Page 1

Page 2

Page 3

Table of Contents

1 INTRODUCTION ............................................................................................ 1

2 DEVICE CONFIGURATIONS ....................................................................... 1

2.1 M2000 DESKTOP .................................................................................................. 1

2.2 M2000 SLIMLINE ................................................................................................... 2

2.3 M2000 NEMA ...................................................................................................... 2

2.4 ON-BOARD WEIGH CENTER .............................................................................. 3

2.5 ON-BOARD COMPACT WEIGH CENTER .......................................................... 4

3 GENERAL OPERATION ................................................................................ 6

3.1 KEYPAD FUNCTIONS KEYS .................................................................................. 6

3.1.1 On/Off Key ............................................................................................................... 6

3.1.2 ZERO Key ................................................................................................................. 7

3.1.3 TARE Key .................................................................................................................. 7

3.1.4 CLEAR Key ................................................................................................................ 7

3.1.5 PRINT SELECT Key ............................................................................................... 7

3.2 SPECIAL KEYPAD FUNCTIONS ............................................................................. 8

3.2.1 Selecting scale channels ....................................................................................... 8

3.2.2 Summing channels in TOTAL mode ................................................................. 8

3.2.3 Scan mode ................................................................................................................ 9

3.2.4 Gross/Net .................................................................................................................. 9

3.2.5 Pound/Kilograms selection ................................................................................... 9

3.2.6 TEST display............................................................................................................. 9

4 APPLICATION PARAMETER SETTINGS ................................................ 10

4.1 ON-BOARD SCALE SETTINGS ........................................................................... 10

4.2 MULTIPLE ANIMAL SCALE SETTINGS ................................................................. 12

5 CALIBRATION AND SEALING .................................................................. 13

5.1 PLACING THE INDICATOR INTO CALIBRATION MODE .................................. 13

5.1.1 Special Keypad function keys during calibration ........................................ 13

5.1.1.1 Selecting a calibration parameter. ........................................... 13

5.1.1.2 Editing a calibration parameter. ............................................... 13

5.1.1.3 Canceling a calibration parameter. ......................................... 14

5.1.1.4 Toggle between weight and AD counts. ............................... 14

5.1.1.5 Exiting Calibration Mode........................................................... 14

5.2 CALIBRATING WITH WEIGHTS.......................................................................... 15

5.2.1 Set the Scale Parameters ................................................................................... 15

5.2.2 Balance the Scale ................................................................................................. 15

5.2.3 Deadloading the Scale (scale zero) ................................................................ 21

5.2.4 Spanning the indicator ........................................................................................ 21

5.3 SEALING THE INDICATOR ................................................................................... 21

5.3.1 Electronic Seal ....................................................................................................... 21

5.3.2 Audit Trail ............................................................................................................... 21

5.3.3 Accessing the Audit Trail .................................................................................... 22

6 WEIGH CENTER CIRCUIT BOARD .......................................................... 23

6.1 SETTING TIME AND DATE .................................................................................. 26

6.2 SETTING UNITS ................................................................................................... 27

Page 4

1

6.3 SETTING SYSTEM ID NUMBER .................................................................. 27

Copyright © 2011 Rice Lake Weighing Systems. All rights reserved.

Printed in the United States of America.

Specifications subject to change without notice.

November 2011

6.4 STANDARD DIP SWITCH SETTINGS ................................................................. 28

7 PRINTERS ....................................................................................................... 29

7.1 TICKET PRINTER .................................................................................................. 29

7.2 ROLL PRINTER ..................................................................................................... 30

8 M2000 INDICATOR PARAMETER LIST .................................................... 31

8.1 CAL INITIALIZATION PARAMETERS ........................................................... 31

8.2 SCALE SETUP PARAMETERS ............................................................................ 31

8.3 SCALE MOTION PARAMETERS ........................................................................ 32

8.4 SCALE ZERO PARAMETERS ............................................................................... 32

8.5 PARAMETERS RELATED TO SCALE CALIBRATION ..................................... 33

8.6 INDICATOR POWER UP PARAMETERS ...................................................... 34

8.7 SCALE TARE PARAMETERS ................................................................................ 35

8.8 SYSTEM SETTINGS PARAMETERS .................................................................. 35

8.9 SERIAL COMMUNICATIONS PARAMETERS .............................................. 36

8.10 SCALE FILTERING PARAMETERS ......................................................................... 38

8.11 PRINTING PARAMETERS .................................................................................. 39

M2000 INDICATOR LIMITED WARRANTY .................................................... 43

FOR MORE INFORMATION ............................................................................... 44

Web Site ............................................................................................................. 44

Contact Information ........................................................................................ 44

Page 5

1

1 Introduction

This manual covers the complete line of the scale instrumentation based on the

M2000 digital indicator, formally manufactured by Norac Systems International.

The list of instrument configurations, along with their part numbers that are

covered by this technical manual are shown in section 2.

Please take the time to read this manual completely through before contacting

Rice Lake Weighing Systems for further technical assistance. If you have any

questions or comments please contact Rice Lake Weighing Systems:

Phone (toll free): 1-800-472-6703

2 Device Configurations

To identify the device you are dealing with, look for a part number on the

unit’s serial plate. The pictures in this section will help identify the various

devices.

2.1 M2000 Desktop

Part Number: 82-M2000A-DT

Page 6

2

2.2 M2000 Slimline

Part Number: 82-M2000A-SL

Note – this part is used in the On-Board Weigh Center (see section 2.4).

2.3 M2000 NEMA

Part Number: 82-M2000A-NEMA

Page 7

3

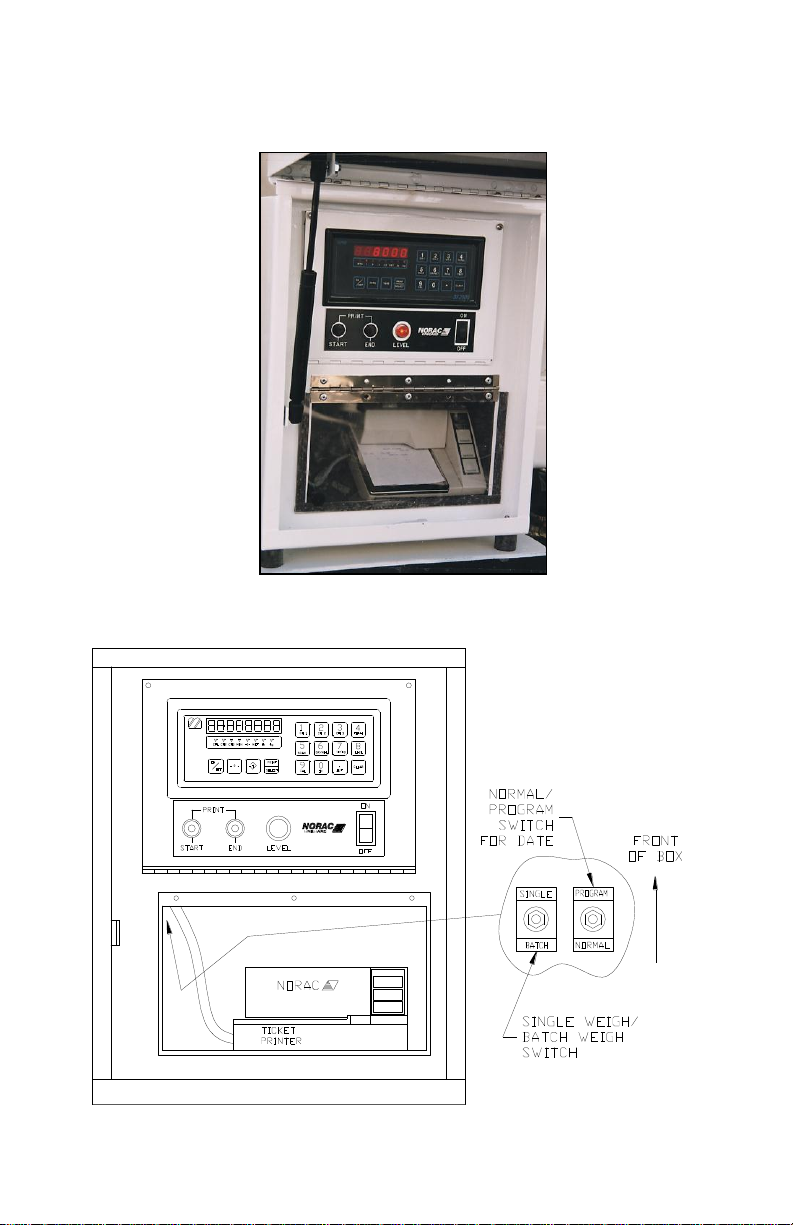

2.4 On-Board Weigh Center

2000

Part Number: 42300, 42300M

Indicator, On-Board Circuit Board and Printer are all housed in the Weigh

Center.

Page 8

4

2.5 On-Board Compact Weigh Center

Part Number: 42301

Cab Mounted Indicator Housing

Level Switch and Load Cell Sum Box (Scale Frame Mounted)

Page 9

5

M2000 Instrument Specifications

Power requirements: 12VDC 1A.

Temperature range: 14°F to 104°F (-10°C to +40°C).

Full scale input signal: 4 ranges: 0-9mV, 0-19mV, 0-39mV and 0-79mV.

Excitation voltage: 7.5VDC, 16x350 Ohm and 32x700 Ohm for all 3 channels combined.

Sense amplifier: Differential amplifier with 4 and 6 wire.

A/D internal resolution: 520,000 counts in both positive and negative direction.

A/D Sampling rate: 100 times a second on each channel.

Span stability: 2ppm/°C.

Zero stability: 5nV/°C.

Linearity correction: 10 span entries.

Calibration method: Calibration through software stored to flash memory.

Calibration sealing: Physical seal or class 1 audit trail system, password protected.

RFI protection: Filtered signal, excitation and sense lines.

Analog output: Optional 4-20mA board via SMART WIRE.

Serial communications: 2 full-duplex RS232/RS422 ports.

I/O interface: Peripheral expansion through SMART WIRE multi drop RS485 port.

External I/O: Up to 6 channel set point board via SMART WIRE.

Set points: 6 programmable set points.

Digital filtering: Adjustable filter parameters with FAST STEP quick response algorithm.

Display modes: Weight can be displayed from CH1, CH2, CH3 and as TOTAL of all

channels.

Tare: Keyboard and scale tare, multiple tare IDs can also be stored in memory.

Time/Date: Y2K compliant time/date clock, internal battery back up.

Truck database: Capable of storing 15-0 truck IDs with associated tare weights.

Truck in/out loop: program for weigh-in and weigh-out applications.

Unit’s conversion: lb/kg.

Zero tracking: 1-99% of 1d, 1d, 2d or 3d.

Ticket editor: Create custom tickets for any serial printer, indicator can store and recall

different tickets.

Enclosure dimensions: SL=9"x4"x1", DT=9.75"x6"x2.5", NSS=10"x7.5"x3".

Approvals: NTEP Class III/IIIL 10000, Measurement Canada Class III 10000 and IIIHD 20000

Page 10

6

2000

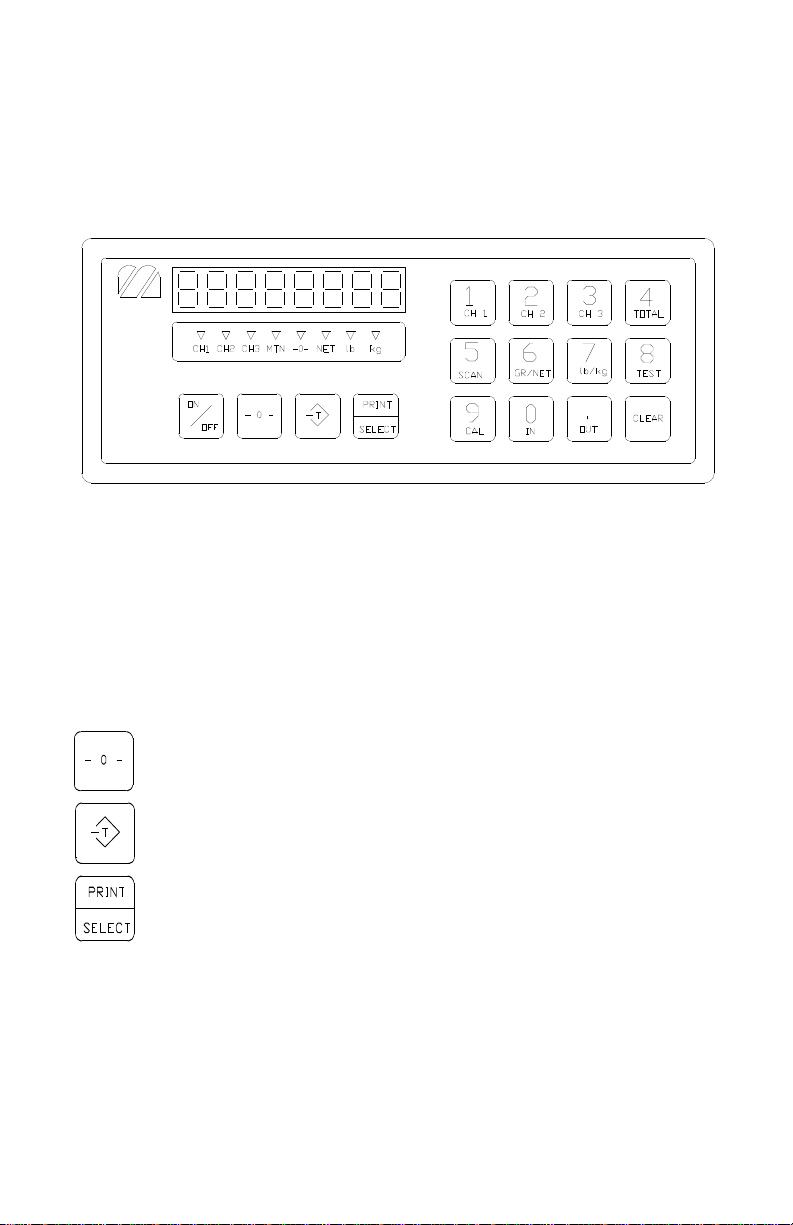

3 General Operation

The layout of the M2000 indicator is shown below.

3.1 Keypad Functions Keys

The M2000 has several function keys, all of which are selected via the front

panel. The function key operations are discussed below. All the keys have

audio feedback when a key is pressed. The sound volume can be set in

calibration mode.

A description of the important keys and buttons are as follows:

Indicator [ZERO] Key

Indicator [TARE] Key

Indicator [PRINT/SELECT] Key

3.1.1 On/Off Key

This is the ON/OFF button for the indicator. Pressing the switch once turns

on the indicator. To turn off the indicator press the switch for 1 second. It is

important to note that there is a power bypass switch option flag that can be

set in calibration (parameter 10). If power bypass is enabled the indicator will

always be on and cannot be turned off via the ON/OFF button. This option

Page 11

7

should be used if the indicator is used in process control applications where

the indicator must power up running after a power outage.

When the indicator starts “m2000" will scroll across the screen followed by

the version number of the software. The indicator performs a full diagnostic

of its internal circuits and will display any error messages if there is an

internal problem with the indicator.

When the indicator is in calibration mode this key can be used to toggle

between displayed weight and AD converter internal counts.

3.1.2 ZERO Key

This key is used to zero the indicator. The scale cannot be zeroed if there is

motion on the scale or the weight on the scale is out of the zero range.

Three quick beeps will sound from the indicator if the zero key is unable to

zero the indicator.

This key also functions as a ZERO key when the indicator is in calibration

mode.

3.1.3 TARE Key

This key is used for taring weight on the scale. A tare can also be entered

from the keypad. To tare from the scale simply press the tare key and what

ever the weight on the scale will be tared. The NET indicator light should be

illuminated showing that the indicator is in net weight display mode.

To manually tare from the keypad enter the weight using the numeric keypad

followed the tare key. The indicator will only accept a tare from a stable and

valid positive weight.

An invalid tare will cause error message 41 to be displayed. Pressing the tare

key will always overwrite any previously stored tare weight. Use the clear key

to clear the tare weight.

It is important to note that the tare key can be disabled in the calibration

menu using parameter 50.

3.1.4 CLEAR Key

This will clear any previously entered tare values entered using the tare key.

Clear will also function as an escape key to cancel any key entry operations.

3.1.5 PRINT SELECT Key

Print select is a dual function key. Pressing the key will cause a ticket to be

printed to a connected printer. If you have typed a numeric value from the

keyboard followed by the PRINT SELECT key then the key acts as a function

select key. More information on this will be discussed below.

Page 12

8

3.2 Special Keypad Functions

Keypad functions are selected by entering a numeric function code on the

keypad followed by the PRINT SELECT key. Some functions are marked on

the key itself. The most common functions are discussed below.

3.2.1 Selecting scale channels

The M2000 has three independent scale channels. Press the channel number

followed by the PRINT SELECT key as shown below.

To select channel 1 press 1 followed by the print select key.

To select channel 2 press 2 followed by the print select key.

To select channel 3 press 3 followed by the print select key.

Note: that by default only channel 1 is enabled. To enable channels 2 and 3 you

must enter calibration mode and use parameter 98 to enable them. Trying to select

a scale channel that is not enabled will display error message 40.

3.2.2 Summing channels in TOTAL mode

Up to 3 channels may me summed together to display a total weight. An

example of an application that may require this operation would be a truck

scale with three sections. Each section would be a separate channel on the

indicator allowing the operator to simultaneously record the total weight of

the vehicle along with the individual axle weights of the truck.

To enter total mode press 4 followed by the print select key. Total mode

must be enabled before it can be used. Parameter 70 in calibration mode is

used to enable the total mode function. Enter 1 followed by the TARE key to

enable TOTAL mode. Total mode cannot be used for legal for trade

applications in Canada. Only channels that are enabled and calibrated with the

same grad size, decimals and units of weight will be displayed in total mode.

Total mode is indicated by illuminating more than one channel on the channel

indicators. Channel 1 is always part of the total.

Example:

Ch1 and 3 are calibrated as 2000 x 2 lbs and Ch2 is calibrated to 500 x 0.2 lb.

When you press 4 followed by the PRINT SELECT key the CH1 and CH3

indicators will illuminate showing that the weight on the display is the sum of

these two channels. Channel 2 however is excluded from the total as it is

calibrated in 0.2d instead of 2d for channels 1 and 3.

When the indicator is in TOTAL mode all the channel operations are

combined. Pressing the ZERO button will zero all the channels that are part

of the total. The TARE function will tare all channels simultaneously displaying

the total net weight. The motion indicator and center of zero indicators will

Page 13

9

indicate the status of all the scales that are part of the total. For example

scale 1 may be at the center of zero, but channel 3 might not be at zero. The

center of zero indicator would then not illuminate reflecting that we are not

at zero.

To set the indicator back to single channel mode, select a channel followed

by the print select

3.2.3 Scan mode

Scan mode allows the indicator to cycle between the scale channels that are

enabled. The indicator will automatically switch the display to the next

available channel and pause for 3 seconds before switching to the next

channel. To stop scanning press a channel key followed by the print select

key.

To enter scan mode press 5 followed by the print select key.

3.2.4 Gross/Net

Pressing 6 followed by the print select key switches between displayed net

weight and gross weight.

3.2.5 Pound/Kilograms selection

To change the displayed units on the display press 7 followed by the print

select key. The indicator will toggle the displayed units on the display from lbs

to kgs or kgs to lbs. The units that the indicator uses as a default when

turning on the indicator is determined by the power up setting set in

calibration.

3.2.6 TEST display

To test the display segments press 8 followed by the print select key. All the

segments in the display will light up for a short period of time.

Page 14

10

4 Application Parameter Settings

M2000

Parameter

Value

2 0 5

2

8 0

9 0 10

1

11

3

19 1

21

2

22

0

23

15

24

16

30

3* 31

0

34

3

38

0

40

0

41

100

42

12 43

8

44

0

50 1

65

2

Parameters not listed in the table should be set to their factory default values.

For factory defaults, see section 8.

4.1 On-Board Scale Settings

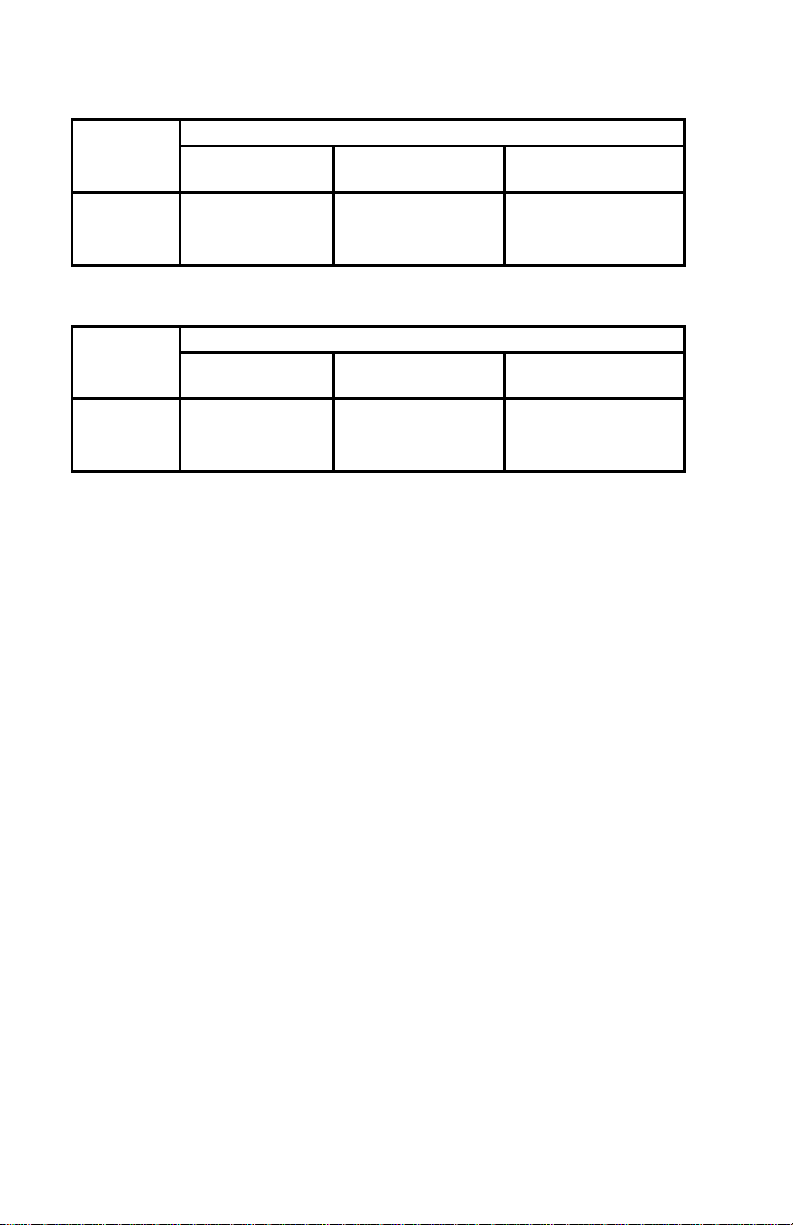

Table 1 – On-board Parameters

Parameters 3 and 4 will vary depending on application see the table below for

the proper values of each.

** Set Parameter 6 power on units to 1 for Kg or 0 for lbs.

*** Set Parameter 30 to 3 for Ticket Printers or 6 for roll printer (Also see

printer section)

Page 15

11

M2000

Parameter

Number

Net Capacity x Divisions

8000 x 2 kg

12,000 x 2 kg

15,000 x 5 kg

3 2 2

5

4**

8400

12600

15750

6 1 1

1

M2000

Parameter

Number

Net Capacity

10,000 x 2 lb

20,000 x 5 lb

60,000 x 10 lb

3 2 5

10

4**

10500

21000

63000

6

1 kg

0

0

Table 2 - Parameter Settings (Metric units)

Table 3 - Parameter Settings (US units)

Notes:

* Set parameter 30 to 3 for ticket printers. Set parameter 30 to 6 for roll

printers.

** Values listed are maximum settings. Parameter 4 may be set anywhere from

net capacity plus one division up to the maximum setting.

Page 16

12

M2000 Parameter

Number

MMAS Model

7-13

(all lengths<14 Ft)

MMAS Model

7-20

(all lengths>14 Ft)

2 0 0

3

2 kg

(5 lb)

2 kg

(5 lb)

4

6900 kg

(15200 lb)

9100 kg

(20060 lb)

5 4 4

6 0 0 8 1

1

9 0 0

10 1 1

11 3 3

19 0 0

21 2 2

22 0 0

24 8 8

25 0 0

30*

3 (ticket printer)

6 (roll printer)

3 (ticket printer)

6 (roll printer)

34 3 3

38 0 0

41

200

200

42 5 5

43

20

20

44 1 1

50 0 0

4.2 Multiple Animal Scale Settings

TABLE 4.0 - M2000 Parameter Settings Multiple Animal Scale

*Also see printer section

Page 17

13

5 Calibration and Sealing

To calibrate a scale the indicator must be placed in calibration mode. Only

qualified scale technicians should be performing these operations. The 3 scale

channels are independent of each other and must be calibrated separately.

5.1 Placing the indicator into Calibration Mode

To calibrate channel 1 press 19 followed by the print select key.

To calibrate channel 2 press 29 followed by the print select key.

To calibrate channel 3 press 39 followed by the print select key.

Note that standard On-Board and Mobile Multiple Animal applications use

single channel indicators. Channels 2 and 3 are not available.

The display will be showing a blinking “PASS” message. This prompts you to

enter a 4 digit password. Key presses are not displayed on the display. If the 4

digit password sequence is correct then the indicator will automatically enter

calibration mode.

The factory default for the password is 1111. This can be changed but we

recommend keeping the password to the factory default, more on this later.

You have 30 seconds to enter calibration mode before the indicator cancels

and returns back to normal weighing mode.

Calibration mode is indicated when there is a blinking ‘C’ displayed in the left

most digit on the display.

5.1.1 Special Keypad function keys during calibration

5.1.1.1 Selecting a calibration parameter.

The M2000 uses parameter numbers to access calibration functions. Each cal

function has a unique number used to access that parameter. In calibration

mode the print select key now becomes the calibration function select key.

Entering a calibration function number followed by the print select key selects

a calibration parameter to edit. Immediately after a function parameter has

been entered followed by the print select key the value of that parameter will

be displayed on the display for a short period of time.

5.1.1.2 Editing a calibration parameter.

After selecting a cal parameter with the print select key a new value for that

cal function can be entered. The TARE key now becomes an ENTER key for

entering calibration parameters. Parameter values entered from the keypad

must immediately follow with the TARE key to take affect.

Page 18

14

5.1.1.3 Canceling a calibration parameter.

If you would like to cancel a calibration function you can use the CLEAR key

as an ESCAPE key. This key will get you out of most calibration operations.

5.1.1.4 Toggle between weight and AD counts.

A unique feature of the M2000 is the ability to toggle between weight and the

AD converters internal counts. This can be an excellent diagnostic tool for

the experience scale technician. Pressing the ON/OFF key will show the

internal AD counts. The blinking ‘C’ will now change to a blinking ‘A’ to

indicate analog AD counts are being displayed. Press the ON/OFF button

again to switch back to weight mode.

5.1.1.5 Exiting Calibration Mode.

To exit calibration mode press 99 followed by the print select key. All

calibration parameters will be saved and the indicator will restart in weighing

mode. Note: Channels 2 and 3 are disabled by default. Remember to enable

them before exiting calibration mode by using parameter 98.

Page 19

15

5.2 Calibrating with Weights

A complete calibration of the scale would include all the steps described in

this section in order: set the parameters, balance the scale, deadload the

indicator, and set the span.

5.2.1 Set the Scale Parameters

Set or verify all the parameter settings for your application. Refer to section 4

for details on the settings for common applications.

5.2.2 Balance the Scale

When loading test weights on the scale (for balancing or calibration), it is

important to position the weights correctly for your application. Imagine lines

connecting the load cell positions (see below). Keep the weights inside the area

defined by the lines connecting the load cell positions. The loading area for a

typical On-Board system is shown below.

Typical Loading Areas

Page 20

16

1. Before the scale can be calibrated, all load cells must be balanced and

responding to loading equally by adjusting the balance trimmers. If you

have a weigh center, the balance trimmers are located on the main

circuit board, inside the control panel. If you do not have a weigh center,

your balance trimmers will be located inside a junction box on the scale.

All trimmers are initially set to 2-Ohm resistance. Use the following

procedure to balance the load cells.

2. Use proper balancing weights to ensure good balancing. Use a minimum

of ¼ of the net capacity of the scale for balancing. I.e. for a 10,000-lb net

capacity, use at least 2500 lbs. for balancing. However, be careful not to

exceed the capacity of the individual load cells.

3. Activate the scale so that the platform is live. Load weights to the full

capacity of the scale: then, unload all the weights. This process

“exercises” the load cells.

4. Press the zero key to obtain a good center of zero. Load one cell by

placing the balancing weights on that corner of the scale (inside the

loading area). Keep the weights as close to the cell as possible directly

above the cell being preferred. Record the weight on the M2000.

5. Repeat step 4 for the other cells with the same procedure (remembering

to press the zero key to obtain a good center of zero). All the readings

should be within approximately one percent (1%) of each other. If the

readings are significantly farther apart, you may not be able to balance

your system. Contact Rice Lake Weighing Systems for technical

assistance.

6. Pick the lowest reading and adjust the other cells down to this value with

the trimmers inside the control box. To adjust a cell use the following

procedure:

7. With no test weights on the scale, press the zero key to obtain a good

center of zero

8. Load the balancing weight over the cell to be adjusted.

9. If you have to adjust the cell by one or two graduations, simply turn the

trimmer clockwise to reduce the displayed reading to the desired

reading. Make sure you are adjusting the appropriate trimmer. Typical

load cell numbering conventions are shown below.

10. If you have to adjust the cell by more than one or two graduations, the

system may undergo a zero shift during the adjustment. Adjust the cell

(by turning the trimmer clockwise) to one graduation LOWER than the

desired value. Remove the weights and check the zero. Re-zero the scale

and repeat the process until the desired reading is obtained.

Page 21

17

11. Test the final balance by loading each cell again and recording the M2000

readings. The cells must read within one graduation of each other for an

acceptable final balance. However, it is more desirable that there be no

difference in the readings (zero balance error).

12. The system can now be spanned.

Page 22

18

EXAMPLE: OB30L-F3 System

English Units (lbs.)

Cell

Metric Units (kg)

M2000 Reading

M2000 Reading

Start

Loaded

Unloaded

Start

Loaded

Unloaded

0

4995

0 1 0

1998

0 0 4990

0 2 0

1996

0

0

5005

0 3 0

2002

0

English Units (lbs.)

Cell

Metric Units (kg)

M2000 Reading

M2000 Reading

Start

Loaded

Unloaded

Start

Loaded

Unloaded

0

4990

0 1 0

1996

0 2

3

English Units (lbs.)

Cell

Metric Units (kg)

M2000 Reading

M2000 Reading

Start

Loaded

Unloaded

Start

Loaded

Unloaded

1

2 0 4985

-5 3 0

1994

-2

English Units (lbs.)

Cell

Metric Units (kg)

M2000 Reading

M2000 Reading

Start

Loaded

Unloaded

Start

Loaded

Unloaded

0

4990

0 1 0

1996

0

0

4990

0 2 0

1996

0

0

4990

0 3 0

1996

0

Balancing Weights: English = 5000 lb. Metric = 2000 KG

Graduations: English = 5 lb. Metric = 2 KG

First Loading

From the above results, it can be seen that cells 1 and 3 must be adjusted down

to read 4990 lbs. (1996 kg in the metric example). First, the trimmer for cell 1

is turned clockwise to bring the reading down (step 6(c)).

Second Loading

Next, the trimmer for cell 3 is turned clockwise to bring its reading down.

Because this cell is being adjusted by three graduations, the procedure in 6(d)

should be followed, adjust cell 3 down to 4985 lbs. (1994 kg in the metric

example) and check for a zero shift.

Third Loading

The unloaded reading is found to be –5 lb (-2 kg), indicating a zero shift. The

scale must therefore be re-zeroed, and cell 3 checked again.

Fourth Loading

THE CELLS ARE NOW BALANCED WITHIN THE TOLERANCE OF ONE

GRADUATION.

Page 23

19

Standard Load Cell Numbering, Cell and Trimmer locations –

Multiple Animal Scales

Page 24

20

Standard Load Cell Numbering, Cell and Trimmer locations –

On-Board Scales

Page 25

21

5.2.3 Deadloading the Scale (scale zero)

Before the indicator can be calibrated the deadload or scale zero value must

be obtained. Remove all test weights from the scale. Key parameter 12

followed by the PRINT/SELECT key. The display will show ‘r’ for “reconfirm”.

Press 1 followed by the TARE key to confirm to continue with deadloading

the scale. The indicator will pause for a short duration and then display the

deadload value in AD counts to the display. The indicator will then return

back to weight display mode. The indicator can now be calibrated with a

known test weight.

5.2.4 Spanning the indicator

Place a known test weight on the scale. Enter 13 followed by the

PRINT/SELECT key. The display will briefly flash “1”. Shortly after, the display

will freeze with the last displayed weight. Enter the value of your test weight

followed by the TARE key. The indicator will immediately calibrate and

return back to weight display mode. If the display shows “EEEEEE” then you

have exceeded the scale capacity value set in parameter 4 and 8. If the display

shows “AAAAAA” then you have exceeded the input analog range of the

indicator. The output voltage from the load cells exceeds the input for the

AD converter.

Once the proper weight is displayed, exit calibration mode by pressing 99

followed by the PRINT/SELECT key.

5.3 Sealing the indicator

The M2000 is sealed electronically with a password. There is also provision

for physical sealing on all products. The 42300 and 42300M have faceplate

screws that accommodate a wire and lead seal.

5.3.1 Electronic Seal

Passwords are 4 digit numbers. The factory default for the password is 1111,

which can be changed in calibration mode. To change or view the password

in calibration mode use parameter 96. Enter a 4 digit password followed by

the TARE key. Important note: if you forget your password you will not be

able to enter calibration mode on the indicator. Contact the factory for

assistance at 604-941-3474.

5.3.2 Audit Trail

The M2000 is equipped with a Category 1 Audit Trail system. It is

important that the correct time and date be set, as this is saved as part of

Page 26

22

the audit trail. The audit trail is permanent and cannot be disabled or erased

by removing the internal battery inside the indicator. The Audit Trail has two

counters, the Calibration counter and the Parameter counter. Changing

parameters that affect the calibration of weight will increment the Calibration

counter by 1. All other parameters will increment the Parameter counter.

The counters will count from 000 to 999 before rolling over again. Changing

one or more parameters will only increment the counter by 1 per calibration

session. Only an actual change of value to the calibration parameter will

register to the audit trail.

Important Note:

Because the audit trail becomes active at the factory, the counters may not show 0

even when the indicator is new out of the box.

5.3.3 Accessing the Audit Trail

The audit trail can only be accessed from normal weighing mode and cannot

be accessed while you are in calibration mode. Enter 1000 followed by the

PRINT SELECT. The message “Audit” will briefly be displayed on the display.

Shortly after the indicator will cycles through 3 times displaying the date of

when the last change was made to the indicators calibration parameters, the

calibration (CAL) counter and the configuration (CFG) counter. You may

press the CLEAR key at any time to cancel this operation.

Page 27

23

6 Weigh Center Circuit Board

TO JUNCTION

The weigh center circuit board is located in the weigh center, behind the

indicator faceplate.

Page 28

24

Indicator Wiring, 42300, 42300M

Power Connections On-Board Application

Power Connections Multiple Animal Scale Applications

Page 29

25

Cab Alarm Wiring (On-Board Applications)

Scale Up Alarm (Magnetic Reed Switch) Wiring On-Board

Applications

Page 30

26

6.1 Setting Time and Date

Inside the control panel, in the ceiling of the printer compartment you will find

two toggle switches near the back (See Error! Reference source not

found.). The right toggle switch is a two-position switch (Program switch) that

puts the indicator PROGRAM TIME AND DATE or NORMAL modes. Pull the

program switch ahead to put the system into indicator PROGRAM TIME AND

DATE mode. Push the switch toward the back of the box to resume NORMAL

operation.

1. Pull the program switch into the PROGRAM TIME AND DATE position as

described above.

2. Place a piece of paper into the printer.

3. Enter the desired date into the indicator set point register in a DDMMYY

(Day Month Year) format using the key sequence outlined below. For

example June 16, 2002 would be entered as:

[2][0] [PRINT/SELECT]

[1][6][0][6][0][2] [PRINT/SELECT]

Note: You have a limited amount of time to enter the actual date

keystrokes (about 4 seconds). If the indicator goes back to GROSS mode

before you get the entire date entered you must type

[2][0][PRINT/SELECT] again then enter the date keystrokes.

4. Hold the [START] button until your keystrokes start to be displayed,

about 5 seconds, then release. The indicator will automatically repeat your

keystrokes and the printer will output the following message:

Enter date please:

date received, start to continue

5. Enter the desired time into the indicator set point register in HHMM

(Hours Minutes) format using the key sequence outlined below. The time

must be in a 24-hour format. For example 1:15 PM (13:15) would be enter

as:

[2][0] [PRINT/SELECT]

[1][3][1][5] [PRINT/SELECT]

Note: You have a limited amount of time to enter the actual time

keystrokes (about 4 seconds). If the indicator goes back to GROSS mode

before you get the entire date entered you must type

[2][0][PRINT/SELECT] again then enter the date keystrokes.

6. Press the [START] button briefly once. The indicator will automatically

repeat your keystrokes and the printer will output the following message:

time received, start to continue

7. Press the [START] button briefly once again. The printer will output the

following message:

1606021315 rec’d

8. Push the program switch back into NORMAL position.

Page 31

27

9. End of procedure.

Note: The toggle switch must be in the NORMAL position for

the normal functions of the system to operate.

6.2 Setting Units

Note: To change units, the Weights and Measures seal will have to be

broken. Contact Rice Lake Weighing Systems prior to breaking the seal or

have a qualified scale dealer break the seal. Breaking the seal may violate the

Weights and Measures approval of the scale.

NOTE: If you attempt to change the units through the indicator, the Weigh

Center will automatically switch the units back to the DIP switch setting (see

below).

1. Open the faceplate where the indicator is mounted. To open the faceplate,

remove the two screws at the top of the panel and fold it forward.

2. Inside the control panel there is a circuit board with a small bank of

switches (DIP switches). These DIP switches are located on the front corner

of the circuit board. As shown in the diagram below, the side of the DIP

switch that is down determines if the switch is in the open or closed position.

3. The units can be in kilograms (kgs) or pounds (lbs). To change this setting

find switch #7 and set appropriately.

Closed = kgs Open = lbs

6.3 SETTING SYSTEM ID NUMBER

Supply 14 Volts potential to the circuit board through the Truck Cable. Power

up the M2000.

Open DIP-switch 3 on the circuit board.

Key in 20 <SELECT> and enter in the last three digits of the indicator serial

number, e.g. S/N S0750 key in 750, and press <SELECT>.

Close DIP-switch 3.

Page 32

28

6.4 Standard DIP Switch Settings

Switch #

Position

Description

1

Open

DO NOT CHANGE

2

Closed

DO NOT CHANGE

3

Closed

DO NOT CHANGE

4

Open

DO NOT CHANGE

5

Open

DO NOT CHANGE

6

Closed

DO NOT CHANGE

7

a) Closed

b) Open

a) Kilograms (kgs)

b) Pounds (lbs)

8

Closed

DO NOT CHANGE

Switch #

Position

Description

1

Open

DO NOT CHANGE

2

Closed

DO NOT CHANGE

3

Closed

System ID number

4

Open

DO NOT CHANGE

5

Open

DO NOT CHANGE

6

Closed

DO NOT CHANGE

7

c) Closed

d) Open

c) Kilograms (KGS)

d) Pounds (LBS)

8

Closed

DO NOT CHANGE

The standard DIP switch settings on the main circuit board should be set as

follows:

Mobile Multiple Animal

On-Board

The standard DIPswitch settings on the main circuit board should be set as

follows:

Page 33

29

7 Printers

1 2 3 4 5 6 7 8 9

10

ON

OFF

OFF

OFF

OFF

OFF

ON

ON

OFF

OFF

7.1 Ticket Printer

Epson TM290, TM295

Printer DIP Switch Settings:

For On-Board and Mobile Multiple Animal Applications:

DIP Switch Settings

THE DIP SWITCHES 6 & 8 ON THE WEIGH CENTER CIRCUIT BOARD MUST BE

CLOSED.

Page 34

30

7.2 Roll Printer

1 2 3 4 5 6 7

8

OFF

OFF

OFF

OFF

OFF

OFF

OFF

ON

1 2 3 4 5 6 7

8

OFF

OFF

OFF

OFF

OFF

OFF

OFF

OFF

Epson TM-U200D

Bank #1

Bank #2

The DIP switches 6 & 8 on the Weigh Center circuit board must be OPEN.

Page 35

31

8 M2000 Indicator Parameter List

The following gives a partial list of the M2000 parameters. The list explains the

use of the most commonly needed parameters on the indicator. However, the

M2000 features over 80 parameters. For a complete list contact Rice Lake

Weighing Systems.

8.1 CAL INITIALIZATION Parameters

1 Reload Factory Default Values

This function will reinitialize the indicators scale calibration parameters for the

specific channel to the default factory values. When you have selected his

function you must confirm by pressing [1] followed by the [TARE] key. This will

only initialize a single channel. The indicator will automatically exit calibration

and reboot to initializing the calibration data to factory default. Any other

values will display error 7. The indicator will reboot after performing a factory

reset. Use parameter 260 below to reinitialize completely to factory defaults.

260 Complete factory initialize

Similar to parameter 1 above. This parameter completely initializes all indicator

settings to factory defaults on all 3 channels. This includes COM port settings

and all other system related settings. Ticket data and tares stored in memory

are not initialized.

98 Enables scale channel (0)

This parameter enables scale channels 2 or 3. Channel 1 is always enabled and

cannot be disabled. By default channels 2 and 3 are turned off. To enable a

channel enter 1followed by the [TARE] key. To disable a channel enter 0

followed by the [TARE] key.

99 Exit calibration mode

This parameter will exit calibration mode and restart the indicator. All

calibration changes are stored to flash memory and the audit trail is updated.

8.2 SCALE SETUP Parameters

2 Decimal Point Position (0)

Sets the decimal position for the display. Values 0 to 4 can be entered followed

by the [TARE] key. An invalid entry will display error 3.

3 Graduation size (1d)

Selects the grad size to be used on the scale. Values that can be entered are 1,

2, 5, 10, 20, 50 and 100 followed by the [TARE] key. An invalid graduation size

will display error 2.

4 Scale Capacity (10000d)

This should be set to the scale capacity for the scale. For example if your scale

capacity is1000 lbs then you would enter would be 1000 followed by the

[TARE] key. The zero range window is calculated from this parameter

Page 36

32

8 Scale Over (1d)

Enter the number of divisions for scale over. For example if your scale capacity

is 1000lbs (parameter 4) and you want the scale to indicate scale over at Scale

Capacity + 9dthen the value you would enter would be 9 followed by the

[TARE] key.

20 Scale Over Message

Scale over is displayed as “EEEEEE” on the M2000 display and in the strings. If

you require maintaining compatibility of older Western Scale equipment then

set this parameter to 1. Scale over will now be displayed with the traditional all

eights “888888”.

98 Enables scale channel (0)

This parameter enables scale channels 2 or 3. Channel 1 is always enabled and

can not be disabled. By default channels 2 and 3 are turned off. To enable a

channel enter 0 followed by the [TARE] key. To disable a channel enter 0

followed by the [TARE] key.

99 Exit calibration mode

This parameter will exit calibration mode and restart the indicator. All

calibration changes are stored to flash memory and the audit trail is updated.

8.3 Scale MOTION Parameters

5 Motion Window (2d)

Enter the value to determine the motion sensitivity. A typical value is 2 times

the graduation size. This is set automatically when the grad size changes

(Parameter 3).

24 Motion Settle Time (8)

Displays the number of ¼ second intervals for which Motion will remain

asserted after the scale reading has stabilized within the motion tolerance.

Enter a value 1-255 followed by the [TARE] key. An invalid motion value will

display error 50.

8.4 Scale ZERO Parameters

9 Power ON Zero Scale Message (0)

With this parameter set to 1 the indicator will power up displaying “Zero” on

the display. The operator must Zero the scale before continuing. This must be

set for certain legal for trade requirements. If the parameter is set to 0 the

indicator powers up displaying weight. An invalid parameter entry will display

error 28.

21 Push to Zero Window or Zero Range (2)

This command displays the percentage of scale capacity that can be zeroed by

the zero key. The allowable range is between 0 and 99%. Enter the range

followed by the [TARE] key. An invalid value will display error 5.

22 Auto Zero Tracking ON/OFF (1)

Page 37

33

This command displays the Auto Zero flag value. The value of 1=ON and

0=OFF. To turn auto zero tracking off enter 0 followed by the [TARE] key. An

invalid entry will display error 4.

23 Auto Zero Tracking Window (AZSM) (60)

This command displays the percentage of a graduation that can be tracked off

during zero tracking. Enter the value followed by the [TARE] key. This value

can be the following:

1-99: to track 1 to 99% of d.

100: to track off 1d.

200: to track off 2d.

300: to track off 3d.

To turn off zero tracking use parameter 22 above. Any other value entered will

display error 6.

45 Power up zero IZSM (0)

When this parameter is set to 1 the indicator will zero the scale automatically

on power up. The maximum range the scale will zero on power is set to +-10%

of full scale capacity. If the initial load on the scale exceeds 10% of scale

capacity then no initial scale zero will take place. Enter 1 to enable or 0 to

disable.

8.5 Parameters related to SCALE CALIBRATION

7 Scale Units

Toggles between pounds and kilos. Make sure that you have selected the units

you are calibrating with. If your test weights are in pounds or kilos then make

sure that the scale unit’s illuminator is displaying the correct units.

11 Indicator Load Cell voltage range (39mV)

This parameter adjusts the input range for the scale-input channel. It is

important that the correct range be selected for optimal performance of the

indicator. Use values 1 to 3 to select the following input ranges:

1 for 0 to +-9mV input range

2 for 0 to +-19mV input range

3 for 0 to +-39mV input range

4 for 0 to +-79mV input range.

If the loadcell input voltage exceeds the input range of the indicator the display

will display ‘AAAAAA’ which means “Analog over-range”. Select the next

highest input range to rectify the problem. Only values 1 to 4 can be entered

and any other value will display error 57. It in important to understand that

selecting a lower input range, for example 9mV range does not necessarily

guarantee better performance. The 9 mV range has more amplification that lets

say the 19 mV or 39mV range. You will get more AD counts for sure, but you

are also amplifying noise. This depends on the scale installation. It most cases

the default 39mV or 19mV range will be adequate.

12 Deadload Scale

Page 38

34

Before spanning the indicator for the first time the indicator must be

deadloaded. Ensure that the scale has all test weights removed from the scale

and the scale is stable before performing a deadload. To perform the deadload

function press 1 followed by the [TARE] key. The indicator will perform the

deadload function. After the deadload has completed the indicator will briefly

display the deadload value in AD raw counts before returning to weight display

mode.

13 Set Span

This command is used to span the indicator with a known test weight. Place

the test weights on the scale. When the set span function has been activated

the current displayed weight will be frozen on the display. Using the numeric

keypad enter the known test weight followed by [TARE]. The display should

now show the new weight on the scale. You can cancel a span any time by

pressing the [CLEAR] button before [TARE] is pressed.

99 Exit calibration mode

This parameter will exit calibration mode and restart the indicator. All

calibration changes are stored to flash memory and the audit trail is updated.

8.6 INDICATOR POWER UP Parameters

6 Power On Units (0)

Determines what units the indicator defaults to when the indicator is turned

on. Entering 1 followed by the [tare] key selects Kilograms. Entering 0 selects

Pounds. An invalid entry will display Error 13.

9 Power ON Zero Scale Message (0)

With this parameter set to 1 the indicator will power up displaying “Zero” on

the display. The operator must Zero the scale before continuing. This must be

set for certain legal for trade requirements. If the parameter is set to 0 the

indicator powers up displaying weight. An invalid parameter entry will display

error 28.

10 Power Switch Bypass (1)

This parameter controls the keypad ON/OFF switch for the indicator. Entering

1 for this parameter disables the ON/OFF switch and the indicator can never

be turned off from the keypad. Also when the indicator power is plugged into

the wall the indicator will turn on without pressing the ON button. This should

be used in applications such as control systems where the indicator must

power up running after a power outage. An invalid entry will display error 56.

46 Power up channel select (1)

This parameter will determine what channel to be the default channel at boot

up. This parameter will only be implemented if the calibration values meet the

criteria.

1 channel 1 as default at startup

2 channel 2 as default at startup (if enabled)

3 channel 3 as default at startup (if enabled)

Page 39

35

4 Total mode (if criteria met)

5 Scan mode

70 Enable Total Mode (0)

Using 4 PRINT/SELECT puts the indicator in total mode and sums channels

into a single total. Total mode is disabled by default. Total mode is not legal for

trade in Canada and can only be used in non-legal for trade applications. 0 Total

mode disabled 1 Total mode enabled

8.7 Scale TARE Parameters

25 Offset Value (0)

Allows the entry of tare offset value. At scale zero, the center of zero light will

illuminate, but the weight will be at the tare offset value. Enter the offset weight

followed by the tare key.

26 Offset flag (0)

This command controls the operating mode of the tare offset. Enter the

parameter followed by the [TARE] key. The following values accepted are:

0=Offset Disabled 1=’Legal for trade mode’ – Indicator cannot be put in ‘NET’

mode if no value has been set for tare. If tare has been entered the offset value

is included in the NET display.80=Not “Legal for Trade mode - Allows

gross/net switching at zero value. If NET is selected, the offset value is

subtracted from the displayed gross weight.

50 Tare function mode (1)

This parameter controls how the tare function works on the indicator. The

options available are: 0: disable keyboard and scale tare No tare can be entered

using the keypad or taring off the scale using push button tare. 1: enable both

keyboard and scale tare Both keyboard tare entry and pushbutton tare can be

used. 2: enable pushbutton tare only Taring is only allowed from the scale. 3:

enable keyboard tare’ Tare entry can only be done from the keyboard 71

Force Zero for keyboard tare (0) This parameter checks if the scale is at

zero before allowing an operator to enter a keyboard tare. If the scale is not at

zero when a keyboard tare is entered then error 35 is displayed. Enter 1 to

enable, 0 to disable.

8.8 SYSTEM SETTINGS Parameters

28 Sound volume (2)

This command controls the volume of the internal buzzer. The following values

can be entered followed by the [TARE] key:

0: sound off

1: volume low

2: volume medium

3: volume high

Error Message 51 will be displayed for an invalid entry.

29 Keypress Feedback

Page 40

36

This function will blink the display every time a key is pressed. This gives a

sense of feedback to the end user when a key is pressed. This is especially

handy in noisy environments where the operator may not be able to here the

key beeps from the indicator. Parameters are 0 (off) or 1 (on) followed by the

[TARE] key. Error 32 will be displayed for an invalid entry.

80 Set Time

Time is set out side of calibration mode in normal weighing mode (you must

exit cal mode). This parameter allows you to set the battery backed real time

clock on the indicator. Pressing 80 followed by the [PRINT/SELECT] key will

display the current time on the display. To change the time, enter your new

time as HHMMSS followed by the [TARE] key. Example: to change the time to

9 hours 33 minutes and 30 seconds enter 093330 followed by the [TARE] key.

81 Set Date

Date is set out side of calibration mode in normal weighing mode. This

parameter allows you to change the battery-backed date on the indicator.

Pressing 81 followed by the [PRINT/SELECT] key will display the current date

on the display. To change the time, enter your new time as YYMMDD followed

by the [TARE] key. Example: to change the date to December 14 year 2001

enter 011214 followed by the [TARE] key.

8.9 SERIAL COMMUNICATIONS Parameters

30 baud rate for COM 1 (6)

Changes the baud rate for COM1. Valid parameters are 0-9. An invalid entry

will display error 52.

32 baud rate for COM 2 (6)

Changes the baud rate for COM1. Valid parameters are 0-9. An invalid entry

will display error 52.

0 : 150

1: 300

2: 600

3: 1200

4: 2400

5: 4800

6: 9600 (factory default)

7: 14400

8: 19200

9: 32400

9600 baud is the default baud rate for both ports. Note: only a single COM port

can be used for printing.

31 Parity for COM 1 (0)

Changes the parity setting for COM1. Valid parameters are 0-2. An invalid

entry will display error 53.

Page 41

37

0: No parity

1: ODD parity

2: Even parity.

33 Parity for COM 2 (0)

34 Stringmode for COM1 (99)

The M2000 supports several string output modes through either COM1 or

COM2. Select the string mode from the table below. Use 99 if you are using

the COM port for ticket printing.

1 DF1000

3 DF2000

5 DF2500 mode1

8 DF1500

9 DF2500 mode 6

10 DF2500 mode 7

12 AD4321, AD4323, AD5000

13 Cardinal 708

14 Cardinal 738

19 Toledo & Fairbanks R2500

16 Weightronix 120

17 Consolodated Controls

18 Analogic 5316

99 Set to ticket printer mode

35 Stringmode for COM2 (8)

36 Flow Control for COM1 (0)

Select 0 for none and 1 for Hardware

37 Flow Control for COM2 (0)

38 String output polled mode for COM1 (5)

39 String output polled mode for COM2 (5)

0 selected output string will be continuously transmitted on COM1

1 selected output string will be transmitted on COM1 when the

PRINT/SELECT key is pressed

2 output when the receive data input is at logic low (-9 volts dc). A

string will be transmitted after each sample whenever the receiver

data line is held low – send on break. output when the receive data

input is at logic high(+9 volts dc). A string will be transmitted after

each sample whenever the receiver data line is held high – send on idle

4 output string to COM1 on ‘?’ character received

5 output string to COM1 continuously

47 Serial String Output Routing FOR COM1 (0)

48 Serial String Output Routing FOR COM2 (0)

Parameter 47 and 48 will determine which channel’s weight will be routed the

COM serial port. This parameter will only be implemented if the calibration

values meet the criteria.

0 COM1 serial output string weight a function of current active channel

1 COM1 serial output string locked on channel 1

Page 42

38

2 COM1 serial output string locked on channel 2

3 COM1 serial output string locked on channel 3

4 COM1 serial output string locked on Total mode

8.10 Scale Filtering Parameters

19 Display Update Rate (0)

This parameter will set the LED display update rate. The update rate has

nothing to do with the actual AD converter update rate or filtering. The

parameter may have a value between 0-9. A value of 0 will introduce no delay

in the display update, while a maximum value of 9 will introduce a display

update rate of a 3-second delay. The update rate at a value of 0 is very fast and

the display may appear jittery in some applications. In this case increase the

value of this parameter.

41 Digital Averaging Filter (64)

Changing this parameter changes the mount of averaging performed on the final

weight. This function is used to help filter the scale from vibrations and display

a stable weight. The default setting should be adequate for most installations

however if heavier filtering is required then increase the filter value. Changing

the filter does alter the settling time for the final weight response. Values that

can be entered are 1-255 followed by the [TARE] key. The higher the number

the heavier the filtering. Error 14 is displayed for an invalid entry.

42 Filter Faststep threshold (8)

The filter averaging system has a filter bypass mode called faststep. Faststep

dramatically improves the display response time for a step change in weight.

When the faststep mode is active the digital averaging filter is bypassed

(parameter 41) displaying an instant change in weight. The threshold or the

amount of instant weight change that has to occur before the indicator is to go

into faststep mode is defined by this parameter. This parameter normally does

not have to be changed. Let us look at an example, we have a 500lb-floor scale.

The faststep value is 8. If a 200 pound man jumps on the scale, the scale will go

into faststep mode, bypassing the averaging filter and displaying a quick jump to

200lbs. When the final weight is settling filter averaging is returned back to

normal weight averaging. If you place a 5 pound weight on the scale the faststep

will not kick in and the weight change will be a little slower. How slow the

weight changes to the 5lb load is a function of parameter 41.

43 Fastep Sensitivity (8)

This parameter normally does not need to be changed, and may be removed in

future releases of the software. This parameter controls how sensitive faststep

is to be (see parameter 42). The value entered here indicates how many AD

samples the weight has to change in a row before the faststep filter kicks in.

For example a 200 pound man jumps on a 500 pound scale. The “Faststep

parameter” 42 has been set to 20 and the “Fastep Sensitivity” parameter 43 has

been set to 5. Only when a weight change of more than 20lbs and has occurred

5 samples in a row then the filter averaging will go into fastep

Page 43

39

mode. Increasing this parameter makes the Fastep filter threshold less sensitive.

44 Disable Faststep (0)

This parameter disables the faststep system altogether. The values for

parameter 42 and 43 are ignored and the system runs in weight averaging

mode only. The response time for the indicator is a function of parameter 41.

Some control batching applications may require that faststep be turned off.

8.11 PRINTING Parameters

84 Add new ticket

This parameter appends a new ticket to the end of the ticket buffer. You can

have several different formatted tickets defined, which can be recalled when

needed. A new ticket number is displayed briefly and then the display will

switch over to tick editor mode. If the user does not want to add a new ticket

but start a new ticket from scratch then the ticket buffer can be cleared using

parameter 88.

85 Edit existing ticket

You can edit an existing ticket by entering the ticket number followed by the

[TARE] key. This will put the display in ticket editing mode with the ticket

loaded. You can now modify the ticket.

86 Number of tickets saved in the ticket buffer

This Parameter displays how many tickets that have been saved in the ticker

buffer. Several different ticket formats can be defined and recalled depending

on the weighing operation.

87 Show available space in Custom ticket buffer

This parameter displays how much room you have left for storing ticket

formats. In most cases you never will run out of room as the ticket buffer can

hold 4000 characters used for formatting 1 or more tickets.

88 Clear Custom Ticket buffer

This parameter will erase all custom ticket formats in memory. Press 1

followed by the [TARE] key to confirm to clear the print buffer. All ticket

formatting will be lost.

89 Print specific ticket

Enter the ticket number you want to print followed by the [TARE] key. The

ticket will be printed with the current displayed weight.

100 Delete Truck IN/OUT Database

This command clears the SRAM based truck in out database. The truck in/out

database is SRAM battery backed up and would only be destroyed if the battery

were removed or low while power is removed from the indicator. After

entering the parameter the command should be completed by pressing key one

followed by PRINT/SELECT followed by TARE.

101 Delete Truck IN/OUT Database

This command clears the FLASH memory based truck in/out database. The

truck in/out database is stored in non-volatile FLASH memory and this is the

only way to clear the database. After entering the parameter the command

Page 44

40

should be completed by pressing key one followed by PRINT/SELECT followed

by TARE. There are a total of 6 set points available on the M2000A. Each set

point can be allocated to any of the 3 channels. This parameter will be used to

enter the weight at which the set point will do its evaluation. This value is

channel dependent as far as the lb/kg units are concerned.

Error Messages

1 Invalid parameter number for calibration mode

2 Graduation size invalid

3 Decimal Position Invalid

4 Flag values must be 1 for ‘ON’ and 0 for ‘OFF’

5 Push to Zero Window must be 0-99

6 Zero tracking must be 1-99 or 100, 200, 300.

7 Only 1 will reset parameters

8 Only 1 will reset span table

9 Span exceeds maximum capacity or span to small

10 IZSM value can be 1 for ON and 0 for OFF

11 Test Weight units must be 0=lb or 1=kg.

12 Motion settle time out of range 1-100

13 Power on units may only be 0=lb, 1=kg.

14 Invalid Time entry HH.MM.SS

15 Invalid Date entry YY.MM.DD

16 Motion value is out of range

17 Press tare to increment span table, any other key invalid

18 Press tare to decrement span table, any other key invalid

19 Span table cannot be decremented passed 1

20 Parameter memory write error, indicator requires service

21 Parameter checksum error, Parameters have been lost.

22 Program check fault, indicator requires service

23 Invalid Serial Port speed setting.

24 Invalid Serial Port Parity parameter

25 Cannot increment Span Table any further

26 Entered offset larger than Capacity

27 Invalid String mode for com port

28 Power on Zero warning 0=Off, 1=On

29 Channel enable is 0=Off and 1=On

30 Only 1 will set the deadload

31 Sound Volume can be between 0-3

32 Keypress feedback can be 0=OFF or 1=ON

33 Invalid Com String mode parameter

34 Invalid Com Port Interface value

35 Scale must be at zero before entering a keyboard tare (see parameter 71)

36 Scale not ready to print

37 Channel 1 cannot be disabled

Page 45

41

38 Invalid Print Select Function Number

39 *

40 Scale channel is not enabled

41 Pushbutton Tare is invalid (Over, Motion, or disabled)

42 Keyboard tare available on channel 1 only.

43 Tare greater than capacity

44 Invalid Password number range, can only be 0000-9999.

45 Parameter 1 to enable password, 0 to disable

46 Only a value of 0, 1 or 80 is accepted as a parameter

47 *

48 Invalid Filter value

49 Invalid Filter Fast step value

50 Invalid Fast step Sensitivity

51 Invalid Fast step on/off

52 Invalid Tare Function Parameter 0-4

53 Invalid input for AD voltage range

90 Calibration checksum failed

100 SRAM failure

110 RTC RAM failure

112 Clock Reset

115 Clock Failed

120 Battery flat or does not exists

121 Battery must be removed

130 COM1 loop back test failed

131 COM2 loop back test failed

133 COM driver chip failed

140 FLASH memory erase failed

141 FLASH memory write failed

151 Database CRC failed

152 CAL copy CRC failed

153 Ticket Buffer CRC failed

150 Audit trail CRC failed

154 DPAGE stack overflow

185 SMART wire COM link not responding SmartWire is enabled and is trying

to find devices. This error will occur as a result of not having devices

connected to the Smart Wire port or a bad wire connection. Hit clear to

bypass this error message. To disable smart wire use parameter 59 in weight

mode. Enter 0 to disable smart wire and 1 to enable it again.

186 SMART wire set-point checksum failed

191 Channel 1 AD converter not responding

192 Channel 2 AD converter not responding

193 Channel 3 AD converter not responding

Error message “Cannot Print”

Note: If you try and print and there is motion, or the scale is overweight

then a message will scroll across the display “Cannot Print”.

Page 46

42

Page 47

43

M2000 Indicator Limited Warranty

Rice Lake Weighing Systems (RLWS) warrants that all RLWS equipment and systems

properly installed by a Distributor or Original Equipment Manufacturer (OEM) will

operate per written specifications as confirmed by the Distributor/OEM and accepted by

RLWS. All systems and components are warranted against defects in materials and

workmanship for two years.

RLWS warrants that the equipment sold hereunder will conform to the current written

specifications authorized by RLWS. RLWS warrants the equipment against faulty

workmanship and defective materials. If any equipment fails to conform to these

warranties, RLWS will, at its option, repair or replace such goods returned within the

warranty period subject to the following conditions:

• Upon discovery by Buyer of such nonconformity, RLWS will be given prompt

written notice with a detailed explanation of the alleged deficiencies.

• Individual electronic components returned to RLWS for warranty purposes

must be packaged to prevent electrostatic discharge (ESD) damage in shipment.

Packaging requirements are listed in a publication, Protecting Your

Components from Static Damage in Shipment, available from RLWS

Equipment Return Department.

• Examination of such equipment by RLWS confirms that the nonconformity

actually exists, and was not caused by accident, misuse, neglect, alteration,

improper installation, improper repair or improper testing; RLWS shall be the

sole judge of all alleged non-conformities.

• Such equipment has not been modified, altered, or changed by any person other

than RLWS or its duly authorized repair agents.

• RLWS will have a reasonable time to repair or replace the defective equipment.

Buyer is responsible for shipping charges both ways.

• In no event will RLWS be responsible for travel time or on-location repairs,

including assembly or disassembly of equipment, nor will RLWS be liable for

THESE WARRANTIES EXCLUDE ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED,

INCLUDING WITHOUT LIMITATION WARRANTIES OF MERCHANTABILITY OR FITNESS FOR

A PARTICULAR PURPOSE. NEITHER RLWS NOR DISTRIBUTOR WILL, IN ANY EVENT, BE

LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES.

RLWS AND BUYER AGREE THAT RLWS’ SOLE AND EXCLUSIVE LIABILITY HEREUNDER IS

LIMITED TO REPAIR OR REPLACEMENT OF SUCH GOODS. IN ACCEPTING THIS WARRANTY,

THE BUYER WAIVES ANY AND ALL OTHER CLAIMS TO WARRANTY.

SHOULD THE SELLER BE OTHER THAN RLWS, THE BUYER AGREES TO LOOK ONLY TO

THE SELLER FOR WARRANTY CLAIMS.

NO TERMS, CONDITIONS, UNDERSTANDING, OR AGREEMENTS PURPORTING TO MODIFY

THE TERMS OF THIS WARRANTY SHALL HAVE ANY LEGAL EFFECT UNLESS MADE IN

WRITING AND SIGNED BY A CORPORATE OFFICER OF RLWS AND THE BUYER.

the cost of any repairs made by others.

© 2011 Rice Lake Weighing Systems, Inc. Rice Lake, WI USA. All Rights Reserved.

RICE LAKE WEIGHING SYSTEMS • 230 WEST COLEMAN STREET • RICE LAKE, WISCONSIN 54868 •

USA

Page 48

44

For More Information

Web Site

• Frequently Asked Questions (FAQs) at

http://www.ricelake.com/faqs.aspx

Contact Information

Knowledgeable customer service representatives are available 6:30 a.m. 6:30 p.m. Monday through Friday and 8 a.m. to 12 noon on Saturday.

(CST)

• Sales/Technical Support 800-472-6703

• Canadian and Mexican Customers 800-321-6703

• International 715-234-9171

For immediate assistance call toll-free 1-800-472-6703 (Canadian and

Mexican customers please call 1-800-321-6703). If you are calling after

standard business hours and have an urgent scale outage or emergency,

press 1 to reach on-call personnel.

Fax Number 715-234-6967

• US sales and product information at

prodinfo@ricelake.com

• International (non-US) sales and product information at

intlsales@ricelake.com

Rice Lake Weighing Systems

230 West Coleman Street

Rice Lake, WI 54868 USA

Page 49

Loading...

Loading...