Page 1

®

RT7291A/B

6A, 23V, 500kHz, ACOTTM Synchronous Buck Converter

with LDO for System 5V

General Description

The RT7291A/B is a synchronous Buck converter with

Advanced Consta nt On-Time (ACOTTM) mode control. The

main control loop of RT7291A/B uses an ACOTTM mode

control which provides a very fast tra nsient response with

no external compensators. The RT7291A/B operates from

5V to 23V input voltage, provides a 5V LDO a nd a 300kHz

CLK to drive an external charge pump. OCP, UVP and

OVP are included in the RT7291A/B. This IC also provides

a 1.5ms internal soft-start function and a n open-drain power

good indicator.

Applications

Laptop Computers

T a blet PCs

Networking Systems

Servers

Personal Video Recorders

Flat Panel Television and Monitors

Distributed Power Systems

Features

5V to 23V Input Voltage Range

Up to 98% Duty for 2S Battery Application

PWM Frequency Fixed 500kHz

ACOT

Integrated MOSFET s

Support Output MLCC Stable

Internal Soft-Start (1.5ms typ)

Built-in OVP/UVP/OCP

Power Good Indicator

Fixed 300kHz VCLK to Support Charge Pump

Individual EN for PWM and LDO

Thermal Shutdown

TM

Mode Performs Fast T ra nsient Re sponse

ΩΩ

31m

Ω of High-Side MOSFET

ΩΩ

ΩΩ

20m

Ω of Low-Side MOSFET

ΩΩ

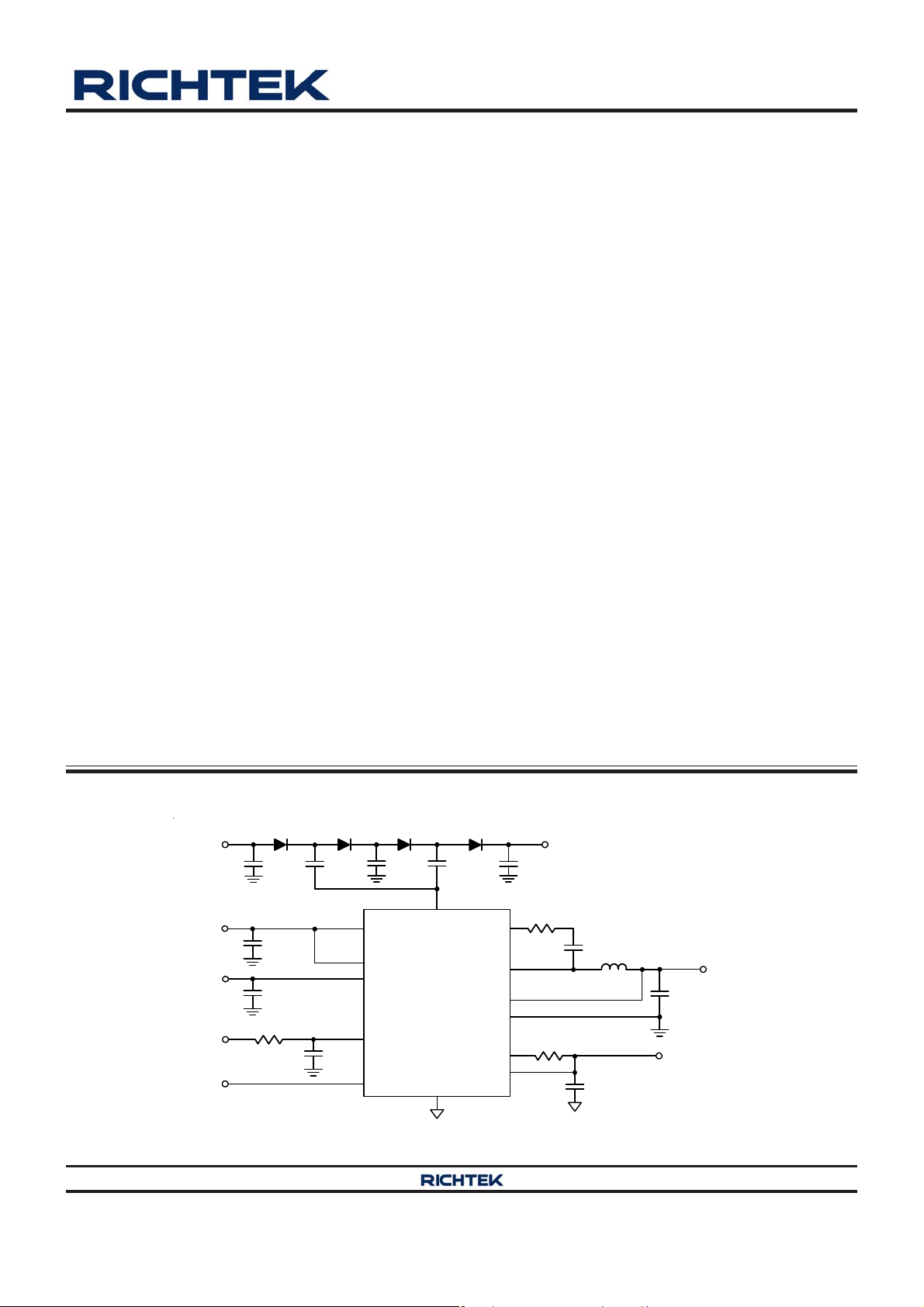

Simplified Application Circuit

V

OUT

C1 C2

D1

V

IN

V

LDO

V

OUT

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

©

C

IN

C

LDO

R

BYP

DS7291A/B-02 September 2015 www.richtek.com

D2 D3

VIN

EN

LDO

VBYP

C

BYP

ENLDO

C3 C4

CLK

RT7291A/B

AGND

D4

BOOT

SW

VOUT

PGND

PGOOD

VCC

C5

R

V

CP

R

B

PGOOD

C

B

L

C

VCC

V

OUT

C

OUT

V

CC

1

Page 2

RT7291A/B

Ordering Information

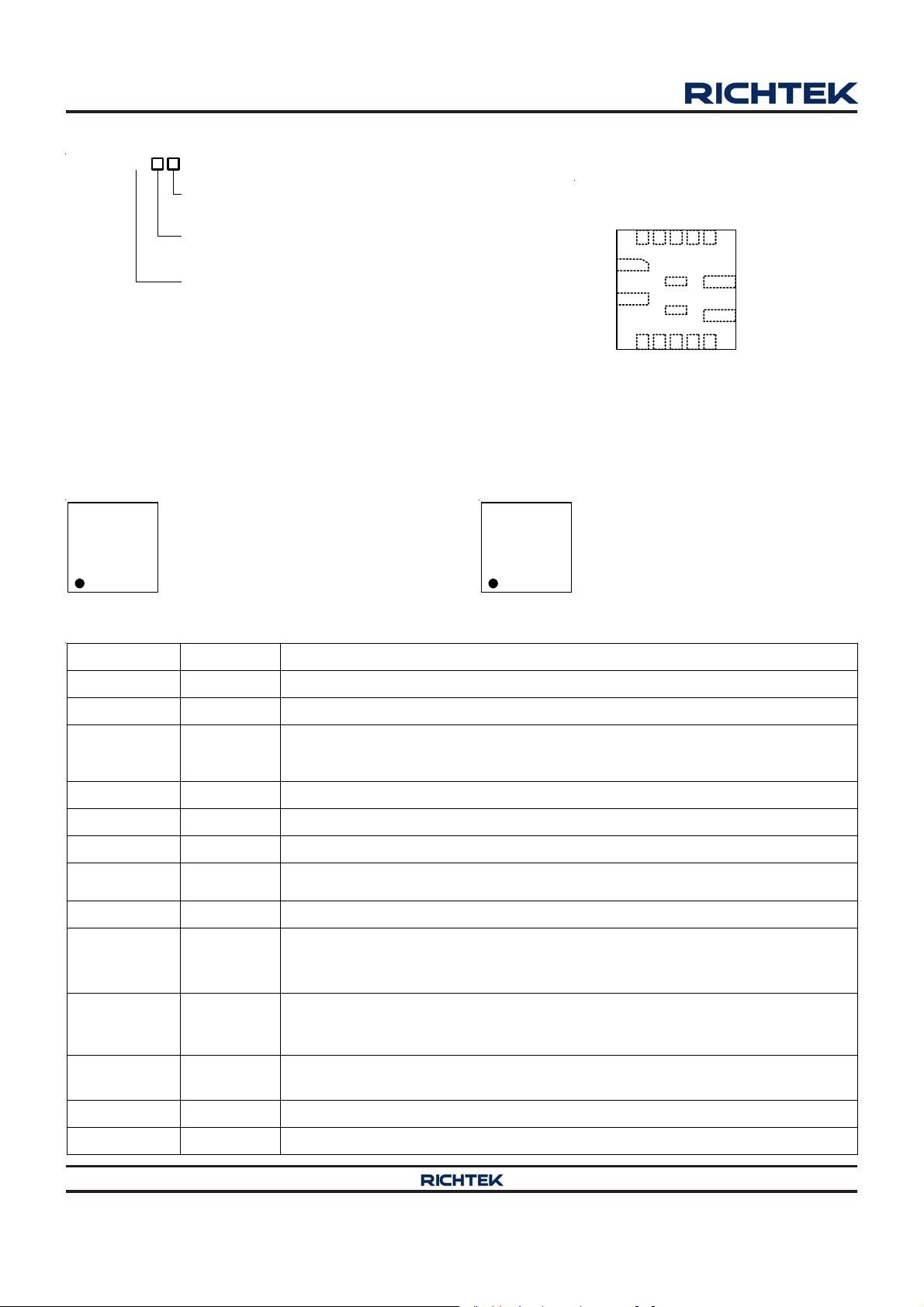

Pin Configurations

RT7291A/B

Package Type

QUF : UQFN-16L 3x3 (FC) (U-Type)

Lead Plating System

G : Green (Halogen Free and Pb Free)

Output Voltage

A : 5V

Note :

Richtek products are :

RoHS compliant and compatible with the current require-

ments of IPC/JEDEC J-STD-020.

Suitable for use in SnPb or Pb-free soldering processes.

B : 5.1V

Marking Information

RT7291AGQUF RT7291BGQUF

39= : Product Code

39=YM

DNN

YMDNN : Date Code

4M=YM

DNN

(TOP VIEW)

AGND

EN

14 13 12 11 10

1

VIN

SW

PGND

2

SW

3 4 5 6 7

VBYP

PGOOD

UQFN-16L 3x3 (FC)

4M= : Product Code

YMDNN : Date Code

15

16

ENLDO

CLK

VCC

BOOT

9

SW

8

SW

LDO

VOUT

Functional Pin Description

Pin No. Pin Name Pin Function

1 VIN Power Input Connect t o High- S ide MOSFET Drain.

2 PGND Power Ground.

Switch Over Source Voltage for VCC. A low pass fil ter should be connected to

3 VBYP

4 PGOOD Open-Drain P ower Good Indicator Output.

5 CLK 300kHz Clock Output t o Drive the External Charge Pump.

6 LDO 5V Linear Regulator Output. Decouple with a minimum 4.7F ceramic capacitor.

7 VOUT

8, 9, 15, 16 SW Switch Node.

10 BOOT

11 VCC

12 ENLDO

AGND, if VBYP is applied. If VBYP is not used, then connect to AGND. Do not

connect to VCC pin.

Output Voltage Sense Input. A n internal discharging ci rcuit is connected to thi s

pin.

Bootstrap Supply for High-Side Gate Driver. A capacitor is needed to drive the

power switch's gate abov e the supply voltage. It is connected bet ween the SW

and BOOT pins to form a floati ng suppl y across the power switch driv er.

5V Linear Regulator Output for Internal Cont rol Circuit. A capacitor (typical 2.2F)

should be connected to AGND. VCC can only supply internal circuits. Do not

connect to external loads.

Enable Control Input for Linear Regulator. This pin is internally pulled up to high by

10A.

13 EN Enable Control I nput. Do not leave this pin floating.

14 AGND Analog Ground.

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

2

©

DS7291A/B-02 September 2015www.richtek.com

Page 3

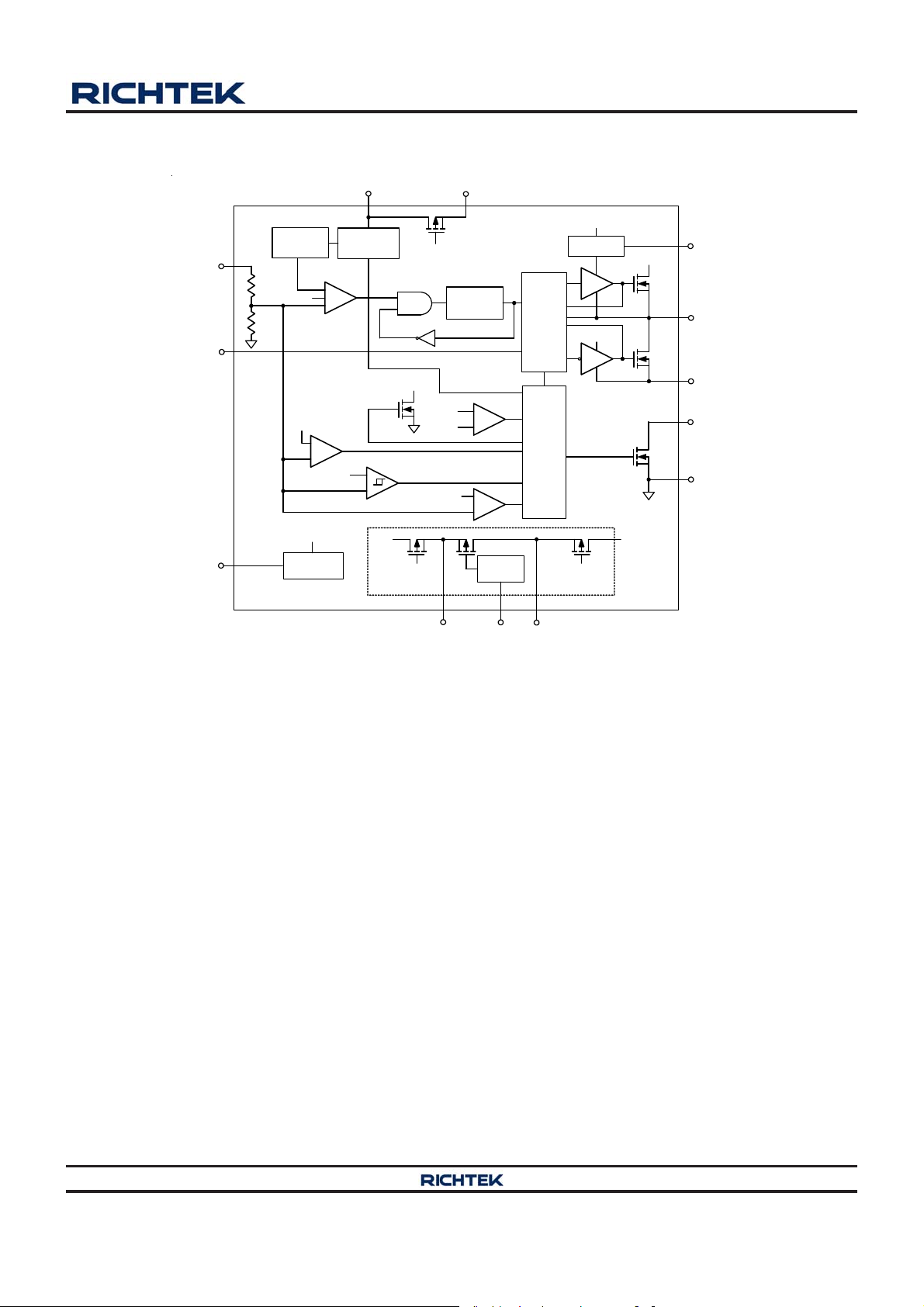

Function Block Diagram

RT7291A/B

VOUT

EN

CLK

Soft-Start

V

REF

V

FB

120% x V

90% x V

V

OUT

CLK

Generator

+

Reference

+

+

-

REF

OVP

REF

VCC

POR &

+

V

V

POK

60% x V

CC

Regulator

VBYP

V

CC

Switch-Over

On-Time

One shot

Min off Time

OUT

+

SW

-

V

OC

+

REF

-

V

CC

VIN LDO

OCP

UVP

LDO

Control

ENLDO

Gate

Control

Logic

Fault

Logic

V

IN

BSTREG

V

CC

LDO

Switch-Over

V

IN

V

OUT

BOOT

SW

PGND

PGOOD

AGND

Operation

Overall

The RT7291A/B is a synchronous step-down converter

with advanced consta nt on-time control mode. Using the

ACOTTM control mode can reduce the output ca pa citance

and provide fast transient response. It can minimize the

component size without additional external compensation

network.

Internal VCC Regulator

The regulator provides 5V power to supply the internal

control circuit. Connecting a 2.2μF cera mic capa citor for

decoupling and stability is required.

Soft-Start

In order to prevent the converter output voltage from

overshooting during the startup period, the soft-start

function is necessary . The soft-start time is internal setting

and the duration is around 1.5ms

OCP

The inductor valley current is monitored via the internal

switches in cycle-by-cycle. Once the output voltage drops

below UV threshold, the device enters latch mode.

Power Good

After soft-start is finished, the power good function will be

activated. The PGOOD pin is a n open-drain output.

CLK Generator

Provide a 300kHz clock to drive external charge pump.

VCC Switch-Over

The internal regulator output will switch over to VBYP if

VBYP level is higher than 4.6V.

LDO

Built-in 5V , 100mA LDO with 1% a ccuracy . The LDO output

will switch over to VOUT once PGOOD goes high.

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

©

DS7291A/B-02 September 2015 www.richtek.com

3

Page 4

RT7291A/B

Absolute Maximum Ratings (Note 1)

Supply Input Voltage, VIN ---------------------------------------------------------------------------------- −0.3V to 27V

Switch Voltage, SW ----------------------------------------------------------------------------------------- −0.3V to (V

<30ns ----------------------------------------------------------------------------------------------------------- −5V to 28V

BOOT Switch Voltage ---------------------------------------------------------------------------------------(V

EN, ENLDO Pin Voltages ---------------------------------------------------------------------------------- −0.3V to 27V

Other I/O Pin Voltages -------------------------------------------------------------------------------------- −0.3V to 6V

Power Dissi pation, P

D

@ T

= 25°C

A

UQF N-16L 3x3 (FC)------------------------------------------------------------------------------------------1.4W

Package Thermal Re sistance (Note 2)

UQF N-16L 3x3 (FC), θJA------------------------------------------------------------------------------------70°C/W

UQF N-16L 3x3 (FC), θJC------------------------------------------------------------------------------------15°C/W

Lead T e mperature (Soldering, 10 sec.)------------------------------------------------------------------260°C

Junction T emperature----------------------------------------------------------------------------------------150°C

Storage T emperature Range ------------------------------------------------------------------------------- − 65°C to 150°C

ESD Susceptibility (Note 3)

HBM (Human Body Model)---------------------------------------------------------------------------------2kV

MM (Machine Model) ---------------------------------------------------------------------------------------- 200V

− 0.3V) to (VSW + 6V)

SW

+ 0.3V)

IN

Recommended Operating Conditions (Note 4)

Supply Input V oltage, VIN ----------------------------------------------------------------------------------5V to 23V

Junction T emperature Range------------------------------------------------------------------------------- − 40°C to 125°C

Ambient T emperature Range------------------------------------------------------------------------------- −40°C to 85°C

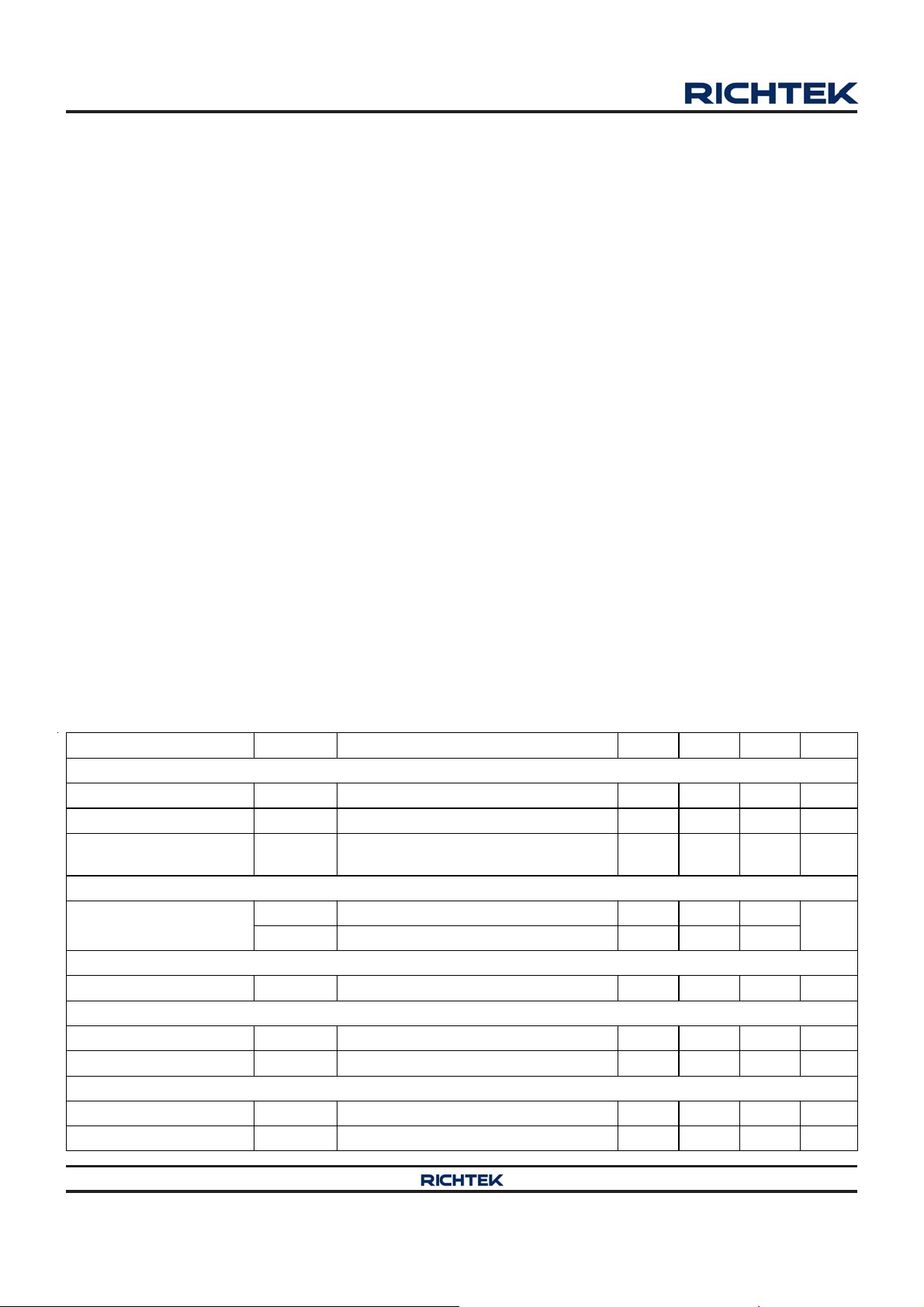

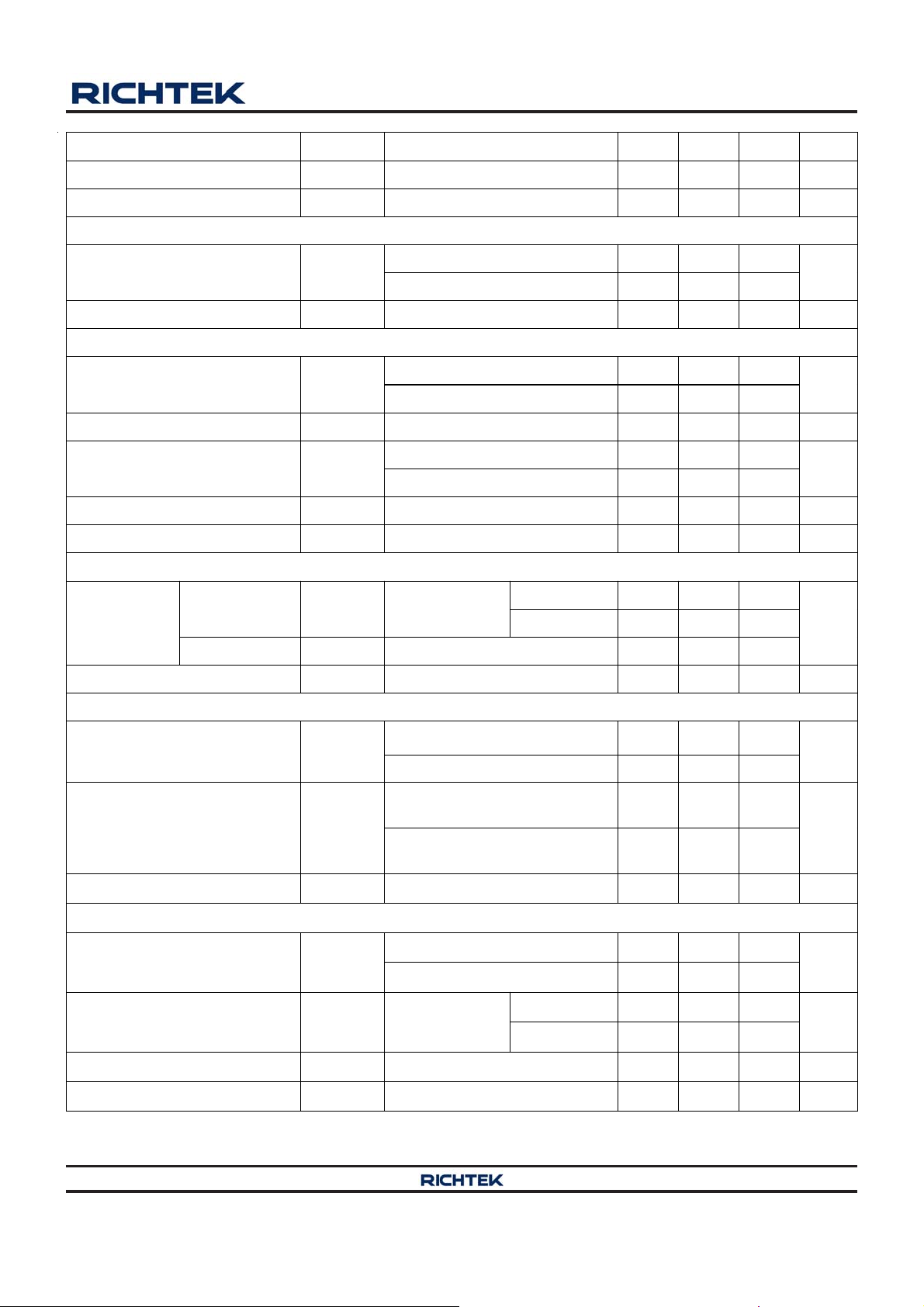

Electrical Characteristics

(V

= 12V, TA = 25°C, unless otherwise specified)

IN

Parameter Symbol Test Conditions Min Typ Max Unit

Supply Current

Shutdown Current V

Quiescent Curr ent V

Standby Current

Switch On-Resistance

R

Switch On-Resi stanc e

DS(ON)_H VBOOT

R

DS(ON)_L

Current Lim it

Current Limit IOC Valley curr ent of low-side s witch 7.6 -- 11.4 A

Switching Frequency and Minimum Off Timer

Switching Frequency fSW 450 500 550 kHz

Minimum Of f -Ti me T

-- 200 -- ns

OFF

Protections

OVP Trip Threshold V

OVP Propagation Delay T

W ith respect to output voltage 115 120 125 %

OVP

OVPDLY

-- 5 -- s

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

4

©

= V

EN

= 2V, V

EN

= 0V, V

V

EN

Current = 0A

= 0V -- 2.5 5 A

ENLDO

= 2V, No Switching -- 100 130 A

ENLDO

= 2V, LDO Load

ENLDO

-- 35 45 A

– VSW = 5V -- 31 --

-- 20 --

DS7291A/B-02 September 2015www.richtek.com

m

Page 5

RT7291A/B

Parameter Symbol Test Conditions Min Typ Max Unit

UVP Trip Threshold V

UVP Propagation Delay T

With respect t o output v oltage 55 60 65 %

UVP

UVPDLY

-- 5 -- s

Reference and Sof t -Start

RT7291A 4.95 5 5.05

Output Voltage Valley V

OUT

V

RT7291B 5.049 5.1 5.151

Soft-Sta r t T i me TSS F r om E N high to PGOOD high 1 1.5 2 ms

Enable and UVLO

RT7291A 1.25 1.35 1.45

EN Input High Volt age V

ENH

V

RT7291B 1.3 1.4 1.5

EN Hysteresis V

EN Input Current IEN

-- 200 -- mV

ENHYS

= 2V -- 1 --

V

EN

A

VEN = 0V -- 0 -VCC UVLO Rising V

VCC UVLO Hysteresis V

CCUVLO

CCHYS

-- 4.2 -- V

-- 400 -- mV

CLK Output

RT7291A -- -- 5.05

CLK Output

Voltage

High-Level V

Low-Level V

I

CLKH

I

CLKL

= 10mA

VCLK

= 10mA 0 0. 1 0.2

VCLK

RT7291B -- -- 5.151

V

CLK Frequency f

-- 300 -- kHz

CLK

LDO Regulator

RT7291A 4.95 5 5.05

LDO Regulator V

LDO

RT7291B 5.049 5.1 5.151

EN = GND,

LDO Load Current = 5mA

-- 1 --

LDO Load Regulation

EN = GND,

LDO Load Current = 100mA

-- 5 --

Switch On-Resi stanc e RSW -- 3 5

VCC Regulator

RT7291A 4.805 5 5.295

VCC Regulator V

VCC

RT7291B 4.905 5.1 5.395

VCC Switch Over Threshold to

VBYP

VCC Switch Over Hyster esi s V

V

Rising

BYP

Edge

Falli ng E dge -- 200 -- mV

BYP

RT7291A 4.45 4.6 4.75

RT7291B 4.542 4.692 4.842

Switch Over On- Resi st anc e -- 3 5

V

%

V

V

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS7291A/B-02 September 2015 www.richtek.com

©

5

Page 6

RT7291A/B

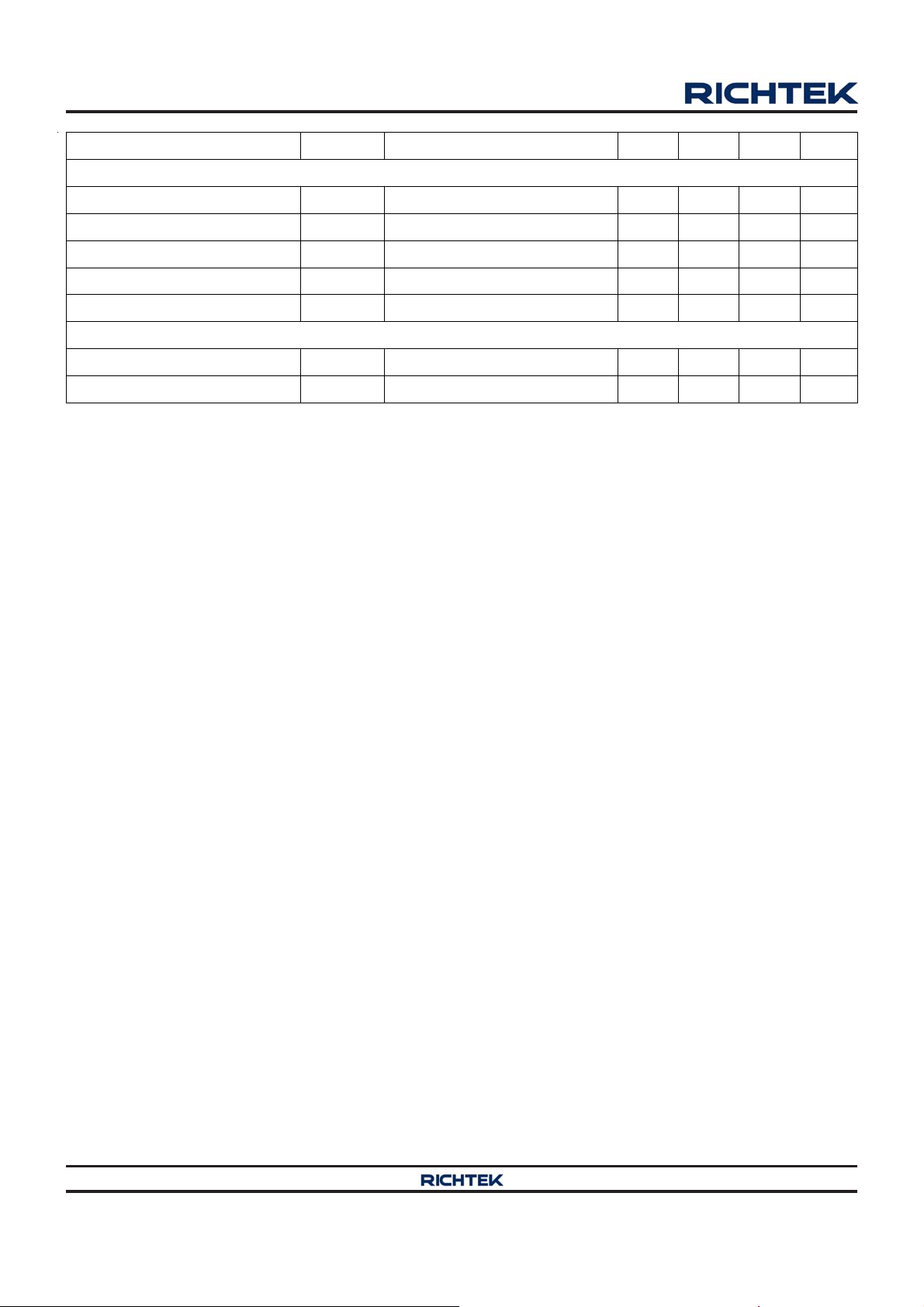

Parameter Symbol Test Conditions Min Typ Max Unit

Power Good Indicat or

PGOOD Threshold Fr om Lower V

PGOOD Low Hysteresis V

PGOOD Low to High Delay T

PGOOD Sink Current Capability V

PGOOD Leakage Current I

-- 0.5 -- ms

PGDLY

PGSINK

PGLEAK

Sink 4mA -- -- 0.4 V

V

Rising 85 90 95 %

OUT

Falling -- 10 -- %

OUT

PGOOD

= 5V -- -- 100 nA

Therma l Shutdown

Thermal Shutdown Threshol d TSD 135 150 -- °C

Thermal Shutdown Hystere si s -- 25 -- ° C

Note 1. Stresses beyond those listed “Absolute Maximum Ratings” may cause permanent damage to the device. These are

stress ratings only, and functional operation of the device at these or any other conditions beyond those indicated in

the operational sections of the specifications is not implied. Exposure to absolute maximum rating conditions may

affect device reliability.

Note 2. θ

Note 3. Devices are ESD sensitive. Handling precaution is recommended.

Note 4. The device is not guaranteed to function outside its operating conditions.

is measured at T

JA

= 25°C on a high effective thermal conductivity four-layer test board per JEDEC 51-7.

A

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

6

©

DS7291A/B-02 September 2015www.richtek.com

Page 7

Typical Application Circuit

RT7291A/B

V

OUT

V

5.2V to 23V

V

LDO

5V

V

OUT

D1

C1 C2

100nF

/ 50V

IN

C

IN

10µF

/25V x 2

C

LDO

4.7µF /10V

R

BYP

5.1

D2 D3

C3 C4

100nF

/ 50V

100nF

/ 50V

110

VIN

CLK

100nF

/ 50V

5

D4

BOOT

C5

100nF

/ 50V

(Optional)

R

2.2

V

CP

B

RT7291A/B

13

C

BYP

2.2µF /

10V

6

3

12

EN

LDO

VBYP

PGOOD

ENLDO

SW

VOUT

PGND

AGND

VCC

8, 9, 15, 16

7

2

14

R

PGOOD

100k

4

11

C

B

0.1µF / 50V

L

1.5µH

C

VCC

2.2µF /

C

OUT

22µF /

6.3V x 4

V

CC

V

OUT

5V/6A

10V

Figure 1. T ypical Application Circuit with Pure MLCC Solution

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

©

DS7291A/B-02 September 2015 www.richtek.com

7

Page 8

RT7291A/B

Typical Operating Characteristics

Efficiency vs. Load Current

100

V

= 7.4V, EN = 2V, ENLDO = floating

IN

95

90

Effici ency (%)

85

80

0.001 0.01 0.1 1 10

Load Current (A)

Efficiency vs . Loa d Current

100

V

= 19V, EN = 2V, ENLDO = floating

IN

95

90

85

Effici ency (%)

80

75

70

0.001 0.01 0.1 1 10

Load Current (A)

Efficiency vs. Load Current

100

V

= 12V, EN = 2V, ENLDO = floating

IN

95

90

85

Effici ency (%)

80

75

70

0.001 0.01 0.1 1 10

Load Current (A)

Switching Frequency vs. Loa d Current

550

V

= 7.4V, EN = 2V, ENLDO = floating

IN

500

450

400

350

300

250

200

150

100

Swit ching Frequency (kHz) 1

50

0

0.001 0.01 0.1 1 10

Load Current (A)

Switching Frequency vs. Load Current

550

V

= 12V, EN = 2V, ENLDO = floating

IN

500

450

400

350

300

250

200

150

100

Switching Fr equency (kHz) 1

50

0

0.001 0.01 0.1 1 10

Load Current (A)

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

©

Swit ching Frequency ( kHz) 1

Switching Frequency vs. Load Current

550

V

= 19V, EN = 2V, ENLDO = floating

IN

500

450

400

350

300

250

200

150

100

50

0

0.001 0.01 0.1 1 10

Load Current (A)

DS7291A/B-02 September 2015www.richtek.com

8

Page 9

RT7291A/B

)

Quiescent Current vs. Input Voltage

100

90

80

70

60

50

40

30

Quiescent Current (µA) 1

20

10

0

5 7 9 11131517192123

Inpu t Volt age (V)

Shutdown Current vs. Input Voltage

10

9

8

7

6

5

4

3

2

Shutdown Current (µA) 1

1

0

5 7 9 11131517192123

Inpu t Voltage ( V )

EN = ENLDO = 0V

Standby Current vs. Input Voltage

80

70

60

50

40

30

20

Standby Cur rent (µA

10

0

5 7 9 11131517192123

EN = 0V , ENLDO = 2V, I

Inpu t Voltage ( V )

Output Voltage vs. Load Current

5.25

5.20

5.15

5.10

5.05

5.00

4.95

4.90

Output Voltage (V)

4.85

4.80

4.75

0.001 0.01 0.1 1 10

V

= 12V, EN = 2V, ENLDO = floating

IN

Load Current (A)

LDO

= 0AEN = 2V, ENLDO = floating, No Switching

LDO Output Voltage vs. Input Voltage

5.25

5.20

5.15

5.10

5.05

5.00

4.95

4.90

4.85

LDO Output Volt age (V)

4.80

4.75

4 6 8 1012141618202224

I

I

I

LDO

LDO

LDO

= 0mA

= 50mA

= 100mA

V

OUT

(5V/Div)

V

CC

(5V/Div)

PGOOD

(5V/Div)

EN

(5V/Div)

Start Up Through EN

V

= 12V , ENLDO = GND, No Loa d

IN

Time (500μs/Div)

Input Voltage (V)

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

©

DS7291A/B-02 September 2015 www.richtek.com

9

Page 10

RT7291A/B

V

LDO

(5V/Div)

V

CC

(5V/Div)

V

CP

(5V/Div)

ENLDO

(5V/Div)

V

LDO

(5V/Div)

Start Up Through ENLDO

V

= 12V, EN = GND, No Load

IN

Time (500μs/Div)

Power Off Through ENLDO

V

OUT

(5V/Div)

V

CC

(5V/Div)

PGOOD

(5V/Div)

EN

(5V/Div)

V

OUT

(30mV/Div)

Power Off Through EN

V

= 12V , ENLDO = GND, No Loa d

IN

Time (500μs/Div)

Load Transient Response

V

CC

(5V/Div)

V

CP

(5V/Div)

ENLDO

(5V/Div)

V

OUT

(5V/Div)

PGOOD

(5V/Div)

SW

(10V/Div)

V

= 12V, EN = GND, No Load

IN

Time (500μs/Div)

UVP

V

= 12V , EN = ENLDO = High

IN

SW

(20V/Div)

I

L

(5A/Div)

V

OUT

(5V/Div)

PGOOD

(5V/Div)

V

IN

(10V/Div)

I

L

(5A/Div)

Time (50μs/Div)

V

= 12V, V

IN

V

= 12V , EN = ENLDO = High

IN

OVP

= 6V, EN = ENLDO = High

OUT

Time (50μs/Div)

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

©

Time (50μs/Div)

DS7291A/B-02 September 2015www.richtek.com

10

Page 11

Application Information

RT7291A/B

The RT7291A/B is high-performa nce 500kHz 6A step-down

regulators with internal power switches and synchronous

rectifiers. It features an Advanced Constant On-Time

(ACOTTM) control architecture that provides stable

operation for ceramic output capacitors without

complicated external compensation, a mong other benefits.

The input voltage range is from 5V to 23V, and the output

voltage is fixed 5V .

The proprietary ACOTTM control scheme improves

conventional constant on-time architectures, achieving

nearly constant switching frequency over line, loa d, and

output voltage ranges. Since there is no internal clock,

response to tran sients is nearly instantaneous a nd inductor

current can ramp quickly to maintain output regulation

without large bulk output ca pacita nce.

TM

ACOT

Control Architecture

In order to achieve good stability with low-ESR ceramic

capa citors, ACOTTM uses a virtual inductor current ra mp

generated inside the IC. This internal ra mp signal repla ces

the ESR ramp normally provided by the output ca pa citor's

ESR. The ra mp signal a nd other internal compensation s

are optimized for low-ESR cera mic output capacitors.

Making the on-time proportional to V

and inversely

OUT

proportional to VIN is not sufficient to achieve good

constant-frequency behavior for several reasons. First,

voltage drops across the MOSFET switches a nd inductor

cause the effective input voltage to be less than the

mea sured input voltage and the effective output voltage to

be greater than the measured output voltage as sensing

input and output voltage. When the load changes, the

switch voltage drops change causing a switching

frequency variation with load current. Also, at light loa ds

if the inductor current goes negative, the switch deadtime between the synchronous rectifier turn-off and the

high-side switch turn-on allows the switching node to rise

to the input voltage. This increases the effective on-ti me

and causes the switching frequency to drop noticea bly.

One way to reduce these effects is to mea sure the a ctual

switching frequency and compare it to the desired ra nge.

This has the a dded benefit eliminating the need to sens e

the actual output voltage, potentially saving one pin

connection. The ACOTTM uses this method, measuring

the actual switching frequency a nd modifying the on-time

with a feedback loop to keep the average switching

frequency in the desired range.

ACOTTM One-shot Operation

The RT7291A/B control algorithm is simple to understa nd.

The feedback voltage, with the virtual inductor current ra mp

added, is compared to the reference voltage. When the

combined signal is less than the reference, the on-time

one-shot is triggered, as long as the minimum off-time

one-shot is clear and the measured inductor current

(through the synchronous rectifier) is below the current

limit. The on-time one-shot turns on the high-side switch

and the inductor current ramps up linearly. After the ontime, the high-side switch is turned off a nd the synchronous

rectifier is turned on and the inductor current ra mps down

linearly . At the sa me time, the mini mum off-time one-shot

is triggered to prevent another immedi ate on-time during

the noisy switching time and allow the feedback voltage

and current sense signals to settle. The minimum off-time

is kept short (200ns typical) so that ra pidly-repeated ontimes ca n raise the inductor current quickly when needed.

Diode Emulation Mode

In diode emulation mode, the RT7291A/B automatically

reduces switching frequency at light load conditions to

maintain high efficiency. This reduction of frequency is

achieved smoothly . As the output current decrea ses from

heavy load conditions, the inductor current is also reduced,

and eventually comes to the point that its current valley

touches zero, which is the boundary between continuous

conduction and discontinuous conduction modes. To

emulate the behavior of diodes, the low-side MOSFET

allows only partial negative current to flow when the

inductor free wheeling current becomes negative. As the

load current is further decrea sed, it takes longer a nd longer

time to discharge the output capacitor to the level that

requires the next “ON” cycle. In reverse, when the output

current increases from light load to heavy load, the

switching frequency increa ses to the preset value as the

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS7291A/B-02 September 2015 www.richtek.com

©

11

Page 12

RT7291A/B

inductor current reaches the continuous conduction. The

transition load point to the light loa d operation is shown in

Figure 2 and ca n be calculated as follows :

I

L

Slope = (VIN- V

t

ON

OUT

) / L

I

PEAK

I

LOAD

= I

/ 2

PEAK

t

Figure 2. Boundary Condition of CCM/DEM

(V V )

It

LOAD ON

IN OUT

2L

where tON is the on-time.

The switching waveforms may appear noisy and

asynchronous when light load causes diode emulation

operation. This is normal and results in high efficiency.

Trade of fs in DEM noise vs. light load eff iciency is mad e

by varying the inductor value. Generally , low inductor values

produce a broader efficiency vs. load curve, while higher

values result in higher full load efficiency (assuming that

the coil resistance remains fixed) a nd less output voltage

ripple. Penalties for using higher inductor values include

larger physical size and degraded load tra nsient response

(especially at low input voltage levels).

During discontinuous switching, the on-time is immediately

increa sed to add “hysteresis” to discourage the IC from

switching back to continuous switching unless the load

increases substantially. The IC returns to continuous

switching as soon as an on-time is generated before the

inductor current reaches zero. The on-ti me is reduced back

to the length needed for 500kHz switching and encouraging

the circuit to remain in continuous conduction, preventing

repetitive mode transition s between continuous switching

and discontinuous switching.

Linear Regulators (LDO & VCC)

The RT7291A/B includes a 5V linear regulator (LDO). The

LDO regulator can supply up to 100mA for external loads.

Bypass LDO with a minimum 4.7μF ceramic capacitor.

When VOUT is powered on and PGOOD is pulled high,

an internal 3Ω P-MOSFET switch connects V

OUT

to the

LDO pin while the internal linear regulator is simulta neously

turned off.

The RT7291A/B also includes a 5V linear regulator (VCC).

The VCC regulator steps down input voltage to supply

both internal circuitry and gate drivers. Do not connect

the VCC pin to external loads. When PGOOD is pulled

high and BYP pin voltage is above 4.6V, an internal 3Ω

P-MOSFET switch connects VCC to the BYP pin while

the VCC linear regulator is simulta neously turned off.

Current Limit

The RT7291A/B current limit is a cycle-by-cycle “valley”

type, measuring the inductor current through the

synchronous rectifier during the off-time while the inductor

current ramps down. The current is determined by

mea suring the voltage between Source and Drain of the

synchronous rectifier, a dding temperature compensation

for greater accuracy. If the current exceeds the current

limit, the on-time one-shot is inhibited until the inductor

current ramps down below the current limit. Thus, only

when the inductor current is well below the current limit,

another on-time is permitted. If the output current exceeds

the available inductor current (controlled by the current

limit mechanism), the output voltage will drop. If it drops

below the output under-voltage protection level (see next

section), the IC will stop switching to avoid excessive

heat.

The RT7291A/B also features a negative current limit to

protect the IC against sinking excessive current and

possibly damage. If the voltage across the synchronous

rectifier indicates the negative current is too high, the

synchronous rectifier turns off.

Output Over-Voltage Protection and Under-Voltage

Protection

The RT7291A/B features an output Over-V oltage Protection

(OVP). If the output voltage rises above the regulation

level, the IC stops switching and is latched off. The

RT7291A/B also features an output Under-Voltage

Protection (UVP). If the output voltage drops below the

UVP trip threshold for longer tha n 2μs (typical), the UVP

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

12

©

DS7291A/B-02 September 2015www.richtek.com

Page 13

RT7291A/B

is triggered, and the IC will shut down. The IC stops

switching and is latched off. To restart operation, toggle

EN or power the IC of f and then on again.

Input Under-Voltage Lockout

In addition to the enable function, the RT7291A/B features

an U nder-V oltage Lockout (UVLO) function that monitors

the input voltage. To prevent operation without fullyenhanced internal MOSFET switche s, this function inhibits

switching when input voltage drops below the UVLO-falling

threshold. The IC resumes switching when input voltage

exceeds the UVLO-rising threshold.

Over-Temperature Protection

The RT7291A/B features an Over-Temperature Protection

(OTP) circuitry to prevent overheating due to excessive

power dissipation. The OTP shuts down switching

operation when the junction temperature exceeds 150°C.

Once the junction temperature cools down by

approxi mately 25°C the IC resumes normal operation with

a complete soft-start. For continuous operation, provide

adequate cooling so that the junction temperature does

not exceed 150°C. Note that the VCC a nd LDO regulator

remains on a s the OTP is triggered.

Enable and Disable

The enable input (EN) ha s a logic-low level of 1.15V . When

VEN is below this level, the IC enters shutdown mode and

supply current drops to less than 5μA (typical). When

VEN exceeds its logic-high level of 1.35V, the IC is fully

operational. The logics of EN and ENLDO to control the

V

, CLK, LDO and VCC are stated in Table 1.

OUT

Soft-Start

The RT7291A/B provides an internal soft-start function to

prevent large inrush current and output voltage overshoot

when the converter starts up. The soft-start (SS)

automatically begins once the chip is enabled. During softstart, it clamps the ra mp of internal reference voltage which

is compared with FB signal. The typical soft-start duration

is 1.5ms.

Power Off

When VEN is pulled to GND or lower than the logic-low

level of 1.15V , there is a n intern al discharging resistor to

discharge the residual charge inside the output ca pacitors.

Besides, the value of discharging resistor is about twenty

ohms.

Power Good Output (PGOOD)

The power good output is an open-drain output that requires

a pull-up resistor. When the output voltage is 20% (typical)

below its set voltage, PGOOD will be pulled low . It is held

low until the output voltage returns to 90% of its set voltage

once more. During soft-start, PGOOD is actively held low

and only allowed to be pulled high after soft-start is over

and the output rea ches 90% of its set voltage. There is a

2μs delay built into PGOOD circuitry to prevent false

transition.

External Bootstra p Ca pacitor (C

BOOT

)

Connect a 0.22μF low ESR ceramic capacitor between

the BOOT and SW pin s. This bootstrap ca pa citor provides

the gate driver supply voltage for the high-side N-MOSFET

switch.

T able 1. EN/ENLDO Control Logics

EN ENLDO VOUT/CLK LDO VCC

The internal power MOSFET switch gate driver is

optimized to turn the switch on fa st enough for low power

loss and good efficiency , a nd slow enough to reduce EMI.

1 1 ON ON ON

1 0 ON ON ON

0 1 OFF ON ON

0 0 OFF OFF OFF

Switch turn-on is when most EMI occurs since VSW rises

rapidly . During switch turn-off, SW is discharged relatively

slowly by the inductor current during the dead-time

between high-side and low-side switch on-time s. In some

cas es it is desirable to reduce EMI further , at the expense

of some additional power dissipation. The switch turn-on

can be slowed by placing a small (<10Ω) resistance

between BOOT and the external bootstra p ca pacitor . This

will slow the high-side switch turn-on and VSW's rise.

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS7291A/B-02 September 2015 www.richtek.com

©

13

Page 14

RT7291A/B

Inductor Selection

Selecting an inductor involves specifying its inductance

and also its required pea k current. The exact inductor value

is generally flexible and is ultimately chosen to obtain the

best mix of cost, physical size, and circuit efficiency.

Lower inductor values benefit from reduced size and cost

and they can improve the circuit's transient response.

However, they increase the inductor ripple current and

output voltage ripple and reduce the ef ficiency due to the

resulting higher peak currents. Conversely , higher inductor

values increa se ef f iciency, but the inductor will either be

physically larger or have higher resistance since more

turns of wire are required and transient response will be

slower since more time is required to change current (up

or down) in the inductor. A good compromise between

size, efficiency, and tra n sient respon se is to use a ri pple

current (ΔIL) about 20-50% of the desired full output load

current. Calculate the approximate inductor value by

selecting the input and output voltages, the switching

frequency (fSW), the maximum output current (I

OUT(MAX)

and estimating a ΔIL as some percentage of that current.

V(VV)

OUT IN OUT

L

Vf I

IN SW L

Once an inductor value is chosen, the ripple current (ΔIL)

is calculated to determine the required peak inductor

current.

V(VV)

L L(PEAK) OUT(MAX)

Vf L 2

IN SW

OUT IN OUT

I and I I

To guarantee the required output current, the inductor

needs a saturation current rating and a thermal rating that

exceeds I

. These are minimum requirements. To

L(PEAK)

maintain control of inductor current in overload and shortcircuit conditions, some applications may desire current

ratings up to the current limit value. However, the IC's

output under-voltage shutdown feature make this

unnecessary for most a pplication s.

For best efficiency, choose an inductor with a low DC

resistance that meets the cost and size requirements.

For low inductor core losses some type of ferrite core is

usually best and a shielded core type, although possibly

larger or more expensive, it will probably give fewer EMI

and other noise problems.

Input Capacitor Selection

High quality ceramic in put decoupling capacitor, such a s

X5R or X7R, with values greater than 20μF are

recommended for the input ca pa citor. The X5R a nd X7R

ceramic ca pa citors are usually selected for power regulator

capacitors because the dielectric material has less

capacitance variation and more temperature stability.

V oltage rating a nd current rating are the key parameters

when selecting an input ca pa citor. Generally , selecting a n

input ca pa citor with voltage rating 1.5 ti mes greater tha n

the maximum input voltage is a conservatively safe design.

The input capacitor is used to supply the input RMS

current, which can be a pproximately calculated using the

following equation :

I(1)I

RMS OUT

VV

OUT OUT

VV 12

IN IN

2

I

2

L

The next step is to select a proper capacitor for RMS

current rating. One good design uses more than one

ca pacitor with low Equivalent Series Resistance (ESR) in

)

parallel to form a capacitor bank. The input capacitance

value determines the input ripple voltage of the regulator .

The input voltage ripple can be a pproxi mately calculated

using the following equation :

IV V

V(1)

IN

OUT IN OUT

Cf V V

IN SW O UT IN

The typical operating circuit is recommended to use two

I

L

10μF low ESR ceramic capa citors on the input.

Output Capacitor Selection

The RT7291A/B is optimized for cera mic output ca pacitors

and best performa nce will be obtained by using them. The

total output capacitance value is usually determined by

the desired output voltage ripple level and tra nsient response

requirements for sag (undershoot on positive load steps)

and soar (overshoot on negative load steps).

Output ripple at the switching frequency is caused by the

inductor current ripple and its effect on the output

capacitor's ESR and stored charge. These two ripple

components are called ESR ripple and capacitive ripple.

Since ceramic capacitors have extremely low ESR and

relatively little cap a cita nce, both components are similar

in amplitude and both should be considered if ripple is

critical.

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

14

©

DS7291A/B-02 September 2015www.richtek.com

Page 15

RT7291A/B

VV V

RIPPLE RIPPLE(ESR) RIPPLE(C)

VIR

RIPPLE(ESR) L ESR

V

RIPPLE(C)

I

8C f

L

OUT SW

In addition to voltage ripple at the switching frequency,

the output capacitor and its ESR also affect the voltage

sag (undershoot) and soar (overshoot) when the load steps

up and down abruptly. The ACOT transient response is

very quick and output transients are usually small.

However, the combination of small ceramic output

capacitors (with little capacitance), low output voltages

(with little stored charge in the output capacitors), and

low duty cycle applications (which require high inducta nce

to get rea sonable ripple currents with high input voltages)

increases the size of voltage variations in response to

very quick load changes. Typically, load changes occur

slowly with respect to the IC's 500kHz switching frequency .

However, some modern digital loads can exhibit nearly

instantaneous load changes and the following section

shows how to calculate the worst-case voltage swings in

response to very fa st load steps.

The amplitude of the ESR step up or down is a function of

the load step and the ESR of the output capa citor :

VIR

ESR_STEP OUT ESR

The amplitude of the capacitive sag is a function of the

load step, the output ca pa citor value, the inductor value,

the input-to-output voltage differential, a nd the maximum

duty cycle. The maximum duty cycle during a fa st tran sient

is a function of the on-time and the mini mum off-time since

the ACOTTM control scheme will ramp the current using

on-times spaced apart with minimum off-times, which is

as fast as allowed. Calculate the approximate on-time

(neglecting parasitics) a nd maximum duty cycle for a given

input and output voltage a s :

Vt

t and D

ON MAX

OUT ON

Vf t t

IN SW ON OFF(MIN)

The actual on-time will be slightly longer as the IC

compensates for voltage drops in the circuit, but we can

neglect both of these since the on-time increases

compensations for the voltage losses. Calculate the output

voltage sag as :

V

()

LI

SAG

2C V D V

OUT IN(MIN) MAX OUT

()

OUT

2

The amplitude of the capacitive soar is a function of the

load step, the output capacitor value, the inductor value

and the output voltage :

V

SOAR

()

LI

2C V

OUT OUT

OUT

2

Most applications never experience in stantaneous full loa d

steps and the RT7291A/B's high switching frequency a nd

fast tra nsient response can e asily control voltage regulation

at all times. Therefore, sag a nd soar are seldom an issue

except in very low-voltage CPU core or DDR memory

supply application s, particularly for devices with high clock

frequencies and quick changes into and out of sleep

modes. In such application s, simply increa sing the amount

of ceramic output capacitor (sag and soar are directly

proportional to capacitance) or adding extra bulk

capacitance can easily eliminate any excessive voltage

transients.

In any application with large quick transients, it should

calculate soar and sag to make sure that over-voltage

protection and under-voltage protection will not be triggered.

Thermal Considerations

For continuous operation, do not exceed absolute

maximum junction temperature. The maximum power

dissipation depends on the thermal resistance of the IC

package, PCB layout, rate of surrounding airflow, and

difference between junction and a mbient temperature. The

maximum power dissipation can be calculated by the

following formula :

P

where T

the ambient temperature, a nd θ

D(MAX)

= (T

J(MAX)

− TA) / θ

J(MAX)

JA

is the maximum junction temperature, TA is

is the junction to ambient

JA

thermal resistance.

For recommended operating condition specifications, the

maximum junction temperature is 125°C. The junction to

ambient thermal re sistance, θJA, is layout dependent. For

UQF N-16L 3x3 (FC) pa ckage, the thermal resistance, θJA,

is 70°C/W on a standard JEDEC 51-7 four-layer thermal

test board. The maximum power dissipation at TA = 25°C

can be calculated by the following f ormula :

P

= (125°C − 25°C) / (70°C/W) = 1.4W for

D(MAX)

UQF N-16L 3x3 (FC) pa ckage

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS7291A/B-02 September 2015 www.richtek.com

©

15

Page 16

RT7291A/B

The maximum power dissipation depends on the operating

ambient temperature for fixed T

and thermal

J(MAX)

resistance, θJA. The derating curve in Figure 3 allows the

designer to see the effect of rising ambient temperature

on the maximum power dissipation.

2.0

Four-Layer PCB

1.6

1.2

0.8

0.4

Maximum Power Dissipation (W) 1

0.0

0 25 50 75 100 125

Ambient Tempera ture (°C)

Figure 3. Derating Curve of Maxi mum Power Dissi pation

Layout Considerations

Layout is very important in high frequency switching

converter design. The PCB can ra diate excessive noise

and contribute to converter insta bility with improper layout.

Certain points must be considered before starting a layout

using the RT7291A/B.

Make tra ces of the main current paths a s short and wide

as possible.

Put the input capa citor a s close a s possible to the device

pins (VIN a nd PGND).

SW node encounters high frequency voltage swings so

it should be kept in a small area. Keep sensitive

components away from the SW node to prevent stray .

The PGND pin should be connected to a strong ground

plane for heat sinking a nd noise protection.

Avoid using via s in the power path connections that have

switched currents (from CIN to PGND and CIN to VIN)

and the switching node (SW).

VIN

The input capacitor must

be placed as close to the

IC as possible.

VIN

C

IN

PGND

GND

Impedance between PGND and AGND should be as small as possible for unified ground voltage.

GND

AGND

1

4

1

2

ENLDO

EN

1

3

1

1

1

2

15

SW

16

SW

34567

VBYP

CLK

PGOOD

Figure 4. Layout Guide

C

VCC

VCC

BOOT

1

0

C

BOOT

The output capacitor must

be placed near the IC

9

L

SW

8

SW

V

OUT

C

OUT

SW should be connected to

inductor by wide and short

V

LDO

VOUT

C

LDO

trace.

OUT

Keep sensitive components

away from this trace.

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

©

DS7291A/B-02 September 2015www.richtek.com

16

Page 17

Outline Dimension

RT7291A/B

Symbol

A 0.500 0.600 0.020 0.024

A1 0.000 0.050 0.000 0.002

A3 0.100 0.175 0.004 0.007

D 2.900 3.100 0.114 0.122

E 2.900 3.100 0.114 0.122

b 0.150 0.250 0.006 0.010

b1 0.100 0.200 0.004 0.008

L 0.350 0.450 0.014 0.018

L1 0.750 0.850 0.030 0.033

L2 0.550 0.650 0.022 0.026

e

K

K1

K2

K3

Dimensions In Millimeters Dimensions In Inches

Min. Max. Min. Max.

0.400 0.016

0.975 0.038

1.335 0.053

1.675 0.066

1.935 0.076

K4

K5

0.975 0.038

1.675 0.066

U-Type 16L QFN 3x3 (FC) Package

Copyright 2014 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS7291A/B-02 September 2015 www.richtek.com

©

17

Page 18

RT7291A/B

Richtek Technology Corporation

14F, No. 8, Tai Yuen 1st Street, Chupei City

Hsinchu, Taiwan, R.O.C.

Tel: (8863)5526789

Richtek products are sold by description only. Richtek reserves the right to change the circuitry and/or specifications without notice at any time. Customers should

obtain the latest relevant information and data sheets before placing orders and should verify that such information is current and complete. Richtek cannot

assume responsibility for use of any circuitry other than circuitry entirely embodied in a Richtek product. Information furnished by Richtek is believed to be

accurate and reliable. However, no responsibility is assumed by Richtek or its subsidiaries for its use; nor for any infringements of patents or other rights of third

parties which may result from its use. No license is granted by implication or otherwise under any patent or patent rights of Richtek or its subsidiaries.

DS7291A/B-02 September 2015www.richtek.com

18

Page 19

Loading...

Loading...