Page 1

TSA

Truck Scale Weigh Module Kit

Installation

Guide

25709

Page 2

Contents

1. Introduction ........................................................................... 1

2. Mechanical Installation ......................................................... 2

2.1 General Installation Guidelines ..................................................2

2.2 Maintaining Scale Height and Center .........................................4

2.3 Mount and Load Procedures ......................................................4

2.31 Installing the Components ..............................................4

2.32 Leveling the Base and Securing the Girder Chair...........5

2.33 Re-leveling and Securing the Base.................................5

2.34 Replacing the Load Cell..................................................6

3. Load Cell Wiring.................................................................... 7

4. Junction Box Connections, Adjustments & Calibration.... 8

5. Troubleshooting .................................................................... 8

6. Maintenance and Replacement Parts................................ 10

6.1 Maintenance.............................................................................10

6.2 Replacement Parts...................................................................10

7. Appendix—Mount Dimensions .......................................... 11

8. Limited Warranty................................................................. 12

3/97

Page 3

1. Introduction

The TSA load cell mount is used for medium to heavy capacity truck, horizontal

vessel, and general purpose weighing applications. The mounts are constructed of

cast steel and iron, and are available in two sizes with capacities of 10,000 lb to

75,000 lb. In most applications, the need for safety check rods, expansion assemblies and other peripheral hardware is eliminated by the "Unilink" suspension

design and the load equalizer pad. These design elements provide self-checking and

improved weight distribution.

The TSA mounts use the Sensortronics 65058 double-ended shear beam load cell,

which is made of high alloy tool steel, environmentally protected, and rated for a

150% maximum overload.

1

Page 4

2. Mechanical Installation

2.1 General Installation Guidelines

• Install a system ground in the pit close to the junction box. Use at least 1/2” x

8’ copper clad ground rod. Hook the indicator, junction box, Scale deck I-beam,

load cell grounding straps, and lightning protection devices to the system

ground. Hook all other devices, such as the printer, to the same AC power

supply as the indicator.

• If the pit fills up with water, proper drainage must be provided so that the

weighing assembly is not standing in water. Also, drip loops should be

provided on any conduit or cables going to the junction box or load cell.

• If safety check rods are necessary, consult your supervising engineer for proper

placement and stability. If bumper bolts are necessary, install them between the

scale platform and the walls of the pit. Leave about 1/8" clearance or as

applicable.

• The mount must be positioned in the direction of

travel. Also the load on each mount assembly should

be equal to each other.

• The mounting surface for the base and loading plate

must be level and parallel so that side loads and

bending moments are minimized. The mount assemblies must be plumb and level within ±0.2°.

• Because the load cell could be damaged during installation, do not use

excessive force or slam parts on the load cell. Also, when any welding is

required on the mount, remove the load cell from the mount so it is not damaged

by welding currents or excessive heat.

Direction of Travel

2

Page 5

a

a

a

a

a

a

a

aa

a

aa

aaa

a

a

a

a

a

a

a

aa

a

a

aa

a

a

a

a

a

aa

aa

a

a

a

a

aa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aa

a

aa

a

a

a

a

a

aaa

a

aa

a

a

a

a

aa

a

a

a

a

a

a

a

a

a

a

a

a

a

aa

aa

a

a

aa

a

a

a

a

a

a

a

a

a

aa

a

a

aa

a

a

aaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aa

a

a

a

a

a

a

a

aa

a

a

a

a

a

a

a

a

a

aa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aa

a

a

aa

a

aa

a

a

a

a

a

a

a

a

aa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aa

a

aa

a

a

a

a

a

a

a

a

aa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aa

a

a

a

aa

a

a

a

aa

a

aaa

aa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaa

a

a

a

a

a

aa

a

a

a

a

a

a

a

a

a

a

a

a

aa

a

a

a

a

a

a

a

a

a

a

a

a

a

aa

a

a

a

a

a

a

aa

a

a

a

a

a

a

a

a

a

a

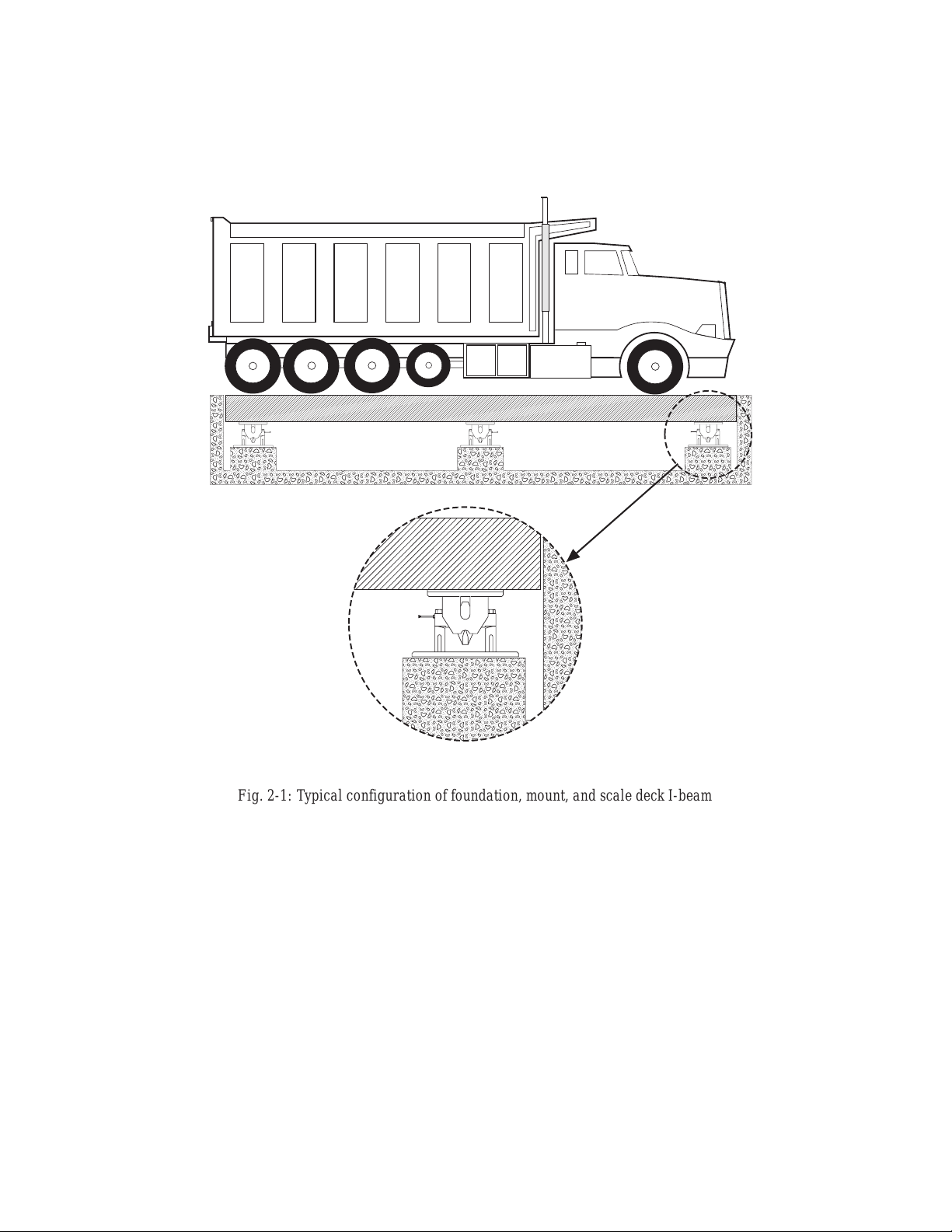

Fig. 2-1: Typical configuration of foundation, mount, and scale deck I-beam

3

Page 6

2.2 Maintaining Scale Height and Center

Whether you are replacing existing scales or installing new load cell mounts, you

will need to maintain the final height of your scale system.

1. On the concrete pier foundations, install blocking to hold up the scale deck

I-beam and platform to the required height for normal truck scale operation. Place wedges between the platform and the pit’s edges to center the

platform.

2. Remove the existing scales and/or install the new mounts one at a time to

continue to maintain the proper height. Installation procedures follow this

section.

2.3 Mount and Load Procedures

2.31 Installing the Components

Caution

!

When placing parts on the load cell, be careful not to drop or slam parts on the load

cell. Damage to the load cell will make the scale inoperable.

1. Start with a flat, rigid foundation

(concrete pier). Position the base

stand onto the foundation. Align

the base stand in the direction of

travel (Fig. 2.1, p. 3).

2. Place the load cell onto the two

stands of the base stand and screw

in the load cell mounting bolts (finger snug tight). The loose bolts

allow the TSA freer movement for

better weighing accuracy.

3. Place the load link on top of the

load cell, the girder chair on top of

the load link, and the rubber pad on

top of the girder chair. (In a multiple cell (more than 4) application,

do something different with the

rubber pads.)

4. Adjust the load link so it is vertical

and centered side to side (in a balanced condition). If the load link is

not vertical and centered side to

side, adjust the base stand.

Rubber

Pad

Girder Chair

Load Link

Load Cell

Base Stand

Fig. 2-2: Component assembly

4

Page 7

2.32 Leveling the Base and Securing the Girder Chair

Leveling is the single most important part of the installation for achieving highaccuracy weighing.

1. Check to see whether the girder chair is centered longitudinally with the

scale deck I-beam, and adjust the mount if necessary. Place shims between

the top of the girder chair and the bottom of the scale deck I-beam, because

the scale deck I-beam is never even. The shims should cover the entire

surface to prevent bending.

2. Using a high-quality bubble level, level the base stand within 0.2° of

horizontal to achieve a scale accuracy of 0.1% or better. The base stand

should be parallel with the girder chair, and the link plumb.

3. Mark the girder chair hole locations on the scale deck I-beam (see

appendix).

Note:

The smaller capacity mount only has four girder chair bolts.

4. Remove the load cell mount while noting the placement and height of the

shims.

5. Use a cutting torch to drill the holes into the scale deck I-beam.

6. Replace the mount and the shims. Bolt the girder chair to the scale deck I-

beam. The TSA will adjust slightly with the I-beam when the bolts are

loosely fitted. If needed, use jam nuts to lock the girder chair bolts in place.

Girder chair bolts are not supplied.

2.33 Re-leveling and Securing the Base

1. Re-level the mount. If necessary, move the base stand around. A perfectly

level system will minimize side loads and bending moments.

2. Remove the blocking for the particular mount, so that the platform and

scale deck I-beam are resting solely on the mount. Re-level the base stand

as necessary.

3. Install all the other mounts in the system in the above manner before

bolting the base stands. After all the mounts are in place, remove all other

blocking, and remove the platform wedges making sure the platform is still

centered in the pit. If not, then re-wedge and adjust the mounts as

necessary. When you are sure that the platform is at the final height and has

the proper clearance, then proceed to anchor the base stands.

4. Drill holes in the concrete foundation. Use concrete stud anchors or

equivalent to bolt the base to the foundation (see appendix). Make a final

check to see that everything is in place and level.

5

Page 8

2.34 Replacing the Load Cell

1. Jack up the girder chair assembly and scale deck I-beam away from the

load cell.

2. Unscrew the load cell mounting bolts, remove the load cell, insert the new

load cell, and tighten (finger snug tight) the load cell mounting bolts.

3. Lower the girder chair assembly and scale deck I-beam GENTLY onto the

load cell.

6

Page 9

3. Load Cell Wiring

a

a

a

aa

a

aa

1. Route the load cell cables so they will not be damaged or cut. Cable should not

be routed near heat sources greater than 400° F. Do not shorten any load cell

cable. The load cell is temperature compensated with the supplied length of

cable. Cutting the cable will affect temperature compensation. Coil and protect

excess cable so it will not be mechanically damaged or be sitting in water.

2. Provide a drip loop in all cables so that water or other liquids will not run

directly down the cables onto either the load cells or the junction box.

3. If conduit protection is necessary against mechanical or rodent damage to the

load cell cables, use flexible conduit and conduit adapters at the load cells.

4. Connect cables for standard RL75060 or Sensortronics 65103 cells to the

summing board in the junction box according to the guide shown below and the

labels on the terminal strips of the junction box. To verify the wiring scheme,

see the certification shipped with each load cell.

5. For better performance, use positive and negative remote sense lines if the

wiring running from the junction box to the indicator is longer than 25 feet.

Drip Loop

LOAD CELL WIRE COLOR

Black

Green +SIG

White - SIG

Figure 3-1: Load Cell Wiring

7

FUNCTION

+EXCRed

- EXC

SHIELDGray or Bare

Page 10

4. Junction Box Connections, Adjustments & Calibration

1. Refer to the Junction Box manual for trimming details.

2. Refer to the indicator manual or the “Technical Information” section in the Rice

Lake Weighing Systems’ Load Cell Product Selection Guide for system

calibration details.

5. Troubleshooting

If the system powers up and gives some type of stable digital readout that varies

with the load on the system, any system problems are probably caused by factors

other than the load cells. The load cells are often blamed for a malfunctioning

system, but the majority of the time, the problem lies elsewhere. Look for

mechanical causes for your problem first.

If the system can be calibrated but doesn’t return to zero, loses calibration, or

demonstrates non-linearity or non-repeatability, see the following chart for possible causes and do the following checks.

Symptom

No return to zero

Non-linearity

Non-repeatability

Lost calibration Out of level or plumb; moisture problem; mechanical binding

Drifting readout Moisture in junction box, cables, or load cell; mechanical binding

Possible Cause

Mechanical binding or debris in seals or under load cells; may have lost system

calibration

Thermal expansion or deflection under load causing binding or side load

Loose load cell mount; drifting caused by moisture, load cell overload or shock

damage; mechanical binding

1. Check load cell mount for debris restricting load cell movement or debris

between scale and structure.

2. Check that tank/vessel and mounts are plumb, level, and square at the

critical areas.

3. Check all piping and conduit for connections which restrict vessel

movement.

4. If check rods are used, loosen all connections to finger tight only for

testing.

5. Check load cell cables for physical or water damage.

6. Check all electrical connections, especially in the junction box.

8

Page 11

If the problem still is not found:

7. Check possible indicator malfunction by using a load cell simulator to

input a known good signal into the indicator.

8. Disconnect each load cell’s signal leads at the junction box and check

individual load cell outputs with a multimeter. Then check input/output

impedances for comparison with load cell manufacturer’s specifications.

If after all these checks the problem still cannot be isolated, reconnect all but one

load cell. Replace the load cell with a load cell simulator. Alternate so that each load

cell is individually disconnected and replaced with a simulator. If there is a problem

with a particular load cell, the symptom should disappear when that load cell is

disconnected and replaced with the simulator.

9

Page 12

6. Maintenance and Replacement Parts

6.1 Maintenance

1. The TSA Truck Scale Assembly can be wiped clean with a cloth to keep the

parts moving freely. Inspect the mount routinely for damage, excessive wear

and corrosion. Replace parts whenever necessary.

2. Use a heavy grease on the three pivot points of the load link.

6.2 Replacement Parts

Rubber Pad

Girder Chair

Load Cell

Load Link

Base Stand

Description Qty 25,000lb 75,000lb

TSA Load cell mount (whole unit) ...................... 17821................ 17822

Rubber Pad..............................................1 ........ 21705 ................ 21706

Base Stand ..............................................1 ........ 18471 ................ 18472

Girder Chair .............................................1 ........ 18475 ................ 18476

Load Link .................................................1 ........ 18473................ 18474

Double-Ended Shear Beam Load Cell ....1 ........ (See Load Cell Selection Guide)

10

Part Numbers

Page 13

7. Appendix—Mount Dimensions

L

L1

L2 (TYP)

W

W1

L5 (TYP)

L3 (2)

T (8) THRU

C (2)

L4

H3

RATED DIMENSIONS-INCHES

CAPACITY

C L L1 L2 L3 L4 L5

10,000lb

20,000lb

25,000lb

50,000lb

60,000lb

1.75 DIA. 14.00 11.00 3.00 .88 6.00 ---

2.00 DIA. 18.00 14.00 3.00 .88 12.75 2.00

75,000lb

RATED DIMENSIONS-INCHES

CAPACITY

HH1H2H3H4 T WW1

10,000lb

20,000lb

25,000lb

50,000lb

60,000lb

8.75 .62 4.62 .62 .25 5/8-11UNC-2B 6.00 3.00

11.00 .75 5.44 .75 .50 3/4-10UNC-2B 7.00 3.50

75,000lb

H4

H2 (REF)

H1

H

11

Page 14

8. TSA Limited Warranty

Rice Lake Weighing Systems (RLWS) warrants that all RLWS brand load cells

properly installed by a Distributor or Original Equipment Manufacturer (OEM) will

operate per written specifications. All load cell products are warranted against

defects in materials and workmanship for two (2) years. Products marked as

“waterproof” are warranted against defects in materials and workmanship relating

to moisture ingress.

RLWS warrants that the equipment sold hereunder will conform to the current

written specifications authorized by RLWS. RLWS warrants the equipment against

faulty workmanship and defective materials. If any equipment fails to conform to

these warranties, RLWS will, at its option, repair or replace such goods returned

within the warranty period subject to the following conditions:

1. Upon discovery by Buyer of such nonconformity, RLWS will be given prompt

written notice with a detailed explanation of the alleged deficiencies.

2. Examination of such equipment by RLWS confirms that the nonconformity

actually exists, and was not caused by accident, misuse, neglect, alteration,

improper installation, improper repair or improper testing; RLWS shall be the

sole judge of all alleged non-conformities.

3. Such equipment has not been modified, altered, or changed by any person

other than RLWS or its duly authorized repair agents.

4. RLWS will have a reasonable time to repair or replace the defective equip-

ment. Buyer is responsible for shipping charges both ways.

5. In no event will RLWS be responsible for travel time or on-location repairs,

including assembly or disassembly of equipment, nor will RLWS be liable for

the cost of any repairs made by others.

THESE WARRANTIES EXCLUDE ALL OTHER WARRANTIES, EXPRESSED

OR IMPLIED, INCLUDING WITHOUT LIMITATION WARRANTIES OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. NEITHER RLWS NOR DISTRIBUTOR WILL, IN ANY EVENT, BE LIABLE FOR

INCIDENTAL OR CONSEQUENTIAL DAMAGES.

RLWS AND BUYER AGREE THAT RLWS’S SOLE AND EXCLUSIVE LIABILITY HEREUNDER IS LIMITED TO REPAIR OR REPLACEMENT OF

SUCH GOODS. IN ACCEPTING THIS WARRANTY, THE BUYER WAIVES

ANY AND ALL OTHER CLAIMS TO WARRANTY.

SHOULD THE SELLER BE OTHER THAN RLWS, THE BUYER AGREES TO

LOOK ONLY TO THE SELLER FOR WARRANTY CLAIMS.

No terms, conditions, understanding, or agreements purporting to modify the terms of

this warranty shall have any legal effect unless made in writing and signed by a corporate

officer of RLWS and the Buyer.

©1997 Rice Lake Weighing Systems, Inc. Rice Lake, WI USA. All Rights Reserved.

RICE LAKE WEIGHING SYSTEMS

230 WEST COLEMAN STREET

• RICE LAKE, WISCONSIN 54868 • USA

12

Loading...

Loading...