Page 1

Single Synchronous Buck Controller

RT8204L

General Description

The RT8204L PWM controller provides high efficiency,

excellent transient response, and high DC output accuracy

needed for stepping down high voltage batteries to

generate low voltage CPU core, I/O, and chipset RAM

supplies in notebook computers.

The constant-on-time PWM control scheme handles wide

input/output voltage ratios with ease and provides 100ns

“instant-on” response to load transients while maintaining

a relatively constant switching frequency.

The RT8204L achieves high efficiency at a reduced cost

by eliminating the current sense resistor found in

traditional current mode PWMs. Efficiency is further

enhanced by its ability to drive very large synchronous

rectifier MOSFETs. The buck conversion allows this device

to directly step down high voltage batteries for the highest

possible efficiency. The RT8204L is intended for CPU core,

chipset, DRAM, or other low voltage supplies as low as

0.75V. The RT8204L is available in a WQFN-16L 3x3

package.

A built in LDO controller can drive an external N-MOSFET

to provide a second output voltage from PWM output or

other power source. The RT8204L can provide adjustable

voltage down to 0.75V and maximum output voltage is

dependen on the selected MOSFET. The internal 0.75V

reference voltage with ±1.5% accuracy provides tight

regulation of the output voltage. Other features such as

independent enable control, open drain power good

indicator, under voltage protection, and soft start make

the RT8204L a system friendly power management solution

for various applications.

Features

zz

PWM Controller

z

zz

``

` Ultra High Efficiency

``

``

` Resistor Progra mmable Current Limit by Low Side

``

R

``

` 4700ppm/

``

``

` Quick Load Step Response within 100ns

``

``

` 1% V

``

``

` Adjustable 0.75V to 3.3V Output Range

``

``

` 4.5V to 26V Battery Input Range

``

``

` Resistor Programmable Frequency

``

``

` Integrated Bootstrap Switch

``

``

` Over/Under Voltage Protection

``

``

` Voltage Ramp Soft-Start

``

``

` Power Good Indicator

``

zz

z LDO Controller

zz

``

` 1.5% accuracy Over Line and Load

``

``

` Independent Enable and Power Good Indicator

``

``

` Drive N-MOSFETs within Rail to Rail Controller

``

Sense (Lossless Limit)

DS(ON)

°°

°C R

°°

Accuracy Over Line and Load

FB

Current Sensing

DS(ON)

Voltage

``

` MLCC and POSCAP Stable

``

zz

z RoHS Compliant and Halogen Free

zz

Applications

z Notebook Computers

z CPU Core Supply

z Chipset/RAM Supply as Low as 0.75V

Ordering Information

RT8204L

Package Type

QW : WQFN-16L 3x3 (W-Type)

Lead Plating System

G : Green (Halogen Free and Pb Free)

Z : ECO (Ecological Element with

Halogen Free and Pb free)

Note :

Richtek products are :

` RoHS compliant and compatible with the current require-

ments of IPC/JEDEC J-STD-020.

` Suitable for use in SnPb or Pb-free soldering processes.

DS8204L-04 April 2011 www.richtek.com

1

Page 2

RT8204L

Marking Information

RT8204LGQW

J8= : Product Code

YMDNN : Data Code

J8=YM

DNN

RT8204LZQW

J8 : Product Code

YMDNN : Data Code

J8 YM

DNN

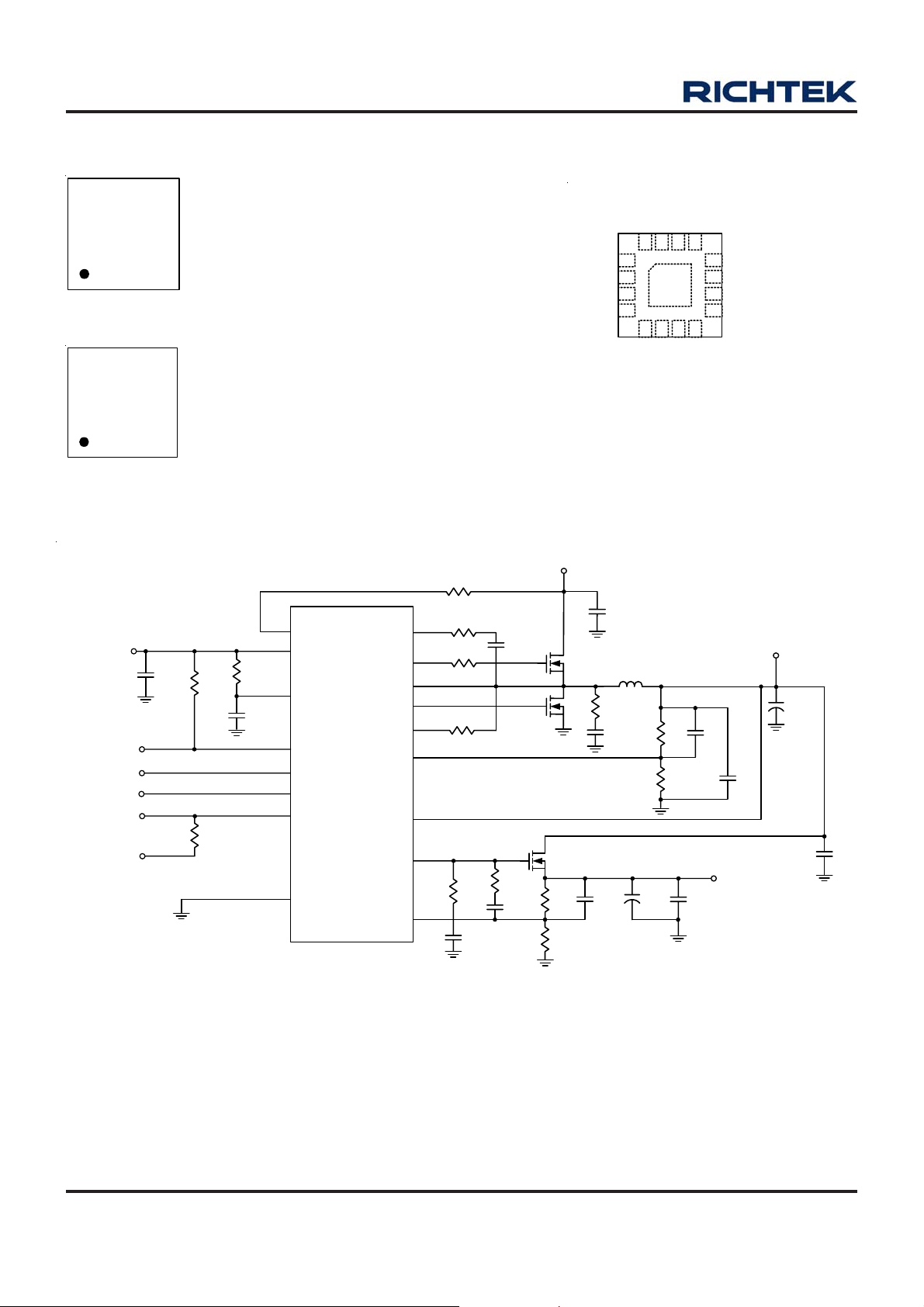

Typical Application Circuit

Pin Configurations

VOUT

VDD

FB

PGOOD

V

N

I

V

5

.

4

o

2

t

6

V

R

T

O

N

(TOP VIEW)

TON

EN/DEM

BOOT

LEN

13141516

1

2

GND

3

4

WQFN-16L 3x3

17

LFB

LDRV

LPGOOD

8765

LGATE

12

11

10

9

UGATE

PHASE

OC

VDDP

C

R

T

8

0

2

4

16

O

N

T

V

P

D

D

V

5

O

G

P

C

C

D

M

/

D

O

L

E

n

a

L

P

D

O

G

O

V

1

C

D

O

M

E

b

e

l

O

D

D

D

P

1

R

3

R

17 (Exposed Pad)

:

*

O

p

o

i

t

9

V

D

D

P

2

R

2

D

D

V

2

C

4

O

O

G

P

15

E

D

N

E

/

14

L

E

N

5

L

P

O

G

D

G

N

n

a

l

L

B

O

T

O

U

G

A

T

E

P

H

S

A

E

L

G

A

T

E

O

C

D

M

O

D

F

B

V

O

U

T

L

D

R

V

L

F

B

13

12

11

8

10

3

1

7

6

R

4

C

R

5

R

I

I

L

M

R

C

3

Q

Q

2

3

Q

R

1

9

0

R

1

C

1

9

1

0

R

1

2

4

V

O

U

T

1

1

L

1

6

R

*

R

7

C

5

*

C

1

C

1

2

1

*

C

6

*

R

8

C

C

V

O

U

T

1

3

C

8

7

*

C

1

4

2

DS8204L-04 April 2011www.richtek.com

2

Page 3

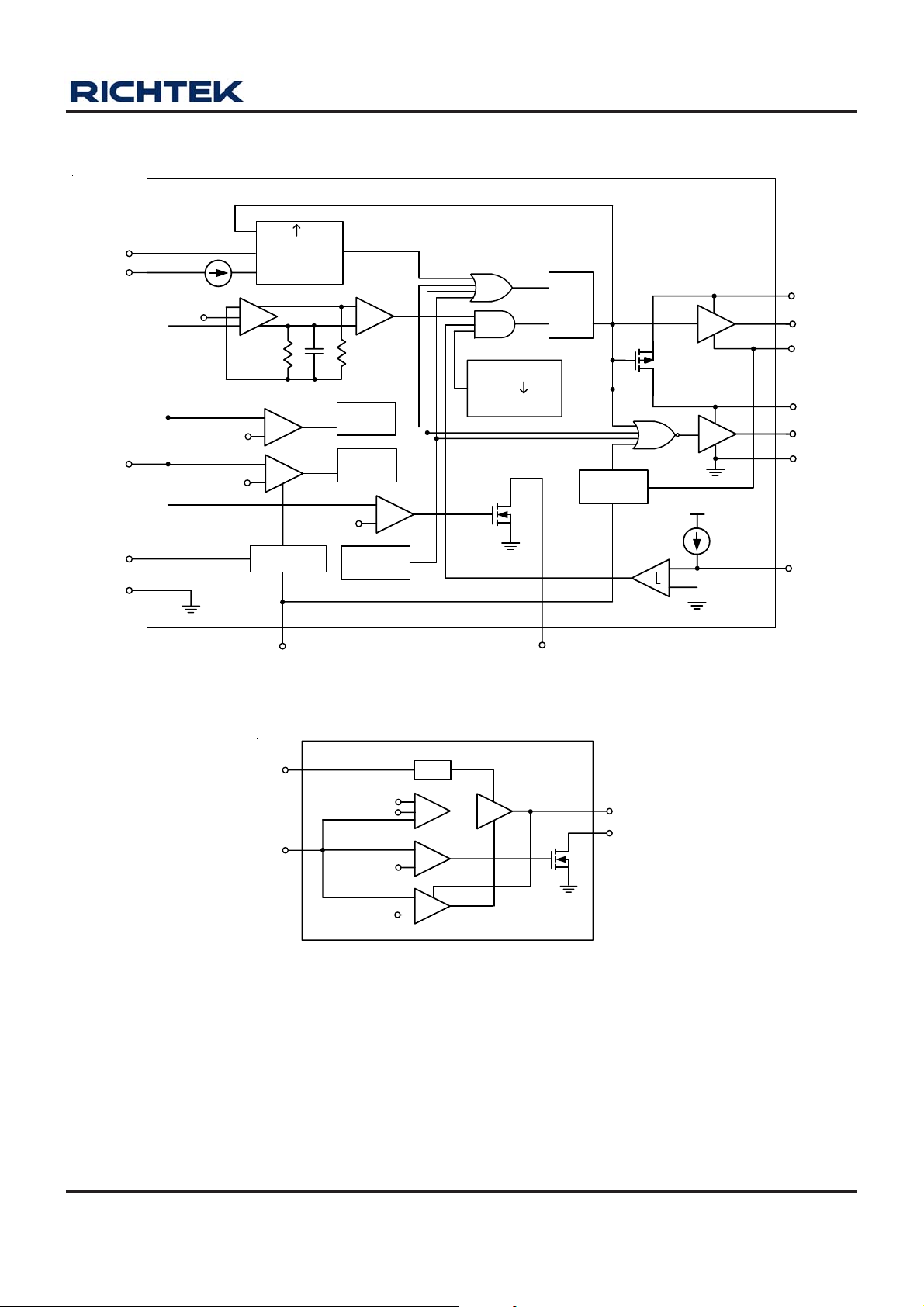

Function Block Diagram

TRIG

+

+

GM

-

-

SS Ramp

On-time

Compute

1-SHOT

+

-

+

-

90% V

OV

UV

VOUT

TON

FB

VDD

GND

SS (Internal)

115% V

70% V

REF

REF

+

Latch

S1 Q

Latch

S1 Q

REF

Thermal

Shutdown

Comp

+

R

QS

Min. T

OFF

QTRIG

1-SHOT

Emulation

Diode

RT8204L

BOOT

DRV

DRV

20µA

+

-

UGATE

PHASE

VDDP

LGATE

PGND

OC

EN/DEM

LEN

LFB

0.75V V

SS Ramp

90% V

50% V

REF

+

-

+

REF

-

REF

+

LDO Controller

SS

X1

PGOOD

LDRV

LPGOOD

DS8204L-04 April 2011 www.richtek.com

3

Page 4

RT8204L

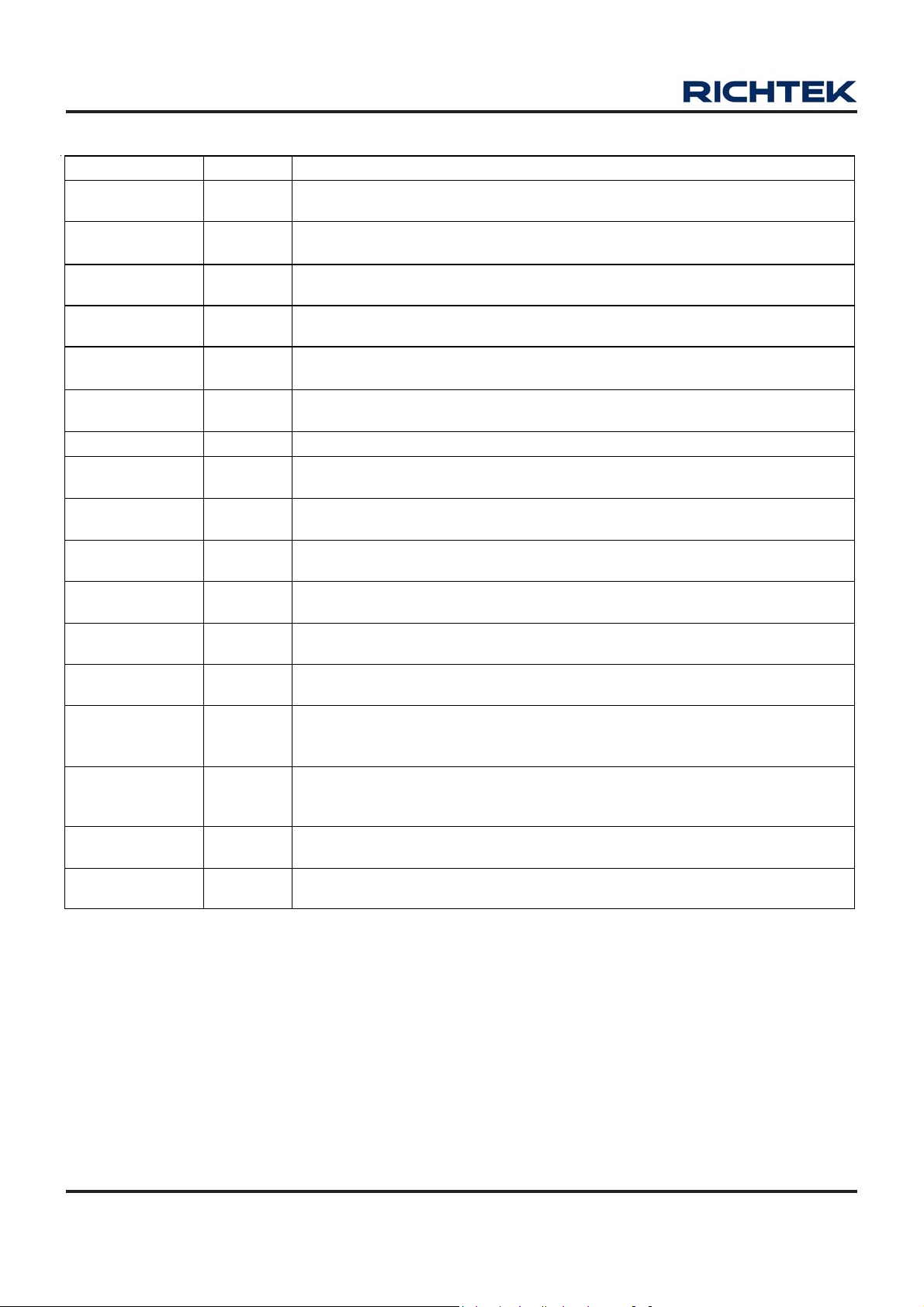

Functional Pin Description

Pin No. Pin Name Pin Function

1 VOUT

2 VDD

3 FB

4 PGOOD

5 LPGOOD

6 LFB

7 LDRV Drive Signal for LDO’s Path MOSFET.

8 LGATE

9 VDDP

10 OC

11 PHASE

12 UGATE

13 BOOT

14 LEN

15 EN/DEM

16 TON

17 (Exposed Pad) GND

Output Voltage Sense Pin. Connect this pin to the output of the PWM converter.

VOUT is an inp ut of the PWM controller.

Analog Supply Voltage Inpu t for Internal Analog In tegrated Circuit. Bypass this

pin to GND with a 1μF ceramic capacitor.

Feedback Input o f PWM Cont roll er. Conn ect FB to a resistive voltage divider

from VOUT to GND t o adjust the output voltage from 0.75V to 3 .3V.

Power Good Signal Open-Drain Output of PW M Cont roller. Th is pin will be

pulled high when the ou tput voltage is within the target r ange .

Power Good Signal Open-Drain Output of the LDO Regulat or. This pin will be

pulled high when the ou tput voltage is within the target range.

Feedback Input of LDO Reg ulator. Th is pin will b e pulled high when the outp ut

voltage is within the target range.

Low Side N-MOSFET Gate-Drive Output for the PWM Controller. This pin

swings between GND to V DDP.

Gate Driver Su pply for external MOSFETs. Bypass this pin to GND with a 1μF

ceramic capacitor.

PWM Current Limit Setting and Sense. Connect a resistor between OC to

PHASE for current limit setting.

Inductor Connect ion. This p in is no t only the zero cur rent se nse inpu t for t he

PWM converter, but also the UGATE high s ide gate driver retu rn.

High Side N-MOSFET Floating Gate-Driver Output for PWM Controller. This pin

swings between PHASE and BOOT.

Boost Capacitor Connecti on for PWM Controller. Connect an external ceram ic

capacitor fro m this pin to PHASE.

LDO Enable Inp ut with In ternal Pull Low Resistor. LDO is enabled if LEN voltage

is greater than t he Logic Hi gh voltage level and disabled if LEN voltag e is les s

than the L ogic Low volt age level.

PWM Enable and Operation Mode Selec tion Input. Connect to VDD for diode

emula tion mode, connect GND for shutdown mo de, and float the pin for CCM

mode .

On Time/Fre quency Adjustment Pin. Connect this pin to VIN through a resistor.

TON is an input of the PWM controller.

Analog Grou nd and Power Groun d. Th e exposed pad must be soldered to a

large PCB and connected to GND for maximum power dissipation.

DS8204L-04 April 2011www.richtek.com

4

Page 5

RT8204L

Absolute Maximum Ratings (Note 1)

z Input Voltage, TON to GND ------------------------------------------------------------------------------------------------ –0.3V to 32V

z BOOT to PHASE ------------------------------------------------------------------------------------------------------------ –0.3V to 6V

z UGATE to PHASE

DC------------------------------------------------------------------------------------------------------------------------------- –0.3V to 6V

< 20ns ------------------------------------------------------------------------------------------------------------------------- −5V to 7.5V

z LGATE to GND

DC------------------------------------------------------------------------------------------------------------------------------- –0.3V to 6V

< 20ns ------------------------------------------------------------------------------------------------------------------------- −2.5V to 7.5V

z PHASE to GND

DC------------------------------------------------------------------------------------------------------------------------------- –0.3V to 32V

< 20ns ------------------------------------------------------------------------------------------------------------------------- −8V to 38V

z VDD, VDDP, VOUT, EN/DEM, LEN, LFB, FB, PGOOD, LPGOOD, LDRV to GND ------------------------- –0.3V to 6V

z OC to GND -------------------------------------------------------------------------------------------------------------------- –0.3V to 28V

z Power Dissipation, P

WQFN-16L 3x3 -------------------------------------------------------------------------------------------------------------- 1.471W

z Package Thermal Resistance (Note 2)

WQFN-16L 3x3, θJA--------------------------------------------------------------------------------------------------------- 68°C/W

WQFN-16L 3x3, θJC-------------------------------------------------------------------------------------------------------- 7.5°C/W

z Lead Temperature (Soldering, 10 sec.) --------------------------------------------------------------------------------- 260°C

z Junction Temperature ------------------------------------------------------------------------------------------------------- 150°C

z Storage Temperature Range ---------------------------------------------------------------------------------------------- –65°C to 150°C

z ESD Susceptibility (Note 3)

HBM (Human Body Mode) ------------------------------------------------------------------------------------------------ 2kV

MM (Machine Mode) -------------------------------------------------------------------------------------------------------- 200V

@ TA = 25°C

D

Recommended Operating Conditions

z Input Voltage, V

z Supply Voltage, V

z Junction Temperature Range --------------------------------------------------------------------------------------------- −40°C to 125°C

z Ambient Temperature Range --------------------------------------------------------------------------------------------- −40°C to 85°C

------------------------------------------------------------------------------------------------------------ 4.5V to 26V

IN

DD, VDDP

------------------------------------------------------------------------------------------------ 4.5V to 5.5V

(Note 4)

Electrical Characteristics

(VDD = V

PWM Controller

Quiescent Current IQ

TON Operating Current -- 15 -- μA

Shutdown Current I

FB Reference Voltage VFB V

= 5V, VIN = 15V, V

DDP

EN/DEM

= VDD, R

= 1MΩ, T

TON

= 25°C, unless otherwise specified)

A

Parameter Symbol Test Conditions Min Typ Max Unit

V

SHDN

+ V

DD

the regulati on point

VDD + V

TON -- 1 5

V

EN/DEM

= 4.5V to 5.5V 0.742 0.75 0.758 V

DD

, VFB = 0.8 V, forced abo ve

DDP

-- 1 10

DDP

-- -- 1250 μA

μA

= 0V −10 −1 --

To be continued

DS8204L-04 April 2011 www.richtek.com

5

Page 6

RT8204L

Parameter Symbol Test Conditions Min Typ Max Unit

FB Input Bias Current VFB = 0.75V −1 0.1 1 μA

Output Voltage Range V

On-Time

Minimum Off-Time 250 400 550 ns

VOUT Shutdown Discharge

Resistance

Current Sensing

Current Limit Source Current LGATE = High 18 20 22 μA

0.75 -- 3.3 V

OUT

= 15V, V

V

IN

R

TON

= 1MΩ

= 1.25V,

OUT

267 334 401 ns

EN/DEM = GND -- 20 -- Ω

Current Limiter Temperature

Coefficient

Current Comparator Offset

Voltage

Zero Crossing Threshold

Voltage

TC

On the basis of 25°C -- 4700 -- ppm/°C

ICS

GND to OC −10 -- 10 mV

PHASE to GND, V

EN/ DEM

= 5V −10 -- 5 mV

Fault Pr otection

Current Limit Sense Voltage GND − PHASE, R

Output Under Voltage Threshold V

Over Voltage Protection

Threshold

60 70 80 %

UVP

V

OVP

With respect to error comparator

threshold

= 10kΩ 170 200 230 mV

ILIM

110 115 120 %

Over Voltage Fault Delay FB forced above OV threshold -- 20 -- μs

Under Voltage Lockout

Threshold

Under Voltage Lockout

Hysteresis

-- 150 -- mV

Soft-Start Ramp Time tSS

Falling edge, PWM disabled below

this level

From EN high to internal V

REF

reaches 0.71V (0Æ95%)

3.7 3.9 4.1 V

-- 1.5 -- ms

Under Voltage Blank Time From EN signal going high -- 4.5 -- ms

Thermal Shutdown T

Thermal Shutdown Hysteresis ΔT

SD_PWM

-- 155 -- °C

SD_PWM

-- 10 -- °C

Driver On-Resistance

UGATE Driver Source R

UGATE Driver Sink R

LGATE Driver Source R

LGATE Driver Sink R

Dead Time

Internal BOOT Charging Switch

On Resistance

Logic I/O

EN/DEM Input

Threshold Voltage

Logic-Low VIL EN/DEM Low -- -- 0.8

Logic-High V

6

UGATEsr

UGATEsk

LGATE sr

LGATE sk

BOOT to PHASE forced to 5V -- 2 -- Ω

BOOT to PHASE forced to 5V -- 1.5 -- Ω

LGATE, High State -- 1.5 -- Ω

LGATE, Low State -- 0.7 -- Ω

LGATE Rising (V

UGATE Rising -- 30 --

= 1.5V) -- 30 --

PHASE

ns

VDDP to BOOT, 10mA -- -- 90 Ω

IH

EN/DEM High 2.9 -- -EN/DEM Float -- 2 --

V

To be continued

DS8204L-04 April 2011www.richtek.com

Page 7

RT8204L

Parameter Symbol Test Conditions Min Typ Max Unit

Logic Input Current

PGOOD (upper side thresh old decide by OV threshold)

Trip Threshold (falling)

Fault Propagation Delay

Output Low Voltage I

Leakage Current High state, forced to 5V -- -- 1 μA

LDO Controller

Quiescent Current I

LEN Threshold

Voltage

Logic-High V

Logic-Low V

LEN Input Current I

LFB Reference Voltage V

LFB Input Current I

LDRV Output Current I

Soft-Start Time V

Output Under Voltage

Protection Threshold

LDO Under Voltage

Blanking Time

Power Good Threshold

(falling)

LDO Power Good

Propagation Delay

LPGOOD Low Voltage I

Leakage Current High state, forced to 5V -- -- 1 μA

Thermal shutdown T

Thermal shutdown

Hysteresis

EN/DEM = VDD -- 1 10

μA

EN/DEM = 0 −10 1 --

Measured at FB, with respect to

reference, no load. Hysteresis = 3%

Falling edge, FB forced below

PGOOD trip threshold

= 1mA -- -- 0.4 V

SINK

PWM Off, LDO On, I

Q_LDO

1.2 -- --

IH_LDO

-- -- 0.8

IL_LDO

V

IN_LEN

REF_LFB

IN_LFB

OUT_LDRV

0.739 0.75 0.761 V

−1 -- 1 μA

= 5V, (internal pull low) -- -- 10 μA

LEN

Sourcing, LFB = 0.72 1.4 2 --

Sinking, LFB = 0.78 1.4 2 --

= 0.75V -- 2 -- ms

LFB

= 0A -- -- 400 μA

LOA D

87 90 93 %

-- 2.5 -- μs

V

mA

Measured at LFB pin 40 50 60 %

-- 4 -- ms

Measured at LFB pin 87 90 93 %

SD _LDO

ΔT

SD_LDO

Falling edge, LFB forced below

LPGOOD trip threshold

= 1mA -- -- 0.4 V

SINK

-- 2.5 -- μs

Hysteresis = 10°C -- 155 -- °C

-- 10 -- °C

Note 1. Stresses listed as the above “Absolute Maximum Ratings” may cause permanent damage to the device. These are for

stress ratings. Functional operation of the device at these or any other conditions beyond those indicated in the

operational sections of the specifications is not implied. Exposure to absolute maximum rating conditions for extended

periods may remain possibility to affect device reliability.

Note 2. θ

Note 3. Devices are ESD sensitive. Handling precaution is recommended.

Note 4. The device is not guaranteed to function outside its operating conditions.

DS8204L-04 April 2011 www.richtek.com

is measured in natural convection at T

JA

JEDEC 51-7 thermal measurement standard. The measurement case position of θ

package.

= 25°C on a high-effective thermal conductivity four- layer test board of

A

is on the exposed pad of the

JC

7

Page 8

RT8204L

Typical Operating Characteristics

V

Efficiency vs. Output Current

100

Efficiency (%)

OUT1

90

80

70

60

50

40

30

20

10

0

0.001 0.01 0.1 1 10 100

DEM

PWM

VIN = 8V, V

OUT1

Output Current (A)

V

Efficiency vs. Output Current

OUT1

DEM

PWM

0

VIN = 12V, V

0.001 0.01 0.1 1 10 100

OUT1

Efficiency (%)

100

90

80

70

60

50

40

30

20

10

Output Current (A)

= 1.05V

= 1.05V

Switching Frequency vs. Output Current

350

325

300

275

250

225

200

175

150

125

100

75

Switching Frequency (kHz) 1

50

25

0

0.001 0.01 0.1 1 10 100

PWM

DEM

VIN = 8V, V

OUT1

Output Current (A)

Switching Frequency vs . Output Current

350

325

300

275

250

225

200

175

150

125

100

75

Switching Frequency (kHz) 1

50

25

0

0.001 0.01 0.1 1 10 100

PWM

DEM

VIN = 12V, V

Output Current (A)

OUT1

= 1.05V

= 1.05V

V

Efficiency vs. Output Current

OUT1

100

90

80

70

60

50

40

Efficiency (%)

30

20

10

0

0.001 0.01 0.1 1 10 100

DEM

PWM

VIN = 20V, V

OUT1

= 1.05V

Output Current (A)

Switching Frequency vs. Output Current

350

325

300

275

250

225

200

175

150

125

100

75

Switching Frequency (kHz) 1

50

25

0

0.001 0.01 0.1 1 10 100

PWM

DEM

VIN = 20V, V

Output Current (A)

OUT1

= 1.05V

DS8204L-04 April 2011www.richtek.com

8

Page 9

RT8204L

1.0640

1.0632

1.0624

1.0616

Output Voltage (V)

1.0608

1.0600

LDO Output Voltage vs. Output Current

V

= 1.5V

IN_LDO

012345

Output Current (A)

Shutdown Current vs. Input Voltage

10

8

520

500

480

460

440

Standby Current (µA) 1

420

400

V

OUT1

(1V/Div)

Standby Current v s . Input Voltage

V

= 5V, No Load

EN/DEM

7 101316192225

Input Voltage (V)

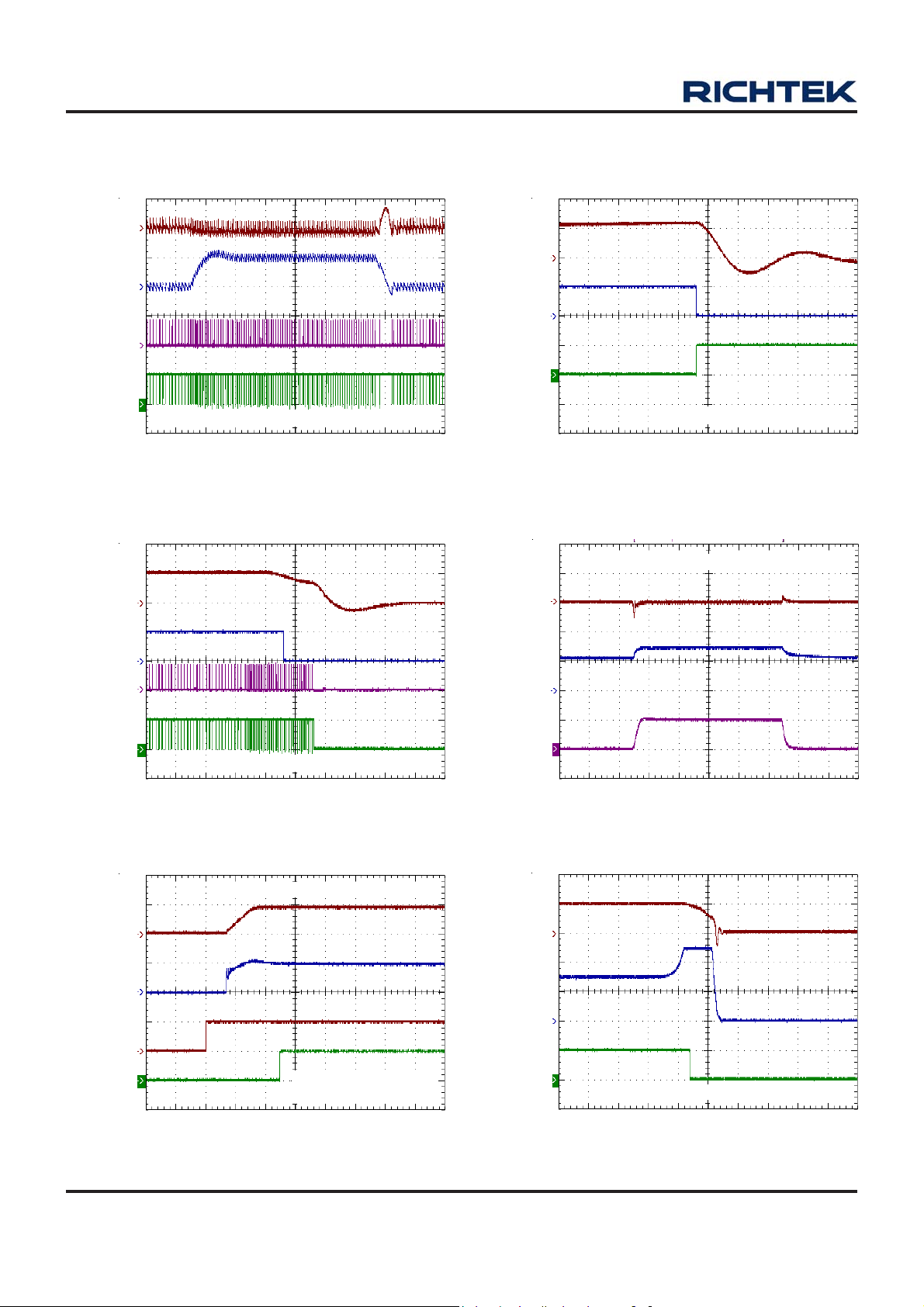

Power On from EN_PWM Mode

6

4

Shutdown Current (µA) 1

2

0

V

OUT1

(1V/Div)

V

PHASE

(10V/Div)

V

EN/DEM

(5V/Div)

V

PGOOD

(5V/Div)

EN/DEM = GND, No Load

7 1013161922 25

Input Voltage (V)

Power On from EN_DEM Mode

VIN = 12V, V

EN_DEM

= 5V, No Load

V

PHASE

(10V/Div)

V

EN/DEM

(2V/Div)

V

PGOOD

(5V/Div)

V

OUT1

(1V/Div)

V

EN/DEM

(2V/Div)

V

UGATE

(20V/Div)

V

LGATE

(5V/Div)

VIN = 12V, EN/DEM = Floating, No Load

Time (1ms/Div)

Power Off from EN

VIN = 12V, EN/DEM = Floating, No Load

Time (1ms/Div)

Time (10ms/Div)

DS8204L-04 April 2011 www.richtek.com

9

Page 10

RT8204L

V

OUT1

V

OUT1

(50mV/Div)

I

L

(20A/Div)

V

UGATE

(20V/Div)

V

LGATE

(5V/Div)

VIN = 12V, EN/DEM = Floating, I

Load Transient Response

= 0A to 20A

OUT1

V

OUT1

(1V/Div)

V

PGOOD

(5V/Div)

V

LGATE

(5V/Div)

Over Voltage Protection

VIN = 12V, V

= 5V, No Load

EN/DEM

V

OUT1

(1V/Div)

V

PGOOD

(5V/Div)

V

UGATE

(20V/Div)

V

LGATE

(5V/Div)

Time (40μs/Div)

Under Voltage Protection

VIN = 12V, EN/DEM = Floating, No Load

Time (40μs/Div)

LDO Power On from LEN

No Load on OUT_PWM and OUT_LDO

V

OUT2

(100mV/Div)

V

LDRV

(2V/Div)

I

LOAD

(5A/Div)

Time (40μs/Div)

LDO Load Transient Response

V

IN_LDO

= 1.5V, C

= 10μF x2, I

OUT

OUT2

= 0A to 5A

Time (100μs/Div)

LDO Short-Circuit Protection

V

10

V

OUT2

(1V/Div)

V

LDRV

(2V/Div)

V

LEN

(5V/Div)

LPGOOD

(5V/Div)

VIN = 12V, V

CIN = 10μF, C

Time (2ms/Div)

IN_LDO

= 10μF x 2

OUT

= 1.5V

V

OUT2

(1V/Div)

V

LDRV

(2V/Div)

V

LPGOOD

(5V/Div)

V

IN_LDO

= 1.5V, C

= 10μF x 2, V

OUT

Time (100μs/Div)

DS8204L-04 April 2011www.richtek.com

OUT2

Short

Page 11

Applications Information

RT8204L

The RT8204L PWM controller provides the high efficiency,

excellent transient response, and high DC output accuracy

needed for stepping down high voltage batteries to

generate low voltage CPU core, I/O, and chipset RAM

supplies in notebook computers. RichTek's Mach

ResponseTM technology is specifically designed for

providing 100ns “instant-on” response to load steps while

maintaining a relatively constant operating frequency and

inductor operating point over a wide range of input voltages.

The topology circumvents the poor load transient timing

problems of fixed frequency current mode PWMs while

also avoiding the problems caused by widely varying

switching frequencies in conventional constant-on-time and

constant- off-time PWM schemes. The DRVTM mode PWM

modulator is specifically designed to have better noise

immunity for such a single output application.

PWM Operation

The Mach Response

TM

DRVTM mode controller relies on

,

the output filter capacitor's effective series resistance

(ESR) to act as a current-sense resistor, so the output

ripple voltage provides the PWM ramp signal. Referring to

the function diagrams of the RT8204L, the synchronous

high side MOSFET is turned on at the beginning of each

cycle. After the internal one shot timer expires, the

MOSFET is turned off. The pulse width of this one shot is

determined by the converter’s input and output voltages

to keep the frequency fairly constant over the input voltage

range. Another one-shot sets a minimum off-time (400ns

typ.).

On-Time Control (TON)

The on-time one-shot comparator has two inputs. One

input looks at the output voltage, while the other input

samples the input voltage and converts it to a current.

This input voltage proportional current is used to charge

an internal on-time capacitor. The on-time is the time

required for the voltage on this capacitor to charge from

zero volts to V

, thereby making the on-time of the high

OUT

side switch directly proportional to the output voltage and

inversely proportional to the input voltage. The

implementation results in a nearly constant switching

frequency without the need of a clock generator.

3.85p x R x V

t =

ON

TON OUT

(V 0.5)−

IN

And then the switching frequency is :

V

Frequency =

R

is a resistor connected from the input supply (VIN)

TON

OUT

(V x t

IN ON

)

to the TON pin.

Mode Selection (EN/DEM) Operation

The EN/DEM pin enables the supply. When EN/DEM is

tied to VDD, the controller is enabled and operates in

diode-emulation mode. When the EN/DEM pin is floating,

the RT8204L will operate in forced-CCM mode.

Diode-Emulation Mode (EN/DEM = High)

In diode-emulation mode, the RT8204L automatically

reduces switching frequency at light load conditions to

maintain high efficiency. This reduction of frequency is

achieved smoothly and without increasing VOUT ripple or

load regulation. As the output current decreases from

heavy-load condition, the inductor current is also reduced,

and eventually comes to the point when its valley touches

zero current, which is the boundary between continuous

conduction and discontinuous conduction modes. By

emulating the behavior of diodes, the low side MOSFET

allows only partial negative current when the inductor

freewheeling current becomes negative. As the load current

is further decreased, it takes longer and longer to discharge

the output capacitor to the level that requires the next

“ON” cycle. The on-time is kept the same as that in the

heavy-load condition. In reverse, when the output current

increases from light load to heavy load, the switching

frequency increases to the preset value as the inductor

current reaches the continuous condition. The transition

load point to the light load operation can be calculated as

follows (Figure 1) :

(V V )

−

I x t

LOAD ON

≈

IN OUT

2L

where tON is the On-time.

DS8204L-04 April 2011 www.richtek.com

11

Page 12

RT8204L

I

L

Slope = (VIN -V

0

t

ON

OUT

) / L

I

L, PEAK

I

LOAD

t

= I

L, PEAK

/ 2

Figure 1. Boundary Condition of CCM/DEM

The switching waveforms may appear noisy and

asynchronous when light loading causes diode-emulation

operation, however, this is a normal operating condition

that results in high light load efficiency. Trade-offs in DEM

noise vs. light load efficiency are made by varying the

inductor value. Generally, low inductor values produce a

broader efficiency vs. load curve, while higher values result

in higher full-load efficiency (assuming that the coil

resistance remains fixed) and less output voltage ripple.

The disadvantages for using higher inductor values include

larger physical size and degraded load-transient response

(especially at low input voltage levels).

I

L

I

L, PEAK

I

LOAD

I

LIM

0

t

Figure 2. Valley Current Limit

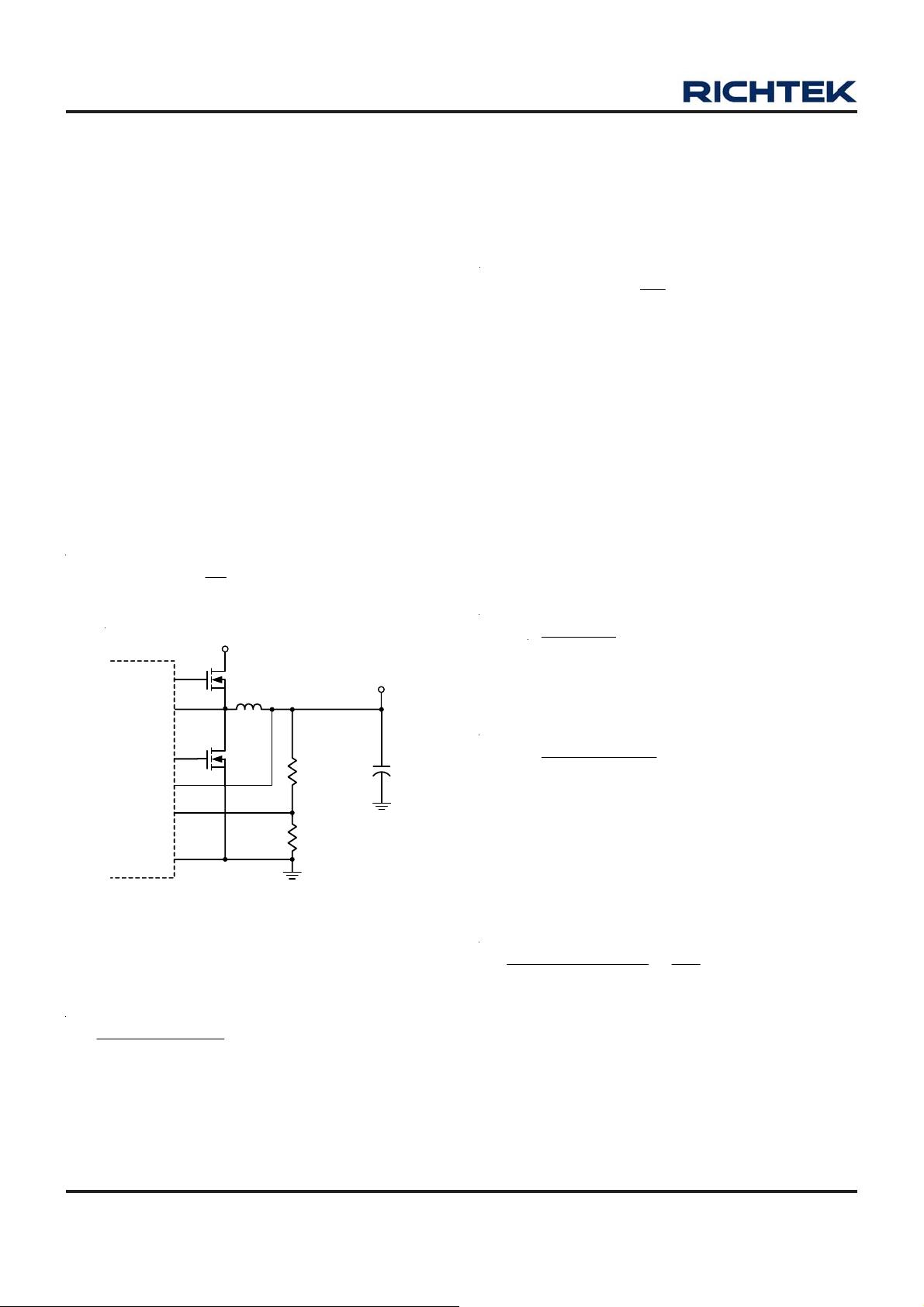

Current sensing of the RT8204L can be accomplished in

two ways. Users can either use a current-sense resistor

or the on-state of the low side MOSFET (R

DS(ON)

). For

resistor sensing, a sense resistor is placed between the

source of low side MOSFET and PGND (Figure 3(a)).

R

sensing is more efficient and less expensive (Figure

DS(ON)

3(b)). However, there is a compromise between current

limit accuracy and sense resistor power dissipation.

PHASE

LGATE

Forced-CCM Mode (EN/DEM = floating)

The low noise, forced-CCM mode (EN/DEM = floating)

disables the zero crossing comparator, which controls

the low side switch on-time. This causes the low side

gate-drive waveform to become the complement of the

high-side gate-drive waveform. This in turn causes the

inductor current to reverse at light loads as the PWM loop

to maintain a duty ratio V

OUT/VIN

. The benefit of forced-

CCM mode is to keep the switching frequency fairly

constant, but it comes at a cost. The no-load battery

current can be as high as 10mA to 40mA, depending on

the external MOSFETs.

Current Limit Setting (OCP)

The RT8204L has a cycle-by-cycle current limiting control.

The current limit circuit employs a unique“valley” current

sensing algorithm. If the magnitude of the current-sense

signal at OC is above the current-limit threshold, the PWM

is not allowed to initiate a new cycle (Figure 2).

OC

R

ILIM

(a)

PHASE

LGATE

OC

R

ILIM

(b)

Figure 3. Current Sense Methods

In both cases, the R

resistor between the OC pin and

ILIM

PHASE pin sets the over current threshold. This resistor

R

is connected to a 20μA current source within the

ILIM

RT8204L which is turned on when the low side MOSFET

turns on. When the voltage drop across the sense resistor

or low side MOSFET equals the voltage across the R

ILIM

resistor, positive current limit will activate. The high side

12

DS8204L-04 April 2011www.richtek.com

Page 13

MOSFET will not be turned on until the voltage drop across

the sense element (resistor or MOSFET) falls below the

voltage across the R

resistor.

ILIM

Choose a current limit resistor by the following equation :

I x R

R =

ILIM

LIMIT SENSE

20μA

Carefully observe the PC board layout guidelines to ensure

that noise and DC errors do not corrupt the current sense

signal seen by OC and PGND. Mount the IC close to the

low-side MOSFET and sense resistor with short, direct

traces, making a Kelvin sense connection to the sense

resistor.

MOSFET Gate Driver (UGATE, LGA TE)

The high side driver is designed to drive high current, low

R

N-MOSFET(s). When configured as a floating driver,

DS(ON)

5V bias voltage is delivered from VDDP supply. The average

drive current is proportional to the gate charge at VGS =

5V times the switching frequency. The instantaneous drive

current is supplied by the flying capacitor between BOOT

and PHASE pins.

A dead time to prevent shoot through is internally

generated between high side MOSFET off to low side

MOSFET on, and low side MOSFET off to high side

MOSFET on.

The low side driver is designed to drive high current, low

R

N-MOSFET(s). The internal pull down transistor

DS(ON)

that drives LGATE low is robust, with a 0.6Ω typical on

resistance. A 5V bias voltage is delivered form VDDP

supply. The instantaneous drive current is supplied by the

flying capacitor between VDDP and PGND.

For high current applications, some combinations of high

and low side MOSFETs might be encountered that will

cause excessive gate-drain coupling, which can lead to

efficiency-killing, EMI producing shoot through currents.

This is often remedied by adding a resistor in series with

BOOT, which increases the turn-on time of the high side

MOSFET without degrading the turn-off time (Figure 4).

RT8204L

V

+5V

BOOT

UGATE

PHASE

R

Figure 4. Reducing the UGATE Rise Time

Power Good Output (PGOOD)

The power good output is an open-drain output and requires

a pull up resistor. When the output voltage is 15% above

or 10% below its set voltage, PGOOD gets pulled low. It

is held low until the output voltage returns to within these

tolerances once more. In soft start, PGOOD is actively

held low and is allowed to transition high until soft start is

over and the output reaches 93% of its set voltage. There

is a 2.5μs delay built into PGOOD circuitry to prevent

false transition.

POR, UVLO and Soft-Start

Power on reset (POR) occurs when VDD rises above to

approximately 4.1V. The RT8204L will reset the fault latch

and prepare the PWM for operation. At below 3.7V (min),

the VDD under voltage lockout (UVLO) circuitry inhibits

switching by keeping UGATE and LGATE low.

A built in soft-start is used to prevent surge current from

power supply input after EN/DEM is enabled. It clamps

the ramping of internal reference voltage which is compared

with the FB signal. The typical soft-start duration is 1.5ms.

Output Over Voltage Protection (OVP)

The output voltage can be continuously monitored for over

voltage protection. When the output voltage exceeds 15%

of its set voltage threshold, over voltage protection is

triggered and the low side MOSFET is latched on. This

activates the low side MOSFET to discharge the output

capacitor.

IN

The RT8204L is latched once OVP is triggered and can

only be released by VDD or EN/DEM power-on reset. There

is a 20μs delay built into the over voltage protection circuit

to prevent false transitions.

DS8204L-04 April 2011 www.richtek.com

13

Page 14

RT8204L

Output Under Voltage Protection (UVP)

The output voltage can be continuously monitored for under

voltage protection. When the output voltage is less than

70% of its set voltage threshold, under voltage protection

is triggered and then both UGATE and LGATE gate drivers

are forced low. In order to remove the residual charge on

the output capacitor during the under voltage period, if

PHASE is greater than 1V, the LGATE is forced high until

PHASE is lower than 1V. There is 2.5μs delay built into

the under voltage protection circuit to prevent false

transitions. During soft-start, the UVP will be blanked

around 4.5ms.

Output V oltage Setting (FB)

The output voltage can be adjusted from 0.75V to 3.3V by

setting the feedback resistors R7 and R8 (Figure 5).

Choose R8 to be approximately 10kΩ, and solve for R7

using the equation :

R7

V = V x 1 +

OUT FB

⎛⎞

⎜⎟

R8

⎝⎠

where VFB is 0.75V.

V

IN

UGATE

PHASE

LGATE

R7

VOUT

FB

R8

GND

V

OUT

Find a low pass inductor having the lowest possible DC

resistance that fits in the allowed dimensions. Ferrite cores

are often the best choice, although powdered iron is

inexpensive and can work well at 200kHz. The core must

be large enough not to saturate at the peak inductor current

(I

) :

PEAK

LIR

I = I + x I

PEAK LOAD(MAX) LOAD(MAX)

⎛⎞

⎜⎟

2

⎝⎠

Output Capacitor Selection

The output filter capacitor must have ESR low enough to

meet output ripple and load transient requirement, yet have

high enough ESR to satisfy stability requirements. Also,

the capacitance value must be high enough to absorb the

inductor energy going from a full load to no load condition

without tripping the OVP circuit.

For CPU core voltage converters and other applications

where the output is subject to violent load transient, the

output capacitor's size depends on how much ESR is

needed to prevent the output from dipping too low under a

load transient. Ignoring the sag due to finite capacitance :

V

P P

ESR

≤

−

I

LOAD(MAX)

In non-CPU applications, the output capacitor's size

depends on how much ESR is needed to maintain at an

acceptable level of output voltage ripple :

V

P P

ESR

≤

LIR x I

−

LOAD(MAX)

Organic semiconductor capacitor(s) or special polymer

capacitor(s) are recommended.

Output Capacitor Stability

Figure 5. Setting The Output Voltage

Output Inductor Selection

The switching frequency (on-time) and operating point

(% ripple or LIR) determine the inductor value as follows :

t x (V V )

ON IN OUT

L =

LIR x I

14

−

LOAD(MAX)

Stability is determined by the value of the ESR zero relative

to the switching frequency. The point of instability is given

by the following equation :

f = <

2 x x ESR x C 4

1

π

OUT

f

SW

Do not put high value ceramic capacitors directly across

the outputs without taking precautions to ensure stability.

Large ceramic capacitors can have a high-ESR zero

frequency and cause erratic and unstable operation.

However, it is easy to add sufficient series resistance by

placing the capacitors a couple of inches downstream from

the inductor and connecting VOUT or the FB divider close

to the inductor.

DS8204L-04 April 2011www.richtek.com

Page 15

RT8204L

There are two related but distinct ways, double pulsing

and feedback loop instability to identify the unstable

operation.

Double pulsing occurs due to noise on the output or

because the ESR is too low such that there is not enough

voltage ramp in the output voltage signal. This“fools” the

error comparator into triggering a new cycle immediately

after the 400ns minimum off-time period has expired.

Double pulsing is more annoying than harmful, resulting

in nothing worse than increased output ripple. However, it

may indicate the possible presence of loop instability,

which is caused by insufficient ESR.

Loop instability can result in oscillation at the output after

line or load perturbations and trip the over voltage

protection latch or cause the output voltage to fall below

the tolerance limit.

The easiest method for stability checking is to apply a

very zero-to-max load transient and carefully observe the

output-voltage-ripple envelope for overshoot and ringing. It

helps to simultaneously monitor the inductor current with

an AC probe. Do not allow more than one ringing cycle

after the initial step response under shoot or over shoot.

LDO Normal Operation

The RT8204L LDO controls an N-MOSFET to produce a

tightly regulated output voltage from higher supply voltage.

It takes 5V power supply for controller and draws maximally

400μA while operating.

The feedback voltage is regulated to compare with the

internal 0.75V reference voltage. To set the output voltage,

feedback the conjunction of a resistive voltage divider from

output node to ground for the LFB pin.

Depending upon the input voltage used for the device, the

LDRV pin can pull up near to VDD. Thus, the device can

be used to regulate a large range of output voltage by

careful selection of the external MOSFETs.

The RT8204L LDO includes an active high enable control

(LEN pin) used to turn on RT8204L LDO. If this pin is

pulled low, the LDRV pin is pulled low, turning off the

N-MOSFET. If this pin is pulled higher than 1.2V, the LDRV

pin is enabled.

The RT8204L LDO contains a power good output pin

(LPGOOD pin), which is an open drain output that pulled

low if the output is below the power good threshold

(typically 90% of the programmed output voltage, or 93%

at start up). The power good detection is active if the

RT8204L LDO is enabled.

Also included is an under voltage protection circuit that

monitors the output voltage. If the output voltage drops

below 50% (typical) of nominal, as would occur during

over current or short condition, the RT8204L LDO will pull

the LDRV pin low and latch off. The RT8204L LDO is

latched once UVP is triggered and can only be relieved

by VDD or LEN power on reset.

LDO Driver and Stability Design

The drive output (LDRV pin) is sink/source capable. The

sink current is typically 2mA, while the source current is

typically 2mA in normal operation.

The drive output is also used for stabilizing the loop of the

system using different types of output capacitors. The

components listed in the table below are used.

Table 1. LDO Configuration and Compensation

LDO Configuration Compensator

Input

Voltage

1.25V 1.05V 33nF 39pF 82Ω

1.5V 1.05V 33nF 47pF 43Ω

1.5V 1.25V 33nF 47pF 30Ω

1.8V 1.5V 33nF 39pF 100Ω

Note : test condition is output capacitor 220μF (ESR : 9 to

25mΩ) or 100μF (ESR : 9 to 15mΩ) +MLCC 10μF output

current is from 0.1A to 5A

Outpu t

Voltage

C9 C10 R9

LDO Output V oltage Protection(UVP)

The RT8204L LDO has output under voltage protection

that monitors at the output to check if RT8204L :

(a) LDO output voltage is less than 50% (typical) of its

nominal value and

(b) V

is within 900mV (typical) of its maximum.

LDRV

This provides inherent immunity to under voltage shut down

at start up since V

has a slow rate of rising at this

LDRV

moment. If both of these criteria are met, the output is

shut down by means of pulling V

to ground

LDRV

immediately.

DS8204L-04 April 2011 www.richtek.com

15

Page 16

RT8204L

If the VDDP input is supplied prior to the LDO_VIN, it

could accidentally meet the UVP fault protection. To avoid

entering UVP latch off, use the enable control (LEN pin)

VDDP

VTH(UV) = 0.88V

LDO_VIN

VTH(LEN) = 1.2V

LEN

RT8204L Supply Comes Up Before MOSFET Drain Supply

VDDP

VTH(UV) = 0.88V

LDO_VIN

to turn the system on after all power supplies are ready.

Refer to the power sequencing example below (Figure 6).

VTH(LEN) occurs after VTH(UV) is reached

VTH(LEN) = 1.2V

LEN

MOSFET Drain Supply Comes Up Before RT8204L Supply

Figure 6. Power Supply Sequencing

LDO Output Voltage Setting

The LFB pin connects directly to the inverting input of the

error amplifier, and the output voltage is set using external

resistors R11 and R12 (Figure 7). The following equation

is for adjusting the output voltage :

R11

V = V x 1 +

OUT LFB

where V

LFB

⎛⎞

⎜⎟

R12

⎝⎠

is 0.75V (typ.).

LDO Output Capacitor Selection

Low ESR capacitors such as Sanyo POSCAPs or

Panasonic SP-caps are recommended for bulk

capacitance, and ceramic bypass capacitors are

recommended for decoupling high frequency transients.

VTH(LEN) occurs after VTH(UV) is reached

LEN rising with VDDP shown

LDO Input Capacitor Selection

Low ESR capacitors such as Sanyo POSCAPs or

Panasonic SP-caps are recommended for the input

capacitors to provide better load transient response. If the

LDO input is connected from the output of buck converter

(V

), a 0.1μF ceramic capacitor will be sufficient.

OUT1

LDO_VIN (V

LDRV

R11

LFB

R12

)

OUT1

LDO_VOUT (V

OUT2

)

16

Figure 7. LDO Output Voltage Setting

DS8204L-04 April 2011www.richtek.com

Page 17

RT8204L

LDO MOSFET Selection

1.60

1.40

Four-Layer PCB

Low threshold N-MOSFETs are required. For the device

to work under all operating conditions, a maximum R

DS(ON)

must be met to ensure that the output will not go into

dropout :

VV

R = ( )

DS(ON)(MAX)

Note that R

DS(ON)

IN(MIN) OUT(MAX)

must be met for operating temperature

−

I

OUT(PEAK)

Ω

range at the minimum VGS condition.

Power consumptions of the N-MOSFETs should be taken

into consideration for the selection of various package

types.

Thermal Considerations

For continuous operation, do not exceed absolute

maximum junction temperature. The maximum power

dissipation depends on the thermal resistance of the IC

package, PCB layout, rate of surrounding airflow, and

difference between junction and ambient temperature. The

1.20

1.00

0.80

0.60

0.40

0.20

Maximum Power Dissipation (W) 1

0.00

0 25 50 75 100 125

Ambient Temperature (°C)

Figure 8. Derating Curve for the RT8204L Package

Layout Consideration

Layout is very important in high frequency switching

converter design. If designed improperly, the PCB could

radiate excessive noise and contribute to converter

instability. Certain points must be considered before

starting a layout for the RT8204L.

maximum power dissipation can be calculated by the

following formula :

` Connect RC low-pass filter from VDDP to VDD, 1μF and

20Ω are recommended. Place the filter capacitor close

P

where T

the ambient temperature, and θ

thermal resistance.

For recommended operating condition specifications of

the RT8204L, the maximum junction temperature is 125°C

and TA is the ambient temperature. The junction to ambient

D(MAX)

= (T

J(MAX)

− TA) /θ

J(MAX)

JA

is the maximum junction temperature, TA is

is the junction to ambient

JA

to the IC.

` Keep current limit setting network as close as possible

to the IC. Routing of the network should avoid coupling

to high-voltage switching node.

` Connections from the drivers to the respective gate of

the high side or low side MOSFET should be as short

as possible to reduce stray inductance.

thermal resistance, θJA, is layout dependent. For WQFN-

16L 3x3 packages, the thermal resistance, θJA, is 68°C/

W on a standard JEDEC 51-7 four-layer thermal test board.

The maximum power dissipation at TA = 25°C can be

calculated by the following formula :

` All sensitive analog traces and components such as

VOUT, FB, GND, EN/DEM, PGOOD, OC, VDD, and

TON should be placed away from high voltage switching

nodes such as PHASE, LGATE, UGATE, or BOOT

nodes to avoid coupling. Use internal layer(s) as ground

P

16L 3x3 package

The maximum power dissipation depends on the operating

ambient temperature for fixed T

resistance, θJA. For the RT8204L package, the derating

= (125°C − 25°C ) / (68°C/W) = 1.471W for WQFN-

D(MAX)

and thermal

J(MAX)

plane(s) and shield the feedback trace from power traces

and components.

` Current sense connections must always be made using

Kelvin connections to ensure an accurate signal, with

the current limit resistor located at the device.

curve in Figure 8 allows the designer to see the effect of

rising ambient temperature on the maximum power

dissipation.

` Power sections should connect directly to ground

plane(s) using multiple vias as required for current

handling (including the chip power ground connections).

Power components should be placed to minimize loops

and reduce losses.

DS8204L-04 April 2011 www.richtek.com

17

Page 18

RT8204L

Outline Dimension

D

D2

L

SEE DETAIL A

1

E

e

A

A3

A1

E2

1

2

b

DETAIL A

1

2

Pin #1 ID and Tie Bar Mark Options

Note : The configuration of the Pin #1 identifier is optional,

but must be located within the zone indicated.

Dimensions In Millimeters Dimensions In Inches

Symbol

Min Max Min Max

A 0.700 0.800 0.028 0.031

A1 0.000 0.050 0.000 0.002

A3 0.175 0.250 0.007 0.010

b 0.180 0.300 0.007 0.012

D 2.950 3.050 0.116 0.120

D2 1.300 1.750 0.051 0.069

E 2.950 3.050 0.116 0.120

E2 1.300 1.750 0.051 0.069

e 0.500 0.020

L 0.350 0.450

Richtek Technology Corporation

Headquarter

5F, No. 20, Taiyuen Street, Chupei City

Hsinchu, Taiwan, R.O.C.

Tel: (8863)5526789 Fax: (8863)5526611

0.014 0.018

W-Type 16L QFN 3x3 Package

Richtek Technology Corporation

Taipei Office (Marketing)

5F, No. 95, Minchiuan Road, Hsintien City

Taipei County, Taiwan, R.O.C.

Tel: (8862)86672399 Fax: (8862)86672377

Email: marketing@richtek.com

Information that is provided by Richtek Technology Corporation is believed to be accurate and reliable. Richtek reserves the right to make any change in circuit

design, specification or other related things if necessary without notice at any time. No third party intellectual property infringement of the applications should be

guaranteed by users when integrating Richtek products into any application. No legal responsibility for any said applications is assumed by Richtek.

DS8204L-04 April 2011www.richtek.com

18

Page 19

Loading...

Loading...