RICHIGER EA-350 UNLOADER

Parts list

Operator's Manual

1

Index

2

page

01.

Warranty Policy and Certificate

page

02. 4

Technical specifications

5

03.

page

Dimensions

604.

page

Safety precautions

7

05.

page

Switching from transport to work

1006.

page

Attaching the bag

1407.

page

Grain extraction procedure

08. 17

page

Ending grain extraction

09. 17

page

Emptying the last section of bag

10.

20

page

Detaching bag from roller

21

page

1

1.

Back to transport mode

22page

12.

Maintenance

13.

23

page

Lubrication chart

14.

25

page

The grain flow concept

15.

26

page

General indications for efficient operation

16.

31

page

Parts List

01

2

This warranty is expressly in lieu of any other warranties, express or implied, including any warranty of merchantability

or fitness for a particular purpose.

Buyer's sole and exclusive remedy under this warranty shall be limited to the repair, replacement or exchange of

warranted parts at our option, F.O.B. our factory, or designated service center, agent or representative. If the agent or

representative grants any warranty greater in scope or time period or labor allowance than that detailed herein,

RICHIGER MAQUINARIAS S.A shall not be liable beyond the herein stated limitations.

Equipment and accessories not of our manufacture are not covered by this warranty. Any claim with regards to

defective aforementioned equipment and accessories shall be submitted by RICHIGER MAQUINARIAS S.A to the

original manufacturers for analysis and subsequent non-approval or approval of repair, replacement or exchange, at

their option.

No special, incidental, consequential or other damages or contingent liabilities including, but not limited to, loss of life,

personal injury, loss of crops, loss due to fire or water damage, loss of business or business income, down time costs

and trade or other commercial loss arising out of the failure of product. The term product and products as used in this

warranty designates the whole finished unit in its entirety, i.e. the complete assembled machine, and/or all and every

individual component, part, equipment and accessory that forms said complete assembled machine.

Normal wear and tear associated with use is expressly excluded from this warranty.

No products shall be returned without prior authorization from RICHIGER MAQUINARIAS S.A

Buyers and their agents shall prepay all transportation charges for the return of such products to RICHIGER

MAQUINARIAS S.A or designated service center. There will be no acceptance of any charges for labor and/or parts

incidental to the removal and remounting of product repaired or replaced under this warranty.

This warranty does not cover conditions over which RICHIGER MAQUINARIAS S.A has no control including, without

limitation, contamination, pressures in excess of the recommended maximum, products damaged or subject to

accident, abuse or misuse after shipment from factory, products altered and repaired by anyone other than RICHIGER

MAQUINARIAS S.A factory personnel or representative or source approved by RICHIGER MAQUINARIAS S.A in

writing prior to commencement of said work.

The first buyer is responsible for proof of delivery date of product for the purpose of establishing warranty time of

validity. Warranty can continue for new user should the product be resold by the first buyer during valid period of

warranty, only if this situation is reported in writing, with enclosed documentation as proof of purchase. Warranty will

not be applicable if series number or other identification markers are erased, obliterated or otherwise altered.

.

.

.

.

Warranty terms

Warranty policy

Limitations on Warranty

Unit: Hydraulic-Mechanical Grain Bag Unloader

Model: EA-350

RICHIGER MAQUINARIAS S.A, located in Avellaneda 661, Sunchales, Santa Fe province, Argentina, warrants its

product EA-350 mechanical grain unloader from defects in materials and workmanship under normal operating

conditions and proper application, in accordance with the specifications for operation as described by the

manufacturer, for the period of 365 days from date of delivery to buyer.

3

Limitations on Warranty

Within 15 days after delivery to or receipt by the buyer of the product, the buyer shall inform the seller in writing if

product is found defective or short in any respect. Failure to so inform the seller or any use by buyer of product shall

constitute conclusive evidence that the seller satisfactorily performed and the buyer waives any right to reject the

product thereafter

The first buyer is responsible for proof of delivery date of product for the purpose of establishing warranty time of

validity. Warranty can continue for new user should the product be resold by the first buyer during valid period of

warranty, only if this situation is reported in writing, with enclosed documentation as proof of purchase. Warranty will

not be applicable if series number or other identification markers are erased, obliterated or otherwise altered.

The following are types of failures which are not attributable to defects in materials and/or workmanship and which

are not considered by RICHIGER MAQUINARIAS S.A as part of the warranty extended hereunder. This listing is by

way of example and is not intended to be exhaustive:

1) Product suffered damages attributable to accident, abuse, neglect or ignorance.

2) Product was not used in accordance with manufacturer's recommendations.

3) Product did not receive required maintenance.

4) Failure ensued after replacement of original parts without express consent of RICHIGER

MAQUINARIAS S.A , or modifications that in RICHIGER MAQUINARIAS S.A.’s judgment may have

affected performance, safety and/or dependability parameters.

5) Product was used in a manner or for a purpose for which it was not designed or intended to be used.

6) Incorrect mounting of external gears, pulleys.

7) Stripped splines or keyways on drive shafts.

8) Damage due to deterioration during periods of storage by the purchaser prior to operation.

9) Damage of any kind from erosive or corrosive action of any gases or liquids handled by the machinery.

10) Lack of or incorrect type of hydraulic fluid, lubricant, oil and/or grease.

11) Contamination of hydraulic fluid.

12) Operating beyond recommended maximum speeds, pressures and temperatures.

13) Repairs or disassembly by unauthorized personnel.

14) Misalignment of drive shafts, gears, sprockets and power driven elements.

15) Damage due to voltage spikes, static discharge, electrical storms, physical abuse, externally controlled

device failure and improper fusing.

.

.

Buyer inspection and acceptance

02

4

Technical specifications

Materials to be extracted

All kinds of dry grains (wheat, sorghum, maize, sunflower, soybeans, rice,

etc.) and pelletized materials

Capacity Up to 300 tons/tour (*)

Minimum power:

60 CV

Tractor

PTO revolutions:

540 rpm

Extraction

High clearance discharge auger, mechanical drive

Drive shaft w / shear bolt protection

PowerTransmission

Mechanical central discharge auger & cross augers

Tires

11 L15 – 10 ply

Extraction system

Automatic bag pickup system

Working height hydraulically controlled

Bag slasher blade

Works mechanically and hydraulically

Adjustable working width

Tire pressure:

30 lbs./sq. in.

Total weight

2000 kg. (4400 lbs.)

(*) Work capacity can vary according to grain type, moisture content and other factors

Manufacturer reserves right to change specifications at any given time without previous notification

4850

2590

3270

5210

5870

5230

3050

6180

1200

3065

2630

1930

5

03

Dimensions in millimeters

Work position

Transport position

IMPORTANT

The operator should become familiarized with machine controls before attempting actual operation. Keep unit in

good working condition. Any modification could cause malfunctioning, potentially dangerous situations, or reduced

machine durability.

04

6

In order to obtain maximum performance from your grain bag unloader, we recommend you keep

the owner's manual in a handy place for quick consultation. Read the manual carefully before

attempting to unload grain from bags and pay special attention to operating and maintenance

instructions.

Safety precautions

For the operator

Before transporting the grain unloader, verify that:

a) The tow bar pin is properly secured

b) Check tire pressure

c) Check that wheel bolts are properly tightened

d) Attach safety chains between machine's tow bar and

tractor drawbar for added security on the road

Most accidents are caused by human error. Follow all safety procedures.

Make sure all people are safely positioned before starting tractor's engine and engaging

the PTO.

Keep unloader clean and sheltered when not in use. This diminishes risk of deterioration

and eventual failure.

Keep a fire extinguisher handy.

Decals with safety indications and warnings should be strictly heeded, kept in good

condition and replaced if necessary.

When towing the machine, drive with the utmost caution on public roads.

Keep hands, feet and clothing well away from moving parts.

Stop the tractor's engine before attempting a hands-on task on the unloader.

05

WARNING:

At no time during the unloading operation should anyone, except the operator standing at the

hydraulic controls, approach unloader or bag, and that includes both tractor and truck drivers.

Onlookers should keep a safe distance. And never allow anyone to lean against the bag: augers are

turning inside.

2) To the side of the machine, on the roller

cross beam, an array of three levers, a turn knob

and a pressure limiting valve control the

unloader's hydraulics. A decal attached next to

them (Fig. 1) shows each control's function.

First step in preparing for work is raising the

discharge auger. With the tractor's hydraulics

turned on, move the first lever to its upward

position (Fig. 2). This will raise the auger tube

slowly.

As soon as auger is fully extended, move back

the lever to its mid (neutral) position. Once the

unloader has finished working and is to be towed

away, the sequence is reversed and the tube is

lowered by moving down the lever.

The sequence ends once the upper half is resting

firmly upon its transport prop and the control lever

is returned to neutral position.

1) Hitch tractor to unloader, connect hoses to

the tractor's hydraulic circuit and connect drive

shaft to the tractor's power take-off.

Fig.1

Fig.2

Switching from transport to work

7

NOTE:

A pressure limiting valve set to 850 PSI is provided as a safeguard against excessive pressure in the hydraulic circuit.

If this value is exceeded, oil will bypass the hydraulic motor and momentarily bring operation to a standstill.

Fig.3

Fig.4

8

3) Next, the second lever is used to regulate working

height (i.e., clearance of the sweep augers to the ground)

by means of a hydraulic cylinder. First, this center lever

should be moved to top position in order to raise the

unloader. To adjust for desired clearance, and the object

here is to set the sweep augers as close to the ground as

possible without scraping against it and compromising

bag integrity (see “General indications for efficient

operation” on page 26), a set of three clamp-on stops of

different size is provided.

Once a combination of stops or a single stop have

been selected and placed around the cylinder rod, the

control lever is pulled down (Fig. 3) so that the weight of

the unloader comes to rest upon the stops (Fig. 4). At this

point the lever is returned to its neutral position. The

height of the machine can be modified at any point, even

when the sweep augers are inside the bag.

IMPORTANT:

The unloader should not be raised or lowered with the hydraulic cylinder if the augers are deep within the grain mass,

as this could place undue strain on some components. The correct procedure is to release a few feet of plastic from

the roller by counter rotating it hydraulically, advance forward with tractor to extricate the sweep augers from the

grain, modify machine clearance with the hydraulic cylinder removing or adding stops as necessary, back the machine

once again into the bag to position the augers next to the grain, and reinitiate PTO and roller to continue unloading.

7) Lower the support stand and reinsert pin

at the base (Fig. 8).

5) Remove the pin at the base of the support stand,

swing the stand upward and attach temporarily to main

beam with same pin (Fig. 5).

4) The third lever, used to control roller rotation,is

not used at this stage.

6) Pull back the

spring-loaded pin that holds the

roller assembly in place during

transport and swivel it 90º to

work position (Figs. 6 & 7).

Fig.5

Fig.7

Fig.8

Fig.6

9

06

Attaching the bag

1) Open the end of the bag

and along the top section make

a lengthwise cut approximately

2 meters (7 ft.) long.

Spread open the resultant flaps

to the side

8) Remove the sweeper

screw extensions from their

transport location and insert

them in the main auger shafts,

not mixing left and right hand

screws. Also remove protection

grids and install (Figs. 9 & 10).

9) The sequence is

reversed when changing back

to transport mode.

Fig.10

Fig.12

Fig.9

Fig.11

10

CAUTION:

Do not prolong the cut to the point where grain is filling the bag and exerting pressure. This could cause a rip that

spreads along the full length of the bag.

4) Use the third hydraulic

lever to rotate the bag pick-up

roller until the row of sharpened

studs that will hold the bag fast

reach the topmost position.

(Figs. 15 & 16).

2) Swivel the cutter blade

around so that its cutting edge

faces outward. The blade will

cut open the bag as the roller

pulls it in.

(Fig. 13).

3) Drive the tractor/unloader pair in reverse

and align with the bag opening as straight and dead

center as possible.

Back up the unloader into the bag until the sweep

augers come lightly in contact with the grain, but do

not shove or attempt to wedge the sweep

augers forcefully into the mass of grain.

Be careful that the wheels are not treading on any

part of the bag (Fig. 14).

Fig.13

Fig.14

Fig.16Fig.15

11

5) Lift the bottom half of the bag bringing it up to

the roller. Notice that the bottom half is one

continuous section of plastic that runs the entire

length of the roller and that it is the black inner layer

of plastic that is visible.

Punch the plastic sheet through each holding stud

(Fig. 17) leaving a remainder of 10 or 20 inches to the

edge. Do not worry if the plastic is not perfectly

distributed along the length of the roller or if folds and

creases remain after attachment (Fig. 18).

Do not worry if the plastic is not perfectly distributed

along the length of the roller or if folds and creases

Fig.17

Fig.18

12

6) Once the bottom half of the bag has been

secured in this manner, place the upper half over the

bottom half already fitted; punch the plastic sheet

through each stud (Fig. 19), starting from the studs at

the end of the roller and progressing toward the

center. Notice that it is the white outer layer that is

now visible and that there are two sections of plastic:

the initial cut has divided the top part of the bag in two

parts. The left segment must be passed to the left of

the discharge auger and fastened to the studs on that

side of the roller, while the right segment must be

passed to the right of the auger tube and fastened to

the studs on that side (Fig. 20). Once unloading

operation is underway, the initial cut will be continued

by the cutter blade.

Once unloading operation is underway, the initial cut

will be continued by the cutter blade.

Fig.19

Fig.20

13

IMPORTANT:

There is no need to be overly precise when fastening the bag to the roller. Even though at this stage the plastic may

look crumpled and in disarray, it will stretch and straighten after a few turns of the roller. The basic consideration here

is having the bottom part of the bag (the part hooked to the roller first) hold some slack relative to the upper part

attached last (one or two feet is enough). The latter should be attached shorter so that the roller tugs at it first. The

small margin of slack in the bottom section plus the plastic sheet's elasticity helps form a rounded shape that contains

the grain as the bag is rolled in. The round shape also helps keep adequate clearance between bag and sweep augers

(see “General indications for efficient operation”, page 26).

2) Engage the tractor PTO with engine idling, throttle so PTO reaches 500/540 rpm's and once the augers are

turning move the roller control lever to its upper position. Normally it is left in that position until the unloading

operation is finished (Fig. 23). Turn to the variable flow valve. This valve handles roller rotation speed through a

turning knob located at the top of the hydraulic valve array (Fig. 24). Turning the knob anti-clockwise increases

rotational speed; turning it clockwise decreases it. The higher the speed, the more grain is brought in. At any point

during operation roller can be brought to a complete halt by closing the valve knob. Open the valve if it was

previously closed and augment speed so that grain begins to be delivered through the discharge auger and to

accumulate at the front end of the bag.

1) Make absolutely sure that the tractor's gear case is disengaged and brakes are off. Failure to

comply with this can result in a torn bag or mechanical malfunction. The machine is now ready to begin

unloading grain. First, use control lever to turn roller forward about half a turn or more so that it gathers

some plastic sheet (Fig. 21) and then move lever back to neutral. Check that the bag passes through the

cutter blade located on the auger tube (Fig. 22) in preparation for beginning work.

07

Grain extraction procedure

Fig.22

Fig.24

Fig.21

Fig.23

14

3) To determine proper speed, wait until grain

reaches a level that is approximately 10 centimeters (4

inches) below the roller's level and keep it there by

adjusting the knob in either direction. (See “General

indications for efficient operation” on page 22 for further

information on regulating grain height within bag).

This can be verified visually by observing the mass of

grain through the cutter blade opening at the top of the

bag. If the gap between grain level and pick-up roller

grows too close, and grain is being pulled up into the

roller with the bag folds, then too much material is

accumulating inside the bag faster than it can be

discharged.

Operating speed must be lowered by turning knob

clockwise. If the gap between roller and grain

increases, more grain must be supplied by turning the

knob anti-clockwise and speeding up the roller. The

knob is turned very gradually, avoiding any abrupt

changes of grain flow.

The unloader should now be delivering a steady

stream of grain to the receiving truck or trailer (Fig.

25). The truck will have to move every so often to stay

alongside the retreating bag.

Fig.25

15

CAUTION:

It is critical that grain not be allowed to collect higher up in the bag than level recommended (see “General

indications for efficient operation”, page 26) because it can be drawn up with the bag, rolled in with the plastic sheet

and form large masses of bulging grain that continue to get bigger. If that happens, operation is stopped, roller is

disengaged (see “Detaching bag from roller, page 20), tractor is made to advance a few meters so that enough plastic

is unrolled to be cut off with a knife, all the used plastic is discarded from the roller and operation is recommenced.

Although it is ideal that no grain be picked up by the roller, small bulges here and there can be put up with as long as

roller speed is decreased and grain ceases to be pulled in.

4) It is advisable to check direction once in a while

and if necessary correct the steering wheel so that the

tractor continues to be pulled back in a straight line. It

is very important to prevent the sweep auger

extremities from touching the bag sidewalls as this

could tear the plastic.

That is the reason tractor and machine should be

positioned in a straight line and aligned with the bag

when initiating labor. If noticed that the unloader is not

working aligned with the bag and that the auger

protection grids have either come into contact with the

plastic or are about to make contact, it may be too

late to correct the situation by steering alone.

When bags are filled on uneven terrain or the tractor

pulling the bagger swerves or the bagger's brakes are

adjusted while working, the bag can curve, and the

curvature can be quite sudden and pronounced. The

operator should watch for this while unloading and try

to follow curvature with the tractor's steering wheel as

far as possible to avoid contact of the augers with the

bag's walls.

16

CAUTION:

When not possible to correct misalignment by steering action only - in situations as described above - operation

should be halted and the unloader realigned before it ruptures the bag and grain is lost. It should be done as follows:

PTO is turned off and the roller is counter-rotated hydraulically to slacken off as much plastic sheet as may be

necessary to provide scope for maneuvers (there is no need to detach bag from roller for this specific correction).

Tractor and unloader are first driven forward to extract the sweep augers from the grain and then maneuvered to line

up straight with the bag, sweep augers placed next to the grain (not wedged forcefully into the grain) ready to initiate

work again once PTO and roller are reengaged.

08

09

Ending grain extraction

When the bag is to be closed because work has been completed and the unloader is being taken away,

sufficient plastic is unrolled, either hydraulically or by mechanically disengaging the roller, for the bag to

be sealed with plastic strips or 2” x 4” boards nailed together.

Emptying the last section of bag

1) When the unloader reaches a point where it can advance no further because the bag is almost

finished and the augers are not picking up any more grain (Fig. 27), it is time to cut short the main

operation. After stopping hydraulics and stopping the PTO for reason of safety, the operator should use a

knife to rip open the upper part of the bag, remove stops and lower the machine so that the augers may

pick up additional grain (Fig. 28) while the roller remains stationary. The tractor can engage in some gentle

forward and reverse action to boost grain collection. Repeating this sweeping action, the volume to be

loaded by hand can be considerably reduced.

17

IMPORTANT:

Whenever grain extraction is ended, either if the unloader will remain with bag attached to continue work later or if it

will be towed away, the correct termination sequence is as follows:

a) The roller is brought to a complete standstill by setting valve lever in neutral position or closing flow

control knob, in order to stop the input of grain.

b) PTO is left engaged and working for a few minutes so that all loose grain is unloaded, ensuring there is

no buildup inside the discharge auger tube that could be cause of transmission overload and breakdown.

WARNING:

At this stage no one should approach the bag to hasten discharge by heaping grain onto the augers, or attempt any

other action in proximity of the augers since these are turning and could cause serious injury or worse. Stay away!

2) Once all grain possible has been picked up in this way the

tractor engine is stopped. For reason of operator safety, it is now

necessary to disconnect the sweep augers from the main

transmission while still allowing the discharge auger to turn and

unload grain. Remove the lock pin from the sweep auger gear

case and pull out the coupling gears' handle (Fig. 28), which will

disconnect the auger drive. With sweep augers disconnected, the

auxiliary hopper is attached to the slot located at the base of the

discharge auger.

At this stage the sliding panel or divider that separates the sweep

augers from the discharge auger is introduced in corresponding

space between auger flightings (Fig. 29). Then provided crescent

shaped covers are attached to the ends of the divider, thus

effectively covering and sealing both openings of the cylinder

shaped grain reception chamber (Fig. 30). In this way the totality

of grain introduced in the auxiliary hopper will be captured by the

discharge auger, valuable loading time gained as no grain is

tossed out of the chamber by the whipping and churning action of

the auger.

Fig.28

Fig.29

18

Fig.27Fig.26

CAUTION:

Always disable the sweep augers when grain is being introduced manually in the hopper in the final stages of

work.

Fig.30

Fig.31

19

The tractor engine is turned on, its PTO is engaged and the last

grain remaining in the bag is shoveled into the auxiliary auger by

hand (Fig. 31). Once unloading is concluded and engine turned

off, the sweep auger coupling gears' handle should be pushed in

and the lock pin reinserted. The coupling gears are connected to

the drive shaft by means of a flange fitted with shear bolts. Should

these bolts be cut, unscrew gear case cover and replace with low

carbon steel SAE 1010 or C10 bolts of same diameter as the

original.

10

a) The front section of the

roller chain cover is unscrewed

from the bottom and pulled up,

where it is secured in place with

the same screw. The double

sprocket and chain that drive

the roller are now visible

(Figs. 32 & 33).

b) Roller hydraulic valve is

opened to advance

transmission until lock pin that

links drive sprocket and roller

comes into view (Figs. 34 & 35).

c) R-clip is removed and

this lets the operator draw out

the lock pin, thus disconnecting

transmission to roller and

allowing it to turn freely and

plastic to be pulled off

(Figs. 36 & 37).

To release the bag from the roller once the bag has been completely emptied,

the following sequence is followed:

Detaching bag from roller

Fig.33Fig.32

Fig.35Fig.34

Fig.37Fig.36

20

21

11

Back to transport mode

Reverse the order of previous steps to set up the machine for transport:

a) Raise hydraulic cylinder to its maximum height, clamp all the stops on the

cylinder rod and lower again to rest machine on stops. It is important to set

highest clearance for the road.

b) Fold the discharge auger.

c) Disconnect hydraulic hoses and remove PTO drive shaft.

d) After lifting up the pivoting support stand, swivel roller cross beam ¼ of a circle

into its transport position. Then remember to secure support stand to its base

once again.

e) Turn cutter blade round so cutting edge faces inward.

f) Remove outer sweeper screws and grids so machine does not exceed road

transport width allowance.

g) Hitch unloader to towing vehicle.

d) The bag is held from its

end as the tractor advances

unrolling plastic until the entire

strip lies on the ground

(Figs. 38 & 39).

Fig.39Fig.38

IMPORTANT:

Plastic sheet litter is an eyesore and doesn't help the environment. Inquire about recycling alternatives

from your plastic bag supplier or local environmental agency.

WARNING:

Fig.40

12

Maintenance

To check for main drive chain slack, remove covers located on front part of frame and discharge auger

tube, and adjust idler sprockets if needed.

The drive shaft that connects to tractor's PTO is

equipped with two shear bolts linking yoke and flange

elements (Fig. 40).

They have been installed there to protect the

unloader's driveline and transmission from overloads.

Should they have to be replaced, use soft low carbon

steel SAE 1010 or C10 bolts of same diameter as the

original.

Never use hardened steel bolts or pins as

replacements.

Shear bolts

Lubrication

Roller gearbox, sweep auger and discharge auger transmission cases and chains:

Use 85W-140 premium heavy duty gear lube.

Bearings and chains:

Use heavy duty lithium grease.

Never perform maintenance or lubrication tasks when there are moving parts. Always stop tractor's engine and

remove the ignition key as an extra precaution.

22

13

Lubrication chart

23

Lubrication chart

24

F

F

E

14

The grain flow concept

The aptitude of different kinds of grain to flow

can be approximately determined by the

angle formed by the sides of a mound lying on

the ground. A steep angle indicates bad grain

flow (Fig. 39) whilst a shallow angle indicates

a good flow rate (Fig. 40).

Some of the factors that contribute to good grain flow are the following:

Remember: the whole working principle of the unloader rests upon the flow characteristics of grain.

Corn above 22% moisture

Soybeans above 22% moisture

Wheat above 20% moisture

Sunflower

Oats

Barley

Paddy rice

Chickpeas

Grains that flow with more difficulty should be extracted at a slower pace as the higher speeds cannot be

attained and if attempted the unloader could suffer mechanical damage. Examples of these grains are:

Corn below 21% moisture

Soybeans below 21% moisture

Wheat below 19% moisture

Examples of grains with good flow characteristics that can be unloaded at higher speeds are:

Low

heap

angle

Bigger grain size

Smooth outer surface

Round shaped grain

Dry grain

Clean grain

Smooth flow,

higher rate of

extraction

Fig.39 Fig.40

25

A

D

C

B

Roller

A

D

C

B B

Roller

A

D

C

Roller

15

General indications

for efficient operation

Sweep auger efficiency is dependent on the type of grain being unloaded. The highest output measured in tons

extracted per hour is obtained with grains that run well. Free running grain results in more efficient auger

operation, a higher discharge rate and less stress on mechanical components.

The opposite is true of grain that does not run so well, that clusters together because of contamination with straw

or twigs, excessive moisture, or because grain shape lends itself to interlocking. In these less than ideal

conditions, work speed

is necessarily compromised.

The following drawings depict magnitudes A, B, C & D. The text that follows can help you assess how

these parameters interact with each other and with different grains to help optimize operation:

“A” is the height that grain within the bag can be taken to by increasing or reducing the pickup roller's RPM's. This

level must not exceed the roller's height to prevent grain from being picked up with the plastic sheet. With this

constraint, grain level should normally be maintained as high as possible so that, with the aid of gravity, it can

readily fall back onto the sweep augers and be directed to the discharge auger.

Fig.41 Fig.43

Fig.42 Fig.44

26

“B” shows the curved shape that the front part of the bag should adopt - Figs. 41 & 42 - in order that the plastic

sheet does not come in contact with the sweep augers or their protection grids with risk of ripping open and losing

contents. The curvature is formed by the grain mass weighing down the tip of the bag as it is rolled in. When grain

does not accumulate there, the plastic will tend to go up to the roller in a straight line - Fig. 43 - dangerously close

to or actually touching the augers, with possibility of bag damage. With grain that flows easily (e.g. dry wheat), if the

sweep augers are set with their normal low clearance to the ground (see “C” below), it can happen that due to quick

passage, no layer of grain is left between the sweep augers and the floor. With no grain weighing down the bottom

part of the bag and grain being unloaded at a very fast pace because it flows freely, it might not accumulate at the

front as in fig. 41 but take on the shape shown in Fig. 43. In this case, sweeper height (“C”) should be increased to

permit some grain to pass beneath the sweepers without being gathered so that it can weigh down the bottom of

the bag and collect at the front (“B”). However, if sweeper height is excessive, too much grain could accumulate

there and project forward, making contact with the unloader's wheels (Fig. 44), a situation that should be avoided.

The weight of grain contained within the curved shape “B” can reach tons. For that reason too it is important to pay

close attention to grain level within the bag and prevent it from climbing above the roller as this will add even more

volume and weight, the problem compounded by a large amount of grain that will immediately be pulled up by the

roller along with the plastic, forming huge lumps of rolled material. If it goes unchecked, this progression could

cause failure of mechanical components.

“C” is the clearance between sweep augers and bag bottom (or ground). This distance should be small so that the

sweep augers lie low inside the bag and are well covered with grain, which ensures adequate delivery to the

discharge auger. The clearance is set via clamp stops placed on the hydraulic cylinder rod. Since the augers

should not touch the ground as this would endanger bag integrity, the convenience of placing the bags on terrain

as flat as possible becomes clear. If the ground is rough, this will force operation with sweeper augers placed

higher up than optimum because a rut will cause the unloader to dip, with the consequence of sweepers bumping

against the ground and ripping the plastic. Especially with grain that clings together and flows badly, it is important

to place the sweeper augers as low as possible. Generally speaking and in average conditions, low may be

considered to be a clearance of about four to six inches from auger flighting to floor.

“D” indicates the slope or angle of grain inside the bag. Materials that flow easily will form a shallow slope Fig. 41

-, whilst those that do not will tend to form a steeper slope - Fig. 42 - that in extreme cases will flow only with great

difficulty and could keep the augers uncovered and visible (or partially visible) while the machine is working,

instead of fully covered with grain which constitutes the most desirable situation. Free flowing grain will typically

cover the augers with a foot thick layer of grain. In relation to this, it is very important to remember that quick

starting the augers deeply immersed in grain will most likely result in shear bolts that snap or transmission

breakages. When labor is interrupted, PTO must not be restarted when augers are deep inside grain. The correct

procedure is to unwind a certain length of plastic by hydraulically turning the roller in reverse and then advancing

forward with tractor and unloader the distance it takes to extricate the augers from the mass of grain. When

reinitiating work, augers should not be thrust into the grain by the tractor, but should be pulled into the mass of

grain by roller action.

27

The main rule when dealing with difficult, hard flowing grain is to slow down the operation.

This means lessening the volume of incoming grain, which in turn means

slowing down the roller's revolutions per minute.

Let us present a practical example applying some of the parameters mentioned above by analyzing an

extraction of “difficult” grain in detail. Most of these indications are applicable grains in general, but grain that

flows with difficulty better exemplifies the precautions that should be taken. Once the operator becomes

knowledgeable about how the unloader handles different types of grain, using the correct approach

becomes a matter of routine. The intention is not to impose a rigid set of rules, but to provide general

guidelines that the operator can follow while he familiarizes himself with the machine.

If we consider a bag filled with grain that will not flow easily, in a situation such as depicted in Fig. 42, the

grain forms a compact mass that the sweep augers can only penetrate with difficulty. The augers will

move less quantity of grain per unit of time compared with free flowing material.

A) First adjust “C” so that sweeper distance to the ground is the minimum possible. This allows the

augers to tackle the mass of grain from a lower point, so that more grain can accumulate above them

and form a steeper angle “D”. This will cause the wall of grain to tumble down more readily and better

feed the augers. Remember that minimum is a relative term and can very well mean 4 or 6 inches or

more from the floor, to compensate for the unloader lurching into a hole or depression and causing the

augers to thump on the ground and rip the plastic. Therefore, sweeper clearance “C” will tend to increase

with ground bumpiness.

B) When backing up the tractor into the bag, the unloader must never be rammed forcefully against

the grain as this can damage the sweeper augers or even bend the beam that supports them. The

unloader should be introduced with prudence in the bag and the augers should not penetrate the mass of

grain, but make light contact with it. See warning (above in “D” section) about not initiating work with

augers surrounded by grain.

C) The PTO should always work within its normal 500/540 rpm range, not slower. Whatever grain

characteristics are, PTO revs are not reduced and augers work at a uniform speed.

28

F) If level of grain inside bag goes too high the roller must be slowed down to allow more grain to

be removed by the sweeper and discharge augers. Grain picked up and rolled as one with the plastic

sheet is the telltale sign that should be watched out for. The roller extremes where the plastic folds

converge on the centering discs is where grain is more likely to collect. If grain is being picked up then

roller speed has to be reduced. If the roller picks up too much grain resulting in prominent and growing

bulges under the plastic, it will be necessary to stop operation, cut the bag, remove plastic sheet from

roller, and reinitiate operation.

G) If grain height reaches point “A”, where a substantial amount of grain is being unloaded with none

being picked up by the roller, then roller speed should be stabilized there. Usually point “A” is the highest

point that the grain can reach without being pulled in with the plastic folds, but the actual clearance to the

roller measured in centimeters can vary. When this plateau is reached, the roller is turning at the correct

speed.

H) This is the point of equilibrium where inflow and outflow of grain are equal. The amount of grain

that can be handled has reached its peak. Increasing discharge speed should not be attempted at this

stage since no benefit in terms of time or volume will be obtained and failure of mechanical parts is a

possibility.

I) If in doubt, first always try working slower before increasing speed in a gradual manner.

E) Grain will start coming out of the discharge auger and simultaneously it will start building up inside

the bag to form shape “B” with a certain gradient “D”. The operator should allow a buildup of grain that

will probably take a few minutes to reach point “A”.

D) Once the bag has been hooked to the roller and the augers are moving, the operator should begin

to haul in the bag by gradually turning open the hydraulic flow control valve (with the roller control lever in

its upper position).

34

29

30

Notes

34

Parts list

31

Diagram 1 - PTO Driveline & wheels

Diagram 2 - Frame

Diagram 3 - Front end driveline & main drive shaft

Diagram 4 - Roller drive

Diagram 5 - Discharge auger, upper section

Diagram 6 - Discharge auger, lower section

Diagram 7 - Rear end driveline

Diagram 8 - Sweep auger drive

Diagram 9 - Sweep augers

Diagram 10 - Gear case

Diagram 11 - Hydraulic controls

Diagram 12 - Gearbox, roller

Diagram 13 - Charging Procedure transmission oil SAE 140

page 32

page 34

page 36

page 38

page 40

page 42

page 44

page 46

page 49

page 51

page 53

page 55

page 57

Diagram 1

PTO driveline & wheels

32

Diagram 1 - PTO driveline & wheels

Nº

DESCRIPTION

CODE

QTY.1Cover guard, lower drive assy.

EX-18070C

12Lock pin, cover guard drive assy.

EX-18070A

13Snap ring DIN 472 75/I

MP0846

24Ball bearing 6009 2RS

MP0124

25Drive shaft housing

EX9-223

1

6

Drive shaft, short

EX-18020

17Square key 10x10x40 (mm.)

EX-18121

18Hex bolt gr. 5 BSW 1/2" x 1 3/4"

MP2066

69Split lock washer 1/2"

MP1504

610Cover guard, upper drive assy.

EX-18070D

1

11

R-clip 2,5 x 50 (mm.)

MP1070

112Split pin 2,5 x 30 (mm.)

MP1008

113Hinge pin, cover guard drive assy.

EX-18070B

1

14

Drive shaft assy., 6 spline, yoke U-joint 30.2 x 92

(mm.)

MP0507

1

15

Shear bolt grade 2 steel 1/4" x 1 3/4"

MP1907

2

16

Bushing 1/4" ID, shear bolt

A-818-83

417Self locking nut BSW 1/4"

MP1329

218Split pin 3 x 40 (mm.)

MP1018

219Snap ring CF-604

MP0545

820Plastic shield, inner

MP0536

121Plastic shield, outer

MP0538

122U-joint K-518 (92 mm.x 30,2mm. cap dia.)

MP0544

223Grease zerk, 45° angle SAE 1/4"

MP1456

2

24

Splined yoke x 35 mm

MP0520

125Female half shaft w/yoke x 800 mm

MP0571

1

Nº

DESCRIPTION

CODE

QTY.26Male half shaft w/yoke x 800 mm

MP0567

127Castle nut UNF 3/4"

MP1320

228Flat washer 3/16" OD 38 / ID 20 (mm.)

AR-483820

129Flanged yoke K-518

MP0524

130Shear bolt flange

A-815-83

1

31

Bearing cap, wheel axle

EX-18013A

332Flat washer 3/16" OD 35 / ID 20 (mm.)

AR-483520

633Split lock washer 3/4"

MP1507

634Hex bolt SAE 3/4" x 5"

MP2158

635Oil seal 48 x 82 x 8 (mm.)

MP2935

2

36

Taper roller bearing 30208

MP0196

237Hex bolt gr. 5 SAE 1/2" x 1 1/2"

MP2133

1238Wheel hub

EX-18009

2

39

Taper roller bearing 30205

MP0193

240Flat washer 3/16" OD 36 / ID 20 (mm.)

AR-483520

241Hub cap

EGH96-001R

242O-ring seal 52,07 x 57,31 x 2,62 (mm.)

MP2975

243Main wheel axle assy.

EX-18012C

144Grease zerk, straight GAS 1/8"

MP1451

345Axle spindle

EX-18011

2

46

Tire rim 15"

MP1821

247Tire 11L-15 10 ply

MP1849

248Lug nut 1/2" UNF

MP1361

12

33

Diagram 2

Frame

34

Diagram 2 - Frame

35

Nº

DESCRIPTION

CODE

QTY.1Hex bolt gr. 5 BSW 1/4" x 5/8"

MP2043

162Tooth lock washer 1/4" x 15 mm.

MP1582

163Cover plate, chain 1"

EX-18085B

24R-clip 2,5 x 50 (mm.)

MP1070

2

5

Lock pin, cover guard drive assy.

EX-18070A

16Split pin 2,5 x 30 (mm.)

MP1008

17Hinge pin, cover guard drive assy.

EX-18070B

18Drawbar w/ clevis hitch

EX-18109

19Hex bolt gr. 5 BSW 1/2" x 1 1/2"

MP2065

6

10

Split lock washer 1/2"

MP1504

1011Hex nut gr. 5 BSW 1/2"

MP1334

612Spring loaded lock pin

EX-18003

1

13

User's manual canister

MP3546

114Wing bolt 3/8"

EGH96-236

115Self locking nut BSW 3/8"

MP1314

216Flat washer galvanized 3/8"

MP1517

217Square socket, screw jack

V-0001

118Hitch pin w/ R-clip, screw jack

EGH96-004

119Screw jack

MP3084

120Cover plate, frame beam

EX-18085D

2

21

Lock pin, roller support pillar

EX-18010A

122Auxiliary bin

MP3549

123R-clip w/ ring

MP3209

4

Nº

DESCRIPTION

CODE

QTY.24Extension spring 2 x 15 x 100 (mm.)

MP2838

425Latch, protection grids

EX-18117

426Snap ring DIN 471 35/A

MP0812

127Support bracket, discharge auger

EX-18113

1

28

Supporting pillar, roller assy.

EX-18010

129Hex bolt gr. 5 BSW 1/2" x 1"

MP2063

430Support bracket, grid extension

EX-24001

4

Diagram 3

Front end driveline & main drive shaft

36

Diagram 3 - Front end driveline & main drive shaft

37

Nº

DESCRIPTION

CODE

QTY.1Square head set screw 3/8" x 1/2"

MP1415

32Sprocket 22 tooth f/ASA 80/1 chain

EX-18024

1

3

Roller chain ASA 80/1

EX-18138

14Connecting link, ASA 80 roller chain

MP1263

15Square key 10x10x50 (mm.)

EX-18120

36Square head set screw 3/8" x 3/4"

MP1417

37Insert bearing UC 208

MP0235

28Bearing housing FC 208

MP0244

29Grease zerk, straight SAE 1/4"

MP1452

210Split lock washer 1/2"

MP1504

911Hex bolt gr. 5 BSW 1/2" x 2"

MP2067

812Idler arm, front

EX-18081

1

13

Flat washer galvanized 1/2"

MP1519

114Hex nut gr. 5 BSW 1/2"

MP1334

115Idler sprocket 12 tooth f/ASA 80/1 chain

EX-18023

116Ball bearing 6205 2RS

MP0151

117Snap ring DIN 472 52/I

MP0841

118Snap ring DIN 471 25/A

MP0807

119Sprocket 17 tooth f/ASA 80/1 chain

EX-18021

220Split lock washer 3/8"

MP1502

4

21

Flat washer galvanized 3/8"

MP1517

422Bearing cap, drive shaft

MP4321

223Long drive shaft

EX-18026C

124Grease zerk, straight SAE 1/8"

MP1451

225Hex bolt gr. 5 BSW 3/8" x 5"

MP2062

4

Diagram 4

Roller drive

38

Diagram 4 - Roller drive

39

Nº

DESCRIPTION

CODE

QTY.1Chain cover

MP3548

12Self locking nut BSW 1/4"

MP1329

4

3

Chain cover, front section

V-0050

14Conical washer, plastic

V-0051

15Socket head cap screw 1/4" x 1 1/4"

MP4007

16Backplate, reflective triangle

EX-20031

17SMV warning triangle

Triangulo

1

8

Torsion spring 5 x 29 x 39 (mm.)

MP2851

19Spindle, idler arm

EX-280R052

110Idler arm, roller chain

EX-280R053

111Socket flat head screw 1/4" x 1"

V-0053

412Plastic hinge

V-0054

113Hex bolt gr. 5 BSW 5/8" x 1 1/2"

MP2075

1414Mounting bracket, roller drive

EX-280060

1

15

Hex bolt gr. 5 BSW 5/8" x 2 1/4"

MP2078

816Flat washer galvanized 5/8"

MP1521

417Self locking nut BSW 5/8"

MP1342

27

18

Bearing housing FC 210

MP0348

219Hex bolt gr. 5 BSW 5/16" x 7/8"

MP2061

220Square key 10x10x60 (mm.)

EX-20021

121Square head set screw 3/8" x 1/2"

MP1415

222Double sprocket 19 teeth, ASA 60/2 chain

EX-20022

123Square head set screw 3/8" x 3/4"

MP1417

124Hex bolt gr. 5 BSW 5/8" x 2 1/2"

MP2079

425Gearbox, roller

MP3787

1

26

Idler arm assy., roller chain

EX-280R054

127Split lock washer 1/4"

MP1500

228Hex bolt gr. 5 BSW 1/4" x 1"

MP2060

229Roller chain ASA 60/2

EX-20033

1

Nº

DESCRIPTION

CODE

QTY.

30

Grease zerk, straight SAE 1/4"

MP1452

531Connecting link, ASA 60/2 roller chain

MP1270

132Bushing, double sprocket 38 teeth

EX-20023

133Insert bearing UC 210

MP0237

2

34

Spacer bushing

EX-20019

135R-clip 2,5 x 50 (mm.)

MP1070

136Woodruff key 1/4" x 25 x 11 (mm.)

V-0048

137Split lock washer 1/2"

MP1504

338Hex bolt gr. 5 BSW 1/2" x 1 1/2"

MP2065

239Sauer Danfoss orbital motor, 50 cc displacement

MP4575

140Hex bolt gr. 5 BSW 1/2" x 1"

MP2063

141Pivot pin, roller assy.

EX-18078

142Drive spindle, roller

EX-20008

143Double sprocket 38 teeth, ASA 60/2 chain

EX-20027

1

44

Washer, pivot pin

EX-18016

145Lock pin, roller

EX-20026

146Hex nut gr. 5 BSW 1/2"

MP1334

247Tightener, gearbox

EX-18071

248Roller w/end spindles

EX-24005

149Mounting bracket, roller

EX-280061

150Pivoting beam, roller assy.

EX-24002

151Complete idler assy., roller chain

EX-280R055

1

52

End cap, spindle

EX-20018

153Spindle, roller

EX-20009

154Centering disc, roller

EX-280089

255Snap ring DIN 471 25/A

MP0807

156Centering ring, idler pulley

EX-280087

157Idler pulley, roller chain

EX-280088

1

Diagram 5

Discharge auger, upper section

40

Diagram 5 - Discharge auger, upper section

41

Nº

DESCRIPTION

CODE

QTY.1Outer tube, upper section

EX-18031

12Discharge auger w/end stubs, upper section

EX-18048

13End stub, upper auger shaft

EX-18041

1

4

Bracket, bearing housing

EX-18031A

15Hex bolt gr. 5 BSW 1/2" x 6" w/40 mm thread

MP1985

46Hex bolt gr. 5 BSW 3/8" x 1"

MP2046

47Split lock washer 3/8"

MP1502

48Flat washer galvanized 3/8"

MP1517

4

9

Self locking nut BSW 3/8"

MP1314

610Flat washer galvanized 3/8"

MP1517

611Trusshead screw BSW galvanized 3/8" x 3/4"

MP1682

612Split pin 3 x 40 (mm.)

MP1018

1

13

Castle nut UNF 3/4"

MP1320

114Flat washer 3/16" OD 36 / ID 20 (mm.)

AR-483620

115Extension

EX-18038

116Grease zerk, straight SAE 1/4"

MP1452

117Insert bearing UC-207 2L

MP0246

118Bearing housing UC 207

EX-18090

1

19

Flat washer galvanized 1/2"

MP1519

420Compression spring 3 x 26 x 120 (mm.)

MP2825

421Hair Pin clip 4,5 x 90 (mm.)

MP1094

222Clevis pin 25 x 94,5 mm., hydraulic cylinder

V-0055

1

23

Hydraulic cylinder 1 1/4" rod diameter x 2 1/2"

sleeve bore x 500 mm. stroke

MP4567

1

24

Split pin 5 x 60 (mm.)

MP1064

125Hinge pin, auger tube

A-83583

1

Nº

DESCRIPTION

CODE

QTY.26Clevis pin 25 x 108 mm., hydraulic cylinder

V-0056

127Flat washer 3/16" OD 50 / ID 30 (mm.)

AR-485030

128Grease zerk, straight SAE 1/8"

MP1451

2

29

Adapter, 3/8" female NPT to 3/8" male NPT

MP4558

2

30

Hydraulic hose 1/4" SAE 100R2 AT x 1100 mm.,

connectors 9/16" male UNF JIC 37° x 3/8" male

NPT

V-0030

2

42

Diagram 6

Discharge auger, lower section

Diagram 6 - Discharge auger, lower section

43

Nº

DESCRIPTION

CODE

QTY.

1

Complete cutter blade assy.

EX-24017

12Holding bracket, cutter blade

EX-24016

13Cutter blade, 600 x 50 x 1.5 (mm.)

MP3791

14Fastening bracket, cutter blade

EX-24012

15Lock pin, cutter blade

EX-18122

26R-clip 2 x 40 (mm.)

MP1078

27Self locking nut BSW 5/16"

MP1315

48Hex bolt gr. 5 BSW 5/16" x 7/8"

MP2061

49Discharge tube, lower section

EX-280R059

110Self locking nut BSW 1/2"

MP1317

211Support bracket, bearing housing

EX-18065

112Hex bolt gr. 5 BSW 1/2" x 1 1/4"

MP2042

2

13

Hex nut gr. 5 BSW 1"

MP1339

114Coupling, auger lower section

EX-18111

115Insert bearing UC-208 3L

MP0248

116Bearing housing UC-208 3L

EX-18065A

117Grease zerk, 45° angle SAE 1/4"

MP1456

118Complete UC-208 bearing & bracket assy.

EX-18373

1

19

Self locking nut BSW 5/8"

MP1342

120Hex bolt gr. 5 BSW 5/8" x 3 1/4"

MP2082

121Discharge auger, lower section

EX-18372

122Grease zerk, straight SAE 1/8"

MP1451

2

44

Diagram 7

Rear end driveline

Diagram 7 - Rear end driveline

45

Nº

DESCRIPTION

CODE

QTY.21Hex bolt gr. 5 BSW 1/4" x 5/8"

MP2043

1622Large cover plate, discharge tube

EX-280024

123Hex bolt gr. 5 BSW 1/2" x 1 1/4"

MP2042

624Gearbox, single input/double output

MP4329

125Small cover plate, discharge tube

R10-190

126Chain drive aasy., discharge auger

MP3704-B

127Disc springs 20x10,2x1,1 (mm.)

MP1583

828Hex bolt gr. 5 BSW 3/8" x 1"

MP2046

829Hex bolt gr. 5 BSW 1/2" x 1"

MP2063

430Right side cover, slide plate

EX-280R009

1

Nº

DESCRIPTION

CODE

QTY.1R-clip w/ ring

MP3209

22Left side cover, slide plate

EX-280R008

13Sprocket 17 tooth f/ASA 80/1 chain

EX-18021

14Square key 10x10x50 (mm.)

EX-18120

25Square head set screw 3/8" x 3/4"

MP1417

26Idler arm, rear

EX-18082

17Idler sprocket 12 tooth f/ASA 80/1 chain

EX-18023

18Ball bearing 6205 2RS

MP0151

19Snap ring DIN 472 52/I

MP0841

110Square head set screw 3/8" x 1/2"

MP1415

1

11

Snap ring DIN 471 25/A

MP0807

112Connecting link, ASA 80 roller chain

MP1263

1

13

Roller chain ASA 80/1

EX-280R028

114Sprocket 22 tooth f/ASA 80/1 chain

EX-18024

115Bracket, driveshaft casing

EX-280R013

1

16

Flat washer galvanized 1/2"

MP1519

717Split lock washer 1/2"

MP1504

1118Hex nut gr. 5 BSW 1/2"

MP1334

119Cover plate chain 1", side

EX-18085A

120Disc springs 14x7,2x0,8 (mm.)

MP1582

16

Diagram 8

Sweep auger drive

46

47

Diagram 8 - Sweep auger drive

Nº

DESCRIPTION

CODE

QTY.1Hex bolt gr. 5 BSW 1/2" x 1"

MP2063

6

2

Split lock washer 1/2"

MP1504

43Insert bearing UC-208 3L

MP0248

14Hex bolt gr. 5 BSW 3/8" x 1"

MP2046

35Flat washer galvanized 3/8"

MP1517

36Self locking nut BSW 3/8"

MP1314

57Bearing housing PF 208

MP0349

18Square key 8x8x40 (mm.)

EX-280058

29Housing, sweep auger drive

EX-280R060

110Square head set screw 5/16" x 1"

MP1412

211Hex nut gr. 5 BSW 5/16"

MP1331

1012Disc springs 16x8,2x0,9 (mm.)

MP1581

16

13

Cover, gearcase

EX-280R004

114Double gear 18 teeth w/ bronze bushing

EX-280R002

115Self locking nut BSW 5/16"

MP1315

116Hex bolt gr. 5 BSW 5/16" x 1 1/4"

MP2041

117Snap ring DIN 471 38/A

MP0813

118Grease zerk, straight SAE 1/4"

MP1452

319Lock pin, sweep augers

EX-280R020

1

20

Bushing, lock pin

EX-280048

121Spring, lock pin

MP2829

122Bushing, small

EX-280069

123Split pin 2 x 20 (mm.)

MP1000

124Complete lock pin assy.

EX-280R026

125Flat washer 5/16"

MP1516

4

Nº

DESCRIPTION

CODE

QTY.26Split lock washer 5/16"

MP1501

4

27

Hex bolt gr. 5 BSW 5/16" x 3/4"

MP2050

428Gear coupling w/ bronze bushing, sweep augers

EX-280R003

129O-ring seal 31,34 x 38,4 x 3,53 (mm.)

MP2965

130Lock, gear coupling

EX-280R061

131Snap ring DIN 471 35/I

MP0849

232Snap ring DIN 471 15/A

MP0848

433Ball bearing 6202 2RS

MP0145

234Bushing, idler gear

EX-280011

235Idler gear

EX-280010

236Hex bolt gr. 5 BSW 3/8" x 2"

MP2051

237Idler arm

EX-280R014

2

38

Idler arm, right side

EX-280R015D

139Snap ring DIN 471 25/A

MP0807

40

Gear coupling, sweep augers

EX-280003

141Ball bearing 6205 2RS

MP0151

142Snap ring DIN 472 52/I

MP0841

143Handle, gear coupling

EX-280051

144Complete gear coupling handle assy.

EX-280R022

1

45

Offset link ASA 50/2 roller chain

MP1300

146Connecting link, ASA 50/2 roller chain

MP1274

147Roller chain ASA 50/2

EX-280R025

148Chain cover

EX-280R005

149Hex bolt gr. 5 BSW 5/16" x 5/8"

MP2086

850Flange bracket, oil seal

EX-280039

1

Nº

DESCRIPTION

CODE

QTY.51Square head set screw 3/8" x 3/4"

MP1417

252Hex nut gr. 5 BSW 3/8"

MP1332

153Outer ring, flange bracket

EX-280006

1

54

Square key 8x8x65 (mm.)

EX-280057

155Hex nut gr. 5 BSW 1/2"

MP1334

256Snap ring DIN 471 62/I

MP0821

157Oil seal 35 x 62 x 10 (mm.)

MP2930

158Hex bolt gr. 5 BSW 3/8" x 3/4"

MP2044

4

59

Idler arm, left side

EX-280R015I

160Double gear 22 teeth, sweep augers

EX-280R000

161Hex bolt gr. 5 BSW 1/2" x 1 1/4"

MP2042

262Flat washer 1/2"

MP1519

4

63

Split lock washer 3/8"

MP1502

4

Diagram 8 - Sweep auger drive

48

Diagram 9

Sweep augers

49

Diagram 9 - Sweep augers

Nº

DESCRIPTION

CODE

QTY.

1

Protection grid, left end section

EX-18035I

1

2

Protection grid, supplementary section

EX-24007

2

3

Protection grid, left middle section

EX-280R032

1

4

Hex bolt gr. 5 BSW 3/8" x 1 1/4"

MP2047

24

5

Protection grid, center section

EX-280R038

1

6

Self locking nut BSW 3/8"

MP1314

34

7

Protection grid, left rear section

EX-280R037I

18Protection grid, right rear section

EX-280R037D

1

9

Hex bolt gr. 5 BSW 3/8" x 1"

MP2046

310Flange bolt gr. 5 BSW 3/8" x 1"

MP2193

10

11

Protection grid, right end section

EX-18035D

1

12

Protection grid, right middle section

EX-280R034

113Sweep auger, center section

EX-280R010

1

14

Hex bolt BSW 3/8" x 2 1/2"

MP1943

2

15

Split lock washer 3/8"

MP1502

2

16

Hex nut gr. 5 BSW 3/8"

MP1332

2

17

Sweep auger, right end section

EX-24006D

118Sweep auger, left end section

EX-24006I

119Support bracket, bearing housing

EX-280R011

1

20

Flat washer galvanized 3/8"

MP1517

4

21

Square head set screw 3/8" x 1/2"

MP1415

122Dust seal

EX-280025

1

23

Insert bearing UC-208 3L

MP0248

1

24

Hex nut gr. 5 BSW 1"

MP1339

1

25

Bearing housing UC-208 3L

EX-18065A

1

26

Grease zerk, 45° angle SAE 1/4"

MP1456

1

27

Complete UC-208 bearing & bracket assy.

EX-18373

1

50

32

33

6

7

24

25

26

27

28

12

10

11

15

16

2

22

4

17

12

8

18

31

3

4

2

5

2

1

7

6

9

2

3

8

13

12

238

20

12

6

7

10

31

19 20

8

30

8

3

34

2

12

19

20

8

21

14

8

10

29

2

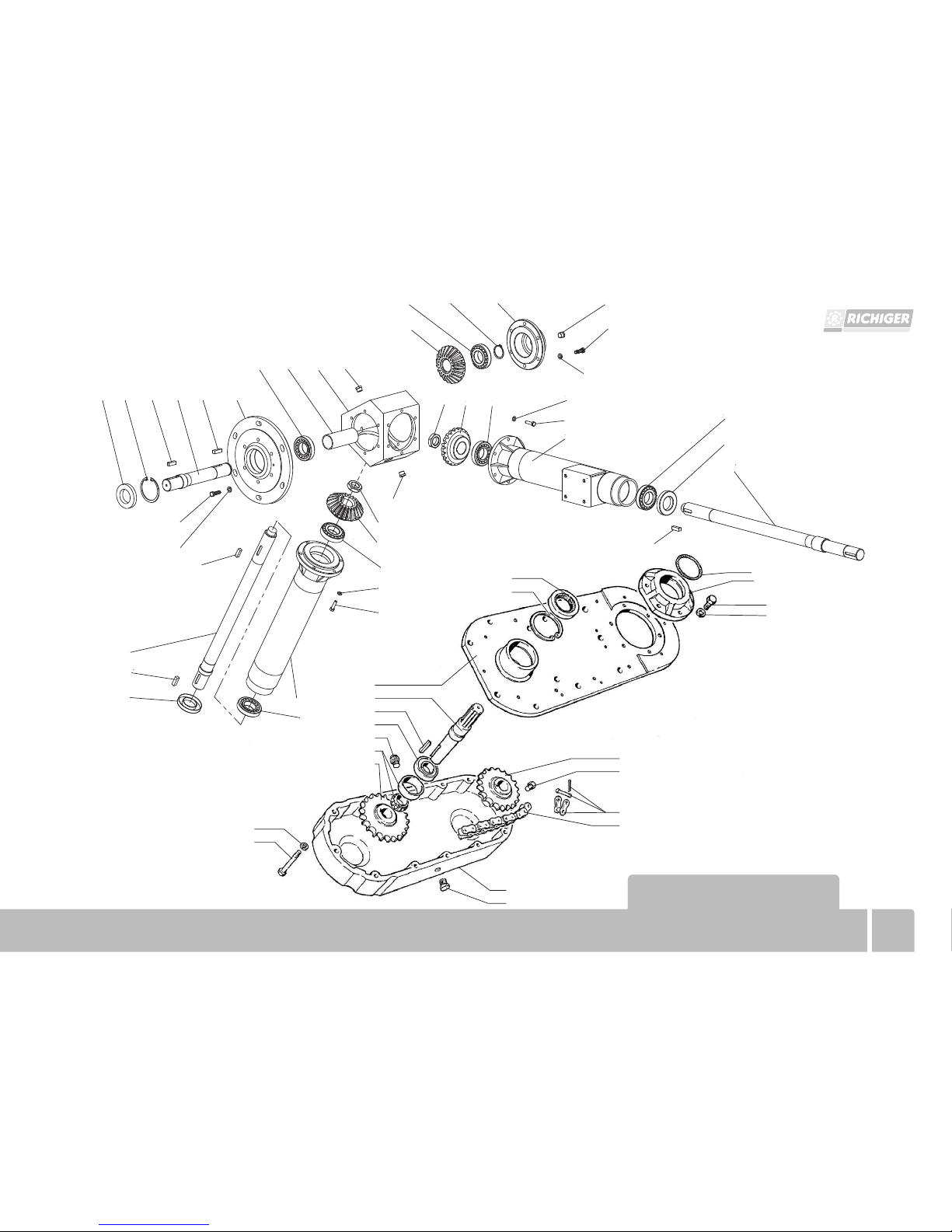

Diagram 10

Gearcase

51

Diagram 10 - Gearcase

Nº

DESCRIPTION

CODE

QTY.1Plate flange, input shaft

EX-18091

1

2

Square key 5 x 10 (mm.)

MP3202

63Oil seal 5367

MP2938

34Snap ring DIN 472 80/I

MP0800

25Input shaft

EX-18092A

16Hex bolt BSW 3/8" x 1 1/4"

MP1938

187Split lock washer 3/8"

MP1502

188Taper roller bearing 30208

MP0196

79Rear driveline

EX-280046

110Split lock washer 5/16"

MP1501

1611Hex bolt gr. 5 BSW 5/16" x 3"

MP2059

412Threaded plug 3/8" GAS

MP3717

4

13

Housing, gearbox

EX-18093A

114Spacer bushing

EX-18094

115Cover plate, chain drive

EX-18098

116Splined shaft, chain drive

EX-18092D

117Ball bearing 6208 2RS

MP0157

118Driven sprocket 18 tooth f/ASA 80/1 chain

EX-18099B

119Hex nut UNF 1 1/8"

MP1355

2

20

Conical gear 21 tooth

EX-18099A

3

52

Nº

DESCRIPTION

CODE

QTY.21Housing, rear driveline

EX-280R012

122Oil seal 6645

MP2939

123Bearing housing 30208

EX-18096

124Drive sprocket 18 tooth f/ASA 80/1 chain

EX-18099C

125Threaded plug 1/4" GAS

MP3718

126Connecting link, ASA 80 roller chain

MP1263

1

27

Roller chain ASA 80/1

MP1203

128Casing, chain drive

EX-18093B

129Snap ring DIN 471 40/A

MP0814

130Housing, sweep auger drive shaft

EX-280R016

131Hex bolt BSW 5/16" x 1 1/4"

MP1919

12

32

O-ring seal 91,67 x 98,73 x 3,53 (mm.)

MP2976

1

33

Base flange, cover plate

EX-18097

134Drive shaft, sweep augers

EX-280021

1

Diagram 11

Hydraulic controls

53

Diagram 11 - Hydraulic controls

Nº

DESCRIPTION

CODE

QTY.1Tie-rod

11926

32Outlet body

35047

13Spring centered spool

11869

2

4

Inlet body w/ flow divider (includes items 5, 6,

7, 11, 12, 13, 14, 15)

504266

1

5

Flow control valve

503651

16Plug, hollow

14224

2

7

Pressure relief valve

500391

18Spring centered spool, 1 position detent

12791

19Closure section

035047

110Central body (includes items 8, 16)

47933

111Plug, solid

12353

1

12

Spring, divider spool

02293

113End section, divider spool

42964

114Replacement plug SVLP

12743

115Divider spool

42398

116Lever actuator assy.

08490

317Central body (includes items 3,16)

14319

2

54

Diagram 12

Gearbox, roller

55

Nº

DESCRIPTION

CODE

QTY.1Housing, front

V-0057

1

2

Housing, rear

V-0058

13Gear 12 teeth

V-0059

14Gear 68 teeth

V-0060

25Gear 18 teeth

V-0061

16Gear 17 teeth

V-0062

1

7

Gear 70 teeth

V-0063

18Output shaft

V-0064

19Intermediate shaft

V-0065

110Housing, output shaft

V-0066

1

11

Oil seal

V-0067

1

12

Sleeve coupling

V-0068

1

13

Ball bearing 6305 2RS

MP0178

2

14

Ball bearing 6206 2RS

MP0153

2

15

Ball bearing 6207 2RS

MP0155

1

16

Ball bearing 6311 2RS

V-0069

1

17

Ball bearing 6306 2RS

MP0179

118Ball bearing 6308 2RS

MP0182

119Hex bolt UNF 5/16" x 2 1/2"

V-0070

1420Flat washer 5/16"

MP1516

2821Self-locking nut UNF 5/16"

V-0071

1422Hex bolt UNF 5/16" x 1"

V-0072

623Lock washer 5/16"

MP1501

624Threaded plug 3/8" GAS

MP3717

1

25

Threaded plug 3/8" GAS

MP3717

1

Diagram 12 - Gearbox, roller

53

56

Nº

DESCRIPTION

CODE

QTY.26Threaded plug 3/8" GAS

MP3717

1

27

Venting valve 3/8" GAS

V-0073

1

28

Square key 1/4"x1/4"x1 1/4"

V-0074

1

29

Square key 8x7x35 (mm.)

V-0075

1

30

Square key 8x7x80 (mm.)

V-0076

1

31

Square key 10x8x65 (mm.)

V-0077

1

32

Square key 10x8x35 (mm.)

V-0078

1

33

Roll pin 5 x 33 (mm.)

V-0079

4

34

Eye bolt 1/2"

V-0080

1

35

Set screw 5/16"

V-0081

1

A

B

A) The driveline case shown in “A” takes about 4 liters of SAE 85W-140 heavy duty gear oil in two stages. The filling procedure is as follows:

Pour in oil until gear case “A” is full. This will require about two liters (slightly over half a gallon) of oil. Leave it standing for about 24 hours, or to

speed up the process connect to tractor and drive the transmission for an hour, preferably with the fill plug removed to facilitate air venting.

The oil will gradually drain down and once it does the gear case must be refilled with about two additional liters. Oil passage is slow, especially in

low temperatures, and this is the reason why two filling steps are required. It helps if oil is warmed slightly.

Before replacing the fill plug, turn transmission on. Any oil quantity in excess will be thrust out through the plug opening. Peering down, oil should

be visible at about mid level to ensure proper gear lubrication. If oil surface is not visible, pour in some additional quantity.

B) The gear case shown in “B” is filled with about 3 liters of SAE 85W-140 gear lube. Oil is poured through the fill opening at the side of the gear case until oil

reaches and flows out of the smaller drain opening. Both fill and drain plugs are then screwed on in place.

Diagram 13

Charging Procedure transmission oil SAE 140

57

Notes

58

Loading...

Loading...