®

43V Asynchronous Boost WLED Driver

RT8511B

General Description

The RT851 1B is an LED driver IC that can support up to

10 WLED in series. It is composed of a current mode

boost converter integrated with a 43V/2.2A power switch

running at a fixed 500kHz frequency and covering a wide

VIN ra nge from 2.7V to 24V.

The white LED current is set with a n external resistor , and

the feedback voltage is regulated to 200mV (typ.). During

operation, the LED current ca n be controlled by the PWM

input signal in which the duty cycle determines the

feedback reference voltage.

For brightness dimming, the RT851 1B is able to maintain

steady control of the LED current. Therefore, no audible

noises are generated on the output cap acitor . The RT851 1B

also has programmable over voltage pin to prevent the

output from exceeding absolute maximum ratings during

open LED conditions. The RT8511B is available in

W DF N-8L 2x2 package.

Features

Wide Input Voltage Range : 2.7V to 24V

High Output Voltage : up to 43V

Direct PWM Dimming Control and Frequency from

100Hz to 8kHz

Internal Soft-Start and Compensation

200mV Reference Voltage

PWM Dimming with Internal Filter

Programmable Over Voltage Protection

Over Temperature Protection

Current Limit Protection

Thin 8-Lead WDFN Package

RoHS Compliant and Halogen Free

Applications

UMPC and Notebook Computer Backlight

GPS, Portable DVD Backlight

Ordering Information

RT8511B

Package Type

QW : WDFN-8L 2x2 (W-Type)

Lead Plating System

G : Green (Halogen Free and Pb Free)

Note :

Richtek products are :

RoHS compliant and compatible with the current require-

ments of IPC/JEDEC J-STD-020.

Suitable for use in SnPb or Pb-free soldering processes.

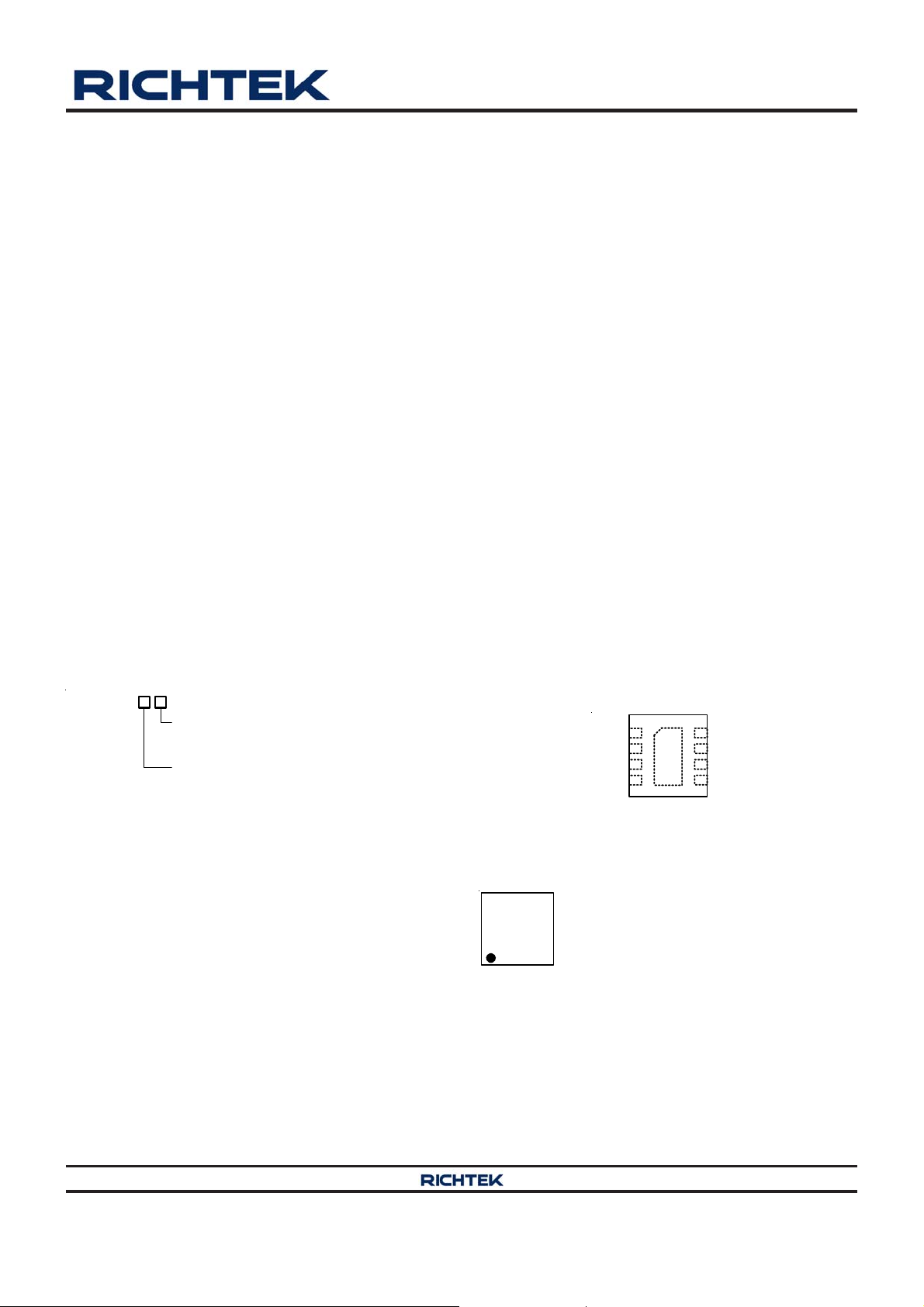

Pin Configurations

(TOP VIEW)

1

OVP

2

FB

3

DIMC

GND

WDFN-8L 2x2

GND

4

9

Marking Information

0F : Product Code

0FW

W : Date Code

8

7

6

5

EN

PWM

VIN

LX

Copyright 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

©

DS8511B-05 February 2015 www.richtek.com

1

RT8511B

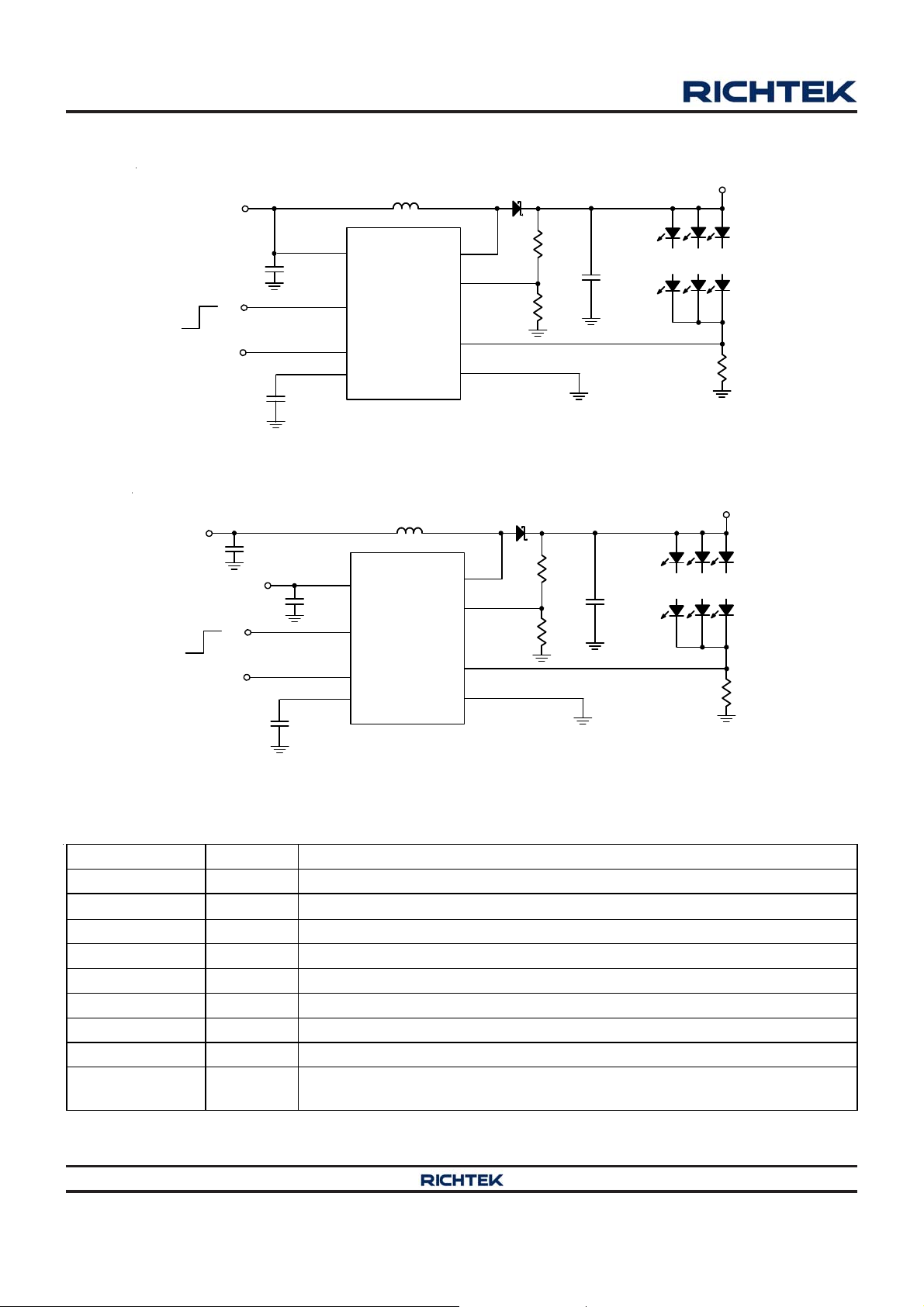

Typical Application Circuit

V

4.2V to 24V

Chip Enable

100Hz to 8kHz

V

2.7V to 24V

Chip Enable

100Hz to 8kHz

IN

PWM

LED

2.7V to 4.2V

PWM

C

IN

1µF x 2

C

DIMC

1µF

Figure 1. T ypical Application Circuit of Normal Operation

C

LED

1µF x 2

V

IN

C

DIMC

1µF

C

1µF

IN

6

8

7

3

6

8

7

3

VIN

EN

PWM

DIMC

VIN

EN

PWM

DIMC

L

10µH

RT8511B

L

10µH

RT8511B

5

LX

1

OVP

2

FB

4, 9 (Exposed Pad)

GND

5

LX

1

OVP

2

FB

4, 9 (Exposed Pad)

GND

V

D

R2

3.3M

C

OUT

1µF x 2

R1

100k

D

R2

3.3M

C

OUT

1µF x 2

R1

100k

:

:

:

:

OUT

:

:

:

:

WLEDs

:

:

:

:

R

SET

3.3

V

OUT

:

:

:

:

:

:

:

:

WLEDs

:

:

:

:

R

SET

3.3

Figure 2. T ypical Application Circuit of Low V oltage Operation

Functional Pin Description

Pin No. Pin Name Pin Function

1 OVP Over Voltage Protection for Boost Converter. The detecting threshold is 1.2V.

2 FB Feedback. Connect a resistor between this pin and GND to set the LED current.

3 DIMC PW M Fil t er. Filter the PW M sig nal to a DC vol t ag e.

4 GND Ground.

5 LX Switch Node for Boost Converter.

6 VIN Power Supply Input.

7 PWM Dimming Control Input.

8 EN Chip Enable (Active High) for Boost Converter.

9 (Exp ose d Pa d) GN D

Copyright 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

2

©

The exposed pad must be soldered to a large PCB and connected to AGND for

ma x imum power dissipation.

DS8511B-05 February 2015www.richtek.com

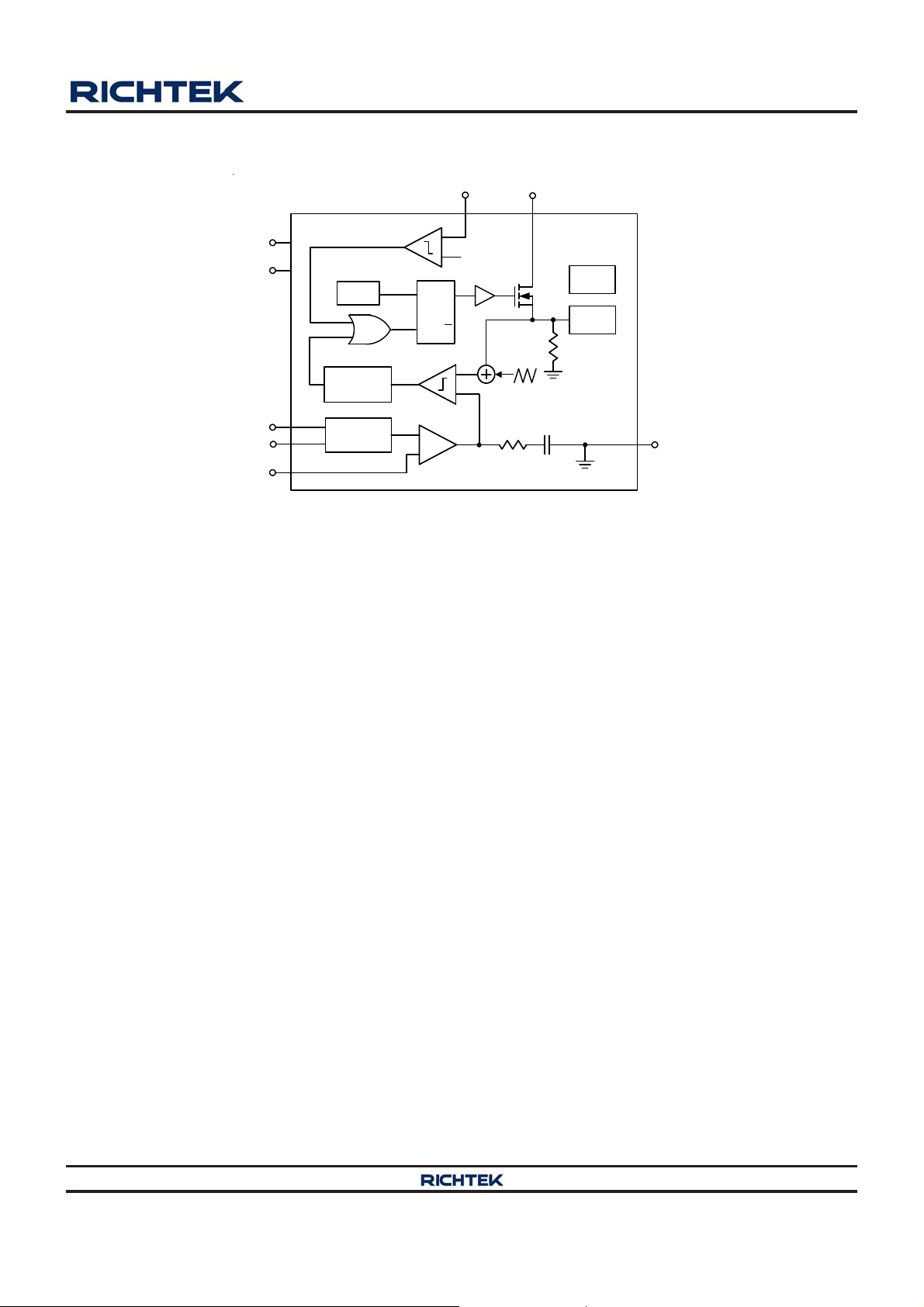

Function Block Diagram

RT8511B

LXOVP

VIN

EN

PWM

DIMC

FB

OSC

PWM

Controller

D/A

Dimming

+

1.2V

-

QS

R

Q

+

+

-

OTP

OCP

GND

Copyright 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

©

DS8511B-05 February 2015 www.richtek.com

3

RT8511B

Absolute Maximum Ratings (Note 1)

VIN, EN, PWM, DIMC to GND------------------------------------------------------------------------------------------ −0.3V to 26.5V

FB, OVP to GND ---------------------------------------------------------------------------------------------------------- −0.3V to 48V

LX to GND ------------------------------------------------------------------------------------------------------------------ −0.3V to 48V

< 500ns ---------------------------------------------------------------------------------------------------------------------- −1V to 48V

Power Dissipation, P

WDFN-8L 2x2 -------------------------------------------------------------------------------------------------------------- 0.833W

Package Thermal Re sistance (Note 2)

W DF N-8L 2x2, θJA--------------------------------------------------------------------------------------------------------- 120°C/W

WDFN-8L 2x2, θJC--------------------------------------------------------------------------------------------------------- 8.2°C/W

Lead Temperature (Soldering, 10 sec.)------------------------------------------------------------------------------- 260°C

Junction T emperature----------------------------------------------------------------------------------------------------- 150°C

Storage T emperature Range -------------------------------------------------------------------------------------------- –65°C to 150°C

ESD Susceptibility (Note 3)

HBM (Human Body Model)---------------------------------------------------------------------------------------------- 2kV

MM (Machine Model) ----------------------------------------------------------------------------------------------------- 200V

@ TA = 25°C

D

Recommended Operating Conditions

Supply Input V oltage, V

Junction T emperature Range-------------------------------------------------------------------------------------------- −40°C to 125°C

Ambient T emperature Range-------------------------------------------------------------------------------------------- −40°C to 85°C

------------------------------------------------------------------------------------------------ 2.7V to 24V

IN

(Note 4)

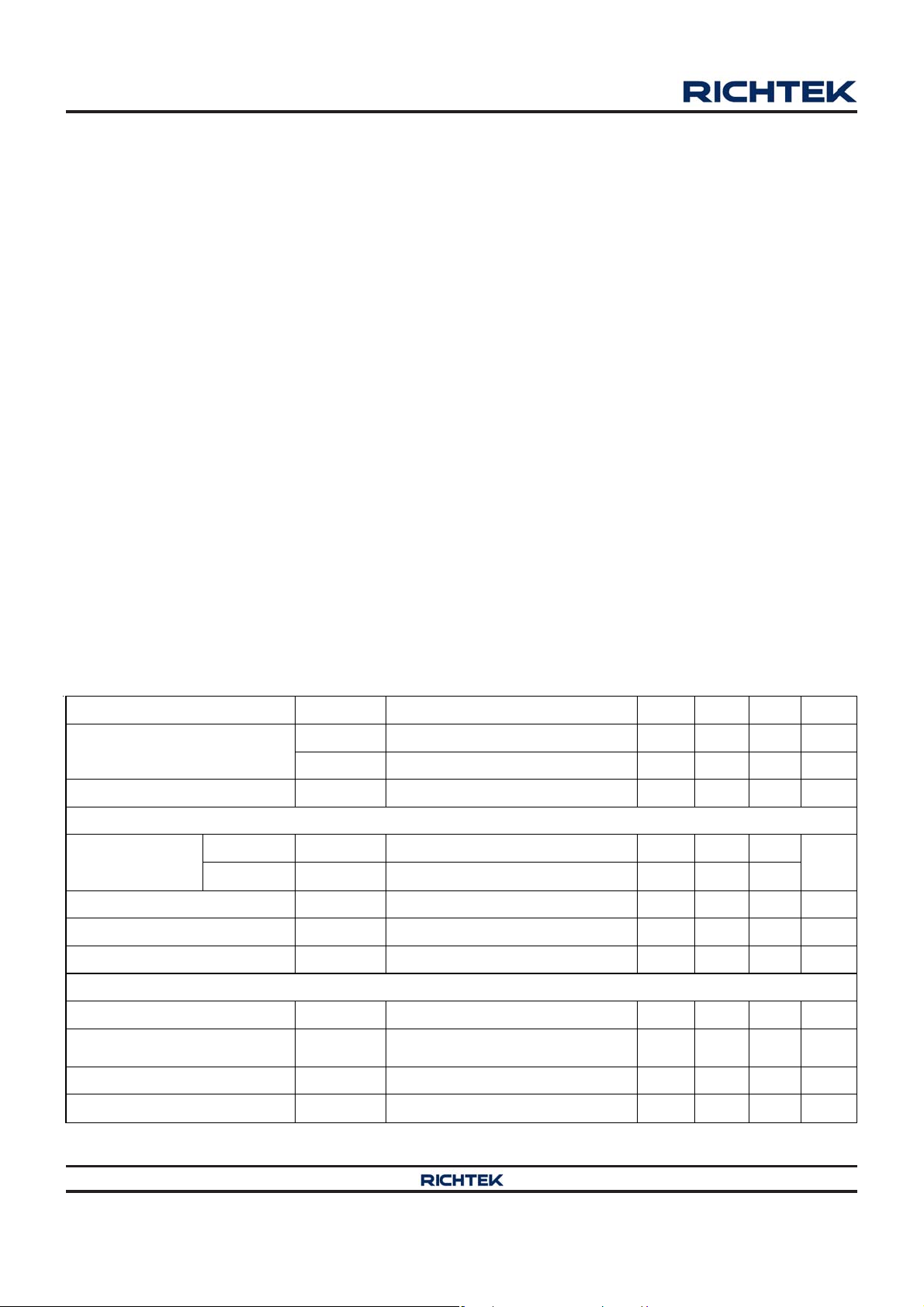

Electrical Characteristics

(V

= 4.5V, T

IN

VIN Quiescent Current

VIN Shutdown Current I

Control In put

EN, PWM

Threshold Voltage

EN Sink Current IIH V

Shutdown Delay t

PWM Dimming Frequenc y 0.1 - - 8 kHz

Boost Converter

= 25°C, unless otherwise specified)

A

Parameter Symbol Test Conditions Min Typ Max Unit

Logic-High V

V

I

Q

I

VFB = 0V, Switching -- -- 2.2 mA

Q_SW

V

SHDN

V

IH

= 1.5V, No Switching -- 725 -- A

FB

= 4.5V, VEN = 0V -- 1 4 A

IN

= 2.7V to 24V 1.6 -- --

IN

V

Logic-Low VIL V

EN high to low 52 64 80 ms

SHDN

= 2.7V to 24V -- -- 0.8

IN

= 3V 1 -- 10 A

EN

Switching Frequency f

LX On Resistance

(N-MOSFET)

V

OSC

R

VIN > 5V -- 0.4 0.6

DS(ON)

= 2.7V to 24V 0.4 0.5 0.6 MHz

IN

Minimum ON T i me -- 6 0 -- ns

Maximum Duty Cycle D

Copyright 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

4

©

V

MAX

= 0V, Switching -- 92 -- %

FB

DS8511B-05 February 2015www.richtek.com

RT8511B

Parameter Symbol Test Conditions Min Typ Max Unit

LED Current

Minimum PWM Dimming Duty

Cycle

Feedback Voltage VFB 195 200 205 mV

Fault Protection

Dimming Freq. = 100Hz to 8kHz 1 -- -- %

D

MIN

LX Current Limit I

Over Voltage Protection

Threshold

Thermal Shutdown

Temperature

1.66 2.2 2.74 A

LIM

1.14 1.2 1.26 V

V

OVP

-- 160 -- °C

T

SD

Thermal Shutdown Hysteresis TSD -- 30 -- °C

Note 1. Stresses beyond those listed “Absolute Maximum Ratings” may cause permanent damage to the device. These are

stress ratings only, and functional operation of the device at these or any other conditions beyond those indicated in

the operational sections of the specifications is not implied. Exposure to absolute maximum rating conditions may

affect device reliability.

Note 2. θ

Note 3. Devices are ESD sensitive. Handling precaution is recommended.

Note 4. The device is not guaranteed to function outside its operating conditions.

is measured at T

JA

measured at the exposed pad of the package.

= 25°C on a high effective thermal conductivity four-layer test board per JEDEC 51-7. θJC is

A

Copyright 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS8511B-05 February 2015 www.richtek.com

©

5

RT8511B

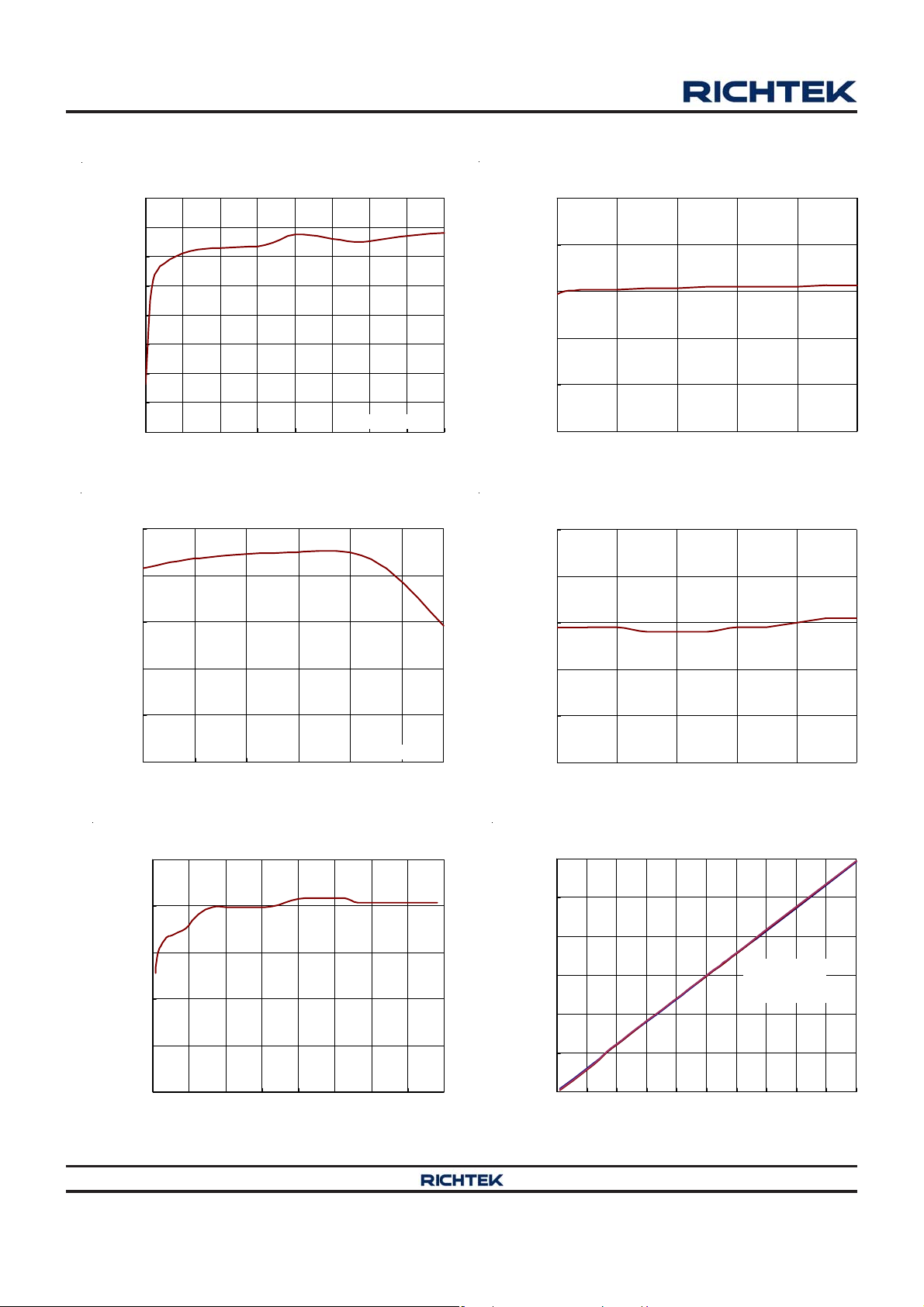

Typical Operating Characteristics

Efficiency vs. Input Voltage

100

95

90

85

80

75

Efficiency (%)

70

65

V

60

4 7 9 121417192224

OUT

Inp ut Vol tage (V)

FB Reference Voltage vs. Te m perature

200

198

196

= 29.5V

FB Reference Voltage vs. Input Voltage

199.5

199.2

198.9

198.6

198.3

FB Refer ence V oltage ( m V)

198.0

4 8 12 16 20 24

Input Vol tage (V)

Frequency vs. Input Voltage

600

550

500

194

192

FB Reference Voltage (mV)

190

-20 5 30 55 80 105

Temperature (°C)

Current Lim it vs. Input Voltage

3.0

2.6

2.2

1.8

Current Lim it ( A)

1.4

1.0

2.5 5.25 8 10.75 13.5 16.25 19 21.75 24.5

Inpu t Voltage (V)

V

IN

= 4.5V

450

Frequency ( kH z) 1

400

350

4 8 12 16 20 24

Input Vol tage (V)

LED Current vs. PWM Duty Cycle

60

50

40

30

20

LED Current (mA)

10

0

0 102030405060708090100

PWM Duty Cycle (%)

PWM = 100Hz

= 2kHz

PWM

PWM = 8kHz

Copyright 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

©

DS8511B-05 February 2015www.richtek.com

6

Application Information

RT8511B

The RT8511B is a current mode boost converter which

operates at a fixed frequency of 500kHz. It is ca pa ble of

driving up to 10 white LEDs in series and integrates

functions such as soft-start, compensation, and internal

analog di mming control. The protection block also provides

over-voltage, over-temperature, and current- limit protection

features.

LED Current Setting

The loop structure of the boost converter keeps the FB

pin voltage equal to the reference voltage VFB. Therefore,

by connecting the resistor, R

between the FB pin and

SET

GND, the LED current will be determined by the current

through R

. The LED current can be calculated by the

SET

following equation :

V

I =

LED

R

FB

SET

Brightness Control

For the brightness dimming control of the RT8511B, the

IC provides typically 200mV reference voltage when the

PWM pin is constantly pulled high. However, the PWM

pin allows a PWM signal to adjust the reference voltage

by changing the PWM duty cycle to achieve LED

brightness dimming control. The relationship between the

duty cycle and the FB voltage can be calculated a ccording

to the following equation :

VFB = 200mV x Duty

where 200mV is the typical internal reference voltage and

Duty is the duty cycle of the PWM signal.

As shown in Figure 3, the duty cycle of the PWM signal

is used to modify the internal 200mV reference voltage.

With an on-chip output clamping amplifier and a serial

resistor, the PWM dimming signal is easily low-pass

filtered to an analog dimming signal with one external

cap a citor, C

, for noise-free PWM dimming. Di mming

DIMC

frequency can be sufficiently a djusted from 100Hz to 8kHz.

However, the LED current cannot be 100% proportion al to

the duty cycle. Referring to T a ble 1, the minimum dimming

duty can be as low as 1% for the frequency range from

100Hz to 8kHz. It should be noted that the accuracy of

1% duty is not guaranteed.

Because the voltage of DIMC a nd FB is small to 2mV a nd

ea sily affected by LX switching noise.

200mV

DIMC

PWM

R

C

DIMC

1µF

FB

+

EA

-

To

Controller

Figure 3. Block Di agra m of Progra mma ble FB Voltage

Table 1. Minimum Duty for Dimming Frequency

Dimming Frequency Minimum Duty Cycle

100Hz to 8kHz 1%

The FB pin voltage will be decrea sed by lower PWM duty

ratio . That will achieve LED current diming function for

different brightness. But LED current is more accurate

when higher PWM duty. The Table 2. shows typical

variation value comparison between different PWM duty

and condition is VIN = 3.7V, LED array = 6S2P, R

SET

5Ω.

Table 2. LED Current Variation vs PWM Duty

PWM Duty

(%)

Variation

(%)

PWM Duty

(%)

Variation

(%)

1 ±60 8 ±7

2 ±25 9 ±6

3 ±17 10 ±5

4 ±13 20 ±4

5 ±10 50 ±3

6 ±9 100 ±2.5

7 ±8

It also should be noted that when the input voltage is too

close to the output voltage [(V

OUT −VIN

audible noise may occur. Additionally, for accurate

brightness dimming control, the input voltage should be

kept lower than the LEDs' turn on voltage. When operating

in the light load, excessive output ripple may occur.

) < 6V] , excessive

=

Copyright 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS8511B-05 February 2015 www.richtek.com

©

7

RT8511B

Soft-Start

The RT851 1B provides a built-in soft-start function to limit

the inrush current, while allowing for an increased PWM

frequency for dimming.

Current Limiting Protection

The RT8511B can limit the peak current to achieve over

current protection. The IC senses the inductor current

through the LX pin in the charging period. When the value

exceeds the current limiting threshold, the internal N-

V

IN

EN

PWM

soft-start

V

OUT

Mode1

MOSFET will be turned off. In the off period, the inductor

current will descend. The internal MOSFET is turned on

by the oscillator during the beginning of the next cycle.

Power Sequence

In order to assure that the normal soft-start function is in

place for suppressing the inrush current, the in put voltage

and enable voltage should be ready before PWM pulls

high. Figure 4 and Figure 5 show the power on and power

off sequences.

V

IN

EN

PWM

V

OUT

Mode1

V

IN

EN

V

OUT

soft-start

Mode2

V

IN

EN

PWM

soft-start

V

OUT

Mode3

Figure 4. Power On Sequence

V

IN

EN

PWM

V

OUT

Mode2

V

IN

EN

PWM

V

OUT

Shutdown

Delay

Mode3

Figure 5. Power Off Sequence

Copyright 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

©

DS8511B-05 February 2015www.richtek.com

8

RT8511B

Over Voltage Protection

The RT8511B equips Over Voltage Protection (OVP)

function. When the voltage at the OVP pin reaches a

threshold of approxi mately 1.2V , the MOSFET drive output

will turn off. The MOSFET drive output will turn on again

once the voltage at the OVP pin drops below the threshold.

Thus, the output voltage can be clamped at a certain

voltage level, as shown in the f ollowing equation :

R2

V = V1+

OUT, OVP OVP

R1

where R1 and R2 ma ke up the voltage divider connected

to the OVP pin.

Over Temperature Protection

The RT851 1B has a n Over T e mperature Protection (OTP)

function to prevent overheating caused by excessive power

dissipation from overheating the device. The OTP will shut

down switching operation if the junction temperature

exceeds 160°C. The boost converter will start switching

again when the junction temperature is cooled down by

a pproximately 30°C.

Inductor Selection

where f

is the switching frequency . For better efficiency ,

OSC

it is suggested to choose an inductor with small series

resistance.

Diode Selection

The Schottky diode is a good choice for an a synchronous

boost converter due to its small forward voltage. However ,

when selecting a Schottky diode, important parameters

such as power dissipation, reverse voltage rating, and

pulsating peak current must all be taken into

consideration. A suitable Schottky diode's reverse voltage

rating must be greater than the maximum output voltage,

and its average current rating must exceed the average

output current.

Capacitor Selection

Two 1μF ceramic input capacitors and two 1μF ceramic

output cap acitors are recommended for driving 10 WLEDs

in series. For better voltage filtering, ceramic capacitors

with low ESR are recommended. Note that the X5R a n d

X7R types are suitable because of their wide voltage and

temperature ranges.

The inductance depends on the maximum in put current.

As a general rule, the inductor ripple current range is 20%

to 40% of the maximum input current. If 40% is selected

as an example, the inductor ripple current can be

calculated according to the following equation :

VI

I =

IN(MAX)

I = 0.4I

RIPPLE IN(MAX)

where η is the ef ficiency of the boost converter , I

the maximum input current, I

all LED strings, and I

OUT OUT

V

(MIN) IN(MIN)

RIPPLE

IN(MAX)

is the total current from

OUT

is the inductor ripple current.

The input peak current can be calculated by maximum

input current plus half of inductor ripple current shown a s

following equation :

I

= 1.2 x I

PEAK

IN(MAX)

Note that the saturated current of the inductor must be

greater than I

. The inductance can eventually be

PEAK

determined according to the following equation :

2

V(VV

L =

0.4 V I f

IN OUT IN

OUT OUT OSC

2

)

Thermal Considerations

For continuous operation, do not exceed absolute

maximum junction temperature. The maximum power

dissipation depends on the thermal resistance of the IC

package, PCB layout, rate of surrounding airflow, and

difference between junction and a mbient temperature. The

maximum power dissipation can be calculated by the

following formula :

is

P

where T

the ambient temperature, a nd θ

D(MAX)

= (T

J(MAX)

− TA) / θ

J(MAX)

JA

is the maximum junction temperature, T

is the junction to ambient

JA

thermal resistance.

For recommended operating condition specifications, the

maximum junction temperature is 125°C. The junction to

ambient thermal re sistance, θJA, is layout dependent. For

WDFN-8L 2x2 package, the thermal resistance, θJA, is

120°C/W on a standard JEDEC 51-7 four-layer thermal

test board. The maximum power dissipation at TA = 25°C

can be calculated by the following f ormulas :

is

A

Copyright 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS8511B-05 February 2015 www.richtek.com

©

9

RT8511B

P

= (125°C − 25°C) / (120°C/W) = 0.833W for

D(MAX)

W DF N-8L 2X2 pa ckage

The maximum power dissipation depends on operating

ambient temperature for fixed T

and thermal

J(MAX)

resistance, θJA. The derating curves in Figure 6 allow the

designer to see the effect of rising ambient temperature

on the maximum power dissipation.

1.0

0.8

0.6

0.4

0.2

Maximum Power Dissipation (W) 1

0.0

0 25 50 75 100 125

Ambient Temperatu re (°C)

Four-Layer PCB

Layout Consideration

For high frequency switching power supplies, the PCB

layout is important to obtain good regulation, high

efficiency and sta bility . The following description s are the

suggestions for better PCB layout.

Input and output capacitors should be placed close to

the IC and connected to the ground plane to reduce

noise coupling.

The GND and Exposed Pad should be connected to a

strong ground plane for heat sinking a nd noise protection.

The components L, D, C

and C

IN

must be placed a s

OUT

close as possible to reduce current loop. Keep the main

current traces as possible as short and wide.

The LX node of the DC/DC converter experiences is with

high frequency voltage swings. It should be kept in a

small area.

The component R

should be placed as close as

SET

possible to the IC and kept away from noisy devices.

Figure 6. Derating Curve of Maxi mum Power Dissi pation

close

SET

R1R2

1

SET

DIMC

V

DIMC

GND

OUT

OVP

FB

2

3

4

R

C

should be connected

WLEDs

Locate R

to FB as possible

:

:

:

:

:

:

:

:

:

:

:

:

The C

OUT

directly from the output schottky

diode to ground rather than

across the WLEDs.

Figure 7. PCB Layout Guide

8

EN

7

PWM

6

VIN

GND

5

9

LX

LD

V

C

OUTCIN

CIN should be placed as

closed as possible to V I N

pin for good filtering.

IN

The inductor should be placed

as close as possible to the

switch pin to minimize the noise

coupling into other circuits.

LX node copper area should be

minimized for reducing EMI

Copyright 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

©

DS8511B-05 February 2015www.richtek.com

10

Outline Dimension

RT8511B

D

E

A

A3

A1

D2

L

E2

SEE DETAIL A

1

e

b

2

1

1

2

DETAIL A

Pin #1 ID a nd T ie Bar Mark Option s

Note : The configuration of the Pin #1 identifier is optional,

but must be located within the zone indicated.

Dimensions In Millimeters Dimensions In Inches

Symbol

Min Max Min Max

A 0.700 0.800 0.028 0.031

A1 0.000 0.050 0.000 0.002

A3 0.175 0.250 0.007 0.010

b 0.200 0.300 0.008 0.012

D 1.950 2.050 0.077 0.081

D2 1.000 1.250 0.039 0.049

E 1.950 2.050 0.077 0.081

E2 0.400 0.650 0.016 0.026

e 0.500 0.020

L 0.300 0.400

W-Type 8L DFN 2x2 Package

0.012 0.016

Richtek Technology Corporation

14F, No. 8, Tai Yuen 1st Street, Chupei City

Hsinchu, Taiwan, R.O.C.

Tel: (8863)5526789

Richtek products are sold by description only. Richtek reserves the right to change the circuitry and/or specifications without notice at any time. Customers should

obtain the latest relevant information and data sheets before placing orders and should verify that such information is current and complete. Richtek cannot

assume responsibility for use of any circuitry other than circuitry entirely embodied in a Richtek product. Information furnished by Richtek is believed to be

accurate and reliable. However, no responsibility is assumed by Richtek or its subsidiaries for its use; nor for any infringements of patents or other rights of third

parties which may result from its use. No license is granted by implication or otherwise under any patent or patent rights of Richtek or its subsidiaries.

DS8511B-05 February 2015 www.richtek.com

11

Loading...

Loading...