Page 1

Installation Manual

Installationshandbuch

Manuel d’installation

Compression Load Cell

PR 6201

500 kg…50 t

Type LA, L, D1, D1E, C3, C3E, C4, C4E,

C5, C5E, C6, C6E

100 t, 200 t, 300 t, 520 t

Type LA, L, LE, N, NE

Dual Bridge (DB)

100 t, 200 t, 300 t, 520 t

Type LDB, LDBE, NDB, NDBE

9499 053 34202

Edition 4

14.02.2012

Sartorius Mechatronics T&H GmbH, Meiendorfer Str. 205, 22145 Hamburg, Germany

Tel:+49.40.67960.303 Fax:+49.40.67960.383

Page 2

Important

Noter s.v.p.

Please note

In any correspondence concerning this instrument, please always quote the type number and serial

number as given on the type plate.

As the instrument is an electrical apparatus, it may be operated only by trained personnel.

Maintenance and repairs may only be carried out by qualified personnel.

Bitte beachten

Bei Schriftwechsel über dieses Gerät wird gebeten, die Typennummer und die Seriennummer

anzugeben. Diese befinden sich auf dem Typenschild.

Wichtig

Da das Gerät ein elektrisches Betriebsmittel ist, darf die Bedienung nur durch eingewiesenes Personal

erfolgen. Wartung und Reparatur dürfen nur von geschultem, fach- und sachkundigem Personal

durchgeführt werden.

Dans votre correspondance et dans vos réclamations se rapportant à cet appareil, veuillez toujours

indiquer le numéro de type et le numéro de série inscrits sur la plaque signalétique.

Important

Comme il s’agit d’un équipement électrique, la maintenance doit être effectuée par du personnel

qualifié. De même, l’entretien et les réparations sont à confier au personnel qualifié.

Page 3

Installation Manual Compression Load Cell PR 6201

Table of Contents

1 Safety Instructions ......................................................................................................................... 3

2 Design Recommendations ............................................................................................................. 3

2.1 Positioning of Load Cells and Constrainers ........................................................................................ 3

2.2 Location of Load Cells and Pivots .......................................................................................................... 4

2.3 Lift-off Protection ....................................................................................................................................... 4

2.4 Capacity Selection ....................................................................................................................................... 4

3 Technical Data ................................................................................................................................ 5

3.1 General ............................................................................................................................................................ 5

3.2 Dual Bridge ..................................................................................................................................................... 5

3.3 Certificates ..................................................................................................................................................... 5

3.4 Equipment Supplied .................................................................................................................................... 6

3.4.1 Load Cells PR 6201/52…54 (max. capacities 500 kg…50 t) .................................................................... 6

3.4.2 Load Cells PR 6201/15, /25, /35 and DB (max. capacities 100 t, 200 t, 300 t) ................................. 6

3.4.3 Load Cell PR 6201/520t and DB (max. capacity 520 t) ........................................................................... 7

3.5 Dimensions ..................................................................................................................................................... 7

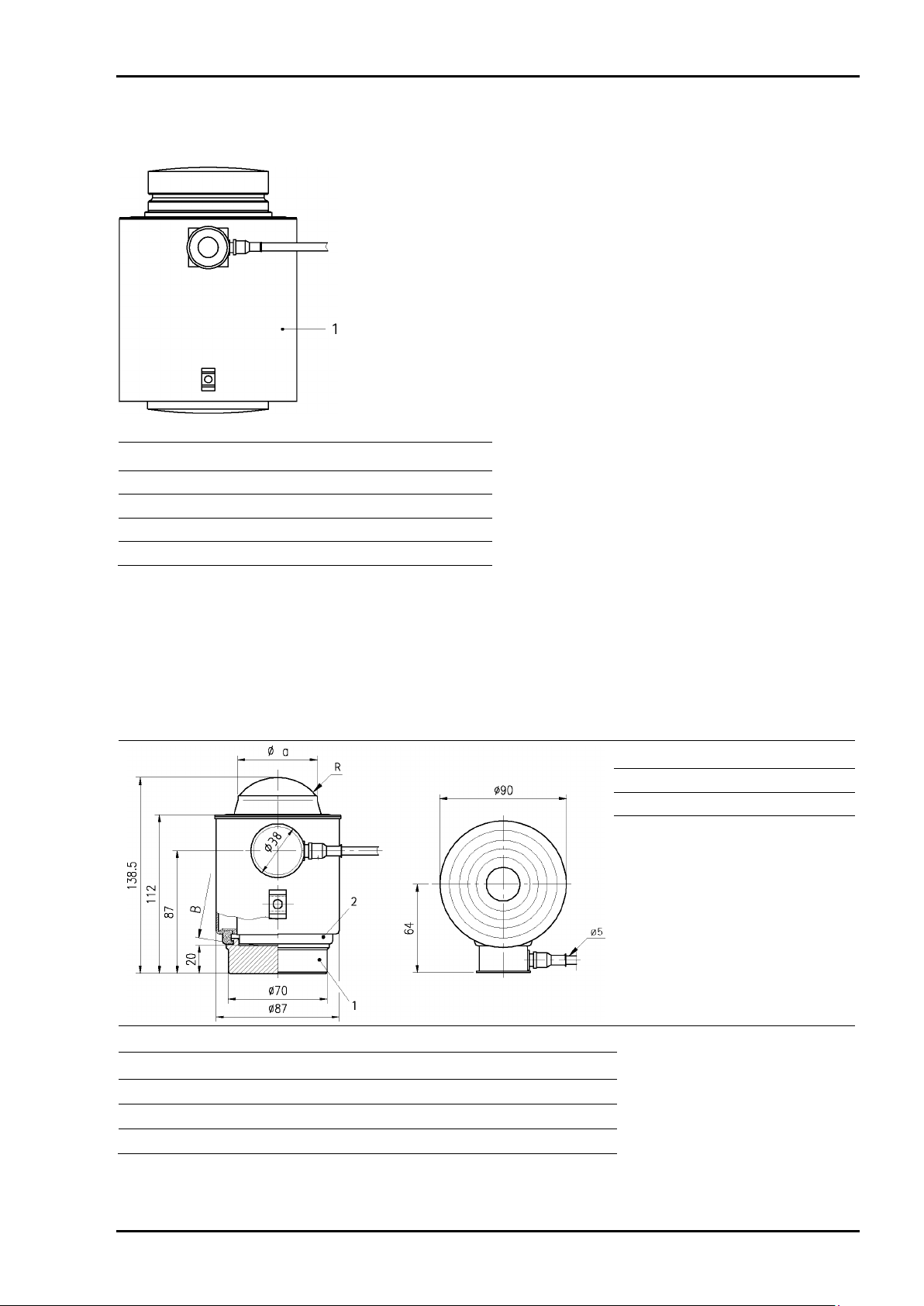

3.5.1 Load Cell PR 6201/52…54 (max. capacity 500 kg…50 t)......................................................................... 7

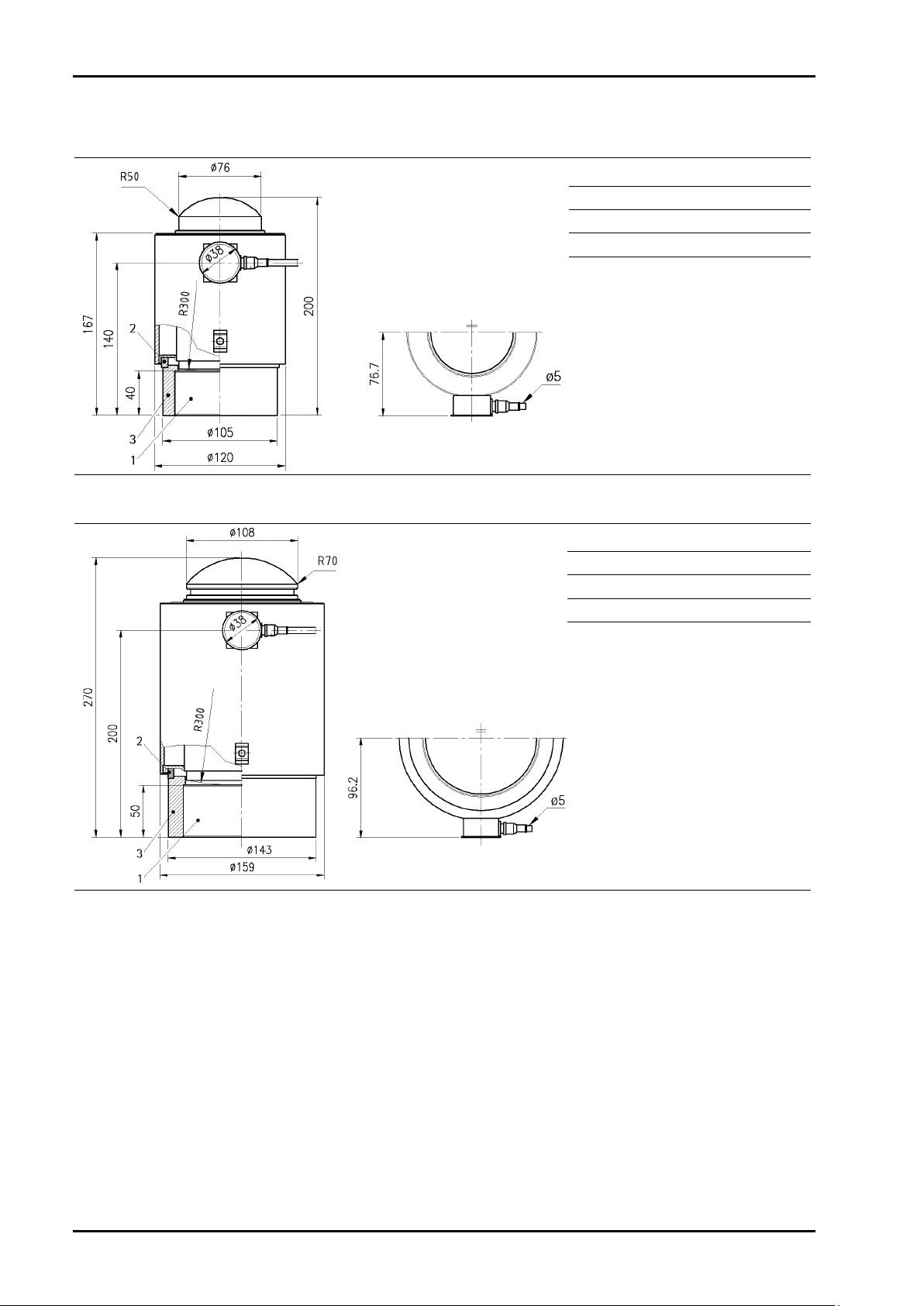

3.5.2 Load Cell PR 6201/15 (max. capacity 100 t) ............................................................................................... 8

3.5.3 Load Cell PR 6201/25 (max. capacity 200 t), PR 6201/35 (max. capacity 300 t) ............................ 8

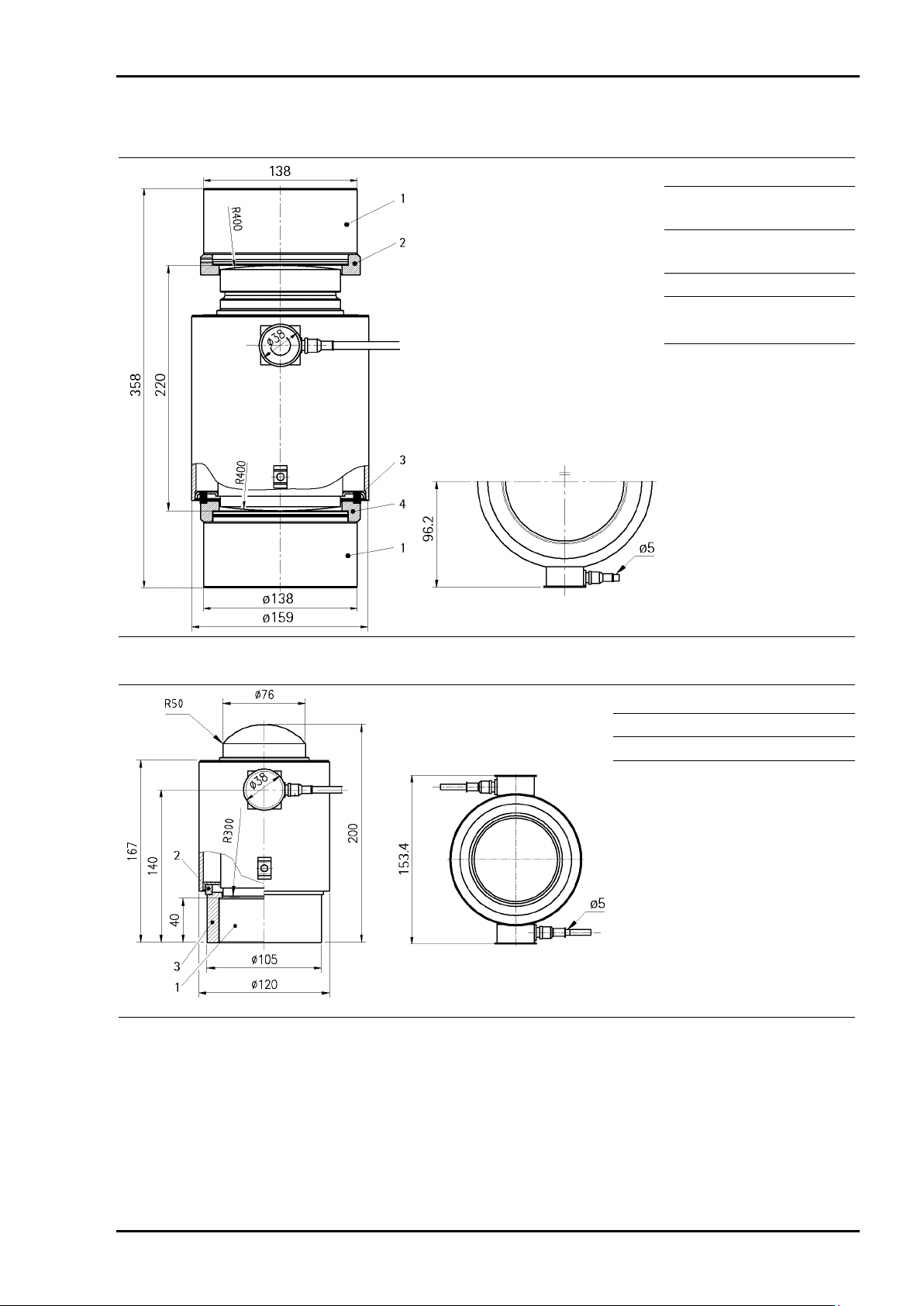

3.5.4 Load Cell PR 6201/520t (max. capacity 520 t) ........................................................................................... 9

3.5.5 Load Cell PR 6201/15 DB (max. capacity 100 t) ........................................................................................ 9

3.5.6

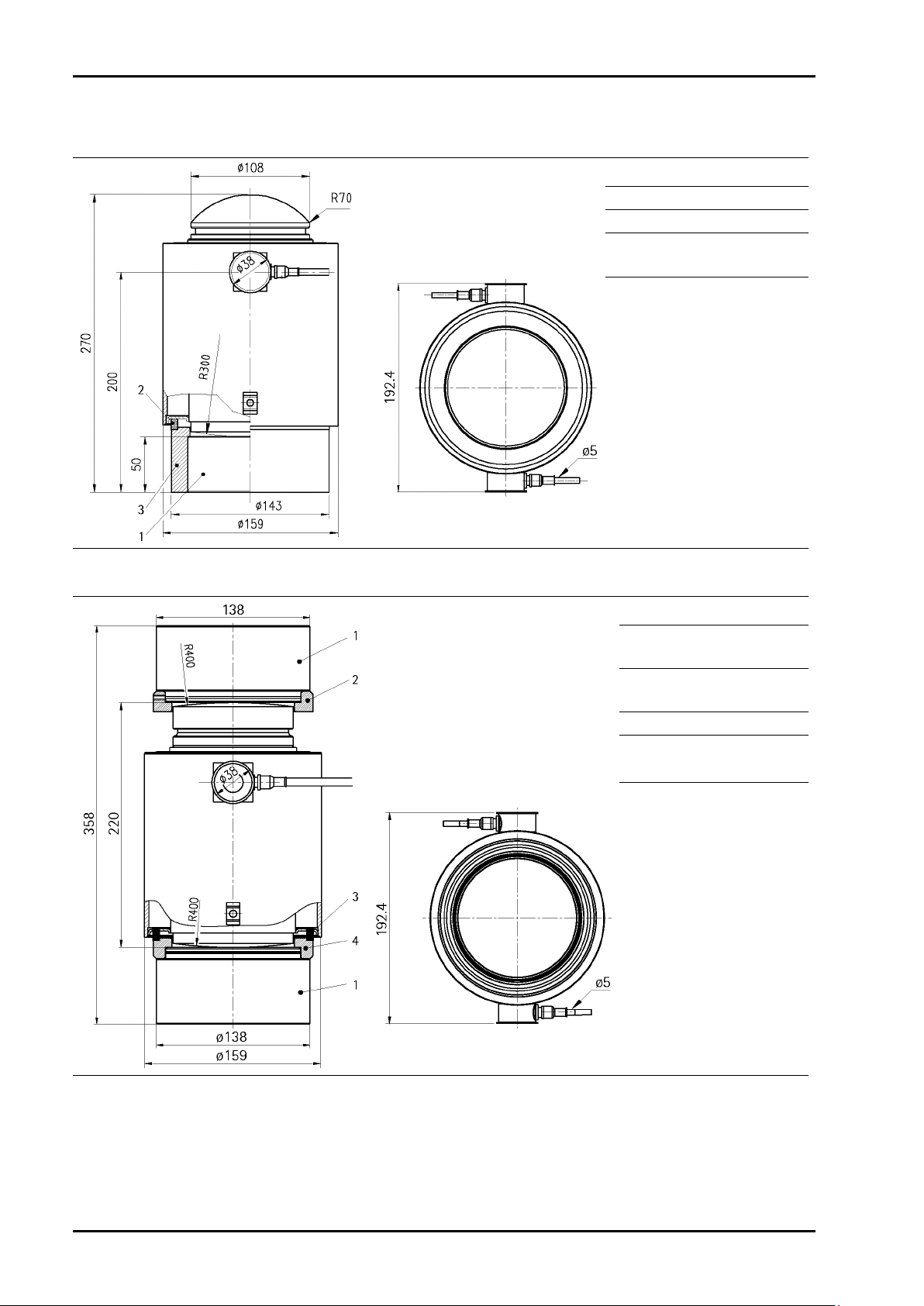

3.5.7 Load Cell PR 6201/520t DB (max. capacity 520 t) ................................................................................. 10

Load Cell PR 6201/25 DB (max. capacity 200 t), PR 6201/35 DB (max. capacity 300 t)

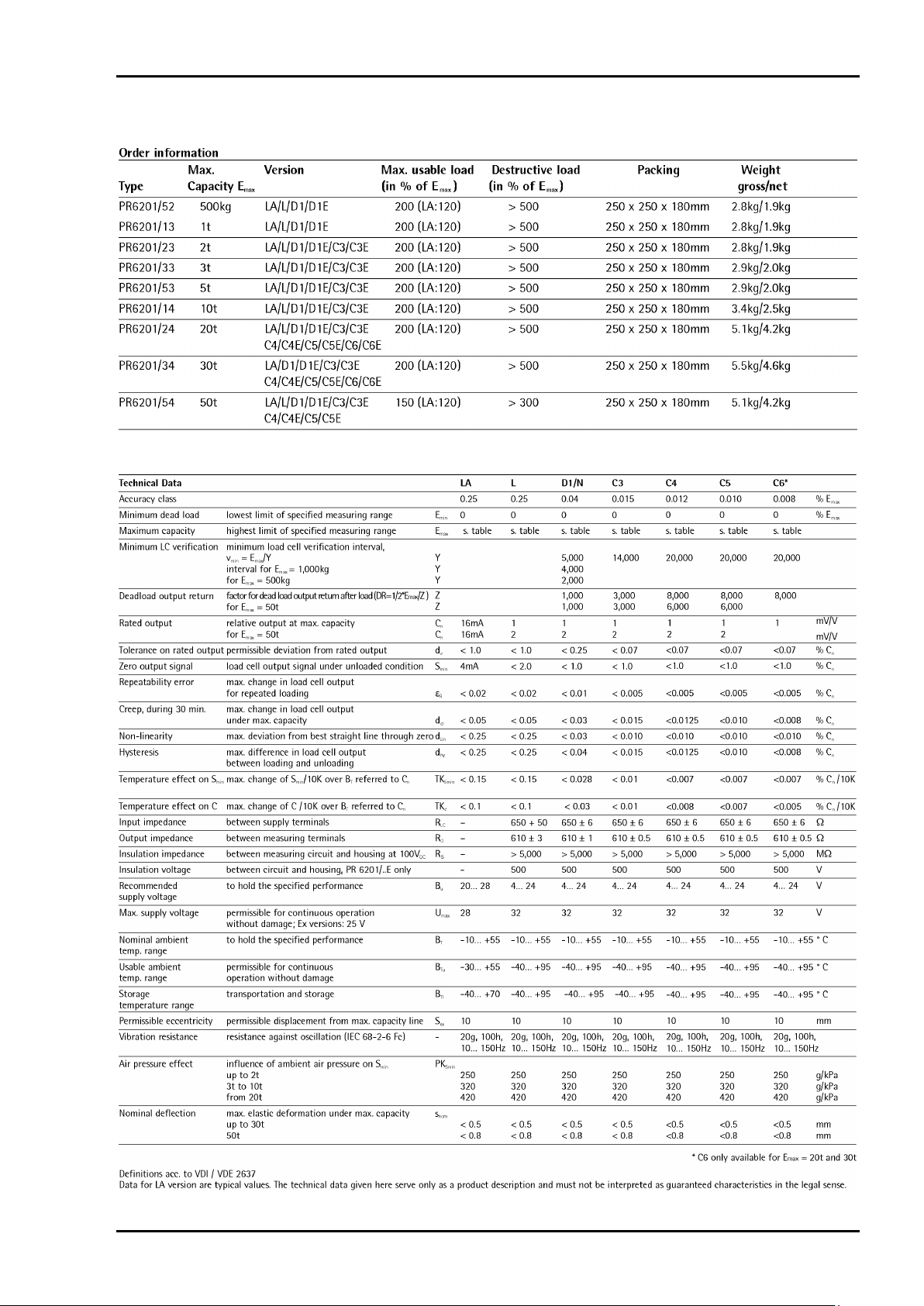

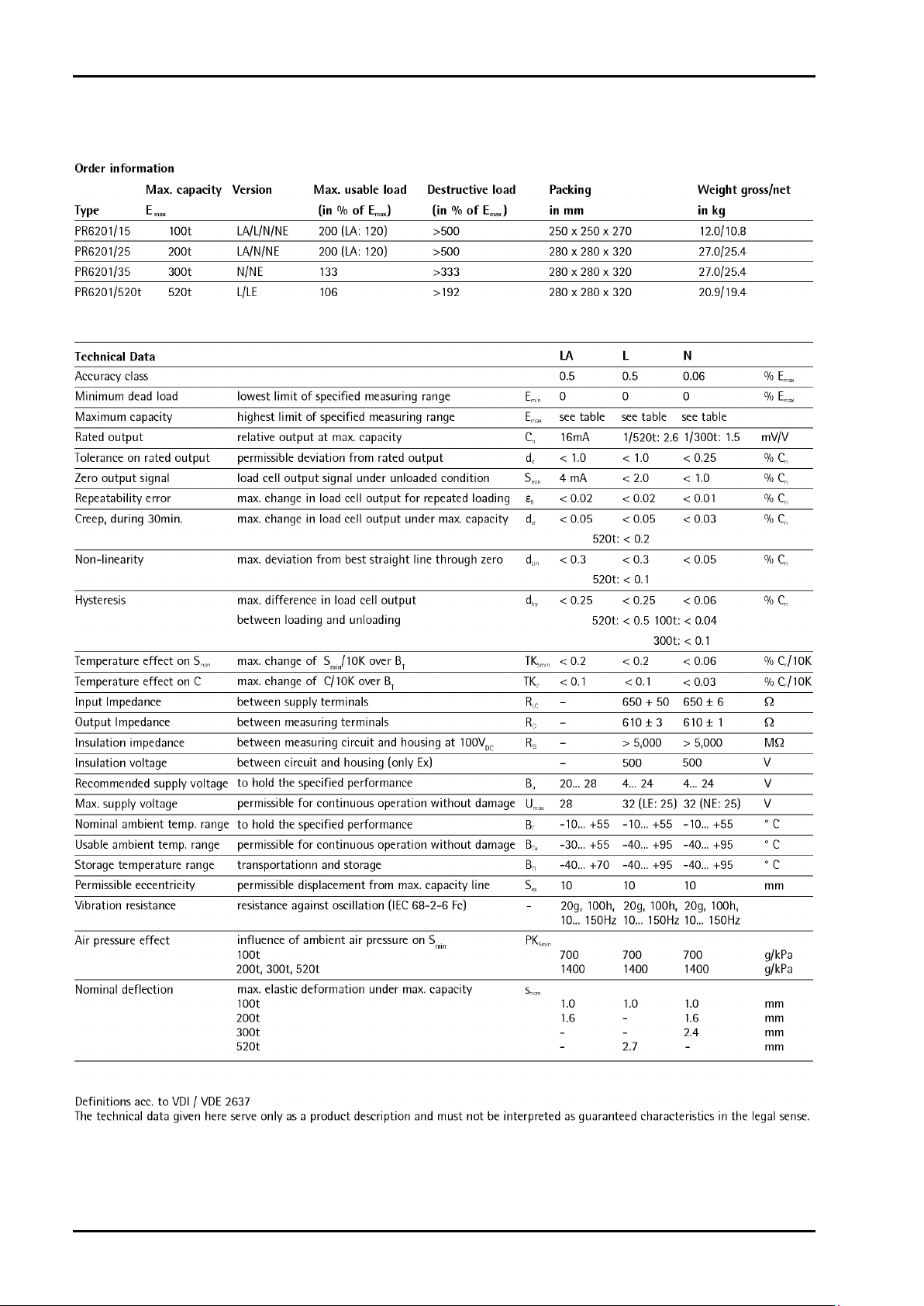

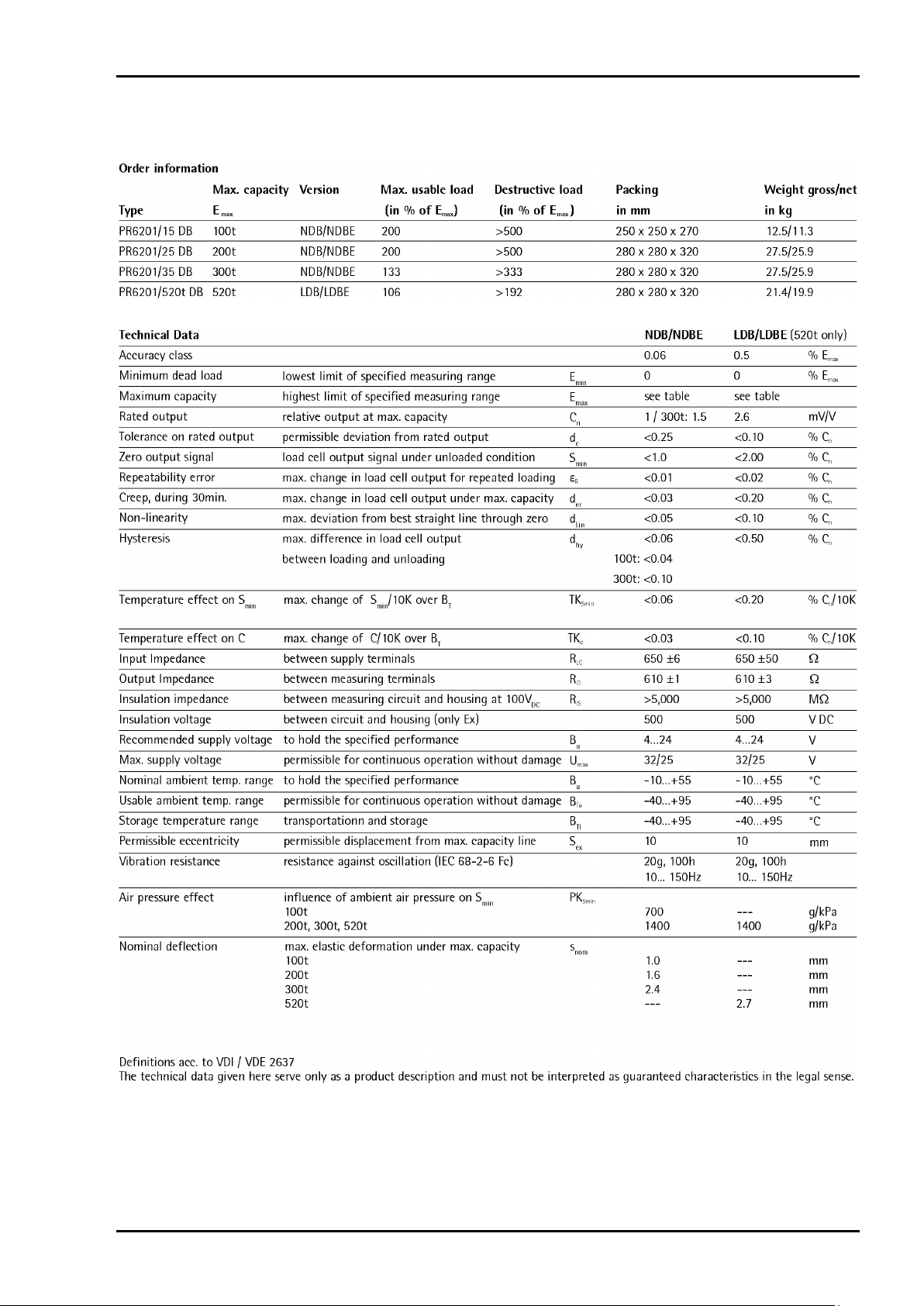

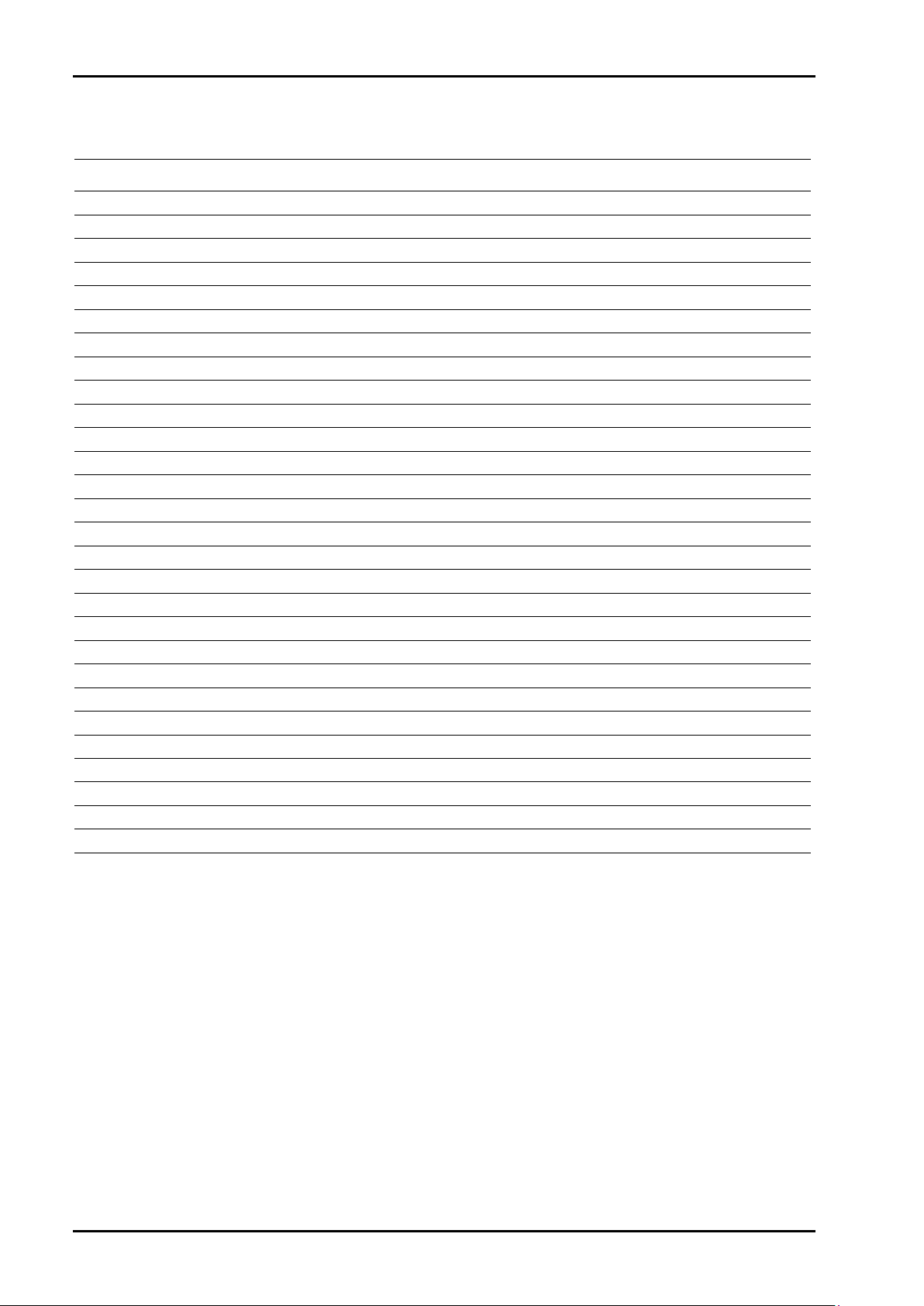

3.6 Technical Data for Max. Capacity 500 kg…50 t .............................................................................. 11

................ 10

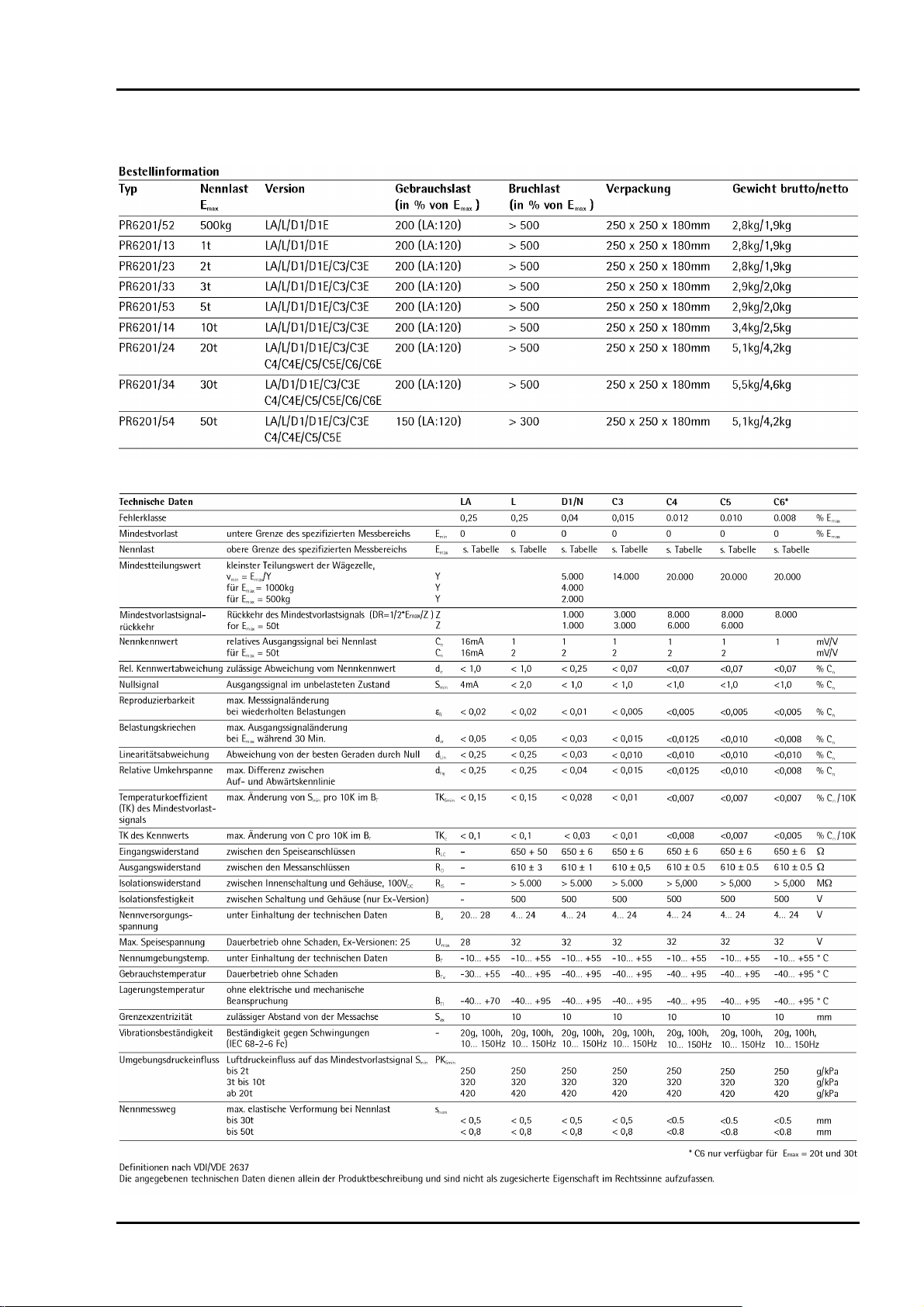

3.7 Technical Data for Max. Capacity 100 t, 200 t, 300 t, 520 t ...................................................... 12

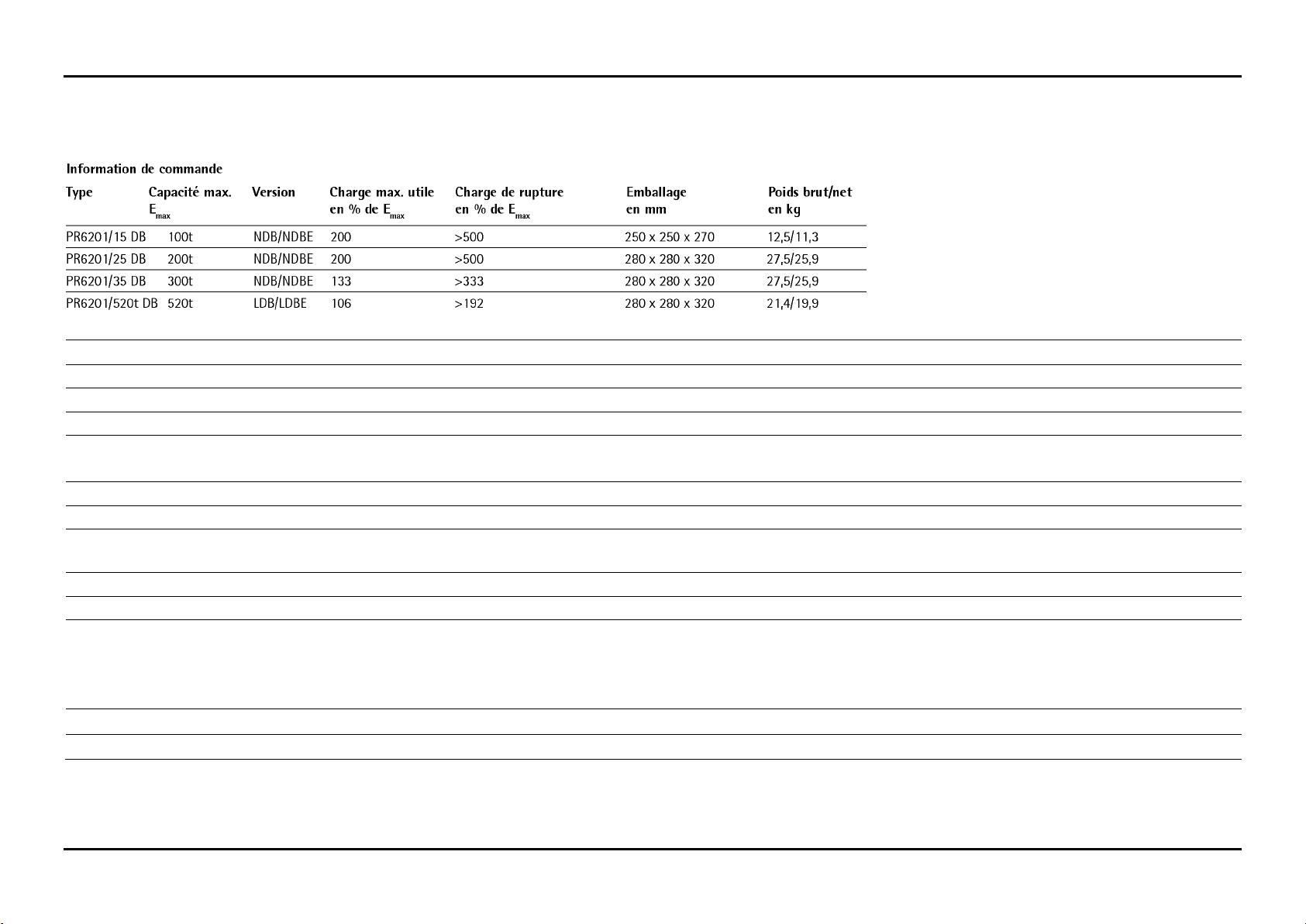

3.8 Technical Data for Dual Bridge; Max. Capacity 100 t, 200 t, 300 t, 520 t ............................ 13

4 Installation .................................................................................................................................... 14

4.1 General .......................................................................................................................................................... 14

4.2 Installation of the Upper Load Disc for Max Capacity of 500 kg…50 t .................................. 15

Sartorius EN-1

Page 4

Compression Load Cell PR 6201 Installation Manual

5 Connection .................................................................................................................................... 16

5.1 General .......................................................................................................................................................... 16

5.2 Load Cell........................................................................................................................................................ 16

5.2.1 Standard (Type L, D1/N, D1E/NE, C3, C3E) ................................................................................................ 16

5.2.2 Load Cell with Integrated Amplifier (Type LA) ........................................................................................ 17

5.3 Connecting Cable ...................................................................................................................................... 19

5.4 Cable Connections ..................................................................................................................................... 19

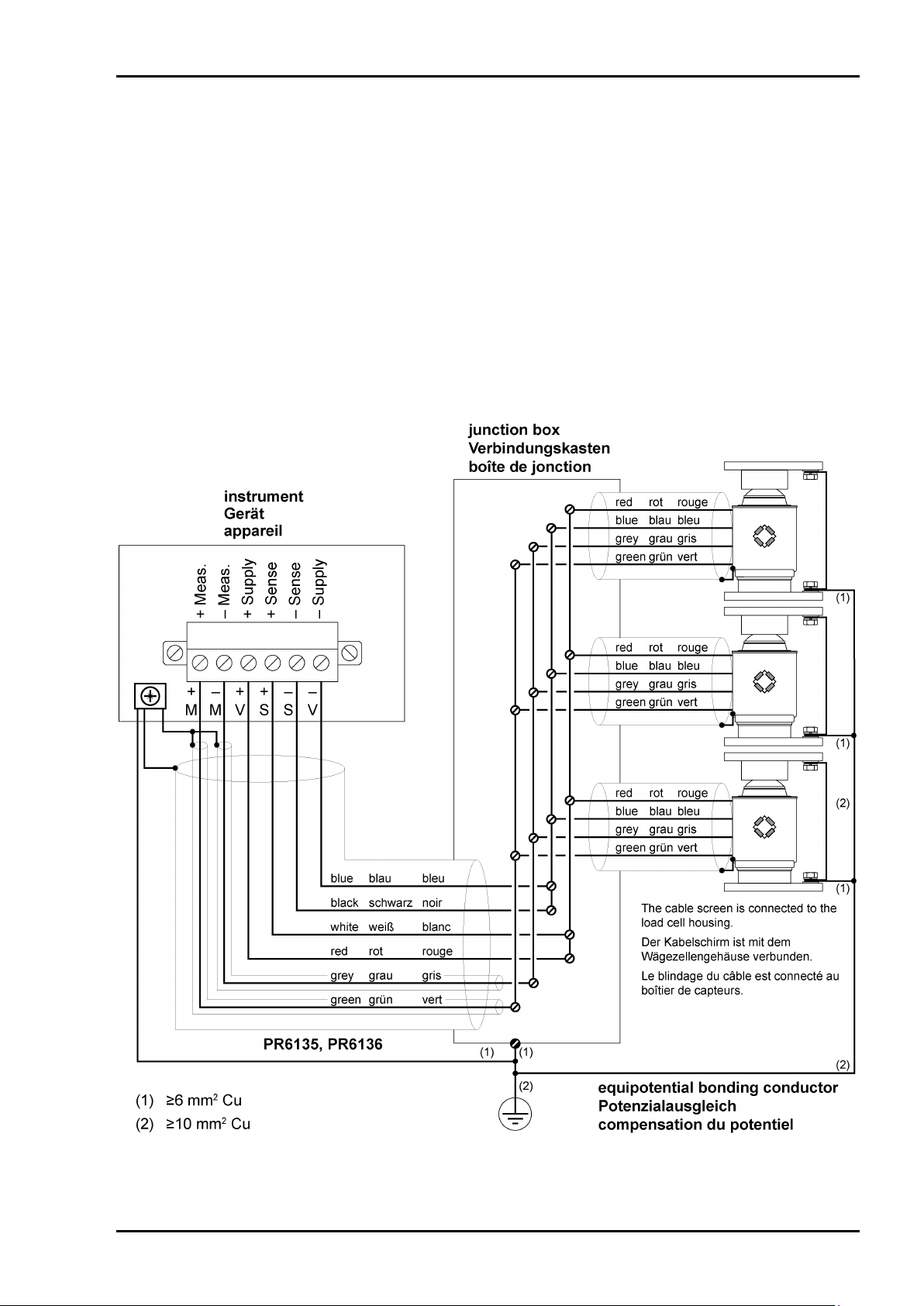

5.4.1 Load Cells with one Measuring Circuit ...................................................................................................... 19

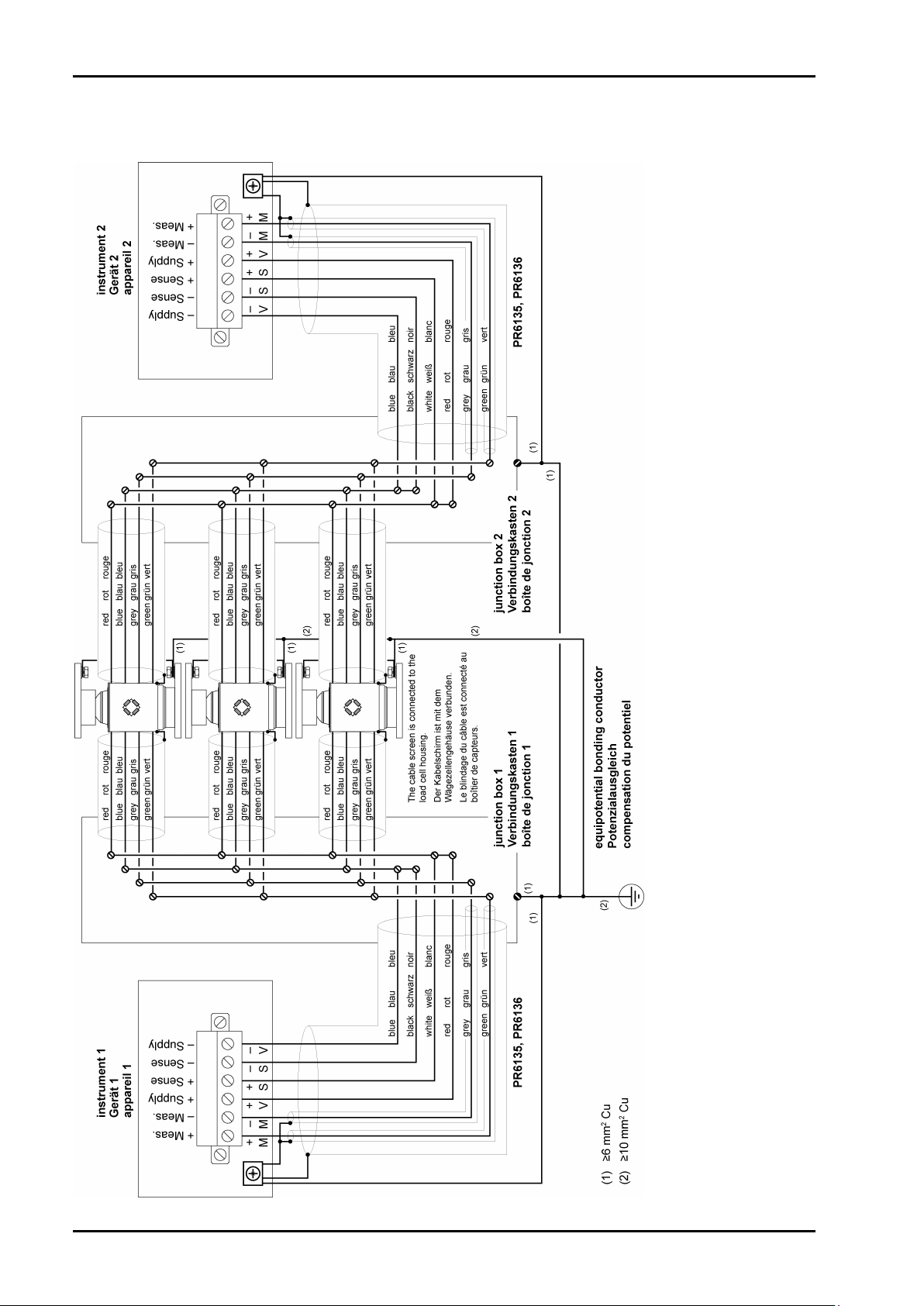

5.4.2 Load Cells with two Separate Measuring Circuits .................................................................................. 20

6 Preparing for Calibration ............................................................................................................ 21

6.1 Mechanical Height Adaptation ............................................................................................................. 21

7 Fault finding hints ....................................................................................................................... 21

7.1 Visual check ................................................................................................................................................. 21

7.2 Checks with Multimeter .......................................................................................................................... 22

7.2.1 Check Zero Output Signal of Load Cell ..................................................................................................... 22

7.2.2 Check the Strain Gauge Bridge .................................................................................................................... 22

7.2.3 Check Insulation Impedance of Load Cell ................................................................................................. 22

7.2.4 Check Insulation Impedance of Connecting Cable ................................................................................ 22

8 Repair/Maintenance .................................................................................................................... 23

8.1 Repair ............................................................................................................................................................. 23

8.2 Maintenance ................................................................................................................................................ 23

9 Spare Parts and Accessories ....................................................................................................... 24

EN-2 Sartorius

Page 5

Installation Manual Compression Load Cell PR 6201

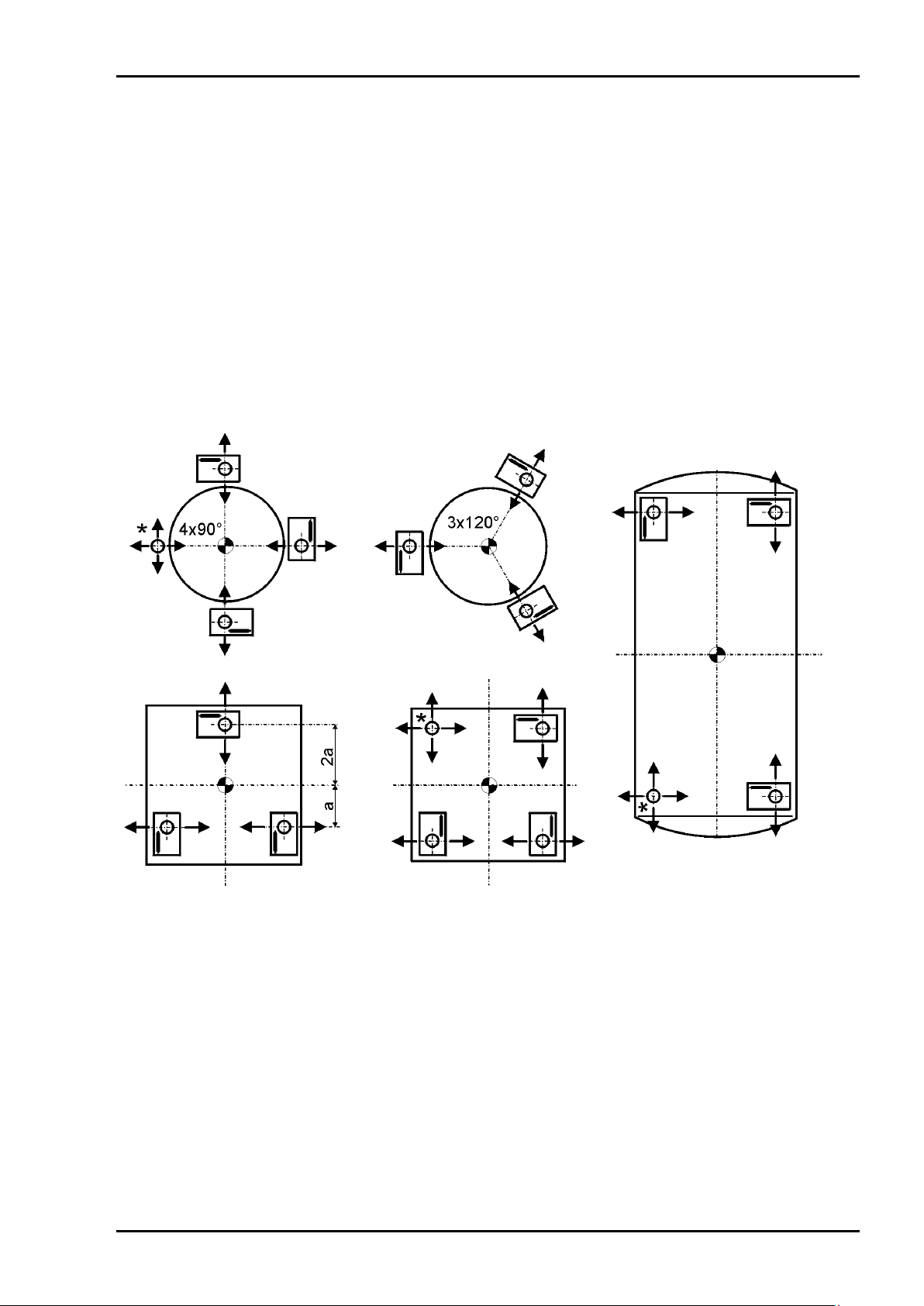

* do not constrain this position

1 Safety Instructions

The PR 6201 with the relevant mounting kits must be used only for the weighing applications for which it

is intended. The dimensions of all mounting and structural components must be calculated so that

sufficient overload capacity is ensured for loads which may occur while taking the relevant standards into

account. In particular, upright weighing objects (vessel etc.) must be safeguarded against the weighing

installation turning over or being shifted, thus eliminating danger to humans, animals or goods even in the

case of a break in a load cell or mounting element.

Installation and repair work must be carried out only by qualified personnel.

2 Design Recommendations

2.1 Positioning of Load Cells and Constrainers

The supporting structure of the scale (i.e. the load cell support) and the vessel must be stable enough to

withstand the maximum design loads, horizontal (check with spirit level!) and flat. Vessels should preferably be

supported by 3 load cells, platforms and weigh bridges by 4 or 6 load cells (see figure).

Parasitic forces, horizontal forces and torques are disturbances which can generate measuring failures and

in case of exceeding the specified limits may damage the load cell.

An accurate constraining of the object prevents of damages and measuring errors without affecting the

required space for movement. Therefore special attention should be paid to the design, arrangement and

condition of the constrainers. Thermal expansion and contractions of the object are to be taken into

account which may affect the required space for vertical movement and thus influence the measuring

results.

Sartorius EN-3

Page 6

Compression Load Cell PR 6201 Installation Manual

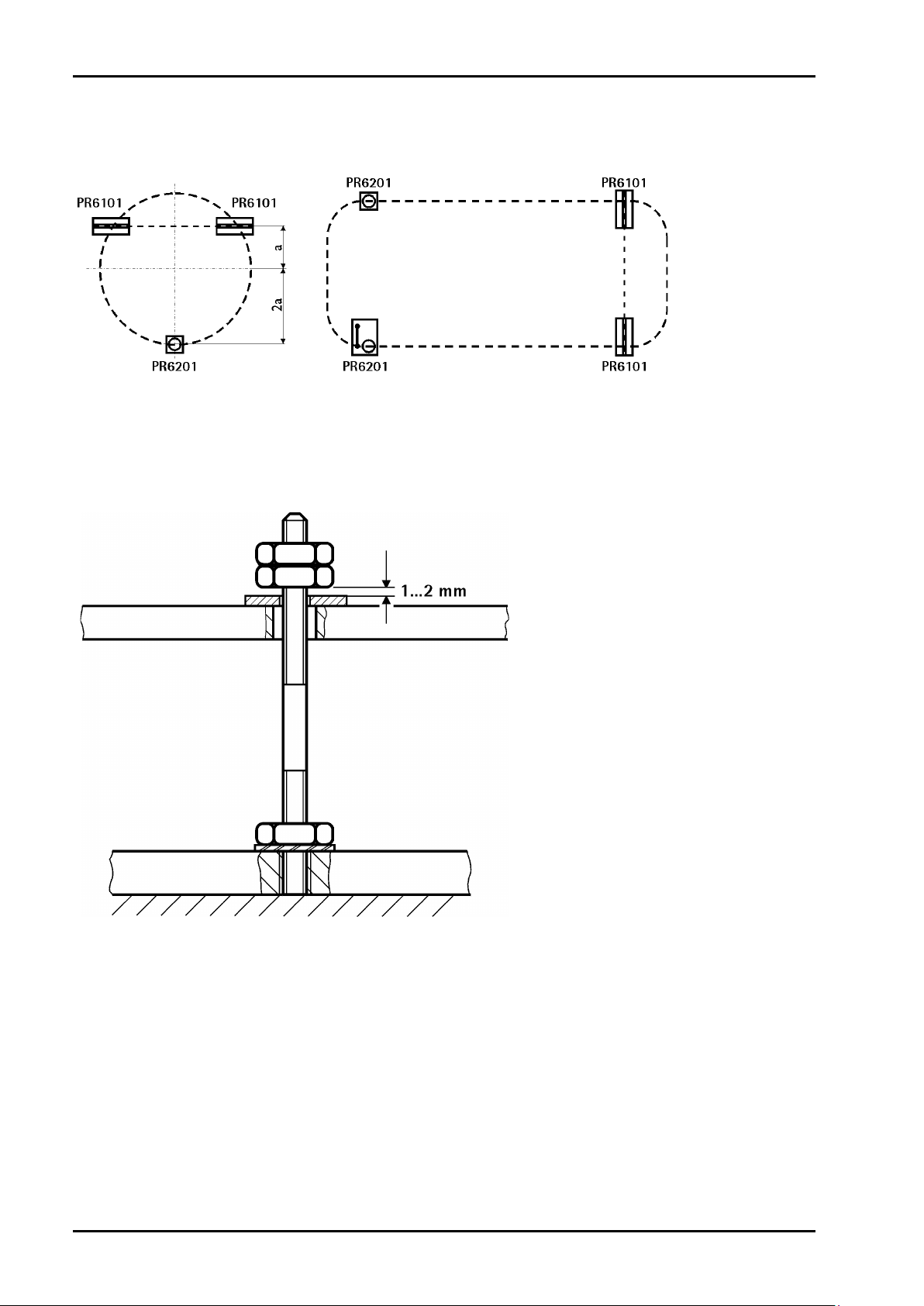

2.2 Location of Load Cells and Pivots

2.3 Lift-off Protection

For safety reasons, a lift-off protection has to be provided generally in all systems of tank and hopper

weighing. It can be realized separately or with the help of mounting kits. The simplest design requires a

threaded rod, three nuts, one serrated lock washer and one washer.

2.4 Capacity Selection

The load cell PR 6201 has a high overload capacity due to the fact that the stress in the measuring element

is low (1 mV/V). Forces which are exceeding the max. load without damage limit may change the

characteristic of the load cell or in the worst case damage the electrical part. If an exceeding of a.m. limit is

possible, e.g. falling loads, a mechanical overload protection (limit stop) is strongly recommended.

EN-4 Sartorius

Page 7

Installation Manual Compression Load Cell PR 6201

max

max

Length

E

>10 t: 12 m

Cross section

Bending radius

≥

3 Technical Data

3.1 General

Restoring force For each mm of displacement that the top of the load cell is shifted from the

vertical axis, a horizontal restoring force is generated:

E

E

E

E

≤10 t:

E

≥20 t:

= 100 t 1.23 % of the vertical load on the load cell

max

= 200 t + 300 t 0.65 % of the vertical load on the load cell

max

= 520 t 1.20 % of the vertical load on the load cell

max

Housing Stainless steel 1.4301, hermetically sealed welded, filled with inert gas

Degree of

protection

IP 68 (water of 1.5 m in depth; 10,000 h) acc. to IEC 60529 (correspond to NEMA 6)

IP69K acc. to DIN 40050

Protection type Intrinsic safety for PR 6201/..E + ..DBE

Cable Diameter 5 mm

Sheath Material: thermopl. Elastomer

Color: grey (Standard version)

0.65% of the vertical load on the load cell

1.55% of the vertical load on the load cell

E

≤10 t: 5 m

max

max

4×0.35 mm2

25 mm (fixed installation)

≥75 mm (repeated bending)

blue (Ex version

green (LA version)

3.2 Dual Bridge

The Dual Bridge load cell has two separate measuring circuits, which are independent of each other. The

measuring circuits are adjusted in two separate adjustment chambers; cable connections see Chapter 5.4.2.

3.3 Certificates

Zone Marking Certificate no. for

0 and 1 II 1G Ex ia IIC T6 PTB 02 ATEX 2059 only PR 6201/..E + ..DBE

20 and 21 II 1 D IP65 T85°C TÜV 03 ATEX 2301X PR 6201/..L, ..LE, ..D1, ..D1E,

..C3-C6, ..C3E-C6E, ..N, ..NE

2 II 3G Ex nA II T6 Manufacturer certificate PR 6201/..L, ..LE, ..D1, ..D1E, ..C3-

C6, ..C3E-C6E, ..N, ..NE,

..LDB, ..LDBE, ..NDB, ..NDBE

22 II 3D Ex tD A22 IP65 T85°C Manufacturer certificate PR 6201/..L, ..LE, ..D1, ..D1E, ..C3-

C6, ..C3E-C6E, ..N, ..NE,

..LDB, ..LDBE, ..NDB, ..NDBE

Class I, II, II Div 1,

Group A, B, C, D, E, F, G

T5 at T

T4A at T

= 55°,

max

max

= 70°

FM: 3001200

CSA: 1058582

PR 6201/..L, ..LE, ..D1, ..D1E, ..C3C6, ..C3E-C6E, ..N, ..NE

Sartorius EN-5

Page 8

Compression Load Cell PR 6201 Installation Manual

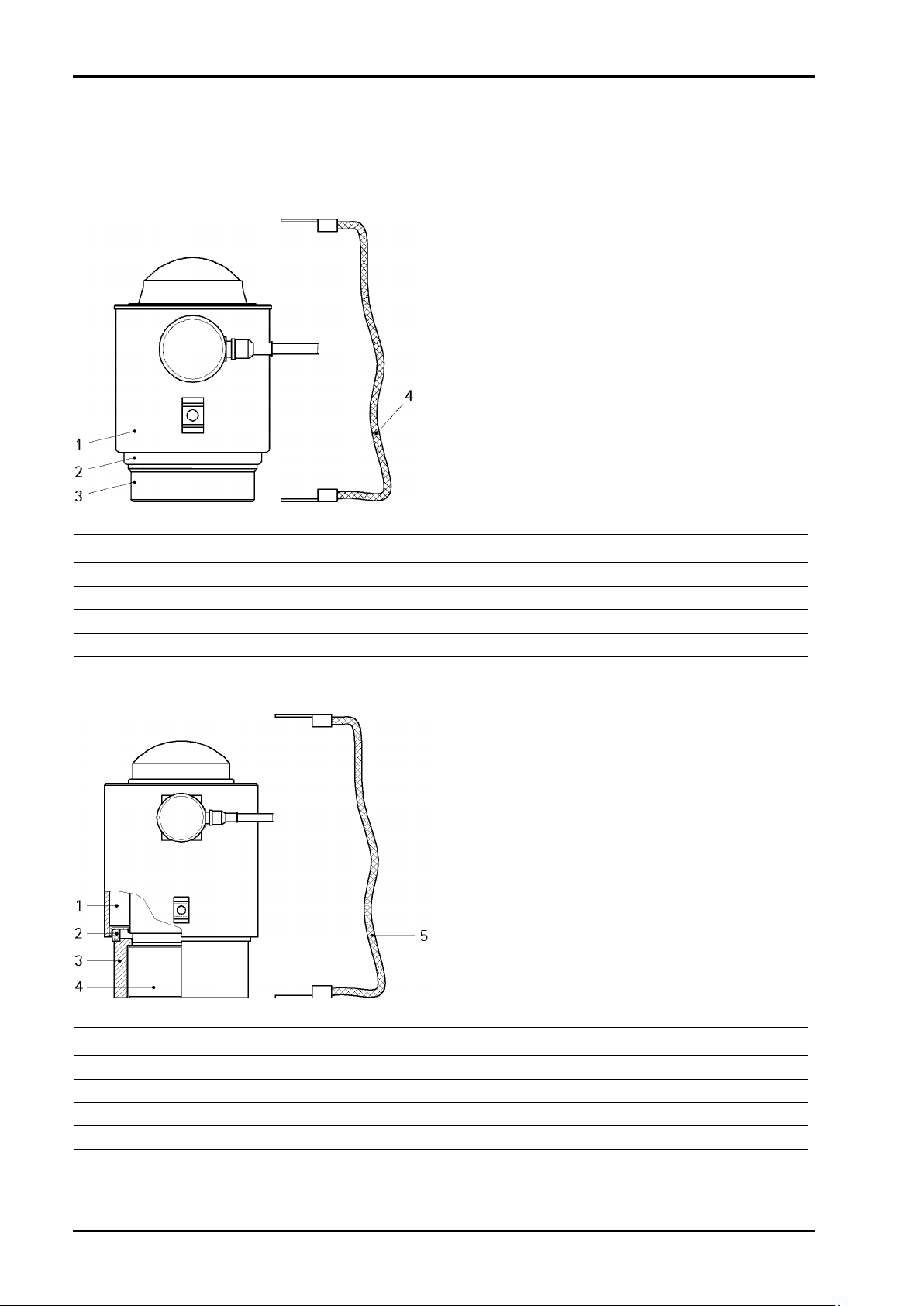

1

Load cell

5

Load cell grease, notes on use included

3.4 Equipment Supplied

3.4.1 Load Cells PR 6201/52…54 (max. capacities 500 kg…50 t)

Pos. Description Pos. Description

2 Rubber ring 6 Installation manual 9499 053 34202

3 Lower load disc 7 Certificate

4 Flexible copper strap

3.4.2 Load Cells PR 6201/15, /25, /35 and DB (max. capacities 100 t, 200 t, 300 t)

Pos. Description Pos. Description

1 Load cell 5 Flexible copper strap

2 Rubber ring 6 Load cell grease , notes on use included

3 Ring for lower load disc 7 Installation manual 9499 053 34202

4 Lower load disc 8 Certificate

EN-6 Sartorius

Page 9

Installation Manual Compression Load Cell PR 6201

2

Load cell grease , notes on use included

Type

ø a [mm]

R [mm]

B [mm]

3.4.3 Load Cell PR 6201/520t and DB (max. capacity 520 t)

Pos. Description

1 Load cell

3 Installation manual 9499 053 34202

4 Certificate

Note:

The load disc set PR 6143/55 has to be ordered separately, see Chapter 9!

3.5 Dimensions

3.5.1 Load Cell PR 6201/52…54 (max. capacity 500 kg…50 t)

Pos. Description

1 Lower load disc

2 Rubber ring

PR 6201/52…23

PR 6201/33…14

PR 6201/24…54

Sartorius EN-7

24 15

34 15

56 35

150

150

220

all dimensions in mm

Page 10

Compression Load Cell PR 6201 Installation Manual

3.5.2 Load Cell PR 6201/15 (max. capacity 100 t)

Pos. Description

1 Lower load disc

2 Rubber ring

3 Ring for lower load disc

all dimensions in mm

3.5.3 Load Cell PR 6201/25 (max. capacity 200 t), PR 6201/35 (max. capacity 300 t)

Pos. Description

1 Lower load disc

2 Rubber ring

3 Ring for lower load disc

all dimensions in mm

EN-8 Sartorius

Page 11

Installation Manual Compression Load Cell PR 6201

3.5.4 Load Cell PR 6201/520t (max. capacity 520 t)

Pos. Description

1 Upper/lower

load disc

2 Ring for

upper load disc

3 Rubber ring

4 Ring for

lower load disc

The scope of delivery

does not include these

parts!

Load disc set PR 6143/55

see Chapter 9

3.5.5 Load Cell PR 6201/15 DB (max. capacity 100 t)

all dimensions in mm

Pos. Description

1 Lower load disc

2 Rubber ring

Ring for

3

all dimensions in mm

lower load disc

Sartorius EN-9

Page 12

Compression Load Cell PR 6201 Installation Manual

3.5.6 Load Cell PR 6201/25 DB (max. capacity 200 t), PR 6201/35 DB (max. capacity 300 t)

Pos. Description

1 Lower load disc

2 Rubber ring

3 Ring for

lower load disc

3.5.7 Load Cell PR 6201/520t DB (max. capacity 520 t)

all dimensions in mm

Pos. Description

1 Upper/lower

load disc

2 Ring for

upper load disc

3 Rubber ring

4 Ring for

lower load disc

The equipment supplied

does not include these

parts!

Load disc set PR 6143/55

see Chapter 9

all dimensions in mm

EN-10 Sartorius

Page 13

Installation Manual Compression Load Cell PR 6201

3.6 Technical Data for Max. Capacity 500 kg…50 t

Sartorius EN-11

Page 14

Compression Load Cell PR 6201 Installation Manual

3.7 Technical Data for Max. Capacity 100 t, 200 t, 300 t, 520 t

EN-12 Sartorius

Page 15

Installation Manual Compression Load Cell PR 6201

3.8

Technical Data for Dual Bridge; Max. Capacity 100 t, 200 t, 300 t, 520 t

Sartorius EN-13

Page 16

Compression Load Cell PR 6201 Installation Manual

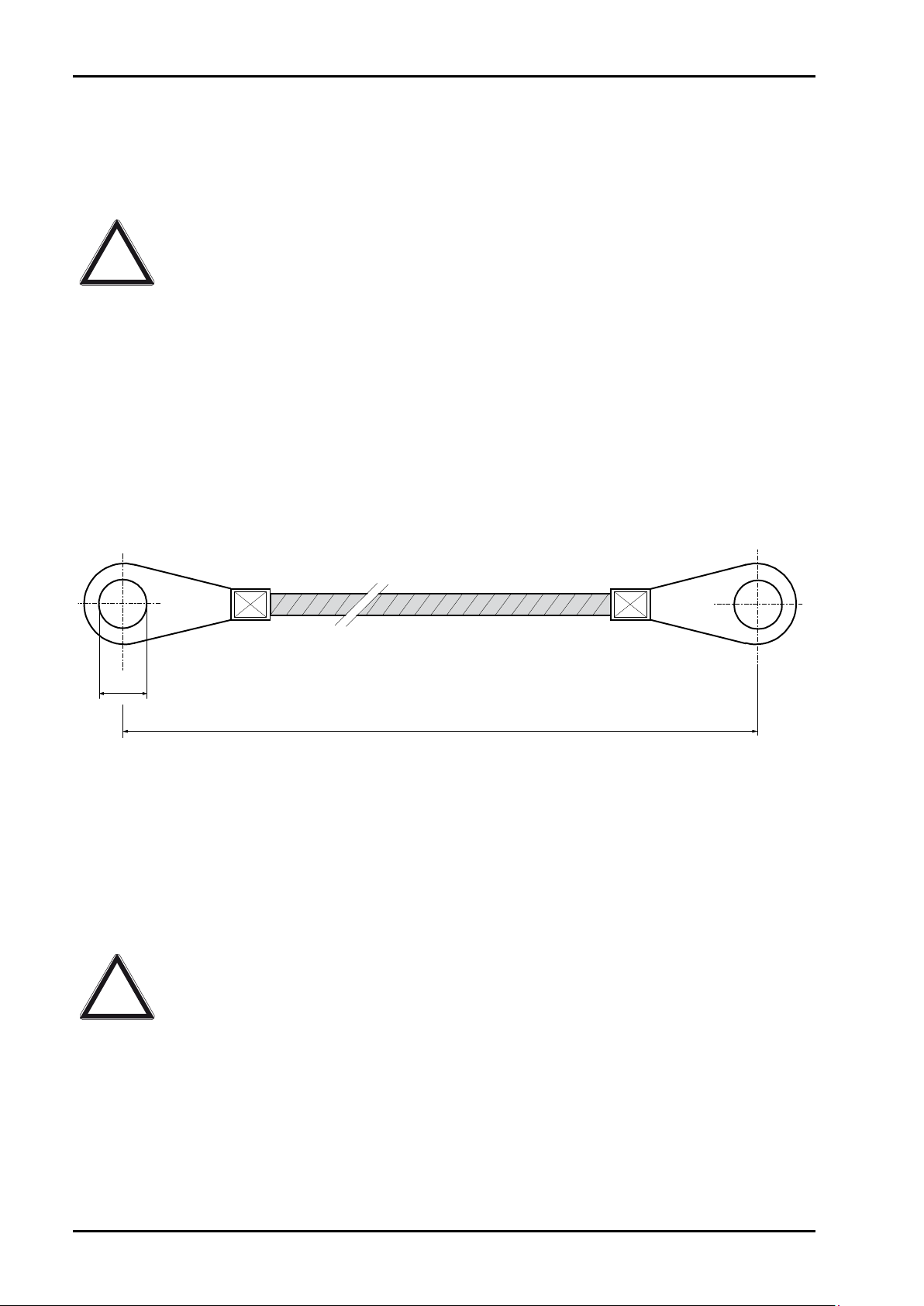

10.5

400

Figure: Flexible copper strap

4 Installation

4.1 General

Caution!

All electrical welding at the weighing facility must be finished before mounting the

load cells!

Directly when installing the load cell, bypass the load cell with the flexible copper

strap provided for this purpose (see figure), to prevent welding or lightning stroke

current from passing through the load cell and damaging it!

In case electrical welding is required subsequently in the neighborhood of the load

cell

• disconnect the load cell cable from the measuring instrument,

• bypass the load cell carefully with the above-mentioned flexible copper strap,

• take care that the grounding clamp of the welding set is fitted as closely as

possible to the welding joint in order to prevent a current flow through the load

cell.

• Do not lift the load cell on its cable.

• Avoid shock stress (falling down, hard shocks)

• The load cell must be installed so that its axis is vertical.

• The load direction must be as close as possible to measuring axis of the load cell.

• All contact points between load cell and load disc must be adequately greased.

Caution!

Changes of temperature >15 K/h may influence the measuring accuracy. To prevent

the load cells from direct heating or cooling effects (sun, wind, heat radiation) heat

protection shields or heat protection housings are to be installed if necessary.

all dimensions in mm

To prevent force shunts, all connections of the weighing facility to the surrounding

construction (pipes, cables, bellows) must be coupled as flexibly as possible.

Even the best load cells must be handled carefully and installed correctly in order to

permanently guarantee good weighing results. It is therefore extremely important to

comply with the rules described here!

EN-14 Sartorius

Page 17

Installation Manual Compression Load Cell PR 6201

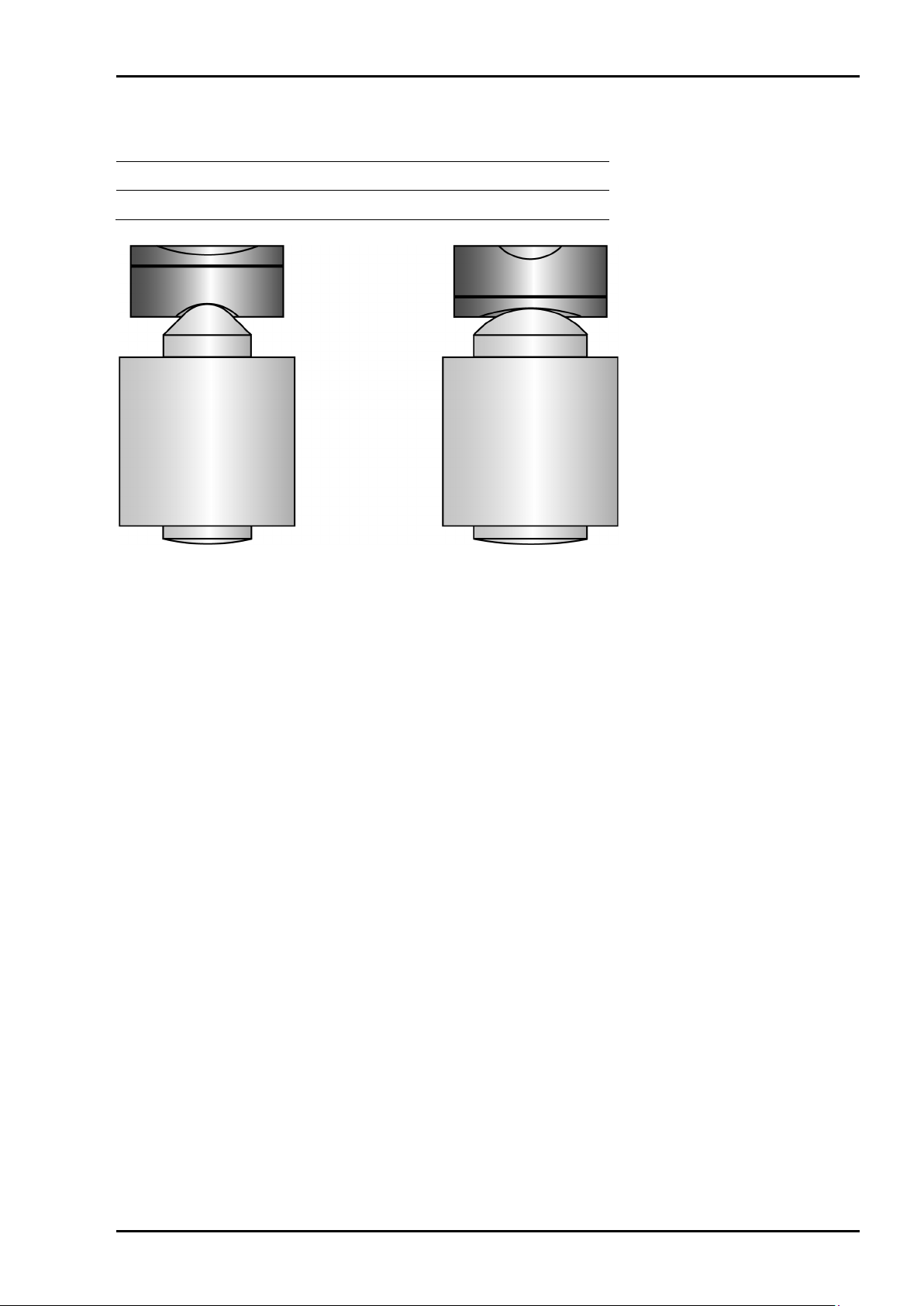

4.2 Installation of the Upper Load Disc for Max Capacity of 500 kg…50 t

small radius (15 mm) big radius (35 mm)

500 kg…10 t 20…50 t

Figure: for LC radius 15 mm Figure: for LC radius 35 mm

Note:

Further installation instructions can be found in the manuals of the respective mounting

kits.

Sartorius EN-15

Page 18

Compression Load Cell PR 6201 Installation Manual

bu =

blue

5 Connection

5.1 General

Caution!

The load cell cable end is protected against contamination and moisture by a

protective sheathing.

Remove the protective sheathing only shortly before connecting!

• Protect the cable ends against contamination. No moisture must penetrate into the open cable end.

• Do not shorten the load cell cable. Connect the prepared cable end and roll up the remaining cable.

• The screen of the load cell cable and the screen of the connecting cable must not be connected

electrically inside the junction box, if connection of both ends is not permissible according to the

regulations for installation in the explosion-hazarded area.

• The measuring cables should be kept away from power equipment.

• The distance between the measuring cables and the power cables should be at least 1 m.

• The measuring cables should be laid in separate cable conduits or steel pipes.

• Power cables should be crossed at right angles.

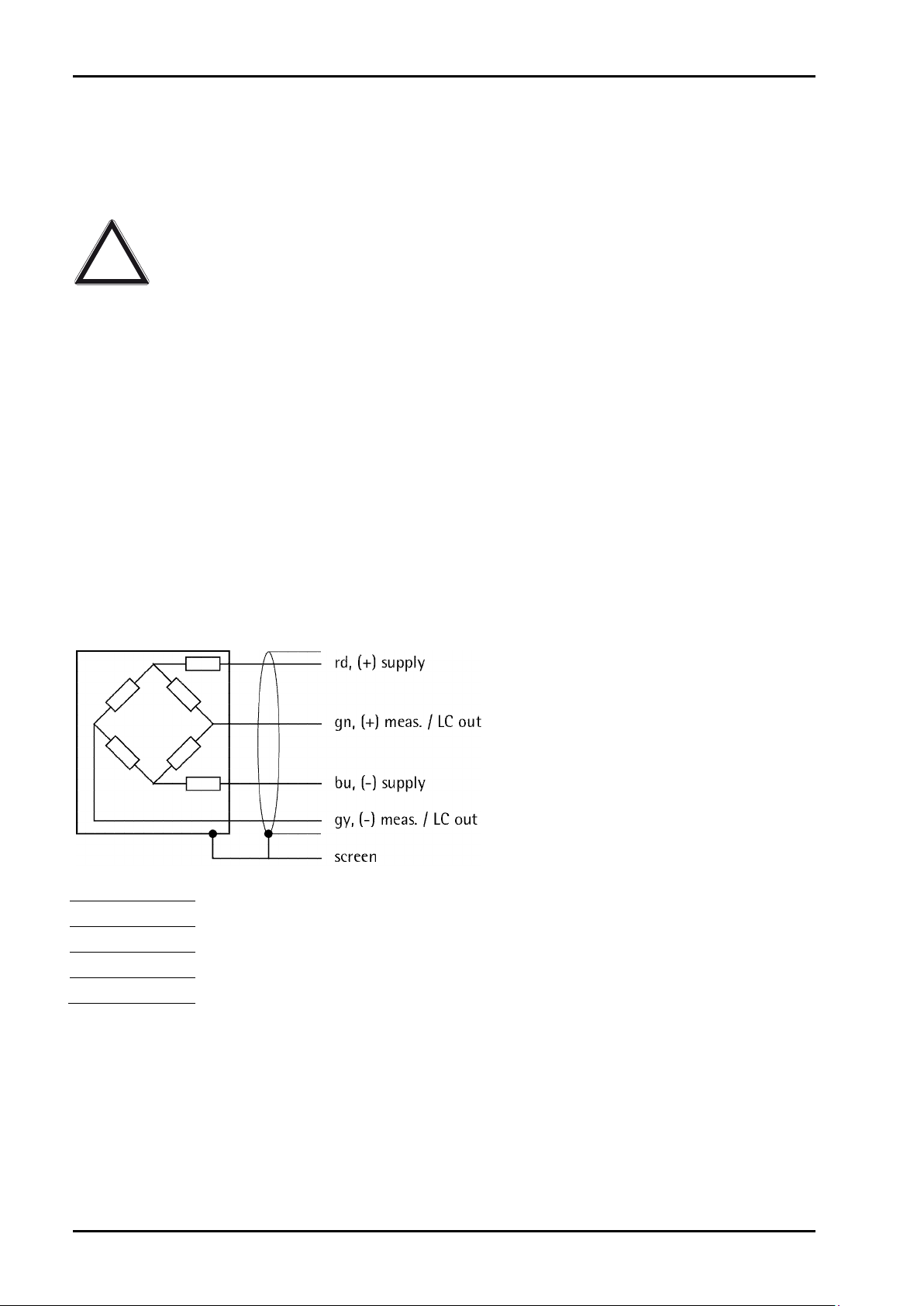

5.2 Load Cell

5.2.1 Standard (Type L, D1/N, D1E/NE, C3, C3E)

Color Code

rd = red

gn = green

gy = grey

+ Supply voltage

+ Meas. voltage / + Load cell output

– Supply voltage

– Meas. voltage / – Load cell output

Screen

EN-16 Sartorius

Page 19

Installation Manual Compression Load Cell PR 6201

out

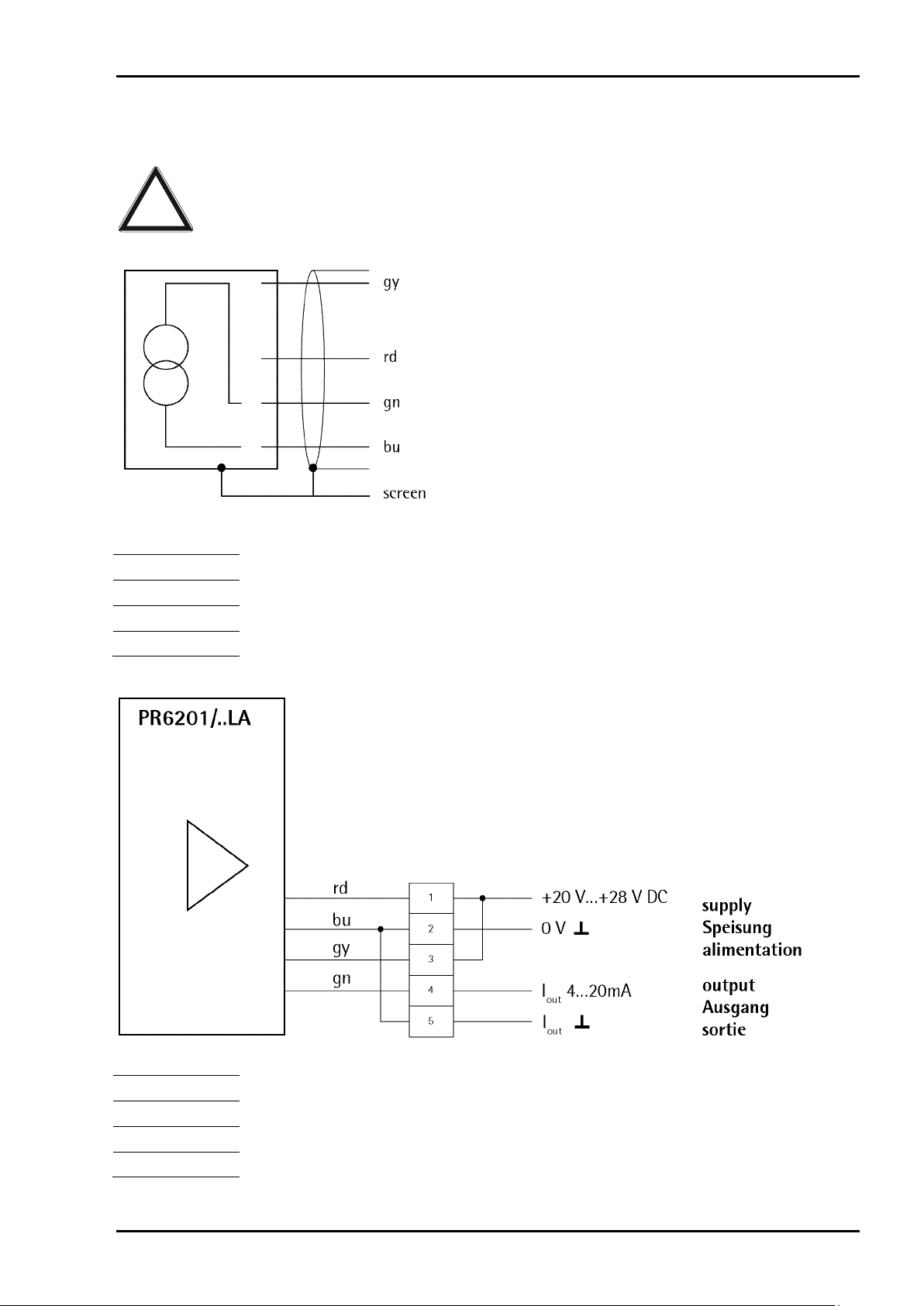

5.2.2 Load Cell with Integrated Amplifier (Type LA)

Caution!

The maximum distance between load cell and electronic instrument is 500 m.

Color Code

rd = red

bu = blue

gn = green

gy = grey

5.2.2.1 Connection of Single Load Cell

GAIN, connected to

+ Supply voltage 20…28 V DC

– Supply voltage 0 V

+ Supply voltage 20…28 V DC

+ Load cell output I

+ Load cell output I

= 4…20 mA

out

= 2…10 mA

– Supply voltage 0 V

– Load cell output

single load cell mode

two load cell mode

single load cell mode

two load cell mode

Color Code

rd = red

bu = blue

gn = green

gy = grey

Sartorius EN-17

Page 20

Compression Load Cell PR 6201 Installation Manual

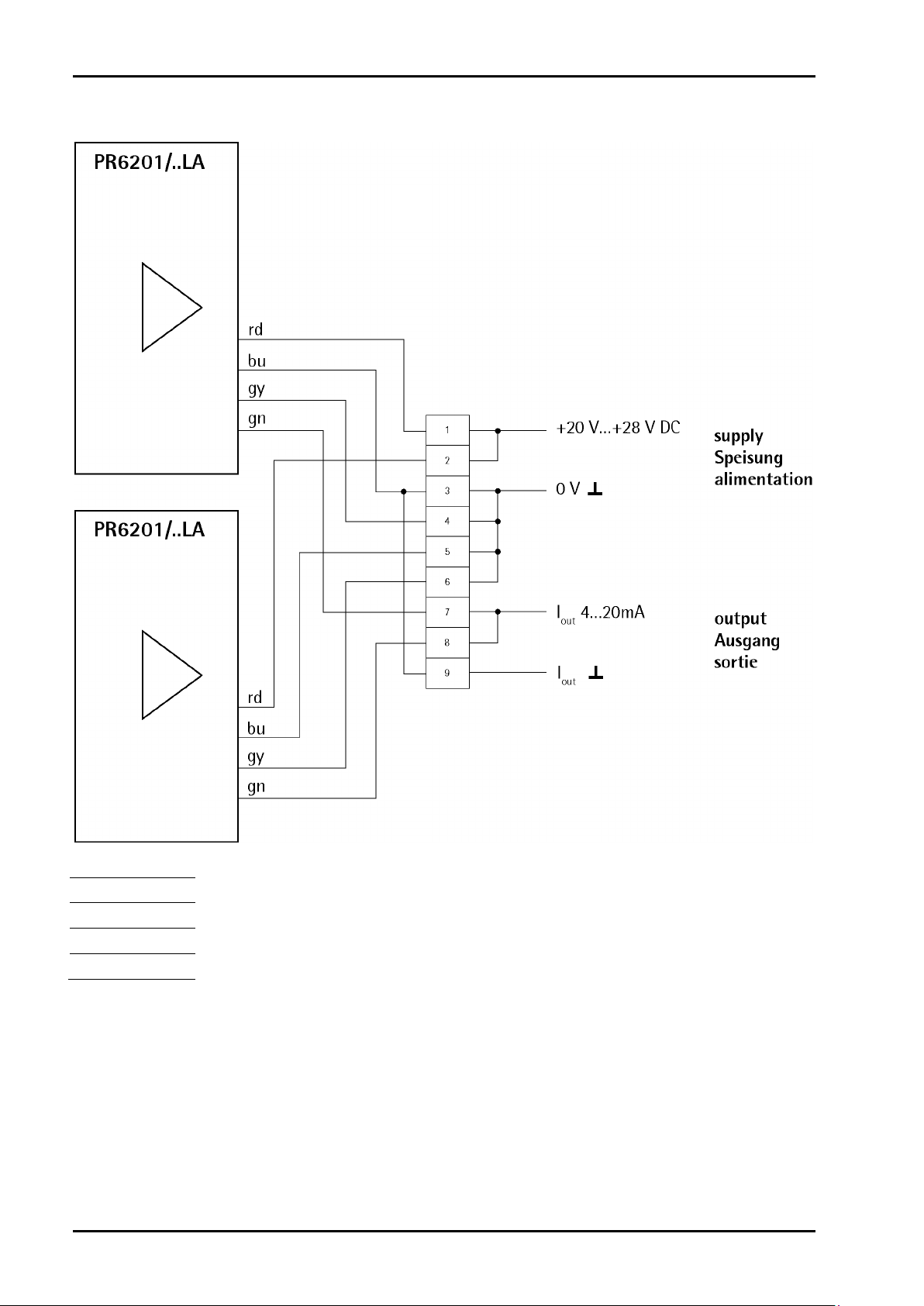

5.2.2.2 Connection of Two Load Cells

Color Code

rd = red

bu = blue

gn = green

gy = grey

EN-18 Sartorius

Page 21

Installation Manual Compression Load Cell PR 6201

5.3 Connecting Cable

For connection from the junction box to the weighing electronics, we recommend using following connecting

cables:

- PR 6135

- PR 6136 (for installation inside the explosion-hazarded area)

- PR 6135A (armored)

- PR 6136A (armored, for installation inside the explosion-hazarded area)

5.4 Cable Connections

5.4.1 Load Cells with one Measuring Circuit

Sartorius EN-19

Page 22

Compression Load Cell PR 6201 Installation Manual

5.4.2 Load Cells with two Separate Measuring Circuits

EN-20 Sartorius

Page 23

Installation Manual Compression Load Cell PR 6201

Junction box

Has moisture penetrated the junction box?

Connecting cable

Is the sheath damaged?

6 Preparing for Calibration

Note:

For calibration of the measuring system, please refer to the manual of the weighing

instrument.

Caution!

A warming-up time of at least 30 minutes for the load cell is required before calibration

of the weighing installation.

6.1 Mechanical Height Adaptation

Before starting calibration it has to be ensured that the load cells are equally loaded. Therefore a height

adaptation has to be performed.

• Place the dead load (e.g. empty hopper) on the load cells.

• Energize the load cells by means of a stabilized voltage of e.g. 12 V DC.

• Measure the output voltage of each individual load cell by means of a high-accuracy digital voltmeter and

compare the individual values.

The load cell output with the lowest voltage must be increased by putting shims between mounting plate and

weighing construction.

• Lift weighing facility near the load cell.

• Put a thin, deburred sheet of metal (0.5 mm to 2 mm thick) between the upper mounting plate and

weighing construction.

• Measure the output voltage of the load cells again and correct the height of this load cell or another

one.

7 Fault finding hints

The following hints will enable a technician for a first diagnostic or help in case of wrong or not

reproducible weighing results after commissioning and calibration.

7.1 Visual check

Weighing facility Are all pipes, hoses, and cables connected as flexibly as possible?

Are devices which are rigidly connected to the weighing facility in direct

contact with the surrounding installation?

Is there friction between the weighing facility and its surrounding (e.g. dirty

apertures etc.)?

Do the screw connections show a good contact?

Has moisture penetrated the cable end?

Mounting kit Is there a contact between lift-off protection and the weighing facility

itself?

Are the constrainers stuck?

Load cell Does the load cell stand vertically?

Is the housing damaged?

Is the sheath of the cable damaged?

Has moisture penetrated the cable end?

Sartorius EN-21

Page 24

Compression Load Cell PR 6201 Installation Manual

≥

7.2 Checks with Multimeter

7.2.1 Check Zero Output Signal of Load Cell

• Unload load cell.

• Disconnect the load cell outputs.

• Check whether the output voltage without load is within the limits.

Type Zero output signal

L 0 mV ±0,02 mV/V

D1/N/C3 0 mV ±0,01 mV/V

(at PR 6201/54.. 0 mV ±0,02 mV/V)

LA 3,2…4 mA

GAIN connected to +Supply Voltage 24 ±4 V, see chapter 5.2.2.1

7.2.2 Check the Strain Gauge Bridge

Note:

• Do not exceed the test voltage.

• Check whether the values of the resistors are within the permissible limits.

Maximum test voltage Standard industrial 32 V DC

Intrinsically safe version (PR …/..E) 25 V DC

Type Input impedance

L

D1/N

C3

Not for load cells type LA.

(red core, blue core)

650 Ω +50 Ω 610 Ω ±3 Ω

650 Ω ±6 Ω 610 Ω ±1 Ω

650 Ω ±6 Ω 610 Ω ±0,5 Ω

Output impedance

(green core, grey core)

7.2.3 Check Insulation Impedance of Load Cell

Note:

• Never apply the test voltage between the cores of the load cell cable (danger of destroying the load

cell).

• Insulate the load cell cores.

maximum test voltage standard industrial 100 V DC

Intrinsically safe version (PR …/..E) 500 V AC

insulation impedance core - housing

core - screen

screen - housing

Not for load cells type LA.

>5000 MΩ

>5000 MΩ

>5000 MΩ

7.2.4 Check Insulation Impedance of Connecting Cable

• Disconnect connecting cable and load cells.

• Insulate the cores of the connecting cable.

insulation impedance core - core

core - screen

≥600 MΩ × km

600 MΩ × km

EN-22 Sartorius

Page 25

Installation Manual Compression Load Cell PR 6201

8 Repair/Maintenance

8.1 Repair

Caution!

The load cells PR 6201 are designed as robust as possible for the required

measuring accuracy and have a high reliability. In case of an electrical or

mechanical defect the load cell must be replaced.

A load cell repair is not possible.

8.2 Maintenance

Load cell PR 6201 needs no maintenance.

Pollution on the load cells and on the moveable parts of the weighing installation have to be cleaned in

due time

- if the pollution influences the weighing or

- if the pollution is aggressive against the different materials of the installation.

The contact surfaces between load cell and load discs are to be protected by grease. The load cell is

surrounding with off shore all weather protection spray in aggressive pollution.

Sartorius EN-23

Page 26

Compression Load Cell PR 6201 Installation Manual

11

Rubber ring

100 t

5322 532 30408

15

Rubber ring

200 t, 300 t

5322 532 30409

19

Mounting kit PR 6001/00N*

0.5…10 t

9405 360 01001

9 Spare Parts and Accessories

Pos. Description Max. capacity Order number

1 Lower load disc with rubber ring 0.5…10 t 5322 693 91416

2 Lower load disc with rubber ring 20 t, 30 t, 50 t 5322 693 91165

3 Lower load disc with rubber ring PR 6143/24S* 0.5…10 t 9405 361 43242

4 Lower load disc with rubber ring PR 6143/54S* 20 t, 30 t, 50 t 9405 361 43542

5 Rubber ring, standard 0.5…50 t 5322 532 70298

6 Rubber ring, food resistance 0.5…50 t 5322 532 70317

7 Upper load disc, standard PR 6143/50N* 0.5…50 t 9405 361 43501

8 Upper load disc, PR 6143/50S* 0.5…50 t 9405 361 43502

9 Lower load disc 100 t 5322 466 81611

10 Ring for lower load disc 100 t 5322 466 81609

12 Upper load disc 100 t 5322 520 10552

13 Lower load disc 200 t, 300 t 5322 466 81613

14 Ring for lower load disc 200 t, 300 t 5322 466 81612

16 Upper load disc 200 t, 300 t 5322 520 10553

17 Load disc set PR 6143/55N* 520 t 9405 361 43551

18 Flexible copper strap 400 mm long 5322 310 30581

20 Mounting kit PR 6001/00S* 0.5…10 t 9405 360 01002

21 Mounting kit PR 6001/01N* 20…50 t 9405 360 01011

22 Mounting kit PR 6001/01S* 20…50 t 9405 360 01012

23 Mounting kit PR 6001/02N* 100 t 9405 360 01021

24 Mounting kit PR 6001/03N* 200 t, 300 t 9405 360 01031

25 Mounting kit PR 6145/00N* 0.5…50 t 9405 361 45001

26 Mounting kit PR 6145/00S* 0.5…20 t 9405 361 45002

27 Mounting kit PR 6145/08N* 100 t 9405 361 45081

28 Mounting kit PR 6145/10S* 200 t, 300 t 9405 361 45101

*N = Steel, zinc plated *S = Stainless steel

EN-24 Sartorius

Page 27

Installation Manual Compression Load Cell PR 6201

≤

≤

≤

37

High Capacity mounting kit PR 6001/30N*

≤

9405 360 01301

38

High Capacity mounting kit PR 6001/31N*

≤

9405 360 01311

≤

≤

≤

≤

≤

≤

≤

50

SeismicMount PR 6144/55

≤

9405 361 44551

≤

≤

≤

57

Junction box PR 6130/64Sa*, for installation inside the explosion-hazarded area

9405 361 30642

Pos. Description Horizontal force Order number

29 MaxiFLEXLOCK PR 6001/10N*

30 MaxiFLEXLOCK PR 6001/10S*

31 MaxiFLEXLOCK PR 6001/11N*

32 MaxiFLEXLOCK PR 6001/11S*

33 MaxiFLEXLOCK PR 6001/20N*

34 MaxiFLEXLOCK PR 6001/20S*

35 MaxiFLEXLOCK PR 6001/21N*

36 MaxiFLEXLOCK PR 6001/21S*

39 High Capacity mounting kit PR 6001/32N*

40 High Capacity mounting kit PR 6001/33N*

41 MiniFLEXLOCK PR 6143/00N*

42 MiniFLEXLOCK PR 6143/00S*

43 MiniFLEXLOCK PR 6143/10N*

44 MiniFLEXLOCK PR 6143/10S*

45 MiniFLEXLOCK PR 6143/15N*

46 MiniFLEXLOCK PR 6143/25N*

47 SeismicMount PR 6144/54

48 SeismicMount PR 6144/15

49 SeismicMount PR 6144/35

51 Constrainer PR 6143/80

52 Constrainer PR 6143/83

53 Horizontal constrainer PR 6152/02

54 Connecting cable PR 6135 9405 361 35..2

55 Connecting cable PR 6136, for installation inside the explosion-hazarded area 9405 361 36..1

56 Junction box PR 6130/08 9405 361 30081

25 kN

≤25 kN

≤25 kN

≤25 kN

≤50 kN

≤50 kN

50 kN

50 kN

200 kN

200 kN

200 kN

200 kN

25 kN

25 kN

≤50 kN

≤50 kN

≤200 kN

≤200 kN

370 kN

440 kN

520 kN

520 kN

2 kN

20 kN

200 kN

9405 360 01101

9405 360 01102

9405 360 01111

9405 360 01112

9405 360 01201

9405 360 01202

9405 360 01211

9405 360 01212

9405 360 01321

9405 360 01331

9405 361 43001

9405 361 43002

9405 361 43101

9405 361 43102

9405 361 43151

9405 361 43251

9405 361 44541

9405 361 44151

9405 361 44351

9405 361 43801

9405 361 43831

9405 361 52021

58 Junction box PR 6130/68S*, for installation inside the explosion-hazarded area 9405 361 30682

*N = Steel, zinc plated *S/Sa = Stainless steel

Sartorius EN-25

Page 28

Page 29

Installationshandbuch Drucklast-Wägezelle PR 6201

Inhaltsverzeichnis

1 Sicherheitshinweise ........................................................................................................................ 3

2 Aufbauempfehlung ........................................................................................................................ 3

2.1 Anordnung der Wägezellen und Fesselungen ................................................................................... 3

2.2 Anordnung von Wägezellen und Festlagern ...................................................................................... 4

2.3 Abhebesicherung ......................................................................................................................................... 4

2.4 Wahl der Nennlast ....................................................................................................................................... 4

3 Technische Daten ............................................................................................................................ 5

3.1 Allgemeines .................................................................................................................................................... 5

3.2 Dual Bridge ..................................................................................................................................................... 5

3.3 Zertifikate ....................................................................................................................................................... 5

3.4 Lieferumfang ................................................................................................................................................. 6

3.4.1 Wägezellen PR 6201/52…54 (Nennlasten 500 kg…50 t) ......................................................................... 6

3.4.2 Wägezellen PR 6201/15, /25, /35 und DB (Nennlasten 100 t, 200 t, 300 t) ..................................... 6

3.4.3 Wägezelle PR 6201/520t und DB (Nennlast 520 t) .................................................................................. 7

3.5 Abmessungen ................................................................................................................................................ 7

3.5.1 Wägezelle PR 6201/52…54 (Nennlasten 500 kg…50 t) ........................................................................... 7

3.5.2 Wägezelle PR 6201/15 (Nennlast 100 t) ...................................................................................................... 8

3.5.3 Wägezelle PR 6201/25 (Nennlast 200 t), PR 6201/35 (Nennlast 300 t) ............................................. 8

3.5.4 Wägezelle PR 6201/520t (Nennlast 520 t) .................................................................................................. 9

3.5.5 Wägezelle PR 6201/15 DB (Nennlast 100 t) ............................................................................................... 9

3.5.6 Wägezelle PR 6201/25 DB (Nennlast 200 t), PR 6201/35 DB (Nennlast 300 t)............................. 10

3.5.7 Wägezelle PR 6201/520t DB (Nennlast 520 t) ........................................................................................ 10

3.6 Technische Daten für Nennlast 500 kg…50 t ................................................................................... 11

3.7 Technische Daten für Nennlast 100 t, 200 t, 300 t, 520 t ........................................................... 12

3.8 Technische Daten für Dual Bridge mit Nennlast 100 t, 200 t, 300 t, 520 t .......................... 13

Sartorius DE-1

Page 30

Drucklast-Wägezelle PR 6201 Installationshandbuch

4 Installation .................................................................................................................................... 14

4.1 Allgemeines .................................................................................................................................................. 14

4.2 Einbau des oberen Druckstückes bei Nennlasten von 500 kg…50 t ........................................ 15

5 Anschluss ....................................................................................................................................... 16

5.1 Allgemeines .................................................................................................................................................. 16

5.2 Wägezelle ..................................................................................................................................................... 16

5.2.1 Standard (Typ L, D1/N, D1E/NE, C3, C3E) .................................................................................................. 16

5.2.2 Mit integriertem Verstärker (Typ LA) ......................................................................................................... 17

5.3 Verbindungskabel ...................................................................................................................................... 19

5.4 Kabelverbindungen ................................................................................................................................... 19

5.4.1 Wägezellen mit einem Messkreis ................................................................................................................. 19

5.4.2 Wägezellen mit zwei getrennten Messkreisen ........................................................................................ 20

6 Vorbereitung zur Justierung ....................................................................................................... 21

6.1 Mechanischer Höhenausgleich ............................................................................................................. 21

7 Fehlersuche ................................................................................................................................... 21

7.1 Sichtprüfung ............................................................................................................................................... 21

7.2 Messtechnische Prüfungen .................................................................................................................... 22

7.2.1 Nullsignal der Wägezelle überprüfen ......................................................................................................... 22

7.2.2 DMS Brückenschaltung der Wägezelle überprüfen ............................................................................... 22

7.2.3 Isolationswiderstand der Wägezelle überprüfen .................................................................................... 22

7.2.4 Isolationswiderstand des Verbindungskabels überprüfen .................................................................... 22

8 Reparatur/Wartung...................................................................................................................... 23

8.1 Reparatur ...................................................................................................................................................... 23

8.2 Wartung ........................................................................................................................................................ 23

9 Ersatzteile und Zubehör .............................................................................................................. 24

DE-2 Sartorius

Page 31

Installationshandbuch Drucklast-Wägezelle PR 6201

* diesen Punkt nicht fesseln

1 Sicherheitshinweise

Die PR 6201 mit den zugehörigen Einbausätzen darf nur bestimmungsgemäß für Wägeaufgaben eingesetzt

werden. Sämtliche Einbau- und Konstruktionsteile sind so zu dimensionieren, dass sie unter Beachtung der

entsprechenden Normen eine genügend große Überlastfestigkeit für alle eventuell auftretenden Lasten

sicherstellen. Insbesondere sind stehende Wägeobjekte (Behälter o. ä.) so zu sichern, dass ein Umkippen oder

Verschieben der Wägeinstallation und damit eine Gefährdung von Personen, Tieren oder Gegenständen

selbst bei Bruch einer Wägezelle oder von Einbauteilen auszuschließen ist.

Installations- und Reparaturarbeiten dürfen nur durch sachkundige/eingewiesene Fachkräfte erfolgen.

2 Aufbauempfehlung

2.1 Anordnung der Wägezellen und Fesselungen

Der Unterbau der Waage (und damit der Wägezellen) sowie der Behälter müssen gegenüber den

vorgegebenen Lasten unnachgiebig, waagerecht (Wasserwaage!) und eben sein. Behälter sollten

vorzugsweise auf 3 Wägezellen (siehe Abbildung), Plattformen und Brückenwaagen auf 4 bzw.

6 Wägezellen gesetzt werden.

Querbelastungen bzw. Seitenkräfte sowie Torsionsmomente sind Störgrößen, die Messfehler erzeugen und

bei Überschreitung der zulässigen Grenzen zu Beschädigungen führen können.

Eine sachgerechte Fesselung des Messobjektes schützt vor Beschädigung und Messfehlern, ohne die

notwendige Bewegungsfreiheit in Messrichtung zu beeinflussen. Dabei ist zu berücksichtigen, dass

Temperaturdehnungen und Verlagerungen eventuell die Bewegungsfreiheit des zu wägenden Objektes

beeinflussen und damit zu erheblichen Verfälschungen des Messergebnisses führen können. Daher ist

besonderer Wert auf die Gestaltung, Anordnung und den Zustand der Fesselungselemente zu legen.

Sartorius DE-3

Page 32

Drucklast-Wägezelle PR 6201 Installationshandbuch

2.2 Anordnung von Wägezellen und Festlagern

2.3 Abhebesicherung

Bei Behältern ist aus Sicherheitsgründen eine Abhebesicherung generell vorzusehen. Diese kann separat

verwirklicht werden oder mit Einbausätzen. In der einfachsten Ausführung sind dafür eine Gewindestange,

drei Muttern, eine Fächerscheibe und eine Unterlegscheibe erforderlich.

2.4 Wahl der Nennlast

Die Wägezelle PR 6201 hat aufgrund ihrer geringen Materialbeanspruchung (1 mV/V) eine hohe

Überlastfestigkeit. Wenn die Gebrauchslast der Wägezelle in Messrichtung überschritten wird, können sich

die Kenndaten verändern oder die Wägezelle beschädigt werden. Bei Überschreiten der Bruchlast der

Wägezelle besteht die Gefahr der mechanischen Zerstörung. Wenn die Gebrauchslast der Wägezelle z. B.

durch fallende Lasten überschritten werden kann, dann ist eine mechanische Begrenzung in Lastrichtung

vorzusehen.

DE-4 Sartorius

Page 33

Installationshandbuch Drucklast-Wägezelle PR 6201

1,55% der vertikal auf der Wägezelle ruhenden Last

E

= 100 t

1,23 % der vertikal auf der Wägezelle ruhenden Last

E

= 200 t + 300 t

0,65 % der vertikal auf der Wägezelle ruhenden Last

max

Mantel

Material:

thermoplastisches Elastomer

max

3 Technische Daten

3.1 Allgemeines

Rückstellkraft Bei einer Auslenkung der Wägezelle aus der Vertikalen wird je Millimeter Auslenkung

(gemessen am Wägezellenkopf) eine horizontal wirkende Rückstellkraft wirksam:

E

E

≤10 t:

max

E

≥20 t:

max

max

max

= 520 t 1,20 % der vertikal auf der Wägezelle ruhenden Last

max

Ausführung Gehäuse, rostfreier Edelstahl 1.4301 (DIN 17440), hermetisch verschlossen durch

Verschweißen; mit Inertgas gefüllt

Schutzart IP 68 (1,5 m Wassertiefe, 10.000 h) nach IEC 60529 (entspricht NEMA 6)

IP69K nach DIN 40050

Zündschutzart Eigensicherheit für PR 6201/..E + ..DBE

Kabel Durchmesser 5 mm

Länge

Querschnitt

Biegeradius

E

4×0,35 mm2

≥25 mm bei fester Verlegung

≥75 mm bei flexibler Verlegung

0,65% der vertikal auf der Wägezelle ruhenden Last

E

≤10 t: 5 m

>10 t: 12 m

max

Farbe: grau (Standardausführung)

blau (Ex-Ausführung)

grün (LA-Ausführung)

3.2 Dual Bridge

Die Dual Bridge Wägezelle hat zwei getrennt voneinander unabhängige Messkreise. Die Messkreise werden

in zwei getrennten Abgleichkammern abgeglichen, Kabelverbindungen siehe Kapitel 5.4.2.

3.3 Zertifikate

Zone Gerätekennzeichnung Nummer des Zertifikates für

0 und 1 II 1G Ex ia IIC T6 PTB 02 ATEX 2059 nur PR 6201/..E + ..DBE

20 und 21 II 1 D IP65 T85°C TÜV 03 ATEX 2301X PR 6201/..L, ..LE, ..D1, ..D1E,

..C3-C6, ..C3E-C6E, ..N, ..NE

2 II 3G Ex nA II T6 Herstellererklärung PR 6201/..L, ..LE, ..D1, ..D1E, ..C3-C6,

..C3E-C6E, ..N, ..NE,

..LDB, ..LDBE, ..NDB, ..NDBE

22 II 3D Ex tD A22 IP65 T85°C Herstellererklärung PR 6201/..L, ..LE, ..D1, ..D1E, ..C3-C6,

..C3E-C6E, ..N, ..NE,

..LDB, ..LDBE, ..NDB, ..NDBE

Class I, II, II Div 1,

Group A, B, C, D, E, F, G

T5 bei T

T4A bei T

= 55°,

max

= 70°

FM: 3001200

CSA: 1058582

PR 6201/..L, ..LE, ..D1, ..D1E, ..C3-C6,

..C3E-C6E, ..N, ..NE

Sartorius DE-5

Page 34

Drucklast-Wägezelle PR 6201 Installationshandbuch

4

Flexible Kupferleitung

3.4 Lieferumfang

3.4.1 Wägezellen PR 6201/52…54 (Nennlasten 500 kg…50 t)

Pos. Bezeichnung Pos. Bezeichnung

1 Wägezelle 5 Wägezellenfett inkl. Verwendungshinweise

2 Dichtring 6 Installationshandbuch 9499 053 34202

3 Unteres Druckstück 7 Zertifikat

3.4.2 Wägezellen PR 6201/15, /25, /35 und DB (Nennlasten 100 t, 200 t, 300 t)

Pos. Bezeichnung Pos. Bezeichnung

1 Wägezelle 5 Flexible Kupferleitung

2 Dichtring 6 Wägezellenfett inkl. Verwendungshinweise

3 Ring für unteres Druckstück 7 Installationshandbuch 9499 053 34202

4 Unteres Druckstück 8 Zertifikat

DE-6 Sartorius

Page 35

Installationshandbuch Drucklast-Wägezelle PR 6201

1

Wägezelle

Typ

ø a [mm]

R [mm]

B [mm]

3.4.3 Wägezelle PR 6201/520t und DB (Nennlast 520 t)

Pos. Bezeichnung

2 Wägezellenfett inkl. Verwendungshinweise

3 Installationshandbuch 9499 053 34202

4 Zertifikat

Hinweis:

Der Druckstücksatz PR 6143/55 muss separat bestellt werden, siehe Kapitel 9!

3.5 Abmessungen

3.5.1 Wägezelle PR 6201/52…54 (Nennlasten 500 kg…50 t)

PR 6201/52…23

24 15

150

Pos. Bezeichnung

1 Unteres Druckstück

2 Dichtring

alle Abmessungen in mm

PR 6201/33…14

PR 6201/24…54

34 15

56 35

150

220

Sartorius DE-7

Page 36

Drucklast-Wägezelle PR 6201 Installationshandbuch

3.5.2 Wägezelle PR 6201/15 (Nennlast 100 t)

Pos. Bezeichnung

1 Unteres Druckstück

2 Dichtring

Ring für unteres

3

alle Abmessungen in mm

3.5.3 Wägezelle PR 6201/25 (Nennlast 200 t), PR 6201/35 (Nennlast 300 t)

Druckstück

Pos. Bezeichnung

1 Unteres Druckstück

2 Dichtring

3 Ring für unteres

Druckstück

alle Abmessungen in mm

DE-8 Sartorius

Page 37

Installationshandbuch Drucklast-Wägezelle PR 6201

3.5.4 Wägezelle PR 6201/520t (Nennlast 520 t)

Pos. Bezeichnung

1 Druckstück

oben/unten

2 Ring für

Druckstück oben

3 Dichtring

4 Ring für

Druckstück unten

Diese Teile sind nicht im

Lieferumfang enthalten!

Druckstücksatz PR

6143/55 siehe Kapitel 9

3.5.5 Wägezelle PR 6201/15 DB (Nennlast 100 t)

alle Abmessungen in mm

Pos. Bezeichnung

1 Unteres Druckstück

2 Dichtring

Ring für unteres

3

alle Abmessungen in mm

Druckstück

Sartorius DE-9

Page 38

Drucklast-Wägezelle PR 6201 Installationshandbuch

3.5.6 Wägezelle PR 6201/25 DB (Nennlast 200 t), PR 6201/35 DB (Nennlast 300 t)

Pos. Bezeichnung

1 Unteres Druckstück

2 Dichtring

3 Ring für unteres

Druckstück

3.5.7 Wägezelle PR 6201/520t DB (Nennlast 520 t)

alle Abmessungen in mm

Pos. Bezeichnung

1 Druckstück

oben/unten

2 Ring für

Druckstück oben

3 Dichtring

4 Ring für

Druckstück unten

Diese Teile sind nicht im

Lieferumfang enthalten!

Druckstücksatz PR

6143/55 siehe Kapitel 9

alle Abmessungen in mm

DE-10 Sartorius

Page 39

Installationshandbuch Drucklast-Wägezelle PR 6201

3.6 Technische Daten für Nennlast 500 kg…50 t

Sartorius DE-11

Page 40

Drucklast-Wägezelle PR 6201 Installationshandbuch

3.7 Technische Daten für Nennlast 100 t, 200 t, 300 t, 520 t

DE-12 Sartorius

Page 41

Installationshandbuch Drucklast-Wägezelle PR 6201

3.8

Technische Daten für Dual Bridge mit Nennlast 100 t, 200 t, 300 t, 520 t

Sartorius DE-13

Page 42

Drucklast-Wägezelle PR 6201 Installationshandbuch

10.5

400

Abbildung: Flexible Kupferleitung

4 Installation

4.1 Allgemeines

Achtung!

Vor dem Einbau der Wägezellen müssen alle Schweißarbeiten an der

Wägeeinrichtung beendet sein!

Unmittelbar beim Einbau die Wägezelle mit einer flexiblen Kupferleitung (siehe

Abbildung) überbrücken, da durch die Zelle fließender Schweiß- oder Blitzstrom zu

Beschädigungen führen kann!

Bei nachträglichen elektrischen Schweißarbeiten in der Nähe der Wägezelle,

• sind die Wägezellenkabel abzuklemmen.

• ist für gute Überbrückung der Zelle durch die flexible Kupferleitung zu sorgen.

• ist die Masseklemme des Schweißgerätes so dicht wie möglich an der

Schweißstelle anzubringen.

alle Abmessungen in mm

• Wägezellen nicht am Kabel anheben oder transportieren.

• Stoßbelastungen (Herunterfallen, harte Stöße) vermeiden.

• Die Wägezellen müssen senkrecht eingebaut werden.

• Die Lasten müssen möglichst genau in der Messrichtung der Wägezellen wirken.

• Alle Berührstellen zwischen Wägezelle und Druckstück müssen ausreichend eingefettet werden.

Achtung!

Temperaturschwankungen >15 K/h können zu Messfehlern führen. Darum sind die

Wägezellen gegen direkte Wärme- bzw. Kälteeinwirkung (Sonne, Wind,

Wärmestrahlung) zu schützen, z. B. durch Schutzbleche oder Schutzgehäuse.

Zur Vermeidung von Kraftnebenschlüssen sind alle Zu- und Ableitungen (Schläuche,

Rohre, Kabel) so flexibel wie möglich an das Messobjekt zu koppeln.

Auch die besten Wägezellen müssen sorgfältig behandelt und korrekt eingebaut

werden, um dauerhaft gute Wägeergebnisse zu garantieren. Die Befolgung der hier

beschriebenen Regeln ist deshalb von größter Wichtigkeit!

DE-14 Sartorius

Page 43

Installationshandbuch Drucklast-Wägezelle PR 6201

Hinweis:

Weitere Installationshinweise entnehmen Sie den Handbüchern der entsprechenden

4.2 Einbau des oberen Druckstückes bei Nennlasten von 500 kg…50 t

kleiner Radius (15 mm) großer Radius (35 mm)

500 kg…10 t 20…50 t

Abbildung: für WZ-Radius 15 mm Abbildung: für WZ-Radius 35 mm

Einbausätze.

Sartorius DE-15

Page 44

Drucklast-Wägezelle PR 6201 Installationshandbuch

bu =

blau

5 Anschluss

5.1 Allgemeines

Achtung!

Das Kabelende der Wägezelle ist durch eine Schutzhülle vor Verschmutzung und

Feuchtigkeit geschützt.

Die Schutzhülle erst unmittelbar vor dem Anschließen entfernen!

• Kabelende vor Verschmutzung schützen. Feuchtigkeit darf nicht in das offene Kabelende dringen.

• Das Wägezellenkabel nicht kürzen. Das vorbereitete Ende anschließen und die überschüssige Länge

aufrollen.

• Der Schirm des Wägezellenkabels und der Schirm des Verbindungskabels dürfen im Verbindungskasten

nicht

elektrisch verbunden sein, wenn ein beidseitiges Anschließen entsprechend der Vorschriften für

die Installation im Ex-Bereich nicht zulässig ist.

• Die Messkabel sind von Starkstromeinrichtungen fernzuhalten.

• Der Abstand zwischen Mess- und Starkstromkabeln bzw. Starkstrom führenden Teilen muss mindestens

1 m betragen (Richtwert).

• Es wird empfohlen, die Messkabel in separaten Kabelwannen bzw. in Stahlpanzerrohren zu verlegen.

• Starkstrom führende Leitungen sind rechtwinklig zu kreuzen.

5.2 Wägezelle

5.2.1 Standard (Typ L, D1/N, D1E/NE, C3, C3E)

Farbcode

rd = rot

gn = grün

gy = grau

+ Speisespannung

+ Messspannung / + Wägezellenausgang

– Speisespannung

– Messspannung / – Wägezellenausgang

Schirm

DE-16 Sartorius

Page 45

Installationshandbuch Drucklast-Wägezelle PR 6201

out

gn =

grün

gn =

grün

5.2.2 Mit integriertem Verstärker (Typ LA)

Achtung!

Die maximale Kabellänge zwischen Wägezelle und Elektronik beträgt 500 m.

Farbcode

rd = rot

bu = blau

gy = grau

5.2.2.1 Anschluss von einer Wägezelle

GAIN, verbunden mit

+ Speisespannung 20…28 V DC

– Speisespannung 0 V

+ Speisespannung 20…28 V DC

+ Wägezellenausgang I

+ Wägezellenausgang I

= 4…20 mA

out

= 2…10 mA

– Speisespannung 0 V

– Wägezellenausgang

Schirm

für Betrieb mit 1 WZ

für Betrieb mit 2 WZ

für Betrieb mit 1 WZ

für Betrieb mit 2 WZ

Farbcode

rd = rot

bu = blau

gy = grau

Sartorius DE-17

Page 46

Drucklast-Wägezelle PR 6201 Installationshandbuch

5.2.2.2 Anschluss von zwei Wägezellen

Farbcode

rd = rot

bu = blau

gn = grün

gy = grau

DE-18 Sartorius

Page 47

Installationshandbuch Drucklast-Wägezelle PR 6201

5.3 Verbindungskabel

Für die Verbindung vom Verbindungskasten zur Wägeelektronik wird die Verwendung folgender

Verbindungskabel empfohlen:

- PR 6135

- PR 6136 (für Ex-Anwendung)

- PR 6135A (armiert)

- PR 6136A (armiert, für Ex-Anwendung)

5.4 Kabelverbindungen

5.4.1 Wägezellen mit einem Messkreis

Sartorius DE-19

Page 48

Drucklast-Wägezelle PR 6201 Installationshandbuch

5.4.2 Wägezellen mit zwei getrennten Messkreisen

DE-20 Sartorius

Page 49

Installationshandbuch Drucklast-Wägezelle PR 6201

Stehen Elemente, die mit der Waage starr verbunden sind, in

Hat sich zwischen dem Wägeobjekt und seiner Umgebung Reibung

Haben die Schraubverbindungen sicheren Kontakt?

Ist Feuchtigkeit eingedrungen?

Sind die Querlenker verklemmt?

Ist das Gehäuse beschädigt?

Ist der Mantel des Anschlusskabels beschädigt?

Ist Feuchtigkeit in das Anschlusskabel eingedrungen?

6 Vorbereitung zur Justierung

Hinweis:

Justierung des Wägesystems siehe Handbuch des Wägegerätes.

Achtung!

Die Wägezelle benötigt eine Aufwärmzeit von mindestens 30 Minuten vor Beginn der

Justierung der Wägeeinrichtung.

6.1 Mechanischer Höhenausgleich

Damit die Wägezellen möglichst gleichmäßig belastet werden, ist vor der Justierung ein Höhenausgleich

vorzunehmen.

• Die Wägezellen der Wägeanlage mit der Totlast (z. B.: leerer Behälter) belasten.

• Die Wägezellen parallel mit einer stabilisierten Spannung, z. B. 12 V DC, speisen.

• Die Ausgangsspannungen der Wägezellen einzeln mit einem Digitalvoltmeter messen und miteinander

vergleichen.

Bei Abweichungen zwischen den Ausgangsspannungen der Wägezellen muss die Wägezelle mit der

niedrigsten Ausgangsspannung durch das Unterlegen von Ausgleichsblechen stärker belastet werden.

• Wägeanlage unmittelbar neben der betroffenen Wägezelle anheben.

• Ein dünnes, entgratetes Blech (0,5…2 mm Dicke) zwischen obere Einbauplatte und Waagenkonstruktion

legen.

• Die Ausgangsspannungen der Wägezellen erneut messen und ggf. Höhe dieser bzw. einer weiteren

Wägezelle korrigieren.

7 Fehlersuche

Wenn nach Inbetriebnahme und Justierung falsche bzw. nicht reproduzierbare Werte gemessen werden,

ermöglichen die folgenden Hinweise eine erste Diagnose und Abhilfe.

7.1 Sichtprüfung

Wägeobjekt Sind alle Rohre, Schläuche, Kabel so locker wie möglich

angekoppelt?

direktem Kontakt mit der Umgebung?

aufgebaut (z. B. verstaubte Durchbrüche, usw.)?

Verbindungskasten Ist Feuchtigkeit eingedrungen?

Verbindungskabel Ist der Mantel beschädigt?

Einbausatz Ist die Abhebesicherung in Kontakt mit der Waage?

Wägezelle Steht die Wägezelle senkrecht?

Sartorius DE-21

Page 50

Drucklast-Wägezelle PR 6201 Installationshandbuch

maximale Prüfspannung

Standardausführung

100 V DC

Isolationswiderstand

Ader – Gehäuse

≥

7.2 Messtechnische Prüfungen

7.2.1 Nullsignal der Wägezelle überprüfen

• Wägezelle entlasten.

• Messausgänge der Wägezellen voneinander trennen.

• Prüfen, ob die Ausgangsspannung ohne Last nicht überschritten wird.

Typ Ausgangsspannung

L 0 mV ±0,02 mV/V

D1/N/C3 0 mV ±0,01 mV/V

(bei PR 6201/54.. 0 mV ±0,02 mV/V)

LA 3,2…4 mA

GAIN mit +Speisespannung 24 ±4 V verbinden, siehe Kapitel 5.2.2.1

7.2.2 DMS Brückenschaltung der Wägezelle überprüfen

Hinweis:

• Prüfspannung darf nicht überschritten werden.

• Prüfen, ob die Widerstandswerte innerhalb der zulässigen Grenzen liegen.

maximale Prüfspannung Standardausführung 32 V DC

Eigensichere Ausführung (PR …/..E) 25 V DC

Typ Eingangswiderstand

L

D1/N

C3

Nicht für Wägezellen Typ LA.

(rote Ader, blaue Ader)

650 Ω +50 Ω 610 Ω ±3 Ω

650 Ω ±6 Ω 610 Ω ±1 Ω

650 Ω ±6 Ω 610 Ω ±0,5 Ω

Ausgangswiderstand

(grüne Ader, graue Ader)

7.2.3 Isolationswiderstand der Wägezelle überprüfen

Hinweis:

• Prüfspannung nie zwischen zwei Adern des Wägezellenkabels legen (Zerstörung der Wägezelle droht).

• Adern der Wägezellen isolieren.

eigensichere Ausführung (PR …/..E) 500 V AC

Ader – Schirm

Schirm – Gehäuse

Nicht für Wägezellen Typ LA.

>5000 MΩ

>5000 MΩ

>5000 MΩ

7.2.4 Isolationswiderstand des Verbindungskabels überprüfen

• Verbindungskabel von Messinstrument und Wägezellen lösen

• Adern des Verbindungskabels isolieren

Isolationswiderstand Ader – Ader

Ader – Schirm

DE-22 Sartorius

600 MΩ × km

≥600 MΩ × km

Page 51

Installationshandbuch Drucklast-Wägezelle PR 6201

8 Reparatur/Wartung

8.1 Reparatur

Achtung!

Die Wägezelle PR 6201 ist, soweit es die hohe Messgenauigkeit erlaubt, robust

gebaut und weist eine hohe Zuverlässigkeit auf. Ist dennoch eine Wägezelle

elektrisch oder mechanisch defekt, muss sie ausgewechselt werden.

Eine Reparatur ist nicht möglich.

8.2 Wartung

Die Wägezelle PR 6201 ist wartungsfrei.

Verunreinigungen an der Wägezelle und an den frei beweglichen Teilen der Waage müssen rechtzeitig

beseitigt werden, wenn diese

- die Wägung beeinflussen oder

- aggressiv gegenüber dem Material von Zellen und Kabel sind.

Die Kontaktflächen zwischen Wägezelle und Druckstücke sind mit Fett zu versehen. In aggressiver

Umgebung kann die Wägezelle großflächig mit Off-Shore Allwetterschutzspray eingesprüht werden.

Sartorius DE-23

Page 52

Drucklast-Wägezelle PR 6201 Installationshandbuch

10

Ring für unteres Druckstück

100 t

5322 466 81609

14

Ring für unteres Druckstück

200 t, 300 t

5322 466 81612

18

Flexible Kupferleitung, 400 mm lang

5322 310 30581

9 Ersatzteile und Zubehör

Pos. Bezeichnung Laststufe Bestell-Nr.

1 Unteres Druckstück mit Dichtring 0,5…10 t 5322 693 91416

2 Unteres Druckstück mit Dichtring 20 t, 30 t, 50 t 5322 693 91165

3 Unteres Druckstück mit Dichtring PR 6143/24S* 0,5…10 t 9405 361 43242

4 Unteres Druckstück mit Dichtring PR 6143/54S* 20 t, 30 t, 50 t 9405 361 43542

5 Dichtring, Standard 0,5…50 t 5322 532 70298

6 Dichtring, lebensmittelecht 0,5…50 t 5322 532 70317

7 Oberes Druckstück, Standard PR 6143/50N* 0,5…50 t 9405 361 43501

8 Oberes Druckstück, PR 6143/50S* 0,5…50 t 9405 361 43502

9 Unteres Druckstück 100 t 5322 466 81611

11 Dichtring 100 t 5322 532 30408

12 Oberes Druckstück 100 t 5322 520 10552

13 Unteres Druckstück 200 t, 300 t 5322 466 81613

15 Dichtring 200 t, 300 t 5322 532 30409

16 Oberes Druckstück 200 t, 300 t 5322 520 10553

17 Druckstücksatz PR 6143/55N* 520 t 9405 361 43551

19 Einbausatz PR 6001/00N* 0,5…10 t 9405 360 01001

20 Einbausatz PR 6001/00S* 0,5…10 t 9405 360 01002

21 Einbausatz PR 6001/01N* 20…50 t 9405 360 01011

22 Einbausatz PR 6001/01S* 20…50 t 9405 360 01012

23 Einbausatz PR 6001/02N* 100 t 9405 360 01021

24 Einbausatz PR 6001/03N* 200 t, 300 t 9405 360 01031

25 Einbausatz PR 6145/00N* 0,5…50 t 9405 361 45001

26 Einbausatz PR 6145/00S* 0,5…20 t 9405 361 45002

27 Einbausatz PR 6145/08N* 100 t 9405 361 45081

28 Einbausatz PR 6145/10S* 200 t, 300 t 9405 361 45101

*N = Stahl galvanisch verzinkt *S = rostfreier Edelstahl

DE-24 Sartorius

Page 53

Installationshandbuch Drucklast-Wägezelle PR 6201

≤

≤

≤

35

MaxiFLEXLOCK PR 6001/21N*

≤

9405 360 01211

≤

≤

≤

≤

≤

≤

≤

47

SeismicMount PR 6144/54

≤

9405 361 44541

≤

≤

≤

≤

56

Verbindungskasten PR 6130/08

9405 361 30081

Pos. Bezeichnung Horizontalkraft Bestell-Nr.

29 MaxiFLEXLOCK PR 6001/10N*

30 MaxiFLEXLOCK PR 6001/10S*

31 MaxiFLEXLOCK PR 6001/11N*

32 MaxiFLEXLOCK PR 6001/11S*

33 MaxiFLEXLOCK PR 6001/20N*

34 MaxiFLEXLOCK PR 6001/20S*

36 MaxiFLEXLOCK PR 6001/21S*

37 Hochlast-Einbausatz PR 6001/30N*

38 Hochlast-Einbausatz PR 6001/31N*

39 Hochlast-Einbausatz PR 6001/32N*

40 Hochlast-Einbausatz PR 6001/33N*

41 MiniFLEXLOCK PR 6143/00N*

42 MiniFLEXLOCK PR 6143/00S*

43 MiniFLEXLOCK PR 6143/10N*

44 MiniFLEXLOCK PR 6143/10S*

45 MiniFLEXLOCK PR 6143/15N*

46 MiniFLEXLOCK PR 6143/25N*

48 SeismicMount PR 6144/15

49 SeismicMount PR 6144/35

50 SeismicMount PR 6144/55

51 Querlenker PR 6143/80

52 Querlenker PR 6143/83

53 Horizontalstoßfänger PR 6152/02

54 Verbindungskabel PR 6135 9405 361 35..2

55 Verbindungskabel PR 6136, für Ex-Anwendung 9405 361 36..1

≤25 kN

≤25 kN

≤25 kN

25 kN

50 kN

50 kN

50 kN

50 kN

200 kN

200 kN

200 kN

≤200 kN

≤25 kN

≤25 kN

≤50 kN

50 kN

200 kN

200 kN

370 kN

440 kN

520 kN

520 kN

2 kN

≤20 kN

≤200 kN

9405 360 01101

9405 360 01102

9405 360 01111

9405 360 01112

9405 360 01201

9405 360 01202

9405 360 01212

9405 360 01301

9405 360 01311

9405 360 01321

9405 360 01331

9405 361 43001

9405 361 43002

9405 361 43101

9405 361 43102

9405 361 43151

9405 361 43251

9405 361 44151

9405 361 44351

9405 361 44551

9405 361 43801

9405 361 43831

9405 361 52021

57 Verbindungskasten PR 6130/64Sa*, für Ex-Anwendung 9405 361 30642

58 Verbindungskasten PR 6130/68S*, für Ex-Anwendung 9405 361 30682

*N = Stahl galvanisch verzinkt *S/Sa = rostfreier Edelstahl

Sartorius DE-25

Page 54

Page 55

Manuel d’installation Capteur de pesage PR 6201

Sommaire

1 Consignes de sécurité .................................................................................................................... 3

2 Recommandation d’installation ................................................................................................... 3

2.1 Disposition des capteurs dans différents cas ..................................................................................... 3

2.2 Disposition des capteurs et des pivots .................................................................................................. 4

2.3 Protection contre le basculement .......................................................................................................... 4

2.4 Sélection de la capacité maximale ........................................................................................................ 4

3 Caractéristiques techniques .......................................................................................................... 5

3.1 Générales ........................................................................................................................................................ 5

3.2 Dual Bridge ..................................................................................................................................................... 5

3.3 Certificats ....................................................................................................................................................... 5

3.4 Contenu de la livraison .............................................................................................................................. 6

3.4.1 Capteurs de pesage PR 6201/52…54 (capacité max. 500 kg…50 t) ..................................................... 6

3.4.2 Capteurs de pesage PR 6201/15, /25, /35 et DB (capacité max. 100 t, 200 t, 300 t) ..................... 6

3.4.3 Capteur de pesage PR 6201/520t et DB (capacité max. 520 t) ............................................................. 7

3.5 Dimensions ..................................................................................................................................................... 7

3.5.1 Capteur de pesage PR 6201/52…54 (capacité max. 500 kg…50 t) ...................................................... 7

3.5.2 Capteur de pesage PR 6201/15 (capacité max. 100 t) ............................................................................. 8

3.5.3 Capteur de pesage PR 6201/25 (capacité max. 200 t), PR 6201/35 (capacité max. 300 t) .......... 8

3.5.4 Capteur de pesage PR 6201/520t (capacité max. 520 t)......................................................................... 9

3.5.5 Capteur de pesage PR 6201/15 DB (capacité max. 100 t) ...................................................................... 9

3.5.6

3.5.7 Capteur de pesage PR 6201/520t DB (capacité max.) .......................................................................... 10

3.6 Caractéristiques techniques pour capacité max. de 500 kg…50 t ............................................ 11

Capteur de pesage PR 6201/25 DB (capacité max. 200 t), PR 6201/35 DB (capacité max. 300 t)

10

3.7 Caractéristiques techniques pour capacité max. de 100 t, 200 t, 300 t, 520 t .................... 14

3.8

Caractéristiques techniques pour Dual Bridge, capacité max. de 100 t, 200 t, 300 t, 520 t

16

4 Installation .................................................................................................................................... 18

4.1 Générales ...................................................................................................................................................... 18

4.2

Installation de la pièce de pression supérieure (capteurs d’une capacité max. de 500 kg à 50 t)

... 19

Sartorius FR-1

Page 56

Capteur de pesage PR 6201 Manuel d’installation

5 Instructions de raccordement .................................................................................................... 20

5.1 Générales ...................................................................................................................................................... 20

5.2 Capteur de pesage ..................................................................................................................................... 20

5.2.1 Standard (Type L, D1/N, D1E/NE, C3, C3E) ................................................................................................ 20

5.2.2 Avec d’amplificateur analogique intégré (Type LA) ............................................................................... 21

5.3 Câble de connexion ................................................................................................................................... 23

5.4 Connexions des câbles ............................................................................................................................. 23

5.4.1 Capteur de pesage avec un circuit de mesure ......................................................................................... 23

5.4.2 Capteur de pesage avec deux circuits de mesure séparés indépendants ........................................ 24

6 Préparations avant l’étalonnage ................................................................................................ 25

6.1 Réglage mécanique de la hauteur ....................................................................................................... 25

7 Localisation des défauts .............................................................................................................. 25

7.1 Vérification visuelle .................................................................................................................................. 25

7.2 Vérification des caractéristiques techniques ................................................................................... 26

7.2.1 Vérifier le signal zéro ...................................................................................................................................... 26

7.2.2 Vérification du circuit de pont des jauges de contrainte .................................................................... 26

7.2.3 Vérification de la résistance d’isolement du capteur de pesage ........................................................ 26

7.2.4 Vérifier la résistance d’isolements du câble de prolongation ............................................................. 26

8 Réparation/Entretien ................................................................................................................... 27

8.1 Réparation .................................................................................................................................................... 27

8.2 Entretien ....................................................................................................................................................... 27

9 Pièces de rechange et accessoires ............................................................................................. 28

FR-2 Sartorius

Page 57

Manuel d’installation Capteur de pesage PR 6201

* ne pas contraindre ce point

1 Consignes de sécurité

Le capteur PR 6201 et les kits de montage correspondants doivent être utilisé seulement pour les tâches de

pesage pour lesquels il a été conçu. Dimensionner toutes les pièces de montage et de construction à ce

qu’une résistance suffisante aux surcharges soit garantie en tenant compte des standards correspondants.

Protéger surtout les objets à peser debout (citernes etc.) à ce que le renversement ou le déplacement de

l’installation de pesage et, par conséquent, tout risque à la vie ou à la santé de personnes ou d’animaux, ou

le risque d’endommager des objets soit évité, même en cas de rupture d’un capteur ou de pièces de

montage.

L’installation et les réparations doivent être faites seulement par des personnes autorisées.

2 Recommandation d’installation

2.1 Disposition des capteurs dans différents cas

La construction portante ainsi que le réservoir doivent être stables envers les charges statiques et

dynamiques maximales. Nous recommandons de monter des réservoirs sur 3 capteurs (voir figure), des

plates-formes sur 4 ou 6 capteurs.

Les forces parasites, les forces horizontales et les couples de torsion sont des grandeurs qui perturbent les

mesures et dans le cas de dépassement des limites spécifiées peuvent endommager les capteurs.

Une contrainte appropriée de l'objet évite les dégâts et les erreurs sans perturber le déplacement nécessaire

dans la direction du pesage. Dans ce but, une attention spéciale doit être accordée au genre de dispositifs

de contrainte, à leur placement et aux conditions de fonctionnement.

Sartorius FR-3

Page 58

Capteur de pesage PR 6201 Manuel d’installation

2.2 Disposition des capteurs et des pivots

2.3 Protection contre le basculement

Une protection contre le basculement est généralement recommandée pour des raisons de sécurité. Elle

peut être réalisée avec le kit de montage. La construction lasse plus simple requiert une tige filetée, trois

écrous, une rondelle à éventail et une rondelle.

2.4 Sélection de la capacité maximale

Le capteur de pesage PR 6201 présente une capacité de surcharge élevée par suite de la faible contrainte du

matériau utilisé (1 mV/V). Des forces dépassant la charge maximum sans dommage dans le sens de mesure

risquent de produire un changement de la précision du capteur ou de l'endommager; des forces dépassant

la charge destructive risquent de détruire le capteur de pesage. Si un danger peut se produire (par exemple

par suite de la chute de la charge sur les pesons) il est recommandé de prévoir une limitation mécanique de

surcharge dans la direction de la charge.

FR-4 Sartorius

Page 59

Manuel d’installation Capteur de pesage PR 6201

Boîtier

Boîtier en acier inoxydable 1.4301, hermétiquement scellé, rempli de gaz inerte

≥

Class I, II, II Div 1,

FM: 3001200

PR 6201/..L, ..LE, ..D1, ..D1E,

3 Caractéristiques techniques

3.1 Générales

Force de rappel En cas de déformation du capteur de pesage de la verticale, à chaque millimètre de

déformation (mesurée sur la tête du capteur de pesage), une force de rappel sur le

capteur de pesage est appliquée horizontale:

E

E

E

E

≤10 t:

max

≥20 t:

E

max

= 100 t 1,23 % de la charge actuelle sur le capteur

max

= 200 t + 300 t 0,65 % de la charge actuelle sur le capteur

max

= 520 t 1,20 % de la charge actuelle sur le capteur

max

Protection IP 68 (à 1,5 m de profondeur, 10.000h) selon IEC 60529 (correspond à NEMA 6)

IP69K selon DIN 40050

Protection contre

Sécurité intrinsèque pour PR 6201/..E

l'inflammation

Câble Diamètre 5 mm

Longueur

Section transversale

Rayon de courbure

Gaine Matériau : TPE

Couleur : gris (version standard)

0,65% de la charge actuelle sur le capteur

1,55% de la charge actuelle sur le capteur

>10 t: 12 m

E

≤10 t: 5 m

max

E

max

4×0,35 mm2

≥25 mm pour la pose fixe

75 mm pour la pose flexible

bleu (version Ex)

vert (version LA)

3.2 Dual Bridge

Le capteur de pesage Dual Bridge possède deux circuits de mesure séparés indépendants. Les circuits de

mesure sont étalonnés dans deux chambres d'étalonnage séparées, connexions des câbles voir le

chapitre 5.4.2.

3.3 Certificats

Zone Marquage No. de certificat pour

0 et 1 II 1G Ex ia IIC T6 PTB 02 ATEX 2059 seulement PR 6201/..E + ..DBE

20 et 21 II 1 D IP65 T85°C TÜV 03 ATEX 2301X PR 6201/..L, ..LE, ..D1, ..D1E,

..C3-C6, ..C3E-C6E, ..N, ..NE

2 II 3G Ex nA II T6 Déclaration du fabricant PR 6201/..L, ..LE, ..D1, ..D1E,

..C3-C6, ..C3E-C6E, ..N, ..NE,

..LDB, ..LDBE, ..NDB, ..NDBE

22 II 3D Ex tD A22 IP65 T85°C Déclaration du fabricant PR 6201/..L, ..LE, ..D1, ..D1E,

..C3-C6, ..C3E-C6E, ..N, ..NE,

..LDB, ..LDBE, ..NDB, ..NDBE

Group A, B, C, D, E, F, G

T5 à T

T4A à T

= 55°,

max

max

= 70°

CSA: 1058582

..C3-C6, ..C3E-C6E, ..N, ..NE

Sartorius FR-5

Page 60

Capteur de pesage PR 6201 Manuel d’installation

1

Capteur de pesage

5

Graisse pour capteurs de pesage y

2

Joint anneau

6