Page 1

®

6-String 43V White LED Driver with Boost Regulator

RT8532

General Description

The RT8532 is a high efficiency white LED driver. It is

designed for LCD pa nel that employs a LED array a s the

lighting source. An integrated switch current mode Boost

controller drives six strings in parallel and supports up to

10 pieces of LEDs per string. The internal current sinks

support maximum ±2% current matching for excellent

brightness uniformity in ea ch LED string. T o provide enough

headroom for the operating of current sink, the Boost

controller monitors the minimum voltage of feedback pin s

and regulates an optimized output voltage for power

efficiency.

The RT8532 has wide input voltage range from 2.5V to

24V and provides adjusta ble 5mA to 50mA LED current.

The internal 200mΩ, 43V power switch with current-mode

control provides cycle-by-cycle over current protection.

The RT8532 also integrates PWM and analog dimming

functions for a ccurate LED current control. The input PWM

dimming frequency can be operated operate from 100Hz

to 20kHz without any inrush current in LED.

The RT8532 is available in WQF N-20L 3x3 pack age.

Features

Wide Input Voltage : VIN 2.5V to 24V

High Output Voltage : V

Programmable Full Channel Current from 5mA to

50mA and Matched to 2%

Channel Current Regulation with

Dimming Controls

Direct PWM Dimming up to 20kHz and Minimum

On-Time to 500ns

PWM to Mixed Analog and PWM Dimming up to

20kHz with Maximum 9 bit Resolution

Built-In Soft Start to Prevent Inrush Current without

External Capacitor

Disconnects LED in Shutdown

Protection

Strings Open Detection

Current Limit Protection

Programmable Over Voltage Protection

Over Temperature Protection

20-Lead WQFN Package

RoHS Compliant and Halogen Free

up to 43V

OUT

±±

±3% Accuracy

±±

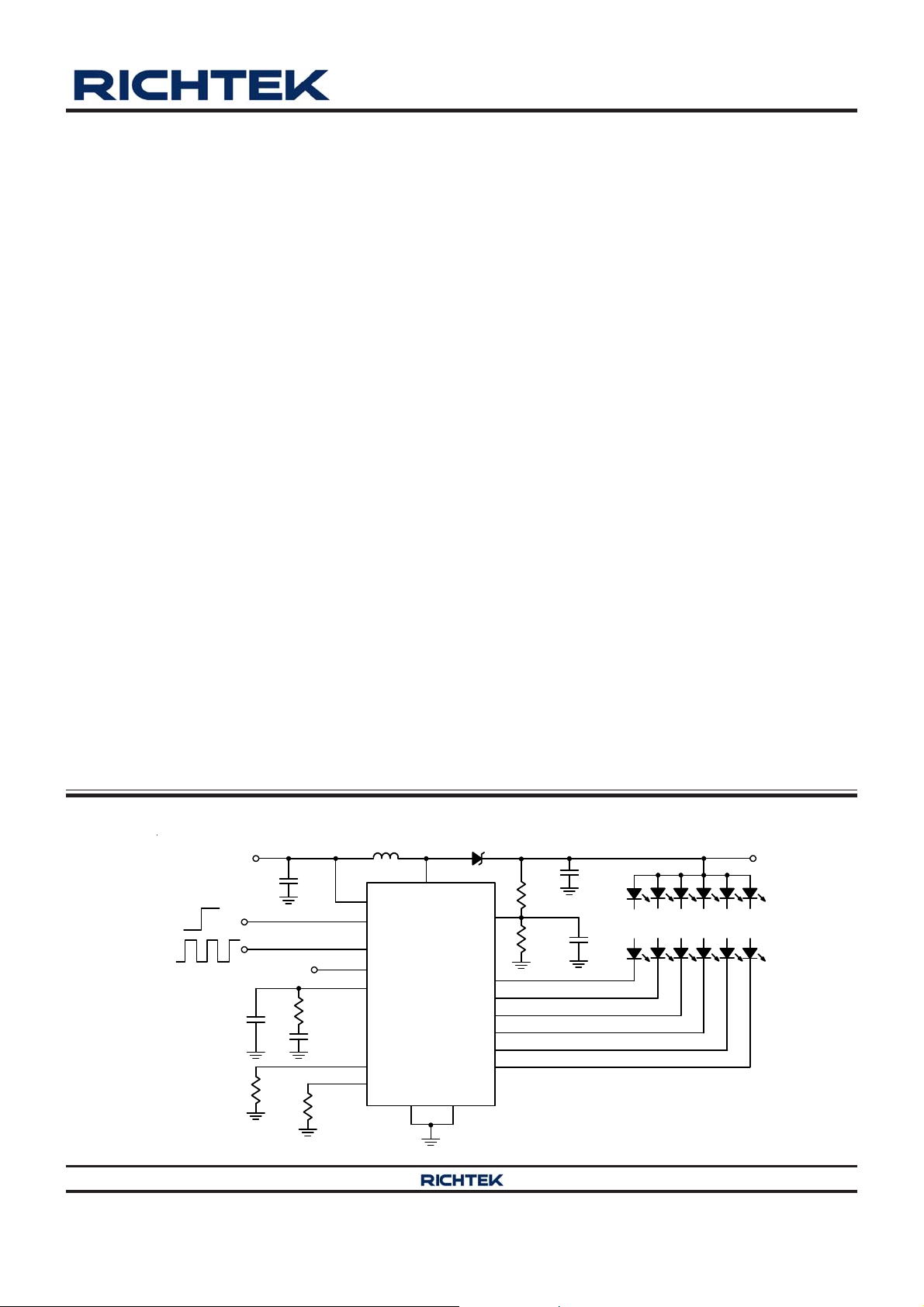

Simplified Application Circuit

V

IN

C

IN

Chip Enable

R

C

ISET

MIX

R

COMP

C

C

COMP

R

FSW

PWM Signal

L1

VIN

EN

PWM

MIX

COMP

ISET

FREQ

AGND

LX

RT8532

PGND

Applications

UMPC and Notebook Computer Backlight

D1

C

OUT

R

OVP

LED1

LED2

LED3

LED4

LED5

LED6

R

OVP2

OVP1

C

OVP

:

:

:

:

:

:

:

:

:

:

:

:

V

OUT

:

:

:

:

:

:

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

©

DS8532-04 January 2014 www.richtek.com

1

Page 2

RT8532

Ordering Information

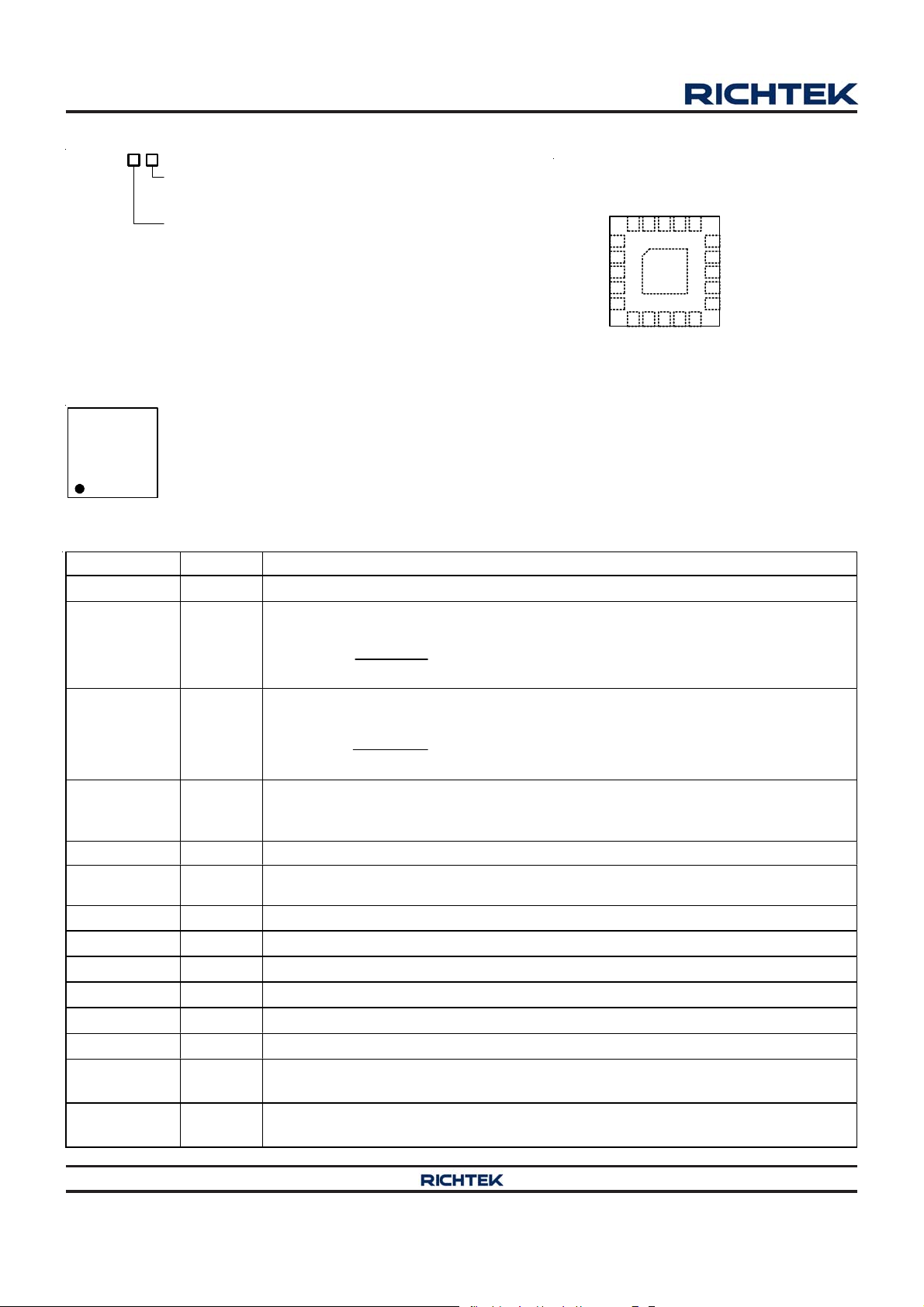

Pin Configurations

RT8532

Package Type

QW : WQFN-20L 3x3 (W-Type)

Lead Plating System

Note :

Richtek products are :

RoHS compliant and compatible with the current require-

ments of IPC/JEDEC J-STD-020.

Suitable for use in SnPb or Pb-free soldering processes.

G : Green (Halogen Free and Pb Free)

Marking Information

89= : Product Code

89=YM

YMDNN : Date Code

DNN

Functional Pin Description

Pin No. Pin Name Pin Function

1 EN Chip Enable (Active High). There is an internal pull low resistor 400k for the EN pin.

Switching Frequency of Boost Converter Setting. Connect a resistor between this pin

2 FREQ

3 ISET

4 MIX

5 AGND Analog Ground of LED Driver.

6, 7, 8, 9, 10,

11

LED6 to

LED1

12 OVP Over Voltage Protection Sense Input. The detecting threshold is 1.2V (typ.).

13, 14 PGND Power Ground of Boost Converter.

15, 16 LX Switching Pin of B oost Converter.

17 PWM PWM Dimming Control Input.

18 VDC Internal Regulator Voltage. Connect a capacitor from this pin to ground.

19 VIN Power Supply Input.

20 COMP

21

(Ex pos ed Pad)

GND

and AGND to set the switching frequency.

R1.1 6 k

FSW

25

F(MHz)

SW

LED C urre nt Set ting. LED cur rent is set by the re sisto r R

ISET pin to ground.

ImA

LED

240

Rk

ISET

Dimm in g Mod e Selec tio n. Th ere is an inte r na l pul l hi gh 4 00k resistor con nec t e d to

VDC. Floating or pulling high for 25% Mixed mode dimming, pulling low for direct

PWM mode dimming. Recommended to mixed mode for high LED efficiency.

Current Sink for LED String. (Leave the pin unconnected or short to GND, if not

used.)

Compensation Note for Boost Converter. Connect a compensation network to this pin

for stability.

Ground. The Exposed Pad must be Soldered to a Large PCB and Connected to GND

for Maximum Power Dissipation.

(TOP VIEW)

VIN

LED5

LX

PWM

VDC

16

17181920

15

LX

14

PGND

13

PGND

12

21

9876

LED4

OVP

115

10

LED3

LED2

con nected from the

ISET

COMP

1

EN

2

FREQ

3

ISET

MIX

AGND LED1

GND

4

LED6

WQFN-20L 3x3

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

www.richtek.com

2

©

DS8532-04 January 2014

Page 3

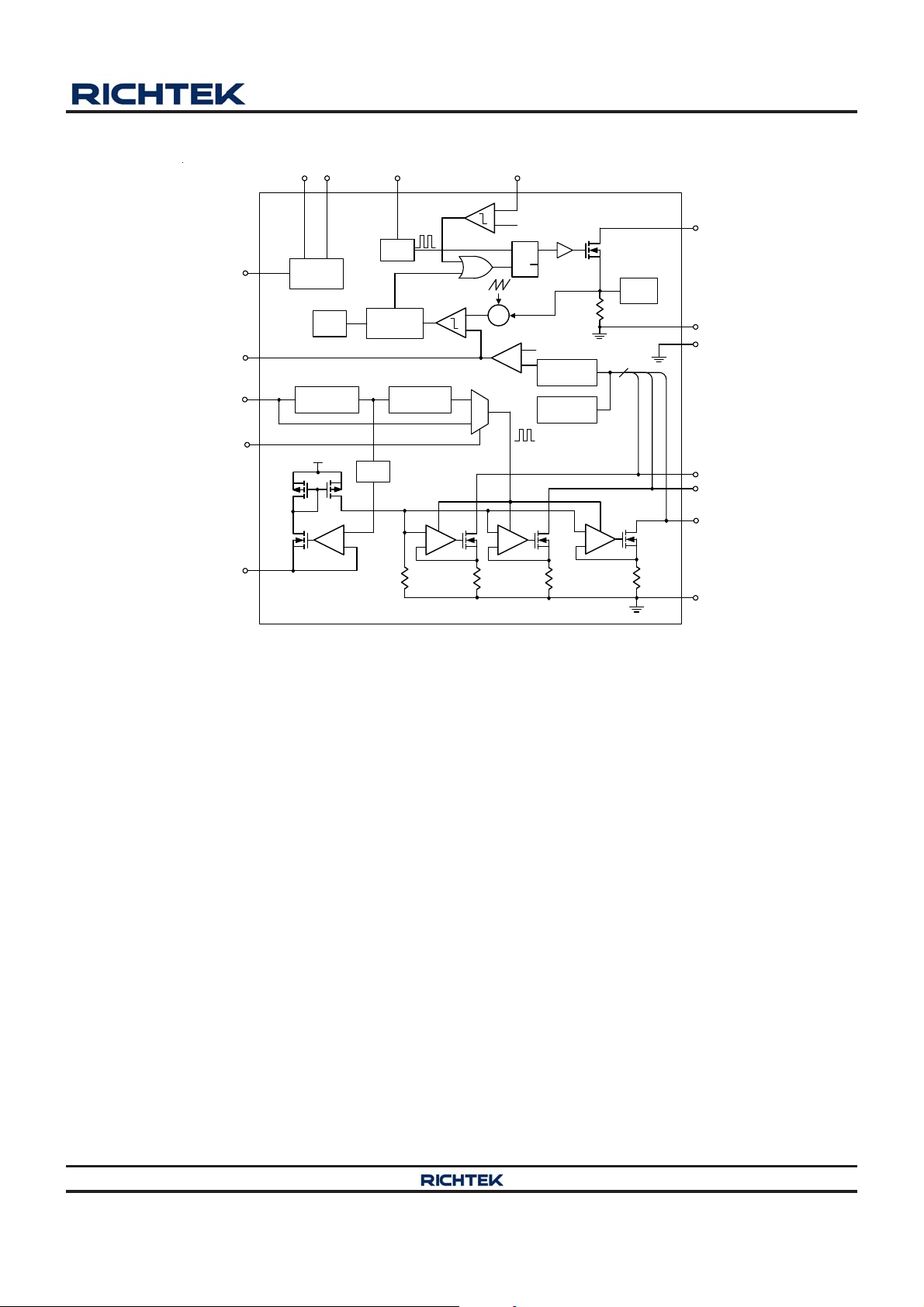

Function Block Diagram

VIN OVP

EN

COMP

PWM

MIX

LDO

PWM-to-DC

VDC

OTP

FREQ

OSC

PWM

Controller

Generator

PWMO

RT8532

+

1.2V

-

SQ

R

Q

OCP

+

+

-

0.6V

MUX

+

-

Mini LED

Selection

LED Open

Detection

6

LX

PGND

GND

DAC

+

-

ISET

+

-

Operation

Enable Control

When VIN is higher than the UVLO voltage and EN pin

input voltage is higher than rising threshold, the VDC will

be regulated around 3.8V if VIN is higher tha n 3.8V .

OSC

The switching frequency is adjustable by the external

resistor connected between the FREQ pin and GND.

PWM Controller

This controller includes some logic circuit to control LX

N-MOSFET on/off. This block controls the minimum on

time and max duty of LX.

LED1

LED2

……

LED6

AGND

+

-

……

+

-

MOSFET will be turned off until the temperature is lower

than the 120°C (typically).

OVP

When OVP pin voltage is higher than 1.2V, the LX

N-MOSFET is turned off immediately to protect the LX

N-MOSFET.

Minimum LED Selection

This block detects all LEDx voltage and select a minim um

voltage to EA (Error Amplifier). This function ca n guarantee

the lowest of LED pin voltage is around 600mV and V

OUT

can be boost to the highest forward voltage of LED strings.

OCP & OTP

When LX N-MOSFET peak current is higher than 2.5A

(typically), the LX N-MOSFET is turned off immediately

and resumed again at next clock pulse. When the junction

temperature is higher than 150°C (typically), the LX N-

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS8532-04 January 2014

©

LED Open Detection

If the voltage at LEDx pin is lower than 100mV, this

channel is defined a s open channel a nd the Minimum LED

Selection function will discard it to regulate other used

channels in proper voltage.

www.richtek.com

3

Page 4

RT8532

Absolute Maximum Ratings (Note 1)

Supply Input V oltage, VIN

EN, PWM, ISET, COMP , MIX, FREQ to GND ---------------------------------------------------------------------- −0.3V to 26.5V

LX, OVP , LED1 to LED6 to GN D--------------------------------------------------------------------------------------- −0.3V to 48V

LX t o G ND ------------------------------------------------------------------------------------------------------------------- −0.3V to 48V

to GND------------------------------------------------------------------------------------ −0.3V to 26.5V

< 500ns ---------------------------------------------------------------------------------------------------------------------- −1V to 48V

V DC to GND ---------------------------------------------------------------------------------------------------------------- −0.3V to 7V

Power Dissipation, P

@ T

D

= 25°C

A

WQFN−20L 3x3------------------------------------------------------------------------------------------------------------ 1.471W

Package Thermal Re sistance (Note 2)

WQFN−20L 3x3, θJA------------------------------------------------------------------------------------------------------ 68°C/W

WQFN−20L 3x3, θJC------------------------------------------------------------------------------------------------------ 7.5°C/W

Lead Temperature (Soldering, 10 sec.)------------------------------------------------------------------------------- 260°C

Junction T emperature----------------------------------------------------------------------------------------------------- 150°C

Storage T emperature Range -------------------------------------------------------------------------------------------- − 65°C to 150°C

ESD Susceptibility (Note 3)

HBM (Human Body Model)---------------------------------------------------------------------------------------------- 2kV

MM (Machine Model) ----------------------------------------------------------------------------------------------------- 200V

Recommended Operating Conditions (Note 4)

Supply Input Voltage, VIN ----------------------------------------------------------------------------------------------- 2.5V to 24V

Junction T emperature Range-------------------------------------------------------------------------------------------- −40°C to 125°C

Ambient T emperature Range-------------------------------------------------------------------------------------------- −40°C to 85°C

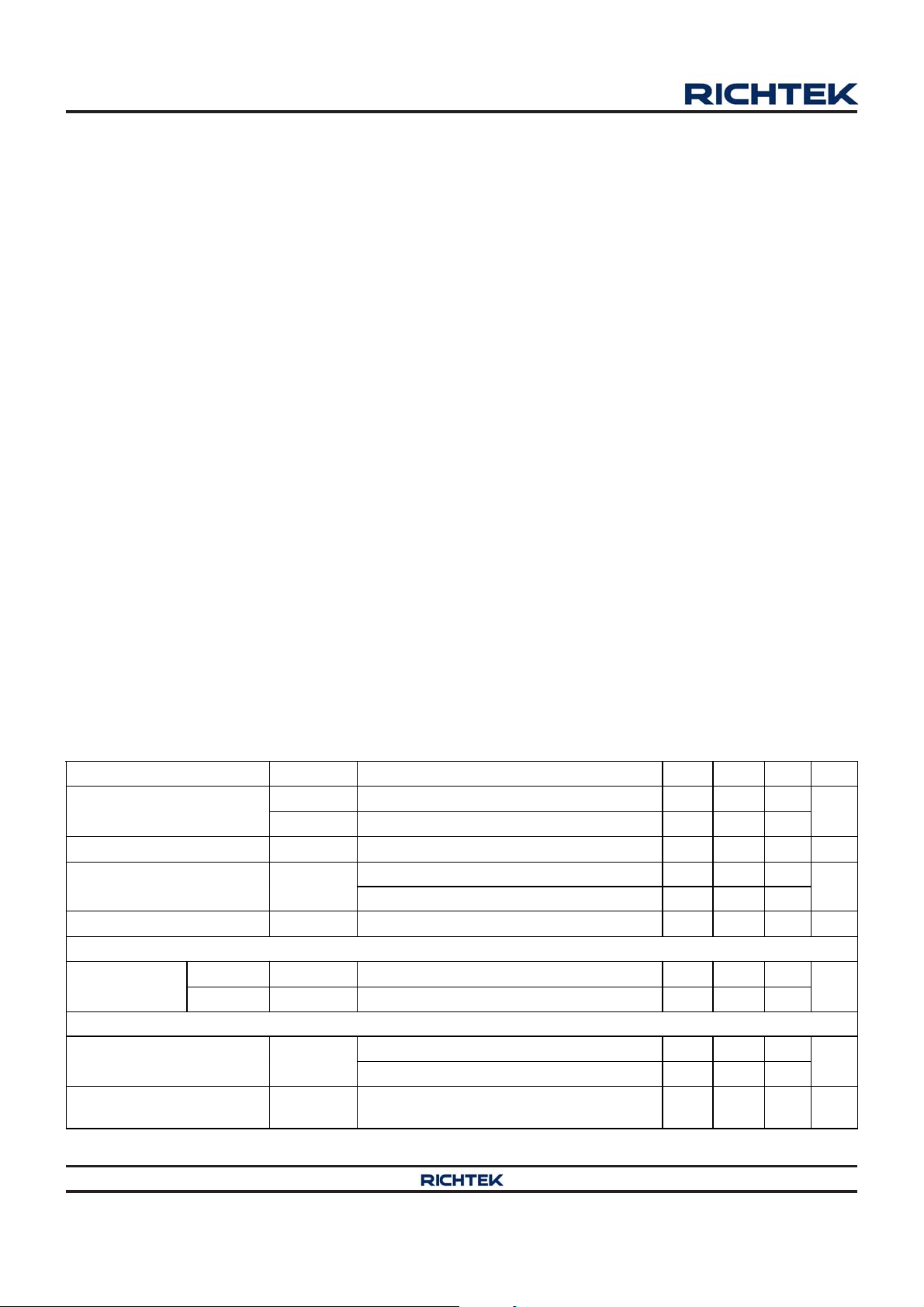

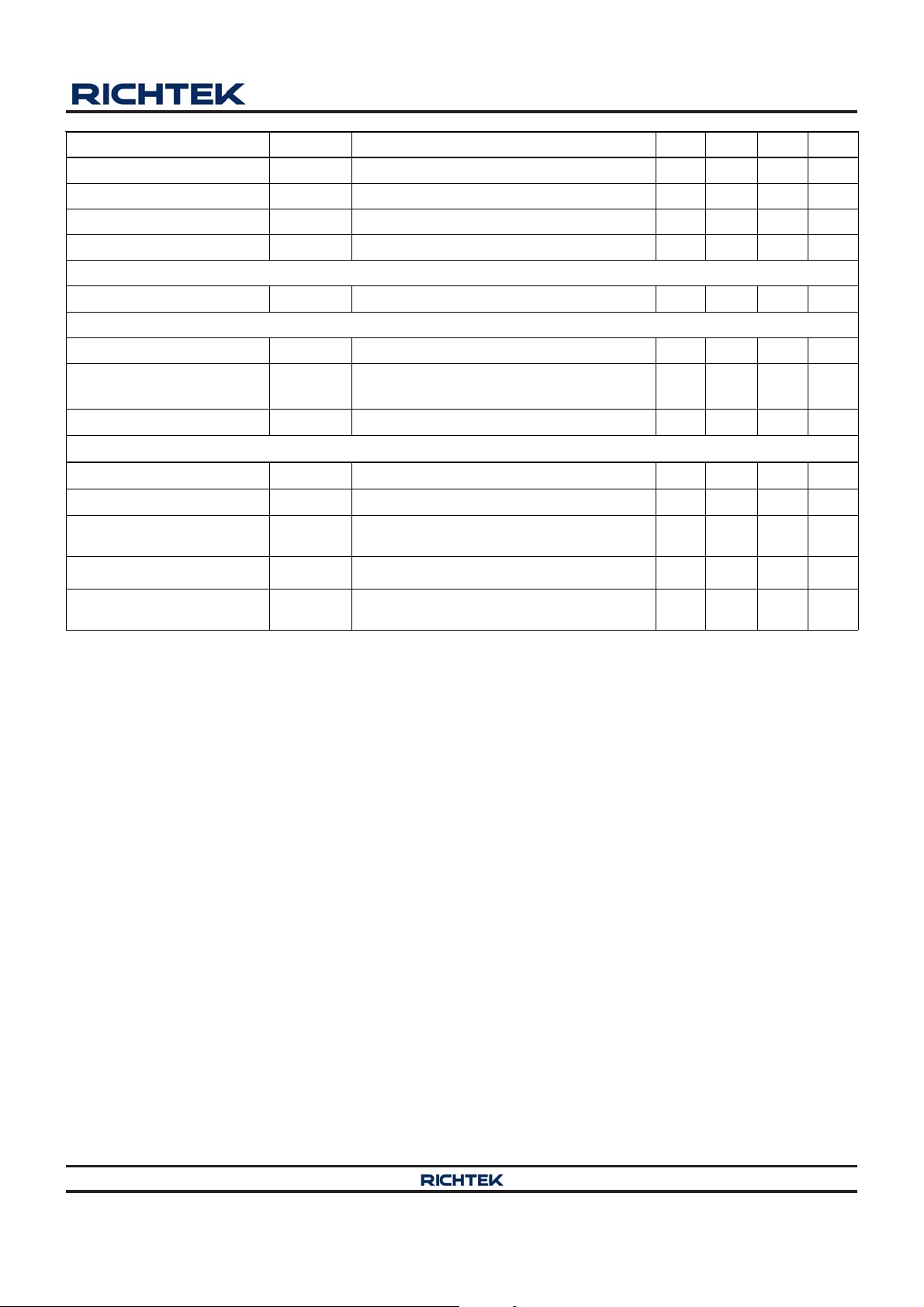

Electrical Characteristics

(V

= 5V, TA = 25°C, unless otherwise specified)

IN

Parameter Symbol Test Conditions Min Typ Max Unit

I

VIN Quiescent Current

VIN Shutdown Current I

VI N Unde r Vol tage Lock ou t

Threshold

PWM Dimm ing Frequency f

VIN

I

VIN_SW

SHDN

V

PWM

Control Input

EN, PWM Inp ut

Voltage

High V

Low VIL

Boost Converter

Switching Frequency fSW

LX On Resista nc e

(N-MOSFET)

R

UVLO

0.1 -- 20 kHz

IH

V

LX

PWM = COMP = 0V, Not Switching

-- 3 --

PWM = COMP = 2V, Sw itching -- 4 --

-- -- 10 A

-- 2.1 --

1.3 -- 24

-- -- 0.5

0.8 1 1.2

0.4 0.5 0.6

= 4.5V, EN = 0V

V

IN

V

Rising -- 2.3 --

IN

VIN Falling

= 2.5V to 24V

V

IN

= 2.5V to 24V

V

IN

R

= 22k

FSW

R

= 51k

FSW

> 4.5V 0 .18 0.2 0 .22

IN

mA

V

V

MHz

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

www.richtek.com

4

©

DS8532-04 January 2014

Page 5

RT8532

A

A

Parameter Symbol Test Conditions Min Typ Max Unit

Minimum On-Time t

ON(MIN)

Maximum Duty D

LX Cur rent Limi t I

Regulat ed V

V

LEDx

LIM

Low Dropout Linear Regulator

LDO O utput Vol tag e Ra nge VDC 3.6 3.8 4 V

LED Current Pr ogramming

LED Current Accuracy I

LE D Curr en t Matc hi ng I

LEDA

LEDM

ISET Pin Voltage V

F ault Protecti on

FSW = 1MHz 40 60 80 n s

FSW = 1MHz 90 93 96 %

MAX

LEDx

ISET

Hi gh est LE D Strin g, I

2V > V

2V > V

Formulated by (I

LEDx

LEDx

> 0.5V, R

> 0.5V, R

LEDx

LED

ISET

ISET

I

= 20mA

= 12k

= 12k,

) / I

VG

x 100%

VG

2.2 2.5 2.8 A

0.5 0.6 0.7 V

19.4 20 20.6 mA

-- -- 2 %

0.76 1 1.24 V

OVP Threshol d V

OVP UVLO Threshold V

T herm al Shutdow n

Temperature

OTP H ysteresis T

LE D Pi n Unde r Vol tag e

Threshold

Note 1. Stresses beyond those listed “Absolute Maximum Ratings” may cause permanent damage to the device. These are

stress ratings only, and functional operation of the device at these or any other conditions beyond those indicated in

the operational sections of the specifications is not implied. Exposure to absolute maximum rating conditions may

affect device reliability.

Note 2. θ

Note 3. Devices are ESD sensitive. Handling precaution is recommended.

Note 4. The device is not guaranteed to function outside its operating conditions.

is measured at T

JA

measured at the exposed pad of the package.

= 25°C on a high effective thermal conductivity four-layer test board per JEDEC 51-7. θJC is

A

1.16 1.2 1.24 V

OVP

OVPF

T

-- 150 -- C

SD

OTP_Hys

V

LSD

-- 30 -- C

Un-Connection -- 0.1 -- V

-- 50 -- mV

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS8532-04 January 2014

©

www.richtek.com

5

Page 6

RT8532

Typical Application Circuit

V

5V to 24V

Chip Enable

PWM Signal

L1

R1

10

C1

100nF

COMP

COMP

R

FSW

51k

10µH

19

1

17

20

3

2

VIN

EN

PWM

COMP

ISET

FREQ

AGND

LX

RT8532

PGND

IN

C

IN

4.7µF

R

5.1k

C

22nF

R

ISET

12k

5

15, 16

13, 14

D1

SS16

R

500k

12

OVP

R

15k

4

MIX

18

VDC

11

LED1

10

LED2

9

LED3

8

LED4

7

LED5

6

LED6

GND

21 (Exposed Pad)

OVP2

OVP1

C

0.1µF

DC

C

OUT

4.7µF

C

OVP

47pF

V

OUT

43V MAX

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

Figure 1. For General Application Circuit

V

2.5V to 24V

IN

5V

Chip Enable

PWM Signal

R1

10

R

12k

ISET

R

COMP

5.1k

C

22nF

R

51k

C

IN

4.7µF

C1

100nF

COMP

FSW

10µH

19

1

17

20

3

2

L1

VIN

EN

PWM

COMP

ISET

FREQ

AGND

LX

RT8532

PGND

5

15, 16

13, 14

D1

SS16

OVP

VDC

LED1

LED2

LED3

LED4

LED5

LED6

GND

R

OVP2

500k

12

R

OVP1

24k

4

MIX

18

C

0.1µF

11

10

9

8

7

6

21 (Exposed Pad)

DC

C

OUT

4.7µF

C

47pF

Figure 2. For Low Input Voltage Application Circuit

OVP

V

OUT

25V MAX

depends

(V

OUT

on D

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

:

MAX

)

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

www.richtek.com

©

DS8532-04 January 2014

6

Page 7

Typical Operating Characteristics

)

)

RT8532

Efficiency vs. Input Voltage

100

90

80

70

60

50

40

Efficiency (%)

30

20

10

0

4 8 12 16 20 24

54 LEDs, fSW = 500kHz, PWM = 3.3V

Inpu t Volta ge (V)

LED Curre nt vs. Temperature

26

24

22

LED Curre nt vs. Input Voltage

26

LED1

24

22

20

18

LED2

LED3

LED4

LED5

LED6

Output Current (mA

16

14

9 LEDs per channel, fSW = 500kHz, PWM = 3.3V

4 8 12 16 20 24

Input Voltage (V)

VDC vs. Temperature

5.0

4.5

4.0

(kHz)

SW

f

20

18

LED Current (mA)

16

14

9 LEDs per channel, fSW = 500kHz, PWM = 3.3V

-50 -25 0 25 50 75 100 125

Tempera ture (°C)

fSW vs. R

2000

1800

1600

1400

1200

1000

800

600

400

200

0 20 40 60 80 100 120 140

R

FSW

FSW

9 LEDs per channel

(kohm)

(kΩ)

3.5

VDC (V)

3.0

2.5

2.0

-50 -25 0 25 50 75 100 125

9 LEDs per channel, fSW = 500kHz

Temperature (°C)

LED Current v s. PWM Duty Cycle

20

16

12

8

LED Current (mA

4

0

0 20406080100

9 LEDs per channel, fSW = 500kHz

PWM 100Hz

PWM 1kHz

PWM 10kHz

PWM 20kHz

PW M Duty Cycle (%)

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS8532-04 January 2014

©

www.richtek.com

7

Page 8

RT8532

)

1.4

1.3

1.2

1.1

OVP Threshold Voltage (V)

1.0

V

IN

(10V/Div)

OVP Threshold Voltage vs. Input Voltage

9 LEDs per channel, fSW = 500kHz

4 8 12 16 20 24

Inp ut Volta g e (V)

Line Transient Response

2.5

2.3

2.0

1.8

Quiescent Current (mA

1.5

V

IN

(10V/Div)

V

EN

(5V/Div)

V

PWM

(5V/Div)

Qu iescent Curren t vs. Input Voltage

Not Switching

3 5 8 10131518202325

Inp ut Volta g e (V)

Power On in PWM Mode

I

LED

(20mA/Div)

V

OUT

(20V/Div)

V

EN

(5V/Div)

V

LX

(20V/Div)

I

LED

(20mA/Div)

VIN = 12V to 18V, fSW = 500kHz, PWM = 3.3V

Time (2.5ms/Div)

Power On from EN

VIN = 12V, fSW = 500kHz, PWM = 3.3V

Time (10ms/Div)

I

LED

(20mA/Div)

V

IN

(20V/Div)

V

PWM

(5V/Div)

V

EN

(5V/Div)

I

LED

(20mA/Div)

VIN = 12V, fSW = 500kHz

Time (10ms/Div)

Power On in Mixed Mode

VIN = 12V, fSW = 500kHz

Time (10ms/Div)

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

www.richtek.com

©

DS8532-04 January 2014

8

Page 9

Application Information

RT8532

The RT8532 is a general purpose 6-CH LED driver ca pable

of delivering an adjustable 5mA to 50mA LED current. The

IC is a current mode boost converter integrated with a

43V/2.5A power switch and can cover a wide VIN ra nge

from 2.5V to 24V. The part integrates both built-in softstart and with PWM dimming control; moreover , it provides

over voltage, over temperature and current limiting

protection features. It also integrates PWM and mixed

mode dimming function for a ccurate LED current control.

The PWM dimming frequency can operate from 100Hz to

20kHz without inducing any inrush current in LED or

inductor.

Input Capacitor Selection

Low ESR ceramic ca pa citors are recommended for input

capacitor applications. Low ESR will effectively reduce

the input ripple voltage caused by the switching operation.

Two 2.2μF low ESR ceramic capa citors are suff icient f or

most applications. Nevertheless, this value can be

decreased for applications with lower output current

requirement. Another consideration is the voltage rating

of the input capacitor, which must be greater than the

maximum input voltage.

where fSW is the switching frequency and ΔIL is the inductor

ripple current. Move C

value of ΔV

V

OUT1

according to the following equation :

OUT1

DI

OUT

Cf

OUT SW

to the left side to estimate the

OUT

Finally, taking ESR into a ccount, the overall output ripple

voltage can be determined by the following equation :

DI

VIESR

OUT IN

Input Current

ΔV

OUT1

OUT

Cf

OUT SW

Inductor Current

Output Current

(1-D)T

S

ΔI

L

Output Ripple

Voltage (ac)

Time

Time

Output Capacitor Selection

Output ripple voltage is an i mportant index f or estimating

chip performa nce. This portion consists of two parts. One

is the product of the inductor current ripple with the ESR

of the output cap acitor, while the other part is formed by

the charging and discharging process of the output

ca pacitor . As shown in Figure 3, ΔV

can be evaluated

OUT1

ba sed on the ideal energy equalization. According to the

definition of Q, the Q value can be calculated as the

following equation :

11 1

QIIIIII

C V

IN L OUT IN L OUT

22 2

V

Vf

OUT SW

IN

1

OUT OUT1

Figure 3. The Output Ripple Voltage without the

Contribution of ESR

Inductor Selection

The inductor value depends on the maximum input current.

As a general rule the inductor ripple current is 20% to

40% of maximum input current. If 40% is selected as an

example, the inductor ripple current can be calculated

according to the f ollowing equation :

VI

OUT OUT(MAX)

I

IN(MAX)

I0.4I

RIPPLE IN(MAX)

V

IN

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS8532-04 January 2014

©

www.richtek.com

9

Page 10

RT8532

where η is the ef ficiency of the boost converter , I

the maximum input current and I

is the inductor ripple

RIPPLE

IN(MAX)

is

current. The input pea k current can be obtained by adding

the maximum input current with half of the inductor ripple

current as shown in the f ollowing equation :

I

= 1.2 x I

PEAK

IN(MAX)

Note that the saturated current of inductor must be greater

than I

. The inductance ca n eventually be determined

PEAK

according to the following equation :

2

VDV V

L1

where V

IN OUT IN

0.4 V I f

is the maximum output voltage, VIN is the

OUT

2

OUT OUT SW

minimum input voltage, fSW is the switching frequency,

and I

is the sum of current from all LED strings.

OUT

LED Soft-Start Function

The soft-start time of the LED boost converter, defined a s

the period from EN to set I

, is several tens of

OUT

milliseconds according to the difference of PWM or Mixed

mode. The LED starts up after VIN, PWM and EN signals

are all ready. The soft-start inrush peak current must be

less than 2.5A.

LED Driver Compensation

The control loop can be compensated by adjusting the

external components connected to the COMP pin. The

COMP pin is the output of the internal error a mplifier. The

compensation capacitors, CC and C

, will adjust the

COMP

integrator zero and pole respectively to maintain stability .

Moreover, the resistor, R

, will adjust the mid-band

COMP

gain for fa st tran sient response.

Diode Selection

Setting and Regulation of LED Current

The LED current can be calculated by the following

equation :

ImA

LED

where R

ISET

240

Rk

ISET

is the resistor between the ISET pin and GND.

This setting is the reference for the LED current at LED1

to LED6 and represents the sensed LED current for ea ch

string. The DC/DC converter regulates the LED current

according to the setting.

PWM Mode and Mixed Mode Brightness Dimming

The RT8532 allows two ways of controlling the LED

brightness.

PWM Mode Di mming : When the MIX pin is connected to

GND, the dimming mode operates in PWM Mode. During

the PWM dimming, the current source turn-on/off is

synchronized with the PWM signal. The LED current

frequency is equivalent to PWM input frequency .

Mixed Mode Di mming : If the MIX pin is floating or tied to

V DC, the dimming mode operates in Mixed Mode. In this

mode the PWM and I

dimming cycle will delay by 2

LED

periods. First cycle delay is required for the period, while

the second cycle delay is for the duty rate calculation.

(a) When 25% ≤ PWM duty ≤ 100%, the current source

outputs are DC dimming, and the PWM duty cycle

modulates the amplitude of the currents.

(b) When PWM Duty < 25%, the DC dimming will tra nslate

to DC-PWM dimming to control the LED current. In this

state, the LED current is fixed at 0.25 x ISET, and the

dimming duty is 4 x PWM duties. The minimum D/A

Converter is 512 steps resolution for I

regulation.

LED

Schottky diodes D1 are recommended for most

applications because of their fast recovery time and low

forward voltage. Power dissipation, reverse voltage rating,

and pulsating pea k current are i mportant parameters for

consideration when making a Schottky diode selection.

Make sure that the diode's peak current rating exceeds

I

and reverse voltage rating exceeds the maximum

PEAK

output voltage.

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

www.richtek.com

10

©

DS8532-04 January 2014

Page 11

RT8532

Brightness Control

The RT8532 features the digital dimming control scheme.

A very high contrast ratio true digital PWM dimming can

be achieved by driving PWM pin with a PWM signal a nd

the recommended PWM frequency is 100Hz to 10kHz.

Dimming frequency can be sufficiently adjusted from

100Hz to 20kHz. However, LED current cannot be 100%

proportional to duty cycle especially for high frequency

and low duty ratio because of physical li mitation caused

by inductor rising time. Plea se refer to T a ble 1 and Table2.

Table 1. Mixed Dimming Mode

Dimming Frequency (Hz) Duty (Min) Duty (Max)

100 < f

200 < f

500 < f

1k < f

2k < f

5k < f

10k < f

200 0.18% 100%

PWM

500 0.18% 100%

PWM

1k 0.2% 100%

PWM

2k 0.2% 100%

PWM

5k 0.3% 100%

PWM

10k 0.3% 100%

PWM

20k 0.6% 100%

PWM

Table 2. PWM Dimming Mode

Dimming Frequency (Hz) Duty (Min) Duty (Max)

100 < f

200 < f

500 < f

1k < f

2k < f

5k < f

10k < f

Note : The minimum duty in T able 1 and Table 2 is based

on the application circuit and does not consider the

deviation of current linearity when f

may not achieve setting current in duty (min.) due to

different VOUT / VIN ratio at VIN = 12V .

200 0.02% 100%

PWM

500 0.02% 100%

PWM

1k 0.04% 100%

PWM

2k 0.06% 100%

PWM

5k 0.15% 100%

PWM

10k 0.3% 100%

PWM

20k 0.6% 100%

PWM

> 10kHz, ILED

PWM

Over Temperature Protection

The RT8532 includes an Over Temperature Protection

(OTP) feature to prevent overheating due to excessive

power dissipation from damaging the device. The OTP

function will shut down LED driver when the junction

temperature exceeds 150°C. It will reactivate the device

when powered on again. T o maintain continuous operation,

the junction temperature should be kept below 125°C.

LED Driver Over Voltage Protection

The LED driver equi ps an Over Voltage Protection (OVP)

function. When the voltage at the OVP pin reaches a

threshold of approximately 1.2V, the driver will turn off.

The drivers turn on again once the voltage at OVP drops

below the threshold voltage. Thus, the output voltage can

be clamped at a certain voltage level. This voltage level

can be calculated by the following equation :

R

VV1

OUT, OVP OVP

where R

and R

OVP1

OVP2

R

OVP1

are the resistors in the voltage

OVP2

divider connected to the OVP pin. It is suggested to use

500kΩ for R

to reduce loading effect.

OVP2

LED Channel Open Circuit Protection

If at least one channel is in normal operation, the LED

driver will automatically ignore the open channels and

continue to regulate current for the channels in normal

operation.

Under Voltage Lockout (UVLO)

The UVLO circuit compares the LED driver input voltage

at VIN with the UVLO threshold to ensure the input voltage

is high enough for reliable operation. The 200mV (typ.)

hysteresis prevents supply transients from causing a

shutdown. Once VIN exceeds the UVLO rising threshold,

the LED soft-start will begin after a several ms delay . When

VIN falls below the UVLO falling threshold, the controller

turns off all LED driver functions.

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS8532-04 January 2014

©

www.richtek.com

11

Page 12

RT8532

Thermal Considerations

For continuous operation, do not exceed absolute

maximum junction temperature. The maximum power

dissipation depends on the thermal resistance of the IC

package, PCB layout, rate of surrounding airflow, and

difference between junction and a mbient temperature. The

maximum power dissipation can be calculated by the

following formula :

P

where T

the ambient temperature, a nd θ

D(MAX)

= (T

J(MAX)

− TA) / θ

J(MAX)

JA

is the maximum junction temperature, TA is

is the junction to ambient

JA

thermal resistance.

For recommended operating condition specifications, the

maximum junction temperature is 125°C. The junction to

ambient thermal resista nce, θJA, is layout dependent. For

WQF N-20L 3x3 pa ckages, the thermal resista nce, θJA, is

68°C/W on a standard JEDEC 51-7 f our-layer thermal test

board. The maximum power dissipation at TA = 25°C can

be calculated by the following formula :

Layout Considerations

PCB layout is very important to design power switching

converter circuits. The following layout guide lines should

be strictly followed for best performa nce of the RT8532.

The power components L1, D1, C

and C

IN

must be

OUT

placed as close as possible to reduce the ac current

loop. The PCB trace between power components must

be short and wide a s possible due to large current flow

through these trace during operation.

Place L1 and D1 as close to LX pins as possible. The

trace should be short a nd wide as possible.

Place the input capacitor C1 close to VIN pin.

Pin 20 is the compensation point to adjust system

stability. Place the compensation components to pin

20 as close as possible.

P

= (125°C − 25°C) / (68°C/W) = 1.471W for

D(MAX)

WQF N-20L 3x3 pa ckage

The maximum power dissipation depends on the operating

ambient temperature for fixed T

and thermal

J(MAX)

resistance, θJA. The derating curve in Figure 4 allows the

designer to see the effect of rising ambient temperature

on the maximum power dissipation.

1.6

1.4

1.2

1.0

0.8

0.6

0.4

0.2

Maximum Pow er Dissipat ion (W) 1

0.0

0 255075100125

Ambient Temperatur e (°C)

Four-Layer PCB

Figure 4. Derating Curve of Maxi mum Power Dissi pation

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

www.richtek.com

12

©

DS8532-04 January 2014

Page 13

Locate the C1

as close to VIN

as possible.

The compensation circuit should be

kept away from the power loops and

should be shielded with a ground

trace to prevent any noise coupling.

C

COMP

R

COMP

GND

Place the power components as

close as possible. The traces should

be wide and short especially for the

high-current loop.

L1

R1

C1

V

C

D1

IN

IN

GND

VOUT

RT8532

C

OUT

Locate the R

to ISET as possible.

GND

ISET

R

as close

ISET

20

VIN

COMP

EN

1

2

FREQ

3

4

5

ISET

MIX

AGND

LED6

GND

LED5

Figure 5. PCB Layout Guide

17

1819

VDC

LED4

897610

PWM

LED3

16

LX

LED2

LX

PGND

PGND

OVP

LED1

15

14

13

12

11

GND

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS8532-04 January 2014

©

www.richtek.com

13

Page 14

RT8532

Outline Dimension

1

2

DETAIL A

Pin #1 ID a nd T ie Bar Mark Option s

Note : The configuration of the Pin #1 identifier is optional,

but must be located within the zone indicated.

Dimensions In Millimeters Dimensio ns In Inches

Symbol

Min Max Min Max

A 0.700 0.800 0.028 0.031

A1 0.000 0.050 0.000 0.002

A3 0.175 0.250 0.007 0.010

b 0.150 0.250 0.006 0.010

D 2.900 3.100 0.114 0.122

D2 1.650 1.750 0.065 0.069

E 2.900 3.100 0.114 0.122

1

2

E2 1.650 1.750 0.065 0.069

e 0.400 0.016

L 0.350 0.450

0.014 0.018

W-Type 20L QFN 3x3 Package

Richtek Technology Corporation

14F, No. 8, Tai Yuen 1st Street, Chupei City

Hsinchu, Taiwan, R.O.C.

Tel: (8863)5526789

Richtek products are sold by description only. Richtek reserves the right to change the circuitry and/or specifications without notice at any time. Customers should

obtain the latest relevant information and data sheets before placing orders and should verify that such information is current and complete. Richtek cannot

assume responsibility for use of any circuitry other than circuitry entirely embodied in a Richtek product. Information furnished by Richtek is believed to be

accurate and reliable. However, no responsibility is assumed by Richtek or its subsidiaries for its use; nor for any infringements of patents or other rights of third

parties which may result from its use. No license is granted by implication or otherwise under any patent or patent rights of Richtek or its subsidiaries.

www.richtek.com

14

DS8532-04 January 2014

Page 15

Loading...

Loading...