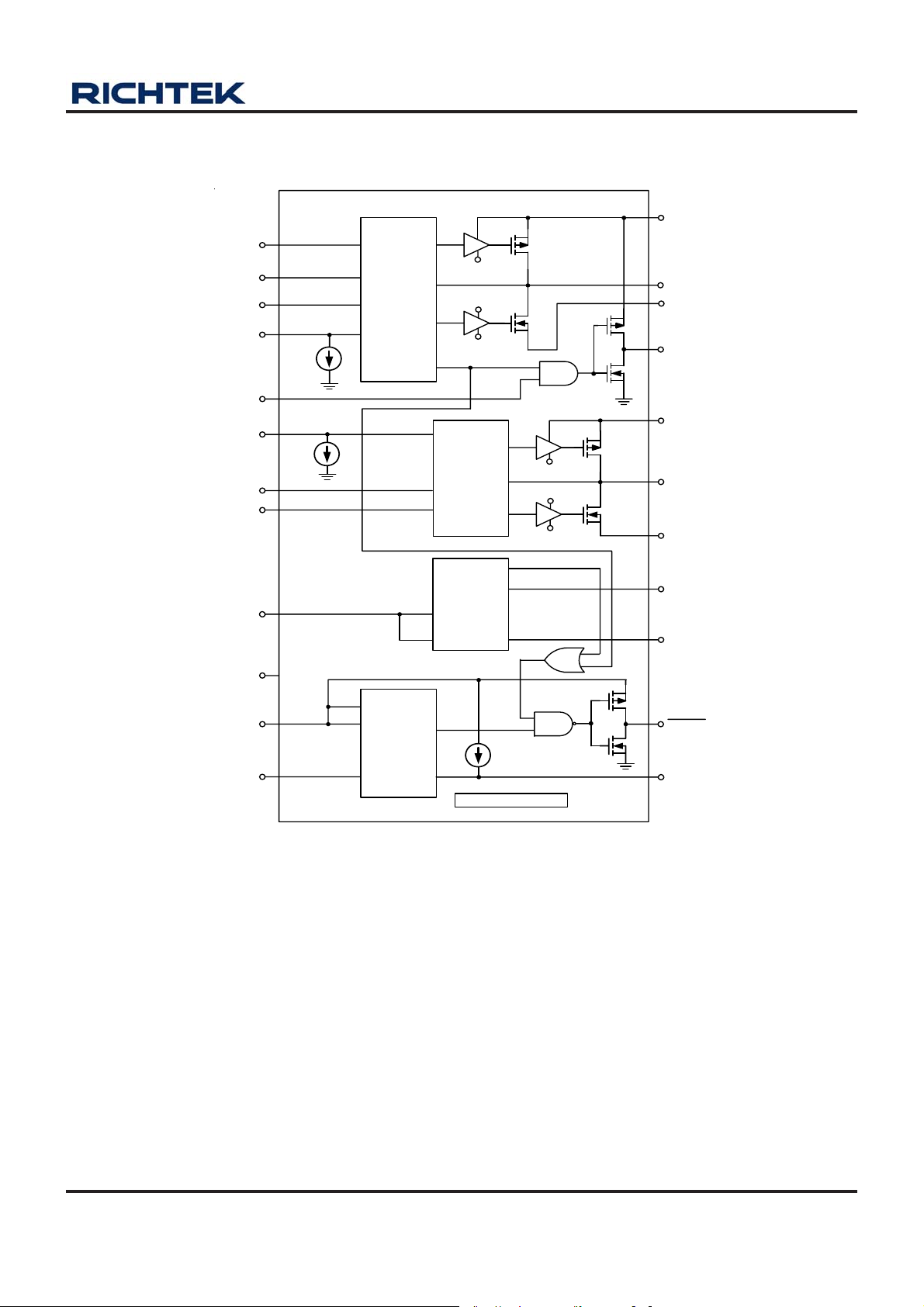

Function Block Diagram

RT9912A

VDD1

VBAT

FB1

ENBST

ENSW

ENBUK

FB2

VDD2

VDD3

VDD1

CH1

Syn-Boost

PFM

CH1

Power

Ready

VDD3

PVDD1

PGND1

PVDD1

PGND1

CH2

Syn-Buck

PFM

CH3

LDO

Regulator

ENLDO

LDOOK

FB3

PVDD2

PGND2

PVDD2

PGND2

VOUT1

LX1

PGND1

PSW

PVDD2

LX2

PGND2

VOUT3

FB3

GND

VDD4

FB4

VDD4

CH4

Reset

Reset

Signal

Delay

RESET

CT

Thermal Protection

DS9912A-01 April 2011 www.richtek.com

3

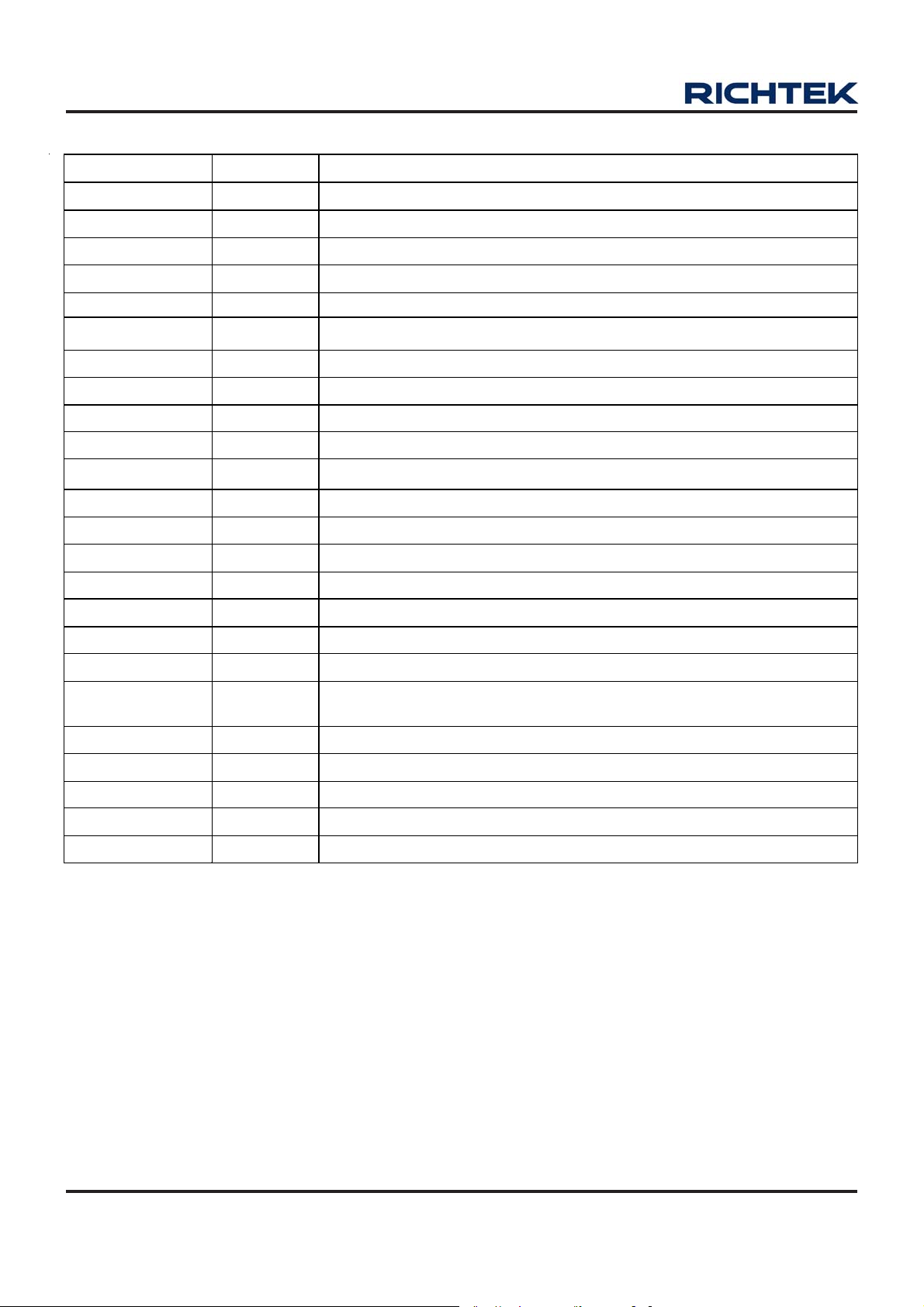

Page 4

RT9912A

Functional Pin Description

Pin No. Pin Na me Pi n Fun cti o n

1 VDD1 CH1 Power Input Pin.

2 FB1 CH1 Feedback Input Pin.

3 ENSW Load Disconnect Enable Pin.

4 PSW Load Disconnect P-MOSFET Gate Drive Pin.

5 NC No Internal Connection. This pin must be floating.

6 ENBST Boost Enable Pin.

7 FB2 CH2 Feedback Input.

8 PGND2 Power Ground for CH2.

9 LX2 CH2 Switch Node.

10 PVDD2 CH2 Power Input Pin.

11 VDD2 CH2 Power Input Pin for Analog.

12 VOUT3 CH3 Output Voltage.

13 FB3 CH3 Feedback Input.

14 VDD3 CH3 Power Input Pin.

15 ENBUK BUCK Enable Pin.

16 RESET Reset Pulse Output, N egative Pulse.

17 VDD4 CH4 Power Input Pin.

18 FB4 CH4 Feedback Input.

19,

Exposed Pad (25)

20 CT

21 PGND1 Power Ground for CH1.

22 VBAT

23 LX1 CH1 Switch Node.

24 VOUT1 CH1 Output Voltage.

GND

Analog Ground. The exposed pad must be soldered to a large PCB and

connected to GND for maximum power dissipation.

External Delay Adjust Pin.

Battery Power Input Pin.

DS9912A-01 April 2011www.richtek.com

4

Page 5

Absolute Maximum Ratings (Note 1)

T

RT9912A

z Supply Voltage, V

z LX1 and LX2 Pin Switch V oltage ---------------------------------------------------------------------------------------- −0.3V to 6.5V

z Other I/O Pin Voltage------------------------------------------------------------------------------------------------------ −0.3V to 6.5V

z Power Dissipation, P

, V

DD1

DD2

@ TA = 25°C

D

, V

DD3

, V

DD4

, PV

-------------------------------------------------------------------- −0.3V to 6.5V

DD2

WQFN-24L 4x4 ------------------------------------------------------------------------------------------------------------- 1.852W

z Package Thermal Resistance (Note 2)

WQF N-24L 4x4, θJA-------------------------------------------------------------------------------------------------------- 54°C/W

WQFN-24L 4x4, θJC------------------------------------------------------------------------------------------------------- 7°C/W

z Junction T emperature------------------------------------------------------------------------------------------------------ 150°C

z Lead T e mperature (Soldering, 10 sec.)-------------------------------------------------------------------------------- 260 °C

z Storage T emperature Range --------------------------------------------------------------------------------------------- −65°C to 150°C

z ESD Susceptibility (Note 3)

HBM (Human Body Mode) ----------------------------------------------------------------------------------------------- 2kV

MM (Ma chine Mode)------------------------------------------------------------------------------------------------------- 200V

Recommended Operating Conditions (Note 4)

z Supply Input Voltage, V

z Junction T emperature Range---------------------------------------------------------------------------------------------

z Ambient T emperature Range---------------------------------------------------------------------------------------------

----------------------------------------------------------------------------------------------- 1.7V to 5V

BAT

−40°C to 125°C

−40°C to 85°C

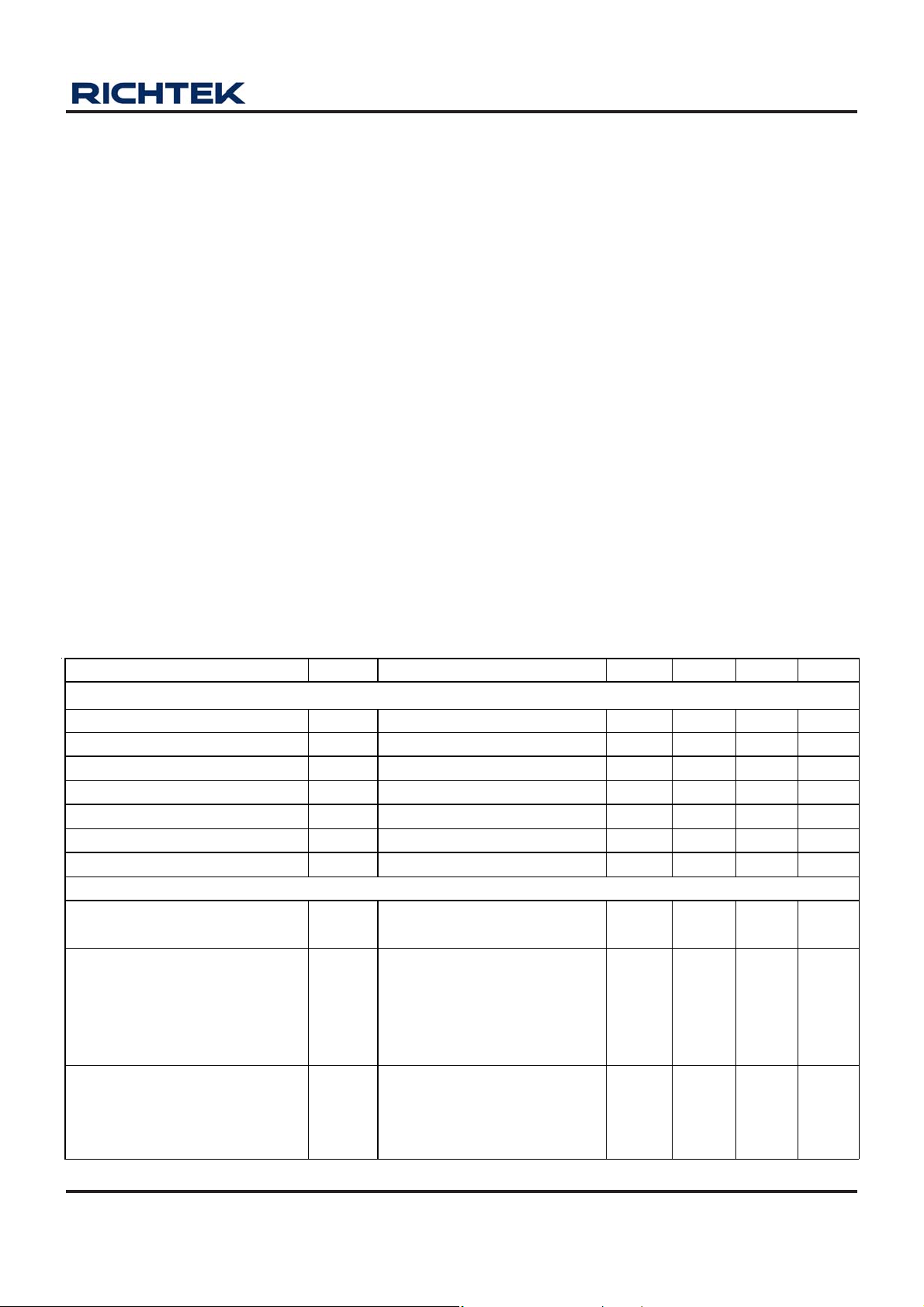

Electrical Characteristics

(V

= V

= V

DD1

DD2

DD3

= V

Parameter Symbol Test Condition Min Typ Max Units

Supply Voltage

Minimum Operating Input Voltage RL = 3kΩ -- -- 1.7 V

Minimum Startup Voltage (Boost) V

VDD1 Operating Voltage V

VDD2 Operating Voltage V

VDD3 Operating Voltage V

VDD4 Operating Voltage V

VDD1 Over Voltage Protection 5.1 6 6.5 V

Supply Current

Shutdown Supply Current I

Boost Supply Current I

Buck Supply Current I

DD4

= 3.3V, T

= 25°C, unless otherwise specified)

A

RL = 3kΩ -- 0.8 1.1 V

S

1.7 -- 5 V

DD1

VDD2, PVDD2 Pin Voltage 1.7 -- 5 V

DD2

2.5 -- 5 V

DD3

1.5 -- 5 V

DD4

OFF

VDD1

V

V

V

V

V

V

ENBST

= 0V = V

DD4

= 3.3V, V

DD1

ENBST

OUT1

= V

DD2

= V

ENSW

= V

ENSW

= 3.3V

DD3

DD3

FB1

= V

= 0V

= 0.9V

= 3.3V

= 0V

DD4

-- -- 10 uA

-- 45 70 uA

(no switching)

V

VDD2

= 3.3V, V

DD2

ENBST

= V

DD1

= V

DD3

V

V

FB2

ENSW

= V

= 0.9V

= 0V

= 0V

DD4

-- 85 140 uA

(no switching)

To be continued

DS9912A-01 April 2011 www.richtek.com

5

Page 6

RT9912A

T

Parameter Symbol Test Condition Min Typ Max Units

= 5 V

V

DD3

LDO Supply Current I

Voltage Detector Supply Current I

VDD3

VDD4

Feedback Voltage (CH1, CH2)

Feedback Voltage VFB FB1, FB2 0.292 0.3 0.312 V

Line Regulation of Feedback

Voltage of CH1

︱ΔV

Pow er Sw i tch

CH1 On Re sistance of MOSFET R

DS(ON)

CH1 Current Limitation (Note 5) -- 1.2 -- A

CH2 On Re sistance of MOSFET R

DS(ON)

CH2 Current Limitation P-MOSFET -- 0.6 -- A

V

ENBST

V

DD1

V

DD4

V

ENBST

V

DD1

I

L

︱

FB

V

N-MOSFET, V

P-MOSFET, V

N-MOSFET, V

P-MOS FET , V

= V

= V

DD2

= 3.3V

= V

= V

DD3

= 30mA, V

= 0.9 to 1.5V

BAT

ENSW

= V

ENSW

= V

OUT

OUT1

OUT1

DD2

= 0V

= 0V

DD4

= 0V

= 0V

DD3

= 2.8V

-- 90 130 uA

-- 10 -- uA

-- -- 8

= 3 . 3V

= 3.3V

-- 200 400 mΩ

= 3 .3V -- 3 20 450 m Ω

= 3.3V -- 400 560 mΩ

DD2

mV

Voltage Detector

Feedback Vol tage V

FB4 Falling Edge 0.292 0.3 0.308 V

FB4

Threshold Hysteresis Refer to FB4 -- 25 -- mV

N-MOSFET, V

= 0.5V

V

RESET Output Current

CT Pin Threshold Voltage VCT V

CT Pin Output Current I

-- 1 -- uA

C

DS

P-MOSFET, V

V

= -0.5V

DS

= 3 .3V 0.65 0.8 1 V

DD4

DD4

DD4

= 3 . 3V,

= 3.3V,

-- 3 -- mA

Linear Regulator

Output Volta ge Ac cura cy

Feedback Voltage V

Current Limit I

OUT3_LIM

Dropout Voltage V

Line Regulation ΔV

Load Regulation ΔV

L

= 3.5V, 3.3V, 3V

V

OUT3

-- 1.2 -- V

FB3

400 600 -- mA

DROP

LINE

OUT3

I

= 200mA -- 0.3 0.4 V

VOUT3

= ( V

V

DD3

I

= 1mA

OUT3

= 50mA to 200mA

I

OUT3

V

= 4.8V , V

DD3

+ 1V) to 5.5V

OUT3

OUT3

= 3.3V

−2 -- +2 %

-- -- 0.5 %

-- -- 30 mV

= 1mA,

I

Control

ENLDO Input High Level

Threshold

V

= 2 . 8V -- - - 1.1 V

DD1

To be continued

DS9912A-01 April 2011www.richtek.com

6

Page 7

RT9912A

Parameter Symbol Test Condition Min Typ Max Units

ENLDO Input Low Level

Threshold

ENBST/ ENSW Input High Level

Threshold

ENBST/ ENSW Input Low Level

Threshold

ENBST Pull Low Current -- 1 -- uA

ENBUK Pull Low Current -- 1 -- uA

Thermal Protection

Thermal Shutdown TSD -- 160 -- °C

Thermal Shutdown Hysteresis ΔTSD -- 10 -- °C

Note 1. Stresses listed as the above “Absolute Maximum Ratings” may cause permanent damage to the device. These are for

stress ratings. Functional operation of the device at these or any other conditions beyond those indicated in the

operational sections of the specifications is not implied. Exposure to absolute maximum rating conditions for extended

periods may remain possibility to affect device reliability.

Note 2. θJA is measured in the natural convection at TA = 25°C on a high effective four layers thermal conductivity test board of

JEDEC 51-7 thermal measurement standard. The case point of θ

Note 3. Devices are ESD sensitive. Handlin

Note 4. The device is not guaranteed to function outside its operating conditions.

V

V

V

g precaution is recommended.

= 2.8V 0.4 -- -- V

DD1

= 1V -- -- 0.7 V

BAT

= 1V 0.2 -- -- V

BAT

is on the expose pad for the package.

JC

DS9912A-01 April 2011 www.richtek.com

7

Page 8

RT9912A

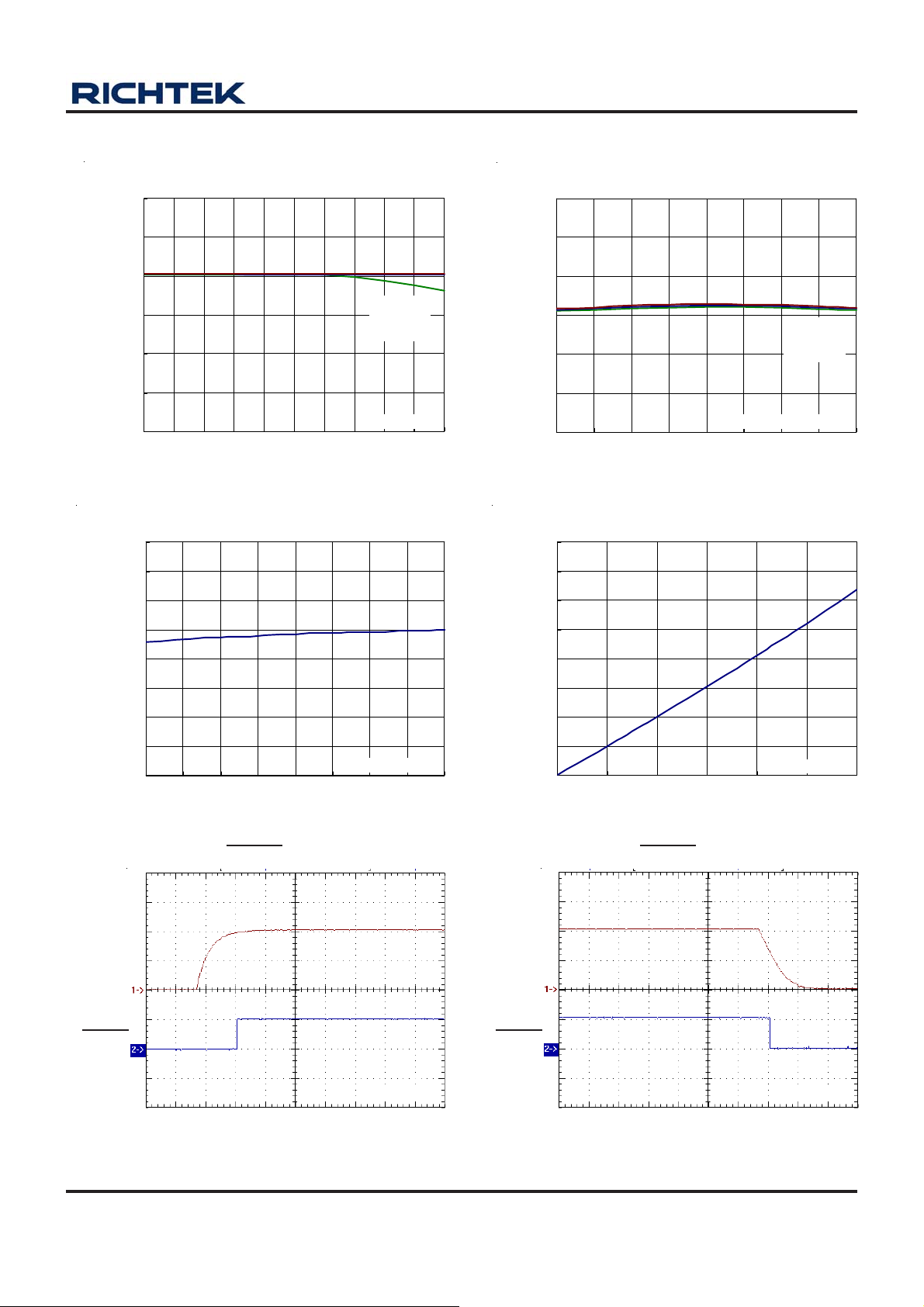

Typical Operating Characteristics

CH1 Efficiency vs. Output Current

100

90

80

70

60

50

40

Efficiency (%)

30

20

10

0

0.001 0.01 0.1 1

Output Current (A)

CH1 Output Voltage vs. Output Current

3.40

3.35

3.30

3.25

3.20

Output Voltage (V)

3.15

3.10

0 0.05 0.1 0.15 0.2 0.25 0.3 0.35 0.4

Output Current (A)

VIN = 3.3V

VIN = 2.5V

V

= 1.8V

IN

VIN = 3V

V

= 2.5V

IN

VIN = 1.8V

V

= 3.3V

OUT

V

= 3.3V

OUT

CH2 Efficiency vs. Output Current

100

90

80

70

60

50

40

Efficiency (%)

30

20

10

0

0.001 0.01 0.1 1

VIN = 3.3V

VIN = 2.5V

VIN = 2V

V

= 1.8V

OUT

Output Current (A)

CH1 Output Voltage vs. Temperature

4.0

3.8

3.5

3.3

3.0

2.8

2.5

Output Voltage (V)

2.3

V

2.0

-40-200 20406080100120

OUT

Temperature

VIN = 3V

VIN = 2.5V

V

= 1.8V

IN

= 3.3V, No Load

(°C)

CH2 Output Voltage vs. Output Current

1.90

1.85

1.80

1.75

1.70

1.65

Output Vol tage(V)

1.60

1.55

1.50

0 0.05 0.1 0.15 0.2 0.25 0.3 0.35 0.4

Output Current (A)

VIN = 4.2V

VIN = 3.3V

VIN = 2.5V

V

= 1.8V

OUT

1.90

1.85

1.80

1.75

1.70

Output Voltage (V )

1.65

1.60

CH2 Output Voltage vs. Temperature

VIN = 3.3V

VIN = 2.5V

VIN = 2V

V

= 1.8V, No Load

OUT

-40 -20 0 20 40 60 80 100 120

Temperature

(°C)

DS9912A-01 April 2011www.richtek.com

8

Page 9

RT9912A

CH3 Output Voltage vs. Output Current

4.0

3.5

3.0

2.5

2.0

Output V oltage (V)

1.5

1.0

0 0.05 0.1 0.15 0.2 0.25 0.3 0.35 0.4 0.45 0.5

Output Current (A)

LDO Output Voltage vs. Input Voltage

3.10

3.08

3.05

3.03

VIN = 4.5V

VIN = 3.9V

V

= 3.3V

IN

V

= 3.3V

OUT

CH3 Output Voltage vs. Temperature

3.3

3.2

3.1

3.0

2.9

VIN = 4.5V

VIN = 3.9V

VIN = 3.3V

Output Voltage (V)

2.8

V

= 3V, No Load

2.7

-40 -20 0 20 40 60 80 100 120

Temperature

OUT

(°C)

LDO Dropout Voltage vs. Output Current

400

350

300

250

3.00

2.98

2.95

Output Voltage (V)

2.93

2.90

FB4

(200mV/Div)

RESET

(1V/Div)

I

= 200mA

OUT

3.3 3.55 3.8 4.05 4.3 4.55 4.8 5.05 5.3

Inp ut Vol tag e (V)

RESET Power On

V

= 1V

DD4

200

150

100

Dropout Voltage (m V)

FB4

(200mV/Div)

RESET

(1V/Div)

50

V

0

0 50 100 150 200 250 300

OUT

Output Current (mA)

RESET Power Off

V

DD4

= 3V

= 1V

Time (5ms/Div)

Time (5ms/Div)

DS9912A-01 April 2011 www.richtek.com

9

Page 10

RT9912A

Application Information

RT9912A is a four-channel power ma nagement IC (PMIC)

including one step-up DC-DC converter (Boost), one stepdown DC-DC converter (Buck), one low dropout regulator

(LDO) and one voltage detector. For optimizing the

application of porta ble hand-held system with one or two

alkaline battery, several special logics are designed in

this chip. An extern al P-MOSFET is also needed for loaddisconnected function.

Step-Up DC-DC Converter (Boost)

The step-up DC-DC convert can start up even with the

input voltage a s low as 0.8V and operates with the input

voltage down to 0.7V. The cost of system is reduced by

the internal synchronous rectifier from eliminating an

external Schottky diode. The efficiency of light load is

improved by the pulse frequency modulation mode (PFM)

low quiescent current 30uA. The efficiency of heavy load

is also maintained by the internal synchronous rectifier

with resistance low to 0.2Ω.

The step-up DC-DC converter is designed as a

bootstrapped structure. As the chip is in the start-up period,

a low voltage start-up circuit will pull the output voltage to

a higher voltage (~1.5V). After the output voltage rea ches

a certain level, the main DC-DC circuitry will keep working

to pull the output voltage to the expected value set by

output divided resistor. The control scheme of the stepup DC-DC converter is pulse frequency modulation mode

(PFM) with constant-on-time a nd minimum-off-ti me. This

scheme can keep high efficiency during a wide loa d range.

An internal soft-start is also included in the step-up DCDC converter to limit the inrush current to less than a hal f

of the OCP level. As the ENBST is pulled low, the step-up

DC-DC converter will enter shutdown mode and all function

will be disabled.

As the ENSW is pulled high, the PSW will be pulled low

when the output of the step-up DC-DC converter is rea dy

(soft-start is finished). An extern al P-MOSFET is needed

to be a load-disconnected switch. The PSW is a signal

to control the external P-MOSFET. All loadings of the

system should be connected to the drain pin of the

P-MOSFET to prevent the step-up DC-DC converter startup in heavy load condition.

The maximum duty (D) of the step-up DC-DC converter is

around 50% so that the maximum output voltage is ideally

to be VIN / (1-D) = 2 x VIN. Actually, some voltage will

drop on the internal N-MOSFET and inductor . Therefore,

the maximum output voltage will be lower than the ideal

value and to be 2 x VIN.

The function of R9 and C14 is preventing the charge sharing

issue from the cap acitor in Q1's source pin to the ca pacitor

in Q1's drain pin. If the cap a citor in Q1's source pin is 10

times larger tha n the capacitor in Q1's drain pin, R9 and

C14 can be removed.

Step-Down DC-DC Converter (Buck)

The step-down DC-DC convert can reduce the cost of

system by the internal synchronous rectifier from

eliminating an external Schottky diode. The light load

efficiency is improved by the pulse frequency modulation

mode (PFM) and internal synchronous rectifier . For heavy

load, the efficiency is maintained by the internal

synchronous rectifier with the resistance low to 0.4Ω. The

control scheme of the step-down DC-DC converter is pulse

frequency modulation mode (PFM) with over-currentprotection (OCP) and minimum-off-ti me. This scheme can

keep high efficiency during a wide load ra nge. An internal

soft-start is also included in the step-down DC-DC

converter to limit the inrush current less than a half of

OCP level.

This step-down converter can operate in low-drop mode

and its output voltage depends on the voltage drop cross

the internal P-MOSFET and inductor . Normally , the value

is near VDD2 as the ESR of inductor is 0.1Ω and 60mA

loading. The minimum output voltage is 0.6V, which is

decided by the operation range of the internal circuit.

Low Dropout Regulator (LDO)

The low dropout regulator can regulate the output voltage

by setting the external resistor of FB3. An internal

compensation structure is designed for keeping stability

as wide range output capacitor and wide range loading.

The voltage detector is a comparator with reference to

detect the voltage of FB4.

10

DS9912A-01 April 2011www.richtek.com

Page 11

RT9912A

The maximum output voltage for LDO depends on the

voltage drop cross the internal P-MOSFET . Normally , the

value is (V DD3 − 0.4V) a s 200mA loading. The mini mum

output voltage is 1.6V, which is decided by the working

range of the internal circuit.

Output Voltage Setting

The regulated output voltage can be calculated following

formula :

R1

V = V 1

OUT FB

⎛⎞

×+

⎜⎟

R2

⎝⎠

To place the resistor-divider as close as possible to chip

can reduce noise sensitivity.

Voltage Detector

The RT9912A integrates a voltage detector with push-pull

output. The voltage detector senses V DD3V3_IO through

a resistor divider and compares it with internal 0.3V

reference voltage. When the sensed voltage is lower than

the reference voltage, the RESET pin output logic low

signal for system access. Connecting a capacitor from

the CT pin to GND ca n set the detect delay time a ccording

to Figure 1.

CH4 Detecter Delay Time

120

100

Inductor Selection

To select suitable inductance value is very important for

optimal performance. For boost converter, the control

method is constant on time and minimum off time. If the

inductance is low, it will cause effects of high in ductor

current and high output voltage ripple. The inductance value

can be calculated by following f ormula.

L

MIN

Where L

V

IN(MAX)

VT

IN(MAX) ON

≥

= minimum inductance

MIN

= maximum input voltage

V

LIM(MIN)

×

TON = 0.75us

I

LIM(MIN)

= 0.8A

A 4.7uH inductor is recommended f or typical a pplication.

For buck converter, a 4.7uH inductor is recommended

when VIN is less than 2.6V.

In addition, make sure the inductor saturation current

rating should be greater than the inductor pea k current.

Input Capacitor Selection

For better input bypa ssing, low-ESR ceramic ca pa citor is

recommended for better performance. A 10uF input

ca pacitor is suff icient and it is flexible to reduce the value

for a lower output power requirement.

80

60

Output Capacitor Selection

For lower output voltage ripple, low-ESR cera mic capa citor

is recommended. The output voltage ripple consists of

40

Delay Time (ms)

20

0

0 102030405060708090100

Capacitance (nF)

Figure 1. Detector Delay T i me

two components : one is the pulsating output ripple current

flowing through the ESR, and the other is the ca pa citive

ripple caused by charging and discharging.

For ceramic capacitor, the voltage ripple value is

approxi mated by :

V V≅

RIPPLE RIPPLE_C

For boost converter, calculate the minimum output

cap acita nce a s the following formula :

PEAK

2

11

L0.5I

≥

×

V

REPPLE_C

C

OUT

DS9912A-01 April 2011 www.richtek.com

Page 12

RT9912A

For buck converter, calculate the minimum output

cap acita nce a s the following formula :

I

⎛⎞

I1

OUT(MAX)

C

≥

OUT

fV

×

OUT(MAX)

×−

⎜⎟

I

PEAK

⎝⎠

REPPLE_C

THERMAL CONSIDERA TIONS

For continuous operation, do not exceed absolute

maximum operation junction temperature. The maximum

power dissipation depends on the thermal resistance of

IC package, PCB layout, the rate of surroundings airflow

and temperature difference between junction to a mbient.

The maximum power dissipation can be calculated by

following formula :

P

D(MAX)

= (T

J(MAX)

− TA) / θ

JA

2

2.0

1.8

1.6

1.4

1.2

1.0

0.8

0.6

0.4

0.2

Maximum Pow er Dissi pation (W )

0.0

0 25 50 75 100 125

Ambient Temper ature (°C)

WQFN-24L 4x4

Four Layers PCB

Figure 2. Derating Curves f or RT9912A Packages

Where T

temperature 125°C, T

θ

is the junction to ambient thermal resistance.

JA

is the maximum operation junction

J(MAX)

is the ambient te mperature and the

A

For recommended operating conditions specification of

RT9912A, where T

is the maximum junction

J(MAX)

temperature of the die (125°C) and TA is the maximum

ambient temperature. The junction to ambient thermal

resistance θJA is layout dependent. For WQFN-24L 4x4

packages, the thermal resistance θJA is 54° C/W on the

standard JEDEC 51-7 four layers thermal test board. The

maximum power dissipation at TA = 25°C can be calculated

by following formula :

P

= (125°C − 25°C) / (54°C/W) = 1.852W for

D(MAX)

WQF N-24L 4x4 pa ckages

The maximum power dissipation depends on operating

ambient temperature for fixed T

and thermal

J(MAX)

resistance θJA. For RT9912A packages, the Figure 2 of

derating curves allows the designer to see the effect of

rising ambient temperature on the maximum power

allowed.

Layout Considerations

For the best performance of the R T9912A, the f ollowing

PCB Layout guidelines must be strictly followed.

` Place the input and output capacitors as close as

possible to the input and output pins respectively for

good filtering.

` Keep the main power traces as possible as wide and

short.

` The switching node area connected to LX and inductor

should be minimized for lower EMI.

` Place the feedback components as close as possible

to the FB pin and keep these components away from

the noisy devices.

` Connect the GND a nd Exposed Pad to a strong ground

plane for maximum thermal dissipation and noise

protection.

12

DS9912A-01 April 2011www.richtek.com

Page 13

RT9912A

LX should be connected to inductor by

wide and short trace, keep sensitive

components away from trace.

PGND

GND

C1

VDD1

FB1

ENSW

PSW

NC

ENBST

C23C7

1

2

3

4

5

6

R8

V

OUT1

3.3V

GND

Q1

C6

VDD3V3_IO

C16

R1

GND

R7

C10

PGND

V

1.8V

PGND

OUT2

Place the feedback components as close

as possible to the FB pin and keep away

from noisy devices.

Input/Output capacitors must be placed

as close as possible to the Input/ Output

pins.

V

PGND

BAT

D1

24 2223

7

C5

L1

VOUT1

LX1

VBAT

21 20 19

GND

8 9 10 12

LX2

FB2

PVDD2 PGND1

PGND2

L2

C11

V

3.3V

11

OUT1

C4

CT

25

VDD2

GND

18

17

16

15

14

13

VOUT3

C9

C12

GND

R4

FB4

VDD4

RESET

ENBUK

VDD3

FB3

R6

GND

Connect the exposed

pad to a ground plane.

VDD3V3_IO

PGND

R3

VDD3V3_IO

C8

R5

C2

C3

PGND

V

OUT3

3.3V

PGND

Figure 3. PCB Layout Guide

DS9912A-01 April 2011 www.richtek.com

13

Page 14

RT9912A

Outline Dimension

D

E

A

A3

A1

D2

SEE DETAIL A

L

1

E2

1

2

be

DETAIL A

Pin #1 ID a nd T ie Bar Mark Option s

Note : The configuration of the Pin #1 identifier is optional,

1

2

but must be located within the zone indicated.

Dimensions In Millimeters Dimensions In Inches

Symbol

Min Max Min Max

A 0.700 0.800 0.028 0.031

A1 0.000 0.050 0.000 0.002

A3 0.175 0.250 0.007 0.010

b 0.180 0.300 0.007 0.012

D 3.950 4.050 0.156 0.159

D2 2.300 2.750 0.091 0.108

E 3.950 4.050 0.156 0.159

E2 2.300 2.750 0.091 0.108

e 0.500 0.020

L 0.350 0.450

Richtek Technology Corporation

Headquarter

5F, No. 20, Taiyuen Street, Chupei City

Hsinchu, Taiwan, R.O.C.

Tel: (8863)5526789 Fax: (8863)5526611

0.014 0.018

W-Type 24L QFN 4x4 Package

Richtek Technology Corporation

Taipei Office (Marketing)

5F, No. 95, Minchiuan Road, Hsintien City

Taipei County, Taiwan, R.O.C.

Tel: (8862)86672399 Fax: (8862)86672377

Email: marketing@richtek.com

Information that is provided by Richtek Technology Corporation is believed to be accurate and reliable. Richtek reserves the right to make any change in circuit

design, specification or other related things if necessary without notice at any time. No third party intellectual property infringement of the applications should be

guaranteed by users when integrating Richtek products into any application. No legal responsibility for any said applications is assumed by Richtek.

DS9912A-01 April 2011www.richtek.com

14

Page 15

Loading...

Loading...