Page 1

MSI-4260B

Port-A-Weigh Crane Scales

Operator’s Manual

152159 Rev A

Page 2

Page 3

Technical training seminars are available through Rice Lake Weighing Systems.

Course descriptions and dates can be viewed at www.ricelake.com/training

or obtained by calling 715-234-9171 and asking for the training department.

Contents

1.0 Introduction ...........................................................................1

1.1 Safety Section .................................................................... 2

1.2 General Information ........................................................... 4

1.2.1 Operator’s Manual & MSI-4260 Conventions .....................4

1.3 MSI-4260 Annunciators ..................................................... 5

1.4 Specifications .................................................................... 6

1.5 Features ............................................................................. 8

1.6 Options ............................................................................... 8

1.7 Unpacking .......................................................................... 8

1.8 Installation .......................................................................... 9

1.9 Battery Pack .................................................................... 10

1.9.1 Battery Life .......................................................................10

1.9.2 Battery Use Guidelines .....................................................10

1.9.3 Battery Charger ................................................................11

1.9.4 Battery Removal & Replacement ......................................12

1.10 Comm Port ....................................................................... 13

1.10.1 Comm Port Cables ..........................................................13

1.11 Servicing the MSI-4260 ................................................... 14

1.12 RF Connectivity ............................................................... 15

1.12.1 FCC Statement (for 802.15.4 Option) ...............................15

1.12.2 International RF Certs (for 802.15.4 Option) .....................15

2.0 Operation .............................................................................16

2.1 Power ............................................................................... 16

2.2 Zero .................................................................................. 16

2.3 Tare .................................................................................. 17

3.0 User Defined Function Keys .................................................18

4.0 Set Up ...................................................................................21

4.1 Menu Map ........................................................................ 21

4.2 Function Keys .................................................................. 22

4.3 Auto- Off ........................................................................... 23

4.4 Sleep ................................................................................ 24

4.5 Display Brightness ........................................................... 25

4.6 Set Points ......................................................................... 26

4.7 Total Mode ....................................................................... 28

4.8 Units ................................................................................. 29

4.9 Filter Setup ....................................................................... 30

© Rice Lake Weighing Systems. All rights reserved. Printed in the United States of America.

Specifications subject to change without notice.

Rice Lake Weighing Systems is an ISO 9001 registered company.

February 2013

Page 4

Rice Lake continually offers web-based video training on a growing selection

of product-related topics at no cost. Visit www.ricelake.com/webinars.

5.0 Calibration ...........................................................................31

5.1 Initial Calibration .............................................................. 34

5.2 Guidelines for Capacity and Resolution ......................... 35

5.3 C-Cal Calibration ............................................................. 36

5.4 Calibration Setup Menu ................................................... 38

5.4.1 Standard ..........................................................................39

5.5 Auto Zero Maintenance ................................................... 40

6.0 RF Remote Control Option ...................................................42

6.1 Description ....................................................................... 42

6.2 Functions ......................................................................... 42

6.3 Setting the Transmitter Address ..................................... 43

6.4 Setting the Receiver Address ......................................... 43

6.4.1 Resetting the 4260 RF Remote Receiver ..........................43

6.5 Contention and Jamming Considerations ...................... 44

6.6 Battery Replacement ....................................................... 44

6.7 RF Remote Control FCC Statement ............................... 45

7.0 RF Remote Display Option ...................................................46

7.1 Introduction ...................................................................... 46

7.2 COMM SEtup Menu ......................................................... 46

7.3 Printer / Serial Output Setup ........................................... 47

7.3.1 Control Modes .................................................................47

7.4 Standard Print Strings ..................................................... 47

7.5 802.15.4 RF Network Setup ........................................... 50

8.0 Appendix ..............................................................................53

8.1 Troubleshooting ............................................................... 53

8.1.1 Service Counters ..............................................................55

8.2 MSI-4260 Port-A-Weigh Dimensions .............................. 56

The MSI Limited Warranty 57

ii MSI-4620 Operator’s Manual

Page 5

1.0 Introduction

The MSI-4260 Port-A-Weigh is a combination of the sound and proven mechanical

design of the industry standard MSI-4260 with today’s most advanced electronics to

provide a superb feature set unmatched by any crane scale in its class or price range.

The MSI-4260 is versatile, reliable, accurate and user friendly to operate.

The MS

OSHA safety standards

and RF Remote Display (using the MSI-8000 Remote Display) are available to further

enhance the performance and application versatility of the MSI-4260.

If you have any questions or comments please contact

I-4260 is designed to meet or exceed requirements of applicable ASME, ANSI,

. Multiple options and accessories, including RF Remote Control

Measurement Systems International

Phone (toll free): 1-800-874-4320

Authorized distributors and their employees can view or download this

manual from the Measurement Systems International site at:

www.msiscales.com.

Introduction 1

Page 6

1.1 Safety Section

CAUTION

WARNING

Important

WARNING

Safety Symbol Definitions:

Indicates a potentially hazardous situation that, if not avoided,

could result in death or serious injury, and includes hazards that

are exposed when guards are removed.

Indicates a potentially hazardous situation that, i

result in minor or moderate injury.

Indicates information about procedures that, if not observed,

could result in damage to equipment or corruption to and loss of

data.

Do not operate or work on this equipment unless you have read and

understand the instructions and warnings in this manual. Contact

any Measurement Systems International dealer for replacement

manuals. Proper care is your responsibility.

f not avoided may

General Safety

Failure to heed may result in serious

DO NOT allow minors (children) or inexperienced persons to operate this unit.

DO NOT stand near the load being lifted as it is a potential falling hazard. Keep a

safe distance.

DO NOT use for purposes other then weigh

DO NOT use any load bearing component that i

dimension.

DO NOT use the Scale if any of the components of the load train are cracked,

deformed, or show signs of fatigue.

DO NOT exceed the rated load limit of the Scal

structure.

DO NOT allow multi-point contact with the hook, shackle, or lifti

Scale.

DO NOT allow high torque on the Scale unless it is specifically designed for high

torque.

DO NOT make alterations or modifications t

devices.

DO NOT use improperly rated or sized shackl

shackles.

DO NOT remove or obscure warning labels.

For guidelines on the safe rigging and l

dynamometers, read the "MSI Crane Scale Safety and Periodic Maintenance

Manual" (available at www.msiscales.com).

Keep hands, feet and loose clothing

There are no user serviceable parts within the MSI-4260. Any repairs are to be

performed

by qualified service personnel only.

away from moving parts.

t taking or dynamic load monitoring.

o the Scale or associated load bearing

oading of overhead scales and

injury of death.

s worn beyond 5% of the original

e, rigging elements, or the lifting

ng eye of the

es. Use only MSI recommended

2 MSI-4260 Port-A-Weigh Operator’s Manual

Page 7

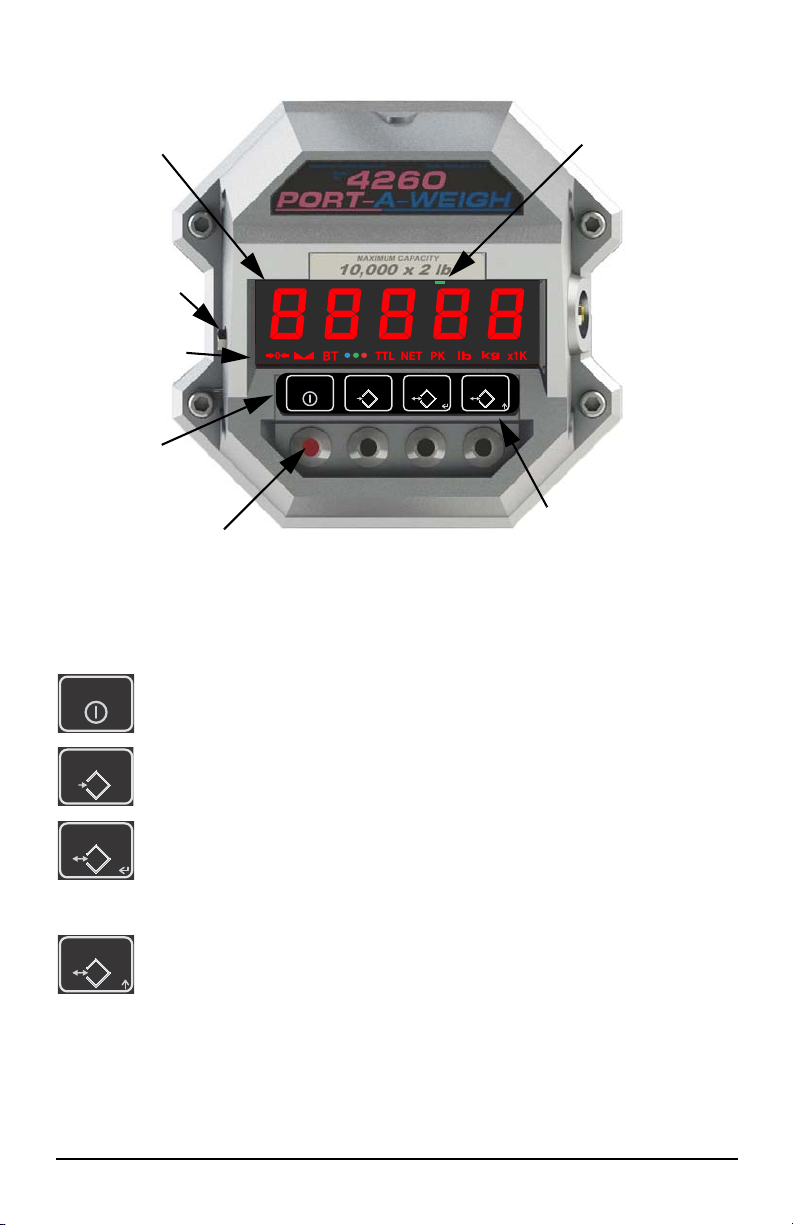

st

ZERO TARE USER

es

POWER

T

F

5 digit 1.2/30.5 mm

high brightness LED

weight display

RS-232 Serial Port

IP-68 rated push buttons

User Programmable

Function Key

Sealed calibration

switch

LED annunciators

Push button legend

Acknowledge

annunciator

Key Descriptions

es

st

ZERO

T

F

POWER

Figure 1-1 MSI-4260 Front Panel

Power Key - Turns the MSI-4260 On and Off.

Zero Key - Used to zero out residual weight on the scale.

TARE

USER

Tare K e y - removes weight of containers, trucks or carriers and places

the scale in the Net weight mode.

TARE key functions Tare In, Tare Out.

To see the gross weight without resetting the Tare value, program the

USER key

User Key- Programmable to user selectable functions. These are

as NET/GROSS.

described in the USER key Setup section. This key is defaulted to the

TEST function.

Introduction 3

Page 8

1.2 General Information

1.2.1 Operator’s Manual & MSI-4260 Conventions

1. Keys used in operations are printed in BLUE and capitalized.

2. Screen shots that are used in menus are displayed in RED and shown in a

7-segment font. Not all characters can be displayed with this font, but a close

approximation is shown.

3. If a function key does not work, it is probably because the MSI-4260 is not setup

to support the key. For example, if the Function Key is set for

also setup the TOTAL mode in the Setup Menu.

4. When in Setup Menus, the ZERO key drops back one menu level. At the root

menu level, the ZERO key stores the changes and returns to the weight mode.

5. When in Setup Menus, the POWER key returns you directly to the Weight

Display without storing the changes.

6. When in Setup Menus, the USER key functions as the scroll key.

7. When in Setup Menus, the TARE key functions as the ENTER/SELECT key.

TOTAL, you must

4 MSI-4260 Port-A-Weigh Operator’s Manual

Page 9

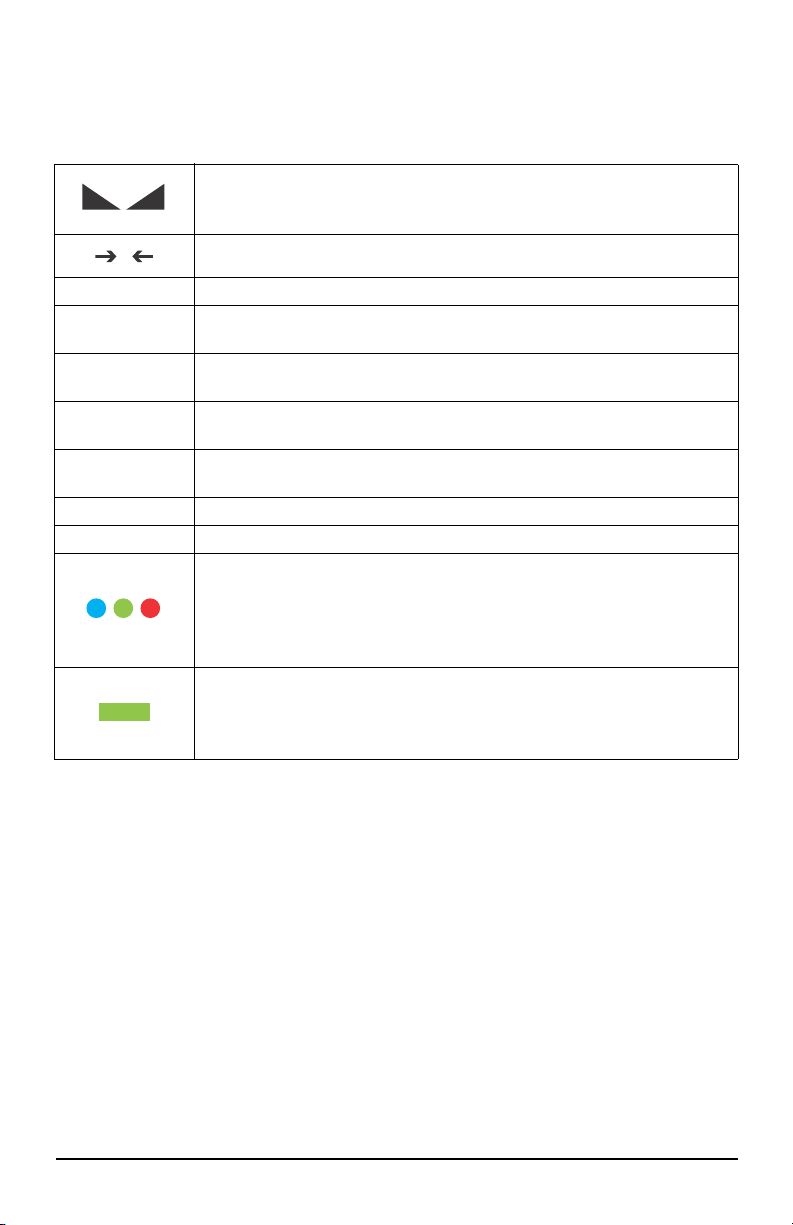

1.3 MSI-4260 Annunciators

The MSI-4260 uses blue and red LEDs to indicate weight mode and other

information.

The STABLE annunciator indicates that the weight has settled within

the motion window (usually ±1d). When this symbol is off the scale

will not zero, tare, or totalize.

0

PK

NET

TTL

x1K

BT

kg

lb

Center-of-Zero – Indicates the weight is within 1/4d of zero.

PEAK - Indicates the scale is in peak hold mode.

NET - Indicates the scale is in Net weight mode.

A Tare weight is subtracted from the gross weight.

TOTAL - (Blue LED) Indicates the scale is displaying the Total weight.

This is a temporary display lasting less than 5 seconds.

X1000 - (Blue LED) Usually used in conjunction with the TOTAL LED

to allow accumulation of weight beyond the 5-digit display capacity.

LO BATT - Appears when approximately 10% of battery life remains,

LED blinks when automatic shutdown is eminent.

kg - (Red LED) Indicates weight display is in kilograms.

lb - (Red LED) Indicates weight display is in pounds.

SET POINTS - User programmable set points for early overload

warnings.

Blue LED - Setpoint 1

Green LED = Setpoint 2

Red LED - Setpoint 3

ACK - Acknowledge LED is used to provide feedback to the

operator that incoming remote commands have been received

(Green LED).

Also used for acknowledging successful Auto-Total operations.

Introduction 5

Page 10

1.4 Specifications

Accuracy ±(0.1% +1d). ‘d’ equals one displayable increment.

Resolution Standard displayed resolution: 2500-3750’d’.

Standard

Capacities

Power Battery operated, 12V rechargeable sealed lead acid battery pack

Display 5 digit, large 1.2 in (30.5 mm) numeric red GaAIAs Light Emitting

Operating

Te mp

Operating Time 100 hours typical/150 hours max. (depends on operating mode)

Enclosure NEMA 4/1P65 powder coated alodined cast aluminum

Load Cell Standard 350 Ω Bridge, MSI Trinocular (>10k lb.)

USER Programmable multifunction button for use as

CAL Wire sealed calibration switch (located on the left side of the front

Auto Zero

Maintenance

Auto-Off Mode Prolongs battery life by turning POWER off after 15, 30, 45 or 60

Auto-Sleep

Mode

Units kg, lb (other units available with custom calibrations)

Filtering Selectable:

Totalization Standard: Press button or Automatic; TOTAL weight up to 99999 X

Peak Uses unfiltered faster reading of A/D (>400 readings per second)

Set Points Three internal standard Set Points and three ultra bright LEDs on

Resolutions to 10000’d’ (non LFT units only) are possible.

Internal A/D resolution 24 bits

lb 500 2000 5000 10000 20000 30000 50000 70000 100000

kg 250 1000 2500 5000 10000 15000 25000 35000 50000

(standard Port-A-Weigh Charger).

Up to 100 hours of battery life with Automatic Sleep Mode and

Automatic Power Off

Diode (LED)

-40°F to +122°F (-40°C to +50°C), LFT range -10°C to +40°C

TEST, TOTAL, UNIT, PEAK, NET/GROSS, VIEW TOTAL, LEARN

(for RF Remote Control)

casting).

Initiates full digital calibration procedure.

Standard, can be disabled internally

minutes (operator determined) of no scale activity

Prolongs battery life by dimming LED display after 5, 15, or 30

minutes of no activity

• OFF, Low (LO)

• Medium (HI-1)

• High (HI-2)

1000 kg or lb

indicator panel.

Set Point relay options are available, contact factory.

Table 1-1. Specifications

6 MSI-4260 Port-A-Weigh Operator’s Manual

Page 11

WARNING

Service

Counter

Construction

OPTIONS

Wireless

Remote

Controler

Wireless

Remote Display

Two independent 32 bit registers;

• Register 1 updated each time weight exceeds 25% of capacity;

• Register 2 updated each time weight exceeds overload;

When register 1 exceeds 16383 or register 2 exceeds 1023, display

reads “LCnt” for load cell counter;

Test function shows the two readings in order

All features are housed in heavy duty, cast aluminum housing

onsisting of three sections:

c

• The front of the scale houses the display, controls and all

electronics

• The center section contains the load cell, lifting eye and hook

• The rear of the scale features a quick access battery

compartment

Table 1-1. Specifications

m) typical range Line-of-Sight. Uses 418 MHz (USA)

50 (15

handheld transmitter. 315MHz and 433MHz options are available

for international applications

100 (30m)

handheld transceiver.

typical range Line-of-Sight. Uses 802.15.4, 2.4GHz

Table 1-2. Options

The MSI-4260 Port-A-Weigh scale has a safe mechanical

overload of 200%, and an ultimate overload of 500%. Overloads

greater than 500% may result in structural failure and dropped

loads. Dropped loads may cause serious personal injury or death.

Introduction 7

Page 12

1.5 Features

• Designed to meet or exceed applicable US and international safety standards.

• Up to 100 hours of weighing time utilizing Automatic Sleep Mode.

• Automatic Power Off conserves battery life by sensing no activity after 15, 30,

45 or 60 minutes, determined by operator, and turns off power.

• Automatic sleep Mode preserves battery life by dimming the LED display after

5, 15, or 30 minutes of no activity.

• Rugged construction throughout. Buttons are sealed and rated for over 1 million

operations.

• Precise high resolution (2500 division standard and up to 10,000 possible) 24 bit

A/D conversion coupled with advanced RISC micro controller provides world

class features and accuracy.

• Five large, 1.2 inch (30.5 mm) LED digits for clear weight readings from a

distance. Display tilted down for easier viewing from below.

• Easy to maintain: Full digital calibration assures reliable, repeatable

measurements. Can be calibrated without test weights using MSI C-Cal

technology.

• Selectable for kg/lb unless prohibited by LFT regulations.

• Automatic or manual weight totalization for loading operations.

• Easily customized for special applications.

• Hi speed PEAK Mode for wire and rope stress analysis.

• Three Set Points can be set for any in-range weight for operator alerts or process

control.

• ScaleCore Technology providing quick and easy software updates and

calibration/setup backup.

• Two Service counters ensure Load Train safety by warning the user to perform a

Load Train safety check when the lift count gets high or the scale has been

overloaded repeatedly.

1.6 Options

Options which you may have ordered with your Port-A-Weigh may include the

following:

• RF Remote Controller

• RF Remote Display

• 802.11 WiFi Connectivity

• 85-265 VAC input power.

• Audible Alarm (triggered by Set Point 1)

1.7 Unpacking

When unpacking the scale from the shipping container, ensure that all assembly parts

are accounted for. Check the scale for any visible damage and immediately report any

damage to your shipper. It is advisable to use the original shipping container when

shipping or transporting the MSI-4260.

8 MSI-4260 Port-A-Weigh Operator’s Manual

Page 13

1.8 Installation

Note

WARNING

Important

The MSI-4260 features a heavy duty, cast aluminum enclosure rated at NEMA 4 IP

66. It installs easily by hanging it on the crane, using properly sized shackles.

Please refer to MSI’s brochure, “Crane Safety” when installing

model

MSI-4260

.

One of the most common installation problems is using an oversize shackle or too

large a hook to interface with the MSI-4260. This can cause off center loading and

stress points that will reduce the life of the lifting eye or hook.

Use the appropriate interface hardware for

• If your interface hardware does not fit

the capacity of the scale.

properly, MSI can supply the MSI-4260

with oversize lifting eyes or shackle interfaces.

• If the crane hook is too large to fit in the lifting eye with s

ingle point interface,

then install the scale using adaptive rigging.

• If multiple attachments are needed, use a shackle or

ring to attach the multiple

lines to thus keeping a single point attachment to the scale.

Single point attachments are necessary to ensure the safety and

accuracy of the scale system.

Regular maintenance inspections of the liftin

performed to ensure safety. Pay particular attention for signs of

stress on any element in the load train.

g system should be

Introduction 9

Page 14

1.9 Ba tte ry Pa ck

Note

Note

The MSI-4260 is powered by a 12 volt Sealed Lead Acid rechargeable battery.

The battery will operate for up to 100 hours (depending on LED brightness setting)

befo

re requiring recharging.

In order to conserve battery life, the scale inc

which senses operational status for no activity after 15, 30, 45, or 60 minutes, and

turns the scale off.

An additional battery saving feature is the Automatic Sleep

preserves battery life by dimming the display after 5, 15, or 30 minutes of no scale

activity.

Charging time for a completely discharged battery is up to 8 hours. A spare battery

pack is recommended to

To obtain maximum service life from your batteries they should be stored

between -4°F and 122°F (-20°C and +50°C). Stored batteries should be

recharged every three months. Battery is fully charged when the status

indicator is flashing.

keep the MSI-4260 in continuous operation.

1.9.1 Battery Life

The MSI-4260 battery life depends on a number of factors:

• Brightness of the LED Display and number of segments lit.

• Amount of RF activity, and the age.

• Condition of the SLA (sealed lead acid) battery.

The MS

approximately 10.5V. You must recharge the battery when this happens.

SLA batteries do not suffer from memory effects and actually benefit from frequent

recharging. Recharge the battery whenever it is convenient even when it still has

available life.

Due to the maintenance discharge imposed on the battery by the M

electronics, do not store the MSI-4260 with the battery inside. Remove the battery

if it will not be used for more than 2 weeks.

I-4260 will automatically turn the scale off when the SLA battery drops to

Leaving a discharged battery in the scale, which has a maintenance

battery drain, can result in a deep discharged battery which will shorten

its service life.

ludes an Automatic Power Off Mode

Mode. This feature

SI-4260

1.9.2 Battery Use Guidelines

• Recharge whenever convenient. Do not wait for the scale to shut itself off if your

work situation permits.

• If you need the scale continuously

the drained battery as close as possible to the low battery warning, or earlier.

• SLA Batteries that have not been deep discharged should withstand 500 to 1500

char

ging cycles.

• The low battery warning will indicate about 2-4 hours of additional use before

the MSI-

•If the MS

4260 turns itself off.

I-4260 is not going to used again soon, remove the SLA battery to

prevent deep discharge while the unit is in storage.

• Recycle the battery to an authorized recycling

20 hours or less.

10 MSI-4260 Port-A-Weigh Operator’s Manual

, keep a fully charged spare battery. Replace

center when average life drops to

Page 15

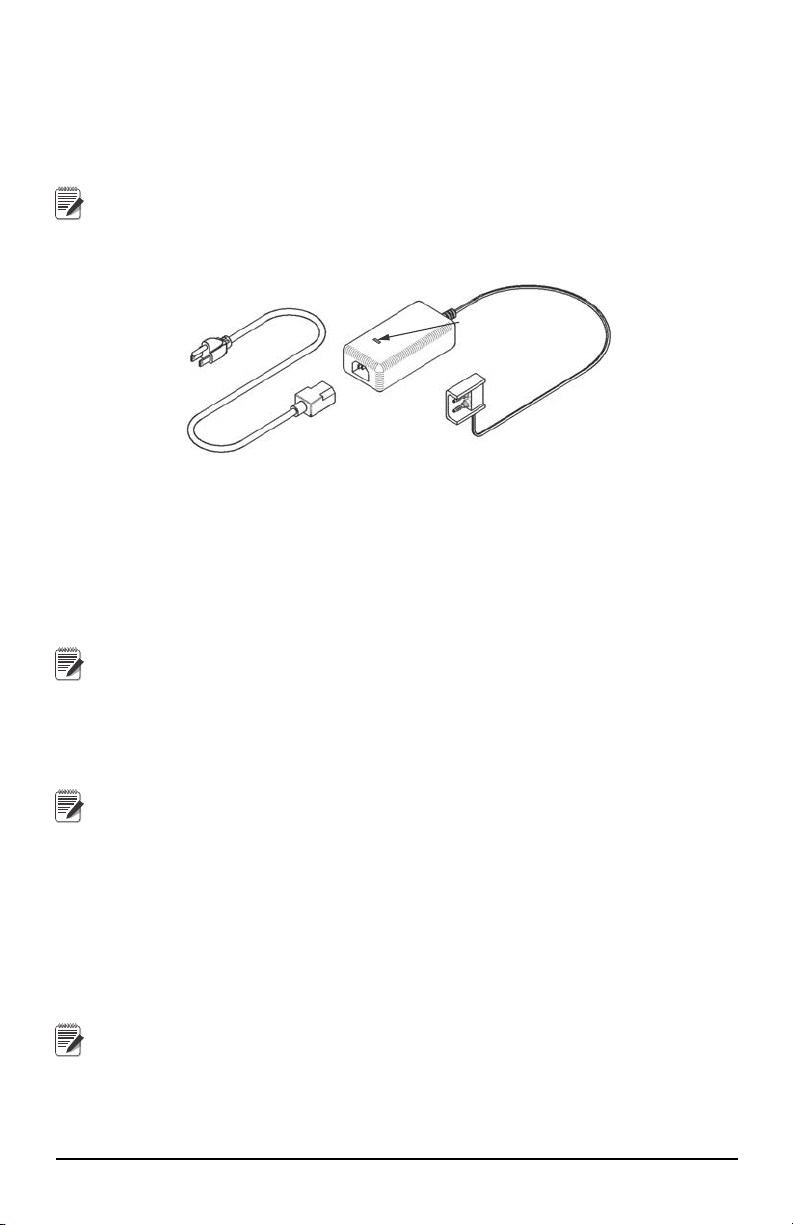

1.9.3 Battery Charger

Note

Charge Indicator Light

Amber = Charging

Green = Float

Note

Note

Note

Each MSI-4260 is shipped with a battery charger designed to charge and maintain the

battery. Exact charging time will depend on the degree of discharge of the battery. A

battery removed when the low battery warning first appears should take about 4 hours

to fully charge.

When the battery is new, it might take significantly longer for the initial

charge. MSI recommends charging a new battery for 24 hours. It might

take several charge/discharge cycles before full capacity is reached.

Deep discharged batteries will also take significantly longer to charge.

Figure 1-2 Batte ry Charger

The charger is a universal input type and is rated for 100-240VAC, 50-60Hz. AC

power cords

Using the Charger

1. Remove the battery from the MSI-426

2. Connect the charger assembly to the AC supply (86-260VAC). The charge

3. Plug in the polarized connector to the jacks on the battery.

4. The Charge Status light should turn AM

5. Charge until the status light turns GREEN.

When the charge cycle is complete you can (and should) leave the battery on the

charger until it is needed. The charger keeps a maintenance float charge on the battery

to ensure the best possible operation times. For scales that are in high usage, MSI

recommends obtaining a spare battery so one can always be on the charger.

suitable for any world location are available from MSI.

0. See Figure 1-3.

icator light should be green.

ind

If the power status light fails to illuminate, check your AC power

connection and make sure the Vin jack is fully seated. AC power cords

suitable for any world location are available from MSI.

BER indicating fast charge.

The charger is a 3 stage float charger that can be left on the battery

indefinitely. It has a dual color LED to indicate the charging state:

RED – Fast Charge Mode.

GREEN – Charged or Float Charge.

If the status light remains Green when the battery is first plugged in, the

batt

ery may be defective.

To obtain maximum service life from your batteries, the manufacturer

suggests recharging after each 20 hours of use. Continuous deep

discharging will reduce maximum battery life cycle estimated at 2000

cycles.

Introduction 11

Page 16

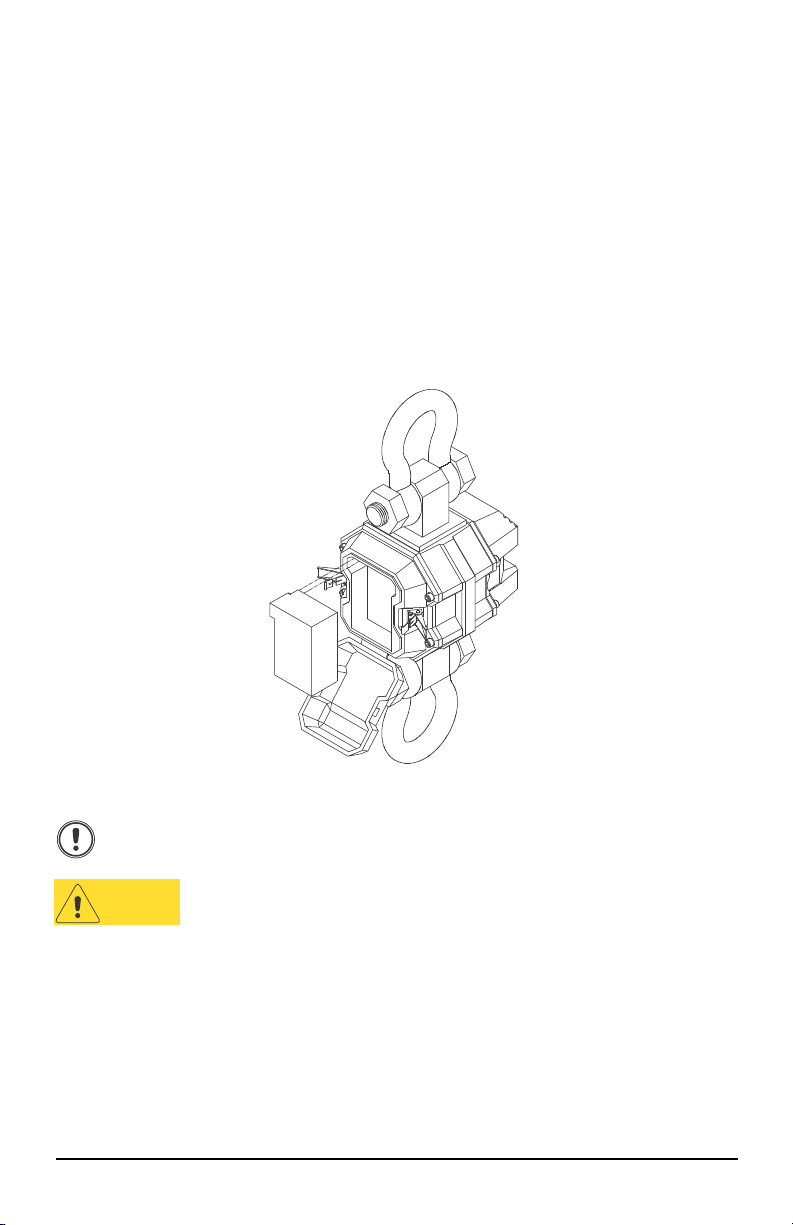

1.9.4 Battery Removal & Replacement

CAUTION

Important

1. Turn the MSI-4260 Off.

2. With one hand, hold the battery access cover.

3. Release the two latches holding the battery access cover. Remove the latch by

sing in on the spring catch, and pull on the latch lever.

pres

4. Carefully lower the cover and when possible, hold the

battery might be loose and subject to falling.

5. Remove the battery by pulling straight back.

6. Install a fully charged battery by plugging it in to the exposed battery jacks. The

MSI-426

0 may or may not turn on once the new battery is installed.

7. Reseat the access panel.

8. Reset the latches. Make sure the latches are completely latched and the plate is

firmly in place.

battery in place. The

Figure 1-3 Remove Battery

Periodically, inspect the battery latches for fit. Adjust the screw

latch by rotating the catch on its threads to maintain a tight seat

on the battery O-ring.

The 12V Sealed Lead Acid Battery can be a dangerous falling

hazard. When opening the battery hatch, be sure to hold the

battery to prevent it from falling. These batteries contain Lead

and should be recycled when it has reached its end of life.

12 MSI-4260 Port-A-Weigh Operator’s Manual

Page 17

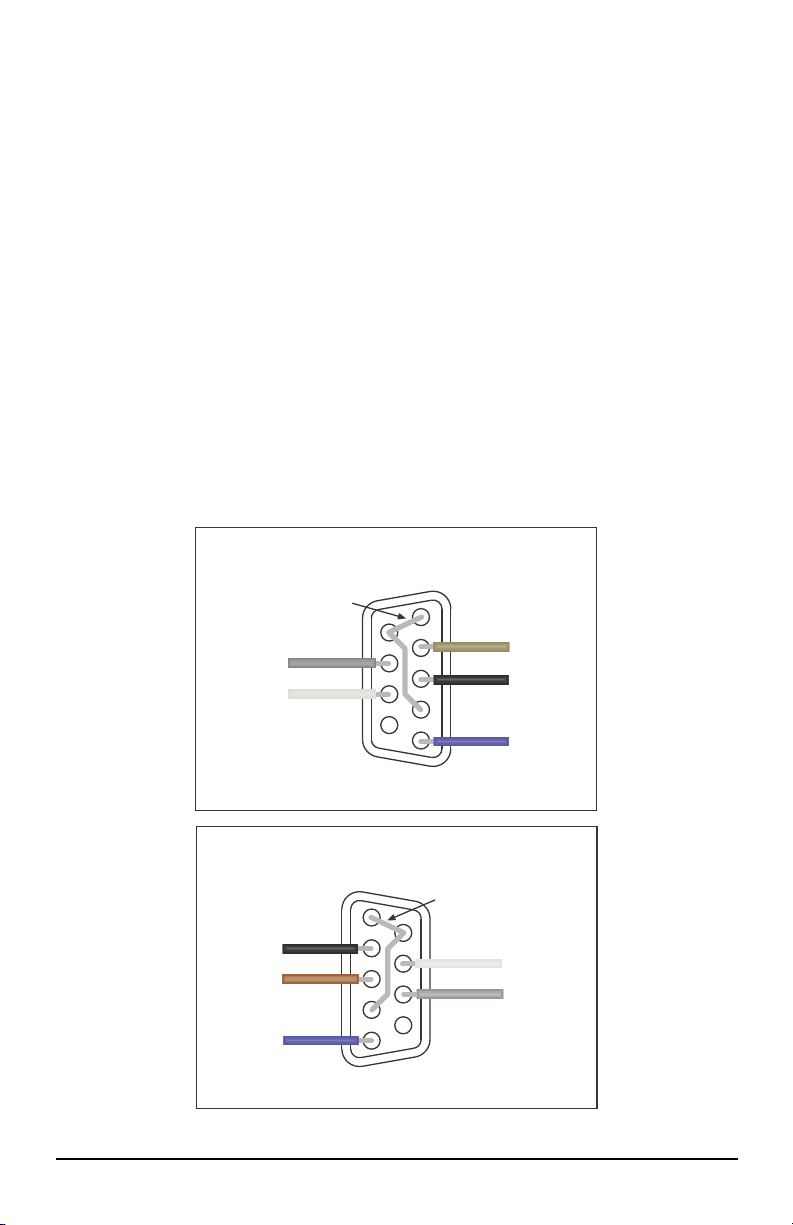

1.10 Com m P ort

1

2

3

4

5

6

7

8

(NC) 9

Brown (TD)

Black (RD)

Blue (GND)

Grey (CTS)

White (RTS)

Jumper 1-6-4

RS-232 DCE

9-Pin Female ‘D’

Solder Cup View

Standard wiring for direct

4260 to Computer connection

1

2

3

4

5

6

7

8

9 (NC)

Brown (TD)

Black (RD)

Blue (GND)

Grey (CTS)

White (RTS)

Jumper 1-6-4

RS-232 DTE

9-Pin Male ‘D’

Solder Cup View

Wiring for direct 4260 to

Printer/Scoreboard connection

The MSI-4260 has a single Comm Port allowing access to the embedded ScaleCore

through the Terminal Access Mode or MSI Software. The Terminal Access Mode is

used for updating scale firmware while MSI Software can be used for calibration and

configuration, backup and adjusting scale settings. This Comm Port is not intended

for output use as it is usually impractical to use a cable connected port on a Crane

Scale.

1.10.1 Comm Port Cables

The MSI-4260 comes standard with one Comm Port Cable wired for RS-232 (MSI P/

N 501705-0001) following the AT standard for 9 pin serial cables (DCE). An unterminated cable is available (MSI P/N 12023) if you wish to wire your own serial

cable for RS-232.

Comm Port Cable Color Code RS-232

• Brown – Transmit output from CellScale, connect to receive

• Black – Receive input to CellScale, co

• Grey – CTS Input to CellScale. Connect to R

nnect to transmit of DTE.

TS or RTR output of DTE.

• White – RTS/RTR output from CellScale. Connect to CTS input of DTE.

• Blue – Signal Ground

• Drain Wire – Connect to metal shell.

of DTE.

Figure 1-4 Comm Port Cable Assignments

Introduction 13

Page 18

1.11 Servicing the MSI-4260

MSI’s Dealer Network provides both on-site and depot servicing of MSI-4260 Crane

Scales. Please contact your local dealer. MSI also operates a service center for all our

products.

Contact MSI Service at 1-206-433-0199 to obtain an RMA (returned material

aut

horization). Due to the weight and size of many of our products, it is not always

necessary to return the whole scale. If the electronics are at fault, you can often return

just the front casting section. See Figure 1-5.

There are no user serviceable parts inside the M

with module and harness swaps.

SI-4260. Depot repair is performed

Figure 1-5 Remove Front Casting

To remove front casting electronics

1. Remove 4 Cap Screws.

2. Unplug connectors.

14 MSI-4260 Port-A-Weigh Operator’s Manual

package:

Page 19

1.12 RF Connectivity

The MSI-4260 has several options for RF Connectivity:

1. 802.15.4 – Standards based DSSS (Direct Sequence Spread Spectrum)

connection at 2.4 GHz This is used for connectivity to MSI’s Model 8000 hand

held remote display. It can also be used with a 802.15.4 modem to connect to

scoreboards or computers.

2. 802.11b,g,n – Standards based DSSS WiFi connection at 2.4 GHz. For operation

on an 802.11 Access Point to Ethernet networks.

This Operator’s Manual will cover option 1 as it is the most common.

Options 2 and 3 are detailed in option manuals.

1.12.1 FCC Statement (for 802.15.4 Option)

Contains FCC ID: OUR-XBEEPRO

The enclosed device complies with Part 15 of the FCC Rules. Operation is subject to

the following two conditions: (i.) this device may not cause harmful interference and

(ii.) this device must accept any interference received, including interference that may

cause undesired operation.

1.12.2 International RF Certs (for 802.15.4 Option)

Canada Radio Cert. No.: IC: 4214A-XBEEPRO

Australia & New Zealand: AS4268:3000

Japan: Certificate of Radio Equipment in Japan No.: 08215111/AA/02

Europe and much of Asia:

The product is compliant with the following standards and/or other normative

documents:

Safety (article 3.1A) EN60950-1:2001

EMC (article 3.1b) ETSI EN 301 489-1 v1.7.1 (2007-04) In accordance with the

specific requirements of ETSI EN 301 489-17 v1.2.1 (2002-08)

Spectrum (article 3.2) ETSI EN 300 328 v1.7.1 (2006-10)

Introduction 15

Page 20

2.0 Operation

es

POWER

st

ZERO

Note

2.1 Power

To turn on the power.

1. Press

• LED will light all segments at full brightness as a display test.

• Display brightness will change to the setting determined in the Display

• Software version number will display.

• The M

2.2 Zero

Sets the Zero reading of the Scale. Use the ZERO key to take out small deviations in

zero when the scale is unloaded. (See Section 2.3 for zeroing (Taring) package or

pallet weights)

1. Press

Rules for Use:

• Works in GROSS mode or NET mode. Zeroing while in Net mode will zero

• The scale must be stable within the Motion window

• The scale will accept a zero setting over the full Range of the scale (NTEP

, the following will display in order:

Menu.

SI-4260 is ready for use.

The weight reading must be stable within the motion window for the zero

function to work.

The scale digits display 0 (or 0.0 or 0.00, et

The backup memory in the MSI-4260 stores the zero reading, and can

restore it

even if the power fails.

c).

the gross weight causing the display to show the negative Tare value.

. The scale will not zero

if the stabilizer annunciator is off. The Scale will “remember” that it has a

zero request for 2 seconds. If motion ceases within the motion window in

that time, the scale will zero.

an

d other Legal-for-trade models may have a limited zero range). Zero

settings above 4% of full scale will subtract from the overall capacity of the

scale.

For example if you zero out 100 lb on a 1000 lb scale the overall capacity of

the scale will

reduce to 900 lb, plus the allowed over-range amount.

16 MSI-4260 Port-A-Weigh Operator’s Manual

Page 21

2.3 Tare

TARE

T

Note

TARE

T

Tare is typically used to zero out a known weight such as a packing container or pallet

and display the load in NET weight. A Tare value is entered by pressing the TARE

key. The TARE function in the MSI-4260 is defined as a Tare-In, Tare-Out operation.

The first press of the TARE key stores the current weight as a tare value and then the

scale subtracts the tare value from the gross weight and changes the display to NET

mode. The next press of the TARE key will clear the Tare value and revert the display

to GROSS mode.

To view the Gross weight without clearing

the function “NET/GROSS.” The RF Remote Control has a Net/Gross permanently

available.

To Tare and Display the Net Weight

1. Press

.

The weight reading must be stable within the motion window for the tare

function to work.

The scale digits display 0 (or 0.0 or 0.00, et

changes to NET.

The backup memory in the MSI-4260 stores the T

restore it even if power fails.

To Clear the Tare and revert to Gross Weight

1. Press

. The Net annunciator will turn off and the Gross annunciator will

turn on.

Tare - Rules for Use:

• Only positive gross weight readings can be tared.

• The stable annunciator (

stable.

• Setting or changing the tare has no effect on the Gross zero setting.

• Taring will reduce the apparent over range of the scale.

For example, taring a 100 lb container on a 1000 lb scale, the scale will

overl

oad at a net weight of 900 lb (1000-100) plus any additional allowed

overload (usually ~4% or 9d).

• The scale stores the Tare value in non-volatile

power is cycled.

the Tare Value, program the USER key to

c) and the weight mode

are reading and can

) must be off. The weight reading must be

memory and is restored when

Operation 17

Page 22

3.0 User Defined Function Keys

Note

The following function descriptions are for optional user defined functions that are

programmed on the front panel USER key or the two function keys (F1 & F2) on the

RF Remote Control. The functions TOTAL, VIEW TOTAL, and NET/GROSS are

available full time on the RF Remote Control. To enable any of the USER key

functions, you must set up the USER keys following the procedures in Section 4.0.

TEST

The TEST function provides an LED test that li

Model number followed by the Software Version number, the battery voltage and then

performs a display test that counts from 00000 to 99999. Other internal tests are

performed and if any test fails, an Error Code will display. See Section 8.1 for a

troubleshooting guide. Press the USER k

single step through all the test functions. In the single step mode, use the USER key

to scroll through the available test functions and the TARE key to start or display the

individual tests. Use the ZERO key to exit individual tests. Use the ZERO key to exit

entirely from the TEST function.

– MSI-

Ve rs io n.

– Batte

– Display T

99999.

–

TOTAL

4260 Software Version Number: Press TARE to see the Software

ry Voltage: Press TARE to see the battery voltage.

est: Press TARE to have the display count up from 00000 to

Cal Constant Display: Press TARE to view the C-CAL value.

The Total Mode must be programmed from the Setup Menus before the

USER key will function.

ghts all LEDs at once, next the SW

ey again within two seconds to enable a

For accumulation of multiple weighments. The accumulator always uses the

displayed weight, so GROSS and NET readings can be added into the same TOTAL.

There are four Modes of totalizing: Manual and three Auto Modes. The Manual Mode

requires the TOTAL button be pressed with the weight on the scale. The weight will

be added to the previously accumulated value. This assures that a weight on the scale

is only added to the total once. Both the manual and three auto total modes require

that the weight on the scale return below 0.5% (relative to full scale) of GROSS

ZERO or NET ZERO before the next weighment can be added. Applied weight must

be ≥1% of full scale above GROSS ZERO or NET ZERO before it can be totaled.

MANUAL TOTAL

The US

Weight is > 1% of Capacity and has not been totaled

add the current weight to the TOTAL weight. The ACK LED’s blink to indicate the

weight was accepted. The TOTAL annunciator lights and the Total weight is

displayed for five seconds and then the number of samples is displayed for two

seconds.

Current Weight has been Totaled

weight for five seconds (View Total) without changing the Total value. The TOTAL

annunciator will light during the TOTAL weight display. After five seconds of Total

Weight display, the number of samples is displayed for two seconds.

18 MSI-4260 Port-A-Weigh Operator’s Manual

ER key under the MANUAL TOTAL mode functions in this manner:

– Pushing the USER key will

– Pushing the USER key will display the Total

Page 23

Weight is <1% of Capacity – The USER key functions as “View Total” only and

Note

Note

functions as View Total until the 1% threshold is exceeded to allow the next addition

to the total value.

AUTO TOTAL

The USER k

ey under the AUTO TOTAL mode functions as Auto Total On / Auto

Tota l O ff.

The Auto Mode has three variations which are programmed in the

• AutoL

oad – Any settled weight above the ‘Rise above’ threshold will be

SETUP menu:

automatically totaled. Then the scale must fall below the ‘Drop below’ threshold

before another total is allowed.

• AutoN

orm – This mode takes the last settled weight to auto total with. The total

occurs only once the scale goes below the threshold. This allows the load to be

adjusted without a total occurring. Once the load is removed, the scale uses the

last settled reading for total.

• AutoHig

h – Similar to the AutoNorm mode except the scale uses the highest

settled reading. Useful for loads that can’t be removed all at once.

Any Total Mode will not function while the scale is in motion. Make sure

the

the filter setting or increase the size of the scale division (d) in the Init Cal

procedure.

is on. If the system fails to achieve stable readings, increase

View Total

The Function key activates the Total weight display followed by the number of

sampl

es. While the display is showing the Total, Total is cleared by pressing ZERO.

Net / Gross

Switches the display between Net and Gross modes. Net

Weight is defined as Gross

Weight minus a Tare Weight.

RF Remote Control, and the MSI-8000 have this function as a standard

feature. On the MSI-8000, you must configure a Function Key to Net/

Gross Mode to enable this feature.

To Switch Between Net Mode and Gross Mode:

1. Press the USER key (Setup to the Net/Gross function).

2. The NET/GROSS key will only function if a Tare value has been established.

3. Switching back to Gross mode from Net mode will not clear the Tare value. This

al

lows the operator to use the Gross Mode temporarily without having to

reestablish the Tare value. Only clearing the Tare or setting a new Tare will

change the tare value held before switching into Gross Mode.

OIML LFT units only: The NET/GROSS key is temporary action only. The Gross

weig

ht is displayed for two seconds and then the display returns to the Net Mode. The

only way to return to permanent Gross readings is to clear the Tare (See Section 2.3).

PRINT

If print option is installed this menu choice wi

ll appear. The setup of the print function

is covered in the Option manual.

User Defined Function Keys 19

Page 24

LEARN

Used for programming the RF Remote Control. This function is detailed in Section

6.0.

PEAK HOLD

Peak Hold will only update the display when a higher peak weight reading is

established.

The Peak Hold function uses a high speed mode of the A/D converter allowing it to

capture transient weights at a far higher rate than typical scales. Peak hold is cleared

and re-enabled with the USER key.

PEAK HOLD is not available on NTEP or OIML LFT certified scales.

UNIT

The Function key will switch the weight units between pounds and kilograms.

UNIT switching is not available on OIML certified LFT scales.

20 MSI-4260 Port-A-Weigh Operator’s Manual

Page 25

4.0 Set Up

)YQF

IYQF

DII

GLVSO

6W3W

6W3W

6W3W

WRWDO

/($51

81L7

ILOWU

2))

WHVW

WRWDO

YWWO

1(W

U

8QLW

3+OG

2II

II

/R

+L

+L

DYWR

/R

/R

+L

+L

kg lb

2))

UHDW

/(66

Number Entry

Off

Test Display

(default)

*Total

*View Total

*Net/Gross

**Units

***Peak Hold

USER KEY

FUNCTIONS

TOTAL MODE

Total Off (default)

Total On Manual

Autototal on Load

Autototal Normal

Autototal on High Load

2II

WWO2Q

$/R$'

$QRU

$+L

USER

F

Function User Key 1

Function User Key 2

Auto Off Time

LED Display Intensity

Set Point 1

Set Point 2

Set Point 3

Total Mode

RF Remote Learn

Weight Units**

Weight Filter***

SETUP MENU

Disabled (default)

15 minutes

30 minutes

45 minutes

1 hour

AUTO OFF TIME

OFF (disabled)

Low (default)

High Filter

Very High Filter

SOFTWARE FILTER

LED DISPLAY INTENSITY

Auto by Light Sensor (default)

Dim (longest battery life)

Medium Dim

Medium Bright

Maximum Bright

See RF Remote

Setup Procedure

POWER

* Function always available on the RF Remote

** Function not available or non-functional in OIML R76 & 1Unit modes

*** Function not available or non-functional in OIML R76 or NTEP HB44 modes

With the Power off, hold

down the USER key, then

turn the Power on

USER

F

TARE

ENTER / SELECT

POWER

EXIT and Cancel Changes

ZERO

EXIT and SAVE

USER

F

SCROLLs through Menu Choices

Set Point Off

(default)

Greater Than

Less Than

Totals on first stable load

Totals the last stable load

Totals the highest stable load

Totals by pressing the USER key

Autototal Normal and Autototal High

do not total until the scale is unloaded.

URVV

QHW

U

WRWDO

W&QW

SP WEIGHT MODE

Gross (default)

Net or Gross

Total

Total Count (n)

4.1 Menu Map

Figure 4-1. Setup Menu Map

Set Up 21

Page 26

4.2 Function Keys

1)

With the 4260 off, press and hold

the USER key, then press the

POWER key.

...or while the 4260 is on, press USER

and POWER simultaneously.

2)

The first item of the Setup Menu

is “Func1”.

3)

To setup the User key press

TARE. The current User key

function is displayed.

4)

Select the User key function by

scrolling through the choices with

the USER key. See the list of

available functions on the Setup

Menu Map.

This procedure scrolls through all

available choices for illustration

purposes only.

In this example, we’ll set F1 to the TEST

function.

5)

When the desired User Key

function is displayed, press

TARE. The next item in the Setup

Menu appears.

6)

Either press ZERO to exit Setup

and store all changes, or

continue to another Setup Menu

item using the USER Key.

Function Key Setup

)YQF

WRWD/

)YQF

Next Setup Menu Item

2II

blinking

QHW U

YWWO

/($U1

blinking

blinking

blinking

blinking

3+/G

2II

XQLW

WHVW

blinking

blinking

blinking

blinking

7HVW

blinking

Store and return to

weight display

6WRUH

USER

F

USER

F

USER

F

USER

F

USER

F

USER

F

USER

F

USER

F

USER

F

USER

F

TARE

T

TARE

T

ZERO

O

sto

Hold

USER

F

esc

POWER

Cancel all setup

changes

esc

POWER

The MSI-4260 has 1 user definable function key on the Front Panel, and an additional

user definable function Function key on the RF Remote Control that can be

programmed to any of several functions.

22 MSI-4260 Port-A-Weigh Operator’s Manual

Figure 4-2. Function Keys

Page 27

4.3 Auto- Off

1)

With the 4260 off, press and hold

the USER key, then press the

POWER key.

...or while the 4260 is on, press USER

and POWER simultaneously.

2)

The first item of the Setup Menu

is “Func1”. Scroll to “A-OFF” with

the USER key.

3)

To setup the A-Off timing, press

TARE. The current Auto-Off time

is displayed.

4)

Select the Auto Off time by

scrolling through the choices with

the USER key.

In this example, we’ll set 60 minutes as

the Auto-Off time.

5)

When the desired time is

displayed, press TARE. The next

item in the Setup Menu appears.

6)

Either press ZERO to exit Setup

and store all changes, or

continue to another Setup Menu

item using the USER Key.

Auto-Off Setup

)YQF

6/((3

Next Setup Menu Item

2II

blinking

blinking

blinking

blinking

blinking

$2))

Store and return to

weight display

6WRUH

Hold

USER

F

esc

POWER

USER

F

USER

F

USER

F

USER

F

USER

F

USER

F

TARE

T

TARE

T

ZERO

O

sto

Cancel all setup

changes

esc

POWER

The Auto-Off feature, when enabled, prolongs the battery life of the scale by turning

POWER off when the scale is not in use. Any time a button is depressed (any button),

or the detected weight is in Motion exceeding 5 or 10d, the time limit is reset.

Therefore, the scale will stay on indefinitely if the weight is changing or any button is

pressed at least once. With Auto-Off disabled, the scale will remain on; only pressing

POWER will turn it off (or if the battery is depleted).

Figure 4-3. Auto-Off

Set Up 23

Page 28

4.4 Sleep

1)

With the 4260 off, press and hold

the USER key, then press the

POWER key.

...or while the 4260 is on, press USER

and POWER simultaneously.

2)

The first item of the Setup Menu

is “Func1”. Scroll to “Sleep” with

the USER key.

3)

To setup the Sleep timing, press

TARE. The current Auto-Off time

is displayed.

4)

Select the Sleep start time by

scrolling through the choices with

the USER key.

In this example, we’ll set 30 minutes as

the Sleep start time.

5)

When the desired time is

displayed, press TARE. The next

item in the Setup Menu appears.

6)

Either press ZERO to exit Setup

and store all changes, or

continue to another Setup Menu

item using the USER Key.

Sleep Setup

)YQF

GLVS/

Next Setup Menu Item

2II

blinking

Store and return to

weight display

blinking

blinking

blinking

6/((3

6WRUH

Hold

USER

F

esc

POWER

USER

F

USER

F

USER

F

USER

F

USER

F

TARE

T

TARE

T

ZERO

O

sto

Note

The SLEEP feature reduces power consumption by automatically turning off the

display during periods of inactivity. While in the Sleep Mode, the Green

Acknowledge annunciator will blink at a 1s rate to indicate the MSI-4260 is in sleep

mode. To wake up either a button must be pushed (front panel or RF remote), or the

weight must change by 5 d or more.

SLEEP must be set to less time than the Auto-Off timer.

For example, set SLEEP to five minutes and Auto-Off to 30 minutes.

24 MSI-4260 Port-A-Weigh Operator’s Manual

Figure 4-4. Sleep Setup

Page 29

4.5 Display Brightness

1)

With the 4260 off, press and hold

the USER

key, then press the

POWER

key.

...or while the 4260 is on, press

USER

and POWER

simultaneously.

2)

The first item of the Setup Menu

is “Func1”. Scroll to “diSPL” with

the USER

key.

3)

To setup the Display brightness,

press

TARE. The current

brightness setting is displayed.

4)

Select the display brightness by

scrolling through the choices with

the USER

key. The menu

brightness changes as you scroll

through the choices.

In this example, we’ll set the brightness

to the AUTO, light sensing brightness

control.

5)

When the desired display

brightness setting is displayed,

press

TARE. The next item in

the Setup Menu appears.

6)

Either press

ZERO to exit Setup

and store all changes, or

continue to another Setup Menu

item using the

USER Key.

Display Brightness Setup

)YQF

+L

6W3W

Next Setup Menu Item

/R

dimmest setting

$YWR

+L

medium high setting

light sensing auto setting

brightest setting

GLVS/

/R

medium low setting

Store and return to

weight display

6WRUH

Hold

USER

F

esc

POWER

USER

F

USER

F

USER

F

USER

F

USER

F

USER

F

Cancel all setup

changes

esc

POWER

TARE

T

TARE

T

ZERO

O

sto

The Display Setup menu is used to set the display brightness. There are four fixed

brightness settings and one automatic light sensing brightness setting.

Auto setting will automatically detect the ambient light and adjust

the display accordingly.

Bright light will cause the display to be at the brightest setting. The display brightness

will reduc

e as ambient light reduces. The four fixed brightness settings, LO-1, LO-2,

HI-1, and HI-2 change the average current in the display. Lower settings increase

battery life.

the brightness of

Figure 4-5. Display Brightness

Set Up 25

Page 30

4.6 Set Points

URV6

1)

With the 4260 Off, press and

hold the USER key, then press

the POWERkey.

...or while the 4260 is on, press USER

and POWER simultaneously.

2)

Scroll through the Setup Menu

choices by pressing the USER

key. Stop when the LED displays

“StPt1”, “StPt2”, or “StPt3”.

3)

When the desired Set Point is

displayed, press TARE. The

display blinks “OFF”, or if

previously programmed, the last

set mode.

4)

Select the Set Point mode by

scrolling through the choices with

the USER key. “GrEAt” (greater

than) indicates the Set Point will

trigger when the weight exceeds

the value. “LESS” (less than) will

trigger the set point when the

weight is less than the value.

This example scrolled through all available

choices for illustration purposes only.

5)

When the desired Set Point

Mode is displayed, press TARE.

6)

Next select the type of weight

value the set point is assigned

to. Use the USER key to scroll

through the choices.

This example scrolled through all

available choices for illustration

purposes only.In this example, we’ll

enter Gross as a weight mode because

we are going to use the set point as a

safety warning.

7)

When the desired weight mode

is shown, push TARE. Next the

current Set Point value is

displayed.

If there was a previous

value, it is displayed. If no value has

been entered, a zero will appear. To

keep the displayed value, press ZERO .

8)

Press the USER key. The first

digit blinks at zero. Use the

USER key to scroll through the

numbers. When the desired

number is shown, push TARE.

In this example, we’ll enter 240 as a

Set Point value.

Set Point Setup

VWSW

UHDW

QHW U

WFQW

URV6

WRWDO

blinking

blinking

blinking

blinking

2II

blinking

/(66

UHDW

blinking

Set Point responds to Gross Weight regardless of the display.

Set Point responds to Net or Gross Weight.

Set Point responds to the Totaled Weight.

Set Point responds to the Total Count (number of samples).

Set Point responds to Gross Weight regardless of the display.

USER

F

USER

F

USER

F

Hold

USER

F

esc

POWER

USER

F

TARE

T

TARE

T

TARE

T

USER

F

USER

F

USER

F

USER

F

USER

F

blinking

USER

F

USER

F

QHW U

blinking

Set Point responds to Net or Gross Weight.

TARE

T

blinking blinking

The MSI-4260 supports three set points. Common uses of set points are for warnings

or process control. The MSI-4260 comes standard with LED outputs for a triggered

set point. Set Point 1 is Blue, Set Point 2 is Green and Set Point 3 is Red. The MSI-

4260 has an audible output option that is triggered by Set Point 1. Contact MSI for

other Set Point Output Options.

26 MSI-4260 Port-A-Weigh Operator’s Manual

Figure 4-6. Set Point Setup

Page 31

TARE

T

TARE

T

TARE

T

USER

F

Number value entry continued

9) When the desired number is

shown, push

TARE

a second

time to set the value. The next

Setup Menu item is displayed.

10) Either press ZERO to exit Setup

and store all changes, or

continue to another Setup Menu

item using the USER Key.

fixed blinking

blinking blinking

6W3W

fixed next setup menu item

Store and return to

weight display

6WRUH

USER

F

USER

F

Cancel all setup

changes

esc

POWER

ZERO

O

sto

To enter a decimal point, push

POWER while the digit is blinking.

Error Correction: If you input a

wrong value, press ZERO to step

back one digit and change the digit

with the USER

key.

USER

F

USER

F

USER

F

TARE

T

fixed blinking

blinking blinking

Set Point Setup (continued)

Figure 4-7. Set Point Setup (continued)

Set Up 27

Page 32

4.7 Total Mode

1)

With the 4260 off, press and hold

the USER key, then press the

POWER key.

...or while the 4260 is on, press USER

and POWER simultaneously.

2)

The first item of the Setup Menu

is “Func1”. Scroll to “totaL” with

the USER key.

3)

To setup the Total Mode, press

TARE. The current Total Mode

setting is displayed.

4)

Select the Total Mode by scrolling

through the choices with the

USER key.

In this example, we’ll set the Total Mode

to the Auto-High mode. The Auto High

mode uses the highest stable reading

as the total value, and totals when the

load is removed.

5)

When the desired Total Mode

setting is displayed, press TARE.

The next item in the Setup Menu

appears.

6)

Either press ZERO to exit Setup

and store all changes, or

continue to another Setup Menu

item using the USER Key.

Total Mode Setup

)YQF

$/RDG

)LOWU

Next Setup Menu Item

2))

blinking, Total Off

$+L +

$/$67

Total on stable load

Total highest stable Load

Total last stable load

WRWD/

WWO2Q

Total with pushbutton

Store and return to

weight display

6WRUH

USER

F

USER

F

Hold

USER

F

esc

POWER

USER

F

USER

F

USER

F

USER

F

TARE

T

TARE

T

ZERO

O

sto

Cancel all setup

changes

esc

POWER

The MSI-4260 can keep track of all weighments using the Total feature. Either

manual total, which totals by pushing a configured USER key on the front panel or

the RF Remote, or Auto-Total, which can be used to automatically add up each

weighment. See the Total mode descriptions for details on the various Total modes.

To use Manual Total, you must also program a User Key. Auto Total modes do not

need a user key, but if a User key is setup for Total, then it will function as a total on /

total off.

28 MSI-4260 Port-A-Weigh Operator’s Manual

Figure 4-8. Total Mode Setup

Page 33

4.8 Units

1)

With the 4260 off, press and hold

the USER key, then press the

POWER key.

...or while the 4260 is on, press USER

and POWER simultaneously.

2)

The first item of the Setup Menu

is “Func1”. Scroll to “Unit” with

the USER key.

3)

To setup the weight units, press

TARE. The display will blink

“Unit”.

4)

Change the weight units by

pressing the USER key. The unit

is indicated by the annunciators.

5)

When the desired unit setting is

annunciated, press TARE. The

next item in the Setup Menu

appears.

6)

Either press ZERO to exit Setup

and store all changes, or

continue to another Setup Menu

item using the USER Key.

Units Setup

)YQF

)YQF

Next Setup Menu Item

8QLW

blinking

Store and return to

weight display

6WRUH

USER

F

8QLW

TARE

T

TARE

T

ZERO

O

sto

Cancel all setup

changes

esc

POWER

8QLW

blinking

lb

8QLW

blinking

kg

USER

F

Hold

USER

F

esc

POWER

USER

F

USER

F

Note

Units can be changed in two ways:

• Program a User Function Key to Units

• Change the units with the setup menu with the following procedure

The OIML LFT scales do not allow units to be changed.

Figure 4-9. Unit s Setup

Set Up 29

Page 34

4.9 Filter Setup

TARE

T

TARE

T

ZERO

O

sto

1)

With the 4260 off, press and hold

the USER key, then press the

POWER

key.

...or while the 4260 is on, press USER

and POWER simultaneously.

2)

The first item of the Setup Menu

is “Func1”. Scroll to “Filtr” with

the USER key.

3)

To setup the filter, press TARE .

The display will blink the current

filter setting.

4)

Change the filter setting by

pressing the USER key.

There are four available filter settings.

Not all choices are shown in this

example.

5)

When the desired filter setting is

annunciated, press TARE. The

next item in the Setup Menu

appears.

6)

Either press ZERO to exit Setup

and store all changes, or

continue to another Setup Menu

item using the USER Key.

)YQF

+L

High Filter 1

2))

Blinking

Store and return to

weight display

)LOWU

2))

Blinking

/2

Low Filter, Blinking

8QLW

Next Setup Menu Item

USER

F

USER

F

Cancel all setup

changes

esc

POWER

Filter Setup

Hold

USER

F

esc

POWER

USER

F

USER

F

USER

F

Changing the filter settings allows the scale to adjust to situations where there is a lot a

movement in the structure. If the reading is not stable, it can often be improved by

increasing the filter setting. Settling time will be longer as the filter setting is increased.

However, the

still controlling vibration even with high filter settings.

MSI-4260 employs algorithms that speed up large weight changes while

Figure 4-10. Filter Setup Menu Map

30 MSI-4260 Port-A-Weigh Operator’s Manual

Page 35

5.0 Calibration

XQ/G

/R$'

Blinks

Capacity

1)

Remove the seal screw. With

a small screwdriver press the

Cal Switch behind the seal

screw.

The CAL Setup Menu

appears.

2)

Press TARE (functioning as

ENTER) to Start the

Calibration Procedure.

3)

The display reads “UnLd”

(unload) indicating you

should remove all weight

from the hook.

4)

Ensure the 4260 is

motionless, then press

TARE. The 4260 sets the

zero calibration point. Wait

while the display is blinking.

5)

If the zero is in range, the

scale will display “PASS”.

Then “LoAd1” is displayed.

6)

Load the scale with a

precision test weight.

For single

span point calibrations a test weight

of 20% of capacity or more is

recommended.

7)

PressTARE. The 4260

flashes the capacity. If you

are loading the scale with

the capacity weight, skip to

step 10.

&$/

Standard Calibration

Procedure

3$66

No weight

on hook

Flashes

Zero

Lift Test

Weight

example capacity

blinking

Remove

Hex Seal

Screw

Cal Switch

Access

Press Switch

behind the hole

with a small

Screwdriver

TARE

T

TARE

T

TARE

T

The MSI-4260 is calibrated using standard weights. It is required that the weight used

is at least 10% of full capacity in order to achieve rated accuracy. For example, use at

least a 500kg test weight to calibrate a 5000kg capacity scale. Although a single span

point is usually adequate for rated accuracy, the MSI-4260 supports Multi-Point

calibration with up to 4 span points + Zero.

When adequate test weights

calculated constant calibration which is referred to as C-Cal. To use C-Cal, a

previously generated C-Cal number must be known. MSI supplies replacement load

cells for the MSI-4260 with the C-Cal value stamped on the serial number label.

There are three aspects of calibration:

• Standard Calibration – is

tial Calibration – is used to setup both the capacity and resolution (d) of the

• Ini

scale. It differs from Standard Calibration only in the initial steps. Initial

Calibration is performed after a Calibration Reset which completely erases the

calibration and setup memory.

• C-Cal – If the las

without weights.

are not available, the MSI-4260 can be calibrated using a

used for maintenance and routine calibration.

t calculated C-Cal values is known, the scale can be calibrated

Figure 5-1. Standard Calibration Procedure

Calibration 31

Page 36

p

8)

To enter a calibration

weight other than

capacity, press USER . The

display far left digit will

flash zero indicating that

a number should be

entered.

blinking

Error Correction: If you input a wrong

value, press ZERO to step back one

digit and reenter.

USER

F

5 times

fixed

blinking blinking

blinking

blinking

blinking

blinking

fixed

fixed

fixed

3DVV

9)

Press the USER key to

scroll the number and

the TARE key to enter

each digit of the

calibration weight.

In this example, we’ll enter 2500

kg on a 5000 kg capacity scale.

Do not push the TARE key two

times in a row until the entire

number is showing..

To add a decimal point, push the

POWER key while the number is

blinking.

10)

When the entire value of

the test weight is displayed

and the weight and scale

are stable, press TARE to

finish off the weight entry.

If the resultant cal value is

within limits, the display will

read “PASS” briefly.

11)

The display now reads

“Load2”. The 4260

allows multipoint

calibration. If more Cal

Points are desired (up to

3 additional) press

TARE. If a single point

cal is all that’s needed,

press ZERO and jump to

step 15.

12)

Load the scale with the next

test weight. The display

offers the reading that will

occur without adjusting the

value. If the weight value

shown is acceptable push

TARE and skip to step 14.

If the calibrated value needs

adjusting, go to step 13.

Test weights can be any in-capacity

weight, the order is not important.

The 4260 supports 5-Point Cal,

Zero

and up to 4 span points.

13)

Press the USER key to

scroll the number and

the TARE key to enter

each digit of the

calibration weight value.

When the entire calibration

weight is displayed, push

TARE a second time to

finalize the calibration span

point. If the resultant cal

value is within limits, the

display will read “PASS”

briefly.

Example Value only.

/RDG

To set Next

Span Point

To skip additional

Span Points

To scroll the digit

To Enter the digit

into the cal weight

value

To complete the cal

weigh value entry

3DVV

USER

F

You can cancel calibration by

pressing Power and the scale

will reset to the previous

calibration constants.

USER

F

USER

F

TARE

T

ZERO

O

sto

TARE

T

USER

F

TARE

T

USER

F

TARE

T

USER

F

TARE

T

TARE

T

TARE

T

USER

F

TARE

T

TARE

T

32 MSI-4260 Port-A-Weigh Operator’s Manual

Figure 5-2. Standard Calibration Procedure (continued)

Page 37

15)

The display shows “CAL’d”

to indicate that the

calibration was successful.

16)

Press TARE. The display

flashes “C-CAL” followed

by the C-CAL number.

Make a note of this number.

If the X1000 annunciator is lit,

also make a note of that.

This number is used to calibrate when

test weights are unavailable. C-CAL

does not replicate multipoint

calibrations.

17) Press ZERO to store the

calibration constants, or

after 8 seconds,the

calibration constants will

automatically stored. After

the Store message is

displayed, the scale goes

to the next item on the Cal

Menu, “SEtuP”.

18)

Press ZERO to exit the Cal

menus and start up the

standard weight display.

The 4260 is ready for use.

19) After ensuring the

calibration is acceptable,

replace the Hex Seal Screw.

&&D/

Example Value only.

VWRUH

&$/G

6HWYS

Flashing

ZERO

O

sto

ZERO

O

sto

ZERO

O

sto

TARE

T

ZERO

O

sto

If the scale is being used as a LegalFor-Trade device, place a LeadWire Seal through the Cal Side

Bored Hex Head Screw over to the

adjacent Side Bored Cap Screw.

To skip the

C-CAL step

14)

The display now reads

“LoAd3” or “LoAd4”.

Repeat steps 12 and 13

for additional span points

press TARE or press

ZERO if you are finished.

After LoAD4 has passed, the 4260

will automatically advance to the next

step.

/RDG

/RDG

or

To enter another

span point

TARE

T

Figure 5-3. Standard Calibration Procedure (continued)

Calibration 33

Page 38

5.1 Initial Calibration

1) Turn the 4260 off.

2) Remove the seal screw. With

a small screwdriver press and

hold the CAL Switch behind

the seal screw.

3) While holding down the CAL

switch, press the POWER

switch.

4) The display blinks “rESEt”.

5) To reset all calibration

constants and setup

parameters, press TARE.

6) The 4260 requests a

confirmation by displaying

“Sure?”.

To cancel the Reset press

the POWER key.

7) To complete the reset, press

TARE. The Calibrate menu

appears. You must now

recalibrate the system.

8) PressTARE to start the initial

calibration procedure. The

display shows "Unit". You

select the units you wish to

calibrate in.

9) Press TARE to select the

calibration unit.

10) Use the USER key to choose

between lb and kg. When the

desired unit is shown, press

TARE.

11) Next, set the capacity in the

selected units. Capacity must

be set no higher than the load

cell rated capacity.

12) Press TARE to enter the

capacity setting screen. A

capacity of 10000 is the initial

value.

If 10000 units is the desired

capacity press TARE and skip to

step 16.

13) To change the capacity, press

USER.

Initial Calibration

Resetting Capacity and Countby (d)

UHVHW

blinking

6YUH"

&$/

8QLW

8QLW

blinking

&$3

blinking

blinking

Error Correction: If you input a

wrong value, press ZERO to step

back one digit and reenter.

To enter a decimal point, push

POWER while the digit is blinking

Remove

Hex Seal

Screw

Cal Switch

Access

Press Switch

behind the hole

with a small

Screwdriver

lb

8QLW

blinking

kg

TARE

T

TARE

T

TARE

T

TARE

T

TARE

T

TARE

T

USER

F

USER

F

Use this procedure only if the capacity and count-by (d) needs to be modified. The

initial steps of the initial calibration will totally erase user setups as well as any

previous calibration.

34 MSI-4260 Port-A-Weigh Operator’s Manual

Figure 5-4. Initial Calibration

Page 39

5 times

blinking

blinking

blinking

fixed

fixed

fixed

Continue inputing the desired

capacity using the USER key

for scrolling the number and

the TARE key to store the

number.

15) Finalize the capacity value

by pressing the TARE key on

an unblinking display. In our

example, once the number

2500 is fixed on the display,

press TARE to store the

capacity value.

16) Next the scale division size

‘d’ is set. Press TARE to

begin.

In this example we’ll set

the ‘d’ to 2 units.

17) Use the USER key to

scroll through the

recommended scale

divisions.

The first ‘d’ offered is

the standard division for the given

capacity. Setting a ‘d’ size that

results in total resolution higher than

1:5000 is not recommended for

stability reasons.

18) When the desired scale ‘d’

is displayed, press TARE.

The “UnLd” display

appears and the scale is

ready for calibration.

Follow the Standard

Calibration procedure

starting at step 3.

G

blinking

blinking

XQ/G

Capacity is set.

‘d’ is set.

Proceed to Standard

Calibration starting at Step 3.

USER

F

TARE

T

TARE

T

TARE

T

TARE

T

TARE

T

TARE

T

USER

F

USER

F

USER

F

USER

F

TARE

T

14) The first digit blinks. Use the

USER key to scroll through

the numbers. When the

desired number is shown,

push TARE.

In this example, we’ll enter

2500 as a capacity.

fixed

blinking blinking

blinking

TARE

T

USER

F

USER

F

USER

F

5.2 Guidelines for Capacity and Resolution

Crane Scales are subject to forces that regular floor scales do not see. Many bridge

cranes, hoist cranes, and mobile cranes lack rigidity and tend to bounce or swing

when loads are lifted. For this reason, MSI recommends that resolution is kept in the

1:2000 to 1:3000 range. Some improvement in stability can be achieved by increasing

the filtering. However, you should never program resolution that is far greater than

you need. If the MSI-4260 display is never stable, it is recommended that the

resolution is reduced and/or filtering increased.

Figure 5-5. Initial Calibration (continued)

Calibration 35

Page 40

Due to LFT requirements and general scale design criteria, the weight must be stable

Note

Important

for certain features to work: ZERO – Weight must be stable to be Zeroed. TARE –

Weight must be stable to be Tared. TOTAL – Weight must be stable to be added to the

total registers. One way to improve the stability is to increase the filtering, at the risk

of increasing settling time. The other is to increase the ‘d’ (reduce resolution). The

third way is to increase the “Motion Window”. The MSI-4260 defaults to ±1d as a