Rice Lake MSI-3460 User Manual

Operator’s Manual

MSI-3460

Challenger 3

152161 Rev C

Technical training seminars are available through Rice Lake Weighing Systems.

Course descriptions and dates can be viewed at www.ricelake.com/training

or obtained by calling 715-234-9171 and asking for the training department.

Contents

1.0 Introduction ...........................................................................1

1.1 Safety ................................................................................... 2

1.2 General Information ............................................................ 4

1.2.1 User Guide & MSI-3460 Conventions .................................4

1.3 MSI3460 Annunciators ........................................................ 5

1.4 Specifications ...................................................................... 6

1.5 Features ............................................................................... 8

1.6 Options ................................................................................ 8

1.7 Unpacking ........................................................................... 8

1.8 Assembly ............................................................................. 9

1.9 Battery Pack ...................................................................... 10

1.10Battery Charger ................................................................ 11

2.0 Operation .............................................................................12

2.1 Power ................................................................................. 12

2.2 Zero ................................................................................... 12

2.3 Tare .................................................................................... 13

3.0 User Defined Function Keys .................................................14

4.0 Configuration .......................................................................16

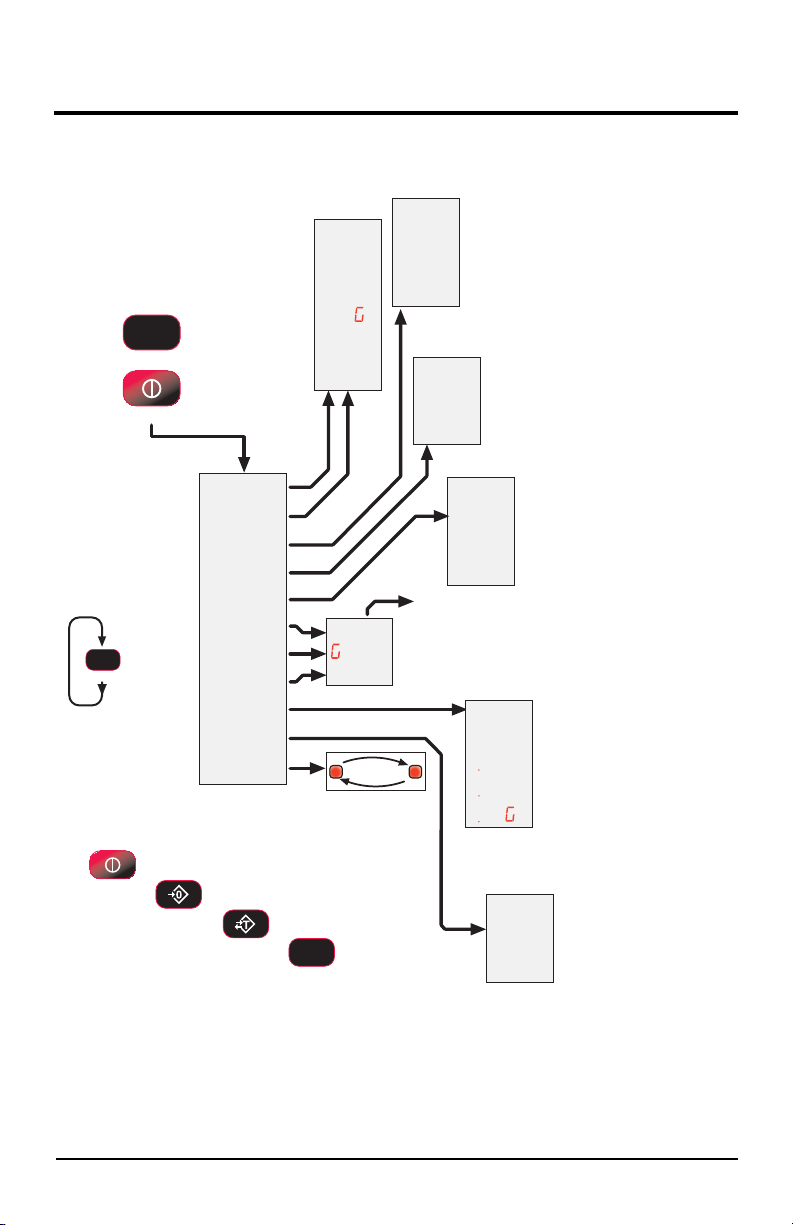

4.1 Menu Map ......................................................................... 16

4.2 Function Keys ................................................................... 17

4.3 Auto- Off ............................................................................ 18

4.4 Sleep .................................................................................. 19

4.5 Display Brightness ............................................................ 20

4.6 Set Points .......................................................................... 21

4.7 Total Mode ........................................................................ 23

4.8 Units ................................................................................... 24

4.9 Filter Setup ........................................................................ 25

5.0 Calibration ...........................................................................26

5.1 Initial Calibration ............................................................... 29

5.2 Guidelines for Capacity and Resolution .......................... 30

5.3 C-Cal Calibration ............................................................... 31

5.4 Calibration Setup Menu .................................................... 34

5.5 Standard ............................................................................ 34

5.6 Auto Zero Maintenance .................................................... 35

© 2013 Rice Lake Weighing Systems. All rights reserved. Printed in the United States of America.

Specifications subject to change without notice.

Rice Lake Weighing Systems is an ISO 9001 registered company.

December 23, 2013 Rev B

6.0 RF Remote Control Option ...................................................37

Rice Lake continually offers web-based video training on a growing selection

of product-related topics at no cost. Visit www.ricelake.com/webinars.

6.1 Description ........................................................................ 37

6.2 Functions ........................................................................... 37

6.3 Setting the Transmitter Address ...................................... 37

6.4 Setting the Receiver Address ........................................... 38

6.4.1 Resetting the MSI-3460 RF Remote Receiver ..................38

6.5 Contention and Jamming Considerations ....................... 38

6.6 Battery Replacement ........................................................ 39

6.7 RF Remote Control FCC Statement ................................. 39

7.0 RF Remote Display Option ...................................................40

7.1 Introduction ....................................................................... 40

7.2 Printer/Serial Output Setup .............................................. 41

7.2.1 Control Modes .................................................................41

7.3 Standard Print Strings ...................................................... 42

7.4 802.15.4 RF Network Setup .............................................. 44

7.5 FCC Statement (for 802.15.4 Option) ............................... 45

7.6 RF Setup Procedure ......................................................... 45

7.7 International RF CERTS (For 802.15.4 OPTION) .............. 47

8.0 Appendix ..............................................................................48

8.1 Troubleshooting ................................................................ 48

8.1.1 Service Counters ..............................................................50

8.2 Software Update for use with SC3 PCA .......................... 51

8.3 MSI-3460 Challenger 3 Dimensions ................................. 54

The MSI Limited Warranty ............................................................55

ii MSI3460 Operator’s Manual

1.0 Introduction

The MSI-3460 Challenger 3 is a combination of the sound and proven mechanical

design of the industry standard Challenger with today’s most advanced electronics. It

provide a superb feature set unmatched by any scale in its class or price range. The

multi-purpose hanging scale is ideal for situations in which headroom is at a

minimum. The MSI-3460 is versatile, reliable, accurate and easy to operate. The MSI-

3460 is designed to meet or exceed the requirements of all regulatory agencies. RF

remote control and remote display options are available to further enhance the safety

and usability of the MSI-3460.

Please take the time to read this manual completely through before attempting to use

the MSI-

of this manual will ensure that you receive the maximum benefit from the system.

If you have any questions or comments, please contact

3460. Although designed for easy set up and use, a thorough understanding

Measurement Systems International

Phone (toll free): 1-800-874-4320

Manuals can be viewed or downloaded from the Measurement Systems

International site at:

www.msiscales.com.

Introduction 1

1. 1 S af e ty

Important

WARNING

WARNING

Safety Symbol Definitions:

Indicates a potentially hazardous situation that, if not avoided,

could result in serious injury or death, and includes hazards that

are exposed when guards are removed.

Indicates information about procedures that, if not observed,

could result in damage to equipment or corruption to

data.

and loss of

General Safety

Do not operate or work on this equipment unless you have read

and understand the instructions and warnings in the Installation,

Operators Manual. Contact any Measurement Systems

International dealer for replacement manuals. Proper care is

your responsibility.

Failure to heed may result in serious injury of death.

DO NOT allow minors (children) or inexperienced persons to operate this unit.

DO NOT stand near the load being lifted as it is a potential falling hazard. Keep a

safe distance.

DO NOT use for purposes other then weigh

DO NOT use any load bearing component that i

dimension.

DO NOT use the scale if any of the components of the load train are cracked,

deformed, or show signs of fatigue.

DO NOT exceed the rated load limit of the scale, ri

structure.

DO NOT allow multi-point contact with the hook, shackle, or lifti

scale.

DO NOT allow high torque on the scale unless it

torque.

DO NOT make alterations or modifications to the scale or associated load bearing

devices.

DO NOT use improperly rated or sized shackl

shackles.

DO NOT remove or obscure warning labels.

For guidelines on the safe rigging and l

dynamometers, read the "MSI Crane Scale Safety and Periodic Maintenance

Manual" (available at www.msiscales.com).

Keep hands, feet and loose clothing

There are no user serviceable parts within the MSI-3460. Any repairs are to be

performed

by qualified service personnel only.

away from moving parts.

t taking or dynamic load monitoring.

s worn beyond 5% of the original

gging elements, or the lifting

ng eye of the

is specifically designed for high

es. Use only MSI recommended

oading of overhead scales and

2 MSI-3460 Operator’s Manual

5 Digit 1.5/3.8mm

high brightness LED

weight display

Wire sealable

calibration port

Light Sensor for auto

brightness Control

User programmable

function key

Key Descriptions

POWER

ZERO

TARE

USER

F

Figure 1-1. MSI-3460 Front Panel

Power Key - Turns the MSI-3460on and off.

Zero Key - Used to zero out residual weight on the scale.

Tare K e y - removes weight of containers, trucks or carriers and places

the scale in the Net weight mode.

TARE key functions tare in, tare out.

To see the gross weight without resetting the tare value, you must

ogram the USER key as NET/GROSS.

pr

User Key- Programmable to user selectable functions. These are

described in the USER key Setup section. This key is defaulted to the

TEST function.

Introduction 3

1.2 General Information

1.2.1 User Guide & MSI-3460 Conventions

1. Keys used in operations are printed in BLUE and capitalized.

2. Screen shots that are used in menus are displayed in RED and shown in a 7-

segment font. Not all characters can be displayed with this font, but a close

approximation is shown.

3. If a function key does not work, it is probably because the MSI-3460 is not setup

to support the key. For example, if the User key is set for TOTAL, you must also

set up the TOTAL mode in the Setup Menu.

4. When in Setup menus, the ZERO key drops back one menu level. At the root

menu level, the ZERO key stores the changes and returns to the weight mode.

5. When in Setup menus, the POWER key returns you directly to the weight

display without storing the changes.

6. When in Setup menus, the USER key functions as the scroll key.

7. When in Setup menus, the TARE key functions as the ENTER/SELECT key.

4 MSI-3460 Operator’s Manual

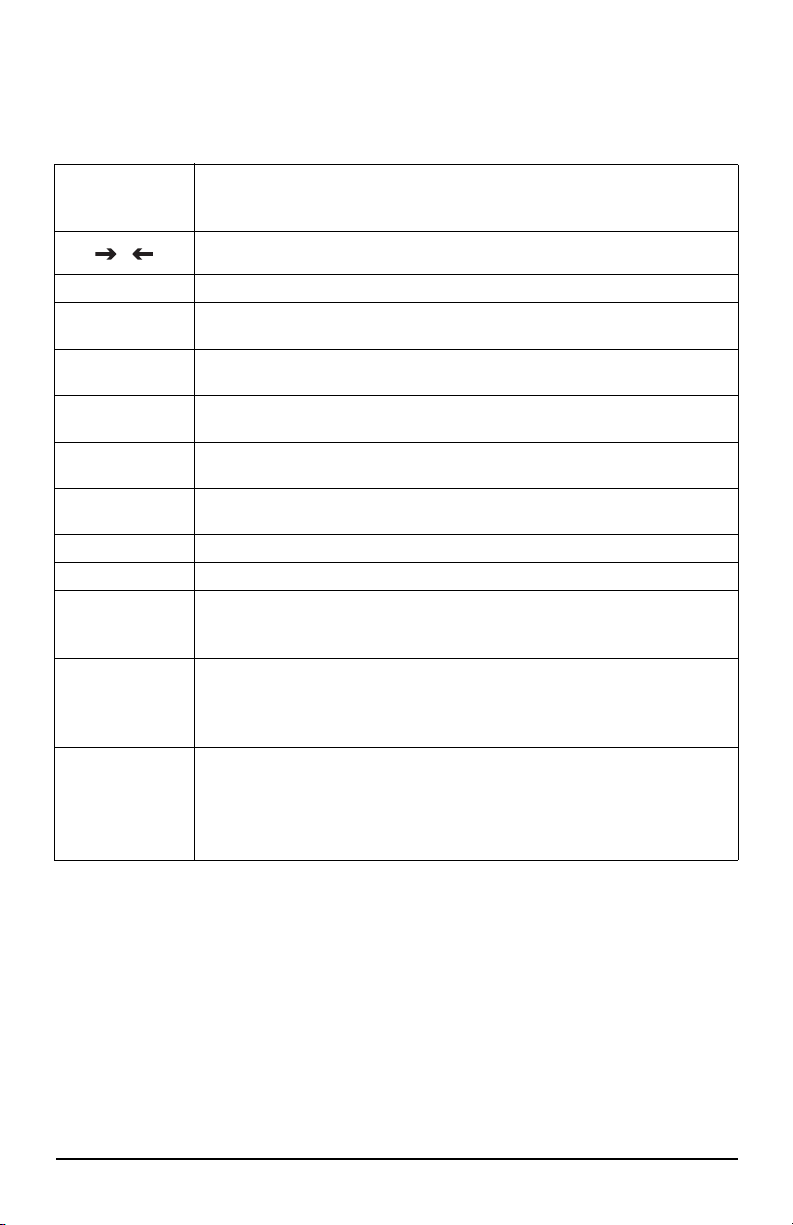

1.3 MSI3460 Annunciators

The MSI-3460 uses blue and red LEDs to indicate weight mode and other

information.

Blue LED - Indicates that the weight has not settled within the motion

MOTION

0

PEAK

NET

GROSS

TOTAL

X1000

LO BATT

kg

lb

SET POINTS

ACK

RF

window (usually ±1d).

While this symbol is illuminated, the scale will not zero, tare or totalize.

Center-of-Zero – Blue LED - Indicates the weight is within 1/4d of zero.

Blue LED - Indicates the scale is in peak hold mode.

Blue LED - Indicates the scale is in Net weight mode.

A tare weight is subtracted from the gross weight.

Blue LED - Indicates the scale is in the Gross weight mode.

All hook weight is displayed minus any zero offset.

Blue LED - Indicates the scale is displaying the Total weight.

This is a temporary display lasting less than five seconds.

Blue LED - Usually used in conjunction with the TOTAL LED allows

accumulation of weight beyond the five digit display capacity.

Appears when approximately 10% of battery life remains and blinks

when automatic shutdown is imminent.

Red LED - Indicates weight display is in kilograms.

Red LED - Indicates weight display is in pounds.

User programmable set points for early overload warnings.

Blue LED - Setpoint 1 and 2

Red LED - Setpoint 3

Acknowledge LEDs are used to provide feedback to the operator

Blue LED - Incoming remote commands hav

Red LED - Light briefly once execut

successful Auto-Total operations.

Blue LED - Indicates carrier detect for RF remote display equipped

ed. Also used for acknowledging

e been received

MSI-3460. If the LED is illuminated, MSI-3460 and remote display are

linked.

On units equipped with the RF remote

when a remote command is received and for the next half second.

control, the LED is illuminated

Introduction 5

1.4 Specifications

Accuracy ±(0.1% +1d). ‘d’ equals one displayable increment.

Resolution Standard displayed resolution: 2500-3750’d’. Resolutions to

Standard

Capacities

Power Battery operated, 6V rechargeable sealed lead acid battery pack

Display Five digit, large 1.5 in (38 mm) numeric red GaAIAs Light Emitting

Operating Temp -40°F to +122°F (-40°C to +50°C), LFT range -10°C to +40°C

Operating Time 50 hours typical/100 hours max. (depends on operating mode)

Enclosure NEMA 4/IP65 powder coated alodined cast aluminum

Load Cell Standard 350 Ω Bridge, S-Beam

USER Programmable multifunction button for use as

CAL Front panel calibration switch (located behind wire sealable screw)

Auto Zero

Maintenance

Auto-Off Mode Prolongs battery life by turning POWER off after 15, 30, 45 or 60

Auto-Sleep Mode Prolongs battery life by dimming LED display after 5, 15, or 30

Units kg, lb (other units available with custom calibrations)

Filtering Selectable: OFF, Low (LO), Medium (HI-1), High (HI-2)

Totalization Standard: Press button or automatic; TOTAL weight up to 99999 X

Peak Uses unfiltered faster reading of A/D, (>220 readings per second)

Setpoints Three internal standard setpoints and three ultra bright LEDs on

Service Counter Two independent 32 bit registers; register 1 updated each time

Construction All of these features are housed in a single, low-profile, cast

10000’d’ (non LFT units only) are possible. Internal A/D resolution

24 bits.

lb 250 500 1000 2000 5000 10,000 15,000

kg 125 250 500 1000 2500 5000 7500

(standard Challenger Charger) Typically 50 hours of battery life with

automatic sleep mode and automatic power off.

Diode (LED)

TEST, TOTAL, UNIT, PEAK, NET/GROSS, VIEW TOTAL, LEARN

(for RF Remote Control), HI-RES

Initiates full digital calibration procedure

Standard, can be disabled internally

minutes (operator determined) of no scale activity

minutes of no activity

1000 kg or lb

front panel

weight exceeds 25% of capacity; register 2 updated each time

weight exceeds overload; when register 1 exceeds 16383 or

register 2 exceeds 1023, display reads “Cnt” for load cell counter;

Test function shows the two readings in order

aluminum housing consisting of three sections:

The front of the scale houses the display, controls and all

electronics

The center section contains the load cell, lifting eye and hook

The rear of the scale features a quick access battery compartment

Table 1-1. Specifications

6 MSI-3460 Operator’s Manual

OPTIONS

WARNING

Wireless Remote

Controler

802.15.4 RF

m for

Mode

connectivity with

MSI-8000 RF

Remote Display

MSI-8000 RF

Remote Display

50 (15 m) typical range Light-of-Sight. Uses 418 MHz (USA)

handheld transmitter.

Integral 802.15.4 RF Modem for connectivity to Optional MSI-8000

RF Remote Display.

100 (30 m) typical range line of sig

transciever

ht. Uses 802.15.4, 2.4 GHz

Table 1-1. Specifications

The MSI-3460 scale has a safe mechanical overload of 200%, and

an ultimate overload of 500%. Overloads greater than 500% may

result in structural failure and dropped loads. Dropped loads may

cause serious personal injury or death.

Introduction 7

1.5 Features

• Designed to meet or exceed all U.S. and international standards.

• Typically 50 hours of weighing time utilizing automatic sleep mode.

• Automatic power off conserves battery life by sensing no activity after 15, 30, 45

or 60 minutes, determined by operator, and turns off power.

• Automatic Sleep Mode preserves battery life by dimming the LED display after

5, 15, or 30 minutes of no activity.

• Rugged construction throughout. Buttons are sealed and rated for over one

million operations.

• Precise high resolution (2500 division standard and up to 10,000 possible) 24 bit

A/D conversion coupled with advanced RISC micro controller provides world

class features and accuracy.

• Five large, 1.5 inch (38 mm) LED digits for clear weight readings from a

distance.

• Easy to maintain: full digital calibration assures reliable, repeatable

measurements. Can be calibrated without test weights using MSI R-Cal

technology.

• Selectable for kg/lb unless prohibited by LFT regulations.

• Automatic or manual weight totalization for loading operations.

• Easily customized for special applications.

• Hi speed PEAK mode for wire and rope stress analysis.

• Three setpoints can be set for any in-range weight for operator alerts or process

control.

• ScaleCore technology provides quick and easy software updates and calibration/

setup backup.

• Two service counters ensure load train safety by warning the user to perform a

load train safety check when the lift count gets high or the scale has been

overloaded repeatedly.

1.6 Options

Options which you may have ordered with your Challenger 3 may include the

following:

• RF remote controller

• RF modem for connectivity to MSI-8000 RF Remote Display

• MSI-8000 RF Display

• 85-265 VAC input power.

• Audible alarm (triggered by setpoint 1)

1.7 Unpacking

When unpacking the scale from the shipping container, ensure that all assembly parts

are accounted for. Check the scale for any visible damage and immediately report any

damage to your shipper. It is advisable to use the original shipping container when

shipping or transporting the Challenger 3.

8 MSI-3460 Operator’s Manual

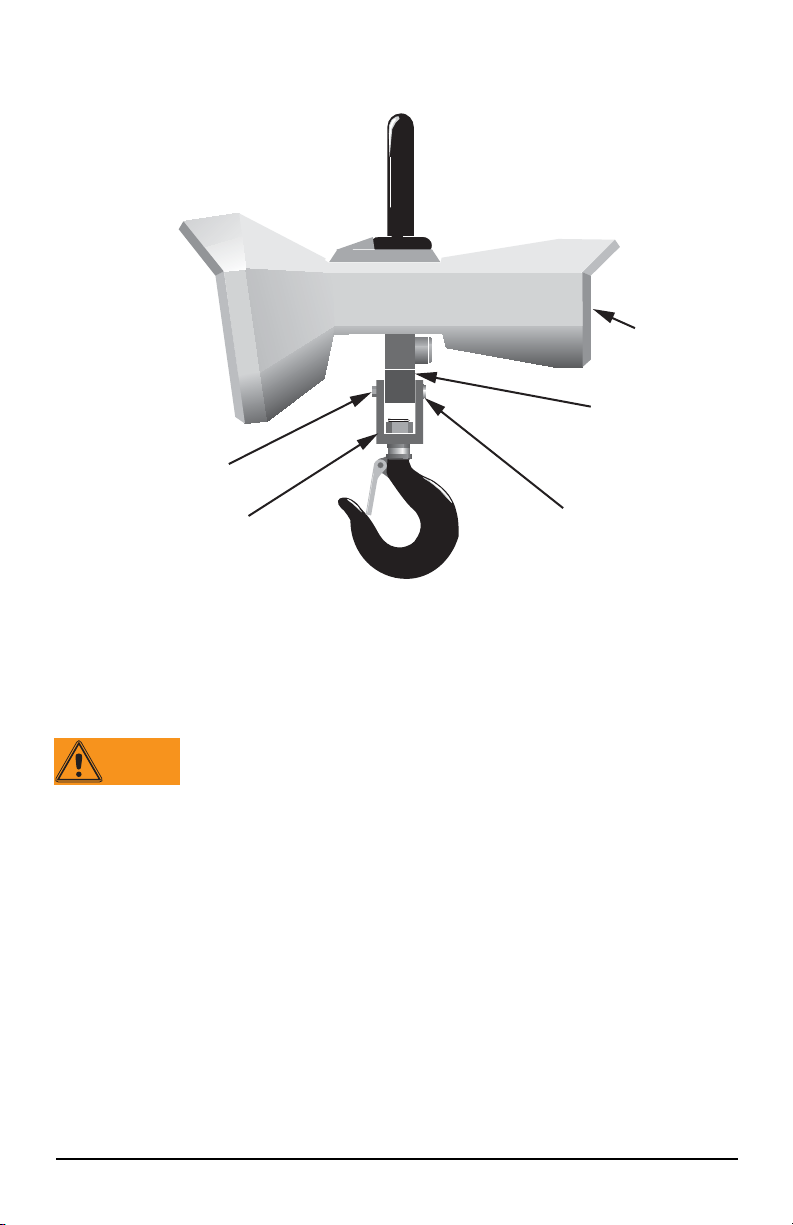

1.8 Assembly

Battery

Cotter

Load

Hook Clevis

Clevis

WARNING

Figure 1-2. MSI-3460 Assembly

1. Slide hook clevis over load cell with open end of hook toward front of scale.

2. Align holes of clevis and load cell.

3. Slide the clevis pin through the clevis

4. Lock clevis pin in place with cotter pin. Bend

Scale will be unsafe for use if clevis pin is not properly secured

with the cotter pin.

and load cell holes.

cotter pin.

5. Slide battery pack into battery compartment. The battery will automatically

engage with its connectors.

6. Secure battery pack by turning the two locking fasteners

on access door

clockwise 1/4 turn.

7. The scale is now ready for use.

Introduction 9

1.9 Bat ter y Pack

Access Door Fastener

Handle

Note

The MSI-3460 is powered by a six volt rechargeable battery. The battery door is part

of the battery pack.

Figure 1-3. Battery Pack Removal

To Remove the Battery Pack

1. Turn the two fasteners on the access door counte

2. Grasp handle and pull the battery pack straight out. The battery will

matically disengage from its connectors.

auto

The battery will operate for up to 100 hours (depending on LED brightness setting)

before req

uiring recharging. In order to conserve battery life, the scale includes an

automatic power off mode which senses operational status for no activity after 15, 30,

45, or 60 minutes, and turns the scale off. An additional battery saving feature is the

automatic sleep mode. This feature preserves battery life by dimming the display after

5, 15, or 30 minutes of no scale activity. Charging time for a completely discharged

battery is up to eight hours. A spare battery pack is recommended to keep the

Challenger 3 in continuous operation.

To obtain maximum service life from your batteries they should be stored

between -4°F and 122°F (-20°C and +50°C). Stored batteries should be

recharged every three months. Battery is fully charged when the status

indicator is flashing.

r clockwise 1/4 turn,

10 MSI-3460 Operator’s Manual

1.10 Battery Charger

Inside of charger

Observation

holes

Charger Connectors

Note

1. Remove the battery from the scale.

2. Plug battery charger into an AC power receptacle. The input voltage is universal

from

115/230 VAC, 50/60 Hz. If the power input plug doesn’t match, contact

MSI for information on international plugs.

3. Slide the battery charger connector plate over

battery terminals mate with the charger connectors, as seen through the two

observation holes.

4. Approximately six to eight hours is required to recharge a fully discharged

battery

. If a battery was deep discharged, more time might be required, but the

MSI-3460 prevents deep discharging. Partially discharged batteries will finish

the charge faster.

The charger is a three stage float charger that can be l

has a dual color LED to indicate the charging state: RED- fast charge mode. GREENcharged or float charge.

the top of the battery until the

eft on the battery indefinitely. It

To obtain maximum service life from your batteries, the manufacturer

suggests recharging after each 20 hours of use. Continuous deep

discharging will reduce maximum battery life cycle estimated at 2000

cycles.

A second battery is recommended to enable you to use your scal

continuously. Keep one on the charger while the other is in service.

Figure 1-4. Battery Charger

e

Introduction 11

2.0 Operation

POWER

Note

2.1 Power

To turn on the power.

1. Press

, the following will display in order:

• LED will light all segments at full brightness as a display test.

• Display brightness will change to the setting determined in the display menu.

• Software version number will display.

• The M

SI-3460 is ready for use.

2.2 Zero

Sets the zero reading of the Scale. Use the ZERO key to take out small deviations in

zero when the scale is unloaded. See “TARE” for zeroing (Taring) package or pallet

weights.

1. Press

Rules for Use:

ZERO

The weight reading must be stable within the motion window for the zero

function to work.

The scale digits display 0 (or 0.0 or 0.00, etc).

The backup memory in the MSI-3460 stores the zero reading, and can

rest

ore it even if the power fails.

• Works in GROSS mode or NET mode. Zeroing while in net mode will zero

the gross weight causing the display to show the negative tare value.

• The scale must be stable within the

motion window. The scale will not zero

if the motion detect annunciator is on. The scale will “remember” that it has

a zero request for two seconds. If motion clears in that time, the scale will

zero.

• The scale will accept a zero setting over the full range of the scale (NTEP

and

other Legal for Trade models may have a limited zero range). Zero

settings above 4% of full scale will subtract from the overall capacity of the

scale. For example if you zero out 100 lb. on a 1000 lb. scale the overall

capacity of the scale will reduce to 900 lb. plus the allowed over-range

amount.

12 MSI-3460 Operator’s Manual

2.3 Tare

TARE

Note

TARE

Tare is typically used to zero out a known weight such as a packing container or pallet

and display the load in NET weight. A tare value is entered by pressing the TARE

key. The TARE function in the MSI-3460 is defined as a Tare-In, Tare-Out operation.

The first press of the TARE key stores the current weight as a tare value and then the

scale subtracts the tare value from the gross weight and changes the display to NET

mode. The next press of the TARE key will clear the tare value and revert the display

to GROSS mode.

To view the gross weight without clearing the tare value, program the USER key to

e function “NET/GROSS.” The RF remote control has a Net/Gross permanently

th

available.

To Tare and Display the Net Weight

1. Press

The weight reading must be stable within the motion window for the tare

function to work.

The scale digits display 0 (or 0.0 or 0.00, etc) and the weight mode

changes to NET

The backup memory in the

restore it even if power fails.

To Clear the Tare and revert to Gross Weight

.

MSI-3460

stores the tare reading and can

1. Press

turn on.

Tare - Rules for Use:

• Only positive gross weight readings can be tared.

• The motion annunciator must be off. The weight reading must be stable.

• Setting or changing the tare has no effect on the Gross zero setting.

• Taring will reduce the apparent over range of the scale. For example, taring a

• The scale stores the tare value in non-volatile memory and is restored when

. The net annunciator will turn off and the gross annunciator will

100

lb container on a 1000 lb scale, the scale will overload at a net weight of

900 lb (1000-100) plus any additional allowed overload (usually ~4% or 9d).

power is

cycled.

Operation 13

3.0 User Defined Function Keys

Note

The following function descriptions are for optional user defined functions that are

programmed on the front panel USER key or the two function keys (F1 & F2) on the

RF remote control. The functions TOTAL, VIEW TOTAL, and NET/GROSS are

available full time on the RF remote control. To enable any of the USER key

functions, you must set up the USER keys following the procedures in Section 4.0.

TEST

The TEST function provides an LED test that li

Model number followed by the software version number, the battery voltage, and then

performs a display test that counts from 00000 to 99999. Other internal tests are

performed and if any test fails, an error code will display. See Section 8.0 for a

description of all error codes. Press the USER key

a single step through all the test functions. In the single step mode, use the USER key

to scroll through the available test functions and the TARE key to start or display the

individual tests. Use the ZERO key to exit individual tests. Use the ZERO key to exit

entirely from the TEST function.

CH3.5n – Ch

version.

bAtt – Battery volt

d.tESt – Di

C-CAL

TOTAL

For accumulation of multiple weighments. The accumulator always uses the

displayed weight, so GROSS and NET readings can be added into the same TOTAL.

There are four modes of totalizing: manual and three auto modes. The manual mode

requires the TOTAL button be pressed with the weight on the scale. The weight will

be added to the previously accumulated value. This assures that a weight on the scale

is only added to the total once. Both the manual and three auto total modes require

that the weight on the scale return below 0.5% (relative to full scale) of GROSS

ZERO or NET ZERO before the next weighment can be added. Applied weight must

be ≥1% of full scale above GROSS ZERO or NET ZERO before it can be totaled.

MANUAL TOTAL

The US

Weight is > 1% of Capacity and has not been totaled –

will add the current weight to the TOTAL weight. The ACK LEDs blink to indicate

the weight was accepted. The TOTAL annunciator lights and the total weight is

displayed for five seconds and then the number of samples is displayed for two

seconds.

Current Weight has been totaled – Pressing the

weight for five seconds (View Total) without changing the total value. The TOTAL

annunciator will light during the TOTAL weight display. After five seconds of total

weight display, the number of samples is displayed for two seconds.

Weight is <1% of Capacity – The US

functions as view total until the 1% threshold is exceeded to allow the next addition to

the total value.

allenger 3 software version number: Press TARE to see the software

age: Press TARE to see the battery voltage.

splay test: Press TARE to have the display count up from 00000 to 99999.

– Cal constant display: Press TARE to view the C-CAL value.

The total mode must be programmed from the setup menus before the

USER key will function.

ER key under the MANUAL TOTAL mode functions in this manner:

ER key functions as “View Total” only and

ghts all LEDs at once, next the SW

again within two seconds to enable

Pressing the USER key

USER key will display the total

14 MSI-3460 Operator’s Manual

AUTO TOTAL

The USER key under the AUTO TOTAL mode functions as Auto Total On / Auto

Total Off .

The auto mode has three variations which are programmed in the SETUP menu:

• AutoLoad – Any settled weight above the ‘Rise above’ threshold will be

automatically totaled. Then the scale must fall below the ‘Drop below’ threshold

before another total is allowed.

• AutoNorm – This mode takes the last settled weight to auto total with. The total

occurs only once the scale goes below the threshold. This allows the load to be

adjusted without a total occurring. Once the load is removed, the scale uses the

last settled reading for total.

• AutoHigh – Similar to the AutoNorm mode except the scale uses the highest

settled reading. Useful for loads that can’t be removed all at once.

View Total

The function key activates the total weight display followed by the number of

samples. While the display is showing the total, total is cleared by pressing ZERO.

Net / Gross

Switches the display between net and gross modes. Net weight is defined as gross

weight minus a tare weight.

To switch between net mode and gross mode:

1. Press the USER key (Setup to the Net/Gross function).

2. The NET/GROSS key will only function if a tare value has been established.

3. Switching back to gross mode from net mode will not clear the tare value. This

allows the operator to use the gross mode temporarily without having to reestablish the tare value. Only clearing the tare or setting a new tare will change

the tare value held before switching into gross mode.

OIML LFT units only: The NET/GROSS key is temporary action only. The gross

weight is displayed for two seconds and then the display returns to the net mode. The

only way to return to permanent gross readings is to clear the tare (see clear tare

procedure).

PRINT

If print option is installed this menu choice will appear. The setup of the print function

is covered in the option manual.

LEARN

Used for programming the RF remote control. This function is detailed in Section 6.0.

PEAK HOLD

Peak hold will only update the display when a higher peak weight reading is

established. The peak hold function uses a high speed mode of the A/D converter

allowing it to capture transient weights at a far higher rate than typical scales. Peak

hold is cleared and re-enabled with the USER key.

PEAK HOLD is not available on NTEP or OIML certified Legal for Trade scales.

UNIT

The function key will switch the weight units between pounds and kilograms.

UNIT switching is not available on OIML certified Legal for Trade scales.

User Defined Function Keys 15

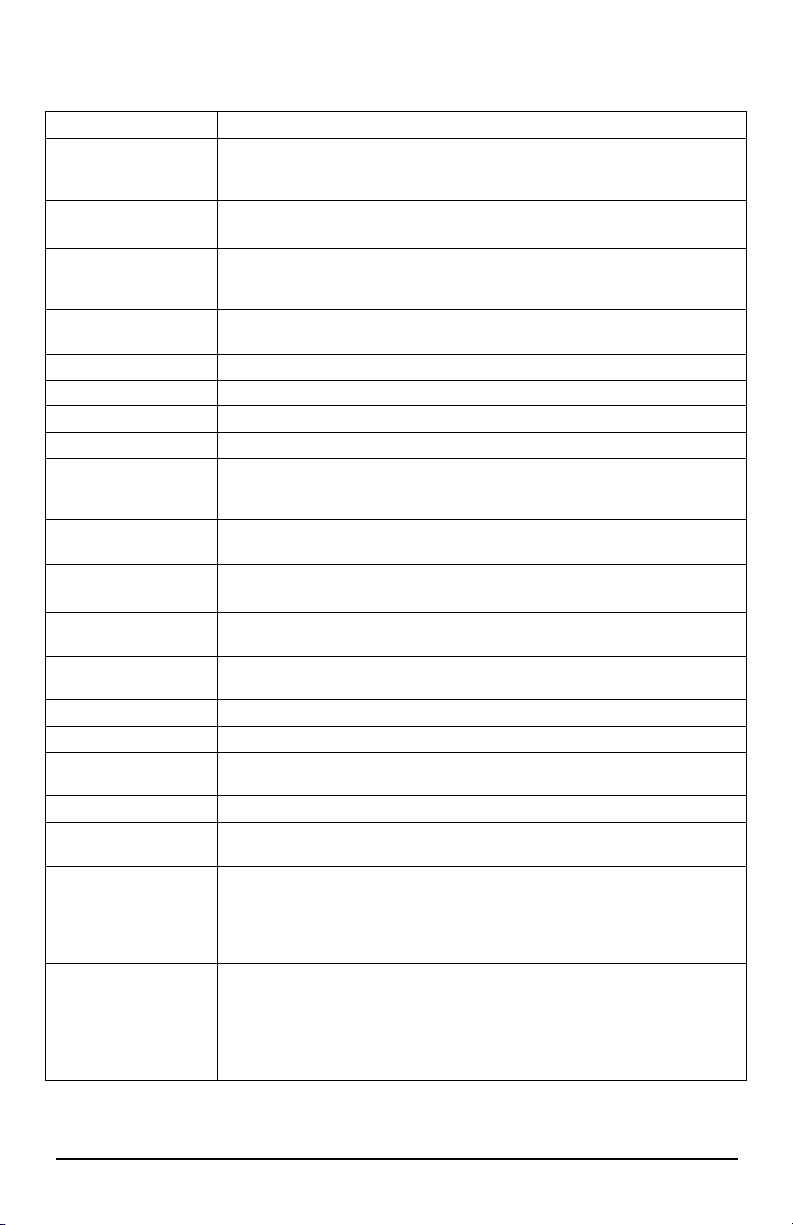

4.0 Configuration

)YQF

IYQF

DII

6/((3

GLVSO

6W3W

6W3W

6W3W

WRWDO

ILOWU

81L7

2))

WHVW

WRWDO

YWWO

1(W

U

/HDUQ

3+OG

8QLW

2II

II

/R

+L

+L

DYWR

/R

/R

+L

+L

kg lb

2))

UHDW

/(66

Number Entry

Off

Test Display

*Total

*View Total

*Net/Gross

Remote Learn

**Units

***Peak Hold

USER KEY

FUNCTIONS

TOTAL MODE

Total Off (default)

Total On Manual

Autototal on Load

Autototal Last

Autototal on High Load

2II

WWO2Q

$/R$'

$/$6W

$+L

K

USER

F

Function User Key 1

Function User Key 2

Auto Off Time

Sleep Mode

Display Intensity

Set Point 1

Set Point 2

Set Point 3

Total Mode

**Weight Filter

***Weight Units

SETUP MENU

Disabled (default)

15 minutes

30 minutes

45 minutes

1 hour

AUTO OFF TIME

OFF (disabled)

Low

(default)

High Filter

Very High Filter

SOFTWARE FILTER

LED DISPLAY INTENSITY

Auto by Light Sensor (default)

Dim (longest battery life)

Medium Dim

Medium Bright

Maximum Bright

POWER

*

Function always available on the RF Remote

**

Function not available or non-functional in OIML R76 & 1Unit modes

***

Function not available or non-functional in OIML R76 or NTEP HB44 modes

With the Power off, hold

down the USER key, then

turn the Power on.

Or press POWER and USER

simultaneously

USER

F

TARE

ENTER / SELECT

POWER

EXIT and Cancel Changes

ZERO

EXIT and SAVE

USER

F

SCROLLs through

Menu Choices

Set Point Off

(default)

Greater Than

Less Than

Totals on first stable load

Totals the last stable load before zero return

Totals the highest stable load

Totals by pressing the USER key

Autototal Last and Autototal High total when the scale is unloaded.

F2 is only on the RF Remote

2))

SLEEP DELAY

Off, Sleep disabled

5 Minutes

(default)

15 Minutes

30 Minutes

(default)

4.1 Menu Map

16 MSI-3460 Operator’s Manual

Figure 4-1. Setup Menu Map

Loading...

Loading...