Page 1

OB-350 Indicator

print

13240lb

zero menu

net

LoadRunner® Series Onboard Weighing System

Operator’s Manual

160914

Page 2

Page 3

Contents

Technical training seminars are available through Rice Lake Weighing Systems.

Course descriptions and dates can be viewed at www.ricelake.com/training

or obtained by calling 715-234-9171 and asking for the training department.

About This Manual ................................................................................................................................... 1

1.0 Introduction..................................................................................................................................... 1

1.1 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2.0 Operation......................................................................................................................................... 2

2.1 Front Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3.0 Installation ...................................................................................................................................... 4

3.1 Mount Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.2 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.3 Electrical Wiring and Data Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.4 Cables and Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.0 Operating Modes............................................................................................................................. 7

4.1 Printing & Print Tickets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.1.1 Truck Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.1.2 Load Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.2 Load Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.2.1 Operator Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5.0 Operator Configuration and Diagnostics ........................................................................................ 9

5.1 User and Setup Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.2 Operator Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.2.1 Display Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.2.2 Diagnostics Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6.0 Technical Settings ........................................................................................................................ 12

6.1 Calibration and Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.2 System Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.2.1 Entering Pin Code (Password) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.2.2 Entering PUK Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6.3 Alarms Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6.3.1 Alarm Setpoints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6.3.2 Set Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

6.4 Options Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.4.1 Select & Change NET, GROSS OR BOTH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.4.2 Load/Channel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

6.5 RS-232 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.5.1 To Select and Change RS-232 Output Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.5.2 RS-232 Output Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.5.3 Scoreboard Format 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.5.4 Scoreboard Format 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.5.5 Scoreboard Format 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.5.6 Scoreboard Format 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.5.7 Scoreboard Format 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.5.8 Scoreboard Format 6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.5.9 Scoreboard Format 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.6 Count by option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.7 Zero Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.8 Inclinometer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.8.1 Calibrate the Inclinometer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

© Rice Lake Weighing Systems. All rights reserved. Printed in the United States of America.

Rice Lake Weighing Systems is an ISO 9001 registered company.

Specifications subject to change without notice.

Version 1.0, April 16, 2014

Contents i

Page 4

Rice Lake continually offers web-based video training on a growing selection

of product-related topics at no cost. Visit www.ricelake.com/webinars.

6.9 Configuration Menu – Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.9.1 Input Channel Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

7.0 Calibration .................................................................................................................................... 22

7.1 Calculating Tare, Gross & Net Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

7.1.1 Enter Tare Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

7.1.2 Set Zero Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7.1.3 Full Span (Net Load) Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

7.1.4 Reverse Zero/Span . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

8.0 Appendix ....................................................................................................................................... 25

8.1 Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

8.2 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

8.2.1 Fusing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

8.2.2 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

8.2.3 Visual Checks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

8.2.4 Load Cell checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Hardware Warranty Statement .............................................................................................................. 28

ii OB-350 Indicator Operator’s Manual

Page 5

About This Manual

Important

CAUTION

WARNING

DANGER

WARNING

This manual is intended for use by trained and qualified personnel for installing and servicing the OB-350 digital

weight indicators. This manual applies to indicators using version 4D-02-05 of the OB-350 software.

Manuals can be viewed and downloaded from the Rice Lake Weighing Systems website at

www.ricelake.com/manuals.

1.0 Introduction

The OB-350 Onboard indicator is for industrial road going vehicles. It has been designed to be simple to operate,

giving the driver precise weight information where and when it is needed. It incorporates a clear, easy-to-read

OLED (organic light emitting diode) display. This is the clearest display currently available.

The OB

1.1 Safety

Safety Symbol Definitions:

-350 digital weighing indicator features:

• Two input channel for separate groups of

load cells

• CANbus (control area network) input & output

• RS-232 output

• ABS injection molded housing

• Organic light emitting diode (OLED) high quality

• Four-button keypad

64 x 264 pixel (picture element) display

Indicates an imminently hazardous situation that, if not avoided, will result in death or serious injury.

Indicates a potentially hazardous situation that, if not avoided

includes hazards that are exposed when guards are removed.

Indicates a potentially hazardous situation

Indicates information about procedures that, if not obser

corruption to and loss of data.

that, if not avoided may result in minor or moderate injury.

General Safety

Do not operate or work on this equipment unless you have read and understand the instructions and

warnings in this manual. Failure to follow the instructions or heed the warnings could result in injury or

death. Contact any Rice Lake Weighing Systems dealer for replacement manuals. Proper care is your

responsibility.

Failure to heed may result in serious injury of death.

Some procedures described in this manual require wo

qualified service personnel only.

Before opening the unit, ensure the power cord

DO NOT allow minors (children) or inexper

DO NOT operate without all shields and guards in place.

DO NOT use for purposes other then weight taking.

DO NOT place fingers into slots or possible pinch points.

DO NOT use any load bearing component that is

DO NOT use this product if any of the

DO NOT exceed the rated load limit of the unit.

DO NOT make alterations or modifications to the unit.

DO NOT remove or obscure warning labels.

DO NOT use near water.

Keep hands, feet and loose clothing away from moving parts.

components are cracked.

is disconnected from the outlet.

ienced persons to operate this unit.

rk inside the indicator. These procedures are to be performed by

worn beyond 5% of the original dimension.

could result in serious injury or death, and

ved, could result in damage to equipment or

Introduction 1

Page 6

2.0 Operation

print

13240

lb

zero menu

A

B

C

D

E

F

net

The OB-350 indicator has a power button, but it can also be p ermanently po wered thro ug h th e ignition 9-30 VDC.

Turn ignition on or press the power button and the software version

welcome screen.

The vehicle’s gross weight will then di splay. Take weight readings when

An empty vehicle may drift from a true zero by a few pounds, press

vehicle is empty. For roll off and dump truck installations, raise body three to four degrees using the inclinometer

screen before zeroing or weighing.

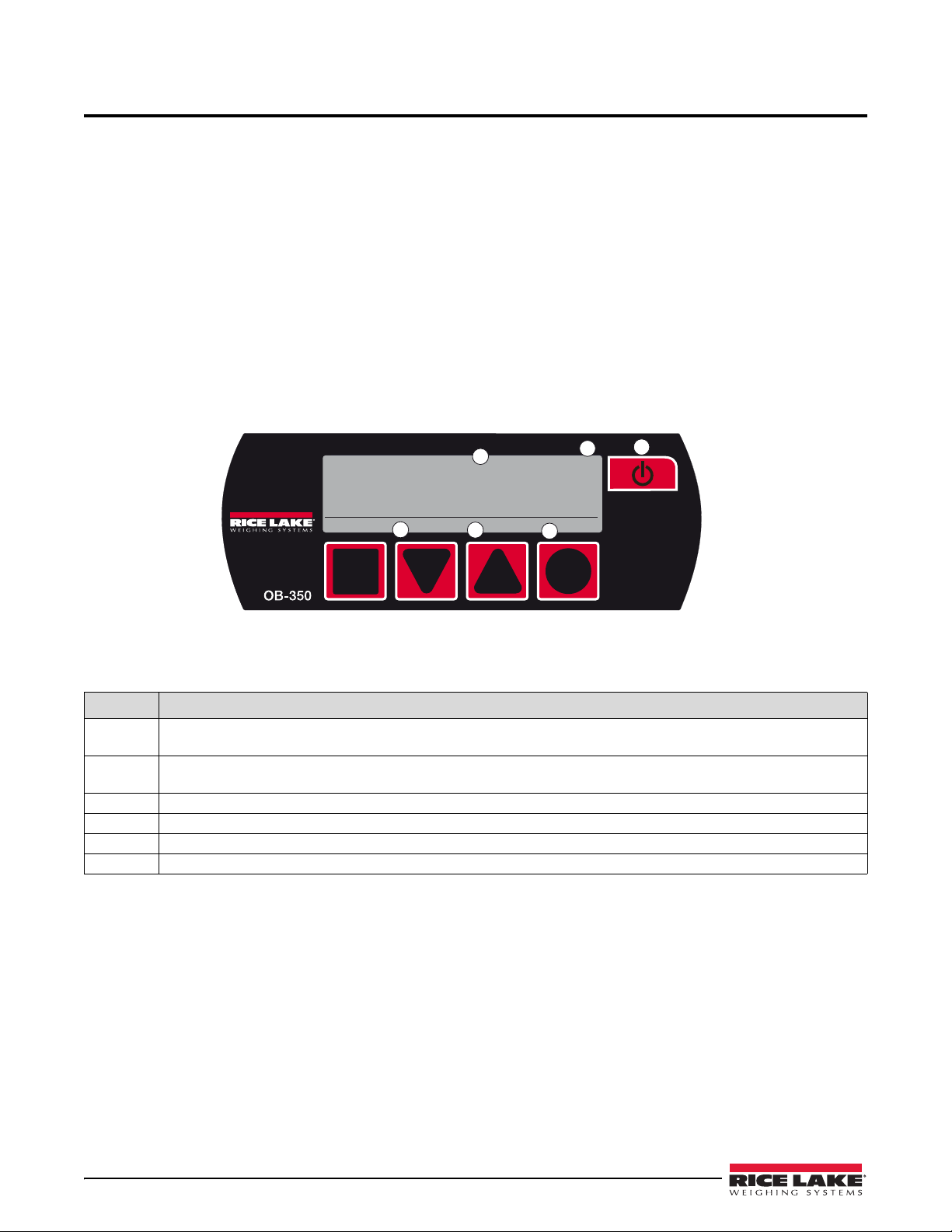

2.1 Front Panel

The four symbol keys: square, down arrow, up arrow and circle on the keypad are assigned in both operator and

setup modes, and are used to navigate through the menus as indicated by the text or symbol in the OLED display.

Weight readings are in lb.

Operator Mode

and serial number appear in the 10 second

the vehicle is static and on level ground.

ZERO to return the display to 0 lb when the

Figure 2-1. Operator Mode

Key Description

A Print key - prints net, gross, time & dat

Acts as an accumulation button

B When the vehicle is completely empty and in th

adjust the display to read ‘00000’, up to 1100 lb.

C MENU key - scrolls through’ NET, GROSS, MENU & any options activated.

D Displayed weight.

E Shows active function or weighing mode.

F Power button.

e in weighing screens when activated.

in load/deliver mode.

e weighing position, the front panel ZERO or TARE can be used to

2 OB-350 Indicator Operator’s Manual

Page 7

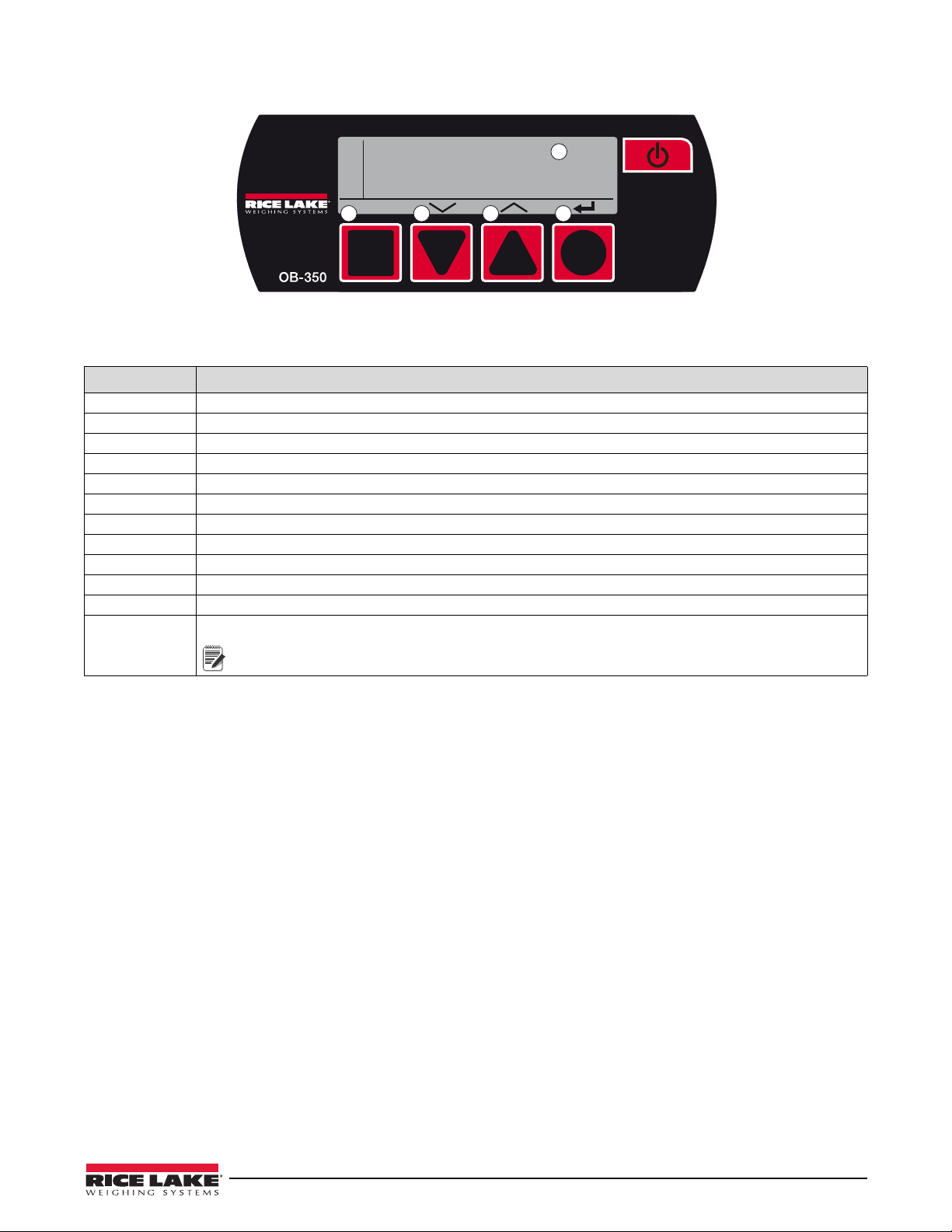

Operator Configuration and Technician Setup Menu

M

E

N

U

(OK)

Display

Diagnostics

Alarms

Options

Configuration

Calibration

System

A B C D

E

Note

Figure 2-2. Setup Mode

Key Description

A OK key - acts as enter or accept key.

B Down arrow key - scr

C Up arrow key - scrolls up menu.

D Back-up key - goes back a step (in some modes, acts as enter or accept key).

E Selectable MENU options.

Display Changes OLED contrast to high, medium or low. Also shows

Diagnostics Shows two channel weights, input mV signals & CANbus connections.

Alarms Two alarm set points - PIN code required to mute Alarm - press any key.

Options Activates options and changes settings.

Configuration Selects 1 channel, or 2 channel, air, oil or fifth wheel, split axle systems, etc.

Calibration Weighing system calibration settings, Tare, Zero & Span.

System Accesses password set and resets.

For PUK (PIN unlock code) contact RLWS service to for instructions through your PIN

retrieval.

olls down menu.

software version and serial number.

Operation 3

Page 8

3.0 Installation

Panel mount

Roof/under dash mount

Dash mount

Optional Radio DIN mount

145

18

62.5

100.5

59

90 centres

dia holes 2 places

122 centres

4 mm self taper

3.5 deep - 4 places

90

40 ctrs

44

145

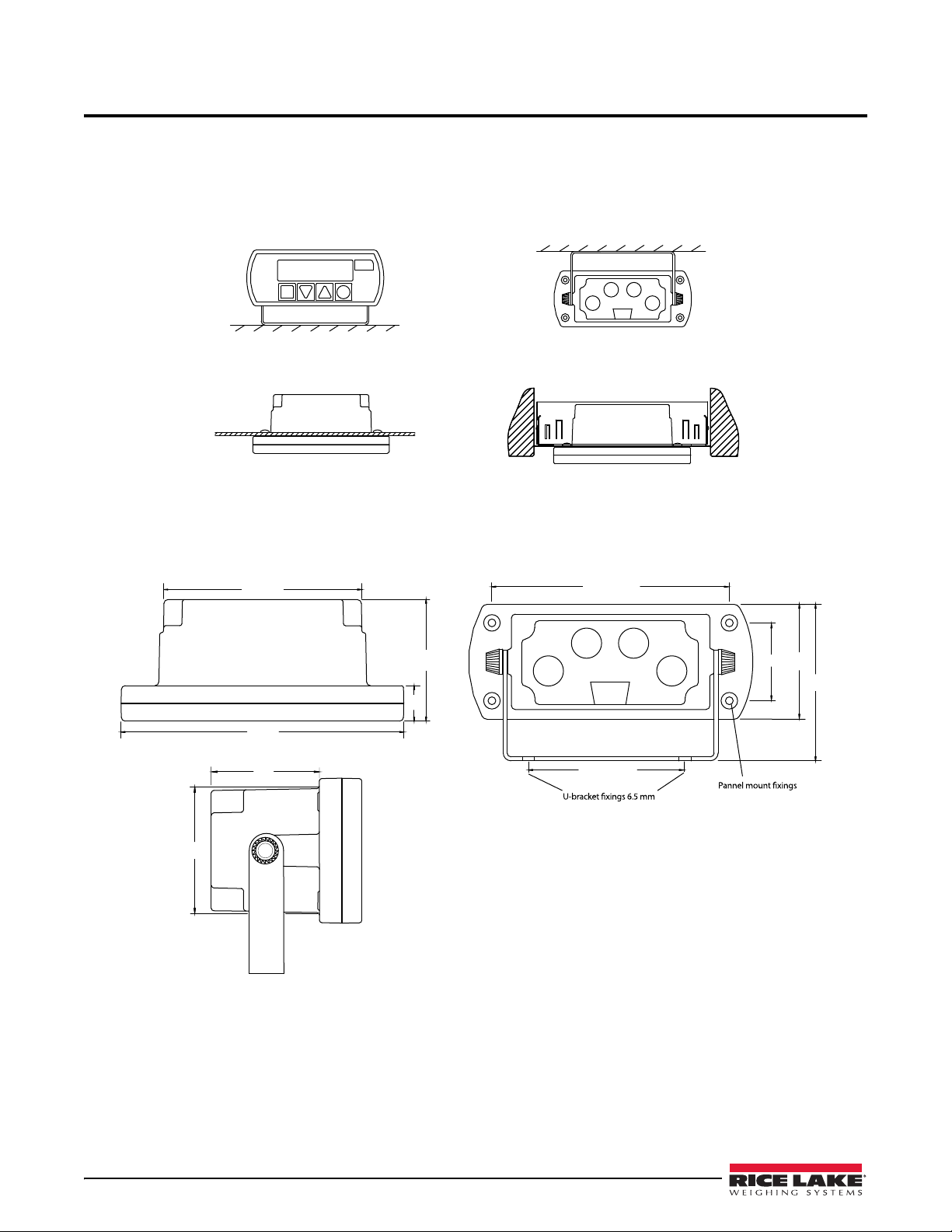

Locate the most convenient place for mounting the indicator. When atta ching the u-bracket, ensure there is

adequate headroom. The cables will be wired into the back of the indicator, so make sure to allocate enough space

for them during installation.

3.1 Mount Options

Figure 3-1. Mounting Options

3.2 Dimensions

Figure 3-2. Dimensions

4 OB-350 Operators Manual

Page 9

3.3 Electrical Wiring and Data Connections

1

3

2

4

5

6

12B1D4FB

T

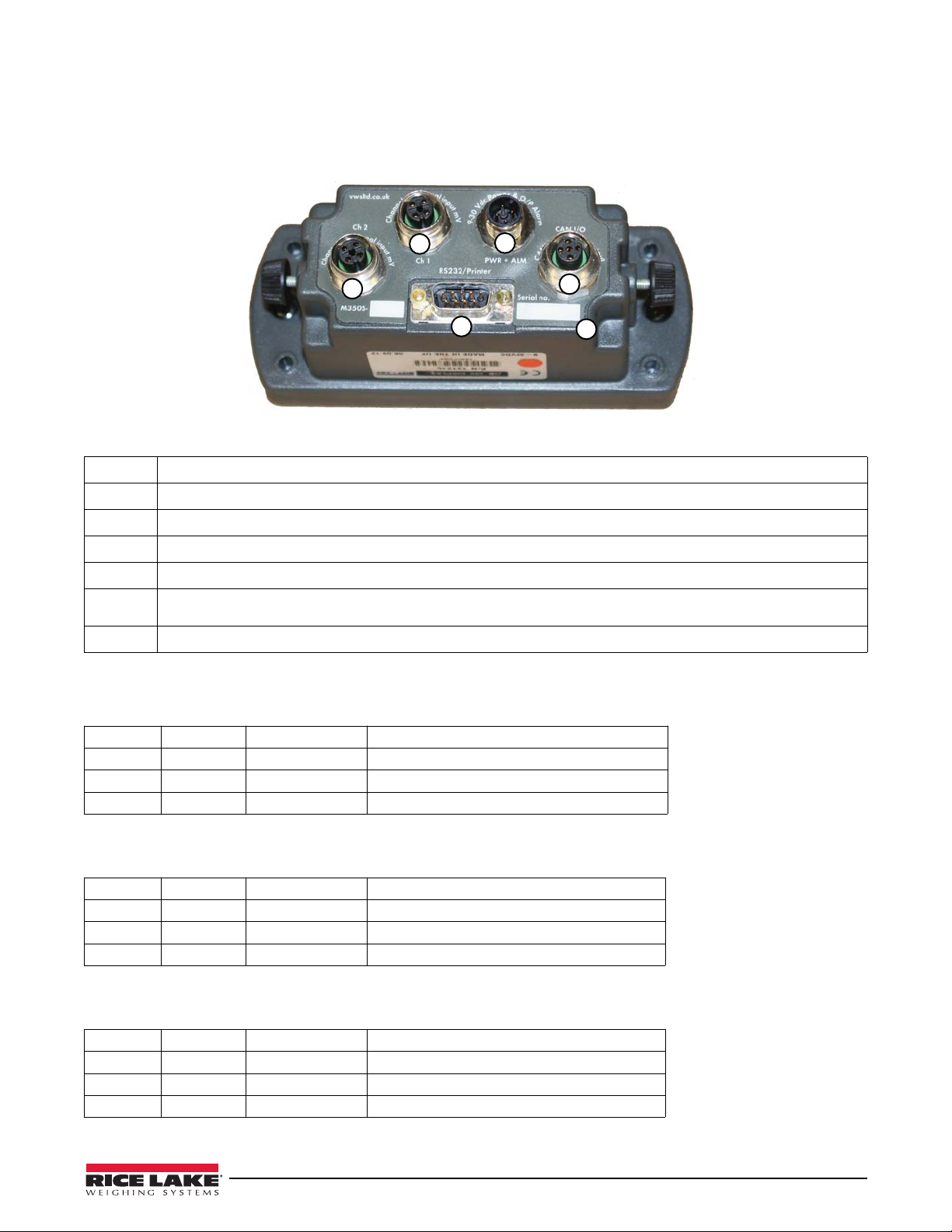

The OB-350 is fitted with one Power and one Input Channel connector as standard. CANbus, Channel 2 and RS-232 are optional.

Full connector options is shown for illustration.

Figure 3-3. Rear Panel Identification and Bulkhead Connectors

Pin Description

1 Input Channel 1, Max +/-39.0625 milli-Volts (also known as analog)

2 Input Channel 2, Max +/-39.0625 milli-Volts (also known as analog)

3 Power Input & Alarm Output

4 CANbus digital input & output

5

6

RS-232 output for printers and data captur

receive)

Alpha-numeric unique indicator serial number, also appears on power-on

e devices (pin 9 = vehicle volts, pin 5 = ground, pin = 2 transmit, pin 3 =

SIGNAL channel 1 & 2, socket is FEMALE. – CON 2 & 3 on PCB

Pin 1

Pin 2

Pin 3

Pin 4

BROWN + Excitation 5 Volts DC

WHITE + Signal milliVolts from the junction box & loadcells

BLUE - Excitation 0 Volts

BLACK - Signal milliVolts from the junction box & loadcells

POWER & ALARM, socket is MALE – CON 1 on PCB

Pin 1

Pin 2

Pin 3

Pin 4

BROWN Vehicle voltage Supply 12V (LCV) or 24V (MCV & HGV)

WHITE Output 1 12V or 24V

BLUE Ground Ground 0 Volts (common)

BLACK Output 2 12V or 24V

CANbus input and output, plug is MALE – CON 5 on PCB

Pin 1

Pin 2

Pin 3

Pin 4

BROWN +24V +24 Volts DC Power Input

WHITE GND CAN bus LOW Output

BLUE CANH 0 Volts Ground

BLACK CANL CAN bus HIGH Output

Installation 5

Page 10

3.4 Cables and Connectors

FEMALE moulded plug

POWER & ALARM

supplied as standard

MALE moulded plug

SIGNAL & CANbus

supplied as standard

MALE rewirable plug

SIGNAL

part no CBL0038

FEMALE rewirable plug

POWER + ALARM

part no CBL0039

Junction boxes

have FEMALE

signal sockets &

MALE indicator

cable socket

LoadRunner connectors have keyways and are gendered and thumb tightened for ease of use. System kits are

supplied with fully molded connectors. Rewirable plugs are available for replacements or repairs. The RS-232

connector is industry standard. This manual also shows interchangeable rewirable plugs.

Figure 3-4. Connectors

RLWS cables and connectors are specially designed to provide maximum signal strength and reliability.

Substitution of cabling other than RL WS supplied cabling may cause inconsistent and erratic readings. Care should

be taken when routing cables to provide protection from sharp edges, drive-line rotation, exha ust pipe, or any o ther

potential damage. Secure in place with cable ties to a snug fit. Locate the junction box mid-chassis at a suitable

accessible position and fix firmly with screws supplied.

6 OB-350 Operators Manual

Page 11

4.0 Operating Modes

4.1 Printing & Print Tickets

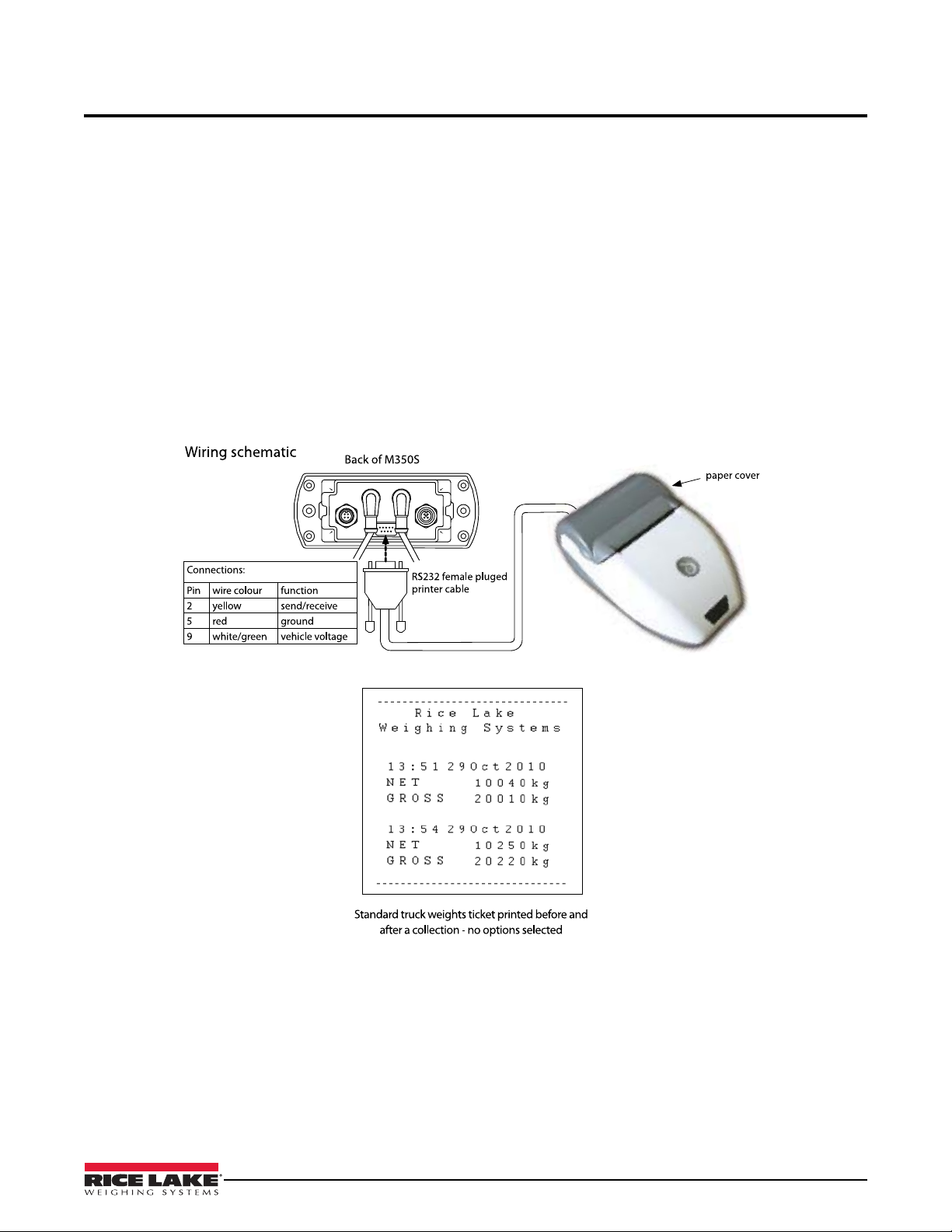

Ensure the RS-232 option is set to PRINTER and a printer is connected with the cable supplied. The printer is

powered through the RS-232 connector and uses a default baud rate of 9600. There are three print tickets available:

4.1.1 Truck Weights

Press print.

Net, gross, time and date is printed

4.1.2 Load Mode

Press print in load mode.

Time & date together with individual and total bin collections from a site and truck information is printed.

This mode can also be used with the additional keyboard to enter an account number for the site.

Figure 4-1. Wiring Schematic

Operating Modes 7

Page 12

4.2 Load Mode

Note

Note

4.2.1 Operator Instructions

Load/Deliver Function

With the load/deliver function turned on, the driver has acce ss to the load/deliver and total screen. This function

allows tracking of the print and accumulate transactions for a load (increase in weight) or delivery (decrease in

weight).

The OB-350 is designed to only accumulate a positive value, either load or delivery.

1. To activate, while in the load/deliver screen, select the ON Site key.

The function keys perform the following:

• Off – turns off load/deliver accumulation mode

• Print – accumulates displayed weight in total value, prints t

• Zero – allows the display to be zeroed.

Total Driver Display

With the load/deliver function on, the total display will continue to accumulate the weight value. To clear the total

weight value, press the zero key.

Zeroing the total display will not affect the load/delivery accumulation window.

and clears the totals accumulation.

icket if printer is attached.

8 OB-350 Operators Manual

Page 13

5.0 Operator Configuration and Diagnostics

Note

OptionsAlarms

Alarm 1

Alarm 2

Cells

CAN

Diagnostics

Menu

OLED

Info

Display

Split

Input 2

Input 1

Configuration

Span

Zero

Tare

Calibration

Modes

RS-232

PRINTER

Count

1 lb

10 lb

20 lb

50 lb

100 lb

200 lb

INC

ON

OFF

System

PUK

Pin

Clock

Net

Gross

Net & Gross

ON

OFF

Chan

Load

Z/Func

Keyboard

Inhibit

Keyboard

Printer

Printer CSV Data

Printer G PVWS

None

Format 1-4

Scoreboard

Net 4

Gross 4-5

G PVWS

BA4840

5.1 User and Setup Menu

The menu structure has two levels of security: an open user menu for driver operators and a password setup menu

for calibrations and options for making changes to the user menu.

The default password is 0350. Keep this for your records.

User and Setup Menu

Parameter Choices

Display OLED

Diagnostics Cells

Alarms Alarm 1

Figure 5-1. User and Setup Menu – Electrical Wiring and Data Connections

Info

CAN

Alarm 2

Adjust the brightness of the display; High, Med or Low.

Firmware version and serial number display.

To display mV/V for load cells or transducers on seperate channels.

To display CANbus diagnostics (not used).

Allows configuration of audible alarms.

Description

Operator Configuration and Diagnostics 9

Page 14

User and Setup Menu

Parameter Choices

Description

Options Modes Select weighing mode to be displayed - Net. Gross or Net & Gross.

Load/Chan Load function gives the option to accumulate the amount of load (weight) delivered or

collected from site.

Channel Function - Split screen function is added to the MENU screen (for semi trucks only).

RS-232 Select or change RS-232 output option.

Count Select count by in lb - 1, 2, 5, 10, 20, 50, 100, 200,

Z/Func Allows operator access to Zero/Tare function on the display.

Inc For use with roll off systems and dump trucks, turn on to calibrate zero degrees of

inclinometer.

Configuration Input 1(F)

Input 2 (R)

Split

CAN

Calibration Ta re

Zero

Span

System Pin

PUK

Clock

Air/Oil pressure transducer or load cell setting based on truck type.

Air/Oil pressure transducer or load cell setting based on truck type.

Setting varies depending on input 1/input 2 values.

Not Used

Entry of empty vehicle weight for gross weight calculation.

No load zero calibration.

Entry of load for span calibration.

Enter a password.

Not Used.

Change system time and date.

10 OB-350 Operators Manual

Page 15

5.2 Operator Settings

lb

Milli-Volt readings will differ according to the combined tare (empty)

weight and any payload in the body. Load cells should only be checked

when the vehicle is unloaded. Max input reading is 39.625 milli-Volt, this

is approx 10 times more than would be expected.

Note

5.2.1 Display Menu

To change the display contrast

1. In MENU, select Display.

2. Press (OK).

3. Select OLED.

4. Press

5. Press toggle between:

6. Press to confirm setting.

To display version and serial number

1. In MENU, select Display.

2. Press (OK).

3. Select

4. Press

5. Firmware version and serial number displays.

6. Press

(OK).

High

Medium

Low.

Info.

(OK)

twice to return to MENU

5.2.2 Diagnostics Menu

To Display Load Cell Diagnostics

1. In MENU, select Diagnostics.

2. Press (OK).

3. Select Cells.

4. Press (OK).

5. Ch a n n e l 1 & 2 weight and input mill-Volt readings are dis pl ay ed . Channel

1 only is the most common setup.

6. Press

To Display CAN Diagnostics

Not currently available.

twice to return to MENU.

Operator Configuration and Diagnostics 11

Page 16

6.0 Technical Settings

Symbols

Keys

Password or PIN is needed for every calibration & calibration change.

PIN codes can be reset to a new code of your choice, select Reset and

repeat steps. This is not recommended, loss of custom password will

require serial number of unit and may take up to 48 hours to process the

code.

Note

Important

6.1 Calibration and Setup

To allow for on-vehicle installation variations, an initial and periodic system calibration is required. The first

calibration should take place a couple of weeks after the onboard weighing system has been used in service.

(OK)

When selecting symbol, press the corresponding key below the symbol.

6.2 System Menu

6.2.1 Entering Pin Code (Password)

1. In MENU screen, select System.

2. Press

3. Press to select Pin.

4. Press

5. Enter default password 0350.

6. Press

7. Press

8. Press

9. To Set PIN, select PIN, press

(OK).

(OK) to display PIN input screen.

• Press

• Press

or to number 0-9.

to move cursor left.

to enter code.

(OK) to accept the password.

to back up to MENU.

(OK) and repeat 2 - 6.

6.2.2 Entering PUK Code

For use if a custom password is used, which is not recommended.

1. In SYSTEM screen, select PUK.

2. Press

3. Call RLWS at 800-472-6703 and give

4. Press

5. Press

6. When PIN is entered press

12 OB-350 Operators Manual

(OK). PUK code enter screen and unique PIN reset code is

displayed.

the unique five-digit number

disp layed. RLWS wi l l prov ide a NEW four digit PIN code.

or to number 0-9.

to move cursor left.

to enter code.

Page 17

6.3 Alarms Menu

lb

lb

lb

lb

lb

lb

lb

lb

lb

lb

lb

lb

lb

lb

lb

6.3.1 Alarm Setpoints

Allows configuration of the audible alarm.

Parameter Choices Description

Alarm Alarm ON Tur n s a l arm o n .

Alarm OFF Turns alarm off.

Output Output Normal +12 VDC to power and alarm on power connector.

Output Invert -12 VDC to power and alarm

Gross Gross PPCO Not used (custom packer-pla

Net Sounder Alarm will display speaker and beep when net weight

eaches Alm value entered.

r

Net PPCO Not used (custom packer-pla

Inc Sounder For use with inclinometers onl

angle reaches above incline (inclinometer setting) in

degrees.

Inc PPCO Not used (custom packer-pla

Gross Sounder Alarm will display spea

reaches Alm value entered.

Alm Alarm Weight

lu e

Va

Hys Hysteresis Value Not currently available.

Tri gg er Off

On 2,5,10 seconds – selectable delay prior to alarm

Edit value of the net or gross weight for alarm.

ctivating in seconds.

a

Table 6-1. Alarm Setpoints Menu

on power connector.

te configuration only).

te configuration only).

y – activates alarm when

te configuration only).

ker and beep when gross weight

6.3.2 Set Alarm

1. In MENU, select Alarms.

2. Press

3. Two setpoints appear. Select Alarm 1.

4. Pressing

5. Pressing

6. Pressing

Gross-PPCO or Net-PPCO.

7. Select

weight displayed. To change target weight, press

setpoint using techniques in previous steps.

8. Select

9. Select

10. When all settings are correct, press

11. For alarm 2, select

(OK)

(OK) toggles between ON and OFF. Select ON.

(OK) toggles between Output Normal and Output Invert.

(OK) toggles between Gross-Sounder, Net-Sounder,

Alm. The alarm (sounder or flashing beacon) will activate at

HYS, reset tolerance is edited in lb using techniques in previous steps.

Trigger, then press (OK) to toggle between: OFF, 2, 5 or 10 seconds.

Alarm 2 and repeat steps 7-10.

edit and set the alarm

(OK) to confirm.

Technical Settings 13

Page 18

6.4 Options Menu

lb

lb

6.4.1 Select & Change NET, GROSS OR BOTH

Configuration of this setting will turn on visible weight screens in the standard

operator mode. Use the menu key to scroll between settings.

1. In MENU, select

2. Press

(OK).

3. In OPTIONS menu, select Modes.

4. Press

(OK).

5. In MODES menu, press to toggle between:

NET & GROSS

GROSS

NET

NET & GROSS is the common option.

6. Press

to confirm setting.

6.4.2 Load/Channel

The load option allows the load/deliver function to be turned ON and OFF.

When turned on, the load/deliver screen and totals

mode.

Options.

screen will be available to the driver during normal operating

Parameter Choices Description

Load Load On Activate the load/delivery function

Chan On For Semi-Trucks only, currently not used.

Load and Chan On For Semi-Trucks only, currently not used.

Load and Chan Off Deactivate the load/delivery function

Table 6-2. Load Menu

Turn Load Option ON and OFF

1. In MENU, select Options.

2. Press

(OK).

3. In OPTIONS menu, select Load.

4. Press (OK).

5. In LOAD option press to toggle between settings.

on the driver display.

on the driver display.

14 OB-350 Operators Manual

Page 19

6.5 RS-232

lb

6.5.1 To Select and Change RS-232 Output Options

1. In MENU, select Options.

2. Press

3. In OPTIONS menu, select RS232 and press (OK).

4. Press toggle between:

(OK).

Printer - printer setup (standard printer setting)

Printer CSV (comma, space, value) Data

Printer GPVWS (not used)

None

Scoreboard Format 1 (remote display)

Scoreboard Format 2 (not used)

Scoreboard Format 3

Scoreboard Format 4 NET (not used)

Scoreboard Format 4 GROSS (not used)

Scoreboard Format 5

Scoreboard Format 6 GPVWS (not used)

Scoreboard Format 7 BA484D (not used)

5. Press to confirm setting.

6.5.2 RS-232 Output Options

• OB-350 Scoreboard Output

• Baud Rate is fixed at 9600,n,8,1

• Data is sent out every 1 second (formats 1, 3 & 4)

• RS-232 - 9 Way ‘D’ Male Plug

Pin Function Notes

1 -

2 Tx

3 Rx

4 -

5 Gnd 0V Ground

6 -

7 -

8 -

9 +24V Vehicle Supply

Transm i t F r o m

Receive into

OB-350

OB-350 (not used)

Technical Settings 15

Page 20

6.5.3 Scoreboard Format 1

ASCII = Character code set 0-127

click: danshort.com/

ASCIImap/

CR = Carriage Return

LF = Line Feed

STX = Start of the text

STA = Status

SGN = milli-Volt load cell Signal

ETX = End of text

U/S = Unspecified

CNT = Count

CHK = Checksum

Tx = Transmit

Rx = Receive

Note

Used for remote displays.

Data output is the NET weight in ASCII + CR and LF

Example

NET 2160 kg

NET 2200 kg

NET 2200 kg

NET 2180 kg

NET 2180 kg

NET 2180 kg

NET 2180 kg

6.5.4 Scoreboard Format 2

Requesting Device sends ASCII command:

“20050026:<CRLF>”

M350S replies

“9F050026: 15.71 t G <CRLF>”

Example:

“9F050026: 15.71 t G <CRLF>”39 46 30 35 30 30 32 36 3A 20 20 31 35 2E

37 31 20 74 20 47 0D 0A

6.5.5 Scoreboard Format 3

Data is output in the following format:

<STX(1)> <STA(1)> <SGN(1)> <PAYLOAD(7)> <UNITS(3)> <ETX(1)>

STX = 0x02 Start of text

STA = “N” Status - N represents NET weight

SGN = 0x20 or “-” Sign – space = pos, minus sign = negative

PAYLOAD Weight – next 7 characters are weight in ASCII

UNITS = “ kg” Units

ETX = 0x03 End of text

Example:

16 OB-350 Operators Manual

(Net weight 15000 kg) 02 4E 20 20 20 31 35 30 30 30 20 6B 67 03

(Net weight 5045 kg) 02 4E 20 20 20 20 35 30 34 35 20 6B 67 03

Page 21

6.5.6 Scoreboard Format 4

(NET / GROSS)

Data is output in the following format:

<STX(1)> <U/S(3)> <CNT(1)> <U/S(5)> <PAYLOAD(3)> <CHK(1)>

STX = 0x01 Start of text

U/S = (3 bytes) Unspecified – 3 bytes do not use

CNT = hex val Count – Incremental message count, from 0x00 to 0xFF hex

U/S = (5 bytes) Unspecified – 5 bytes do not use

PAYL O A D = (3 bytes) Weight – 3 characters of weight value in hex (note1)

CHK = hex val Checksum – longitudinal checksum value not including STX

Example:

Messages with weight 18520 kg (0x004858)

Select the weight value either NET or GROSS in the M350S set-up.

01 00 0A 81 BE 01 01 00 01 00 00 48 58 EC

01 00 0A 81 BF 01 01 00 01 00 00 48 58 ED

01 00 0A 81 C0 01 01 00 01 00 00 48 58 EE

01 00 0A 81 C1 01 01 00 01 00 00 48 58 EF

6.5.7 Scoreboard Format 5

Data is output in the following format:

<STX(1)> <SGN(1)> <PAYLOAD(7)> <STA(1)> <ETX(1)>

STX = 0x02 Start of text

SGN = 0x20 or “-“ Sign – space = pos, minus sign = negative

PAYLOAD Weight – next 7 characters are weight in ASCII

STA = “N” Status - N represents NET weight

ETX = 0x03 End of text

Example:

(Net weight 1 5000 kg) 02 20 20 20 31 35 30 30 30 4E 03

(Net weight 5045 kg) 02 20 20 20 20 35 30 34 35 4E 03

Technical Settings 17

Page 22

6.5.8 Scoreboard Format 6

Data is output in the following format every 60 seconds:

$GPVWS,<type>,<sgn>,<net>,<gvw>,<alarm1>,<alarm2>,<set1>,<set2>,HHMMSS,DDMTYY*XX

type = 01 Unit type 01 = M350S under body weigher: LOADWEIGH

sgn = “+” or “-“ Sign of Net – plus sign = positive, minus sign = negative

net Net weight – 5 characters

gvw Gross Vehicle Weight – 5 characters

alarm1 Alarm 1 set point – 5 characters

alarm2 Alarm 2 set point – 5 characters

Set 1 N = Net, G = Gross: S = Sounder, P = PPCO: 0 = not Activated, 1 = Activated

Set 2 N = Net, G = Gross: S = Sounder, P = PPCO: 0 = not Activated, 1 = Activated

HHMMSS Hours, Minutes and Seconds

DDMTYY Day, Month and Year

*XX Checksum

Example:

Net = 15000kg, gvw = 25000kg, alarm 1 Net sounder at 15500kg, alarm 2 Gross PPCO at 26000kg

$GPVWS,01,+,15000,25000,15500,26000,NS0,GP0,164100,280210*XX

Net = 15900kg, gvw = 25900kg, alarm 1 Net sounder activated at 15500kg, alarm 2 Gross PPCO at

26000kg $GPVWS,01,+,15900,25900,15500,26000,NS1,GP0,164200,280210*XX

6.5.9 Scoreboard Format 7

Data is output in the following format for interface with a BA484D Serial Display:

<CVn,string> Cyclic Variable

Parameters

n = 1 or 2 Input Variable number, where 1 = net & 2 = gross, string = any 7-bit numeric ASCII string

The <CV> Cyclic Variable is used to update the BA484D display with each variable indi vidually by sending the

numeric value as a simple ASCII string. The syntax is <CVn,string> where n represents the input variable to be

updated (= 1 or 2) and string is the numeric value to be displayed.

Example:

The command <CV1,123456.0> will set the input variable 1 (net) to a value of “123456.”

18 OB-350 Operators Manual

Page 23

6.6 Count by option

lb

lb

Note

lb

1. In MENU, select Options.

2. Press

(OK).

3. In OPTIONS menu, select Count

4. Press (OK).

5. Press to toggle between:

1 lb, 2 lb, 5 lb, 10 lb, 20 lb, 50 lb, 100 lb, 200 lb

6. Press to confirm setting.

Rice Lake Weighing Systems recommends using 50 lb minimum. Choosing a lower weight value may cause

your weight to fluctuate on the display and returning t

o zero may be difficult.

6.7 Zero Function

Allows the Zero key to be turned on or off when in normal weighing mode.

Parameter Choices Description

Z/Func Allow Keypad Zero Activate container tare (Gross Mode) or Zer

on main menu to allow operator to zero up to 1100 lb of weight.

Inhibit Zero Deactivate operator zero functionality.

Figure 6-1. Zero Function Menu

o (Net Mode) button

Turn Z/Func On and Off

1. In MENU, select Options.

2. Press (OK).

3. In OPTIONS menu, select Z/Func.

4. Press

(OK).

5. Press to select Z/Func setting.

6. Press

to confirm setting.

7. Zero is added to the MENU screen.

Technical Settings 19

Page 24

6.8 Inclinometer

lb

On dump trucks and roll off applications, the LoadRunner system uses load

pins and a hydraulic pressure transducer to determine a weight value. To

achieve the best accuracy, calibrate the system at the same incline that will be

used for determining the weight value, within ±1-2 degrees.

The inclinometer setup screen shows both

and absolute angle (abs 0.0). For this application, use the level indicators that

light up for every degree the body is raised.

The numeric value will indicate a negative value as the body is raise

normal. The level to the right will light up one circle at a time.

The inclinometer function allows visual determinatio

achieves to accurately weigh consistently.

6.8.1 Calibrate the Inclinometer

1. Ensure the truck is on a level surface and the body is in the down

position.

2. In MENU, select

3. Press

(OK).

4. In OPTIONS menu, select Inc.

5. Press (OK).

6. Press to select On.

7. Press

8. Press

9. Press

CAL to calibrate the inclinometer.

(OK) to confirm inclinometer zero.

to return to options menu.

Inclinometer screen will be added to the MENU options.

Options.

the body angle in a numeric value

d. This is

n of the height the body

20 OB-350 Operators Manual

Page 25

6.9 Configuration Menu – Input

Input one is channel 1.

Note

Transducers are load cells, oil & air pressure sensors, etc.

Note

The Input Channel configuration determines what type of truck the LoadRunner system is being installed on. Use

the following settings and instructions for each type of truck used. Configuring the system differently will affect

how the unit performs. The input channel referenced also references the connection on the back of the indicator.

Roll Off/Dump Truck Configuration Settings

Parameter Choices Description

Input 1 (F) Air/Oil Transducer Air or Hydraulic Pressure Transducer

Input 1 (R) Cell x 4 Load Cells

Split Channel 2 fix

Straight Truck Configuration Settings

Parameter Choices Description

Input 1 (F) Air/Oil Transducer Air or Hydraulic Pressure Transducer

Input 1 (R) Cell x 4 Load Cells

Split Single Channel Cal

6.9.1 Input Channel Configuration

1. In MENU, select Configuration.

2. Press

3. In CONFIGURATION, select

4. Press (OK).

(OK).

Input 1.

5. Warning message appears, press (OK) to continue.

6.

Press to select transducer type.

7. Press to confirm setting.

8. If Input Channel 2 is connected, select

Activating Input Channel 2 changes

Split to Dual.

Input 2 and repeat 4-7.

Definitions

•Input and Channel are used interchangeably.

•Transducers = load cells, oil & air pressure sensors,

•Split: single = One input channel, all transducers connected into

•Split: dual = Separate input channels, i.e. front

•Dual = Input channels 1 & 2 added together

fifth-wheel load cells, etc.

one junction box (in parallel)

and rear transducer sets are connected into the M350S

, the total weight of channel 1 & 2 will be displayed. Most VWS

load cells can be connected together in parallel as the milli-Volts signals are compatible. VWS load cells, oil

& air pressure transducers and fifth wheel load cells have different milli-Volt outputs and cannot be connected

into one junction box (with the exception of CANbus enabled sensors).

•Twin = Input channels 1 & 2 are displayed separately (e.g. the front a

nd rear of a vehicle). Separate calibrations

are required which require weighing the front and rear axle/s separately and entering the data.

Technical Settings 21

Page 26

7.0 Calibration

Truck Scale

Note

lb

22000

lb

lb

lb

lb

Drive empty truck onto the scale to determine empty weight. Perform span calibration.

For span calibration, use 3/4 of the full body load.

7.1 Calculating Tare, Gross & Net Weights

1. To determine actual TARE weight, run the empty vehicle onto a truck scale and note the total weight.

Figure 7-1. Vehicle on Truck Scale

2. Load the vehicle as close to its legal maximum as possible.

3. Weigh the Loaded Gross vehicle – run the vehicle across

weight.

4. Calculate NET weight using: Gross - Tare = Net.

5. Use the NET weight as the span weight

during the calibration procedure.

the same truck scale and record the Gross vehicle

7.1.1 Enter Tare Weight

1. Ensure vehicle is empty, then weigh and record TARE (empty

vehicle).

2. In MENU screen, select

3. Select

Tare.

4. Press (OK) (defaults to 22,000 lb).

5. Press

edit.

6. Enter vehicle TARE (empty) weight recorded in step 1.

7. Press

8.

Press again to return to MENU screen.

.

Calibration press (OK).

22 OB-350 Operators Manual

Page 27

7.1.2 Set Zero Calibration

lb

lb

lb

lb

lb

lb

lb

lb

62000

lb

Reverse ZERO/ SPAN (For Straight Trucks Only)

The reverse zero/span option allows the weighing system to be first

calibrated when the truck is full (swapping step 3 & 4), discharging its

load then performing calibration zero. You must be in single channel

mode: Ch1 only. See Section 7.1.4.

Note

1. Make sure the vehicle is empty and on level ground.

For dump trucks and roll off trucks, raise the body clear of the chassis

approximately three

2. In CAL menu, press

3. Press

4. Press

5. Press

6. Press

(OK).

cal.

(OK) to Confirm Ch 1 Zero.

to return to CAL menu.

to four degrees.

to select Zero.

7.1.3 Full Span (Net Load) Calibration

1. Load vehicle to its legal max and record GROSS weight.

2. Weigh and record the TARE (empty) vehicle.

3. Subtract the TARE (or KERB) weight from the GROSS weig ht t o giv e

the

SPAN (NET) weight.

31900 -12500 =19400 lb SPAN (NET) PAYLOAD

4. In CAL menu, press

5. Press

6. Press

7. Edit the SPAN (NET) weight, as in steps 1 & 2 above.

8. Press

9. Press

10. Pres s

11. Press

If the vehicle is a tipper, raise the body clear of the chassis.

to Span.

(OK) (defaults to 62,000 lb).

edit.

when done.

cal.

(OK) to Confirm Ch 1 Span cal.

twice to return to MENU screen.

Calibration 23

Page 28

7.1.4 Reverse Zero/Span

lb

lb

lb

62000

Z

S

Reverse Zero/Span is an alternative to Full Span Calibration. The reverse zero/

span is used to perform a simultaneous zero and span calibration with the

vehicle fully loaded. Y ou must be in single channel mode, ch1only.

1. Weigh and record the vehicle fully loaded.

2. Do a normal span cal 1 (actual span figures not important). See

Section 7.1.2

3. Empty the vehicle, weigh and record the TARE weight.

4. In SPAN menu, check and edit the SPAN figure if required bu t do

not pres

5. In CAL menu, press

s ‘cal’.

to select Zero.

6. Press

corner of display.

7. Press

8. Press

cal.

(OK) to confirm channel 1 Zero CAL.

9. Press

to activate zero/span. Reverse span figure shown top-right

to return to CAL menu.

24 OB-350 Operators Manual

Page 29

8.0 Appendix

8.1 Terms

The following abbreviations, phrases and terms used in this manual are widely used in the truck weighing industry.

ALARM An alarm sounder or flashing beacon (where fitted) will activate when

alarm set point is reached.

BOGY Refers to a group of axles fixed close to each other, also known as dual or tri-axles.

CHANNEL Is the Input Channel.

DUAL Input channels 1 & 2 added together, the total weight of channel 1 & 2 will be

displayed. Most RLWS load cells can be connected together in parallel as the milli-

volts signals are compatible. Load cells, oil & air pressure transducers and

fifth wheel load cells have different millivolt outputs and cannot be connected

into one junction box (with the exception of CANbus enabled sensors).

GROSS GVW or GMW (gross vehicle weight or gross mass weight) is the total truck

weight (NET + TARE).

HYS Hysteresis - gives the option to activate the alarm in a window range above

and below the alarm set point (an alarm reset tolerance).

INPUT The input channel load cell groups are connected to the INPUT.

LOAD Part load collected or delivered – press PRINT to print and zero the load,

weight collected is stored as an accumulation to NET & GROSS.

NET The payload weight in the truck body.

ON SITE When Load is turned ON in options, on site allows logging onto site and

off site for weighing loads collected from a site with multiple bins (waste only).

OUTPUT No rmal = +12 VDC to power and alarm, Output invert = -12 vdc to deactivate

(a packer plate).

PIN Personal Identification Number – password.

PPCO Packer-plate cut-off, refuse trucks only.

PUK Pin Unlock Code.

SPAN The NET weight used to calibrate the scale. It is the difference between

the tare (curb or empty weight) and the gross weight.

SPLIT DUAL Separate input channels, i.e. front and rear transducer sets are connected.

SPLIT SINGLE One input channel, all transducers connected into one junction box (in parallel).

TARE Means the weight of the empty (no load) vehicle.

TRIGGER This is a selectable time delay prior to alarm activation.

TRANSDUCER Load cells, oil & air pressure sensors, fifth wheel load cells etc.

TWIN Input channels 1 & 2 are displayed separately (e.g. the front and rear of a vehicle).

Separate calibrations are required which require weighing the front and rear axle/s

separately and entering the data.

ZERO Zero Functionality:

• No load zero, any minor discrepancies (+/-1100 lb) because the truck body has

‘normalized’, e.g. stresses and strains incumbent in the mechanical construction of the

truck has weakened and dissipated.

• Driver zero allows the driver to zero the weight taken from a site to allow the next site’s

printed ticket to show as a separate set of weighting transactions.

Appendix 25

Page 30

8.2 Troubleshooting

Note

8.2.1 Fusing

The OB-350 is fitted with a self-resetting thermal fuse. In the event of a fault or an electrical surge, the thermal fuse

will activate and cut power. The fuse will reactivate after a few seconds, once the fault has been removed. Trip

current is 300 mV or greater than 30 VDC.

Perform the following simple checks to

1. If the readings are incorrect, but consistency is high or low

2. If the weight values are erratic, check the power supply

replace the indicator.

3. If the indicator is found to be defective, remove

problem has not been isolated, continue with the troubleshoot procedures.

Recalibration at this stage could complicate the problem. However, once the problem has been identified and

corrected, it would be advisable to refer again to Section 7.0 for calibration details.

8.2.2 Diagnostics

The diagnostic tool displays the electronic signals coming in from load cells, sensors or CANbus enabled devices.

Values shown will vary according to tare weights, any load in the body of the vehicle and mechanical installation

integrity. Look for consistency, positive values, and pairs of cells showing similar or dissimilar readings. Typical

millivolts readings may range from 1 to 8 mV, (no load to full load).

8.2.3 Visual Checks

If no indicator defects can be found, the fault may be in the cables or lo ad cells. A v is ua l in sp ec ti on o f ca bl es f or

damage or chafing, crushing. Make sure the cables connections are secure and thumb tightened. Make sure

exposed connections are clean and dry.

determine that the system is working correctly.

, recalibrate the system.

(9-30VDC). If the power supply is functional,

and contact RLWS service for a replacement. If the

8.2.4 Load Cell checks

If the display still shows an erratic reading or unusual high reading, disconnect one load cell from the junction box and note

its effect on the display. If the display shows a significant impediment, the load cell is probably at fault and will need

replacing. If no significant improvement is noticed, reconnect the load cell and repeat the procedure for the remaining load

cells.

26 OB-350 Operators Manual

Page 31

Condition Cause

Note

No indicator display • Power cable disconnected

• Power connection fault

• Defective indicator

Erratic indicator readings • Erratic supply voltage - loose cables/connectors

• Defective cable or connectors

• Defective load cell/s

• Deffective indicator

• Loose load cell bolts

Incorrect weight readings

(not erratic)

Unable to calibrate • Top load cell mounting bolts too long to calibrate maximum weight

Unable to zero • Defective load cell

• Incorrect calibration

• Dirty connectors

• Defective cable

• Defective load cells

• Top load cell mounting bolts too long - always weighing light

• Body rubbing on the chassis

• Build-up of dirt or grit in the loadcell slot

• Loose or broken connectors

Table 8-1. Troubleshooting Chart

Your RLWS LoadRunner system should be serviced & re-calibrated annually.

Appendix 27

Page 32

Hardware Warranty Statement

Rice Lake Weighing Systems (RLWS) warrants that all RLWS brand equipment and systems properly installed by

a Distributor or Original Equipment Manufacturer (OEM) will operate per written specifications as confirmed by

the Distributor/OEM and accepted by RLWS. All systems and components are warranted against defects in

materials and workmanship for two (2) years, unless otherwise stated.

RLWS warrants that the equipment sold hereunder will conform to the current written specifications authorized by

RLWS. RLWS warrants the equipment against faulty workmanship and defective materials. If any equipment fails

to conform to these warranties, RLWS will, at its option, repair or replace such goods returned within the warranty

period subject to the following conditions:

Upon discovery by Buyer of such non-conformity, RLWS will be given prompt written notice with a detailed

explanation of the alleged deficiencies.

Individual electronic components returned to RLWS for warranty purposes must be packaged to prevent

electrostatic discharge (ESD) damage in shipment. Packaging requirements are listed in a publication, "Protecting

Your Components From Static Damage in Shipment," available from RLWS Equipment Return Department.

Examination of such equipment by RLWS confirms that the non-conformity actually exists, and was not caused by

accident, misuse, neglect, alteration, improper installation, improper repair, or improper testing. RLWS shall be the

sole judge of all alleged non-conformities.

Such equipment has not been modified, altered, or changed by any person other than RLWS or its duly authorized

repair agents.

RLWS will have a reasonable time to repair or replace the defective equipment. Buyer is responsible for shipping

charges both ways

In no event will RLWS be responsible for travel time or on-location repairs, including assembly or disassembly of

equipment. Nor will RLWS be liable for the cost of any repairs made by others.

Installer is completely responsible for the design and fitting of the installation, and any changes which might result

in voidance of the warranty of the manufacturer of equipment to which the products are installed.

THESE WARRANTIES EXCLUDE ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED,

INCLUDING WITHOUT LIMIT ATION WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. NEITHER RLWS NOR DISTRIBUTOR WILL, IN ANY EVENT, BE LIABLE

FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES.

RLWS AND BUYER AGREE THAT RLWS' SOLE AND EXCLUSIVE LIABILITY HEREUNDER IS

LIMITED TO REPAIR OR REPLACEMENT OF SUCH GOODS. IN ACCEPTING THIS WA RRANTY,

THE BUYER WAIVES ANY AND ALL OTHER CLAIMS TO WARRANTY.

SHOULD THE SELLER BE OTHER THAN RLWS, THE BUYER AGREES TO LOOK ONLY TO THE

SELLER FOR WARRANTY CLAIMS.

No terms, conditions, understanding, or agreements purporting to modify the terms of this warranty shall have any

legal effect unless made in writing and signed by a corporate officer of RLWS and the Buyer.

© Rice Lake Weighing Systems, Inc. Rice Lake, WI USA. All Rights Reserved.

RICE LAKE WEIGHING SYSTEMS • 230 WEST COLEMAN STREET • RICE LAKE, WISCONSIN 54868 • USA

28 OB-350 Operators Manual

Page 33

Page 34

230 W. Coleman St. • Rice Lake, WI 54868 • USA

U.S. 800-472-6703 • Canada/Mexico 800-321-6703 • International 715-234-9171 • Europe +31 (0) 88 2349171

www.ricelake.com www.ricelake.mx www.ricelake.eu www.ricelake.co.in m.ricelake.com

© Rice Lake Weighing Systems 04/2014 PN 160914

Loading...

Loading...