Page 1

Specs no. D-F0446

Provisional version

Product Specifications

2 & 3-inch Super High Speed Kiosk Printer

NP-2511

NP-3511

Revision 0.01 2006.11.30 Provisional version

Revision 0.07 2007.05.21 Provisional version

※Since the product is under designing, the specifications described can be changed.

※All specifications of 2-inch version is the provisional.

All specifications described are subject to change without prior notice.

Though we made assurance dubly sure to write this product specifications,

Please contact us if you find foul play, mistake and erroneous omitting.

Nippon Primex Inc.

Head Office:

1-5-12 Unoki Ohta-ku Tokyo 146-8650 Japan

TEL :+81-3-3750-1234 FAX :+81-3-3750-4555

E-mail : overseas@primex.co.jp

URL : http://www.primex.jp

D-F0446 NP-2511/3511 series Specifications Ver.0.07

Page 2

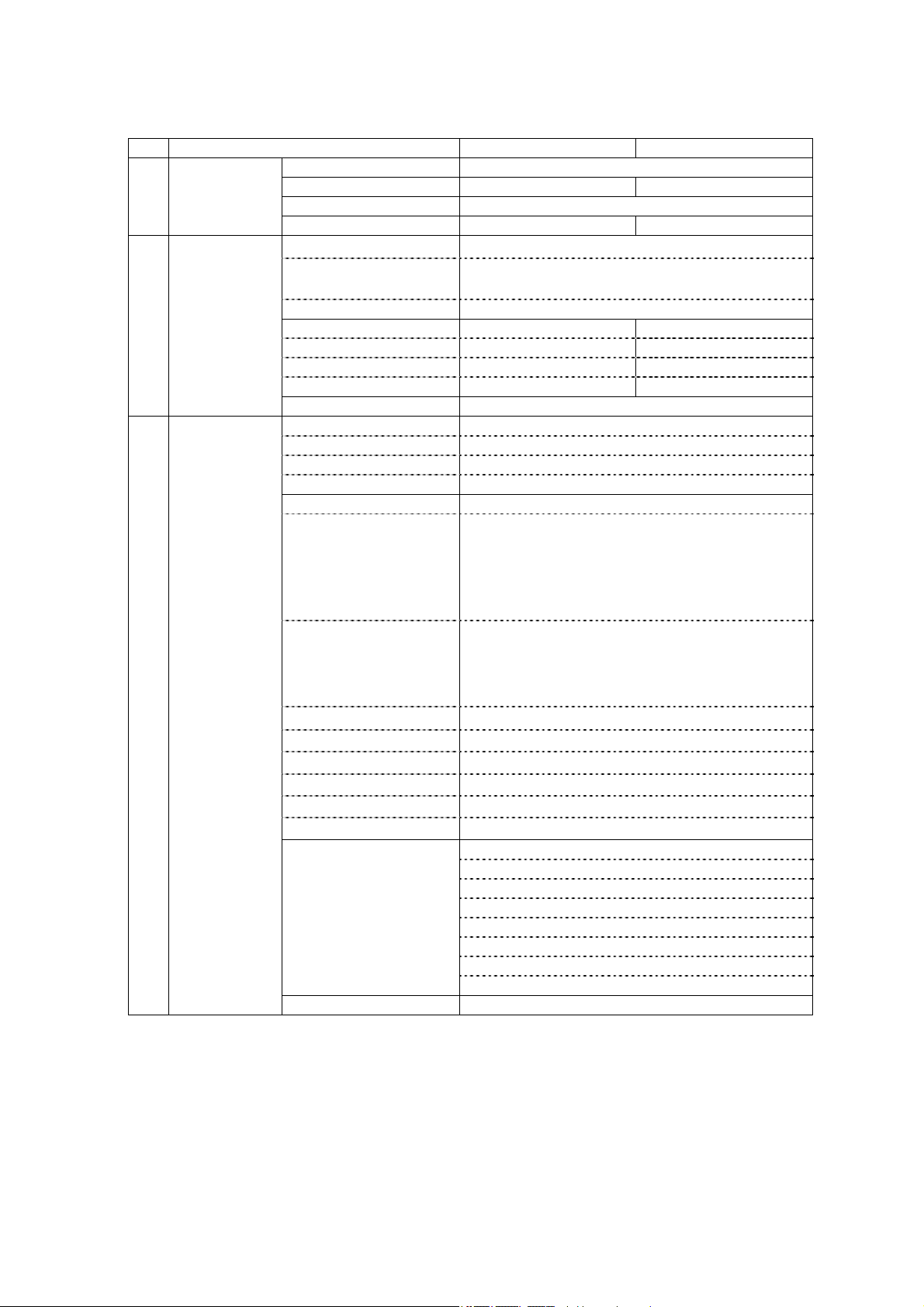

Record of Revision 1

Rev. V.

0.01

page item change

Pv

New release (prov.) Abe

0.02

Pv

3 Print Speed

0.03

Pv

25)engine motor Added Abe

Descriptions

Deleted page/line mode and

mentioned MAX.200mm/sec

approval PIC

2006.11.30

Abe

2006.12.13

1 Features 12) * added test schedule 2006.12.26

3 Print Speed Condition Optimized to drive

6

9、10

Consumption current conditon

Receiption control signal

Optimized to drive

Integrated to RTS

15 Select drive Optimized to drive

Optimized to drive

19~

45~

Command Added

Character code table Added

atch Kanji code table Added

atch

atch KSX1001-1992 Added

0.04

Pv

Chinese(GB18030-200)

1

Outline option (in review)

Added

Factory setting、 added black mark sensor

Abe

1 Feauters 12) * delete test schedule 2007.01.24

3 Print speed condition Added storage mothod

Ratio for print 50%→less than 50%

4 Print mode, page mode Added under development

4

5

Operating environment Temparature

Print area & Cutting Positoin

Changed -20~60→-20~45

Changed 3→2

Changed 12.5→11.5

5

7

7

Print area & Cutting Position

Operating environment Specs temparature

Operating environment Specs

Added *Preprint

Changed -20~60→-20~45

Changed testing→retesting schedule

Added next production

7

Storage environment Specifications Changed testing→retesting schedule

7 Safety standard Changed standard

7 UL60950-1 Changed approved

9 Interface USB Delete inspect *4)

11 4)CN7:Presenter Delete except NPT-301

Added NPT-305/NPO1201

12 Momory switch Added M2-6 option select

13

Memory switch manual setting

Added

13 Fig.3 Language font Added MS2

13 Seft Print

Changed Korean→Chinese

Changed Chinese→Korean

Changed control~function→control~operation

Deleted printer mechanism function

Deleted print quality

Deleted printer mechanism auto

14 Cutter abnormal status Deleted not-connect

14 Cutter abnormal cancell

14

Blackmark detective error

14 Presenter abnormal Added

Changed thermal head cover open

Deleted

D-F0446 NP-2511/3511 series Specifications Ver.0.07

Page 3

Record of Revison 2

Rev. V

0.04

pv

page item change

16

ALARM display pattern

Descritpion

Deleted Recovery Abe

Approved PIC

Added paper near empty 2007.01.24

19、35

19、38

Macro definition start/finish

Deleted

Macro excution Deleted

20

Command table Added *print method

31 Raster image bit Added serial interface

35

Black/white reverse printe set/reset

Changed download→Raster

36 Print start/end setting Changed fig. n(hex)

Changed print length 210→160

Deleted *Storage Print

Added *USB interface

39 Barcode Print

40 Print density set

Changed not barcode print over

Change stardard print desity~

Added Print start/finish~

0.05

pv

1 Option Added A:5 series blackmark Abe

Deleted blackmark in review 2007.02.08

5

Print area and cut position

Added specs of blackmark print

Added postion of partial cut

Added limited area

12 Memroy switch Changed MS2-6 revervation

14

Details of error detection

Deleted *MS2-6 option selection

Changed *MS2-6、MS2-7、MS2~

Added print start status

Added presenter abnormal→detected paper error

Deleted priority

16

16 FEED switch

19、32

20

ALARM Display pattern

Added priority

Changed Presenter abnormal→paper deted error

Deleted Cancel Mark detection

Detection blackmark Added

Plan to add~

deleted

31 Raster image bit Deleted serial interface

34 Printer status transmit

Presenter abnormal→detect paper error

Deleted Fig.

39

Print status auto-transmit

Changed Presentor abnorma→Paper detect error

Deleted fig.

0.06

pv

- NP-2511 Added provional specs. Abe

- Annotation

1

1

1

①paper size

②paper holder

④Option・OEM etc

Deleted 3 papers but recomended~

Deleted 7)low tempt.or highhumidity~

Deleted 24)preprinted~

Added 2:2inch(standard:58mm)

Changed 1:holder for roll paper

Deleted A:5 series blackmark

2007.05.01

D-F0446 NP-2511/3511 series Specifications Ver.0.07

Page 4

Record of Revison 3

Rev. V

0.06

1

page Item Change

pv

1 Feature Changed partly Abe

Feature 1)~3)

1 Feature 8)

Description

Consolidated in 1) 2007.05.01

Changed holder for roll paper

Approval PIC

2 constitution Added NP-2511

3 Specifications Added NP-2511

3 Print specifications

Separated in head specs and print specs.

3 Number of total dot Changed 576→640

3 Max. print width Changed 72→80

3 Number of print digit Changed max. print digit

Changed Font A 48→53

Changed Font B 64→71

Changed Kanji 24→26

4 Autocutter(partly) Move to other page

4 Paper Specifications Move to other page

4 Near empty Move to other page

4 Environmental Specs. Move to other page

5

Print area & cut position Changed Paper specifications

7 Print Area Added

8 Cutter Specs Added

9 Position of Blackmark Added

11 Consumption current

Separated 2 and 3 inch model

Ajusted supply voltage

Changed 25% 4→3.5

Changed 100% 15→14

11 Condition

Changed 2-fraction drive print

12 reliability Changed reliability Specs.

13 Environmental Specs. Added

19 Functions setting Added NP-2511

19 Memory Switch

Changed MS2-6 Mark sensor

Deleted MS2-6

26

26

27、36

27~

28、47

28、47

28、47

28、48

28、48

28

28

How to remove jammed paper

How to clean Thermal head

Back Feed

Detected Blackmark Deleted

Cue operaiton

How to detect mark and set the positioning offset

Set cue disposal when paper set

Set Print area

Set Max. print speed

*51)~53)Black~

*17)、51)~55) NP-

39 Raster Bit Image

0.07

pv

15

External measurement

Added *fig.NP-3511~

Changed 1)~4)

ADDED (NP-3511 F/W Ver1.10 and later)

Added(NP-3511F/W Ver1.10 and later)

Added (NP-3511 F/W Ver1.10 and later)

Added(NP-3511 F/W Ver1.10 and later)

Added(NP-3511 F/W Ver1.10 and later)

Added (NP-3511 F/W Ver1.10 and later)

Added

Added

Delete command~

Added NP-2511 Abe

2007.05.21

D-F0446 NP-2511/3511 series Specifications Ver.0.07

Page 5

Read Carefully Before Using the Printer

Wrong handling of the printer may cause its performance declined and the product damaged. Please read

the notes below before handling.

1. Static discharge prevention must be made for installation and removal of the printer to protect IC and

other electrical parts. Connect it to the earth ground. It is also requested to remove the static from body

of the person before handling, especially, the input terminal.

2. Avoid excessive force to the input terminal for handling.

3. Avoid printing with no paper loaded. It damages platen and thermal head, printer life will be shorten.

4. Do not scrabble thermal head with sharp edge or something hard, or give impact. The heat element

may be damaged.

5. Set the power of printer off before connecting or removing connecters.

6. The printer is not protected from water or dew formed. Do not water the printer or handle it with a wet

hand, which may cause damage to the printer due to short circuit, or heat or fire.

7. The printer is not protected from dust or dirt. If it is used at dusty place, the thermal head may be

damaged or paper feed is not operated properly.

8. When cooling the printer with a fan, avoid the printer’s paper outlet from locating fan’s air inlet. It may

cause mal-function of printer.

9. Reflection type of infrared ray sensors are used at some locations in the printer. Direct sun light may

cause mal-function of printer. Avoid from such a location for installation.

10. This printer does not support any operations caused by the commands or control commands not

specified in this manual.

11. Please use both hand when you hold the printer.

12. In order to prevent excess current, please put elemental device to external 24V power line (Please refer

to the power supply specification for the details), and also put fuse.

13. Please plug off the printer when you do not use the product for a long time. Please also insert paper

between the platen.

14. When paper jam occurred, please make sure to slowly remove the paper to paper exit direction after

head up status.

15. The product is designed to use with general electronic devices (Computer, PC, OA, others). This is not

designed and not guaranteed to use with extremely high quality, high reliability product or product whose

failure may danger human life (Atomic power control device, aerospace aircraft devices, Transportation

devices, Traffic signal devices, Ignition control devices, Medical devices, other safety equipments: we call

“Specific application” thereafter). Users take full responsibility for using with such specific application.

16. The product uses part that includes GaAS (Gallium arsenide). Please do not break the product, no

chemical splitting ,otherwise it may harm human with such part broken pieces.

17. The product should not be installed where it is tend to take place static easily, shaking strongly and

electromagnetic field, corrosive gas, rain, fog and direct sunlight.

18. There is some possibility that cut surface of steel plate on principal structural part of the product is to

rust easily.

19. Don’t re-create the product.

20. Don’t pull the paper while printing and paper-feeding. When thermal head cover is closed, don’t pull the

paper except for patial cut. When patial cut, you should pull either right or left on the edge of paper to

separate.

21. When you get rid of the proucting, you must dispose of according to local autholities.

22. In case the motor in engine of the product has been working for a long time or stopped and worked at

very short interval, the motor produces heat and doesn’t execised fully capacity. To avoid it, you should

get the motor stop for the same period of working time. The continuous working time is 6 minites one

time.

23. The coverage of warranty is limited within the product itself, Nippon Primex Inc is not responsible for

anything induced by the defect of the product, and don’t pay for any compensation.

D-F0446 NP-2511/3511 series Specifications Ver.0.07

Page 6

Table Contents

1. Overview·········································································································································1

1.1 Overview ·······························································································································1

1.2 Features ································································································································1

1.3 Configulations························································································································2

2. Specifications··································································································································3

2.1 Basic Specifications···············································································································3

2.2 Paper Specifictions················································································································5

2.3 Print Area·······························································································································7

2.4 Specifictions of Cutter············································································································8

2.5 Postion of Black Mark············································································································9

2.6 Power Supply Specifications ······························································································· 11

2.7 Reliability Specifications ······································································································12

2.8 Environment Specifications ·································································································13

2.9 Dimenssions························································································································14

3. Configurations ······························································································································16

3.1 Interface specifications : RS-232C ······················································································16

3.2 Interface specifications: USB (V2.0 Full Speed)··································································16

3.3 Connecter Signal Details ·····································································································17

4. Functions······································································································································19

4.1 Function Setting ··················································································································19

4.2 Processing error ··················································································································21

4.3 Buffer full print ·····················································································································21

4.4. Drive Select ························································································································22

4.5 Select Full size and half size character ···············································································22

4.6 Operation panel···················································································································23

4.7 How to set roll paper············································································································24

4.8 How to remove the jammed paper·······················································································26

4.9 How to clean Thermal Head ································································································26

5. Command·····································································································································27

5.1 Command Table ··················································································································27

5.2 Printer Driver ·······················································································································29

5.3 Command details·················································································································29

6. Character code table ····················································································································52

6.1 Domestic Character code table(International character set:Japanese)························52

6.2 Overseas character code(International set: USA)···························································53

6.3 CODE PAGE858 ·················································································································54

6.4 International character code table ·······················································································54

6.5 CODE PAGE1250 ···············································································································55

6.6 CODE PAGE1251 ···············································································································56

6.7 CODE PAGE1252 ···············································································································57

6.8 CODE PAGE1253 ···············································································································58

6.9 CODE PAGE1254 ···············································································································59

Appendix Kanji code table, Chinese(GB18030-2000)、KSX1001-1992

D-F0446 NP-2511/3511 series Specifications Ver.0.07

Page 7

1. Overview

1.1 Overview

Model name is specified as follows;

NP-3511

① ② ③

1. Paper Width (Factory Setting)

3: 3 inch ( Standard: 80mm)

2: 2 inch (Standard: 58mm)

* 2 inch in review

3. Interface (Factory Setting)

No mark: Serial (RS-232C), USB (V2.0 Full Speed) by user’s selection.

U : USB (V2.0 Full Speed) only.

4. Options or OEM etc.

No mark: original model (without option)

* Option: Bezel in review

1.2 Features

This model mounted with new developed small and low-cost in-house printer

mechanism is small and low-cost module printer for improving usability.

Installation at apparatuses has been finished with power supply (DC24V) and data

supply only, and this model can be used under the wide range of temperature

environment. Threrefore, the user can install this model freely. We can realize high

liability and quality by mounting in-house printer mechanism.

1) Small, light weight. Since this model is low-profile, it is easy to install on apparatuses

2) High Speed Printing & High Quality Printing

3) Interface available for Serial (RS232C) and USB (v2.0 High Speed)

4) Adaptation to various types of 1D barcode

5) Adaptation to various applications

6) Easy operational adjustable paper holder with detective sensor of near-empty

7) Drivers for various Operation Systems (optional)

Windows 2000/XP/CE5.0 Linux(sample)

8) Easy to re-write firm ware with Flash Memory & 3 patterns of registration available with

NV bit image.

9) Comply with Multiple Languages

10) Controllable external paper feeding(Presenter:NPT-301)

11) Easy to change roll paper by auto-loading

12) Wide range of operation temperature

U- *

④

2. Paper Holder Type (Factory Setting)

1. Holder for Roll Paper

D-F0446 NP-2511/3511 series Specifications Ver.0.07

1

Page 8

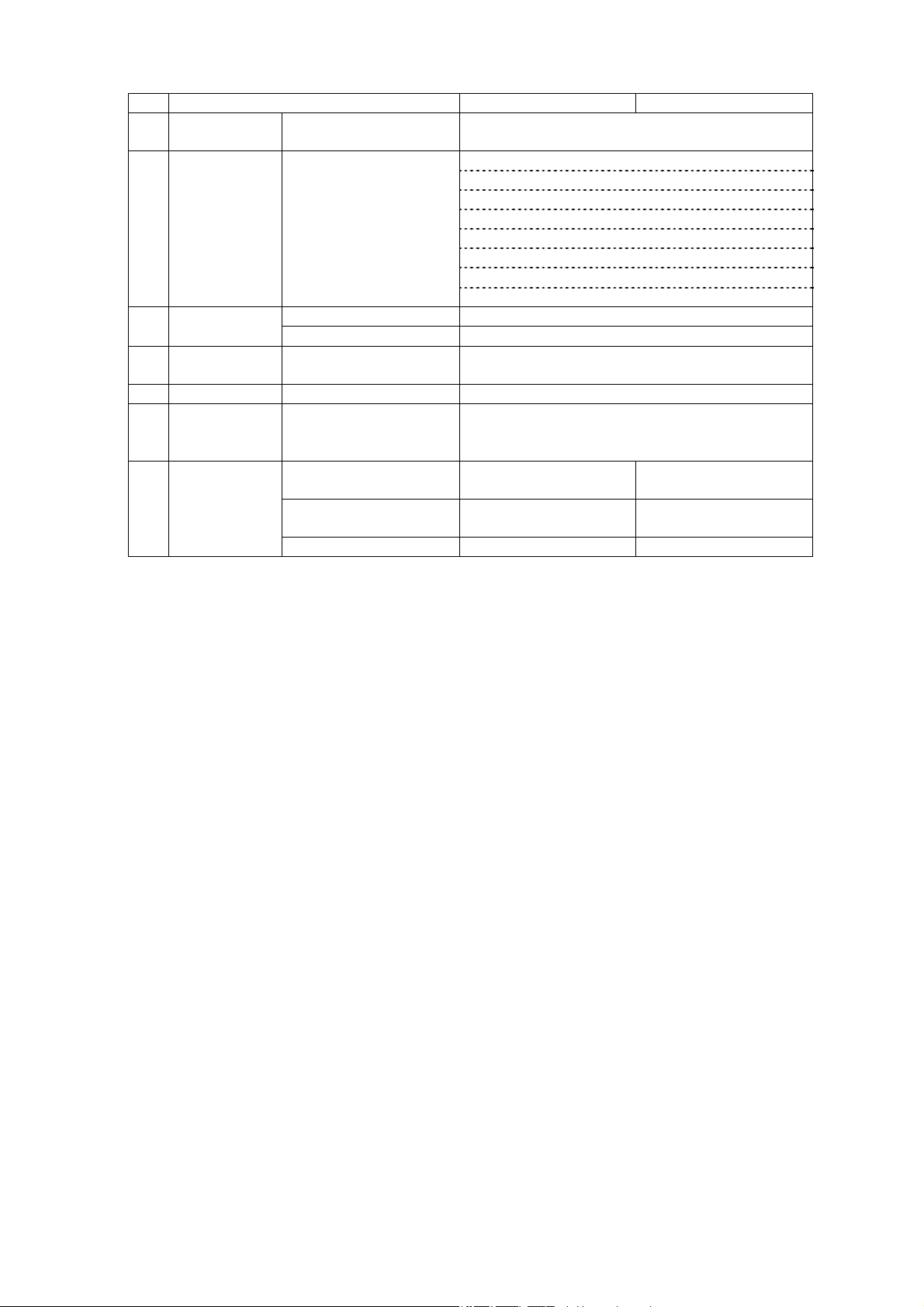

1.3 Configulations

model specifications Part# Q’ty NP-3511 NP-3511U

NP-3511 USB & Serial 70-00170-00 1 ○

NP-3511U USB only 70-00171-00 1 ○

Thermal roll paper W80xφ30(IDφ12) 24-00018-00 1 ○ ○

Model Specifications Part No. Q’ty NP-2511 NP-2511U

NP-2511 USB / Serial 70-00330-00 1 ○

NP-2511U USB 70-00331-00 1 ○

thermal roll paper W58xφ30(IDφ12) 24-00017-00 1 ○ ○

D-F0446 NP-2511/3511 series Specifications Ver.0.07

2

Page 9

2. Specifications

2.1 Basic Specifications

No.

Specifications 2 inch (tentative) 3 inch

1 Print head 1:Print method Line thermal dot

2:Total Dot 448 dots 640 dots

3:Dot density 8dot/mm

4:Print width (MAX) 56mm 80mm

2 Printing 1:Print speed(MAX)

conditions

*1

MAX.200mm/sec

Head temp.35℃and more、bufferful method

Optimized drive print ratio 50% or less

* except communication time

2:Max. print digit

Font A(12×24) 37 digit 53 digit

Font B( 9×17) 49 digit 71 digit

Kanji (24×24) 18 disit 26 digit

3:Paper feed pitch 0.125mm

3 Character 1:Character size

Font A(12×24) 1.50×3.00mm

Font B( 9×17) 1.13×2.13mm

Kanji (24×24) 3.00×3.00mm

2:Charactoers

Japanese

Korean

Chinese

Greek

Polish

Russian

Scandinavian

Turkish

Extended graphic character set(Half size)

Extended graphic character set(Half size)

JIS C 6226・1983(Full size)

Katakana character set(Half size)

Code Page 858(Half size)

International character set(Half size)

KS X 1001:1992(Full size)

Katakana character set(Half size)

Code Page 858(Half size)

GB18030-2000(Half/Full size)

Code Page 1253(Full size)

Code Page 1250(Half size)

Code Page 1251(Half size)

Code Page 1252(Half size)

Code Page 1254(Half size)

3:Character Double width

Modifications Double Height

Quadruple

Bold print

Double strike

Inverted

90°clock-wise rotaion

underlined

4:Line feed Q’ty (Default)

4.25mm (1/6 inch)

*1 Print speed fluctuates depending on the condition.

*2 KS X 1001:1992 Build-in Font

*2

*2

D-F0446 NP-2511/3511 series Specifications Ver.0.07

3

Page 10

No.

Specifications 2 inch (tentative) 3 inch

4 Print mode Line mode

Page mode (under development)

5

Barcode spec

1:1D Symbology UPC-A

UPC-E

JAN-13(EAN-13)

JAN-8(EAN-8)

CODE39

ITF

CODABAR

CODE128

6 inerface 1:Serial (dual tipe) RS232C compliance

2:USB(dual U type) V2.0 FULL SPEED compliance

7 Autocutter 1:cut mode Full/Partial cut

* by command selection

8

Receive buffer

Approx. 15K byte

9 Operation ALARM LED OUT

Switch input FEED Switch Input

Reset Switch

10 Appearance 1:Dimensions 106(W) x 150(D) x 127(W) x 150(D) x

Without connector&roll paper

75(H) mm 75(H) mm

2:Weight Approx. 640g Approx. 750g

Without roll paper

3:Mounting note*4 Horizetal Position Horizental Position

*3 Paper roll should be wind tightly. If not, can’t detect corectly.

Can’t detect near-end when you use wider core diameter than value set of near-end due to

reflective type photo sensor.

*4 This printer should be installed horizontally.

D-F0446 NP-2511/3511 series Specifications Ver.0.07

4

Page 11

2.2 Paper Specifictions

1) Printermechanism

2 inch (tentative) 3 inch

Paper wide 58/60-1mm 65/76/80-1mm

Paper thickness

65~150µm

・Do not change narrow paper to wide paper on using.(In case you use narrower paper

than wide of Thermal head, the uncovered part by paper on thermal head grazes

directly with palaten roller and the thermal head could be destoried.)

・In case you use paper wide 60, 65 and 76mm, please contact us. (Settnng of paper wide

for printers should be at Factory.

① Thermal Roll Paper Specifications.

a) External Dimensions of Thermal Roll Paper

max. external diameter:φ83mm

※Now we’d prepare paper holder PH-8L only. (uptoφ83mm)

When you use paper withφ84 and more, please contact us.

(In the case of using paper with φ100 and more, we adapt axis-suppot and

need additional cushion device.)

b) Paper Core Specificaitons

Paper thickness Inner core diameter Outer core diameter

65~85µm

100~150µm

φ12.0mm φ18.0mm

φ25.4mm φ33.4mm

※Width of paper core should be same as width of width of roll paper.

c) Conditions of using thermal paper

You should keep stricktly the following conditions;

・Do not stick end of paper with glue and scotch tape.

・The core of paper roll should not be deformed.

・The core of paper should not be sticked out over the side of paper roll.

・Don’t keep paper rolls on condition of heat and humidity

2) Paper Holder

① roll paper

Name Paper wide

PH-8L 80-1mm φ83mm

PH-10

* 1

-

External

diameter

φ83mm

Paper core Near Empty

Innerφ12.0mm

Outterφ18.0mm

Innerφ12.0mm

Outterφ18.0mm

φ22.0±2mm

φ22.0±2mm

* 1 Now PH-10 is under design for NP-2511.

By attaching the addional part, you can extend to Inner coreφ25.4mm、

Outer coreφ33.4mm.(in this case, we are confirming Near Empty.)

D-F0446 NP-2511/3511 series Specifications Ver.0.07

5

Page 12

3) Recommended Thermal Paper

Base paper # Paper thickness manufacturer Printing dentisy

PD160R

PD450-145

75µm

145µm

Oji Paper Co

Oji Paper Co

100%

5℃~60℃ :100%

-20℃~5℃ :120%

4) Remarks

・When printing on low temperature or high humidity on highly printing ratio, there is a

case that the recording paper get filthy due to water vapor generated from recording

paper and the printer builds up condensation. Please pay attention that a drop of

water doesn’t falls on thermal head. In the case of condensation, you should switch

off until the condemsation disappears. You should use the reliable and confirmed

fully thermal paper that has little Na+ ion, K+ion, Cl-ion.

D-F0446 NP-2511/3511 series Specifications Ver.0.07

6

Page 13

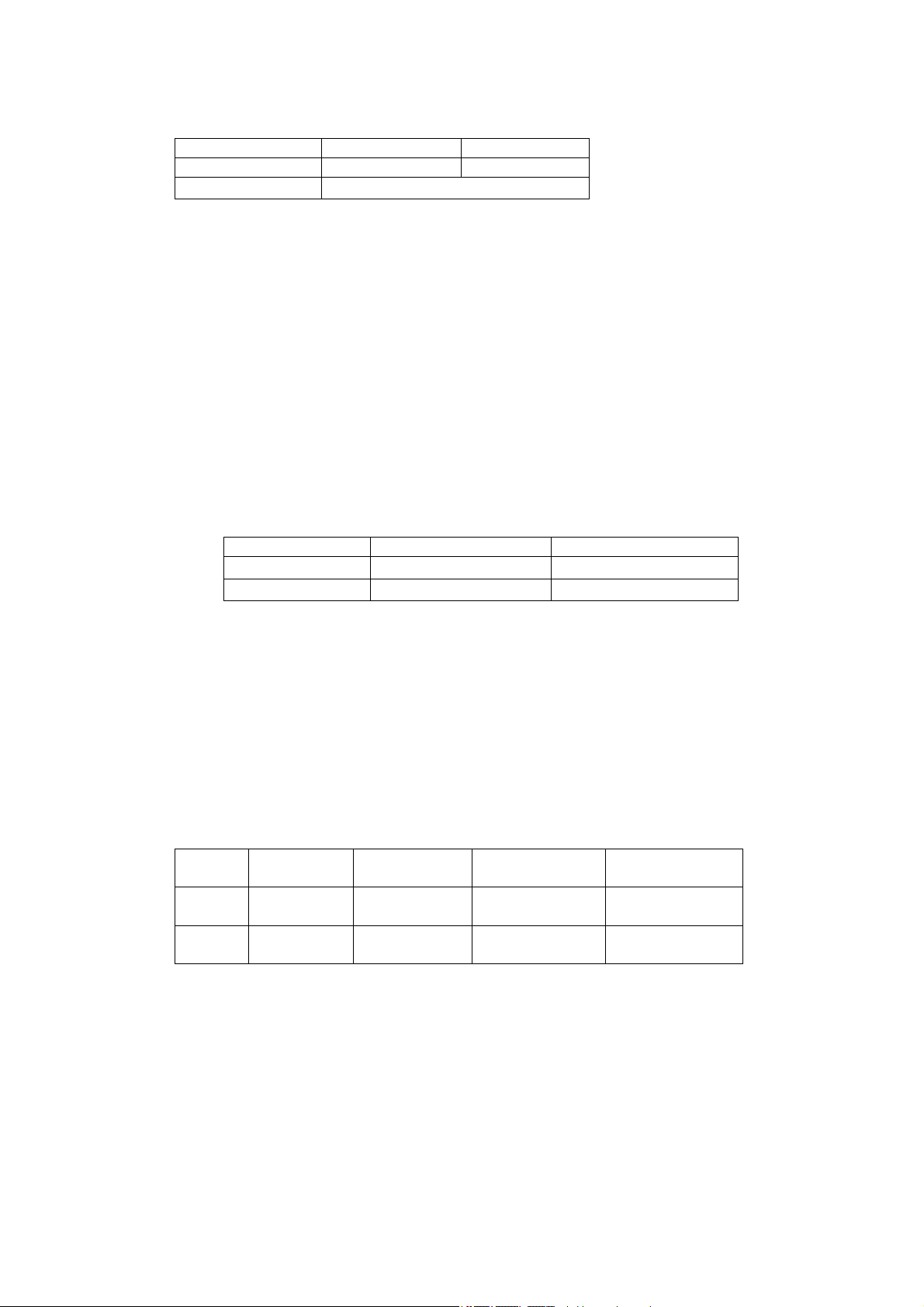

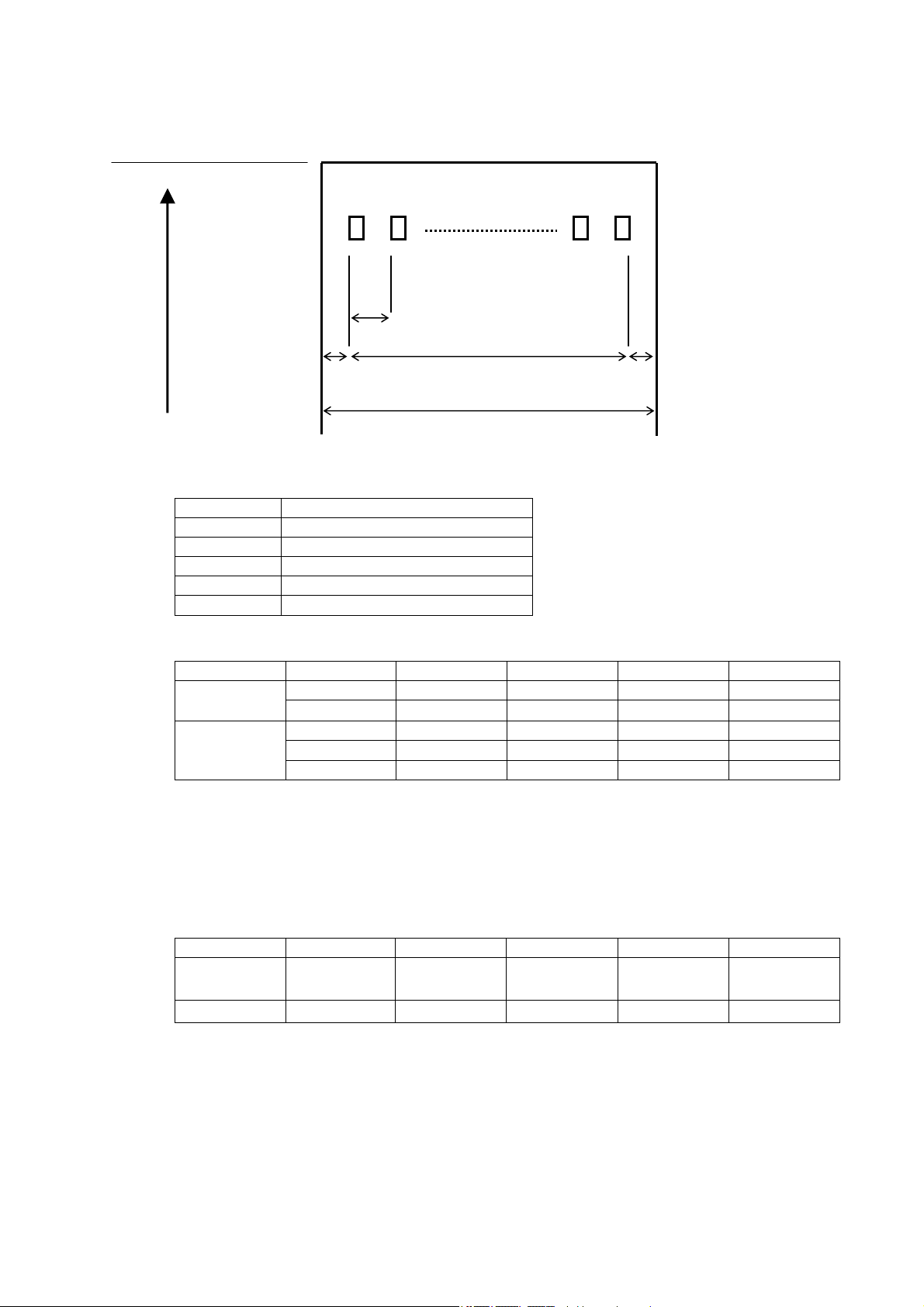

2.3 Print Area

Print Area

1) Name of Symbols

2) Paper Width and Example of Printing Area Setting

In case the margin on Left and Right is not enough, printing is run off due to directional

3) Factory Setting

Factory setting as follows:

Feed direction

Symbol Name

A The number of dot for Printing

B Left Margin

C Area of Printing

D Right Margin

E Paper Width

A(dot) B(±1mm) C(±0.2mm) D(±1mm) E(-1mm)

(tentative)

3inch

bias on paper. (We recommended more than 3mm) Printing Area can be changed by

command.

A(dot) B(±1mm) C(±0.2mm) D(±1mm) E(-1mm)

2inch

(tentative)

3inch

1dot 2dot

B

0.125mm

C

Adot

D

E

416 3 52 3 58 2inch

432 3 54 3 60

472 3 59 3 65

560 3 70 3 76

576 4 72 4 80

416 3 52 3 58

576 4 72 4 80

D-F0446 NP-2511/3511 series Specifications Ver.0.07

7

Page 14

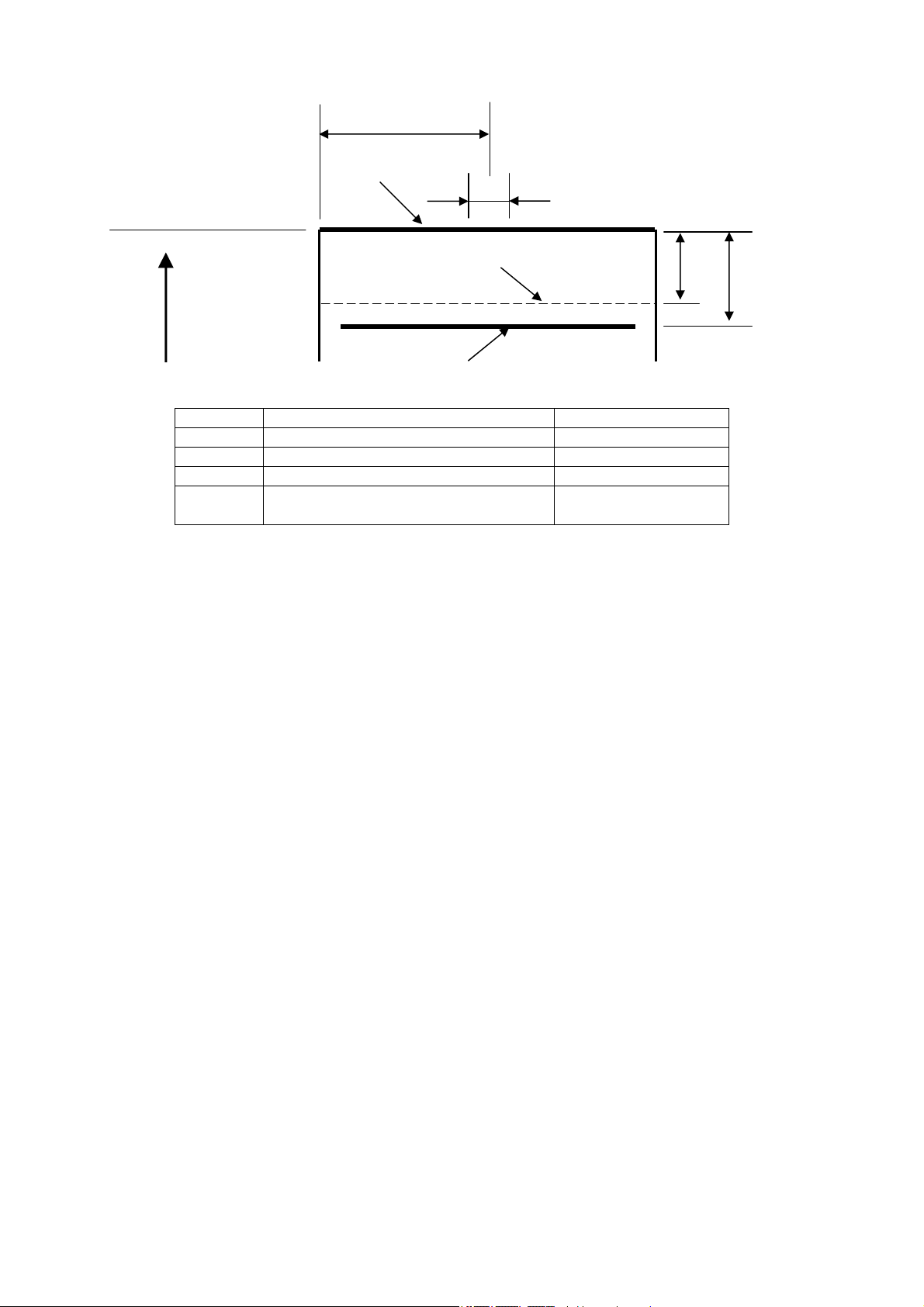

2.4 Specifictions of Cutter

Print Area

※Value of D doesn’t change in case paper wide changes to 75 or 65mm

1) Cutting Method :Slide System

2) Cutting Mode :Full cut/Partial Cut A/Partial Cut B

※Selectable by Command

3) Allowance of Cutting Frequency :30 cuts per minutes

4) Paper Thickness :65~150µm

※In case Partial Cut B is conducted with the paper with 75µm and

5) Note:

・In case you burden palaten like drawing paper strongly after partial cut etc, please pay

・2mm paper feed is automatically effected to avoid paper jam after cutting, the above

Feed Direction

Symbol Descriptions Meaurement

A Tab size on Partial Cutting 1.5±0.5mm

B Position of Printer Head (Cut to Print) 9.5±1mm

C Limit of Backfeed 6.5mm

D From edge of pape (1 dot~) to the

center of tab on partial cutting

attention there is a case that the next line is not properly printed. You should pull left or

right end of paper to avoid burdening palaten or taking measure of feeding the paper by

approx. 1mm before printing.

mentioned cutting margin is 11.5±1mm.

Cutting Postion

Backfeed Limit

Position of Printing Head

D

A

C

B

30±0.5mm(NP-2511)

40±0.5mm(NP-3511)

more thicker, there may be a case that paper is drawn from

mechanism side at the time of extracting paper.

D-F0446 NP-2511/3511 series Specifications Ver.0.07

8

Page 15

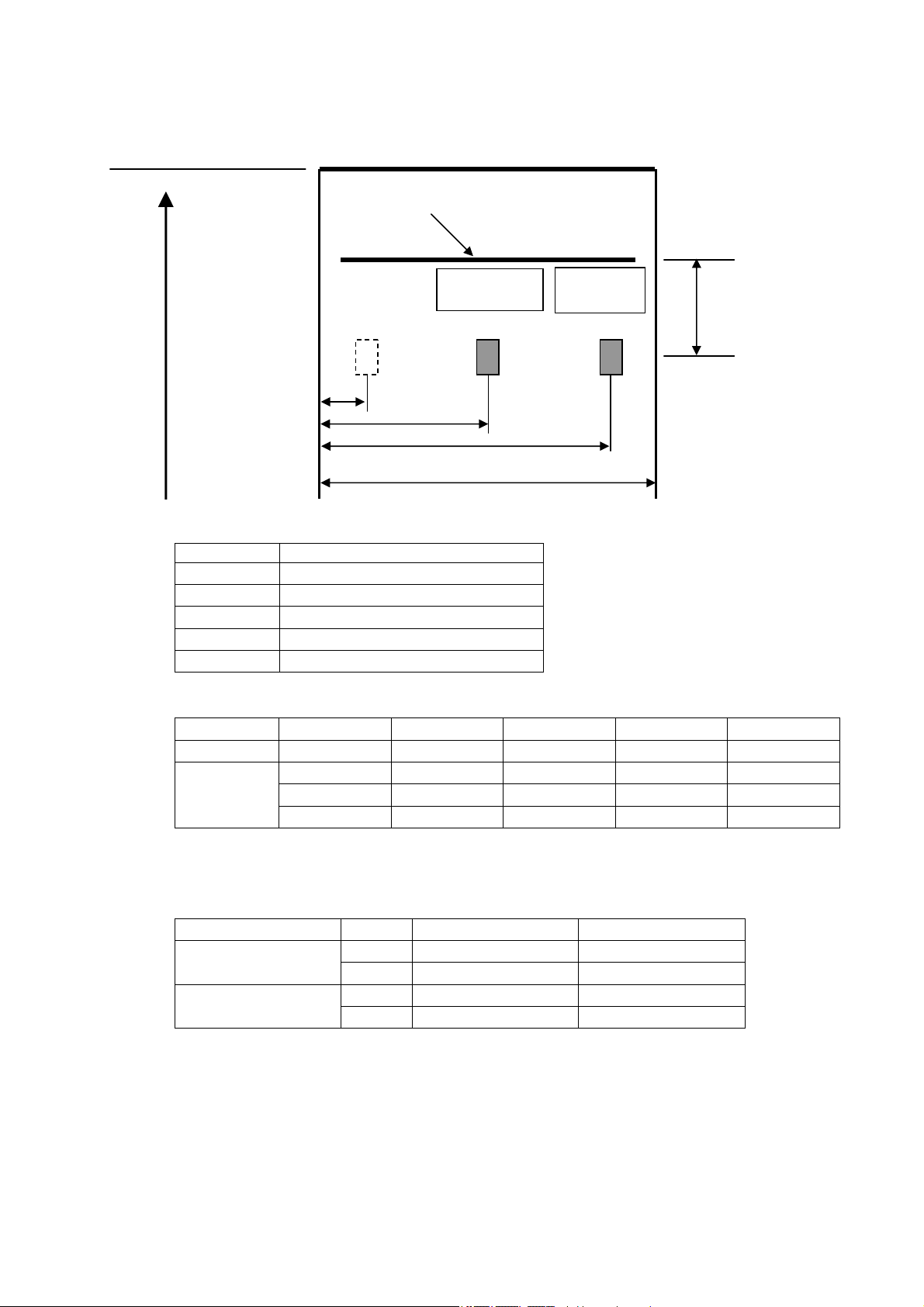

2.5 Postion of Black Mark

p

Print surface

Printing Head Position

Feed direction

Sensor ①

Defaut:

Pa

eroutsensor

Sensor ② Sensor ③

Default:

Mark sensor

B

C

D

E

1) Name of Symbol

Symbol Descriptons

A Printer Head~Sensor Position

B Sensor①position

C Sensor②positon

D Sensor③position

E

Paper Width

2) Sensor Positon

A(±1mm) B(±0.5mm) C(±0.5mm) D(±0.5mm) E(-1mm)

2inch

11.5 8.0 30.0 52.0 58

11.5 7.5 40 N.A. 65

3inch

11.5 7.5 40 72.5 76

11.5 7.5 40 72.5 80

3) Sensor Specifications

Sensor①and③ are selectable. Standard is Sensor③.

Mark Sensor and No paper Sensor are selectable by MS2-6.

MS2-6

Standard

Options

OFF Sensor③ Sensor②

ON Sensor② Sensor③

OFF Sensor① Sensor②

ON Sensor② Sensor①

Mark Sensor No Paper Sensor

※Please remove dust and paper powder etc on Sensor periodically.

A

D-F0446 NP-2511/3511 series Specifications Ver.0.07

9

Page 16

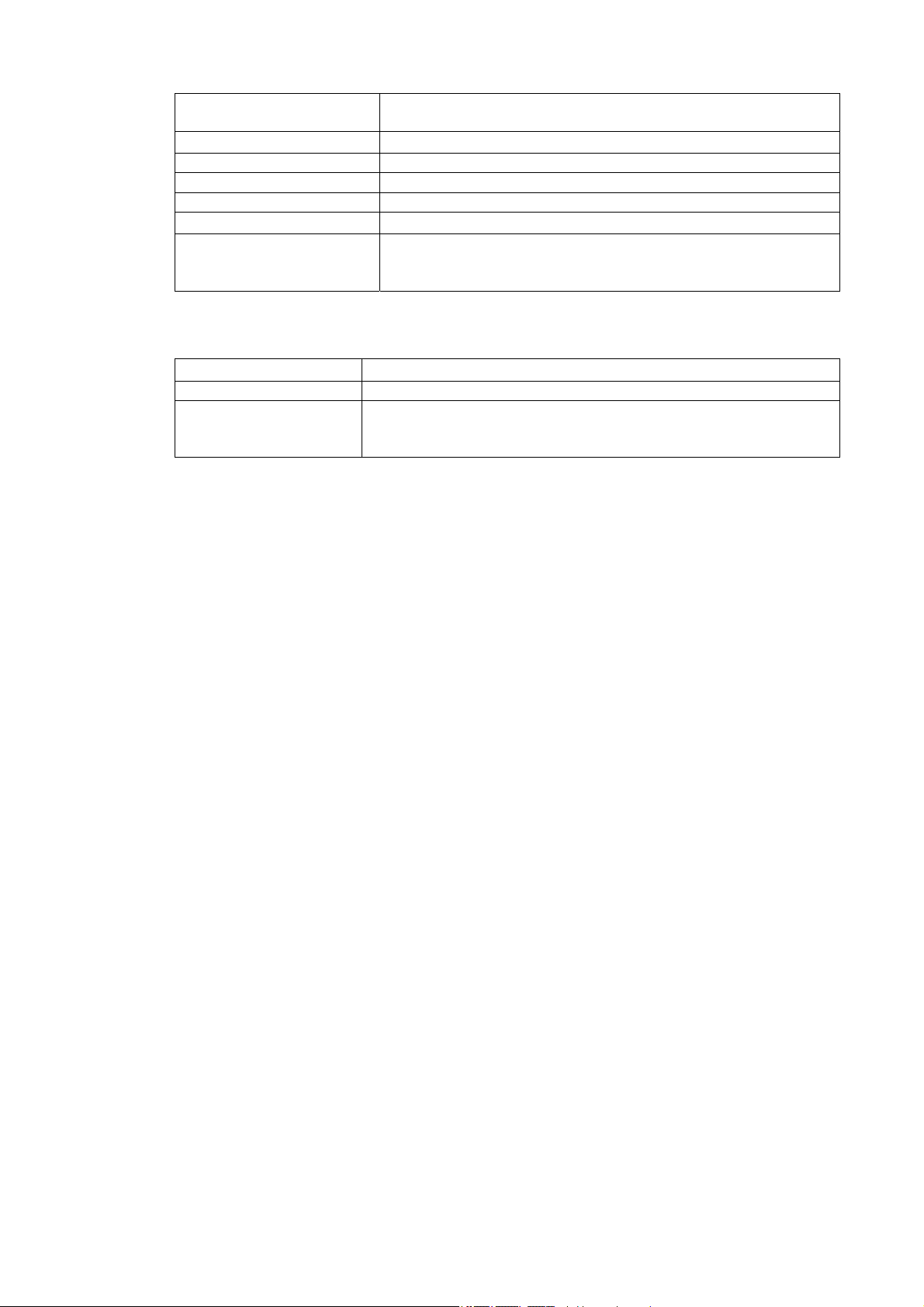

4) Black Mark Printing Specifications

Mark Print position *1 The center of Sensor set by Mark Sensor is reference

position.

Mark Width(Min) *1

left and right 7.5mm(Min 15mm)from reference position

Height of Mark (Min) 5mm

Printing Side Not Printing Side

PCS value 0.9

Reflectance Ratio

Preprint limited Area

*1

Reflectance less 7% of 900nm(infra-red)

Preprint with dark color is prohibited on the area on left and

right 7.5mm from reference position. You should fully confirm

to use paper preprinted.

*1:In case you set Mark Sensor on Sensor③ in using paper width 76mm, specifications

is partly changed as per below mentioned.

Mark Print Positon

Paper edge on Sensor③ side is reference position.

Mark Width(Min) 10mm from reference point.

Preprint limited area Preprint with dark color is prohibited on the area on 10mm from

reference point. You should fully confirm to use paper

preprinted.

D-F0446 NP-2511/3511 series Specifications Ver.0.07

10

Page 17

2.6 Power Supply Specifications

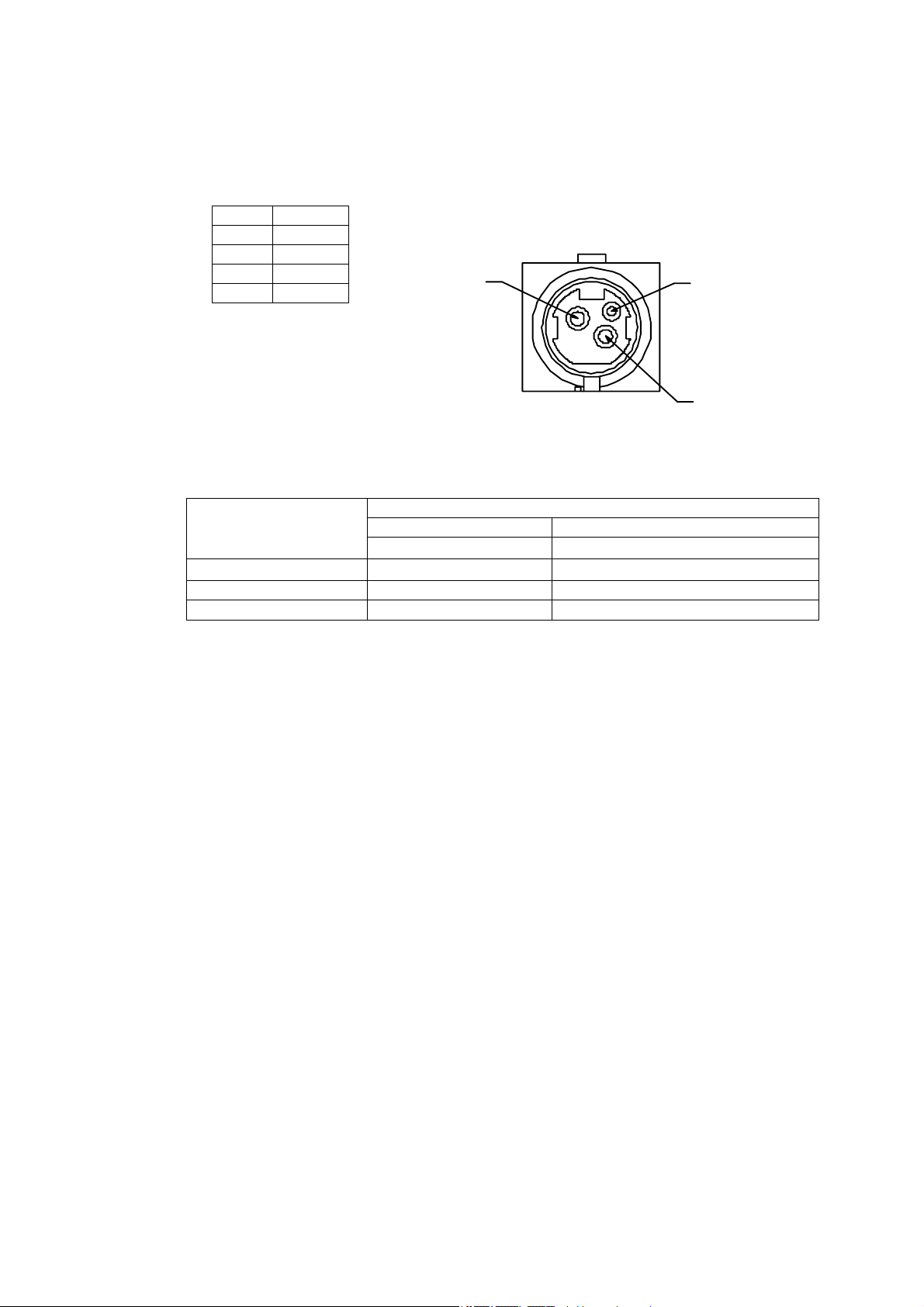

1) Power supply input connector

The printer should be connected with the specific AC adaptor.

Connector on printer side: TCS7960-5320177 Hoshiden or equivalent

Connector on Adaptor side: TCP8927-631177 Hoshiden or equivalent

2) Power Supply Voltage:DC24V±5%

3) Current Consumption

Condition:Optimized drive print、dual partitioning print

*1 A power supply with enough capacity is required in order to secure a good printing

*2 If power supply cable is excessively long, the operation may become unstable. Cable

No function

1 +24V

2 GND

3 N.C

shell FG

Connector Fig.

1

3

2

※1※2

Consumption Current

Power supply

Standby

Print avarage 25% Max. approx. 3.5A

Print avarage 100% Max. approx. 14A

quality. Depending on the printing contents, the current may be big at the peak time.

should be made as short as possible. If not available, connect cables near the printer

and place an electrolysis condenser of 2200µ between power supply and ground.

Voltage resistance should be higher than 35V.

2-inch 3-inch

+24V±5% +24V±5%

約 80mA(typ)

D-F0446 NP-2511/3511 series Specifications Ver.0.07

11

Page 18

2.7 Reliability Specifications

1) Head Life

①Thermal Head

Anti-Pulse Characterics :100 million pulse

Anti-abration characteristic :100km

②Cutter Life :1 milions

③Life Definition

・ Entering period abrasion of failure period.

・ Condition to satifiy life is as follows:;

Average Print Ratio:12.5%

Recommended Thermal Paper:PD160R/PD450-145

Print Density :100%

※If paper but recommended paper is used, there will be different life by

the paper of quality, width and thickness. The user must confirm the

abovementioned paper actually.

2) MTBF(Mean Time Between Failfure)

5

2.3×10

hours

D-F0446 NP-2511/3511 series Specifications Ver.0.07

12

Page 19

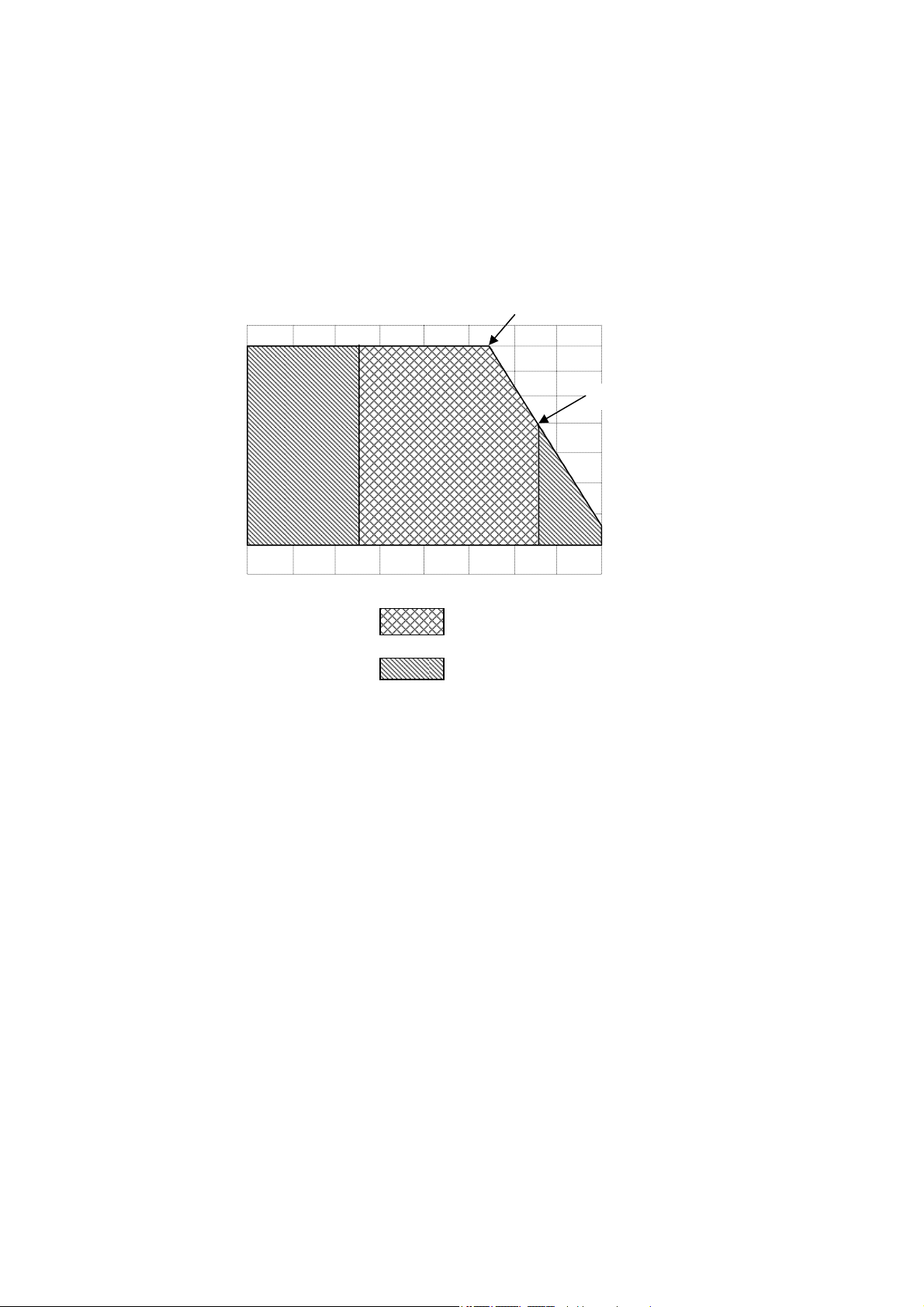

2.8 Environment Specifications

1) Operating Envirnment

Temperature : -20~60℃ *NP-3511Rev「01A」

*in case of NP-3511Rev「no mark」-20~45℃

Humidity: 10~80%RH

Non Codensing, 80%RH supposed 35℃

*Warrant scope of print quality (P/Q) & Print operatable (P/O) scope

85%R

80

35℃ 80%

60

45℃ 50%

40

20

-20

0

20

40

Guarantee of P/Q temp&humid

60℃

Guarantee of P/O temp&humid

2)Archiving environment(except for papers)

Temparature : -30~70℃

Humidity : 10~90%RH

Non Condensing

High-temparature and humidity:40℃ 90%RH(non condesing)is the worst.

3)Safety Regulations

CE mark (Approved)

UL60950-1(Approved)

VCCI : Class A (Approved)

FCC : Class A (Approved)

*The above regulations are adapted to NP3511, but NP2511 in review.

D-F0446 NP-2511/3511 series Specifications Ver.0.07

13

Page 20

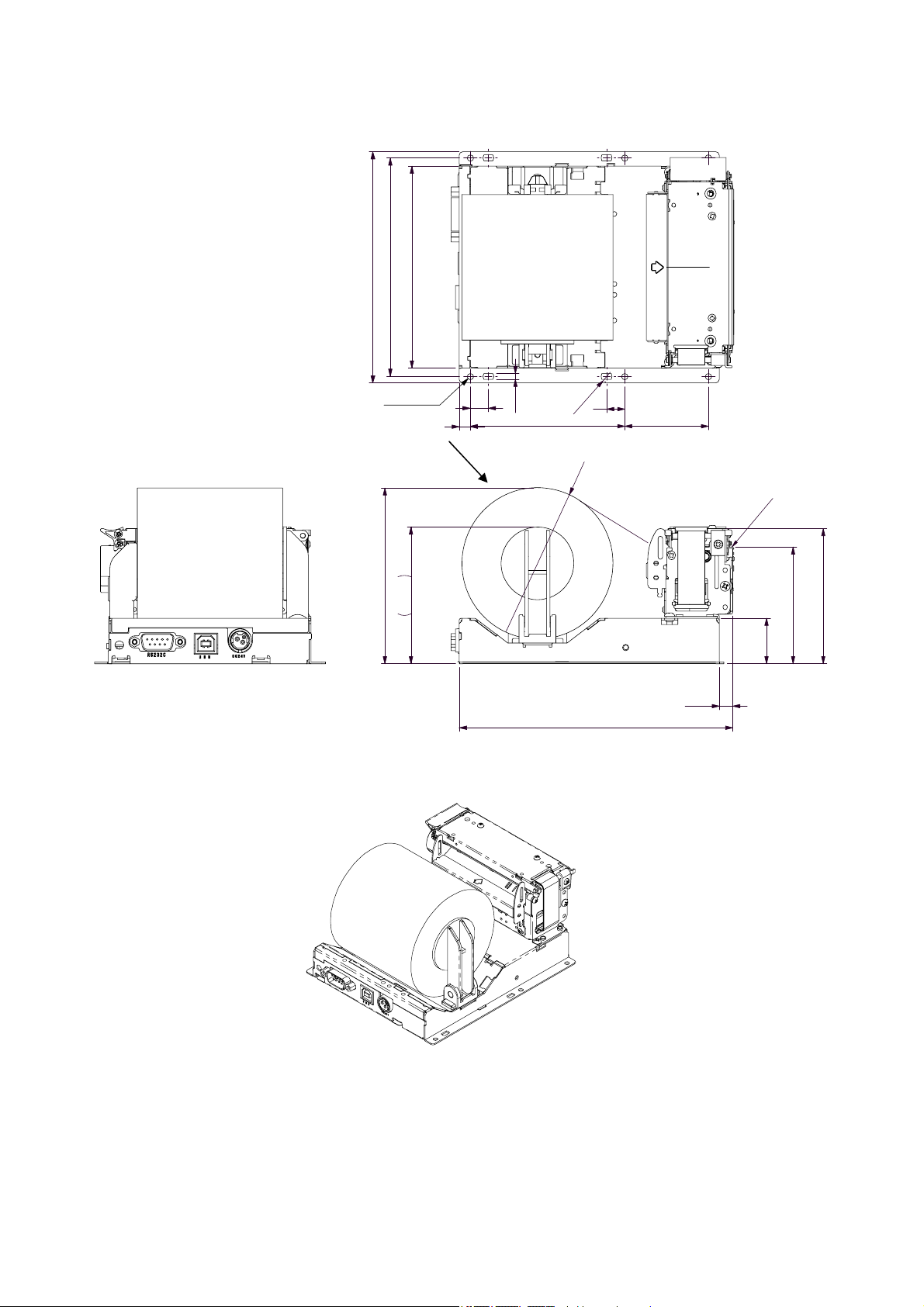

2.9 Dimenssions

1) NP-3511

120

127

111

85

φ

φ

8

6

10

46

3

6- φ 3.5

Paper

10

3.2

6

96.7

75.2

150.4

7.4

* The above is the external drawing of NP-3511 USB/Serial multiple Interface type.

Paper Exit position

用紙排出位置

74.43

64.1

25

D-F0446 NP-2511/3511 series Specifications Ver.0.07

14

Page 21

2) NP-2511

Paper Exit position

46

10

143

6

φ

85

3.2

10

6

6- φ 3.5

75.2

64.1 用紙排出位置

7.4

150.4

φ

3

8

99

ロール紙

Paper

25

106

72.2

91

97.1

* The above is the external drawing of NP-2511 USB/Serial multiple Interface type.

D-F0446 NP-2511/3511 series Specifications Ver.0.07

※本図はシリアル, USBコネクタ併設タイプ (NP-2511)を

図面化したものである。

15

Page 22

3. Configurations

3.1 Interface specifications : RS-232C

1) Synchronization : Asynchronous

2) Transmission speed : 9600, 19200, 38400, 115200bps (user selectable)

3) A word consists of

Start bit : 1bit

Data bit : 7 or 8 bit (user selectable)

Parity bit : odd, even or no parity (user selectable)

Stop bit : more than 1 bit

4) Signal polarity

RS-232C

Mark = Logic “1” (-3V -- -12V)

Space = Logic “0” (+3V -- +12V)

5) Receive data (RXD signal)

Mark = 1

Space = 0

6) Transmit data (TXD signal)

Mark = 1

Space = 0

XON/XOFF when controlled

DC1(11) h code, XON :possible to receive data

DC3(13) h code, XOFF :Impossible to receive data

7) Receive-Control (RTS signal)

Mark : Impossible to receive data

Space: Possible to receive data

8) Transmit-Permission (CTS signal)

Mark: Impossible to transfer data

Space: Possible to transfer data

3.2 Interface specifications: USB (V2.0 Full Speed)

1) Version :V2.0 FULL SPEED (12Mbps)

2) Port :Upstreamport (B jack)

3) Power Supply : Self Powered

4) Reset function : Automatic reset by insert and remove USB cable

D-F0446 NP-2511/3511 series Specifications Ver.0.07

16

Page 23

3.3 Connecter Signal Details

1) CN1: Power Input Connecter

Printer side: TCS7960-5320177(Hoshiden) or equivalent

Adaptor side: TCP8927-531177, TCP8927-631177,

TCP8935-531177(Hoshiden)equivalent (Hoshiden) or Equivalent

Pin No. Signal name Input/Output Function

1 VH Input Power DC +24V

2 GND - Power ground

3 N.C -

Shell FG - FG

*A sufficient volume of power supply is required to maintain print quality due to high peak current

that may run according to printing contents.

*If power supply cable is excessively long, the operation may become unstable. Cable should be

as short as possible. If not available, connect cables near the printer and place an electrolysis

condenser of 2200µ between power supply and ground. Voltage resistance should be higher

than 35V.

2) CN2: Serial Data signal input connector (Multiple Interface type only)

Printer side: JEC-9P (JST) or equivalent

Host side: JEC-9S (JST) or equivalent

Pin No. Signal Input/Output Function Remark

2 RXD Input Serial receiving data

3 TXD Output Serial transmitting data

4 RTS Output Receiving permission signal Connect to No.7

5 GND - Singnal ground

7 RTS Output Receiving permission signal Connect to No. 4

8 CTS Input Transmit permission signal

1, 6, 9 N.C -

3) CN3: USB data signal input connector

Printer side: B jack DUSB-BRA42-T11 (DDK) or equivalent

Host side: B plug or equivalent

Pin No. Signal Input / Output Function Remark

1 VBUS Input Power line Non twist power line

2 D- Input and output Data line Twist pair signal line

3 D+ Input and output Data line Twist pair signal line

4 GND - Power line Non twist power line

Shell Shield -

* Use USB cable which conforms to the standard (V2.0 FULL SPEED)

* We shall not be liable for operation using the connector not comformed with the standard.

D-F0446 NP-2511/3511 series Specifications Ver.0.07

17

Page 24

4) CN7: connecting to presenter (NPT-301)

Printer side: 53047-0810 (Molex) or equivalent

Host side: 51021-0800 (Molex) or equivalent

Pin no Signal Input/Output Function

1

2

3

4

5

6

7

8

LED1+ output To sensorLED1

sensor1 input From sensor1

GND

-

Signal GND

LED2+ output To Sensor LED2

sensor2 input From Sensor2

GND

-

Signal GND

M+ output Motor drive output

M- output Motor drive output

* Please do not connect any presenter except NPT-301.

There may be failure when other presenter connected.

* NPT-305/NP01201/NP01301 in review

D-F0446 NP-2511/3511 series Specifications Ver.0.07

18

Page 25

4. Functions

4.1 Function Setting

4.1.1 Dip Switch

Functions O N OFF

Factory setting

NP-2511

NP-3511

NP-2511U

NP-3511U

DS1-1 OFF OFF

DS1-2 OFF OFF

DS1-3

DS1-4 OFF OFF

DS1-5

Transmit setting See Fig.1

Serial transmit speed See Fig.2

OFF OFF

OFF OFF

DS1-6 Serial flow control XON/XOFF RTS/CTS OFF OFF

DS1-7 Autocutter no yes OFF OFF

DS1-8

Reserved

- -

OFF

OFF

* DS1-8 must be “OFF”

Fig.1 Transmit Setting

Interface Bit length Parity setting DS1-1 DS1-2 DS1-3

USB - - OFF OFF OFF

nil O N OFF OFF

8bit odd OFF O N OFF

Serial

even O N O N OFF

nil OFF OFF O N

7bit odd O N OFF O N

even OFF O N O N

Reserved - - O N O N O N

Fig.2 Serial transmit speed

Serial transmit speed DS1-4 DS1-5

115200 OFF OFF

38400 O N OFF

19200 OFF O N

9600 O N O N

4.1.2 Memory Switch

Function O N OFF

Factory setting

NP-2511

NP-3511

NP-2511U

NP-3511U

MS2-1 Japanese Kanji code Shift JIS JIS OFF OFF

MS2-2 OFF OFF

MS2-3

Built-in Language font

Switch

See Fig.3

OFF OFF

MS2-4 Near empty no yes OFF OFF

MS2-5 Presenter (NPT-301) Yes No OFF OFF

MS2-6 Black mark sensor Center Side OFF OFF

MS2-7 Reserved - - OFF OFF

MS2-8 Reserved - - OFF OFF

* MS2-7 and MS2-8 must be “OFF”.

D-F0446 NP-2511/3511 series Specifications Ver.0.07

19

Page 26

How to set Memory Switch

1. Tharmal head cover is opened and push FEED switch more than 3 seconds. Re-write mode of

Memory Switch is activated. (ALARM red: flash)

2. Lift your finger off FEED switch, set Memory Switch on dip switch.

3. By pushing FEED switch, setting of dip switch is copied to Memory Switch. (ALARM red:light)

Return dip switch setting to original position, and thermal head cover is closed. The contents of

Memory Switch is printed for confirmation.

* Pleas do not forget to return Dip switch setting to original position.

* When you cancel Rewrite mode of Memory Switch, let thermal head cover be closed.

* After setting of Memory Switch, transition to the self print is not available when thermal head

cover is closed.

Fig.3 Installed Language Fonts

Installed language fonts MS2-2 MS2-3

Japanese OFF OFF

Chinese O N OFF

Korean OFF O N

Greek O N O N

* Japanse JIS C 6226 :Full size

Katakana character set+Extended graphic character set +Code Page 858+International

character:Half size

* Korean KS X 1001:1992 :Full size

Katakana character set+Extended graphic character set+Code Page 858 :Half size

(KS X 1001:1992 installed font)

* Chinese GB18030-2000 :Half/Full size

* Greek Code Page1253 :Full size (1 byte code)

Please refer to [select character code table] for other language.

4.1.3 Self Print

1) By performing self-diagnostic print following items are checked.

* Proper function of control circuitry

* Control F/W version

* Status of Dip switch setting and memory switch setting

* Correct function of paper out sensor

2) Start and end of self diagnostic print

Turn on the power while pressing the FEED switch and release the FEED switch after

initializing print mechanism. Self diagnostic print will take place.

The self diagnostic print automatically ends when a preset print pattern are printed.

While printing, the printer is in Off-line mode.

4.1.4 Paper sensor

Paper end sensor equipped in the paper course of the printer mechanism, and it detects

paper end status. It stops printing by error bit ON, when detected the paper end.

The sensor can not detect paper end glued to the core. Please exchange the paper roll

shortly after detecting the paper end.

D-F0446 NP-2511/3511 series Specifications Ver.0.07

20

Page 27

4.2 Processing error

1) Error detection details

Name Status

Status

Info

Alarm

Status

Removal

Comm. Error 232C Comm.error - - Adjust comm.condtion

Parity

Overrun

Framing

Normal Normal - OFF

Print start status Print start setting by bit7 1 OFF Print end setting by

command(not error ) command

Paper near empty Remaining paper detect bit0 1 Blink Paper replenishment

Paper near empty sensor

detect

(MS2-4:OFF)

Paper end No paper bit2 1 ON Paper replenishment

Thermal head cover Thermal head cover open bit1 1 ON Thermal head cover

open close

Head Temparature

Head Tempt. over 70°

C

bit3 1 Blink Automatically recover

at 65°

C

Cuttter error Cutter Paper Jam bit4 1 Blink Open head cover,.

Not connected remove error factor,

Paper detect error Paper not detected during bit5 1 Blink close head cover

presenter operation or Mark

detection.

Presenter clamp Presenter clamps paper bit6 1 Blink Extract paper

When the above errors are detected (except transmission error and paper near empty , print

start status ), printer stops all operation.

・It turns ON error bit of the status information.

2) Return to normal status from error statuses

Remove causes of error statuses and turn the power on again or push the RESET switch

to return to normal. When this process is activated, at the time of power switch turned off,

the printer will be initialized, so that settings are required again.

If data remains in the buffer, attention should be paid

4.3 Buffer full print

If there remains data after one line of data is received, printer automatically prints preceding

data. The volume of buffer full data varies depending on ANK, Kanji or bit images.

D-F0446 NP-2511/3511 series Specifications Ver.0.07

21

Page 28

4.4. Drive Select

Select optimization, fixed division (no division / dual partitioning) by command.

Select depending on provided power and print duty.

1) Select Partition Drive

Please refer command table.

* Prinint speed is decreased when select dual partitioning.

2) Optimization

Select no division or dual partitioning according to the number of total dot of print per

line.

No division Dual partitioning

3-inch model 352dotl or less 353dot or more

* When select optimization, printing speed changed depending on printing ratio, and

printing noise occurred somewhat.

* When select optimization, printing quality is descended somewhat.

4.5 Select Full size and half size character

Character How to select

Japanese Command[FS &],[FS .] or Switching Shift JIS code

Korean

Command[FS &]、[FS .]

Please refer to the followings

Chinese

1 byte code (Half size) 2 byte code (Full size)

st

byte

1

nd

2

byte

rd

byte

3

th

byte

4

00 h ~ 80 h 81 h ~ FE h 81 h ~ FE h

40 h ~ 7E h

80 h ~ FE h

4 byte code (Full

size)

30 h ~ 39 h

81 h ~ FE h

30 h ~ 39 h

Greek No switch (Only Full size)

Polish No switch (Only half size)

Russian No switch (Only half size)

Scandinavian No switch (Only half size)

Turkish No switch (Only half size)

D-F0446 NP-2511/3511 series Specifications Ver.0.07

22

Page 29

4.6 Operation panel

The printer is ready for the following operations;

1) ALARM (red) [alarm lamp]

Will turn on (or blink) when printer is on error status.

Will blink/ turn on/ turn off when rewriting Flash Rom

※The pattern of the ALARM indication is in the following chart.

Display pattern Printer status

1

0

1

0

1

0

1

0

0.1secc

0.1sec

0.2secc

0.2sec

1

0

1

0

0.2sec

0.2sec 1.0sec

2.2sec

2.2sec

Normal Status

Print(receive) ready

No paper

Thermal head cover open

F/W write mode 9

Paper near empty 2

Head temperature over 70℃

Or, Wrong head connection

Auto cutter error 6

Paper detect error 7

Presenter clamp

( detects remaining paper)

Priority

(9:High ~ 1:Low)

1

3

4

5

8

2) FEED Switch [Paper feed switch]

Switch to feed paper in the forward direction

Also, used in self-printing .

3) Reset SW

Reset SW is placed on the right side of FEED SW, and you cannot push Reset SW

with your finger to avoid misoperation. (Push Reset SW lightly with ballpoint pen etc,

and release.)

By activating Reset SW, the printer is initialized at the time of power on.

* Reset Switch will be implemented on production February 2007.

D-F0446 NP-2511/3511 series Specifications Ver.0.07

23

Page 30

4.7 How to set roll paper

1) NP-3511

- As illustrated, you lift the shaft vertically and set a roll paper passing through the shaft

(Pay attention to the direction of roll paper.)

- Set shaft back to previous position.

- Put the edge of paper into loading slot. (Put it straight into slot, not curl)

- Retract the paper automatically with sensor detected. (In case of power on)

- Paper is retracted into a certain length and can print after cut the excess of it.

(Attention): The leading edge of paper should be straight and at right angle.

Paper at cutout state might be retracted at an angle.

Roll paper

Print side

Winding direc.

Paper Support Shaft

Guide for paper

D-F0446 NP-2511/3511 series Specifications Ver.0.07

24

Page 31

2) NP-2511

D-F0446 NP-2511/3511 series Specifications Ver.0.07

25

Page 32

4.8 How to remove the jammed paper

- Pull up head open lever at the direction as illustrated.

- Remove all jammed paper on the route of paper.

- Close thermal head cover completely.(Until hearing click)

Attentions: Since the thermal head reaches a high temperature, please don’t touch it. If a

paper jam occurr, a cutter blade may stick out. DO NOT TOUCH IT.

Head Open Lever

* This is drawing of NP3511

4.9 How to clean Thermal Head

In case the heat generation part of the thermal head gets wisps of paper, the quality of print

may drop. In this case, you should clean the thermal head as following procedures.

1) Thermal Head

Remove wips of paper and grim with swab moistened alcohols solvent (ethanol / IPA) on

the heat generation part of thermal head. The use of methanol in alcohols solvent is

prohibited.

2) Platen

Remove wips of paper and dust on the surface by wiping like rubbing slightly with dry cloth.

3) Mark Sensor/No paper sensor and its surrounding

Remove wips and paper and dust on sensors with swab moistened slightly.

4) Attentions

・Since the thermal head reach a high temperature shorly after printing, don’t touch it with

hands.

・Don’t touch the heat generation part of thermal head with hands and metal materials.

・When you clean thermal head, you should pay fully attention to the risk of breaking of

thermal head due to static electricity.

・In case a lot of wips of paper are genrated depending on paper, timing of maintenaunce

should be decided after confirming the paper.

・You should power on after completely driy on the printer.

D-F0446 NP-2511/3511 series Specifications Ver.0.07

26

Page 33

5. Command

5.1 Command Table

1) 【Horizental Tab】《HT》································································································29

2) 【Line feed】《LF》 ········································································································29

3) 【Carriage return】《CR》 ······························································································29

4) 【Software Reset】《DC1》····························································································29

5) 【Barcode termination change】《ESC RS c n》 ···························································29

6) 【Setting character right space quantity】《ESC SP n》 ················································29

7) 【Print mode batch setting】《ESC ! n》 ········································································30

8) 【Absolute position setting】《ESC $ n1 n2》 ································································30

9) ■【Download characters set set/reset】《ESC % n》 ···················································30

10) ■【Defintion of Download Characters】《ESC & s n m a Dn》 ·····································31

11) 【Bit Image mode Set】《ESC * m n1 n2 Dn》 ······························································33

12) 【Underline Set/Reset】《ESC - n》···············································································35

13) 【1/6

inch line feed pitch】《ESC 2》··············································································35

14) 【Sets smallest pitch line feed】《ESC 3 n》··································································35

15) 【Data input control】《ESC = n》··················································································35

16) 【Printer initialization】《ESC @》 ·················································································35

17) 【Back feed】《ESC B n》····························································································36

18) 【Horizental tab position set】《ESC D n1 n2 --- NUL》·················································36

19) 【Bold print set/reset】《ESC E n》················································································36

20) 【Double strike print set/reset】《ESC G n》 ·································································36

21) 【Print and smallest pitch line feed】《ESC J n》···························································37

22) ■【International character select】《ESC R n》····························································37

23) 【90° clockwise rotated character set and reset】《ESC V n》 ······································37

24) 【Relative position set】《ESC ¥ n1 n2》·······································································37

25) 【Position alignment】《ESC a n》·················································································38

26) 【Raster Bit Image】《ESC b n1 n2 n3 Dn》··································································39

27) 【FEED Switch enable/disable】《ESC c 5 n》 ······························································40

28) 【Print and “n” line feed】《ESC d n》············································································40

29) 【Presenter ejection mode set】《ESC h n》 ·································································40

30) 【Full Cut】《ESC i》······································································································40

31) 【Partial Cut A】《ESC m》 ····························································································40

32) 【Partial Cut B】《ESC n》·····························································································40

33) 【Compulsary Feed】《ESC r n》 ··················································································41

34) 【Printer information transitting】《ESC s n》 ································································41

35) ▲【Select Character code table】《ESC t n》 ·······························································41

36) 【Printer status transmit】《ESC v》 ··············································································41

37) 【Inverted Character Set・Reset】《ESC { n》······························································42

38) 【Select division drive】《GS % n》 ···············································································42

39) 【Black and white reverse print set and reset】《GS B n》 ············································42

40) 【Print start/Print finish setting】《GS G n》·································································43

41) 【Selection of printing position of HRI character】《GS H n》········································43

42) 【NV Bit Image Print】《GS P n》 ··················································································44

43) 【NV Bit Image registration】《GS T n》 ········································································44

44) 【Firmfare downloading】《GS d Dn》 ···········································································44

45) 【Select font of HRI character】《GS f n》 ·····································································44

46) 【Setting of the height of barcode】《GS h n》 ······························································45

D-F0446 NP-2511/3511 series Specifications Ver.0.07

27

Page 34

47) 【Barcode Print】《GS k n Dn NUL》·············································································45

48) 【Auto-Transmitting of Printer Status】《GS v NUL》·····················································45

49) 【Select horizontal size of Barcode】《GS w n》 ···························································45

50) 【Print density set】《GS ~ n》 ······················································································46

51) 【Cue Operation】《Gs FF n》 ·······················································································46

52) 【mark detection method & position correction feed quantity set】《Gs ( m a n1 n2》···46

53) 【cue process set at setting paper】《Gs m n 》 ···························································46

54) 【Printable area set】《Gs W n1 n2》 ············································································47

55) 【maximum printing speed set】《GS S n》 ···································································47

56) 【butch set of Japanese Kanji print mode】《FS ! n》····················································47

57) ▲【Japanese Kainji mode set】《FS &》·······································································47

58) 【Japanese Kanji underline set/reset】《FS - n》···························································48

59) ▲【Reset Japanese Kanji mode】《FS .》 ····································································48

60) ■【Definition of additional Characters】《FS 2 a1 a2 Dn》···········································49

61) ■【Select Japanese Kanji code】《FS C n》 ································································50

62) 【Japanese Kanji Space setting】《FS S n1 n2》 ··························································50

63) 【Select character table code】《FS T n》 ·····································································51

64) 【Set/Reset Quadruple Japanese Kanji character】《FS W n》·····································51

▲ is effected on Japanese/Korean font selected from language font.

■ is effected on Japanese font selected.

※51)~53 is related to Black Mark Commands.

※17)、51)~55) is valid for Firm Ware Ver.1.10 afterwards in NP-3511

※In case print method is storage, print speed will be max. 200mm /sec.

D-F0446 NP-2511/3511 series Specifications Ver.0.07

28

Page 35

5.2 Printer Driver

Please apply the driver stated below for using under Windows environment.

Windows 2000/Windows XP/Windows CE 5.0/Linux(only sample)

5.3 Command details

1) 【Horizental Tab】《HT》

Code:〔09〕h

Print position is moved at next horizental tab.

* Horizental tab is set by【Horizental tab position set】command.

th

* Default of【Horizental tab】is every 8

character(9 digit,17 digit,・・,41digit)in font A.

* If the next【Horizental tab】is not set, this command is disregarded.

2) 【Line feed】《LF》

Code:〔0A〕h

Data in print line buffer is printed, and linefeed is conducted based on preset line feed

quantity.

3) 【Carriage return】《CR》

Code:〔0D〕h

* This command is disregarded.

4) 【Software Reset】《DC1》

Code:〔11 〕h

Let Farmware restarted as same procedures when power-on

* Since this command stored on internal reception input buffer executes sequential, the

timing of receptin of command is different from that of command execution.

* Software reset is activated after auto-cutter finished driving.

5) 【Barcode termination change】《ESC RS c n》

Code:〔1B〕h+〔1E〕h+〔63〕+n ※〔n=00,80〕h

Change terminator of 【Barcode print】command with n.

* n is indicated as follows;

n(hex) termination

00

80

〔00〕h

〔FF〕h

* Default of n is〔00〕h

6) 【Setting character right space quantity】《ESC SP n》

Code:〔1B〕h+〔20〕h+n ※〔00≤n≤20〕h

Set the value of right space of character by dot (by 1/203 inch)

* Right space is reflected with zoom when double width zoom mode

* Default of n is〔00〕h.

D-F0446 NP-2511/3511 series Specifications Ver.0.07

29

Page 36

7) 【Print mode batch setting】《ESC ! n》

Code:〔1B〕h+〔21〕h+n ※〔00≤n≤FF〕h

Print mode setting

* n has the following meanings.

bit funciton

value

0 1

0 Character font Font A Font B

1 Undifined

2 Undifined

3 Bold reset set

4 Double height reset set

5 Double width reset set

6 Undifined

7 Underline reset set

* If double height and double width are set at the same time, quadruple character will be

formed.

* All of the printed characters will be underlined except for the 90° rotated characters and

spaces created by horizontal tab.

* Underline width is determined by the value set in [Underline set/reset] section.

The default value is 1 dot width.

* Bold print control is effected when Kanji mode

* Different sizes of character mixed such as double width and normal size can be

printed.

* The default of n is〔00〕h.

8) 【Absolute position setting】《ESC $ n1 n2》

Code:〔1B〕h+〔24〕h+n1+n2 ※〔00≤n1≤FF〕h

※〔00≤n2≤02〕h

Setting from the front on position of start of print by the number of dot

(by 1/203-inch position)

* 256 into the number of dot at print start point is n2、remainder is n1

* print start point is n1+n2×256 from the front of the line.

* Disregard the setting when beyond the end of the line.

* When this command is received on the middle of line, it is efective not to over the

current position.

9) ■【Download characters set set/reset】《ESC % n》

※Effective only when Japanese is selected.

Code:〔1B〕h+〔25〕h+n ※〔00≤n≤FF〕h

Set/Reset Download characters

* n is the bottom bit. Effective on only(b0). b0 mentioned as follows;

b0 Function

0 Reset Download character set

1 Set Downlaod character set

* Default of n is 〔00〕h

D-F0446 NP-2511/3511 series Specifications Ver.0.07

30

Page 37

10) ■【Defintion of Download Characters】《ESC & s n m a Dn》

※Efective only when selected Japanese.

Code:〔1B〕h+〔26〕h+s+n+m+a+Dn ※〔s=03〕h

※〔20≤ n≤ 7E〕h,〔20≤ m≤ 7E〕h

※ Font A〔01≤a≤0C〕h

※ Font B〔01≤a≤09〕h

Definition of font of Download characters on alphanumeric characters.

* “s” indicates a number of bytes in a vertical direction and “a” is a number of dots in

horizontal direction.

* “n” indicates the start character code, and “m” means the end character code. If only 1

character should be defined, then n = m.

* Definable characters are from (20)h to (7E)h on ASCII code. (95 characters)

* Dn indicates data to be defined, It indicates the“a” dot pattern from the left.

Remaining area on the right of character is filled with space.

* Once a download character defined by command, it remains valid until execution

of (Software Reset) and Reset Switch or the power is turned off.

* Redefined character is only effective to specified area.

<Reference>

In the case of Font A

12dots

P1

P4

P7 P34

MSB

24dots

P2

P5

P35

P3

P6

P36

LSB

P1=〔00〕h,P4=〔00〕h,P7=〔00〕h,P10=〔00〕h,…

P2=〔00〕h,P5=〔00〕h,P8=〔0F〕h,P11=〔72〕h,…

P3=〔08〕h,P6=〔F8〕h,P9=〔08〕h,P12=〔00〕h,…

D-F0446 NP-2511/3511 series Specifications Ver.0.07

31

Page 38

<Refernce>

In the case of Font B

9dots

MSB

P1

P4

P7 P25

17dots

P2

P5

P26

LSB

MSB

P27 P6 P3

LSB

P1=〔40〕h,P4=〔7F〕h,P7=〔41〕h,P10=〔41〕h,…

P2=〔04〕h,P5=〔FC〕h,P8=〔04〕h,P11=〔04〕h,…

P3=〔00〕h,P6=〔00〕h,P9=〔00〕h,P12=〔00〕h,…

D-F0446 NP-2511/3511 series Specifications Ver.0.07

32

Page 39

11) 【Bit Image mode Set】《ESC * m n1 n2 Dn》

Code:〔1B〕h+〔2A〕h+m+n1+n2+Dn ※〔m=indicated below〕h

※〔00≤n1≤FF〕h

※〔00≤n2≤02〕h

* Data is printed in bit image mode for resolution specified by “m”.

* Total print dots are divided by 256, quotient is n2 and remainder is n1.

* Total print dots in bit image mode is n1+(256×n2).

* If the bit image input data exceeds specified position, the exceeded data will be

disregarded.

* Bit image data (Dn) interprets bit 1 as print and bit 0 as not print.

* Bit image mode is indicated below;

<Standard>

Vertical direction Horizental direction

m(hex) Bit image mode

00

01

20

21,23

8 dot

single density

8 dot

double density

24 dot

single density

24 dot]

double density

Dot quantity

Dot

density

Dot

density

8 67DPI 101DPI 288

8 67DPI 203DPI 576

24 203DPI 101DPI 288

24 203DPI 203DPI 576

Maximum dot number

3-inch

model

D-F0446 NP-2511/3511 series Specifications Ver.0.07

33

Page 40

<Relationship between Bit Image data and Printed dot>

・8 dot bit image

MSB

D1 D2 D3

D1 D2 D3

LSB

Print data

=1dot

Single density Double density

・24 dot image bit

D1 D4 D7 MSB

D1 D2 D3 D7 D8 D9

D4

D5 D6

D2

D5

D8

D3

D6 D9

LSB

Print data

=1dot

Single density Double density

D-F0446 NP-2511/3511 series Specifications Ver.0.07

34

Page 41

12) 【Underline Set/Reset】《ESC - n》

Code:〔1B〕h+〔2D〕h+n ※〔00≤n≤02〕h

Sets and Resets Underline

* Underline is valid for all characters except for the area skipped by horizontal tab. Also

Underline is not valid for 90° rotated character.

* This command is not valid when Kanji mode.

* Underline is verified with n value as shown bellow.

n(hex) Type of underlines

00 Reset underline

01 Set one dot underline

02 Set two dot underline

* Default value of n is 〔00〕h.

13) 【1/6

inch line feed pitch】《ESC 2》

Code:〔1B〕h+〔32〕h

Sets one line feed to 1/6th of an inch.

14) 【Sets smallest pitch line feed】《ESC 3 n》

Code:〔1B〕h+〔33〕h+n ※〔00≤n≤FF〕h

Sets a line feed pitch to n/203rd of an inch.

* Despite of height set by value, the same space with character height is sent by line

feed.

* Default value of n is 〔22〕h.

15) 【Data input control】《ESC = n》

Code:〔1B〕h+〔3D〕h+n ※〔00≤n≤FF〕h

Select apparatus to be data input from host

* Each bit of N indicates below;

bit function

value

0 1

0 Printer invalid valid

1 Undefined

2 Undefined

3 Undefined

4 Undefined

5 Undefined

6 Undefined

7 Undefined

* When printer is not selected、all receiption data is disregarded until this printer is

selected by this command.

* When printer is not selected, busy situation may remains by operation of printer.

* Default value of n is〔01〕h.

16) 【Printer initialization】《ESC @》

Code:〔1B〕h+〔40〕h

Clears the data stored in the print buffer and resets each setting to default values.

* It does not clear the data stored in the internal receive buffer.

* re-reads the dip switch and memory switch.

* It is stored in the internal receive buffer and activated in sequential.

D-F0446 NP-2511/3511 series Specifications Ver.0.07

35

Page 42

17) 【Back feed】《ESC B n》

Code:〔1B〕h+〔42〕h+n ※〔00≤n≤FF〕h

This command is for forwarding paper in reverse direction.

* Set forwarding length in n Dot line. In case of set〔00〕h, no forwarding.

* You should set this command once only due to avoid paper jam, and then forward

paper in right direction.

* Backlash may let paper not put properly.

* In case there is print data on buffer of Print Line buffer, it should be backfeed after

prining.

* Tip of paper should not be exceed the limited of backfeed.

(Use〔n≤34〕h)

18) 【Horizental tab position set】《ESC D n1 n2 --- NUL》

Code:〔1B〕h+〔44〕h+n1+n2+---+〔00〕h ※〔00≤n≤FF〕h

Sets horizental tab position.

* “n” indicates the digits number from the head to the tab position. In this case, [n = tab

position – 1].

* Tab position is set at the location of character width x n from the beginning of a line.

The character width in this case includes character right space. When double width

function is set, then the width becomes double of ordinary character.

* Maximum number of tab positions is 32. If setting exceeds 32, then

the exceeded values are neglected.

* < ESC D NUL > clears all tab positions being set. After the tab is cleared,

(horizontal tab) will be ignored.

th

* Default value is set at every 8 characters of font A (at 9

, 17th, 25th, 33rd and 41st digit).

19) 【Bold print set/reset】《ESC E n》

Code:〔1B〕h+〔45〕h+n ※〔00≤n≤FF〕h

Set and Reset Bold Print

* “n” is only valid for LSB (b0)

* LSB (b0) is defined as following.

b0 Value

0 Resets Bold print

1 Sets Bold print

* When bold print, the result of print may be deformed.

* Default value of n is〔00〕h.

20) 【Double strike print set/reset】《ESC G n》

Code:〔1B〕h+〔47〕h+n ※〔00≤n≤FF〕h

Set and Reset Double Strike Print Function.

* “n” is only valid for LSB (b0)

Control by LSB (b0) is explained as following.

b0 Descriptions

0 Reset Double Strike print

1 Set Double Strike print

* When Double Strike print, the result of print may be deformed.

* Default value of n is 〔00〕h.

D-F0446 NP-2511/3511 series Specifications Ver.0.07

36

Page 43

21) 【Print and smallest pitch line feed】《ESC J n》

Code:〔1B〕h+〔4A〕h+n ※〔00≤n≤FF〕h

Prints the data in the print line buffer and feeds the paper by n/203rd of an inch.

* Line feed quantity does not remain.

* Beginning of a line is a print start position.

* The height of character for a line is always sent by line feed. If the value of height is set

by “n” below the height of character, the same space with character height is sent by

line feed.

22) ■【International character select】《ESC R n》

Effective only when selecting either overseas or domestic code in [character code

table select] and Japanese in language font.

Code:〔1B〕h+〔52〕h+n ※〔00≤n≤0A〕h

Selects International characters

* The values of “n” have following meanings

n(hex) Character set

00 U.S.A.

01 France

02 Germany

03 U.K.

04 Denmark I

05 Sweden

06 Italy

07 Spain

08 Japan

09 Norway

0A Denmark II

* Default value of n is〔08〕h.

23) 【90° clockwise rotated character set and reset】《ESC V n》

Code:〔1B〕h+〔56〕h+n ※〔00≤n≤01〕h

Sets and resets 90° clockwise rotated character.

* (Underline set) is invalid when the 90° clockwise rotated character set.

* “n” has the following meaning.

n(hex) Descriptions

00

01

Reset 90° rotated character

Set 90° rotated character

* Default value of n is〔00〕h.

24) 【Relative position set】《ESC ¥ n1 n2》

Code:〔1B〕h+〔5C〕h+n1+n2 ※〔00≤n1≤FF〕h

※〔00≤n2≤FF〕h

Print start position is assigned by dots in 1/203rd of inch from the current postion.

* Divide the value of dot by 256, place quotient to n2, and remainder to n1.

* Rightward defines plus, leftward defines minus.

* When n dot is set on rightward, the value is n1 + n2 x 256.

* When n dot is set on leftward, the value is set by n’s complement.

n dot = 65536-n

* Setting which exceeds end of line is ignored.

D-F0446 NP-2511/3511 series Specifications Ver.0.07

37

Page 44

25) 【Position alignment】《ESC a n》

Code:〔1B〕h+〔61〕h+n ※〔00≤n≤02〕h

Align print data in a line at the specfied position.

(Except for definite Bit Image)

* n has the following meanings;

n(hex) Position

00 Left alignment

01 Centering

02 Right alignment

* Effective only when input on the beginning of the line.

* Default value ofnis〔00〕h

D-F0446 NP-2511/3511 series Specifications Ver.0.07

38

Page 45

26) 【Raster Bit Image】《ESC b n1 n2 n3 Dn》

Code:〔1B〕h+〔62〕h+n1+n2+n3+Dn

※〔01≤n1≤48〕h:3-inch model

※〔00≤n2≤FF〕h

※〔00≤n3≤FF〕h

Print data in raster bit image.

* Dn is raster bit image data.

* The printer prints raster bit image of width n1 byte by height n2+(256*n3) dot lines.

* The total byte of the requested raster bit image data (Dn) is n1*(n2+(256*n3)).

* Raster bit image data (Dn) exceeding the printing field will be disregarded.

* Raster bit image data (Dn) interprets bit”1” as print and bit”0” as not print.

* Relation between raster bit image data (Dn) and printed dots are as follows.

n1 byte

D1 D2 Dn1

Dn1+1 Dn1+2 Dn1*2

Dn1*2+1 Dn1*2+2 Dn1*3

n2+(256*n3)dots

n1*(n2+(256*n3))

MSB LSB

* Please add < ESC J 00h > ([1B] h + [4A] h + [00] h) at the end of this command.

* Data of this command is started printing after storage regardless of <start print/end of

set>.

D-F0446 NP-2511/3511 series Specifications Ver.0.07

39

Page 46

27) 【FEED Switch enable/disable】《ESC c 5 n》

Code:〔1B〕h+〔63〕h+〔35〕h+n ※〔00≤n≤FF〕h

Changes the FEED switch valid or invalid

* “n” is only valid for LSB (b0)

* “n” bit has a following meanings

B0 Description

0 Enable FEED switch

1 Disable FEED switch

* Default value of “n” is [00] h.

28) 【Print and “n” line feed】《ESC d n》

Code:〔1B〕h+〔64〕h+n ※〔00≤n≤FF〕h

Prints the data in the print line buffer and feeds paper by “n” lines.

* The setting value by this command will not remain, so please set the value every time

you use this command.

* Beginning of a line is a next print start position.

* If there is print data remained, line feed should be always activated for th same height

of character.

29) 【Presenter ejection mode set】《ESC h n》

※This command is effective only when you use Presenter(NPT-301)

Code:〔1B〕h+〔68〕h+n ※〔00≤n≤01〕h

Select “Clamp Feed” or “All Feed” on Presenter Feed mode

*n has a following meanings.

n(hex) Function

00 Clamp Feed

01 All Feed

* Default of n is〔00〕h.

30) 【Full Cut】《ESC i》

Code:〔1B〕h+〔69〕h

* Full cut the paper is activated.

* Effective at the head of a line

31) 【Partial Cut A】《ESC m》

Code:〔1B〕h+〔6D〕h

* conduct partial cut (center is left uncut.)

* Effective at the head of a line

32) 【Partial Cut B】《ESC n》

Code:〔1B〕h+〔6E〕h

* conduct partial cut (a few mm in the center is left uncut.)

* Effective at the head of a line.

* The part of Uncut is thicker than one on (Partial Cut A).

D-F0446 NP-2511/3511 series Specifications Ver.0.07

40

Page 47

33) 【Compulsary Feed】《ESC r n》

※This command is effective only when you use Presenter(NPT-301)

Code:〔1B〕h+〔72〕h+n ※〔00≤n≤01〕h

(Compulsary Feed) is used for compulsary feed / (All Feed) with status of unremoval of

paper in a certain time running after (Clamp Feed).

* This command let motor normal or reverse rotate the motor until feed all paper.

* n has the following meanings.

n(hex) Motor

00 Forward Rotation

01 Reverse Rotation

34) 【Printer information transitting】《ESC s n》

Code:〔1B〕h+〔73〕h+n

Conduct printer information transmitting.

* Details of n and return information mentioned as the following;

n(hex)

02 Model info.

03

04

05

Category of Printer

Information

Return Data format Return data length

Variable length string

(terminal NULL=00h)

F/W version info. Fixed length string

Boot version info. Fixed length string

SW setting info. Fix Length Hex data

Max32Byte

8Byte

8Byte

4Byte

Return Transimit Format

〔FF〕h + n(※1) +return data

※1 n is designated by command.

35) ▲【Select Character code table】《ESC t n》

※Effective only when Japanese and Korean selected

Code:〔1B〕h+〔74〕h+n ※〔00≤n≤06〕h

Conduct selection of Character code table

* n has the following meaning.

n(hex) Font Table

00 International Code page

01 Japanese Code page

02 Code Page 858

03 Code Page 1250

04 Code Page 1251

05 Code Page 1252

06 Code Page 1254

* Default value of n is〔01〕h

36) 【Printer status transmit】《ESC v》

Code:〔1B〕h+〔76〕h

Transmit current printer status

* Status transmit is one byte. Please refer to the error detection for the details.

* Transmit one byte after confirmation of receivable on host (CTS singnalon space status)

* When host is unreceivable (CTS singnal at Mark status), printer is waiting until host is

receivable.