Instrument Manual

Ethernet Transmitter Series PR 5220

PR 5220/00 Ethernet Transmitter

PR 5220/01 Ethernet Transmitter with ProfiBus

PR 5220/04 Ethernet Transmitter with DeviceNet

PR 5220/06 Ethernet Transmitter with ProfiNet I/O

PR 5220/07 Ethernet Transmitter with EtherNet-IP

for PR 5220

Release: 2.10

Instrument Manual

Sartorius Mechatronics T&H GmbH, Meiendorfer Str. 205, 22145 Hamburg, Germany

9499 050 52201

Edition 6 08.07.2013

Tel:+49.40.67960.303 Fax:+49.40.67960.383

Please note

Any information in this document is subject to change without notice and does not represent a commitment on the part of

SARTORIUS unless legally prescribed. This product should be operated only by trained and qualified personnel. In correspondence

concerning this product the type, name and release number as well as all license numbers in relation to the product have to be

quoted.

Bitte beachten

Alle Angaben in diesem Dokument sind - soweit nicht gesetzlich vorgegeben - unverbindlich für SARTORIUS und stehen unter

Änderungsvorbehalt. Die Bedienung des Produktes darf nur von geschultem, fach- und sachkundigem Personal durchgeführt

werden. Bei Schriftwechsel über dieses Produkt bitte Typ, Bezeichnung und Versionsnummer sowie alle mit dem Produkt in

Zusammenhang stehenden Lizenznummern angeben.

PR 5220 Instrument Manual Table of Contents

1 Safety Information ...................................................................................................................................................................................... 7

2 Ethernet Transmitter Series .................................................................................................................................................................... 10

3 Installing the Instrument ........................................................................................................................................................................ 20

Table of Contents

1.1 General Information .................................................................................................................................................................................... 7

1.2 Intended Use .................................................................................................................................................................................................. 7

1.3 Initial Inspection ........................................................................................................................................................................................... 7

1.4 Before Commissioning ................................................................................................................................................................................ 7

1.4.1 Installation ........................................................................................................................................................................................ 8

1.4.2 Electrostatically Sensitive Components ................................................................................................................................... 8

1.4.3 Protective Earth ............................................................................................................................................................................... 8

1.4.4 Supply Voltage Connection ......................................................................................................................................................... 8

1.4.5 Failure and Excessive Stress ......................................................................................................................................................... 9

1.4.6 Fuse ...................................................................................................................................................................................................... 9

1.4.7 EMC-Compliant Installation ........................................................................................................................................................ 9

2.1 The Transmitter Versions .......................................................................................................................................................................... 10

2.1.1 PR 5220/00 Version ...................................................................................................................................................................... 10

2.1.2 PR 5220/01 ProfibBus .................................................................................................................................................................. 10

2.1.3 PR 5220/04 DeviceNet ................................................................................................................................................................. 10

2.1.4 PR 5220/06 ProfiNet I/O ............................................................................................................................................................. 10

2.1.5 PR 5220/07 EtherNet-IP ............................................................................................................................................................. 10

2.2 Overview of the Instrument ................................................................................................................................................................... 11

2.3 Label on the Housing ................................................................................................................................................................................ 12

2.4 Housing Dimensions .................................................................................................................................................................................. 12

2.5 Display and Controls ................................................................................................................................................................................. 13

2.5.1 Status LEDs ...................................................................................................................................................................................... 13

2.5.2 Operation Using the VNC Program ......................................................................................................................................... 14

2.6 Overview of Connections ......................................................................................................................................................................... 19

3.1 Connections ................................................................................................................................................................................................. 20

3.1.1 Network Port .................................................................................................................................................................................. 20

3.1.2 RS-485 Interface ........................................................................................................................................................................... 21

3.1.3 Analog Output ............................................................................................................................................................................... 25

3.1.4 Optocoupler Inputs ....................................................................................................................................................................... 26

3.1.5 Optocoupler Outputs ................................................................................................................................................................... 27

3.1.6 Load Cell Connection ................................................................................................................................................................... 28

3.1.7 Connecting Analog Platforms (CAP...) .................................................................................................................................... 31

3.1.8 Connecting xBPI Platforms (IS...) ............................................................................................................................................. 32

3.1.9 Connection of Digital Load Cells .............................................................................................................................................. 32

3.1.10 ProfiBus Interface (PR 5220/01 only) ..................................................................................................................................... 33

3.1.11 DeviceNet Interface (PR 5220/04 only) ................................................................................................................................. 34

3.1.12 ProfiNet I/O Interface (PR 5220/06 only) .............................................................................................................................. 35

3.1.13 EtherNet-IP Interface (PR 5220/07 only) .............................................................................................................................. 36

Sartorius EN-3

Table of Contents

4 Commissioning ........................................................................................................................................................................................... 37

PR 5220 Instrument Manual

4.1 Data Backup/Power Failure .................................................................................................................................................................... 37

4.1.1 CAL Switch ..................................................................................................................................................................................... 37

4.1.2 Factory Settings ............................................................................................................................................................................ 38

4.2 Switching on the Instrument ................................................................................................................................................................ 38

4.3 Configuration and Calibration .............................................................................................................................................................. 38

4.3.1 Connecting the Device to the Network and Finding out the IP address ................................................................... 38

4.3.2 Resetting the Instrument/Activating Network'DHCP' ...................................................................................................... 41

4.3.3 Searching the Instrument in the Network Using 'IndicatorBrowser' .......................................................................... 44

4.3.4 Operation Using the VNC Program ......................................................................................................................................... 45

4.3.5 Operation Using Internet Browser .......................................................................................................................................... 46

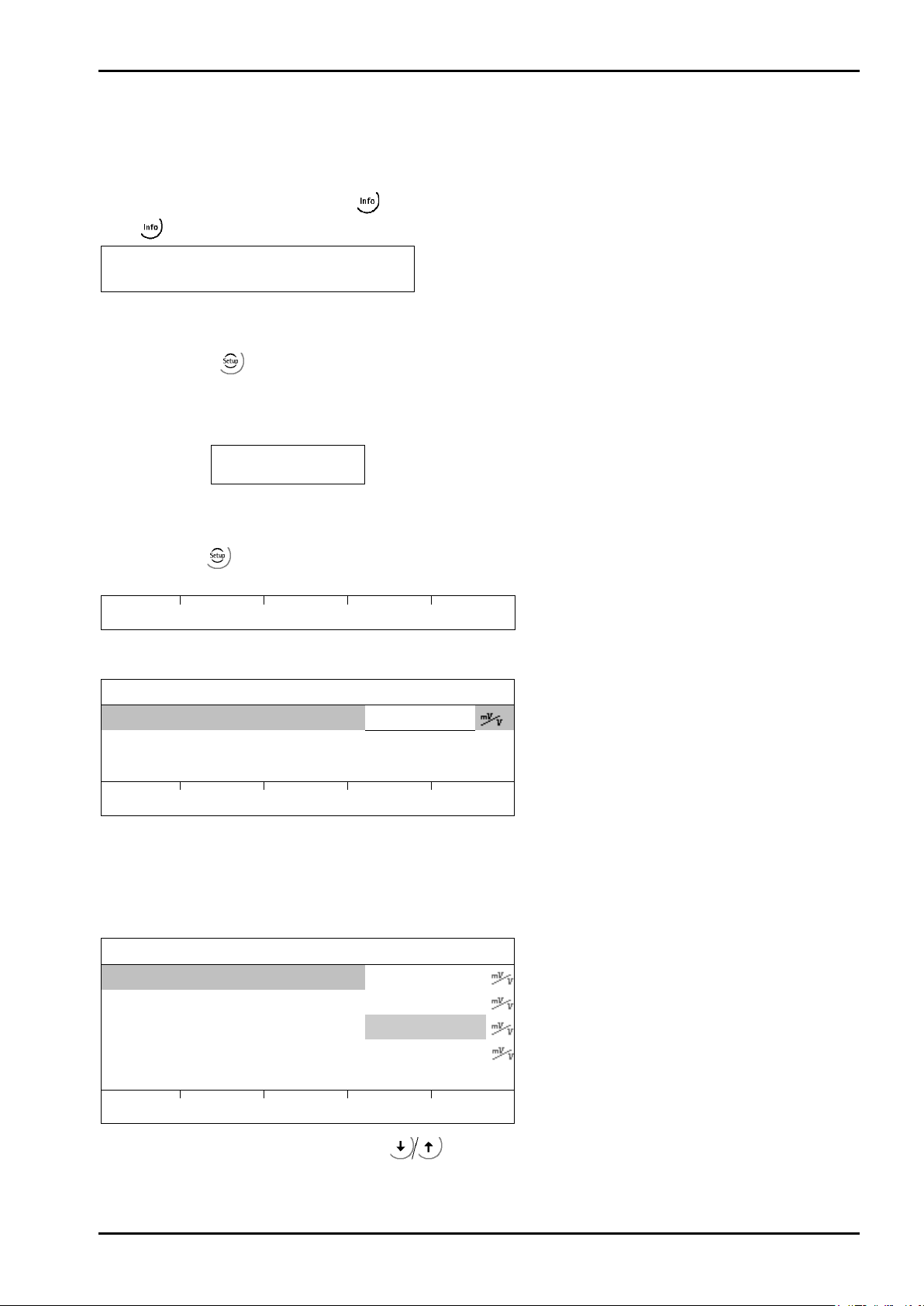

4.3.6 INFO Function ................................................................................................................................................................................ 48

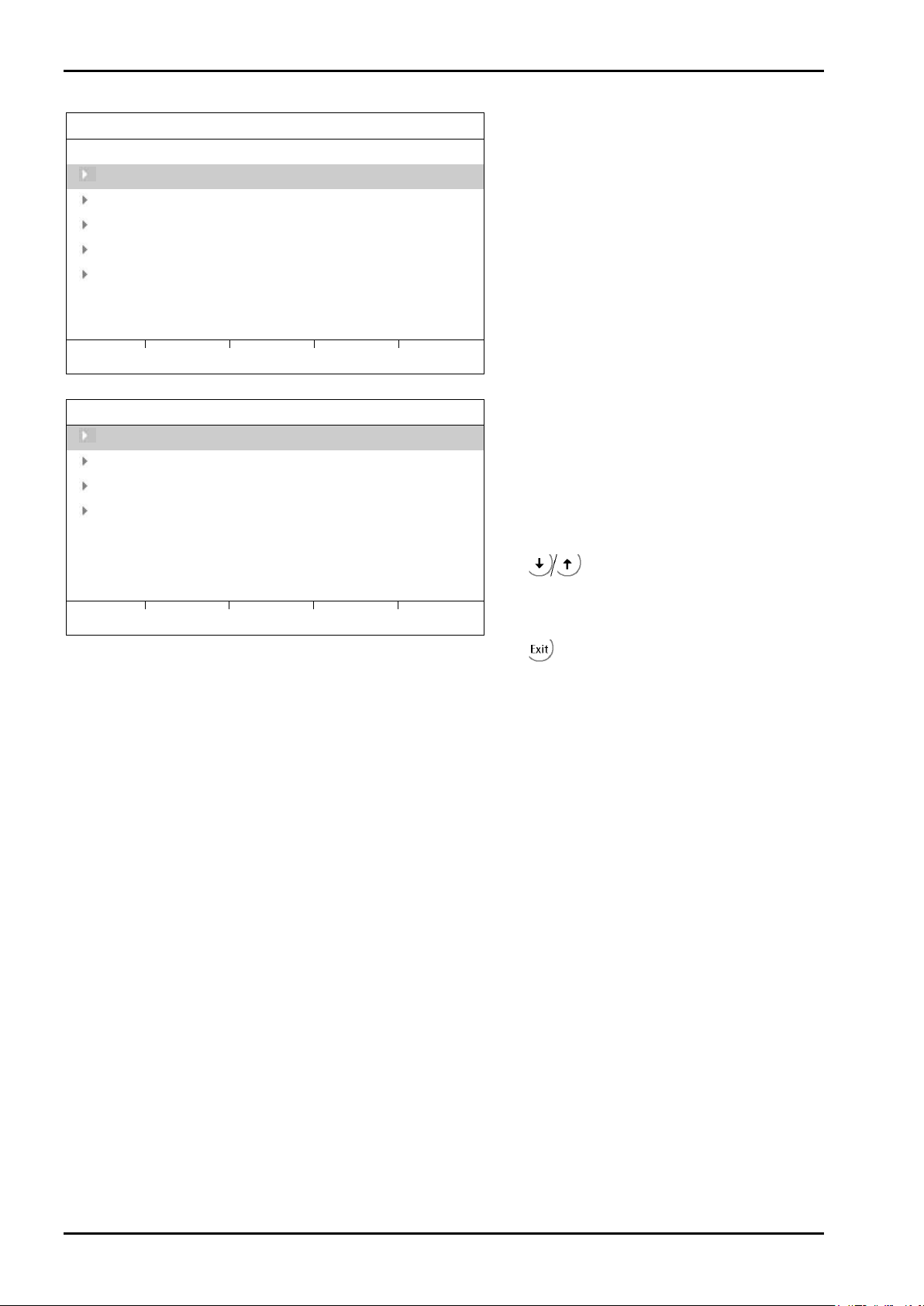

4.3.7 Setup Function (VNC) ................................................................................................................................................................. 48

4.3.8 Setup Menu .................................................................................................................................................................................... 49

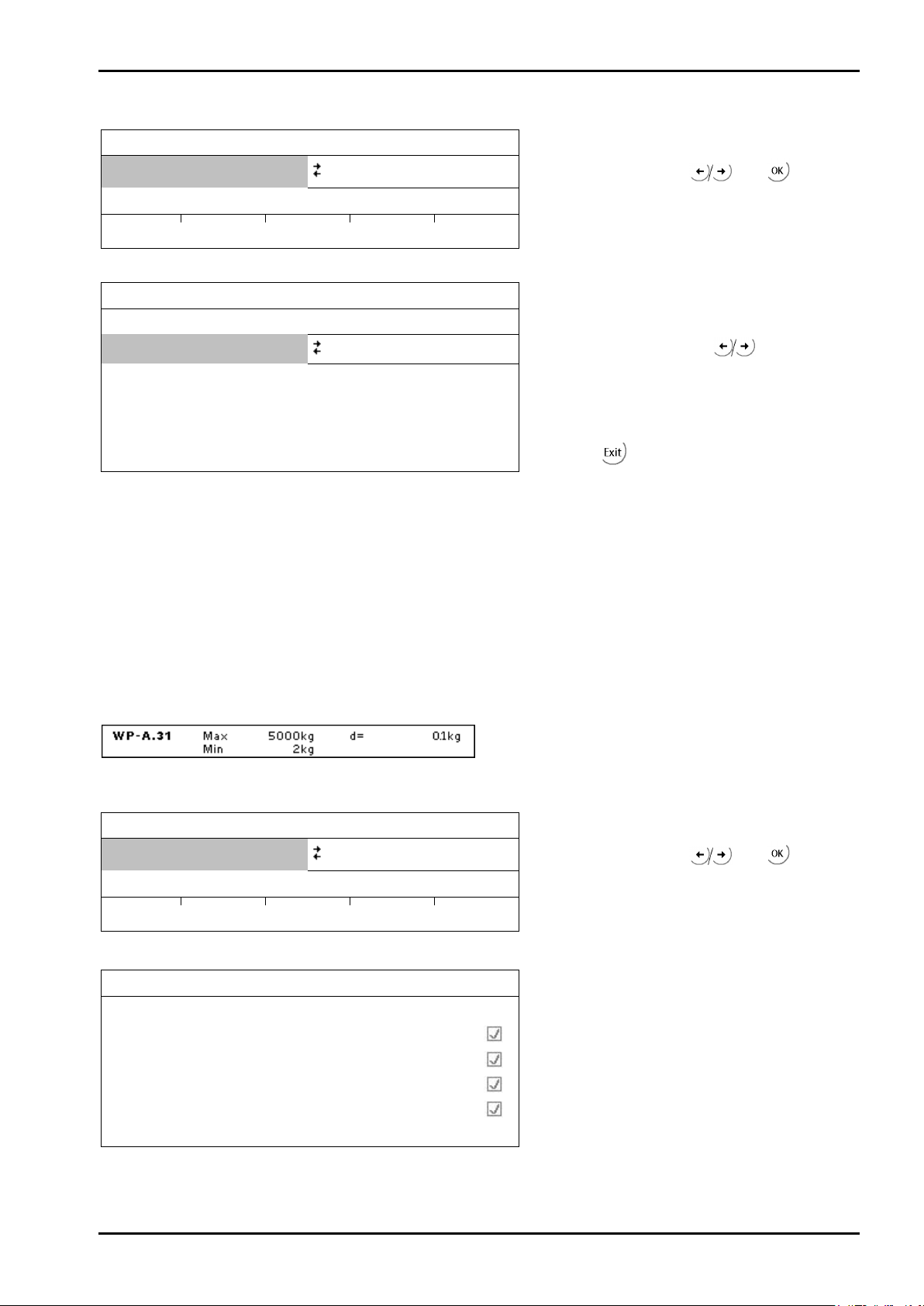

4.4 Calibration Weighing Point ‚Internal A’ ............................................................................................................................................. 55

4.4.1 Displaying Calibration Data ...................................................................................................................................................... 55

4.4.2 Selecting the Calibration Mode ............................................................................................................................................... 56

4.4.3 Determining the Maximum Capacity (Max) ........................................................................................................................ 57

4.4.4 Determining the Scale Interval ................................................................................................................................................ 59

4.4.5 Determining the Dead Load ...................................................................................................................................................... 60

4.4.6 Calibration with Weight (by Load) ......................................................................................................................................... 62

4.4.7 Calibration with mV/V Value [by mV/V] ................................................................................................................................ 63

4.4.8 Calibration with Load Cell Data (“Smart Calibration“) ..................................................................................................... 64

4.4.9 Subsequent Dead Load Correction ......................................................................................................................................... 65

4.4.10 Linearization .................................................................................................................................................................................. 65

4.4.11 Test Value Determination/Display ........................................................................................................................................... 66

4.4.12 Finishing/Saving the Calibration ............................................................................................................................................. 66

4.4.13 Parameter Input ............................................................................................................................................................................ 67

4.5 Calibrating an xBPI Scale ........................................................................................................................................................................ 70

4.5.1 xBPI Set-up for Serial Port ........................................................................................................................................................ 70

4.5.2 xBPI Scale Function ..................................................................................................................................................................... 71

4.5.3 xBPI Platform Configuration .................................................................................................................................................... 71

4.5.4 xBPI Scale Parameter .................................................................................................................................................................. 73

4.5.5 xBPI Parameter Tables ................................................................................................................................................................ 74

4.5.6 xBPI Setting Dead Load .............................................................................................................................................................. 77

4.5.7 xBPI Calibration with the User Weight ................................................................................................................................. 78

4.5.8 xBPI Calibration with Automatic Weight Detection ......................................................................................................... 79

4.5.9 xBPI Calibration with Default Weight ................................................................................................................................... 80

4.5.10 xBPI Calibration with Built-in Weight .................................................................................................................................. 82

4.6 Calibrating Digital Load Cells Type ‘Pendeo®’ .................................................................................................................................. 83

4.6.1 General Information .................................................................................................................................................................... 83

4.6.2 Viewing the Interfaces ................................................................................................................................................................ 83

4.6.3 Selecting and Setting up the Interface ................................................................................................................................. 83

4.6.4 Selecting the Load Cell Type ..................................................................................................................................................... 84

4.6.5 Adjustment Sequence ................................................................................................................................................................. 85

4.6.6 Search for Load Cells ................................................................................................................................................................... 85

4.6.7 Assigning Load Cells .................................................................................................................................................................... 87

EN-4 Sartorius

PR 5220 Instrument Manual Table of Contents

5 J-Bus/ModBus Protocol ........................................................................................................................................................................ 117

6 SMA Protocol ........................................................................................................................................................................................... 125

7 Fieldbus Interface ................................................................................................................................................................................... 134

8 Global SPM Variables ............................................................................................................................................................................. 145

9 Configuration Print-Out ....................................................................................................................................................................... 148

10 Extended Functions ................................................................................................................................................................................ 150

4.6.8 Calibrating Load Cells .................................................................................................................................................................. 88

4.6.9 Corner Correction ......................................................................................................................................................................... 91

4.6.10 Finishing/Saving the Calibration .............................................................................................................................................. 92

4.6.11 Parameter Input ............................................................................................................................................................................ 93

4.6.12 Subsequent Dead Load Correction .......................................................................................................................................... 95

4.7 Configuring General Parameters........................................................................................................................................................... 96

4.7.1 Serial Interfaces [Serial ports parameter] ............................................................................................................................. 96

4.7.2 Operating Parameters .................................................................................................................................................................. 98

4.7.3 Fieldbus Parameters ..................................................................................................................................................................... 99

4.7.4 Network Parameters .................................................................................................................................................................. 101

4.8 Configuring Limit Values ...................................................................................................................................................................... 102

4.9 Digital Outputs and Inputs .................................................................................................................................................................. 106

4.9.1 Configuring Digital Outputs ................................................................................................................................................... 106

4.9.2 Configuring Digital Inputs ...................................................................................................................................................... 108

4.10 Analog Output ......................................................................................................................................................................................... 110

4.10.1 Adapting the Analog Output ................................................................................................................................................. 111

4.11 Logfiles ....................................................................................................................................................................................................... 112

4.12 Saving Configuration Data [Backup of EAROM] ........................................................................................................................... 113

4.12.1 Saving Configuration and Calibration Data ...................................................................................................................... 113

4.12.2 Loading Configuration and Calibration Data into the Device ..................................................................................... 115

5.1 General Description ................................................................................................................................................................................ 117

5.2 ModBus-TCP/-UDP .................................................................................................................................................................................. 118

5.3 Functions ................................................................................................................................................................................................... 119

5.4 Error Messages ......................................................................................................................................................................................... 123

5.5 Word Addresses ....................................................................................................................................................................................... 124

6.1 General ....................................................................................................................................................................................................... 125

6.2 Description of Used Symbols ............................................................................................................................................................... 125

6.3 SMA Command Set ................................................................................................................................................................................. 126

6.4 SMA Reply Messages .............................................................................................................................................................................. 129

6.5 Communication Error ............................................................................................................................................................................ 134

7.1 Fieldbus Interface Protocol .................................................................................................................................................................. 134

7.2 Description of the I/O Area (Read / Write Window) .................................................................................................................... 136

7.3 Special hints for DeviceNet and EtherNet-IP ................................................................................................................................. 140

7.4 Fieldbus Register ..................................................................................................................................................................................... 141

10.1 Resetting the Instrument to the Factory Settings........................................................................................................................ 150

10.2 Updating a new Software with ‚FlashIt’ .......................................................................................................................................... 151

Sartorius EN-5

Table of Contents

11 Repairs and Maintenance ..................................................................................................................................................................... 153

12 Disposal ...................................................................................................................................................................................................... 153

13 Error Messages ......................................................................................................................................................................................... 154

14 Specifications ........................................................................................................................................................................................... 159

15 Index ............................................................................................................................................................................................................ 163

16 Appendix .................................................................................................................................................................................................... 166

PR 5220 Instrument Manual

11.1 Solder Work ............................................................................................................................................................................................... 153

11.2 Cleaning ..................................................................................................................................................................................................... 153

13.1 Measuring Circuit Error Messages ..................................................................................................................................................... 154

13.2 Weight Error Status ................................................................................................................................................................................ 155

13.3 Error Messages with xBPI Scales ........................................................................................................................................................ 155

13.4 Error messages of the Calibration ...................................................................................................................................................... 156

13.5 Show Error Log ......................................................................................................................................................................................... 158

14.1 Instructions for Use of 'Free Software' ............................................................................................................................................ 159

14.2 General Data ............................................................................................................................................................................................. 160

14.2.1 Power Supply ............................................................................................................................................................................... 160

14.3 Effect of Ambient Conditions ............................................................................................................................................................. 160

14.3.1 Environmental Conditions ....................................................................................................................................................... 160

14.3.2 Electromagnetic Compatibility (EMC) ................................................................................................................................. 160

14.3.3 RF Interference Suppression ................................................................................................................................................... 160

14.4 Weighing Electronics ............................................................................................................................................................................. 161

14.4.1 Load Cells ...................................................................................................................................................................................... 161

14.4.2 Principle ........................................................................................................................................................................................ 161

14.4.3 Accuracy and Stability .............................................................................................................................................................. 161

14.4.4 Sensitivity ..................................................................................................................................................................................... 161

14.5 Mechanical Data ...................................................................................................................................................................................... 162

14.5.1 Construction ................................................................................................................................................................................ 162

14.5.2 Dimensions ................................................................................................................................................................................... 162

14.5.3 Weight ........................................................................................................................................................................................... 162

14.6 Use in Legal-for-Trade Mode .............................................................................................................................................................. 162

14.6.1 Documentation for Verification on the Enclosed CD ..................................................................................................... 162

14.6.2 Additional Instructions ............................................................................................................................................................. 162

16.1 Pin Assignment for Interface RS-485 ............................................................................................................................................... 166

16.2 Network Settings under Windows XP ............................................................................................................................................... 167

16.3 Network Settings under Windows 7 ................................................................................................................................................. 168

EN-6 Sartorius

PR 5220 Instrument Manual Safety Information

1 Safety Information

1.1 General Information

The instrument was in perfect condition with regard to safety features when it left the

factory. To maintain this condition and to ensure safe operation, the operator must follow

the instructions and observe the warnings in this manual.

1.2 Intended Use

The instrument is intended for use as an indicator for weighing functions. Product operation, commissioning

and maintenance must be performed by trained and qualified personnel who are aware of and able to deal

with the related hazards and take suitable measures for self-protection.

The instrument reflects the state of the art. The manufacturer does not accept any liability for damage caused

by other system components or due to incorrect use of the product.

1.3 Initial Inspection

Check the content of the consignment for completeness and inspect it visually for signs of damage that may

have occurred during transport. If there are grounds for rejection of the goods, a claim must be filed with the

carrier immediately and the Sartorius sales or service organization must be notified.

1.4 Before Commissioning

Visual inspection:

Before commissioning and after and storage or transport, inspect the instrument visually

for signs of mechanical damage.

Sartorius EN-7

Safety Information

The supply voltage is 24V DC +10% / -15%.

PR 5220 Instrument Manual

1.4.1 Installation

The instrument is designed for mounting on standard rails (35 mm, acc. to DIN 46277).

Caution!

Excessive heat may reduce the instrument lifetime!

When mounting on the rail, make sure that the distance from other instruments left

and right of the module is at least 20 mm.

1.4.2 Electrostatically Sensitive Components

This instrument contains electrostatically sensitive components. For this reason, an equipotential bonding

conductor must be connected when working on the open instrument (antistatic protection).

1.4.3 Protective Earth

Connection to protective earth must be performed via the mounting rail.

1.4.4 Supply Voltage Connection

Max. power consumption of

- PR 5220/00: 6.5 W

- PR 5220/01: 8.5 W

- PR 5220/04: 8.5 W

- PR 5220/06: 8.5 W

- PR 5220/07: 8.5 W

For connection to 230/115 V AC, an external power supply

EN-8 Sartorius

(e.g. Sartorius PR 1624/00 or Phoenix Mini Power) is required.

PR 5220 Instrument Manual Safety Information

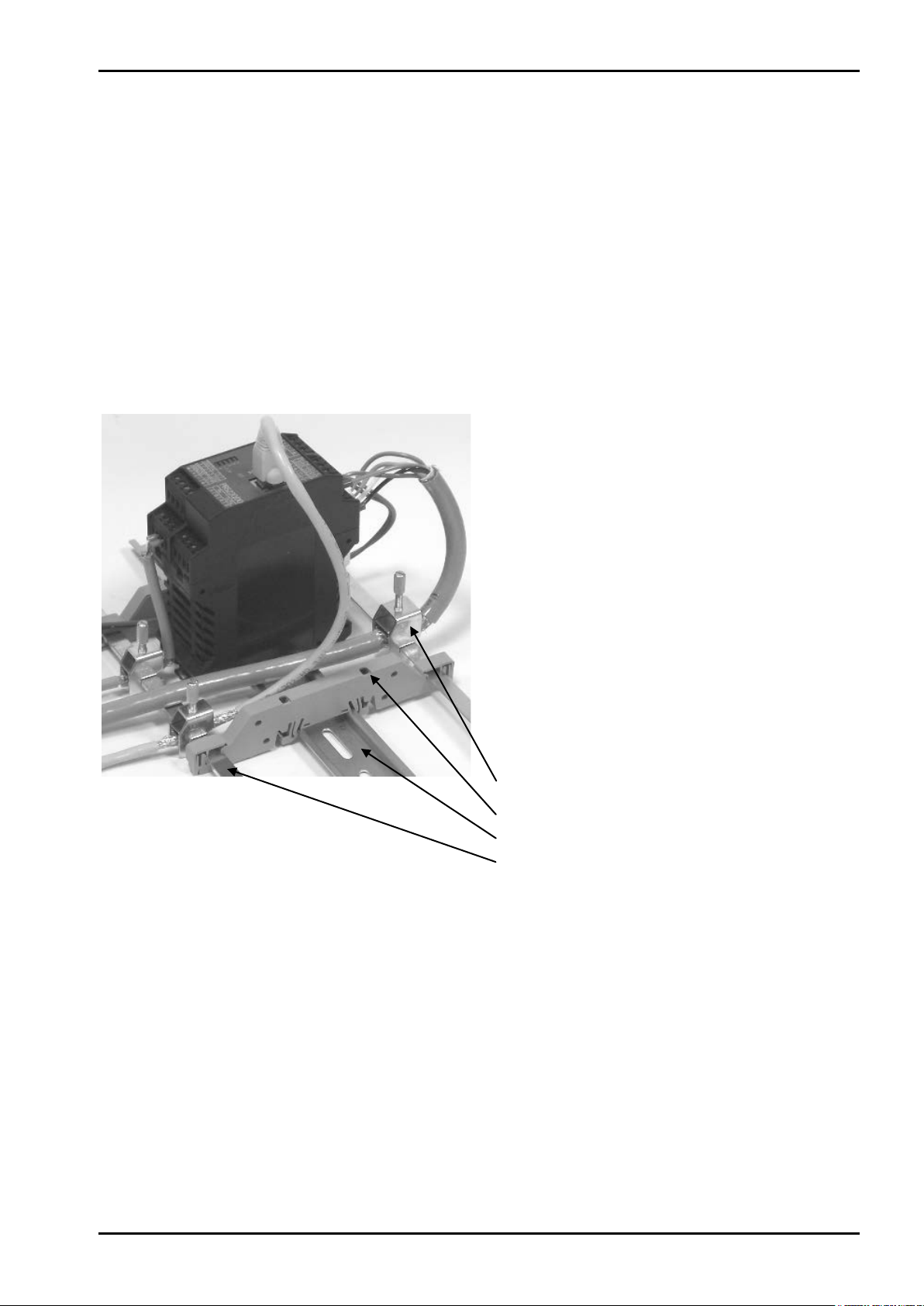

Screen clamp (e.g. Phoenix SK8-D)

Rail connection (e.g. Phoenix AB-SK 65D)

Mounting rail (35 mm)

Screen rail (e.g. Phoenix NLS-CU 3/10)

1.4.5 Failure and Excessive Stress

If there is any reason to assume that safe operation of the instrument is no longer ensured, shut it down and

make sure it cannot be used. Safe operation is no longer ensured if any of the following is true:

- The instrument is physically damaged

- The instrument does not function

- The instrument has been subjected to stresses beyond the tolerance limits (e.g., during storage or

transport).

1.4.6 Fuse

This instrument does not have a replaceable fuse. The load cell supply voltage is protected against short circuit.

In case of failure of the load cell supply voltage, disconnect the instrument from the supply voltage, determine

the cause and take remedial measures. Subsequently, the supply voltage can be switched on again.

1.4.7 EMC-Compliant Installation

- Use only screened data cables.

- Connect screens on both ends with ground.

- Keep unscreened cable ends short.

- Connect screen rail to cabinet / housing with

low impedance.

- Use metal or metallized connector housings.

- Establish equipotential bonding between

instruments / system modules (Mandatory for

Ex-applications).

- Use standard reference potential.

- Connect mounting rail to protective earth.

- Install measure and data cables separately from

power cables.

Sartorius EN-9

Ethernet Transmitter Series

PR 5220 Instrument Manual

2 Ethernet Transmitter Series

2.1 The Transmitter Versions

Three PR 5220 series transmitter versions are available; subsequent extension of the version is not possible.

The version is determined unambiguously by the type number. The front foils are adapted to the version.

PR 5220/00 PR 5220/01 PR 5220/04

PR 5220/06 PR 5220/07

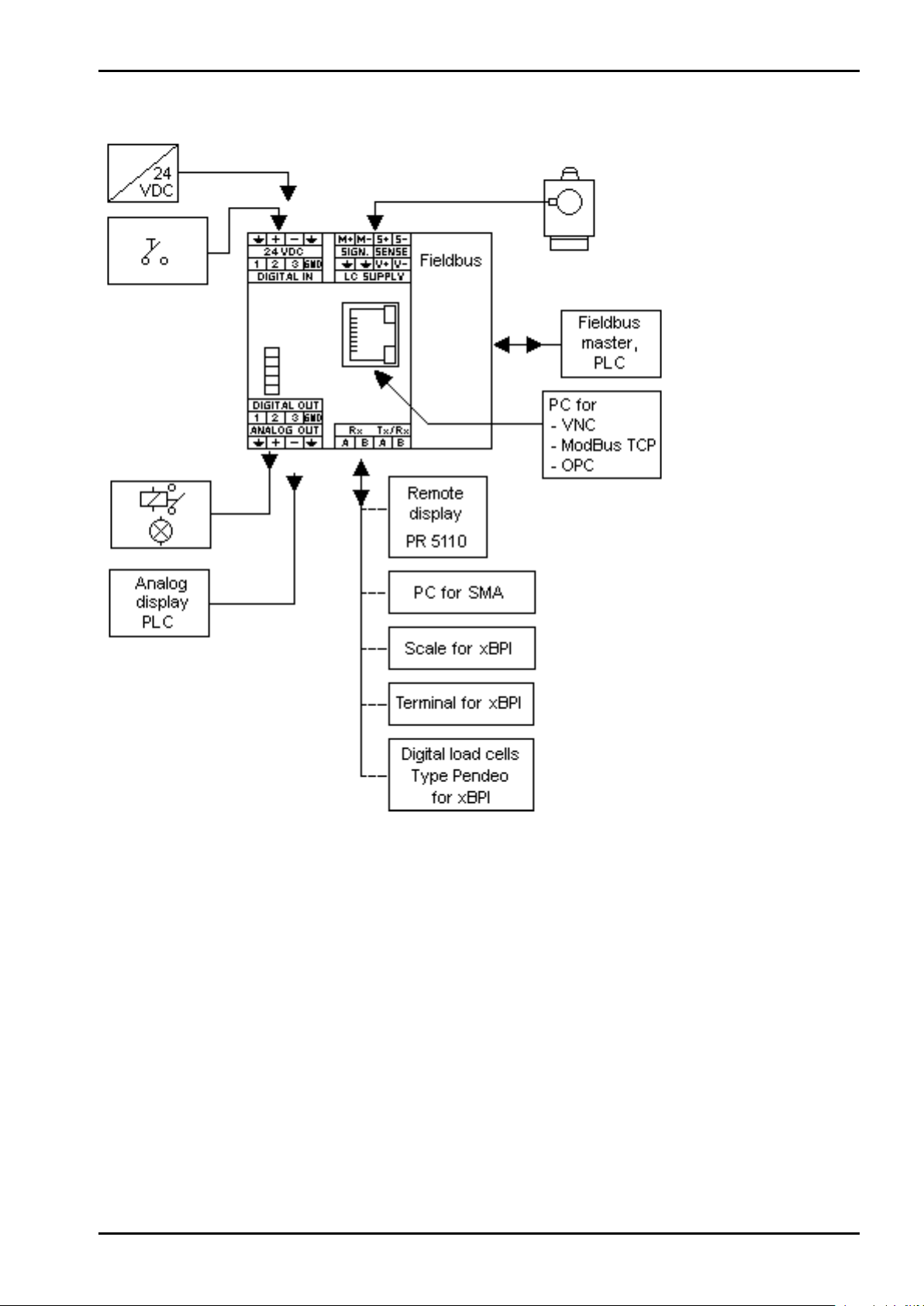

2.1.1 PR 5220/00 Version

This version has digital inputs and outputs as well as an analog output and a LAN adaptor for configuration

and operation of the instrument. Connecting e.g. a remote indicator is possible via the serial output.

2.1.2 PR 5220/01 ProfibBus

In addition to PR 5220/00, the instrument is provided with a ProfiBus port.

2.1.3 PR 5220/04 DeviceNet

In addition to PR 5220/00, the instrument is provided with a DeviceNet port.

2.1.4 PR 5220/06 ProfiNet I/O

In addition to PR 5220/00, the instrument is provided with a ProfiNet I/O port.

2.1.5 PR 5220/07 EtherNet-IP

In addition to PR 5220/00, the instrument is provided with a EtherNet-IP port.

EN-10 Sartorius

PR 5220 Instrument Manual Ethernet Transmitter Series

Accuracy 10,000 e @ 6 samples/sec

2.2 Overview of the Instrument

-

- Internal resolution: 7.5 million counts

- Linearity: < 0.002%

- Sampling rate: 6 ... 100/sec selectable

- Digital filter with selectable characteristic

- Electrically isolated interfaces

- 3 programmable pairs of limit values

- 24 VDC supply voltage connection

- Connection using plug-in terminal blocks

- Socket for LAN adaptor

- The instrument is provided for snap-on mounting on a standard

rail.

- 5 status LEDs für supply voltage, communication, error detection

Calibration and configuration of the instrument are menu guided using a PC.

- Calibration with weight, using the mV/V method or with load cell

data (“smart calibration”)

- 0/4 ... 20 mA analog output, configurable for gross/net weight

- Analog value via fieldbus

- 3 digital input channels, electrically isolated

- 3 digital output channels, electrically isolated

Communication protocols

For the internal RS-485:

- Remote display protocol

- SMA protocol

- xBPI protocol

For the internal LAN:

- ModBus-TCP

- Ethernet-TCP/IP

- OPC

Fieldbus slave:

- PR 5220/01 ProfiBus-DP

- PR 5220/04 DeviceNet

- PR 5220/06 ProfiNet I/O

- PR 5220/07 EtherNet-IP

Sartorius EN-11

Ethernet Transmitter Series

2.3 Label on the Housing

A label with the wiring diagram is located on one side of the instrument:

2.4 Housing Dimensions

PR 5220 Instrument Manual

PR 5220/00 PR 5220/01, -/04, -/06, -/07

EN-12 Sartorius

PR 5220 Instrument Manual Ethernet Transmitter Series

Power on

Bus

Bus connection not provided

Standstill

Center zero

Below zero or above max. capacity

lit

lit

lit

Note:

2.5 Display and Controls

2.5.1 Status LEDs

The instrument has 5 green LEDs for display of the operating or error status.

2.5.1.1 Power Supply, Bus Connection

lit

* The LED for the bus activity (PR 5220/01 a. PR 5220/04) is lit as soon as there is a connection. It continues

being lit, also when there is no communication, or when the physical connection is cut.

lit * blinks 1 Hz

2.5.1.2 Weight Status Indicator

The weight error status sees in Chapter 13.2.

Sartorius EN-13

Ethernet Transmitter Series

Display

Function keys

Alphanumeric keys

Softkeys

Indicator keys

Navigation/menu keys

2.5.2 Operation Using the VNC Program

2.5.2.1 Operator Interface

PR 5220 Instrument Manual

EN-14 Sartorius

PR 5220 Instrument Manual Ethernet Transmitter Series

Available mass units are mg, g, kg, t, lb or oz.

The display shows weight values of up to 7 digits with decimal point and plus or minus sign.

lb and oz units are not permitted for use in legal

metrology in the EU and EEC.

The weight readout shows the current weight on a

bar graph that indicates proportion of the

maximum capacity (Max), with 0 on the left and

100 % on the right.

2.5.2.2 Status Symbols

The following status symbols can be shown:

Symbol Description

Gross weight (Brutto)

Gross weight in NTEP or NSC mode

, Tare weight, fixtare

Net weight (Net = gross – Tare)

The display shows the test value without mass unit

Positive value

Negative value

The weight value is within ±¼ d of zero

The weight value is stable.

Value not permissible in legal metrology (e.g., 10-fold resolution).

Range 1

Range 2

Range 3

Sartorius EN-15

Ethernet Transmitter Series

PR 5220 Instrument Manual

2.5.2.3 Keys

The following tables show the basic meanings of symbols on the operator interface.

Indicator key Description

Display gross weight

Display tare weight

Taring; the current gross weight is stored in the tare memory, provided that:

- weight value is stable.

- instrument is not in error status (function dependent on configuration).

Sets gross weight to zero, provided that (function dependent on configuration):

- weight value is stable.

- weight is within zero setting range

Start printing.

Navigation key Description

Cursor moves to the right.

Menu key Description

Selection

Cursor moves to the left.

Selection

Scroll up in the menu.

Scroll down in the menu.

Softkey: select function

Backspace/delete

Exit from current menu; continue operation on next higher level.

Enter/confirm

EN-16 Sartorius

PR 5220 Instrument Manual Ethernet Transmitter Series

Setup

Config

Calib

Param

Function key Description

Information on version number, fitted hardware,10-fold resolution

Without function

Test

Open the setup menu

Toggle to alphabetic input mode.

2.5.2.4 Operation Using Softkeys

During configuration, you can switch between the mass units by pressing this key.

The functions of the five softkeys below the graphic display are indicated in the bottommost text line of

the display. Softkey functions shown in gray are not available on the active menu level, or not with the active

access privileges.

When operating steps involving softkeys are described in this manual, the softkey labels are shown in square

brackets, rather than in graphics of the softkeys.

Sartorius EN-17

Ethernet Transmitter Series

Info

Show status

Show HW-slots

Weighingpoint/WP A/Calibration

Digital filter

off

Test mode

absolute

W & M

none

Standstill time

0.50 s

Standstill range

1.00 d

Weighingpoint/WP A/Calibration

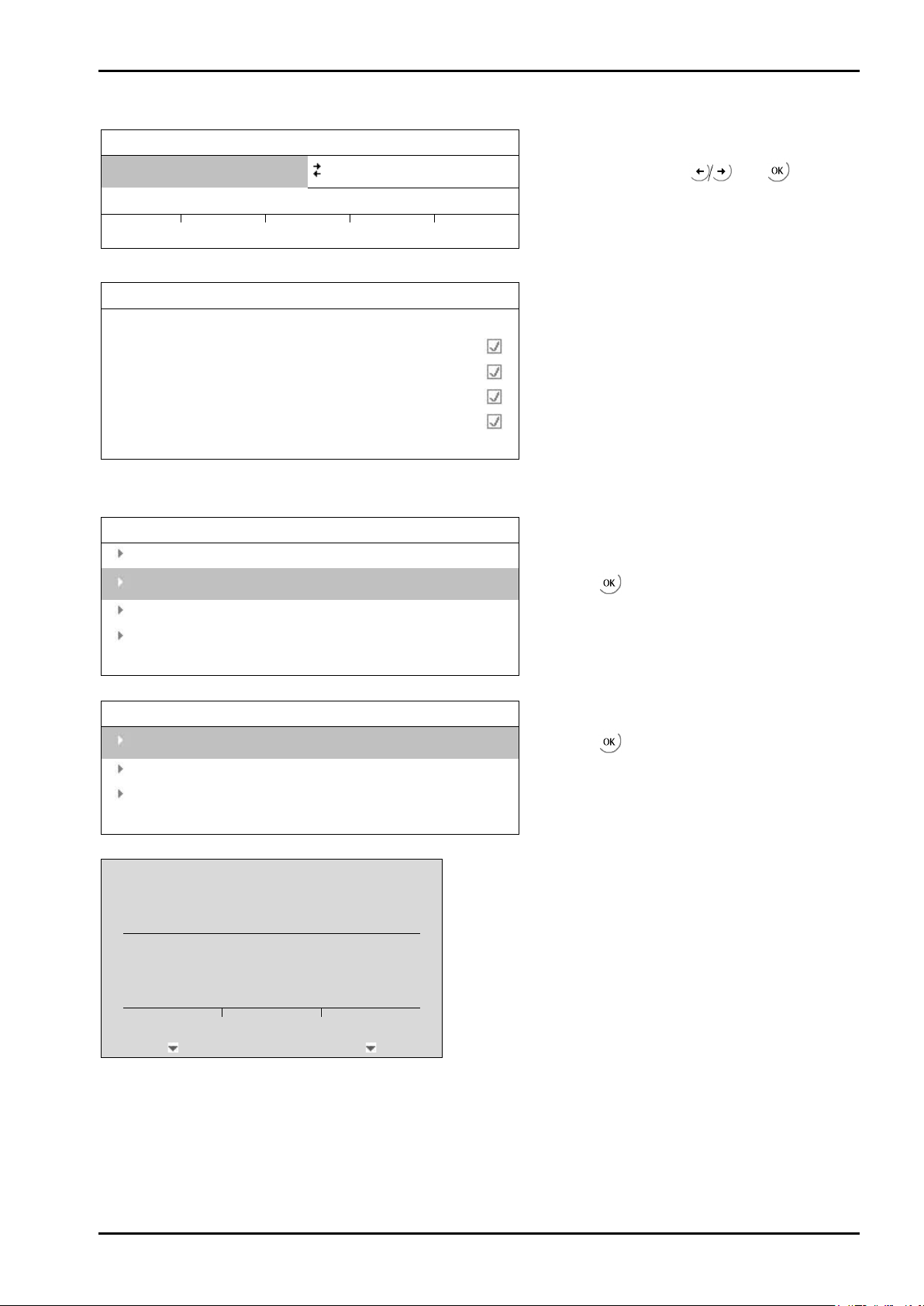

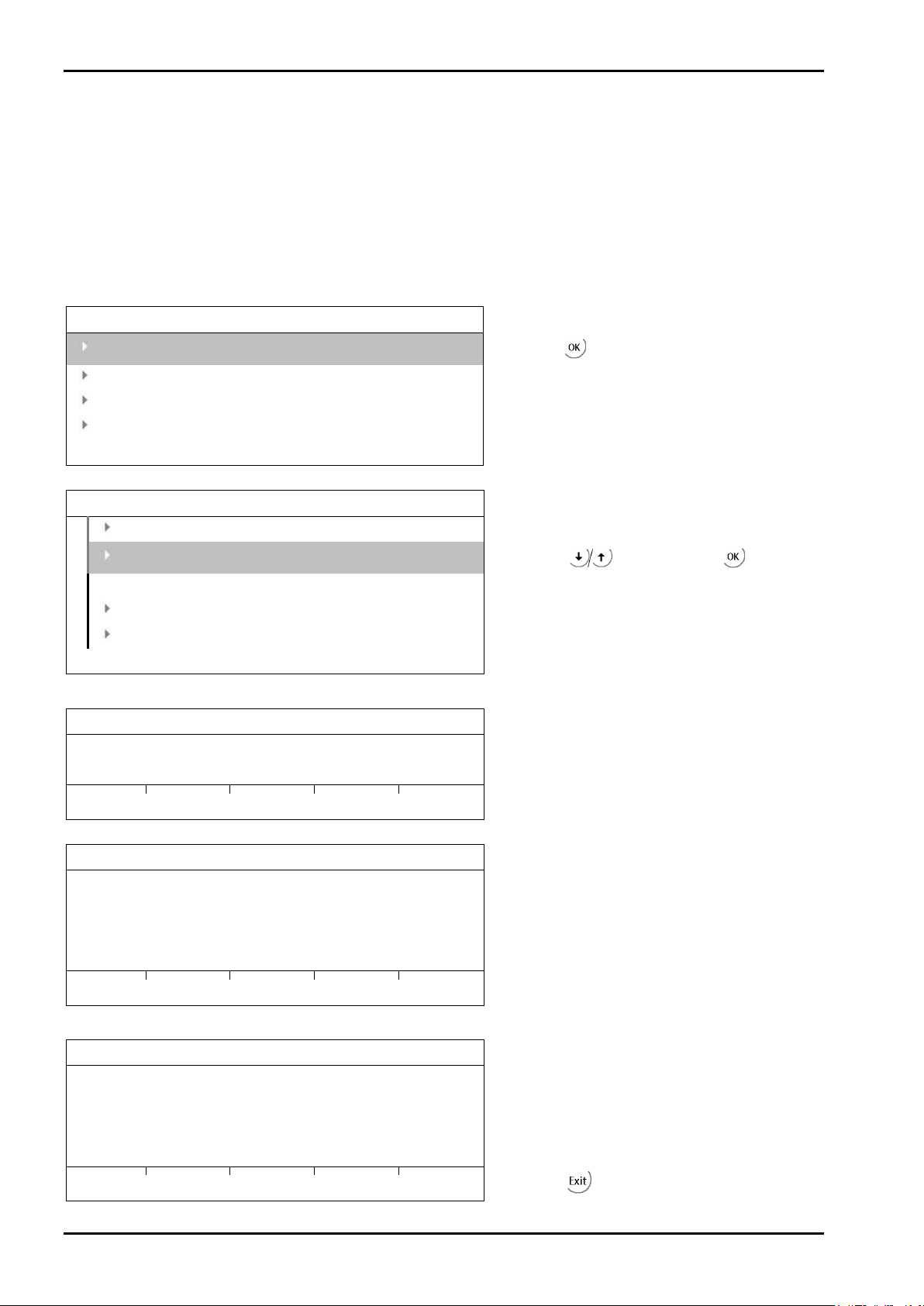

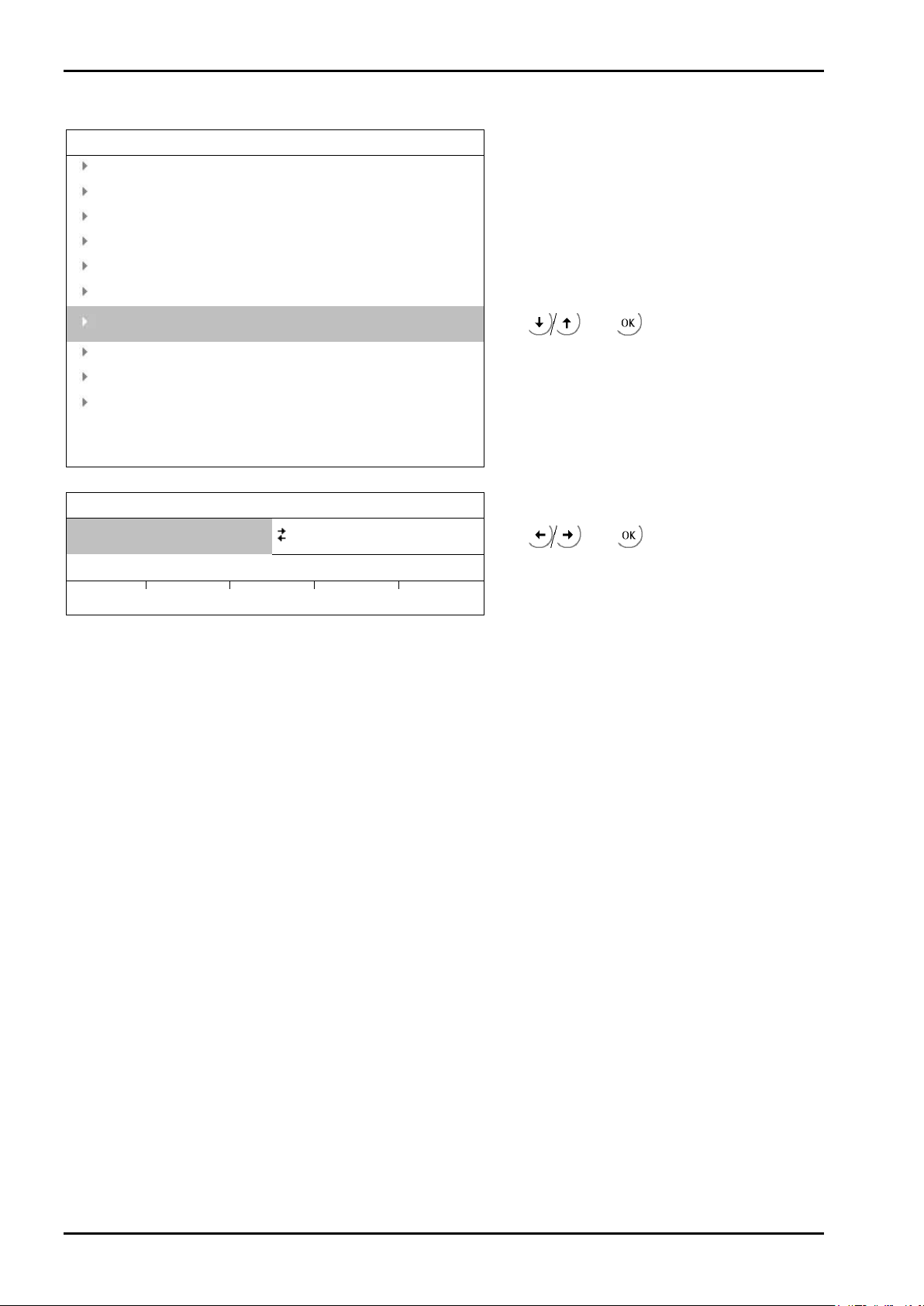

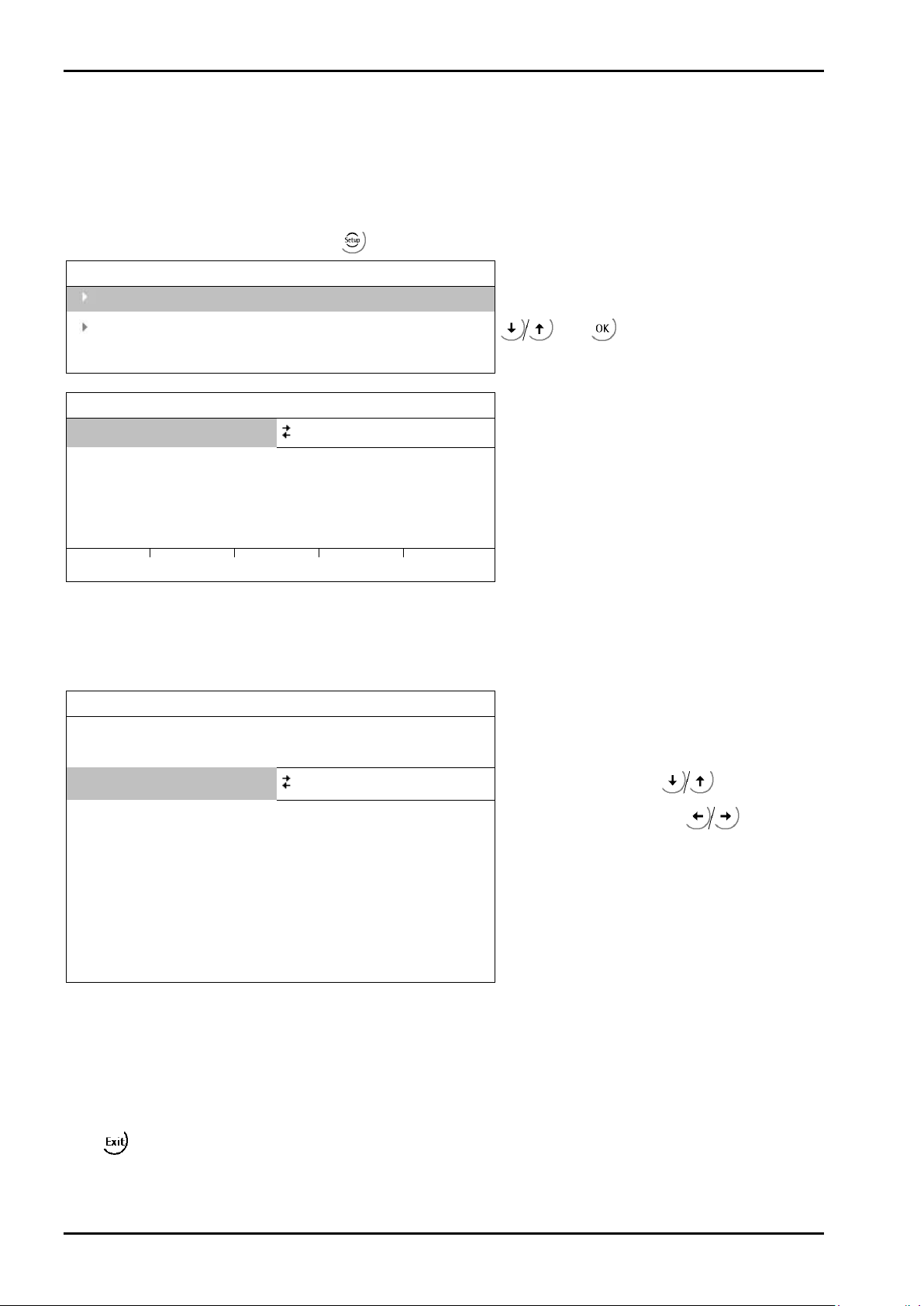

2.5.2.5 Selection Using the Navigation Keys

Press to scroll down, or to scroll up in a menu.

PR 5220 Instrument Manual

Press

Press

An arrow

pressing

If the list of menu items is long, a vertical bar graph on the left (black and gray) shows which part of the list is

displayed.

to select a menu item. To select the desired setting for the selected menu item, press .

to exit the menu and continue the operation on the next higher level.

in front of a menu item indicates that there are menu sublevels. The menu item selected by

is shown inversely.

Show version

Measuretime

320 ms

Press

to select an item.

Availability of additional settings options selectable with is indicated by preceding double arrows .

Measuretime

640 ms

Press

to select the measuring time.

EN-18 Sartorius

PR 5220 Instrument Manual Ethernet Transmitter Series

2.6 Overview of Connections

Sartorius EN-19

Installing the Instrument

Connection

Remote operation of the instrument from the notebook/PC is

PR 5220 Instrument Manual

3 Installing the Instrument

• Before starting work, please read Chapter 1 and follow all instructions.

Further procedures:

• Check the consignment: unpack the components specific to the application.

• Safety check: inspect all components for damage.

• Make sure the on-site installation is correct and complete including cables, e.g. power cable fuse

protection, load cells, cable junction box, data cable, console/cabinet, etc.

• Follow the instructions for installation of the unit relating to application, safety, ventilation, sealing and

environmental influences.

• Connect the cable from cable junction box or platform/load cell.

• If applicable: connect other data cables, network cables, etc.

• Connect the instrument to the supply voltage.

• Check the installation.

3.1 Connections

3.1.1 Network Port

The network port is built in as standard equipment. The port contains powerful TCP/IP connection circuitry

with transfer rates of 10 or 100 Mbit/sec. The LEDs on the connector (RJ-45) indicate whether the port is

functioning.

Transfer rate

Connection method

Cable

Cable impedance

Electrical isolation

possible; install VNC program version 3.3.7* on the

notebook/PC. For setting the network address, see

Chapter

* Sartorius guarantees the functionality only if this version is

used!

10 Mbit/sec, 100 Mbit/sec,

full/half duplex, auto-detection

Point to point

CAT 5 patch cable, shielded twisted pair

150 ¥

yes

RJ-45 socket on top of housing

4.3.3.

EN-20 Sartorius

PR 5220 Instrument Manual Installing the Instrument

3.1.2 RS-485 Interface

The interface is intended for connecting a remote display, a PC for data transmission using the SMA protocol

or scale/terminal/digital load cells, type Pendeo for data transmission using the xBPI protocol.

Connection method

Number of channels/type

Transfer rate (Bits/s)

Bits/stop bits

Parity

Signals

Electrical isolation

Cable length

Cable type

<...> = default settings (factory settings)

4-pin plug-in terminal block

1 RS-485, full/half duplex

300, 600, 1200, 2400, 4800, <9600>, 19200

<8/1> or 7/1

<even>, <odd>, <none>

RxA (R-), RxB (R+), TxA, TxB

yes

max. 1000 m

Shielded twisted pair (e.g. LifYCY 2x2x0.20)

Sartorius EN-21

Installing the Instrument

Note:

ON:

S1, S2, S3

ON:

S2

OFF:

S4, S5

OFF:

S1, S3,

S4 is not relevant!

PR 5220 Instrument Manual

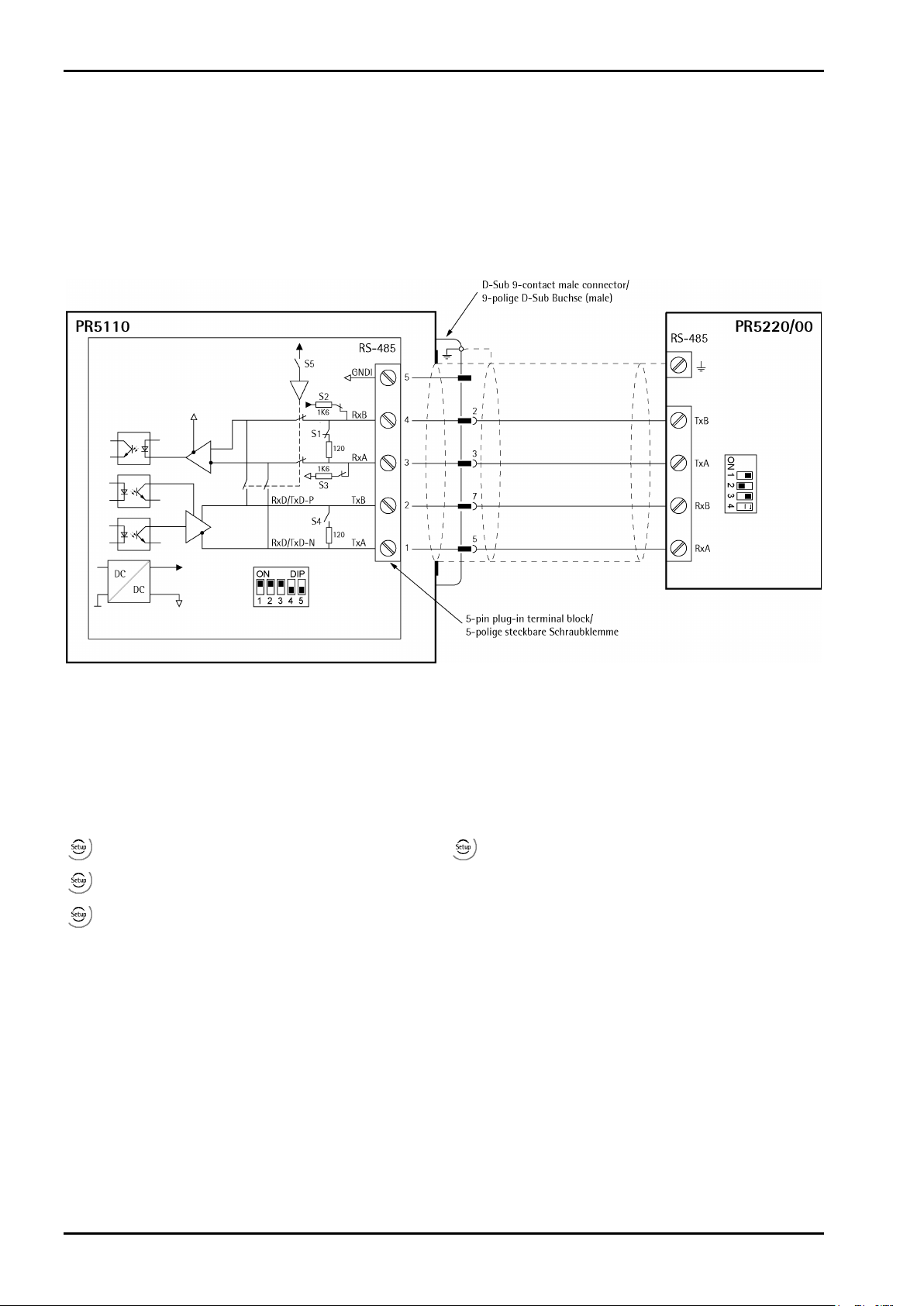

3.1.2.1 Connecting of a PR 5110 Remote Display

Four-wire transmission, point to point, full duplex (simultaneous sending and receiving possible) with

PR 5110 remote display.

When replacing PR 1627/PR 1628 with PR 5110, note that the pin assignment must be

attended, see Chapter 16.1.

Description see instrument manual PR 5110.

Switch settings Switch settings

Configuration PR 5110 Configuration PR 5220/00

- - –

- [Serial ports parameter]-[Remote display][Builtin RS485]

- – -

[Param]: [Mode]-[single transmitter]

- – -

The following operations are possible from the connected remote display:

- Switch over to another weighing point

- Indicate current value type

- Set tare

- Reset tare

- Set zero

- Start Print

EN-22 Sartorius

PR 5220 Instrument Manual Installing the Instrument

ON:

S1, S3

OFF:

S2 S4 is not relevant!

ON:

S1, S3

OFF:

S2 S4 is not relevant!

3.1.2.2 Connection of a xBPI Platform

Switch settings

Configuration PR 5220

-[Serial ports parameter]-[xBPI-Port]-[Builtin RS485]

3.1.2.3 Connection of a xBPI terminal

Switch settings

Configuration PR 5220

Sartorius EN-23

-[Serial ports parameter]-[xBPI-Port]-[ Builtin RS485]

Installing the Instrument

ON:

S1, S3

OFF:

S2 S4 is not relevant!

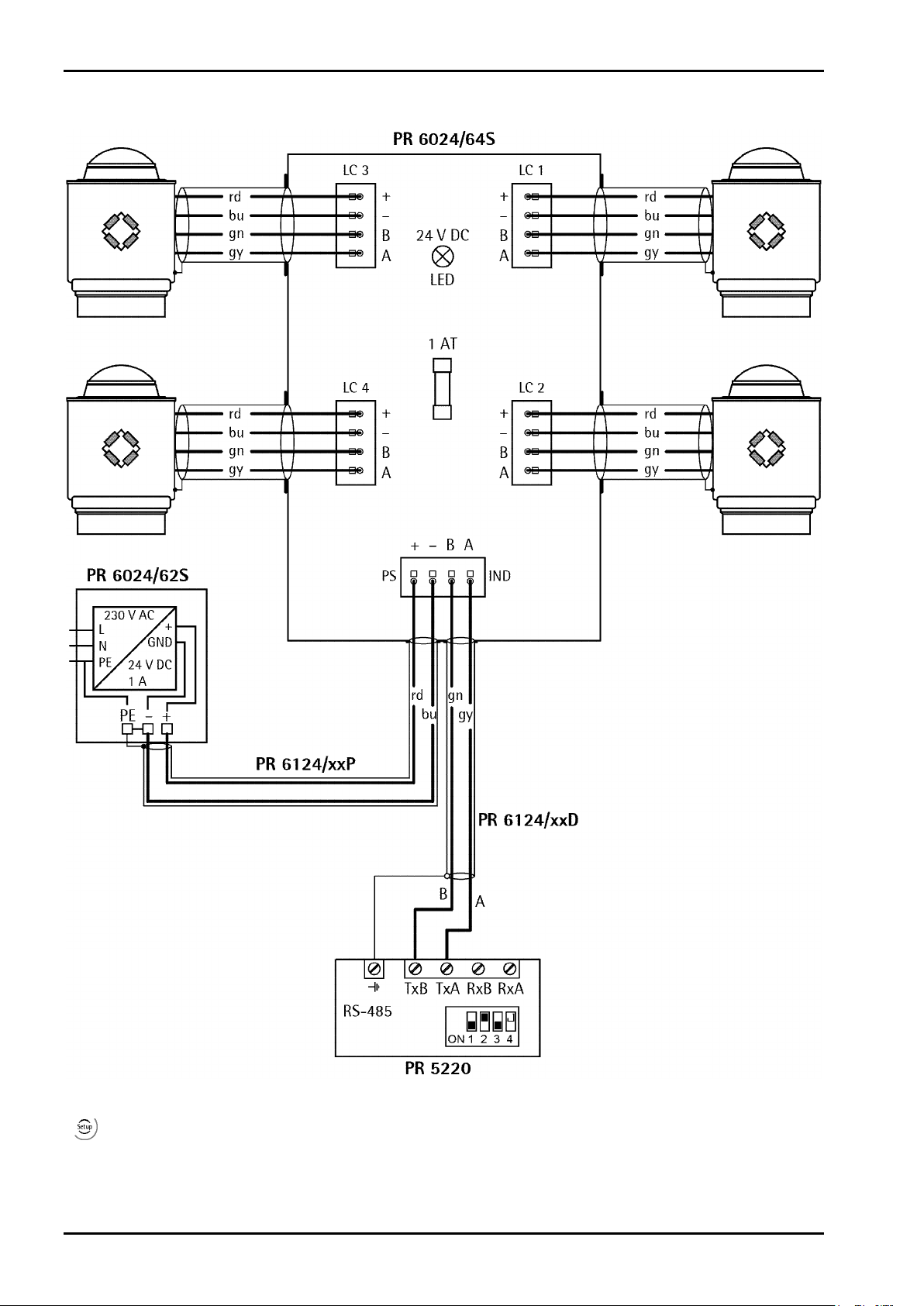

3.1.2.4 Connecting 4 Digital Load Cells Type ‚Pendeo®‘

PR 5220 Instrument Manual

Switch settings

Configuration PR 5220

-[Serial ports parameter]-[xBPI-Port]-[ Builtin RS485]

EN-24 Sartorius

PR 5220 Instrument Manual Installing the Instrument

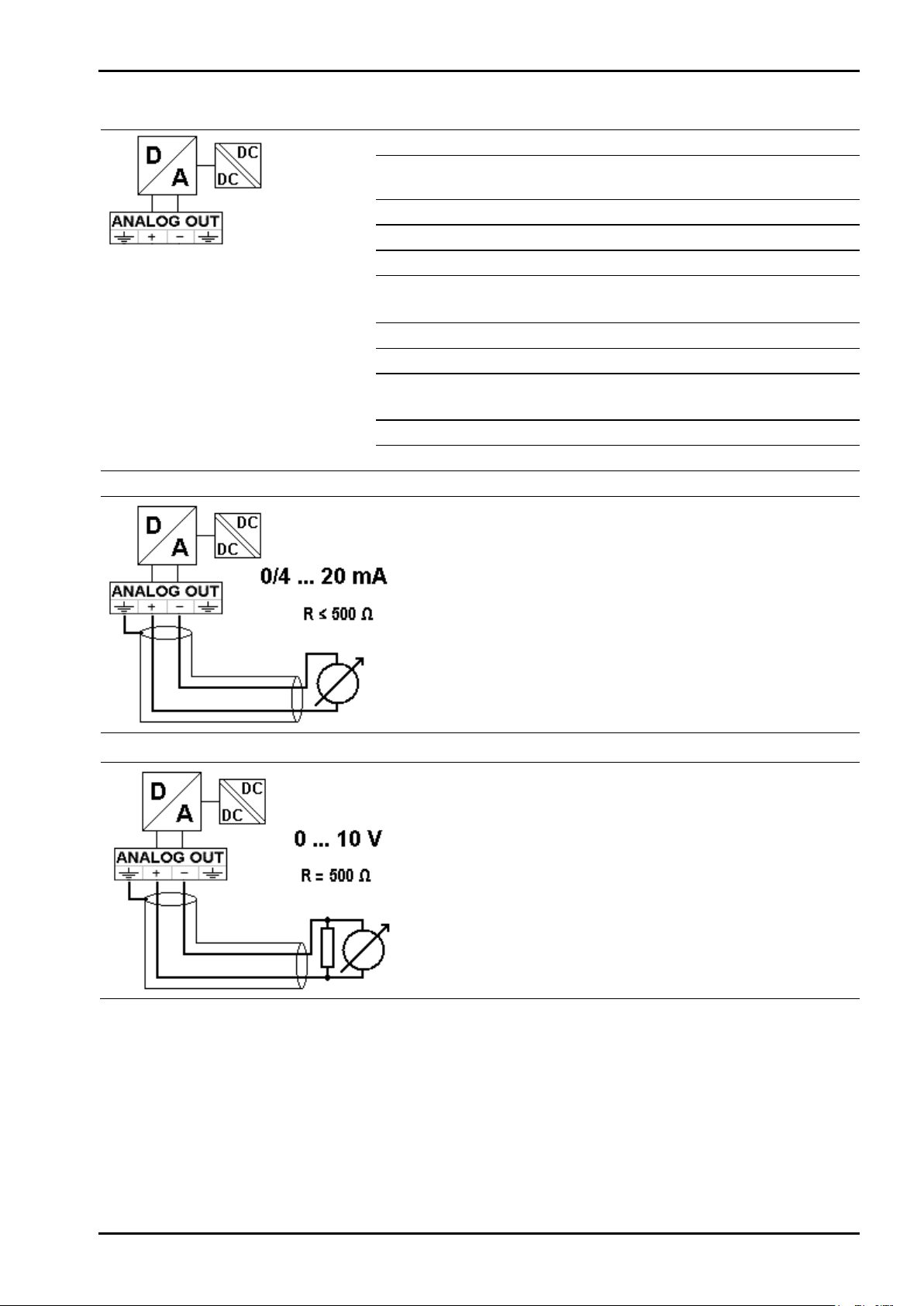

3.1.3 Analog Output

Connection method

Number of outputs

Output

Range

Resolution

Linearity error

Temperature effect

Load

Protected against short

circuit

Electrical isolation

Cable length (shielded)

4-pin plug-in terminal block

1 current output,

output voltage via external resistor

Gross, net weight or via ProfiBus

0/4 ... 20mA, configurable

e.g. 0 - 20 mA in max. 40,000 counts

@ 0 - 20mA: <0,05 %

@ 4 - 20 mA: <0,025 %

<100 ppm/K

0 ... max. 500 ¥

yes

yes

150 m (current output)

0/4…20mA

Analog signal,

current output

The current is supplied directly via

the terminals.

0…10V

Analog signal,

voltage output

The voltage level corresponds to the

voltage drop across the 500 ¥

(10 ppm/K) resistor.

Sartorius EN-25

Installing the Instrument

PR 5220 Instrument Manual

3.1.4 Optocoupler Inputs

The 3 optocoupler inputs have one common potential (GND) for the input group that is separated from the

common potential of the output group.

Example: contact input connection

Connection method

Cable

Number of outputs

Input signal

Input voltage

Input current

Electrical isolation

When a voltage ≥10 V DC is applied to the terminals (in the

example:1-GND), input 1 is active (true).

4-pin plug-in terminal block

Shielded, max. 50 m

3

External supply required

10…28 V DC for 'high' level

0…5 V DC for 'low' level

Max. 28 V DC

<11 mA @ 24 V DC

<5 mA @ 12 V DC

Yes; a common minus potential for the group

of 3 inputs

EN-26 Sartorius

PR 5220 Instrument Manual Installing the Instrument

When output 1 is active (true), the relay switches.

When output 1 is active (true), the output voltage

3.1.5 Optocoupler Outputs

The 3 optocoupler outputs have one common potential (GND) for the output group that is separated from the

common potential of the input group.

Example: relay control connection

Connection method

Cable

Number of outputs

Output signal

Output current

Output voltage

Electrical isolation

For protection of the output circuit, relays with

free-wheel diode must be provided.

4-pin plug-in terminal block

Shielded, max. 50 m

3

External supply required

Max. 30 mA

Max. switching voltage: 28 VDC

Yes; a common minus potential for the group

of 3 outputs

Example: voltage output connection

changes from 24/12 V DC into <3 V DC.

A load resistance of 2.2/1 k¥ must be provided.

Sartorius EN-27

Installing the Instrument

The cable colors shown in this chapter are applicable to the Sartorius PR 62XX series load cells.

PR 5220 Instrument Manual

3.1.6 Load Cell Connection

Before connecting other types, carefully follow the information related to the assignment of

load cell/platform cable colors.

• The distance between the measuring cables and the power cables should be at least 1 m.

• The measuring cables should be laid in separate cable conduits or steel pipes connected to earth potential.

• Power cables should be crossed at right angles.

Load cell supply circuit

The load cell supply voltage is fixed to 12 V DC and protected against short circuit.

Load resistance of load cells ≥75 ¥, e.g. 8 load cells of 650 ¥ each.

3.1.6.1 Connection Using 6-Wire Technology

See also label on the housing outside (Chapter 2.3) and manual of the junction box.

Terminal Description

SIGN. M+

SIGN. MSENSE S+

SENSE SLC SUPPLY V+

LC SUPPLY V-

+ signal/LC output

- signal/LC output

+ sense

- sense

+ supply/excitation

- supply/excitation

3.1.6.2 Connection of a Load Cell in 4-Wire Technology

Note that links between SENSE S+ and LC SUPPLY V+ and between SENSE S- and LC SUPPLY V- directly at the

transmitter must be provided.

Terminal Description

SIGN. M+

SIGN. MSENSE S+

SENSE SLC SUPPLY V+

LC SUPPLY V-

+ signal/LC output

- signal/LC output

+ sense

- sense

+ supply/excitation

- supply/excitation

3.1.6.3 Connecting PR 6221 Load Cells

See installation manual PR 6221 and PR 6021/08, -/68.

EN-28 Sartorius

PR 5220 Instrument Manual Installing the Instrument

Testing the Measuring Circuit

A simple test with the load cells connected can be carried out with a multimeter

(not with external supply or intrinsically safe load cell interface):

Supply voltage

12 V ±0,8 V

(symmetrical to housing GND)

Sense voltage

12 V ±0,8 V

(symmetrical to housing GND)

Measuring voltage

Measuring voltage

0 - 12 mV @ WZ mit 1,0 mV/V

0 - 24 mV @ WZ mit 2,0 mV/V

0 V ±0,5 V

Sartorius EN-29

Installing the Instrument

PR 5220 Instrument Manual

3.1.6.4 External Load Cell Supply

The internal load cell supply voltage of PR 5220 (V+, V-) is not connected.

The common line of the symmetrical external supply must be connected to the same terminal of PR 5220 as

the shield of the load cell/extension cable.

Specification of external supply: ±6 V DC +5 %, -30 %; max ripple. 50 mVpp; max. asymmetry ±3 %.

An external supply voltage smaller than 8 V DC (±4 V DC) must be set under

[Calibration]-[Param]-[External supply].

-[Weighingpoint]-[WP A]-

3.1.6.5 Connection via Intrinsically Safe Interface PR 1626/60

Connect the instrument to PR 1626/60 as described below. For additional connections, refer to the PR 1626/60

instrument manual. The internal load cell supply voltage of PR 5220 (V+, V-) is not connected.

Note:

If MX8 is closed in PR 1626/60,

[below 8 V DC] must be set under

-[Weighingpoint]-[WP A]-[Calibration]-

[Param]- [External supply].

EN-30 Sartorius

PR 5220 Instrument Manual Installing the Instrument

Platform with 6-wire connection

Platform with 4-wire connection

Platforms with 4-wire connection require following

Caution!

3.1.7 Connecting Analog Platforms (CAP...)

One Combics analog platform (CAP... series) can be connected to the instrument.

The following example shows a platform with 6-wire connection and another one with 4-wire connection.

links:

- between +V and +S

The cable colors shown above are valid for a CAPP4 500 x 400 and a CAPP1 320 x 420,

as an example.

The assignments of cable colors are given in the platform operating manual.

Pin allocation Combics 1…3-instruments Pin allocation PR 5220

BR_POS V+ LC SUPPLY

SENSE_POS S+ SENSE

OUT_POS M+ SIGN.

OUT_NEG M- SIGN.

SENSE_NEG S- SENSE

BR_NEG V- LC SUPPLY

Connect the cable screens with the ground terminal of the instrument. If the measuring leads (+M, -M) are

screened individually, these screens must also be connected to the ground terminal (see also Chapter 1.4.7).

- between –V and –S

Sartorius EN-31

Installing the Instrument

3.1.8 Connecting xBPI Platforms (IS...)

One xBPI platform (IS... series) can be connected to the instrument.

PR 5220 Instrument Manual

Connection to a RS-485 interface, see Chapter 3.1.2.2.

3.1.9 Connection of Digital Load Cells

Digital load cells can be connected to the device via xBPI port and RS-485 interface.

Connection to an RS-485 interface, see Chapter 3.1.2.4.

EN-32 Sartorius

PR 5220 Instrument Manual Installing the Instrument

3.1.10 ProfiBus Interface (PR 5220/01 only)

Communication protocols and syntax comply with the ProfiBus-DP standard to IEC 61158 with transfer rates

up to 12 Mbit/s.

Transfer rate

Protocol

Configuration

Cable

Cable impedance

Certificates

Electrical isolation

Cable length

Connection to the ProfiBus is using the 9-contact plug-in socket on the front panel.

9.6 kbit/s to 12 Mbit/s,

baud rate auto-detection

PR OFIBUS-DP-V0 slave

to EN 50 170 (DIN 19245),

mono or multi-master systems are

supported. Master and slave devices,

max. 126 nodes possible.

Watchdog timer

GSD file (‚SART5220.gsd’ stored on the

CD in directory ‘Fieldbus’)

Special ProfiBus color: violet

Shielded twisted pair cable

150 ¥

ProfiBus test center Comdec in

Germany and PNO (ProfiBus User

Organization).

Suitable for industrial applications to

CE, UL and cUL

Optocoupler in lines A and B (RS-485)

Max. distances 200 m can be extended

with 1.5 Mbit/s by means of additional

repeater

The transmitter is the only

or last slave on the bus

The transmitter is not the only

or last slave on the bus

PIN Signal

3

4

5

6

8

RxD/TxD-P

CNTR-P

DGND

VP

RxD/TxD-P

Sartorius EN-33

Installing the Instrument

PR 5220 Instrument Manual

3.1.11 DeviceNet Interface (PR 5220/04 only)

It is a complete DeviceNet adapter (SLAVE) with CAN controller and transfer rates of up to 500 kbit/s.

Connection

Transfer rate

Topology

Protocol

Configuration

Certificates/

conformity

Cable

Cable impedance

Bus termination

Bus load

Electrical isolation

5-contact screw terminal block (plug-in)

125, 250 and 500 kbit/s

Parallel bus

DeviceNet master/slave

Polling method (polled I/O)

CRC error detection

to IEC 62026 (EN50325)

Max. 64 station nodes

Max. data width 512 bytes input & output

EDS file (‚sag_5220.eds’ stored on the CD in

directory ‘Fieldbus’)

MAC-ID (1…62)

Compatible with DeviceNet specification

Vol 1: 2.0, Vol 2: 2.0

ODVA certificate in accordance with

conformity test software version A-12

Suitable for industrial applications to CE,

UL and cUL

DeviceNet, color: petrol-green

2x 2 shielded twisted pair

150 ¥

120 ¥ at the cable ends

30 mA @ 24 V DC

Yes, optocoupler and DC/DC converter

Connecting diagram for a master with three slaves

EN-34 Sartorius

PR 5220 Instrument Manual Installing the Instrument

W

3.1.12 ProfiNet I/O Interface (PR 5220/06 only)

It is a complete ProfiNet I/O interface (SLAVE). It contains a powerful UDP/IP connecting circuitry with transfer

rates of 10 and 100 Mbits/s.

Note:

Connection

Transfer rate

Connection mode

Protocol

Configuration

Certificate

Cable

Cable impedance

Potential isolation

Recommendation for e.g. Siemens S7

Fieldbus slave setting:

Use DHCP [on] as default and activate the master as a DHCP server

(

[assign IP Adr via IO controller]).

RJ-45 connecting socket

10 Mbit/sec and 100 Mbit/sec

Autodetection (10/100, HalfDX/FullDX)

Network

ProfiNet I/O

XML file (‚GSDML-xxx-Sartorius-PR5220-

xxx.xml’ stored on the CD in directory

‘Fieldbus’)

ProfiBus Nutzerorganisation e.V.

for HMS Industrial Networks AB

Certificate no.: Z10006

Report: PN005-1, 12.02.2007

Twisted pairs, screened,

e.g. patch cable CAT5

Autolink (straight oder crossover

150 ¥

Yes

Slave – master device names

A unique device name must be assigned out of the master. This name is given highest priority

when establishing the communication.

When changing instruments/servicing, please note:

Apart from the IP address, the device name must correspond to the one of the replacement

device. Explicit assignment out of the master is required.

Example:

Sartorius EN-35

Installing the Instrument

PR 5220 Instrument Manual

3.1.13 EtherNet-IP Interface (PR 5220/07 only)

It is a complete EtherNet-IP adapter (SLAVE). It contains a powerful TCP/IP and EtherNet-IP connecting

circuitry with transfer rates of 10 and 100 Mbits/s.

Connection

Transfer rate

Network Connection mode

Protocol

Configuration

Certificates/

conformity

Cable

Cable impedance

Electrical isolation

RJ-45 connecting socket

10 Mbit/sec and 100 Mbit/sec

Autodetection (10/100, HalfDX/FullDX)

EtherNet-IP

EDS file (‚sag_5220_ethernetip.eds’ stored

on the CD in directory ‘Fieldbus’)

ODVA für HMS Industrial Networks AB

Product code: 99

Product name: Anybus-CC EtherNet/IP

SOC file name: ABCC_EIP_205_2.stc

17.04.2009

Twisted pairs, screened,

e.g. patch cable CAT5

Autolink (straight oder crossover)

150 ¥

Yes

EN-36 Sartorius

PR 5220 Instrument Manual Commissioning

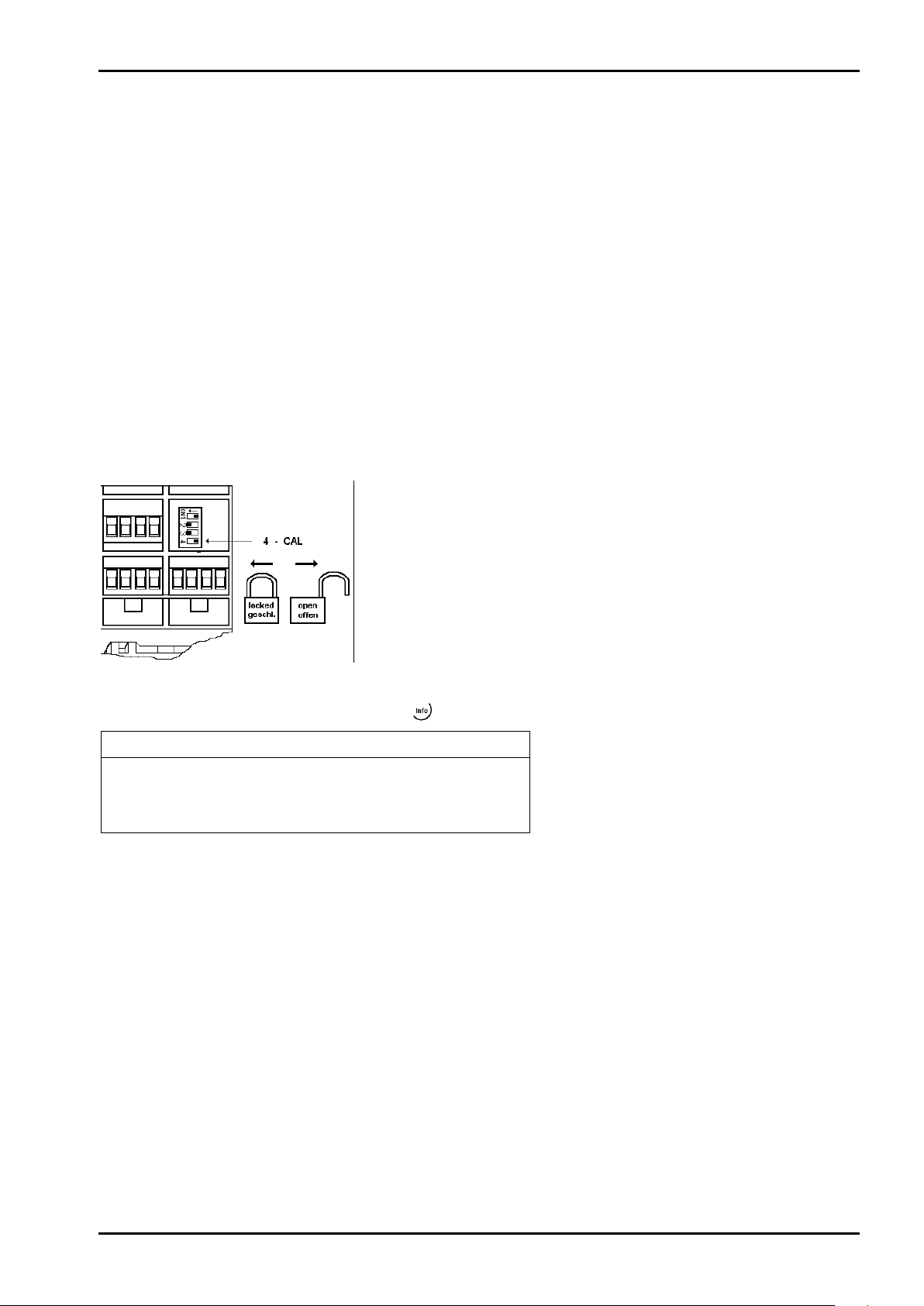

The CAL switch is located under a cover that can be opened by means

Info/Status

Free system RAM

4128 of 15184 kb

Cal-Switch

opened

[opened] = opened; no write protection

[closed] = closed; write protection is active

4 Commissioning

The meaning of indicator LEDs is described in Chapter 2.5.

4.1 Data Backup/Power Failure

The calibration data and parameters as well as all configuration and interface data are stored in a

non-volatile (EAROM) memory. Unauthorized data changing can be prevented by an access code. Additional

write protection is provided for calibration data and parameters (CAL switch, see Chapter 4.1.1).

In case of power failure, all entered data and parameters remain unchanged.

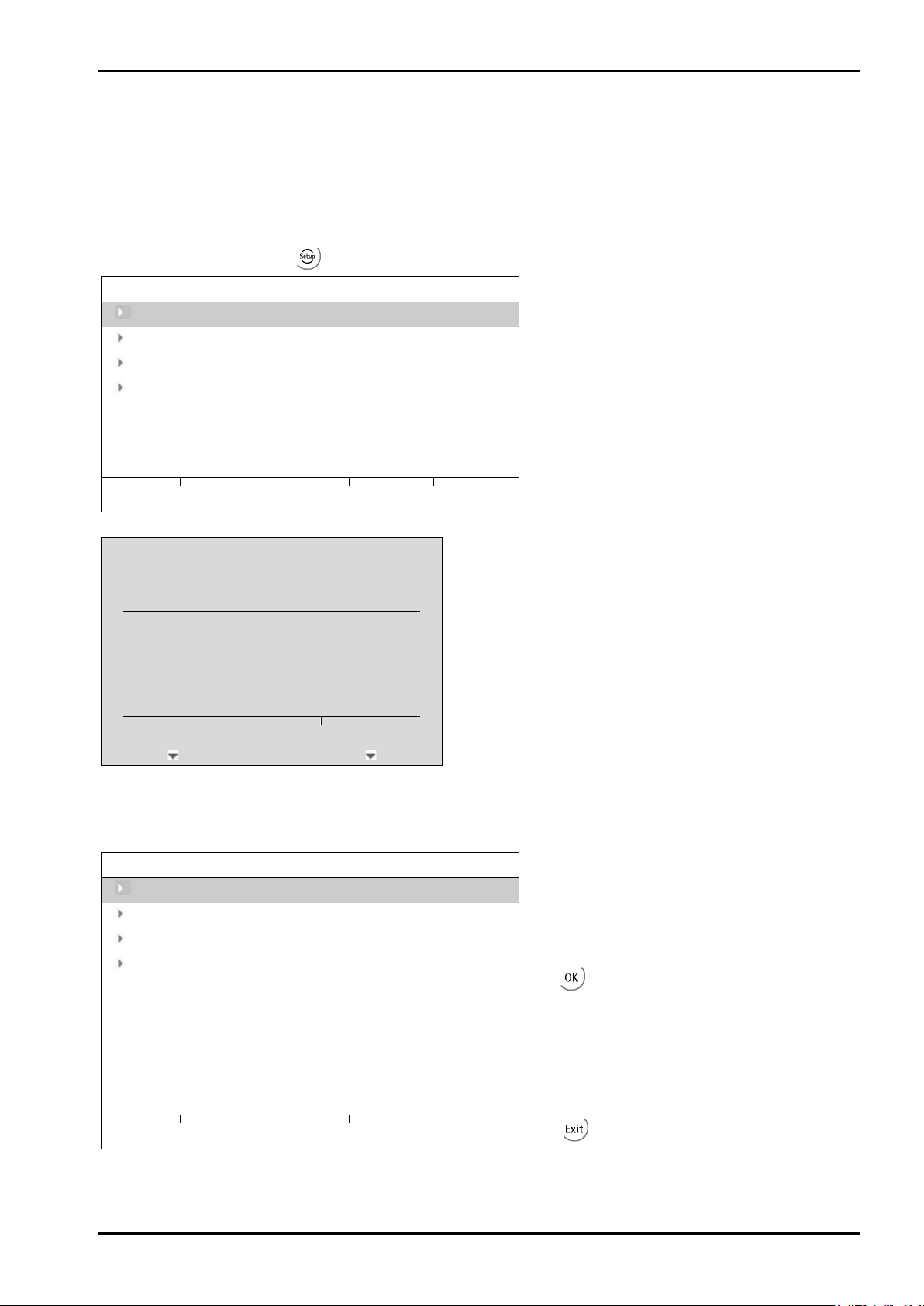

4.1.1 CAL Switch

The CAL switch protects the calibration data and parameters against unauthorized access.

When the CAL switch is in 'open' position, the calibration data and parameters can be changed using the

PC program or via the ProfiBus connection.

With the CAL switch in the 'closed' position, the calibration data (e.g. dead load, Span) and Parameters (e.g.

measure time, zero tracking etc.) cannot be changed.

of a knife.

For ’legal-for-trade’ applications, set the CAL switch (4) to the left

position (ON) and seal the cover.

To view the position of the CAL switch, select

-[Show status]:

Sartorius EN-37

Commissioning

PR 5220 Instrument Manual

4.1.2 Factory Settings

Calibration data <default> Calibration data <default>

Full scale (Max) <3000> <Kg> Measure time (M) <320>ms

Scale interval <1> Measuring rate <160>ms

Dead load <0.000000>mV/V Standstill time <1>M

Span <1.000000>mV/V Standstill range <1.00>d

Tare timeout <8>M

Calibration parameters <default>

Overload (range above Max) <9>d Zero-setting range <50.00>d

* W & M mode <off>

Filter <off> Zero-tracking step <0.25>d

Frequency <1.56 Hz> Zerotrack repeat <0>M

* Parameter W&M must be set to 'on' or 'off' prior to input of the calibration data, see Chapter 4.4.13.1.

.

<Absolute> test mode

Zero-tracking range <0.25>d

4.2 Switching on the Instrument

The instrument can be put into operation and calibrated using a notebook/PC with the VNC program (on the

CD packed with the instrument) and an Internet Browser.

4.3 Configuration and Calibration

There are following possibilities:

- with VNC viewer (on the enclosed CD-ROM), see Chapter 4.3.4

- with an Internet Browser (‚Microsoft InternetExplorer’ or ‚Mozilla Firefox Webbrowser’), see Chapter 4.3.5.

The prerequisite is an installed and activated Java (Sun) ’applet’.

4.3.1 Connecting the Device to the Network and Finding out the IP address

The DHCP server is active in the network

An IP address is assigned to the device automatically.

The DHCP server is not active in the network

If the device is connected to a notebook/PC via a point-to-point connection, an IP address is negotiated via

function ‘AutoIP’. This can take up to 2 minutes!

IndikatorBowser

The IP address can be found out using the ‘IndicatorBrowser’ (supplied on CD-ROM) and via the ‘host name’ of

the device (see also Chapter 4.3.3). The ‘host name’ is composed of the device name and the last 3 bytes of the

MAC ID. A label with the complete MAC ID is fitted inside the door of the instrument.

Hostname: PR5220-6B6A5E

EN-38 Sartorius

PR 5220 Instrument Manual Commissioning

1. Click ‘Start’ -> ‘Control Panel’ -> ‘System’.

3. Double-click the icon for the network

UPnP view with Microsoft Windows XP

The IP address can be found out also using the ‘Microsoft InternetExplorer’ under ‘Network’, if the ‘UPnP’ view

is switched on (default: off).

Procedure:

The display shows:

Note:

At least ‘Service Pack 2’ or higher must be installed.

environment on the ‘desktop’.

The display shows:

2. Click ‚OK’.

4. Click menu item ‘Tools’ -> ‘Folder Options…’.

Sartorius EN-39

Commissioning

8. Click ‚Yes’.

The display shows:

5. Click item ‘Show common tasks in folders’.

PR 5220 Instrument Manual

6. Click ‚OK’.

7. Click item ‘Show icons for networked UPnP

devices’ in window ‘Network Tasks’ under

The display shows:

‘My Network Places’.

EN-40 Sartorius

PR 5220 Instrument Manual Commissioning

9. Click the relevant icon with the right mouse key and select

The instrument can be reset using a pin with a diameter of 1.0 mm (e.g.

The icons for the devices are displayed.

menu item ‘Properties’.

10. Read the IP address.

UPnP view with Microsoft Windows 7

The device icons are displayed automatically under ‘Network’.

4.3.2 Resetting the Instrument/Activating Network'DHCP'

paper clip).

The instrument is re-started by a short-time actuating of the reset switch (function like switch-off/-on).

Pressing the reset switch during a long time (wait until the 3 upper LEDs are lit simultaneously) resets the

network settings to default/factory settings.

That means:

- 'DHCP' is activated.

- ‚Host name’ is initialized e.g. PR 5220-6B6A5E (instrument type -MAC-ID).

Example of MAC ID: 00-90-6C-6B-6A-5E

This ensures that a valid address for identification of the instrument in the network can be assigned to the

instrument, see Chapter 4.7.4.

Note:

The last 3 bytes of the MAC ID are displayed. A label with the complete MAC ID is fitted to the

outside of the device.

An device set to ’on’ DHCP (default/factory setting) and connected to an IT network (company

network) with a DHCP server does not require further actions except for a 2...3-minute waiting

time. Subsequently, a network connection is established automatically (device <->

workstation/PC).

Sartorius EN-41

Commissioning

Temporarily connected PCs must have the following network adaptor properties (DHCP/DNS automatic):

PR 5220 Instrument Manual

PR 5220 can be operated only, if a notebook/PC is connected!

For commissioning, the first network contact is possible only by finding the IP address/subnet mask under

DHCP ’on’ (factory setting) automatically.

4.3.2.1 MAC ID

The MAC ID or (6-digit) hardware address, e.g. 00-90-6C-6B-6A-5E is a unique number for identification of

any network adaptors.

A label with the complete MAC ID is fitted outside the instrument.

Due to the last 3 bytes, the initialized host name is always unique.

EN-42 Sartorius

PR 5220 Instrument Manual Commissioning

Caution!

4.3.2.2 DHCP

Normally, DHCP servers are provided only in IT-supported company networks and not on locally (directly)

connected notebooks/PCs or notebooks.

Nevertheless, ’DHCP’ must be activated on the notebooks/PC. The ’DHCP’ devices find each other because they

fall into a so-called auto-IP address in the range 169.254.0.1…169.254.255.254 with the associated autosubnet mask 255.255.0.0 after a cyclical automatic ’DHCP’ server search run due to time overflow

(2…3 minutes).

When connecting the IT/DHCP network cable temporarily from the PC to a device, the

DHCP server is lost and the PC returns to the auto-IP address within approx. 2 minutes.

Reason: The DHCP server/client relationship is checked cyclically in 2…3-minute intervals.

Example

If the search time is exceeded (due to the result ’no server found’), the PR 5220 is provided with an IP address

(e.g. 169.254.0.123) automatically. The same applies to the notebook/PC (e.g. 169.254.0.54). These IP addresses

are different on both sides:

- equal regarding the first 3 octets of the IP address (e.g. network ID 169.254.)

- different in the last 2 octets of the IP address (e.g. host ID 0.123.)

4.3.2.3 Host Name (device name)

With DHCP applications, this must be a unique name.

If own names are defined (host name is editable)

- the same host name must not exist twice within the network ID.

Correct is e.g. host name device 1: PR 5220 scale1, device 2: PR 5220 scale2

Always correct is the ’default’ with PR 5220-8BB499, whereby the last 3 bytes of the MAC-ID are unique.

- there is a limitation to 2…24 characters.

Permitted are

- letters A…Z, a…z

- digits 0…9, which must not be the first or last character

- character "-", which must not be the first or last character

Sartorius EN-43

Commissioning

PR 5220 Instrument Manual

4.3.3 Searching the Instrument in the Network Using 'IndicatorBrowser'

The address can be determined using the 'IndicatorBrowser' program (on the enclosed CD-ROM).

Install and start the 'IndicatorBrowser'.

The ’IndicatorBrowser’ searches within the current

network ID, e.g. 169.254. and 172.24., on all available

network adaptors in the PC (several

possible/recommended, e.g. LAN global/LAN local)

Result:

List of all connected devices with status:

search??? – online - byebye – lost???

Click the button to open the ’standard’

Internet Browser, e.g. Microsoft InternetExplorer,

directly with the marked IP address.

Click the button

to re-start the network search run.

Waiting 2…3 minutes is essential!

Acoustic signal for each device that was found

’online’.

Click the button to localize the associated device.

Short-term visual response of the device:

Regular running light in LED 1, 2, 3.

If the browser window remains empty after a minimum waiting time, or if the expected device is not listed, the

network ID of the local notebook/PC must be checked and changed, if necessary!

Note:

Only certain Sartorius devices are supported by the ’IndicatorBrowser’!

EN-44 Sartorius

PR 5220 Instrument Manual Commissioning

Caution!

The address range of the controlling

Instead of the VNC viewer, the web browser, e.g. Microsoft InternetExplorer, ‚Mozilla Firefox

4.3.4 Operation Using the VNC Program

VNC (on the enclosed CD-ROM) stands for 'virtual network computing' and is a program for remote operation

of computers.

The program distinguishes between the VNC server and VNC client (viewer). The server program is part of the

instrument software. The client program (viewer) must be executed on the notebook/PC to be used for

operating the instrument.

The VNC version provided on CD must be used.

More recent VNC versions (freeware) from the Internet are not supported by the device!

For direct operation using the VNC program, the IP address

(extended by :1) must be specified when you run the

program, e.g. 172.24.21.85:1.

Note:

notebook/PC can be limited in the instrument;

see Chapter

The operator interface of the VNC program

appears:

Webbrowser’ etc., can be used directly.

The disadvantage is that an additional ‘Java’ installation is required.

In addition to VNC, this includes:

- easy operation for back-up/restore

- easy operation for analysis

- easy operation for data of the entire device configuration, see page 47.

4.7.4.

Sartorius EN-45

Commissioning

PR 5220 Instrument Manual

4.3.5 Operation Using Internet Browser

Example: Microsoft InternetExplorer under Windows XP

With Internet Explorer, check if the required Java (Sun) ’applet’ is installed and activated.

• Start the Internet Explorer

• Click [Tools] – [Internet Options…].

• Click the [Advanced] tab.

Note:

•

• If so, check

• If no entries are provided, load ’Java (Sun)

In earlier Windows installations, Java was provided as standard, but not activated.

[Java (Sun)]: Check whether entries are

provided.

with [IRE 1.6.xxx …]

(not activated by default).

applet’ as freeware from the Internet and

install it.

Example: Microsoft InternetExplorer under Windows 7

With InternetExplorer, check if the required Java (Sun) ‘applet’ is installed.

If it is not installed, the link for a ‘Java’ download is suggested automatically.

EN-46 Sartorius

PR 5220 Instrument Manual Commissioning

The menu appears on the monitor.

The weight value is displayed with the unit and status symbols.

With the Internet browser, the [IP address] must be filled in.

Example:

The line in brackets below the

header corresponds to the device

name specified in [Hostname].

[Remote Configuration (VNC)], [Remote Configuration (VNC) Pop up Window]

For instrument operation using the VNC program without additional installation of VNC, see page 46.

[Indicator], [Indicator Pop up Window]

[Configuration Printout]

Displaying and saving the configuration data as a text file, see Chapter 9.

[Logfiles]

Displaying the log files, see Chapter 4.11.

[Screenshot]

Device display for saving the display

[Show error Log]

Displaying and saving the error logs, see Chapter 13.5.

[Backup of Earom]

Saving and restoring the configuration and calibration data, see Chapter 4.12.

Sartorius EN-47

Commissioning

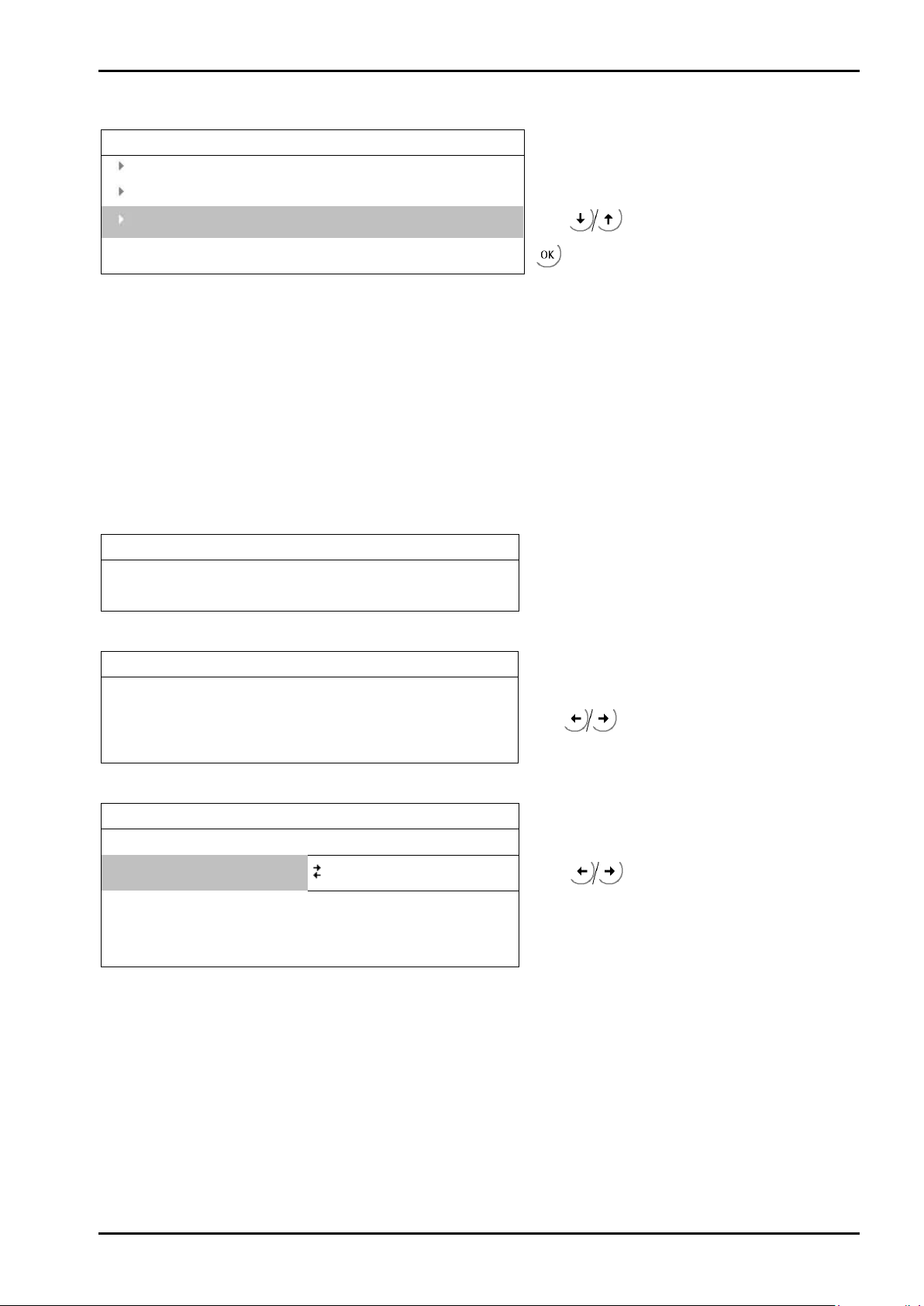

Info

Show version

Show status

Show HW-slots

Info/Version

Firmware release and creation date

Application release and creation date

BIOS release and creation date

Main board identification number

(different from the device serial number)

Info/Status

Free system RAM

6328 of 15212 kb

Cal-Switch

closed

(‘opened’ if CAL switch is open)

Info/HW-Slots

PR 5220 Instrument Manual

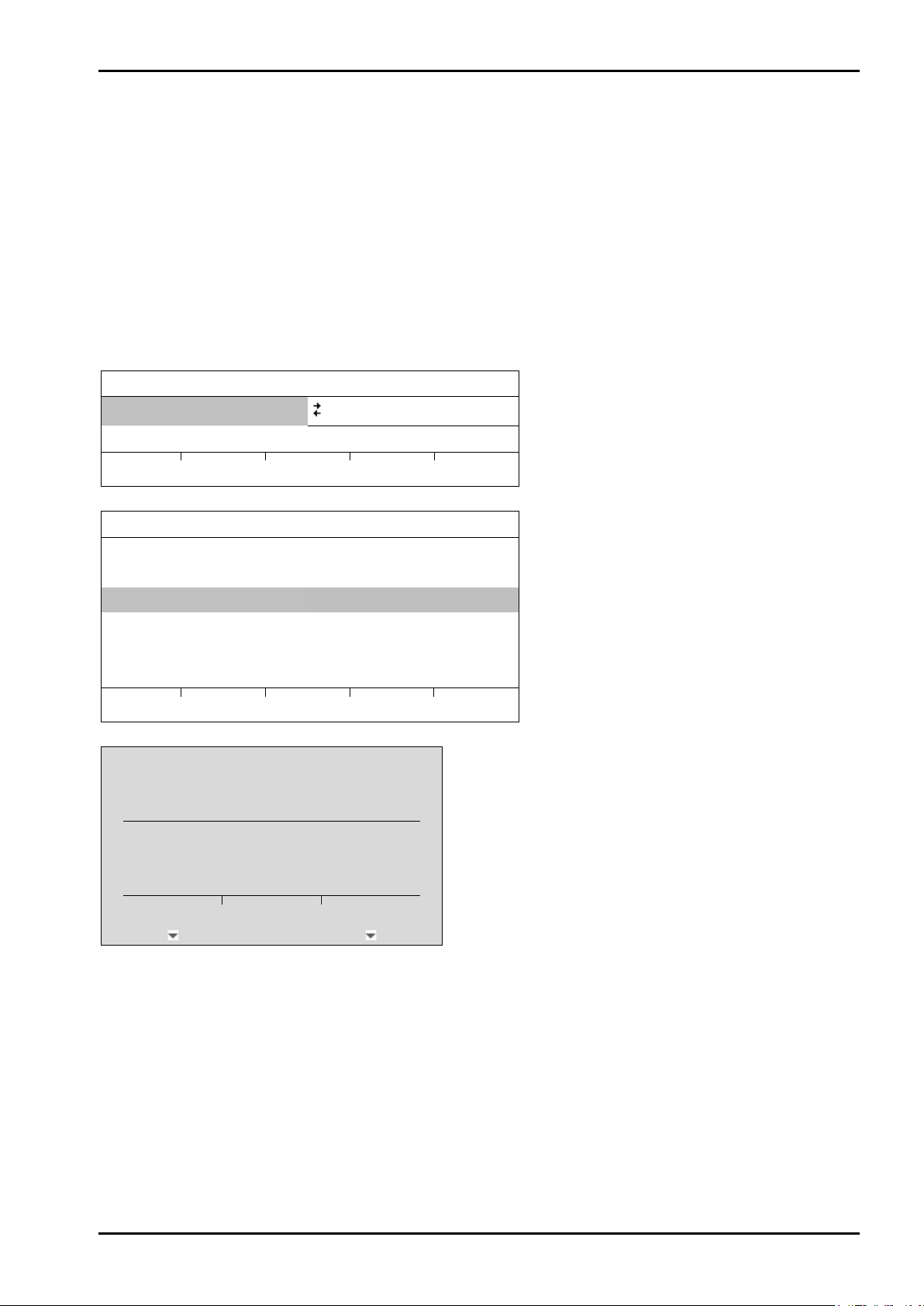

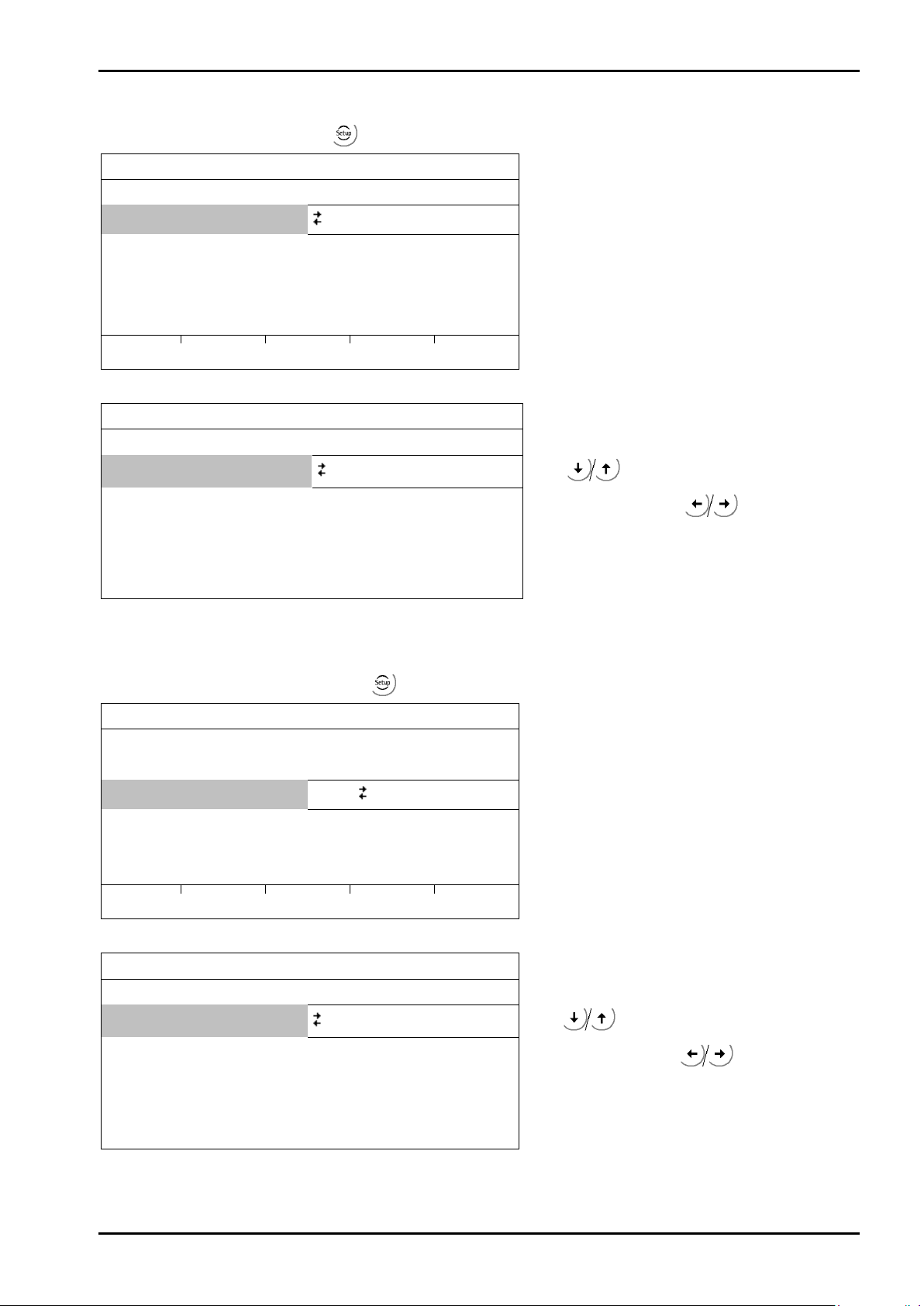

4.3.6 INFO Function

When you press , the program releases and status messages are displayed. The key also has other

functions; see Chapters 4.4.1.1 and 4.4.9.

When you select [Show version], the installed program releases and the board number are displayed:

Firmware

PR5220-Application Rel. 01.20.06

Bios

Boardnumber 275401089