Page 1

Pipe Lever Scale

Stainless Steel and Mild Steel Versions

Installation Manual

64506 Rev A

Page 2

Page 3

Content

Technical training seminars are available through Rice Lake Weighing Systems.

Course descriptions and dates can be viewed at www.ricelake.com/training

or obtained by calling 715-234-9171 and asking for the training department.

1.0 Introduction.................................................................................................................................. 1

1.1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2.0 Assembly Instructions ................................................................................................................. 2

3.0 Safety Chain Option Assembly Instructions ................................................................................ 5

4.0 Replacement Parts ..................................................................................................................... 6

Pipe Lever Scale Limited Warranty......................................................................................................... 8

For More Information ............................................................................................................................... 9

© Rice Lake Weighing Systems. All rights reserved. Printed in the United States of America.

Rice Lake Weighing Systems is an ISO 9001 registered company.

Specifications subject to change without notice.

May 16, 2013

Page 4

ii Pipe Lever Scale Installation Manual

Rice Lake continually offers web-based video training on a growing selection

of product-related topics at no cost. Visit www.ricelake.com/webinars.

Page 5

1.0 Introduction

Important

WARNING

WARNING

This manual is intended for use by service technicians when installing and servicing mild steel and stainless steel

pipe lever scales.

This manual includes assembly instructions and a replacement p

Authorized distributors and their employees can view or download this manual from the Rice Lake

Weighing Systems distributor site at

www.ricelake.com.

1. 1 S af et y

Safety Symbol Definitions:

Indicates a potentially hazardous situation that, if not avoided could result in serious injury or death, and

includes hazards that are exposed when guards are removed.

Indicates information about procedures that, if not obser

corruption to and loss of data.

Safety Precautions

Do not operate or work on this equipment unless you have read and understand the instructions and

warnings in this Manual. Failure to follow the instructions o

death. Contact any Rice Lake Weighing System dealer for replacement manuals. Proper care is your

responsibility.

arts list for the pipe lever scale.

ved, could result in damage to equipment or

r heed the warnings could result in injury or

General Safety

Failure to heed may result in serious injury of death.

DO NOT allow minors (children) or inexper

DO NOT operate without all shields and guards in place.

DO NOT jump on the scale.

DO NOT use for purposes other then weight taking.

DO NOT place fingers into slots or possible pinch points.

DO NOT use any load bearing component that is

DO NOT use this product if any of the

DO NOT exceed the rated load limit of the unit.

DO NOT make alterations or modifications to the unit.

DO NOT remove or obscure warning labels.

Keep hands, feet and loose clothing away from moving parts.

ienced persons to operate this unit.

worn beyond 5% of the original dimension.

components are cracked.

Introduction 1

Page 6

Load Cell

Stand

Center Connection

Shackle

Nose Iron

Main Pipe Lever

Fulcrum Stand

Loop Side Plate

Inside Pivot

Bearing

Girder Chair

Trunnion Pin

Outside Pivot

Spool

Fulcrum Stand

Bearing

Loop Assembly

Inside Pivot

Bearing

Girder Chair

Trunnion Pin

Outside Pivot

Spool

Side Plates

Drive

Screws

Fulcrum

Stand

Main

Pipe

Lever

Nose Iron

Type II

Type I

2.0 Assembly Instructions

Before installing the pipe lever scale, ensure the base on which the scale will be built is plumb and level. The base

must be a suitable, poured-concrete foundation, built according to standard construction practices. Full grouting is

recommended under the fulcrum stands.

2 Pipe Lever Scale Installation Manual

Figure 2-1. Pipe Lever Assembly

Page 7

1. Position the four fulcrum stands (Figure 2-1) on the concrete base with gussets facing outward from the

Note

Jam Nuts

Center Connection

Shackle

ITCM Hardware

Nose Irons

Load Cell Stand

Grider Chair

Bearing

Fulcrum

Stand Bearing

Outside Pivot

Inside Pivot

Spool

Trunnion Pin

Fulcrum Stand

Type II

Grider Chair

Bearing

Fulcrum

Stand Bearing

Outside Pivot

Inside Pivot

Spool

Trunnion Pin

Fulcrum Stand

Type I

Important

Important

scale. Ensure fulcrum stands are square and level with each

If mounting the scale to a frame, ensure the frame is square and all stands are positioned squarely on the

frame.

other.

2. Assemble the load cell, ITCM hardware, and center connection shackle to support the nose irons, see

Figure 2-2.

3. Temporarily secure load cell assembly with top and bottom

jam nuts on top plate of load cell stand.

Figure 2-2. Load Cell Assembly

4. Loosely bolt nose irons to ends of main pipe levers.

5. Set pipe levers in place with outside pivots

on bearings of fulcrum stands (see Figure 2-3) with nose irons

supported by center connection shackle in load cell stand.

Center load cell stand between main levers. Levers must be level when suspended by the center

connection shackle.

Figure 2-3. Fulcrum Stand Assembly

6. Locate and assemble the loop assembly spool using two bolts and two washers. Position loop assembly

under inside pivot. Attach bearing to two loop side plates using two clevis pins and two cotter pins with

loop bearing resting on inside pivot. Insert trunnion pin.

Bolt heads must face the fulcrum stands.

Assembly Instructions 3

Page 8

7. Hold trunnion pins in place on loop assemblies and set girder chairs on trunnion pins (see Figure 2-1). Tilt

Note

Important

Note

Note

Nose Iron

Nose Iron

X X

PivotPivot

chairs inward against main pipes to support

chairs until hopper or tank is added.

8. Clamp or loosely bolt hopper or tank to top plates of girder chairs.

9. Check each pivot to make sure it is contacting the bearing. Shim under the fulcrum stand or betwee

n the

girder chair base plate and the hopper or tank if necessary to obtain even pressure on all pivots.

On Type II scales, ensure levers have equal gap at both ends of each bearing in the fulcrum stand.

10. Secure fulcrum stands to concrete base.

Bolt or weld stands to frame, if used.

To prevent damage to the system, the welder must be grounded near the weld point before welding.

11. Bolt or weld girder chairs to hopper or tank.

12. Adjust nose irons in bolt slots (see Figure 2-4) so distance X from each nose iron pivot to the end of its

lever is equal.

13. Tighten nose iron bolts securely.

14. Position load cell stand over nose iron

pivots so load cell assembly hangs plumb. Anchor load cell stand to

concrete.

Bolt or weld the load cell stand to frame, if used.

15. Secure jam nuts on top of plate of load cell stand.

The scale is now fully assembled.

Figure 2-4. Nose Iron Adjustment

4 Pipe Lever Scale Installation Manual

Page 9

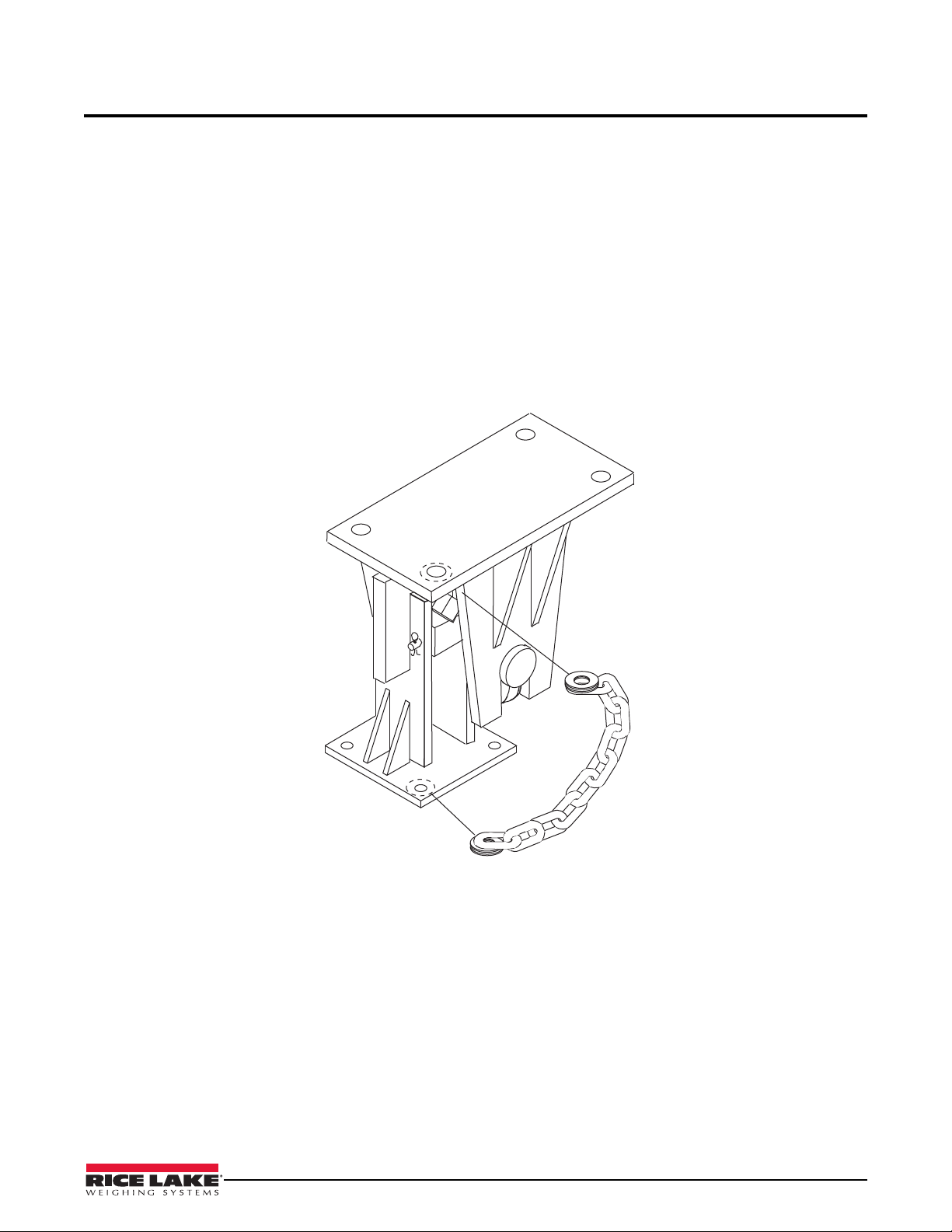

3.0 Safety Chain Option Assembly Instructions

A

B

The safety chain provides four chains and 16 washers to anchor the hopper and girder chair to the pipe lever

fulcrum stand. This helps prevent the hopper from tilting too far off the girder chair and becoming unstable. The

optional safety chain kit provides the chains and washers only. All other hardware (bolts, nuts, etc.) must be

provided by the customer. Use Figure 3-1 and the procedure below to install the chain option on your pipe lever

scale.

1. Place one chain and four washers at each of the

2. Place two stacked washers and upper end link underneath girder chair baseplate (Position A). B

washers are between girder chair baseplate and end link.

3. Secure washers and upper end link to girder cha

4. Place lower end link and two stacked washers over fulcrum

are positioned between end link and fulcrum stand baseplate.

5. Secure washers and lower end link

to fulcrum stand baseplate with customer-provided hardware.

four scale base corners.

e sure

ir baseplate with customer-provided hardware.

stand baseplate (Position B). Be sure washers

Figure 3-1. Safety Chain Option Assembly

Safety Chain Option Assembly Instructions 5

Page 10

4.0 Replacement Parts

5

11

3

6

7

8

9

10

12

2

25

23

22

25

27

26

24

28

1

4

13

14

6

17

16

18

19

20

21

22

30

36

5

10

12

4

13

14

3

37

11

8

15

6

7

Type I

Type II

29

33

31

32

34

35

32

31

9

Figure 4-1. Pipe Lever Scale Parts Illustration

6 Pipe Lever Scale Installation Manual

Page 11

Item No. Description

1 Main Pipe Lever, Left

2Main Pipe Lever, Right

16 Nose Iron, Left

17 Nose Iron, Right

18 Pivot

19 Cap Screw

20 Washer, Plain

21 Lock Nut

22 Shackle Loop, Large**

23 Shackle Support Block**

24 Shackle Loop, Small**

25 Bearing Assembly**

26 Clevis Pin**

27 Cotter Pin**

28 Machine Screw**

29 Load Cell, SBM RL 20000-3K

30 Ground Strap

31 Rod End

32 Clevis Assembly

33 Shackle Support Rod

34 Jam Nut

35 Threaded Adaptor

36 Load Cell Stand

37 Hold-down chain option

Washer, plain 3/4 Type A

Chain, 5/8 Grade 40

Table 4-1. Type I & II Pipe Lever Scale Parts List

Item No. Description

3 Girder chair

4 Bearing

5 Trunnion Pin

6Washer

7 Lock nut

8Bolt

9 Lock nut

Washer

10 Loop side plate

11 Spool

12 Bolt

Pivot

13 Fulcrum Weldment

14 Bearing

15 Drive screw

Table 4-2. Type I Pipe Lever Scale Parts List

Item No. Description

3Girder Chair

4 Bearing*

5Trunion Pin

6 Cotter Pin*

7Clevis Pin*

8 Cap Screw (Stainless Steel)

Bolt, Hex (Mild Steel)*

9Washer, Plain STD*

10 Slide Plate, Loop*

11 Spool*

12 Pivot

13 Fulcrum Stand

14 Bearing

Table 4-3. Type II Pipe Lever Scale Parts List

For Mild Steel Models

* Loop Assembly (PN CM729)

** Shackle Assembly (PN N110)

Note

Replacement Parts 7

Page 12

Pipe Lever Scale Limited Warranty

Rice Lake Weighing Systems (RLWS) warrants that all RLWS equipment and systems properly installed by a

Distributor or Original Equipment Manufacturer (OEM) will operate in accordance with written specifications as

confirmed by the Distributor/OEM and accepted by RLWS. All systems and components are warranted against

defects in materials and workmanship for two years.

RLWS warrants that the equipment sold hereunder will conform to the current written specifications authorized by

RLWS. RLWS warrants the equipment against faulty workmanship and defective materials. If any equipment fails

to conform to these warranties, RLWS will, at its option, repair or replace such goods returned within the warranty

period subject to the following conditions:

• Upon discovery by Buyer of such nonconformity, RLWS will be given prompt written notice with a

detailed explanation of the alleged deficiencies.

• Individual electronic components returned to RLWS for warranty purposes must be packaged to

prevent electrostatic discharge (ESD) damage in shipment. Packaging requirements are listed in a

publication, Protecting Your Components From Static Damage in Shipment, available from RLWS

Equipment Return Department.

• Examination of such equipment by RLWS confirms that the nonconformity actually exists, and was

not caused by accident, misuse, neglect, alteration, improper installation, improper repair or improper

testing; RLWS shall be the sole judge of all alleged non-conformities.

• Such equipment has not been modified, altered, or changed by any person other than RLWS or its duly

authorized repair agents.

• RLWS will have a reasonable time to repair or replace the defective equipment. Buyer is responsible

for shipping charges both ways.

• In no event will RLWS be responsible for travel time or on-location repairs, including assembly or

disassembly of equipment, nor will RLWS be liable for the cost of any repairs made by others.

THESE WARRANTIES EXCLUDE ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING WITHOUT

LIMITATION WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. NEITHER RLWS

NOR DISTRIBUTOR WILL, IN ANY EVENT, BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES.

RLWS AND BUYER AGREE THAT RLWS’S SOLE AND EXCLUSIVE LIABILITY HEREUNDER IS LIMITED TO REPAIR

OR REPLACEMENT OF SUCH GOODS. IN ACCEPTING THIS WARRANTY, THE BUYER WAIVES ANY AND ALL OTHER

CLAIMS TO WARRANTY.

SHOULD THE SELLER BE OTHER THAN RLWS, THE BUYER AGREES TO LOOK ONLY TO THE SELLER FOR

WARRANTY CLAIMS.

NO TERMS, CONDITIONS, UNDERSTANDING, OR AGREEMENTS PURPORTING TO MODIFY THE TERMS OF THIS

WARRANTY SHALL HAVE ANY LEGAL EFFECT UNLESS MADE IN WRITING AND SIGNED BY A CORPORATE

OFFICER OF RLWS AND THE BUYER.

© Rice Lake Weighing Systems, Inc. Rice Lake, WI USA. All Rights Reserved.

RICE LAKE WEIGHING SYSTEMS • 230 WEST COLEMAN STREET • RICE LAKE, WISCONSIN 54868 • USA

8 Pipe Lever Scale Installation Manual

Page 13

For More Information

Contact Information

Hours of Operation

Knowledgeable customer service representatives are available 6:30 a.m. - 6:30 p.m. Monday through Friday and 8

a.m. to 12 noon on Saturday. (CST)

Telephone

• Sales/Technical Support 800-472-6703

• Canadian and Mexican Customers 800-321-6703

• International 715-234-9171

Immediate/Emergency Service

For immediate assistance call toll-free 1-800-472-6703 (Canadian and Mexican customers please call

1-800-321-6703). If you are calling after standard business hours and have an urgent scale outage or emergency,

press 1 to reach on-call personnel.

Fax

Fax Number 715-234-6967

E-mail

• US sales and product information at

• prodinfo@ricelake.com

International (non-US) sales and product information at

• intlsales@ricelake.com

Mailing Address

Rice Lake Weighing Systems

230 West Coleman Street

Rice Lake, WI 54868 USA

Replacement Parts 9

Page 14

10 Pipe Lever Scale Installation Manual

Page 15

Page 16

Rice Lake Weighing Systems

May 16, 2013 PN 64506 Rev A

Loading...

Loading...