Page 1

®

5A, 24V, 570kHz Step-Down Converter

RT8251

General Description

The RT8251 is a monolithic step-down switch mode

converter with a built-in internal power MOSFET . It a chieves

5A continuous output current over a wide input supply

range with excellent load a nd line regulation. Current mode

operation provides fast tra nsient response a nd ea ses loop

stabilization.

The RT8251 provides protection functions such as

cycle-by-cycle current limiting and thermal shutdown. In

shutdown mode, the regulator draws 25μA of supply

current. Programmable soft-start minimizes the inrush

supply current and the output overshoot at initial startup.

The RT8251 requires a minimum number of external

components. The RT8251 is available in WQ F N-16L 3x3

and SOP-8 (Exposed Pad) pa ckages.

Pin Configurations

(TOP VIEW)

Features

zz

Wide Operating Input Voltage Range : 4.75V to 24V

z

zz

zz

z Adjustable Output Voltage Range : 0.8V to 15V

zz

zz

z Output Current up to 5A

zz

μμ

zz

z 25

μA Low Shutdown Current

zz

μμ

zz

z Internal Power MOSFET : 70m

zz

zz

z High Efficiency up to 95%

zz

zz

z 570kHz Fixed Switching Frequency

zz

zz

z Stable with Low ESR Output Ceramic Capacitors

zz

zz

z Thermal Shutdown Protection

zz

zz

z Cycle-By-Cycle Over Current Protection

zz

zz

z RoHS Compliant and Halogen Free

zz

ΩΩ

Ω

ΩΩ

Applications

z Distributed Power Systems

z Battery Charger

z DSL Modems

z Pre-regulator for Linear Regulators

VIN

VINSWSW

VIN

1

2

VIN

VIN

GND

GND

3

4

FB

COMP

WQFN-16L 3x3

BOOT

VIN

SW

GND

2

GND

3

4

SOP-8 (Exposed Pad)

17

EN

13141516

SW

12

11

SW

10

SW

BOOT

9

8765

SS

Ordering Information

RT8251

Package Type

QW : WQFN-16L 3x3 (W-Type)

SP : SOP-8 (Exposed Pad-Option 1)

Lead Plating System

G : Green (Halogen Free and Pb Free)

Note :

Richtek products are :

` RoHS compliant and compatible with the current require-

8

SS

7

EN

6

9

COMP

5

FB

ments of IPC/JEDEC J-STD-020.

` Suitable for use in SnPb or Pb-free soldering processes.

Copyright 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

©

DS8251-04 February 2013 www.richtek.com

1

Page 2

RT8251

Marking Information

RT8251GQW

GE= : Product Code

GE=YM

DNN

Typical Application Circuit

YMDNN : Date Code

RT8251GSP

RT8251

GSPYMDNN

RT8251GSP : Product Number

YMDNN : Date Code

4.75V to 24V

V

Chip Enable

4.75V to 24V

Chip Enable

IN

C

10µF x 2

C

SS

10nF

Exposed Pad (17)

V

IN

C

SS

10nF

Exposed Pad(9)

1, 2, 3,

15, 16

IN

VIN

RT8251

7

EN

8

SS

4,

GND

BOOT

SW

FB

COMP

9

10 to 14

5

2.2nF

6

C

C

(Open)

C

C

100nF

D

B540C

R

22k

P

BOOT

C

L

4.7µH

Figure 1. T ypical Application Circuit for WQFN-16L 3x3

C

IN

10µF x 2

2

VIN

RT8251

7

EN

8

SS

4,

GND

BOOT

SW

FB

COMP

1

C

BOOT

100nF

3

D

B540C

5

C

C

2.2nF

6

4.7µH

R

C

22k

L

R1

30.9k

R2

10k

R1

30.9k

R2

10k

C

OUT

22µF x 2

V

3.3V/5A

C

OUT

22µF x 2

V

OUT

3.3V/5A

OUT

C

P

NC

Figure 2. T ypical Application Circuit for SOP-8 (Exposed Pa d)

Table 1. Recommended Component Selection

V

(V) R1 (kΩ) R2 (kΩ) RC (kΩ) CC (nF) L1 (μH) C

OUT

OUT

(μF)

15 182 10 51 1 22 44

10 115 10 43 1.2 10 44

8 91 10 39 1.5 10 44

5 52.3 10 30 1.5 6.8 44

3.3 30.9 10 22 2.2 4.7 44

2.5 21.5 10 16 2.2 4.7 44

1.8 12.4 10 13 2.2 2.2 44

1.2 4.99 10 13 2.2 2.2 44

Copyright 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

2

©

DS8251-04 February 2013www.richtek.com

Page 3

Functional Pin Description

Pin No.

WQFN-16L 3x3

1, 2, 3, 15, 16 2 VIN

4,

17 (Exposed Pad )

5 5 FB

6 6 COMP

7 7 EN

8 8 SS

9 1 BOOT

10, 11, 12, 13,

14

SOP-8

(Exposed Pad)

4,

9 (Exposed Pad)

3 SW

Pin Name Pin Function

GND

RT8251

Power Input. VIN supplies the power to the IC, as well as the

step-down converter switches. Connect VIN with a 4.75V to 24V

power source. Connect VIN to GND with a capacitor that the

capacitance is large enough to eliminate noise on the input to the

IC.

Ground. This pin is the voltage reference for the regulated output

voltage. For this reason, care must be taken in its layout. This

node should be placed outside of the D1 to C

prevent switching current spikes from inducing voltage noise into

the part. The exposed pad must be soldered to a large PCB and

connected to GND for maximum power dissipation.

Feedback Input. An external resistor divider from the output to

GND, tapped to the FB pin, sets the output voltage.

Compensation Node. This node is the output of the

transconductance error amplifier and the input to the current

comparator. Frequency compensation is done at this node by

connecting a series R-C to ground.

Enable Input. EN is a digital input that turns the regulator on or

off. Drive EN higher than 1.4V to turn on the regulator, lower

than 0.4V to turn it off. For automatic startup, leave EN

unconnected.

Soft-Start Control Input. SS controls the soft start period.

Connect a capacitor (≧ 10nF) from SS to GND to set the

soft-start period. A 10nF capacitor sets the Soft-Start period to

1ms.

Bootstrap. This capacitor C

switch’s gate above the supply voltage. It is connected between

the SW and BS pins to form a floating supply across the power

switch driver. The voltage across C

supplied by the internal +5V supply when the SW pin voltage is

low.

Power Switching Output. SW is the switching node that supplies

power to the output. Connect the output LC filter from SW to the

output load. Note that a capacitor is required from SW to BOOT

to power the high-side switch.

is needed to drive the power

BOOT

BOOT

ground path to

IN

is about 5V and is

Copyright 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS8251-04 February 2013 www.richtek.com

©

3

Page 4

RT8251

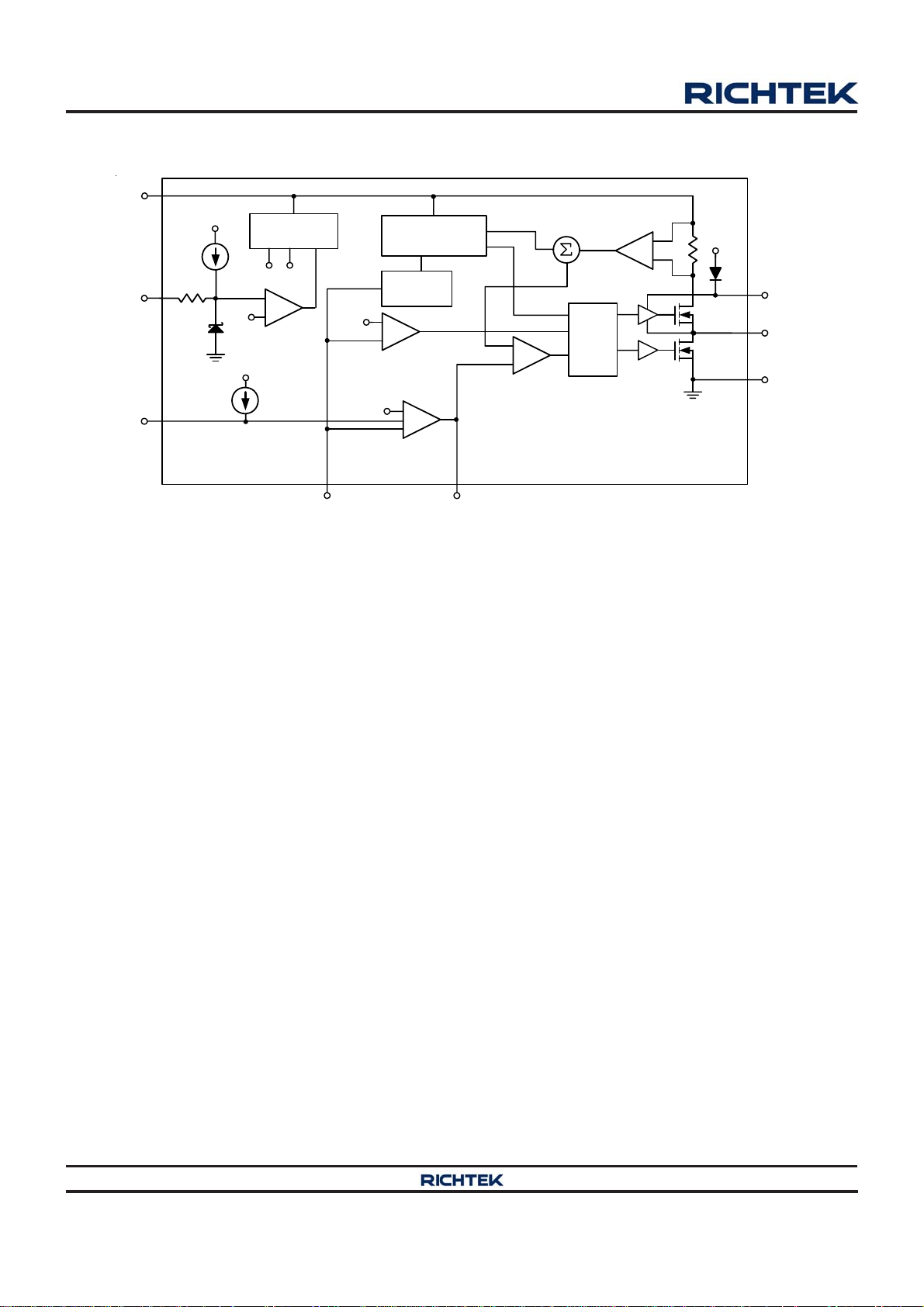

Function Block Diagram

VIN

EN

SS

1µA

10k

3V

V

CC

1.1V

Regulator

VA

-

+

Shutdown

Comparator

V

CC

10µA

Internal

V

CC

0.4V

Comparator

0.8V

Gm = 820µA/V

FB

Oscillator

570kHz

Foldback

Control

+

-

UV

+

EA

+

-

COMP

Slope Comp

+

Current

Comparator

Current Sense

Amplifier

Logic

+

-

VA

Absolute Maximum Ratings (Note 1)

z Supply Voltage, V

z Switching Voltage, V

z BOOT V oltage, V

z All Other Pins -------------------------------------------------------------------------------------------------−0.3V to 6V

z Power Dissipation, P

WQFN-16L 3x3 -----------------------------------------------------------------------------------------------1.471W

SOP-8 (Exposed Pad) --------------------------------------------------------------------------------------1.333W

z Package Thermal Re sistance (Note 2)

WQF N-16L 3x3, θJA------------------------------------------------------------------------------------------68°C/W

WQFN-16L 3x3, θJC-----------------------------------------------------------------------------------------7.5°C/W

SOP-8 (Exposed pad), θJA---------------------------------------------------------------------------------75°C/W

SOP-8 (Exposed Pad), θJC--------------------------------------------------------------------------------15°C/W

z Junction T emperature----------------------------------------------------------------------------------------150°C

z Lead T e mperature (Soldering, 10 sec.)------------------------------------------------------------------260 °C

z Storage T emperature Range -------------------------------------------------------------------------------−65°C to 150°C

z ESD Susceptibility (Note 3)

HBM (Human Body Model)---------------------------------------------------------------------------------2kV

------------------------------------------------------------------------------------------−0.3V to 26V

IN

-------------------------------------------------------------------------------------−0.3V to (VIN + 0.3V)

SW

---------------------------------------------------------------------------------------(V

BOOT

@ TA = 25°C

D

− 0.3V) to (V

SW

BOOT

SW

GND

SW

+ 6V)

Recommended Operating Conditions (Note 4)

z Supply Voltage, V

z Enable Voltage, V

z Junction T emperature Range-------------------------------------------------------------------------------−40°C to 125°C

z Ambient T emperature Range-------------------------------------------------------------------------------−40°C to 85°C

Copyright 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

©

4

------------------------------------------------------------------------------------------4.75V to 24V

IN

-----------------------------------------------------------------------------------------0V to 5.5V

EN

DS8251-04 February 2013www.richtek.com

Page 5

RT8251

Electrical Characteristics

(VIN = 12V, TA = 25°C unless otherwise specified)

Parameter Symbol Test Conditions Min Typ Max Unit

Feedb ack Ref eren ce V olt age VFB 4.75V ≦ VIN ≦ 24V 0.784 0.8 0.816 V

High-Side Switch-On Resistance R

Low -Side Swi tch -On Res is tanc e R

DS(ON)1

DS(ON)2

High-Side Switch Leakage V

Current Limit I

LIM

Current Sense Transconductance GCS Output Current to V

Erro r Amplifi er T ansc onduct ance gm ΔIC = ±10μA -- 920 -- μA/V

Oscillator Frequency fSW 420 570 720 kHz

Short Circuit Oscillation Frequency V

Maximum Duty Cycle D

MAX

Mini mum On- Ti me tON -- 100 -- ns

UVLO Threshold Rising -- 4.1 -- V

UVL O Thresh old Hyst eresis -- 200 -- mV

Logic Low VIL -- -- 0.4

EN Input Voltage

Logic High V

IH

Enable Pu l l Up Cu r r en t V

Shutdown Current I

SHDN

Quies cen t Curr ent IQ V

Soft-Start Current ISS V

Soft-Start Period C

Thermal Shutdown TSD -- 150 -- °C

Note 1. Stresses beyond those listed “Absolute Maximum Ratings” may cause permanent damage to the device. These are

stress ratings only, and functional operation of the device at these or any other conditions beyond those indicated in

the operational sections of the specifications is not implied. Exposure to absolute maximum rating conditions may

affect device reliability.

Note 2. θ

Note 3. Devices are ESD sensitive. Handling precaution is recommended.

Note 4. The device is not guaranteed to function outside its operating conditions.

is measured at T

JA

measured at the exposed pad of the package.

= 25°C on a high effective thermal conductivity four-layer test board per JEDEC 51-7. θJC is

A

-- 70 -- mΩ

-- 15 -- Ω

= 0V, V

EN

Duty = 85%; V

= 0V -- 185 -- kHz

FB

V

= 0.7V -- 85 -- %

FB

= 0V -- -- 10 μA

SW

BOOT−SW

= 4.8V -- 6.8 -- A

-- 4.6 -- A/V

COMP

1.4 -- 5.5

= 0V -- 1 -- μA

EN

VEN = 0V -- 25 -- μA

= 2V, VFB = 1V -- 0.8 1 mA

EN

= 0V -- 10 -- μA

SS

= 10nF -- 1 -- ms

SS

V

Copyright 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS8251-04 February 2013 www.richtek.com

©

5

Page 6

RT8251

)

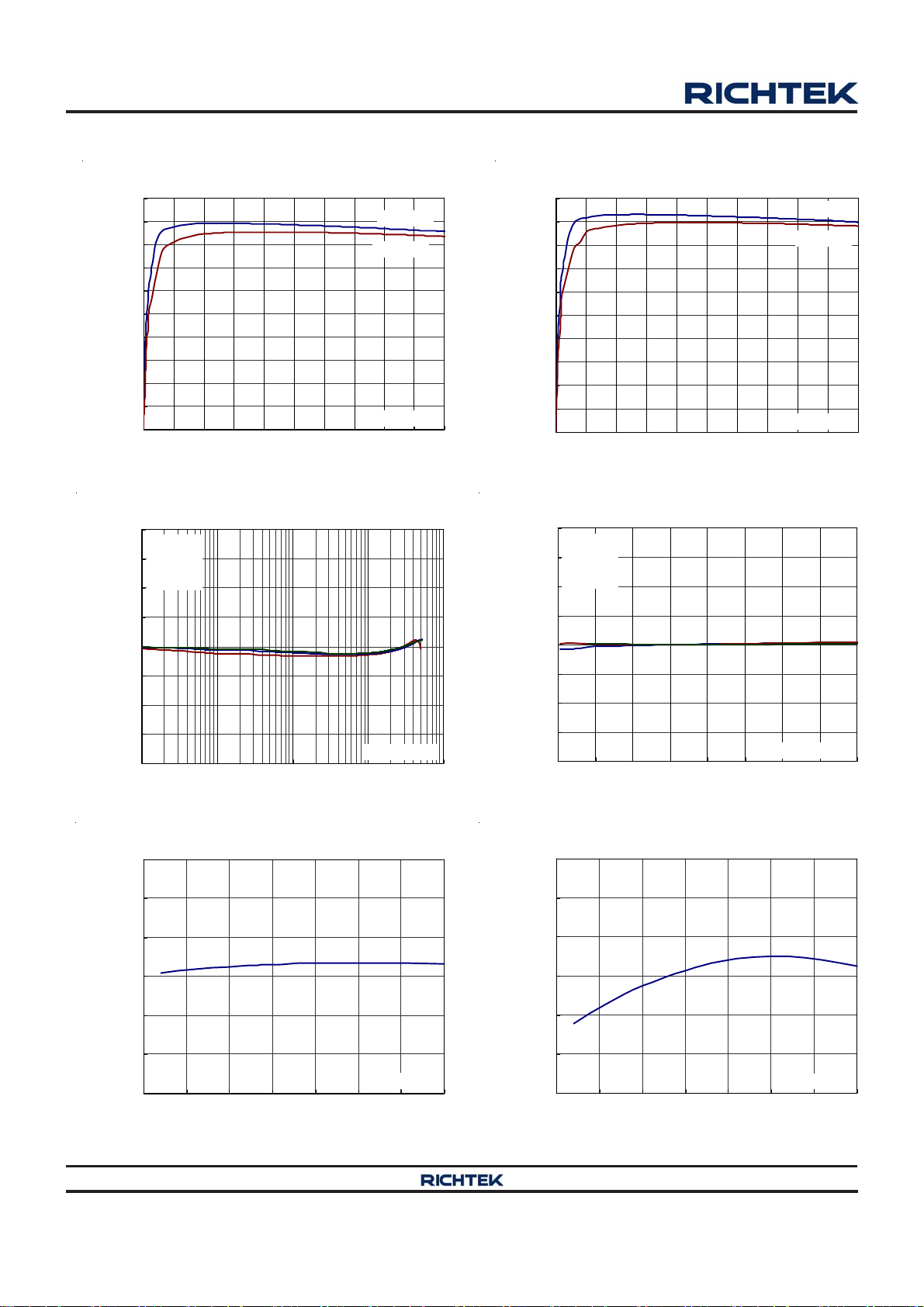

Typical Operating Characteristics

Efficiency vs. Load Current

100

90

80

70

60

50

40

Eff iciency (%)

30

20

10

0

00.511.522.533.544.55

VIN = 24V

V

Load Current (A)

Output Voltag Deviation vs. Load Current

2

VIN = 24V

1.5

0.5

1

= 12V

V

IN

VIN = 5V

VIN = 12V

= 3.3V

OUT

Efficiency vs. Load Current

100

90

80

70

60

50

40

Efficiency(%)

30

20

10

0

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5

VIN = 24V

V

OUT

Load Current (A)

Output Voltage Deviation vs. Input Voltage

2

I

= 5A

OUT

1.5

I

= 3A

OUT

= 0A

I

OUT

1

0.5

VIN = 12V

= 5V

Reference Volt age (V)

0

-0.5

-1

-1.5

Output Voltage Deviati on (%) 1

-2

4 6.5 9 11.5 14 16.5 19 21.5 24

V

Inpu t Volt age (V)

Reference Voltage vs. Temperature

0.816

0.811

0.806

0.801

0.796

0.791

0.786

-50 -25 0 25 50 75 100 125

Temperature (°C)

= 3.3V

OUT

VIN = 12V

0

-0.5

-1

-1.5

Output V oltage Deviati on (%) 1

-2

0.001 0.01 0.1 1 10

V

Load Current (A)

Quiescent Current vs. Temperature

1.2

1

0.8

0.6

0.4

Quiescent C urrent (mA

0.2

0

-50 -25 0 25 50 75 100 125

Temperature (°C)

= 3.3V

OUT

VIN = 12V

Copyright 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

©

DS8251-04 February 2013www.richtek.com

6

Page 7

RT8251

)

Switching Frequency vs. Input Voltage

610

600

590

580

570

560

Switcing Fr equency (kHz) 1

V

= 3.3V, I

550

4 6.5 9 11.5 14 16.5 19 21.5 24

OUT

OUT

= 1A

Switching Fr equenc (kHz) 1 11

Inp ut Vol tage (V)

Current Limit vs. Duty Cycle

9.3

V

OUT

8.7

8.1

(10mV/Div)

Switching Frequency vs. Temperature

630

610

590

VIN = 12V

570

550

530

V

= 3.3V, I

510

-50 -25 0 25 50 75 100 125

OUT

VIN = 24V

OUT

Temperature (°C)

Output Ripple

= 1A

Peak Current (A

V

OUT

(200mV/Div)

I

OUT

(2A/Div)

7.5

6.9

6.3

5.7

0 102030405060708090100

Duty Cycle (%)

Load Transient Response

VIN = 12V, V

I

= 0A to 5A

OUT

OUT

= 3.3V

V

SW

(10V/Div)

I

SW

(2A/Div)

V

OUT

(200mV/Div)

I

OUT

(2A/Div)

Time (1μs/Div)

Load Transient Response

VIN = 12V, V

= 2.5A to 5A

I

OUT

OUT

= 3.3V

VIN = 12V

V

= 3.3V

OUT

I

= 5A

OUT

Time (100μs/Div)

Copyright 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS8251-04 February 2013 www.richtek.com

©

Time (100μs/Div)

7

Page 8

RT8251

V

EN

(5V/Div)

V

OUT

(2V/Div)

Power On from EN

VIN = 12V, V

Time (250μs/Div)

= 3.3V, I

OUT

OUT

= 5A

V

EN

(5V/Div)

V

OUT

(2V/Div)

Power Off from EN

VIN = 12V, V

Time (25μs/Div)

= 3.3V, I

OUT

OUT

= 5A

Copyright 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

©

DS8251-04 February 2013www.richtek.com

8

Page 9

Application Information

RT8251

The RT8251 is an asynchronous high voltage buck

converter that can support the input voltage range from

4.75V to 24V and the output current can be up to 5A.

Output Voltage Setting

The resistive divider allows the FB pin to sense the output

voltage as shown in Figure 3.

V

OUT

R1

FB

RT8251

GND

R2

Figure 3. Output Voltage Setting

The output voltage is set by an external resistive divider

according to the f ollowing equation :

R1

⎛⎞

V = V1

OUT FB

+

⎜⎟

R2

⎝⎠

Where VFB is the feedback reference voltage (0.8V typ.).

External Bootstrap Diode

Connect a 100nF low ESR ceramic capacitor between

the BOOT pin and SW pin. This capacitor provides the

gate driver voltage for the high side MOSFET.

It is recommended to add an external bootstrap diode

between an external 5V and the BOOT pin for ef ficiency

improvement when input voltage is lower tha n 5.5V or duty

cycle is higher than 65%. The bootstrap diode can be a

low cost one such as 1N4148 or BAT54.

The external 5V can be a 5V fixed input from system or a

5V output of the RT8251.

5V

BOOT

RT8251

SW

100nF

Figure 4. External Bootstra p Diode

Soft-Start

The RT8251 contains an external soft-start clamp that

gradually raises the output voltage. The soft-start timming

can be set by the external ca p a citor between SS pin an d

GND. The chip provides a 10μA charge current for the

external capacitor. If 10nF capacitor is used to set the

soft-start time, its period will be 1ms (typ.).

Chip Enable Operation

The EN pin is the chip enable input. Pull the EN pin low

(<0.4V) will shutdown the device. During shutdown mode,

the RT8251 quiescent current drops to lower than 25μA.

Drive the EN pin to high ( >1.4V, < 5.5V) will turn on the

device again. If the EN pin is open, it will be pulled to high

by internal circuit. For external timing control (e.g.RC),

the EN pin ca n also be extern ally pulled to High by a dding

a100kΩ or greater resistor from the VIN pin (see Figure 5).

Inductor Selection

The inductor value and operating frequency determine the

ripple current according to a specific input and output

voltage. The ripple current ΔI

increases with higher V

L

and decrea ses with higher inducta nce.

VV

⎡⎤⎡ ⎤

OUT OUT

I = 1

Δ×−

L

⎢⎥⎢ ⎥

fL V

×

⎣⎦⎣ ⎦

IN

Having a lower ripple current reduces not only the ESR

losses in the output capa citors but also the output voltage

ripple. High frequency with small ripple current ca n achieve

highest efficiency operation. However , it requires a large

inductor to achieve this goal.

For the ripple current selection, the value of ΔI

= 0.24(I

L

MAX

will be a rea sonable starting point. The largest ripple current

occurs at the highest VIN. To guarantee that the ripple

current stays below the specified maximum, the inductor

value should be chosen according to the following

equation :

⎡⎤⎡ ⎤

VV

L = 1

OUT OUT

⎢⎥⎢ ⎥

fI V

×Δ

L(MAX) IN(MAX)

⎣⎦⎣ ⎦

×−

The inductor 's current rating (caused a 40°C temperature

rising from 25°C ambient) should be greater than the

maximum load current and its saturation current should

be greater than the short circuit pea k current limit. Plea se

see Table 2 for the inductor selection reference.

IN

)

Copyright 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS8251-04 February 2013 www.richtek.com

©

9

Page 10

RT8251

Table 2. Suggested Inductors for Typical

Application Circuit

Component

Supplier

Series Dim ensions (mm)

TDK SLF10165 10.1x10.1x7

TAIYO YUDE N NR 10050 10x9.8x5

TDK VLF12060 12x11.7x6

Diode Selection

When the power switch turns off, the path for the current

is through the diode connected between the switch output

and ground. This forward biased diode must have a

minimum voltage drop and recovery ti mes. Schottky diode

is recommended and it should be able to handle those

current. The reverse voltage rating of the diode should be

greater than the maximum input voltage, a nd current rating

should be greater than the maximum load current. For

more detail plea se refer to Table 4.

CIN and C

Selection

OUT

The input capacitance, CIN, is needed to filter the

trapezoidal current at the source of the high side MOSFET.

T o prevent large ripple current, a low ESR in put cap acitor

sized for the maximum RMS current should be used. The

RMS current is given by :

V

I = I 1

RMS OUT(MAX)

OUT

VV

This formula has a maximum at V

I

= I

RMS

/2. This simple worst-case condition is

OUT

V

IN

IN OUT

−

IN

= 2V

OUT

, where

commonly used for design because even significant

deviations do not offer much relief.

Choose a capacitor rated at a higher temperature than

required. Several capacitors may also be paralleled to

meet size or height requirements in the design.

For the input capacitor, two 10μF low ESR ceramic

capacitors are recommended. For the recommended

cap a citor , plea se refer to ta ble 3 for more detail.

The output ripple, ΔV

VIESR

Δ≤Δ +

OUT L

⎡⎤

⎢⎥

⎣⎦

, is determined by :

OUT

1

8fC

OUT

The output ripple will be highest at the maximum input

voltage since ΔIL increases with input voltage. Multiple

cap a citors placed in parallel may be needed to meet the

ESR and RMS current ha ndling requirement. Dry ta ntalum,

special polymer, aluminum electrolytic and ceramic

capacitors are all available in surface mount packages.

Special polymer capacitors offer very low ESR value.

However, it provides lower ca pa citance density tha n other

types. Although Tantalum capacitors have the highest

cap a cita nce density, it is importa nt to only use types that

pass the surge test for use in switching power supplies.

Aluminum electrolytic capa citors have significa ntly higher

ESR. However, it ca n be used in cost-sensitive application s

for ripple current rating and long term reliability

considerations. Ceramic capacitors have excellent low

ESR characteristics but ca n have a high voltage coefficient

and audible piezoelectric effe cts. The high Q of ceramic

cap acitors with trace inducta nce can also lea d to significant

ringing.

Higher values, lower cost ceramic capacitors are now

becoming available in smaller ca se sizes. Their high ripple

current, high voltage rating and low ESR ma ke them ideal

for switching regulator a pplications. However , care must

be taken when these capacitors are used at input and

output. When a ceramic capacitor is used at the input

and the power is supplied by a wall ad a pter through long

wires, a load step at the output can induce ringing at the

input, VIN. At best, this ringing can couple to the output

and be mistaken as loop instability. At worst, a sudden

inrush of current through the long wires can potentially

cause a voltage spike at V

large enough to damage the

IN

part.

Checking Tra n sient Re spon se

The selection of C

is determined by the required ESR

OUT

to minimize voltage ripple.

Moreover, the amount of bulk capacitance is also a key

for C

selection to ensure that the control loop is stable.

OUT

Loop stability can be checked by viewing the load tra nsient

response a s described in a later section.

Copyright 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

10

©

The regulator loop response can be checked by looking

at the load transient respon se. Switching regulators take

several cycles to respond to a step in load current. When

a load step occurs, V

equal to ΔI

C

generating a feedback error signal f or the regulator

OUT

(ESR) also begins to charge or discharge

LOAD

immediately shifts by a n amount

OUT

DS8251-04 February 2013www.richtek.com

Page 11

RT8251

to return V

recovery time, V

to its steady-state value. During this

OUT

can be monitored for overshoot or

OUT

ringing that would indicate a stability problem.

EMI Consideration

Since parasitic inducta nce and ca pa citance effects in PCB

circuitry would cause a spike voltage on the SW pin when

high-side MOSFET is turned-on/off, this spike voltage on

SW may impact on EMI performance in the system. In

order to enhance EMI performa nce, there are two methods

to suppress the spike voltage. One is to place an R-C

4.75V to 24V

V

Chip Enable

* : Optional

IN

REN*

CEN*

C

SS

10nF

C

10µF x 2

Exposed Pad(9)

2

IN

VIN

RT8251

7

EN

8

SS

4,

GND

Figure 5. Reference Circuit with Snubber and Enable Timing Control

snubber between SW and GND and make them as close

a s possible to the SW pin (see Figure 5). Another method

is to add a resistor in series with the bootstra p capacitor,

C

. But this method will decrea se the driving capa bility

BOOT

to the high-side MOSFET . It is strongly recommended to

reserve the R-C snubber during PCB layout for EMI

improvement. Moreover , reducing the SW trace area a nd

keeping the main power in a small loop will be helpful on

EMI performance. For detailed PCB layout guide, plea se

refer to the section of Layout Consideration.

R

*

BOOT

1

BOOT

SW

FB

COMP

3

5

6

RS*

C

*

S

C

C

2.2nF

C

BOOT

100nF

D

B540C

R

22k

C

P

NC

C

L

4.7µH

R1

30.9k

R2

10k

V

3.3V/5A

C

OUT

22µF x 2

OUT

Thermal Considerations

For continuous operation, do not exceed the maximum

operation junction temperature 125°C. The maximum

power dissipation depends on the thermal resistance of

IC package, PCB layout, the rate of surroundings airflow

and temperature difference between junction to a mbient.

The maximum power dissipation can be calculated by

following formula :

P

Where T

temperature , T

D(MAX)

= (T

J(MAX)

− TA ) / θ

J(MAX)

JA

is the maximum operation junction

is the ambient te mperature and the θ

A

JA

the junction to ambient thermal resistance.

For recommended operating conditions specification of

RT8251, the maximum junction temperature is 125°C. The

junction to ambient thermal resistance θJA is layout

dependent. For PSOP-8 and WQF N pa ckages, the thermal

resistance θJA are 75°C/W and 68°C/W on the standard

JEDEC 51-7 four-layers thermal test board. The maximum

power dissipation at TA = 25°C can be calculated by

following formula :

P

= (125°C − 25°C) / (75°C/W) = 1.333W for

D(MAX)

PSOP-8

P

= (125°C − 25°C) / (68°C/W) = 1.471W for

D(MAX)

WQF N

(min.copper area PCB layout)

P

D(MAX)

= (125°C − 25°C) / (49°C/W) = 2.04W for

PSOP-8 (70mm2copper area PCB layout)

The thermal resistance θJA of SOP-8 (Exposed Pad) is

determined by the package architecture design and the

is

PCB layout design. However, the package architecture

design had been designed. If possible, it's useful to

increa se thermal performance by the PCB layout copper

design. The thermal resistance θ

can be decreased by

JA

adding copper area under the exposed pad of SOP-8

(Exposed Pad) package.

As shown in Figure 6, the amount of copper area to which

the SOP-8 (Exposed Pad) is mounted affects thermal

performance. When mounted to the standard

Copyright 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

©

DS8251-04 February 2013 www.richtek.com

11

Page 12

RT8251

P

Di

i

i

(W)

SOP-8 (Exposed Pad) pad (Figure 6a), θ

is 75°C/W.

JA

Adding copper area of pad under the SOP-8 (Exposed

Pad) (Figure 6.b) reduces the θ

to 64°C/W. Even further ,

JA

increa sing the copper area of pad to 70mm2 (Figure 6.e)

reduces the θ

to 49°C/W.

JA

The maximum power dissipation depends on operating

ambient temperature for fixed T

and thermal

J(MAX)

resistance θJA. For RT8251 packages, the derating curves

in Figure 7 and Figure 8 allow the designer to see the

effect of rising a mbient temperature on the maximum power

dissipation allowed.

2.2

2.0

1.8

1.6

on

1.4

1.2

pat

ss

1.0

0.8

0.6

ower

0.4

0.2

0.0

0 255075100125

Ambient Temperature

Four Layer PCB

Copper Area

2

70mm

2

50mm

2

30mm

2

10mm

Min.Layout

(°C)

(a) Copper Area = (2.3 x 2.3) mm2,

(b) Copper Area = 10mm2,

(c) Copper Area = 30mm2 ,

θ

JA

θ

JA

θ

= 75°C/W

JA

= 64°C/W

= 54°C/W

Figure 7. Derating Curves for PSOP-8 Pa ckage

1.6

1.4

1.2

1.0

0.8

0.6

0.4

0.2

Maximum Power Dissipation (W) 1

0.0

0 153045607590105120135

Ambient Temperature (°C )

Four Layer PCB

WQFN-16L 3x3

Figure 8. Derating Curves f or WQF N Pack age

(d) Copper Area = 50mm2 ,

θ

= 51°C/W

JA

(e) Copper Area = 70mm2 ,

Figure 6. Themal Resistance vs. Copper Area Layout

Design

θ

= 49°C/W

JA

Copyright 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

©

DS8251-04 February 2013www.richtek.com

12

Page 13

RT8251

Layout Consideration

Follow the PCB layout guidelines for optimal performa nce

of the RT8251.

` Keep the traces of the main current paths as short and

wide as possible.

` Put the input ca pacitor a s close a s possible to the device

pins (VIN a nd GND).

` LX node is with high frequency voltage swing and should

be kept at small area. Keep analog components away

from the LX node to prevent stray cap acitive noise pickup.

Input capacitor must be placed

as close as to the IC as possible.

GND

VIN

VIN

VIN

GND

C

IN

VIN

1

2

3

4

VINSWSW

GND

` Connect feedba ck network behind the output capa citors.

Keep the loop area small. Place the feedback

components near the RT8251.

` Connect all analog grounds to a command node and

then connect the command node to the power ground

behind the output cap acitors.

` Examples of PCB layout guide are shown in Figure 9

and Figure 10 for reference.

C

OUT

C

D

13141516

17

8765

12

11

10

9

S

R

S

SW

SW

SW

BOOT

L

VOUT

SW should be connected

to inductor by Wide and

C

short trace. Keep sensitive

BOOT

components away from

this trace.

FB

R1 R2

R

VOUT

GND

The feedback components must be connected

as close to the device as possible.

C

C

C

COMP

EN

SS

C

SS

C

P

Figure 9. PCB Layout Guide f or WQFN Pack age

Copyright 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS8251-04 February 2013 www.richtek.com

©

13

Page 14

RT8251

GND

Input capacitor must

be placed as close

to the IC as possible.

V

C

OUT

OUT

SW

V

IN

C

IN

D

C

S

R

S

L

SW should be connected to inductor by

wide and short trace. Keep sensitive

components away from this trace.

C

BOOT

BOOT

VIN

SW

GND

GND

2

GND

3

4

The feedback components

must be connected as close

to the device as possible.

C

SS

8

SS

7

EN

6

9

COMP

FB

R2

R1

V

5

C

C

OUT

C

P

GND

R

C

Figure 10. PCB Layout Guide f or PSOP-8 Pack age

Table 3. Suggested Capacitors for CIN and C

OUT

Location Component Supplier Part No. Capacitance (μF) Case Size

CIN

CIN

MURATA GRM31ER61E226K 22 1210

TDK C4535X5R1E226M 22 1812

CIN

C

C

C

C

OUT

OUT

OUT

OUT

TAIYO YUDEN TMK325BJ226MM 22 1210

MURATA GRM32ER61C476M 47 1210

MURATA GRM31CR60J476M 47 1206

TDK C3216X5R0J476M 47 1206

TAIYO YUDEN LMK316BJ476MM 47 1206

Table 4. Suggested Diode

Component Supplier Part No. V

DIODES B540C 40 5 SMC

ON MBRS540T3 40 5 SMC

RRM

(V) I

(A) Package

OUT

Copyright 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

©

DS8251-04 February 2013www.richtek.com

14

Page 15

Outline Dimension

RT8251

D

E

A

A3

A1

D2

e

SEE DETAIL A

1

b

E2

L

1

2

1

2

DETAIL A

Pin #1 ID a nd T ie Bar Mark Option s

Note : The configuration of the Pin #1 identifier is optional,

but must be located within the zone indicated.

Dimensions In Millimeters Dimensions In Inches

Symbol

Min Max Min Max

A 0.700 0.800 0.028 0.031

A1 0.000 0.050 0.000 0.002

A3 0.175 0.250 0.007 0.010

b 0.180 0.300 0.007 0.012

D 2.950 3.050 0.116 0.120

D2 1.300 1.750 0.051 0.069

E 2.950 3.050 0.116 0.120

E2 1.300 1.750 0.051 0.069

e 0.500 0.020

L 0.350 0.450

0.014 0.018

W-Type 16L QFN 3x3 Package

Copyright 2013 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS8251-04 February 2013 www.richtek.com

©

15

Page 16

RT8251

H

M

EXPOSED THERMAL PAD

(Bottom of Package)

A

Y

J

I

B

X

F

C

D

Dimensions In Millimeters Dimensions In Inches

Symbol

Min Max Min Max

A 4.801 5.004 0.189 0.197

B 3.810 4.000 0.150 0.157

C 1.346 1.753 0.053 0.069

D 0.330 0.510 0.013 0.020

F 1.194 1.346 0.047 0.053

H 0.170 0.254 0.007 0.010

I 0.000 0.152 0.000 0.006

J 5.791 6.200 0.228 0.244

M 0.406 1.270 0.016 0.050

X 2.000 2.300 0.079 0.091

Option 1

Y 2.000 2.300 0.079 0.091

X 2.100 2.500 0.083 0.098

Option 2

Y 3.000 3.500 0.118 0.138

8-Lead SOP (Exposed Pad) Plastic Package

Richtek Technology Corporation

5F, No. 20, Taiyuen Street, Chupei City

Hsinchu, Taiwan, R.O.C.

Tel: (8863)5526789

Richtek products are sold by description only. Richtek reserves the right to change the circuitry and/or specifications without notice at any time. Customers should

obtain the latest relevant information and data sheets before placing orders and should verify that such information is current and complete. Richtek cannot

assume responsibility for use of any circuitry other than circuitry entirely embodied in a Richtek product. Information furnished by Richtek is believed to be

accurate and reliable. However, no responsibility is assumed by Richtek or its subsidiaries for its use; nor for any infringements of patents or other rights of third

parties which may result from its use. No license is granted by implication or otherwise under any patent or patent rights of Richtek or its subsidiaries.

www.richtek.com

16

DS8251-04 February 2013

Page 17

Loading...

Loading...