Page 1

INST ALLA TION AND

SYSTEM GUIDELINES

43918

Page 2

CONTENTS

Vessel W eighing System Design......................................................... Section 1

Bulk Material Weighing Systems • Load Introduction Principles • Maximizing System Accuracy •

Selecting Number of Supports & Load Cell Capacity • Choosing the Correct Load Cell • Calibrating

Thermal Expansion of Vessels & Stay Rods • Calculating T ank V olumes • Densities of Common Materials

• Load Cell Bolt Torque Values • Wind and Seismic Effects on Vessel Stability

Weigh Modules ................................................................................ Section 2

Single-End Beam Load Cell Modules • Double-End Beam Load Cell Modules • Compression Canister

Load Cell Modules • S-Beam Load Cell Modules • Mounting Assemblies and Compatible Load Cells

Vessel Attachments .......................................................................... Section 3

Attaching Piping to Weigh Vessels • Piping Guidelines • Vessel Restraint Systems • Low-Accuracy

Systems: Partial Mounting on Flexures

Installation & Service Tips ............................................................... Section 4

Before Installing • Determining Microvolts per Graduation • Load Cell Mounting Hardware Safety

Guidelines • Load Cell T rimming • Load Cell Troubleshooting • Selecting Replacement Load Cells •

Load Cell Wiring Guide • Calibrating Vessel W eighing Systems

Glossary.......................................................................................... Section G

!

All vessel weighing system installations should be planned by a qualified structural engineer.

Warning

This manual is intended to serve only as a general guide to planning, installation, and servicing of these

systems; no attempt has been made to provide a comprehensive study of all possible system configurations.

Copyright © 1997 Rice Lake Weighing Systems. All rights reserved. Printed in the United States of America.

Specifications of products described in this handbook are subject to change without notice.

December 1997

Page 3

SYSTEM DESIGN

VESSEL WEIGHING SYSTEM DESIGN

Bulk Material Weighing Systems ...................................................................................1-2

Custody T ransfer................................................................................................................................................................ 1-2

Material Proportioning ...................................................................................................................................................... 1-2

Loss in Weight ................................................................................................................................................................... 1-2

Common Hopper Scale Arrangements .............................................................................................................................. 1-3

Load Introduction Principles......................................................................................... 1-6

The Ideal... ......................................................................................................................................................................... 1-6

Angular Loading ................................................................................................................................................................ 1-6

Eccentric Loading.............................................................................................................................................................. 1-6

Side Loading ...................................................................................................................................................................... 1-7

Twisting Loads ................................................................................................................................................................... 1-7

Contents

Maximizing System Accuracy ........................................................................................ 1-8

Environmental................................................................................................................................................................... 1-8

Load Cell and Mount.......................................................................................................................................................... 1-8

Mechanical/Structural ....................................................................................................................................................... 1-8

Calibration ......................................................................................................................................................................... 1-8

Operational Considerations ............................................................................................................................................... 1-8

Selecting Number of Supports & Load Cell Capacity....................................................... 1-9

Number of Supports .......................................................................................................................................................... 1-9

Load Cell Capacity ............................................................................................................................................................. 1-9

Choosing the Correct Load Cell ................................................................................... 1-10

Environmentally Protected...............................................................................................................................................1-10

Hermetically Sealed ..........................................................................................................................................................1-10

International Protection (IP) Rating Guide ......................................................................................................................1-11

Calculating Thermal Expansion of Vessels & Stay Rods ................................................ 1-12

Stay Rod Expansion/Contraction.................................................................................................................................................1-12

Vessel Expansion/Contraction .....................................................................................................................................................1-12

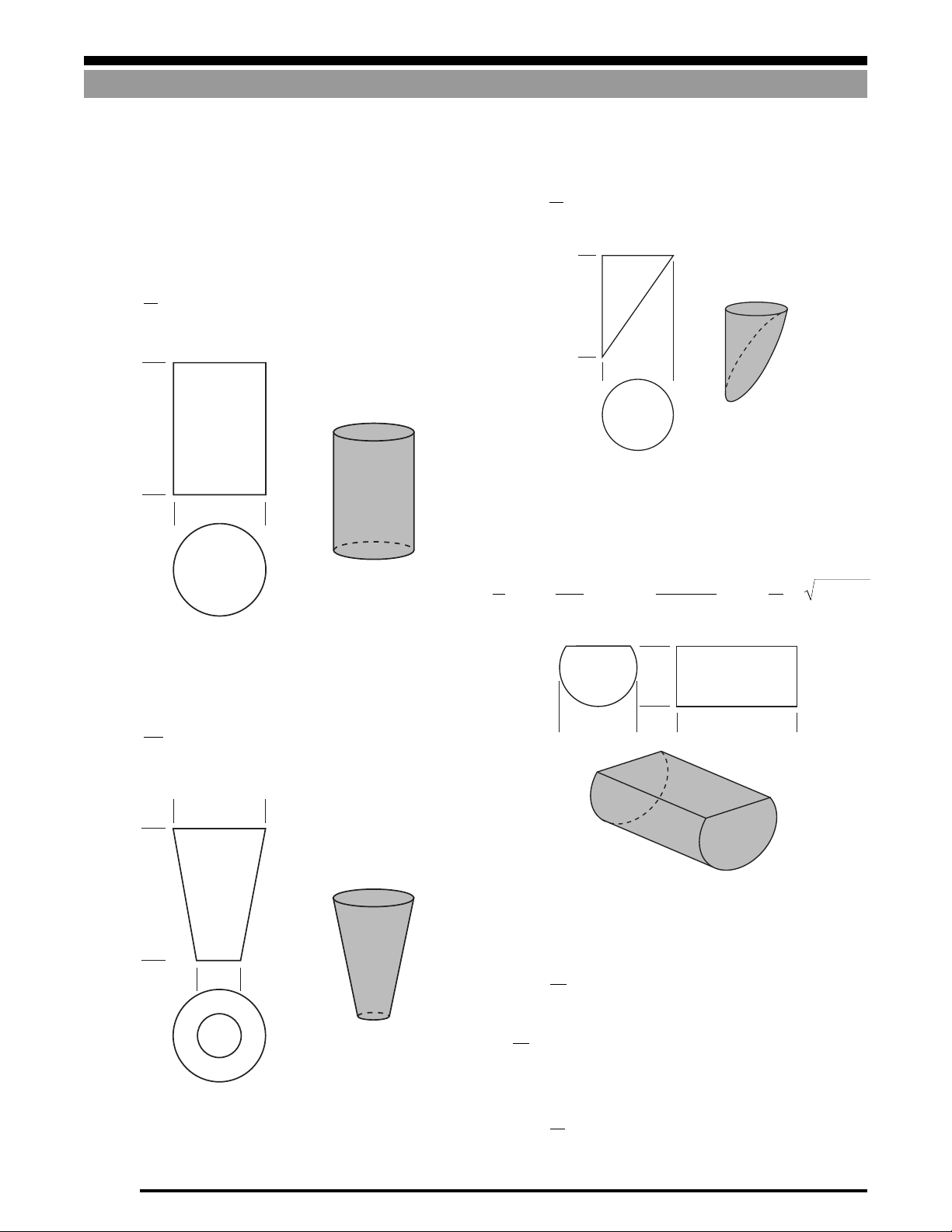

Calculating Tank Volumes........................................................................................... 1-14

Formulas for Various Tank Shapes and Sections ..............................................................................................................1-14

Calculation Examples .......................................................................................................................................................1-17

Densities of Common Materials ................................................................................... 1-19

Load Cell Bolt Torque Values....................................................................................... 1-23

Wind and Seismic Effects on Vessel Stability................................................................ 1-24

1-1

Page 4

SYSTEM DESIGN

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aa

a

aa

aaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aa

a

aa

aaa

a

a

a

a

a

a

a

aa

a

a

aa

a

a

a

a

a

aa

aa

a

a

a

a

aa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aa

a

aa

a

a

a

a

a

aaa

a

aa

a

a

a

a

aa

a

a

a

a

a

a

a

a

a

a

a

a

a

aa

aa

a

a

aa

a

a

a

a

a

a

a

a

a

aa

a

a

aa

a

a

aaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aa

a

a

a

a

a

a

a

aa

a

a

a

a

a

a

a

a

a

aa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaa

a

a

a

a

a

Bulk Material W eighing Systems

Bulk materials are weighed for various reasons. Although this discussion focuses on the weighing of bulk solids, many of the principles

are equally applicable to the weighing of bulk liquids. For the sake of convenience, we have classified bulk material weighing into three

general types:

Custody Transfer

Figure 1-1

Weighing bulk material on a truck scale is a typical example of

custody transfer weighing where material is being traded for

dollars. The filled truck is weighed and the known tare weight of

the truck is subtracted to determine the net weight of product. This

may be done for invoicing or inventory-control purposes. Typically, achieving a predetermined weight is not important in this

situation. What is important is knowing how much material

entered or left the facility.

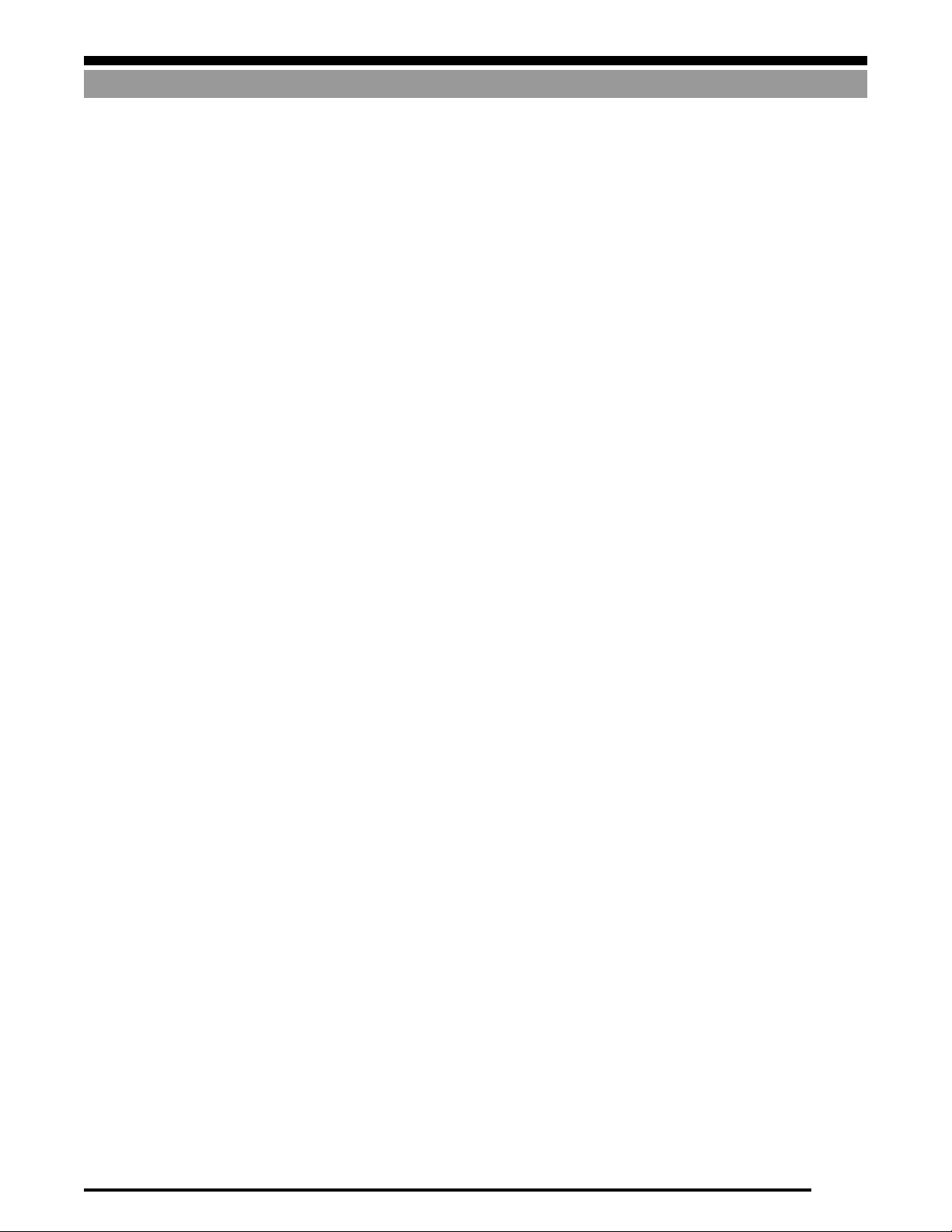

Material Proportioning

Figure 1-2 shows various ingredients being weighed on separate

scales, then mixed. Each scale must be accurate, or there could

be a detrimental effect on the proportions of each ingredient in

the finished product.

Figure 1-3 shows several materials being mixed to a given recipe

and batched one at a time into a single weigh hopper. As all

ingredients are weighed in the same weigh hopper, the weighing

system must be linear to achieve correct proportioning. It does not

need to be calibrated accurately if the final net weight of product

is not critical.

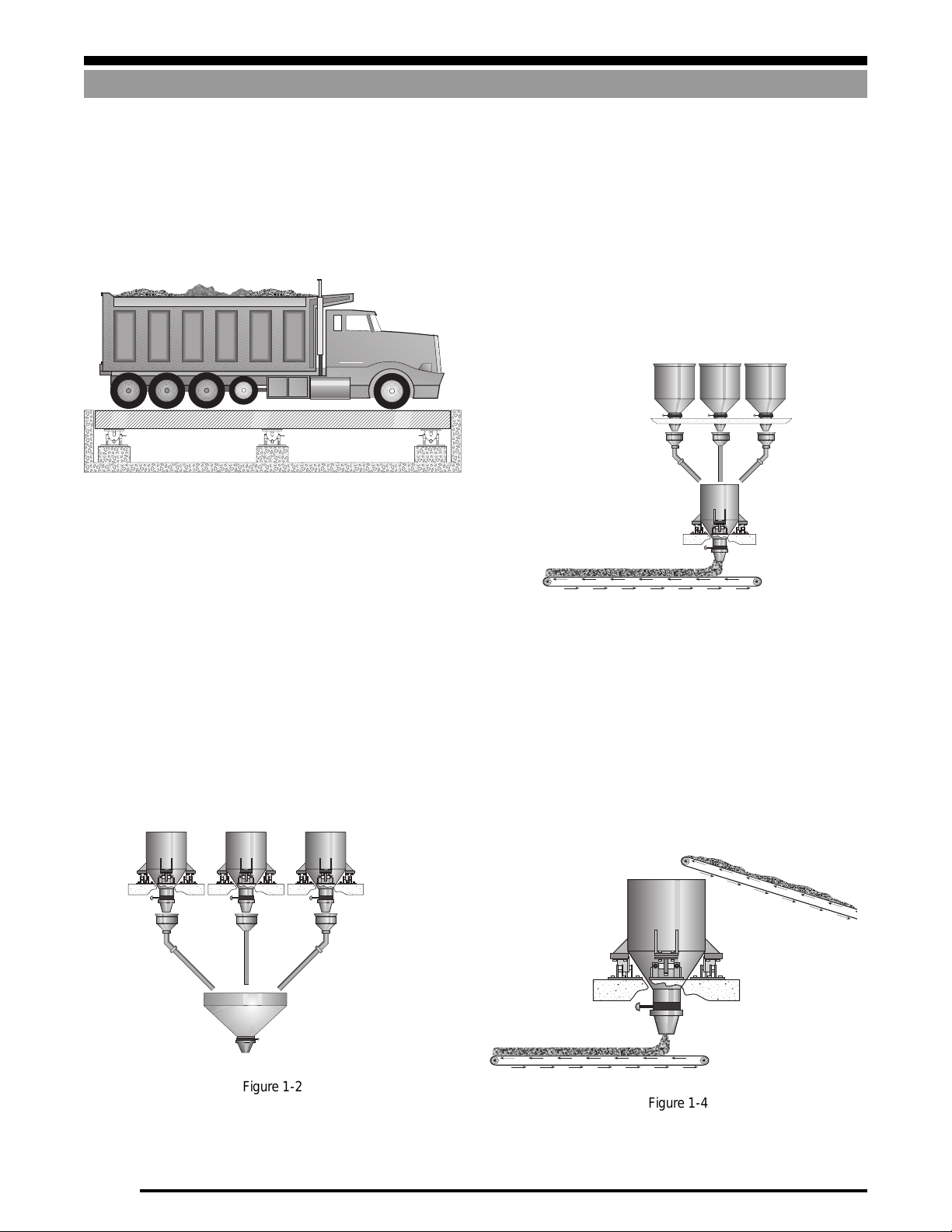

Loss in Weight

Figure 1-4 shows a situation where the weigh hopper is first topped

up and when the filling process stops, the material is fed out at a

controlled rate. The total amount of material supplied to the

process may be important, but the rate at which product is fed into

the batching process from the weigh hopper is usually more

important.

Bulk Material Weighing Systems

Figure 1-3

Figure 1-2

Figure 1-4

1-2

Page 5

Bulk Material Weighing Systems

a

a

a

a

a

a

a

aa

a

aa

aaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aa

a

aa

aaa

a

a

a

a

a

a

a

Common Hopper Scale Arrangements

SYSTEM DESIGN

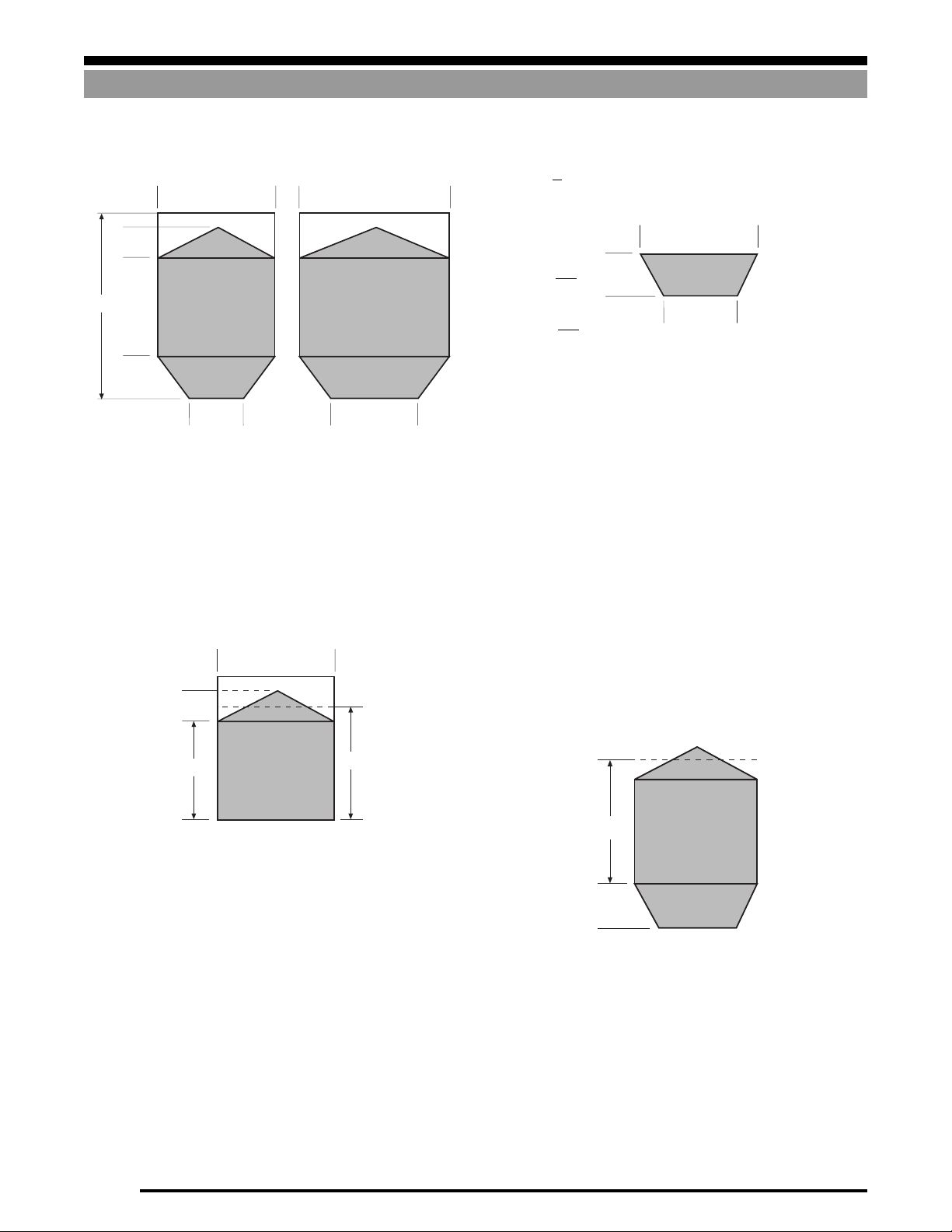

A. One of the simplest hopper weighing systems is illustrated

below in Figure 1-5. The weigh hopper may be filled using a

feed conveyor, front-end loader, auger, etc., and the material

may be removed from the hopper using a discharge conveyor.

Figure 1-5

Advantages of this system are:

• Low cost compared to other systems.

• Low overall height.

Disadvantages of this system are:

• Slow fill and discharge (low throughput).

• Difficult to achieve an accurate prescribed weight because

of inconsistency in input material flow.

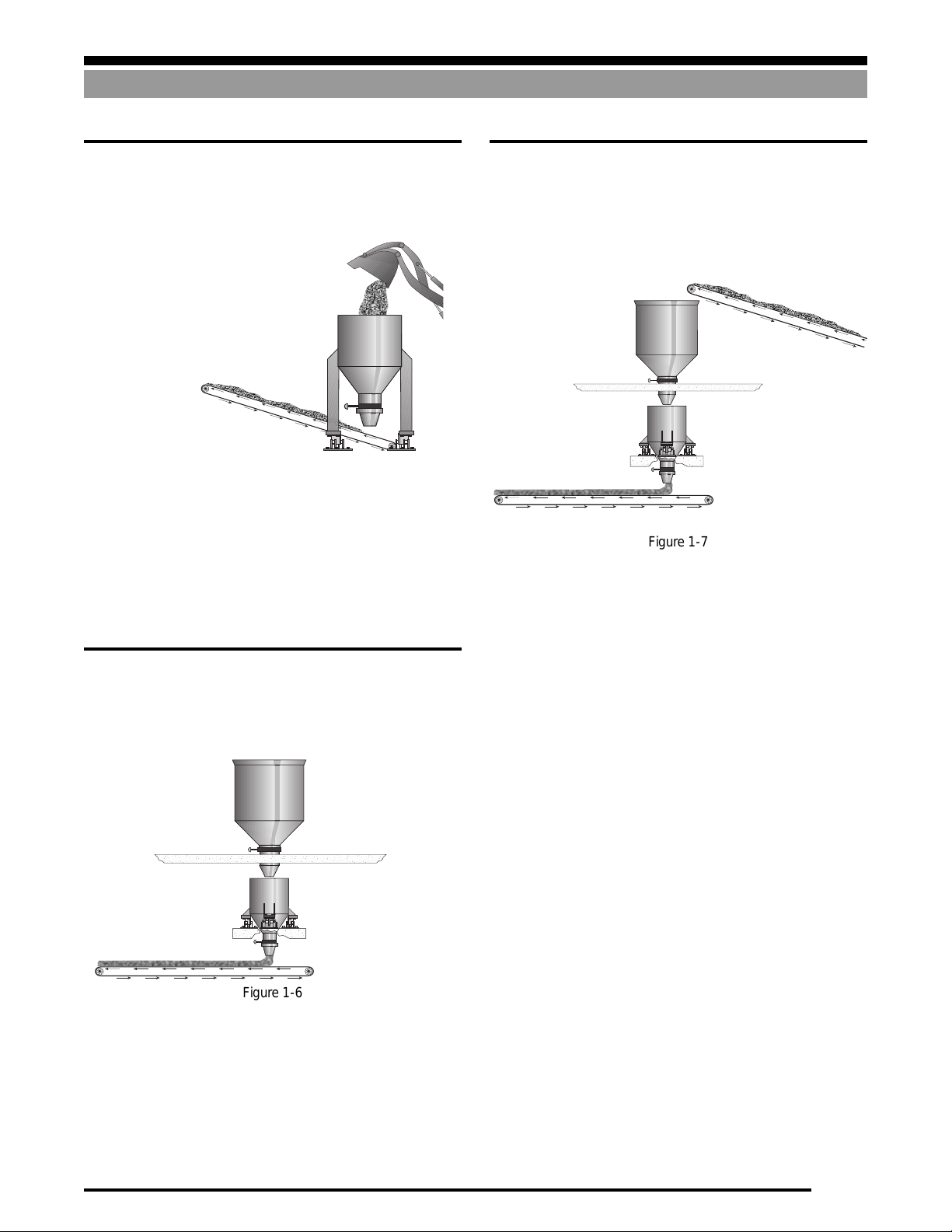

B. Figure 1-6 below illustrates a weigh hopper positioned

directly under the storage silo.

Advantages of this system are:

C. A conveyor-fed system can be improved by adding an upper

surge hopper as shown in Figure 1-7. The surge hopper allows

the conveyor to be run continuously and isolates the weigh

hopper from the sometimes erratic flow of material from the

conveyor.

Figure 1-7

Advantages of this system are:

• Weigh hopper isolated from the feed conveyor.

• The input conveyor can run continuously.

• Surge hopper serves as a buffer to smooth out demand.

• 2-speed fill is possible.

• Faster fill and higher throughput possible.

Disadvantages of this system are:

• Higher overall height.

• Higher cost.

• More complex controls and mechanical arrangement.

Figure 1-6

• The weigh hopper is gravity-fed, simplifying the feed process

and providing a more uniform flow.

• Faster fill cycle and hence greater throughput.

• 2-speed fill may be used for greater target accuracy.

Disadvantages of this system are:

• Higher overall height.

• Material must be conveyed higher to storage silo.

1-3

Page 6

SYSTEM DESIGN

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aa

a

aa

aaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aa

a

aa

aaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aa

a

aa

aaa

a

a

a

a

a

a

a

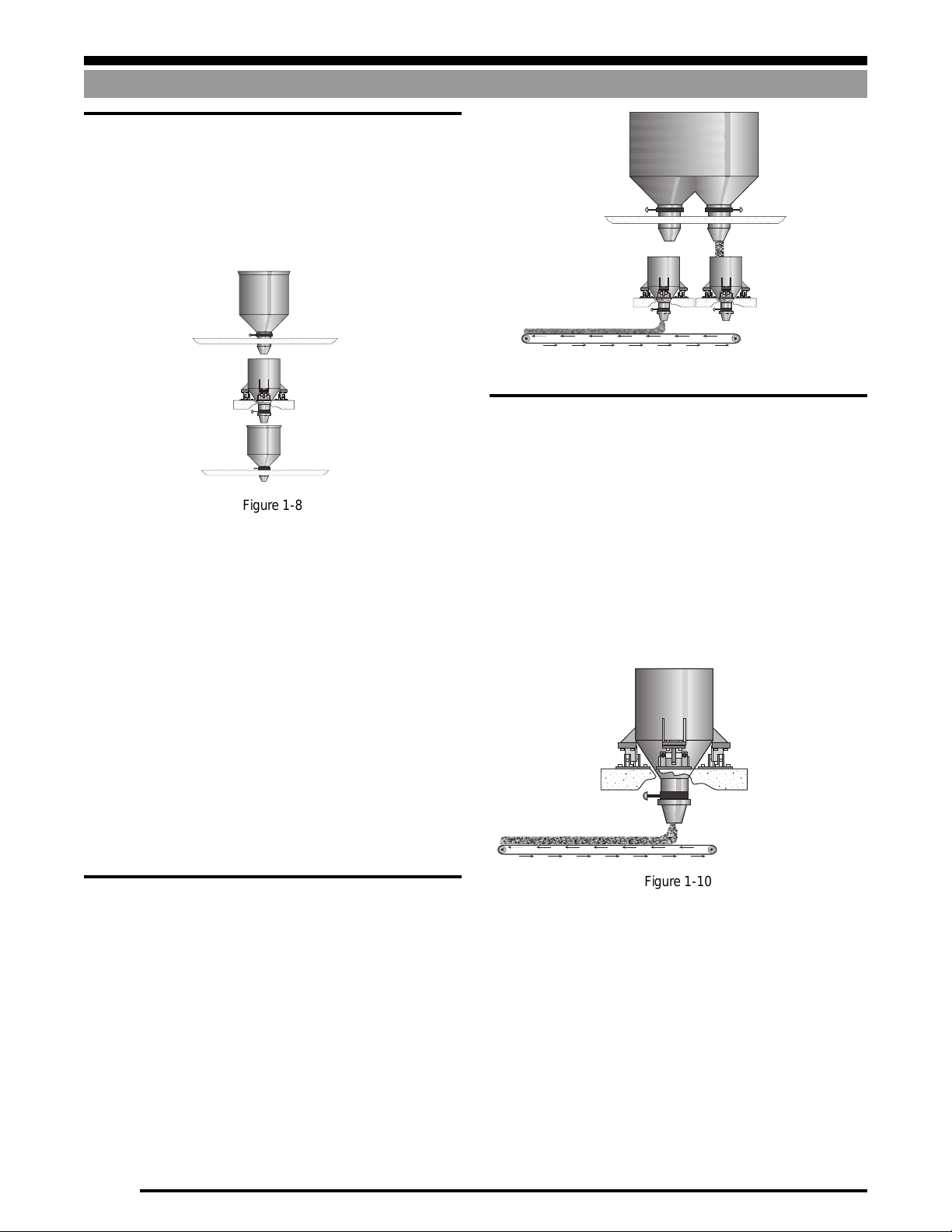

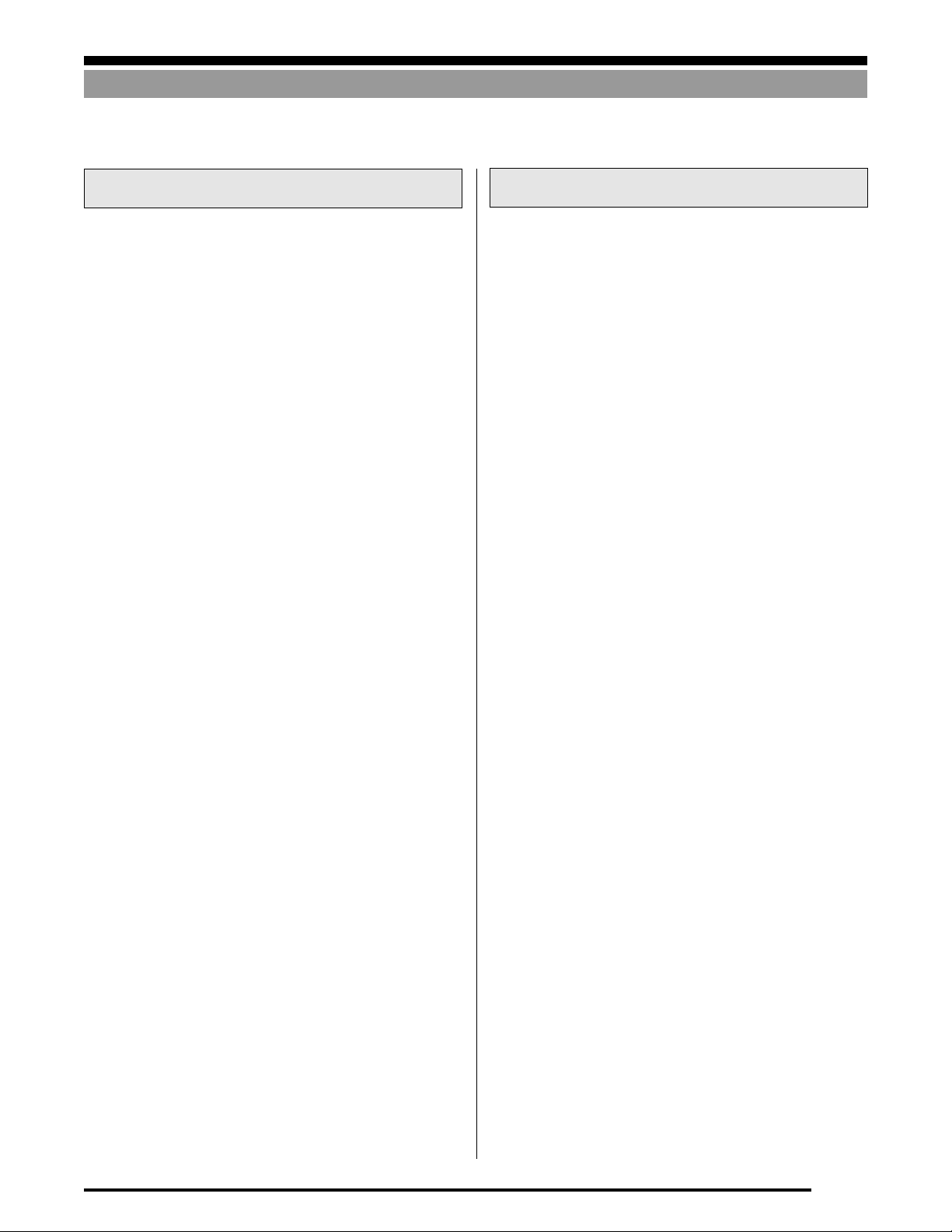

D. This arrangement is similar to Example C, however, a lower

surge hopper has been added to speed up the discharge cycle.

This system, shown in Figure 1-8, is typically used in multidraft grain loadout systems where multiple drafts are required to fill a rail car or barge. The weight of each draft can

be accumulated and the target weight of the final draft

adjusted to achieve the desired car net load.

Figure 1-8

Advantages of this system are:

• Weigh hopper isolated from feed conveyor.

• Surge hopper serves as a buffer to smooth out demand.

• 2-speed fill is possible.

• Faster fill, discharge, and throughput possible.

Bulk Material Weighing Systems

Figure 1-9

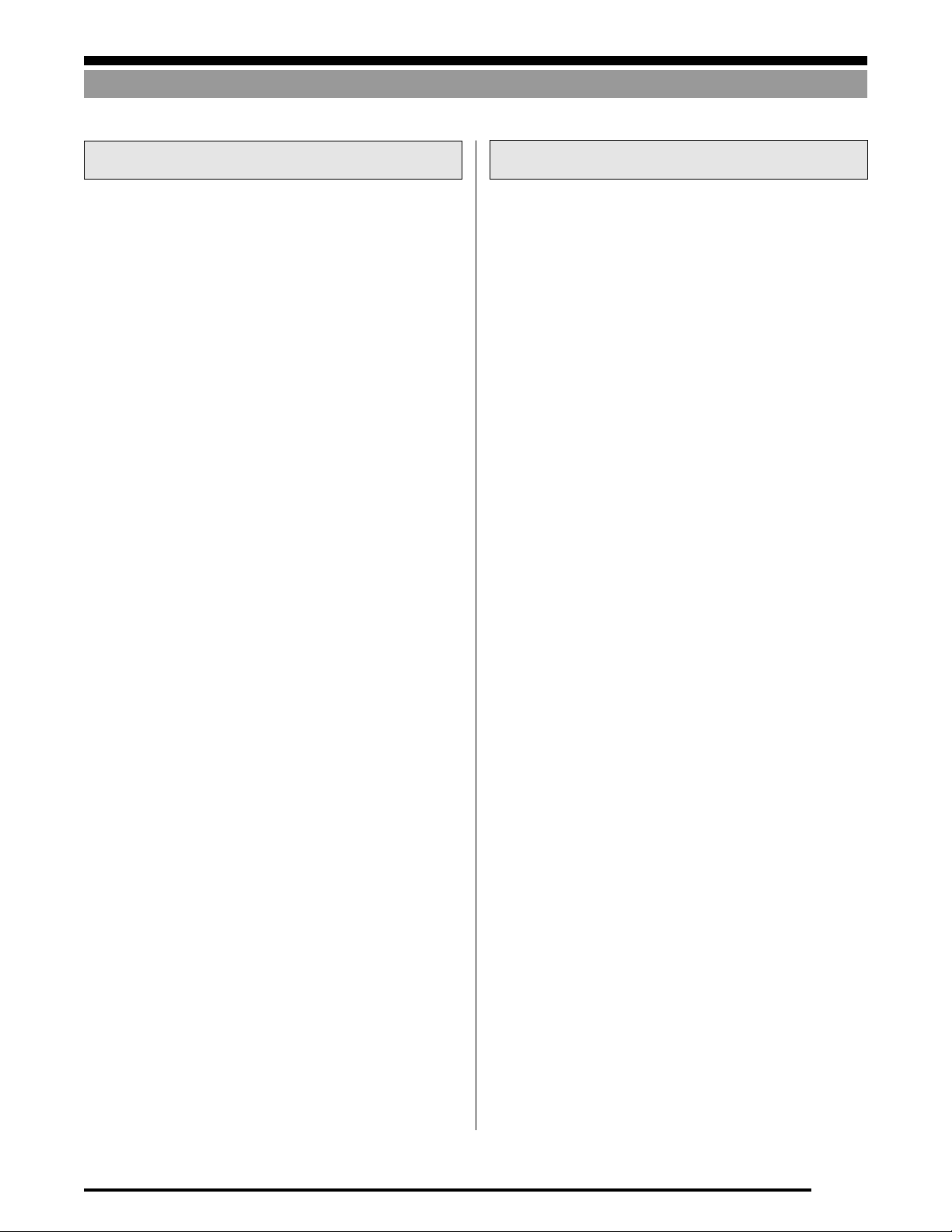

F. Figure 1-10 illustrates a loss in weight system. This is used

where a process needs a batch of material (not more than the

capacity of the weigh hopper), but that material needs to be

fed to the process at a controlled rate.

The process starts by filling the hopper with at least enough

material for the upcoming process. The fill is then stopped

and the discharge commences. The rate at which the discharge takes place is controlled by monitoring the “loss in

weight” of the hopper and then modulating the discharge

rates to maintain the desired flow rate. The discharge may be

ended at the completion of the process step, or when a specific

amount of material has been discharged.

Disadvantages of this system are:

• Higher overall height.

• Higher cost.

• More complex controls and mechanical arrangement.

The systems described up to this point deliver a single material in

pulses rather than from a continuous flow. They may be used for

in-plant process weighing or custody transfer. Figures 1-9 and 110, described below, provide a continuous material flow and are

more often used for process weighing.

E. Figure 1-9 illustrates a single storage silo with two weigh

hoppers suspended underneath. This arrangement can be

used to provide material continuously to a process. As one

hopper is emptying, the other can be filling If the system is

sized correctly, there is no interruption to the material flow

on the discharge belt.

Advantages of this system are:

• Continuous material flow.

• High throughput possible.

Disadvantages of this system are:

• Higher overall height.

• Higher cost than pulse discharge systems.

• More complex controls and mechanical arrangement.

Advantages of this system are:

• Gives the ability to supply material at a constant rate

Disadvantages of this system are:

• Complex controls and mechanical arrangement

• Higher cost than pulse discharge systems.

Figure 1-10

1-4

Page 7

Bulk Material Weighing Systems

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aa

a

aa

aaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aa

a

aa

aaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

SYSTEM DESIGN

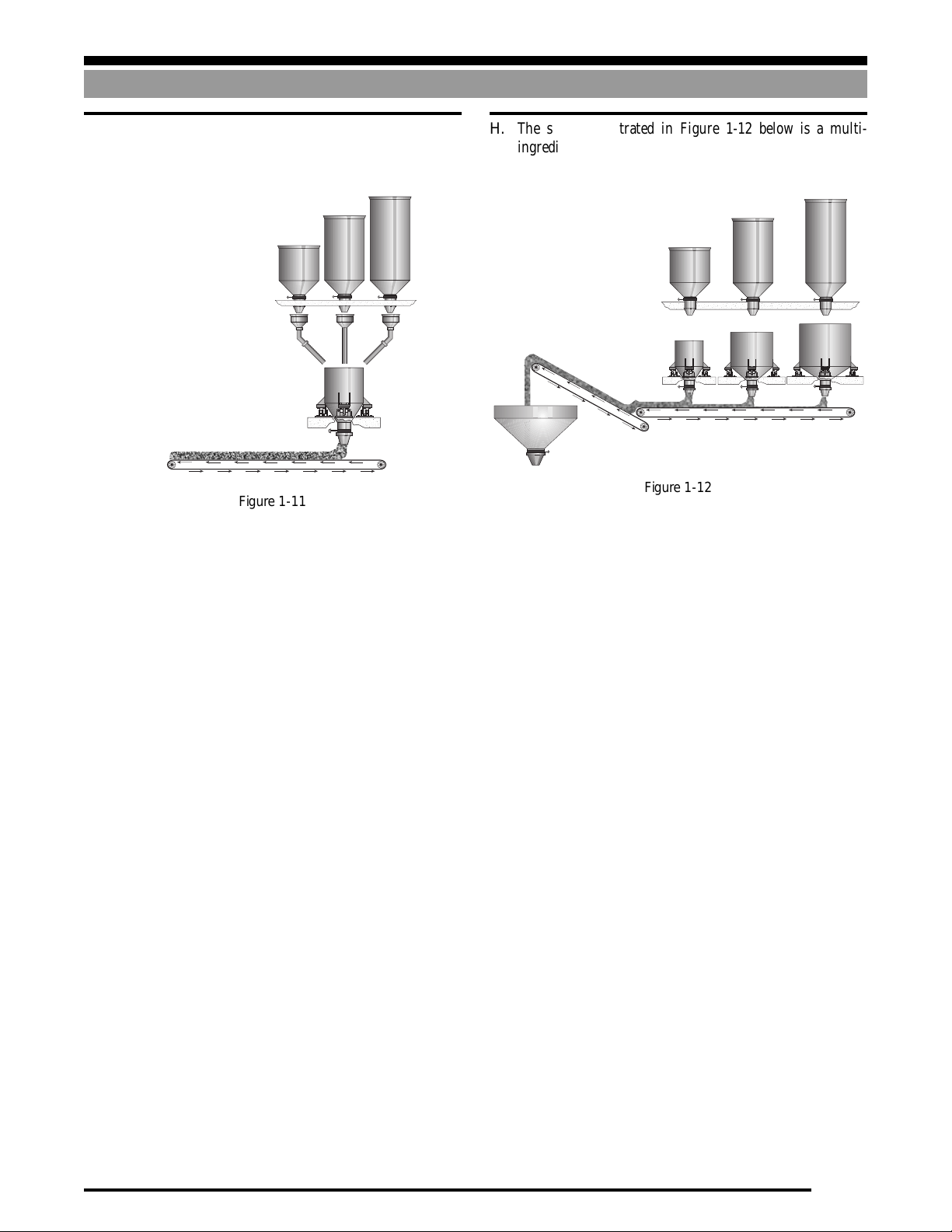

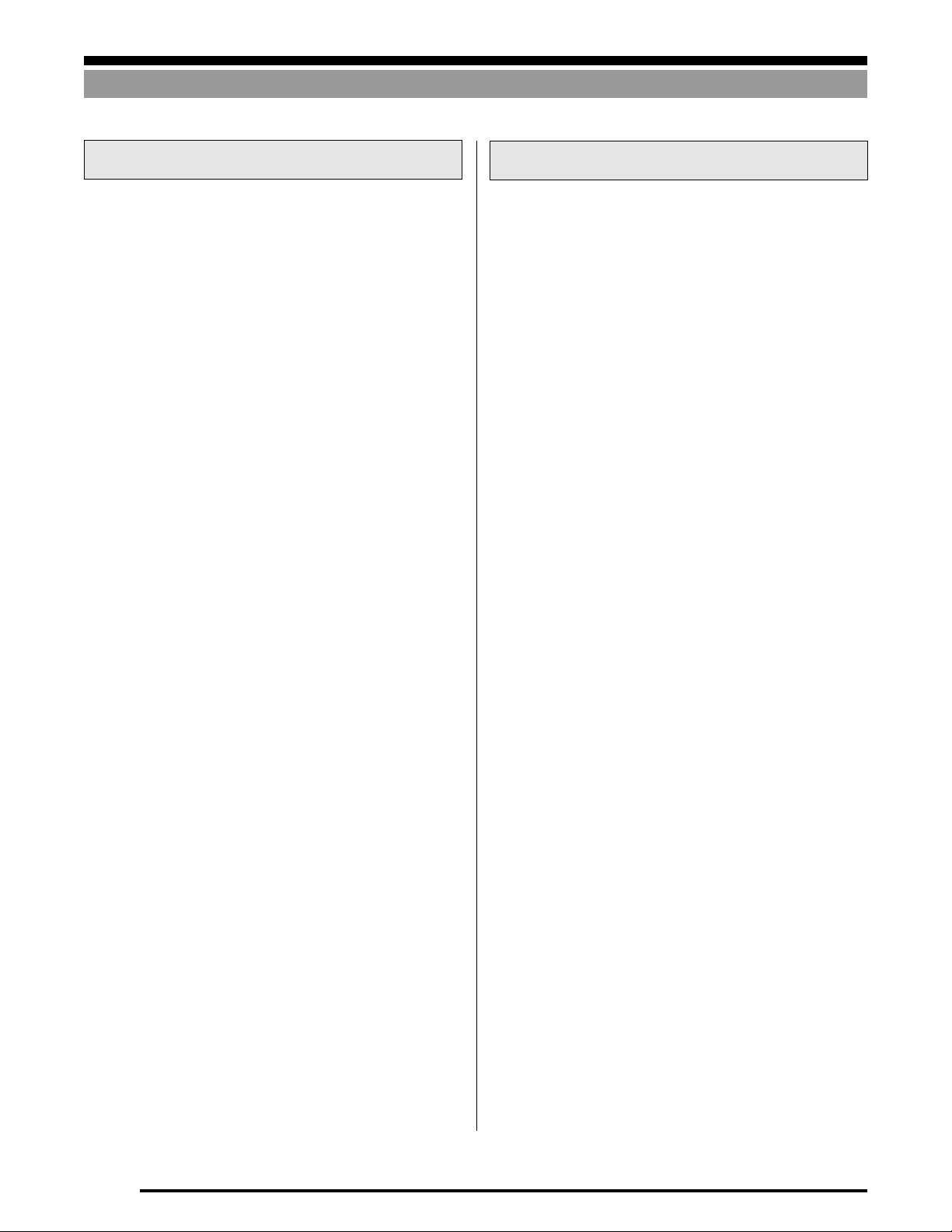

G. Figure 1-11 illustrates a multiple-ingredient batching sys-

tem where all the ingredients are weighed one at a time in a

single weigh hopper.

Figure 1-11

Advantages of this system are:

• Lower cost than multiple-weigh hoppers

• Scale calibration may not be critical, as all ingredients are

weighed in a single scale, assuring correct proportions.

Disadvantages of this system are:

• The accuracy of minor ingredients may suffer where the scale

capacity is large compared to the weight of ingredient.

• System is somewhat slow because each material must be

batched in one at a time, and the cycle cannot repeat until the

weigh hopper has been discharged.

H. The system illustrated in Figure 1-12 below is a multi-

ingredient batching system which has a separate weigh hopper for each ingredient.

Figure 1-12

Advantages of this system are:

• Weigh hopper capacity can be sized appropriately for each

material so that each weighment is close to the scale capacity,

providing greater accuracy.

• Faster throughput, since all materials can be weighed and

discharged simultaneously.

Disadvantages of this system are:

• Higher cost.

• Each scale must be accurate to ensure correct proportioning.

Note: We recommend that you do not attempt to weigh a batch of

material which is less than 20 scale divisions since the accuracy

will be questionable.

For example, if a hopper scale has a .5 lb division size, we recommend that you not weigh less than a 10-lb batch on that scale. It’s

better to weigh minor ingredients accurately on a scale suited to

the purpose, and add those ingredients to the batch by hand. For

example, if making raisin oatmeal cookies, it may not be too much

of a problem to batch-weigh the raisins along with the oatmeal.

However, it may be prudent to weigh the salt on a more sensitive

bench scale and hand-add it to the hopper at completion of the

weigh cycle.

1-5

Page 8

SYSTEM DESIGN

Load Introduction Principles

Load Introduction Principles

A clear understanding of the exact manner in which a load must be placed on a load cell will assist you in both designing a vessel that is

to be equipped with load cells, and in choosing the correct type of load cells and mounts for your application.

The Ideal...

Load cell specifications are derived under laboratory conditions,

where load is applied to the cell under near-perfect conditions. The

performance of load cells in an actual process weighing application

can be greatly degraded if care is not taken in the means by which

the load is applied to the cell.

If the direction of the force is constant, calibration will compensate

for this and the scale will weigh accurately. However, if the angle

changes as the force is applied, it will cause nonlinearity and if

there is friction in the mechanical system, hysteresis will also be

present. Angular loads can be caused by mounts that are out of

level, a nonrigid foundation, thermal expansion/contraction, structure deflection under load, and the unavoidable deflection of the

load cell itself.

C

L

C

L

Figure 1-14

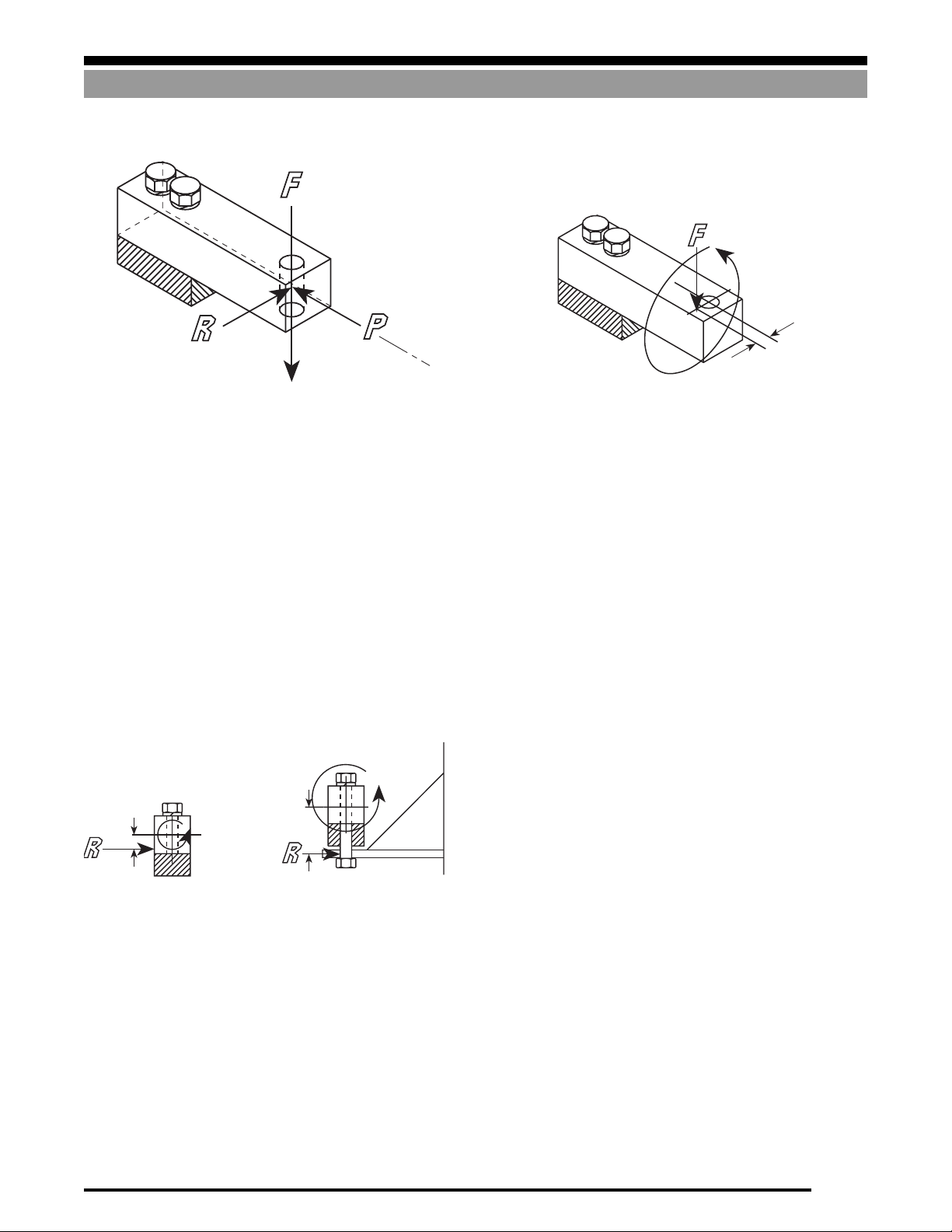

Figure 1-13

Figure 1-13 shows a typical mounting arrangement for a singleended beam. The fixed end is fastened to a “rigid” foundation, while

the free end is cantilevered to allow downward deflection as load

(F) is applied. Under ideal conditions, the mounting surface would

be flat, horizontal and perfectly rigid. The load F would be introduced vertically with minimal extraneous forces applied, and the

load cell would be totally insensitive to all forces other than

precisely vertical ones.

However, in the real world, load cell mounting and loading conditions are far from ideal. Incorrect loading is by far the most

common cause of accuracy problems encountered by service

technicians. Understanding the following common load introduction problems will prevent loading errors in your vessel weighing

application.

Though the discussion is confined to single-ended beams, many of

the principles apply equally to other load cell types.

Angular Loading

This is a condition where the load F is introduced through the

loading hole, but at an angle to its center line. This angular force

can be broken up into its vertical component along the loading

hole center line which the cell will register and its horizontal

component at 90° from the center line. This horizontal component

is a side force to which, ideally, the load cell would be totally

insensitive. For example, if force F is inclined to the load hole

center line at an angle of 5°, then the force registered by the cell is

reduced by .4% while a side force of .01F is also applied.

Eccentric Loading

This is a condition where the force F is applied vertically to the cell,

but its line of action is shifted away from the vertical line through

the loading hole. This is not a detrimental condition if the force is

applied consistently at the same point, since calibration will

compensate for this effect. However, if the point of application

moves horizontally as the scale is loaded, it will cause nonlinearity

and possibly hysteresis. Eccentric loads may be caused by poorlydesigned mounting arrangements and thermal expansion/contraction of the scale.

Figure 1-15

1-6

Page 9

Load Introduction Principles

SYSTEM DESIGN

Side Loading

Figure 1-18 illustrates a torque of magnitude Fy exerted as the

result of the load F being applied at a distance y from the loading

hole center line.

Figure 1-16

This is a condition where the vertical force F (which you are trying

to measure) is accompanied by a side force R applied at 90° to F.

This force can be constant, but more typically is a force that varies

over time and hence affects the linearity and possibly the hysteresis

of the scale. The ideal load cell would be totally insensitive to side

loads. However, in practice these extraneous forces do affect the

Mounts which are out of level, thermal expansion/contraction,

structure deflection under load and dynamic side forces (caused by

rotating mixers, etc.) all cause twisting of the load cell. Since these

forces tend to vary in magnitude as a function of time, temperature

and/or load, the effects are not predictable, and will degrade system

accuracy.

output of the cell and two seemingly identical cells can react

differently to the same side load. A related condition is the END

FORCE, P, which is similar to a side force, except that it acts on the

end face of the cell. Side forces are the result, typically, of thermal

expansion/contraction, mounts which are not level, and vessel

dynamics (caused by mixers, etc.).

T

y

Figure 1-18

Twisting Loads

T

T

C

h

L

(a) (b)

Figure 1-17

Typically, a side force does not act exactly at the neutral axis and

hence produces a torque or twisting effect in addition to the side

force. A load cell can be subjected to a torque (T) in a number of

ways. Figure 1-17 (a) illustrates a condition where the line of action

of a side force is moved away from the neutral axis by a distance h

resulting in a torque of Rh. Figure 1-17 (b) illustrates a situation

where the load is hung from the cell using a bolt. Any side force

applied by this arrangement has a much larger twisting effect on

the cell because of the increased distance h1 to the neutral axis.

h

1

1-7

Page 10

SYSTEM DESIGN

Design Elements

Maximizing System Accuracy

High-accuracy systems are generally considered to have system errors of ±.25% or less; lower accuracy systems will have system errors

of ±.50% or greater. Most weight indicators typically have an error of ±.01%, hence, the main source of error will be the load cells and,

more importantly, the mechanical arrangement of the scale itself. In vessel weighing, each installation is unique in terms of the

mechanical arrangement, site conditions and environmental factors. Therefore, it is impossible to be specific in this publication about

the system accuracy that can be achieved. The first requirement is to determine what the customer’s accuracy expectations/requirements

are, then design the system accordingly. Grouped under various subheadings below are various recommendations that contribute to high

accuracy. It will not be possible to comply with all these recommendations; however, they should be kept in mind when designing a system.

Environmental

■ Install the vessel in a controlled environment where seasonal

temperature fluctuations are minimized. If this is not feasible, use load cells with temperature compensation specifications that will allow satisfactory performance over the expected temperature range.

■ Use a metal shield to protect the load cells from radiant heat

sources. Use an insulating pad between the vessel and load cell

mount if heat is being conducted.

■ If thermal expansion/contraction of the vessel is expected,

choose a mount which will allow unhindered lateral movement. If stay rods are required, position them so that thermally-induced movement is minimized. See Vessel Restraint

Systems in Section 3 for more information.

■ Place the vessel indoors, if possible, where it will be protected

from wind and drafts.

■ Do not place the vessel in an environment where its support

structure is subject to vibration. Ensure that vibrations are

not transmitted via attached piping or stay rods.

■ Select load cells and mounts that will give the degree of

corrosion protection required.

■ Use load cells that have the degree of environmental protection required for the application. For example, avoid possible

drifting problems with standard load cells in washdown applications by specifying hermetically-sealed cells.

Load Cell and Mount

■ Choose load cells whose accuracy is consistent with the

desired system accuracy.

■ Do not grossly oversize the load cells; see Load Cell Capacity

on page 1-9. Best accuracy will be achieved when weighing

loads close to the vessel capacity. As a general rule, do not

attempt to weigh a load of less than 20 graduations.

■ If it is not possible to trim the corners, use load cells with

matched outputs, particularly if the vessel is not symmetrical

and/or the material is not self-leveling. Otherwise, use a

pretrimmed junction box.

■ Support the vessel entirely on load cells; do not use dummy

cells or flexures that would hinder a good calibration. See

Partial Mounting on Flexures on page 3-11.

■ Use proven load cell mounts that will provide optimal loading

conditions.

■ Orient the mounts as recommended in the installation manual.

Mechanical/Structural

■ Support the load cell mounts on a rigid structure; this will

ensure a high natural frequency and reduce the amount of

bounce and instability. All support points must be equally

rigid to avoid tipping of the vessel as load is applied. Minimize

interaction between adjacent weigh vessels mounted on the

same structure. Vehicular traffic must not cause deflection of

the vessel’s support structure.

■ Ladders, pipes and check rods, etc. should not be allowed to

shunt the weight that should rest on the load cells.

■ Where piping or conduit must be attached to the vessel, use

the smallest diameter acceptable for the application. Use the

longest unsupported horizontal length of pipe possible to

connect to the vessel.

■ Use an indicator that is EMI/RFI protected. Provide grounding and transient protection in accordance with the

manufacturer’s recommendations. In general, take measures

to reduce electrical interference.

■ Use a good-quality junction box which remains stable with

changing temperatures. Look for a junction board which has

a solder mask at a minimum and which preferably is

conformally coated also. Ensure that the enclosure is suited

to the environment.

Calibration

■ Design in a convenient means of hanging weight from the

corners of the vessel to trim the load cell outputs and for

calibration. Use weights as described above, or known weight

of material to perform the calibration. See Calibrating Vessel

Weighing Systems in Section 4.

Operational Considerations

■ Maintain an even and consistent flow of material.

■ Avoid simultaneous fill/discharge of weigh vessel.

■ Slow down the filling cycle as much as possible and/or use a

2-speed fill cycle.

■ Reduce to a minimum the amount of “in flight” material.

■ Use preact learning to predict the optimum cutoff point based

on past performance.

■ Use Auto Jog to top off contents after fill.

■ If possible, switch off any vibrating or mixing equipment

while the weight is being determined.

■ Reduce to a minimum the surging of liquids while a weight

reading is being taken.

1-8

Page 11

Design Elements

VESSEL WEIGHING SYSTEMS

Selecting Number of Supports & Load Cell Capacity

Number of Supports

The number of supports to be recommended is dependent on the

geometry, gross weight, structural strength and stability of the

vessel. The number of supports chosen for a vessel obviously

influences the capacity of the load cells required. In general, no

more than eight supports should be used. It becomes more difficult

to get even weight distribution on all supports as the number

increases beyond three. Below is a look at a number of examples.

Suspended Vessels

These vessels are very often suspended from an existing structure

which will sometimes dictate how many supports will be used. In

general, one or more supports may be used. Using three supports

or fewer has the advantage of not requiring adjustment of

the length of the support linkages to distribute the load

equally between all supports (assuming the cells are arranged

symmetrically on the vessel).

Upright cylindrical vessels in compression

The most convenient method of mounting is with three supports

arranged at 120° degree intervals. Correct weight distribution is

inherent to 3-point support and is preferred whenever possible.

With tall slender vessels or vessels subject to fluid sloshing, wind

or seismic loads, stability against tipping becomes a consideration.

In these situations, four or more supports should be considered.

See Appendix section on wind and seismic effects.

Square, rectangular or horizontal cylindrical

vessels mounted in compression

Because of geometry, it is usually most convenient to mount these

vessels on four supports, close to each corner. Higher capacities

may, of course, require more than four.

Load Cell Capacity

It is vital to the performance of a weighing system to select load

cells of the correct capacity. Here are some guidelines:

■ All load cells selected must be of the same capacity.

■ Estimate the vessel dead weight, including all piping, pumps,

■ Add the maximum live weight of product to be weighed to the

■ Divide the gross weight by the number of legs or support

■ Select a load cell with a capacity somewhat greater than the

A good rule of thumb is to select a load cell with a capacity 50 –

100% in excess of the calculated nominal load per cell. Once the

load cell capacity has been determined, check that the live weight

signal is adequate for the instrumentation selected; see Section 4

for information on how to determine the microvolt-per-graduation for your system. This is particularly important when the ratio

of dead weight to live weight is high.

■ Additional factors to consider:

■ See page 2-22 for compatibility information on mounts and

agitators, insulation and vessel heating fluids.

dead weight. This is the gross weight of the vessel and

contents.

points. This is the nominal weight which will be carried by

each load cell.

nominal weight. The following should be considered when

determining how much greater the load cell capacity should

be:

1. Is your dead weight accurate?

2. Will the load be evenly distributed on all cells?

3. Is the vessel fitted with an agitator or subjected to shock

loading?

4. Is it possible the vessel will be overfilled, exceeding your

live weight value?

5. Will the vessel be subjected to wind or seismic loading?

For more information, see Wind and Seismic Effects on

Vessel Stability.

Load Cell Construction Material — In a corrosive environment, stainless steel outperforms nickel-plated alloy steel.

Load Cell Protection — The ultimate degree of protection

can be achieved with hermetically-sealed load cells which

ensure the integrity of the strain gauge section of the cell in

corrosive or washdown applications.

Cable Length — Check that the standard cable length will

be adequate for your installation. Longer cable lengths are

available on special order.

load cells by capacity. Capacity requirements may limit

practical applications of many models.

1-9

Page 12

SYSTEM DESIGN

Choosing the Correct Load Cell

Misuse of any product can cause major cost and safety problems;

load cells are no exception. Unfortunately, the load cell protection

rating systems used in the industry today are inadequate in some

ways. That’s why Rice Lake Weighing Systems, with years of load

cell experience, has developed its own rating system for load cells.

Our system categorizes load cells in two major groups: hermetically-sealed (HS), and environmentally-protected (EP). Hermetically-sealed cells are then further characterized by IP (International Protection) numbers. We feel this system effectively matches

load cell to application for optimal results.

To choose the proper load cell protection qualities, a fundamental

understanding of the differences between “environmentally-protected” and “hermetically-sealed” load cells is necessary. The

inappropriate use of environmentally-protected load cells in harsh

conditions is a prescription for load cell failure. Because of the

extra manufacturing steps, hermetically-sealed load cells cost

more than environmentally-protected versions. Despite the higher

initial cost, hermetically-sealed load cells may be the best longterm choice for harsh chemical, washdown, and unprotected

outdoor applications.

Environmentally Protected

Environmentally-protected load cells are designed for “normal”

environmental factors encountered in indoor or protected outdoor

weighing applications. By far the most popular type, these load

cells may employ strategies like potting, rubber booting, or redundant sealing to afford some protection from moisture infiltration.

Potted load cells utilize one of several types of industrial potting

materials. The liquid potting material fills the strain gauge cavity

then gels, completely covering the strain gauge and wiring surfaces. While this may significantly diminish the chance of moisture contamination, it does not guarantee extended waterproof

performance, nor does it withstand corrosive attack.

A second method of protection uses an adhesive foam-backed plate.

This protection affords some moisture and foreign object protection, but less than potted cells. In many cases, manufacturers will

use a caulking material to seal the plate to decrease the potential

for cavity contamination. A common approach among manufacturers to further decrease the entry of moisture to the strain gauge

combines both a potted cavity and a foam-backed plate, in a process

called redundant sealing.

Yet another strain gauge cavity protection strategy is the rubber

boot. Commonly employed with cantilever and bending beam

models, the boot covers the cavity and is secured by clamps. While

this provides easy access for repairs, the boot may crack if not

lubricated regularly, allowing contaminants into the load cell

cavity. Lubricating the rubber boot during routine inspections will

contribute to the long-term durability of the load cell.

Protecting the strain gauge cavity is just one consideration in

protecting a load cell from contamination. Another susceptible

area is the cable entry into the body of the load cell. Most environmentally-protected load cells incorporate an “O” ring and cable

compression fitting to seal the entry area. This design provides

protection only in applications with minimal moisture. In highmoisture areas, it is safest to install all cabling in conduit, providing both a moisture barrier and mechanical protection.

Although environmentally-protected load cells keep out unwanted

contaminants, they are not suited for high moisture, steam, or

direct washdown applications. The only long-term strategy for

these applications is to use true hermetically-sealed load cells.

Hermetically Sealed

Hermetically-sealed load cells offer the best protection available

for the weighing market. Using advanced welding techniques and

ultra-thin metal seals, these load cells handle the extremes of

harsh chemical and washdown applications. What makes the seal

unique is the process of laser-welding metal covers to protect the

strain gauge and compensation chambers. The cavities are then

injected with potting or, in the case of glass-to-metal seals, filled

with a pressurized inert gas, providing a redundant seal. As a final

assurance of the integrity of the seal, a leak test is conducted to

reveal any microscopic flaws in the sealing weld.

True hermetic protection addresses both the strain gauge cavity

and cable entry area. The most advanced cable entry design

employs a unique glass-to-metal bonding seal which makes the

cable termination area impervious to moisture. Cable wires terminate at the point of connection to the load cell, where they are

soldered to hermetically-sealed pins that carry signals to the sealed

strain gauge area through a glass-to-metal seal. Water or other

contaminants cannot “wick up” into the load cell, since the cable

ends at the entry point. This design allows for field-replaceable

cable, since the connection is outside the load cell.

A word of caution: stainless steel load cells are not synonymous

with hermetically-sealed load cells. While environmentally-

protected stainless steel load cells may be suitable for dry

chemical corrosive environments, hermetically-sealed stainless

steel models are the appropriate choice for high moisture or

washdown applications.

Design Elements

1-10

Page 13

Design Elements

VESSEL WEIGHING SYSTEMS

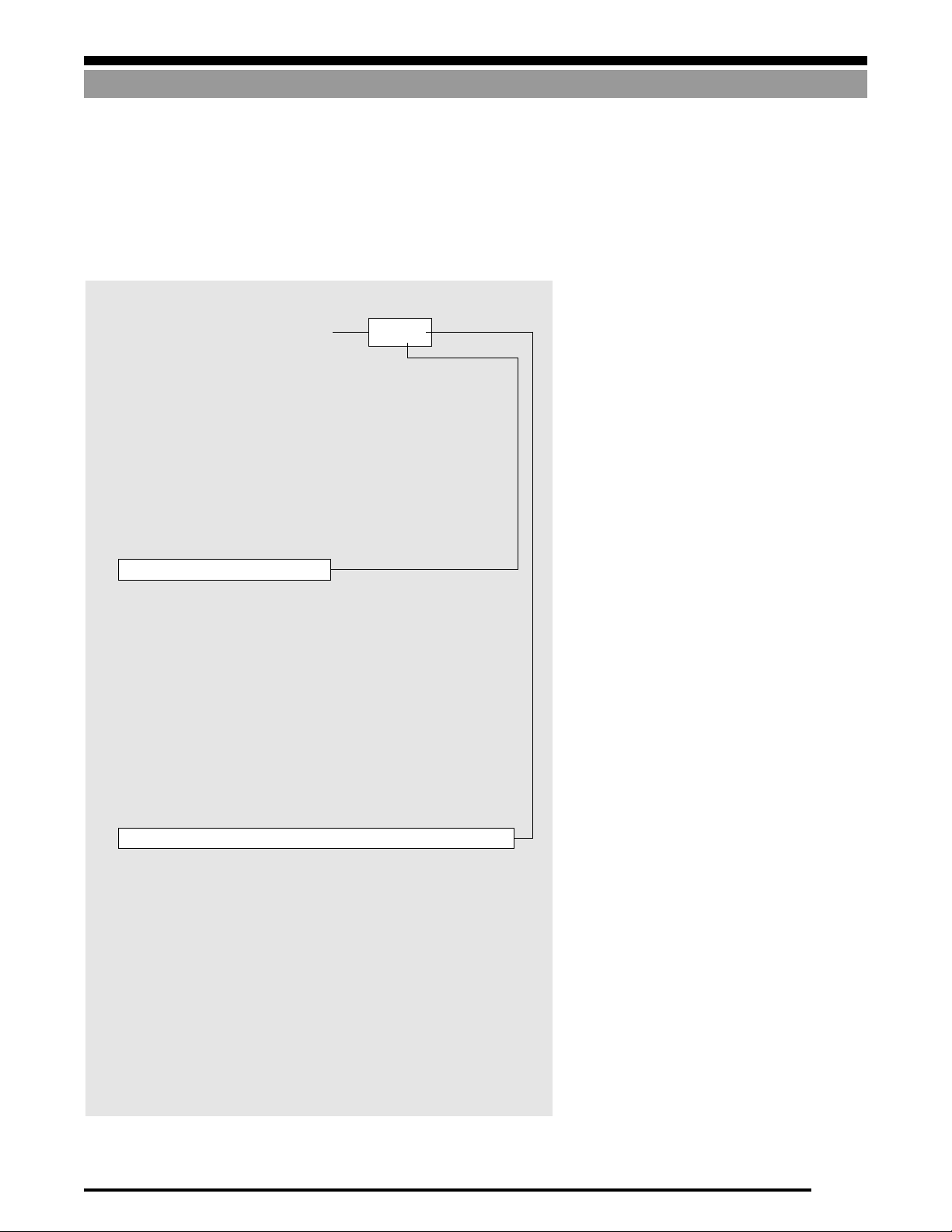

International Protection (IP) Rating Guide

If a hermetically-sealed cell is necessary, further classification is needed to be sure of the type of protection a particular cell offers. For

hermetically-sealed cells, Rice Lake Weighing Systems uses the International Protection (IP) rating system. We find the IP numbers and

their definitions are suitable for the classification of hermetically-sealed load cells, and only apply IP numbers to such cells. The IP

numbers on a hermetically-sealed cell further specify the treatment a specific cell can endure in environments more severe than simple

washdown. The following tables define the IP numbers alone and in conjunction with the hermetically-sealed rating.

▲

Example: Protection level offered

by an IP67 rated product

▲

Protection against solid objects

First number (in this case 6)

No protection

0

1

Protected from solid objects up to 50 mm (e.g., accidental touch

by hands)

2

Protected from solid objects up to 12 mm (e.g., fingers)

3

Protected from solid objects more than 2.5 mm (e.g., tools and

small wires)

4

Protected from solid objects more than 1 mm (e.g., small wires)

5

Protected from dust; limited entrance (no harmful deposit)

6

Totally protected from dust

IP 67

Manufacturers may give a NEMA rating to

cells. This system was established for electrical enclosures and is difficult to apply to load

cells. However, if you see a NEMA rating and

need a general idea of what it means, IP67

and NEMA 6 cells are comparable and meet

similar requirements.

Time invested in a well-considered choice

offers large returns in the long run. If there

is any doubt as to which cell to use, consult

with a company such as Rice Lake Weighing

Systems that offers experience and knowledge with every load cell.

▲

Protection against liquids

Second number (in this case 7)

No protection

0

1

Protected from vertically-falling drops of water (e.g.,

condensation)

2

Protected from direct sprays of water up to 15° from vertical

3

Protected from direct sprays of water up to 60° from vertical

4

Protected from water sprayed

entrance allowed

5

Protected from low pressure jets of water from all directions;

limited entrance allowed

6

Protected from strong jets of water (e.g., for use on ship decks);

limited entrance allowed

7

Protected from the effects of immersion between 15cm and 1m

8

Protected from extended periods of immersion under pressure

from all directions; limited

IP Numbers with Hermetically Sealed (HS) or Environmentally

Protected (EP) Ratings

Rating Protection

EP

HS-IP65

HS-IP66

HS-IP67

HS-IP68

HS-IP66/68

Dust proof, not protected from moisture or water

Dust proof, protected from splashes and low-pressure jets

Dust proof, protected from strong water jets

Dust proof, protected from temporary immersion in

water 1 meter deep for 30 minutes

Dust proof, protected from continuous immersion in

water under more severe conditions than IP67

Dust proof, protected from strong water jets and/or

constant immersion

1-11

Page 14

SYSTEM DESIGN

Thermal Expansion

Calculating Thermal Expansion of V essels & Stay Rods

Stay Rod Expansion/Contraction

Stay rods attached to vessels subjected to thermal changes can

introduce significant forces which affect system accuracy. The

method of attachment and the length of the stay rods directly affect

these forces.

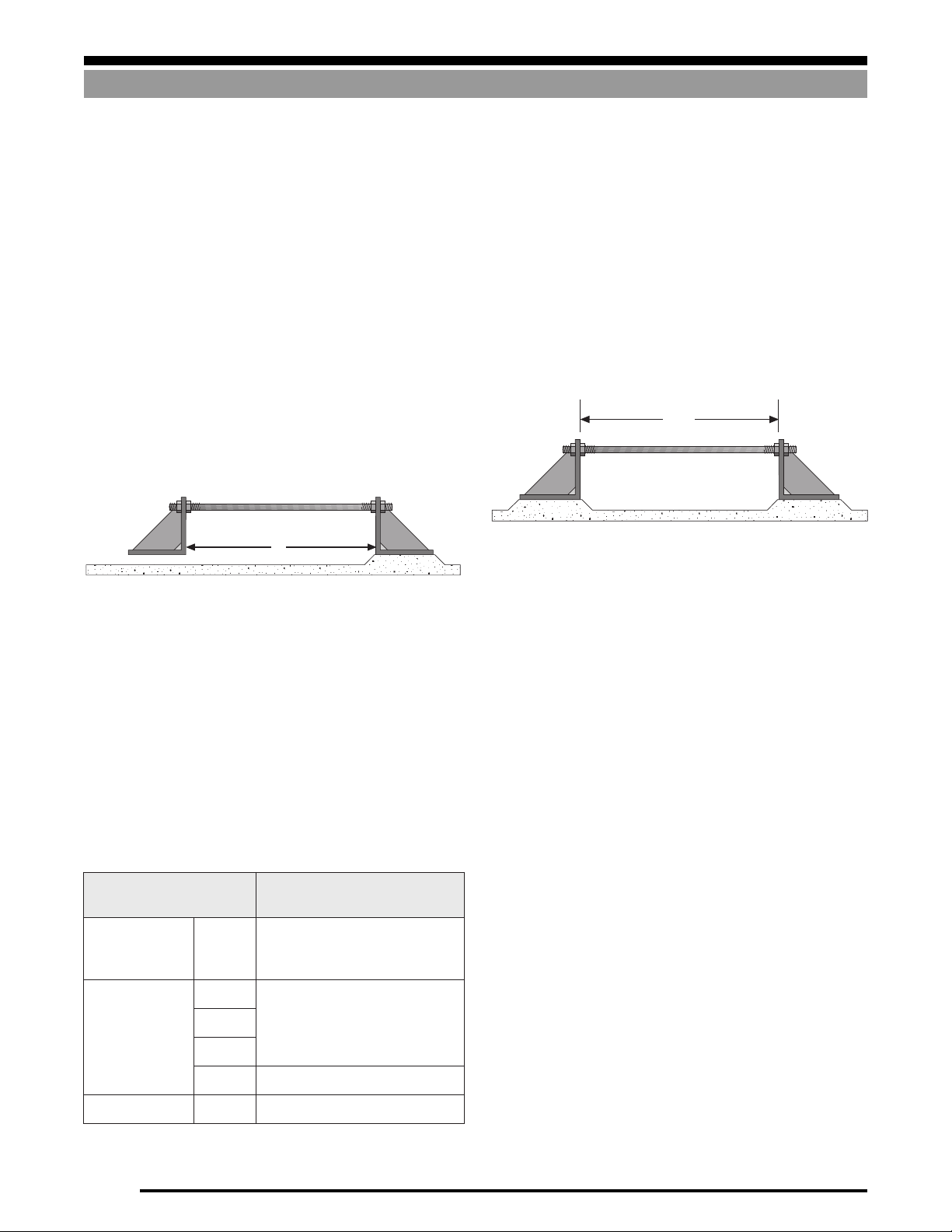

Figure 1-19 illustrates a stay rod rigidly attached to a bracket on

each end—one bracket is rigidly mounted, the other is unattached,

thus allowing the rod to expand and contract freely. As the temperature rises or drops, the length of the rod will increase or

decrease respectively. The change in length (∆L) is proportional to

the original length (L), the change in temperature (∆T), and the

This shows that a 48" steel rod will increase by .019" as a result of

a 60°F temperature rise. This may seem insignificant, until you

consider the forces which can result if the stay rod is confined

rigidly at each end, as in Figure 1-20.

In Figure 1-20, a 1" steel rod 48" long is attached to a bracket on

each end, and both brackets are rigidly attached. If the rod is

initially adjusted so that there is no strain, a subsequent 60°F rise

in temperature will cause the rod to exert a force of 9,000 lb on each

bracket. Hence, vessel restraint systems must be designed and

installed properly so that they don’t move and/or apply large lateral

forces to the weigh vessel.

coefficient of linear expansion (a) which is a characteristic of the

rod material.

∆L can be calculated from the following equation:

∆L = a x L x ∆T

L

Vessel Expansion/Contraction

Figure 1-19

Table 1-1 below lists the coefficient of thermal expansion (α) for

various materials used to construct vessels and stay rods.

Example:

If the rod in Figure 1-19 is made from 1018 steel, then a = 6.5 x 10

6

from Table 1-1. If the rod is 48" long and the temperature

increases by 60°F, the length of the rod will increase by:

∆L = a x L x ∆T

∆L = 6.5 x 10-6 x 48" x 60

∆L = .019

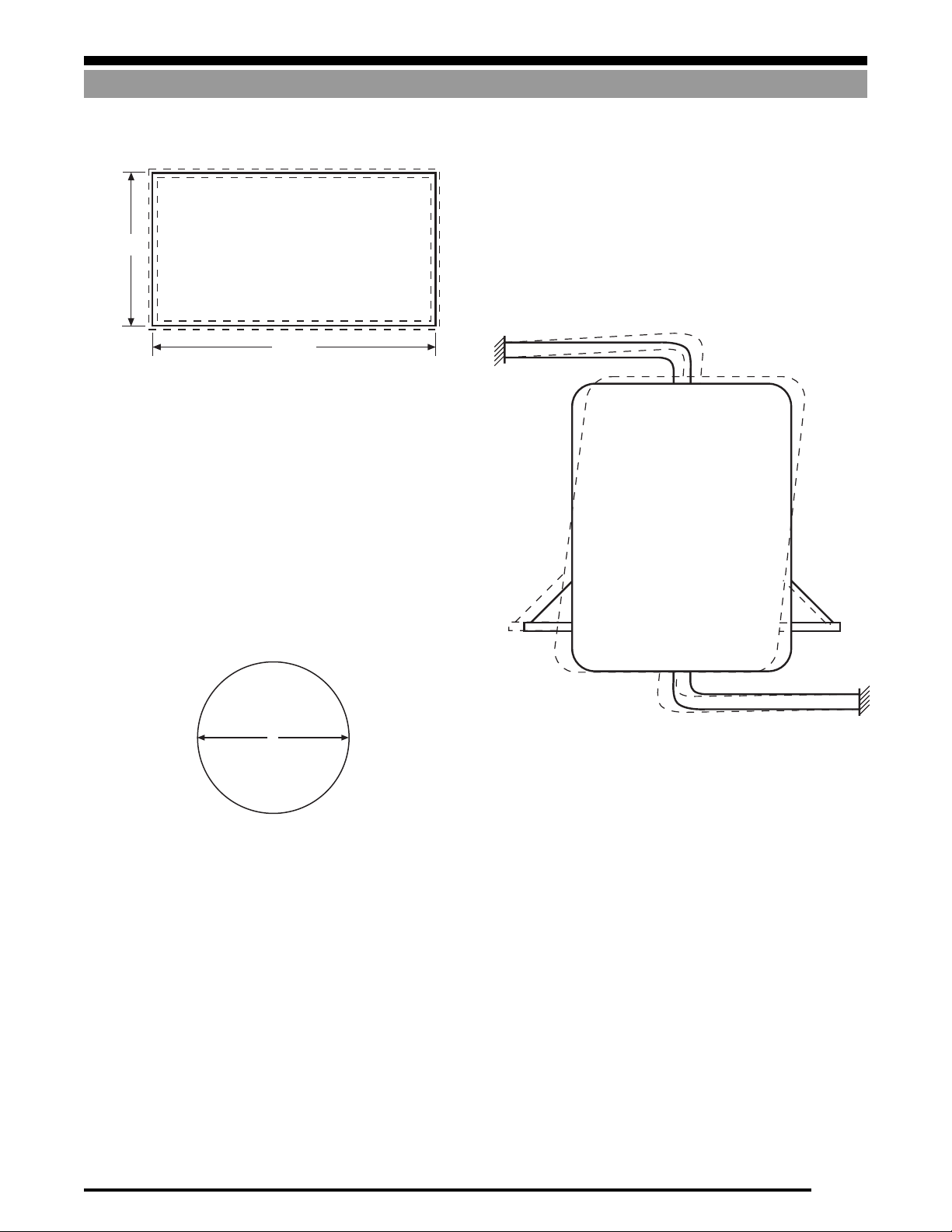

Temperature fluctuations will cause weigh vessels to grow and

contract. Figure 1-21 on the following page best illustrates this.

Shown is a top view of a rectangular vessel. The solid line repre-

sents its size at 70°F and the inner and outer broken lines represent

its size at 40°F and 100°F respectively. The amount that the sides

-

will increase/decrease in length can be found using the expansion

formula discussed previously.

48"

1" Dia

Figure 1-20

Therefore: ∆L = X x L x ∆T

lairetaM

leetSwoL

nobrac

)8101(

leetssselniatS20301x6.9

303

403

61301x9.8

munimulA160601x0.31

Table 1-1

1-12

6-

01x5.6

6-

6-

6-

noisnapxEraeniLfotneiciffeoC

repsehcni( ° )F

Page 15

Thermal Expansion

Vessels with attached piping can be subjected to severe side forces

as a result of temperature variations if the connections are not

executed properly. It is worth noting that vessels expand and

84.0"

144.0"

Figure 1-21

If the vessel is made from mild steel, the length will vary by ± .028"

(6.5 x 10-6 x 144 x 30), and the width will vary by ± .016"

(6.5 x 10-6 x 84 x 30) as the temperature fluctuates by ± 30°F. It will

be apparent that if the load cell is held rigidly by the mount,

enormous side forces will be applied to the cell, hence the need to

use a mount which can accommodate vessel expansion/contraction due to changes in temperature.

In the case of a cylindrical vessel, the change in diameter (∆D)

resulting from a change in temperature (∆T) is given by:

∆D = a x D x ∆T

contract vertically as well as horizontally with changes in tempera-

ture. Rigidly-attached piping may magnify the effects of this

expansion, as seen in Figure 1-23. See Attaching Piping to Weigh

Vessels in Section 3 for detailed guidelines on this subject.

SYSTEM DESIGN

D

Figure 1-22

Example:

If a cylindrical vessel is 96" in diameter and made from 304

stainless steel and is subjected to a temperature rise of 80°F

as the result of being filled with a hot liquid, then the diameter

will increase by:

∆D = 9.6 x 10-6 x 96 x 80

= .074"

Figure 1-23

1-13

Page 16

SYSTEM DESIGN

Calculating Tank V olumes

Calculating Tank Volumes

Formulas for V arious Tank Shapes and Sections

Cylinder

π

Volume =

D2H

4

H

D

Portion of Cylinder

π

2

Volume =

hD

8

h

D

Horizontal Cylinder (Partially Filled)

Volume =

π

D2L −

4

π

720

D2Lcos

2h − D

()

−1

D

+h−

D

2

LhD−h

2

Frustum of Cone

π

hD2+dD+ d

Volume =

()

12

D

h

d

h

L

π

4

D

D2L

2

In the special cases where h=D (that is, the vessel is filled com-

pletely) then this formula reduces to:

Volume =

D

h =

(that is, the vessel is filled half way) then this formula

2

reduces to:

π

Volume =

D2L

8

1-14

Page 17

Calculating Tank Volumes

SYSTEM DESIGN

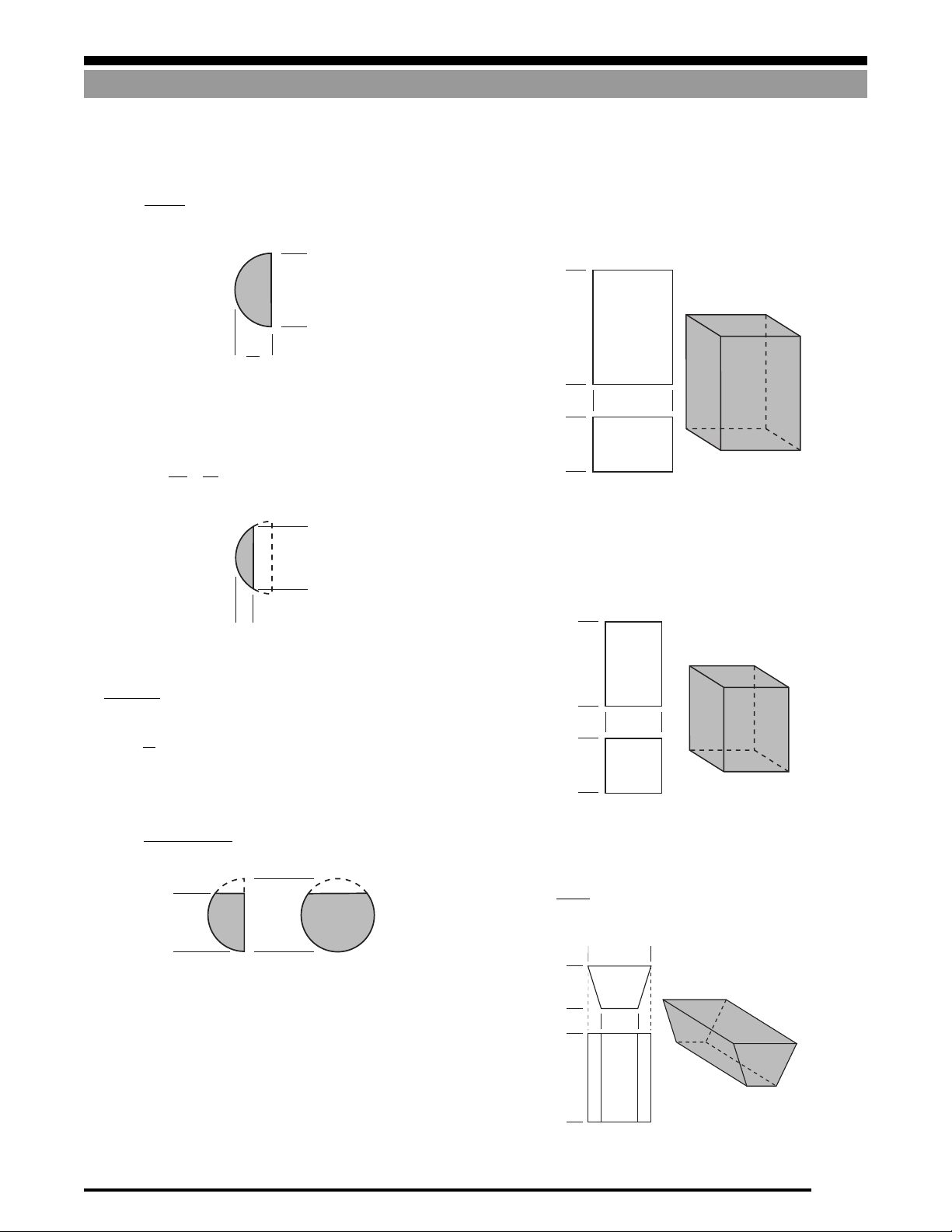

Hemispherical End

3

π

D

Volume =

12

Spherical Segment

2

Volume =

π

L

2

D

L

+

8

6

Square Prism

(Rectangular Cross Section)

Volume =ABH

D

H

D

2

A

B

Square Prism (Square Cr oss Section)

D

Volume = A2H

L

The radius of the sphere from which the segment is cut is

2

D2+ 4L

r =

8L

D

Note: r

≠

(D is the diameter of the vessel)

2

Hemispherical End (Partially Filled)

π

Volume =

(3h2D− 2h3)

12

h

Wedge I

Volume =

D

a + A

H

A

A

Bh

2

A

h

a

B

1-15

Page 18

SYSTEM DESIGN

13'

4.5'

15'

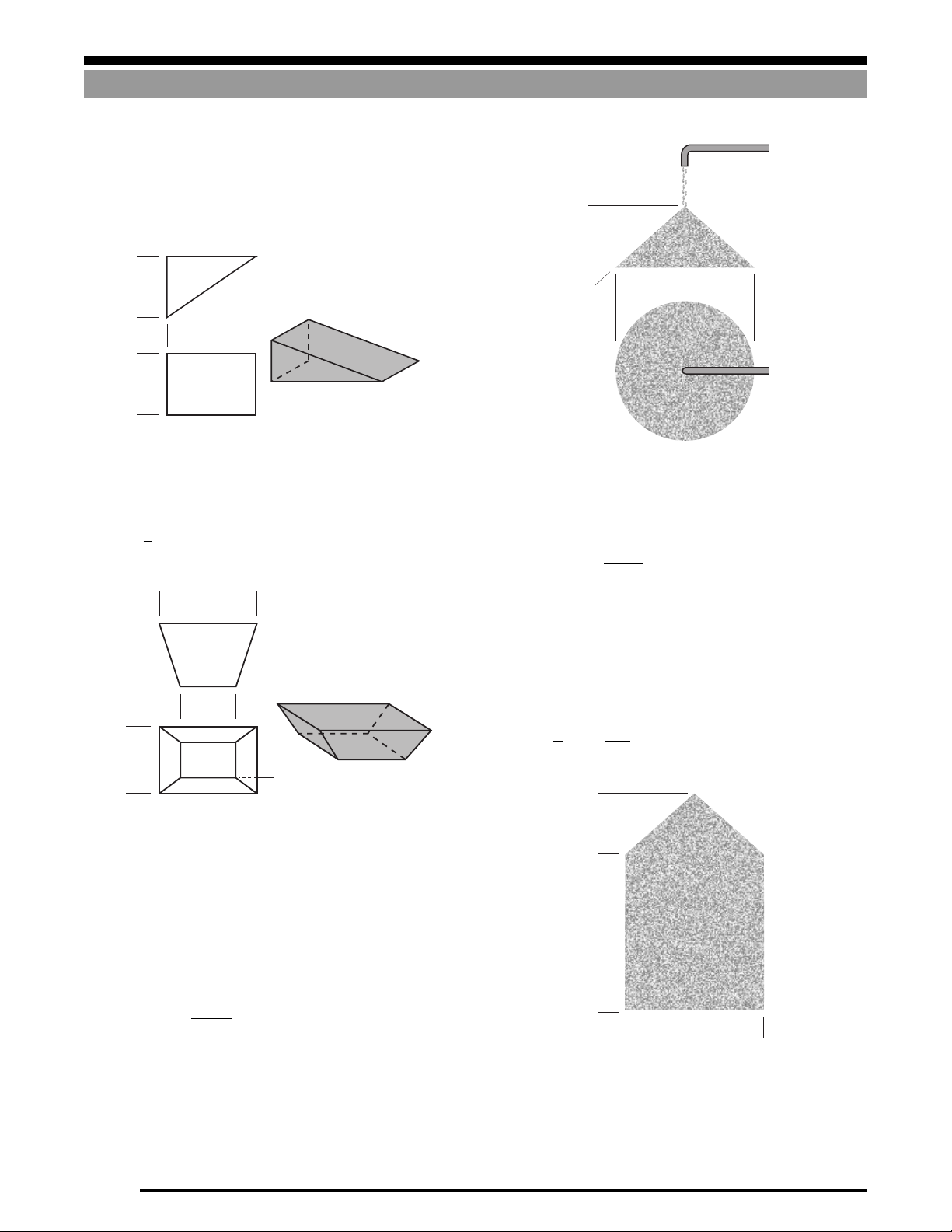

Wedge II

Volume =

hAB

2

Calculating Tank Volumes

h

h

A

B

Frustum of Pyramid

Volume =

h

2 AB + Ab + aB + 2ab

()

6

A

h

a

B

b

α

D

Figure 1-24

The volume of any cone is:

height

x area of base

3

In calculating the volume of material in a vessel, an adequate

approximation can be made by adding 1/3 of the height of the cone

to the height of material up to the cone.

For example, in Figure 1-25, assume the height of the material in

the cylindrical vessel to be 15'+1.5'=16.5 feet.

Thus the volume is calculated using the following formula:

Volume =

π

4

D2h

=

3.14

x (13)2 x 16.5 = 2190 cubic feet

4

Angle of Repose

When a granular material is dropped from above onto a flat surface

it tends to form a cone, as shown in Figure 1-24. The shape of this

cone is described by the angle of repose, α, which is a characteristic

of the material. The angle of repose varies somewhat with particle

size, moisture content, etc. The relationship between α, h, and D

(see Figure 1-24) is:

α

D tan

h =

2

1-16

Figure 1-25

Page 19

Calculating Tank Volumes

SYSTEM DESIGN

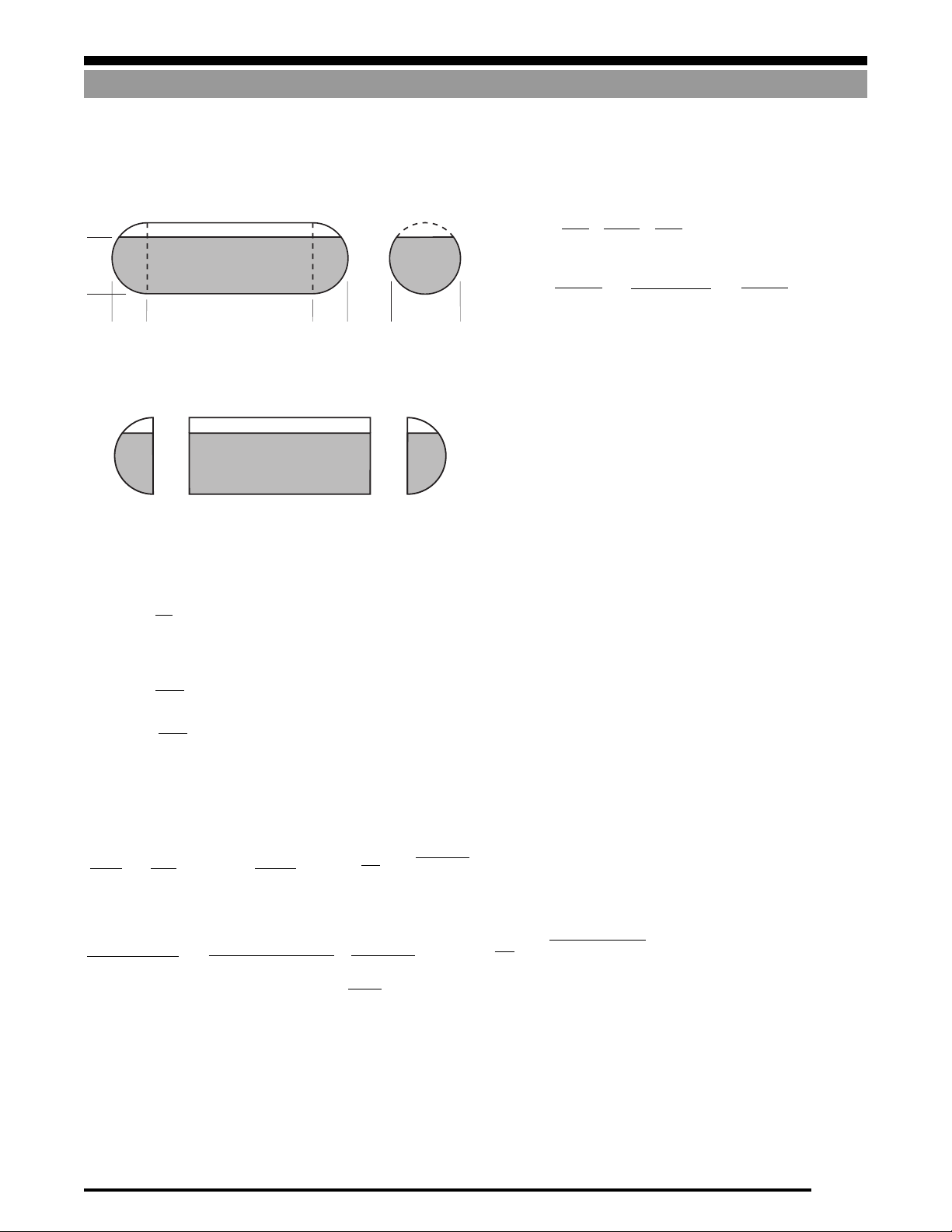

Calculation Examples

Example 1

Calculate the volume of liquid in the horizontal tank shown below.

It has hemispherical ends and is filled to a height of 4.5 feet.

4.5'

3' 20' 3' 6'

For ease of calculation, this can be broken into 3 sections

Example 2

If, in the last example, the vessel were filled completely, then the

volume would be:

Total Volume = Volume(a) + Volume(b) + Volume(c)

Example 3

If the vessel in Example 2 is filled with linseed oil, calculate the

weight of material when the vessel is full.

From the section Density of Common Materials, we know that the

density of linseed oil is 58.5 lb/cu. ft. From Example 2, we know

(a) (b) (c)

Step 1

The volume of section (a) or (c) is given by the formula:

Volume =

π

12

where

(3h2D – 2h3)

π

= 3.14,

h = 4.5

,

D = 6

that the volume of the vessel is 678.2 cubic feet.

Weight of Material = Volume x Density

3

π

D

π

D2L

π

D

+

12

3.14(62) x 20

4

= 678.2 x 58.5

= 39,675 lb

12

3.14(63)

12

+

4

+

=

= 56.5 + 565.2 + 56.5

= 678.2 cu ft

3

3.14(63)

+

12

=

3.14

=

=

= 47.7 cu ft

((3 x 4.52 x 6) – (2 x 4.53))

12

3.14

(182.25)

12

Step 2

The volume of (b) is given by the formula:

πD2L

4

3.14 x 62 x 20

π

–

720

where π = 3.14, h = 4.5, D = 6, L = 20

4

=

565.2 – 3.14cos

= 565.2 – 188.4 + 77.94

= 454.7 cu ft

2h – D

D2Lcos

–1

( )

3.14 x 62 x 20cos

–

720

+ h –

D

–1

(.5) + 30√6.75

D

( )

2

–1

2 x 4.5 – 6

( )

6

Step 3

Total Volume=Volume(a)+Volume (b)+Volume(c)

= 47.7 + 454.7 + 47.7

= 550.1 cu ft

L√hD – h

+ 4.5 –

( )

2

6

20√4.5 x 6 – 4.5

2

2

1-17

Page 20

SYSTEM DESIGN

5'

3'

3'

(b)

9.7'

Volume (a)

Volume (b)

3'

Calculating Tank Volumes

Example 4

Calculate the volume of material in the hopper shown below.

Step 2

The volume of section (b) is given by:

Volume =

12'

5'

2'

6'

3'

3'

7'

5'

Step 3

For ease of calculation, this may be broken into 2 sections as

follows:

Step 1

The volume of section (a) is given by:

Volume = ABh

= 5 x 7 x 6.7 = 234.5 cu ft

Example 5

If, in the last example, the vessel was filled to overflowing, then the

volume would be :

5'

Volume(Total) =Volume (a) + Volume (b)

Volume(b) is same as the previous example (73.0 cu ft)

2'

Volume(a) = 5 x 7 x 9.7 = 339.5 cu ft

h

2AB+ Ab + aB +2ab

()

6

3

6

3

6

= x ((2 x 5 x 7) + (5 x 5) + (3 x 7) + (2 x 3 x 5))

= x 146 = 73.0 cu ft

Total Volume=Volume (a) + Volume (b)

= 234.5 + 73.0

= 307.5 cu ft

6'

(a)

6.7'

where the “leveled height” is assumed to be 6.7'.

1-18

Volume(Total) = 339.5 + 73.0 = 412.5 cu ft

Page 21

Material Densities

Densities of Common Materials

SYSTEM DESIGN

Bulk Density Angle of

Material lb/cu. ft. Repose

Abrasive 150

Abrasive Mix 153

Acetylenogen 70-80

Acid Phosphate 60

Adipic Acid 45

Alfalfa, ground 16 45

Alfalfa, seed 48

Almonds, broken or whole 28-30

Alum, pulverized 45-50 30-45

Alumina 60-120 30-45

Aluminate Gell 45

Aluminum Chips 7-15

Aluminum Etchant 54

Aluminum Filament 74

Aluminum Ore (Bauxite) 89-94

Aluminum Powder 47-79

Aluminum Sulfate 58-69

Amianthus 20-40

Ammonium Chloride 52

Ammonium Nitrate 45-62

Andalusite 49

Antimony Oxide 45

Apple Slices, dried 15

Apple Pumice, dried 15

Arsenic 30

Arsenic Oxide 100-120

Asbestos Fiber 19

Asbestos Ore 81

Asbestos Shorts 25

Ashes, dry 35-40 45+

Asphalt, crushed 45 30-45

Bagasse 7-10 45+

Bakelite, powdered 30-40

Barite 100-160

Barium Carbonate 45-97

Bark, wood 10-20 45+

Barley 38 up to 30

Basalt 184

Batch, glass 90-100

Bauxite, crushed 75-85 30-45

Beans, castor 36 up to 30

Beans, navy 48-54 up to 30

Beans, soy 45 up to 30

Beets 45

Beet pulp 25-45

Benzene Hexachloride 56

Bicarbonate of Soda 41

Binder 812 41

Black Coloring 30

Blood, ground 30

Bluestone 60-70

Bulk Density Angle of

Material lb/cu. ft. Repose

Bones, crushed 35-40

Bones, ground 50

Boneblack 20-25

Bonechar 40

Borax 60

Borax, powdered 53

Borton 75

Bran 10-20 30-45

Brass, cast 519

Brass, rolled 534

Brewers grain, wet 55-60 45 & up

Brick, best pressed 150

Brick, tire 137

Brick, soft interior 100

Bromoseltzer 37

Bronze chips 30-50

Bronze powder 75

Cab O Sil 1

Calcin flour 75-85

Calcium Fluoride 82

Calcium Lactate 26-29

Calcium Phosphate 40-50

Carbon activated 8-20

Carbon, black pellet 25 up to 30

Carbon, black powdered 4-6

Carbon lampback 7

Carbon, masterbatch 40

Carborundum 100

Casem 38

Caustic, soda 88

Caustic, soda flakes 47

Celation FP4 14

Celite 535 9

Cement Bulk 75-95

Cement, clinker 75-85 30-40

Cement, portland 90 30-45

Cement, slurry 90-100

Chalk, crushed 85-90

Chalk, ground 70-75

Chalk, lumpy 82-95 45 & up

Chalk, pulverized 70-75

Charcoal 18-25

Cherry wood 42

Chickory 33

Chili spice 45

Chocolate powder 40

Chrome ore 125-150

Cinders, coal 40 25-40

Clay, ceramic, dry 65-80

Clay, fire 40

Clay 96

1-19

Page 22

SYSTEM DESIGN

Material Densities

Bulk Density Angle of

Material lb/cu. ft. Repose

Clay, potters 100-120

Clay, product 36

Clover, seed 48

CMC Powder 52

Coal Anthracite (solid) 94

Coal Bituminous (loose) 43-50 30-45

Coal Char 24

Coal, dust 35

Coal, sized 50

Cobalt Oxide 114

Cocoa, beans 30-45

Cocoa, flavoring 55

Cocoa, powdered 33-35

Coconut 20-22

Coconut, shredded 20-25 45 & up

Coffee 20

Coffee, fresh beans 30-40 30-45

Coffee, green beans 32-45

Coffee, roasted bean 22-30 up to 30

Coffee, soluble 19

Coke, calcined 35-45

Coke, loose 23-32 30-45

Collupulin 19

Compost 28 30-45

Concrete, sand & gravel 150

Cookie Meal 38

Copper, cast 542

Copper, ore 120-150 30-45

Copper, sulfate 60-70 31

Copra 22-33

Copra, cake ground 40-45

Copra, meal 40-45

Cork, granulate (1/2) 12-15

Cork, granules 4

Cork, solid 15

Corn, cracked 40-50

Corn, grits 40-45 30-45

Corn, meal 32-40

Corn, seed 45

Corn, shelled 45 up to 30

Cottonseed, cake 40-45 30-45

Cottonseed, flakes 20-25

Cottonseed, meals 35-40 30-45

Cottonseed, meats 40 30-45

Cryolate (1/2) 90-110 30-45

Cryolite (100) 50-75

Diatomaceous Earth 11-17

Dracalcium Phosphate 40-50

Disodium Phosphate 25-31

Dolomite 83

Dolomite, lumpy 90-100 30-45

Bulk Density Angle of

Material lb/cu. ft. Repose

Dolomite, pulverized 46

Donut Mix 45

Earth 76

Earth, common dry 70-80 30-45

Earth, moist 30-35 30-45

Ebonite 65-70

Egg Yolk 23

Elm, dry 35

Feldspar (1/8) 100-160

Feldspar, (1-100) 65-75

Feldspar, ground 65-70

Feldspar, lumps 85-95 34

Ferro Silicon 87

Ferrous sulfate 50-75

Fine, powder 127

Fit 24-33

Fish, scrap 40-50

Flaxseed 43-45

Flaxseed, meal 25

Flaxseed, whole 45 up to 30

Flour 42-48

Flour, wheat 35-40 45 & up

Flue, dust, dry 110-125

Fluospar 82

Fluospar, lumps 80-110 45 & up

Fluospar, solid 200

Fly ash 61-95

Fly ash, dry 35-40

Foundry sand, loose 80-90

Foundry sand, rammed 100-110

Frodex 24 38

Fullers Earth (burnt) 40 23

Galena 240-260

Garbage 30

Geon Resin 22

Gilsonite 37

Glass, broken 80-100

Glass, frits 128

Glass (window and plate) 161

Glue 52

Glue, ground 40

Glue, pearl 40

Gluten meal 40 30-45

Gold powder 53

Granite, lumps 96 30-45

Granite, solid 150-170 30-45

Granular material 48

Graphite, flake 40

Graphite, ore 65-75

Grape pomace 15-20

Grass, seed 10-12

1-20

Page 23

Material Densities

SYSTEM DESIGN

Bulk Density Angle of

Material lb/cu. ft. Repose

Gravel, dry 90-100 30-45

Green powder 57

Green stone 107

Ground bone 50

Guar Gum 35

Gumbase 42

Guano 70

Gypsum, crushed 90-100

Gypsum, ground 75-80

Hash, spice 66

Hay, loose 5

Hell blue dye 19

Hemlock 25

Hexanedioic Acid 45

Hickory, dry 25

Ice, crushed 35-45 up to 30

Ice, solid 57.4

Insecticide 46

Ional 47

Iron, cast ductile 444

Iron, cast gray 450

Iron Ore 120-180

Iron oxide 174

Iron oxide, black 160

Iron Sulfate 50-75

Kaolin, clay 160

Kaolin, talc 42-56

Lactose 32

Lamisay flour 34

Latikra 34

Lead, arsenal 72

Lead, carbonate 240-260

Lead, ore 180-230

Lead, red 230

Lead, white 250-260

Lignite 42-55 30-45

Limanite 120

Lime, bricks 41-83

Lime, ground 60

Lime, hydrated 40 30-45

Lime, pebble 53-56

Lime, quick 54

Limestone 100

Limestone, agriculture 68

Limestone, dust 55-95

Limestone, filler 63

Limestone, loose 100

Limestone, pulverized 85-90 45 & up

Lindane 56

Linseed, cake 48-50

Linseed, whole 45-50 up to 30

Bulk Density Angle of

Material lb/cu. ft. Repose

Magnesia 77

Magnesium chloride 33

Magnesium oxide 10-135

Magnesium, sulfate 40-50

Mahogany Spinach 53

Maize 45

Malt, flour 40

Malt, meal 36-40

Malt, powder 40

Malt, wheat 41

Manganese Ore 125-180

Manganese Oxide 120

Manganese Sulfate 70

Manganese Solid 475

Manure 25

Marble, crushed 80-95 30-45

Maple 49

Masonry 185

Material 199 67

Meat 50-55

Mercury 849

Metallic, flake 35

Mica, ground 13-15 30-45

Mica, flakes 17-22

Mica, solid 181

Mica, soapstone 46

Milk, malted 27-35 45 & up

Milk, powdered 36 45 & up

Mill Scale 100-125

Milltown 35

Mineral Oxide 35

Molybdenum 107

Mortar, wet 150

Moulding compound 42

Muriate of Potash 77

Mustard, powdered 16

Mustard, spice B 45

Naphthalene Flakes 36

Neutral Granules 24

Nickel Ore 150

Nicotinic Acid 35

Oskite 60

Oak, live, dry 59

Oats 25-35 32

Oat flour 33

Oil cake 48-50

Oil, linseed 58.8

Oleomargarine 59

Orange Peel, dry 15

Paper Pulp (15%) 62

Paper Pulp (6 15%) 60-62

1-21

Page 24

SYSTEM DESIGN

Material Densities

Bulk Density Angle of

Material lb/cu. ft. Repose

Parazate 18

Peanut Brittle 36

Peanuts, unshelled 15-24 30-45

Peas 45-50

Pentserythritol 43

Peppermint 32

Pharmaceutical Mix 39

Pharmaceutical Lubricant 9

Phenol Formaldehyde 30

Phosphate 94

Phosphate, crushed 75-85 26

Phosphate, granular 90-100

Phosphate, soda 25-31

Phosphoprotein 36

Pie Crust Mix 34

Pine, white, dry 26

Pine, yellow south 45

Pitch 72

Plastic beads 46

Plastics, chopped 37

Plastics, lrg. flakes 19

Plastics, small flakes 34

Plastics material color 34

Plastics, spheres 42

Plastics, Powder B 25

Plastics, Scrap 40

Polyester, film 5

Polyethylene 42

Polyethylene, flakes 6

Polyethylene, pellets 35

Polyvinyl Chloride 40

Pork Spice 72

Potassium Bromide 114

Potassium Chloride 73 30-45

Potassium Iodate 128

Potassium Nitrate (1/2) 76

Potassium Sulfate 42-48

Potatoes, dried 58

Pie Mix 34

Protein Supplement 33

PVC Powder 30

Quartz 85

Raisins 48

Red Oxide 72

Red Color Concentrates 32

Redwood 26-30

Resin 30-37

Resin Luron 39

Rice, chopped 64

Rice, grits 42-45 up to 30

Rice, rough 32-36 30-45

Rip Rap 80-105

Bulk Density Angle of

Material lb/cu. ft. Repose

Rolaids 64

Rosin 67

Rubber Composition 33

Rubber Caoutchouc 59

Rubber, mfg. 95

Safflower 45

Safflower, cake 50

Sal Ammoniac 52

Salicylic Acid 29

Salt (1/8) 50

Salt, coarse 45-55 30-45

Salt, dry coarse 45-50

Salt, fine 70-80

Sand, damp 110-130 45 & up

Sand, dry 90-110

Sand, foundry (1/8) 90

Sand, foundry (1/2) 90

Sand, rammed 100-110

Sandvoids full of H2O 110-130 15-30

Santonox 18-45

Saran Powder 35

Sawdust (wet) 24

Scale 125-160 36

Sewage 40-50

Shale, crushed 85-90 39

Shale, solid 162

Shavings, wood 15

Silene 15

Silene & Zinc 15

Silica Gel 42

Silicon Carbide 15-88

Silver Powder 69

Sinter 90-110

Slag Furnace (+1/2) 60-65

Slate, crushed 80-90 28

Slate, solid 165-175

Sludge 45-55

Snow, packed 15-35

Soap, flakes 5-20 30-45

Soap, powdered 20-25 30-45

Soapstone 40-50

Soda Ash, heavy 55-65 30-45

Sodium Aluminate 72

Sodium Bisulfate 90

Sodium Chloride 84

Sodium Nitrate 70-80 24

Sodium Phospho Aluminate 67

Sodium Pysophosphate 63

Sodium Sulfate, dry (1/8) 65-85

Sodium Tripolyphosphate 58-64

Sorghum, seed 32-52

Soybeans, cake 40-43

1-22

Page 25

Material Densities

SYSTEM DESIGN

Bulk Density Angle of

Material lb/cu. ft. Repose

Soybeans, flakes, raw 20-26

Soybeans, meal, cold 40

Soybeans, meal, hot 40

Spice (Vienna) 63

Spruce 28

Stabilizer 71

Sta-nut 52

Steatite 25-50

Steel, solid 469.6

Steel Turnings 60-120 45 & up

Sugar Beet, dry 12-15

Sugar Beet, wet 25-45

Sugar, powdered 50-60

Sugarcane 15-18 45 & up

Sulphur, crushed 50-60

Sulphur, dust 50-70 30-45

Sulphur, powdered 50-60

Taconite 116-130

Talc, granulated 50-65

Talcum powder 55

Tanbark 55

Tar 69-75

Tea 27

Tin Cast 459

Timothy, seed 36

Titanium Sponge 60-70

Bulk Density Angle of

Material lb/cu. ft. Repose

Tobacco, scraps 15-25 45 & up

Tobacco, stems 16-25 45 & up

Traprock, compact 187

Tricalcium Phosphate 40-50

Trichlorocyanuric Acid 50

Triple Super Phosphate 50-55

Trisodium Phosphate 60 40

Tumeric 51

Ulexite 75

Vermiculite 62

Vermiculite, ore 80

Vicrum 35

Vinyl Resin 36

Vitamin Mix 43-49

Walnuts 35-40

Wax 26

Wheat, cracked 46 30-46

Wheat, cut 45-48

Wheat germ 35-40

White Powder 28-45

Wood, bark 10-20

Wood, chips 10-30 45 & up

Yellow Corn Flour 33

Zinc Concentrate 75-80

Zinc Hydrosulphate 44

Zinc Oxide, heavy 10-15 45 & up

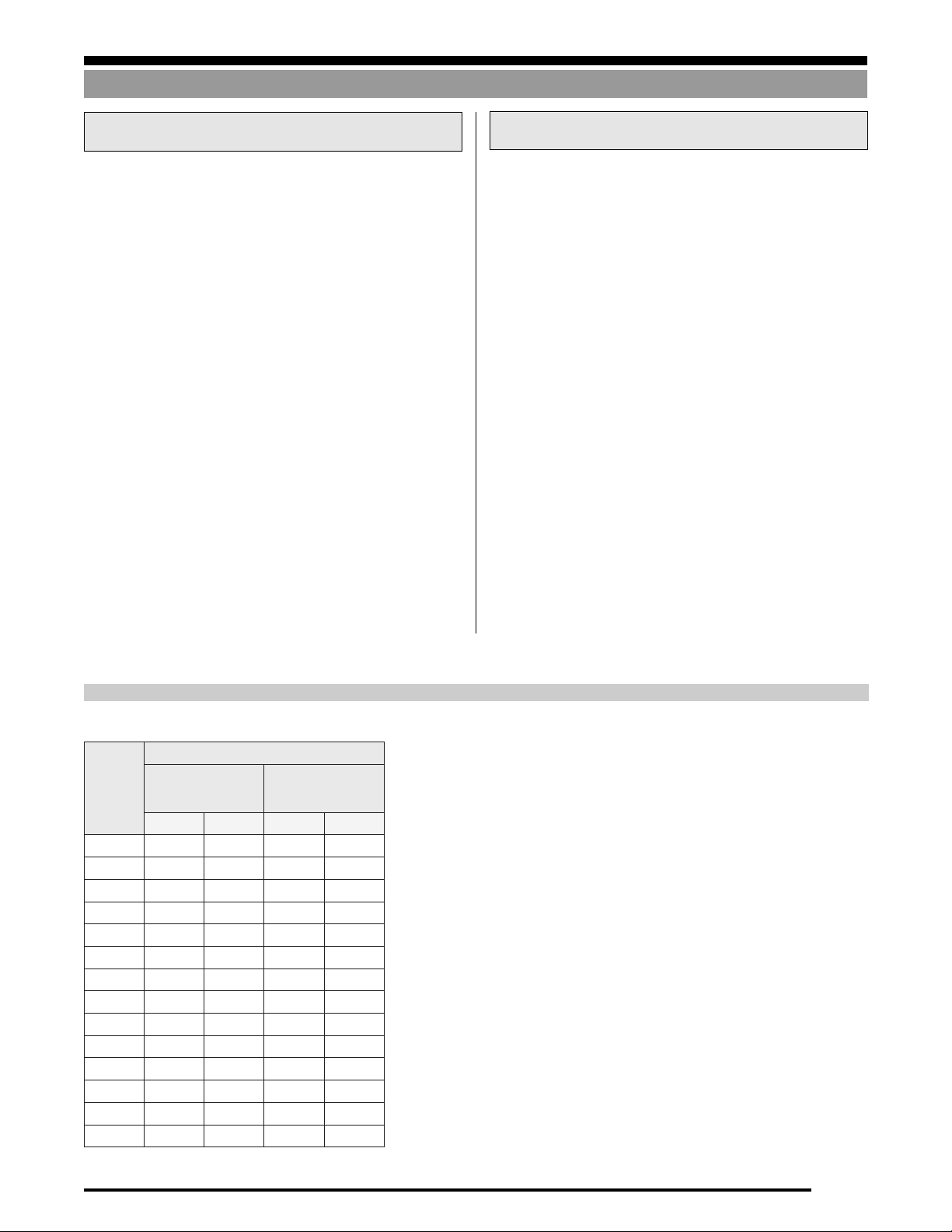

Load Cell Bolt Torque Values

)bltf(euqroTdednemmoceR

8301detaert-taeH

paC

wercs

retemaid

"4/111312151

"61/512325203

"8/383040506

"61/755065859

"2/15859521041

"61/9521041571591

"8/5571012542072

"4/3003033524064

"8/7054094066007

"10865170990501

"8/1-158809907415561

"4/1-15521083100120132

"8/3-15361578105720113

"2/1-10812034204630014

daehxeh

5edargEAS

CNU FNU CNU FNU

daehxehyollA

8edargEAS

Notes:

1) Based on dry assembly. Variables such as lubrication, plating, etc. may

reduce the values listed above as much as 20%, and must be taken into

consideration.

2) General formula for calculating Torque is as follows: Torque in Inch

lb=0.2 x Nominal Diameter of Screw x Load in lb, where load = 80% of yield

strength, expressed in lb, not pounds per square inch.

3) The tension induced in a cap screw may be checked by measuring overall

length before torquing and then under torque load. The screw stretches

.001" per inch of screw length for each 30,000# PSI induced tension.

Applies only to loads below the yield point.

1-23

Page 26

SYSTEM DESIGN

Wind and Seismic Effects

Wind and Seismic Effects on Vessel Stability

Other than forces resulting from the impact of a vehicle, wind and

seismic forces are the most important external forces which might

affect a weigh vessel. The threat from vehicular traffic can be

guarded against using properly-designed guard rails. The effects of

wind and seismic forces, where they are a factor, must be accounted for in the design of a weigh vessel. At a minimum,

consideration of these forces might affect the capacity of load cells

selected. In more extreme cases they may dictate the use of

additional restraints on a vessel. In general, weigh modules have a

lift-off capacity of 150% of capacity, and a side-load capacity of

100% of capacity.

1/4W + F0T. On the right-hand side load cell mounts, a force of F

is also induced as a result of F, however, this force is in the opposite

direction to the existing 1/4W and the total force here is reduced

to 1/4W - F0T. Hence, you will see that load is being transferred from

the mounts on one side of the vessel to those on the other. The load

cell capacity selected must be capable of withstanding this additional force for the extremes of wind or seismic forces expected. If

F was increased to where F

load on the right hand mounts and the load would have doubled to

W/2 on the left-hand mounts. Further increase in F will cause the

vessel to lift up on the right-hand mounts and may, in the extreme

case, cause the vessel to tip.

0T

equalled W/4 then there would be zero

0T

Figure 1-26

In general, these forces act horizontally at the center of gravity

(CG) of the weigh vessel. Figure 1-26 illustrates a four-legged

vertical cylindrical vessel and the forces acting on it in the absence

of wind or seismic forces. W is the vessel’s weight (an empty and full

vessel should be considered separately, as either one may be the

limiting case), and it acts through the vessel’s center of gravity.

Assuming that the four legs are arranged symmetrically, then each

leg will exert a force of 1/4W on each mount.

Figure 1-27 illustrates the same vessel with the addition of a

horizontal force F (the result of wind or seismic activity.) The

vessel exerts a horizontal force of 1/4 F on each load cell mount.

Also, there is an additional force of F0T acting on the left-hand side

load cell mounts, which means that each is now carrying a load of

1-24

The relationship between F0T and F may be stated as follows for the

vessel shown in Figure 1-27:

where h = height to the center of gravity and D = vessel diameter.

It is desirable to reduce F0T; this can be done as might be expected

by reducing F or h or by increasing D. Dimension h can be reduced

by reducing the vessel height (not always practical) or by placing

the mounts at the vessel’s center of gravity as illustrated earlier. In

this case h = 0 and hence F0T = 0.

Figure 1-27

F0T = .7Fh/D

Page 27

Wind and Seismic Effects

SYSTEM DESIGN

It is interesting to compare the stability of a vessel supported on 3

and 4 load cell mounts. Figure 1-28 shows a top view of a vertical

cylindrical vessel supported at 3 and 4 points (broken and solid

lines respectively). The vessel will tend to tip about a straight line

drawn between adjacent support points; the greater the distance

from the center of gravity to this line the more stable the vessel will

be. A vessel supported at 3 points will be approximately 29% less

stable than if it were supported at 4 points.

Wind Forces

Consideration must be given to the effects of wind loading when a

weigh vessel is installed outdoors. This is particularly important

for tall slender vessels, vessels installed in exposed locations (for

example, facing a large body of water), or those installed in a high

wind-speed location. In analyzing the effects of wind loading, it

must be assumed that the wind may blow at a vessel in any

horizontal direction.

Figure 1-29 illustrates the effect of wind blowing at a vertical

cylindrical vessel. Note that not only is there a force exerted against

the windward side of the vessel, but there is also a suction force on

the leeward side. These forces are additive, and tend to tip the vessel

in the direction of the wind. At right angles to the wind direction

are suction forces pulling on each side due to the increased speed

of the wind at these points. Since these are equal and opposite in

.25D

CG

.5D

.35D

direction, they have no net effect on the stability of the vessel.

D = Diameter

CG = Center of Gravity

= 3 point support

= 4 point support

Figure 1-28: Top view of cylindrical vessel

Because of the many variables in vessel design and site conditions,

it is impossible to deal comprehensively with the calculation of

wind and seismic forces in this text. However, the following

subsections deal with these forces in general terms and point out

the information necessary for a complete analysis. Refer to the

Uniform Building Code (UBC) for further details.

While the effects of both wind and seismic forces should be

considered, it is acceptable to consider these forces in isolation.

To perform a complete wind force analysis, the following

information is necessary:

■ Vessel: The vessel’s dead and live weights, number of supports,

and overall dimensions such as height, length of legs, diameter,

etc.

■ Minimum basic wind speed: This may be taken from Figure

1-30, which is a map of the USA superimposed with wind speed

contours. This map is based on a 50-year mean recurrence interval

which has traditionally been accepted as a reasonable risk. If local

records indicate higher 50-year wind speeds, then the higher

values should be used. This map does not consider the effects of

tornadoes.

WIND DIRECTION

Figure 1-29

1-25

Page 28

SYSTEM DESIGN

Wind and Seismic Effects

■ Exposure: The exposure conditions at the site must be known.

Built up or rough terrain can cause a substantial reduction in wind

speed. The United Building Code (UBC) defines 3 exposure categories:

Exposure B: has terrain with buildings, forest or surface irregularities 20 feet or more in height covering at least 20% of the area

extending one mile or more from the site.