Page 1

RT8241

®

DS8241-03 January 2014 www.richtek.com

1

©

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

High Efficiency Single Synchronous Buck PWM Controller

General Description

The RT8241 PWM controller provides high efficiency,

excellent transient response, a nd high DC output a ccuracy

needed for stepping down high voltage batteries to

generate low voltage CPU core, I/O, and chipset RAM

supplies in notebook computers.

The RT8241 supports on chip voltage progra mming function

between 0.675V and 0.9V by controlling GX digital inputs.

The constant-on-time PWM control sche me handles wide

input/output voltage ratios with ea se and provides 100ns

“instant-on” response to load transients while maintaining

a relatively constant switching frequency .

The RT8241 achieves high efficiency at a reduced cost

by eliminating the current-sense resistor found in

traditional current-mode PWMs. Efficiency is further

enhanced by its ability to drive very large synchronous

rectifier MOSFETs and enter diode emulation mode at

light load condition. The buck conversion allows this device

to directly step down high voltage batteries at the highest

possible efficiency . The RT8241 is intended for CPU core,

chipset, DRAM, or other low voltage supplies as low as

0.675V.

The RT8241 is available in a WQFN-12L 2x2 pack age.

Features

z Meet Intel VCCSA Voltage Slew Rate

z Built-in 1% Reference Voltage

z 2-Bit Programma ble Output V oltage with Integrated

Tra n sition Support

z Quick Load-Step Response within 100ns

z 4700ppm/

°°

°°

°C Programmable Current Limit by Low

Side R

DS(ON)

Sensing

z 4.5V to 26V Battery Input Range

z Internal Ramp Current Limit Soft-Start Control

z Drives Large Synchronous Rectifier FET s

z Integrated Boost Switch

z Over/Under Voltage Protection

z Thermal Shutdown

z Power Good Indicator

z RoHS Compliant and Halogen Free

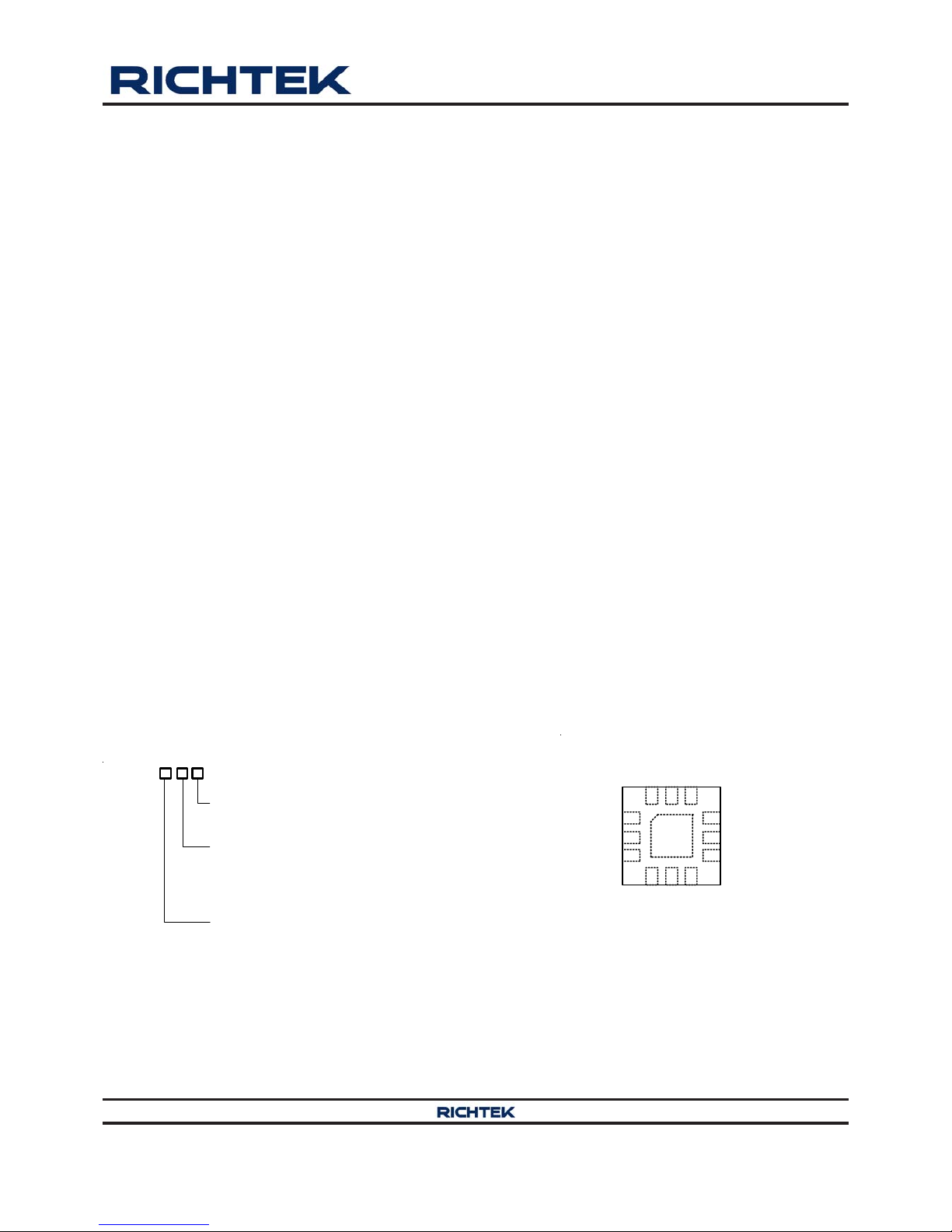

Pin Configurations

(TOP VIEW)

WQFN-12L 2x2

Ordering Information

Applications

z Notebook Computers

z CPU/GPU Core Supply

z Chipset/RAM Supply

z Generic DC/DC Power Regulator

Note :

Richtek products are :

` RoHS compliant and compatible with the current require-

ments of IPC/JEDEC J-STD-020.

` Suitable for use in SnPb or Pb-free soldering processes.

LGATE PGOOD

UGATE

PHASE

G0

G1

BOOT

VCC

EN

GNDCSFB

654

12 1011

1

2

3

9

8

7

GND

13

RT8241

Package Type

QW : WQFN-12L 2x2 (W-Type)

Lead Plating System

G : Green (Halogen Free and Pb Free)

Z : ECO (Ecological Element with

Halogen Free and Pb free)

Switching Frequency Operation

A : 300kHz

B : 400kHz

C : 500kHz

Page 2

2

DS8241-03 January 2014www.richtek.com

RT8241

©

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

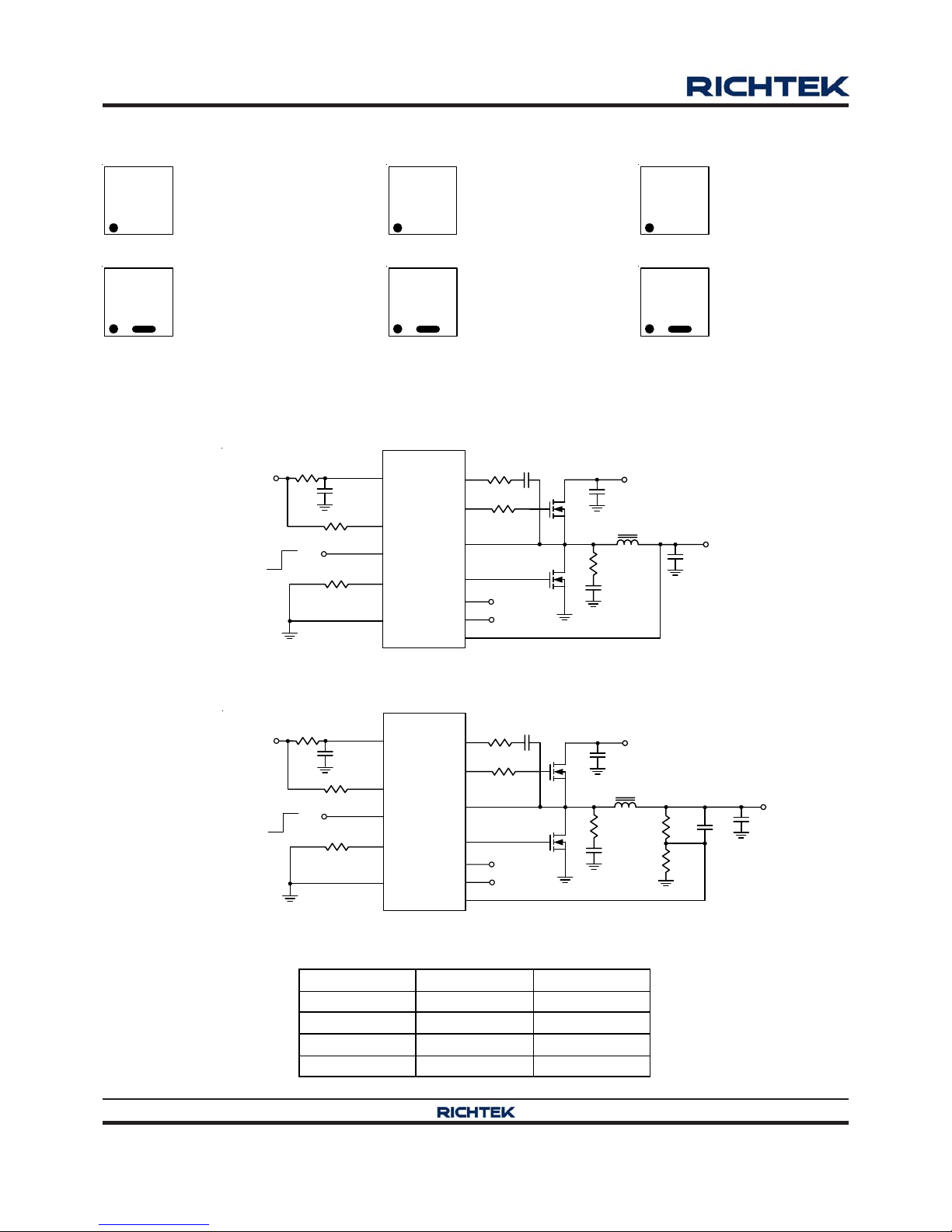

Typical Application Circuit

For Fixed V oltage Regulator :

For Adjustable Voltage Regulator :

VCC

RT8241

V

CC

5

9

6

PGOOD

EN

11

CS

12,

13 (Exposed Pad)

GND

4

BOOT

3

2

1

7

10

UGATE

PHASE

LGATE

G0

FB

R1

C

BYPASS

R

CS

R3

C1

R4

Q1

Q2

R5*

C2*

L

OUT

8

G1

V

IN

C

IN

V

OUT

C

OUT

* : Optional

R2

Chip Enable

VCC

RT8241

V

CC

5

9

6

PGOOD

EN

11

CS

12,

13 (Exposed Pad)

GND

4

BOOT

3

2

1

7

10

UGATE

PHASE

LGATE

G0

FB

R1

C

BYPASS

R

CS

R3

C1

R4

Q1

Q2

R5*

C2*

L

OUT

8

G1

V

IN

C

IN

V

OUT

C

OUT

* : Optional

C3*

R

FB1

R

FB2

R2

Chip Enable

Marking Information

30W

30 : Product Code

W : Date Code

RT8241AGQW

41W 40W

41 : Product Code

W : Date Code

40 : Product Code

W : Date Code

30 : Product Code

W : Date Code

41 : Product Code

W : Date Code

40 : Product Code

W : Date Code

RT8241BGQW RT8241CGQW

RT8241AZQW RT8241BZQW RT8241CZQW

G0 G1 VFB

0 0 0.9V

0 1 0.8V

1 0 0.725V

1 1 0.675V

Table 1. VID Table

30W 41W 40W

Page 3

3

DS8241-03 January 2014 www.richtek.com

RT8241

©

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

Functional Pin Description

Pin N o. Pin N am e Pin Fu nc t io n

1 LGATE Gate Dr ive Output for Low Side Ext er nal MOSFET.

2 PHASE

External Inductor Connection Pin for PWM Converter. It behaves as the

current sense comparator input for low side MOSFET R

DS(ON)

sensing and

refere nce v ol tag e for on time gener at ion.

3 UGATE Gate Drive Output for the H igh Side External MOSFET.

4 BOOT

Supply Input for High Side Driver. Connect a capacitor to the floating node

(PHASE ) pin .

5 VCC

Control Voltage Input. Provides the power for the buck controller, the low

side dr iv er and t he bootstrap circuit for high side driver. Bypass to GND wi t h

a 4.7μF ceramic capa citor.

6 EN Chi p Enabl e (Ac tive Hi gh) .

7 G0 2-Bit Input Pin.

8 G1 2- Bit Input Pin.

9 PGOOD

Open Drain Power Good Indicator. High impedance indicates power is

good.

10 FB Output Vol tage Feedback Input .

11 CS

Current Limit Threshold Setting Input. Connect a setting resistor to GND

and the current limit threshold is equal to 1/8 of the voltage seen at this pin.

12, 13 (Exposed Pad) GND

Ground. The expos ed pad must be soldered to a large PCB and conn ecte d

to GND for maxi mu m pow er dissipation.

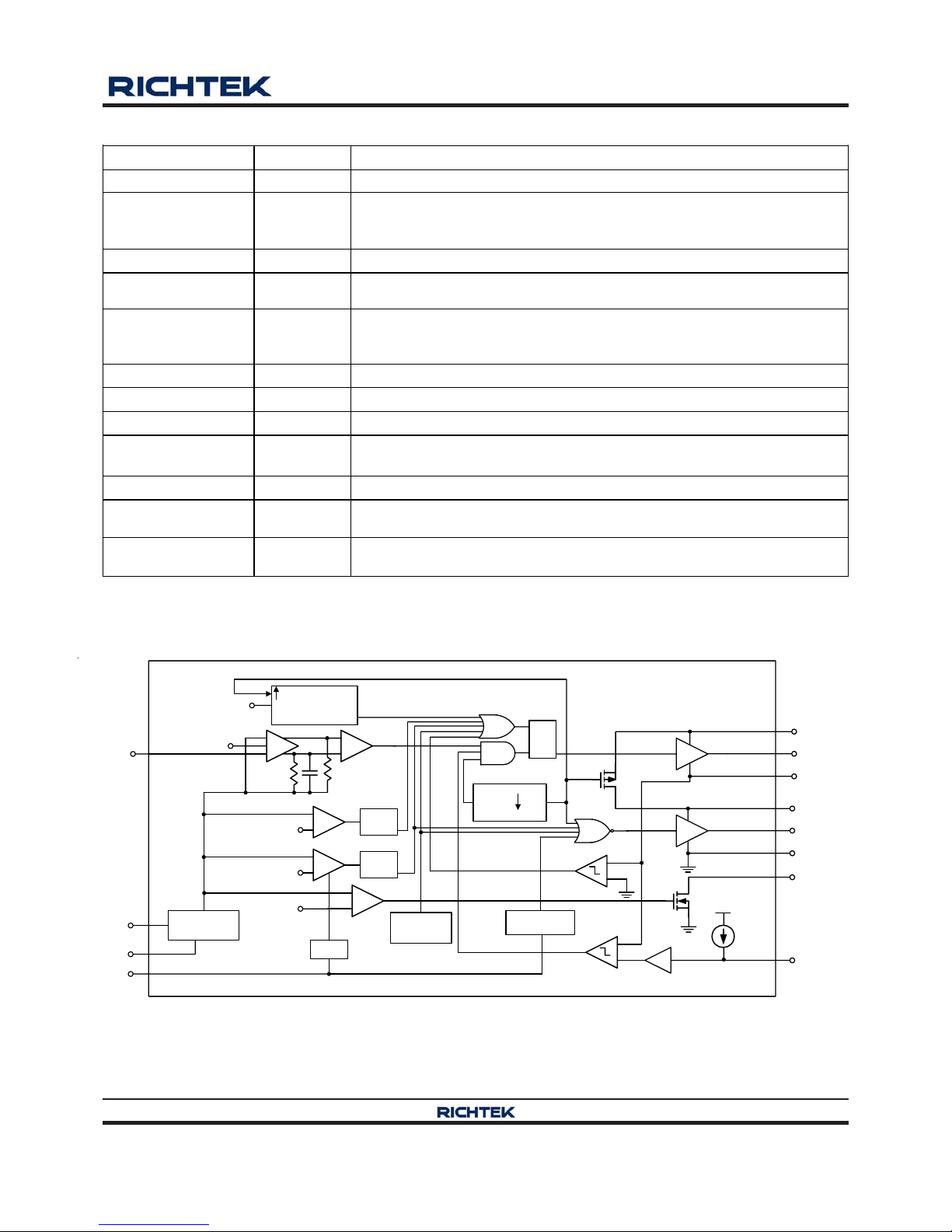

Function Block Diagram

DRV

DRV

+

-

1/8

10µA

+

-

Diode

Emuation

R

SQ

Min toff

TRIGQ

One shot

TRIG

On-time compute

PHASE

One shot

Thermal

Shutdown

+

-

85% V

REF

SS

Voltage

Programmer

+

-

0.45V

S1 Q

Latch

UV

+

-

1.1V

S1 Q

Latch

OV

+

-

+

-

GM

V

REF

COMP

TON

ZCD

OC threshold

leakage

LG R

DS(ON)

UG R

DS(ON)

BST switch

resistance

VCC

PGOOD

EN

G0

GND

CS

BOOT

UGATE

PHASE

LGATE

G1

FB

SS

(Internal)

Page 4

4

DS8241-03 January 2014www.richtek.com

RT8241

©

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

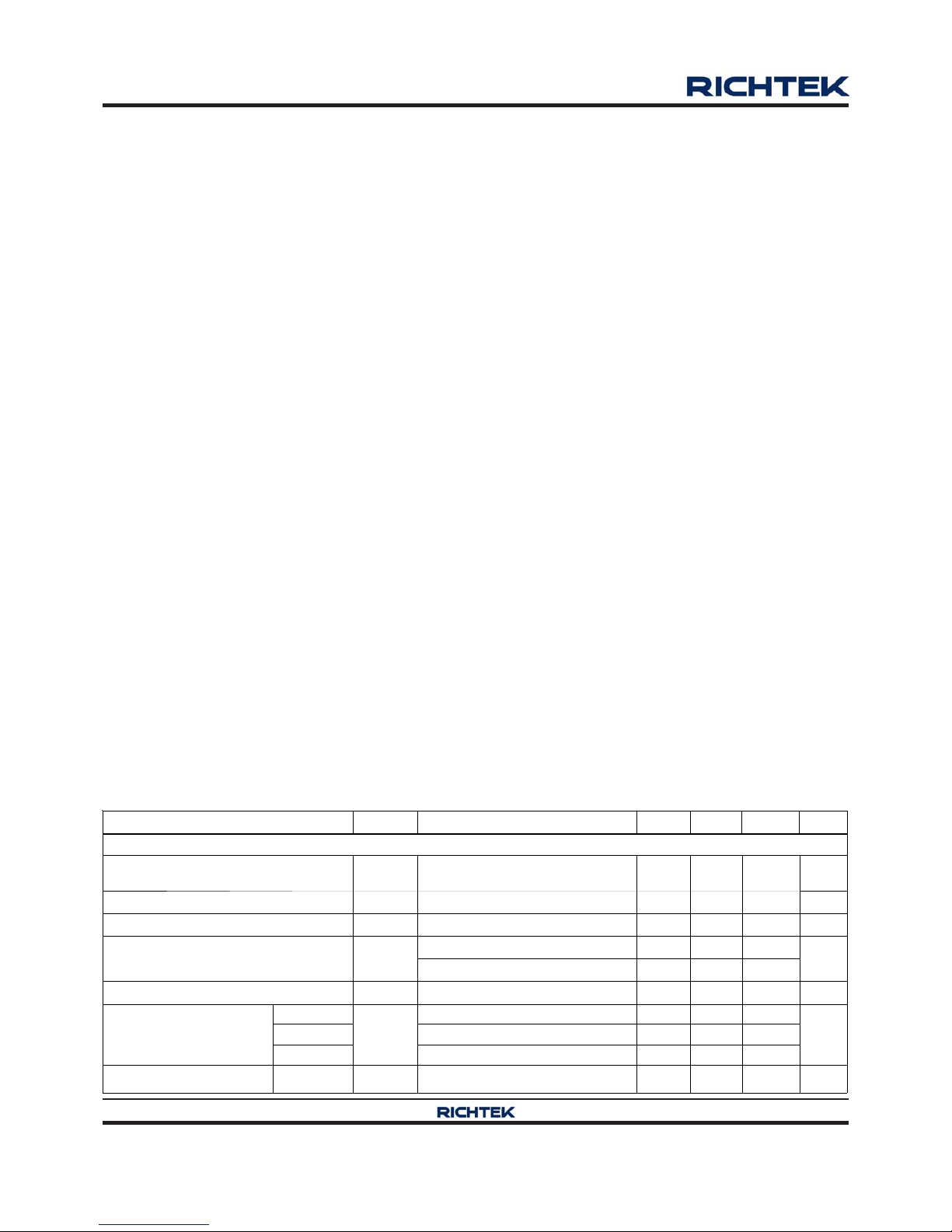

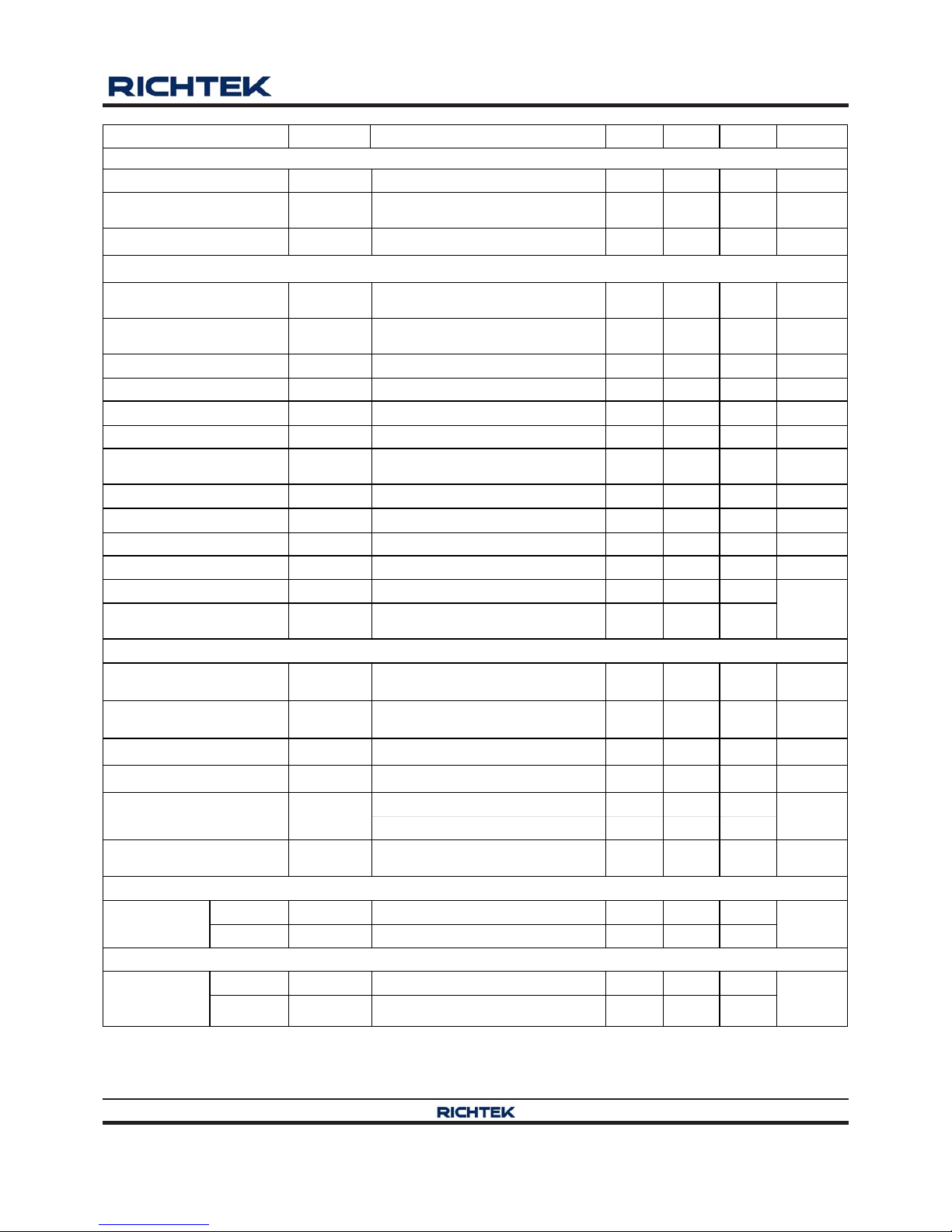

Electrical Characteristics

Absolute Maximum Ratings (Note 1)

z VCC, FB, PGOOD, EN, CS, G0, G1 to GN D----------------------------------------------------------------------- −0.3V to 6V

z PHASE to GND

DC----------------------------------------------------------------------------------------------------------------------------- −0.3V to 32V

<20ns ------------------------------------------------------------------------------------------------------------------------ −8V to 38V

z BOOT to PHASE ----------------------------------------------------------------------------------------------------------- −0.3V to 6V

z UGATE to PHASE

DC----------------------------------------------------------------------------------------------------------------------------- −0.3V to 6V

<20ns ------------------------------------------------------------------------------------------------------------------------ −5V to 7.5V

z LGATE to GND

DC----------------------------------------------------------------------------------------------------------------------------- −0.3V to 6V

<20ns ------------------------------------------------------------------------------------------------------------------------ −2.5V to 7.5V

z Power Dissipation, P

D

@ T

A

= 25°C

WQFN-12L 2x2 ------------------------------------------------------------------------------------------------------------ 0.606W

z Package Thermal Re sistance (Note 2)

WQFN-12L 2x2, θJA------------------------------------------------------------------------------------------------------- 165°C/W

z Junction T emperature----------------------------------------------------------------------------------------------------- 150°C

z Lead Temperature (Soldering, 10 sec.)------------------------------------------------------------------------------- 260°C

z Storage T emperature Range -------------------------------------------------------------------------------------------- −65°C to 150°C

z ESD Susceptibility (Note 3)

HBM (Human Body Mode) ---------------------------------------------------------------------------------------------- 2kV

MM (Ma chine Mode)------------------------------------------------------------------------------------------------------ 200V

Recommended Operating Conditions (Note 4)

z Supply Input V oltage, V

IN

------------------------------------------------------------------------------------------------ 4.5V to 26V

z Control Voltage, V

CC

------------------------------------------------------------------------------------------------------ 4.5V to 5.5V

z Junction T emperature Range-------------------------------------------------------------------------------------------- −40°C to 125°C

z Ambient T emperature Range-------------------------------------------------------------------------------------------- −40°C to 85°C

(V

CC

= 5V, V

IN

= 8V, V

EN

= 5V, T

A

= 25°C, unless otherwise specified)

Parameter Symbol Test Conditions Min Typ Max Unit

PWM Controller

VCC Quiescent Supply Current IQ

FB forced above the regulation

point, V

EN

= 5V

-- 500 1250 μA

VCC Shutdown Current I

SHDN

VCC current, V

EN

= 0V -- -- 1 μA

CS Shutdown Current CS pull to GND -- -- 1 μA

TA = 25°C −1 0 1

FB Error Comparator Threshold VFB

T

A

= −40°C to 85°C (Note 5) −1.5 0 1.5

%

V

OUT

Voltage Rang e V

OUT

0.675 -- 3.3 V

RT8241A VFB = 0.9V (f

SW

= 300kHz) -- 400 --

RT8241B VFB = 0.9V (f

SW

= 400kHz) -- 300 -- On-Time, Pulse Width

RT8241C

tON

V

FB

= 0.9V (f

SW

= 500kHz) -- 240 --

ns

Minimum Off-Time t

OFF

250 400 550 ns

Page 5

5

DS8241-03 January 2014 www.richtek.com

RT8241

©

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

Parameter Symbol Test Conditions Min Typ Max Unit

Current Sensing

CS Source Current 9 10 11 μA

CS Source Current

Temperature Coefficient

-- 4700 -- ppm/°C

Zero Crossing Threshold

PHASE − GND −10

-- 5 mV

Protection Function

Current Limit Threshold

Offset

GND − PHASE = VCS/8 −20 0 20 mV

Neg ative Cur ren t Limit

Threshold Offset

PHASE − GND = VCS/8 -- 3 -- mV

Under Voltage Protection UVP Detect, Falling Edge 0.41 0.45 0.49 V

UVP Fa ult Delay VFB = 0.375V -- 3.5 -- μs

Over Voltage Protection OVP Detect, Rising Edge 1.065 1.1 1.133 V

OVP F ault Delay VFB = 1.183V -- 5 -- μs

VCC Under Voltage Lockout

(UVLO) Threshold

V

UVLO

Falling edge, PWM disabled below

this level

3.5 3.7 3.9 V

VCC UVLO Hysteresis ΔV

UVLO

-- 100 -- mV

VOUT Soft-Start From EN = High to V

OUT

= 95% -- 0.8 - - ms

Dynamic VID Slew Rat e SGX G0/G1 Transition 1.75 -- 10 mV/μs

UVP Blank Time Fr om EN signal going high -- 3 - ms

T herm al Shut d ow n TSD -- 150 --

T herm al Shut d ow n

Hysteresis

ΔT

SD

-- 10 --

°C

Driver On-Resistance

UGATE Driver Source

R

UGATEsr

BOOT−PHASE forced to 5V,

U GATE Hig h St a t e

-- 1.8 3.6 Ω

UGATE Driver Sink

R

UGATEsk

BOOT−PHASE forced to 5V,

UGATE Low State

-- 1.2 2.4 Ω

LGATE Driver Source

R

LGATEsr

LGATE, High State

-- 1.8 3.6 Ω

LGAT E Driver Sink

R

LGATEsk

LGATE, Low State

-- 0.8 1.34 Ω

LGATE Rising (V

PHASE

= 1.5V)

--

30

--

Dead Time

U GATE Ris ing

--

30

--

ns

Internal Boost Charging

Swit c h On- Re si sta nc e

VCC to BOOT, 10mA

--

--

80

Ω

EN Threshold

Logic-High

V

IH

1.8 -- --

EN Threshold

Voltage

Logic-Low

V

IL

-- -- 0.5

V

Voltage Programming (G0, G1)

Logic-High 750 -- --

G0, G1 I nput

Threshold

Voltage

Logic-Low -- -- 300

mV

Page 6

6

DS8241-03 January 2014www.richtek.com

RT8241

©

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

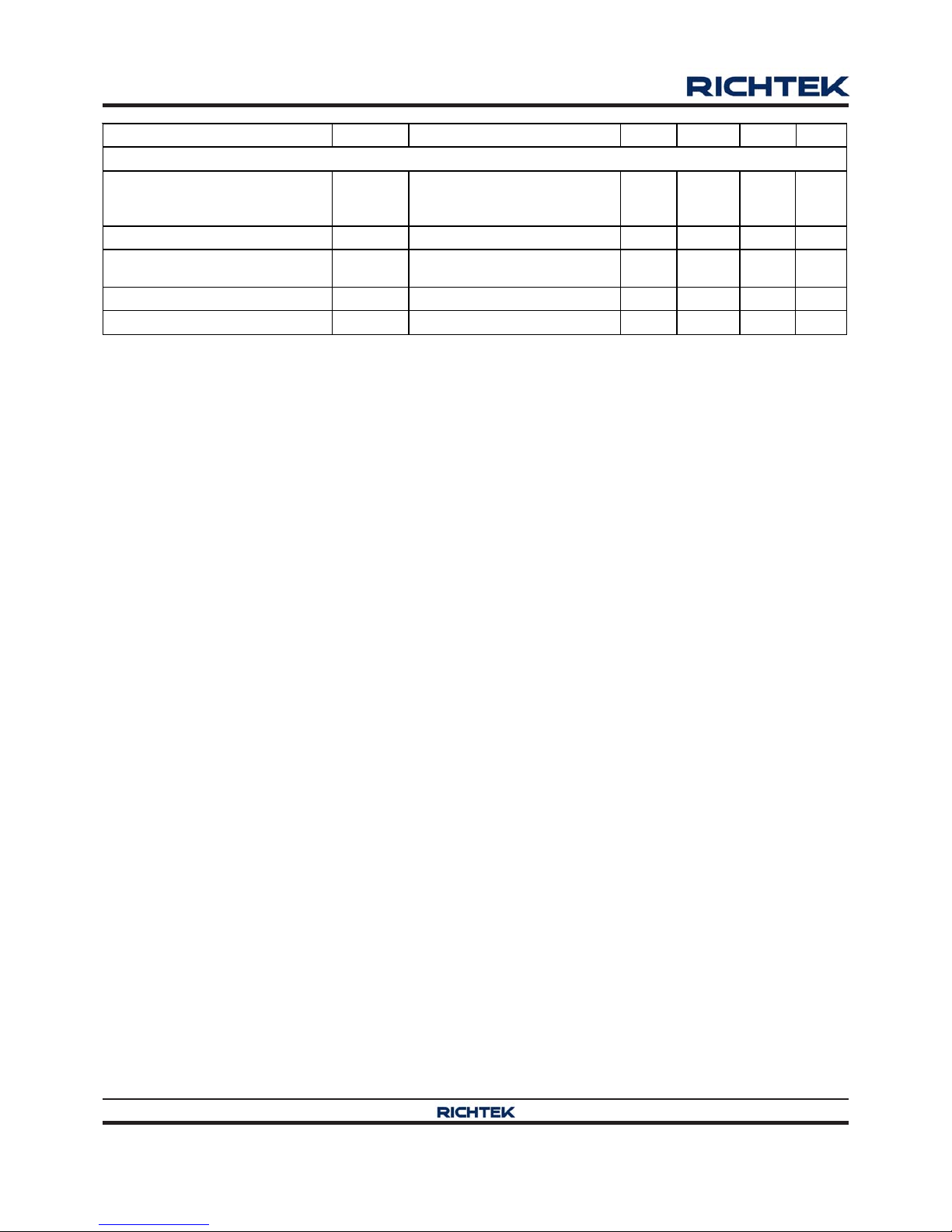

Parameter Symbol Test Conditions Min Typ Max Unit

PGOOD (upper side threshold determined by OVP threshold)

Trip Threshold

Falling edge, measured at FB,

with respect to reference, no

load.

−19 −15 −11

%

Trip Hysteresis -- 3 --

%

Fa ult Pr opa gat ion Dela y

Fal lin g edge , FB forc ed bel ow

PGOOD trip threshold

-- 2.5 --

μs

Output Low Voltage

I

SINK

= 1m A

-- -- 0.4

V

Leakage Current High State, forced to 5V -- -- 1

μA

Note 1. Stresses listed as the above "Absolute Maximum Ratings" may cause permanent damage to the device. These are for

stress ratings. Functional operation of the device at these or any other conditions beyond those indicated in the

operational sections of the specifications is not implied. Exposure to absolute maximum rating conditions for extended

periods may remain possibility to affect device reliability.

Note 2. θ

JA

is measured in natural convection at TA = 25°C on a low effective thermal conductivity test board of JEDEC 51-3

thermal measurement standard.

Note 3. Devices are ESD sensitive. Handling precaution is recommended.

Note 4. The device is not guaranteed to function outside its operating conditions.

Note 5. Guaranteed by Design.

Page 7

7

DS8241-03 January 2014 www.richtek.com

RT8241

©

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

Typical Operating Characteristics

Efficiency vs. Output Current

60

65

70

75

80

85

90

95

100

0.001 0.01 0.1 1 10

Output Current (A)

Eff iciency (%)

V

IN

= 8V , V

CC

= V

EN

= 5V , V

OUT

= 0.9V

Switching Frequenc y v s . Output Current

0

25

50

75

100

125

150

175

200

225

250

275

300

325

350

0.001 0.01 0.1 1 10

Output Current (A)

Swit ching Frequency (kHz) 1

V

IN

= 8V , V

CC

= V

EN

= 5V , V

OUT

= 0.9V

Efficiency vs. Output Current

60

65

70

75

80

85

90

95

100

0.001 0.01 0.1 1 10

Output Current (A)

Eff iciency (%)

V

IN

= 12V, V

CC

= V

EN

= 5V, V

OUT

= 0.9V

Switching Frequenc y vs. Output Current

0

25

50

75

100

125

150

175

200

225

250

275

300

325

350

0.001 0.01 0.1 1 10

Output Current (A)

Swit ching Frequency (kHz) 1

V

IN

= 12V, V

CC

= V

EN

= 5V, V

OUT

= 0.9V

Efficiency vs. Output Current

60

65

70

75

80

85

90

95

100

0.001 0.01 0.1 1 10

Output Current (A)

Eff iciency (%)

V

IN

= 20V, V

CC

= V

EN

= 5V, V

OUT

= 0.9V

Switching Frequency vs. Output Current

0

25

50

75

100

125

150

175

200

225

250

275

300

325

350

0.001 0.01 0.1 1 10

Output Cu rren t (A)

Swit ching Frequency (kHz) 1

V

IN

= 20V, V

CC

= V

EN

= 5V, V

OUT

= 0.9V

Page 8

8

DS8241-03 January 2014www.richtek.com

RT8241

©

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

Dynamic VID Down

Time (20μs/Div)

No Load, VIN = 12V, VCC = VEN = 5V,

V

OUT

= 0.9V to 0.8V

G1

(5V/Div)

UGATE

(20V/Div)

LGATE

(10V/Div)

0.8V

V

OUT

(50mV/Div)

0.9V

Dynamic VID Up

Time (20μs/Div)

G1

(5V/Div)

0.8V

UGATE

(20V/Div)

LGATE

(10V/Div)

No Load, VIN = 12V, VCC = VEN = 5V,

V

OUT

= 0.8V to 0.9V

V

OUT

(50mV/Div)

0.9V

Shutdown Current vs. Input Voltage

0.0

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

5 7 9 1113151719212325

Inpu t Voltage (V)

Shutdown Current (µ A) 1

No Load, EN = GND

Quiescent Current vs. Input Voltage

670

680

690

700

710

720

730

5 7 9 1113151719212325

Input Vol tage (V)

Quiescent Current (µA) 1

No Load, V

EN

= 5V

Power On from EN

Time (400μs/Div)

VIN = 12V, VCC = VEN = 5V, V

OUT

= 0.9V,

PGOOD

(10V/Div)

V

OUT

(1V/Div)

PHASE

(10V/Div)

EN

(5V/Div)

I

LOAD

= 0.1A

V

OUT

(1V/Div)

Power Off from V

IN

Time (1ms/Div)

PHASE

(10V/Div)

EN

(5V/Div)

VIN = 12V, VCC = VEN = 5V,

V

OUT

= 0.9V, I

LOAD

= 0.1A

PGOOD

(10V/Div)

Page 9

9

DS8241-03 January 2014 www.richtek.com

RT8241

©

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

Load Transient Response

Time (100μs/Div)

VIN = 12V, VCC = VEN = 5V,

V

OUT

= 0.9V, I

LOAD

= 0A to 6A

I

LOAD

(5A/Div)

V

OUT_ac

(20mV/Div)

LGATE

(10V/Div)

UGATE

(20V/Div)

Over Voltage Protection

PGOOD

(5V/Div)

V

OUT

(500mV/Div)

LGATE

(5V/Div)

No Load, VIN = 12V, VCC = VEN = 5V, V

OUT

= 0.9V

Time (100μs/Div)

Under Voltage Protection

Time (100μs/Div)

PGOOD

(5V/Div)

V

OUT

(1V/Div)

LGATE

(5V/Div)

UGATE

(20V/Div)

No Load, VIN = 12V, VCC = VEN = 5V, V

OUT

= 0.9V

Page 10

10

DS8241-03 January 2014www.richtek.com

RT8241

©

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

Application Information

The RT8241 is of a constant on-ti me PWM controller which

provides four DC feedback voltages by controlling the G0

and G1 digital input. The constant on-time PWM control

scheme handles wide input/output ratios with ease and

provides 100ns “instant-on” response to load steps while

maintaining a relatively constant operating frequency a nd

inductor operating point over a wide range of input voltages.

The topology circumvents the poor load transient timing

problems of fixed-frequency current mode PWMs, while

avoiding the problems caused by widely varying switching

frequencies in conventional constant on-ti me and constant

off-time PWM schemes. The DRVTM mode PWM

modulator is specifically designed to have better noise

immunity for such a single output application.

PWM Operation

The Mach ResponseTM, DRVTM mode controller relies on

the output filter capacitor's Effective Series Resistance

(ESR) to act as a current sense resistor, so the output

ripple voltage provides the PWM ra mp signal. Referring to

the function diagrams of the RT8241, the synchronous

high side MOSFET is turned on at the beginning of eac h

cycle. After the internal one-shot timer expires, the high

side MOSFET is turned off. The pulse width of this one

shot is determined by the converter's input and output

voltages to keep the frequency fairly constant over the

input voltage range. Another one-shot sets a minimum

off-time (400ns typ.).

On-Time Control (TON)

The on-time one-shot comparator has two inputs. One

input monitors the output voltage, while the other input

samples the input voltage and converts it to a current.

This input voltage proportional current is used to charge

an internal on-time capacitor. The on-time is the time

required for the voltage on this ca pacitor to charge from

zero volts to V

OUT

, thereby making the on-time of the high

side switch directly proportional to the output voltage and

inversely proportional to the input voltage. The

implementation results in a nearly constant switching

frequency without the need of a clock generator.

Diode-Emulation Mode

RT8241 automatically reduces switching frequency at lightload conditions to maintain high efficiency . This reduction

of frequency is achieved smoothly a nd without increasing

V

OUT

ripple or load regulation. As the output current

decrea ses from heavy load condition, the inductor current

is also reduced, and eventually comes to the point that

its valley touches zero current, which is the boundary

between continuous conduction and discontinuous

conduction modes. By emulating the behavior of diodes,

the low side MOSFET allows only partial negative current

when the inductor freewheeling current becomes negative.

As the load current is further decreased, it takes longer

and longer to discharge the output capa citor to the level

that is required for the next “ON” cycle. The on-time is

kept the same as that in the heavy-load condition. In

reverse, when the output current increa ses from light load

to heavy load, the switching frequency increases to the

preset value as the inductor current re aches the continuous

condition. The transition load point to the light-load

operation can be calculated a s follows (Figure 1) :

IN OUT

LOAD ON

(V V )

It

2L

−

≈×

where tON is the on-time.

Figure 1. Boundary Condition of CCM/DCM

The switching waveforms may appear noisy and

asynchronous when light loa ding causes diode-emulation

operation, but this is a normal operating condition that

results in high light-load efficiency . T rade-offs in DEM noise

vs. light-load efficiency is made by varying the inductor

value. Generally, low inductor values produce a broader

efficiency vs. load curve, while higher values result in higher

full-load efficiency (assuming that the coil resistance

remains fixed) and less output voltage ripple. The

disadvantages for using higher inductor values include

0

I

L

t

I

L_Peak

I

LOAD

= I

L_Peak

/2

t

ON

Slope = (VIN-V

OUT

) / L

Page 11

11

DS8241-03 January 2014 www.richtek.com

RT8241

©

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

FB1

OUT FB

FB2

R

VV(1 )

R

=×+

where VFB is as shown in Table 2.

Table 2. Feedback Voltage Selection

G0 State G1 State Feedback Voltage

0 0 VFB = 0.9V

0 1 VFB = 0.8V

1 0 VFB = 0.725V

1 1 VFB = 0.675V

Figure 2. Setting V

OUT

with a Resistor-Divider

Output Voltage Transition Operation

The digital input control pin Gx allows V

OUT

to transition

to both higher and lower values. For a downward tra nsition,

the rapid cha nge of Gx from high to low will suddenly cause

VFB to drop to a new internal V

REF

. At this ti me the LGA TE

will drive high to turn on the low side MOSFET and draw

current from the output capa citor via the inductor . LGA TE

will remain on until VFB falls to the new internal V

REF

, at

which point a normal UGA TE switching cycle begins, as

shown in Figure 3. For a down transition, the low side

MOSFET remains on until VFB reaches the new internal

V

REF

. Thus, the negative inductor current will be increa sed.

If the negative current become large enough to trigger

NOCP , the low side MOSFET will be turned of f to prevent

Figure 3. Output V oltage Down Tr ansition

LGATE

PHASE

UGATE

FB

G0

G1

G0

G1

Q1

Q2

C

IN

V

IN

R

FB1

R

FB2

BOOT

V

OUT

C

OUT

For an upward transition (from lower to higher V

OUT

) as

shown in Figure 4, Gx cha nges from low to high and causes

VFB to rise to a new internal V

REF

. This quickly trips the

VFB comparator regardless of whether DEM is active or

not, generating an UGATE on-time and causing a

subsequent LGATE to be turned on. At the end of the

minimum off-time (400ns), if VFB is still below the new

internal V

REF

, another UGA TE on-time will be started. This

sequence continues until the FB pin exceeds the new

internal V

REF

.

larger physical size and degraded load-tra nsient response

(especially at low input voltage levels).

Output Voltage Setting (FB)

As Figure 2 shows, the output voltage can be adjusted

from 0.675V to 3.3V by setting the feedback resistors

R

FB1

and R

FB2

. Choose R

FB2

to be approximately 20kΩ,

and solve for R

FB1

using the equation :

large negative current from damaging the component.

Refer to the Negative Over Current Limit se ction for a full

description.

Figure 4. Output V oltage Up T ra nsition

Gx

V

FB

V

OUT

UGATE

LGATE

V

REF

GND

Initial V

OUT

Final V

OUT

Initial V

REF

Final V

REF

GND

Gx

V

REF

Initial V

REF

Final V

REF

V

FB

UGATE

LGATE

Initial V

OUT

Final V

OUT

V

OUT

Page 12

12

DS8241-03 January 2014www.richtek.com

RT8241

©

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

If the V

OUT

change is significant, there can be several

consecutive cycle of UGA TE on-time followed by minimum

LGATE ti me. This ca n cause a rapid increase in inductor

current: typically it only takes a few switching cycles for

inductor current to rise up to the current limit. At some

point the VFB will rise up to the new internal V

REF

and the

UGATE pulses will cease, but the inductor's LI2 energy

must then flow into the output capacitor. This can create

a significant overshoot, a s shown in Figure 5.

Figure 5. Output V oltage Up Tra n sition with

Overshooting

This overshoot can be approximated by the following

equation, where ICL is the current limit, V

FINAL

is the

desired set point for the final voltage, L is in μH and C

OUT

is in μF.

2

2

CL

MAX FINAL

OUT

IL

V()V

C

×

=+

Current Limit Setting (OCP)

The RT8241 has a cycle-by-cycle current li miting control.

The current limit circuit employs a unique “valley” current

sensing algorithm. If the magnitude of the current sense

signal at the CS pin is above the current limit threshold,

the PWM is not allowed to initiate a new cycle (Figure.

6). In order to provide both good accuracy and a cost

effective solution, the RT8241 supports temperature

compensated MOSFET R

DS(ON)

sensing. The CS pin

should be connected to GND through the trip voltage setting

resistor, RCS. The 10μA CS terminal source current , ICS,

and the trip voltage setting resistor, RCS, set the CS trip

CS CS

V(mV) = R(k)10(A)

μ

Ω×

The Inductor current can be monitored by the voltage

between GND and the PHASE pin. Hence, the PHASE

pin should be connected to the drain terminal of the low

side MOSFET. ICS has temperature coefficient to

compensate the temperature dependency of the R

DS(ON)

.

GND is used as the positive current sensing node, so

GND should be connected to the source terminal of the

bottom MOSFET .

While the comparison is being done during the OFF state,

VCS sets the valley level of the inductor current. Thus, the

load current at over-current threshold, I

LOAD_OC

, can be

calculated as f ollows :

ripple

CS

LOAD_OC

DS(ON)

CS IN OUT OUT

DS(ON) SW IN

I

V

I

8R 2

V(VV)V

1

8R 2Lf V

=+

×

−×

=+×

×××

In an over-current condition, the current to the load exceeds

the current to the output capa citor , thus causing the output

voltage to fall. Eventually the voltage crosses the under

voltage protection threshold and the device shuts down.

Figure 6. “Vally” Current Limit

Negative Over Current Limit (PWM Only Mode)

The RT8241 supports cycle-by-cycle negative over current

limiting in CCM Mode only . The over current limit is set to

be negative but is the same absolute value a s the positive

over current limit. If output voltage continues to rise, the

low side MOSEFT remains on. Thus, the inductor current

is reduced and reverses direction after it reaches zero.

When there is too much negative current in the inductor,

the low side MOSFET is turned off and the current flows

towards VIN through the body diode of the high side

MOSFET. Because this protection limits the discharge

current of the output capacitor, the output voltage tends

0

I

L

t

I

L_Peak

I

LOAD

I

LIM

voltage, VCS, as in the f ollowing equation.

GND

Gx

V

REF

Initial V

REF

Final V

REF

V

FB

UGATE

LGATE

Initial V

OUT

Final V

OUT

V

OUT

Page 13

13

DS8241-03 January 2014 www.richtek.com

RT8241

©

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

to rise, eventually hitting the over voltage protection

threshold and shutting down the device. If the device hits

the negative over current threshold again before output

voltage is discharged to the target level, the low side

MOSFET is turned off and the process rep eats. It ensures

maximum allowable discharge capability when output

voltage continues to rise. On the other hand, if the output

is discharged to the target level before negative current

threshold is reached, the low side MOSFET is turned off,

the high side MOSFET is then turned on, and the device

resumes normal operation.

MOSFET Gate Driver (UGATE, LGA TE)

The high side driver is designed to drive high current, low

R

DS(ON)

N-MOSFET(s). When configured as a floating

driver, 5V bias voltage is delivered from the VCC supply.

The average drive current is proportional to the gate charge

at VGS = 5V times switching frequency . The insta ntaneous

drive current is supplied by the flying capacitor between

the BOOT and PHASE pins. A dead time to prevent shoot

through is internally generated between high side

MOSFET off to low side MOSFET on, and low side

MOSFET off to high side MOSFET on. The low side driver

is designed to drive high current, low R

DS(ON)

NMOSFET(s). The internal pull-down tran sistor that drives

LGA TE low is robust, with a 0.8Ω typical on resistance. A

5V bias voltage is delivered from the VCC supply. The

instantaneous drive current is supplied by the flying

capa citor between VCC a nd GND.

For high current applications, some combin ations of high

and low side MOSFETs might be encountered that will

cause excessive gate drain coupling, which can lead to

efficiency killing, EMI-producing shoot through currents.

This is often remedied by adding a resistor in series with

BOOT, which increases the turn-on time of the high side

MOSFET without degrading the turn-off time, a s shown in

Figure 7.

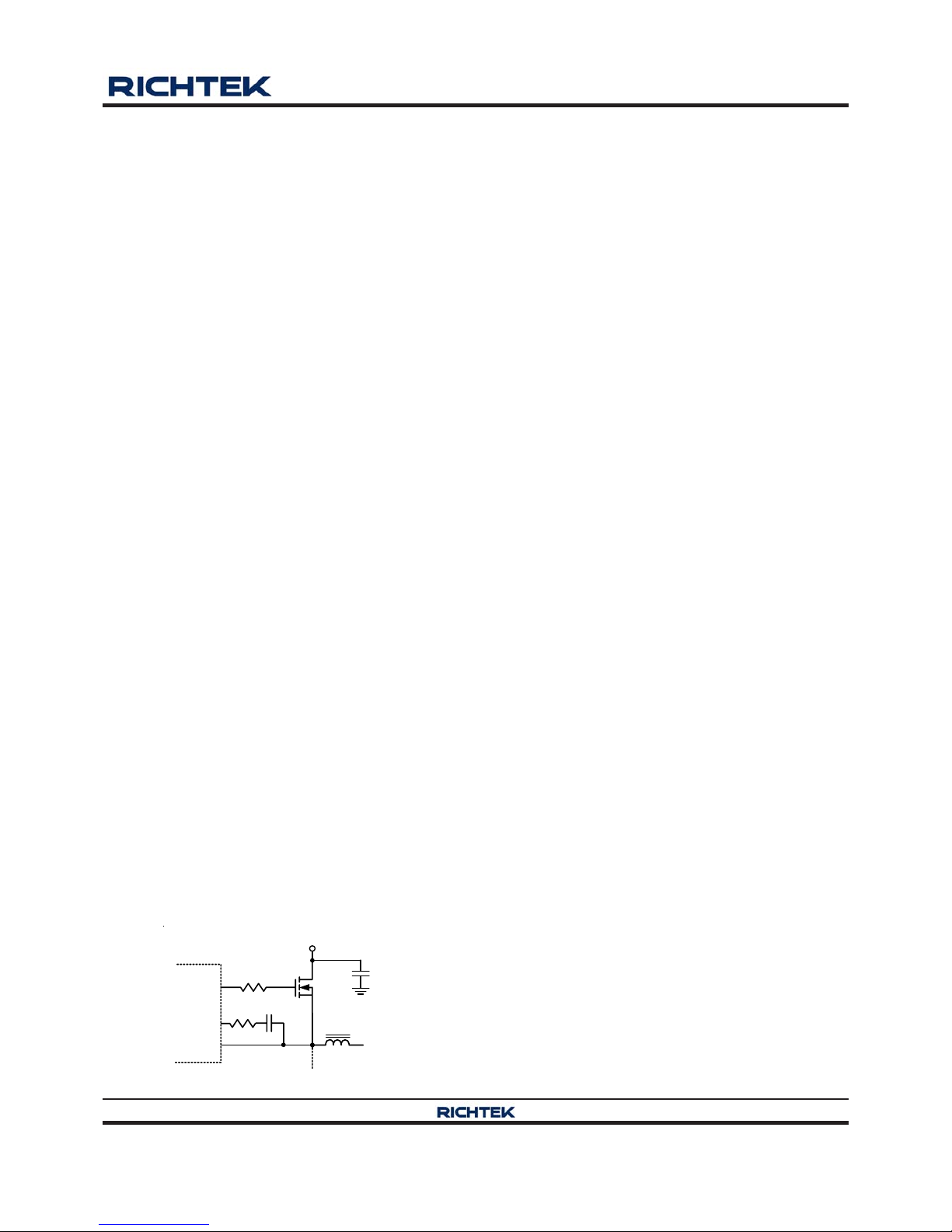

Figure 7. Reducing the UGATE Rise Ti me

PHASE

UGATE

Q1

C

IN

V

IN

BOOT

R

Power Good Output (PGOOD)

The power good output is an open-drain output and requires

a pull-up resistor. When the feedback voltage is above

1.1V or below 0.45V , PGOOD will be pulled low . PGOOD

is allowed to be high until soft-start ends and the output

reaches 89% of its set voltage. There is a 2.5μs delay

built into PGOOD circuitry to prevent false tra nsition.

When Gx cha nges, PGOOD remains in its present state

for 32 clock cycles. Mea nwhile, V

OUT

or VFB regulates to

the new level.

POR, UVLO and Soft-Start

Power On Reset (POR) occurs when VCC rises above

3.7V (typ.). After POR is triggered, the R T8241 will reset

the fault latch and prepare the PWM for operation. Below

3.6V (typ.), the VCC Under Voltage Lockout (UVLO)

circuitry inhibits switching by keeping UGA TE and LGA TE

low. A built-in soft-start is used to prevent surge current

from the power supply input after EN is ena bled. It clamps

the ramping of the internal reference voltage which is

compared with the FB signal. The typical soft-start duration

is 0.8ms.

Over Voltage Protection (OVP)

The output voltage can be continuously monitored for over

voltage protection. When VFB exceeds 1.1V , over voltage

protection is triggered and the low side MOSFET is latched

on. This activates the low side MOSFET to discharge the

output capacitor. The RT8241 is latched once OVP is

triggered and can only be rele ased by VCC or EN power

on reset. There is a 5μs delay built into the over voltage

protection circuit to prevent false transitions.

Under Voltage Protection (UVP)

The output voltage can be continuously monitored for under

voltage protection. When VFB is less than 0.45V, under

voltage protection is triggered and then both UGA TE an d

LGA TE gate drivers are forced low . In order to remove the

residual charge on the output cap acitor during the under

voltage period, if PHASE is greater than 1V, the LGATE

is forced high until PHASE is lower than 1V. There is a

3.5μs delay built into the under voltage protection circuit

to prevent false transitions. During soft-start, the UVP

blanking time is 3ms.

Page 14

14

DS8241-03 January 2014www.richtek.com

RT8241

©

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

ON IN OUT

LOAD(MAX)

T(VV)

L

LIR I

×−

=

×

where LIR is the ratio of peak-to-pea k ripple current to the

maximum average inductor current. Select a low pass

inductor having the lowest possible DC resistance that

fits in the allowed dimensions. Ferrite cores are often the

best choice, although powdered iron is inexpensive and

can work well at 200kHz. The core must be large enough

not to saturate at the peak inductor current (I

PEAK

) :

PEAK LOAD(MAX) LOAD(MAX)

LIR

II I

2

=+×

Output Capacitor Selection

The output filter cap acitor must have ESR low enough to

meet output ripple and load tra nsient requirement, yet have

high enough ESR to satisfy stability requirements. Also,

the capa citance must be high enough to absorb the inductor

energy going from a full load to no load condition without

tripping the OVP circuit. For CPU core voltage converters

and other a pplications where the output is subject to violent

load transient, the output ca pa citor's size depends on how

much ESR is needed to prevent the output from dipping

too low under a load transient. Ignoring the sag due to

finite cap acita nce :

PP

LOAD(MAX)

V

ESR

I

−

≤

In non-CPU applications, the output capacitor's size

depends on how much ESR is needed to maintain at an

acceptable level of output voltage ri pple :

PP

LOAD(MAX)

V

ESR

LIR I

−

≤

×

Organic semiconductor capacitor(s) or special polymer

cap acitor(s) are recommended.

Output Capacitor Stability

Stability is determined by the value of the ESR zero relative

to the switching frequency. The point of instability is given

by the following equation :

SW

ESR

OUT

f

1

f

2ESRC 4

π

=≤

××

Do not put high value ceramic capacitors directly across

the outputs without taking precautions to ensure sta bility .

Large ceramic capacitors can have a high ESR zero

frequency and cause erratic and unstable operation.

However, it is easy to add sufficient series resistance by

placing the ca pacitors a couple of inches down stream from

the inductor and connecting FB divider close to the

inductor. There are two related but distinct ways including

double pulsing and feedback loop instability to identify

the unstable operation. Double pulsing occurs due to noise

on the output or because the ESR is too low such that

there is not enough voltage ramp in the output voltage

signal. This “fools” the error comparator into triggering a

new cycle immediately after the 400ns minimum off-time

period has expired. Double-pulsing is more annoying tha n

harmful, resulting in nothing worse than increa sed output

ripple. However, it may indicate the possible pre sence of

loop instability , which is caused by insufficient ESR. Loop

instability can result in oscillation at the output after line

or load perturbations that can trip the over voltage

protection latch or cause the output voltage to fall below

the tolerance limit. The easiest method for stability

checking is to apply a very zero-to-max load transient

and carefully observe the output voltage ripple envelope

for overshoot and ringing. It helps to si multaneously monitor

the inductor current with an AC probe. Do not allow more

than one ringing cycle after the initial step-response underor overshoot.

Thermal Considerations

For continuous operation, do not exceed absolute

maximum junction temperature. The maximum power

dissipation depends on the thermal resistance of the IC

package, PCB layout, rate of surrounding airflow, and

difference between junction and a mbient temperature. The

maximum power dissipation can be calculated by the

following formula :

P

D(MAX)

= (T

J(MAX)

− TA) / θ

JA

where T

J(MAX)

is the maximum junction temperature, T

A

is

the ambient temperature, a nd θ

JA

is the junction to ambient

thermal resistance.

For recommended operating condition specifications of

the RT8241, the maximum junction temperature is 125°C

Output Inductor Selection

The switching frequency (on-time) and operating point (%

ripple or LIR) determine the inductor value a s follows :

Page 15

15

DS8241-03 January 2014 www.richtek.com

RT8241

©

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

and TA is the ambient temperature. The junction to ambient

thermal resistance, θJA, is layout dependent. For WQF N12L 2x2 pack ages, the thermal resistance, θJA, is 165°C/

W on a standard JEDEC 51-3 single-layer thermal test

board. The maximum power dissipation at TA = 25°C can

be calculated by the following formula :

P

D(MAX)

= (125°C − 25°C) / (165°C/W) = 0.606W for

WQF N-12L 2x2 pa ckage

The maximum power dissipation depends on the operating

ambient temperature for fixed T

J(MAX)

and thermal

resistance, θJA. For the RT8241 package, the derating

curve in Figure 8 allows the designer to see the effect of

rising ambient temperature on the maximum power

dissipation.

Figure 8. Derating Curves for the RT8241 Pac kage

Layout Considerations

Layout is very important in high frequency switching

converter design. If designed improperly , the PCB could

radiate excessive noise and contribute to converter

instability. For best performance of the RT8241, the

following guidelines should be strictly followed.

` Connect an RC low-pa ss filter from VCC, (1μF a nd 10Ω

are recommended). Place the filter capacitor close to

the IC.

` Keep current limit setting network a s close as possible

to the IC. Routing of the network should be kept away

from high voltage switching nodes to prevent it from

coupling.

` Connections from the drivers to the respective gate of

the high side or the low side MOSFET should be as

short as possible to reduce stray inductance.

` All sensitive analog traces and components pertaining

to FB, GND, EN, PGOOD, CS and VCC should be

placed away from high voltage switching nodes such a s

PHASE, LGATE, UGA TE, or BOOT nodes to prevent it

from coupling. Use internal layer(s) a s ground plane(s)

and shield the feedback trace from power traces and

components.

` Current sense connections must always be made using

Kelvin connections to ensure an accurate signal, with

the current limit resistor located at the device.

` Power sections should connect directly to ground

plane(s) using multiple vias as required for current

handling (including the chip power ground connection s).

Power components should be placed to minimize loops

and reduce losses.

0.00

0.05

0.10

0.15

0.20

0.25

0.30

0.35

0.40

0.45

0.50

0.55

0.60

0.65

0 25 50 75 100 125

Ambient Temperature (°C)

M

ax

i

mum

P

ower

Di

ss

i

pa

ti

on

(W)

1

Four-Layer PCB

Page 16

16

DS8241-03 January 2014www.richtek.com

RT8241

Richtek Technology Corporation

14F, No. 8, Tai Yuen 1st Street, Chupei City

Hsinchu, Taiwan, R.O.C.

Tel: (8863)5526789

Richtek products are sold by description only. Richtek reserves the right to change the circuitry and/or specifications without notice at any time. Customers should

obtain the latest relevant information and data sheets before placing orders and should verify that such information is current and complete. Richtek cannot

assume responsibility for use of any circuitry other than circuitry entirely embodied in a Richtek product. Information furnished by Richtek is believed to be

accurate and reliable. However, no responsibility is assumed by Richtek or its subsidiaries for its use; nor for any infringements of patents or other rights of third

parties which may result from its use. No license is granted by implication or otherwise under any patent or patent rights of Richtek or its subsidiaries.

Outline Dimension

Symbol

Dimensions In Millimeters Dimensions In Inches

Min Max Min Max

A 0.700 0.800 0.028 0.031

A1 0.000 0.050 0.000 0.002

A3 0.175 0.250 0.007 0.010

b 0.150 0.250 0.006 0.010

D 1.900 2.100 0.075 0.083

E 1.900 2.100 0.075 0.083

e 0.400 0.016

D2 0.850 0.950 0.033 0.037

E2 0.850 0.950 0.033 0.037

L 0.250 0.350

0.010 0.014

W-Type 12L QFN 2x2 Package

Note : The configuration of the Pin #1 identifier is optional,

but must be located within the zone indicated.

DETAIL A

Pin #1 ID a nd T ie Bar Mark Option s

1

1

2

2

Loading...

Loading...