Page 1

MSI9750A

RF Remote Weight Indicator

Operator’s Manual

Page 2

HANDHELD RF REMOTE INDICATOR for CELLSCALE

®

This Page Intentionally Left Blank

Page 2 MSI-9750A RF Remote Indicator • User Guide

Page 3

MEASUREMENT SYSTEMS INTERNATIONAL

Firmware Version 5-XX for 2450 Modems

TABLE OF CONTENTS

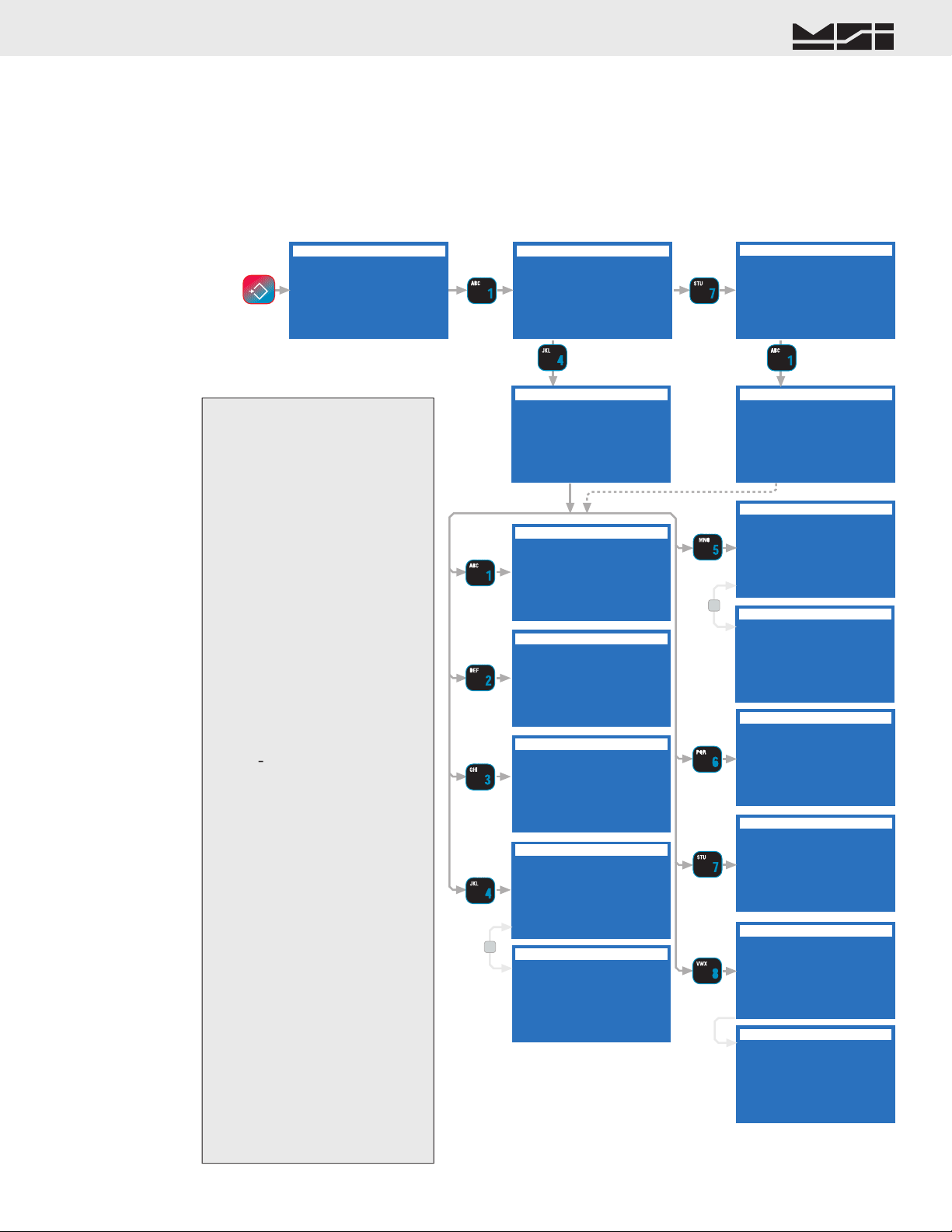

SECTION 1 – INTRODUCTION & ORIENTATION

................................

Introduction

.........................................................................

9750A Keyboard

.................................................................

4

Key Descriptions

.................................................................

5

9750A Display Symbols

......................................................

6

General Information

............................................................

7

Manual & 9750A Conventions

...........................................

7

Features

...............................................................................

8

9750A Block Diagram

........................................................

8

The CellScale Family

..........................................................

9

Unit Setup

.........................................................................

0

Battery

...............................................................................

0

Replacing the Battery

........................................................

0

Charger Adapter

................................................................

0

Charging the Battery

.........................................................

0

SECTION 2 – RF SCALE COMMUNICATIONS

..................................

FCC Statemen

t

..................................................................

Network Description

.........................................................

Antenna

.............................................................................

RF Network Setup

.............................................................

Advanced Modem Settings

...............................................

3

Confi guring for multiple networks

....................................

4

Troubleshooting RF Connection Problems

.......................

5

RF Site Testing

..................................................................

6

CellScale Network Auto Scan

...........................................

6

SECTION 3 – SCALE OPERATION

.................................................

7

Power

...............................................................................

7

Multiple Scale Channels

...................................................

7

Selecting The Active Channel

...........................................

7

To Select The Display Channel

.........................................

8

Zero

...................................................................................

9

Tare

....................................................................................

2

0

Setup Tare Menu

...............................................................

2

Net / Gross

........................................................................

2

Units

..................................................................................

2

2

Peak Hold (Function Key Option)

....................................

Send / Print

........................................................................

Display Test

.......................................................................

ulti-Channel Systems

.....................................................

8

SECTION 4 – FUNCTION KEYS

....................................................

3

Setup Function Keys

.........................................................

3

Default Function Keys

......................................................

2

4

Custom Function Key Labels

............................................

2

6

SECTION 5 – ID CODES

..............................................................

2

7

ID Code Organization

.......................................................

2

7

Setup ID Codes Menu

.......................................................

2

8

Using ID Codes

.................................................................

9

ID Code String 1 & String 2

.............................................

3

0

SECTION 6 – TOTAL / STATISTICS

................................................

3

Total

...................................................................................

3

Auto Total

..........................................................................

3

Setup Total Menu

..............................................................

3

View Total

.........................................................................

3

3

Statistics

...........................................................................

3

4

SECTION 7 – 9750A SETUP

.......................................................

3

6

System Setup Menu

..........................................................

3

6

Password Locks

.................................................................

3

7

Keyboard Lock

..................................................................

3

8

Display Setup

....................................................................

3

8

Display Setup Menu

..........................................................

0

Scale Display Setup Menu – Preset Displays

...................

Using Display Setup

..........................................................

Custom Display Setup

.......................................................

4

3

Custom Screen Setup Procedure

.......................................

4

6

Custom Single Channel Display Setup Menu

...................

4

7

Custom Multi-channel Display Setup Menu

.....................

4

8

SECTION 8 – SET POINTS

...........................................................

4

9

Introduction

.......................................................................

9

Set Point Setup Menu

........................................................

5

0

Program Set Point Menu

...................................................

5

9750A Response Menu

.....................................................

5

Set Point Formula Menu

...................................................

5

3

Direct Relay Control

.........................................................

5

3

SECTION 9 – COMMUNICATION PORTS

.........................................

5

4

Introduction

.......................................................................

5

4

Electrical Conformance

.....................................................

5

4

Mating Cable

.....................................................................

5

4

Data Confi guration

............................................................

5

Trigger Print

......................................................................

5

Comm Port Setup Menu

....................................................

5

5

General Text Entry

............................................................

5

7

General Text Entry Menu

..................................................

5

8

Printer / Output Formatting

...............................................

5

9

Example Printer Formatting

..............................................

5

9

Programming the End of Line or Start of Line StringS

....

6

0

Editing the Print String

.....................................................

6

0

General Text / Control Character Entry

...........................

6

0

Serial Output “@” Commands

..........................................

6

SECTION 10 – DATA LOGGING

...................................................

6

Introduction

.......................................................................

6

Data Logging Setup

..........................................................

6

Data Logging Control Menu

.............................................

6

5

SECTION 11 – TEXT MESSAGING

................................................

6

6

Host Message Design

........................................................

6

6

9750A to Host Messages

...................................................

6

7

SECTION 12 – BAR CODE

..........................................................

6

9

Bar Code Setup Menu

.......................................................

6

9

SECTION 13 – CHANNEL SETUP & CALIBRATION

.........................

7

Channel Setup Menu

.........................................................

7

Calibrate General Information

..........................................

7

Enable Calibration

.............................................................

7

To Calibrate

......................................................................

7

To Enable / Disable AZM (Auto Zero Maintenance)

........

7

Motion Band

.....................................................................

7

4

Center-of-Zero (COZ) Indicator

.......................................

7

5

Reset All

............................................................................

7

5

Installing Firmware Updates

.............................................

7

6

9750A Setup Duplicating

..................................................

7

8

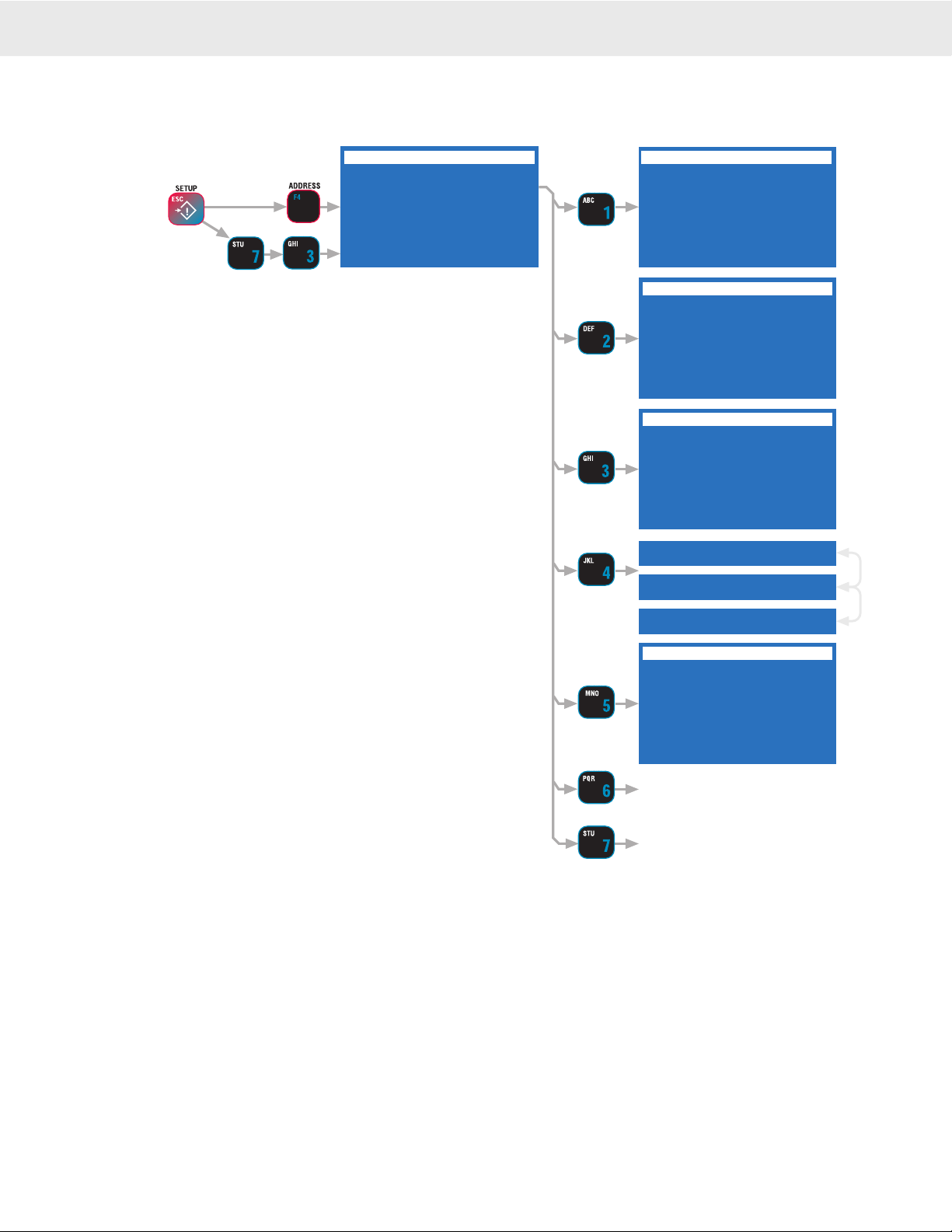

APPENDIX A – MENU MAPS

......................................................

7

9

Setup Select Menu

............................................................

7

9

Total Settings

.....................................................................

7

9

Password Locks

.................................................................

7

9

Function Keys

...................................................................

8

0

Serial & Strings

.................................................................

8

Product ID Codes

..............................................................

8

2

Bar Code Setup

.................................................................

8

2

Tare Settings

......................................................................

8

3

RF Modem Settings

..........................................................

8

3

Scale Display Setup

..........................................................

8

Scale Single Channel Custom Display Setup

...................

8

5

Scale Multi-Channel Custom Display Setup

....................

8

6

Channel / Calibrate Settings

.............................................

8

7

System Settings

.................................................................

8

8

Display Test

.......................................................................

8

8

Monitor Batteries

..............................................................

8

8

Calibration

.........................................................................

8

9

Reset All or Reset RF Modem

..........................................

8

9

General Text Entry

............................................................

9

0

Set Points

...........................................................................

9

APPENDIX B – ASCII CHART

....................................................

9

APPENDIX C – SPECIFICATIONS & SUMMARY OF FEATURES

..........

9

3

THE MSI LIMITED WARRANTY

..................................................

9

MSI CellScale® System • 9750A User Guide Page 3

Page 4

SECTION 1 – INTRODUCTION & ORIENTATION

INTRODUCTION

The Measurement Systems International MSI-9750A RF Remote Indicator is an accessory component of MSI's

CellScale

®

System. Combined with 1 or more CellScales, the 9750A provides complete control over all scale and

data functions. The 9750A serves as a remote terminal for any CellScale and has no internal measurement capa-

bility. One 9750A can read the output of many CellScales, and 1 CellScale can also provide data to many 9750's.

The backlit, alphanumeric graphic display provides precise, unambiguous indication of operating modes such as

Net, Gross, or Total. The 9750A can calibrate a CellScale remotely and provides a user interface to the advanced

features of the CellScale. The CellScale system is digitally calibrated from either the 3750CS Indicator, a 9750A

Indicator, or with a terminal program hooked directly to the CellScale model 9000. The 9750A combined with a

CellScale is designed to meet or exceed the requirements of all regulatory agencies.

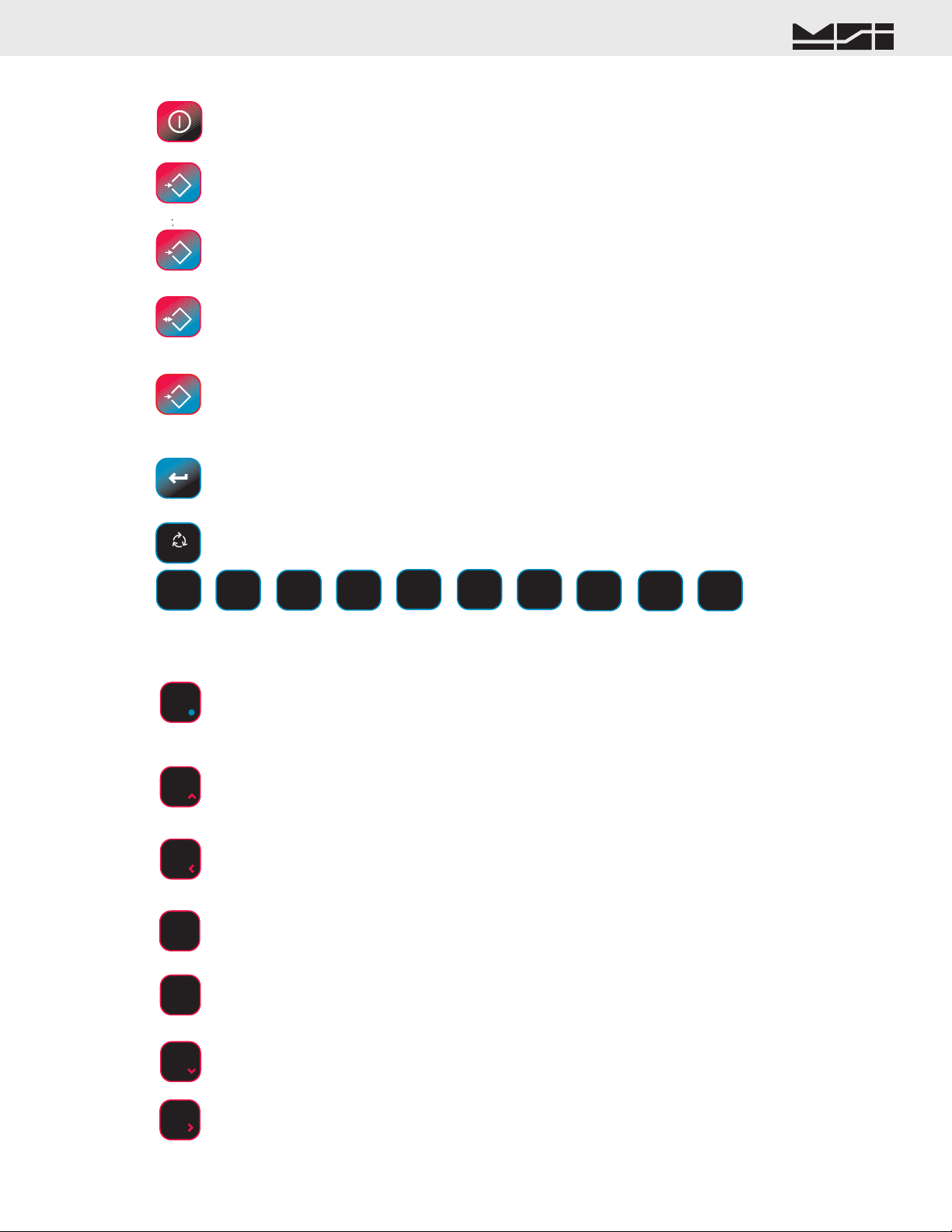

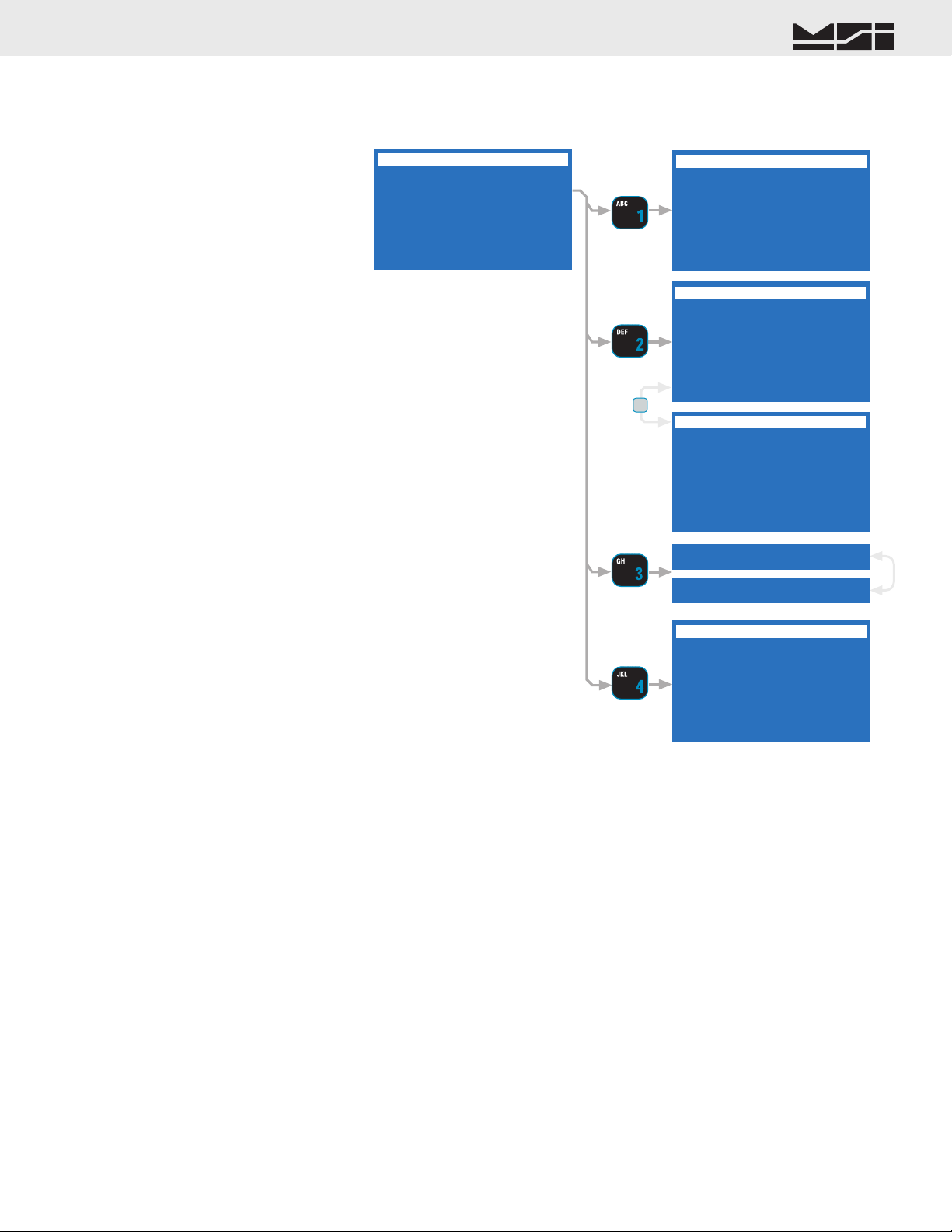

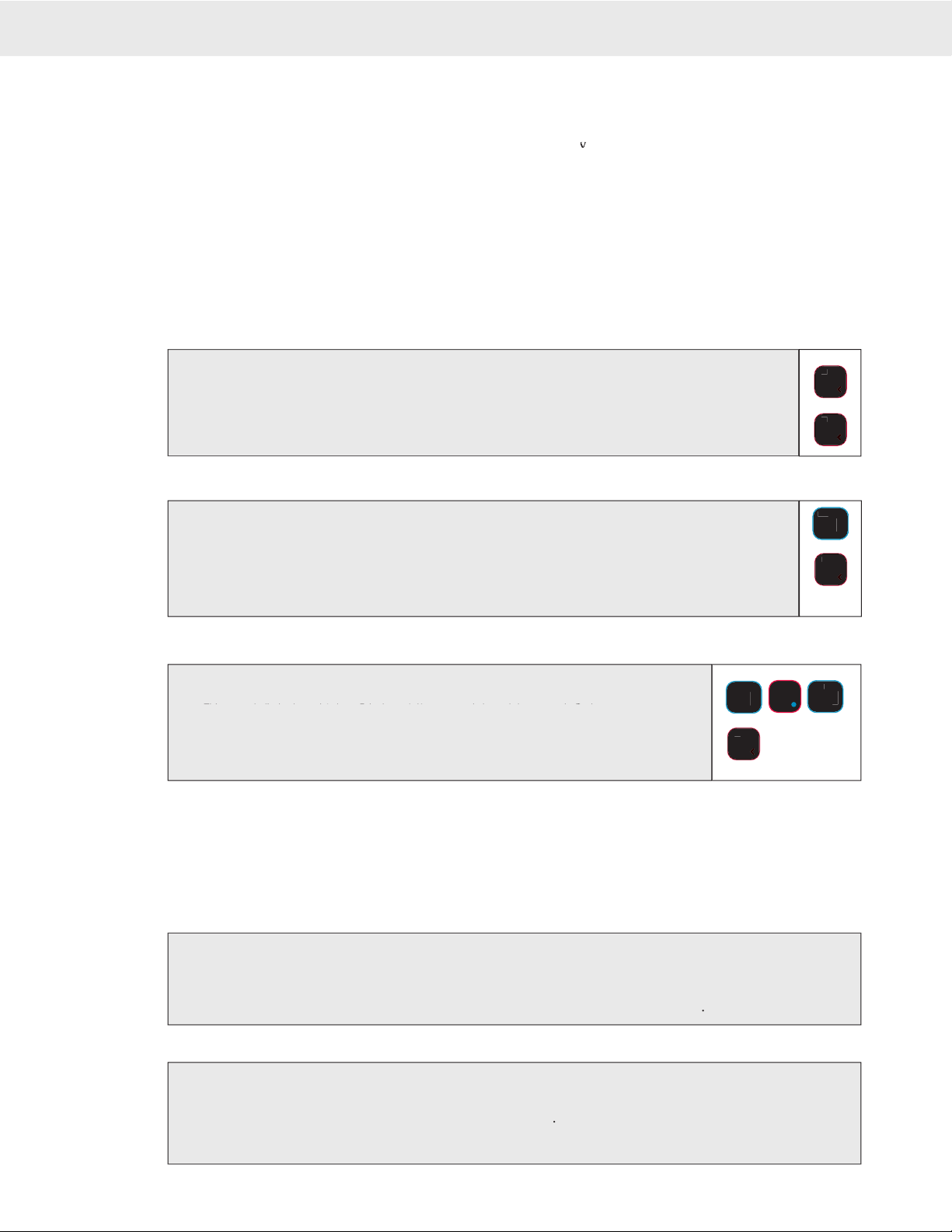

9750A KEYBOARD

PRE SS ENTER

TWICE TO VIEW

FUNCTION KEY

ASSI GNMENT S

HANDHELD RF REMOTE INDICATOR for CELLSCALE

®

Page 4 MSI-9750A RF Remote Indicator • User Guide

Page 5

MEASUREMENT SYSTEMS INTERNATIONAL

Firmware Version 5-XX for 2450 Modems

The

key turns the 9750A On and Off. The

key must be held for 1 second to ensure startup.

The

key is used to zero out residual weight on the scale. When entering numbers or strings the

key is used

to Clear (delete) characters.

The

key is used to zero out the weight of containers, trucks, or carriers and to place the scale in the Net weight

mode.

The

key allows the operator to alternate the weight display from Net (Tared) weight to Gross weight. In

some Legal-for-trade jurisdictions, the Gross weight display is limited to 3 seconds.

The

key allows entry into the setup submenus. Use this to fi nd menus for setting the Date and Time, setting up

the function keys, controlling the display mode and backlight, password locks, calibration, etc.. The key is also used for

ape. Use

to return to the previous menu, or display mode.

The

key fi nalizes the entry of numeric or alphanumeric text entries. It also provides an alternate way to maneu-

ver through menus combined with the cursor keys. Pressing

before certain keys takes you directly into various

modes. Pressing

before a Function key enacts the alternate Function key mode.

The

key is used during text entries to select upper case, lower case or numbers. Sometimes used for negative.

The numeric keypad provides all numerals and letters for data entry. Submenus provide punctuation and control charac-

ters.

The

key is used to alternate between single channel displays and multiple channel displays. While in the

multiple channel display, highlight the desired channel using the numeric keys, then press DISPLAY to bring up the

large display. This selected channel is the “Active” channel to which all subsequent actions will be applied. Provides

the decimal point or period in numeric and text entries. Functions as EXIT in menus returning directly to weight display

without having to back through all previous menus.

F1 defaults to

. Pressing this key will cause the current weighment to be added to the total register. In Auto-Total

modes, the

key turns Auto-total off and on. Up Cursor in menus.

F2 defaults to

. When the CellScale has more than 1 channel defi ned in its Scan List, the

key

will select the next active channel in the list. Precede the

key with a numeric entry (1-32) to switch directly

to a channel scan list position. Press

for a shortcut to the “Channel Setup Menu”. Left Cursor in

menus.

F3 defaults to

. The action of this key is dictated by the Function key menu, but is usually used to send

data to the CellScale or one of its hosts. Used for Insert in text and number entry screens.

F4 defaults to

. The

key is used to log on to other CellScale Networks. Pressing the

key alone will change the active network to the next defi ned Network. Preceding the

key with a Network

number (0-31) will cause the 9750A to log directly on the entered Network, if it exists and is active.

F5 defaults to

. Pressing this key will change the operational units (if enabled) of the current focus channel.

F6 defaults to

. Pressing

will change you to the next defi ned ID. Right Cursor in menus.

POWER

ZERO

CLR

0

T

ARE

T

NET/GROSS

B/G

ESC

!

SETUP

ENTER

ALPHA

A

a

1

1

ABC

F1

TOTAL

F2

CHANNEL

F4

ADDRESS

DISPLAY

EXIT

IN

F3

SEND/PRINT

UNITS

F5

ID

F6

9

@YZ

8

VWX7STU

6

PQR5MNO4JKL

3

GHI

2

DEF

0

SPACE

POWER

ZERO

TARE

NET/GROSS

SETUP

ESC

ENTER

ALPHA

POWER

ZERO

ESC

ENTER

ENTER

DISPLAY

TOTAL

TOTAL

CHANNEL

SEND/PRINT

ADDRESS

UNITS

ID

ADDRESS

ID

CHANNEL

CHANNEL

SETUP CHANNEL

ADDRESS

ADDRESS

MSI CellScale® System • 9750A User Guide Page 5

Page 6

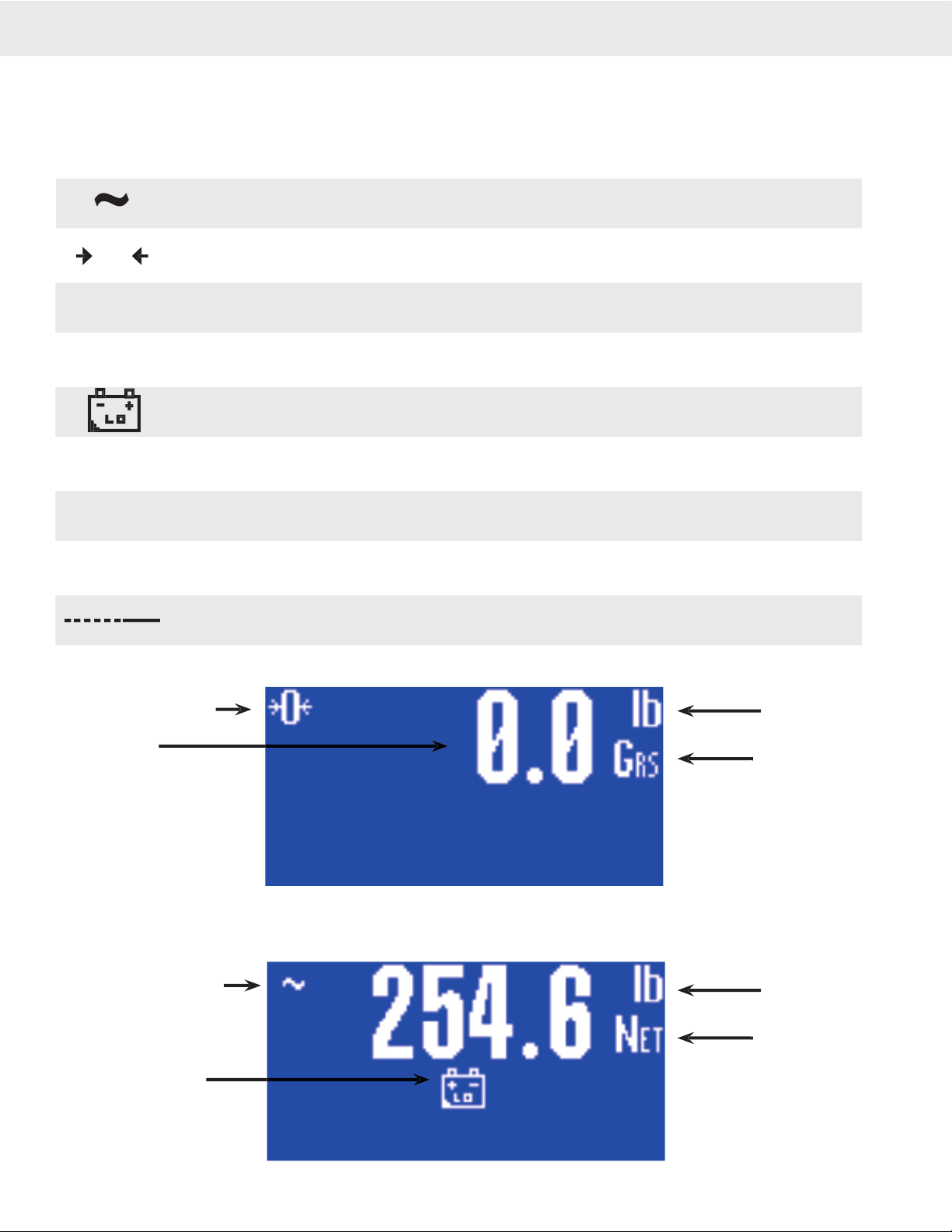

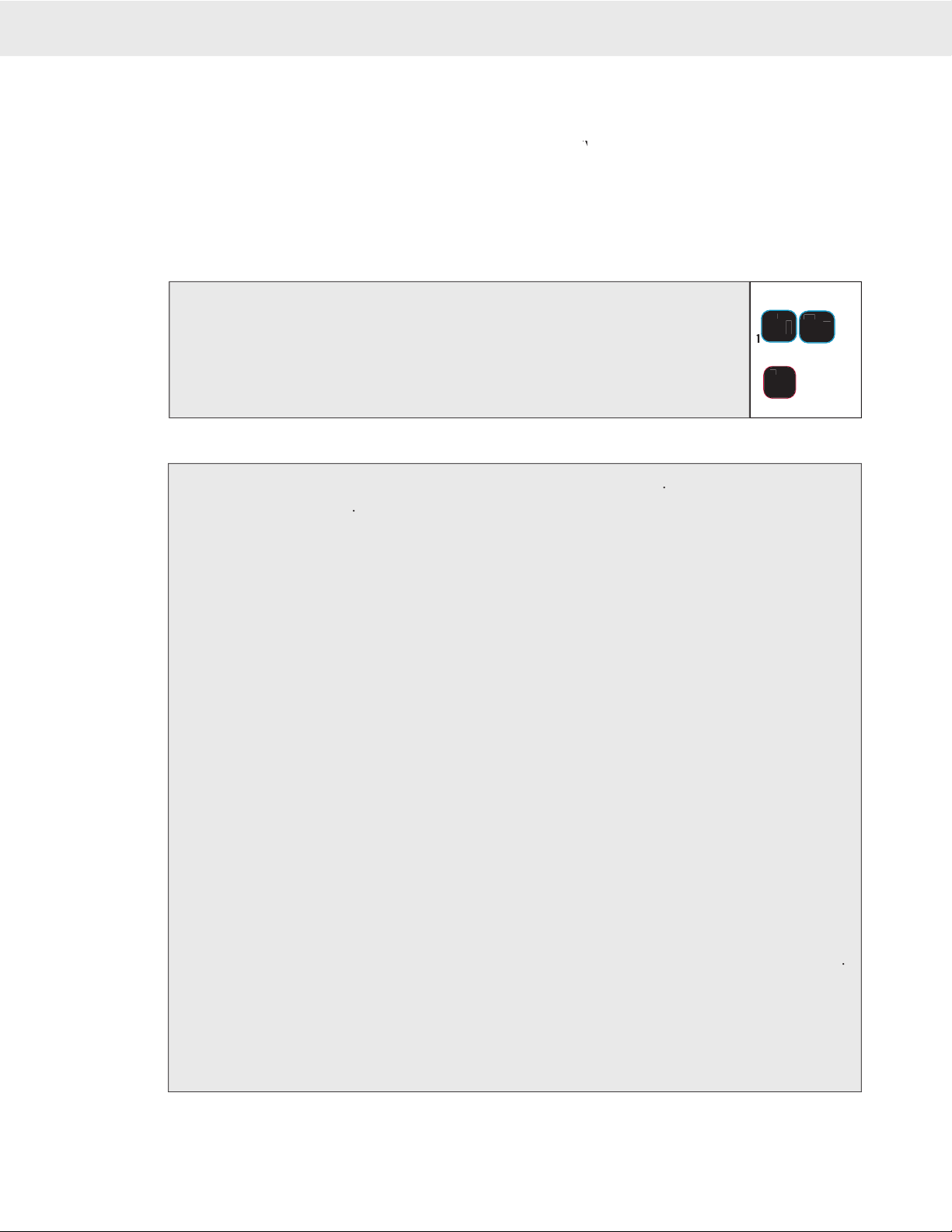

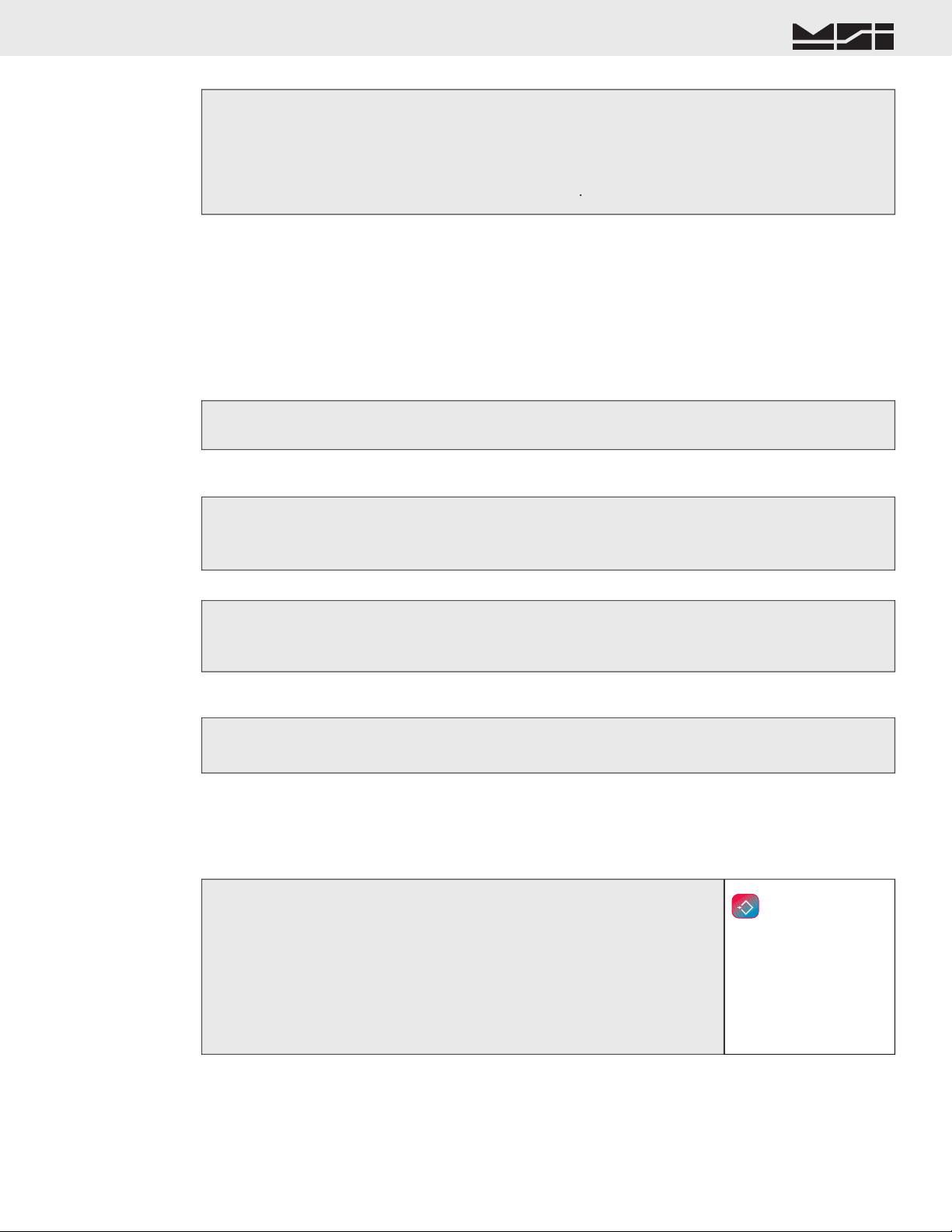

9750A DISPLAY SYMBOLS

The 9750A uses a full dot matrix graphics display which allows 3 sizes of fonts and full use of graphic symbols.

On standard single channel and multi-channel displays, certain symbols are used for scale specifi c indications.

The motion symbol indicates that the weight has not settled within the motion window (usually ±1d). While this

symbol is illuminated, the scale will not zero, tare, or totalize.

Center-of-Zero – Indicates the weight is within 1/4d of zero. In the small font it appears as “

”.

The Sigma symbol is used to indicate a total weight

GRS – Abbreviation for Gross Weight

Low Battery Symbol – Appears when approximately 10% of battery life remains. The 9750A places the indicator

in various locations depending on the display mode

ton– Indicates US short tons equal to 2000 lb.

tne – Indicates metric tons equal to 1000 kg.

daN – Indicates the force measurement unit dekaNewtons.

Dashes indicate data not yet received from the CellScale, or the RF network is disconnected.

∑

G

RS

ton

tne

daN

Center of Zero Indicator

Weight Display

Scale in Motion Indicator

Low Battery Indicator

Units Indicator

Weight Mode

(Gross, Net, Tare)

Units Indicator

Weight Mode

(Gross, Net, Tare)

Typical weight displays showing the use of common symbols

HANDHELD RF REMOTE INDICATOR for CELLSCALE

®

Page 6 MSI-9750A RF Remote Indicator • User Guide

Page 7

MEASUREMENT SYSTEMS INTERNATIONAL

Firmware Version 5-XX for 2450 Modems

GENERAL INFORMATION

The 9750A is a versatile indicator capable of displaying many data items. As a member of the CellScale family

the 9750A does not stand alone. It is a slave device to a MSI-9000 CellScale. All data displayed on the 9750A is

received via RF from a master CellScale. Many menus in the 9750A depend on information from the CellScale.

Therefore, turn the CellScale on before using the 9750A.

Due to the high data rates in the CellScale system menus usually respond instantly. However there are times

when the CellScale is busy and it will not “service” the 9750A instantly in all circumstances. At these times you

may see the word “Pending” or dashes, or data placeholders which will indicate the CellScale has not yet sent

the required information. Weight displays have priority and are sent before all text strings are updated (such as

channel name, ID name, etc.).

The majority of CellScale installations have only a single scale input. In this case the Multiple Display modes

are not needed. However, even with only a single scale input, Math Channels are available which can be applied

for specialized applications.

1) Keys used in operations are printed in

and capitalized. Numeric keys are bracketed (e.g.

).

2) Setup procedures are usually shown with the shortcut method of reaching the menu. All menus can also be

reached through the “Setup Select Menu”. Use the

key to see all available menu choices.

3) Screen shots are shown for example. Many screens provide additional information to orient the user to the

scale channel, or ID, or selections made. For example, the Function Key Setup menu will show you the current

selection for each key. When you change the function, the previous menu changes to refl ect your choice.

4) If a function key does not work, it is probably because the CellScale is not setup to support the key. For

example, if only one channel is defi ned in the CellScale, pressing the

key will have no effect.

This also applies to the

key. If only one Network has been defi ned, the

key has no

other Network to log onto.

5) Menu Titles are shown at the top of the LCD screen and are fully capitalized.

6) When space permits, selected parameters are shown at the right side fully capitalized.

7) Submenus with multiple choices use a highlighted arrow “

” to indicate current choice(s).

8) When in menus, the

key (same as

) drops back one menu level.

9) When in Setup Menus, the

key returns you directly to the Weight Display (Exit mode).

10) Cursor Keys (alternate functions of F1, F2, F5 and F6) only function in menus. Use the DOWN (

) cursor

key to enable the cursors then use the UP (

) or DOWN (

) cursor to select line items. Use,

, LEFT

(<), or RIGHT (

) cursor keys to rotate through menu choices or select the associated submenu.

11) If a submenu is associated with a menu choice, either highlight the menu choice with the cursor keys and

press

, or press the numbered key corresponding to the desired menu item.

12) If a menu applies to any channel, pressing the

key will select the next channel in the CellScale’s

scan list.

13) If a menu applies to any ID, pressing the

key will select the next ID in the CellScale’s ID list.

14) To input, for example, an ‘E’, fi rst use the

key to change to alpha mode, then press

twice. If you

need two ‘E’s, pause briefl y until the display cursor has moved to the next position, then press

twice.

15) In single display modes, pressing the

key highlights the whole display to indicate the next press of

a Function key will use the alternate mode (Enter-Function Key).

ENTER

ESC

>

ADDRESS

DISPLAY

BLUE

SETUP

^

[7]

CHANNEL

[5]

CHANNEL

ADDRESS

v

v

ENTER

ID

ALPHA

ENTER

MSI CellScale® System • 9750A User Guide Page 7

[2]

[2]

Page 8

• Designed to meet or exceed all US and international standards.

• Multiple Customized Display Modes, single channel or multiple channel modes

• Reliable 2.4 GHz Frequency Hopping RF communications. Highly immune to interference and multi-path

problems. Range in excess of 500 feet indoors (LOS).

• Each 9750A can act as a terminal for any CellScale. A 9750A can monitor multiple scale channels on a single

CellScale, or multiple scales tied to multiple CellScales.

• Store up to 32 per connected CellScale ID Codes with separate Alphanumeric Names, Tare, Mode, and Totals.

ID Codes are addressed by any customer given name or number. Two user entered ID data strings are available

for each ID code. Support for up to four Bar Code entry strings.

• Easy to read annunciation of ID Names and Menu Prompts are provided on the fully customer defi ned display

screen.

• Full RS-232 output formatting offers exceptionally versatile data output. Weight data can be printed in any

desired way. The customer can add any alpha characters and/or printer formatting commands; including for-

matting for Bar Code printers. Bar Code readers can also be attached to the Comm Port.

• Manual or Automatic Data Logging into battery backed memory. Any data can be stored for later downloading

into a computer.

• Display illumination uses rugged, long life, LED backlighting coupled with a transfl ective LCD to provide

optimum display contrast under all ambient conditions from full sunlight to total darkness. The backlight

automatically turns off and on when needed to conserve battery life.

• NiMH battery pack provides up to 9 hours of continuous operation. The built in charger operates, with the

proper adapters, from 90-260 VAC (45-65 Hz), or 12-24 VDC Input (optional Cigarette Lighter Adapter avail-

able). Accessory power supplies are available to allow charging from 250 VDC as well.

• Selectable for lb., kg, g, tons, metric tons, ounces, and daN for force measurement (some units and /or units

switching may be prohibited in legal for trade units).

• Multi-mode automatic or manual weight totalizing with multiple ID registers.

• Weather resistant sealing ensures reliable operations under harsh conditions. Rugged, gasketed, PVC package

is rated to NEMA 3 and IP54.

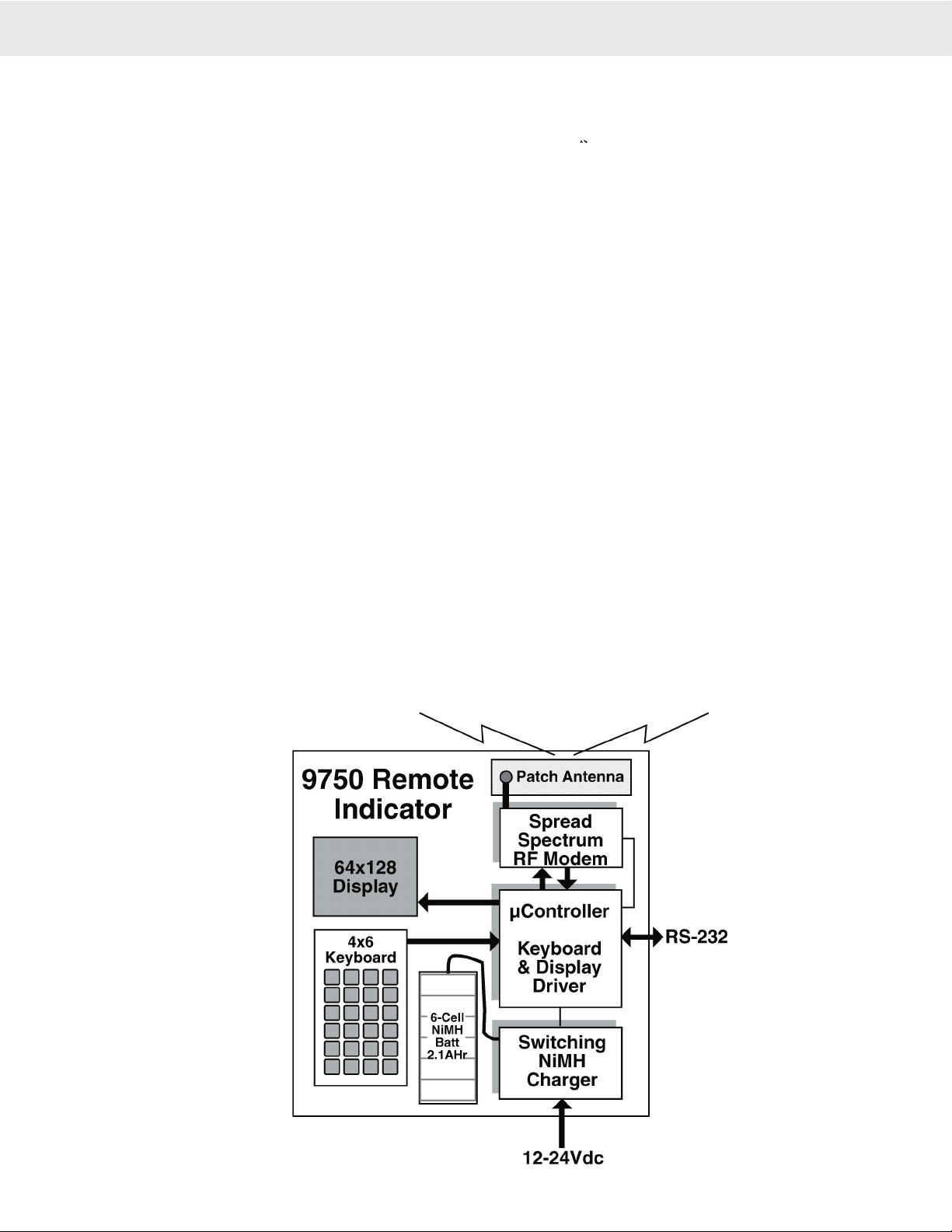

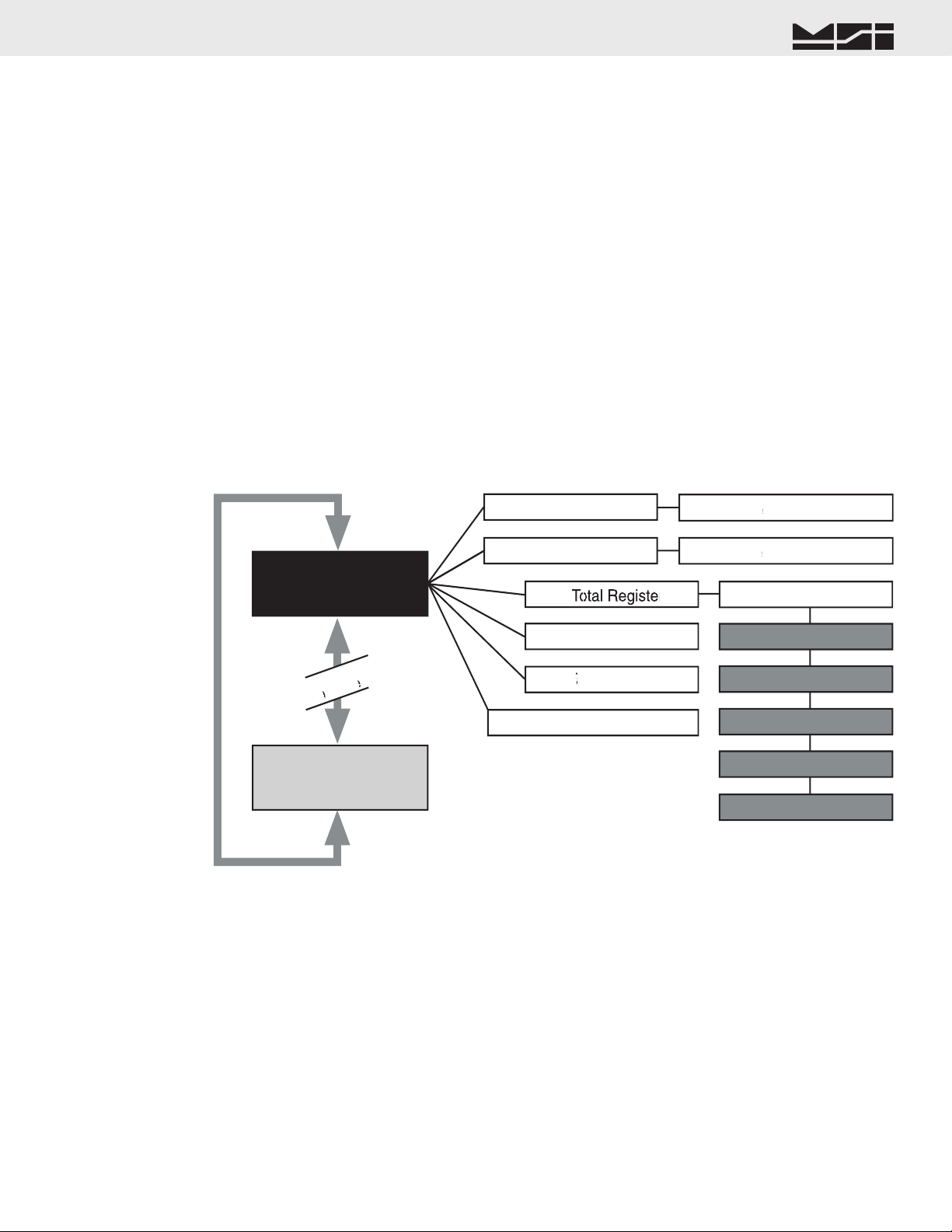

9750A BLOCK DIAGRAM

HANDHELD RF REMOTE INDICATOR for CELLSCALE

®

Page 8 MSI-9750A RF Remote Indicator • User Guide

Page 9

MEASUREMENT SYSTEMS INTERNATIONAL

Firmware Version 5-XX for 2450 Modems

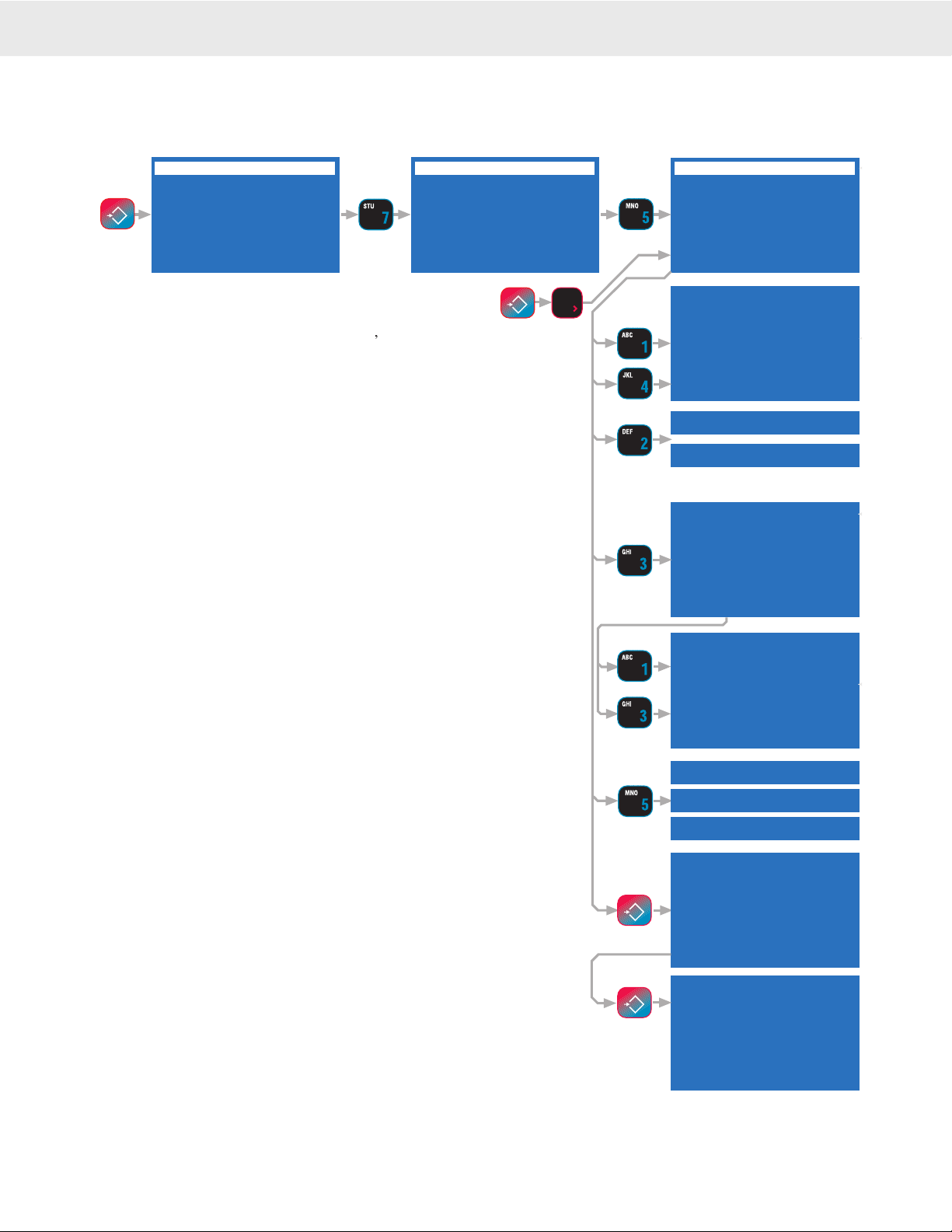

THE CELLSCALE FAMILY

2) Model 9008 Multiplexer – Allows up to eight scales with independent calibrations, to share a single CellScale

input channel.

3) Model 9020 CellModem – For interfacing peripheral devices to a CellScale.

4) Model 3750CS – Fixed mount indicator for CellScales. Capable of control and calibration.

5) Model 9750A – Portable remote indicator for CellScales. Capable of control and calibration. Can display

multiple channels.

6) Model 9300 – CellScale based Crane Scale with local LED display.

7) Model 6260CS – CellScale based Crane Scale. Available in standard capacities up to 100000 lb (50000 kg)

and by special order up to 250 tons

Model 9260 – (Not pictured) Motion Compensated Crane Scale used in scrap metal weighing.

Model 9002 Summing Box – (Not pictured) Single or Dual Channel summing of up to 4 load cells.

Model 9850 – (Not pictured) Advanced Capability Fixed mount Remote Indicator. Avail 3rd Quarter 2006.

2

4

5

6

7

MSI CellScale® System • 9750A User Guide Page 9

Page 10

The 9750A is simple to setup and use. If there are no peripheral devices such as a printer or bar code scanner,

setup consists of charging the battery, and setting the modem controls to talk to a 9000 CellScale.

The 9750A uses a high capacity Nickel Metal Hydride Rechargeable battery pack. The battery pack will power

the 9750A for up to 8 hours depending mainly on how much the LCD backlight is on. This is a custom battery

pack with over-temp and over-current protection designed for fast charging that must be replaced with MSI P/N

and can be charged at any time in the discharge cycle. NiMH batteries do have a fairly high self-discharge rate,

so if the unit is unplugged and idle for a long period of time, the batteries will require charging.

The 9750A LCD will display a low battery warning when there is about a half hour to an hour (depends on back-

light and battery age) of operating time remaining.

The 9750A is shipped with the battery pre installed. When the battery needs replacing, remove the 6 screws on

the back panel to gain access to the NiMH battery. Gently pull out the battery cable from the interior of the case.

There is a single latch on the connector that must be pushed to separate the battery cable from the 9750A. After

plugging the new battery in, stuff the connector back into the case interior, then reseal the battery cover.

CHARGER ADAPTER

The 9750A battery charger is integral to the 9750A. Input power can any source of 12-24VDC with a minimum

of 20 watts of power. MSI provides two charger sources: 1) Universal AC power: Operates from 86 to 265 VAC

45 to 440 Hz. 2) Vehicle Power: Works with vehicles with 12-24 VDC battery systems (cigarette lighter adapter).

The maximum drain on the power source is 20 watts, but this amount of drain is brief. The source current tapers

down as the battery charges. For 12V systems the maximum drain is about 1.5 amps. A 5A fuse is suffi cient to

protect the vehicle electrical system while still providing enough peak power to charge the battery. The MSI

Cigarette Lighter Adapter (MSI P/N 12674) is internally fused with a 5A fuse.

CHARGING THE BATTERY

Turn off the 9750A. Plug in the Charger Adapter in the charge port. Charging will take up to 2 hours depending

on how much the battery was discharged. The 9750A has a charge status indicator on the front panel. The charger

is in fast charge mode when the light is Red. When the light turns Green, the 9750A is ready for use.

Charge Indicator

Off External Power Not Present

Blinking Red/Grn Charge Pending. Either the battery temperature is too high, or the cell voltage is below what

is safe to fast charge. The battery is trickle charged until these conditions are cleared.

Steady Red Fast Charge in progress.

Green Fast Charge Completed. Charger enters pulse phase charge top off. You can use the system

as soon as the green light is on. However, maximum charge capacity is reached about 30

minutes after the light turns green. The Green light will pulse often while in top off phase,

less often during maintenance phases.

adapter, let it cool for 1/2 hour, and then plug it back in. This will initiate another fast

charge cycle that should only last a short time if the battery is functioning properly.

The internal charger is a multi-stage charger. The external adapter can be left plugged in indefi nitely. It will

continually pulse charge the battery preventing self discharge and keeping the battery topped off. If the 9750A is

used sporadically, MSI recommends leaving the adapter plugged in while the system is idle.

battery, turn the 9750A off, remove the power plug, then plug it back in.

HANDHELD RF REMOTE INDICATOR for CELLSCALE

®

Page 10 MSI-9750A RF Remote Indicator • User Guide

Page 11

MEASUREMENT SYSTEMS INTERNATIONAL

Firmware Version 5-XX for 2450 Modems

SECTION 2 – RF SCALE COMMUNICATIONS

The 9750A is a component of the MSI CellScale System. The CellScale system uses frequency hopping

spread-spectrum RF Modem technology transmitting in the 2.4 GHz ISM band.

RF Modems have been problematic as the RF bands are very hostile, corrupted by noise, path loss and inter-

fering transmission from other radios. Even in a pure interference-free environment, radio performance faces

serious degradation through a phenomenon known as multipath fading, a problem particularly prevalent for

indoor installations. Multipath fading results when two or more refl ected rays of the transmitted signal arrive

at the receiving antenna with opposing phase, thereby partially or completely cancelling the desired signal.

Spread spectrum reduces the vulnerability of a radio system to both interference from jammers and multipath

fading by distributing the transmitted signal over a larger region of the frequency band than would otherwise

be necessary to send the information. This allows the signal to be reconstructed even though part of it may be

lost or corrupted in transit.

Spectrum has been set aside at 2.4 GHz in most countries for the purpose of allowing compliant spread spec-

trum systems to operate freely without the requirement of a site license. In the USA, there are absolutely no

site licensing requirements. The CellScale system is also programmable for use in most European countries.

Please contact MSI for worldwide compliance information.

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide reason-

able protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may cause harmful interfer-

ence to radio communications. Operation of this equipment in a residential area is likely to

cause harmful interference in which case the user will be required to correct the interference

at their expense.

The CellScale system uses frequency hopping which is produced by transmitting the data signal as usual, but

varying the carrier frequency rapidly according to a pseudo-random pattern over a broad range of channels, in

this case 86 discreet frequencies. These 86 frequencies are combined in different “hopping patterns” to provide 64

(0-63) separate networks. The CellScale network uses a ‘Star’ network topology. One unit, usually the CellScale,

is designated a ‘Master’. The Master transmits a sync pulse on a regular basis, providing synchronization of all

remotes in the designated Network. Thus it forms the center of a cell. MSI provides three products capable of

being the master unit: the CellScale, the 9300 Crane Scale, or the 6260 Trans-Weigh CS Crane Scale. Up to 16

remotes can access the master unit. Current MSI provided remote devices include the 3750CS Indicator, the 9750A

Handheld Indicator, the 9850 Indicator, and the 9020 CellModem. Multiple remotes can coexist on one network,

or can be easily switched to other networks as required.

The CellScale system uses TDMA (Time Division Multiple Access) to arbitrate between multiple remotes. Each

remote is assigned a specifi c time slot thus guaranteeing data throughput. The CellScale network uses a ‘Star’

network topology. One unit, usually the CellScale, is designated a ‘Master’. The Master transmits a sync pulse on

a regular basis, providing synchronization of all remotes in the designated Network. MSI provides fi ve products

capable of being the master unit: the CellScale, the Smart CellModem 9000 (not 9020), the MSI-9260 ruggedized

Crane Scale, the MSI-9300 Porta-Weigh+ Crane Scale (with local display), or the MSI-6260CS Trans-Weigh CS

Crane Scale. Up to 15 slaves can access the master unit. The 9750A is always a ‘Slave’. Multiple 9750A units

can coexist on one network, or can be easily switched to other networks as required.

For more on setting up CellScale networks, please refer to the MSI-9000 CellScale User Guide.

ANTENNA

The 9750A uses a built in “Patch” antenna with no external visible element. The patch is located in the end of the

9750A above the display. In most installed CellScale networks, the patch antenna is essentially omnidirectional.

However, in systems where the 9750A is reaching the limits of transmission range, the 9750A will achieve better

range by pointing it toward the master CellScale’s antenna.

MSI CellScale® System • 9750A User Guide Page 11

Page 12

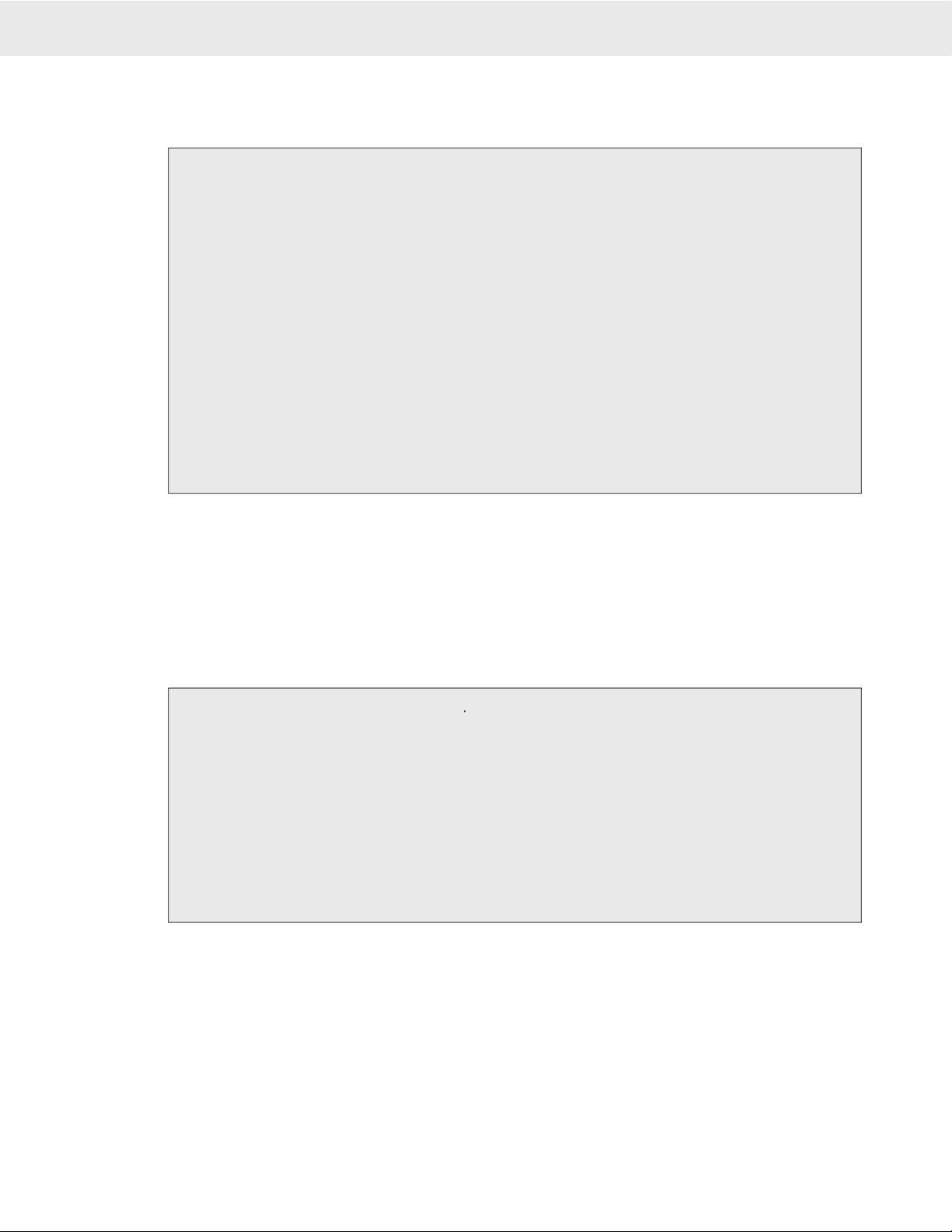

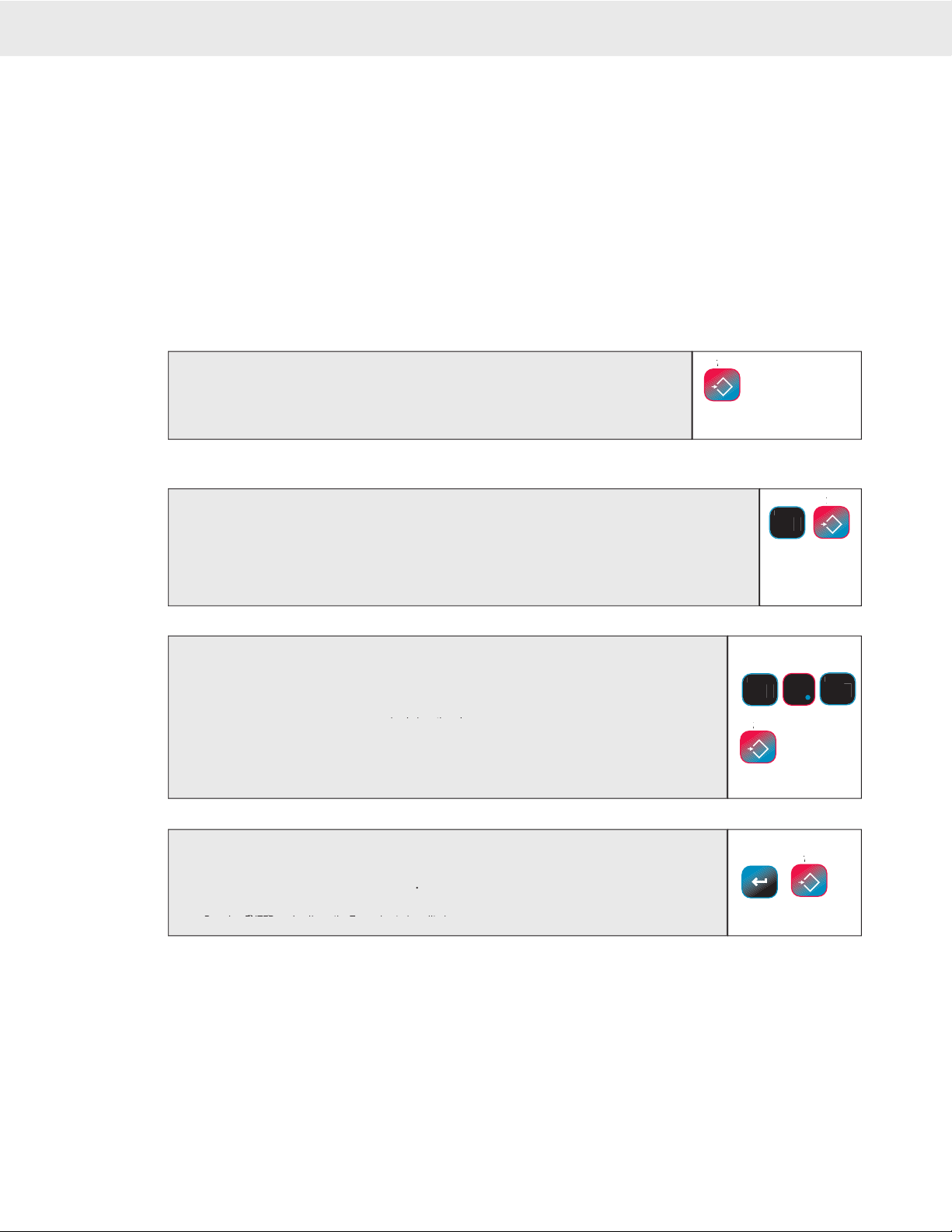

MODEM SETTINGS v2.05

1 Network Address 17

2 CS Address 17

3 My Address 57

4 Transmit Power HI

5 Timeout 1Øs

6 Advanced Settings

7 Save Settings Now

NETWORK ADDRESS

ESC exits no change

ENTER saves value

0-9 replaces value

17

min = 0, max = 63

^ incs, v decs value

CELLSCALE ADDRESS

ESC exits no change

ENTER saves value

0-9 replaces value

17

min = 5, max = 251

^ incs, v decs value

MY ADDRESS

ESC exits no change

ENTER saves value

0-9 replaces value

57

mmin = 5, max = 251

^ incs, v decs value

TIMEOUT THIS NETWORK

ESC exits no change

ENTER saves value

0-9 replaces value

1Ø

min = 1, max = 1800

^ incs, v decs value

4 Transmit Power HI

4 Transmit Power MED

Saves Settings to Memory

Shortcut

4 Transmit Power LO

See

Advanced Settings

MODEM SETTINGS v2.05

NETWORK ADDRESS

CELLSCALE ADDRESS

MY ADDRESS

TIMEOUT THIS NETWORK

The 9750A is a RF Modem connected device. The RF Modem requires setup to connect to one or more CellScales.

The 9750A stores information for all 64 possible networks. Each network setting can be modifi ed with the “Modem

Settings Menu”.

NETWORK ADDRESS – Sets the primary network

address number. Set this number to match the Network

number of the CellScale master the 9750A must com-

municate to. Ranges from 0 to 63.

CS ADDRESS – Sets the primary master CellScale ID

number. This number must match the Source Address

number of the primary master CellScale. Ranges from

5 (default) to 251. This number is usually 5.

MY ADDRESS – Any 9750A unit in a given Network

must have a unique ID number. Enter up to three digits

to designate the 9750A ID number. Ranges from 5 to

251. Make sure no other devices have this same number.

Other devices that must have unique numbers are 9020

Modems, 3750CS Indicators, and 9300 and/or 6260CS

crane scales used as slave units.

TRANSMIT POWER – Sets the RF power level between

applications power should be set to High. Reduced

energy can reduce the size of the coverage / interfer-

ence zone which may be desirable for multiple-network

applications. Always check for adequate range coverage

when using the Low setting. Only a minor improvement

in battery life (~10%) is achieved by using the Lo set-

ting.

TIMEOUT – Sets the time in seconds (0-1800) that the

9750A will wait for data from the CellScale Master. The

display will blank out if no data is received within this

time period. MSI recommends at least a 10 second time

out period to handle small lapses in transmissions. The

system defaults to 10 seconds.

ADJUST MODEM – Advanced features settings of the

Modem. See “ADJUST MODEM MENU” on the fol-

lowing page. This line also shows the fi rmware version

of the RF Modem (v2.0x).

SAVE SETTINGS NOW – Commits the settings to the

Modems Memory. The Modem settings will be automati-

cally saved at power down if changed.

SCAN NETWORK – Setting the Scan Network ON places

the network in the list of addresses reached by pressing

the ADDRESS key. Setting the Scan Network OFF still

allows you to pre confi gure the network settings, but the

Network will not be in the list of available networks.

[1]

[2]

[3]

HANDHELD RF REMOTE INDICATOR for CELLSCALE

®

[4]

[5]

[6]

[7]

Page 12 MSI-9750A RF Remote Indicator • User Guide

Page 13

MEASUREMENT SYSTEMS INTERNATIONAL

Firmware Version 5-XX for 2450 Modems

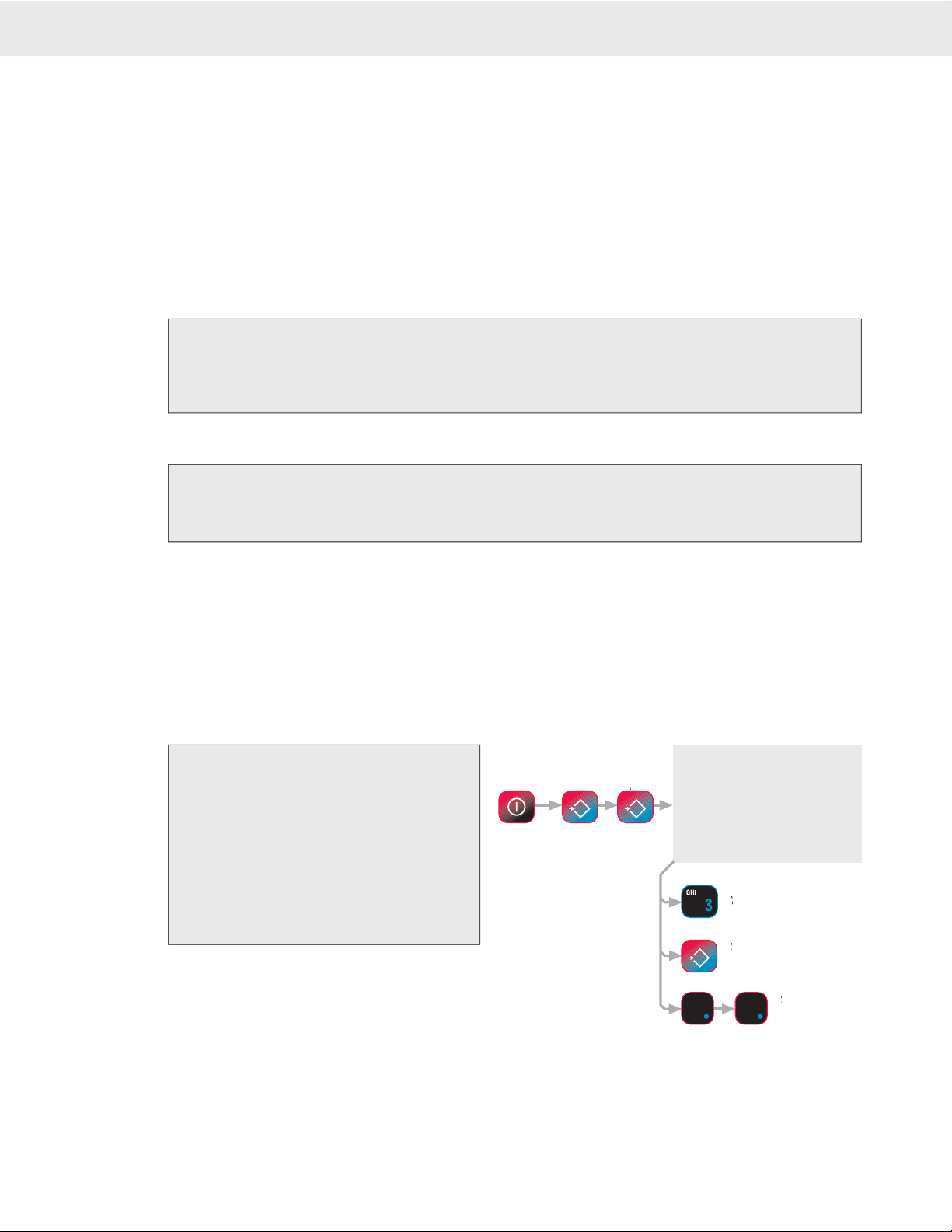

ADVANCED MODEM SETTINGS

The “ADVANCED SETTINGS’ menu provides access to some of the advanced features of the 9750A’s RF

Modem. These features are not usually needed and should be left to defaults.

1 Lock Out Key Ø

2 802.11 Avoid OFF

3 Scan Network OFF

4 Reranging 652.7 sec

Signal Strength 13Ø

Modem Ser. # ØØ-Ø2-46

ESC exits no change

ENTER saves value

Ø-9 replaces value

Ø

min = Ø, max = 255

^ incs, v decs value

1 OFF, FCC/ETSI LEGAL

2 Bands 1 & 2

3 Bands 3 & 4

4 Bands 5 & 6

5 Bands 7 & 8

6 Bands 9 & 10

7 MORE 1/2

ESC exits no change

ENTER saves value

Ø-9 replaces value

652

min = Ø, max = 655

^ incs, v decs value

3 Scan Network OFF

3 Scan Network ON

802.11b AVOIDANCE

1 Bands 11&12, France

2 Bands 1 & 10 to 12

3 Bands 1 to 6

4 Bands 6 to 12

5 Bands 1 to 3 & 11

7 MORE 2/2

7

ADVANCED SETTINGS

LOCK OUT KEY

802.11b AVOIDANCE

802.11b AVOIDANCE

RERANGING PERIOD, SEC

1) Lock Out Key – For added security in environments

where other CellScale modems are operating on the

same network, a Lock Out Key can be set which will

prevent modems from communicating. The Lock Out

key must also match in the master CellScale Modem.

DO NOT change this number from 0 unless all modem

elements are also changed as this will cause severe com-

munications problems.

2) 802.11 Avoidance – The 9750As modem can be set to

minimize interference with 802.11b RF networks in

common use for computer networks. You must deter-

mine which band the 802.11b modem is operating on

and then select the corresponding band to avoid. The

second page also includes a setting making the cellscale

legal in France. The CellScale master must also have the

same setting. DO NOT change the setting in this menu

without corresponding changes in all CellScale devices

in the network.

3) Scan Network – When On, this feature adds Network

address information to a current networks list. If this

9750A is to be used on multiple networks, turn the

“Scan Network” “ON” every time you log onto another

network that you may want to go back to. Then using

the

key, you can quickly scroll through all

stored networks.

4) Reranging – This feature sets the interval in which the

modem requests recomputation of the distance compen-

sation. The default is suitable for standard operation and

should not be altered.

The next line below Reranging gives a relative receive

signal strength. This value reports the relative signal

strength averaged over the last 10 hops. Larger values

indicate stronger signals.

The next line indicates the RF Serial Number of the

embedded modem.

ADDRESS

MSI CellScale® System • 9750A User Guide Page 13

Page 14

1) Enter the number of the CellScale network.

In this example we’ll use network 12. Use the appropriate numbers for your CellScale master. It is not necessary to enter a ‘0’

for networks below 10.

2) Press the

key. The Network Address Changes to the new Address and is

added to the Network Scan List.

It can take up to 8 seconds to log on to a new network, and for the weight data to appear. If the 9750A is unable to locate a

Master CellScale at the entered address, the message “NO NETWORK” will appear.

1

ABC

2

DEF

2

ADDRESS

Setting the Network Address (shortcut method)

1) Press

. From the “SETUP SELECT MENU” , select “MORE”

.

2) Select “RF Modem”

.

Steps 1 and 2 have a shortcut. Press SETUP followed by ADDRESS.

3) Select “Network Address”

. This calls the Network Address data entry screen.

4) Using the keypad, key in the desired Network Address (0-63). The Address used must match the Network

address of the CellScale master. Press

to store the address.

5) Select “CS Address”

. This calls the CellScale Address data entry screen.

6) Using the keypad, key in the desired CellScale Address (5-251). The Address used must match the ID address

of the CellScale master (2nd number, e.g. 23-

23)

. Usually CellScale masters are usually confi gured with

the ID Address number set to the same number as the master. Networks 0-5 usually are set to the Network

number +64 (e.g. Net 4, CS address 68). DO NOT use a CS Address below 5.

7) Select “My Address”

. This calls the My Address data entry screen.

8) Using the keypad, key in the desired My Address (5-251). The Address used must be unique within all

possible networks this 9750A is to contact. Press

to store the address.

9) Select HI, MED, or LO transmit power using the

key. Usually this should be set to HI for maximum

range.

10) Select Timeout

. The Timeout period is the time the 9750A will wait before reporting loss of updated

data from the Master. When the timeout period is completed without new data transmitted, the weight

display will change to dashes.

11) Using the keypad, set the Timeout in Seconds. A timeout from 5 to 20 seconds is recommended (10 seconds

is the default). Press

to store the timeout.

12) Set this network active by pressing

. From the ADVANCED SETTING menu, choose

ON. This

places the Network in the 9750’s active network list, allowing use of the

key to switch the

9750A to this and other stored Modem settings. Resturn to the Modem settings menu by pressing

.

13) Store the Modem settings by pressing

. The unit will pause with a key tone while the settings are

stored.

14) Return to weight reading (assuming there is a CellScale at the address you just set) by pressing

or press

to return to the Setup Menu. There may be a delay while the new address request is processed

by the CellScale.

Setting the Network Address (standard method), and RF Modem Confi guration

Access to all user configured parameters in the RF Modem.

CS Address equals Network number (e.g. 12-12, 1-65, 9-9, etc.), unless the network number is 5 or below, then

the CS address equals the Network number + 64

CONFIGURING FOR MULTIPLE NETWORKS

The 9750A can access multiple CellScales by switching Networks. A press of the

key will change the

network allowing the 9750A to monitor and control different scales. Because each CellScale has both a network

and a CS address, these must be set up with the “SETUP RF NETWORK” menu and made active. The 9750A

®

®

can access up to 64 CellScale based Networks. It takes the 9750A from 4 to 8 seconds to switch networks, as

it has to sync with a new hopping pattern. Networks that are inactive but were set up can be reached by typing

the Network Address (0-31) followed by the

key. New networks not previously set up can also be

reached this way, but the modem confi guration will set to defaults.

HANDHELD RF REMOTE INDICATOR for CELLSCALE

ADDRESS

®

ADDRESS

ADDRESS

SETUP

[5]

[3]

[1]

[2]

[3]

ENTER

ENTER

[6]

[7]

ENTER

[4]

[3]

ADDRESS

ESC

[7]

ESC

Page 14 MSI-9750A RF Remote Indicator • User Guide

DISPLAY

Page 15

MEASUREMENT SYSTEMS INTERNATIONAL

Firmware Version 5-XX for 2450 Modems

Transmit power set to HI.

Time out set to 10 seconds.

My Address remains unchanged and is the same in any network.

TROUBLESHOOTING RF CONNECTION PROBLEMS

Most connection problems are caused by improperly set up RF Networks. Both the 9750A and the master CellScale

unit must have identical Network numbers. In addition, the CS Address must match on both units. If the Net-

work and/or CS Address of the CellScale is in question, you might have to connect a terminal to the CellScale to

determine its exact settings. See the CellScale manual for this procedure. Verify the 9750A settings are proper

by using the “CONFIGURE RF MODEM” procedure. Each slave device (9750As, 3750CS, and 9020s) must

have unique “My Address”.

A common cause of perceived problems is the “Phantom Network”. This occurs when there is a confl icting Net-

work within broadcast range. Multi-CellScale sites must be planned carefully so that there are never two master

CellScales on the same Network within range of each other. Since the CellScale can broadcast for miles with

good LOS (line of sight) conditions, this consideration is very important. If you suspect your 9750A has locked

on to a distant (Phantom) network, try switching both the master CellScale and the 9750A slave to another unused

Network. MSI advises avoiding Network #0 when possible, as this is the Modem default, and therefore most

likely to be found on units that were left in default settings.

Weight displays, but 9750A keys don’t work

This is a result of changing the CS Address in the slave 9750A so it no longer matches the master CellScale. The

modem is still registered by the master CellScale, but control codes are not received because the master assumes

the codes are intended for a different slave CellScale. Change the CS Address in the 9750A back to the number

that matches the master CellScale.

This is usually a result of being in or near an “RF Null” zone. Because of multiple echoes of signals there is

sometimes locations that are particularly problematic even for Frequency Hoppers. Usually moving the antenna

location even a small distance can clear up this kind of problem. Avoid placing the antenna up against large metal

walls. Concrete walls can also be problematic due to their high moisture content. The antenna should be at least

4 inches away from large metal or concrete surfaces. Mounting the antenna too close to a wall has the effect of

making the Antenna directional and can attenuate the output.

Antenna placement is the most common cause of poor range. Check that the RF power level of the master and

slave units is on “High”. Radio signals in nearby bands that have signifi cant power can also reduce range. Lon-

gest range will always be achieved by Line-of-sight (LOS) antenna placement. Any obstacle that interferes with

LOS will reduce the range. Signifi cant blocking is caused by metal buildings, solid concrete walls, and any other

object that has fairly high electrical conductance. Raising the master antenna higher can help. Just moving the

relative antenna placement a short distance might fi nd an RF “path” that will improve distance. The CellScale

can sometimes take advantage of refl ecting surfaces to get around obstacles. CellScale device antennas should

always be placed in vertical polarization; that is the shaft of the antenna should be perpendicular to the earth,

not parallel. It is OK to mount the Antenna upside down. This is a good solution when an antenna is mounted on

the ceiling for communication with CellScale components in the building. The 9750A internal antenna is mildly

directional. Aim the end of the 9750A towards the CellScale master for longest range. In short range applications

(LOS and <500 feet) the 9750A is essentially omni-directional.

Some CellScale master units can take advantage of higher gain antennas.Yagi Antennas can greatly improve the

range of a CellScale system when installed on the master CellScale. These multi-element antennas are highly

directional and must be aimed towards the 9750A area of operation.

The CellScale system is designed using state of the art RF Modems. However there will be conditions and envi-

ronments where communication of telemetry is sporadic or impossible. Jamming of FHSS systems is diffi cult,

but not impossible. Bear in mind that the most likely source of jamming will be other CellScale systems on the

same network, within transmission range. The new breed of wireless phones (not Cell Phones) operating in the

2.4GHz bands will not jam a CellScale. However the CellScale may be received on the wireless phone and will

sound like a background ticking noise. Standard Cell Phones do not operate in the same bands as the CellScale and

will not interfere with CellScale components. However, a Cell Phone repeater tower nearby might have enough

out of band interference to reduce the range of CellScale equipment.

MSI CellScale® System • 9750A User Guide Page 15

Page 16

1) Place the 9750A in close proximity of the master CellScale unit. Make sure communications are good

(weight is on the display, all data types have been reported).

2) Press the function key programmed for “RF Site Testing”. The bottom right side of the display will read

“RF xx%”. The per cent reading indicates the ratio of successful transmissions. It will start low at fi rst,

then creep up. It should approach 100%, with an average reading of >96%.

If the reading does not achieve >96% within 1 minute try changing the CellScale Master device (MSI-9000, MSI-6260, MSI-9300, etc.) to a new network.

master.

3) Now start walking around the site with the 9750A. If the RF% reading starts down, stop and wait. Aim the

9750A towards the CellScale master and see if the RF% reading begins to rise again. If the display suddenly

reads “NETWORK”, you have lost communication. Return to the last place that communications were

working and wait for the 9750A to reconnect. In this way you can establish the range of adequate com-

munications, and note any areas with severe RF dropout. The location and height of the CellScale master

also plays a big part in range so be sure to run the site test with the CellScale in typical locations used in

your application.

4) Cancel the RF Site Test by pressing the function key again. If needed for some other function, reprogram

the function key.

The 9750A provides a means to check the effi ciency of RF transmissions using the RF Site Testing function.

Program a function key (use the procedure in Section 4) to “RF Site Testing” to run the test.

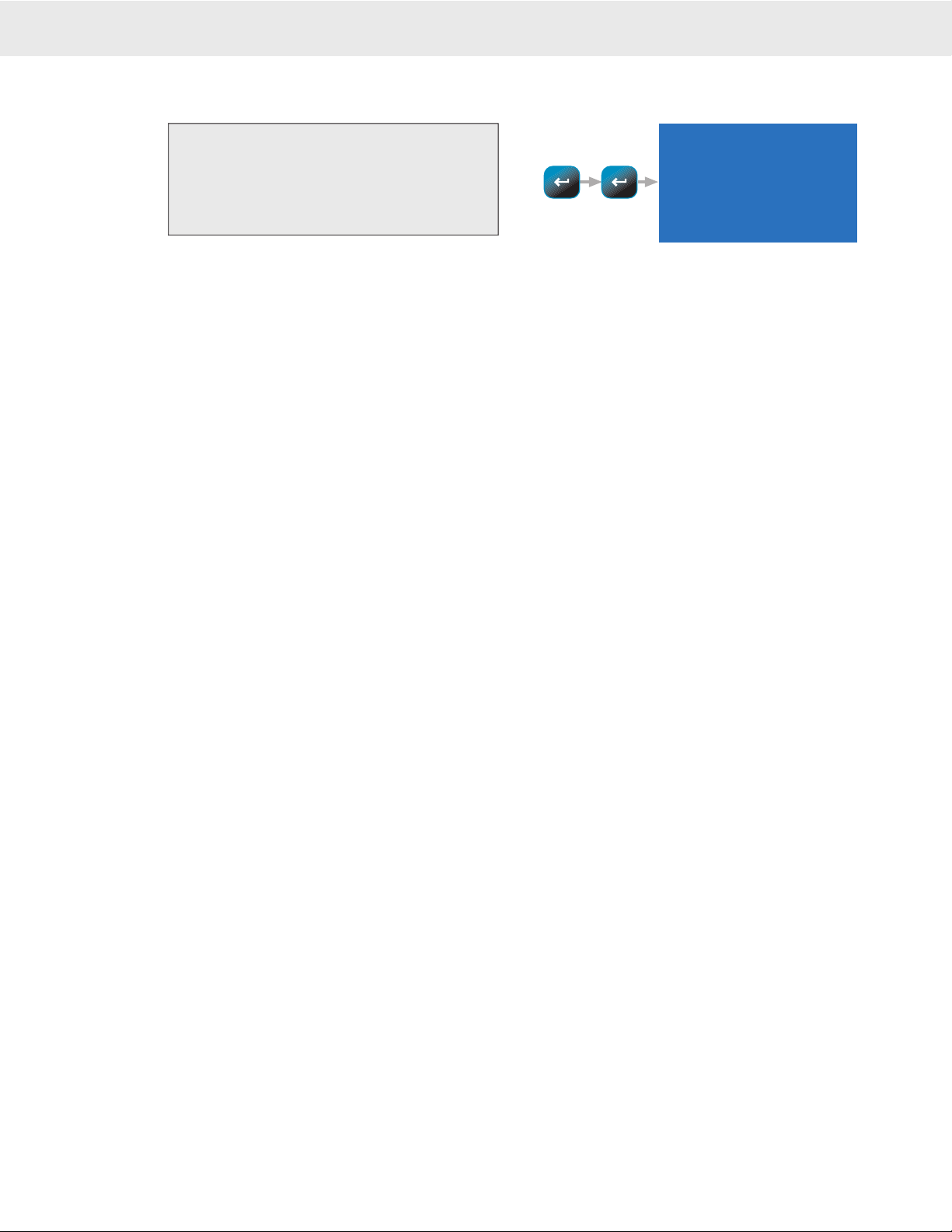

CELLSCALE NETWORK AUTO SCAN

For installations where multiple CellScale systems are present, the 9750A can scan every network and determine

if a CellScale master device is broadcasting. Found CellScales can be copied directly into the RF Scan List at the

end of the test. Turn on all CellScale masters (MSI-9000, 6260CS, 9300, etc.) that your 9750A will be used with.

Ensure that each CellScale master is on unique network addresses (see product User Guides).

1) Press

followed quickly by

.

It doesn’t matter if the 9750A is on or off.

2) Press

to start the scan. The 9750A will begin a progressive scan of all 64 (0-63) net-

works.

3) Every CellScale master found will display along with its address. The end of the test will be indicated by

the display reading “ENTER Copy to Scan”.

4) If you want to store the found CellScale addresses, push

. The display will read “COPYING RF

SCAN”.

5) Press

to return to weight reading.

HANDHELD RF REMOTE INDICATOR for CELLSCALE

®

POWER

NET/GROSS

DISPLAY

ESC

ENTER

Page 16 MSI-9750A RF Remote Indicator • User Guide

Page 17

MEASUREMENT SYSTEMS INTERNATIONAL

Firmware Version 5-XX for 2450 Modems

SECTION 3 – SCALE OPERATION

To Turn On the Power

POWER

If the system fails

to connect in 8 seconds or

less, press the ADDRESS

key to select a different

Network, or enter the

number of a working net-

work and press ADDRESS.

If this fails check RF

network setups, or decrease

the range between the

CellScale and the 9750A.

1) Press and hold

for 1 second

. The display should light and show the MSI

Logo.

2) The LCD then displays “MSI-9750A-5”, the Network currently loaded as the active

Address, and the software version number. The display will read “Searching Add

XX” while establishing communications with the master CellScale.

3) Next the RF network is contacted. If the network is functional, the display switches

to normal weight display mode. This usually takes 4-15 seconds. If the Network

is not available, the screen will continue to display the desired Network. Either

change the Scan Network with the

key or turn on the proper CellScale

Master. Use of the

key assumes that multiple networks have previ-

ously set up. See “Setting the Network Address” on page 12.

Each CellScale is capable of hosting up to 32 independent scale inputs. Since any 9750A can communicate with

any CellScale, theoretically hundreds of scales can be controlled by a single 9750A. Because of the complexi-

ties of multiple channel setups, the 9750A is designed to access channels that have been previously setup in the

CellScale through its terminal interface or virtual meter interface.

Channels in the CellScale are organized by the A/D input channel followed by a Mux sub channel value. The

standard CellScale has two A/D inputs, but can be ordered with four A/D inputs with the addition of a second

A/D Converter module. Each A/D channel can be further divided by the use of external multiplexers into eight

additional inputs per channel, providing a total of up to 32 independent scale inputs. The channels are designated

like this:

Channel (A/D 1-4)

Sub channel (mux 1-8)

The channel will vary from 1-4 and the sub channel from 1-8. In addition the CellScale provides channel 5 for

slave CellScales, and channel 6 for math channels. Math Channels allow the user to add or subtract channels from

each other or perform other mathematical manipulations of the data. All calibration data for the 32 channels is

stored in the CellScale and is independent of the 9750A. Therefore any 9750A can receive calibrated data from

any CellScale provided the RF network is set up properly.

It should be noted that sub channels are useful even when the multiplexer option is not used. For example, chan-

nel 1-1 could be calibrated as a 1000 x 0.5 kg scale, and channel 1-2 as a 2000 x 1 kg scale, making a dual range

platform (of course this assumes the platform is capable of handling 2000 kg). This will work as long as the main

channel remains constant. So, in theory, 1 platform could be calibrated as 8 independent scales. This works because

the CellScale does not know or care if a Multiplexer is actually present. It treats the input as a separate scale.

The 9750A reads multiple channels by using the Scan list index. The “Scan list” is stored in the CellScale, with

up to 32 channels present in the list. The fi rst number in the scan list is called the Scan List Index number. The

CellScale can have up to 32 Scan List indices. A scan list can include “Math Channels” which provide a means

to digitally add the results of multiple scales.

When dealing with multiple channels it is recommended that you set up the display to always show either the

Channel Number or the Channel Name or both. This will help in identifying which scale you are observing.

SELECTING THE ACTIVE CHANNEL

Before standard scale functions are performed, you must select the “Active Channel”. The “Active Channel” is the

channel that commands such as Zero, Tare, Total, etc. will be performed on. On single channel display screens,

the channel shown is the active channel. On Multiple channel displays, you must highlight the desired channel.

This is done with the Cursor Keys. Once highlighted you can perform all the standard scale functions (except

Total and View Total, these only work from the single channel display). You can also switch to the single channel

display by pressing the

key.

See the “DISPLAY MODE SETUP” section 7 for information on multiple and single channel weight display modes. For more information on Scan Lists and multiple

scale channels, please refer to the CellScale MSI-9000 Users Guide.

POWER

ADDRESS

ADDRESS

DISPLAY

MSI CellScale® System • 9750A User Guide Page 17

Page 18

1) Press the

key

. The weight display will temporarily display dashes while it

queries the CellScale for the next channel information.

2) Keep pressing the

key as desired until the channel of interest is displayed.

been altered)

CHANNEL

2

F2

CHANNEL

TO SELECT THE DISPLAY CHANNEL

As mentioned above, the 9750A will access any channels setup in the CellScale. It does this with the “CHAN-

NEL” function. Use the

key to step from channel to channel as dictated by the Scan list stored in the

CellScale. If the CellScale has only one scale channel defi ned, only 1 display mode is necessary. This is usually

®

®

the case for MSI-6260CS, MSI-9300 Crane Scales, and other single load cell systems. However, even single load

cell systems can have math channels defi ned to add functionality.

For systems with multiple scales attached to any given CellScale the setup procedure is:

1) Program the CellScale Scan List as required (see the CellScale Manual). It is recommended that each channel

is assigned a channel name to aid in identifying the scale in various display modes.

2) Optional, but recommended so you can readily identify which scale you are monitoring and controlling

– Program the display mode to show the Channel Name, or Channel Number, or both with the Display Setup

procedures in Section 7.

To Change the Scale Channel (Single Channel Display)

1) Using the numeric keys, input the number (1-32) corresponding to the desired channel in the

scan list.

2) Press the

key

. The weight display will temporarily display dashes while it

queries the CellScale for the desired channel information.

JKL

CHANNEL

To Change the Scale Channel Using Scan List Position (Single Channel Display)

To Change Scale Channel Using the Channel Number (Single Channel Display)

1) Using the numeric keys, input the number corresponding to the desired channel

number. Use the decimal point as the channel-subchannel separator.

is ignored by the CellScale.

2) Press the

key

. The weight display will temporarily display dashes

while it queries the CellScale for the desired channel information.

1

6

PQR

DISPLAY

EXIT

ABC

F2

CHANNEL

In CellScale systems with multiple channels, you can choose to see more than one channel at a time (See Display

Setup in Section 7). In order to zero, tare, or totalize with channels in a multiple channel display, you must fi rst

select the channel to operate on. This is referred to as the “Active” channel, because this is the only channel that

any scale function can be performed on.

To Select the Active Channel (multi-channel display)

1) Highlight the channel you wish to make Active by pressing the UP (

) or DOWN (

) cursor keys.

2) Once highlighted you can Zero the channel, set and clear Tare, and switch between Net and Gross with the

key, just press the appropriate key. For Total, View Total, Statistics and other ID functions,

you must switch the display to the single channel display by pressing

.

To Change a Channel in the Multi-Channel Display

1) Highlight the channel you wish to change by pressing the UP (

) or DOWN (

) cursor keys.

2) Once highlighted enter the scan list position (1-32) or the channel number (1-1 to 6-32 using the decimal

point for the sub channel entry). Then press

.

HANDHELD RF REMOTE INDICATOR for CELLSCALE

CHANNEL

®

CHANNEL

CHANNEL

CHANNEL

CHANNEL

[F2]

[F2]

[F2]

^

NET/GROSS

DISPLAY

^

CHANNEL

Page 18 MSI-9750A RF Remote Indicator • User Guide

v

v

Page 19

MEASUREMENT SYSTEMS INTERNATIONAL

Firmware Version 5-XX for 2450 Modems

To Switch Between Multi-Channel Display and Single Channel Displays

1) Highlight the channel you wish to see in the single channel mode by pressing the UP (

) or DOWN (

)

cursor keys.

2) Once highlighted press

. The highlighted channel will appear in the single channel mode.

3) Perform any scale function while in the single channel mode.

4) To return to the multi-channel display, press

.

When a multi-channel display mode is selected that shows fewer channels than are available from the CellScale,

the user can view all channels with the page mode.

Any channel can appear on any page by changing the preset channel using the “To Change Scale Channel...”

procedure. This allows a primary channel to show always, and secondary channels to change using the

key. This applies very well to the 3 channel preset display where one channel is large and the other 2 channels

are small.

To Change to the Next Page

Press the

key. The next group of channels appears. The action of the

key is circular, return-

ing to page 1 after the last page.

To Copy the Current Page

Sometimes it is advantageous to copy the current page and then make channel changes on the new page.

1) Press the

key. The entire screen will reverse.

2) Press the

key. The new copied page will appear. Make modifi cations with the enter channel pro-

cedures as desired.

To Delete the Current Page

1) Press the

(SPACE)

key.

2) Press the

key. The current page will be deleted and the display will revert to the fi rst page.

To Move Around in Pages

If you have many preset pages, you can move directly to pages by number entry.

1) Enter the number corresponding to the page you wish to see.

2) Press the

key. The new page will appear.

1) In single channel mode, go to step 2. In multi-channel mode, highlight a channel

with the up (

) or down (

) cursor keys to make it active.

2) Press

. The weight reading must be stable within the motion window for

the zero function to work. The display temporarily reads “ZEROING” and then

“ZEROED” after the CellScale acknowledges the command. The scale digits

display 0 (or 0.0 or 0.00, etc..). The backup memory in the CellScale stores the

zero reading, and can restore it even if power fails.

instantly, but the scale will zero.

ZERO

CLR

0

ZERO

Sets the zero reading of the scale. Use the

key to take out small deviations in zero when the scale is

unloaded. (See “TARE SET” for zeroing (Taring) package or pallet weights)

To Zero

Zero Rules for Use:

1) Works in GROSS mode or NET mode. Zeroing while in Net mode will zero the gross weight causing the display

to show the negative Tare value.

2) The scale must be stable within the Motion window. The scale will not zero if the motion detect annunciator

is on. The CellScale will “remember” that it has a zero request for 2 seconds. If motion clears in that time,

ALPHA

ENTER

ALPHA

DISPLAY

DISPLAY

ALPHA

^

v

ALPHA

[0]

ALPHA

ALPHA

ZERO

ZERO

^

v

ZEROING

ZEROED

MSI CellScale® System • 9750A User Guide Page 19

Page 20

the scale will zero.

3) The scale will accept a zero setting over the full Range of the scale (NTEP and other Legal-for-trade models may

have a limited zero range). Zero settings above 4% of full scale will subtract from the overall capacity of the scale.

For example if you zero out 100 lb. on a 1000 lb. scale the overall capacity of the scale will reduce to 900 lb. plus

the allowed over-range amount.

TARE

Tare is typically used to zero out a known weight such as a packing container or pallet and display the load in

NET weight. A Tare value is entered in either of two ways:

key is pressed, the current weight is zeroed and Net Weight is

displayed.

2) KEYBOARD TARE – Using the numeric keys, the operator keys in the desired Tare Weight then presses the

Key.

For Pushbutton Tare

To Clear Tare and Revert to Gross Mode

If the goal is to see the Gross Weight, use the Net/Gross key instead.

T

ARE

T

1) In single channel mode, go to step 2. In multi-channel mode, highlight a channel

with the up (

) or down (

) cursor keys to make it active.

2) Press

. The current Gross Weight will be stored in the Tare register and

the weight mode will change to NET (single display modes).

0

SPACE

T

1) In single channel mode, go to step 2. In multi-channel mode, highlight a channel with the

up (

) or down (

) cursor keys to make it active.

2) Press

followed by

. The Tare value will clear and the scale returns to the GROSS

mode.

Alternate method: Remove all weight from the scale (Gross Zero) and press TARE. The message display temporarily reads “TARING”.

To Keyboard Tare

Tare - Rules for Use:

When in the NET mode, the TARE is not cumulative, all the weight is tared off (to Net zero).

2) The motion annunciator must be off. The weight reading must be stable.

3) Setting or changing the tare has no effect on the Gross zero setting.

4) Taring will reduce the apparent over range of the scale. For example, taring a 10 lb. container on a 60 lb.

scale, the scale will overload at a net weight of 50 lb. (60-10) plus any additional allowed overload (usually

~4% or 9d).

5) The scale stores the Tare value in the current ID Code memory until cleared. Each available ID Code can

store independent Tare values.

2

0

SPACE

DISPLAY

EXIT

5

MNO

3

T

1) In single channel mode, go to step 2. In multi-channel mode, highlight a channel with

the up (

) or down (

) cursor keys to make it active.

2) Using the numeric keys input the value desired. In this example we’ll use 0.5 lb. as

a Tare Value. Press

. The Enter Line displays “0.5”.

. The Enter Line displays “0.5”.

. The Enter Line displays “0.5”.

3) Press

to place the value in the Tare Register (Current Channel, current ID).

The display reads “TARE SET” when the CellScale responds. All subsequent read-

ings have the Tare value subtracted and are displayed in “NET” weight.

To View the Tare Value

T

ARE

T

1) In single channel mode, go to step 2. In multi-channel mode, highlight a channel with

the up (

) or down (

) cursor keys to make it active.

2) Press

followed by

.

3) The display shows the current Tare value

Pressing ENTER again allows the Tare value to be edited.

TARE

HANDHELD RF REMOTE INDICATOR for CELLSCALE

®

TARE

TARE

^

[0]

TARE

^

v

TARING

v

TARE

^

v

[0] [.] [5]

^

ENTER

Page 20 MSI-9750A RF Remote Indicator • User Guide

v

TARE

Page 21

MEASUREMENT SYSTEMS INTERNATIONAL

Firmware Version 5-XX for 2450 Modems

TARE SETTINGS

-CHANNEL NAME or NUM-

1 Disable Auto Clear

2 Set Clear on Minus

3 Set Clear on Total

4 Tare by Product ID

5 Same Tare All ID’s

Shortcut

TARE SETTINGS

ESC

!

SETUP

T

ARE

T

6

PQR

7

STU

1) In single channel mode, go to step 2. In multi-

channel mode, highlight a channel with the up

(^) or down (

) cursor keys to make it active.

2) Standar d Method - Press

. Se lect

“MORE”

. Select “Tare Setup”

.

Shortcut Method - Press

followed by

.

The 9750A is capable of storing Tare values through the use of the ID Codes. Each ID code stores an independent

Tare. See Section 3 “ID Codes” for more information.

SETUP TARE MENU

Programs the automatic TARE Clear function (Auto Clear), and the various Tare Modes including a means to

disable Tare.

The Auto Tare Clear is intended to automate loading operations where packaging must be tared out, but there is a

risk that the operator will forget to re tare each new package. It does this by automatically clearing the tare value

and reverting the weight mode back to Gross. The Setup Tare menu permits three modes of Auto Tare Clear: 1)

Disabled. 2) Set Clear on Minus - When the Net Weight goes negative (as it will when a tared package is removed),

the Tare value is cleared and the weight mode reverts to Gross. 3) Set Clear on Total - When the Total function

is enacted, the Tare value is cleared and the weight mode reverts to Gross.

4-5 UNIVERSAL TARE

The Universal Tare feature allows a single Tare value to be shared by all ID Codes. With “Same Tare All IDs”

enabled the individual Tares stored with each ID Code are ignored (but not erased). Selecting “Tare by Product

ID” will restore the original Tare values. Universal Tare is intended for those applications where a common car-

rier or pallet is used, but multiple ID Codes are necessary for data collection. To select Universal Tare choose

“Same Tare All ID’s” on the TARE SETUP MENU. This effects all IDs on any given scale channel, but not the

IDs associated with other scale channels.

Tare Settings Menu

Set Auto Clear Mode with the 1-3 keys. Only 1 item from 1-3 can be enabled at a time. Set the Universal Tare

mode with the 4-5 keys.

1 Disable Auto Clear – Pressing the

key turns off the function (default).

2 Set Clear on Minus – When the Net Weight goes negative (as it will when a tared package is removed), the

Tare value is cleared and the weight mode reverts to Gross.

3 Set Clear on Total – When the Total function is enacted, the Tare value is cleared and the weight mode reverts

to Gross.

4 Tare by Product ID – Each ID has a unique Tare when this selection is chosen (default).

5 Same Tare All ID’s – Pressing the

key enables the Universal Tare Mode.

Switches the display between Net and Gross modes. Net Weight is defi ned as Gross Weight minus a Tare

Weight.

To Switch Between Net Mode and Gross Mode press the

key.

The

key will only function if a Tare value has been established for the current channel and the Tare

Mode is “NET/GROSS”. The Net/Gross function will affect all meters displaying this channel.

Switching back to Gross mode from Net mode will not clear the Tare value. This allows the operator to use the Gross Mode temporarily without having to reestablish

the Tare value. Only manually clearing the Tare or setting a new Tare will change the tare value held before switching into Gross Mode. In displays that include

the Net and Gross readings, the NET/GROSS key has no effect since both weight types are already displayed. However, other channels displaying just one weight

type will change.

returns to the Net Mode. The only way to return to permanent Gross readings is to clear the Tare (see Clear Tare procedure).

[7]

TARE

NET/GROSS

v

SET UP

[6]

SETUP

[1]

[5]

NET/GROSS

MSI CellScale® System • 9750A User Guide Page 21

Page 22

Allows easy weight units conversions. Up to 8 Units are available. See “SETUP UNITS” in the CellScale Manual

for details on activating the available units. Since Units are stored with each ID Code, the menu item for chang-

ing units is found in the “Product ID Codes” Menu. See section 3. Alternately, if changing Units is a common

operation, a Function key can be programmed for the task.

For example, if

is programmed for UNITS, then