Page 1

Instrument Manual

Transmitter in Field Housing PR 5230

Instrument Manual

9499 050 52301

Edition 8

14.12.2012

for PR 5230

Release: 3.00

Sartorius Mechatronics T&H GmbH, Meiendorfer Str. 205, 22145 Hamburg, Germany

Tel:+49.40.67960.303 Fax:+49.40.67960.383

Page 2

Please note

Bitte beachten

Any information in this document is subject to change without notice and does not represent a commitment on the part of

Sartorius unless legally prescribed. This product should be operated only by trained and qualified personnel. In correspondence

concerning this product the type, name and release number as well as all license numbers in relation to the product have to be

quoted.

Alle Angaben in diesem Dokument sind - soweit nicht gesetzlich vorgegeben - unverbindlich für Sartorius und stehen unter

Änderungsvorbehalt. Die Bedienung des Produktes darf nur von geschultem, fach- und sachkundigem Personal durchgeführt

werden. Bei Schriftwechsel über dieses Produkt bitte Typ, Bezeichnung und Versionsnummer sowie alle mit dem Produkt in

Zusammenhang stehenden Lizenznummern angeben.

Page 3

PR 5230 Instrument Manual Table of Contents

1

Safety Information ............................................................................................................................................................................... 9

2

Transmitter in Field Housing ........................................................................................................................................................... 12

3

Options ................................................................................................................................................................................................... 25

Table of Contents

1.1 Electrical Protective Class .......................................................................................................................................................................... 9

1.2 Intended Use .................................................................................................................................................................................................. 9

1.3 Initial Inspection ........................................................................................................................................................................................... 9

1.4 Before Commissioning ................................................................................................................................................................................ 9

1.4.1 Installation ........................................................................................................................................................................................ 9

1.4.2 Opening the Instrument ............................................................................................................................................................. 10

1.4.3 Connection of a protective earth conductor to PR 5230 ................................................................................................ 10

1.4.4 Power Connection PR 5230 ....................................................................................................................................................... 10

1.4.5 Failure and Excessive Stress ....................................................................................................................................................... 11

1.4.6 Important Note .............................................................................................................................................................................. 11

1.4.7 Maintenance and Repair ............................................................................................................................................................. 11

2.1 Overview of the Instrument ................................................................................................................................................................... 12

2.2 Housing ......................................................................................................................................................................................................... 13

2.3 Display and Controls ................................................................................................................................................................................. 14

2.3.1 Display .............................................................................................................................................................................................. 14

2.3.2 Status LEDs ...................................................................................................................................................................................... 16

2.3.3 Buttons ............................................................................................................................................................................................. 17

2.3.4 Operating via VNC ........................................................................................................................................................................ 18

2.4 Overview of Connections ......................................................................................................................................................................... 23

2.4.1 Plug-in Cards/Junction Board ................................................................................................................................................... 24

3.1 Option Y2 ...................................................................................................................................................................................................... 26

3.1.1 Safety Instructions ........................................................................................................................................................................ 26

3.1.2 Description ...................................................................................................................................................................................... 26

3.1.3 Marking ............................................................................................................................................................................................ 26

3.1.4 Outputs ............................................................................................................................................................................................. 26

3.1.5 In Connection with Option W1 ................................................................................................................................................ 26

3.1.6 In Connection with Option WE1 .............................................................................................................................................. 26

3.1.7 Installation ...................................................................................................................................................................................... 27

3.1.8 Repairs/Cleaning/Maintenance ................................................................................................................................................. 27

3.1.9 Environmental Conditions .......................................................................................................................................................... 27

3.2 Option WE1 .................................................................................................................................................................................................. 28

3.2.1 Safety Instructions ........................................................................................................................................................................ 28

3.2.2 Description ...................................................................................................................................................................................... 28

3.2.3 Marking ............................................................................................................................................................................................ 28

3.2.4 Display .............................................................................................................................................................................................. 28

3.2.5 In Connection with Option Y2 .................................................................................................................................................. 28

3.2.6 Weighing Electronics Board for Zone 1 and 21 .................................................................................................................. 29

3.2.7 Connection within the Ex Area ................................................................................................................................................ 30

3.2.8 Installation ...................................................................................................................................................................................... 31

3.2.9 Repairs/Cleaning/Maintenance ................................................................................................................................................. 35

3.2.10 Technical Data ................................................................................................................................................................................ 36

Sartorius EN-3

Page 4

Table of Contents

4

Installing the Instrument and Plug-in Cards .............................................................................................................................. 38

4.1 Mechanical Preparation .......................................................................................................................................................................... 38

4.2 Hardware Construction ........................................................................................................................................................................... 38

4.2.1 Main Board ..................................................................................................................................................................................... 39

4.2.2 Display Board ................................................................................................................................................................................. 40

4.2.3 Weighing Electronics Board ...................................................................................................................................................... 40

4.2.4 Cable Gland and Connection .................................................................................................................................................... 41

4.2.5 Network Port ................................................................................................................................................................................. 43

4.2.6 Optocoupler Inputs ...................................................................................................................................................................... 43

4.2.7 Opto-decoupled Outputs (optional) ....................................................................................................................................... 45

4.2.8 Relay Outputs ................................................................................................................................................................................ 46

4.2.9 Interface RS-485 .......................................................................................................................................................................... 47

4.2.10 Interface RS-232 .......................................................................................................................................................................... 56

4.3 Connecting Load Cells ............................................................................................................................................................................. 60

4.3.1 Connecting a Load Cell with 4-Wire Cable .......................................................................................................................... 60

4.3.2 Connecting PR 6221 Load Cells ............................................................................................................................................... 60

4.3.3 Connecting up 2 to 4 Load Cells via PR 5230/22 Load Cell Junction Board ............................................................. 61

4.3.4 Connecting up 2 to 8 Load Cells using 6-Wire Connecting Cable ............................................................................... 65

4.3.5 Connecting Load Cells with External Supply ....................................................................................................................... 67

4.3.6 Connecting Analog Platforms (CAP...) ................................................................................................................................... 68

4.3.7 Connecting xBPI Platforms (IS...) ............................................................................................................................................ 69

4.4 Accessories ................................................................................................................................................................................................... 70

4.4.1 Installing Plug-in Cards .............................................................................................................................................................. 70

4.4.2 PR 5230/06 Analog Output Board .......................................................................................................................................... 71

4.4.3 PR 5230/22 Load Cell Junction Board ................................................................................................................................... 72

4.4.4 PR 1721/41 ProfiBus-DP Interface ......................................................................................................................................... 73

4.4.5 PR 1721/42 InterBus-S Interface ............................................................................................................................................ 77

4.4.6 PR 1721/44 DeviceNet Interface ............................................................................................................................................. 81

4.4.7 PR 1721/45 CC-Link Interface ................................................................................................................................................. 84

4.4.8 PR 1721/46 ProfiNet I/O Interface ......................................................................................................................................... 86

4.4.9 PR 1721/47 EtherNet-IP Interface .......................................................................................................................................... 88

4.4.10 PR 5230/30 Ethernet Socket .................................................................................................................................................... 91

4.4.11 PR 5230/31 Ethernet Cable ....................................................................................................................................................... 91

PR 5230 Instrument Manual

EN-4 Sartorius

Page 5

PR 5230 Instrument Manual Table of Contents

5

Commissioning .................................................................................................................................................................................... 92

5.1 Data Protection/Power Failure............................................................................................................................................................... 92

5.1.1 CAL Switch ...................................................................................................................................................................................... 92

5.2 Switching on the Instrument ................................................................................................................................................................. 93

5.3 Configuration and Calibration ............................................................................................................................................................... 93

5.3.1 Connecting the Device to the Network and Finding out the IP address .................................................................... 93

5.3.2 Resetting the Network Address/Activating Network ‚DHCP’ .......................................................................................... 96

5.3.3 Searching the Instrument in the Network with 'Indicator Browser' ............................................................................ 99

5.3.4 Operation Using the VNC Program ...................................................................................................................................... 100

5.3.5 Operation Using InternetBrowser ......................................................................................................................................... 101

5.3.6 Function INFO ............................................................................................................................................................................. 103

5.3.7 Setup Function (VNC) ............................................................................................................................................................... 103

5.3.8 Setup Menu (VNC) ..................................................................................................................................................................... 104

5.4 Calibration of the Internal Weighing Point .................................................................................................................................... 109

5.4.1 Displaying Calibration Data .................................................................................................................................................... 109

5.4.2 Selecting the Calibration Mode ............................................................................................................................................. 110

5.4.3 Determining the Maximum Capacity [Max] ...................................................................................................................... 111

5.4.4 Determining the Scale Interval .............................................................................................................................................. 114

5.4.5 Determining the Dead Load .................................................................................................................................................... 115

5.4.6 Calibration with Weight [by load] ........................................................................................................................................ 117

5.4.7 Calibration with mV/V Value [by mV/V] .............................................................................................................................. 118

5.4.8 Calibration with Load Cell Data (smart calibration) ....................................................................................................... 119

5.4.9 Subsequent Dead Load Correction ....................................................................................................................................... 120

5.4.10 Linearization ................................................................................................................................................................................ 120

5.4.11 Determination Test Value/Display Test Value .................................................................................................................... 121

5.4.12 Finishing/Saving the Calibration ........................................................................................................................................... 121

5.4.13 Parameter Input ......................................................................................................................................................................... 122

5.5 Calibrating a xBPI Scale ........................................................................................................................................................................ 126

5.5.1 xBPI Set-up for Serial Port ...................................................................................................................................................... 126

5.5.2 xBPI Scale Function ................................................................................................................................................................... 127

5.5.3 xBPI Platform Configuration .................................................................................................................................................. 127

5.5.4 xBPI Scale Parameter ................................................................................................................................................................ 129

5.5.5 xBPI Parameter Tables .............................................................................................................................................................. 130

5.5.6 xBPI Setting Dead Load ............................................................................................................................................................ 133

5.5.7 xBPI Calibration with the User Weight ............................................................................................................................... 134

5.5.8 xBPI Calibration with Automatic Weight Detection....................................................................................................... 135

5.5.9 xBPI Calibration with Default Weight ................................................................................................................................. 136

5.5.10 xBPI Calibration with Built-in Weight ................................................................................................................................ 138

5.6 Configuring General Parameters........................................................................................................................................................ 139

5.6.1 Serial Interfaces [Serial ports parameter] .......................................................................................................................... 139

5.6.2 Date and Time ............................................................................................................................................................................. 144

5.6.3 Operating parameters ............................................................................................................................................................... 144

5.6.4 Printing parameter .................................................................................................................................................................... 145

5.6.5 Fieldbus parameter .................................................................................................................................................................... 146

5.6.6 Network parameter ................................................................................................................................................................... 148

5.6.7 Display items ................................................................................................................................................................................ 149

Sartorius EN-5

Page 6

Table of Contents

6

J-Bus/ModBus Protocol .................................................................................................................................................................. 167

7

SMA Protocol ..................................................................................................................................................................................... 176

8

Asycom Protocol ............................................................................................................................................................................... 186

5.7 Configuring Limit Values ...................................................................................................................................................................... 150

5.8 Digital Outputs and Inputs ................................................................................................................................................................... 154

5.8.1 Configuring Digital Outputs ................................................................................................................................................... 154

5.8.2 Configuring Digital Inputs ...................................................................................................................................................... 156

5.9 Display of Limits and Digital Inputs/Outputs ................................................................................................................................. 157

5.9.1 VNC Display .................................................................................................................................................................................. 157

5.9.2 Instrument Display ..................................................................................................................................................................... 157

5.10 Analog Output.......................................................................................................................................................................................... 158

5.10.1 Adapting the Analog Output .................................................................................................................................................. 159

5.11 Logfiles ........................................................................................................................................................................................................ 160

5.12 Retrieve Eventlog Memory ................................................................................................................................................................... 161

5.12.1 FatalError ...................................................................................................................................................................................... 161

5.12.2 Setup .............................................................................................................................................................................................. 162

5.12.3 Indicator ........................................................................................................................................................................................ 162

5.12.4 Powerfail ....................................................................................................................................................................................... 162

5.13 Saving Configuration Data [Backup of EAROM] ........................................................................................................................... 163

5.13.1 Saving Configuration and Calibration Data ...................................................................................................................... 163

5.13.2 Loading Configuration and Calibration Data into the Device ..................................................................................... 165

PR 5230 Instrument Manual

6.1 General Description ................................................................................................................................................................................ 167

6.2 ModBus-RTU ............................................................................................................................................................................................. 168

6.3 ModBus-TCP/-UDP .................................................................................................................................................................................. 169

6.4 Functions .................................................................................................................................................................................................... 170

6.5 Error Messages ......................................................................................................................................................................................... 174

6.6 Word Addresses ........................................................................................................................................................................................ 175

7.1 General ....................................................................................................................................................................................................... 176

7.2 Description of Used Symbols ............................................................................................................................................................... 176

7.3 SMA Command Set ................................................................................................................................................................................. 177

7.4 SMA Reply Messages .............................................................................................................................................................................. 180

7.5 Communication Error ............................................................................................................................................................................ 185

8.1 Commands of the Weight Function .................................................................................................................................................. 186

8.2 Other Commands..................................................................................................................................................................................... 187

8.3 SPM Commands ....................................................................................................................................................................................... 187

8.4 Error Messages for Asycom Commands ........................................................................................................................................... 188

EN-6 Sartorius

Page 7

PR 5230 Instrument Manual Table of Contents

9

Fieldbus Interface ............................................................................................................................................................................ 189

10

Global SPM Variables ...................................................................................................................................................................... 200

11

Configuration Print-out ................................................................................................................................................................ 203

12

Extended Functions ......................................................................................................................................................................... 205

13

Repairs and Maintenance .............................................................................................................................................................. 212

14

Disposal ............................................................................................................................................................................................... 213

15

Error Messages .................................................................................................................................................................................. 214

9.1 Fieldbus Interface Protocol .................................................................................................................................................................. 189

9.2 Description of the I/O Area (Read / Write Window) .................................................................................................................... 191

9.3 Special hints for DeviceNet and EtherNet-IP ................................................................................................................................. 195

9.4 Fieldbus Register ..................................................................................................................................................................................... 196

12.1 Resetting the Instrument to the Factory Settings........................................................................................................................ 205

12.2 Updating a new Software with ‚FlashIt’ .......................................................................................................................................... 206

12.2.1 Updating in a Network Using DHCP Service ..................................................................................................................... 206

12.2.2 Updating via a Point-to-Point Connection with DHCP Service .................................................................................. 208

12.2.3 Updating the Software in a Network with a Fixed IP Address .................................................................................... 209

13.1 Battery for Date/Time ............................................................................................................................................................................ 212

13.1.1 Battery Replacement ................................................................................................................................................................. 212

13.2 Solder Work .............................................................................................................................................................................................. 213

13.3 Cleaning ..................................................................................................................................................................................................... 213

15.1 Error Messages in Measuring Circuit ................................................................................................................................................ 214

15.2 Weight Error Status ................................................................................................................................................................................ 215

15.3 Error Messages with xBPI Scales ........................................................................................................................................................ 215

15.4 Error messages of the Calibration ..................................................................................................................................................... 216

15.5 General Error Messages ......................................................................................................................................................................... 218

15.6 Error Messages with Ex Applications ................................................................................................................................................ 218

15.7 Show Error Log ........................................................................................................................................................................................ 219

Sartorius EN-7

Page 8

Table of Contents

16

Specifications ..................................................................................................................................................................................... 220

17

Index ..................................................................................................................................................................................................... 225

18

Appendix ............................................................................................................................................................................................. 229

16.1 Instructions for Use of 'Free Software' ............................................................................................................................................ 220

16.2 Decoding of the Serial Number .......................................................................................................................................................... 220

16.3 General Data ............................................................................................................................................................................................. 220

16.3.1 Backup Battery for Time/Date ................................................................................................................................................ 220

16.3.2 Power Connection 230 V AC .................................................................................................................................................. 220

16.3.3 Power Connection 24 V DC ..................................................................................................................................................... 220

16.4 Effect of Ambient Conditions ............................................................................................................................................................. 221

16.4.1 Environmental Conditions ....................................................................................................................................................... 221

16.4.2 Electromagnetic Compatibility (EMC) ................................................................................................................................. 221

16.4.3 RF Interference Suppression ................................................................................................................................................... 221

16.5 Weighing Electronics ............................................................................................................................................................................. 222

16.5.1 Load Cells ...................................................................................................................................................................................... 222

16.5.2 Connecting Cable ....................................................................................................................................................................... 222

16.5.3 Principle ........................................................................................................................................................................................ 222

16.5.4 Accuracy and Stability .............................................................................................................................................................. 222

16.5.5 Sensitivity ..................................................................................................................................................................................... 222

16.5.6 Analog Output (Option PR 5230/06) ................................................................................................................................... 223

16.5.7 Digital Inputs ............................................................................................................................................................................... 223

16.5.8 Digital Outputs ............................................................................................................................................................................ 223

16.5.9 Serial Interfaces .......................................................................................................................................................................... 223

16.5.10 Network Interface ...................................................................................................................................................................... 224

16.5.11 Fieldbus Interfaces (Options) .................................................................................................................................................. 224

16.6 Mechanical Data ...................................................................................................................................................................................... 224

16.6.1 Construction ................................................................................................................................................................................ 224

16.6.2 Dimensions/Weights .................................................................................................................................................................. 224

16.7 Use in Legal-for-Trade Mode .............................................................................................................................................................. 224

16.7.1 Documentation for Verification on the Enclosed CD ..................................................................................................... 224

16.7.2 Additional Instructions ............................................................................................................................................................. 224

PR 5230 Instrument Manual

18.1 Spare Parts ................................................................................................................................................................................................ 229

18.1.1 Weighing electronics board .................................................................................................................................................... 229

18.1.2 Display Board ............................................................................................................................................................................... 230

18.1.3 Fuses/Accessorie Kits ................................................................................................................................................................. 230

18.2 Network Settings under Windows XP ............................................................................................................................................... 231

18.3 Network Settings under Windows 7 ................................................................................................................................................. 232

18.4 Technical Documents/Certificates...................................................................................................................................................... 234

EN-8 Sartorius

Page 9

PR 5230 Instrument Manual

This instrument has been built and tested in compliance with the safety regulations for

Safety Information

1 Safety Information

1.1 Electrical Protective Class

measuring and control instrumentation for protective class I (protective earth

connection) according to IEC 1010/EN61010 or VDE 0411. The instrument was in perfect

condition with regard to safety features when it left the factory. To maintain this

condition and to ensure safe operation, the operator must follow the instructions and

observe the warnings in this manual.

1.2 Intended Use

The instrument is intended for use as an indicator for weighing functions. Product operation, commissioning

and maintenance must be performed by trained and qualified personnel who are aware of and able to deal

with the related hazards and take suitable measures for self-protection.

The instrument reflects the state of the art. The manufacturer does not accept any liability for damage caused

by other system components or due to incorrect use of the product.

1.3 Initial Inspection

Check the content of the consignment for completeness and inspect it visually for signs of damage that may

have occurred during transport. If there are grounds for rejection of the goods, a claim must be filed with the

carrier immediately and the Sartorius sales or service organization must be notified.

1.4 Before Commissioning

Visual inspection!

Before commissioning and after and storage or transport, inspect the instrument visually for signs

of mechanical damage.

1.4.1 Installation

The instrument housing meets IP 66. Mount the instrument with the cable entry glands pointing downwards.

To ensure proper cooling of the instrument, make sure air circulation around the instrument is not blocked.

Avoid exposing the instrument to excessive heat; e.g., from direct sunlight. Ambient conditions must be taken

into account at all times.

With outdoor mounting, make sure that adequate weather protection is provided (for temperatures, see

Chapter 16.4.1).

Sartorius EN-9

Page 10

Safety Information PR 5230 Instrument Manual

1.4.2 Opening the Instrument

Danger! High Voltage!

Working on the instrument while it is switched on may have life-threatening

consequences.

Disconnect the instrument from the supply voltage. Any time covers or parts are

removed; live parts or terminals may be exposed. Capacitors in the unit may still be

charged also after disconnecting the unit from all voltage sources.

This instrument contains electrostatically sensitive components. For this reason, an equipotential bonding

conductor must be connected when working on the open instrument (antistatic protection).

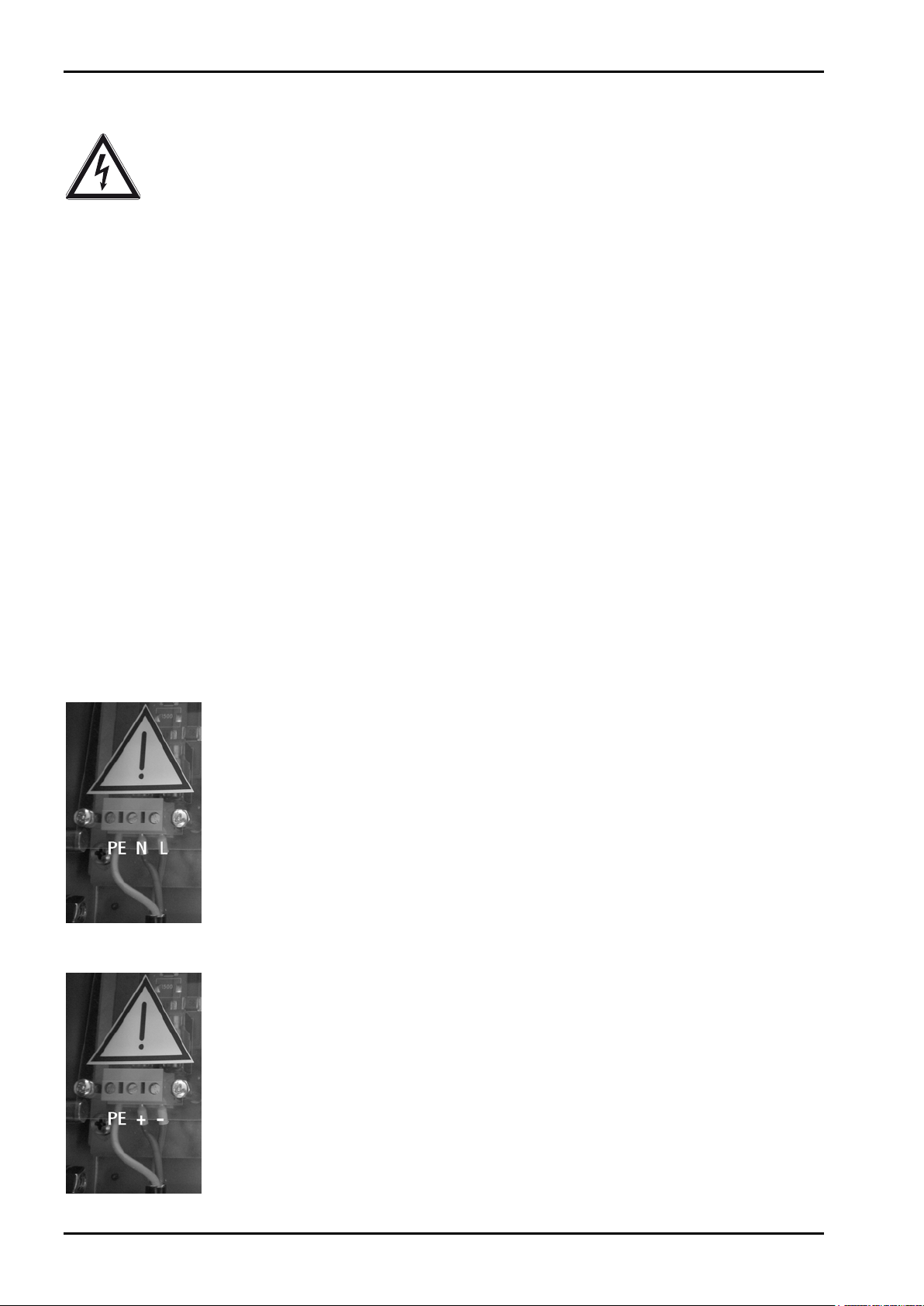

1.4.3 Connection of a protective earth conductor to PR 5230

1.4.3.1 Version 230 V AC

The instrument must be connected to protective earth via a protective earth conductor (PE) in the power

connector.

The power cable contains a protective earth conductor which must not be interrupted inside or outside the

instrument. The PE conductor is connected to the housing inside the instrument.

1.4.3.2 Version 24 V DC

The instrument must be connected to the protective earth conductor. The connection can be established via

the housing side wall.

1.4.4 Power Connection PR 5230

The instrument does not have a power switch and is ready for operation immediately after connecting the

supply voltage.

1.4.4.1 Version 230 V AC

Safe interruption of both supply voltage conductors must be provided for, either by

disconnecting the power connector or using a separate switch.

The instrument is equipped with a wide range power supply and covers AC systems with

a frequency of 50 Hz/60 Hz and a voltage range of 100 V AC to 240 V AC +10 %/-15 %

automatically (without manual selection). The power supply is protected against short

circuits.

1.4.4.2 Version 24 V DC

This version is designed for 24 V direct current.

The supply is done with a 3-pin connector (PE/+/-). The instrument is protected against

wrong polarity.

The instrument is primary protected by internal fuses in the + and – conductor.

EN-10 Sartorius

Page 11

PR 5230 Instrument Manual

Caution!

Safety Information

1.4.5 Failure and Excessive Stress

If there is any reason to assume that safe operation of the instrument is no longer ensured, shut it down and

make sure it cannot be used. Safe operation is no longer ensured if any of the following is true:

- The instrument is physically damaged.

- The instrument does not function.

- The instrument has been subjected to stresses beyond the tolerance limits (e.g., during storage or

transport).

1.4.6 Important Note

Make sure that the construction of the instrument is not altered to the detriment of safety. In particular,

leakage paths, air gaps (of live parts) and insulating layers must not be reduced. Sartorius cannot be held

responsible for personal injury or property damage caused by an instrument repaired incorrectly by a user or

installer.

1.4.7 Maintenance and Repair

Maintenance work must be carried out only by a trained technician aware of the involved hazards, whereby

the relevant precautions must be taken in account.

1.4.7.1 Static Sensitive Components

This instrument contains electro-statically sensitive components. Therefore, potential equalization must be

provided when working at the instrument (antistatic protection).

1.4.7.2 Replacing of Fuses in PR 5230 with Option Y2/WE1

In PR 5230 with option Y2/WE1 the replacing of fuses are not allowed!

1.4.7.3 Replacing of Fuses in PR 5230 without Option Y2/WE1

Only the fuses specified in Chapter 16.3 are permissible!

Sartorius EN-11

Page 12

Transmitter in Field Housing PR 5230 Instrument Manual

For the internal RS-232 or RS-485:

2 Transmitter in Field Housing

The instrument is equipped with a 128 x 64 pixel display for weight values with max. 6 digits and additional

status indication.

2.1 Overview of the Instrument

- Accuracy 10,000 e (Class III) for the weighing electronics

- High-speed conversion with response times from 5 msec

- Weight indication with status by monochrome 128 x 64 pixel display

- 3 function keys in the housing, function configurable

- Wall-mounted stainless steel housing, with IP 66 protection

- LAN adaptor with 10/100 Mbit/sec for data transfer, calibration, parameterization

- RS-232 interface, built-in; for connecting e.g. a printer or a remote indicator

- RS-485 interface, built-in; for connecting e.g. PC

- Expansion possible by addition of following plug-in circuit boards (3 slots):

- Analog output board PR 5230/06

- Load cell junction board PR 5230/22

- Interfaces PR 1721/4x

- 3 opto-decoupled outputs (optional)

- 3 configurable relay outputs with change-over contact

- 3 configurable optocoupler inputs, potential-free internal supply possible (optional)

- Galvanically isolated interfaces (except RS-232)

- Wide range power supply for 100 to 240 V AC, protection class I (protective earth)

- Version PR 5230 for 24 V direct current

- Version PR 5230 with intrinsically safe load cell supply (optional)

- Plug-in connections inside the instrument for load cells, inputs/outputs, LAN adaptor, serial interfaces

- Calibration using PC tool (Browser/VNC)

- Calibration using weights, by entering mV/V values, or directly, using load cell data ("smart calibration")

- Software configuration of the interface cards, e.g. for remote display or printer

- Analog test for the weighing electronics

Communication Protocols

Fieldbus Slave (accessories):

- Remote display protocol - PR 1721/41 ProfiBus-DP

- Printer - PR 1721/42 InterBus-S

- J-Bus/ModBus (Slave) - PR 1721/44 DeviceNet

- SMA protocol - PR 1721/45 CC-Link

- xBPI protocol - PR 1721/46 ProfiNet I/O

- Asycom protocol - PR 1721/47 EtherNet-IP

For the internal LAN:

- ModBus-TCP

- Ethernet-TCP/IP

- OPC

EN-12 Sartorius

Page 13

PR 5230 Instrument Manual

Height = approx. 120 mm

Transmitter in Field Housing

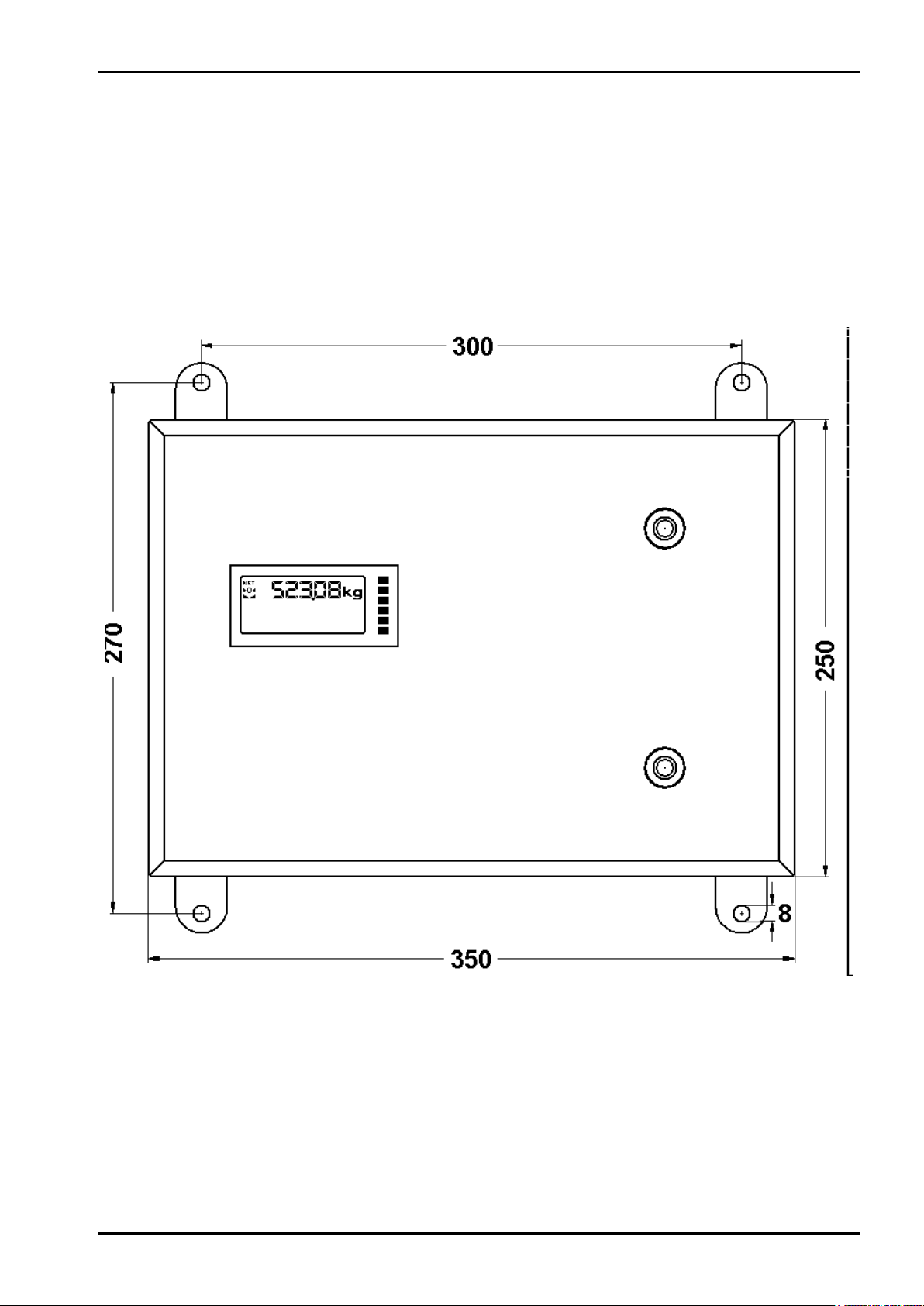

2.2 Housing

The transmitter is installed in a stainless steel field housing with protection type IP66. It is intended for wall

mounting. The door is left-hinged and opens towards the front. The environmental conditions specified for the

instrument must be observed (see Chapter 16.4.1). The housing is mounted using 4 screws. When the housing is

closed, no controls are visible from outside.

The 128 x 64 pixel display and 6 additional status indicator LEDs are visible through a glass pane in the housing

door.

Housing Dimensions

Sartorius EN-13

Page 14

Transmitter in Field Housing PR 5230 Instrument Manual

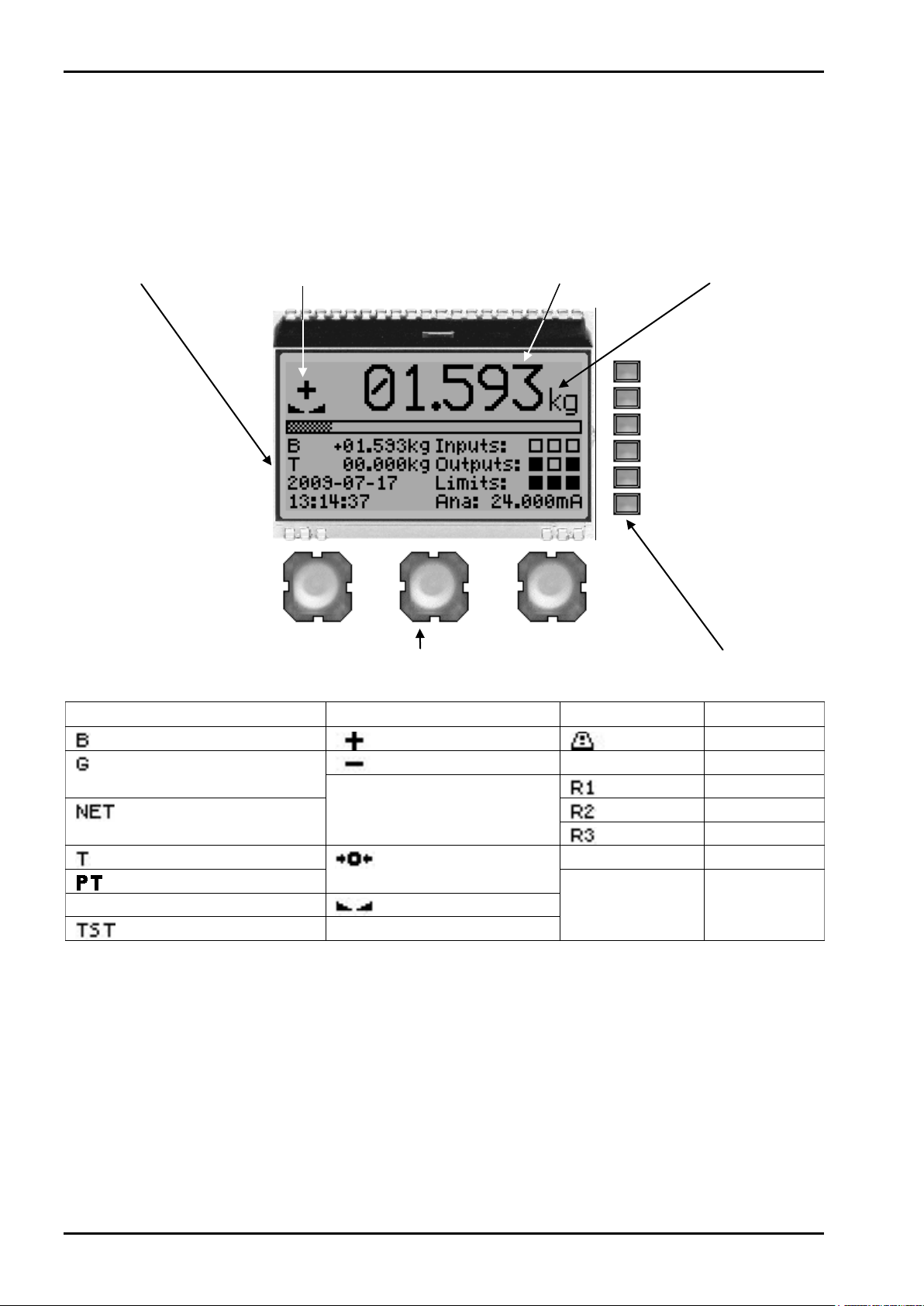

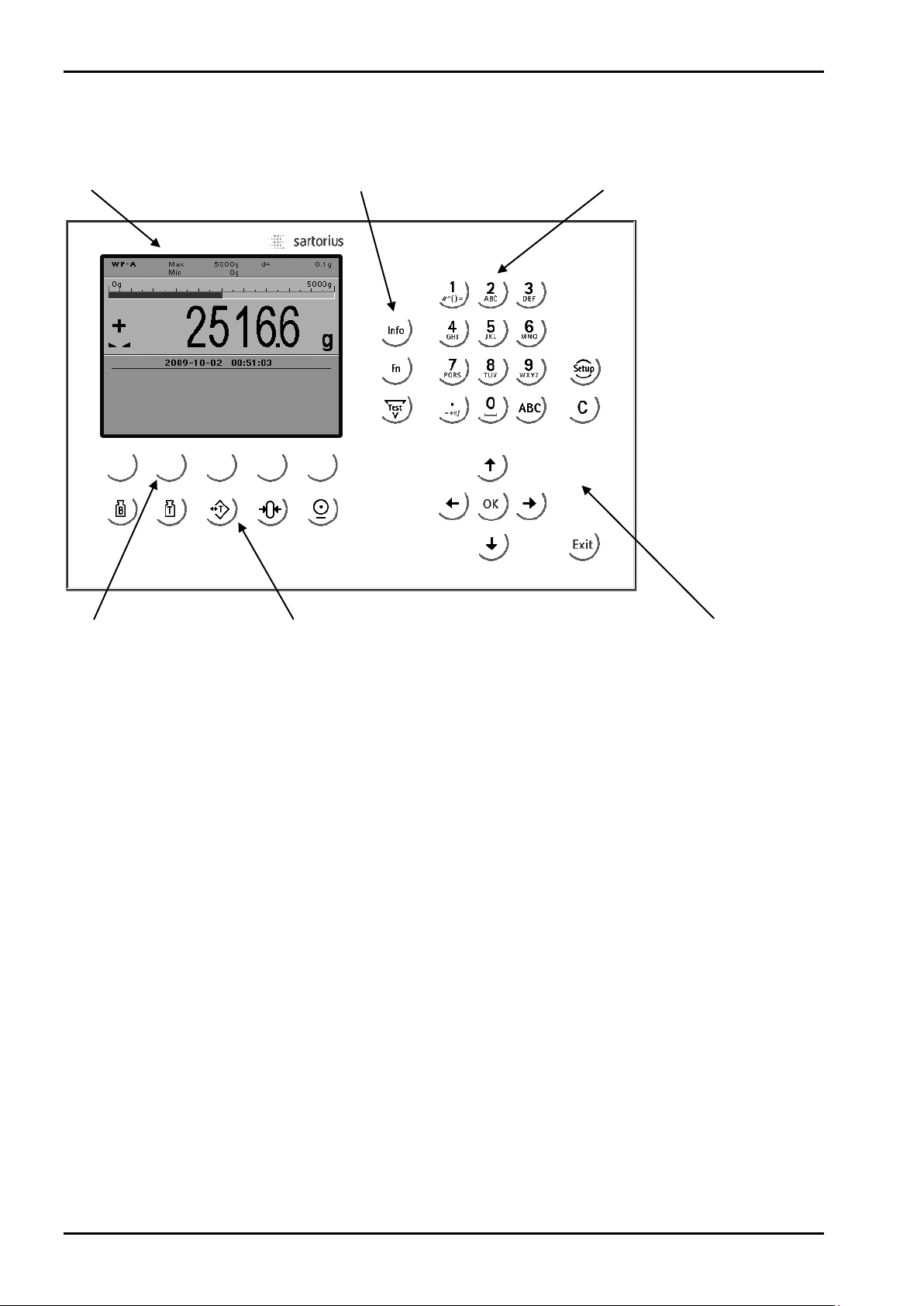

Status indication

Value type/polarity sign/Standstill

Weight value

Symbols/Mass unit

Keys

Status LEDs

Note:

2.3 Display and Controls

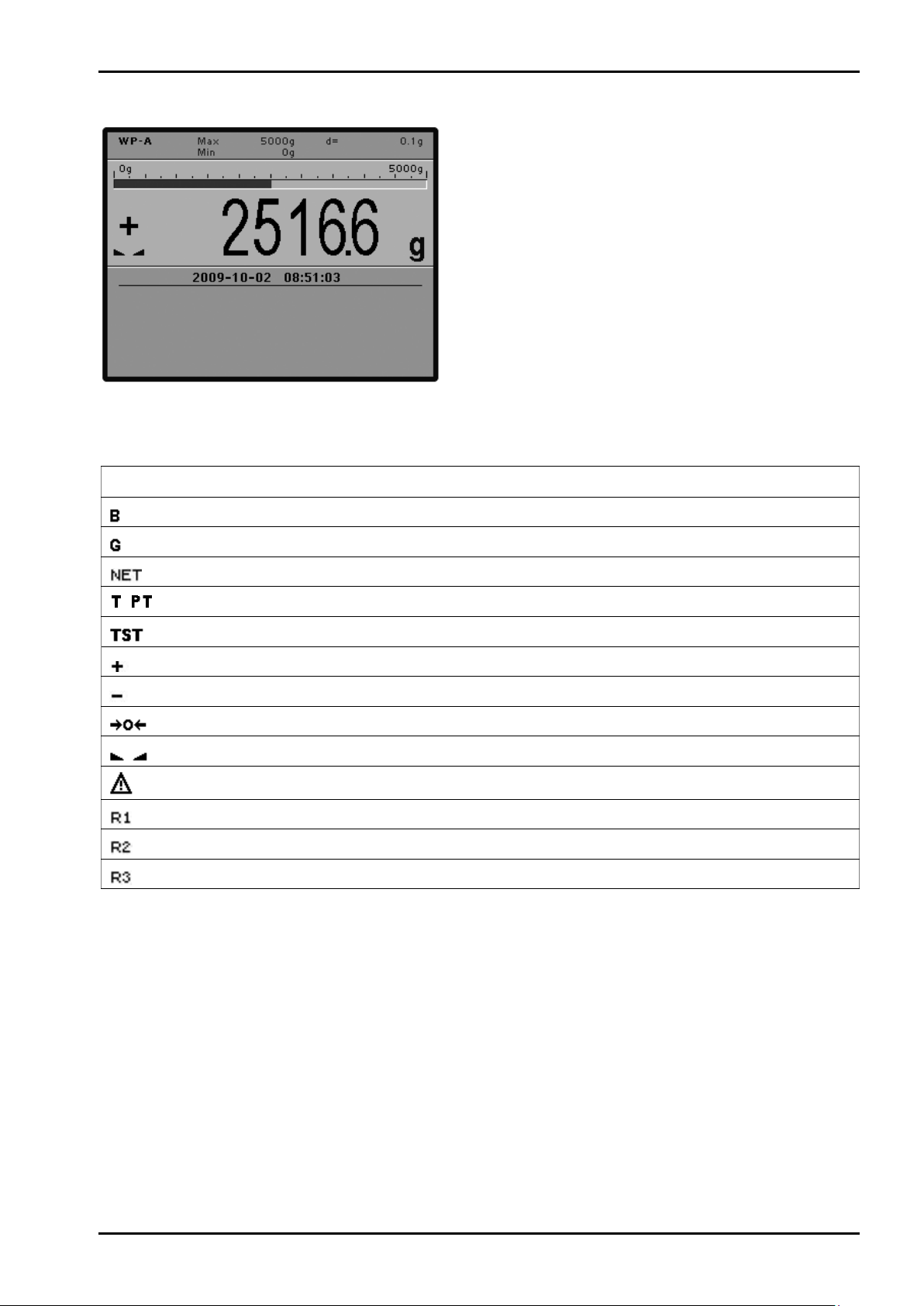

2.3.1 Display

The display permits indication of 6-digit weight values (digit height 18 mm) with decimal point.

Possible units of mass are mg, g, kg, t, lb or oz.

Value type Polarity sign/Standstill Symbols Mass unit

Gross weight (Brutto)

Gross weight

at NTEP or NSC mode The weight value is

Net weight

(Net = Gross – Tare)

Tare weight

Fixtare

Not tared

Test value

In W&M mode an invalid weight is shown without mass unit.

Positive value

Negative value g

between ¼ d and ½ d.

The weight value is

within ±¼ d of zero.

Standstill

oz

Warning mg

Range 1 kg

Range 2 t

Range 3 lb

EN-14 Sartorius

Page 15

PR 5230 Instrument Manual

Transmitter in Field Housing

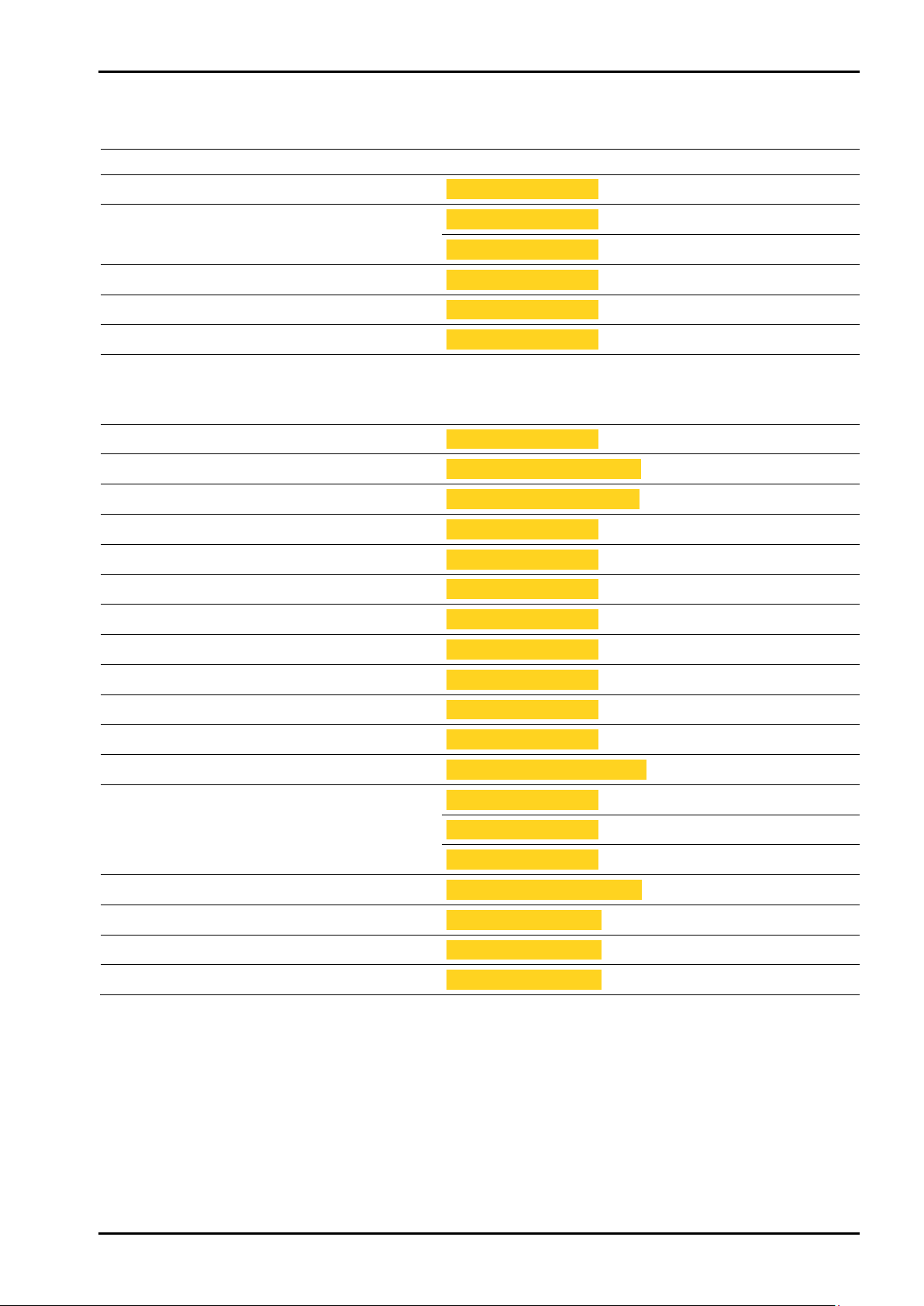

2.3.1.1 Status Indication

For status indication, max. 5 lines can be configured by selecting from a menu (see Chapter 5.6.7).

Selection Width Height Example Description

Empty ½ Display 1 Line

Gross/Net/Tare ½ Display 1 Line

Gross ½ Display 1 Line

Net ½ Display 1 Line

Tare ½ Display 1 Line

Bargraph 1 Display 1 Line

Fieldbus LEDs ½ Display 1 Line

Fieldbus Inputs 1 Display 1 Line

Fieldbus Outputs 1 Display 1 Line

Digital inputs ½ Display 1 Line

Digital outputs ½ Display 1 Line

Digital I/O ½ Display 1 Line

Analog output ½ Display 1 Line

B +123.45kg

B E:Sense

B +123.45kg

NET +123.45kg

T +123.45kg

––– red ––– grn

FB-Inp: 01.23.45.67.89.AB.CD.EF

FB-Out: 01.23.45.67.89.AB.CD.EF

Inputs:

Outputs:

I: O:

Ana: 12.345mA

Empty line

Gross/Net/Tare

Error, see Chapter 15.1

Gross

Net

Tare

Shows the weight in

proportion to nominal

capacity.

See Chapter 4.4.

Fieldbus Inputs

Fieldbus Outputs

Digital inputs: 1, 2, 3

Digital outputs: 1, 2, 3

Digital

Analog output

in-/outputs

: 1, 2, 3

Limits ½ Display 1 Line

Date ½ Display 1 Line

Time ½ Display 1 Line

Hostname ½ Display 1 Line

Hostname (long) 1 Display 1 Line

IP-Address ½ Display 1 Line

IP-Address (long) 1 Display 1 Line

Gross (2 lines high) 1 Display 2 Lines

Net (2 lines high) 1 Display 2 Lines

Tare (2 lines high) 1 Display 2 Lines

Limits:

2009-12-31

10:37:34

HOPPER1

Small Material Hopper

192.168.1.1

---.---.---.---

??.??.??.??

172.200.280.255

B +123.45 kg

NET +123.45 kg

T +123.45 kg

Limits: 1, 2, 3

Date

Time

Device name in the network

Device name (long)

Network address

No network

Search DHCP server

Network address (long)

Gross (2 lines high)

Net (2 lines high)

Tare (2 lines high)

Sartorius EN-15

Page 16

Transmitter in Field Housing PR 5230 Instrument Manual

Note:

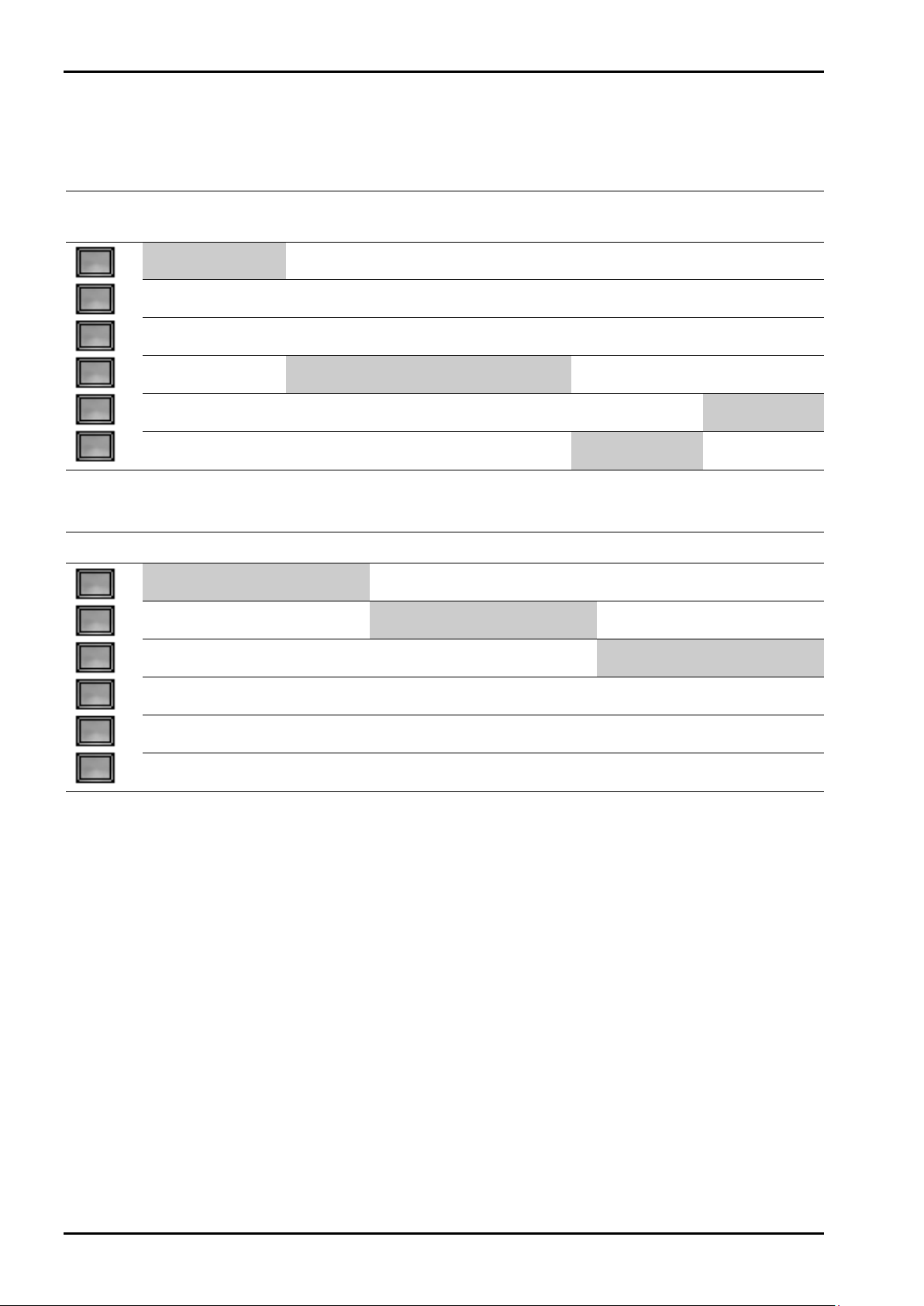

2.3.2 Status LEDs

The instrument has 6 green LEDs for display of the operating or error status.

2.3.2.1 Hardware, Bus Connection (Fieldbus plug-in cards), Network, Power supply

Hardware error

E:HardE

flashing 1 Hz

Bus connection

provided

lit flashing 1 Hz

flashing acc.

lit

2.3.2.2 Weight Status Indicator

Standstill Center zero

lit

lit

Bus connection not

provided

Power on Network active

Below zero or above MAX

lit

The weight error status sees in Chapter 15.2.

EN-16 Sartorius

Page 17

PR 5230 Instrument Manual

1

2

3

Transmitter in Field Housing

2.3.3 Buttons

Danger! High Voltage!

Working on the opened instrument while it is switched on may have life-threatening

consequences.

Product operation must be performed by trained and qualified personnel who are aware

of and able to deal with the related hazards and take suitable measures for

self-protection.

The 3 buttons are accessible only when the housing door is open. The following functions can be performed:

- zero setting (1)

- taring (2)

- test measurement (3)

- display of software version and board number by simultaneous actuation of push-buttons (1) and (3)

- Updating a Software with ‚FlashIt!32’ (see Chapter 12.2) by pressing the keys (1) and (3) simultaneously

and pressing key (2) three times.

Adjustment or parameter entry is

- not possible using the push-buttons.

- only possible using a Notebook/PC via Internet browser (see Chapter 5.3.5) and VNC (see Chapter 5.3.4).

Sartorius EN-17

Page 18

Transmitter in Field Housing PR 5230 Instrument Manual

Display

Function keys

Alphanumeric keys

Softkeys

Indicator keys

Navigation/menu keys

2.3.4 Operating via VNC

2.3.4.1 Operator Interface

EN-18 Sartorius

Page 19

PR 5230 Instrument Manual

Available mass units are mg, g, kg, t, lb or oz.

The display shows weight values of up to 7 digits with decimal point and plus or minus sign.

lb and oz units are not permitted for use in legal

metrology in the EU and EEC.

The weight readout shows the current weight on a

bar graph that indicates proportion of the

maximum capacity (Max), with 0 on the left and

100 % on the right.

Transmitter in Field Housing

2.3.4.2 Status Symbols

The following status symbols can be shown:

Symbol Description

Gross weight (Brutto)

Gross weight in NTEP or NSC mode

Net weight (Net = gross – Tare)

, Tare weight, fixtare

The display shows the test value without mass unit

Positive value

Negative value

The weight value is within ±¼ d of zero

The weight value is stable.

Value not permissible in legal metrology (e.g., 10-fold resolution).

Range 1

Range 2

Range 3

Sartorius EN-19

Page 20

Transmitter in Field Housing PR 5230 Instrument Manual

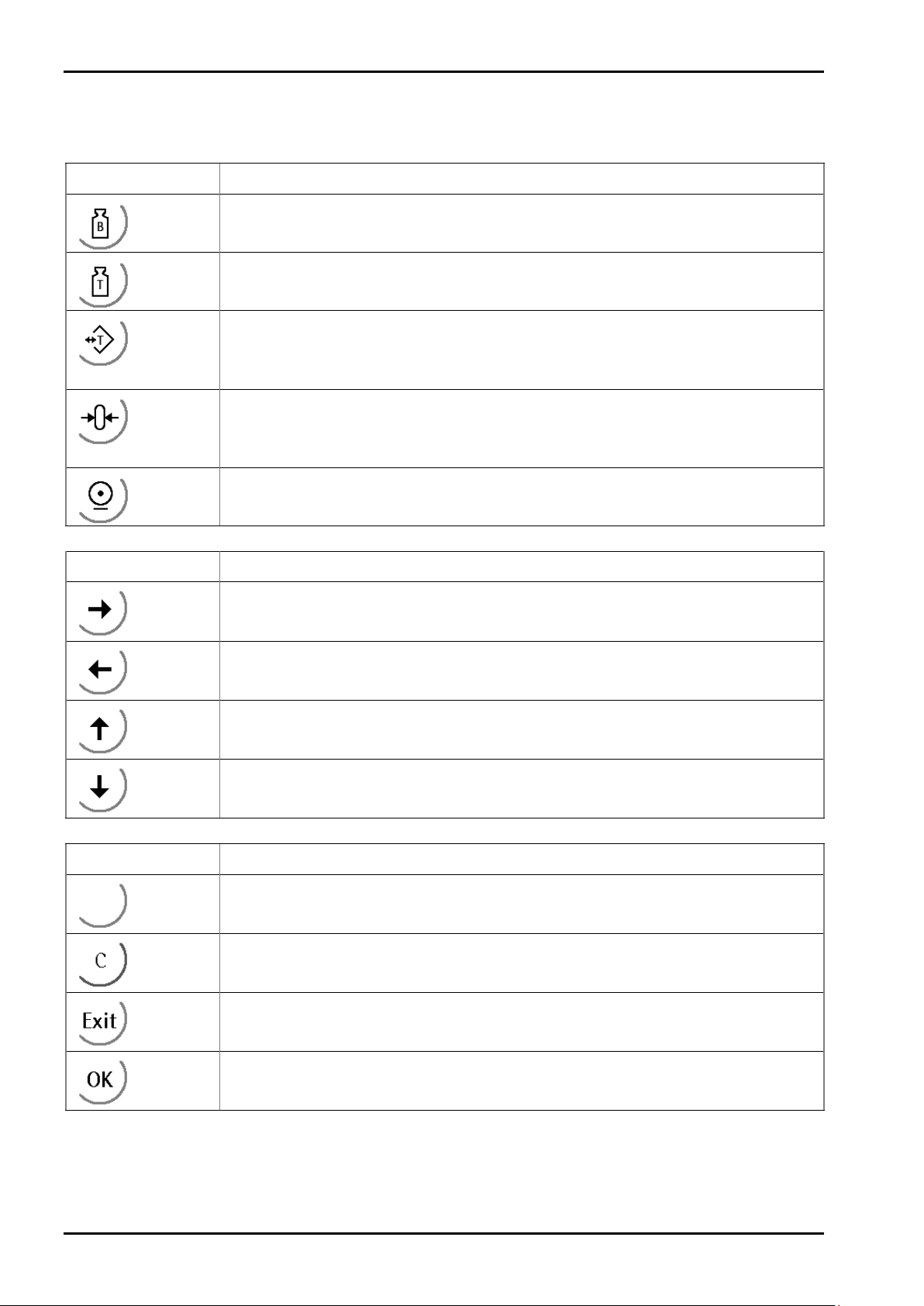

2.3.4.3 Keys

The following tables show the basic meanings of symbols on the operator interface.

Indicator key Description

Display gross weight

Display tare weight

Taring; the current gross weight is stored in the tare memory, provided that:

- weight value is stable.

- instrument is not in error status (function dependent on configuration).

Sets gross weight to zero, provided that (function dependent on configuration):

- weight value is stable.

- weight is within zero setting range

Start printing.

Navigation key Description

Cursor moves to the right.

Menu key Description

Selection

Cursor moves to the left.

Selection

Scroll up in the menu.

Scroll down in the menu.

Softkey: select function

Backspace/delete

Exit from current menu; continue operation on next higher level.

Enter/confirm

EN-20 Sartorius

Page 21

PR 5230 Instrument Manual

Setup

Config

Calib

Param

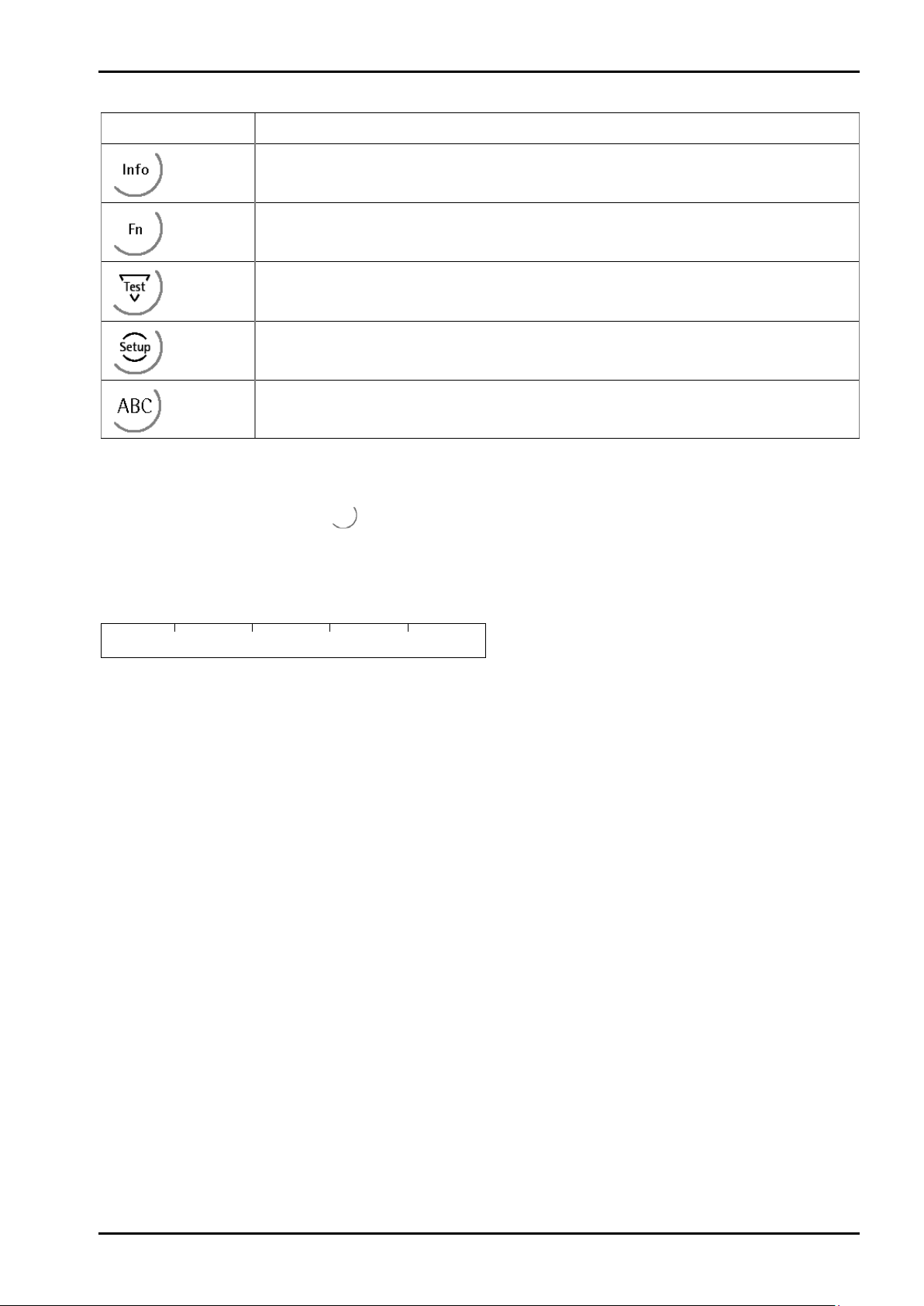

Function key Description

Information on version number, fitted hardware,10-fold resolution

Without function

Test

Open the setup menu

Toggle to alphabetic input mode.

During configuration, you can switch between the mass units by pressing this key.

2.3.4.4 Operation Using Softkeys

Transmitter in Field Housing

The functions of the five softkeys below the graphic display are indicated in the bottommost text line of

the display. Softkey functions shown in gray are not available on the active menu level, or not with the active

access privileges.

When operating steps involving softkeys are described in this manual, the softkey labels are shown in square

brackets, rather than in graphics of the softkeys.

Sartorius EN-21

Page 22

Transmitter in Field Housing PR 5230 Instrument Manual

Info

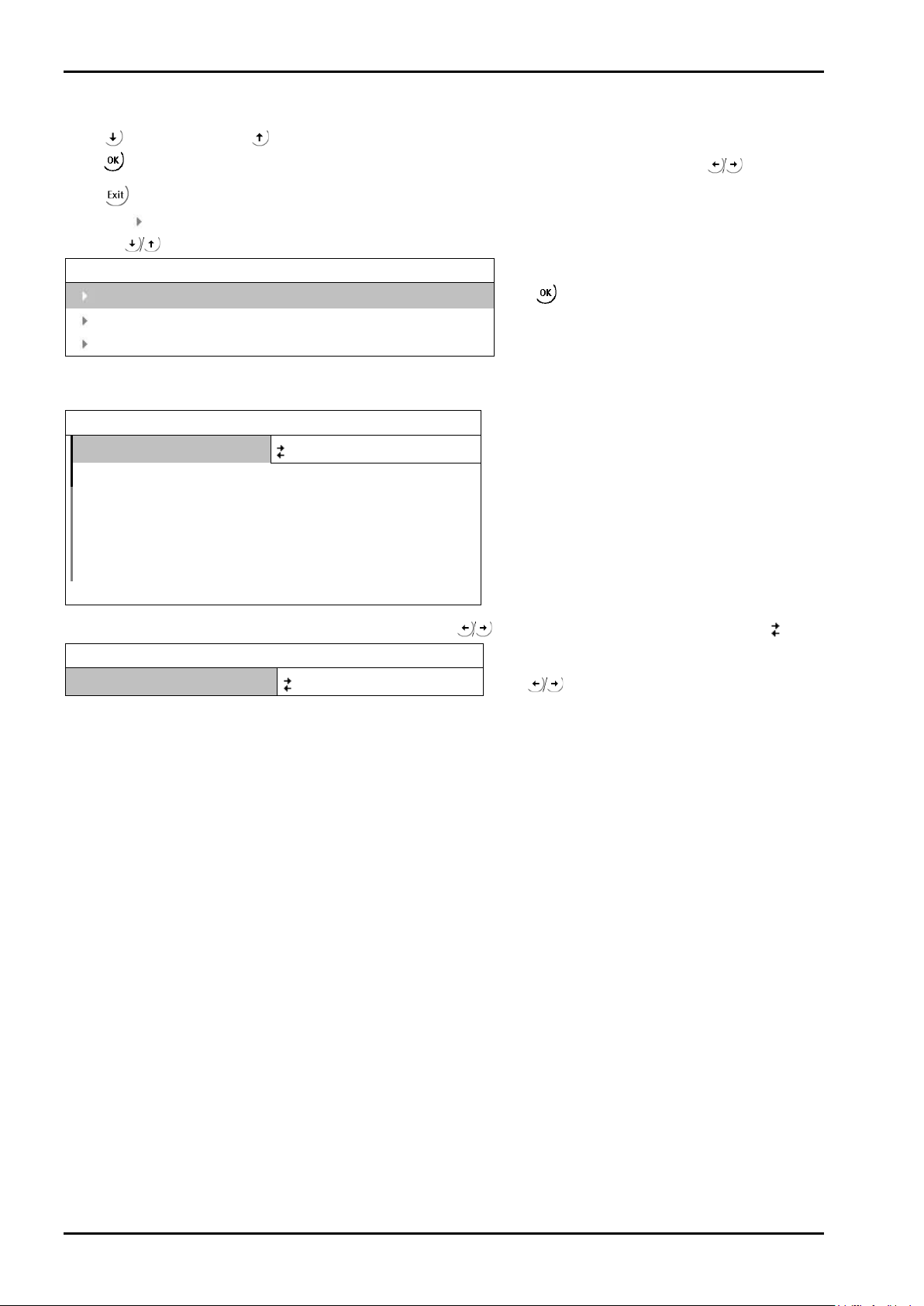

2.3.4.5 Selection Using the Navigation Keys (VNC)

Press to scroll down, or to scroll up in a menu.

Press

Press

An arrow

pressing

If the list of menu items is long, a vertical bar graph on the left (black and gray) shows which part of the list is

displayed.

to select a menu item. To select the desired setting for the selected menu item, press .

to exit the menu and continue the operation on the next higher level.

in front of a menu item indicates that there are menu sublevels. The menu item selected by

is shown inversely.

Show version

Show status

Show HW-slots

Weighingpoint/WP A/Calibration

Measuretime

Digital filter off

External supply above 8V

Test mode absolute

W & M

Standstill time 0.50 s

160 ms

none

Press

to select an item.

Availability of additional settings options selectable with is indicated by preceding double arrows .

Weighingpoint/WP A/Calibration

Measuretime

640 ms

Press

to select the measuring time.

EN-22 Sartorius

Page 23

PR 5230 Instrument Manual

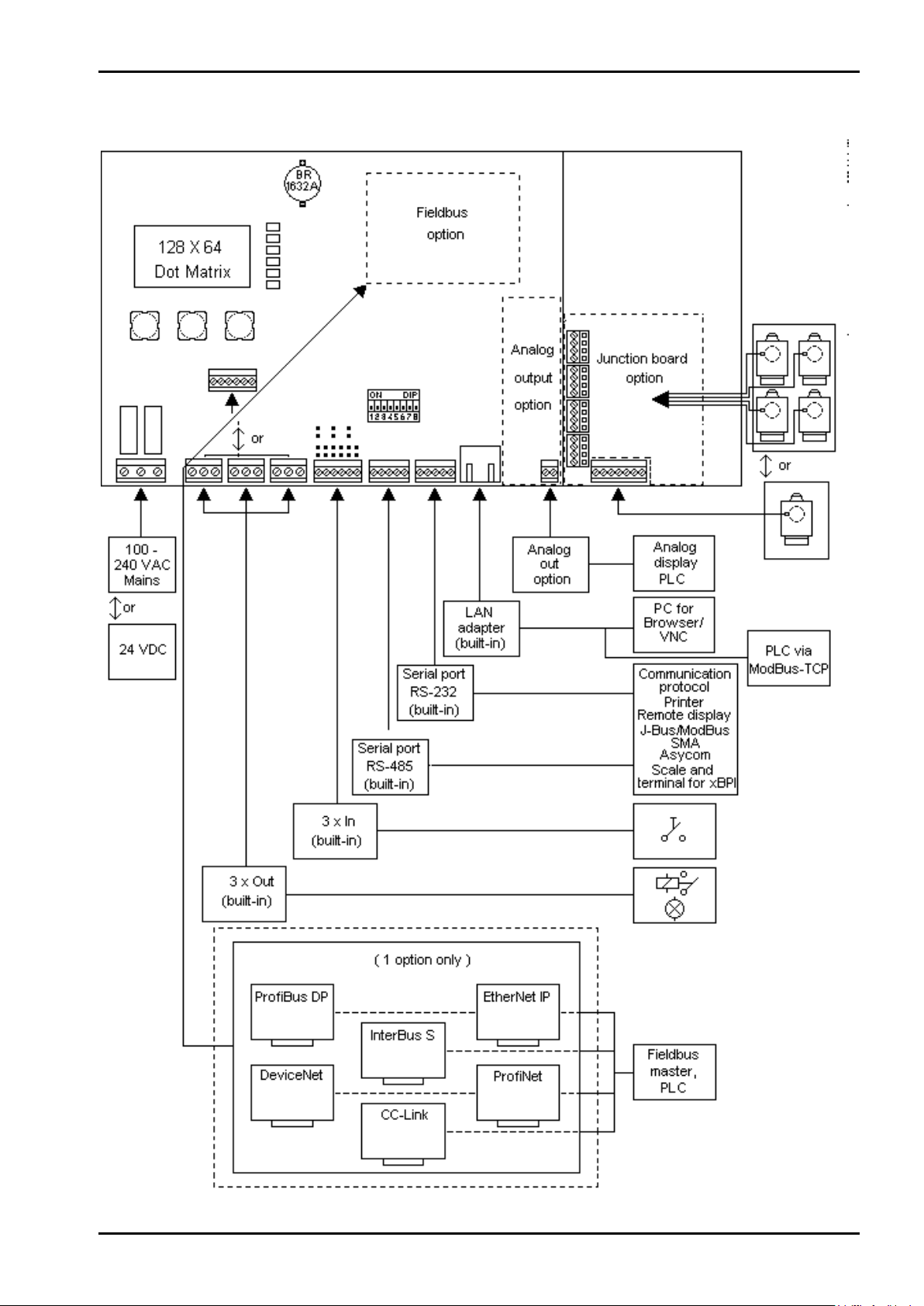

2.4 Overview of Connections

Transmitter in Field Housing

Sartorius EN-23

Page 24

Transmitter in Field Housing PR 5230 Instrument Manual

2.4.1 Plug-in Cards/Junction Board

On the main board, the PR 5230 can be fitted with 1 fieldbus card and 1 analog output board.

The load cell junction board is connected to the weighing electronics board by a flat cables plug.

Product Function Position

PR 5230/06

Analog output

PR 5230/22

Load cell junction board

PR 1721/41

ProfiBus-DP

PR 1721/42

InterBus-S

PR 1721/44

DeviceNet

PR 1721/45

CC-Link

PR 1721/46

ProfiNet I/O

PR 1721/47

EtherNet-IP

For product details, see Chapter 4.2 and 4.3.

Analog output 16 bits, 0/4 - 20 mA Analog output

Junction board for 2…4 load cells Junction board

ProfiBus-DP Slave acc. IEC 61158 with

max. 12 Mbit/s

InterBus-S Slave with max. 500 kbit/s Fieldbus

DeviceNet Slave with max. 500 kbit/s Fieldbus

CC-Link with 156 kbit/s…10 Mbit/s Fieldbus

ProfiNet I/O with 10 / 100 Mbit/s Fieldbus

EtherNet-IP with 10 / 100 Mbit/s Fieldbus

Fieldbus

EN-24 Sartorius

Page 25

PR 5230 Instrument Manual

Fehler!

Verweisquell

e konnte

nicht

gefunden

werden.

Options

3 Options

Designation Code no. Description Chapter

Analog/digital

converter

W1 Weighing electronics board

EX WE1 Weighing electronics board with

power supply Standard L0 Version 230 V 1.4.4.1

L8 Version 24 V 1.4.4.2

IP protection I66 IP66

Digital input DE1 Digital input, passive (external supply) 4.2.6.1

DE2 Digital input aktive (internal 12 V supply) 4.2.6.2

Digital output DA1 Digital output relay 4.2.8

DA2 Digital output Optocoupler 4.2.7

EX Zone Standard none

Y2 Approval ATEX/EU, Zone 2/22 3.1

Interface Slot 1 Standard none

C11 Analog output 16 bits, 0/4 - 20 mA 4.4.2

Interface Slot 2 Standard none

C21 ProfiBus-DP 4.4.4

C22 InterBus-S 4.4.5

C24 DeviceNet 4.4.6

C25 CC-Link 4.4.7

C26 ProfiNet I/O 4.4.8

C27 EtherNet-IP 4.4.9

Interface Slot 3 Standard none

C31 Load cell junction board 4.4.3

Connecting cable Standard none

for network M39* Ethernet socket, RJ-45 plug, IP67 4.4.10

M40* Ethernet cable, 7m long,

* For the Builtin Ethernet interface only!

Standard none

intrinsically safe load cell supply for

operation of load cells/platforms

in Zones 1 and 21

4.4.11

metric cable gland, RJ-45 plug,

industry version

3.2

Instrument Option

The marking (e.g. PR 5230-WE1- Y2-C21-DA2) of the instrument option is located on a label inside the door of

the instrument.

Sartorius EN-25

Page 26

Options PR 5230 Instrument Manual

3.1 Option Y2

3.1.1 Safety Instructions

Caution!

It is essential to observe the safety instruction in Chapter 18.4!

3.1.2 Description

PR 5230 with option Y2 is only suitable for using within Ex areas Zone 2 and 22 (non conductive dust)

according European directive 94/9/EG and related harmonized European standards (see also Chapter 18.4).

The Ex design for Zone 2/22 see Chapter 18.4.

3.1.3 Marking

II 3G Ex nA nC IIC T4

II 3D Ex tD A22 IP6X T80°C

SAG 09ATEX004X

See also Chapter 18.4.

3.1.4 Outputs

With option Y2 are following outputs possible:

- Opto-decoupled outputs (option DA2): Technical Data see Chapter 16.5.8.2.

- Relays (option DA1): Only external circuits with voltages up to 60 V AC or 75 V DC are allowed to be

connected to the relays, see Safety Instruction in Chapter 18.4.

3.1.5 In Connection with Option W1

Connected load cells or weighing platforms must be certified for use in Ex areas Zone 2 or Zone 22 and for

load cell supply voltages of more than 13.2 V DC.

When use

- in Zone 2 observe gas group and temperature class.

- in Zone 22 observe the allowed surface temperature.

3.1.6 In Connection with Option WE1

The combination Y2 and WE1 is also possible; see Ex design for Zone 2/22 and Zone 1/21 in Chapter 18.4.

EN-26 Sartorius

Page 27

PR 5230 Instrument Manual

Danger!

Options

3.1.7 Installation

The installation must be performed by qualified personnel in compliance with the applicable laws, regulations,

ordinances and standards. In particular, the standards EN 60079-14 (gas) and EN 61241-14 (dust) must be

taken into account.

All cables to and from PR 5230 have to be installed firmly.

It is only allowed to connect instruments (not sparking during operation) to power circuits in Zone 2 which are

suitable for Zone 2 and the local conditions at the operating location.

Not used cable glands must be closed with ATEX approved screwings in order to secure IP65 protection.

Working at the switched on unit may be dangerous to life!

• Disconnect the instrument from the supply voltage.

• When removing covers or parts by means of tools, live parts or terminals may be

exposed.

• Capacitors in the unit may still be charged also after disconnecting the unit from all

voltage sources.

3.1.8 Repairs/Cleaning/Maintenance

Warning!

In the Ex atmosphere it’s not permissible to mount/loose plug connectors or to change

fuses!

Any modifications to the instrument (except by persons authorized by Sartorius) cause loss of conformity for

use in Zone 2 and 22 hazardous areas and invalidate all guarantee claims. Similary, the instrument may only be

opened by qualified and authorized persons.

Repairs are subject to inspection and must be carried out at Sartorius. In case of defect or malfunction, please

contact your local Sartorius dealer or service center for repair. When returning the instrument for repair,

please include a precise and complete description of the problem.

Instruments used in Zone 22 remove dust regulary. Dust layers >5 mm are not permitted.

Maintenance work may be carried out only by a trained technician with expert knowledge of the hazards

involved and the required precautions.

3.1.9 Environmental Conditions

Use the transmitter only within the temperature range of -10 °C…+40 °C. Avoid the inadmissible exposure of

heat, cold, direct sunlight, UV radiation or vibration. Install the instrument in that way, that air circulation is

possible and heat sources are sufficient far away.

Sartorius EN-27

Page 28

Options PR 5230 Instrument Manual

3.2 Option WE1

3.2.1 Safety Instructions

Caution!

It is essential to observe the safety instruction in Chapter 18.4!

3.2.2 Description

The option WE1 is used for an intrinsically safe interface of load cells or weighing platforms situated in a

hazardous (Ex) area Zone 1 and 21 with PR 5230 installed in a safe area according European directive 94/9/EG

and related harmonized European standards (see also Chapter 18.4).

The unit is designed for weighing applications requiring intrinsically safe interfacing. This is achieved by use of

double provided current and voltage limiters in the supply circuit and voltage limiters in the analogue

elektonic (weighing electronics board) of the PR 5230 with option WE1.

The PR 5230 with option WE1 provides the intrinsically safe interfacing of:

- 1 voltage output for the supply of load cells or weighing platforms situated in Zone 1 or 21,

- 1 measuring voltage input from Zone 1 or 21 and

- 1 sense voltage input from Zone 1 or 21.

3.2.3 Marking

II (2) G [Ex ib] IIC

II (2) D [Ex ib D]

KEMA 10 ATEX 0065 X

See also Chapter 18.4.

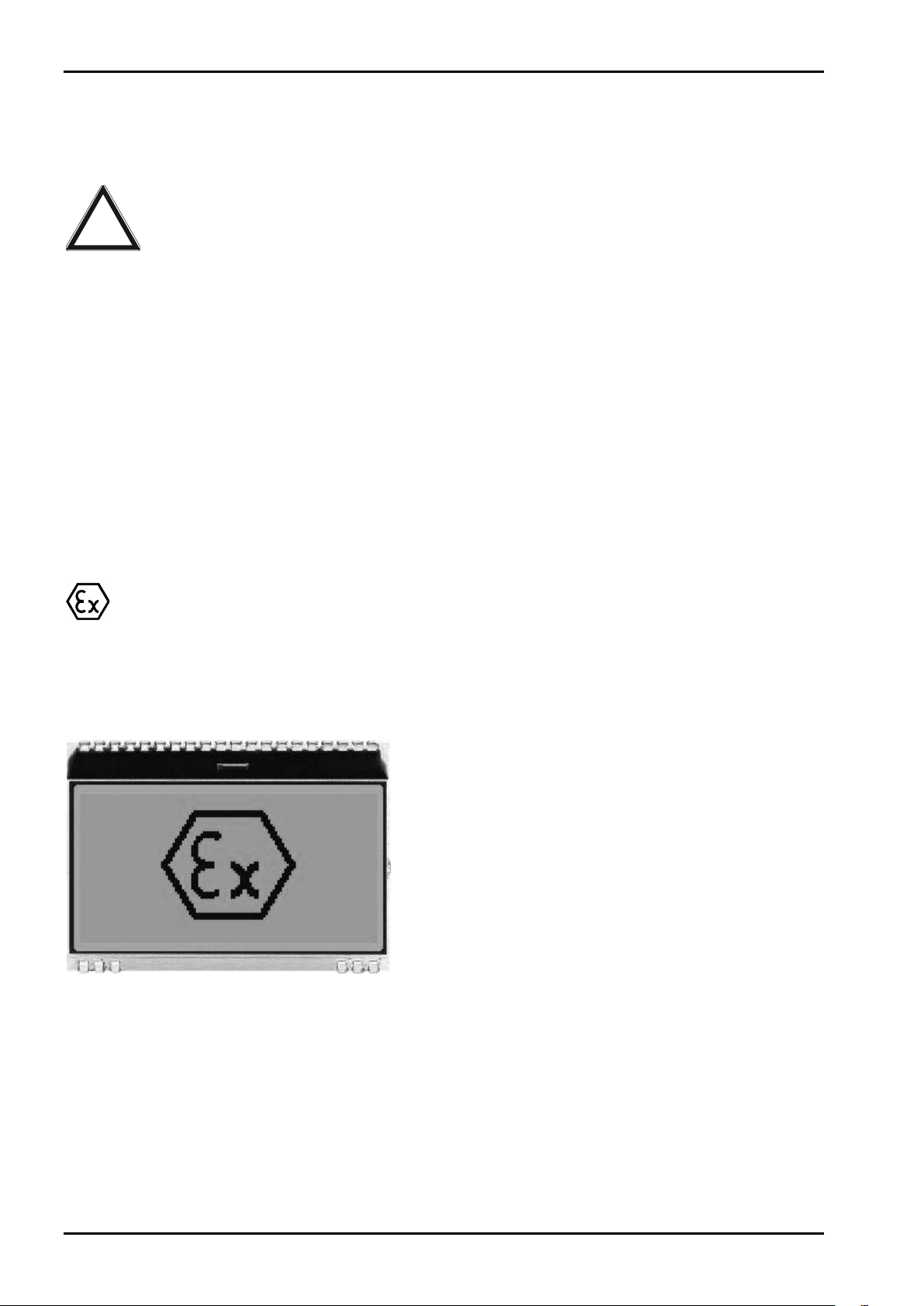

3.2.4 Display

After switching on the instrument the following information is short-time displayed:

3.2.5 In Connection with Option Y2

The combination WE1 and Y2 is also possible; see Ex design for Zone 2/22 and Zone 1/21 in Chapter 18.4.

EN-28 Sartorius

Page 29

PR 5230 Instrument Manual

Options

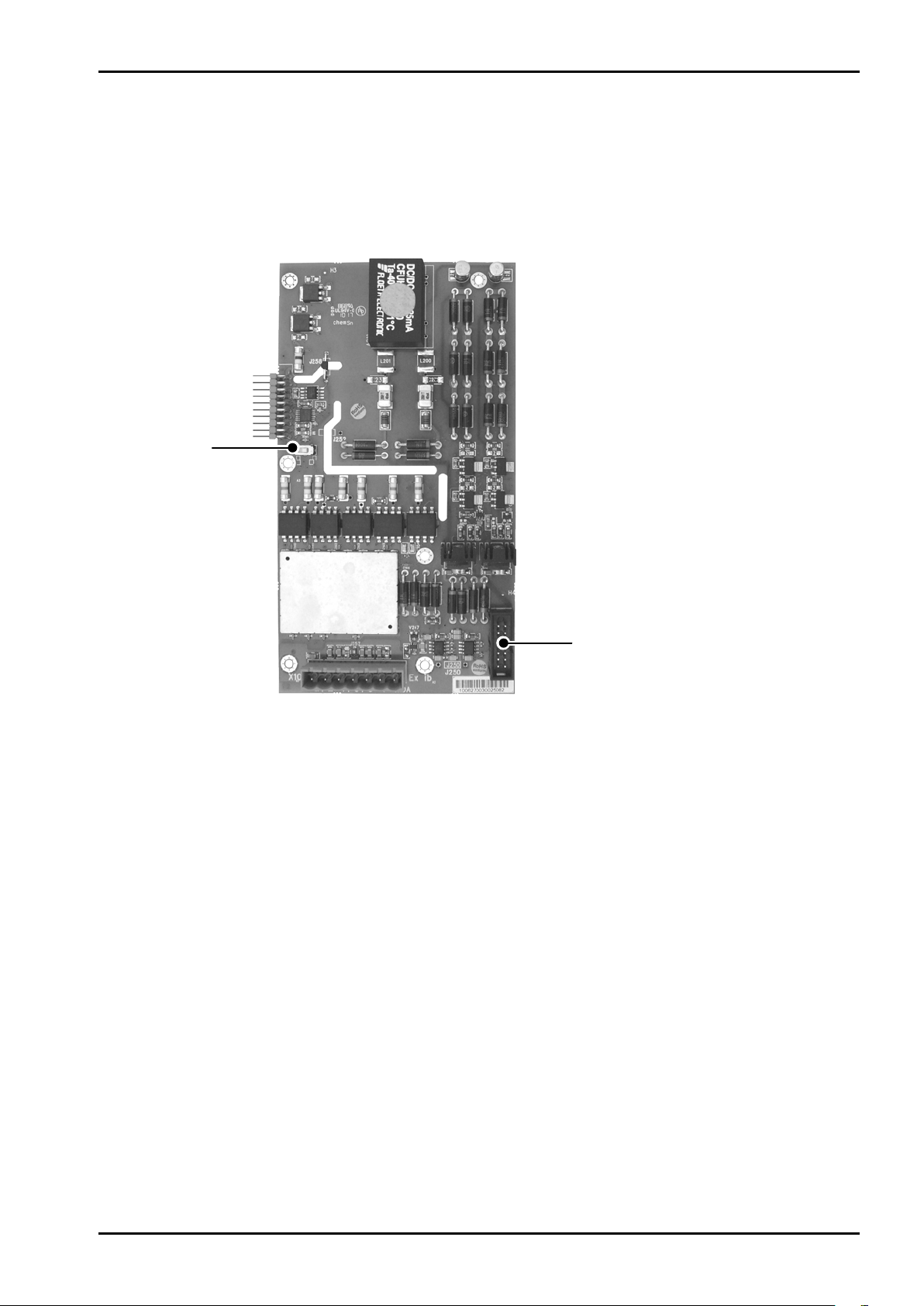

3.2.6 Weighing Electronics Board for Zone 1 and 21

Two weighing electronics board versions are available:

- Standard (W1), see Chapter 4.2.3

- With intrinsically safe load cell supply for operation of load cells/platforms in Zones 1 and 21 (WE1)

The load cell junction board (see Chapter 4.4.3) is connected to the weighing electronics board via a ribbon

cable (also permitted for WE1) for direct connection of up to four load cells.

CAL switch

Connector load cell junction board

Sartorius EN-29

Page 30

Options PR 5230 Instrument Manual

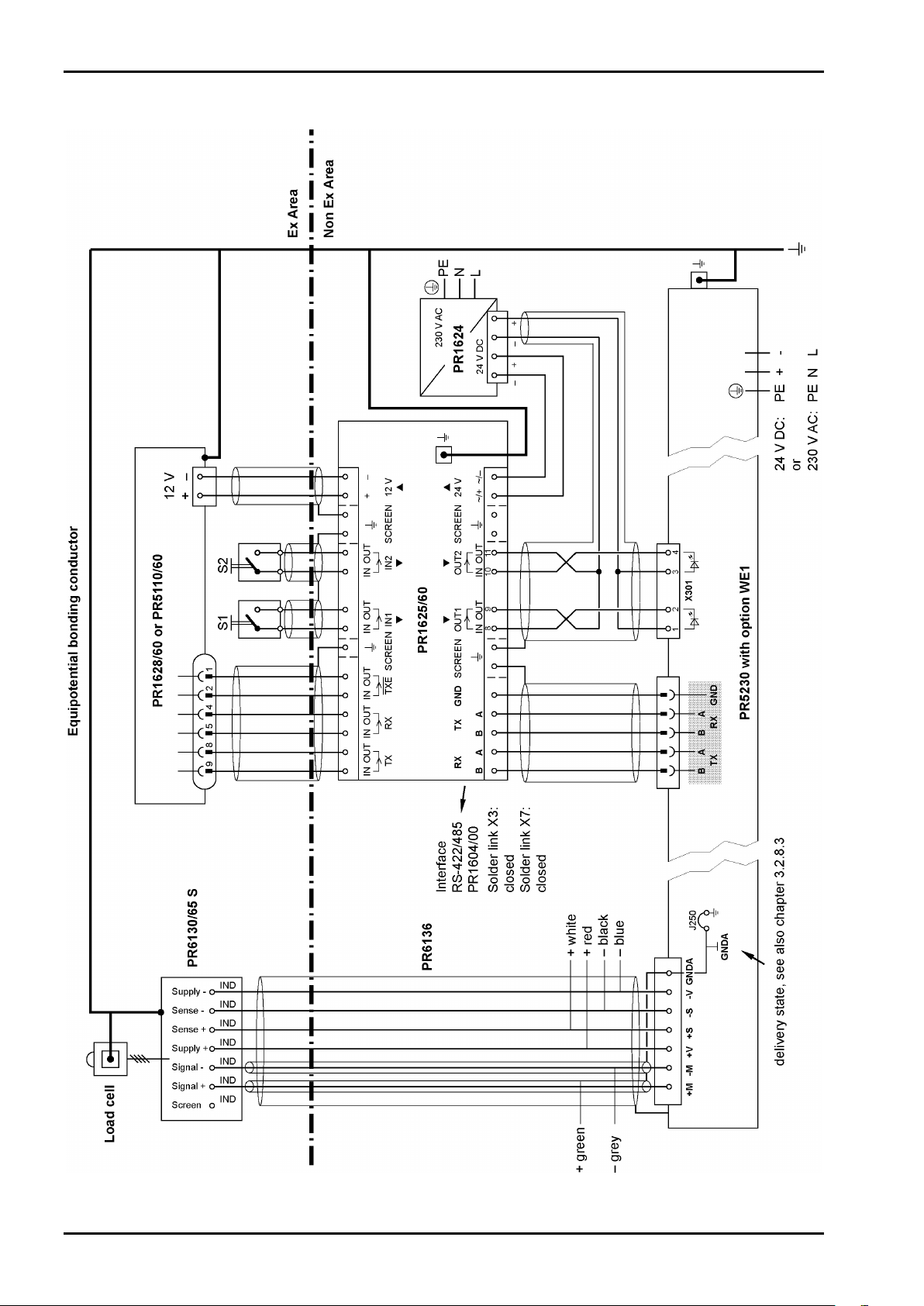

3.2.7 Connection within the Ex Area

EN-30 Sartorius

Page 31

PR 5230 Instrument Manual

Danger!

Options

3.2.8 Installation

3.2.8.1 General

The installation must be performed by qualified personnel in compliance with the applicable laws, regulations,

ordinances and standards. In particular, the standards EN 60079-14 (gas) and EN 61241-14 (dust) must be

taken into account.

All cables to and from PR 5230 have to be installed firmly.

Not used cable glands must be closed with ATEX approved screwings in order to secure IP65 protection.

Working at the switched on unit may be dangerous to life!

• Disconnect the instrument from the supply voltage.

• When removing covers or parts by means of tools, live parts or terminals may be

exposed.

• Capacitors in the unit may still be charged also after disconnecting the unit from all

voltage sources.

Sartorius EN-31

Page 32

Options PR 5230 Instrument Manual

3.2.8.2 Reduction in the Load Cell Supply Voltage

The solder links ‚J203’ and ‚J204’ are situated on the weighing electronics board.

The load cell supply voltage can be changed by closing the solder links.

Load Cell Supply Voltage

open 12 V DC nominal, if RLC ≥150 ¥

closed 7,2 V DC nominal, if 80 ¥ ≤RLC <150 ¥

J203

J204

Solder links

open (delivery state)

closed

open (delivery state)

closed

J203

J204

EN-32 Sartorius

Page 33

PR 5230 Instrument Manual

Options

3.2.8.3 Potential-free Load Cell Supply Voltage

The instrument with option WE1 will be delivered with an intrinsically safe circuit which is galvanically

connected with the equipotential bonding (PA).

Jumper J250

At distances >50 m a potential-free load cell supply voltage is required. This is done as follows:

• Cut the jumper J250 on the weighing electronics board.

• Turn the remaining wire leads upward and cut them just above the board. Make sure that both contacts

have a minimum distance of 2 mm and don’t touch other potentials.

If the jumper J250 is open, the intrinsically safe circuit is isolated from the housing (PA) at a minimum test

voltage of 500 V.

Sartorius EN-33

Page 34

Options PR 5230 Instrument Manual

PR5230-WE1-…

Load Cells

Wägezellen

Junction Box

Verbindungskasten

Ex Area Zone 1/21

Ex-Bereich Zone 1/21

Non Ex Area

Kein Ex-Bereich

(1) (2) (1) (1) (2) (3)

(6) (6)

(A)

(4)

(4) (4)

(A) (A) (A) (A) (A) (A)

(E)

(5)

(B)

(1)

≥

≥

≥

3.2.8.4 Potential Equalization

Possible compensatory currents between several conducting plant sections will be avoid by installing a

potential equalization in the ex areas.

Pos. Component Cross-section

(1) Conductor for additional potential equalization

(2) Conductor for potential equalization

(3) Conductor for potential equalization

(4) Main conductor for potential equalization

(5) Earthing conductor

(6) Load cell by-pass

4.0 mm² Cu

6.0 mm² Cu

10.0 mm² Cu

≥10.0 mm² Cu

≥10.0 mm² Cu

≥10.0 mm² Cu

(A) Sub potential equalization terminal

(B) Main potential equalization terminal

(E) To earth electrode

EN-34 Sartorius

Page 35

PR 5230 Instrument Manual

3.2.8.5 Screenings

Danger!

Incorrect connection of the connecting cable screens may have consequences of severe

damage for personal and plant!

At distances >50 m the screen may only be connected at one end:

• Connect the connecting cable screen to PR 5230, see Chapter 4.2.4.

• Open the jumper J250 on the weighing electronics board, see Chapter 3.2.8.3.

• Load cells with cable screen connected to the housing and using the

junction box PR 6130/64 Sa:

• Connect the connecting cable screen, see Installation Manual.

• Open the link above the Sense terminal block on the board of the junction, see

Installation Manual.

• Load cells with cable screen connected to the housing and using the

junction box PR 6130/65 S:

• Don’t connect the connecting cable screen, see also Chapter 3.2.7.

Options

3.2.9 Repairs/Cleaning/Maintenance

Warning!

In PR 5230 with option WE1 it’s not permissible to mount/loose plug connectors or to

change fuses!

Repairs are subject to inspection and must be carried out at Sartorius. In case of defect or malfunction, please

contact your local Sartorius dealer or service center for repair. When returning the instrument for repair,

please include a precise and complete description of the problem.

Maintenance work may be carried out only by a trained technician with expert knowledge of the hazards

involved and the required precautions.

Sartorius EN-35

Page 36

Options PR 5230 Instrument Manual

3.2.10 Technical Data

Note:

Further technical data of PR 5230 see Chapter 15.

3.2.10.1 General Data

Accuracy <10000 e (Klasse III) according to OIML R76/EN 45501

Connection for the non Ex area via 4mm2 screw terminals

Connection for the Ex area via 4mm2 screw terminals

Intrinsically safe output Protection class Ex ib IIC

Potential equalization Via screw terminal PE, see Chapter 3.2.8.4

3.2.10.2 Power Connection 230 V AC

Supply voltage 100…230 V AC ±10 %

Power consumption 16 VA

Frequency 50…60 Hz ±2 Hz

3.2.10.3 Power Connection 24 V DC

Supply voltage 24 V DC ±10 %