Page 1

Translink

W eigh Module

Installation

Guide

™

25708

1

Page 2

Contents

1. Introduction ............................................................................. 1

2. Mechanical Installation............................................................ 2

2.1 General Installation Guidelines for Translink ................................2

2.2 Maintaining Scale Height and Center ........................................... 3

2.3 Mount and Load Cell Installation Procedures ...............................3

2.3.1 Assembling and Installing the Components ............................3

2.3.2 Leveling the Mount and Securing the Girder Chair .................4

2.3.3 Re-leveling, Securing, and Grouting the Base........................4

3. Load Cell Wiring...................................................................... 5

4. Adjustments and Calibration ................................................... 6

5. Troubleshooting....................................................................... 6

6. Maintenance and Replacement Parts ..................................... 7

6.1 Replacing a Load Cell...................................................................7

6.2 Replacement Parts ....................................................................... 7

8. Appendix ................................................................................. 8

9. Translink Limited Warranty...................................................... 9

Copyright © 1999 Rice Lake Weighing Systems. All rights reserved.

Printed in the United States of America.

Specifications subject to change without notice.

2/99

Page 3

1. Introduction

In this Translink™ manual, you will find a step-by-step approach to installing the

load cell mount in an easy, logical manner. You'll find complete information from

assembling and installing the components to testing the scale for weighing accuracy. Troubleshooting and replacement parts sections are also included in this

manual.

The Translink load cell mount is used for heavy capacity tank and truck weighing

applications. The mount is made of fabricated and hardened tool steel in capacities

of 25,000 lb to 100,000 lb. The pendulous action of the links allows self-centering

of the weighing platform, and the platform has free movement in all directions in

the horizontal plane. Install platform bumpers to prevent overtravel.

The mount is compatible with four different tool steel, double-ended shear beam

load cells. The RL75040A and the Sensortronics 65040A load cells are environmentally protected styles, whereas the RL75223, RTI 5223, and Sensortronics

65040S load cells are hermetically sealed styles.

The installation should be planned by a qualified structural engineer. Each installation is unique, and this manual is meant to serve only as a general guideline for

installation.

Authorized distributors and their employees can view or

download this manual from the Rice Lake Weighing

Systems distributor site at www.rlws.com.

3

Page 4

2. Mechanical Installation

a

a

a

a

a

a

a

aa

a

aa

aaa

a

a

a

a

a

a

a

aa

a

a

aa

a

a

a

a

a

aa

aa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aa

a

a

aa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aa

aaa

a

a

a

a

aaa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aaa

a

2.1 General Installation Guidelines for Translink

1. Unless a good ground is already provided, install a system ground in the pit in

close proximity to the junction box. Use at least 1/2" x 8' copper-clad ground

rod. The indicator, junction box, weighbridge, and lightening protection

devices will be hooked to the system ground. Hook all other devices, such as

the printer, to the same AC power supply and ground as the indicator.

2. If the pit fills with water, proper drainage must be provided so that the load cell

mounts are not standing in water. Also, drainage loops should be provided on

any conduit or cables going to the junction box or load cells.

3. Install bumper bolts between the scale platform and the walls of the pit. Leave

about 1/8" clearance or as applicable for

temperature changes.

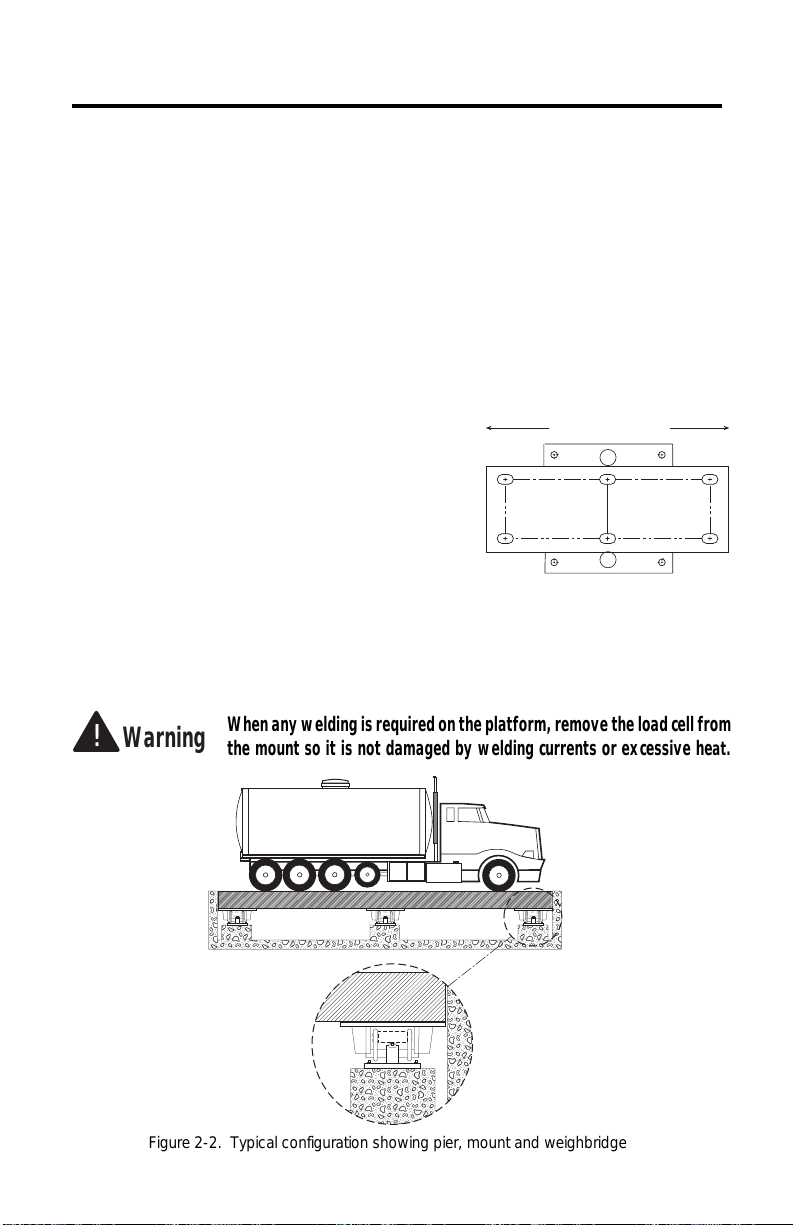

4. The mount must be positioned in the

direction of travel (Fig. 2-1).

5. The mounting surface for the base plate

and girder chair must be level and parallel

so that side loads and bending moments

are minimized. The mount assemblies

must be plumb and level within ±0.5°.

6. Because the load cell could be damaged during installation, do not use

excessive force or slam parts on the load cell.

Figure 2-1. Direction of travel (top view)

Direction of Travel

!

Warning

Figure 2-2. Typical configuration showing pier, mount and weighbridge

When any welding is required on the platform, remove the load cell from

the mount so it is not damaged by welding currents or excessive heat.

4

Page 5

2.2 Maintaining Scale Height and Center

Whether you are replacing an existing scale or installing all new load cell mounts,

you will need to maintain the required final height of your scale system.

• Build up the piers to ensure a minimum of 1/2" gap between each pier and base

plate for the final grout. See Appendix on page 8, for load cell mount height.

• Install cribbing to hold up the girder and platform to the required height for

normal truck scale operation. Make sure the cribbing is safe, before removing

any existing levers or mounts. Place wedges between the platform and the pit's

edges to center the platform in the pit.

• Remove the existing levers or mounts and install the new mounts one at a time

to continue to maintain the proper height. Remove all old scale parts from the

pit as soon as possible to prevent stumbling over them. Installation procedures

follow this section.

2.3 Mount and Load Cell Installation Procedures

2.3.1 Assembling and Installing the Components

Wherever the components come in contact with each other, such as the links with

the pin, pack well with grease.

When placing parts on the load cell, do not drop or slam parts on the load cell. This

sudden force could damage your load cell.

Caution

Do not weld on the girder or platform after the load cell

mounts have been installed.

1. If there is sufficient clearance between the pier and the underside of the

platform, place the base place on the pier in approximately its final position.

Otherwise, assemble the mount on the edge of the pier (away from the main

girder) and then slide it into the final position after assembly.

2. Screw the leveling bolts into the base plate until flush with the bottom of the

base. Place the bearing pad on the stand of

the base plate. Insert the two tension pins

Girder Chair

into the top of the stand. Position the load

cell on the bearing pad.

Load Cell

Bearing Pad

Base Plate

with

Leveling Bolts

Figure 2-3. Base Plate, Bearing Pad,

and Load Cell Assembly

Load cell models RL75040A and Sensortronics 65040A are shown. Load cell models

RL75223 and RTI5223 are slightly different.

Tension Pin

Figure 2-4. Links, Pin, Tension Pin, and

5

NOTE: Size

Markers Must

Face Outward

Two Links

Girder Chair Assembly

Pin

Page 6

3. Attach the two links to each end of the load cell so the raised lettering (size) on

each link is facing away from the load cell to avoid any interference. Slide the

pin in through the hole of the stand. Position the links on each end of the pin.

Place the girder chair on the ends of the pin (Fig. 2-4 on page 3).

4. Slide the load cell mount into place on the pier under the main girder. Align the

load cell mount in the direction of travel. (Fig. 2-1on page 2).

2.3.2 Leveling the Mount and Securing the Girder Chair

Leveling is the single most important part of the installation for acheiving highaccuracy weighing.

1. Adjust the leveling bolts equally to bring the top of the girder chair flush with

the bottom of the girder. Check to see whether the load cell mount is centered

under the girder, and adjust the mount if neccessary.

2. Mark the girder chair hold locations on the girder. See Appendix on page 8, for

girder chair mounting hole dimensions. Remove the load cell mount.

3. Use a cutting torch to make the holds in the girder. Be careful not to weaken the

structure unduly by making the holes too large.

4. Replace the mount, and bolt the girder chair to the girder (finger tight). Girder

chair bolts are not supplied. Recommended girder chair bolt size: 3/4", grade

5 or better.

5. Place shims, if necessary, between the top of the girder chair and the bottom of

the girder to level the girder chair within 0.5 degree of horizontal. Using a highquality bubble level (preferably a machinist's level), level the girder chair in

both directions (front to back and left to right). The shims should be as large as

possible to distribute the load. If necessary, adjust the leveling bolts to insert

the shims.

6. Level the base plate within 0.5 degree of horizontal to achieve a scale accuracy

of 0.1% or better. Level the base plate in both directions (front to back and right

to left). The base plate should be parallel with the girder chair, and the links

should be plumb.

2.3.3 Re-leveling, Securing, and Grouting the Base

1. Remove the cribbing for the particular mount and lower the platform gently so

it is resting soley on the mount. Again, adjust the leveling bolts if the deck is

not quite level with the top of the pit.

2. Re-level the mount and ensure that the links are hanging plumb. A perfectly

level system will minimize side load and bending moments.

3. Install all the other mounts in the system in the above manner before bolting and

grouting the base plates. After all the mounts are in place, remove all other

cribbing, and remove the platform wedges making sure it is still centered in the

pit. If not, then re-wedge and adjust the mounts as necessary. When you are sure

that the platform is at the final height and has the proper clearance, anchor the

base plates.

6

Page 7

4. Drill holes in the concrete pier maintaining the height of the leveling bolts. See

a

a

a

a

a

a

a

aa

a

aa

aaa

a

a

a

a

a

a

a

aa

a

a

aa

a

a

a

a

a

aa

aa

a

a

a

a

aa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

aa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

Appendix on page 8, for base plate mounting hole locations. Use concrete stud

anchors or equivalent to secure the base plate. Use no less than a 7/8"x 7" anchor

bolt. Drive each anchor bolt, with the nut and washer on, to firmly set the anchor

in place. Tighten the nuts (finger tight).

5. Make a final check to see that the girder chairs and base plates are level, the

platform is at the final height, and proper clearance has been maintained.

6. After building a structure around the base plates to contain the grout, pour the

liquid ground under the base plates. Use good-quality, non-shrinking grout.

Push under the base plate to remove any air pockets.

7. After the grout has hardend (time specified by grout supplier), tighten all girder

chair bolts and base plate anchors. Back the four leveling bolts out of the grout.

Attach a grounding strap from the girder chair to the base plate. While you are

waiting for the grout to harden, you can start hooking up the electrical

connections (see Section 3, below).

3. Load Cell Wiring

1. Route the load cell cables so they will not be damaged or cut. Cable should not

be routed near heat sources greater than

150°F. Do not shorten any load cell cable.

The load cell is temperature complensated

with the supplied length of cable. Cutting

the cable will affect temperature compensation. Coil and protect excess cable so it

will not be mechanically damaged or be

sitting in water. It is highly recommended

protecting the cables in steel conduit.

2. Provide a drip loop in all cables so that water or other liquids will not run

directly down the cables onto either the load cells or the junction box. Attach

load cell cable to the dead structure, not the vessel.

3. For better performance, use positive and negative remote sense lines if the

wiring running from the junction box to the indicator is longer than 25 feet.

4. Connect cables for load cells to the summing board in the junction box

according to the guide shown below and the labels on the terminal strips of the

junction box. To verify the wiring scheme, see the certification shipped with

each load cell.

Figure 3-1. Drip loop cabling

Junction

Box

sroloCeriWlleCdaoLsroloCeriWlleCdaoL

sroloCeriWlleCdaoLsroloCeriWlleCdaoL

sroloCeriWlleCdaoL

roloCeriW

deRCXE+CXE+

kcalBCXE–CXE–

neerGGIS+GIS–

etihWGIS–GIS+

eraBroyarGDLEIHSDLEIHS

7

noitcnuF

gnidaeRevitageN gnidaeRevitisoP

Page 8

4. Adjustments and Calibration

Note: Proceed with the adjustments and calibration only after the grout under the

base plates is completely hardened and all mounts are firmly bolted in place.

1. Your local Weights and Measures regulations will dictate the type of test required, such as section test, corner test,

build up, etc.

2. Adjust the junction box potentiometers

so that a weight placed anywhere on the

platform gives the same reading at each

load cell. For more detailed instructions

refer to the instructions sent with the

junction box.

Figure 4-1. Summing board and potentiometers

3. Watch for any unusual readings, which might indicate problems in the

installation. Remember, on any adjustment that you make, you should be able

to predict the outcome.

4. After you install the bumper bolts, re-test the scale to see that it is weighing

properly. If the scale changes calibration, you know the problem is from the

bumper bolts, and not from the load cell mounting installation.

Refer to the digital indicator installation manual for specific calibration procedures

to use with the particular indicator.

+EX

–EX

SHD

SHD

–EX

+EX

+SI

–SI

–SI

+SI

CELL 1

CELL 4

Potentiometers

100 K

JU1

INDICATOR

SHD

–SI

+SI

–SE

–EX

JU4

+SE

+EX

100 K

23126

Rev. A

100 K

100 K

+EX

CELL 2

–EX

JU2

+SI

–SI

SHD

SHD

–SI

+SI

JU3

–EX

+EX

CELL 3

5. Troubleshooting

1. If the system powers up and gives some sort of stable digital readout that varies

with the load on the system, any system problems are probably caused by

factors other than the load cells. The load cells are often blamed for a

malfunctioning system, but 90% of the time, the problem lies elsewhere. Look

for mechanical causes for your problem first.

2. If the system can be calibrated but doesn't return to zero, loses calibration, or

demonstrates non-linearity or non-repeatability, see the following chart for

possible causes and do the following checks.

motpmySmotpmyS

motpmySmotpmyS esuaCelbissoPesuaCelbissoP

motpmyS

orezotnruteroN

ytiraenil-noN daoledisrognidnibgnisuacdaolrednunoitcelfedronoisnapxelamrehT

ytilibataeper-noN

noitarbilactsoL gnidniblacinahcem;melborperutsiom;bmulprolevelfotuO

tuodaergnitfirD gnidniblacinahcem;llecdaolro,selbac,xobnoitcnujnierutsioM

noitarbilac

esuaCelbissoPesuaCelbissoP

esuaCelbissoP

metsystsolevahyam;sllecdaolrednuroslaesnisirbedrognidniblacinahceM

gnidniblacinahcem;egamad

kcohsrodaolrevollecdaol,erutsiomybdesuacgnitfird;tnuomllecdaolesooL

8

Page 9

6. Maintenance and Replacement Parts

6.1 Replacing a Load Cell

1. Jack up the girder chair and weighbridge away from the pin in the load cell

assembly. Jack it high enough only to remove the pin.

2. Remove the pin from the links and pull it through the hold on the stand. Remove

the links from the load cell, and remove the load cell.

3. Position the new load cell on the bearing pad. Attach the two links to each end

of the load cell. Slide the pin in through the hold of the stand. Position the links

on each end of the pin.

4. Lower the girder chair and weighbridge Gently onto the pin so the load cell is

not damaged by excessive shock.

5. Check if the load cell mounts are level (see Section 2.33 Re-leveling, Securing,

and Grouting the Base, on page 4).

6. Test the scale, and recalibrate if necessary.

6.2 Replacement Parts

Tension Pin

Pin

Base Plate

Leveling Bolt

Girder Chair

Load Cell

Link

Bearing Pad

Description Qty A* B* C*

TranslinkTM Mount (excluding load cell).....................17970.........17971.........17972

Tension Pin..................................................2..........15302........15300.........15300

Base Plate...................................................1 ........ 18458.........18455 ........18458

Leveling Screw.............................................4.........H702-1........H702-1......H702-1

Pin...............................................................1.........18470.........18468.........18469

Bearing Pad.................................................1.........18452.........18453.........18453

Link, Weldless End.......................................2.........17809.........17810.........17809

Girder Chair.................................................1..........18465.........18467 ........18466

Double-Ended Shear Beam Load Cell .........1..........(see Load Cell Product Selection

Guide for load cell part numbers).

*A – mount compatible with load cells RL75223/5223 in capacities of 50,000,

65,000 and 100,000 lb each.

*B – mount compatible with load cells RL75040A/65040A in capacities of

25,000 and 40,000 lb each.

*C – mount capatible with load cells RL75040A/65040A in capacities of 50,000,

60,000 and 75,000 lb each.

9

Page 10

8. Appendix

W2

W

L

W3

L3

L3

W1

H1

H

H2

L2

L1

C

W4

L5

L4

detaR

C H 1H 2H L 1L 2L 3L 4L 5L W 1W 2W 3W 4W 5W

.paC

A*05.139.2100.100.105.2205.157.105.957.1188.557.719.52.552.152.957.11

B*05.188.900.100.105.8105.157.105.757.1188.557.719.52.552.152.957.11

C*05.128.2100.100.105.2205.157.105.957.1188.557.719.52.552.152.957.11

W5

SEHCNI-SNOISNEMID

*A – mount for load cells RL75223/5223 in capacities of 50,000 to 100,000 lb.

*B – mount for load cells RL75040A/65040A in capacities of 25,000 to 40,000 lb.

*C – mount for load cells RL75040A/65040A in capacities of 50,000 to 75,000 lb.

10

Page 11

9. Translink Limited Warranty

Rice Lake Weighing Systems (RLWS) warrants that all RLWS brand load cells properly

installed by a Distributor or Original Equipment Manufacturer (OEM) will operate per

written specifications. All load cell products are warranted against defects in materials and

workmanship for two (2) years. Products marked as “waterproof” are warranted against

defects in materials and workmanship relating to moisture ingress.

RLWS warrants that the equipment sold hereunder will conform to the current written

specifications authorized by RLWS. RLWS warrants the equipment against faulty workmanship and defective materials. If any equipment fails to conform to these warranties, RLWS

will, at its option, repair or replace such goods returned within the warranty period subject to

the following conditions:

• Upon discovery by Buyer of such non-conformity, RLWS will be given prompt written

notice with a detailed explanation of the alleged deficiencies.

• Examination of such equipment by RLWS confirms that the non-conformity actually

exists, and was not caused by accident, misuse, neglect, alteration, improper installation,

improper repair or improper testing; RLWS shall be the sole judge of all alleged nonconformities.

• Such equipment has not been modified, altered, or changed by any person other than

RLWS or its duly authorized repair agents.

• RLWS will have a reasonable time to repair or replace the defective equipment. Buyer

is responsible for shipping charges both ways.

• In no event will RLWS be responsible for travel time or on-location repairs, including

assembly or disassembly of equipment, nor will RLWS be liable for the cost of any

repairs made by others.

THESE WARRANTIES EXCLUDE ALL OTHER WARRANTIES, EXPRESSED OR

IMPLIED, INCLUDING WITHOUT LIMITATION WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. NEITHER RLWS NOR

DISTRIBUTOR WILL, IN ANY EVENT, BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES.

RLWS AND BUYER AGREE THAT RLWS’S SOLE AND EXCLUSIVE LIABILITY

HEREUNDER IS LIMITED TO REPAIR OR REPLACEMENT OF SUCH GOODS. IN

ACCEPTING THIS WARRANTY, THE BUYER WAIVES ANY AND ALL OTHER

CLAIMS TO WARRANTY.

SHOULD THE SELLER BE OTHER THAN RLWS, THE BUYER AGREES TO LOOK

ONLY TO THE SELLER FOR WARRANTY CLAIMS.

No terms, conditions, understanding, or agreements purporting to modify the terms of this

warranty shall have any legal effect unless made in writing and signed by a corporate officer

of RLWS and the Buyer.

© 1999 Rice Lake Weighing Systems, Inc. Rice Lake, WI USA. All Rights Reserved.

RICE LAKE WEIGHING SYSTEMS • 230 WEST COLEMAN STREET

RICE LAKE, WISCONSIN 54868 • USA

11

Loading...

Loading...