Page 1

234HE

Hostile Environment Remote Display

Installation and

Operation Manual

16945

9

Page 2

Contents

1. Specifications ....................................................................................................1

2. Serial Communication Connections ...................................................................2

3. Configuration of Dip Switches ...........................................................................4

4. Troubleshooting Guide.......................................................................................5

5. Remote Display/Indicator Programs ..................................................................6

6. Replacement Parts.............................................................................................7

7. 234HE Limited Warranty ....................................................................................8

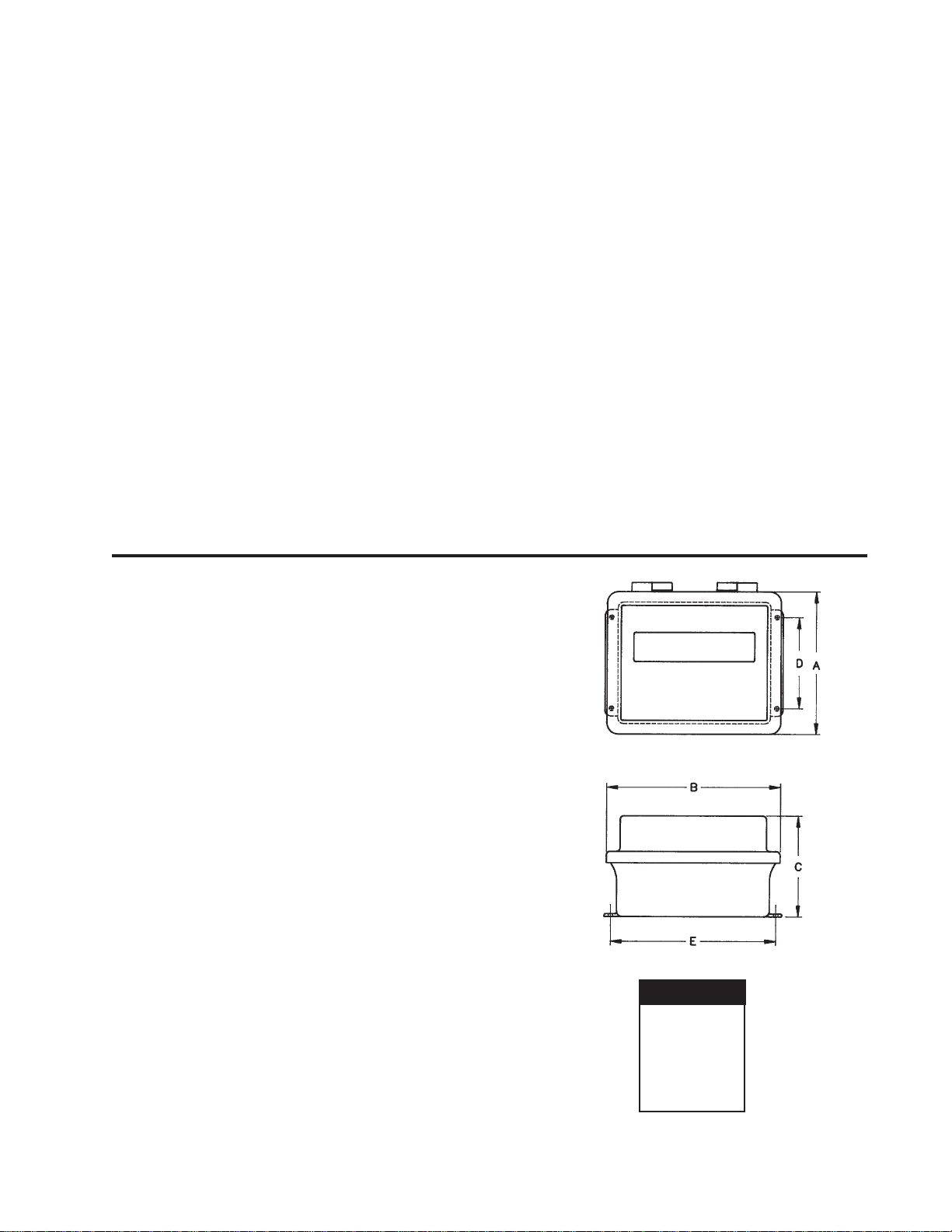

1. Specifications

DISPLAY:

6 1.5" active, high visibility fluorescent yellow digits

ENCLOSURE:

NEMA 4X Fiberglass Reinforced Polyester

INPUT INTERFACE:

20 mA current loop (active/passive), RS-232C,

standard ASCII serial characters

BAUD RATE:

Dip switch selectable 1200 and 2400

CHARACTER FORMAT:

Dip switch selectable character format,

7 or 8 data bits, odd or even parity, 1 or 2 stop bits

UPDATE:

Continuous update

POWER CONSUMPTION:

24 watts, typical

SHIPPING WEIGHT:

Approx. 13 lbs

Dimensions

A= 9.38"

B=11.38"

C= 6.63"

D= 6.00"

E=10.81"

10/96

1

Page 3

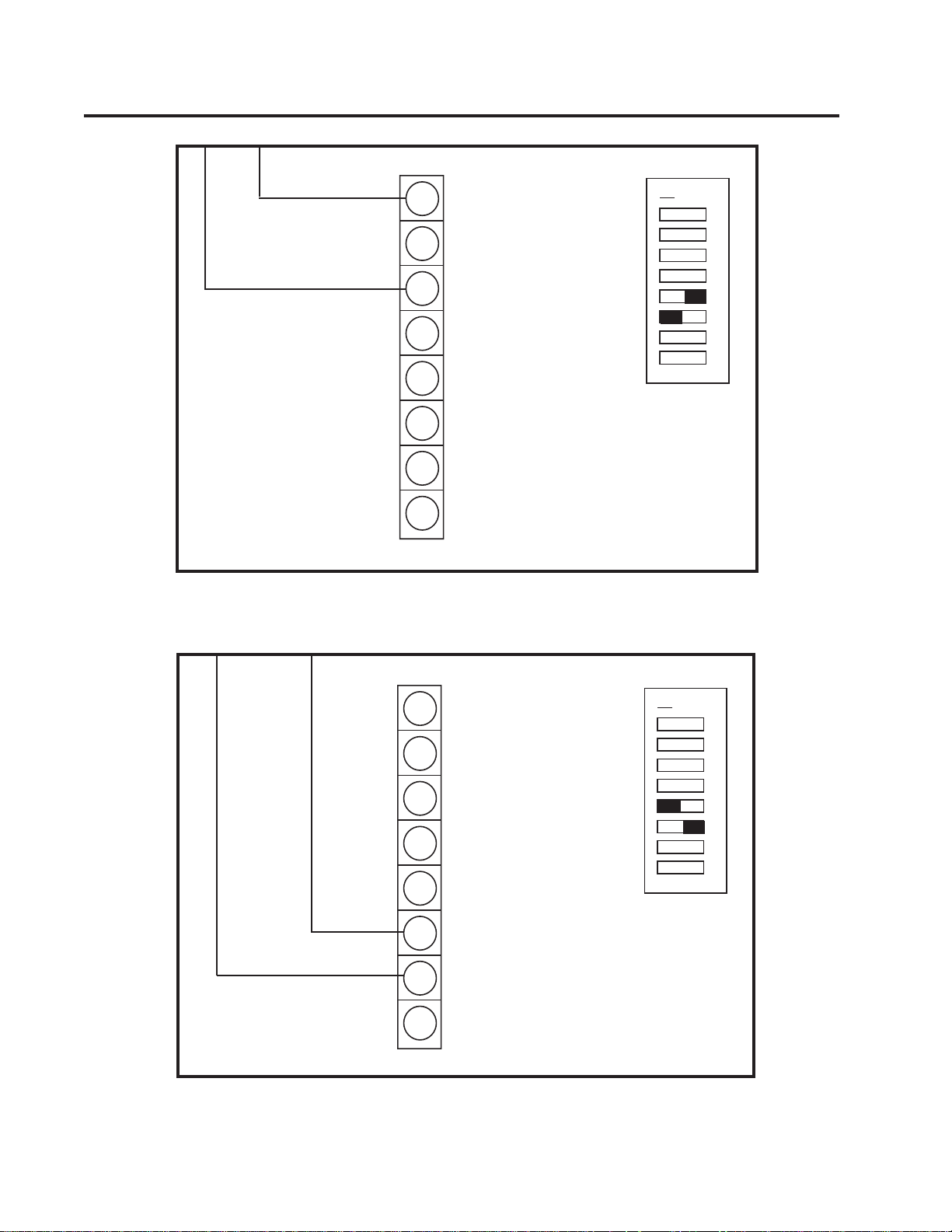

2. Serial Communications Connections

GROUND

SIGNAL IN

GROUND

TX

DATA

RX

DATA

+XMIT

CL RETURN

-XMIT

CL DATA

+RECEIVE

CL DATA

-RECEIVE

CL RETURN

V+

0

N

∆

1 2 3 4 5 6 7 8

J1

Communications Connections: RS-232C

GROUND

TX

DATA

RX

DATA

+XMIT

CL RETURN

-XMIT

CL DATA

20 mA +

+RECEIVE

CL DATA

20 mA -

-RECEIVE

CL RETURN

0

N

∆

1 2 3 4 5 6 7 8

V+

J1

Communications Connections: 20 mA Current Loop Passive

2

Page 4

GROUND

TX

DATA

RX

DATA

+20 mA

+XMIT

CL RETURN

-XMIT

CL DATA

–20 mA

+RECEIVE

CL DATA

-RECEIVE

CL RETURN

V+

J1

Communications Connections: 20 mA Current Loop Active

0

N

∆

1 2 3 4 5 6 7 8

3

Page 5

3. Configuration of Dip Switches

The purpose of dip switches #1-#6 is to ensure that the remote display and the indicator

are communicating in the same format. Consult your indicator manual to find the indicator's

current configuration. Check that the correct EPROM has been installed. Disconnect power

and set switches 1-6. Switches #7 and #8 enable the time and temperature display if those

options are installed.

Switch #1--Data Transfer Rate

(F 1.5 Series EPROM Version) (Series 1, 2, or 3 EPROM Version)

off 1200 BAUD off 300 BAUD

on 2400 BAUD on 1200 BAUD

Switch #2--Number of Data Bits

off 7 data bits

on 8 data bits

Switch #3--Number of Stop Bits

off 1 stop bit

on 2 stop bits

Switch #4--Odd Parity

off no parity or parity disabled

on odd / even parity enabled

Switch #5 and #6--Serial Input Format

5 off 6 on 20 mA Current Loop

5 on 6 off RS232C

Switch #7--Time Display (Unavailable Option)

off time display disabled

on time display enabled

Switch #8--Temperature Display (Unavailalble Option)

off temperature display disabled

on temperature display enabled

4

Page 6

4. Troubleshooting Guide

PROBLEM SOLUTION

A. No display check at power-up. Replace fuse (1/4 A Slo-Blo).

Check AC receptacle for proper 120V

power supply.

Press reset switch on circuit board.

B. Display shows no or different data than Check that serial communication lines

indicator. are connected properly.

Check that the indicator and remote display

are configured in the same format.

Display has incorrect program for indicator

(see Sec. 5).

5

Page 7

5. Remote Display / Indicator Programs

Program # Indicator and Operating Mode

F1_5-1D UMC1000, UMC2000, IQ600, IQ700 — Continuous

F1_5-1D Thurman EDS4 - EPROM in indicator is Continuous Condec format

F1_5-2B UMC 1000, 2000 — Demand

F1_5-3B Toledo 8140, 8142, 8530, 81321, 9481 — Continuous

F1_5-3B Fairbanks 9201RS-232 (Use COM port 1 only)

F1_5-4D IQplus 800/810, IQplus 310 Continuous (End of line set to CR/LF)

F1_5-5A StreeterAmet 9000 — Continuous

F1_5-6A Cardinal 738 — Continuous

F1_5-7A Western DF1000 — Continuous

F1_5-8A Pennsylvania 5600 — Continuous

F1_5-9A Flexweigh DWM IV — Continuous

F1_5-10A IDS print w/BCD to 20 mA conversion — Continuous

F1_5-11A AD 4321 — Continuous (Format 1, display will not show negative sign)

F1_5-12A IQ700 Truck ID for KBB 8-1, Ver. EF EPROM

F1_5-13A Analogic 5316 — Continuous, HB 44 (EPROM 13.0 shows gross only)

F1_5-14A Electroscale 533 — Continuous

F1_5-15A IQ700, IQplus 310 Demand (Net or Gross) with Time and Date

F1_5-16A WI-110, WI-120, WI-130 — Continuous

F1_5-17A Toledo 8142 with BCD Converter

F1_5-18A Doran 7000 — Continuous

F1_5-19A Fairbanks 90-164-1, 90-166-1, 9201 (out Com 2) — Continuous (20 mA passive only)

F1_5-1C UMC 1000, UMC 2000, IQ600, IQ700 — Continuous

F1_5-21A Electroscale 551 — Continuous

F1_5-22A Analogic 5316, EPROM Revision 13.0.9 — Continuous

F1_5-23A General Freedom I and II — Continuous

F1_5-24A ACCU-WEIGH SEP-12K, Format 8 — Continuous

F1_5-25A Kubota KA-10 — Continuous

F1_5-26A Flexweigh DWMIV Continuous w/Post & Preamble (02H, 03H)

F1_5-27A MSI TRANS-WEIGH — Continuous

F1_5-28A OHAUS 1150 — Continuous

F1_5-29A Hardy HI 2151 WC — Continuous

F1_5-30A Pennsylvania 3100 — Continuous

F1_5-31A IQplus 800/810 — Demand (Standard default format)

F1_5-32A IQplus 310 — Demand (Net Weight Only)

F1_5-33A IQplus 310 — Demand (Gross Weight Only)

F1_5-34A Fairbanks 90-163-1 — Continuous

F1_5-36A IQ700, IQplus 310, — Demand (Net or Gross) with Time and Date

F1_5-37A Tyrel TC-10 / Howe-Richardson HR500k Continuous

F1_5-38A Tara TR-1 Continuous, 1200 baud, fixed 8 bits, no parity, 2 stop bits

F1_5-39A Allegany Mega 8—Continuous

F1_5-40A A-N-D FG Bench Scale

F1_5-41A Cardinal 748 — Continuous

F1_5-42A 3-weight 810 — Continuous

3

4

2

Notes:

1 The Toledo 8132 meter will not work with the 234HE without special programming to operate the 234HE at 4800 baud.

2 The WI130 indicator must be programmed to stream out in the standard Weightronix format to use the WI110/WI120 flip digit driver.

3 The Allegany Mega 8 sends out eight weight display digits. The EL234HE Remote Display shows the least significant six digits.

4 This special format contains three weight strings within one serial string. Dip switches 7 and 8 in switchbank 2 control which of the three

strings are displayed as follows:

2-7 2-8 String Displayed

off off 1st

off on 2nd

on off 3rd

6

Page 8

6. Replacement Parts for 234HE 1.5" Flip Digit Display

DESCRIPTION PART NUMBER

1.5" Display, CPU Board................................................................... 21024

1.5" Display, Mounting Board............................................................ 21025

Enclosure, Fiberglass Reinforced Polyester ..................................... 16019

Back Panel ........................................................................................ 16084

EPROM, F1.5-XXX (programmed as required)................................. 16246

Cord Grip Assembly for Power Cord, 1/2" NPT ................................ 15671

Desiccant, 5 Gram Package .............................................................16038

Power Cord Pigtail ............................................................................15436

Lexan Window, 9 X 4 3/4 .................................................................. 16083

“High Voltage” Warning Label for Lexan Shield ................................ 16861

16 Pin Connector ..............................................................................15823

Fuse, 1/4A SLO-BLO ........................................................................ 16444

Fuse Holder, Single Pole ..................................................................16771

Fuse Cover........................................................................................ 16772

Installation Manual, 243HE Remote Display..................................... 16945

7

Page 9

7. 234HE Limited Warranty

Rice Lake Weighing Systems (RLWS) warrants that all RLWS equipment and systems properly installed by a

Distributor or Original Equipment Manufacturer (OEM) will operate per written specifications as confirmed

by the Distributor/OEM and accepted by RLWS. All systems and components are warranted against defects

in materials and workmanship for one (1) year.

RLWS warrants that the equipment sold hereunder will conform to the current written specifications authorized by RLWS. RLWS warrants the equipment against faulty workmanship and defective materials. If any

equipment fails to conform to these warranties, RLWS will, at its option, repair or replace such goods returned within the warranty period subject to the following conditions:

1. Upon discovery by Buyer of such non-conformity, RLWS will be given prompt written notice with a detailed explanation

of the alleged deficiencies.

2. Individual electronic components returned to RLWS for warranty purposes must be packaged to prevent electrostatic

discharge (ESD) damage in shipment. Packaging requirements are listed in a publication, “Protecting Your Components

From Static Damage in Shipment,” available from RLWS Equipment Return Department.

3. Examination of such equipment by RLWS confirms that the non-conformity actually exists, and was not caused by

accident, misuse, neglect, alteration, improper installation, improper repair or improper testing; RLWS shall be the sole

judge of all alleged non-conformities.

4. Such equipment has not been modified, altered, or changed by any person other than RLWS or its duly authorized repair

agents.

5. RLWS will have a reasonable time to repair or replace the defective equipment. Buyer is responsible for shipping charges

both ways.

6. In no event will RLWS be responsible for travel time or on-location repairs, including assembly or disassembly of

equipment, nor will RLWS be liable for the cost of any repairs made by others.

THESE WARRANTIES EXCLUDE ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED,

INCLUDING WITHOUT LIMITATION WARRANTIES OF MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE. NEITHER RLWS NOR DISTRIBUTOR WILL, IN ANY EVENT,

BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES.

RLWS AND BUYER AGREE THAT RLSW’S SOLE AND EXCLUSIVE LIABILITY HEREUNDER

IS LIMITED TO REPAIR OR REPLACEMENT OF SUCH GOODS. IN ACCEPTING THIS WARRANTY, THE BUYER WAIVES ANY AND ALL OTHER CLAIMS TO WARRANTY.

SHOULD THE SELLER BE OTHER THAN RLWS, THE BUYER AGREES TO LOOK ONLY TO

THE SELLER FOR WARRANTY CLAIMS.

No terms, conditions, understanding, or agreements purporting to modify the terms of this warranty shall have any legal effect unless

made in writing and signed by a corporate officer of RLWS and the Buyer.

© 1996 Rice Lake Weighing Systems, Inc. Rice Lake, WI USA. All Rights Reserved.

RICE LAKE WEIGHING SYSTEMS

Tel: 715-234-9171 Service Hotline: 715-234-2003 Fax: 715-234-6967

• 230 WEST COLEMAN STREET • RICE LAKE, WISCONSIN 54868 • USA

8

Loading...

Loading...