Page 1

®

3A, 1MHz, Synchronous Step-Down Converter

RT8061A

General Description

The RT8061A is a high efficiency synchronous, step-down

DC/DC converter. Its input voltage ra nge from 2.7V to 5.5V

that provides an adjustable regulated output voltage from

0.6V to V

while delivering up to 3A of output current.

IN

The internal synchronous low on resistance power

switches increase efficiency and eliminate the need for

an external Schottky diode. The switching frequency is

fixed internally at 1MHz. The 100% duty cycle provides

low dropout operation, hence extending battery life in

portable systems. Current mode operation with internal

compensation allows the transient response to be

optimized over a wide range of loa ds and output ca pacitors.

The RT8061A is operated in PWM/PSM mode to a chieve

high efficiency for a wide load range. The RT8061A is

available in a W DFN-10L 3x3 pack age.

Ordering Information

RT8061A

Package Type

QW : WDFN-10L 3x3 (W-Type)

Lead Plating System

Z : ECO (Ecological Element with

Halogen Free and Pb free)

Note :

Richtek products are :

` RoHS compliant and compatible with the current require-

ments of IPC/JEDEC J-STD-020.

` Suitable for use in SnPb or Pb-free soldering processes.

Features

zz

High Efficiency : Up to 95%

z

zz

zz

z Low R

zz

Internal Switches : 69m

DS(ON)

ΩΩ

Ω/49m

ΩΩ

= 5V

zz

z Fixed Frequency : 1MHz

zz

zz

z No Schottky Diode Required

zz

zz

z 0.6V Reference Allows Low Output Voltage

zz

zz

z PWM/PSM Mode Operation

zz

zz

z Low Dropout Operation : 100% Duty Cycle

zz

zz

z OCP, UVP, OVP, OTP

zz

z RoHS Compliant and Halogen Free

Applications

z Portable Instruments

z Battery-Powered Equipment

z Notebook Computers

z Distributed Power Systems

z IP Phones

z Digital Camera s

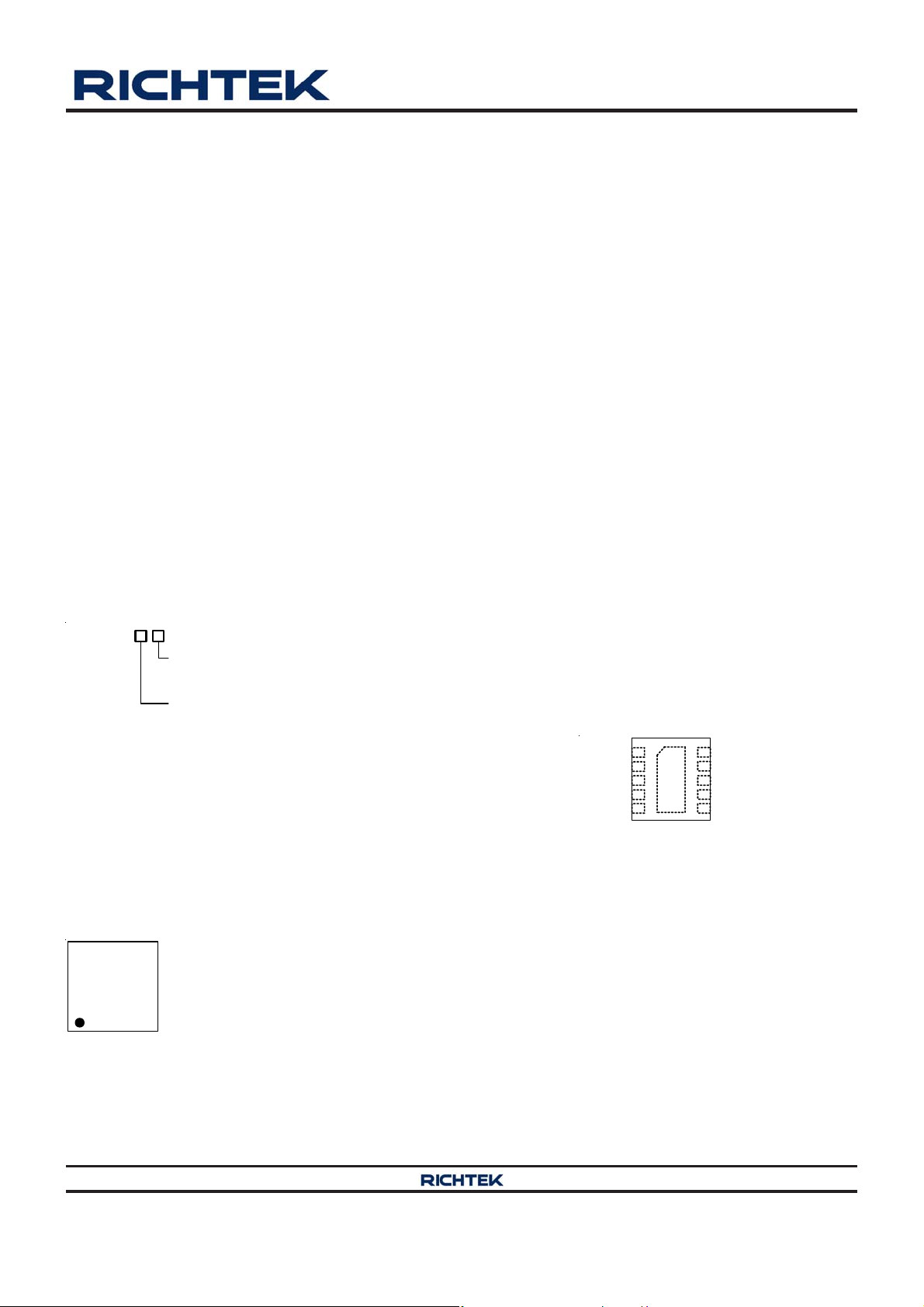

Pin Configurations

(TOP VIEW)

GND

11

10

PVIN

9

PVIN

8

SVIN

7

NC

6

FB

NC

LX

LX

PGOOD

EN

WDFN-10L 3x3

1

2

3

4

5

ΩΩ

Ω at V

ΩΩ

IN

Marking Information

11 : Product Code

11 YM

DNN

Copyright 2012 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS8061A-04 September 2012 www.richtek.com

©

YMDNN : Date Code

1

Page 2

RT8061A

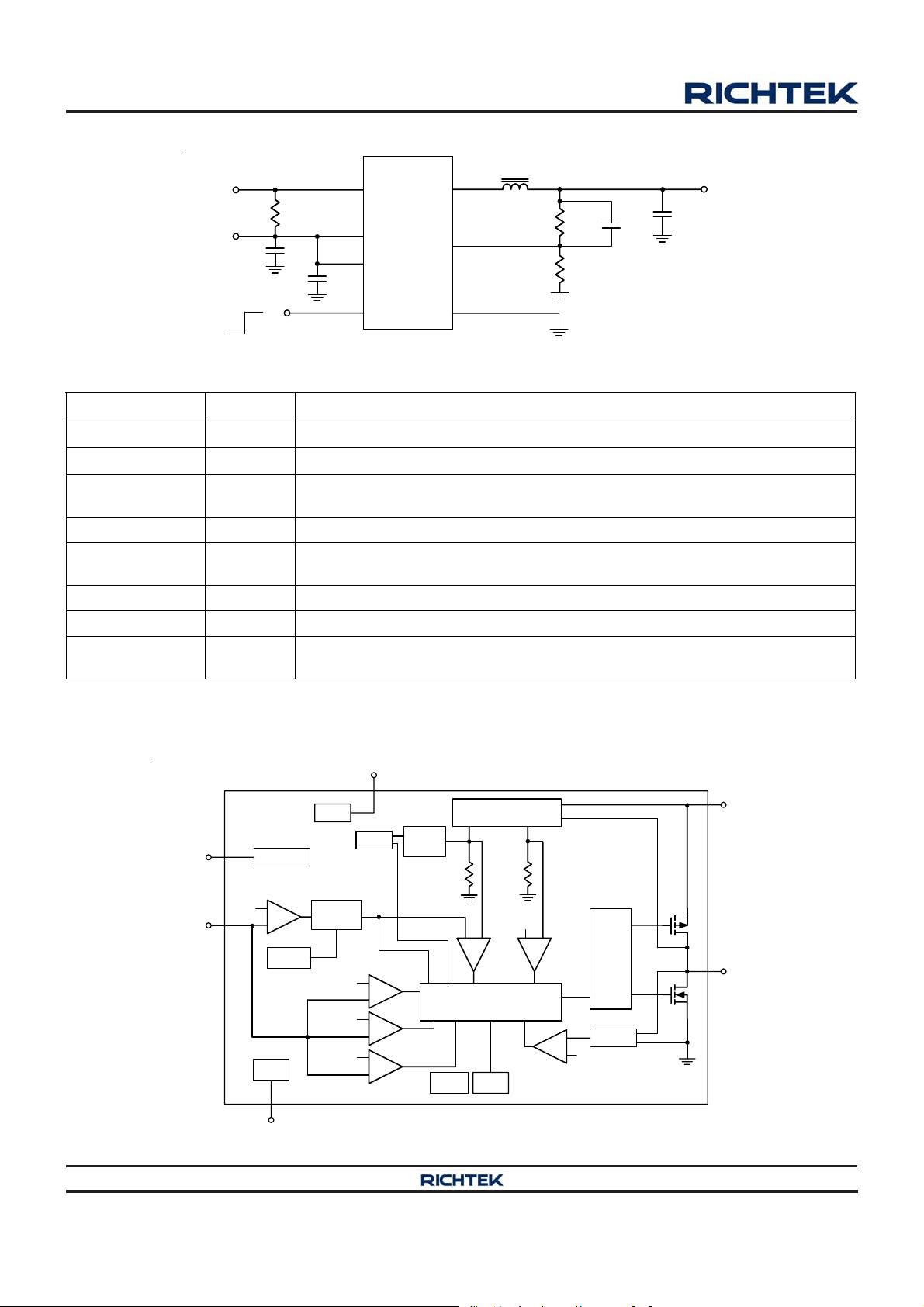

Typical Application Circuit

RT8061A

4

PGOOD

V

IN

Chip Enable

R1

PGOOD

9, 10

C1

8

5

PVIN

SVIN

EN

C

IN

LX

FB

11 (Exposed Pad)

GND

Functional Pin Description

Pin No. Pin Name Pin Function

1, 7 NC No Internal Connection.

2, 3 LX Switch Node. Connection this pin to the inductor.

2, 3

6

L

OUT

R

R

FB1

FB2

V

OUT

C

C

FF

OUT

4 PGOOD

Power Good Indicator. This pin is an open drain logic output that is pulled to

ground when the output voltage is less than 90% of the target output voltage.

5 EN Enable Control. Pull high to turn on. Do not float.

6 FB

Feed back . Th is pin rec eiv es the fe edb ac k vol tag e fro m a resi stiv e vo lta ge div id er

connected across the output.

8 SVIN Signal Input. Decouple this pin to GND with at least 1μF ceramic cap.

9, 10 PVIN Power Input. Decouple this pin to GND with at least 4.7μF ceramic cap.

11 (Exposed Pad) GND

The exposed pad must be soldered to a large PCB and connected to GND for

maximum power dissipation.

Function Block Diagram

0.6V

PGOOD

EN

PGOOD

FB

EN

Output

Clamp

EN

OSC

Slope

Com

ISEN

OC

Limit

PVIN

Int-SS

0.72V

OV

0.54V

POR

SVIN

Copyright 2012 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

©

0.4V

PGOOD

UV

Control

Logic

OTP

V

REF

Driver

LX

NISEN

Zero Current

DS8061A-04 September 2012www.richtek.com

2

Page 3

RT8061A

Absolute Maximum Ratings (Note 1)

z Supply Input V oltage, PVIN, SVIN-------------------------------------------------------------------------------- −0.3V to 6.5V

z LX Pin V oltage--------------------------------------------------------------------------------------------------------- (V

z Other I/O Pin Voltage------------------------------------------------------------------------------------------------ −0.3V to 6.5V

z Power Dissipation, P

@ TA = 25°C

D

WDNF-10L 3x3-------------------------------------------------------------------------------------------------------- 1.429W

z Package Thermal Resistance (Note 2)

W DFN-10L 3x3, θJA-------------------------------------------------------------------------------------------------- 70°C/W

WDFN-10L 3x3

z Junction T emperature------------------------------------------------------------------------------------------------ 150°C

z Lead Temperature (Soldering, 10 sec.)-------------------------------------------------------------------------- 260°C

z Storage T emperature Range --------------------------------------------------------------------------------------- −65°C to 150°C

z ESD Susceptibility (Note 3)

-------------------------------------------------------------------------------------------------- 8.2°C/W

θJC

HBM (Human Body Model)----------------------------------------------------------------------------------------- 2kV

Recommended Operating Conditions (Note 4)

0.3V) to 6.8V

IN +

z Supply Input V oltage, PVIN, SVIN--------------------------------------------------------------------------------

z Junction T emperature Range---------------------------------------------------------------------------------------

z Ambient T emperature Range---------------------------------------------------------------------------------------

2.7V to 5.5V

−40°C to 125°C

−40°C to 85°C

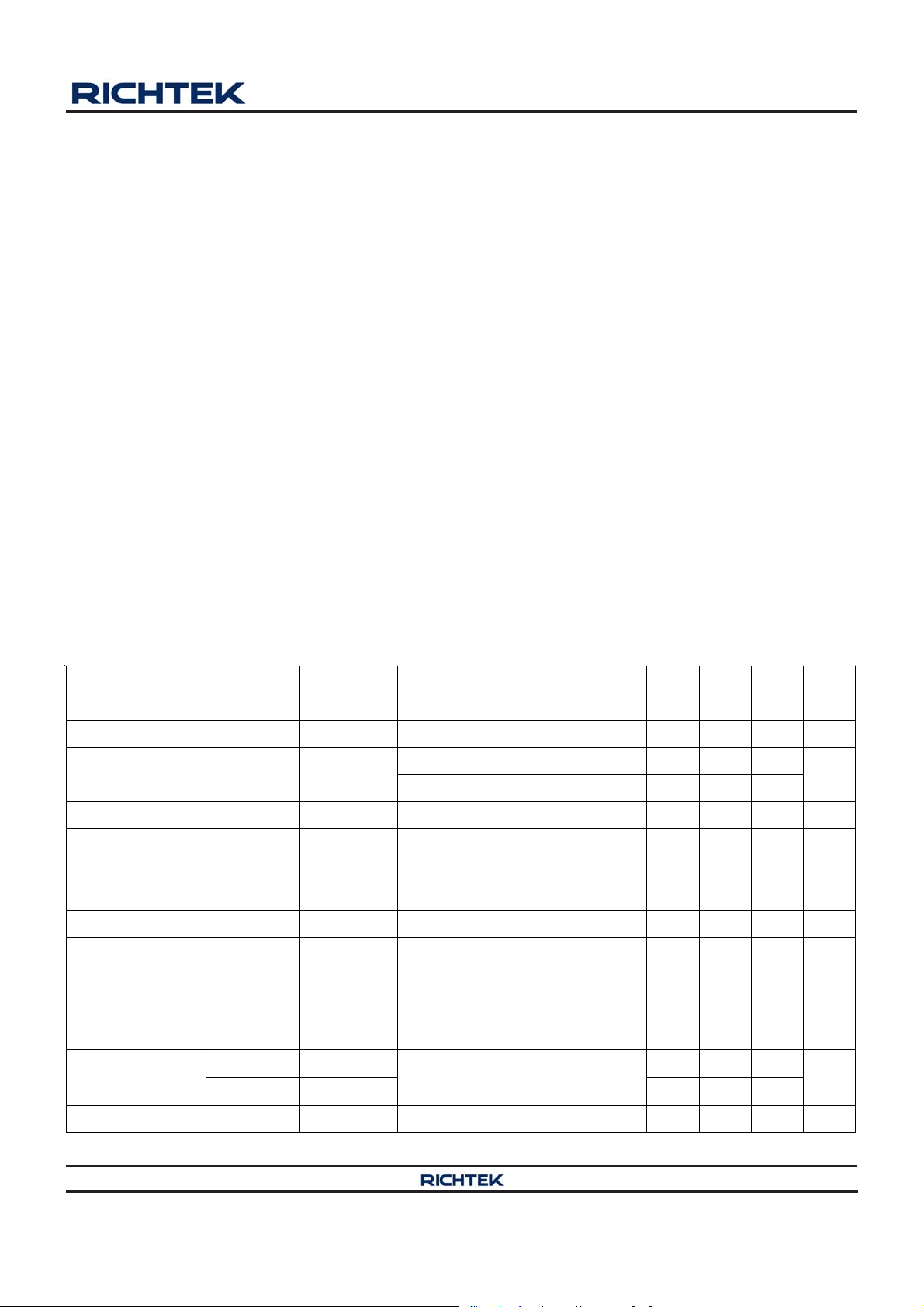

Electrical Characteristics

(VIN = 3.3V, T

Feedback Reference Voltage V

Feedback Leakage Current IFB -- 0.1 0.4 μA

DC Bias Current

Output Voltage Line Regulation V

Output Voltage Load Regulation I

Switch Leakage Current VEN = 0A -- -- 1 μA

Switching Frequency 0.8 1 1.2 MHz

Switch On Resistance, High R

Switch On Resistance, Low R

PMOS Current Lim it (latch-off) I

Under Voltage Lock out

Threshold

= 25°C, unless otherwise specified)

A

Parameter Symbol Test Conditions Min Typ Max Unit

0.594 0.6 0.606 V

REF

Active , V

0.7V, Not Switching -- 110 140

FB =

μA

Shutdown -- -- 1

2.7V to 5.5V I

IN =

= 0A to 3A −1 -- 1 %

OUT

DS(ON)_P

DS(ON)_N

LIM

V

V

4 -- -- A

5V -- 69 -- mΩ

IN =

5V -- 49 -- mΩ

IN =

= 0A -- 0.3 -- %/V

OUT

VIN Rising 2.2 2.4 2.6

V

UVLO

V

IN Falling 2 2.2 2.4

V

EN Threshold

Voltage

Logic-High VIH 1.6 -- -Logic-Low V

IL

-- -- 0.4

V

EN Pull Low Resistance -- 500 -- kΩ

Copyright 2012 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS8061A-04 September 2012 www.richtek.com

©

3

Page 4

RT8061A

Parameter Symbol Test Conditions Min Typ Max Unit

Ove r T emperature

Protection (latch-off)

Soft-Start Time tSS 500 -- -- μs

V

Discharge Resistance -- 1 00 -- Ω

OUT

V

Over Vol tage

OUT

Protection (latch-off, delay

time = 10μs)

V

Under Vol tage

OUT

Lockout Threshold

(latch-off)

Power Good Measured FB, With Respect to V

Power Good Hysteresis -- 5 -- %

Note 1. Stresses beyond those listed “Absolute Maximum Ratings” may cause permanent damage to the device. These are

stress ratings only, and functional operation of the device at these or any other conditions beyond those indicated in

the operational sections of the specifications is not implied. Exposure to absolute maximum rating conditions may

affect device reliability.

Note 2. θ

Note 3. Devices are ESD sensitive. Handling precaution is recommended.

Note 4. The device is not guaranteed to function outside its operating conditions.

is measured at T

JA

measured at the exposed pad of the package.

= 25°C on a high effective thermal conductivity four-layer test board per JEDEC 51-7. θJC is

A

-- 150 -- °C

T

SD

115 120 130 %

57 66 75 %

85 90 -- %

REF

Copyright 2012 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

4

©

DS8061A-04 September 2012www.richtek.com

Page 5

Typical Operating Characteristics

RT8061A

Efficiency vs. Load Current

100

98

96

V

V

IN

V

IN

= 4.2V

OUT

94

92

Efficiency (%)

90

88

86

00.511.522.53

Load Current (A)

Efficiency vs. Load Current

100

95

90

85

Eff iciency (%)

80

75

70

00.511.522.53

V

IN

Load Current (A)

= 3.3V

V

OUT

V

IN

= 1.05V

= 5V

= 3.3V

= 5V

Output Voltage (V)

Efficiency vs. Load Current

100

98

96

94

92

= 3.3V

V

V

OUT

90

88

Eff iciency (%)

86

84

82

80

00.511.522.53

V

IN

Load Current (A)

Output Voltage vs . Output Current

1.820

1.812

1.804

V

= 3.3V

1.796

1.788

1.780

0 0.6 1.2 1.8 2.4 3

Output Current (A)

IN

V

= 5V

IN

V

OUT

= 5V

IN

= 1.8V

= 1.8V

Current Limit vs. Input Voltage

7.0

6.5

6.0

5.5

5.0

4.5

Curr ent Limit (A)

4.0

3.5

V

= 1.05V

3.0

2.5 3 3.5 4 4.5 5 5.5

OUT

Input Voltage (V)

Copyright 2012 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

©

7.0

6.2

5.4

4.6

Curr ent Limit (A)

3.8

3.0

Current Limit vs. Temperature

V

= 5V

IN

V

= 3.3V

IN

V

= 1.05V

OUT

-50 -25 0 25 50 75 100 125

Temperatur e (°C)

DS8061A-04 September 2012 www.richtek.com

5

Page 6

RT8061A

90

79

Ω

68

(m )

57

DS(ON)

R

46

35

V

OUT

(50mV/Div)

R

-50 -25 0 25 50 75 100 125

vs. Temperature

DS(ON)

P-MOSFET

N-MOSFET

V

= 5V

IN

Temperatur e (°C)

Load Transient Response

V

OUT

(50mV/Div)

I

OUT

(2A/Div)

V

OUT

(5mV/Div)

Load Transient Response

VIN = 5V, V

Time (50μs/Div)

OUT

= 1.8V, I

= 0.5A to 3A

OUT

Switching

I

OUT

(2A/Div)

V

OUT

(5mV/Div)

V

LX

(500mV/Div)

I

LX

(2A/Div)

VIN = 5V, V

Time (50μs/Div)

Switching

VIN = 5V, V

OUT

= 1.8V, I

OUT

= 1.5A to 3A

OUT

= 1.8V, I

OUT

= 3A

V

LX

(500mV/Div)

I

LX

(1A/Div)

V

OUT

(1V/Div)

V

LX

(2V/Div)

VIN = 5V, V

= 1.8V, I

OUT

OUT

Time (500ns/Div)

Over Voltage Protection

VIN = 5V, V

= 1.8V, I

OUT

= 1.5A

= 1A

OUT

Time (500ns/Div)

Copyright 2012 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

©

Time (10μs/Div)

DS8061A-04 September 2012www.richtek.com

6

Page 7

RT8061A

V

OUT

(1V/Div)

V

LX

(2V/Div)

V

IN

(2V/Div)

Under Voltage Protection

VIN = 5V, V

Time (5μs/Div)

Power On from V

OUT

IN

= 1.8V

I

LX

(5A/Div)

V

OUT

(1V/Div)

V

LX

(5V/Div)

V

IN

(2V/Div)

Over Current Protection

VIN = 5V, V

Time (2.5μs/Div)

Power Off from V

OUT

IN

= 1.8V

V

OUT

(1V/Div)

I

LX

(2A/Div)

V

EN

(5V/Div)

V

OUT

(1V/Div)

I

LX

(2A/Div)

V

= 1.8V, I

OUT

Time (2.5ms/Div)

Power On from EN

VIN = 5V, V

= 1.8V, I

OUT

OUT

OUT

= 3A

= 3A

V

OUT

(1V/Div)

I

LX

(2A/Div)

V

EN

(5V/Div)

V

OUT

(1V/Div)

I

LX

(2A/Div)

V

= 1.8V, I

OUT

Time (2.5ms/Div)

Power Off from EN

VIN = 5V, V

= 1.8V, I

OUT

OUT

OUT

= 3A

= 3A

Time (200μs/Div)

Copyright 2012 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

©

Time (40μs/Div)

DS8061A-04 September 2012 www.richtek.com

7

Page 8

RT8061A

)

Application Information

The RT8061A is a single-phase buck PWM converter. It

provides single feedback loop, current mode control with

fast tra nsient response. An internal 0.6V reference allows

the output voltage to be precisely regulated for low output

voltage application s. A fixed switching frequency (1MHz)

oscillator and internal compensation are integrated to

minimize external component count. Protection features

include over current protection, under voltage protection,

over voltage protection and over temperature protection.

PWM Operation

The RT8061A utilizes DEM control to improve light load

efficiency. Depending on the load current, the controller

automatically operates in Diode-Emulation Mode (DEM)

or in Continuous Conduction Mode (CCM) with fixedfrequency PWM.

At light load condition, the RT8061A automatically operates

in diode-emulation mode to reduce switching frequency

and improve efficiency. As the output current decreases

from heavy load condition, the inductor current is also

reduced and eventually comes to the point where its valley

touches zero current, which is the boundary between

continuous conduction and discontinuous conduction

modes. By emulating the behavior of diodes, the low side

MOSFET allows only partial negative current to flow when

the inductor freewheeling current reaches negative. As the

load current further decrea ses, it tak es longer and longer

to discharge the output capacitor to the level that that

requires the next UGA TE “ON” cycle. In contrast, when

the output current increa ses from light load to heavy load,

the switching frequency increa ses to the preset value a s

the inductor current reaches the continuous conduction.

The controller will then operate in continuous conduction

mode with 1MHz fixed PWM switching frequency .

Output Voltage Setting

Connect a resistive voltage divider at the FB between V

and GND to adjust the output voltage. The output voltage

is set according to the following equation :

R1

⎛⎞

V= V 1+

OUT FB

×

⎜⎟

R2

⎝⎠

where VFB is 0.6V (typ.).

OUT

V

OUT

R1

FB

R2

GND

Figure 1. Setting V

with a V oltage Divider

OUT

Chip Enable and Disable

The EN pin allows for power sequencing between the

controller bias voltage and another voltage rail. The

RT8061A remains in shutdown if the EN pin is lower tha n

400mV. When the EN pin rises above the VEN trip point,

the RT8061A begins a new initialization and soft-start cycle.

Internal Soft-Start

The RT8061A provides an internal soft-start function to

prevent large inrush current and output voltage overshoot

when the converter starts up. The Soft-Start (SS)

automatically begins once the chip is enabled. During softstart, the internal soft-start capacitor becomes charged

and generates a linear ramping up voltage across the

cap a citor. This voltage clamps the voltage at the FB pin,

causing PWM pulse width to increa se slowly and in turn

reduce the output surge current. The internal 0.6V

reference takes over the loop control once the internal

ramping-up voltage becomes higher tha n 0.6V .

UVLO Protection

The RT8061A ha s input U nder V oltage Lockout protection

(UVLO). If the input voltage exceeds the UVLO rising

threshold voltage (2.4V typ.), the converter resets and

prepares the PWM for operation. If the input voltage falls

below the UVLO falling threshold voltage during normal

operation, the device will stop switching. The UVLO rising

and falling threshold voltage has a hysteresis to prevent

noise-caused reset.

Inductor Selection

The switching frequency (on-time) and operating point (%

ripple or LIR) determine the inductor value as shown below :

VVV

×−

(

L =

OUT IN OUT

fLIRI V

×× ×

SW LOAD(MAX) IN

Copyright 2012 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

8

©

DS8061A-04 September 2012www.richtek.com

Page 9

RT8061A

where LIR is the ratio of the peak-to-pea k ripple current to

the average inductor current.

Find a low loss inductor having the lowest possible DC

resistance that fits in the allotted di mensions. Ferrite cores

are often the best choice, although powdered iron is

inexpensive and ca n work well at 200kHz. The core must

be large enough not to saturate at the peak inductor current

(I

) :

PEAK

LIR

⎛⎞

I = I I

PEAK LOAD(MAX) LOAD(MAX)

+×

⎜⎟

2

⎝⎠

The calculation above serves a s a general reference. To

further improve transient response, the output inductor

can be further reduced. This relation should be considered

along with the selection of the output cap a citor.

Input Capacitor Selection

High quality ceramic in put decoupling capacitor, such as

X5R or X7R, with values greater than 20μF are

recommended for the input ca pa citor. The X5R and X7R

ceramic ca pa citors are usually selected for power regulator

capacitors because the dielectric material has less

cap acita nce variation and more temperature stability .

V oltage rating a nd current rating are the key parameters

when selecting an input ca pa citor. Generally , selecting a n

input ca pa citor with voltage rating 1.5 ti mes greater tha n

the maximum input voltage is a conservatively safe design.

The input capacitor is used to supply the input RMS

current, which can be a pproximately calculated using the

following equation :

II 1

IN_RMS LOAD

=× ×−

VV

⎛⎞

OUT OUT

⎜⎟

VV

IN IN

⎝⎠

The next step is selecting a proper capacitor for RMS

current rating. One good design is using more than one

ca pacitor with low Equivalent Series Resistance (ESR) in

parallel to form a ca pa citor bank.

The input capacitance value determines the input ripple

voltage of the regulator. The input voltage ripple can be

a pproximately calculated using the f ollowing equation :

I0.25

V

IN

OUT(MAX)

Cf

Δ=

For example, if I

×

×

IN SW

OUT(MAX)

= 3A, CIN = 20μF, fSW = 1MHz,

the input voltage ripple will be 37.5mV.

Output Capacitor Selection

The output capacitor and the inductor form a low pass

filter in the buck topology. In steady state condition, the

ripple current flowing into/out of the capacitor results in

ripple voltage. The output voltage ripple (V

) can be

P-P

calculated by the following equation :

=× × +

V LIR I ESR

P-P LOAD(MAX)

⎛⎞

⎜⎟

⎝⎠

8C f

1

××

OUT SW

When load tran sient occurs, the output capa citor supplies

the load current before the controller can respond.

Therefore, the ESR will dominate the output voltage sag

during load tran sient. The output voltage undershoot (V

SAG

can be calculated by the following equation :

=Δ ×

VIESR

SAG LOAD

For a given output voltage sag specification, the ESR value

can be determined.

Another parameter that ha s influence on the output voltage

sag is the equivalent series inductance (ESL). The rapid

change in load current results in di/dt during transient.

Therefore, the ESL contributes to part of the voltage sag.

Using a capa citor with low ESL ca n obtain better transient

performance. Generally, using several capacitors

connected in parallel can have better tra nsient performance

than using a single capacitor for the sa me total ESR.

Unlike the electrolytic ca pa citor, the cera mic ca pacitor ha s

relatively low ESR and ca n reduce the voltage deviation

during load transient. However , the cera mic ca pacitor ca n

only provide low capa citance value. Theref ore, use a mixed

combination of electrolytic ca pacitor and cera mic ca pa citor

to obtain better transient performa nce.

Power Good Output (PGOOD)

PGOOD is a n open-drain type output and requires a pullup resistor. PGOOD is actively held low in soft-start,

standby, and shutdown. It is released when the output

voltage rises above 90% of nominal regulation point. The

PGOOD signal goes low if the output is turned off or is

10% below its nominal regulation point.

)

Copyright 2012 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS8061A-04 September 2012 www.richtek.com

©

9

Page 10

RT8061A

Under Voltage Protection (UVP)

The output voltage can be continuously monitored for under

voltage. When under voltage protection is enabled, both

UGA TE and LGATE gate drivers will be forced low if the

output is less than 66% of its set voltage threshold. The

UVP will be ignored for at lea st 3ms (typ.) after start up or

a rising edge on the EN threshold. T oggle EN threshold or

cycle VIN to reset the UVP fault latch and restart the

controller.

Over Voltage Protection (OVP)

The RT8061A is latched once OVP is triggered and ca n

only be relea sed by toggling EN threshold or cycling VIN.

There is a 10μs delay built into the over voltage protection

circuit to prevent false transition.

Over Current Protection (OCP)

The RT8061A provides over current protection by detecting

high side MOSFET peak inductor current. If the sensed

peak inductor current remains over 4A (typ) for 5 clock

cycles, OCP will be triggered. When OCP trips, the

RT8061A will shut down and enter Latch-Off Mode to stop

the energy transfer to the load. In Latch-Off Mode, the

RT8061A can only be reset by EN or VIN.

Thermal Shutdown (OTP)

The device implements internal thermal shutdown when

the junction temperature exceeds 150°C. When the OTP

function is triggered, the RT8061A shuts down a nd enters

Latch-Off Mode. In Latch-Off Mode, the RT8061A can be

reset by EN or VIN.

where T

the ambient temperature, a nd θ

is the maximum junction temperature, T

J(MAX)

is the junction to ambient

JA

A

thermal resistance.

For recommended operating condition specifications, the

maximum junction temperature is 125°C. The junction to

a mbient thermal resistance, θJA, is layout dependent. For

W DFN-10L 3x3 packages, the thermal resista nce, θJA, is

70°C/W on a standard JEDEC 51-7 f our-layer thermal test

board. The maximum power dissipation at TA = 25°C can

be calculated by the following formula :

P

= (125°C − 25°C) / (70°C/W) = 1.429W for

D(MAX)

W DF N-10L 3x3 pa ckage

The maximum power dissipation depends on the operating

ambient temperature for fixed T

and thermal

J(MAX)

resistance, θJA. The derating curve in Figure 2 allows the

designer to see the effect of rising ambient temperature

on the maximum power dissipation.

1.6

1.4

1.2

1.0

0.8

0.6

0.4

0.2

Maximum Power Dissipation (W) 1

0.0

0 25 50 75 100 125

Ambient Temperature ( °C)

Four-Layer PCB

is

Thermal Considerations

Figure 2. Derating Curve of Maxi mum Power Dissi pation

For continuous operation, do not exceed absolute

maximum junction temperature. The maximum power

dissipation depends on the thermal resistance of the IC

package, PCB layout, rate of surrounding airflow, and

difference between junction and a mbient temperature. The

maximum power dissipation can be calculated by the

following formula :

P

Copyright 2012 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

10

D(MAX)

= (T

©

J(MAX)

− TA) / θ

JA

DS8061A-04 September 2012www.richtek.com

Page 11

RT8061A

Layout Considerations

Layout is very important in high frequency switching

converter design. The PCB can ra diate excessive noise

and contribute to converter insta bility with improper layout.

Certain points must be considered before starting a layout

using the RT8061A.

` Make the tra ces of the main current paths a s short a nd

wide as possible.

` Put the input capa citor a s close a s possible to the device

pins (VIN and GND).

` LX node encounters high frequency voltage swings so

it should be kept in a small area. Keep sensitive

components away from the LX node to prevent stray

cap acitive noise pick-up.

` Ensure all feedback network connections are short a nd

direct. Place the feedba ck network a s close to the chi p

as possible.

` The GND pin a nd Exposed Pad should be connected to

a strong ground plane for heat sinking and noise

protection.

The output capacitor must

be placed near the IC.

C

OUT

V

OUT

R

PGOOD

V

IN

R

EN

LX should be connected to inductor by

wide and short trace. Keep sensitive

components away from this trace.

NC

LX

LX

PGOOD

EN

Input capacitor must be placed

as close to the IC as possible.

GND

1

2

3

GND

4

11

5

Figure 3. PCB Layout Guide

C

10

PVIN

9

PVIN

8

SVIN

7

NC

6

FB

The voltage divider must

be connected as close to

the device as possible.

IN1

R1

C

IN2

R2

V

OUT

` An example of PCB layout guide is shown in Figure 3.

for reference.

Copyright 2012 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

©

DS8061A-04 September 2012 www.richtek.com

11

Page 12

RT8061A

Outline Dimension

D

D2

L

E

e

A

A3

A1

1

b

E2

SEE DETAIL A

2

1

DETAIL A

1

2

Pin #1 ID a nd T ie Bar Mark Option s

Note : The configuration of the Pin #1 identifier is optional,

but must be located within the zone indicated.

Dimensions In Millimeters Dimensions In Inches

Symbol

Min Max Min Max

A 0.700 0.800 0.028 0.031

A1 0.000 0.050 0.000 0.002

A3 0.175 0.250 0.007 0.010

b 0.180 0.300 0.007 0.012

D 2.950 3.050 0.116 0.120

D2 2.300 2.650 0.091 0.104

E 2.950 3.050 0.116 0.120

E2 1.500 1.750 0.059 0.069

e 0.500 0.020

L 0.350 0.450

W-Type 10L DFN 3x3 Package

0.014 0.018

Richtek Technology Corporation

5F, No. 20, Taiyuen Street, Chupei City

Hsinchu, Taiwan, R.O.C.

Tel: (8863)5526789

Richtek products are sold by description only. Richtek reserves the right to change the circuitry and/or specifications without notice at any time. Customers should

obtain the latest relevant information and data sheets before placing orders and should verify that such information is current and complete. Richtek cannot

assume responsibility for use of any circuitry other than circuitry entirely embodied in a Richtek product. Information furnished by Richtek is believed to be

accurate and reliable. However, no responsibility is assumed by Richtek or its subsidiaries for its use; nor for any infringements of patents or other rights of third

parties which may result from its use. No license is granted by implication or otherwise under any patent or patent rights of Richtek or its subsidiaries.

DS8061A-04 September 2012www.richtek.com

12

Page 13

Loading...

Loading...