Page 1

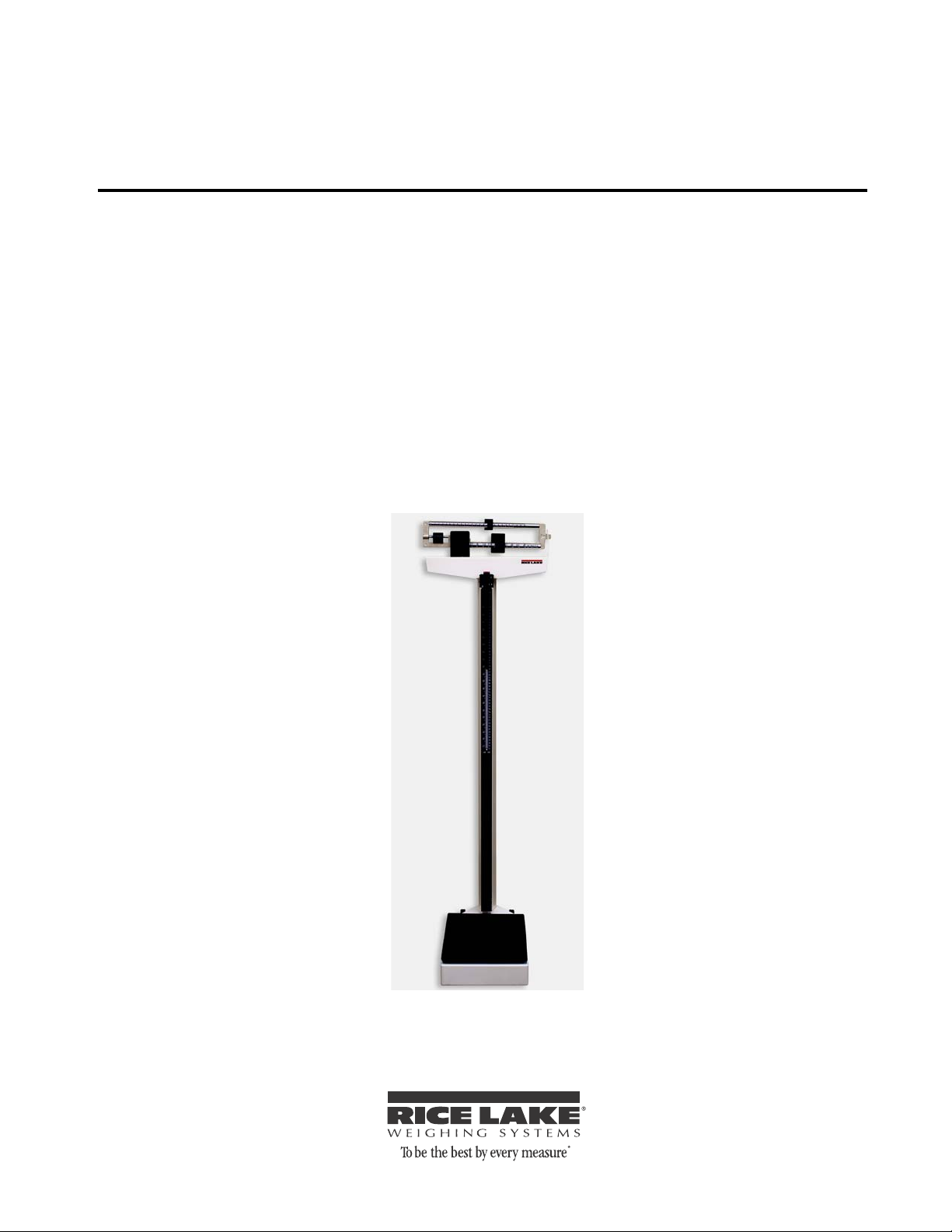

Rice Lake Mechanical Physician Scale

Model RL-MPS, RL-MPS-10, RS-MPS-20

Operation Instructions

102696

Page 2

Page 3

Contents

Technical training seminars are available through Rice Lake Weighing Systems.

Course descriptions and dates can be viewed at www.ricelake.com or obtained

by calling 715-234-9171 and asking for the training department

1.0 Introduction................................................................................................................................. 1

2.0 Installation Instructions

2.1 Pillar Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.2 Steelyard Rod Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Height Rod Installation (for those models equipped with height rod) . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.4 Wheel Installation (for those models equipped with wheels) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

............................................................................................................... 2

. . . . . 3

3.0 Zero Adjustment........................................................................................................................... 7

4.0 Troubleshooting ........................................................................................................................... 8

5.0 Specifications.............................................................................................................................. 8

© Rice Lake Weighing Systems. All rights reserved. Specifications subject to change without notice.

Model RL-MPS, RL-MPS-10, RL-MPS-20, Rice Lake Weighing Systems is an ISO 9001 registered company.

November, 2012

Page 4

Rice Lake continually offers web-based video training on a growing selection

of product-related topics at no cost. Visit www.ricelake.com/webinars.

ii Mechanical Physician Installation and Operation Instructions

Page 5

1.0 Introduction

Weight beam

Height rod (if

applicable to model

selected)

Pillar

Platform/Scale Base

Rear wheels (if

applicable to model

selected)

Frame

Poise weight (upper

small and lower large)

Internet

The Rice Lake Mechanical Physician Scale is ideal for use in health clinics and doctors’ practices for height and

weight measurement. The scale comes in a variety of configurations. Those configurations include:

• RL-MPS: Lb/kg model with height rod and rear wheels

• RL-MPS-10: Lb only model with height rod and rear wheels

• RL-MPS-20: Lb/kg model

The scale is durable, having a sturdy en ameled steel body

models come with a retractable aluminum height rod and rear wheels. These installation and operating

instructions will guide the user through basic instructions on pillar assembly, wheel installation, pillar height rod

installation, and the zero adjustment of the scale.

, removable slip resistant plastic cover and some

Figure 1-1. Mechanical Physician Scale Parts Breakdown (lb/kg version with height rod and rear wheels shown)

This manual can be viewed and downloaded from the Rice Lake Weighing Systems web site

at www.ricelake.com/health. Rice Lake Weighing Systems is

company.

an ISO 9001 registered

1

Page 6

2.0 Installation Instructions

Remove twisty ties from

scale parts

Remove cable tie from steelyard rod

You will receive your Mechanical Physician Scale partially assembled. Those items that need additional

assembly are:

• Pillar assembly

• Steelyard rod connection

• Height rod installation (for mod

• Wheel installation (for models having wheels)

Remove all components from the shipping box (shown in Figure 2-1) and lay out in a convenient place.

2.1 Pillar Installation

Prior to assembly, you’ll need the following tools to finish assembling the Mechanical Physician Scale.

• Phillips head

• Wrench (included)

The pillar comes separate from the scale base and must be att

the pillar to the scale base.

1. Set the scale base on a table or other convenient place.

2. Remove the twisty ties off the scale base

tie that holds the steelyard rod from shifting during transit (shown on right side of Figure 2-2).

screwdriver

els having a height rod)

Figure 2-1. Box Contents

ached prior to use. Use the following steps to attach

as shown on the left hand side of Figure 2-2. Remove the cable

Figure 2-2. Remove Twisty Ties and Cable Ties

2 Mechanical Physician Scale Installation and Operation Instructions

Page 7

3. Insert the pillar into the scale base assembly ensuring that the RLWS logo located on the weight beam

Scale base

Pillar

faces the

scale base.

Figure 2-3. Attach the Pillar to the Scale Base

4. Using a phillips head screwdriver, screw in the eight bolts and washers to secure the pillar to scale base.

Figure 2-4. Attach Eight Bolts and Washers to Secure the Pillar to the Scale Base

Mechanical Physician Scale Installation and Operation Instructions - Installation Instructions 3

Page 8

2.2 Steelyard Rod Connection

The steelyard rod is located inside the scale pillar. Once the pillar is attached to the scale base, the steelyard rod

must be attached to the bottom of the scale.

1. Lay the scale on a table as shown in Figure 2-5.

Figure 2-5. Lay Scale on Table to Access Bottom of Scale

2. There are tie wrap wires that prevent the underside of the scale carriage from shifting during shipping.

Remove and discard the wires on the levers as shown in Figure 2-5.

3. Insert the wrench (included) to the small hole in front of the steelyard rod, and pull the hook of the

steelyard rod with the hook of the wrench to connect it to the scale base as shown in

Figure 2-6.

Figure 2-6. Connecting the Steelyard Rod to the Scale Base

4. Push the long lever frontward, then hook the bearing of the steelyard rod on the pivot of the long lever.

NOTE: Visually ensure that the force lever assembly linkage is centered and properly aligned. Occasionally during

shipping, the alignment will become skewed however a plug is installed to ensure that the linkage stays aligned. The

linkage must be free floating in order for the scale to weigh properly. The linkage can be seen by looking up underneath

4 Mechanical Physician Scale Installation and Operation Instructions

Page 9

the top weigh beam if the scale is slightly tipped to one side.

Force lever

assembly

linkage must

be properly

aligned in

order to

weigh

Linkage

alignment

plug

Figure 2-7. View Looking up at Linkage up Underneath the Top Weigh Beam

5. Place the scale gently back on the floor.

Mechanical Physician Scale Installation and Operation Instructions - Installation Instructions 5

Page 10

2.3 Height Rod Installation (for those models equipped with height rods)

Slotted holes

Some models of the Mechanical Physician Scale comes with height rods. Use the following steps to install the

height rod.

1. Insert the back side slotted holes of the height rod into the two bolts

shown in Figure 2-8. One is located at the top of the pillar and the other towards the bottom of the pillar.

on the front side of the pillar as

Figure 2-8. Attach the Slotted Screw Location onto the Pillar Bolt Location

2. Use the enclosed wrench to tighten the two hex-head screws, but ensure not to over tighten.

3. To raise or lower the height rod, press the red button at the top of the heig ht rod and raise up or down.

6 Mechanical Physician Scale Installation and Operation Instructions

Page 11

2.4 Wheel Installation (for those models equipped with wheels)

Note

To p

Bottom

Some models of the Mechanical Physician Scale comes with sturdy wheels for easy portability. To install the

wheels onto the scale, use the following instructions.

Mounting the wheels upside down can create scale errors.

1. Align the angle iron of the wheel base to the scale platform as shown in Figure 2-9.

Figure 2-9. Attach the Scale Wheels onto the Scale Base

2. Use the screws and washers that are included with the scale to fix the wheel to the platform, adjusting the

angle iron at a level position, then tighten screws.

3. When moving the scale, hold the two side faces of the pillar to keep the front side of the platform away

from the ground.

Figure 2-10. Wheels Offer Easy Portability

Mechanical Physician Scale Installation and Operation Instructions - Installation Instructions 7

Page 12

3.0 Zero Adjustment

Zero

adjusting

screw

Weigh beam

Scale pointer

Eye loop area

T o ensure accurate weighments, a zero adjustment should be done to the scale upon arrival and setup. To perform

a zero adjustment, perform the following steps.

1. Ensure the scale is sitting on a level surface.

2. Check the eye loop area of the scale to

loop area. This can be accomplished by gently holding the scale pointer with your finger until it touches

the bottom of the eye loop area. Release the scale pointer and let it rise freely up and down between the

eye loop area until

the scale pointer settles in the middle of

ensure that the scale pointer is equally balanced between the eye

the eye loop area.

Figure 3-1. Eye Loop Area and Zero Adjusting Screw Location (Lb and kg version without height rod shown)

3. If the scale is not balancing properly, then the small zero balance weight must be adjusted. Turn the zero

adjusting screw (shown in Figure 3-1) using a flat head screwdriver. By adjusting the screw, the zero

balance weight will move accordingly.

8 Mechanical Physician Scale Installation and Operation Instructions

Page 13

4.0 Troubleshooting

The accuracy of the Mechanical Physician Scale, when calibrated at the factory, falls within plus or minus 1/4

pound accuracy. For the most accurate weight, always use the scale on a hard, level surface and stand in the

center of the scale platform with the weight distributed as evenly as possible. If an error occurs or seems

excessive, check the following:

Problem Possible Fix

Zero balance of beam The weigh beam must be balanced so the pointer comes to a rest in the

center of the eye loop (shown in Figure 3-1) when both poise weights are set

at zero (see Figure 1-1 for poise weight location). Adjust the balance by

turning the zero adjusting screw at the left end of the weigh beam (see

Figure 3-1).

Beam does not move freely Check if the beam pointer is touching the side of the eye loop in its range of

travel.

Visually ensure that the linkage is centered and properly aligned. Occasionally

during shipping, the alignment will become skewed. The linkage must be free

floating in order for the scale to weigh properly. The linkage can be seen by

looking up underneath the top weigh beam if the scale is slightly tipped to one

side.

Platform rocks excessively When you push down on any corner of the platform, you should not feel any

significant rocking. Ensure scale is setting on a level surface.

Beam does not move at all during a weighment This can be caused by the poise weights being set to a higher weight than the

person’s actual weight. Reset the weights to a lower weight. Also check to

see that the steelyard rod is properly connected and aligned (see

Scale is out of calibration Recalibrate the scale by placing a known weight on the scale and moving the

zero adjusting screw to bring the scale back to zero.

Figure 2-7).

Table 4-1. Troubleshooting Guide

5.0 Specifications

RL-MPS RL-MPS-10 RL-MPS-20

Maximum Capacity 440 lb (200 kg) 450 lb (204 kg) 440 lb (200 kg)

Graduation 0.25 lb (0.1 kg)

Height Rod Range 24-84" (60-212 cm) N/A

Min. Value of Height per Division 0.125" (0.1 cm) N/A

Platform Size 14.75" x 10.75" (374.65 x 273.05 mm)

Table 5-1. Model Specifications

Mechanical Physician Scale Installation and Operation Instructions - Troubleshooting 9

Page 14

For More Information

Web Site

• http://www.ricelake.com/health

Contact Information

Hours of Operation

Knowledgeable customer service representatives are available 6:30 a.m. - 6:30 p.m. Monday through Friday and

8 a.m. to 12 noon on Saturday. (CST)

Telephone

• Sales/Technical Support 800-472-6703

• Canadian and Mexican Customers 800-321-6703

• International 715-234-9171

Fax

• Fax Number 715-234-6967

Email

• US sales and product information at prodinfo@ricelake.com

• International (non-US) sales and product informat

Mailing Address

Rice Lake Weighing Systems

230 West Coleman Street

Rice Lake, WI 54868 USA

ion at intlsales@ricelake.com

10 Mechanical Physician Scale Installation and Operation Instructions

Page 15

Mechanical Physician Scale Limited Warranty

Rice Lake Weighing Systems warrants that all RLWS equipment and systems properly installed by a Distributor

or Original Equipment Manufacturer (OEM) will operate per written specifications as confirmed by the

Distributor/OEM and accepted by RL WS. All systems and components are warranted against defects in materials

and workmanship for two years.

RLWS warrants that the equipment sold hereunder will conform

by RLWS. RLWS warrants the equipment against faulty workmanship and defective materials. If any equipment

fails to conform to these warranties, RLWS will, at its option, repair or replace such goods returned within the

warranty period subject to the following conditions:

• Upon discovery by Buyer of such nonconformity

, RLWS will be given prompt written notice with a

detailed explanation of the alleged deficiencies.

• Examination of such equipment by RLWS confirms that

not RL

WS shall be the sole judge of all alleged non-conformities.

• Such equipment has not been modified, altered, or ch

duly authorized repair agents.

• RLWS will have a reasonable time to repair or replac

for shipping charges both ways.

• In no event will RLWS be responsible for travel time or on-location r

disassembly of equipment, nor will

HESE WARRANTIES EXCLUDE ALL OTHER WARRANTIES, EXPRESSED OR IMPLIED, INCLUDING WITHOUT

T

LIMITATION WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. NEITHER

RLWS

RLWS

REPAIR OR REPLACEMENT OF SUCH GOODS. IN ACCE PT ING THIS WARRANTY, THE BUYER WAIVES ANY AND

ALL OTHER CLAIMS TO WARRANTY.

S

WARRANTY CLAIMS.

N

WARRANTY SHALL HAVE ANY LEGAL EFFECT UNLESS MADE IN WRITING AND SIGNED BY A CORPORATE

OFFICER

NOR DISTRIBUTOR WILL, IN ANY EVENT, BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES.

AND BUYER AGREE THAT RLWS’S SOLE AND EXCLUSIVE LIABILITY HEREUNDER IS LIMITED TO

HOULD THE SELLER BE OTHER THAN RLWS, THE BUYER AGREES TO LOOK ONLY TO THE SELLER FOR

O TERMS, CONDITIONS, UNDERSTANDING, OR AGREEMENTS PURPORTING TO MODIFY THE TERMS OF THIS

OF RLWS AND THE BUYER.

RLWS be liable for the cost of any repairs made by others.

to the current written specifications authorized

the nonconformity actually exists, and was

anged by any person other than RLWS or its

e the defective equipment. Buyer is responsible

epairs, including assembly or

© 2012 Rice Lake Weighing Systems, Inc. Rice Lake, WI USA. All Rights Reserved.

RICE LAKE WEIGHING SYSTEMS • 230 WEST COLEMAN STREET • RICE LAKE, WISCONSIN 54868 • USA

Mechanical Physician Scale Installation and Operation Instructions - Specifications 11

Page 16

12 Mechanical Physician Scale Installation and Operation Instructions

Page 17

Page 18

PN 102696 11/12

Loading...

Loading...