Page 1

®

PMIC for Industrial Application

RT5028

General Description

The RT5028 is a highly-integrated low-power highperformance analog SOC with PMIC in one single chip

designed for Industrial a pplications.

The RT5028 includes four synchronous step-down DC/

DC converters and eight LDOs for syste m power.

The RT5028 also embeds one EEPROM (MTP) for setting

sequence and timing etc.

Additionally, the RT5028 PMIC also includes one IRQ

report.

Applications

Industrial

Ordering Information

RT5028

Package Type

QW : WQFN-56L 7x7 (W-Type)

Lead Plating System

G : Green (Halogen Free and Pb Free)

Note :

Richtek products are :

RoHS compliant and compatible with the current require-

ments of IPC/JEDEC J-STD-020.

Suitable for use in SnPb or Pb-free soldering processes.

Features

Input Voltage Operating Range is 3.3V to 5.5V

Step-Down Regulator : V

Max Current 2.4A/2A/1.6A/2A

Programmable Frequency from 500kHz to 2MHz

2

I

C Programmable Output Level

2

I

C Programmable Operation Mode (Force PWM

or Auto PSM/PWM)

2

I

C Programmable Output Discharge Mode

(Discharge or Flatting)

Linear Regulators : V

Max Current 0.3A

2

I

C Programmable Output Level

Embedded 32Bytes MTP for Factory T uning

External MTP Pin for Write Protection

Sequence can be Controlled by I

Defined by MASK_GPIO pin.

OT/UVP/VIN LV/POWRON press Time Interrupt

(IRQ).

2

I

C Control Interface: Support Fast Mode up to

400kb/s

RoHS Compliant and Halogen Free

Range is 3.3V to 5.5V

IN

Range is 2.5V to 5.5V

IN

2

C or each EN pins

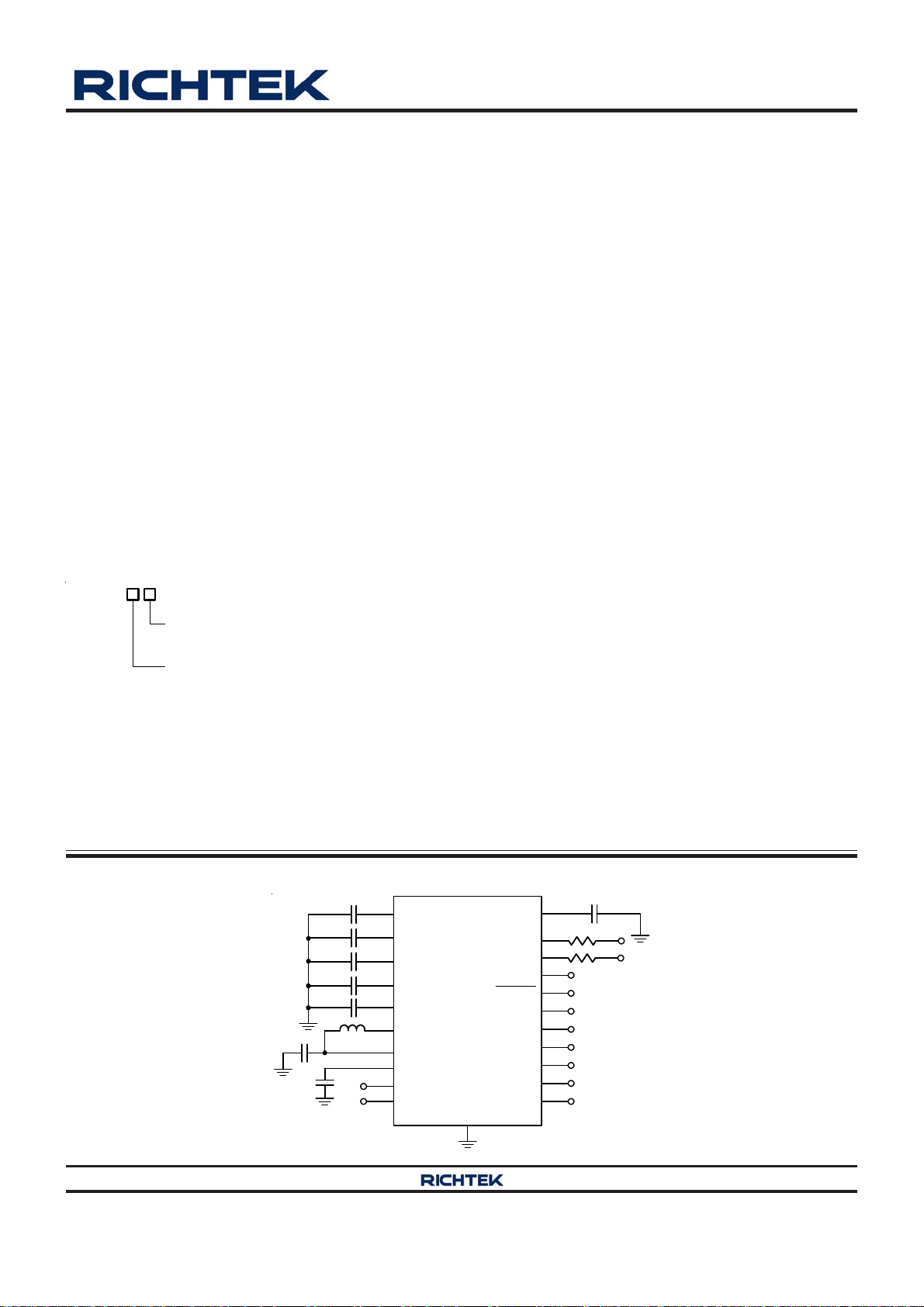

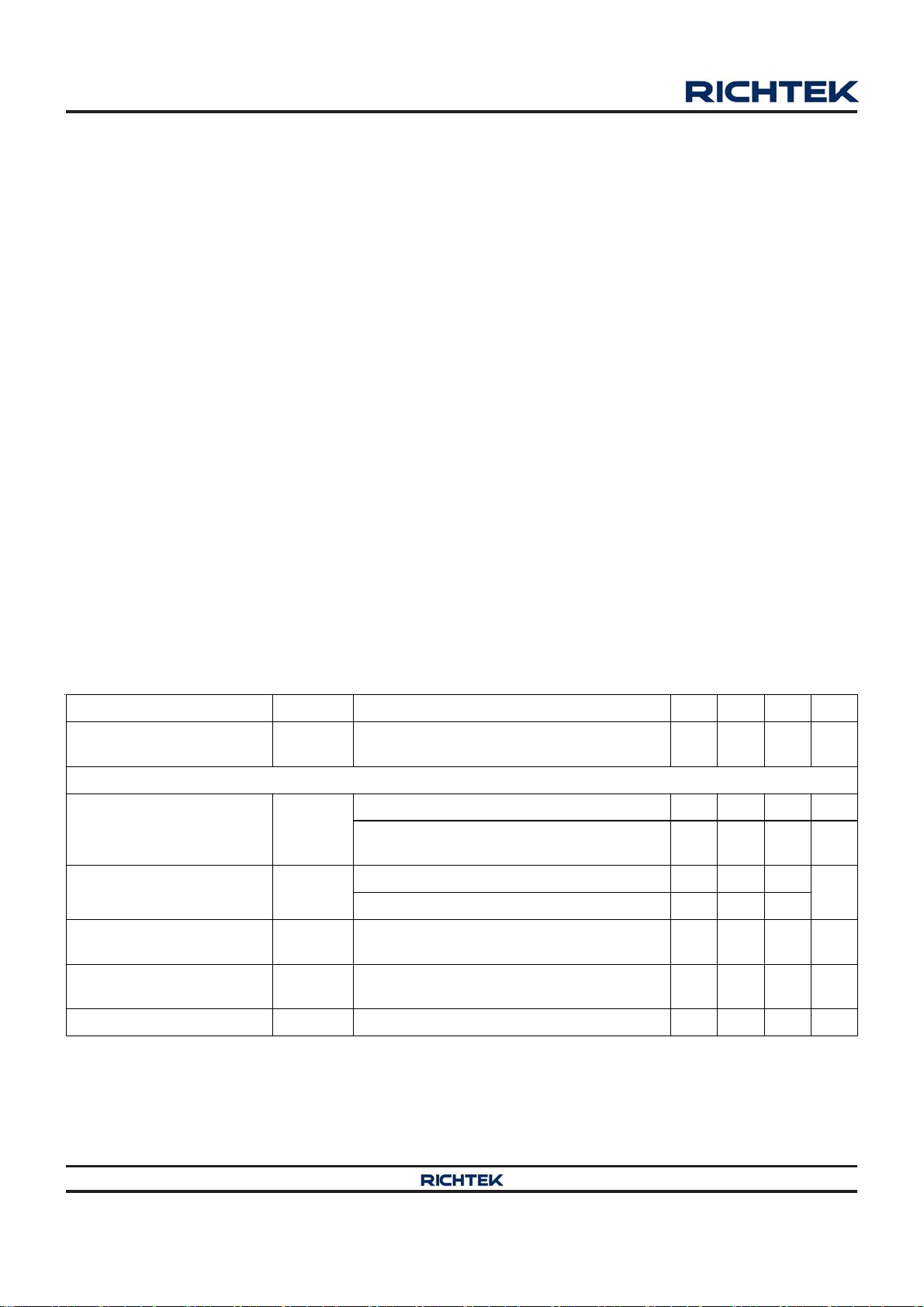

Simplified Application Circuit

VIN

VDDP

VINL123

VINL456

VINL78

LXBx

VOUTBxS

VINBx

ENBx

ENLx

Copyright 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

©

DS5028-01 January 2015 www.richtek.com

RT5028

PWRHOLD

REBOOT

MASK_GPIO

AGND

VOUTLx

SCL

SDA

IRQ

RESET

PWRON

MTP

SADDR

1

Page 2

RT5028

Marking Information

RT5028GQW : Product Number

RT5028

GQW

YMDNN

YMDNN : Date Code

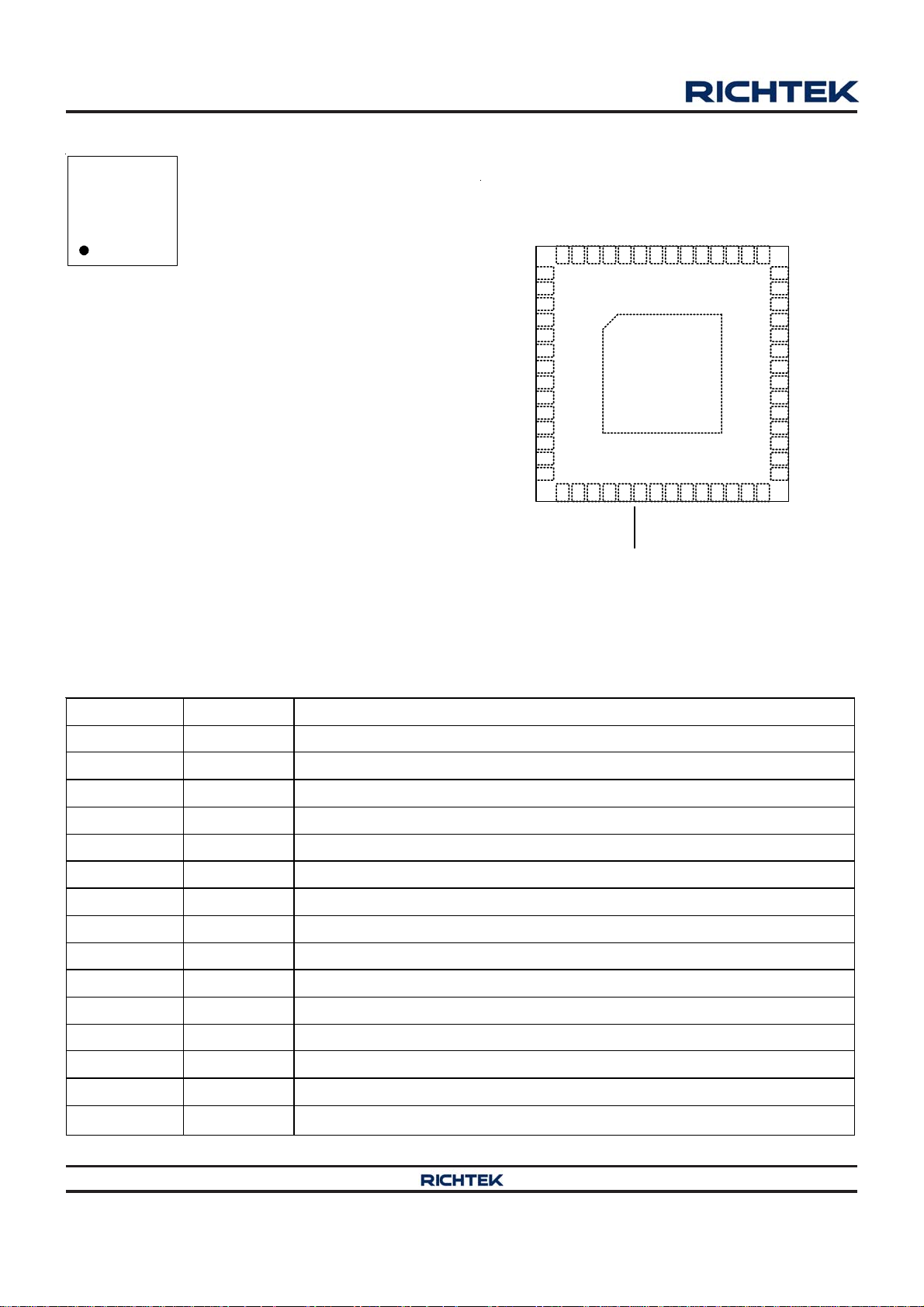

Pin Configurations

(TOP VIEW)

ENL3

ENL2

ENL1

VIN

VDDP

IRQ

VOUTB1S

AGND

AGND

RESET

VOUTL1

VINL123

VOUTL2

VOUTL3

VOUTL6

VOUTL5

VINL456

VOUTL4

VOUTL7

VINL78

VOUTL8

ENL4

ENL5

ENL6

AGND

1

2

3

4

5

6

7

8

9

10

11

12

13

14

SCL

SDA

ENL7

ENL8

ENB1

PWRON

LXB1

LXB1

57

MTP

REBOOT

VINB1

VINB1

454647484950515253545556

44

262524232221201918171615

27

PWRHOLD

MASK_GPIO

VINB2

43

28

SADDR

VINB2

42

41

40

39

38

37

36

35

34

33

32

31

30

29

ENB4

LXB2

LXB2

ENB2

VOUTB2S

VINB3

VINB3

LXB3

LXB3

AGND

VOUTB3S

VINB4

LXB4

ENB3

VOUTB4S

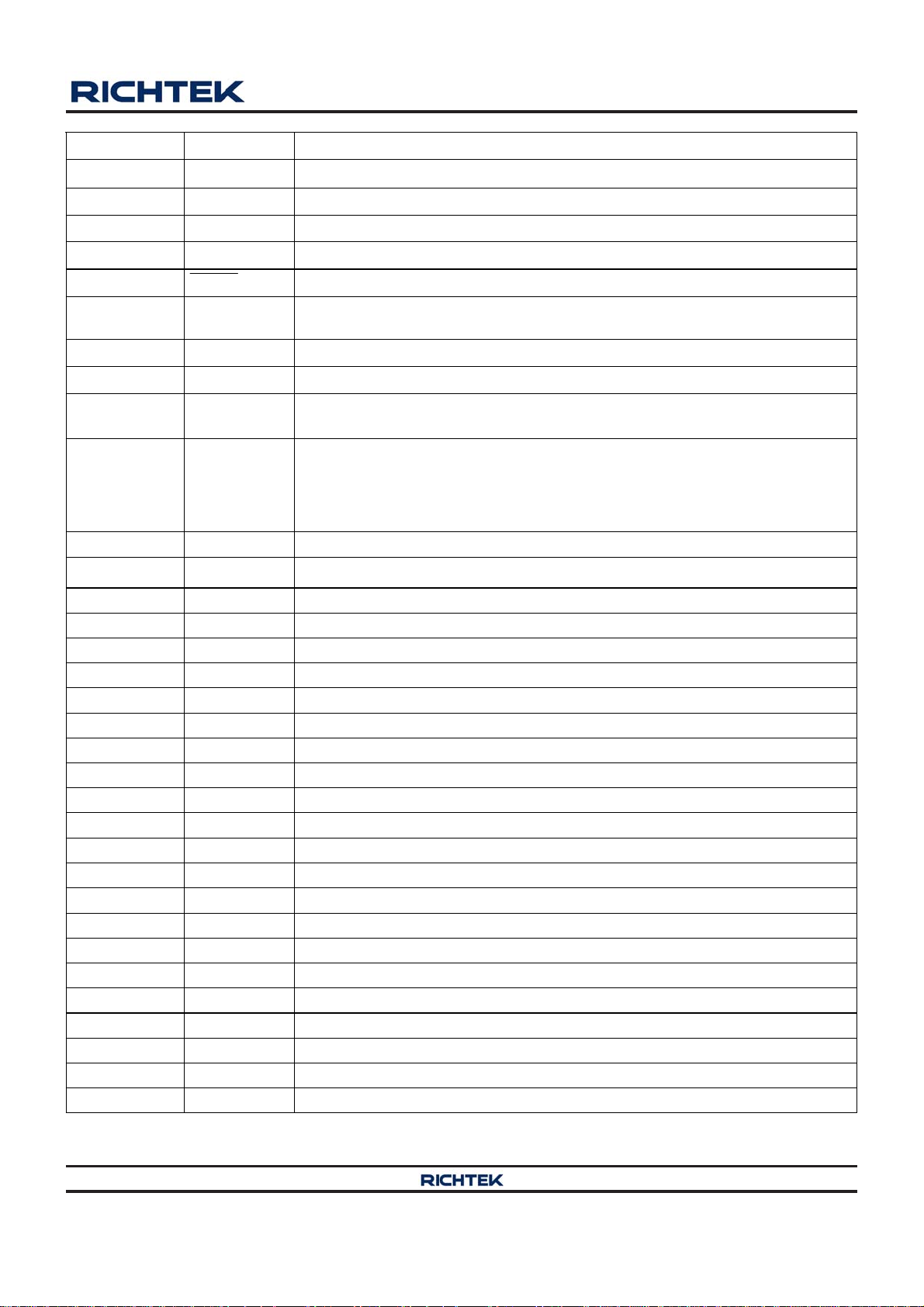

Functional Pin Description

Pin No. Pin Name Pin Function

1 VOUTL1 Output Voltage Regulation Node for LDO1.

2 VINL123 Input Power f or LDO1, LDO2 and LDO3.

3 VOUTL2 Output Voltage Regulation Node for LDO2.

4 VOUTL3 Output Voltage Regulation Node for LDO3.

5 VOUTL6 Output Voltage Regulation Node for LDO6.

6 VOUTL5 Output Voltage Regulation Node for LDO5.

7 VINL456 Input Power f or LDO4, LDO5 and LDO6.

8 VOUTL4 Output Voltage Regulation Node for LDO4.

9 VOUTL7 Output Voltage Regulation Node for LDO7.

10 VINL78 Input Power for LDO7 and LDO8.

11 VOUTL8 Output Voltage Regulation Node for LDO8.

12 ENL4 Enable Control Input for LDO4. Connect a 100k pull-low resistor.

WQFN-56L 7x7

13 ENL5 Enable Control Input for LDO5. Connect a 100k pull-low resistor.

14 ENL6 Enable Control Input for LDO6. Connect a 100k pull-low resistor.

15 SCL Clock Input for I2C. Open-drain output, connect a 10k pull-up resistor.

Copyright 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

2

©

DS5028-01 January 2015www.richtek.com

Page 3

Pin No. Pin Name Pin Function

16 SDA

Data Input for I

2

C. Open-drain output, c onnec t a 10k pull-up resistor.

17 ENL7 Enabl e Control Input for LDO7. Connect a 100k pull-low resistor.

18 ENL8 Enabl e Control Input for LDO8. Connect a 100k pull-low resistor.

19 IRQ Open-Drain IRQ Output Node.

RT5028

20

21, 34, 56, 57

(Exposed Pad)

RESET

AGND

Reset Output.

Analog Ground. The exposed pad must be soldered to a large PCB and

connected to AGND for maximum power dissipation.

22 PWRON Manual Power On. Connect a 100k pull - up resistor.

23 REBOOT System Power Reboot. Connec t a 100k pull-low resistor.

24 MTP

25 MASK_GPIO

MTP Write Protection Pin. Connect a 100k pull-low resistor, logic low is

inhibit ed and logic high is permit to write.

Select I

2

C or use EN pin for Bucks and LDOs. Connect a 100k pull-low resistor.

As MASK_GPIO is high, ignor e all E N pins.

As MASK_GPIO is low, EN pins and I

2

higher than I

C.

2

C both can control. EN pins priority is

26 PWRHOL D Power Hold Input. Connec t a 100k p ull -low resistor.

27 SADDR I2C Slave Address. Connect a 100k pull-low resistor.

28 ENB4 Enable Control Input for Buck4. Connect a 100k pull -low resi stor.

29 VOUTB4S Output Voltage Regulation Node for Buck4.

30 ENB3 Enable Control Input for Buck3. Connect a 100k pull -low resist or.

31 LXB4 Internal Switc h Node to Output Inductor Connecti on for Buck4.

32 VINB4 Input Power for Buck 4.

33 VOUTB3S Output Voltage Regulation Node for Buck3.

35, 36 LXB3 Internal Switch Node t o Output Inductor Connection for Buc k 3.

37, 38 VINB3 I nput Power for Buck3.

39 VOUTB2S Output Voltage Regulation Node for Buck2.

40 ENB2 Enable Control Input for Buck2. Connect a 100k pull -low resi stor.

41, 42 LXB2 Internal Switch Node t o Output Inductor Connection for Buc k 2.

43, 44 VINB2 I nput Power for Buck2.

45, 46 VINB1 I nput Power for Buck1.

47, 48 LXB1 Internal Switch Node t o Output Inductor Connection for Buc k 1.

49 ENB1 Enable Control Input for Buck1. Connect a 100k pull -low resi stor.

50 VOUTB1S Output Voltage Regulation Node for Buck1

51 VDDP Internal Bi as Regulator Voltage. Exter nal load on this pin is not allowed.

52 VIN Input Power for Analog B ase.

53 ENL1 Enabl e Control Input for LDO1. Connect a 100k pull-low resistor.

54 ENL2 Enabl e Control Input for LDO2. Connect a 100k pull-low resistor.

55 ENL3 Enabl e Control Input for LDO3. Connect a 100k pull-low resistor.

Copyright 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS5028-01 January 2015 www.richtek.com

©

3

Page 4

RT5028

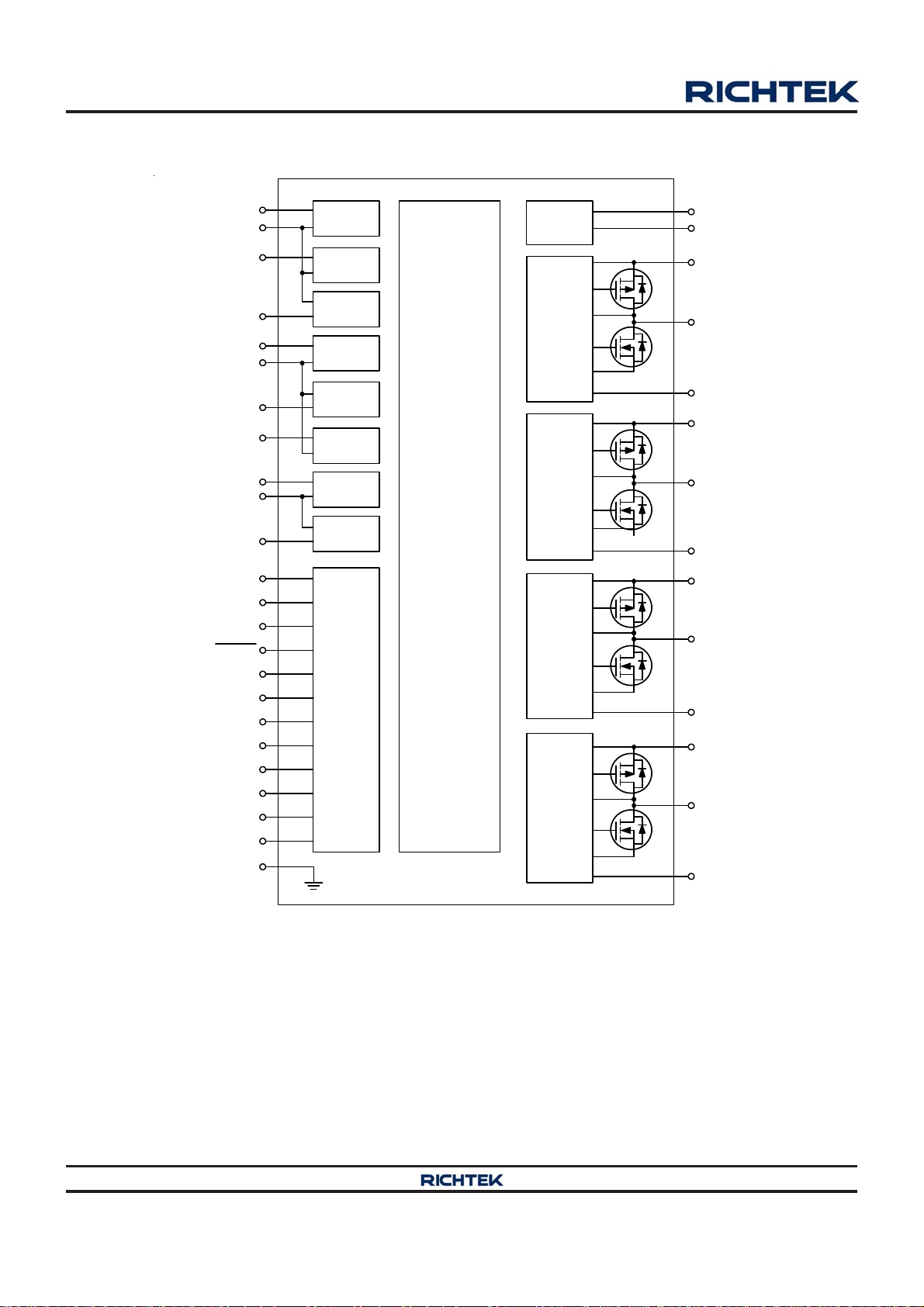

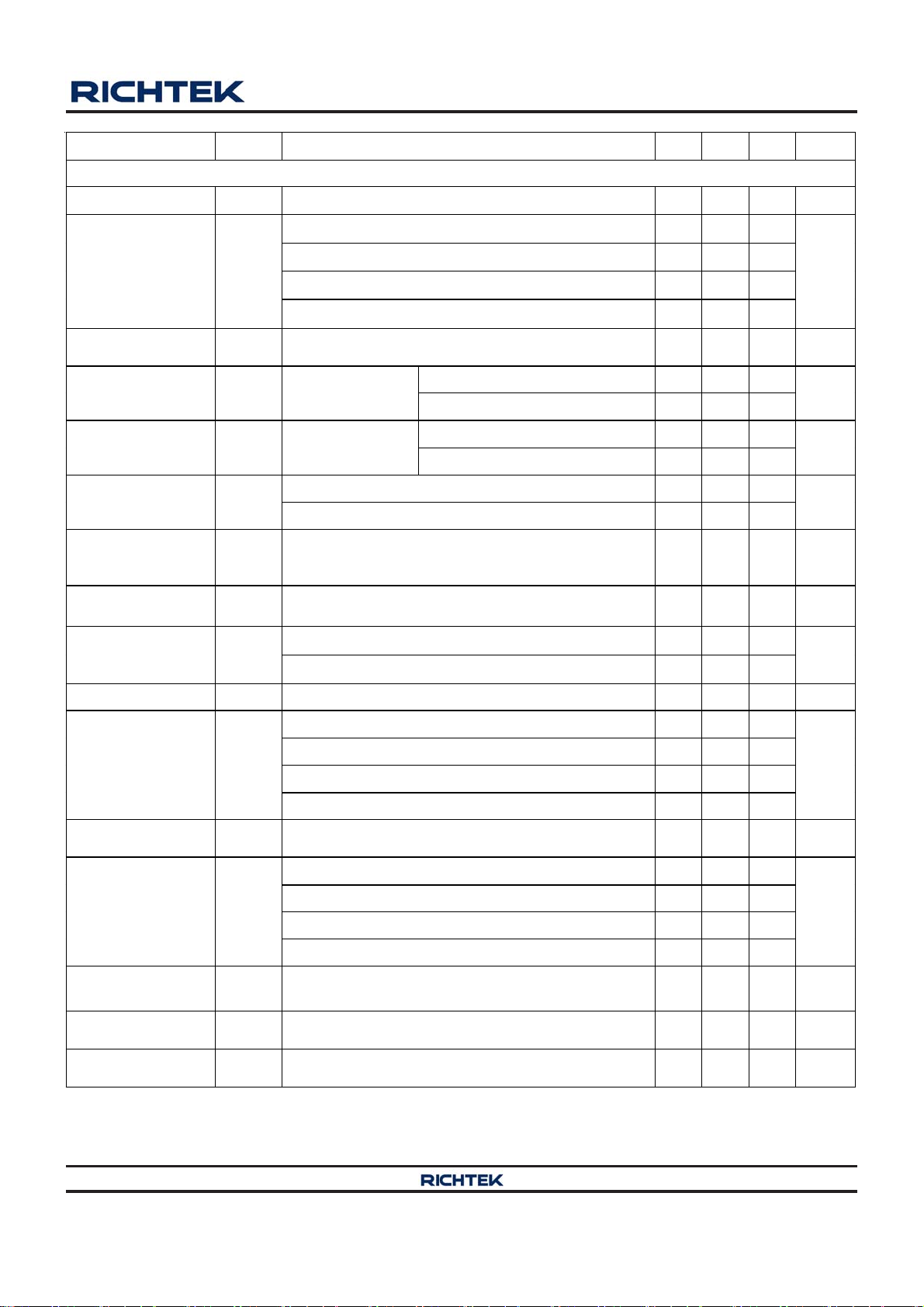

Function Block Diagram

VOUTL1

VINL123

VOUTL2

VOUTL3

VOUTL4

VINL456

VOUTL5

VOUTL6

VOUTL7

VINL78

VOUTL8

SDA

SCL

IRQ

RESET

PWRHOLD

REBOOT

MTP

MASK_GPIO

SADDR

PWRON

ENB1 to ENB4

ENL1 to ENL8

AGND

LDO1

300mA

LDO2

300mA

LDO3

300mA

LDO4

300mA

LDO5

300mA

LDO6

300mA

LDO7

300mA

LDO8

300mA

State

Machine

Central

Controller

2

C

I

Programmable

Analog

Base

Buck1

2.4A

Buck2

2A

Buck3

1.6A

Buck4

2A

GND

GND

GND

GND

VIN

VDDP

VINB1

LXB1

VOUTB1S

VINB2

LXB2

VOUTB2S

VINB3

LXB3

VOUTB3S

VINB4

LXB4

VOUTB4S

Copyright 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

©

DS5028-01 January 2015www.richtek.com

4

Page 5

Operation

RT5028

The RT5028 is a highly-integrated solution for industrial

system including 4-CH step-down DC/DC converters a nd

8-CH LDOs. The RT5028 a pplication mecha nism will be

introduced in later sections.

The power-on and power-off sequences ca n be controlled

by I2C or each EN pin and detected in MASK_GPIO pin.

When the MASK_GPIO pin is at Hi level, the PMIC follows

the power-on sequence to turn on channels. When the

MASK_GPIO pin is at Lo level, the channels of PMIC will

be controlled by the EN pin.

Synchronous Step-Down DC/DC Converter

Four current mode synchronous step-down DC/DC

converters operate with internal power MOSFETs, FB

resistors and compensation network. These cha nnels are

suitable for core power in industrial system. They ca n be

operated at 100% maximum duty cycle to extend battery

operating voltage range. When the input voltage is close

to the output voltage, the converter enters low dropout

mode with low output ripple. The operating frequency of

step-down converter is adjustable from 500kHz to 2MHz

and is controlled by I2C. Besides, the I2C interface also

can be used to select different operation mode s, On/Off

Sequence, programmable the output voltage, RAMP

control and discharge function. To enable AUTO Mode, it

is used to improve the efficiency at light load. If the AUTO

Mode is disabled, the converter operates in force PWM

mode with fixed switching frequency .

Over-Temperature Protection

An Over-T emperature Protection (OTP) is contained in the

device. The protection is triggered to force the device

shutdown for protecting itself when the junction

temperature exceeds 165°C typically. Once the junction

temperature drops below the hysteresis 10°C typically,

the device must be re-send PWRON to start system.

Output Under-Voltage Protection

The output under-voltage protection is implemented in order

to prevent operation at low output voltage conditions.

When the step-down DC/DC converters output voltage is

lower than 1/2 x (V

turns off immediately.

), the UVP event triggers and PMIC

OUT

Linear Regulator

Eight generic low voltage LDOs for multiple purpose power .

The LDOs are stable over the entire operating load ra nge

with the use of external ceramic capacitors. The LDOs

also have I2C programm able power on/off sequence a nd

discharge function. The output voltage is adjustable by

the I2C interface in the ra nge of 1.6V to 3.6V.

Copyright 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS5028-01 January 2015 www.richtek.com

©

5

Page 6

RT5028

Absolute Maximum Ratings (Note 1)

Analog Ba se Input Voltage, VIN ---------------------------------------------------------------------------------------- −0.3V to 6V

PMIC Input V oltage, VINL123/456/78, VINB1/2/3/4 ---------------------------------------------------------------- −0.3V to 6V

PMIC Output V oltage, VOUTLx, VOUTBxS, LXBx----------------------------------------------------------------- −0.3V to 6V

PMIC related Other Pins-------------------------------------------------------------------------------------------------- −0.3V to 6V

Power Dissipation, P

WQFN-56L 7x7 ------------------------------------------------------------------------------------------------------------- 3.7W

Package Thermal Re sistance (Note 2)

WQF N-56L 7x7, θJA-------------------------------------------------------------------------------------------------------- 27°C/W

WQFN-56L 7x7, θJC------------------------------------------------------------------------------------------------------- 7°C/W

Junction T emperature------------------------------------------------------------------------------------------------------ 150°C

Lead T e mperature (Soldering, 10 sec.)-------------------------------------------------------------------------------- 260°C

Storage T emperature Range --------------------------------------------------------------------------------------------- −65°C to 150°C

ESD Susceptibility (Note 3)

HBM (Human Body Model)----------------------------------------------------------------------------------------------- 2kV

MM (Machine Model) ------------------------------------------------------------------------------------------------------ 200V

@ T

D

= 25°C

A

Recommended Operating Conditions (Note 4)

Junction T emperature Range--------------------------------------------------------------------------------------------- − 40°C to 125°C

Ambient T emperature Range--------------------------------------------------------------------------------------------- − 40°C to 85°C

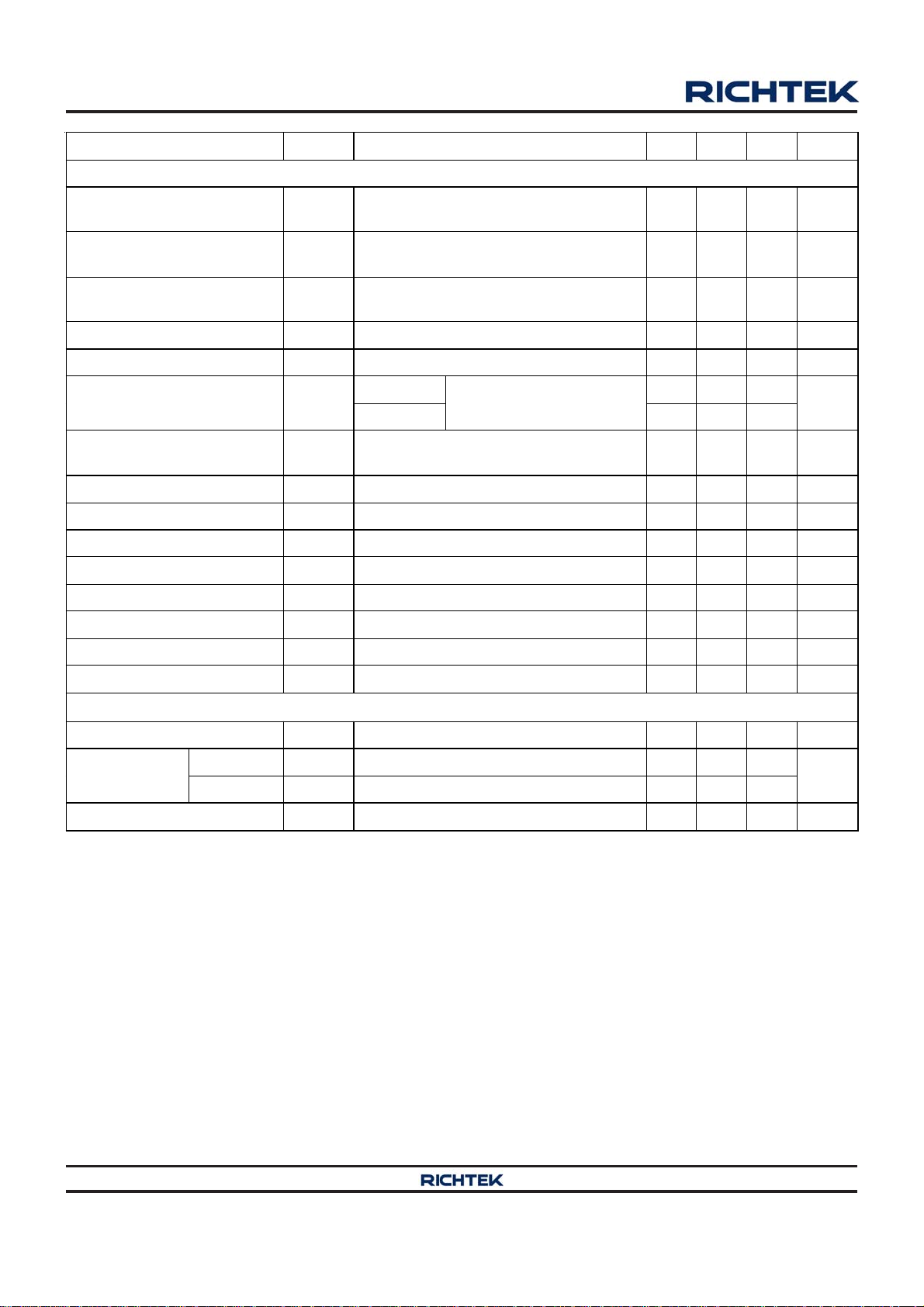

Electrical Characteristics

(VIN = 3.3V to 5.5V, TA = −40°C to 85°C, unless otherwise specified)

Parameter Symbol Test Conditions Min Typ Max Unit

As f

> 1MHz, 3.3V VIN 5.5 V.

Operation Voltage of VIN

PMIC

Quiescent Curr ent IIN

Warning for Die

Temperature

Over-Temperature

Protection

OTP and Warning

Hysteresis

OTW

OTP -- 165 -- C

-- 10 -- C

SW

1MHz, VIN 4V.

If f

SW

VIN = 5V, LDOs, Bucks are ON with No Load. 300 450 600 A

= 5V, LDOs, Bucks are OFF.

V

IN

SCL = SDA = 0V

Temperature 1 -- 100 -Temperature 2 -- 125 --

3.3 -- 5.5 V

5 20 40 A

C

Input Pull-low 100k Resistor R

VIN = 5V, Temperature = 40C to 125C 70 115 160 k

Low

Copyright 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

6

©

DS5028-01 January 2015www.richtek.com

Page 7

RT5028

t

Parameter Symbol Test Conditions Min Typ Max Unit

Buck1 to Buck4

Input Voltage V

Output Voltage V

Consumption

Current

INB

OUTB

I

VINB

Effi ciency Peak Eff

Output Voltage

Accuracy

Output Voltage

Ripple

V

OUTAcc

V

Rip

Output Voltage

Temperature

Coefficien

Switching

Frequency

Switching

Frequency Accuracy

-- ±100 -- ppm/C

f

SW

3.3 -- 5.5 V

Buck1 I

2

C Programmable per step 25mV

Buck2 I2C Programmable per step 25mV

Buck3 I2C Programmable per step 50mV

Buck4 I2C Programmable per step 50mV

AUTO Mode I

V

= 1.2V, V

OUT

3.6V

3.1V < V

1mA < I

I

OUT

I

OUT

I

2

C Pr ogr amma ble 0. 43 - - 2 M H z

1MHz f

IN

OUT

= 1m A , C

= 1A , C

SW

< 5.5V,

= 0mA, Each Buck 10 20 40 A

OUT

I

= CCM -- 88 --

LOAD

=

IN

I

= 1mA -- 80 --

LOAD

As VOUTB1S to VOUTB4 S 1V. 3 -- 3

< I

MAX

As VOUTB1S to VOUTB4S < 1V. 30 -- 30

= 10F, 2MHz -- 25 --

OUT

= 10F, 2MHz -- 8 --

OUT

10 -- 10

0.7 -- 1.8

0.7 -- 1.8

V

0.7 -- 3.6

0.7 -- 3.6

%

%mV

mV

%

fSW 1MHz 20 -- 20

S ugg est Induc t or L

Buck

Peak Current Limit OCP

Under-Voltage

Protection

Maximum Output

Current

Out put Transient

Response

High-Side

On-Resistance

Low-Side

On-Resistance

UVP VOUTB1S to VOUTB4S < 0.66 x (V

I

MAX

V

peak

R

pon

R

non

-- 2.2 -- H

Buck1 3.1 4.4 5.8

Buck2 2.8 4 5.2

A

Buck3 2.6 3.7 4.8

Buck4 2.8 4.1 5.3

Target) 56 66 76 %

OUT

Buck1 2.4 -- -Buck2 2 -- --

A

Buck3 1.6 -- -Buck4 2.0 -- --

0.8A to 1.6A at 20s, V

Buck1 and Buck2

OUT

= 1.2V

4 -- 4 %

VIN = 3.7V 50 150 250 m

VIN = 3.7V 40 110 160 m

Copyright 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS5028-01 January 2015 www.richtek.com

©

7

Page 8

RT5028

Parameter Symbol Test Conditions Min Typ Max Unit

LDO1 to LDO8

Input Voltage for

VINL123/456/78

Output Voltage LDO123/78 V

Output Voltage LDO456 V

Output Current I

2.5 -- 5.5 V

V

INL

3.1V VIN 5.5V, 50A I

OUTL

3.1V V

OUTL

300 -- -- mA

OUT

5. 5V, 50A I

IN

OUT

OUT

I

I

3%

MAX

3%

MAX

1.6 to

3.6

3 to

3.6

3% V

3% V

Output Short Current Isht 330 450 600 mA

> 3.1V

V

V

Voltage Difference

Output Voltage Temperature

Coefficient

IN

V

OUT

-- ±100 -- ppm/C

Supply Current ISS I

Shutdown Current I

0 1 2 A

OFF

IN

VIN > 2.5V 0. 05 0. 11 0.5

= 0mA 10 35 60 A

OUT

V

IN

= V

SET

, I

OUT

= I

OUTMAX

0.05 0.1 0.3

V

Line Regulation Input 3V to 5V, load = 100mA 0 1 5 mV

Load Regulation V

T ra n sien t R espo n s e V

OUT

Ri pp le R eje cti on f = 1 0 kHz, I

Ri si ng Tim e V

Falling Time V

= 5V, Load 100mA to 300mA 0 0.1 1 %

IN

50A I

0.7 x V

OUT

0.3 x V

OUT

OUTMAX

/ 2 (⊿t = 1s) -- 50 -- mV

OUT

= I

Target

Target

OUTMAX

/ 2 -- 60 -- dB

, I

= 0mA 150 220 300 s

OUT

, I

= 0mA 300 600 1000 s

OUT

I2C Interface Elect rical Charac teristics

Voltage Output Low VOL -- -- 0.4 V

Input Voltage

High-Level V

1.5 -- --

IH

V

Low-Level VIL -- -- 0.4

SCL Clock SCL -- -- 400 kHz

Note 1. Stresses beyond those listed “Absolute Maximum Ratings” may cause permanent damage to the device. These are

stress ratings only, and functional operation of the device at these or any other conditions beyond those indicated in

the operational sections of the specifications is not implied. Exposure to absolute maximum rating conditions may

affect device reliability.

Note 2. θ

Note 3. Devices are ESD sensitive. Handling precaution is recommended.

Note 4. The device is not guaranteed to function outside its operating conditions.

is measured at T

JA

measured at the exposed pad of the package.

= 25°C on a high effective thermal conductivity four-layer test board per JEDEC 51-7. θJC is

A

Copyright 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

8

©

DS5028-01 January 2015www.richtek.com

Page 9

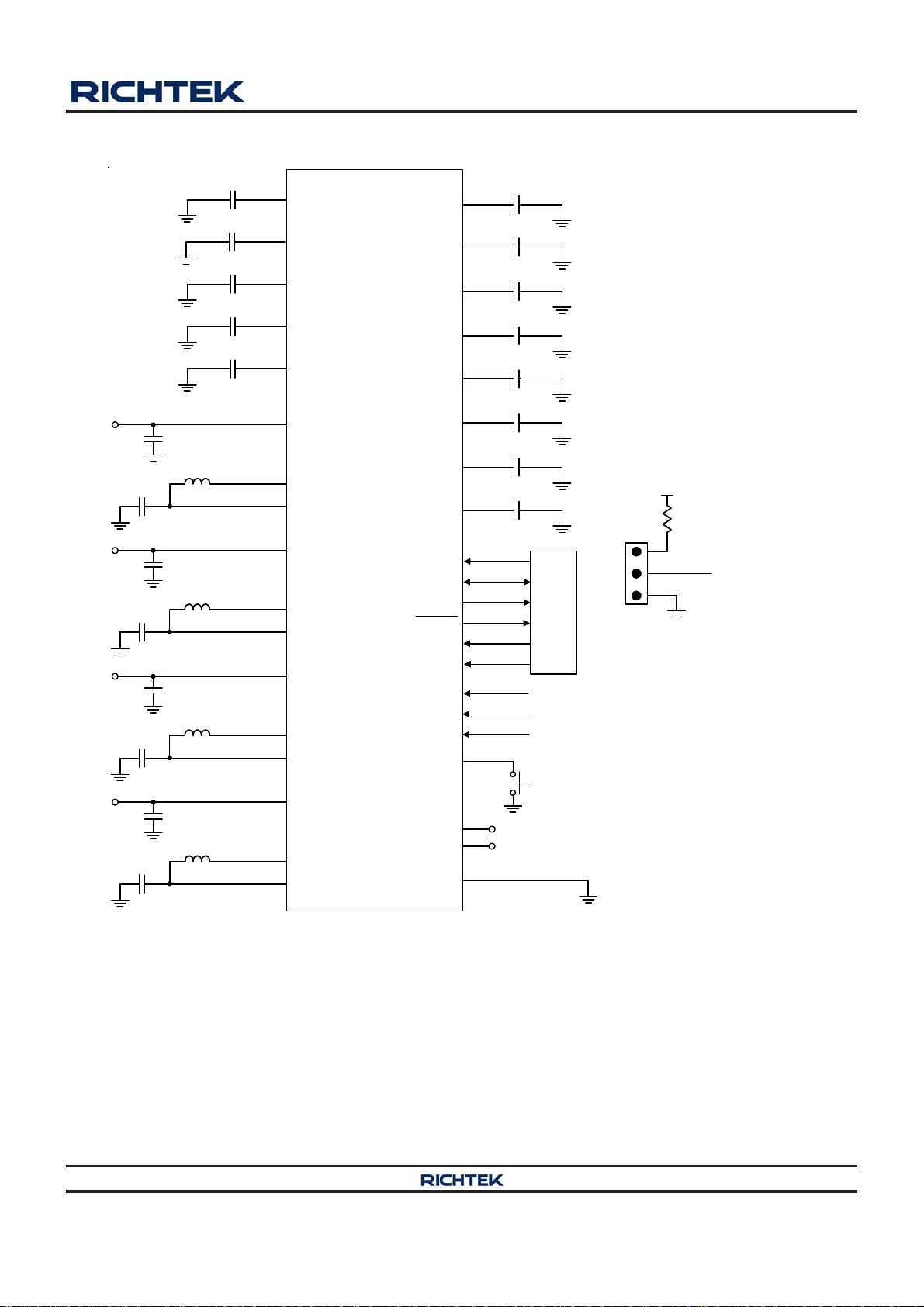

Typical Application Circuit

RT5028

22µF

22µF

22µF

22µF

10µF

10µF

10µF

10µF

2.2µH

2.2µH

2.2µH

2.2µH

1µF

1µF

1µF

1µF

1µF

52

10

45, 46

47, 48

50

43, 44

41, 42

39

37, 38

35, 36

33

32

31

29

VIN

51

VDDP

2

VINL123

7

VINL456

VINL78

VINB1

LXB1

VOUTB1S

VINB2

LXB2

VOUTB2S

VINB3

LXB3

VOUTB3S

VINB4

LXB4

VOUTB4S

RT5028

PWRHOLD

MASK_GPIO

ENL1 to ENL8

ENB1 to ENB4

VOUTL1

VOUTL2

VOUTL3

VOUTL4

VOUTL5

VOUTL6

VOUTL7

VOUTL8

SCL

SDA

IRQ

RESET

REBOOT

MTP

SADDR

PWRON

AGND

1µF

1

1µF

3

1µF

4

1µF

8

1µF

6

1µF

5

1µF

9

1µF

11

15

16

19

20

26

23

24

25

27

22

21, 34, 56,

57 (Exposed Pad)

AP

VIN

SADDR

MASK_GPIOMTP

AGND

As SADDR connect to AGND

slave address

=0111111

As SADDR connect to VIN

slave address

=0110111

As MASK_GPIO connect to AGND

EN pins can control.

As MASK_GPIO connect to VIN

Ignore all EN pins.

As MTP connect to AGND

Inhibit to write MTP.

As MTP connect to VIN

Permit to write MTP.

Copyright 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

©

DS5028-01 January 2015 www.richtek.com

9

Page 10

RT5028

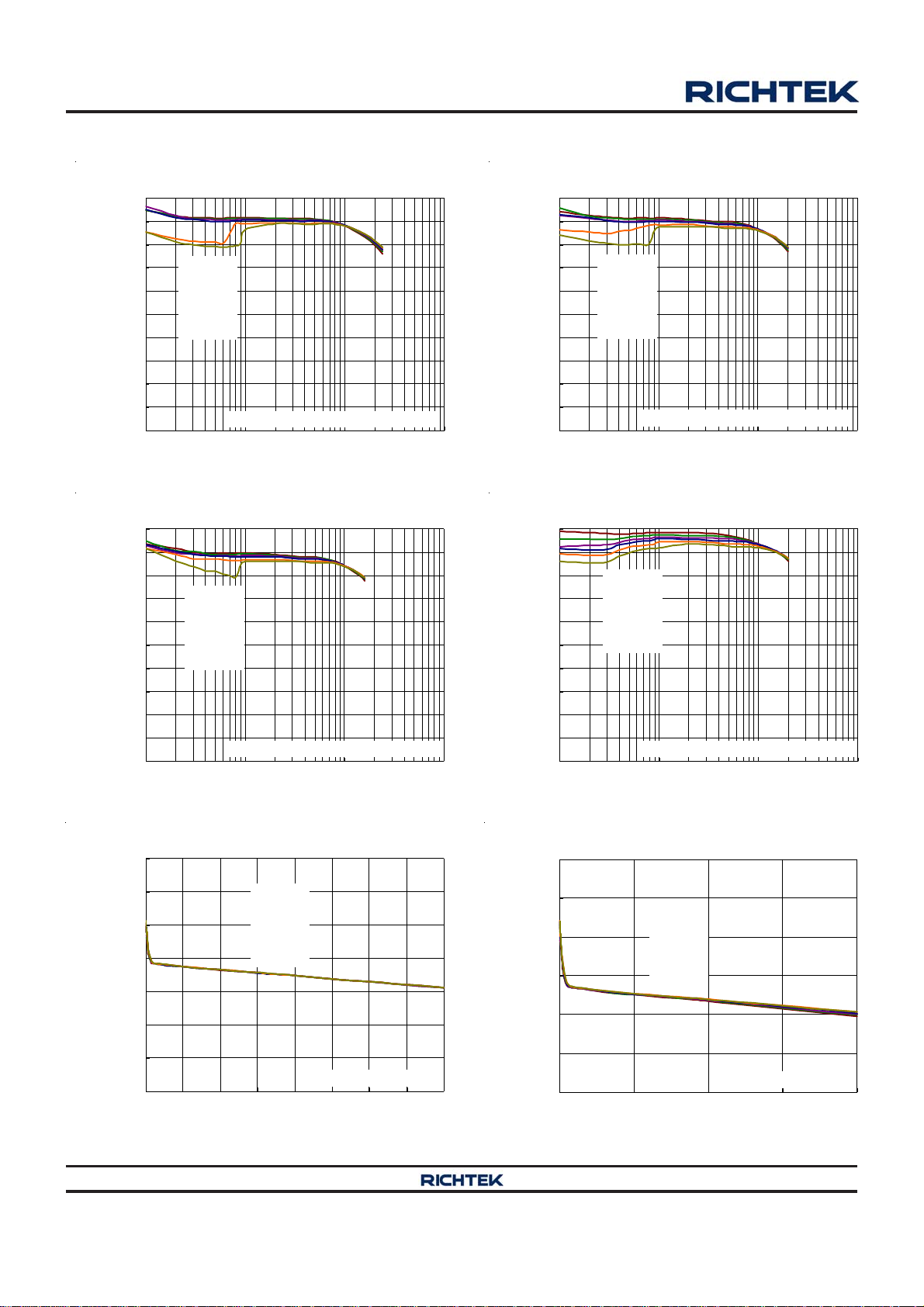

Typical Operating Characteristics

CH1 Buck Efficiency vs. Output Current

100

90

80

70

60

50

40

Effici ency (%)

30

20

10

0

VIN = 3.3V

VIN = 3.6V

VIN = 3.9V

VIN = 4.2V

VIN = 5V

VIN = 5.5V

V

= 1.35V, L = 2.2μH, C

OUT

10 100 1000 10000

OUT

Output Current (mA)

CH3 Buck Efficiency vs. Output Current

100

90

80

70

60

50

40

Effici ency (%)

30

20

10

0

VIN = 3.3V

VIN = 3.6V

VIN = 3.9V

VIN = 4.2V

VIN = 5V

VIN = 5.5V

V

= 1.2V, L = 2.2μH, C

OUT

10 100 1000 10000

OUT

Output Current (mA)

= 10μF

= 10μF

CH2 Buck Efficiency vs. Output Current

100

90

80

70

60

50

40

Efficiency (%)

30

20

10

0

VIN = 3.3V

VIN = 3.6V

VIN = 3.9V

VIN = 4.2V

VIN = 5V

VIN = 5.5V

V

= 1.5V, L = 2.2μH, C

OUT

10 100 1000 10000

OUT

Output Current (mA)

CH4 Buck Efficiency vs. Output Current

100

90

80

70

60

50

40

Eff iciency (%)

30

20

10

0

10 100 1000 10000

VIN = 3.6V

VIN = 3.9V

VIN = 4.2V

VIN = 4.5V

VIN = 5V

VIN = 5.5V

V

OUT

Output Current (mA)

= 3.3V, L = 2.2μH, C

OUT

= 10μF

= 10μF

CH1 Buck Output Voltage vs. Output Current

1.39

1.38

1.37

1.36

1.35

1.34

Output Voltage (V)

1.33

1.32

0 300 600 900 1200 1500 1800 2100 2400

Copyright 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

©

VIN = 3.3V

VIN = 3.6V

VIN = 3.9V

VIN = 4.2V

VIN = 5V

VIN = 5.5V

L = 2.2μH, C

Output Current (mA)

OUT

= 10μF

CH2 Buck Output Voltage vs. Outpu t Current

1.53

1.52

1.51

1.50

1.49

Output Voltage (V)

1.48

1.47

0 500 1000 1500 2000

VIN = 3.3V

VIN = 3.6V

VIN = 3.9V

VIN = 4.2V

VIN = 5V

VIN = 5.5V

L = 2.2μH, C

Output Current (A)

OUT

DS5028-01 January 2015www.richtek.com

10

= 10μF

Page 11

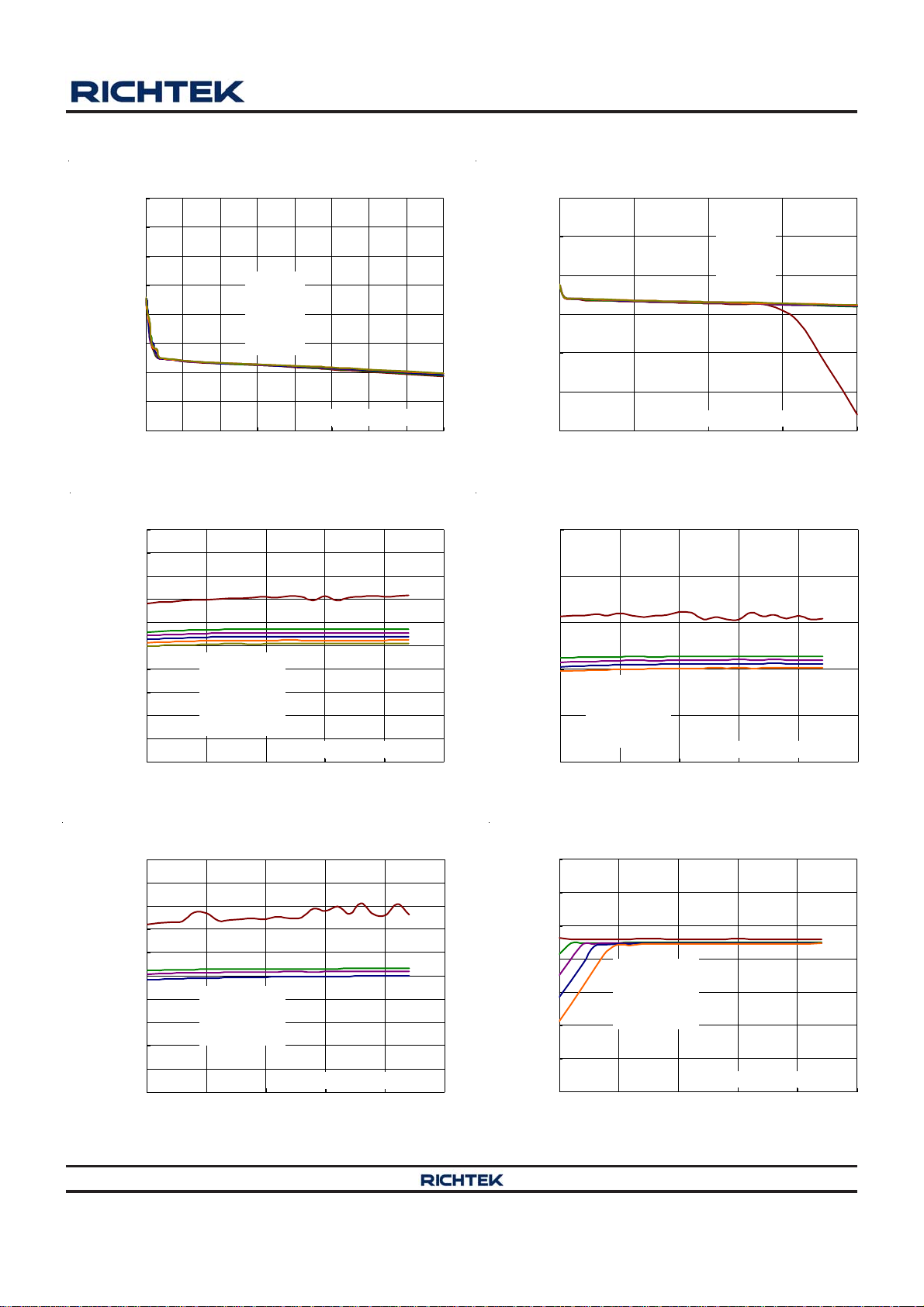

RT5028

CH3 Buck Output Voltage vs. Output Current

1.25

1.24

1.23

1.22

1.21

1.20

Output Voltage (V)

1.19

1.18

1.17

0 200 400 600 800 1000 1200 1400 1600

VIN = 3.3V

VIN = 3.6V

VIN = 3.9V

VIN = 4.2V

VIN = 5V

VIN = 5.5V

L = 2.2μH, C

OUT

= 10μF

Output Current (mA)

CH1 Buck Output Voltage vs. Input Voltage

1.40

1.39

1.38

1.37

1.36

1.35

1.34

1.33

Output Voltage (V)

1.32

1.31

1.30

3.3 3.8 4.3 4.8 5.3 5.8

I

= 0mA

OUT

I

= 500mA

OUT

I

= 1000mA

OUT

I

= 1500mA

OUT

I

= 2000mA

OUT

I

= 2400mA

OUT

Input Voltage (V)

L = 2.2μH, C

OUT

= 10μF

CH4 Buck Output Voltage vs. Output Current

3.38

VIN = 3.6V

3.33

VIN = 3.9V

VIN = 4.2V

VIN = 4.5V

3.28

3.23

3.18

VIN = 5V

VIN = 5.5V

Output Voltage (V)

3.13

3.08

L = 2.2μH, C

0 500 1000 1500 2000

OUT

= 10μF

Output Current (mA)

CH2 Buck Output Voltage vs. Input Voltage

1.55

1.53

1.51

Output V oltage (V)

1.49

1.47

1.45

I

= 0mA

OUT

I

= 500mA

OUT

I

= 1000mA

OUT

I

= 1500mA

OUT

I

= 2000mA

OUT

3.3 3.8 4.3 4.8 5.3 5.8

L = 2.2μH, C

OUT

= 10μF

Inpu t Voltage (V)

CH3 Buck Output Voltage vs. Input Voltage

1.24

1.23

1.22

1.21

1.20

1.19

1.18

1.17

Output Volt age (V)

1.16

1.15

1.14

3.3 3.8 4.3 4.8 5.3 5.8

Copyright 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

©

I

= 0mA

OUT

I

= 500mA

OUT

I

= 1000mA

OUT

I

= 1600mA

OUT

Input Vol tage (V)

L = 2.2μH, C

OUT

= 10μF

CH4 Buck Output Voltage vs. Input Voltage

3.80

3.60

3.40

3.20

3.00

2.80

Output Voltage (V)

2.60

2.40

3.3 3.8 4.3 4.8 5.3 5.8

I

= 0mA

OUT

I

= 500mA

OUT

I

= 1000mA

OUT

I

= 1500mA

OUT

I

= 2000mA

OUT

Inp ut Voltage (V)

L = 2.2μH, C

OUT

= 10μF

DS5028-01 January 2015 www.richtek.com

11

Page 12

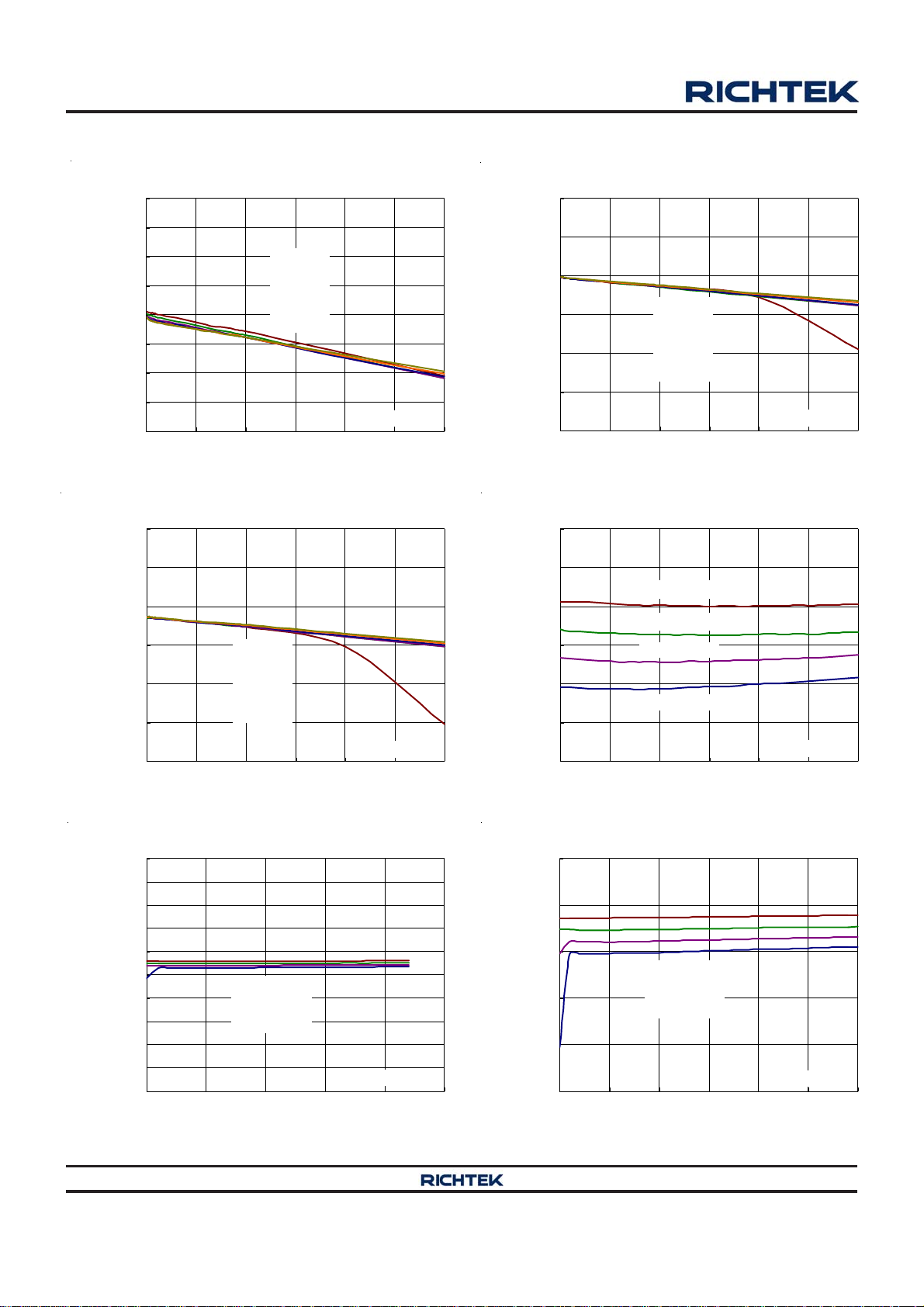

RT5028

Output Volt age (V)

Output Voltage (V)

LDO2 Output Voltage vs. Output Current

1.790

1.785

1.780

1.775

1.770

1.765

1.760

1.755

1.750

0 50 100 150 200 250 300

VIN = 2.5V

VIN = 3V

VIN = 3.6V

VIN = 4.2V

VIN = 5V

VIN = 5.5V

Output Current (mA)

LDO7 Output Voltage vs. Output Current

2.52

2.50

2.48

2.46

2.44

2.42

2.40

0 50 100 150 200 250 300

VIN = 2.5V

VIN = 3V

VIN = 3.6V

VIN = 4.2V

VIN = 5V

VIN = 5.5V

Output Current (mA)

LDO5 Output Voltage vs. Output Current

3.32

3.30

3.28

3.26

VIN = 3.3V

VIN = 3.6V

VIN = 3.9V

3.24

Output Voltage (V)

3.22

C

= 1μF

OUT

3.20

0 50 100 150 200 250 300

VIN = 4.2V

VIN = 5V

VIN = 5.5V

C

= 1μF

OUT

Output Current (mA)

LDO2 Output Voltage vs. Input Voltage

1.78

1.78

I

= 0mA

OUT

1.77

1.77

1.76

Output Voltage (V)

1.76

C

= 1μF

OUT

1.75

2.5 3 3.5 4 4.5 5 5.5

I

= 100mA

OUT

I

= 200mA

OUT

I

= 300mA

OUT

Input Voltage (V)

C

= 1μF

OUT

LDO5 Out put Volt age vs. Input Volt age

3.50

3.45

3.40

3.35

3.30

3.25

3.20

3.15

Output Voltage (V)

3.10

3.05

3.00

3.3 3.8 4.3 4.8 5.3 5.8

Copyright 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

©

I

= 0mA

OUT

I

= 100mA

OUT

I

= 200mA

OUT

I

= 300mA

OUT

Inp ut Voltage (V)

Output Voltage (V)

C

= 1μF

OUT

LDO7 Output Voltage vs. Input Voltage

2.50

2.48

2.46

2.44

2.42

2.40

2.5 3 3.5 4 4.5 5 5.5

I

= 0mA

OUT

I

= 100mA

OUT

I

= 200mA

OUT

I

= 300mA

OUT

Input Voltage (V)

C

OUT

DS5028-01 January 2015www.richtek.com

12

= 1μF

Page 13

Application Information

RT5028

The RT5028 is a highly-integrated solution for industrial

system including PMIC and memory system. The R T5028

application me cha nism a nd I2C compatible interface are

introduced in later sections. The system's slave address

Detail time sequence control is described in Power ON/

OFF diagram. The I2C interface can program individual

regulator output voltage as well as on/off control and

voltage setting.

is 01 10111 (As SADDR = high) or 0111111(As SADDR =

low).

PMIC - Power management system provides 8 low dropout

linear regulator and 4 high efficiency synchronous ste pdown DC/DC converters. Power-On and Power-Off

sequences are control by PWRON and RESET in put pins.

I2C Interface Timing Diagram

The RT5028 acts a s an I2C -bus slave. The I2C-bus master

configures the settings for all function blocks by sending

command bytes to the RT5028 vi a the 2-wire I2C-bus. The

I2C timing diagrams are list in the following.

Read Function

Reading One Indexed Byte of Data from RT (With 1-Byte)

Acknowledge from RT Acknowledge from RT Acknowledge from Master

S Slave Address 0 A Register Address A Data Byte A P

R/W

Repeated Start R/W

Sr Slave Address 1 A

Acknowledge from RT

1Byte

Reading n Indexed W ords of Data from RT (With N-Byte)

Acknowledge from RT Acknowledge from RT

Acknowledge from RT

S Slave Address 0 A Register Address A

Repeated Start

Acknowledge from Master Acknowledge from Master

Data Byte A Data Byte A

1st Byte 2nd Byte (n-1)th Byte nth Byte

Sr Slave Address 1 A

R/WR/W

Acknowledge from Master Acknowledge from Master

……

Data Byte A Data Byte A P

Write Function

Writing One Byte of Data to RT (With 1-Byte)

Acknowledge from RT Acknowledge from RT Acknowledge from RT

S Slave Address 0 A Register Address A Data Byte A P

R/W

1Byte

Writing n Bytes of Data to RT (With N-Byte)

Acknowledge from RT Acknowledge from RT

S Slave Address 0 A Register Address A

R/W

Acknowledge from RT

Data Byte

1st Byte

Acknowledge from RT Acknowledge from RT

Acknowledge from RT

A

Data Byte

2nd Byte

A

…

Data Byte A Data Byte A P

(n-1)th Byte nth By te

Copyright 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

©

DS5028-01 January 2015 www.richtek.com

13

Page 14

RT5028

PMIC

Power Channels Control Methodology

When VIN power Good or PW RON event occurs, the PMIC

will follow the power on sequence to turn on channels.

During normal operation, users can use the REBOOT pin

Power Off

Edge

trigger

No

PWRON

Check

Yes

1

(Internal I

2

C)

Mask_GPIO

to restart PMIC again. Another PWROFF event, OTP or

UVP occurs, PMIC will execute the power off. In the

RT5028 PMIC, the UVP event will be set out when the

Buck1 to Buck4s' output voltage is lower than 1/2 x (V

Edge

trigger

VIN Power

Good

No

Yes

0

(External Enable Control)

OUT

).

Yes

REBOOT

Check

Power On

Sequence

Normal Operation

No

OTP Check UVP Check

External EN

Check

Yes

NoNo

YesYes Yes

Power Off

No

PWROFF

Check

Yes

REBOOT

Check

No

Copyright 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

©

DS5028-01 January 2015www.richtek.com

14

Page 15

PMIC - POWER ON/OFF Setting

The circuit setting for communication between RT5028

and A P is showed as below.

SCL

SDA

IRQ

RESET

PWRHOLD

State

Machine

REBOOT

MTP

MASK_GPIO

SADDR

PWRON

ENL1 to ENL8

ENB1 to ENB4

VIN

SADDR

MASK_GPIOMTP

AGND

AP

As SADDR connect ot AGND

slave address

=0111111

As SADDR connect ot VIN

slave address

=0110111

As MASK_GPIO connect ot

AGND

EN pins can control.

As MASK_GPIO connect ot VIN

Ignore all EN pins.

RT5028

Power Hold Function

When the “PWRHOLD” signal does not come during

THOLD time, the RT5028 will do shutdown sequence.

START_TIME

PWRON

BUCK1

……

BUCK4

LDO1

……

LDO8

As MTP connect ot AGND

Inhibit to write MTP.

As MTP connect ot VIN

Permit to write MTP.

If users want to disable power hold function, set

“DisTHOLD” bit in I2C register 10 bit[0] to disable this

function. In the timing diagra m below, the “THOLD” and

“RESET_DLY” can be set by MTP program.

RESET_DLY

Turn off sequence :

First-on-last-Off

RESET

PWRHOLD

Copyright 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

©

Always Low

THOLD

DS5028-01 January 2015 www.richtek.com

15

Page 16

RT5028

When AP sends the “PWRHOLD” signal during THOLD ti me, the RT5028 will keep power-on.

START_TIME

PWRON

BUCK1

……

BUCK4

LDO1

……

LDO8

RESET_DLY

RESET

PWRHOLD

Timing Based ON/OFF Sequence

START_TIME

PWRON

BUCK1

TSS

BUCK2

……

BUCK4

LDO1

……

LDO8

Normal power on

TSS

...

SHDN_PRESS

RESET_DLY

THOLD

Low to High signal from AP.

Normal power off

TSS

TSS

RESET

Copyright 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

©

DS5028-01 January 2015www.richtek.com

16

Page 17

Level Based ON/OFF Sequence

RT5028

PWRON

BUCK1

BUCK2

……

BUCK4

LDO1

……

LDO8

RESET

START_TIME

Normal power on

>80 %

>80 %

>80 %

>80 %

RESET_DLY

SHDN_PRESS

Normal power off

8ms

8ms

Abnormal OFF

PWRON

BUCK1

BUCK2

BUCK4

IRQ

……

LDO1

……

LDO8

START_TIME

TSS

Normal power on

TSS

RESET_DLY

IRQ Even Occur

SHDN_DLYTIME

Abnormal power off

RESET

Copyright 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

©

DS5028-01 January 2015 www.richtek.com

17

Page 18

RT5028

PMU On/Off Sequence Setting

In the RT5028, users can set the power on/of f sequence and output voltage by I2C register 0x01 to 0x04 for Buck output

voltage, 0x07 to 0x0E for LDO output voltage and 0x2C to 0X32 f or startup sequence setting.

In the table below, users must set one by one (continue s number) a nd missing code is not allowed.

If users miss sequence code, the RT5028 will wait for next channel and the IC will be hold in waiting status.

Output Voltage Setting Startup Sequence Setting

Buck1

Buck1Output[5:0] Buck1_Seq[3:0]

[000000] [0001]

Buck2

Buck2Output[5:0] Buck2_Seq[3:0]

[101100] [0010]

Buck3

Buck3Output[5:0] Buck3_Seq[3:0]

[000000] [0011]

Buck4

Buck4Output[5:0] Buck4_Seq[3:0]

[101100] [0100]

LDO1

LDO1OUT[6:0] LDO1_Seq[3:0]

[0000000] [0101]

LDO2

LDO2OUT[6:0] LDO2_Seq[3:0]

[0101000] [0110]

LDO3

LDO3OUT[6:0] LDO3_Seq[3:0]

[0000000] [0111]

LDO4

LDO4OUT[6:0] LDO4_Seq[3:0]

[0101000] [1000]

LDO5

LDO5OUT[6:0] LDO5_Seq[3:0]

[0000000] [1001]

LDO6

LDO6OUT[6:0] LDO6_Seq[3:0]

[0101000] [1010]

LDO7

LDO7OUT[6:0] LDO7_Seq[3:0]

[0000000] [1011]

LDO8

LDO8OUT[6:0] LDO8_Seq[3:0]

[0101000] [1100]

Startup Enable Method

(Soft-Start Control)

[10]

Note :

* Output Voltage Setting: fill relative binary code to set the output voltage.

* Startup Sequence Setting :

“0000” denotes no operation (disable).

“0001” denotes first-startup.

“1100 to 1111” denotes last-startup.

If same number, it means startup at the same time.

*Startup Enable Method :

[01] to [11] : each startup enable interval time (1ms, 4ms, 8ms).

[00] : start end voltage (the output voltage's 80%)

Copyright 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

18

©

DS5028-01 January 2015www.richtek.com

Page 19

RT5028

Synchronous Step-Down DC/DC Converter

Four current mode synchronous step-down DC/DC

converters operate with internal power MOSFETs and

compensation network. These channels supply the power

core chip of portable system. They can be operated at

100% maximum duty cycle to extend battery operating

voltage range. When the input voltage is close to the output

voltage, the converter enters low dropout mode with low

output ripple. The operating frequency range of ste p-down

converter is 0.5MHz to 2MHz.

Four step-down converters have RAMP control function

a s the following diagra m.

DC/DC 1/2/3/4

Output Voltage4

DC/DC 1/2/3/4

Output Voltage2

DC/DC 1/2/3/4

Output Voltage1

DC/DC 1/2/3/4

Output Voltage3

REBOOT Function

As the REBOOT pin is set from low to high, the REBOOT

function will be active. The REBOOT's FSM is shown as

below. It concludes 100ms de-bouncing ti me and delay1/

delay2 power off delay time.

Table 1. REBOOT Input Control Setting

Description Default

delayed2 10

delayed1

Action

00 : 100ms 10 : 1s

01 : 500ms 11 : 2s

delayed1 power-off then

delayed2 power-on PMIC

10

From “LOW“ to “HIGH” rising

input into REBOOT pin with

100ms debouncing time

Wait for delayed1 time

Power off the PMIC

Wait for delayed2 time

Power on the PMIC

IRQ Table

We summarize all IRQ items in the register table. All IRQ_status registers are implemented as reset after read. If

IRQ_enable bit is Low , the IRQ_status bit will not update status. IRQ_enable will ma sk IRQ_status to trigger IRQ_PMIC

Low, so the system can decide which interrupt is necessary.

Waveform - (when the other IRQ_status are low)

IRQ_Enable_OVP

OVP

IRQ_Status_OVP

IRQ_PMIC

Reset after

Read

Mask

IRQ_Status

Reset after

Read

Waveform - (when the other IRQ_status are low)

* OTW125/OTW100 means the 125°C/100°C pre-warming over temperature. It only change IRQ status bits and don't

trigger IRQ pin.

Copyright 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS5028-01 January 2015 www.richtek.com

©

19

Page 20

RT5028

EEPROM (MTP) Control Flow

The RT5028 embeds 32 bytes MTP memory , a nd it allows

users to save some I2C register bank data to MTP. When

the I2C register 0x3A Bit[0]/Bit[1] is wrote to “1”, the

MTP Page1/Page2 will execute era se proce ss firstly.

Because the erase process will be done in every writing

time, the MTP data will be missed. So it would be best

for users to read data from MTP to I2C first before

executing writing process.

Page 1 writing follow :

Set I2C Register 0x3A Bit[4] =1

Reading MTP process

PMU will read MTP data to

relative I

Set I2C Register 0x3A Bit[0]

PMU will erase the MTP page1

2

C register bank.

data

Writing MTP process

Thermal Considerations

For continuous operation, do not exceed absolute

maximum junction temperature. The maximum power

dissipation depends on the thermal resistance of the IC

package, PCB layout, rate of surrounding airflow, and

difference between junction and a mbient temperature. The

maximum power dissipation can be calculated by the

following formula :

P

where T

the ambient temperature, a nd θ

D(MAX)

= (T

J(MAX)

− TA) / θ

J(MAX)

JA

is the maximum junction temperature, TA is

is the junction to ambient

JA

thermal resistance.

For recommended operating condition specifications, the

maximum junction temperature is 125°C. The junction to

a mbient thermal resistance, θJA, is layout dependent. For

WQFN-56L 7x7 package, the thermal resistance, θJA, is

27°C/W on a standard JEDEC 51-7 f our-layer thermal test

board. The maximum power dissipation at TA = 25°C can

be calculated by the following formula :

P

= (125°C − 25°C) / (27°C/W) = 3.7W for

D(MAX)

WQF N-56L 7x7 pa ckage

PMU will move relative I2C

register bank data to MTP

Page 2 writing follow :

Set I2C Register 0x3A Bit[5] =1

PMU will read MTP data to

relative I

Set I2C Register 0x3A Bit[1]

PMU will erase the MTP page2

PMU will move relative I2C

register bank data to MTP

2

C register bank.

data

Reading MTP process

Writing MTP process

The maximum power dissipation depends on the operating

ambient temperature for fixed T

and thermal

J(MAX)

resistance, θJA. The derating curve in Figure 1 allows the

designer to see the effect of rising ambient temperature

on the maximum power dissipation.

4.0

3.5

3.0

2.5

2.0

1.5

1.0

0.5

Maximum Power Dissipation (W) 1

0.0

0 25 50 75 100 125

Ambient Temperature (°C)

Four-Layer PCB

Figure 1. Derating Curve of Maxi mum Power Dissi pation

Copyright 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

©

DS5028-01 January 2015www.richtek.com

20

Page 21

RT5028

Layout Consideration

For the best performance of the RT5028, the following

PCB layout guidelines must be strictly followed.

Place the input and output capacitors as close as

possible to the input and output pins respectively for

good filtering.

Keep the main power traces as wide and short as

possible.

GND

Input/Output capacitors must be

placed as close as possible to the

Input/Output pins.

VIN

AGND

ENL3

VIN

ENL1

ENL2

The switching node area connected to LX and inductor

should be minimized for lower EMI.

Connect the GND a nd Exposed Pad to a strong ground

plane for maxi mum thermal dissipation a nd noise

protection.

Directly connect the output ca p acitors to the feedback

network of each cha nnel to avoid bouncing caused by

parasitic re sistance and inducta nce from the PCB trace.

VOUTB1

LX should be connected to Inductor by wide and short

trace, keep sensitive compontents away from this trace.

VIN

VIN

VINB1

VDDP

LXB1

ENB1

VOUTB1S

47484950515253545556

VINB1

LXB1

VINB2

VINB2

43444546

GND

GND

VIN

VIN

VIN

VOUTL1

VINL123

VOUTL2

VOUTL3

VOUTL6

VOUTL5

VINL456

VOUTL4

VOUTL7

VINL78

VOUTL8

ENL4

ENL5

ENL6

LXB2

1

2

MTP

REBOOT

GNDGND

25 26 27 28

PWRHOLD

MASK_GPIO

3

4

5

6

7

8

9

10

10

11

12

13

14

GND GND

16

15

17 18 19 20 21 22 23 24

SCL

SDA

ENL7

ENL8

GND

IRQ

AGND

/RESET

PWRON

42

LXB2

41

ENB2

40

VOUTB2S

39

38

37

36

35

34

33

32

31

30

29

ENB4

SADDR

VIN

VINB3

VINB3

LXB3

LXB3

AGND

VOUTB3S

VINB4

LXB4

ENB3

VOUTB4S

Connect the Exposed

Pad to a ground plane.

GND

VIN

VOUTB2

GND

VOUTB3

GND

VOUTB4

GND

Figure 2. PCB Layout Guide

Copyright 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS5028-01 January 2015 www.richtek.com

©

21

Page 22

RT5028

Table 2. I2C Register Table

Detail Description

Address 00 Device ID

Bit Name Description Read/Write Reset Value

[7:4] VENDOR_ID Vendor Identification : Richtek : 1000b R 1000

[3:0] CHIP_REV Chip Revision R 0001

Address 01 BUCKcontrol1

Bit Name Description R/W Reset Value

Buck1 output voltage regulation

000000 : 0.7V, 25mV per step

000001 : 0.725V

[7:2] Buck1Output[5:0]

[1:0] Buck1VRC

Address 02 BUCKcontrol2

Bit Name Description R/W Reset Value

[7:2] Buck2Output[5:0]

[1:0] Buck2VRC

Address 03 BUCKcontrol3

Bit Name Description R/W Reset Value

[7:2] Buck3Output[5:0]

[1:0] Buck3VRC

…

101100 : 1.8V

…

111111 : 1.8V

VRC setting

00 : 50mV/10s, 01 : 50mV/10s,

10 : 100mV/10s, 11 : 200mV/10s

Buck2 output voltage regulation

000000 : 0.7V, 25mV per step

000001 : 0.725V

…

101100 : 1.8V

…

111111 : 1.8V

VRC setting

00 : 50mV/10s, 01 : 50mV/10s,

10 : 100mV/10s, 11 : 200mV/10s

Buck3 output voltage regulation

000000 : 0.7V, 50mV per step

000001 : 0.75V

…

111010 : 3.6V

…

111111 : 3.6V

VRC setting

00 : 50mV/10s, 01 : 100mV/10s,

10 : 200mV/10s, 11 : 400mV/10s

R/W Option

R/W Option

R/W Option

R/W Option

R/W Option

R/W Option

Copyright 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

22

©

DS5028-01 January 2015www.richtek.com

Page 23

RT5028

Address 04 BUCKcontrol4

Bit Name Description R/W Reset Value

Buck4 output v oltage regulation

000000 : 0.7V, 50mV per step

000001 : 0.75V

[7:2] Buck4Output[5:0]

[1:0] Buck4VRC

Address 05 VRC Control

Bit Name Description R/W Reset Value

7 Buck1VRC_EN

…

111010 : 3.6V

…

111111 : 3.6V

VRC setting

00 : 50mV/10s, 01 : 100mV/10s,

10 : 200mV/10s, 11 : 400mV /10s

Buck1 VRC

0 : disable - voltage r am ps up to target voltage

with one time

1 : enable - voltage ram ps up to target voltage

with slope control

R/W Option

R/W Option

R/W Option

Buck2 VRC

0 - disable - voltage ram ps up to target voltage

6 Buck2VRC_EN

5 Buck3VRC_EN

4 Buck4VRC_EN

[3:0] Reserved R/W 0000

Address 06 BUCK Mode

Bit Name Description R/W Reset Value

7 Buck1mode

6 Buck2mode

5 Buck3mode

with one time

1 - enable - voltage ramps up to target voltage

with slope control

Buck3 VRC

0 : disable - voltage r am ps up to target voltage

with one time

1 : enable - voltage ram ps up to target voltage

with slope control

Buck4 VRC

0 : disable - voltage r am ps up to target voltage

with one time

1 : enable - voltage ram ps up to target voltage

with slope control

Buck1 mode

0 : Force PWM

1 : Auto Mode (PSM/PWM)

Buck2 mode

0 : Force PWM

1 : Auto Mode (PSM/PWM)

Buck3 mode

0 : Force PWM

1 : Auto Mode (PSM/PWM)

R/W Option

R/W Option

R/W Option

R/W 1

R/W 1

R/W 1

Copyright 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS5028-01 January 2015 www.richtek.com

©

23

Page 24

RT5028

Buck4 mode

4 Buck4mode

3 Buck1oms

2 Buck2oms

1 Buck3oms

0 Buck4oms

Address 07 LDOcontrol1

Bit Name Description R/W Reset Value

7 Reserved R/W 0

[6:0] LDO1OUT[6:0]

Address 08 LDOcontrol2

Bit Name Description R/W Reset Value

7 Reserved R/W 0

[6:0] LDO2OUT[6:0]

Address 09 LDOcontrol3

Bit Name Description R/W Reset Value

7 Reserved R/W 0

[6:0] LDO3OUT[6:0]

0 : Force PWM

1 : Auto Mode (PSM/PWM)

Buck1 output off mode state

0 : floating

1 : Ground-discharged

Buck2 output off mode state

0 : floating

1 : Ground-discharged

Buck3 output off mode state

0 : floating

1 : Ground-discharged

Buck4 output off mode state

0 : floating

1 : Ground-discharged

LDO1 output voltage regulation

0000000 : 1.6V, 25mV per step

0000001 : 1.625V

...

0101000 : 3.6V (MAX)

…

1111111 : 3.6V (MAX)

LDO2 output voltage regulation

0000000 : 1.6V, 25mV per step

0000001 : 1.625V

...

0101000 : 3.6V (MAX)

…

1111111 : 3.6V (MAX)

LDO3 output voltage regulation

0000000 : 1.6V, 25mV per step

0000001 : 1.625V

...

0101000 : 3.6V (MAX)

…

1111111 : 3.6V (MAX)

R/W 1

R/W 1

R/W 1

R/W 1

R/W 1

R/W Option

R/W Option

R/W Option

Copyright 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

24

©

DS5028-01 January 2015www.richtek.com

Page 25

RT5028

Address 0A LDOcontrol4

Bit Name Description R/W Reset Value

7 Reserved R/W 0

LDO4 output voltage regulation

0000000 : 3 V, 25mV per step

0000001 : 3.025V

[6:0] LDO4OUT[6:0]

Address 0B LDOcontrol5

Bit Name Description R/W Reset Value

7 Reserved R/W 0

[6:0] LDO5OUT[6:0]

Address 0C LDOcontrol6

Bit Name Description R/W Reset Value

7 Reserved R/W 0

[6:0] LDO6OUT[6:0]

Address 0D LDOcontrol7

Bit Name Description R/W Reset Value

7 Reserved R/W 0

[6:0] LDO7UT[6:0]

...

0011000 : 3.6V (MAX)

…

1111111 : 3.6V (MAX)

LDO5 output voltage regulation

0000000 : 3V, 25mV per step

0000001 : 3.025V

...

0011000 : 3.6V (MAX)

…

1111111 : 3.6V (MAX)

LDO6 output voltage regulation

0000000 : 3.0V, 25mV per step

0000001 : 3.025V

...

0011000 : 3.6V (MAX)

…

1111111 : 3.6V (MAX)

LDO7output voltage regulation

0000000 : 1.6V, 25mV per step

0000001 : 1.625V

...

0101000 : 3.6V (MAX)

…

1111111 : 3.6V (MAX)

R/W Option

R/W Option

R/W Option

R/W Option

Copyright 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS5028-01 January 2015 www.richtek.com

©

25

Page 26

RT5028

Address 0E LDOcontrol8

Bit Name Description R/W Reset Value

7 Reserved R/W 0

LDO8utput voltage regulation

0000000 : 1.6V, 25m V per step

0000001 : 1.625V

[6:0] LDO8T[6:0]

Address 0F LDOs off mode stat e

Bit Name Description R/W Reset Value

7 LDO8oms

6 LDO7oms

5 LDO6oms

4 LDO5oms

3 LDO4oms

2 LDO3oms

1 LDO2oms

0 LDO1ms

Address 10 REBOO T/PWRHOLD delay time contr ol

Bit Name Description R/W Reset Value

[7:6] Delayed2[1:0]

[5:4] Delayed1[1:0]

[3:2] THOLD[1:0]

1 Reserved R/W 0

0 DisTHOLD

Copyright 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

26

©

...

0101000 : 3.6V (MA X)

…

1111111 : 3.6V (MA X)

LDO8 output off m ode state

0 : floating

1 : Ground-discharged

LDO7 output off m ode state

0 : floating

1 : Ground-discharged

LDO6 output off m ode state

0 : floating

1 : Ground-discharged

LDO5 output off m ode state

0 : floating

1 : Ground-discharged

LDO4 output off m ode state

0 : floating

1 : Ground-discharged

LDO3 output off m ode state

0 : floating

1 : Ground-discharged

LDO2 output off m ode state

0 : floating

1 : Ground-discharged

LDO1output off m ode state

0 : floating

1 : Ground-discharged

Delayed2 setti ng

(00 : 100ms/01 : 500m s/10 : 1s/11 : 2s)

Delayed1 setti ng

(00 : 100ms/01 : 500m s/10 : 1s/11 : 2s)

THOLD setting

(00 : 100ms/01 : 500m s/10 : 1s/11 : 2s)

Ignore THOLD Tim e.

0 : Keep PWRHOLD functi on.

1 : Ignore PWRHOLD function.

R/W Option

R/W 1

R/W 1

R/W 1

R/W 1

R/W 1

R/W 1

R/W 1

R/W 1

R/W Option

R/W Option

R/W Option

R/W Option

DS5028-01 January 2015www.richtek.com

Page 27

RT5028

Address 11 ON Event Setting

Bit Name Description R/W Reset Value

Powered on because of

000 : PWRON key-pressed

[7:5] On_Event

[4:0] Reserved R/W 0

Address 12 VIN UVLO/Buck On/Off

Bit Name Description R/W Reset Value

[7:5] VOFF setting

4 Reserved R/W 0

3 Buck4

2 Buck3

1 Buck2

0 Buck1

Address 13 LDOs On/Off

Bit Name Description R/W Reset Value

7 LDO8

6 LDO7

5 LDO6

4 LDO5

3 LDO4

2 LDO3

1 LDO2

0 LDO1

Copyright 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS5028-01 January 2015 www.richtek.com

©

001 : VIN plugged in

010 : from REBOOT pin event

111 : No event happen

VIN UVLO 2.8V to 3.5V per 0.1V to power off

PMIC

000 : 2.8V

001 : 2.9V

010 : 3V

011 : 3.1V (Default)

100 : 3.2V

101 : 3.3V

110 : 3.4V

111 : 3.5V

Buck4 control

(0 : Disable Buck4/1 : Enable Buck4)

Buck3 control

(0 : Disable Buck3/1 : Enable Buck3)

Buck2 control

(0 : Disable Buck2/1 : Enable Buck2)

Buck1 control

(0 : Disable Buck1/1 : Enable Buck1)

LDO8 control

(0 : Disable LDO8 / 1 : Enable LDO8)

LDO7 control

(0 : Disable LDO7 / 1 : Enable LDO7)

LDO6 control

(0 : Disable LDO6 / 1 : Enable LDO6)

LDO5 control

(0 : Disable LDO5 / 1 : Enable LDO5)

LDO4 control (0 : Disable LDO4 / 1 : Enable

LDO4)

LDO3 control

(0 : Disable LDO3 / 1 : Enable LDO3)

LDO2 control

(0 : Disable LDO2 / 1 : Enable LDO2)

LDO1 control

(0 : Disable LDO1 / 1 : Enable LDO1)

R 111

R/W Option

R/W Option

R/W Option

R/W Option

R/W Option

R/W Option

R/W Option

R/W Option

R/W Option

R/W Option

R/W Option

R/W Option

R/W Option

27

Page 28

RT5028

Address 14

Bit Name Description R/W Reset Value

[7:6] START_TIME

[5:4] L_PRESS_TIME

[3:2] SHDN_PRESS

[1:0]

Address 15 SHDN Control

Bit Name Description Read/Write Reset Value

RESET_DLY

7 SHDN_CTRL

PWRON(Power On Key) time Parameters

Setting / RESET delay

Startup time setting

00 : 100us (pressing time - low level)

01 : 100ms

10 : 1s

11 : 2s

Long-press time setting (after Power-On,

00 : 1s (falling edge to rising edge)

01 : 1.5s

10 : 2s

11 : 2.5s

Sending short/long-press IRQ to CPU

ex :1.5s

=> low time < 1.5s (short IRQ)

=> low time > 1.5s but < 6s(shutdown time)

(long IRQ)

=> low time > 6s(shutdown time) (shutdown)

Key-press forced shutdown time setting

00 : 4s (pressing time : low level)

01 : 6s

10 : 8s

11 : 10s

RESET signal delay after the last power startup

is done

00 : 10ms

01 : 50ms

10 : 100ms

11 : 200ms

Power Off setting by CPU, after set, 100ms

delayed power off

0 : Normal operation

1 : Disable the PMIC output

R/W Option

R/W Option

R/W Option

R/W Option

R/W Option

Disable Buck/LDO only for normal power off

(SHDN_CTRL=1)

6 SHDN_TIMING

[5:4] SHDN_DLYTIME

[3:0] Reserved R/W 0000

Copyright 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

28

©

0 : disable at the same time

1 : contrary to the startup timing

(first_on-last_off)

Delayed shutdown time after send the

(PWRON)key-press-forced-shutdown IRQ

(when IRQ is disable, there is no delay)

00 : 100ms

01 : 500ms

10 : 1s

11 : 2s

R/W Option

R/W Option

DS5028-01 January 2015www.richtek.com

Page 29

RT5028

Address 16 Powered off conditions enable setting

Bit Name Description Read/Write Reset Value

7 BCK1LV_ENSHDN

6 BCK2LV_ENSHDN

5 BCK3LV_ENSHDN

4 BCK4LV_ENSHDN

3 PWRON_ENSHDN

2 OT_ENSHDN

1 VINLV_ENSHDN

0 Reserved R/W 0

Address 17 OFF Event (Only reset by POR)

Bit Name Description Read/Write Reset Value

[7:4] OFF_Event

[3:0] Reserved R 0000

Address 18 to 27

Buck1 output voltage low SHDN

0 : disable this event. 1 : enable this event

Buck2 output voltage low SHDN

0 : disable this event. 1 : enable this event

Buck3 output voltage low SHDN

0 : disable this event. 1 : enable this event

Buck4 output voltage low SHDN

0 : disable this event. 1 : enable this event

PWRON key-pressed forced SHDN

0 : disable this event. 1 : enable this event

Over temperature SHDN

0 : disable this event. 1 : enable this event

VIN voltage low (VOFF) (Set by reg) SHDN

0 : disable this event. 1 : enable this event

Powered off because of (Only shows last

power-off event)

0000 : VIN voltage low (VOFF) (Set by reg)

0001 : Buck1 output voltage low

0010 : Buck2 output voltage low

0011 : Buck3 output voltage low

0100 : PWRON key-pressed forced shutdown

0101 : Power Off register setting

0110 : Over temperature event

0111 : Reboot restart.

1000 : Buck4 output voltage low

1001 : PWR_HOLD fail.

1010 : No event happen.

….

1111 : No event happen

16 bytes registers Data Cache (Only reset by

POR)

R/W 0

R/W 0

R/W 0

R/W 0

R/W 1

R/W 1

R/W 0

R 1111

R/W 0

Copyright 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS5028-01 January 2015 www.richtek.com

©

29

Page 30

RT5028

IRQ_PMIC (Power Channels)

Address 28 IRQ Enable1

Bit Name Description Read/Write Reset Value

7 OT_IRQ

6 Bck1LV_IRQ

5 Bck2LV_IRQ

4 Bck3LV_IRQ

3 Bck4LV_IRQ

2 PWRONSP_IRQ

1 PWRONLP_IRQ

0 SYSLV_IRQ VIN voltage is lower than VOFF, IRQ enable R/W 0

Address 29 IRQ Status1

Bit Name Description Read/Write Reset Value

7 OT Internal over-temperature R 0

6 Bck1LV Buck1 output voltage equal 66% x V

5 Bck2LV Buck2 output voltage equal 66% x V

4 Bck3LV Buck3 output voltage equal 66% x V

3 Bck4LV Buck4 output voltage equal 66% x V

2 PWRONSP PWRON short press (32s deglitch time) R 0

1 PWRONLP PWRON long press (32s deglitch time) R 0

0 VINLV VIN voltage is lower than VOFF R 0

Address 2A IRQ Enable2

Bit Name Description Read/Write Reset Value

7 KPSHDN_IRQ Key-press forced shutdown, IRQ enable R/W 1

6 PWRONR_IRQ PWRON press rising edge, IRQ enable R/W 0

5 PWRONF_IRQ PWRON press falling edge, IRQ enable R/W 0

[4:0] Reserved R 0000

Address 2B IRQ Status2

Bit Name Description Read/Write Reset Value

7 KPSHDN Key-press forced shutdown R 0

6 PWRONR PWRON press rising edge R 0

5 PWRONF PWRON press falling edge R 0

[4:2] Reserved R 000

1 OTW125 Internal 125C pre- warning over-temperature. R 0

0 OTW100 Internal 100C pre- warning over-temperature. R 0

Copyright 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

30

©

Internal over-temperature was triggered, IRQ

enable

Buck1 output voltage equal 66% x V

Target

, IRQ

enable

Buck2 output voltage equal 66% x V

Target

, IRQ

enable

Buck3 output voltage equal 66% x V

Target

, IRQ

enable

Buck4 output voltage equal 66% x V

Target

, IRQ

enable

PWRON short press, IRQ enable

(32s deglitch time)

PWRON long press, IRQ enable

(32s deglitch time)

R 0

Target

R 0

Target

R 0

Target

R 0

Target

R/W 1

R/W 1

R/W 1

R/W 1

R/W 1

R/W 0

R/W 0

DS5028-01 January 2015www.richtek.com

Page 31

RT5028

Address 2C PMU On/Off Sequence1

Description (Setting on/off sequence priority)

Bit Name

[7:4] Buck2_Seq[3:0] Setting Buck2 on/off sequence priority R/W Option

[3:0] Buck1_Seq[3:0] Setting Buck1 on/off sequence priority R/W Option

Address 2D PMU On/Off Sequence2

Bit Name

[7:4] Buck4_Seq[3:0] Setting Buck4 on/off sequence priority R/W Option

[3:0] Buck3_Seq[3:0] Setting Buck3 on/off sequence priority R/W Option

Address 2E PMU On/Off Sequence3

Bit Name

[7:4] LDO2_Seq[3:0] Setting LDO2 on/off sequence priority R/W Option

[3:0] LDO1_Seq[3:0] Setting LDO1 on/off sequence priority R/W Option

Address 2F PMU On/Off Sequence4

Bit Name

[7:4] LDO4_Seq[3:0] Setting LDO4 on/off sequence priority R/W Option

[3:0] LDO3_Seq[3:0] Setting LDO3 on/off sequence priority R/W Option

Address 30 PMU On/Off Sequence5

Bit Name

[7:4] LDO6_Seq[3:0] Setting LDO6 on/off sequence priority R/W Option

[3:0] LDO5_Seq[3:0] Setting LDO5 on/off sequence priority R/W Option

Address 31 PMU On/Off Sequence5

Bit Name

[7:4] LDO8_Seq[3:0] Setting LDO8 on/off sequence priority R/W Option

[3:0] LDO7_Seq[3:0] Setting LDO7 on/off sequence priority R/W Option

Address 32 Soft-Start Control

Bit Name Description Read/Write Reset Value

[7:6] Reserved R Option

(0000 : off, 0001 : first on, 1100 : last on)

(The sequence is planed by first on last off)

Description (Setting on/off sequence priority)

(0000 : off, 0001 : first on, 1100 : last on)

(The sequence is planed by first on last off)

Description (Setting on/off sequence priority)

(0000 : off, 0001 : first on, 1100 : last on)

(The sequence is planed by first on last off)

Description (Setting on/off sequence priority)

(0000 : off, 0001 : first on, 1100 : last on)

(The sequence is planed by first on last off)

Description (Setting on/off sequence priority)

(0000 : off, 0001 : first on, 1100 : last on)

(The sequence is planed by first on last off)

Description (Setting on/off sequence priority)

(0000 : off, 0001 : first on, 1100 : last on)

(The sequence is planed by first on last off)

Read/Write Reset Value

Read/Write Reset Value

Read/Write Reset Value

Read/Write Reset Value

Read/Write Reset Value

Read/Write Reset Value

Copyright 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS5028-01 January 2015 www.richtek.com

©

31

Page 32

RT5028

0000 : First tur n on channel deci de the

RESET_DLY time.

0001 : Buck1 decide t he RESET_DLY time.

Soft-Start End Control

[5:2]

[1:0]

Address 33 Buck Syn-Clock Control

Bit Name Description Read/Write Reset Value

[7:6] VCO_VRC

[5:0] VCO_DVS

Address 34 Buc k S yn-Clock Spread Spectrum Contr ol

Bit Name Description Read/Write Reset Value

[7:1] Reserved R/W 0000000

Address 3A EEPROM (MTP) Control

Bit Name Description Read/Write Reset Value

[7:6] Reserved R/W 00

[3:2] Reserved R/W 00

Copyright 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

32

@ MASK_GPIO = 0

(External Enable pin

define)

Soft-Sta rt Vo l ta g e le ve l

/ time soft-start control.

0 SSOSC

5 MTP Page 2 Read Read MTP Page 2 R 0

4 MTP Page 1 Read Read MTP Page 1 R 0

1 MTP Page 2 write

0 MTP Page 1 write

©

….

0100 : Buck1 decide t he RESET_DLY time.

0101 : LDO1 decide the RESET _DLY time.

….

1100 : LDO8 decide the RESET _DLY time.

….

1111 : LDO8 decide the RESET _DLY time.

Voltage Level

00 : When output volt age arrives to 80%

, next c hannel will turn on.

V

Target

Soft-start time i nterval (TSS) :

01 : 1ms

10 : 4ms

11 : 8ms

VCO input voltage slop.

00: 25mV/10s, 01: 25m V/ 20s

10: 25mV/40s, 11: 25m V/ 80s

Note :

The VCO’s voltage input r ange is 0.375V to

1.8V and the output f r equenc y is 500kHz to

2.18MHz.

VCO input voltage DVS control

000000 : 0.375V (500kHz )

………

111001 : 1.8V (2MHz)

………

111111 : 1.8V (2MHz)

Buck Clock Spre ad S pectr um Control

0 : Disable spread spectrum function.

1 : Turn on spread spectrum function.

Write MTP Page 2, and MTP also needs to be

logic high.

Write MTP Page 1, and MTP also needs to be

logic high.

R/W Option

R/W Option

R/W Option

R/W Option

R/W Option

W 0

W 0

DS5028-01 January 2015www.richtek.com

Page 33

MTP

Address

RT5028

Table 3. I2C to MTP Mapping Table

MTP Pa ge-1

2

I

C Register Address Bit7 Bit6 Bit5 Bit4 Bit3 Bit 2 Bit1 Bit0

Function BUCKcontrol1

Meaning Buck1Output[5:0] Buck1VRC

0X00 0X01

Reset Condition A A A A A A B B

0X01 0X02

Reset Condition A A A A A A B B

0X02 0X03

Reset Condition A A A A A A B B

0X03 0X04

Reset Condition A A A A A A B B

Default 0 1 1 0 1 0 0 0

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Function BUCKcontrol2

Meaning Buck2Output[5:0] Buck2VRC

Default 1 0 0 0 0 0 0 0

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Function BUCKcontrol3

Meaning Buck3Output[5:0] Buck3VRC

Default 0 0 1 0 1 0 0 0

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Function BUCKcontrol4

Meaning Buck4Output[5:0] Buck4VRC

Default 1 1 0 0 1 1 0 0

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Function VRC Control

Meaning

0X0D 0X05

0X04 0X07

Copyright 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS5028-01 January 2015 www.richtek.com

©

Default 1 1 1 1 0 0 0 0

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Reset

Condition

Function LDOcontrol1

Meaning Reserved LDO1OUT[6:0]

Default 0 0 1 1 0 1 1 1

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Reset Condition B A A A A A A A

Buck1V

RC_EN

Buck2V

RC _EN

B B B B B B B B

Buck3V

RC_EN

Buck4V

RC _EN

Reserved Reserved Reserved Reserved

33

Page 34

RT5028

MTP

Address

0X05 0X08

0X06 0X09

0x07 0x0A

2

I

C Register Address Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

Function LDOcontrol2

Meaning Reserved LDO2OUT[6:0]

Default 0 0 0 0 0 1 1 1

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Reset Condition B A A A A A A A

Function LDOcontrol3

Meaning Reserved LDO3OUT[6:0]

Default 0 0 1 1 0 1 1 1

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Reset Condition B A A A A A A A

Function LDOcontrol4

Meaning Reserved LDO4OUT[6:0]

Default 0 0 0 1 1 0 0 0

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Reset Condition B A A A A A A A

Function LDOcontrol5

Meaning Reserved LDO5OUT[6:0]

0x08 0x0B

0x09 0x0C

0x0A 0x0D

0x0B 0x0E

Default 0 0 0 0 1 0 1 1

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Reset Condition B A A A A A A A

Function LDOcontrol6

Meaning Reserved LDO6OUT[6:0]

Default 0 0 0 0 1 0 1 1

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Reset Condition B A A A A A A A

Function LDOcontrol7

Meaning Reserved LDO7OUT[6:0]

Default 0 0 1 0 0 0 1 1

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Reset Condition B A A A A A A A

Function LDOcontrol8

Meaning Reserved LDO8OUT[6:0]

Default 0 1 0 0 0 0 1 1

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Reset Condition B A A A A A A A

Copyright 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

34

©

DS5028-01 January 2015www.richtek.com

Page 35

RT5028

MTP

Address

0x0C 0x12

0x0F

2

I

C Register Address Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

No

mapping

Function VIN UVLO (update default value after power on)

Meaning VOFF setting Reserved Reserved Reserved Reserved Reserved

Default 0 1 1 0 0 0 0 0

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Reset Condition A A A B B B B B

Function x

Meaning Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved

Default 0 0 0 0 0 0 0 0

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Reset Condition B B B B B B B B

Copyright 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS5028-01 January 2015 www.richtek.com

©

35

Page 36

RT5028

MTP

Address

0x00 0x10

2

C Register Address Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

I

MT P Page-2

Function REBOOT/PWRHOLD delay time control

Meaning Delayed2[1:0] Delayed1[1:0] THOLD Reserved DisTHOLD

Default 1 0 1 0 1 1 0 0

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Reset Condition B B B B B B B B

0x01 0x14

Reset Condition A A A A A A A A

0x02 0x15

Reset Condition B B B B B B B B

0x03 0x2C

Reset Condition A A A A A A A A

Function

Meaning START_TIME L_PRESS_TIME SHDN_PRESS RESET_DLY

Default 1 1 1 0 0 0 0 1

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Function SHDN Control

Meaning

Default 0 1 1 0 0 0 0 0

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Function PMU On/Off Sequence1

Meaning Buck2_Seq[3:0] Buck1_Seq[3:0]

Default 0 0 1 0 0 0 0 1

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Function PMU On/Off Sequence2

Meaning Buck4_Seq[3:0] Buck3_Seq[3:0]

SHDN_

CTRL

SHDN_

TIMING

PW RON time Par ameters S ettin g / RESET delay

SHDN_DLYTIME Reserved Reserved Reserved Reserved

0x04 0x2D

0x05 0x2E

Default 0 1 0 0 0 0 1 1

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Reset Condition A A A A A A A A

Function PMU On/Off Sequence3

Meaning LDO2_Seq[3:0] LDO1_Seq[3:0]

Default 0 1 1 0 0 1 0 1

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Reset Condition A A A A A A A A

Copyright 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

36

©

DS5028-01 January 2015www.richtek.com

Page 37

RT5028

MTP

Address

0x06 0x2F

0x07 0x30

0x08 0x31

2

I

C Register Address Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

Function PMU On/Off Sequence4

Meaning LDO4_Seq[3:0] LDO3_Seq[3:0]

Default 1 0 0 0 0 1 1 1

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Reset Condition A A A A A A A A

Function PMU On/Off Sequence5

Meaning LDO6_Seq[3:0] LDO5_Seq[3:0]

Default 1 0 0 1 1 0 0 1

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Reset Condition A A A A A A A A

Function PMU On/Off Sequence6

Meaning LDO8_Seq[3:0] LDO7_Seq[3:0]

Default 1 0 0 1 1 0 0 1

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Reset Condition A A A A A A A A

Function Soft-Start Control

0x09 0x32

0x0A 0x33

0x0B 0x34

0x0C

No

mapping

Mean ing Reversed Reverse d Soft-Start E nd Select @MASK_GPIO= 1 Soft-Start Co ntrol

Default 0 0 0 0 0 0 0 0

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Reset Condition B B A A A A B B

Function Buck Syn-Clock Control

Meaning VCO_VRC VCO_DVS

Default 0 0 0 0 0 0 0 0

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Reset Condition B B A A A A B B

Function Buck Sy n-Cloc k Spread Spectrum Control

Meaning Reversed Reversed Reversed Reversed Reversed Reversed Reversed SSOSC

Default 0 0 0 0 0 0 0 0

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Reset Condition B B B B B B B B

Function x

Meaning Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved

Default 0 0 0 0 0 0 0 0

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Reset Condition B B B B B B B B

Copyright 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

DS5028-01 January 2015 www.richtek.com

©

37

Page 38

RT5028

MTP

Address

0x0D

0x0E

0x0F

2

C Register Address Bit7 Bit6 Bit5 Bit4 Bit3 Bit2 Bit1 Bit0

I

Function x

Meaning Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved

No

mapping

No

mapping

No

mapping

Default 0 0 0 0 0 0 0 0

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Reset Condition B B B B B B B B

Function x

Meaning Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved

Default 0 0 0 0 0 0 0 0

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Reset Condition B B B B B B B B

Function x

Meaning Reserved Reserved Reserved Reserved Reserved Reserved Reserved Reserved

Default 0 0 0 0 0 0 0 0

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Reset Condition B B B B B B B B

Reset Condition

A Reset by MTP (Register 0x12 VOFF Setti ng) .

B Reset when VIN <1.7V.

Copyright 2015 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.

38

©

DS5028-01 January 2015www.richtek.com

Page 39