Page 1

Survivor PL

Pitless Modular Railroad Track Scale

Installation Manual

®

98740 Rev B

Page 2

Page 3

Contents

Technical training seminars are available through Rice Lake Weighing Systems.

Course descriptions and dates can be viewed at www.ricelake.com/training

or obtained by calling 715-234-9171 and asking for the training department.

About This Manual ................................................................................................................................... 1

1.0 Introduction.................................................................................................................................. 1

1.1 Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.0 Installation ................................................................................................................................... 3

2.1 Foundation Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Weighbridge Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Approach and Dead Space Hardware Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.4 Rail Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 Grouting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.0 Junction Box and Grounding ....................................................................................................... 8

3.1 Load Cells to Junction Box. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2 Junction Box Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Junction Box to Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 Indicator to Peripherals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 Single-Point Ground Conductor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

6 Electrical Ground Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.

Survivor PL Limited Warranty.................................................................................................................. 8

. . . . . 3

. . . . . . . . . 7

. . . . . . . . . 7

. . . . 9

. . . . . 9

. . . . . 9

. . 9

© Rice Lake Weighing Systems. All rights reserved. Printed in the United States of America.

Rice Lake Weighing Systems is an ISO 9001 registered company.

Specifications subject to change without notice.

Version 1.0,

May 31, 2013

Page 4

ii Survivor® PL Installation Manual

Rice Lake continually offers web-based video training on a growing selection

of product-related topics at no cost. Visit www.ricelake.com/webinars.

Page 5

About This Manual

This manual is intended for use by service technicians responsible for installing and servicing Survivor® PL pitless

modular railroad track scales.

Authorized distributors and their employees can view or download this manual from the Rice Lake

Weighing Systems distributor site at

www.ricelake.com/manuals.

1.0 Introduction

The Survivor® PL is a low-profile, pitless modular railroad track scale. This heavy-duty workhorse should provide

decades of accurate rail car weighing.

Onboard Features

Features of the basic Surv

• Gross capacity - 85 tons to 175 tons.

• Sectional capacity - 85 tons.

• Module sizes available in 12’6”, 15’, 18’, and 25’.

• Platform width - 7’8”, 18.5” low-profile design.

• Bolted checkered steel top plate; side accessible.

• Designed for 115 lb. and 132 lb. rail.

• Longitudinal and lateral c

• 100K CSP1 100K load cells.

• Lightning and SS suppression kit.

• Rail clips for deck.

• Anti-creep angles.

• Low-profile above-grade installation.

• Outside access covers for load cells.

• Copper transient bypass cables.

• NTEP-certified, CC#02-087, A1.

• Meets AREMA and Cooper E-80 design specs.

Optional features and accessories include:

• Approach rail base plates, rail clips, nuts,

• Anchor bolts for approach rail plates.

• Custom sizes available.

• Hardware for intermediate section.

• Anchor bolts for load cell and check stands.

The Su

conducted in-house under exacting quality control standards. Each railroad track scale is manufactured under the

precise guidelines outlined by ISO 9001 standards. All weighbridge components are sandblasted to SSPC-A-SP6

standards and cleaned with a hot phosphate cleaning process to remove grease and oil contaminants. After

assembly, all Survivor

finish coat of a two-component high solids urethane paint that protects the weighbridge’s structural integrity and

ensures a long life.

rvivor

®

PL is manufactured on-site at Rice Lake Weighing Systems. All railroad track scale production is

ivor® PL include:

ecking assemblies.

h

w

ashers, and anti-creep angles.

®

track scales are painted with a two-component high solids urethane primer, as well as a

Introduction 1

Page 6

1. 1 S af et y

WARNING

Important

CAUTION

WARNING

DANGER

Safety Symbol Definitions:

Indicates an imminently hazardous situation that, if not avoided, will result in death or serious injury.

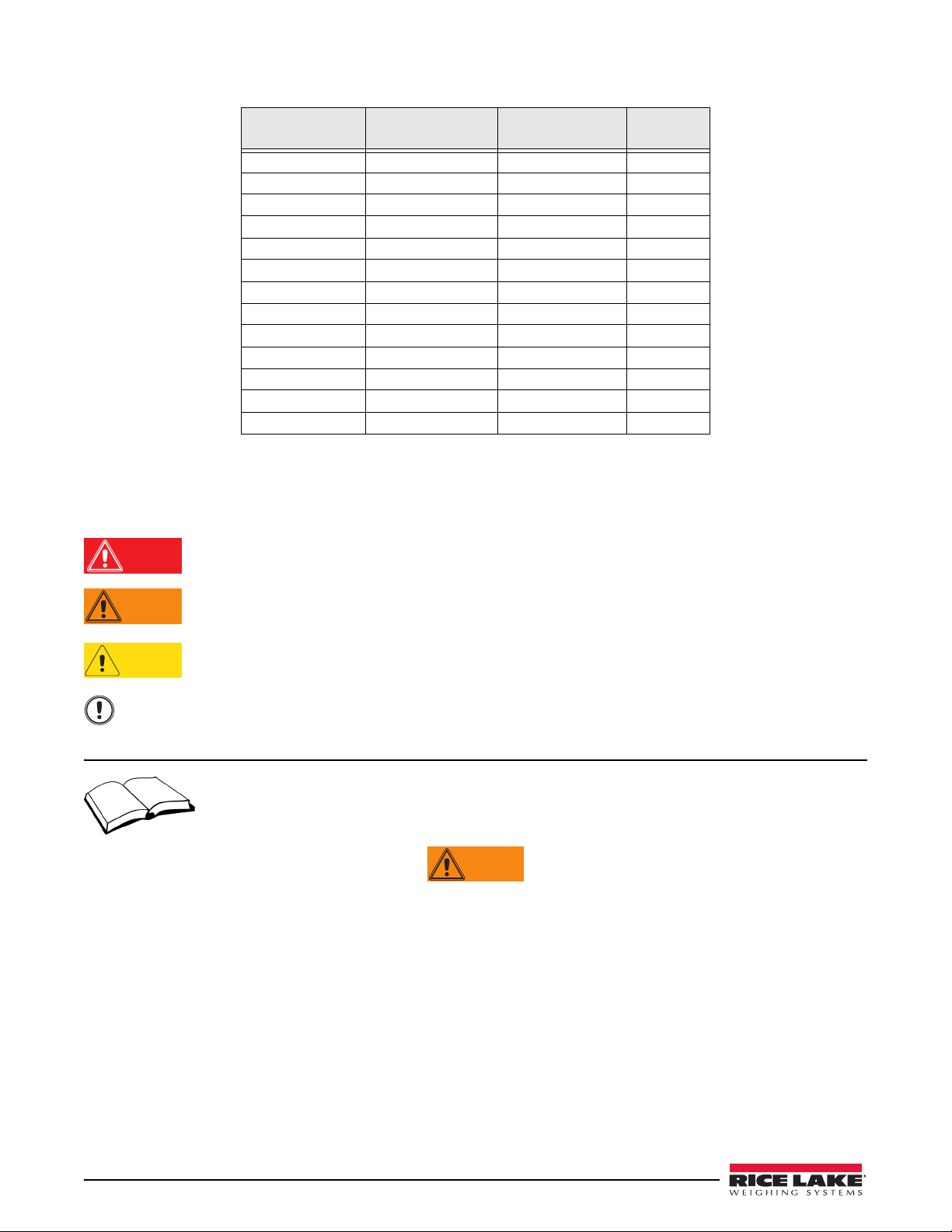

Model Configuration

PL-12-85 Single 12’6” 85 tons

PL-15-85 Single 15’ 85 tons

PL-18-85 Single 18’ 85 tons

PL-12-12-170 Single/Single 12’6” + 12’6” 170 tons

PL-12-18-170 Single/Single 12’6” + 18’ 170 tons

PL-12-15 Single/Single 15’ + 12’ 170 tons

PL-15-18 Single/Single 15’ + 18’ 170 tons

PL-18-18-170 Single/Single 18’ + 18’ 170 tons

PL-15-15 Single/Single 15’ + 15’ 170 tons

PL-12-25-200 Single/Double 12’6” + 25’ 175 tons

PL-15-25 Single/Double 15’ + 25’ 175 tons

PL-25 Double 25’ 175 tons

PL-25-25-230 Double/Double 25’ + 25’ 175 tons

Platform

Size Capacity

Table 1-1. Survivor® PL Series Platform Sizes

Indicates a potentially hazardous situation that, if not avoided

includes hazards that are exposed when guards are removed.

Indicates a potentially hazardous situation that, if not avoided may result in minor or moderate injury.

Indicates information about procedures that, if not observed, could result in damage to equipment or

corruption to and loss of data.

General Safety

Do not operate or work on this equipment unless you have read and understand the instructions and

warnings in this manual. Failure to follow the instructions or

death. Contact any Rice Lake Weighing Systems dealer for replacement manuals. Proper care is your

responsibility.

Failure to heed may result in serious injury of death.

Some procedures described in this manual ar

service personnel only

DO NOT allow minors (children) or inexperience

DO NOT operate without all shields and guards in place.

DO NOT use for purposes other then weight taking.

DO NOT place fingers into slots or possible pinch points.

DO NOT use any load bearing component that is

DO NOT use this product if any of the c

DO NOT exceed the rated load limit of the unit.

DO NOT make alterations or modifications to the unit.

DO NOT remove or obscure warning labels.

Keep hands, feet and loose clothing away from moving parts.

e potentia

d persons to operate this unit.

omponents are cracked.

lly dangerous. These procedures are to be performed by qualified

wor

n beyond 5% of the original dimension.

could result in serious injury or death, and

heed the warnings could result in injury or

2 Survivor

®

PL Installation Manual

Page 7

2.0 Installation

Note

Leveling bolts

Load cell lower

base plate

Anchor bolts

Load cell

Load cell base plate

Load Cell Installed

Load cell spacer plate

This section describes procedures for installing the foundation and weighbridge for of the Survivor® PL railroad

track scale.

2.1 Foundation Installation

Please reference foundation drawings supplied by Rice Lake Weighing Systems for the scale you have purchased.

Do not start construction of the foundation if you do not have certified prints.

1. Pour the scale slab(s).

2. Pour the approach slab and, if applicable, dead

Anchor bolts should protrude from the concrete enough for the lower base plates to be secured onto them.

2.2 Weighbridge Installation

The following steps describe the procedure for installing the Survivor® PL weighbridge.

1. Set load cell lower base plates over the pre-cast anchor bolts.

2. Install leveling bolts into base plates as shown in Figure 2-1.

slab over rebar or optional anchor bolts.

3. Install load cell, spacer plate, and base plate onto lower base plates.

Figure 2-1. Leveling Bolts Installed into Lower Base Plate

Figure 2-2. Load Cell, Spacer Block, and Base Plate

Installation 3

Page 8

4. Set longitudinal brackets (2) and side brackets (2) over pre-cast anchor bolts.

Check rod bracket

End rail support plate

Note

Install upper load

cell components

Weighbridge module pocket

Ground strap

hole

When bolts are tight,

plates will be moveable

WARNING

Figure 2-3. Install Brackets

The rods for the checking system, should be placed beneath the scale prior to setting of the modules.

5. Remove steel top plates from weighbridge module. Mark plates to identify location for re-assembly.

6. Install bearing block, upper mount plate, spacer tubes, bearing cus

7. Set the weighbridge module on 5” setting blocks. Center the module between approaches.

hions, and shim plate in each load cell

pocket of weighbridge module.

Figure 2-4. Upper Load Cell Plate Mounting Procedure

4 Survivor

Crush hazard, keep hands, feet and other body parts clear when setting weighbridge modules in place.

Moving parts can crush and cut.

®

PL Installation Manual

Page 9

Wooden setting

block

Figure 2-5. Weighbridge Module on Setting Blocks

Jack

Load cell

leveling bolts

Upper load cell

mount plate

Note

8. Using a jack and shims, level the module and set its elevation between 2 1/8” and 2 1/4” above concrete

approaches.

Figure 2-6. Module Elevation

9. Using leveling bolts, raise and level the load cell assemblies to contact the upper mount bearing plates.

Figure 2-7. Load Cell Assembly

10. Jack the weighbridge to allow removal of setting blocks and shims.

11. Install lower base plate washers and nuts.

Do not torque nuts until after plates are grouted.

12. Install check rods and hardware. Set check rods level with a horizontal plane to within +/- 2 degree.

Installation 5

Page 10

Check Rod

Figure 2-8. Check Rod Level with Horizontal Plane

Note

13. Weld spacer plates (P/N 71860) to weighbridge to secure it in place.

14. Repeat steps 1-13 for the seco

nd weighbridge module.

2.3 Approach and Dead Space Hardware Installation

The below instructions describe the installation of approach and dead space hardware.

Reference drawings provided for approach and dead space for important details.

1. Install approach plates on anchor bolts.

Figure 2-9. Approach Plate on Anchor Bolts

2. Install approach plates at the required elevation using shims or jam nuts beneath each plate.

3. Install dead space rail plates on anchor bolts.

4. Install dead space rail plates at the required elevation.

5. The rail can now be installed.

6. Once the rail is installed, the elevation plat

es are ready to grout.

6 Survivor

®

PL Installation Manual

Page 11

2.4 Rail Installation

Note

Note

The following instructions describe the installation of rail sections on the Survivor® PL.

1. Cut A.R.E.A. rail sections using 45-degree mitered rail head cuts at the weigh

transitions.

Figure 2-10. Mitered Rail Head Cuts Location

2. Set rail support plates over the pre-cast anchor bolts on the approach and center section foundations.

3. Set weigh rails and approach rails onto the rail support plates.

4. Shim and align rails to match elevation of scale and set the desired grade.

rail and approach rail

Option: Install jam nuts under approach rail support plates to act as a leveling device.

5. Install rail clips and secure rails in place.

6. Install anti-creep rail anchors.

2.5 Grouting

Prior to grouting, re-check all weighbridge and rail alignment, levels, and elevations.

1. Use an epoxy-type 9000 psi grout under the load cell base plates, and a non-shrink cement-type grout

under the approac

Do not grout under the longitudinal check brackets or side check brackets.

2. After grout has hardened, tighten/torque nuts on all anchor bolts.

3. The checking system can now be tightened. Bri

h and center section rail support plates.

ng the nuts up to snug, then use jam nuts to jam.

Installation 7

Page 12

3.0 Junction Box and Grounding

Load Cell

Cable to

Connector

SI - White

SI - Red

EX - Green

EX - Black

SHD - Shield

+

+

-

+SI

-SI

+EX

-EX

SHD

+SI

-SI

+EX

-EX

SHD

+SI

-SI

+EX

-EX

SHD

+SI

-SI

+EX

-EX

SHD

J3

J4

J7

J8

J6

J5

J2

J1

+SI

-SI

+EX

-EX

SHD

+SI

-SI

+EX

-EX

SHD

+SI

-SI

+EX

-EX

SHD

+SI

-SI

+EX

-EX

SHD

Load Cell #1 Load Cell #3

Load Cell #8 Load Cell #6

Load Cell #2 Load Cell #4

Load Cell #7 Load Cell #5

+SI

-SI

+EX

-EX

SHD

-SEN

+SEN

SHD - Shield

+SI

-SI

+EX

-EX

SHD

-SEN

+SEN

Indicator/J10

Expansion/J9

Cable to Indicator

SI - White+

SI - Red-

EX - Green+

EX - Black-

SEN - Yellow-

SEN - Blue+

Load Cell

Cable to

Connector

SI - White

SI - Red

EX - Green

EX - Black

SHD - Shield

+

+

-

+SI

-SI

+EX

-EX

SHD

+SI

-SI

+EX

-EX

SHD

J3

J4

J2

J1

+SI

-SI

+EX

-EX

SHD

+SI

-SI

+EX

-EX

SHD

Load Cell #1 Load Cell #3

Load Cell #8 Load Cell #6

+SI

-SI

+EX

-EX

SHD

-SEN

+SEN

SHD - Shield

+SI

-SI

+EX

-EX

SHD

-SEN

+SEN

Indicator/J10

Expansion/J9

Cable to Indicator

SI - White+

SI - Red-

EX - Green+

EX - Black-

SEN - Yellow-

SEN - Blue+

Detail A

Detail B

Pocket 1

Conduit

Pocket 1 and 4

Conduit run to J-Box

Pocket 2 and 3

Conduit run to J-Box

Module A Module B

Pocket 2

Conduit

Pocket 3

Conduit

Pocket 3 and 4

Conduit run to J-Box

Module C

Conc.

Pier

3

4

2

1

6

5

4

3

2

1

Pockets 1, 2, 5, 6

Conduit run to J-Box

Pocket 1 Conduit

Pocket 1and 6 Conduit

Pocket 2

Conduit

Detail A

Detail B

Note

Cable installation instructions for the weigh module(s) are included in the following paragraphs.

3.1 Load Cells to Junction Box

Each load cell is equipped with 30' of load cell cable, sufficient to reach a centrally-located junction box on

standard scales. A conduit adapter and a 14" section of 3/4" flexible conduit is supplied for both ends of each load

cell cable located at the load cell and at the junction box. Main conduit runs between these 14" flexible end sections

are 3/4" galvanized metal conduit already installed on the deck as shown above.

Flexible conduit can not come in contact with the ground. Plastic tie wraps are included in the hardware

shipping box and should be used to tie up the flexible conduit.

8 Survivor

®

PL Installation Manual

Figure 3-1. J-Box Wiring and Conduit

Page 13

3.2 Junction Box Connections

Important

Each junction box is large enough to hold the summing board, transient protection devices, packaged desiccant,

and extra load cell cable coiled inside the enclosure. An industrial corrosion inhibitor and desiccant such as the

RLWS Industrial Corrosion Inhibitor (PN 16037) should be added to the junction box enclosure before final

closure.

A summing card mounted within the junction box is u

are clearly marked as to function.

sed to make all cable terminal connections. All terminal pins

3.3 Junction Box to Indicator

Sixty feet of six-wire homerun cable is supplied for wiring the junction box to the indicator. It is run in 3/4"

galvanized metal conduit from the junction box to the indicator. Conduit for this purpose is to be obtained locally.

A 30" flexible conduit section and conduit connector is provided where this cable exits the junction box. Do not run

any other electrical cables in or near the conduit to the indicator.

3.4 Indicator to Peripherals

All 3/4" conduit for cabling from the indicator to remote displays and other peripheral devices is to be obtained

locally. Conduit runs may be buried in a trench or secured above ground. Use separate conduit runs for AC power

and DC data lines to avoid interference. As a general guideline, run AC and DC cables in separate trenches if

possible. When DC data cables must run in the same trench as AC power lines, separate cables as much as possible

(preferably more than 34" apart).

3.5 Single-Point Ground Conductor

A bare 10 gauge solid wire is to be run from the scale frame to the grounding lug on the junction box then

underground to the main AC power earth ground. If the DC transient protection board is installed, the ground

conductor should also be connected to the transient protection board’s ground lug.

3.6 Electrical Ground Connections

Improper grounding systems are often a cause of corrupted data from ground loop current flows and

costly lightning damage to electronics.

Always strive for a single-point grounding system. Do not drive ground rods at the scale location which

establishes separate earth grounds for the scale. These separate earth grounds will not share the same zero reference

as the existing earth ground for the AC power system. This difference in electrical potential invites ground-loop

current flow between the separate grounds, often corrupting serial data like RS-232 which depends on a stable zero

reference.

In addition, a separate earth ground system at the scale can actually invite lightning

• A minor power line surge should immediately be shunted to ground. If a separate ground system exists at

the scale with a lower

damaging load cells on its way.

• A nearby lightning ground strike may instantly raise the zero pote

while leaving the scale house ground rod unaffected. That lightning surge will now take the easiest path to

the lower-potential ground—through the scale wiring and back to the scale house ground, possibly

damaging the indicator on its way.

Therefore, the best grounding system for the scale is the same grounding s

system. The 120 VAC power source used to power the indicator will be connected to an existing earth grounded

rod system at the scale house or other building where the indicator is located. This should consist of a double

ground rod system of two 5/8" x 8' copper rods driven 8' deep at the service entrance where the local utility

company brings their lines into the building.

The local utility company can test the resistance of the existing ground rods with a clamp-on megohmeter th

measures zero resistance.

grounding system is inadequate, the utility company can suggest methods to improve the system. It’s crucial that

the scale owner authorize and make the recommended improvements to assure an adequate electrical ground. Do

not connect the scale to the AC power supply until the grounding system is adequate.

potential than the main ground, the surge may travel out to the scale ground rod,

ntial of a ground rod at the scale location,

ystem used for the incoming AC power

A reading of 3¾ or less is acceptable as a ground. If the test determines that the

or power surg

e damage:

at

Junction Box and Grounding 9

Page 14

Be certain each load cell grounding strap is securely connected to the top plate and bottom plate of each load cell

Grounding

Strap

To DC Protection Ground

Connection before Indicator

10 ga. Bare Ground Wire

Ground Lug

R41

JP17

JP7

R52

R50

R40

R24

R14

R15

JP20

JP10

R26

R51

R49

R47

JP16

R45

R43

JP9

R23

R21

JP6

JP8

R17

R38

R36

R34

JP11

R32

R30

R28

R10

R8

JP1

R4

R2

R33

JP12

JP2

VR9

JP19

R48

VR7

JP18

R42

R44

R22

R25 R16

R18

VR2

R19

R39

VR10

R35

R37

VR11

R27

R29

R31

R9

R11

R12

R1

R3

R5

VR5

R6

JP5

JMP/NEGJMP/POS

VR8

VR3

VR1

VR12

VR6

J1

VR4

J2

R13

R7

EXPANSION/J9

J5

ARC

R46

JP4

JP3

ARGND

JP14

JP15

JP13

L3

L4

L2

J8

J4

J3

J6

L1

R20

J7

INDICATOR/J10

JP

TRIM

TRIM

TO

-EX

+EX

+SI

-EX

+EX

+SI

-EX

+EX

1

+SI

-EX

+EX

+SI

JP

JP

TO

SIGNAL

2005

SIGNAL

CUT

TO

DISABLE

CUT

CELL#

CELL#

CELL#

SHD

1

SHD

-SI

1

-SI

SHD

-SI

1

-SI

SHD

SIGNAL

CUT

TO

CUT

SECT#

DISABLE

CELL#

CELL#

SIGNAL

SIGNAL SIGNAL

D

L

D

DISABLE

CELL#

SECT#

DISABLE

CELL#

RICE LAKE WEIGHING SYSTEMS

JP

-EX

+EX

+SI

-EX

+EX

+SI

-EX

+EX

+SI

-EX

+EX

+SI

SIGNAL

TRIM

TRIM

TRIM

TRIM

TRIM

TRIM

Assembly

-EX

-EX

+EX

+SI

SHD

1

SHD

-SI

1

-SI

1

-SI

SHD

1

-SI

SHD

CONNECT BOTH SHUNTS

TO APPLY SIGNAL

SECT#

SIGNAL

SIGNAL

SIGNAL

CELL#

PN Rev.

+SI

-SI

-SI

SECT#

+SEN

SHD

+SEN

SHD

DISCONNECT BOTH SHUNTS

TO REMOVE SIGNAL

+EX

-SEN

-SEN

CUT TRACE TO ISOLATE SENSE LINE

Transient Board Connectors

Grounding Lug

Note

mount. There should be metal-to-metal contact with no presence of paint or grout. This strap is designed to channel

power surges on the deck around—rather than through—the load cell to ground.

Figure 3-2. Grounding Strap on Load Cell Mount

These, and all, ground connections must be torqued to a specified value and retorqued at regular service intervals.

A thick coating of anti-oxidant grease should be maintained on all ground connections to prevent corrosion.

A separate grounding system conductor must extend uninterrupted from the ma

in service panel ground to the scale

to protect load cells and scale wiring from lightning and other transient damage. This ground wire conductor must

be an unsheathed #10 copper wire or larger. Run the bare ground wire conductor intact from the AC power ground

rod to the scale in a separate trench. Bring the wire up from the trench near the junction box and attach it to the

ground lug of the junction box. A #10 bare ground wire is run from the ground lug of the junction box to one of the

junction box mounting studs on the scale frame, thus grounding the scale frame to the same single-point ground as

the AC power for the indicator.

Figure 3-3. Junction Box Ground Wire Connections.

The scale frame must be connected with 10 ga. wire to the ground lug of the transient protection board inside

the junction box.

Scales with more than one junction box require ground straps t

boxes need to be connected to the scale frame.

The final ground wire connection must be at the AC pow

10 Survivor

®

PL Installation Manual

er supply ground terminal or ground rod.

o be

installed between modules. In addition, all junction

Page 15

AC Power

Supply

#10 Copper

Ground Wire

Serial

Communication

Homerun

Cable

Load Cell

Cable

UJB-3T6

DC Transient Protection

RLWS PN 21134

TP-232

DC Transient Protection

RLWS PN 33185

TP-232

DC Transient Protection

RLWS PN 33185

SOLA S1K 520

AC Transient Protection

RLWS PN 110812

AC Outlet

SOLA S1K520

AC Transient Protection

RLWS PN 110812

AC Outlet

Power Company Ground Rod

*Always verify that installed wiring is properly grounded

R41

JP17

JP7

R52

R50

R40

R24

R14

R15

JP20

JP10

R26

R51

R49

R47

JP16

R45

R43

JP9

R23

R21

JP6

JP8

R17

R38

R36

R34

JP11

R32

R30

R28

R10

R8

JP1

R4

R2

R33

JP12

JP2

VR9

JP19

R48

VR7

JP18

R42

R44

R22

R25 R16

R18

VR2

R19

R39

VR10

R35

R37

VR11

R27

R29

R31

R9

R11

R12

R1

R3

R5

VR5

R6

JP5

JMP/NEGJMP/POS

VR8

VR3

VR1

VR12

VR6

J1

VR4

J2

R13

R7

EXPANSION/J9

J5

ARC

R46

JP4

JP3

ARGND

JP14

JP15

JP13

L3

L4

L2

J8

J4

J3

J6

L1

R20

J7

INDICATOR/J10

JP

TRIM

TRIM

TO

-EX

+EX

+SI

-EX

+EX

+SI

-EX

+EX

1

+SI

-EX

+EX

+SI

JP

JP

TO

SIGNAL

2005

SIGNAL

CUT

TO

DISABLE

CUT

CELL#

CELL#

CELL#

SHD

1

SHD

-SI

1

-SI

SHD

-SI

1

-SI

SHD

SIGNAL

CUT

TO

CUT

SECT#

DISABLE

CELL#

CELL#

SIGNAL

SIGNAL SIGNAL

D

L

D

DISABLE

CELL#

SECT#

DISABLE

CELL#

RICE LAKE WEIGHING SYSTEMS

JP

-EX

+EX

+SI

-EX

+EX

+SI

-EX

+EX

+SI

-EX

+EX

+SI

SIGNAL

TRIM

TRIM

TRIM

TRIM

TRIM

TRIM

Assembly

-EX

-EX

+EX

+SI

SHD

1

SHD

-SI

1

-SI

1

-SI

SHD

1

-SI

SHD

CONNECT BOTH SHUNTS

TO APPLY SIGNAL

SECT#

SIGNAL

SIGNAL

SIGNAL

CELL#

PN Rev.

+SI

-SI

-SI

SECT#

+SEN

SHD

+SEN

SHD

DISCONNECT BOTH SHUNTS

TO REMOVE SIGNAL

+EX

-SEN

-SEN

CUT TRACE TO ISOLATE SENSE LINE

Transient Board Connectors

Grounding Lug

186210

R41

JP17

JP7

R52

R50

R40

R24

R14

R15

JP20

JP10

R26

R51

R49

R47

JP16

R45

R43

JP9

R23

R21

JP6

JP8

R17

R38

R36

R34

JP11

R32

R30

R28

R10

R8

JP1

R4

R2

R33

JP12

JP2

VR9

JP19

R48

VR7

JP18

R42

R44

R22

R25 R16

R18

VR2

R19

R39

VR10

R35

R37

VR11

R27

R29

R31

R9

R11

R12

R1

R3

R5

VR5

R6

JP5

JMP/NEGJMP/POS

VR8

VR3

VR1

VR12

VR6

J1

VR4

J2

R13

R7

EXPANSION/J9

J5

ARC

R46

JP4

JP3

ARGND

JP14

JP15

JP13

L3

L4

L2

J8

J4

J3

J6

L1

R20

J7

INDICATOR/J10

JP

TRIM

TRIM

TO

-EX

+EX

+SI

-EX

+EX

+SI

-EX

+EX

1

+SI

-EX

+EX

+SI

JP

JP

TO

SIGNAL

2005

SIGNAL

CUT

TO

DISABLE

CUT

CELL#

CELL#

CELL#

SHD

1

SHD

-SI

1

-SI

SHD

-SI

1

-SI

SHD

SIGNAL

CUT

TO

CUT

SECT#

DISABLE

CELL#

CELL#

SIGNAL

SIGNAL SIGNAL

D

L

D

DISABLE

CELL#

SECT#

DISABLE

CELL#

RICE LAKE WEIGHING SYSTEMS

JP

-EX

+EX

+SI

-EX

+EX

+SI

-EX

+EX

+SI

-EX

+EX

+SI

SIGNAL

TRIM

TRIM

TRIM

TRIM

TRIM

TRIM

Assembly

-EX

-EX

+EX

+SI

SHD

1

SHD

-SI

1

-SI

1

-SI

SHD

1

-SI

SHD

CONNECT BOTH SHUNTS

TO APPLY SIGNAL

SECT#

SIGNAL

SIGNAL

SIGNAL

CELL#

PN Rev.

+SI

-SI

-SI

SECT#

+SEN

SHD

+SEN

SHD

DISCONNECT BOTH SHUNTS

TO REMOVE SIGNAL

+EX

-SEN

-SEN

CUT TRACE TO ISOLATE SENSE LINE

Transient Board Connectors

Grounding Lug

JB8SPT Junction Box

With Transient Protection

RLWS PN 91783

JB8SPT Junction Box

With Transient Protection

RLWS PN 91783

Figure 3-4. Single-Point Grounding Diagram

Junction Box and Grounding 11

Page 16

Survivor PL Limited Warranty

Statement of Limited Warranty

Subject to the terms and conditions as stated herein: Rice Lake Weighing Systems (hereafter referred to as “RLWS”) warrants its equipment

to be free from defects in material and factory workmanship for a period of time from the date of shipment as stated in this document.

Electronic Components

Load cells, junction boxes, and internal cabling are warranted against manufacturing defects provided the scale and all electronic devices

have been properly installed, grounded and sealed by RLWS dealer.

Weighbridge Components

Applies to RICE LAKE

SURVIVOR® models

Five

(5)

years -

and RT

weighbridge structure

Terms and Conditions of Limited Warranty

and is subject to the inspection, analysis and determination by RLWS regarding the nature and cause of any failure.

Defective components – mechanical or electrical – will be repaired or replaced free of any obligation to the owner within ninety (90) days after

date of installation. For the remainder of the product warranty period, defective components (mechanical or electrical), will be repaired or

replaced provided such services are preformed by an authorized RLWS Dealer and equipment owner agrees to pay Dealer for these services.

Service technician labor and travel expenses are not covered by this warranty. RLWS may require the faulty components be returned to the

factory, freight prepaid, at the discretion and authorization of RLWS.

This warranty does not extend to any labor, material, or service charges involved in removal or replacement of equipment.

RLWS is not responsible and will not be held liable for losses, injury or damage caused to persons or property resulting during installation or

failure during use of RLWS products or any consequential damages that may arise from their use.

RLWS reserves the right to incorporate improvements in material and design of the products without notice and is not obligated to incorporate

the same improvements in equipment previously manufactured.

In certain cases, such as used equipment or peripheral equipment not manufactured by RLWS, a reduced warranty may apply. Specific

details to these exceptions are provided separately or at the time of purchase.

Two (2) years - load cells, junction boxes, suspension system. This covers SURVIVOR PL and RT Rail Scales.

Exclusions to the warranty include but are not limited to: corrosion, lightning,

SURVIVOR PL

surges concrete & rebar or any other items supplied by others, excessive wear,

cosmetic defects that do not affect performance, use and damage caused by electrical

surges resulting from welding on or near scale.

This obligation is limited exclusively to original equipment manufactured or supplied by RLWS

RLWS shall not be obligated under any warranty different than as set forth herein. The RLWS warranty is limited to the initial customer and

installation and is not transferable in the event of resale.

Conditions Which Void Limited Warranty

This warranty shall not apply to equipment which:

• Has had repairs and modifications not authorized by RLWS which in RLWS’ judgment has affected the performance

• Has been subject to misuse “overloading”,

or act of God

• Has had serial number altered, defaced or removed

• Had not followed RLWS recommendations for epoxy, galvanizing, or

environments

• Has not been grounded according to RLWS recommended procedure

Freight Carrier Damage Claims for equipment damaged in transit must be referred to the freight carrier. Visible damage should be reported

immediately. Concealed damage as soon as possible in any case, within fifteen (15) days of receipt of shipment, in accordance with freight

carrier regulations.

THE FOREGOING IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED O

DESCRIPTION OF THE PRODUCT. This warranty statement sets forth the extent of our liability for breach of any warranty or deficiency in

connection with the sale or use of the product. It is understood that RLWS will not be liable for consequential damages or any nature, including but

not limited to, loss of profit, delays or expenses, whether based on tort or contract.

negligent handling, improper installation, accident, damage by fire, water, submersion

stainless steel construction for installation in harsh

R IMPLIED INCLUDING ANY WARRANTY EXTENDED BEYOND THE

© Rice Lake Weighing Systems, Inc. Rice Lake, WI USA. All Rights Reserved.

RICE LAKE WEIGHING SYSTEMS • 230 WEST COLEMAN STREET • RICE LAKE, WISCONSIN 54868 • USA

8 Survivor

®

PL Installation Manual

Page 17

Page 18

Rice Lake Weighing Systems

May 31, 2013 PN 118677 Rev B

Loading...

Loading...