Page 1

SURVIVOR PT

Pit-Type Truck Scale

Installation Manual

®

53280 Rev C

Page 2

Page 3

Contents

Technical training seminars are available through Rice Lake Weighing Systems.

Course descriptions and dates can be viewed at www.ricelake.com/training

or obtained by calling 715-234-9171 and asking for the training department.

1.0 Introduction..................................................................................................................................... 1

1.1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2.1 Foundation Slab Cure Period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2.2 Assembly Time Estimates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.2.3 Recommended Tools and Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3 Lifting and Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.4 Temporary Setting Blocks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.0 Assemble Deck Modules ................................................................................................................ 4

2.1 Place End Module A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2 Place and Attach Center Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3 Install Outriggers and Deck Coping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.4 Level Module Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.0 Load Cell Mount Installation........................................................................................................... 7

3.1 Attach Upper Mount Chair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2 Prepare Baseplate and Mount Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.3 Raise Mount into Final Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.4 Attach Flexible Conduit Sections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.4.1 Attach Grounding Strap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.4.2 Install Lower Module Assembly Bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.4.3 Install Anchor Bolts and Grout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.5 Install Support Bars, Corrugated Metal, and Deck Rebar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.5.1 Corrugated Metal Sheeting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.6 Deck Rebar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.0 Pour and Finish Concrete Deck .................................................................................................... 12

4.1 Optional Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.0 Cable Installation.......................................................................................................................... 14

5.1 Load Cells to J-Box. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.2 Junction Box to Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.3 Indicator to Peripherals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.4 Single-Point Ground Conductor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.5 J-Box Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5.6 Electrical Ground Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.7 Install Transient Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.0 Trimming and Calibration............................................................................................................. 19

6.1 Overview and Equipment Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.2 Trimming Individual Cells . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.3 Trimming Paired Sections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.4 Calibration with Test Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

7.0 Load Cell Replacement................................................................................................................. 23

7.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7.2 Replacement Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

© Rice Lake Weighing Systems. All rights reserved. Printed in the United States of America.

Rice Lake Weighing Systems is an ISO 9001 registered company.

Specifications subject to change without notice.

November 5, 2014

Contents i

Page 4

Vehicle Scale Limited Warranty............................................................................................................... 24

Rice Lake continually offers web-based video training on a growing selection

of product-related topics at no cost. Visit www.ricelake.com/webinars.

For More Information ................................................................................................................................ 25

ii Survivor PT - Pit Type Truck Scale

Page 5

1.0 Introduction

Note

DANGER

WARNING

CAUTION

Important

WARNING

This manual is intended for use by technicians responsible for installing and servicing the Survivor PT series truck

scale. You will find that the scale has been designed so that your on-site installation time is reduced as much as

possible. A well-organized, experienced installation crew should be able to install a typical 70’x 11’ truck scale in

one day.

This booklet covers the Survivor PT truck scale installations. Use these instructions as general installation

guidelines unless the engineering drawings furnished with the scale differ from the instruction in this booklet.

Engineering drawings furnished with the scale always take priority over these general installation guidelines.

Refer to the engineering drawings furnished with the scale for all component numbering sequences.

Manuals can be viewed or downloaded from the Rice Lake Weighing Systems website at

www.ricelake.com.

1. 1 S af e ty

Safety Symbol Definitions:

Indicates an imminently hazardous situation that, if not avoided, will result in death or serious injury.

Indicates a potentially hazardous situation that, if not avoided, could result in serious injury or death and

includes hazards that are exposed when guards are removed.

Indicates a potentially hazardous situation that, if not avoided, may result in minor or moderate injury.

Indicates information about procedures that, if not observed, could result in damage to equipment or

corruption of and loss of data.

General Safety

Do not operate or work on this equipment unless you have read and understand the instructions and

warnings in this manual. Failure to follow the instructions or heed the warnings could result in injury or

death. Contact Rice Lake Weighing Systems for replacement manuals. Proper care is your

responsibility.

Failure to heed may result in serious injury or death.

DO NOT allow minors (children) or inexperienced persons to operate this unit.

DO NOT operate without all shields and guards in place.

DO NOT use for purposes other than weight measurement.

DO NOT place fingers into slots or possible pinch points.

DO NOT use any load-bearing component that is worn beyond 5% of the original dimension.

DO NOT use this product if any of the components are cracked.

DO NOT exceed the rated load limit of the unit.

DO NOT make alterations or modifications to the unit.

DO NOT remove or obscure warning labels.

Keep hands, feet and loose clothing away from moving parts.

Introduction 1

Page 6

1.2 Installation

Note

The modular sections of the Survivor PT truck scale are shipped pre-assembled and ready to be placed into position

on temporary setting blocks using a crane capable of handling 10,000 lbs. The individual modules are bolted

together and the deck is leveled in final position flush with the top of the pit. Mounts are shipped pre-assembled

with load cells, adapters, and flexible conduit sections attached. Mounts are installed to the level of the deck, then

anchored and grouted to the foundation. Cabling is run in conduit and electronic equipment connected to finish the

installation.

The general assembly order is summarized below:

1. Set deck modules into position on setting blocks and bolt deck modules together.

2. Install outriggers and deck channel coping.

3. Place deck into final position even with top of pit.

4. Assemble mounts with load cells to the deck unit; remove setting blocks.

5. Install mount anchor bolts and grout beneath mount plates.

6. Install corrugated sheet metal, rebar and pour concrete.

7. Run cabling through conduit; make electrical connections.

8. Connect indicator and peripheral devices.

9. Calibrate scale.

1.2.1 Foundation Slab Cure Period

Standard concrete reaches full strength after a 28-day cure. Note that the concrete foundation must cure in a moist

state for at least seven days (three days for high-early concrete). At seven days, standard concrete is approximately

75% of its maximum strength and can handle moderate loads. Loading of a slab before it reaches 75% of maximum

strength may damage the foundation.

1.2.2 Assembly Time Estimates

When scheduling installation for a typical three-section, 70' truck scale, plan for a two-hour minimum crane rental

to position the sections.

A two-man crew, aided by a crane operator, can unload modules from the truck, place them into position and bolt

them together in one to two hours. Mount and load cell installation requires approximately two hours. All electrical

wiring and final connections can normally be completed the same day.

These estimated times may vary.

1.2.3 Recommended Tools and Equipment

The following is a list of recommended tools and equipment necessary to assemble and install the Survivor PT

truck scale:

• One heavy duty crane, equipped with chains or cables, for module placement;

• Rotary hammer drill (3/4");

• Drill with 5/16" socket for installing sheet metal screws through corrugated sheeting;

• Carbide masonry bit (3/4" x 30");

• Two low-profile, four-ton hydraulic jacks;

• Setting blocks (15-1/4") and shims to total 13-3/4" height;

• Torque wrench (800 ft-lb);

• Socket wrenches to 1-5/8" (drive compatible with torque wrench);

• Box end wrenches to 1-1/2";

• Open end wrench set (7/16"-3/4");

• Four-foot bubble or construction level (transit);

• Small torpedo level;

• Spacers for deck-to-pit wall alignment;

• Hammers, maul, pry bar;

• Hand tools for pulling and connecting electrical wiring and sheet metal cutting and trimming.

2 Survivor PT - Pit Type Truck Scale

Page 7

1.3 Lifting and Handling

Note

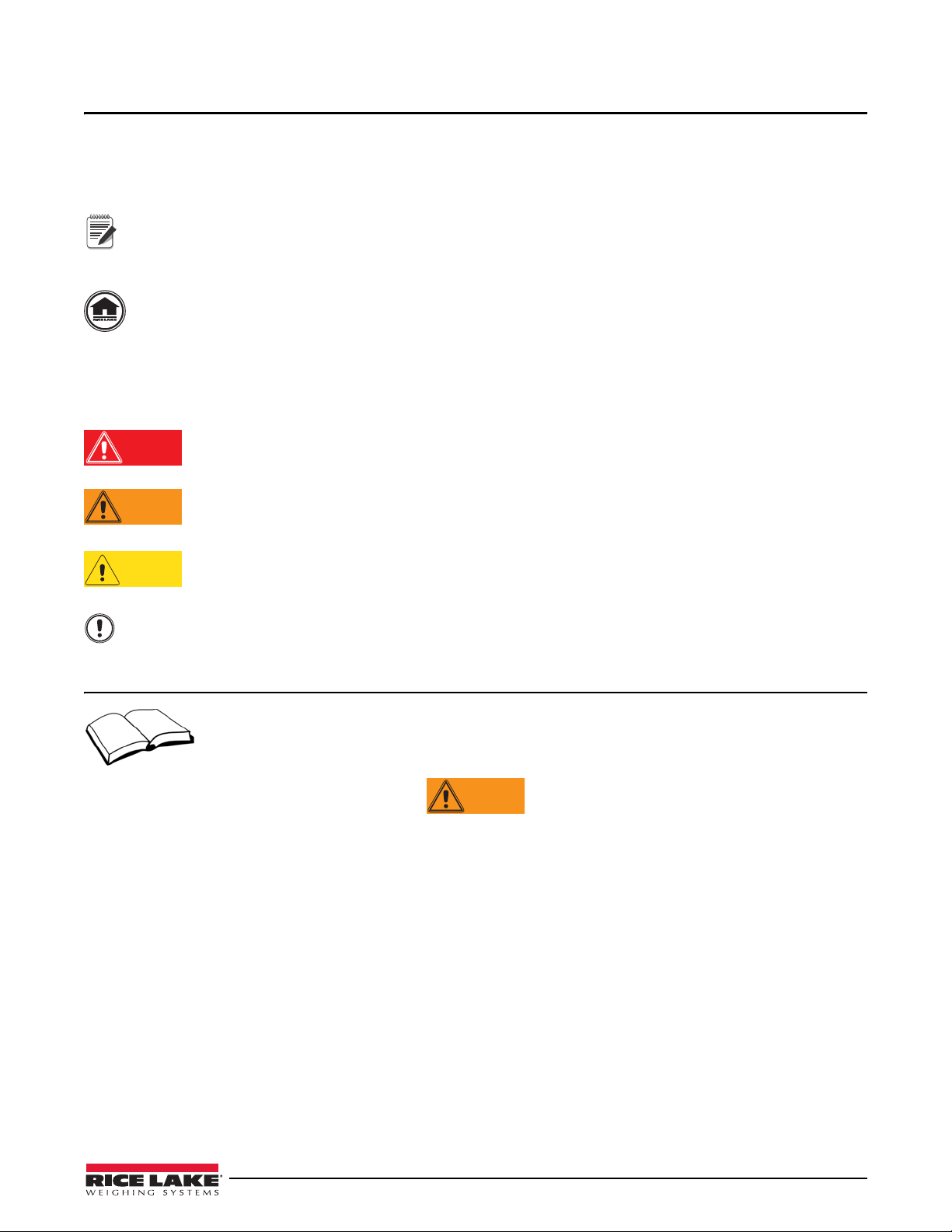

7.5"

15.25"

45.5" with grout

44.38" with out grout

23.92"

6.33"

Figure 1-1. Setting Block Diagram.

Note

The top module can be lifted using four chains attached to the four lift lugs

provided with the scale. Once the first module is removed from the truck and is

placed on the setting blocks, the four lift lugs can be removed and used for lifting

and positioning the other modules.

Rice Lake Weighing Systems will credit the customer for the return of the four lift lugs. Please call for an RMA

number.

1.4 Temporary Setting Blocks

Most installers use 15-1/4" temporary setting

blocks for initial module positioning and to aid

in installing deck module bolts. When an end

module is placed into position on the setting

blocks, the top of the module will be 6-1/3"

below the top of the pit. The outriggers and deck

coping are assembled before the load cells

mounts are installed and will bring the top of the

scale to approximately 1/3" below the top of the

pit. Shims are added during final leveling to

raise the deck surface the last 1/3".

Please refer to the construction prints included with the SURVIVOR® Survivor PT truck scale to confirm all

foundation and scale dimensions.

Do not place the setting blocks in the location on the piers where the load cell mounts are to be placed.

Introduction 3

Page 8

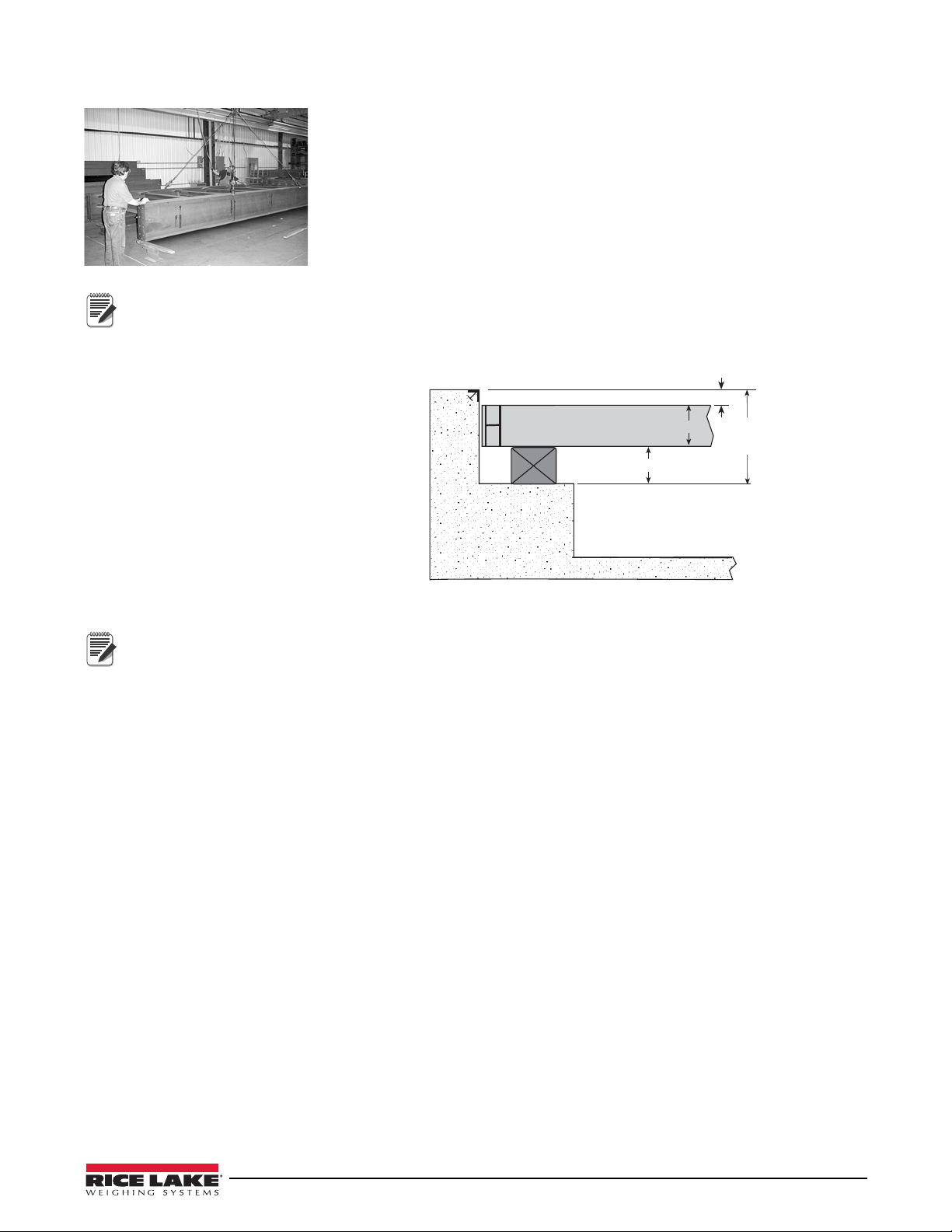

2.0 Assemble Deck Modules

CENTEREND END

Note

Note

Note

Note

The modules are designated either as an end module or a center module. All two-module scales will have two end

modules, while longer scales will have two end modules and one or more center module (Figure 2-1).

Figure 2-1. Center and End Modules

In a three module scale, the end module is the first to be positioned on setting blocks followed by the center

module. The last module to be assembled is an end module. Scales with more than three modules will have

additional center modules installed.

Example – a 100' scale would have two end modules and three center modules.

2.1 Place End Module A

Place one 15 1/4" temporary setting block on the top of each pier and position them so that they will not interfere

with the installation of the load cell mounts. The scale module should be 3/4" away from the bulkhead ramp and

3/4" from each pit wall side. By using the 15 1/4" blocks, the top of the main beam will be approximately 6-1/3"

below the top of the pit.

2.2 Place and Attach Center Module

To assist in easy assembly of the center module, make sure that both modules have direct end-to-end surface

contact.

10. Place four 15 1/4" setting blocks on top of the piers in the center sections.

11. Position and place the center module on the setting blocks, making sure that both the end module and

center module end plates are aligned.

12. Check that the module is centered side-to-side in the pit.

At the installer’s discretion, install the center section with the J-box on the near side to the scale house.

13. When both modules are aligned, insert the top three 1 1/8" bolts with flat washers, lock washers and nuts

on the outside of the beam. (Leave out the bottom bolt to facilitate load cell mount installation).

Tighten bolts and nuts finger tight until all modules are in place.

A long pry bar can be used to make small adjustments in module alignment, but it is easier to leave the

second module attached to the crane for making small alignment changes.

14. Install the three top bolts, washers and nuts on the inside of the beam. Install the bolts, washers and nuts on

the opposite beam using six bolts, washers and nuts. Tighten only finger tight.

Figure 2-2. Top Bolts, Washers, and Nuts Installed

Do not install the bottom bolt at this time.

4 Survivor PT - Pit Type Truck Scale

Page 9

15. If required, place and install any additional center modules in a similar manner.

Note

Manhole Frame

(24" square)

Note

Top View

To Scale House

Suggested Location of Manhole

Junction Box

Corrugation Support Bar

(remove material as needed

to install manhole frame)

16. Install the remaining end module on four setting blocks ensuring the end beams are aligned with and in

direct surface contact with the center module.

Figure 2-3. Module Installation

17. Center the module side-to-side and check that the end of the main beam is 3/4" from the end of the

concrete pit wall. Install and tighten the three top bolts on each beam (inside and outside) finger tight as in

the previous operation.

Do not install the bottom bolt at this time.

18. To reduce the on-site crane operating time, the manhole frame (shown in Figure 2-4 on page 5) can be

installed at this time. It is recommended to locate the frame in a central location close to the J box as shown

in Figure 2-5 on page 5.

Figure 2-4. Manhole Frame

Before installing the manhole frame, remove a section of the corrugation support bar in the location where the

manhole frame is to be installed. Additional manholes are available as options. Consult with local weights and

measures officials for any state restrictions or access in the state being installed.

OSHA may have restrictions on pit access. Consult with customer’s safety engineers for details.

Figure 2-5. Optimal Manhole Frame Location

Assemble Deck Modules 5

Page 10

2.3 Install Outriggers and Deck Coping

Outrigger

Note

1/2" Shims Installed

Here if Required

Note

1. Install the outriggers on each module section using 3/4" x 2 1/2" bolts, washe rs and nuts at the locations

shown on the drawing. Torque all bolts to 260 ft-lb.

Figure 2-6. Outrigger Location

2. Position an L-shaped deck coping on top of the outriggers and secure it to the module frame with 1/2" x 2"

bolts, nuts and washers.

3. Assemble the center section deck coping to the end channels using four 2 1/2" bolts, washers and nuts.

4. Attach the third module deck coping to the center section and to the end of the module assembly.

To compensate for irregularities in pit dimensions, 1/2" shims are provided with the truck scale kit assembly.

These shims are to be inserted (if required) between the coping attach points and the module frame assembly.

5. Repeat procedure for the opposite side. Recheck module assembly to see if it is centered side-to-side in the

pit.

Figure 2-7. Optional Shim Placement

As an optional recommended procedure, and to make the module deck coping more rigid, each deck coping may be

tack welded to the outrigger at each contact location. It should be noted that during the concrete pour the deck

coping may bow outward towards the pit walls. To maintain a 3/4" gap between the deck coping and the side of the

pit, it is recommended that temporary spacers (3/4" bolts or shim stock) be used

between the deck coping and the pit wall. Remove spacers after the concrete has set and before the scale is put into

service.

Install the 3/4" bolts or shim stock and space at equal intervals between the deck coping and the pit wall

coping before welding.

2.4 Level Module Assembly

Using a suitable jack and shims, raise each module section so that the top of the deck coping is level with the top of

the pit. After raising module assembly, re-check module alignment to make sure that the top is level and centered

side-to-side in the pit.

6 Survivor PT - Pit Type Truck Scale

Page 11

3.0 Load Cell Mount Installation

Note

Note

Load cell mounts, complete with load cells and conduit adapters, have been assembled at the factory to save on-site

installation time. Load cell mount installation consists of sliding the complete unit into place beneath the deck,

raising the mount with the leveling screws to the deck, and connecting the grounding strap.

When installing load cell mounts, start at one corner of the module assembly and install the remaining load cell

mounts on that side. Likewise, when the load cell mounts are installed on the other side, start with the corner of the

module assembly.

The lower mounts assemblies come complete with load cells installed, so complete any necessary welding on the

scale before installing mounts.

Remove load cell mount from packing box and file printed load cell Certification of Conformance (CC) in a safe

place for future reference.

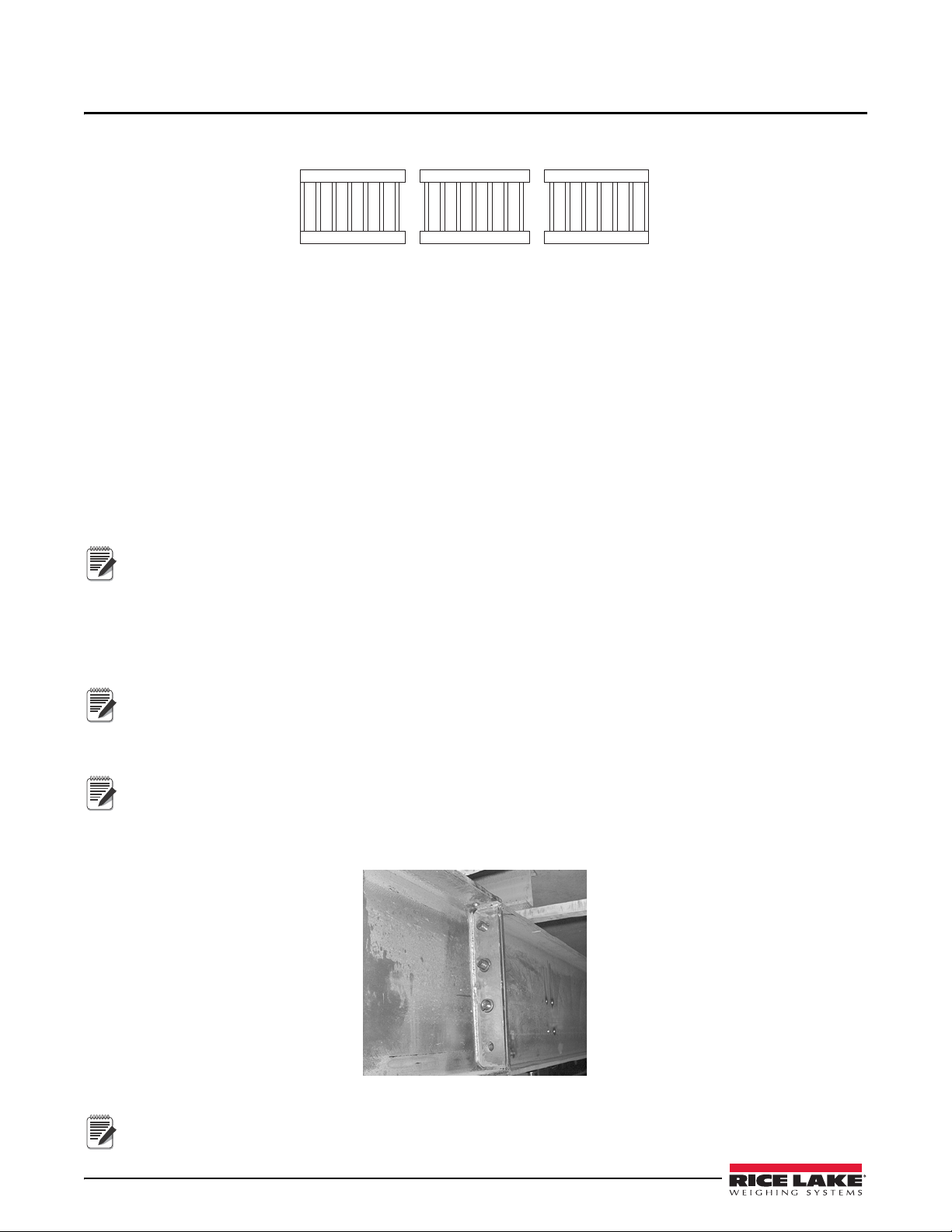

3.1 Attach Upper Mount Chair

1. Attach the upper chair to the bottom of the module assembly by using four 3/4" bolts with washers making

sure that the 1/4" hole for ground strap installation is toward the center of the scale module.

Figure 3-1. Upper Chair Bolts Installed.

2. Torque upper chair bolts to 200 ft-lb.

3.2 Prepare Baseplate and Mount Installation

1. Turn the four leveling screws through the baseplate so approximately 1/2" extends beyond the bottom

surface.

2. Each load cell mount comes equipped with a 90 degree threaded LB conduit adapter. Orient the adapter so

that the cable will point toward the inside of the scale when mounted.

Each mount must be oriented so the cable exit from the load cell is facing the interior of the module to which

it will be attached. The correct orientation will place the flexible conduit section on the load cell near the rigid

conduit attached to the weighbridge.

3. If a load cell must be reversed to achieve correct orientation, remove a load cell and reverse its direction in

the field. When re-tightening load cell bolts, torque to 70 to 80 ft-lb. The 90 degree fitting on the flexible

conduit attached to a load cell can rotate 180 degrees to allow for correct conduit placement.

4. Set the mount assembly on the concrete pier directly in front of its final position. Carefully slide the mount

into position under the upper chair.

Load Cell Mount Installation 7

Page 12

3.3 Raise Mount into Final Position

UPPER CHAIR

LINK

1/4" PROTRUSION

LOAD CELL

LEVELING SCREW

BASEPLATE

1/2"

Note

1. Turn the leveling screws to raise the mount until the link is centered in the chair bearing and lightly

touching.

2. Level the plate in both directions. When the baseplate is directly under the chair, the link will be hanging

vertical when centered in the chair, see Figure 3-2. Approximately 1/4" of the link should protrude beyond

each side of the chair, seeFigure 3-3.

Figure 3-2. Final Mount Position

3. If adjustment is necessary, tap baseplate edges lightly with a hammer to slide the entire mount sideways.

Figure 3-3. Load Cell Mount Parts

3.4 Attach Flexible Conduit Sections

A 30" section of flexible conduit (Figure 3-4) is included on each load cell.One end is threaded for mating with the

LB connector at the load cell. The other end adapts to 3/4" galvanized rigid conduit.

Flexible conduit may also be plastic-coated metal (flex conduit).

8 Survivor PT - Pit Type Truck Scale

Figure 3-4. Flexible conduit.

Page 13

3.4.1 Attach Grounding Strap

Grounding Strap

Attachment Point

Note

NOTE: Do not drive anchor bolt

without driver pipe.

1. Remove the 1/4-20 hex bolt with washer in the upper chair. Use this bolt to attach the braided grounding

strap to the upper chair as shown below.

Figure 3-5. Grounding Strap Location.

2. Attach lower end of grounding strap to either one of the two holes in the baseplate.

3.4.2 Install Lower Module Assembly Bolts

Upon completing the load cell mount installation, the lower module assembly bolts can be installed at each

location. Torque all module assembly bolts to 200 ft-lb.

3.4.3 Install Anchor Bolts and Grout

Install Anchor Bolts

Each mount requires two anchor bolts to prevent lateral motion. Two 7" x 3/4" anchor bolts with expansion heads

are supplied with the scale for each load cell. The anchor bolts are installed in holes in each module pier.

1. Use an industrial hammer drill with a 3/4" carbide masonry bit at least 36" long to drill anchor bolt holes.

This long bit allows the drill body to clear the side rail so the hole can be drilled nearly vertical. Hold the

bit as close to vertical as possible and drill a 3/4" hole at least 6" into the concrete pier beneath each anchor

bolt slot on both sides of the baseplate.

2. Place a washer and nut on each anchor bolt. Use a 24" long driver pipe with an inside diameter slightly

larger than the 3/4" bolt (shown in the illustration below) to drive anchors into the drilled holes until the

washer is solid against the baseplate.

Do not apply excessive force to the anchor bolt. Bending of the baseplate could occur.

Figure 3-6. Drive anchors into drilled holes.

Load Cell Mount Installation 9

Page 14

Grouting

Note

CHANNEL

NELSON STUD

CANTILEVER

SUPPORT

MAIN BEAM

CROSS BEAM

CORRUGATED METAL

MINIMUM OVERLAP

DRAWING NOT TO SCALE)

1. Erect temporary dams around each baseplate and inject 9000 psi non-shrinking, epoxy/cement grout.

2. Take care not to leave air voids; the baseplate must have even support from continuous grout contact.

After the grout has hardened, tighten anchor bolt nuts until the heads expand and the bolts are solidly

anchored.

Figure 3-7. Grout example.

3.5 Install Support Bars, Corrugated Metal, and Deck Rebar

3.5.1 Corrugated Metal Sheeting

To support the concrete deck pour, 26-gauge galvanized corrugated metal sheeting (15/16" by 3 3/4" wide

corrugations) is installed on the main frame assembly. The panels are installed perpendicular to the cross beams

and rest on the cantilever support channels, the main beams, and the frame cross beams.

1. Install the sheet metal starting below the Nelson studs along one side of the frame.

2. Form the sheet metal to the contour of the frame assembly and overlap adjoining panels a minimum of 15"

or four full corrugations.

Figure 3-8. Installation of Support Bars, Corrugated Metal, and Deck Rebar.

Panels must fit closely to the vertical webs of all support beams to prevent concrete run-out during the

deck pour .

10 Survivor PT - Pit Type Truck Scale

Page 15

3. Trim sheet metal as needed for clearance around any vertical gussets in the support beams and around the

Note

Note

manhole on the cross beams. Figure 3-9 shows the metal sheeting used on a EZ-SR truck scale installation.

Figure 3-9. Metal sheeting example.

Secure the corrugated metal sheet to the manhole frame by installing 12 sheet metal screws (or tack weld)

around base of manhole frame.

When pouring concrete, make sure that concrete is poured over the overlap not into the overlap.

3.6 Deck Rebar

Concrete deck reinforcing consists of installing #5 rebar on 12" centers at the locations shown on the drawing

along with using standard construction practices.

At the installer’s discretion, rebar may or may not be tied together.

The first (bottom) layer of rebar installation consist of positioning 6'-3" rebars perpendicular to the main beams and

on 1-1/2" chairs (bolsters) located on top of the corrugated sheet metal. On top of this rebar layer, a second layer

(70' rebar) is installed perpendicular to the first layer and parallel to the main beam.

The third layer will be the 2' rebar placed on chairs. On top of these will be another layer of 70' rebar running the

length of the frame assembly.

The final two layers will require installing 9'-4' rebar on the appropriate chairs. On this will be the top layer of 70'

rebar.

Load Cell Mount Installation 11

Page 16

4.0 Pour and Finish Concrete Deck

With a concrete crew of three experienced workers, a 70' by 10' scale can be

poured and finished in approximately three hours. Access to only one side of

the scale is necessary as most concrete trucks carry extension chutes at least 16'

long. If possible, order concrete in front-unloading trucks. The truck will be

moving slowly while filling; the improved driver-visibility with frontunloading makes that process faster and more accurate.

To protect against unsightly concrete splatters on the top of the support

channels, mask off the top of the channel with tape or use 4 to 6 mil plastic to

cover the top surface.

Position the unloading chute at the near left side of the scale and begin filling

having the truck move slowly to the right.

T o ensure concrete flowing evenly into the frame and encasing all Nelson studs and

rebar, a concrete vibrator is highly recommended. These units are available for rent

at most construction equipment rental sources. They work very quickly to level

concrete, settle out surface stones, and leave a stone-free layer at the top surface to

make finishing easier.

After vibrating to approximate level, screed the concrete to the level of the top of

the support channels with a 2x4 board cut to length

With the deck level and floated, finish with either a magnesium float or steel

trowel for a neat deck line level with the top of the support beams and top of the

pit.

When the entire frame has been floated with a magnesium float and has set

enough for finishing, use a radius edger to finish the metal/concrete joint.

For a non-skid surface, use a stiff bristle broom for a brushed finish when the

concrete has set enough for final finishing. It is recommended that a non-skid

surface be applied for all northern tier states.

12 Survivor PT - Pit Type Truck Scale

Page 17

Curing the Completed Concrete Deck

The concrete deck must be maintained in a moist state for at least seven days for a satisfactor y cure. If the top

surface of the deck is allowed to dry during this time, the finished surface will be prone to unsightly spalling and be

weakened from surface cracking.

A moist surface can be maintained by covering the entire deck with a continuous 4 to 6 mil sheet of polyethylene

plastic turned up and dammed at the ends and kept filled with 1" of water. Alternately, an epoxy-based concrete

curing solution can be sprayed or rolled onto the deck surface immediately after final finishing and while the

concrete surface is still moist. As the epoxy curing solution will also seal in concrete stains on the exposed support

beams, clean off stains with a damp sponge before applying the curing solution to the deck. Epoxy-based concrete

curing products are available at contractor-supply companies. Do not use the petroleum-based or paraffin-based

waterproofing agents specifically advertised for wood decks and concrete patios. These products are not curing

agents, and will allow the deck surface to rapidly dry.

4.1 Optional Equipment

The following is a brief summary of the optional Survivor SR-PT equipment available from RLWS.

Eighteen Inch Main Beam Module

An 18" main beam module is available from RLWS as an option. Use of this option will require increasing the pit

pillar height approximately 6". Refer to the appropriate drawing for exact pit dimensions. This option should only

be used in states where there is a requirement for a minimum of 48" clearance below the main I-beam flange. (Steel

weight is increased approximately 1/3 when selecting this option.)

Pour and Finish Concrete Deck 13

Page 18

5.0 Cable Installation

Load Cell

Cable to

Connector

Pocket 1 Conduit

Pocket 8 Conduit

Pockets 1, 2, 3, 4

Conduit runs to J-Box

Pocket 5 Conduit

Module A Module B

Pocket 3 Conduit

1

8

2

7

SI - Green

SI - White

EX - Red

EX - Black

SHD - Shield

+

+

-

+SI

-SI

+EX

-EX

SHD

+SI

-SI

+EX

-EX

SHD

+SI

-SI

+EX

-EX

SHD

+SI

-SI

+EX

-EX

SHD

J3

J4

J7

J8

J6

J5

J2

J1

+SI

-SI

+EX

-EX

SHD

+SI

-SI

+EX

-EX

SHD

+SI

-SI

+EX

-EX

SHD

+SI

-SI

+EX

-EX

SHD

Load Cell #1 Load Cell #3

Load Cell #8 Load Cell #6

Load Cell #2 Load Cell #4

Load Cell #7 Load Cell #5

+SI

-SI

+EX

-EX

SHD

-SEN

+SEN

SHD - Shield

+SI

-SI

+EX

-EX

SHD

-SEN

+SEN

Indicator/J10

Expansion/J9

Cable to Indicator

SI - Green+

SI - White-

EX - Red+

EX - Black-

SEN - Yellow-

SEN - Blue+

Pocket 4 Conduit

Pocket 6 Conduit

6

3

Pocket 4 Conduit

Pocket 5 Conduit

5

4

Module C

Note

5.1 Load Cells to J-Box

If using a single center module, some of the conduit runs are not used. These conduit runs are used when

Figure 5-1. J-Box Wiring and Conduit Runs for a Four Secti on/ Three Module Scale

more than one center module is installed.

14 Survivor PT - Pit Type Truck Scale

Page 19

Pocket 1 Conduit

Pockets 1 and 2

Conduit runs to J-Box

Pocket 3 Conduit

Pocket Conduit for J-Box 2

cable to Expansion Slot in J-Box 1

Pocket 5 Conduit

Load Cell

Cable to

Connector

Pocket 9 and 10

Conduit runs to J-Box

SI - Green

SI - White

EX - Red

EX - Black

SHD - Shield

+

+

-

+SI

-SI

+EX

-EX

SHD

+SI

-SI

+EX

-EX

SHD

+SI

-SI

+EX

-EX

SHD

+SI

-SI

+EX

-EX

SHD

J3

J4

J7

J8

J6

J5

J2

J1

+SI

-SI

+EX

-EX

SHD

+SI

-SI

+EX

-EX

SHD

+SI

-SI

+EX

-EX

SHD

+SI

-SI

+EX

-EX

SHD

Load Cell #1

Load Cell #2

Load Cell #9

Load Cell #3

Load Cell #10

Load Cell #8

+SI

-SI

+EX

-EX

SHD

-SEN

+SEN

SHD - Shield

+SI

-SI

+EX

-EX

SHD

-SEN

+SEN

Indicator/J10

Expansion/J9

Cable from J-Box 2

SI - Green+

SI - White-

EX - Red+

EX - Black-

SEN - Yellow-

SEN - Blue+

Pocket 10 Conduit

Module C Module B Module AModule D

Pocket 4 Conduit

3

8

2

1

10

9

5

4

Section 1B

Section 1A

Section 2B

Section 2A

Section 3B

Section 3A

Section 4B

Section 4A

Section 5B

Section 5A

6

7

Pocket 5 and 6 Conduit

J-Box 2

J-Box 1

Load Cell

Cable to

Connector

SI - Green

SI - White

EX - Red

EX - Black

SHD - Shield

+

+

-

+SI

-SI

+EX

-EX

SHD

+SI

-SI

+EX

-EX

SHD

J3

J4

J2

J1

+SI

-SI

+EX

-EX

SHD

+SI

-SI

+EX

-EX

SHD

Load Cell #4 Load Cell #7

Load Cell #5 Load Cell #6

+SI

-SI

+EX

-EX

SHD

-SEN

+SEN

SHD - Shield

+SI

-SI

+EX

-EX

SHD

-SEN

+SEN

Indicator/J10

Expansion/J9

Cable to J-Box 1

SI - Green+

SI - White-

EX - Red+

EX - Black-

SEN - Yellow-

SEN - Blue+

Detail A

Detail B

SHD - Shield

Cable to Indicator

SI - Green+

SI - White-

EX - Red+

EX - Black-

SEN - Yellow-

SEN - Blue+

J-Box 1 - Detail A

J-Box 2 - Detail B

Each load cell is equipped with 60' of load cell cable, sufficient to reach a centrally-located junction box on

standard scales. A watertight conduit adapter and a 30" section of 3/4" flexible conduit is supplied for both ends of

each load cell cable located at the load cell and at the junction box. Main conduit runs between these 30" flexible

end sections are 3/4" galvanized metal conduit already installed on the deck.

Figure 5-2. J-Box W i ring and Conduit Runs for a Five Section/Four Module Option

Cable Installation 15

Page 20

5.2 Junction Box to Indicator

Note

Ground Lug

(located next to J-box)

R41

JP17

JP7

R52

R50

R40

R24

R14

R15

JP20

JP10

R26

R51

R49

R47

JP16

R45

R43

JP9

R23

R21

JP6

JP8

R17

R38

R36

R34

JP11

R32

R30

R28

R10

R8

JP1

R4

R2

R33

JP12

JP2

VR9

JP19

R48

VR7

JP18

R42

R44

R22

R25 R16

R18

VR2

R19

R39

VR10

R35

R37

VR11

R27

R29

R31

R9

R11

R12

R1

R3

R5

VR5

R6

JP5

JMP/NEGJMP/POS

VR8

VR3

VR1

VR12

VR6

J1

VR4

J2

R13

R7

EXPANSION/J9

J5

ARC

R46

JP4

JP3

ARGND

JP14

JP15

JP13

L3

L4

L2

J8

J4

J3

J6

L1

R20

J7

INDICATOR/J10

JP

TRIM

TRIM

TO

-EX

+EX

+SI

-EX

+EX

+SI

-EX

+EX

1

+SI

-EX

+EX

+SI

JP

JP

TO

SIGNAL

2005

SIGNAL

CUT

TO

DISABLE

CUT

CELL#

CELL#

CELL#

SHD

1

SHD

-SI

1

-SI

SHD

-SI

1

-SI

SHD

SIGNAL

CUT

TO

CUT

SECT#

DISABLE

CELL#

CELL#

SIGNAL

SIGNAL SIGNAL

D

L

D

DISABLE

CELL#

SECT#

DISABLE

CELL#

RICE LAKE WEIGHING SYSTEMS

JP

-EX

+EX

+SI

-EX

+EX

+SI

-EX

+EX

+SI

-EX

+EX

+SI

SIGNAL

TRIM

TRIM

TRIM

TRIM

TRIM

TRIM

Assembly

-EX

-EX

+EX

+SI

SHD

1

SHD

-SI

1

-SI

1

-SI

SHD

1

-SI

SHD

CONNECT BOTH SHUNTS

TO APPLY SIGNAL

SECT#

SIGNAL

SIGNAL

SIGNAL

CELL#

PN Rev.

+SI

-SI

-SI

SECT#

+SEN

SHD

+SEN

SHD

DISCONNECT BOTH SHUNTS

TO REMOVE SIGNAL

+EX

-SEN

-SEN

CUT TRACE TO ISOLATE SENSE LINE

Transient Board Connectors

Grounding Lug

10 ga. bare ground wire

to DC protection ground

connection before indicator

Figure 5-3. J-Box Grounding.

Note

A 60' section of 6-wire home run cable is supplied. It is to be run in 3/4" galvanized metal conduit from the

junction box to the indicator. A 30" flexible conduit section and watertight conduit connector is provided where

this cable exits the junction box. Galvanized metal conduit must be obtained locally.

Scales over 70 feet in length have two or three j-boxes. Refer to Engineering Drawings provided with scale for

details.

5.3 Indicator to Peripherals

All 3/4" metal conduit for cabling from the indicator to remote displays and other peripheral devices must be

obtained locally. Conduit runs may be buried in a trench or secured above ground. Use separate conduit runs for

AC power and DC data lines to avoid interference. As a general guideline, run AC and DC cables in separate

trenches if possible. When DC data cables must run in the same trench as AC power lines, separate cables as much

as possible.

5.4 Single-Point Ground Conductor

A bare 10-gauge solid wire is run from the scale frame to the grounding lug on the junction box, then underground

to the main AC power earth ground. If the optional DC transient protection board is installed, the ground conductor

should also be connected to the transient protection board’s ground lug. Consult with the local power utility for

restrictions or requirements for utility ground rod connections.

5.5 J-Box Connections

Each JB8SPT j-box is large enough to hold the summing

board, transient protection devices, desiccant package, and

extra load cell cable coiled inside the enclosure.

In a single-platform scale, the single j-box location is

determined by the length of the load cell cables and the four

mounting studs on the outside main beams. Both A and B

modules are equipped with mounting studs. In a multi-axle

scale with independent sections, each section requires its own

junction box to sum the load cell signals from that section.

A summing card mounted within the junction box is used to

make all cable terminal connections. All terminal pin

functions are clearly marked.

A 10-gauge bare ground wire is run from one of the junction

box mounting studs to the ground lug of the junction box as

shown in the figure below. The ground lug on the bottom of

the junction box is connected to a buried ground cable from

the AC power ground terminal or ground rod, thus grounding

the scale frame to the same single-point ground point as the

AC power for the indicator.

Before final closure, add an industrial corrosion inhibitor and

desiccant (RLWS Industrial Corrosion Inhibitor, PN 16037)

to the junction box enclosure. This desiccant protects an enclosure up to 5 ft

approximately 1 year.

3

from internal corrosion for

Make sure that the 10 gauge ground wire makes connection to bare metal.

16 Survivor PT - Pit Type Truck Scale

Page 21

5.6 Electrical Ground Connections

Note

Improper grounding systems on outdoor truck scales often cause corrupted data as a result from ground-loop

current flows. Improper grounding systems may also invite possible lightning strikes and cause damage to

costly electronic systems. Always attempt to establish a single-point grounding system.

When establishing a ground system for the scale installation, do not install more than one ground rod for each scale

location. Separate earth grounds do not share the same zero reference as the existing earth ground for the AC power

system. The difference in electrical potential invites ground-loop current flow between the separate grounds, often

corrupting serial data, such as RS-232, which depends on a stable zero reference.

In addition, a separate earth ground system at the scale can actually invite lightning or power surge damage:

• A minor power line surge in the scale house electrical supply should immediately be shunted to ground. If a

separate ground system exists at the scale with a lower potential than the main ground, the surge may travel to

the scale ground rod, damaging load cells on its way.

• A lightning ground strike may instantly raise the zero potential of a ground rod at the scale location while

leaving the scale house ground rod unaffected. A lightning surge takes the easiest path to the lower-potential

ground: through the scale wiring and back to the scale house ground, therefore possibly damaging the indicator

on its way.

The best grounding system for the scale is the same grounding system used for the incoming AC power system.

The 120 VAC power source used to power the indicator is connected to an existing earth ground rod system at the

scale house or other building where the indicator is located. This consist of a double ground rod system of two 5/8"

x 8' copper rods driven 8' deep at the service entrance where the local utility company brings their lines into the

building. The local utility company can test the resistance of the existing ground rods with a clamp-on megohmeter

to measure resistance. A reading of 3 3/4" or less is acceptable as a ground. If the test determines that the grounding

system is inadequate, the utility company can suggest methods to improve the system. It is crucial that the scale

owner authorize and make the recommended improvements to assure an adequate electrical ground. Do not

connect the scale to the AC power supply until the grounding system is adequate.

Each load cell grounding strap is securely fastened to the top and bottom plates of each load cell mount. The

grounding strap is designed to channel power surges on the deck around—rather than through—the load cell to

ground. All ground connections must be properly torqued and rechecked at regular service intervals. After

connecting to bare metal apply a thick coating of anti-oxidant grease on all ground connections to prevent

corrosion.

A separate grounding system conductor must extend uninterrupted from the main service panel ground to the scale

to protect load cells and scale wiring from lightning and other transient damage. As a minimum requirement for

ground wire installation, the conductor must be at least a 10-gauge unsheathed copper wire. Run the bare ground

wire conductor intact from the AC power ground rod to the scale in a separate trench. Bring the wire up from the

trench near the junction box and attach it to the ground lug of the junction box. Use a short piece of 10-gauge wire

to ground the scale frame by running a ground wire from the junction box ground lug to a junction box mounting

bolt on the scale frame.

5.7 Install Transient Protection

An five-year lightning protection package comes standard on all SURVIVOR® 920i truck scales. This package is

designed to protect the AC and DC portions of the system. The package includes:

• A DC transient protection board mounted within the junction box. This DC transient protector can

accommodate up to eight load cells and will help protect serial communication lines. Scales with more than

eight load cells require a DC transient protection board in each junction box.

• A self-contained DC transient protection unit in the homerun cable at the indicator.

• A 10-gauge bare ground conductor cable. This conductor cable, to be buried underground, runs from the scale

frame to the junction box DC transient board, to the indicator DC transient board, and finally to the AC power

ground lug.

• A 120 VAC uninterruptable power supply/surge protector in the AC line before the indicator.

Transient protection for additional peripheral devices (except some boards) is not included in the standard

transient protection package. Call the Rice Lake Weighing Systems Sales Department at (715) 234-9171 for

additional transient protection for these devices.

Cable Installation 17

Page 22

AC Power

Supply

#10 Copper

Ground Wire

Serial

Communication

Homerun

Cable

Load Cell

Cable

UJB-3T6

DC Transient Protection

RLWS PN 21134

TP-232

DC Transient Protection

RLWS PN 33185

TP-232

DC Transient Protection

RLWS PN 33185

AC Outlet

Leviton U0425-AKP

AC Transient Protection

RLWS PN 99224

AC Outlet

Power Company Ground Rod

*Always verify that installed wiring is properly grounded

JB8SPT

Junction Box

With Transient Protection

RLWS PN 91783

R41

JP17

JP7

R52

R50

R40

R24

R14

R15

JP20

JP10

R26

R51

R49

R47

JP16

R45

R43

JP9

R23

R21

JP6

JP8

R17

R38

R36

R34

JP11

R32

R30

R28

R10

R8

JP1

R4

R2

R33

JP12

JP2

VR9

JP19

R48

VR7

JP18

R42

R44

R22

R25 R16

R18

VR2

R19

R39

VR10

R35

R37

VR11

R27

R29

R31

R9

R11

R12

R1

R3

R5

VR5

R6

JP5

JMP/NEGJMP/POS

VR8

VR3

VR1

VR12

VR6

J1

VR4

J2

R13

R7

EXPANSION/J9

J5

ARC

R46

JP4

JP3

ARGND

JP14

JP15

JP13

L3

L4

L2

J8

J4

J3

J6

L1

R20

J7

INDICATOR/J10

JP

TRIM

TRIM

TO

-EX

+EX

+SI

-EX

+EX

+SI

-EX

+EX

1

+SI

-EX

+EX

+SI

JP

JP

TO

SIGNAL

2005

SIGNAL

CUT

TO

DISABLE

CUT

CELL#

CELL#

CELL#

SHD

1

SHD

-SI

1

-SI

SHD

-SI

1

-SI

SHD

SIGNAL

CUT

TO

CUT

SECT#

DISABLE

CELL#

CELL#

SIGNAL

SIGNAL SIGNAL

D

L

D

DISABLE

CELL#

SECT#

DISABLE

CELL#

RICE LAKE WEIGHING SYSTEMS

JP

-EX

+EX

+SI

-EX

+EX

+SI

-EX

+EX

+SI

-EX

+EX

+SI

SIGNAL

TRIM

TRIM

TRIM

TRIM

TRIM

TRIM

Assembly

-EX

-EX

+EX

+SI

SHD

1

SHD

-SI

1

-SI

1

-SI

SHD

1

-SI

SHD

CONNECT BOTH SHUNTS

TO APPLY SIGNAL

SECT#

SIGNAL

SIGNAL

SIGNAL

CELL#

PN Rev.

+SI

-SI

-SI

SECT#

+SEN

SHD

+SEN

SHD

DISCONNECT BOTH SHUNTS

TO REMOVE SIGNAL

+EX

-SEN

-SEN

CUT TRACE TO ISOLATE SENSE LINE

Transient Board Connectors

Grounding Lug

Leviton U0425-AKP

AC Transient Protection

RLWS PN 99224

Figure 5-4. Single-Point Grounding Diagram.

18 Survivor PT - Pit Type Truck Scale

Page 23

6.0 Trimming and Calibration

1st – Trim Side 1 Cells

(1, 2, 3, 4)

2nd – Trim Side 2 Cells

(5, 6, 7, 8)

3rd – Trim Sections

(1, 8; 2, 7; 3, 6; 4, 5)

Weight

Cart

1 432

8 567

Load Cell numbers

as viewed from

Digital Indicator

6.1 Overview and Equipment Required

Load Cell Trimming

Individual load cell signal trimming (equalizing the signal output from each load cell) must be done first along

each side of the scale so all cells on a side have equal signal output. Adjustments are somewhat interactive, so each

side should be done at least twice.

Once that is done, load cell pairs—one from each side—are trimmed as paired sections until each sectional output

is equal. Adjustments to each section should also be done at least twice.

Equipment Required

Both of these trimming operations can be done u sing only a weight cart parked in various locations on the scale.

Final verification of equal output trimming, however, will require test weights to be placed on the deck in various

locations.

6.2 Trimming Individual Cells

1. Connect all load cells to the summing board terminals in the junction box.

2. Connect the main interface cable from the junction box to the indicator.

3. Power up the indicator .

4. Turn all load cell potentiometers (individual and section) in the junction box clockwise until a clicking

noise is heard when you continue turning. This eliminates any initial resistance so all signals are at full

strength. You’re now ready to do individual signal trimming.

Side 1

The first objective is to adjust individual load cells along one side of the scale for equal signal output when equal

weight is put on those cells. For convenience, that side of the scale will be referred to as Side 1. The trimming

weight you will use will be the loaded weight cart.

1. Park the cart as close as possible to Side 1 being trimmed with the wheels centered over the end load cell

mount (No. 1 in drawing to below). Record the indicator reading. Remember that the scale is still

uncalibrated, so the indicator readings are simply raw counts rather than weight units.

Figure 6-1. Load Cell Trimming Diagram

Trimming and Calibration 19

Page 24

Figure 6-2. Trimming Load Cell Number One

1 432

8 567

1 432

8 567

1 432

8 567

Note

2. Move the cart directly over mount No. 2 and record that reading. Move the cart directly over mount No. 3

and record that reading. Move the cart so the wheels are centered directly over mount No. 4 (you may have

to turn the weight cart around so all wheels remain on the scale) and record the reading.

Figure 6-3. Trimming Load Cell Numb ers Two, Three, and Four

3. The lowest reading of the four will be your reference cell. You won’t change that cell’s signal. Instead

you’ll use the individual cell potentiometers for the other three cells to reduce those signals to match your

reference cell. Remember that you turned all pots to full signal (0 resistance) before starting. So you can’t

increase the signal from any cell—you can only decrease signal by trimming with the pots.

4. Note that the best trim is always the least trim. If one of the four readings differs from the others by more

than 5% of the displayed counts, there is probably a mechanical problem with that load cell mount causing

the large difference. Find it and correct it before going on. Check for binding, an out-of-level or misalign ed

link, or similar problems with the load cell and mount. Do not try to trim down large signal differences

with resistance pots—you’ll only add larger problems for yourself later because of interaction between

mounts.

5. Park the loaded weight cart over one of the high-reading cells on Side 1. Turn that cell’s individual

potentiometer until the displayed reading equals your recorded reference cell reading. Repeat for the other

two high-reading cells on side 1.

6. As adjustments are somewhat interactive, repeat the process in Steps 1 through 5 until all four cells on Side

1 read within 1% of each other.

7. Side 2. Move to the Side 2 of the scale. Load each cell in turn with the weight cart and record readings on

those four cells in the same way . The cell which r eads the closest to the Side 1 r efer ence cell will be used as

your reference cell for trimming the other cells on side 2.

Figure 6-4. Trimming Load Cell Number Five.

The reference cell on Side 2 should be the same as the Side 1 readings. Move the weight cart over the cell

chosen for the Side 2 reference cell. Adjust the cell’s individual pot to equal the final Side 1 readings. In the

example at left, Cell 8 has been chosen as the Side 2 reference cell.

8. Reload the other Side 2 cells (5, 6, 7 in the example) in turn with the weight cart and adjust their individual

pots so their readings are equal to the Side 2 reference cell (8 in the example).

20 Survivor PT - Pit Type Truck Scale

Page 25

Figure 6-5. Trimming Lo ad Cell Number Eight.

1 432

8 567

1 432

8 567

1 432

8 567

9. Repeat Steps 7 through 9 if needed to get all Side 2 cells reading within 1% of each other and within 1% of

the Side 1 reference cell.

6.3 Trimming Paired Sections

Now that you’ve trimmed all individual load cells for equal output, pairs of load cells on opposite sides of the scale

must be trimmed for equal sectional output. This process is called section signal trimming.

1. Park the loaded weight cart in the middle of the scale and directly over an imaginary line connecting an

end pair of cells (1 and 8 in the example at right). Record the indicator reading.

Figure 6-6. Trimming Paired Section 1:8.

2. Move the weight cart directly over the next paired cell section (2, 7 in Figure 6-7) and record the indicator

reading.

Do the same for the last two paired sections (cells 3, 6 and 4, 5).

3. Choose the lowest reading of the four as your reference section, which will not be adjusted. Using the

4. As a final verification of the load cell trimming, do a final corner check. Place a 1000 lb. weight on one

Figure 6-7. Trimming Paired Sections 2:7, 3:6, and 4:5.

section potentiometers, reload the other three sections in turn and trim the sections to match the reading of

the reference section. Recheck section readings a second time as the adjustment made may be somewhat

interactive.

corner of the platform and record the raw-count reading on the indicator. Move the weight to all the other

corners in turn and record those readings. The readings should be within 1% of each other.

Trimming and Calibration 21

Page 26

6.4 Calibration with Test Weights

1 432

8 567

The calibration procedure can only be done after all trimming as described above has been completed. A qualified

scale technician with a test weight truck and the expertise to access the scale indicator’s Setup or Calibration mode

must perform the calibration procedure.

Figure 6-8. Calibration with T est Weights.

Equipment Required

Truck scales are routinely calibrated using 25% of the capacity weight of the scale. Certified Class F test weights

equaling at least 12.5% of the scale’s capacity will be required for calibrating a commercial legal-for-trade truck

scale. In addition, some type of weight for a substitution test of an additional 12.5% of the capacity will be

required. This can be the test-weight truck, bags of sand, or any convenient items easy to load onto the scale. This

total calibration weight of 25% of scale capacity (12.5% test weights, 12.5% substitution weight) is required by

weights and measures officials for commercial truck scales in most states. Check with your local weights and

measures officials for the requirements in your jurisdiction.

Industrial scales not used for legal-for-trade transactions do not require certified test weights. Weight equal to 25%

of scale capacity is recommended for calibrating such scales.

See Handbook 44 for detailed calibration requirements and procedures.

22 Survivor PT - Pit Type Truck Scale

Page 27

7.0 Load Cell Replacement

Upper Chair Bolts

Load Cell

Bolts

Baseplate

Link

Load Cell

Upper

Mount

Chair

Load cell replacement procedures are included in the following paragraphs.

7. 1 O v e r v i e w

Load cells are replaced on the 920i truck scale by jacking up the scale deck approximately 1/4" at the location of the

load cell mount and removing the upper mount chair, load cell and link as a unit.

After loosening the load cell bolts so they clear the threads in the baseplate columns, the four bolts holding the

upper chair to the deck are removed, allowing the chair, load cell and link to be slid out as an assembly. Replace the

load cell and reassemble in the reverse order.

If a low-profile hydraulic jack under 7-1/2" in height is not available, a bracket can be ordered from RLWS (PN

49523) to provide clearance for higher jacks.

Figure 7-1. Load cell mount.

7.2 Replacement Procedure

1. Remove the upper bolt and washer holding the ground strap to the upper chair.

2. Disconnect the flexible conduit section from the rigid metal conduit.

3. Disconnect the load cell terminal connections in the junction box. Attach a pull cord to the end of the load

cell cable and pull the cable out of the rigid conduit to free the load cell cable from the scale deck. Tie off

pull cable so that it will not pull itself back into the conduit.

4. Loosen the two load cell bolts until they disengage from the column threads.

5. Remove the four bolts that hold the upper mount chair to the deck frame.

6. Jack up the scale deck approximately 1/4" at the load cell location. Install blocking for safety.

7. Hold the loosened load cell bolts up to clear the threaded holes in the column and slide the upper chair,

load cell and link straight out as an assembly.

8. Set the chair aside until reassembly.

9. Lift the load cell bolts out of the damaged load cell and remove the cell from its link.

10. Remove flexible conduit section from the 90° elbow conduit connector.

11. Remove two small screws on the side of the 90° elbow connector and remove the access plate.

12. Pull the cable out the access hole. Remove the 90° elbow connector from the load cell.

13. Install the 90° elbow connector and flexible conduit section on the new load cell.

14. Complete reassembly by following Steps 1 through 9 in reverse order.

15. Use the pull cord to get the new load cell cable back into the summing box for connection.

Load Cell Replacement 23

Page 28

Vehicle Scale Limited Warranty

Rice Lake Weighing Systems (RLWS) warrants that all RLWS brand equipment and systems properly installed by

a Distributor will operate in accordance with written specifications as confirmed by the Distributor and accepted by

RLWS. All systems and components are warranted against defects in materia ls and workmanship for 5 years from

date of shipment from the manufacturer. Furthermore, the seller warrants the fabricated weighbridge against faulty

workmanship and defective materials for 10 years from the date of shipment from the manufacturer.

RLWS warrants that the equipment sold hereunder will conform to the current written specifications authorized by

RLWS. RLWS warrants the equipment against faulty workmanship and defective materials. If any equipment fails

to conform to these warranties, RLWS will, at its option, repair or replace such goods returned within the warranty

period subject to the following:

• Upon discovery by Buyer of such non-conformity, RLWS will be given prompt written notice with a

detailed explanation of the alleged deficiencies.

• Individual electronic components returned to RLWS for warranty purposes must be packaged to prevent

electrostatic discharge (ESD) damage in shipment. Packaging requirements are listed in a publication,

“Protecting Your Components From Static Damage in Shipment,” available from RLWS Equipment

Return Department.

• Examination of such equipment by RLWS confirms that the non-conformity actually exists, and was not

caused by accident, misuse, neglect, alteration, improper installation, improper repair, or improper testing.

RLWS shall be the sole judge of all alleged non-conformities.

• Such equipment has not been modified, altered or changed by any person other than RLWS or its duly

authorized repair agents.

• RLWS will have a reasonable time to repair or replace the defective equipment. Buyer is responsible for

shipping charges both ways.

• Vehicle scale procts are eligible for warranty labor and mileage charges with pre-approval by RLWS

Service Department, and only to the limits described in the vehicle scale reimbursement program.

• RLWS will not be liable for the cost of any repairs made by others.

T

HESE WARRANTIES EXCLUDE ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING WITHOUT

LIMITATION

NOR DISTRIBUTOR WILL BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES.

RLWS

OR

REPLACEMENT OF SUCH GOODS. IN ACCEPTING THIS WARRANTY, THE BUYER WAIVES ALL OTHER CLAIMS

WARRANTY.

TO

S

HOULD THE SELLER BE OTHER THAN RLWS, THE BUYER AGREES TO L OOK ONLY TO THE SELLER FOR

WARRANTY

No terms, conditions, understanding, or agreements purporting to modify the terms of this warranty shall have any

legal effect unless made in writing and signed by a corporate officer of RLWS and the Buyer.

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. NEITHER RLWS

AND BUYER AGREE THAT RLWS’ SOLE AND EXCLUSIVE LIABILITY HEREUNDER IS LIMITED TO REPAIR

CLAIMS.

© Rice Lake Weighing Systems, Inc. Rice Lake, WI USA. All Rights Reserved.

RICE LAKE WEIGHING SYSTEMS • 230 WEST COLEMAN STREET • RICE LAKE, WISCONSIN 54868 • USA

24 Survivor PT - Pit Type Truck Scale

Page 29

For More Information

Web Site

• Frequently Asked Questions (FAQs) at

• http://www.ricelake.com/faqs.aspx

Contact Information

Hours of Operation

Knowledgeable customer service representatives are available 6:30 a.m. - 6:30 p.m. Monday through Friday and 8

a.m. to 12 noon on Saturday. (CST)

Telephone

• Sales/Technical Support 800-472-6703

• Canadian and Mexican Customers 800-321-6703

• International 715-234-9171

Immediate/Emergency Service

For immediate assistance call toll-free 1-800-472-6703 (Canadian and Mexican customers please call

1-800-321-6703). If you are calling after standard business hours and have an urgent scale outage or emergency,

press 1 to reach on-call personnel.

Fax

Fax Number 715-234-6967

Email

• US sales and product information at

• prodinfo@ricelake.com

• International (non-US) sales and product information at

• intlsales@ricelake.com

Mailing Address

Rice Lake Weighing Systems

230 West Coleman Street

Rice Lake, WI 54868 USA

25

Page 30

26 Survivor PT - Pit Type Truck Scale

Page 31

Page 32

230 W. Coleman St. • Rice Lake, WI 54868 • USA

U.S. 800-472-6703 • Canada/Mexico 800-321-6703 • International 715-234-9171 • Europe +31 (0) 88 2349171

www.ricelake.com www.ricelake.mx www.ricelake.eu www.ricelake.co.in m.ricelake.com

Rice Lake Weighing Systems is an ISO 9001 registered company.

© Rice Lake Weighing Systems Specifications subject to change without notice.

© Rice Lake Weighing systems 11/05/2014 PN 53280 Rev C

Loading...

Loading...