Page 1

Tracer AVi

Aviation Baggage Instrumentation

Installation Manual

93633

Page 2

Page 3

Contents

1.0 Introduction.................................................................................................................................. 1

2.0 Installation ................................................................................................................................... 2

2.1 Unpacking and Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.2 Mounting the iQube and Remote Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.3 Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.4 Load Cells . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.5 Serial Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.6 Core Module DIP Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.7 Core Module Reset Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.8 The Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.9 Fuse Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.10 Interface Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.11 Replacement Parts and Drawings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.0 PC Configuration .......................................................................................................................... 7

3.1 Introduction to VIRTUi. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1.1 Authentication/Authorization System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1.2 Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.1.3 Function Keys and Annunciators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.1.4 VIRTUi Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.1.5 Web Browser-Based Cell Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1.6 System Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.2 VIRTUI Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.2.1 Downloading to the Tr a c e r A V i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.0 Calibration ................................................................................................................................. 13

5.0 Diagnostics ................................................................................................................................ 16

5.1 Diagnostic Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.2 Diagnostic Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.0 Specifications............................................................................................................................ 17

Tracer AVi Limited Warranty.................................................................................................................. 18

Technical training seminars are available through Rice Lake Weighing Systems.

Course descriptions and dates can be viewed at www.ricelake.com or obtained by

calling 715-234-9171 and asking for the training department.

© 2007 Rice Lake Weighing Systems. All rights reserved. Printed in the United States of America.

Specifications subject to change without notice.

November 2007

Page 4

Page 5

About This Manual

This manual is intended for use by service technicians

responsible for installing and servicing the

Tracer AVi

single channel diagnostic junction box and bagwell

display.

Authorized distributors and their employees

can view or download this manual from the

Rice Lake Weighing Systems distributor

www.ricelake.com.

site at

1.0 Introduction

The Tracer AVi system consists of three components:

• iQubeTM, a digital programmable junction box

used with an analog load cell. It outputs a

serial string that can be directly input to the

remote display and

• RD-1 remote display, a .8”, six-digit,

seven-segment LED display.

• VIRTUiTM, a PC-based indicator for iQube.

The virtual front panel consists of display and

five-button keypad.

The iQube consists of three boards:

•The connector board provides the physical

connections for the load cell, serial

communications, and power.

•The core module, which plugs into the

connector board, contains the

processor and stores configuration and

calibration data for the

module provides a discrete A/D input and

converts the analog load cell signal to a digital

serial output.

•The 7.5 VDC power supply mounts inside the

enclosure and requires a 115/230 VAC input.

Configuration

The Tra cer AVi system can be configured by using a

PC running the

VIRTUi configuration program. This

method defines the load cell connected to

which is associated with a platform, and the platform

that makes up the scale. Even though the

single-channel

iQube is just one cell, one platform,

and one scale; the association of scale and platform is

required because the software is also used on multiple

cell and multiple platform scales.

Configuration consists of the following steps:

Define Load Cell: This is the electrical sensitivity

(mV/V output) and capacity specification of the load

cell. Load cell name and serial number can also be

specified.

VIRTUi.

Tracer AVi’s

Tracer AVi. The core

iQube,

Some procedures described in this manual

require work inside the iQube enclosure.

These procedures are to be performed by

qualified service personnel only.

The Tracer AVi does not have an on/off switch and therefore

must be installed near a power outlet that is easily accessible

and in accordance with UL/CSA Safety Standards.

Define Platforms: The iQube board must assign a

load cell to the platform.

Define System: The iQube board must assign the

platform to the system.

Load Cell Trimming and Calibration

iQube supports calibration of multiple load cells with

corner match and section match calibration.

For the single cell iQube, only multi-point linear

calibration and theoretical calibration apply. Each type

of calibration captures the initial dead load of the scale

and provides a means to trim the output of the load

cell.

Based on the cell capacity and sensitivity, the

theoretical calibration calculates weight values based

on the total signal from the cell.

Single Cell Diagnostic

Diagnostic functionality can be enabled for the iQube

to identify abnormal load cell output. The diagnostic

conditions that can be identified are open bridge open

channel, drifting, peak-to-peak noise, cell at rail, and

cell over/under range.

Error conditions generate a displayed error message if

connected to

VIRTUi which can be configured to

email the alert message to an address.

Introduction 1

Page 6

2.0 Installation

This section describes procedures for connecting load

cell, power, and serial communications cables to the

TM

iQube

enclosure. Drawings and replac ement parts

lists are included for the service technician.

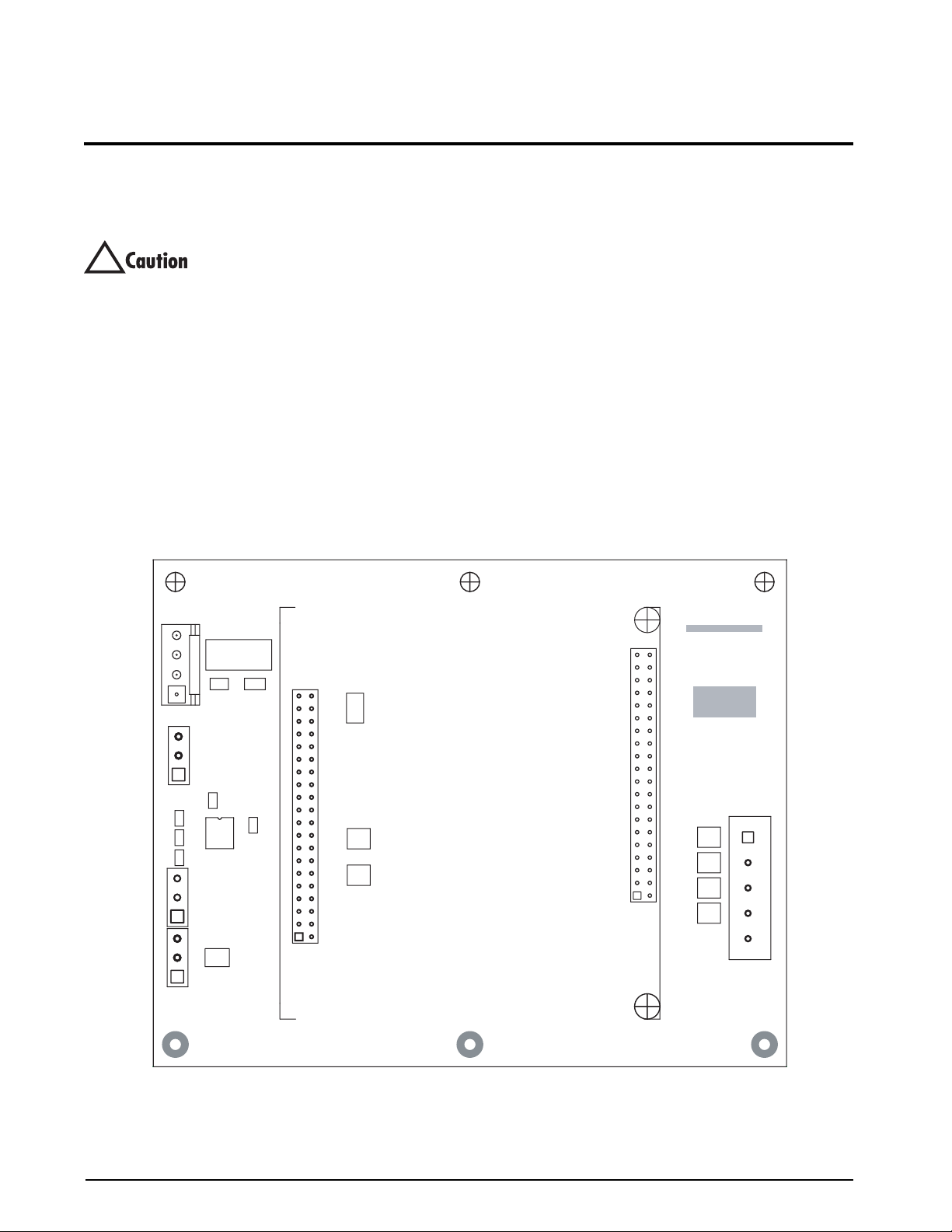

Use a wrist strap to ground yourself and

!

protect components from electrostatic

discharge (ESD) when working inside the

iQube enclosure.

Disconnect AC power from the main module before installing

remote displays.

2.1 Unpacking and Assembly

Immediately after unpacking, visually inspect the

contents to ensure all components are included and

undamaged. The shipping carton should contain the

iQube, the remote display, this manual, and

connection cables. If any parts were damaged in

shipment, notify Rice Lake Weighing Systems and the

shipper immediately.

See Table 2-4 on page 4 for the iQube cables.

2.2 Mounting the iQube and Remote Display

The iQube and remote display are two separate

components. The main board is installed in the

iQube.

All components can be installed in separate locations.

The iQube can be placed either upright or on its side.

Mounting hardware is not included in the parts kit.

2.3 Cable Connections

The single channel iQube provides one load cell

connector, two remote display connectors, one host

(PC) com port connector for connecting to the PC

running

VIRTUi, and an AC power cord.

2.4 Load Cells

The load cell wired to connector J3 in the iQube, is

assigned a default name A1. J3 is wired to a DB-9 on

the enclosure panel.

.

DC IN

1

HOST SERIAL

1

REMOTE

1

REMOTE

1

J7

J5

C2

C3

C5

GNDTxDDC+TxD

DC+GND

RxD

TxDGND

J4

J6

G2E

R1

F1

J2

R2

D1

C4

C1

U1

C6

TVS5

TVS6

J1

RICE LAKE

Assembly

P/N

TVS4

TVS3

TVS2

TVS1

Rev.

1

+SIG

–SIG +EXC

–EXC

SHLD

J3

Figure 2-1. iQube Connector Board with Core Module

2 Trac er AVi Installation Manual

Page 7

Load Cell Wiring

To attach the load cell cable to the connector board,

plug the cable into external connector (see

Figure 2-6

on page 6).

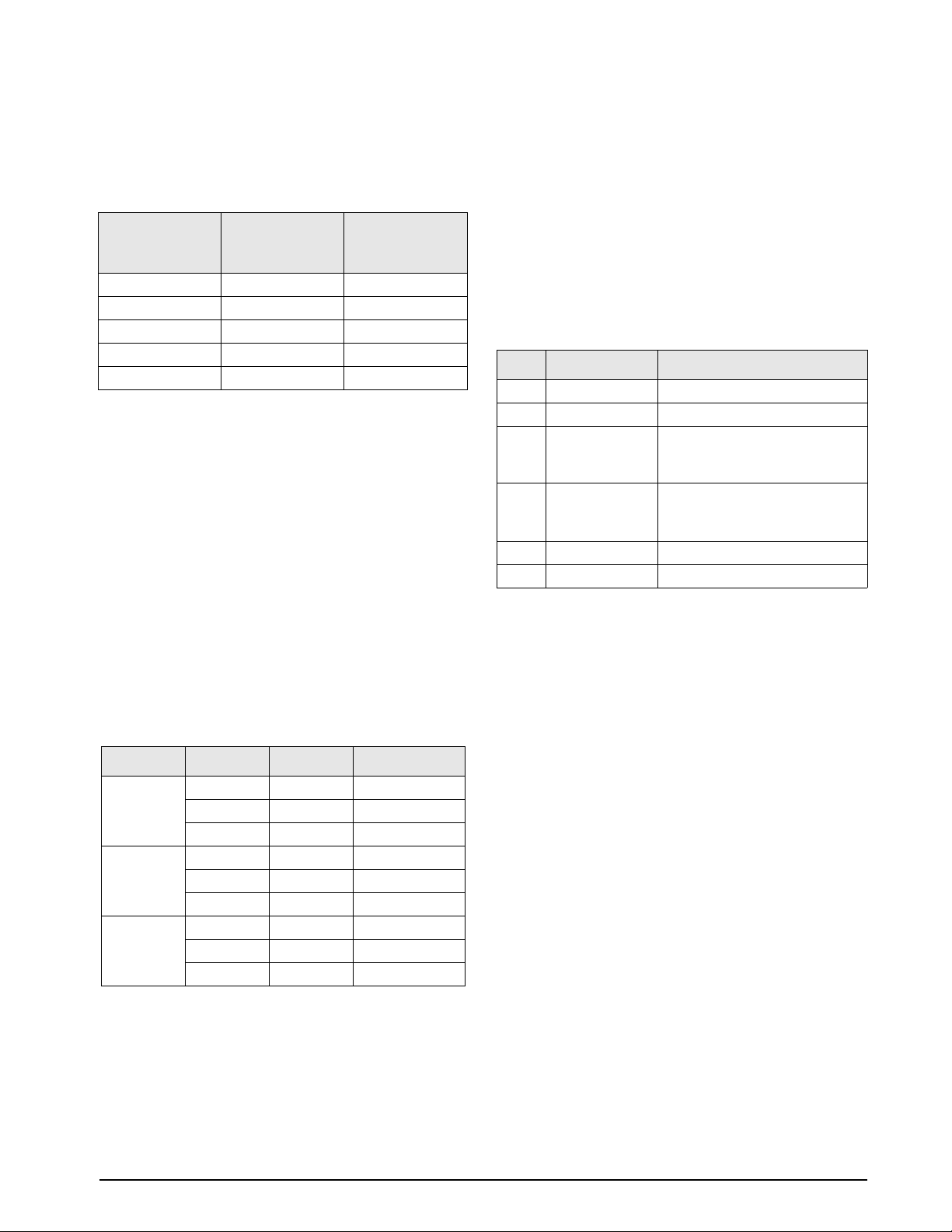

Wire load cell cables as shown in Table 2-1.

Given that these and other factors will affect the

maximum usable cable length, the following distances

can be used as a general guide for

iQube

communications cabling (10 ft cable is provided):

RS-232: 50 ft (15 m)

On-Board

DB-9 Pin

Female Connector

7 1 +SIG

3 2 –SIG

4 3 +EXC

6 4 –EXC

5 5 SHIELD

Table 2-1. Load Cell Connector Pin Assignments

Connector

(J3) Function

2.5 Serial Communications

The J4, J6 and J7 serial communications ports on the

iQube connector board support communications

between the

remote display.)

• Port J4 supports full-duplex RS-232

To attach serial communications cables, plug cable

into the external DB-9 connectors labeled Remote

Display.

Table 2-2 shows the pin assignments for connectors

J4, J6, and J7.

Connector DB-9 Pin Pin Signal

J4

(Host Com)

J6

(Remote)

J7

(Remote)

iQube and a host device (PC and/or

communications between the

iQube unit and a

host device.

Port J6 and J7 are used to connect to the

remote display(s).

Male 2 1 TxD

Male 3 2 RxD

Male 5 3 Gnd

Female 1 1 DC+

Female 2 2 GnD

Female 9 3 TxD

Female 1 1 DC+

Female 2 2 GnD

Female 9 3 TxD

2.6 Core Module DIP Switches

The DIP switches on the iQube core module must be

set to configure the

iQube as a primary or secondary

unit, and to specify the type of serial communications

provided by the unit.

Table 2-3 lists the DIP switches

and their functions.

Switch Function Values

1–3 Primary OFF, OFF, OFF = PRIMARY

4 Setup enable ON = setup enabled

5 Host

communication

protocol

6 Host

communication

port

7 Reserved OFF

8 Load default OFF

Table 2-3. Core Module DIP Switch Settings

OFF = RS-232

OFF = Port J7

2.7 Core Module Reset Procedure

If VIRTUi does not recognize the connection to the

load cell, the core module may need to be reset to

initialize the

To reload the default firmware into the iQube core

module, do the following:

1. Power-off the iQube. Remotely powered units

2. Set core module DIP switch 8 ON.

3. Power-on the iQube.

4. Power-off the iQube.

5. Set DIP switch 8 OFF.

6. Power-on the iQube. The reset is now complete.

iQube firmware.

can be powered off by temporarily removing

fuse F1 (see

Figure 2-1 on page 2).

Table 2-2. Serial Port Pin Assignments

Communications Cable Distance Limitations

The maximum cable lengths that can be used for

various communications types depend on a number of

factors. These include: output impedance of the

transmitter; electrical noise in the environment; cable

capacitance, gauge, termination, and shielding.

Installation 3

Page 8

2.8 The Power Supply

The internal power supply provides 7.5VDC power

for the

iQube from 115 or 230 VAC power sources.

Figure 2-2. iQube 7.5V Power Supply

2.11 Replacement Parts and Drawings

Table 2-5 lists replacement parts for the Trac er AVi.

2.9 Fuse Replacement

Fuse F1 on the iQube connector board (see Figure 2-1

on page 2) provides protection for power supplied to

the connector board and core module at connector J5.

Fuse F1 is poly resettable and does not need

replacement. See

Section 6.0 on page 17 for complete

fuse specifications.

2.10 Interface Cables

Table 2-4 lists the cables for the iQube.

PN Description

50749 Cable for com port to PC

72704 RS-232/USB connector

93563 Cable for remote display

Table 2-4. iQube Cables

PN Description (Quantity)

93550

93552 Connector board (1)

93553

76556 Power supply (1)

93213 Remote display enclosure, front (1)

93214 Remote display, back (1)

93561 Remote display CPU board (1)

93215 Display lens (1)

93633 Installation manual (1)

iQube enclosure (1)

iQube core module (1)

Table 2-5. Replacement Parts

4 Trac er AVi Installation Manual

Page 9

NETWORK

PC

running

VIRTUi

USB

A

C

P

O

W

E

R

RS-232 to USB

CONVERTER CABLE

PORT

iQUBE

Remote Display Remote Display #2

CAPACITY 500 x 0.5lb/250 x 0.2kg CLASS III n

lb

kg

1000

max.

Gr

Nt

CAPACITY 500 x 0.5lb/250 x 0.2kg CLASS III n

Gr

lb

kg

1000

max.

Nt

Benchmark HD Scale Base

LOAD CELL CABLE

Figure 2-3. System Configuration

Figure 2-4. Remote Display Cutout

Installation 5

Page 10

Figure 2-5. Remote Display Drawing

85-265 VAC,

50-60Hz,

2A

6 Trac er AVi Installation Manual

Remote Display

Remote Display

Com Port

Figure 2-6. iQube Cable Connections

Load Cell

Page 11

3.0 PC Configuration

The iQubeTM can be configured using a PC running VIRTUi.

3.1 Introduction to VIRTUi

VIRTUi is a PC-based virtual indicator designed to replicate the form and function of a single function indicator.

The virtual front panel consists of a display and five-button keypad. Keys are activated by a mouse click.

Features included:

• Electronic data processing (EDP) port for

full-duplex, RS-232 communications up to

57600 bps

• Printer port for output-only, RS-232

communications up to 57600 bps

Figure 3-1. VIRTUi Main Screen

VIRTUi is NTEP-Certified for Classes III and III L at

10,000 divisions

NOTES:

To send and receive commands from VIRTUi using

HyperTerminal:

1. Open HyperTerminal on the PC

2. Connect to “localhost” on port 20355 using

TCP/IP

By default, VIRTUi is always the top window within

®

Windows

. This is required by NTEP to ensure the

weight is visible at all times. This can be changed in

the Application Settings if Legal-for-Trade

requirements are

not necessary.

Auto-Update Feature

If connected to the Internet, VIRTUi’s Auto-update

feature will automatically download updates to the

program. The auto-update feature will only function if

the user is logged in to Windows as “Administrator”

and/or if the user has “write” access to the application

installation directory.

PC Configuration 7

Page 12

3.1.1 Authentication/Authorization System

The User Manager is a security feature of VIRTUi and

is used to set up

VIRTUi users, their “roles” and the

permissions for those roles. The User Manager for

authentication/authorization can be found under the

File menu. After installing

VIRTUi, the user must

logon as “Administrator” to access the User Manager.

Figure 3-3. Username and Password

Figure 3-2. Logon

Certain VIRTUi functions can be disabled for particular users, or roles. Only the Administrator can configure the

User Manager.

8 Trac er AVi Installation Manual

Figure 3-4. User Manager

Page 13

To add a new user, a user name and password must be configured.

Figure 3-5. Add User

Using the Permissions Manager, resources and allowed roles can be configured for each role.

Figure 3-6. Permissions Manager

PC Configuration 9

Page 14

3.1.2 Communication

The steps in this section summarize how to configure VIRTUi to communicate with the iQube and a remote

display.

1. With the PC and iQube connected and the

VIRTUi program running, select

Communications Settings from the Settings menu.

2. Select iQube Port in the left section of the

4. Select Stream format in the left section of the

screen under the Communications folder

5. Select Rice Lake Extended from the drop-down

box and click

Save.

screen under the Communications folder.

3. Mark the Streaming Port checkbox, shown in

Figure 3-7, and click Save.

Figure 3-8. Stream Format

Figure 3-7. iQube Port

3.1.3 Function Keys and Annunciators

Function keys and annunciators are summarized in this section.

Function Keys

The function keys below perform the front panel functions via the computer keyboard:

Key F5 F6 F7 F8 F9

Function Zero Gross/Net Ta re Units Print

Table 3-1. Function Keys

Annunciators

The VIRTUi display uses a set of eight annunciators to provide additional information about the value being

displayed:

• Gross and Net annunciators are lit to show whether the display weight is a gross or net weight

• Center of Zero: Gross weight is within 0.25 graduations of zero. This annunciator lights when the scale is

zeroed

• Standstill: Scale is at standstill or within the specified motion band. Some operations, including tare

functions and printing, can only be done when the standstill symbol is shown

• The display units can also be set to short tons (tn), metric tons (t), or NONE (no units information

displayed). The lb and kg annunciators default as primary and secondary unit annunciators. Changing

unit annunciators under the Settings menu will also change the annunciators on the

3.1.4 VIRTUi Operations

VIRTUi display.

This section summarizes the basic operations of VIRTUi.

Toggle Gross/Net Mode

Press the Gross/Net key to switch the display mode between Gross and Net. If a tare value has been entered or

acquired, the net value is the gross weight minus the tare. Gross mode is shown by the Gross annunciator; Net

mode is shown by the Net annunciator.

10 Tracer AVi Installation Manual

Page 15

Zero Scale

1. In gross mode, remove all weight from the

scale and wait for the standstill annunciator.

2. Press the Zero key. The Center of Zero

annunciator lights to indicate the scale is

zeroed.

Remove Stored Tare Value

1. Remove all weight from the scale and wait for

the standstill annunciator.

2. Press the T ARE key. The indicator switches to

gross mode, indicating the tare value has been

removed.

Acquire Tare

1. Place container on scale and wait for standstill

annunciator.

2. Press the TARE key to acquire the tare weight

Print Ticket

1. Wait for standstill annunciator.

2. Press the Print key to send data to the serial

port.

of the container. The indicator switches to net

mode.

3.1.5 Web Browser-Based Cell Status

iQube load cell status can be reported via a standard web browser . A “http://localhost:5050” URL is used to view

the status page. “Http” must be included as it is not inferred, and “localhost” can be replaced with the appropriate

IP address or domain name.

Figure 3-9. Cell Status

3.1.6 System Requirements

Minimum

• Windows 98 or greater

• I nternet Explorer 5.5 or greater

• .NET Framework 1.1

•64 MB RAM

• 30 MB free hard drive space

• Serial port connection for connection to

iQube

Additional serial ports are required for connection to

printers/remote displays.

Recommended

• Windows 2000 or greater

• I nternet Explorer 6.0 SP1

• . Net Framework 1.1

•128 MB RAM

• 30 MB free hard drive space

• Serial port for connection to iQube

Additional serial ports are required for connection to

printers/remote displays.

PC Configuration 11

Page 16

3.2 VIRTUI Configuration

VIRTUi can be used to set iQube configuration parameters. When configuration is complete, data is downloaded

iQube.

to the

To configure the iQube using VIRTUi:

1. With the PC and iQube connected and the VIRTUi program running, select iQube Configuration from the

Settings menu.

Figure 3-10. VIRTUi Tracer AVi Display

2. Select the Cells display. Use this display to select the load cell used in the Tracer AVi system by checking

the box to the left of the cell. Enter load cell data such as factory sensitivity, serial number, and capacity

on the General Information sheet for the cell.

3. Select the Platforms display. The cell that was checked on the Cells screen is now listed as Available

Load Cell for the iQube.

4. Click on Platform 1.

5. Double-click on the load cell to move the cell into the Assigned Load Cell column for Platform 1.

As the cell is added to the Assigned Cell column, a Section Format Diagram is displayed at the bottom of

the screen.

6. Select the Systems display.

7. Click on System 1.

8. Platform 1 is now shown in the Assigned Platforms field. Click the Platform 1 box to assign Platform 1 to

System 1. Use the General display to enter scale system parameters.

3.2.1 Downloading to the Tracer AVi

Once configuration is complete, you must download the configuration data from the PC to the iQube.

1. Select Send Configuration to write the values to the iQube.

2. Click Begin to initiate the download. Downloading may take up to 30 seconds.

12 Tracer AVi Installation Manual

Page 17

4.0 Calibration

VIRTUi Calibration

With the iQube connected to a PC running the VIRTUi program, do the following:

1. From the Settings menu, select Calibration then Multi-Point.

Figure 4-1. Platform Selection

2. Remove all weight from the scale platform. Click on Calibrate. The word Tr an sm it ti ng is displayed while

the zero value is calculated. This process can last up to 45 seconds.

Figure 4-2. Calibration

3. Enter the test weight value in the Calibration Weight field. You are now ready to measure the load cell

output using the Multi-Point procedure.

Calibration 13

Page 18

4. Place the test weight over the cell to be measured.

Figure 4-3. Multi-Point Calibration

5. Click the first Measure box.

Figure 4-4. Step Complete

14 Tracer AVi Installation Manual

Page 19

6. Click Finish. Multi-Point automatically calculates the load cell trim factor.

Figure 4-5. Calibration Complete

7. Click Exit.

iQube calibration is complete. You can view the active status of the cell, platform, or system by returning to the

Tools menu and selecting Cell Diagnostic Monitor. Click on the Auto Refresh box to automatically update the readings

from the

iQube.

Calibration 15

Page 20

5.0 Diagnostics

5.1 Diagnostic Tests

The iQube provides a number of diagnostic tests, including boundary, weighing, and system tests.

5.2 Diagnostic Setup

Parameters associated with each of the iQube’s diagnostic tests can be set using VIRTUi.

Figure 5-1. VIRTUi Diagnostic Setup Display

16 Tracer AVi Installation Manual

Page 21

6.0 Specifications

Power

Power Consumption (+7.5 VDC)

1-channel, 350Ω load cell 75 mA (0.563 W)

Fuse 2A TR5 subminiature fuse

Wickmann Time-Lag 19374 Series

UL Listed, CSA Certified and Approved

A/D Specifications

Excitation Voltage 4 VDC (+4V and ground, single-sided)

Analog Signal Input Range –11.7 mV to +27.3 mV

A/D Sample Rate 15 Hz

Serial Communications

J4 Port Full duplex RS-232

J6 Port Simplex RS-232

J7 Port Simplex RS-232

Environmental

Operating Temperature–10 to +40 C (14 to 104 F)

Storage Temperature –10 to +70 C (14 to 158 F)

Humidity 0–95% relative humidity

Enclosure

Enclosure Dimensions 8.00 in x 6.00 in x 3.5 in

20 cm x 15 cm x 9 cm

Weight 1.0 lb (.453 Kg)

Certifications and Approvals

O

C

N

NTEP

F

L

E

A

R

N

E

O

I

N

T

C

A

E

N

•

•

O

N

W

E

I

G

H

T

CoC Number 03-032

S

E

R

U

S

A

Accuracy Class III/IIIL n

E

S

M

A

D

N

: 10 00000

max

Specifications 17

Page 22

Tracer AVi Limited Warranty

Rice Lake Weighing Systems (RLWS) warrants that all RLWS equipment and systems properly installed by a

Distributor or Original Equipment Manufacturer (OEM) will operate per written specifications as confirmed by

the Distributor/OEM and accepted by RLWS. All systems and components are warranted against defects in

materials and workmanship for two years.

RLWS warrants that the equipment sold hereunder will conform to the current written specifications authorized

by RLWS. RLWS warrants the equipment against faulty workmanship and defective materials. If any equipment

fails to conform to these warranties, RLWS will, at its option, repair or replace such goods returned within the

warranty period subject to the following conditions:

• Upon discovery by Buyer of such nonconformity, RLWS will be given prompt written notice with a

detailed explanation of the alleged deficiencies.

• Individual electronic components returned to RLWS for warranty purposes must be packaged to

prevent electrostatic discharge (ESD) damage in shipment. Packaging requirements are listed in a

publication, Protecting Your Components From Static Damage in Shipment, available from RLWS

Equipment Return Department.

• Examination of such equipment by RLWS confirms that the nonconformity actually exists, and was

not caused by accident, misuse, neglect, alteration, improper installation, improper repair or

improper testing; RLWS shall be the sole judge of all alleged non-conformities.

• S uch equipment has not been modified, altered, or changed by any person other than RLWS or its

duly authorized repair agents.

• RLWS will have a reasonable time to repair or replace the defective equipment. Buyer is responsible

for shipping charges both ways.

• In no event will RLWS be responsible for travel time or on-location repairs, including assembly or

disassembly of equipment, nor will RLWS be liable for the cost of any repairs made by others.

THESE WARRANTIES EXCLUDE ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING WITHOUT

LIMITATION WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. NEITHER

RLWS

NOR DISTRIBUTOR WILL, IN ANY EVENT, BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES.

RLWS AND BUYER AGREE THAT RLWS’ SOLE AND EXCLUSIVE LIABILITY H EREUNDER IS LIMITED TO

REPAIR OR REPLACEMENT OF SUCH GOODS. IN ACCEPTING THIS WARRANTY, THE BUYER WAIVES ANY AND

ALL OTHER CLAIMS TO WARRANTY.

SHOULD THE SELLER BE OTHER THAN RLWS, THE BUYER AGREES TO LOOK ONLY TO THE SELLER FOR

WARRANTY CLAIMS.

NO TERMS, CONDITIONS, UNDERSTANDING, OR AGREEMENTS PURPORTING TO MODIFY THE TERMS OF THIS

WARRANTY SHALL HAVE ANY LEGAL EFFECT UNLESS MADE IN WRITING AND SIGNED BY A CORPORATE

OFFICER OF RLWS AND THE BUYER.

© 2007 Rice Lake Weighing Systems, Inc. Rice Lake, WI USA. All Rights Reserved.

RICE LAKE WEIGHING SYSTEMS • 230 WEST COLEMAN STREET • RICE LAKE, WISCONSIN 54868 • USA

18 Tracer AVi Installation Manual

Loading...

Loading...