Page 1

Disponible

en Español

Visite ricelake.com/spanish

para ver todos los materiales

RLWS disponibles en Español

Digital Weight Indicator

Version 2.0

Installation Manual

120

76699 Rev A

Page 2

Page 3

Technical training seminars are available through Rice Lake Weighing Systems.

Course descriptions and dates can be viewed at www.ricelake.com/training

or obtained by calling 715-234-9171 and asking for the training department.

Contents

About This Manual ................................................................................................................................... 1

1.0 Introduction.................................................................................................................................. 1

1.1 Operating Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Front Panel Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.3 LED Annunciators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1.4 Indicator Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.4.1 Weighing Mode Operations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.4.2 Panel Mode Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.0 Installation ................................................................................................................................... 5

2.1 Unpacking and Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Enclosure and Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2.1 Serial Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2.2 Load Cells. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3 Enclosure Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.4 Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.0 Configuration ............................................................................................................................... 7

3.1 Configuration Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1.1 Revolution® Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1.2 EDP Command Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1.3 Front Panel Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2 Menu Structures and Parameter Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.2.1 Configuration Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.2.2 Format Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.2.3 Calibration Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.2.4 Serial Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2.5 Program Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.2.6 Print Format Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.2.7 Time Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.2.8 Date Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.2.9 Version Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.0 Calibration ................................................................................................................................ 21

4.1 Front Panel Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4.2 EDP Command Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5.0 EDP Commands.......................................................................................................................... 23

5.1 The EDP Command Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.1.1 Key Press Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.1.2 Reporting Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.1.3 The RS Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.1.4 Parameter Setting Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.2 Saving and Transferring Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.2.1 Saving Indicator Data to a Personal Computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.2.2 Downloading Configuration Data from PC to Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

© Rice Lake Weighing Systems. All rights reserved. Printed in the United States of America.

Rice Lake Weighing Systems is an ISO 9001 registered company.

Specifications subject to change without notice.

Version 2.0, February 04, 2014

Contents i

Page 4

Rice Lake continually offers web-based video training on a growing selection

of product-related topics at no cost. Visit www.ricelake.com/webinars.

6.0 Print Formatting ......................................................................................................................... 27

6.1 Print Formatting Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.2 Customizing Print Formats. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.2.1 Using the EDP Port. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.2.2 Using the Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

7.0 Appendix .................................................................................................................................... 29

7.1 Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

7.2 Continuous Output (Stream) Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

7.3 Front Panel Display Characters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

7.4 ASCII Character Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

7.5 Conversion Factors for Secondary Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.6 Digital Filtering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7.6.1 DIGFLx Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7.6.2 DFSENS and DFTHRH Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7.6.3 Setting the Digital Filter Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

7.7 Test Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

7.8 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

120 Limited Warranty............................................................................................................................. 37

ii Installation Manual

Page 5

About This Manual

WARNING

This manual is intended for use by service technicians

responsible for installing and servicing 120 digital

weight indicators. This manual applies to indicators

using Version 2.02 of the 120 software.

Configuration and calibration of the indic

ator can be

accomplished using the indicator front panel keys, the

EDP command set, or Version 3.0 or later of the

Revolution

page 7 for information about

®

configuration utility. See Section 3.1 on

configuration methods.

The Operator Car

Some procedures described in this

manual require work inside the indicator

enc

losure. These procedures are to be

performed by qualified service personnel

only.

Authorized distributors and their employees

can view or download this manual from the

Lake Weighing Systems distributor site

Rice

www.ricelake.com.

at

d included with this manual

provides basic operating instructions for users of the

120. Please leave the Operator Card with the

indicator when installation and configuration are

complete.

1.0 Introduction

The 120 is a single-channel digital weight indicator housed in a durable plastic enclosure. The indicator front

panel consists of a large (.8 in, 20 mm), six-digit, sev en-segment LED dis play and five -button keyp ad. Features

include:

• Drives up to four 350or eig

• Supports 4- and 6-wire load cell connections

• Electronic data processing (EDP) port for full duplex, RS-232 communications at up to 38400 bps

• Printer port for output-only RS-232 and 20 mA current loop communications at up to 9600 bps

The 12

0 is NTEP-certified for Classes III and III L at 6,000 divisions. See Section 7.8 on page 36 for detailed

specifications.

ht 700 load cells

1.1 Operating Modes

The 120 supports the following modes of operation:

Normal (weighing) mode

Normal mode is the “production” mode of the indicator. The indicator displays gross or net weights as

required, using the LED annunciators described in Section 1.3 on page 2 to indicate scale status and the type

of weight value displayed. Once configuration i

indicator, this is the only mode in which the 120 can operate. See Section 1.4.1 on page 3 for more

information about normal mode operations.

Panel mode

Panel mode allows the time, date, consecutive number, and consecutive number start-up value to be set

without entering configuration mode. To enter panel mode, press and hold the GROSS/NET key until the TIME

menu is shown. See Section 1.4.2 on page 4 for more information about panel mode.

Configuration mode

Most of the procedures described in this manual require the indicator to be in configuration mode, including

configuration and calibration.

To enter configuration mode, remove the l

screwdriver or a similar tool into the access hole and press the setup switch once. The indicator display

changes to show the word

Test mo de

CONFIG.

Test mode provides a number of diagnostic functions for the 120 indicator. Like setup mode, test mode is

entered using the setup switch. See Section 7.7 on page 35 for more information about en

test mode.

s complete and a legal seal is affixed to the back of the

arge fillister head screw from the enclosure backplate. Insert a

tering and using

Introduction 1

Page 6

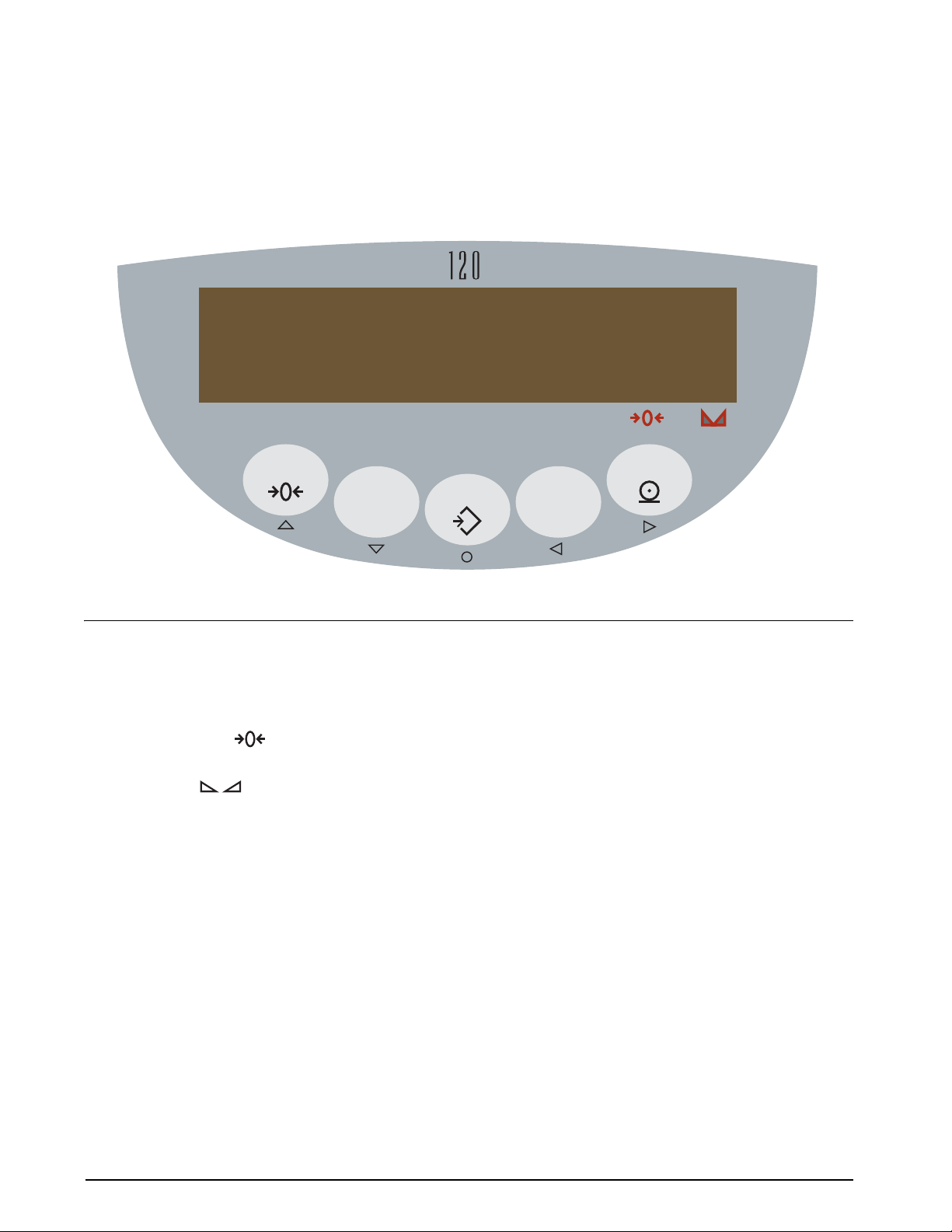

1.2 Front Panel Keypad

LH

MC

H

P[

(S

/U

;&30

(3044

/&5

#/

5"3&

4

6/*54

6OJUT

13*/5

Figure 1-1 shows the 120 keypad and LED annunciators.

The symbols shown under the keys (representing up, down, enter

in configuration and panel modes. In these modes, the keys are used to navigate through menus, select digits

within numeric values, and increment/decrement values. See Section 3.1.3 on page 8 for information about using

the front panel keys in configuration mode.

, left, right) describe the key functions assigned

Figure 1-1. 120 Front Panel

1.3 LED Annunciators

The 120 display uses a set of eight LED annunciators to provide additional information about the value being

displayed:

Gr (gross) and Nt (net) annunciators are lit to show whether the displayed weight is a gross or net weight.

•

• Center of zero (

scale is zeroed.

• Standstill (

tare functions and printing, can only be done when the standstill symbol is shown.

lb, kg, oz, and g annunciators indicate the units associated with the displayed value: lb=pounds,

•

kg=kilograms, oz=ounces, g=grams.

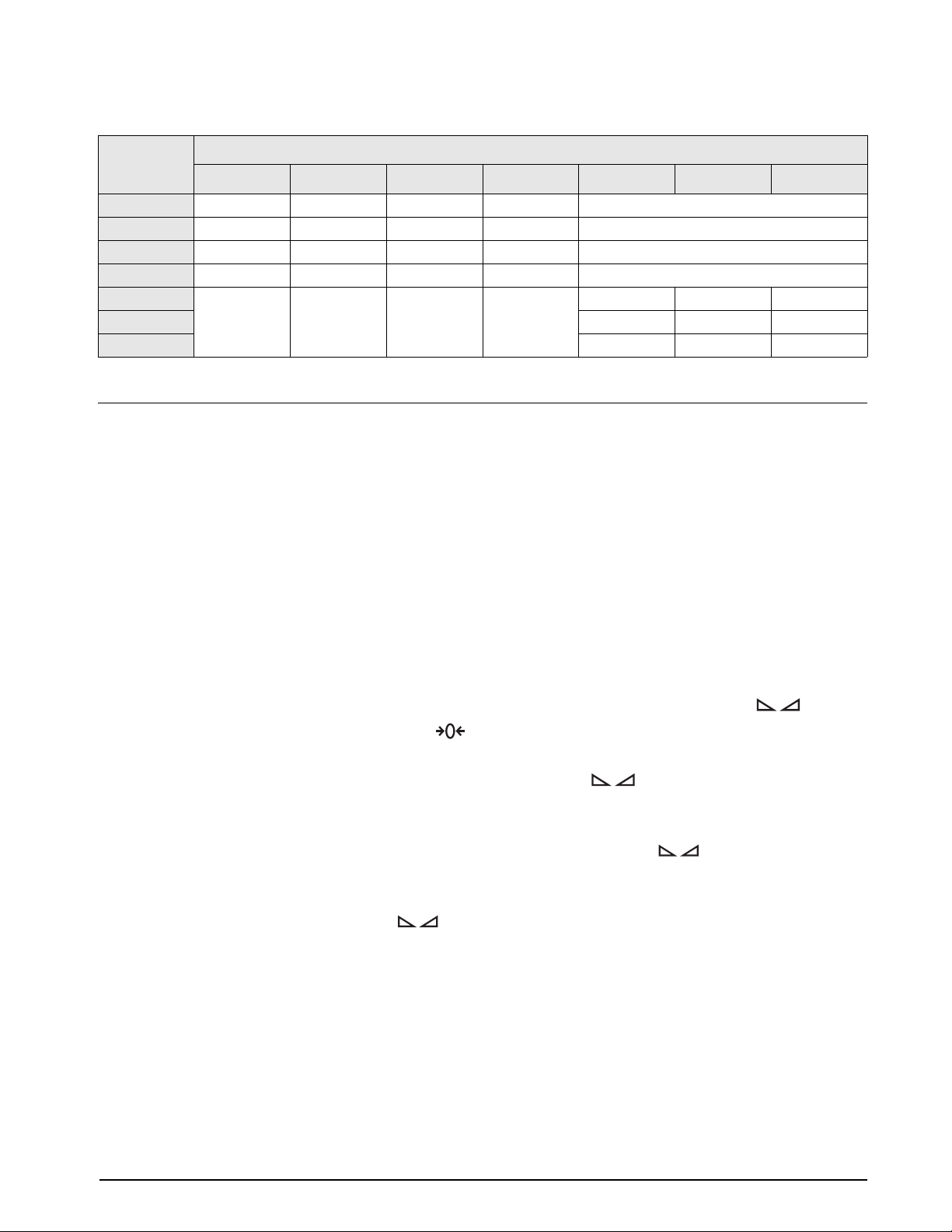

The displayed units can also be set to short tons (tn),

displayed). The

combinations of primary and secondary units. If neither primary nor secondary units are lb, kg, oz, or g, the

lb annunciator is lit for primary units, kg for secondary units.

Table 1-1 on page 3 shows which annunciators are used for all

secondary units. For example:

• If the primary unit is poun ds (lb) and the secondary u nit is kilograms (kg), the

kg for secondary units.

units,

• If th e primary unit is pounds (lb) and the secondary

kg for secondary units. There is no LED for short tons, so the kg LED is used as the secondary units

units,

annunciator.

• If the primary unit is short tons (tn) and the

units (tn), and

are used as primary and secondary units annunciators.

2 120 Installation Manual

): Gross weight is within ±0.25 graduations of zero. This annunciator lights when the

): Scale is at standstill or within the specified motion band. Some operations, including

metric tons (t), or NONE (no units information

lb and kg LEDs function as primary and secondary units annunciators for some

combinations of configured primary and

lb LED is lit for primary

unit is short tons (tn), the lb LED is lit for primary

secondary unit is pounds (lb), the lb LED is lit for primary

kg is lit for secondary units (lb). Because there is no LED for short tons, the lb and kg LEDs

Page 7

See Section 3.2.2 on page 12 for more information about configuring primary and secondary display units.

Secondary Unit

Primary Unit

lb lb / lb lb / kg lb / oz lb / g lb / kg

kg kg / lb kg / kg kg / oz kg / g lb / kg

oz oz / lb oz / kg oz / oz oz / g oz / kg

g g / lb g / kg g / oz g / g g / kg

tn lb / kg lb / kg lb / oz lb / g lb / lb lb / kg lb / kg

t lb / kg lb / lb lb / kg

none lb / kg lb / kg lb / lb

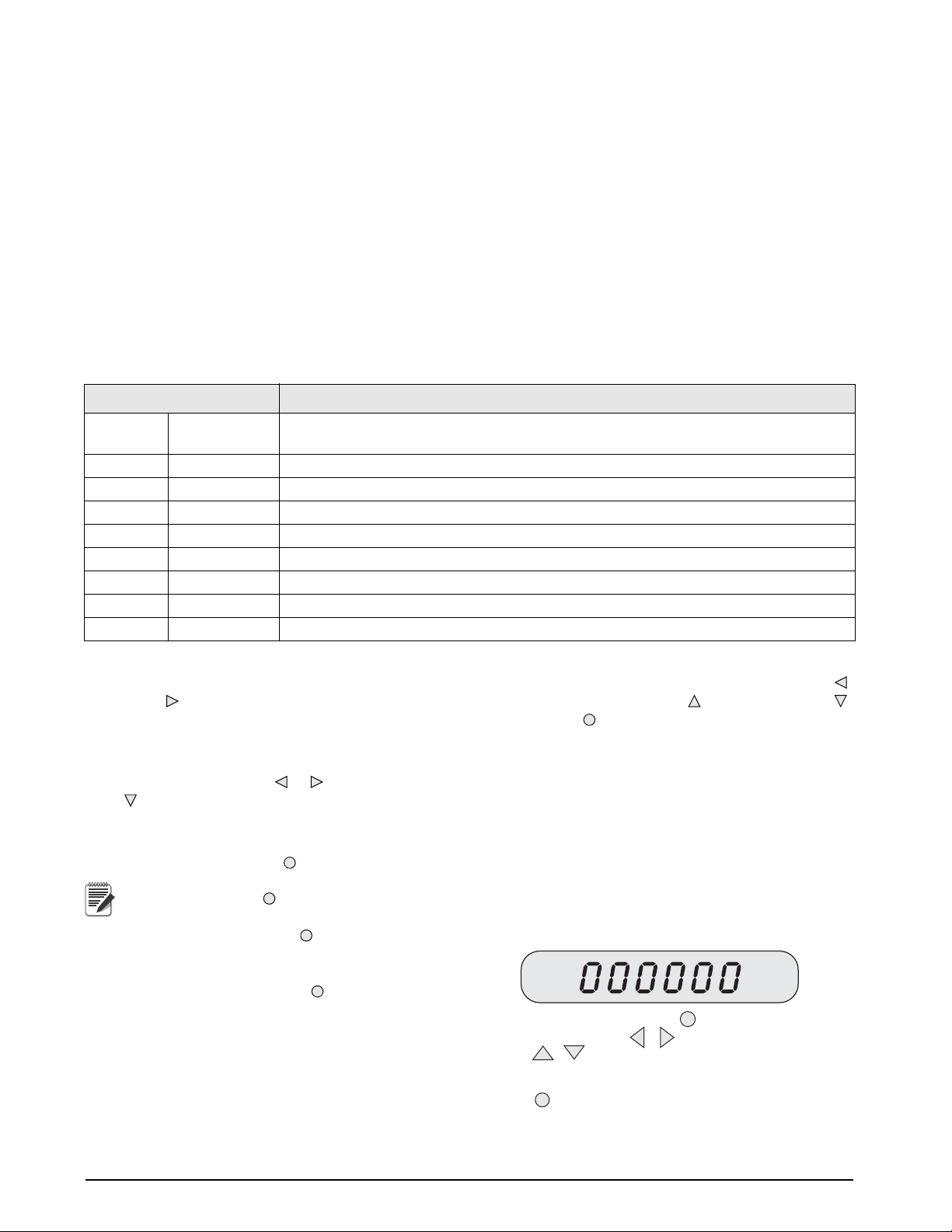

Table 1-1. Units Annunciators, Showing Primary / Secondary LEDs Used for All Configurations

lb kg oz g tn t none

1.4 Indicator Operations

1.4.1 Weighing Mode Operations

Basic 120 operations are summarized below:

Toggle Gross/Net Mode

Press the GROSS/NET key to switch the display mode from gross to net, or from net to gross. If a tare value has

been entered or acquired, the net value is the gross weight minus the tare.

Gross mode is shown by the

Toggle Units

Press the UNITS key to switch between primary and secondary units. The units LED to the right of the display is

lit.

Gross annunciator; net mode is shown by the Net annunciator.

Zero Scale

1. In gross mode, remove all weight from the scale and wait for the standstill annunciator ( ).

2. Press the

Acquire Tare

ZERO key. The center of zero ( ) annunciator lights to indicate the scale is zeroed.

1. Place container on scale and wait for the standstill annunciator ( ).

2. Press the

Remove Stored Tare Value

TARE key to acquire the tare weight of the container. The indicator switches to net mode.

1. Remove all weight from the scale and wait for the standstill annunciator ( ).

2. Press the

Print Ticket

TARE key. The indicator switches to gross mode, indicating the tare value has been removed.

1. Wait for the standstill annunciator ( ).

2. Press the

PRINT key to send data to the serial port.

Introduction 3

Page 8

1.4.2 Panel Mode Operations

Note

The following operations are available by placing the indicator in panel mode:

•Set time

•Set date

• S et consecutive number

• Set consecutive number start-up value

To enter panel mode, press and hold the

GROSS/NET key until the TIME menu is displayed. Use the navigation

keys to move around the menu; to change a value, use the navigation keys to select the digit and increment or

decrement its value. Press the

Enter (TAR E) key to set the value and return to the menu level above. Figure 1-2

shows the structure of the panel mode menu.

To enter a 2 digit month, the lower digit must be a “1” then the upper digit is incremented to “1”. The lower

digit can then be changed to 0, 1 or 2 as required.

TIME

SHOW

hh.mm.ss

HOUR

hh

MINUTE

mm

DATE

SECOND

ss

SHOW

yy.mm.dd

YEAR

yy

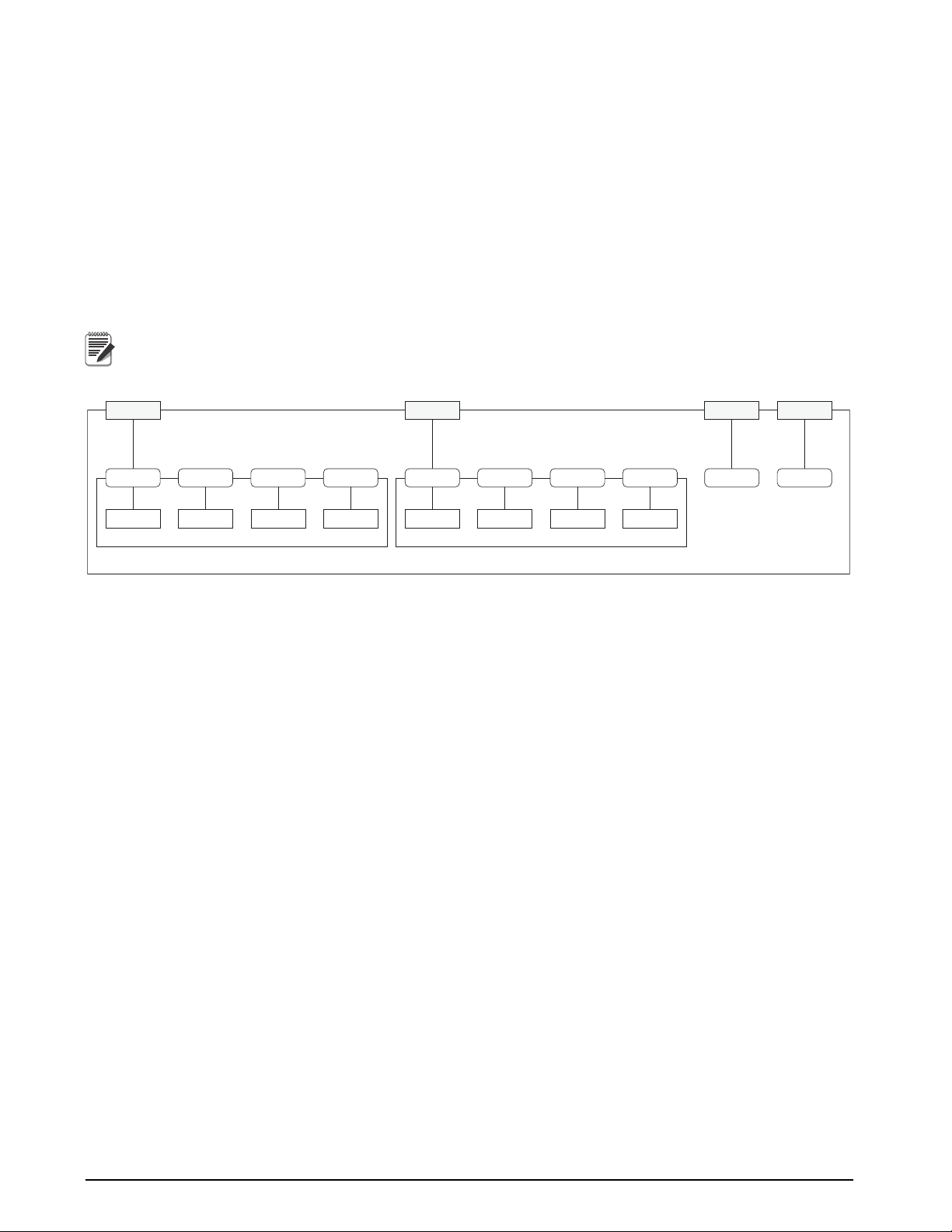

Figure 1-2. Panel Mode Menu Structure

MONTH

mm

DAY

dd

CONSNU

number

CONSTU

number

4 120 Installation Manual

Page 9

2.0 Installation

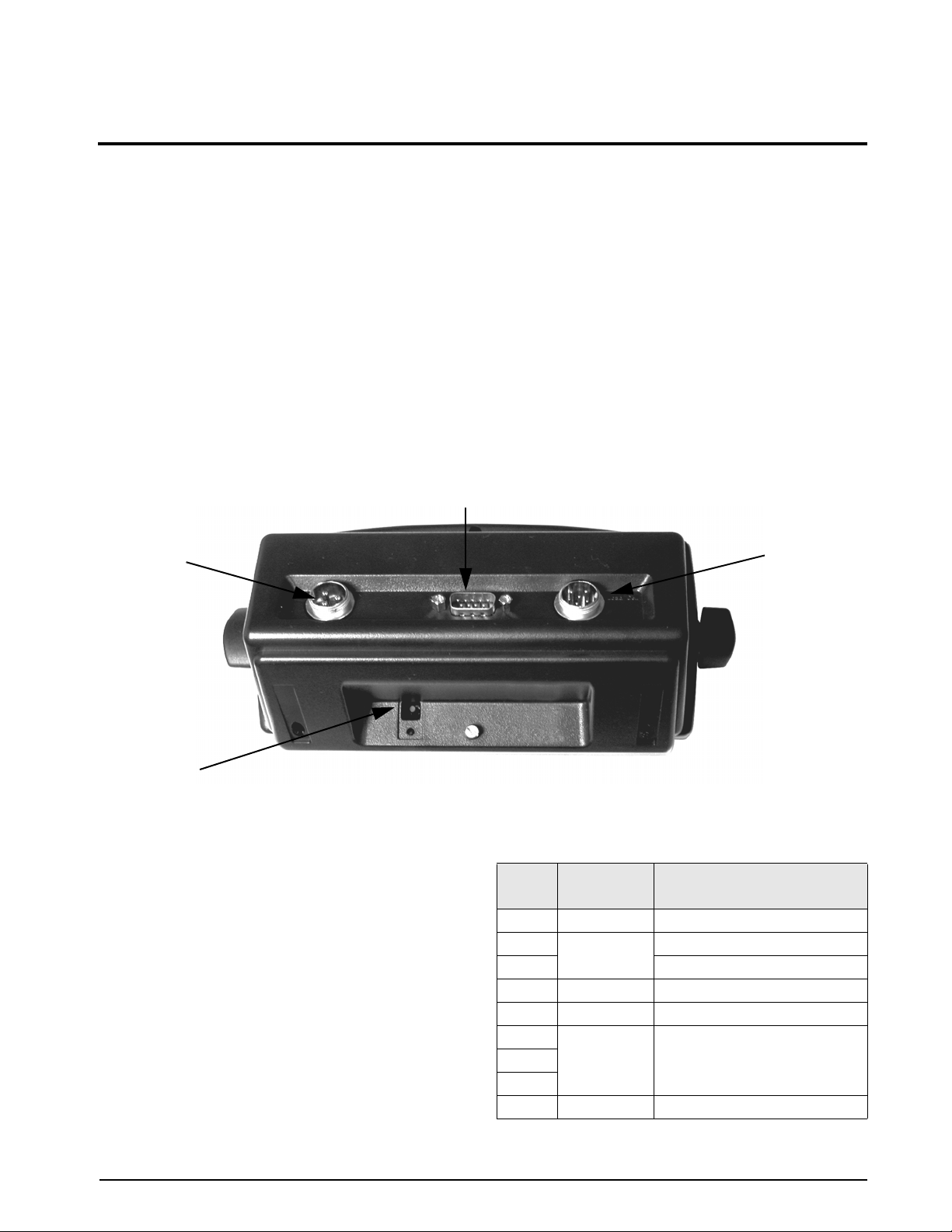

SETUP

PORT 1 PORT 2

COMMUNICATIONS

LOAD CELL

9VDC ADAPTER

SWITCH

DB-9

Connecto

r

Load Cell

Connection

shown with

6-pin

Connector

(Port 2)

Load Cell

Cord Grip

Available

Communications Port 1

Setup Switch

This section provides information for connecting load cell and serial communications cables to the 120 indicator .

2.1 Unpacking and Assembly

Immediately after unpacking, visually inspect the 120 to ensure all components are included and undamaged.

The shipping carton should contain the indicator with attached tilt stand, this manual, and a parts kit. If any parts

were damaged in shipment, notify Rice Lake Weighing Systems and the shipper immediately.

The parts kit contains the items listed below:

• Capacity and identification labels

• Load cell connector (PN 82505)

• 9V power supply adapter (PN 78611 for 115 VAC units, PN 78612 for 230 VAC units)

2.2 Enclosure and Connectors

The back of the 120 enclosure provides a 3-pin power connection, 9-pin D-sub connector for communicatio ns,

and an available 6-pin connector or load cell cord grip connector for load cell connection (see Figure 2-1).

The setup switch, used for placing the indicator into

of the enclosure. The setup switch is protected by a cover plate and secured with a fillister head screw (not shown

in Figure 2-1).

configuration mode, is located in the recess on the underside

Figure 2-1. Back View of 120 Enclosure, Showing Load Cell DB-9 Connector, Communications Connectors and Setup

Switch Location

2.2.1 Serial Communications

The serial communications cable attaches to the male

D-Sub connector, Port 1 (see Figure 2-1 on page 5).

Port 1 provides connections

for the EDP (Electronic

Data Processing) port and the printer port. Table 2-1.

shows the pin assignments for Port 1.

The EDP port supports RS-232 communications only;

the print

er port provides either active 20 mA output or

RS-232 transmission. Both ports are configured using

the SERIAL menu. See Section 3.0 on page 7 for

configuration information.

Port 1

Pin

1 Printer RS-232 TxD

2 EDP RS-232 TxD

3 RS-232 RxD

4 — not used

5 EDP/Printer RS-232 Ground / –20 mA OUT

6 N/C not used

7

8

9 Printer +20 mA OUT

Table 2-1. Serial Connector (Port 1) Pin Assignments

Port Function

Installation 5

Page 10

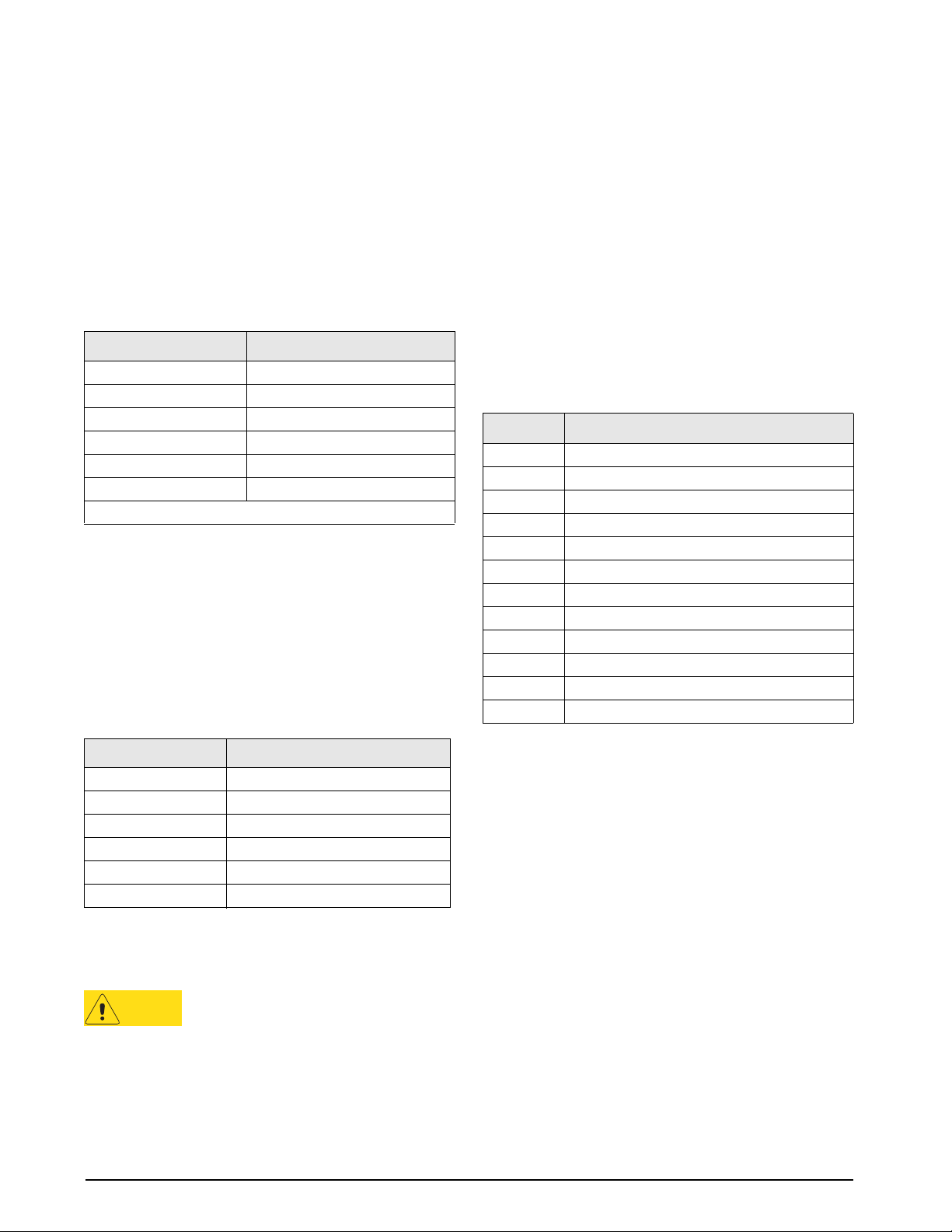

2.2.2 Load Cells

CAUTION

Load cell wires can be wired up one of two ways

depending upon which indicator model is purchased.

Refer to the 6-pin connector instructions or the load

cell cord grip plug instructions to connect to the load

cell wires.

6-Pin Connector

The load cell or junction box cable attaches to the

round 6-pin connector, Port 2 (see Figure 2-1 on

page 5). Table 2-2 shows the pin assignments for

Port 2.

Port 2 Pin Function

1 +SIG

2 +EXC

3 +SENSE *

4 –EXC

5 –SENSE *

6 –SIG

* For 4-wire connections, short pin 2 to pin 3, pin 4 to pin 5.

Table 2-2. Load Cell Connector (Port 2) Pin Assignments

Load Cell Cord Grip Plug

For models having the load cell cord grip, route cable

through the load cell cord grip and tighten the cord

grip. Next, remove connector J1 from the CPU board

which is located in the lower right side of the CPU

board. The connector plugs into a header on the board.

Wire the load cell cable from the load cell or junction

box to connector J1 as shown in Table 2-3.

J1 Function

1 –EXC

2 –SEN

3 –SIG

4 +SIG

5 +SEN

6 +EXC

h cover plate from back of enclosure.

switc

3. Loosen self-tapping screw at top center of back

of en

closure.

4. Lift up the forward edge of the rubber feet on

bottom of enclosure

for access to two additional

self-tapping screws. Loosen both screws.

5. Press down on top of back half of the enclosure

ase tabs. Open enclosure by separating the

to rele

housing at the top of the indicator. (CPU board

is mounted to front half of enclosure; power,

communications, and load cell connections all

connect to the bottom of the CPU board.)

6. Reverse steps to reassemble enclosure.

2.4 Replacement Parts

Table 2-4 lists replacement parts for the 120 indicator.

PN Description

78609 CPU Board

78610 Switch panel membrane

15799 9-pin socket for D-sub communi

15774 Shell for D-sub communications cable

83429 Setup switch cover plate

83430 Fillister head screw

83432 Self-tapping screw (enclosure)

83431 Rubber foot

83428 Tilt stand wing knob

78949 Optional wall-mount

78611 9V power supply adapter for 115V units

78612 9V power supply adapter for 230V units

Table 2-4. Replacement Parts

tilt stand

cations cable

2.3 Enclosure Disassembly

If the indicator enclosure must be opened for

maintenance, do the following:

6 120 Installation Manual

Table 2-3. J1 Pin Assignments with Load Cell Cord Grip

Use a wrist strap to ground yourself and

protect components from electrostatic

harge (ESD) when working inside the

disc

indicator enclosure.

1. Disconnect power to the unit. Remove tilt stand.

2. Remove two fillister head screws and the setup

Page 11

3.0 Configuration

SETUP SWITCH

FILLISTER-HEAD SCREW

To configure the 120 indicator, the indicator must be placed in setup

mode. The setup switch is accessed

screw on underside of the enclosure and removing the rectangular

switch cover plate. Switch position is changed by inserting a

screwdriver into the access hole and pressing the switch.

When the indicator is placed in setup mode, the word

on the display. The CONFIG menu is the first of nine main menus

used to configure the indicator. Detailed descriptions of these menus

are given in Section 3.2. When configuration is complete, ret

CONFIG menu and press the

3.1 Configuration Methods

The 120 indicator can be configured by using the front panel keys to navigate through a series of configuration

menus or by sending commands or configuration data to the EDP port. Configuration using the menus is

described in Section 3.1.3. Configuration using the EDP port can be accomplished u

described in Section 5.0 or by using the

by removing the left fillister head

CONFIG is shown

urn to the

(ZERO) key to exit setup mode, then replace the setup switch access screw.

sing the EDP command set

Revolution III configuration utility.

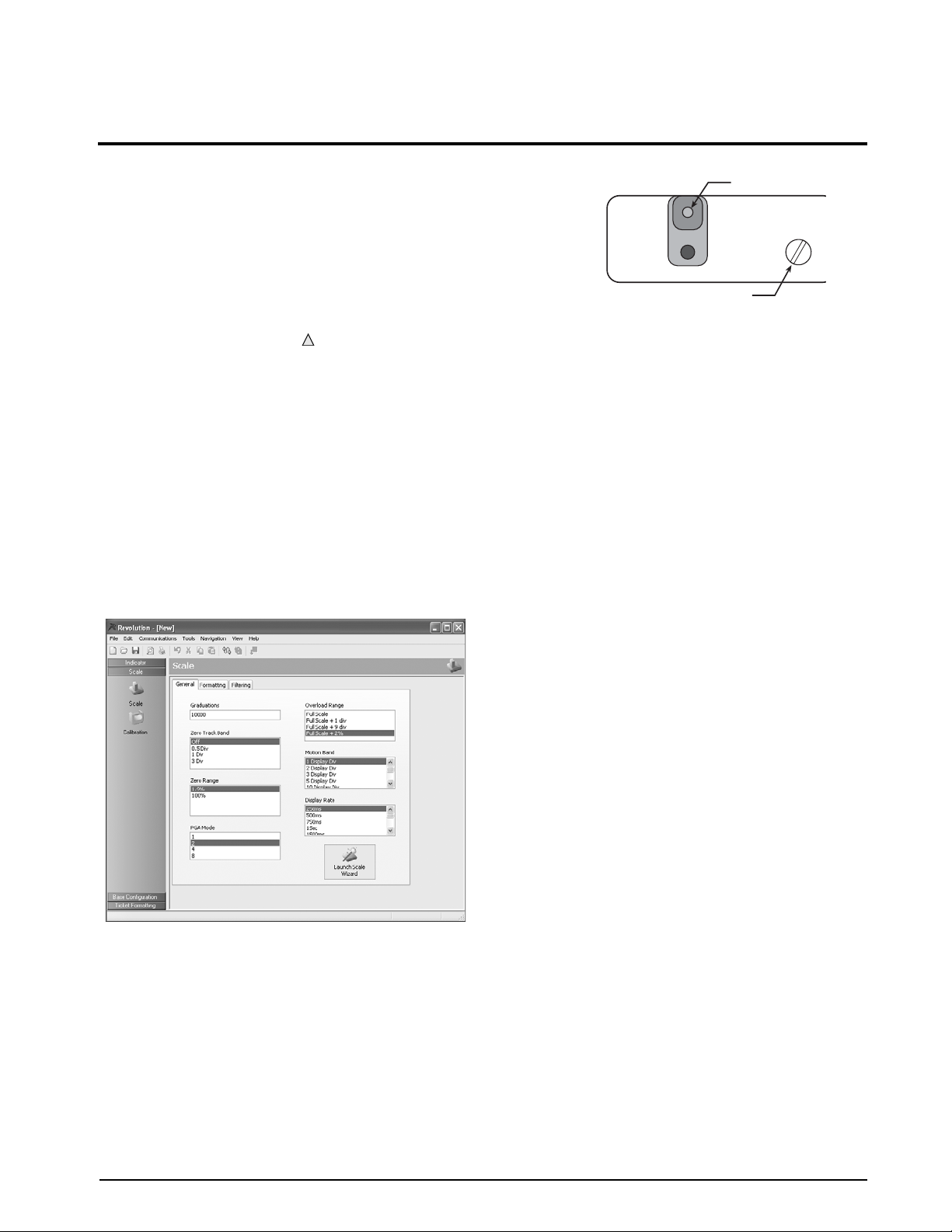

3.1.1 Revolution® Configuration

The Revolution III configuration utility provides the

preferred method for configuring the 120 indicator.

Revolution runs on a personal computer to set

configuration parameters for the indicator. When

Revolution configuration is complete, configuration

data is downloaded to the indicator.

To use

Revolution III, do the following:

1. Install

Revolution III (Version 3.1 or later) on an

IBM-compatible personal computer running

®

Windows

98 or later. Minimum system

requirements include a processor speed of at

least 166MHz, 32MB of memory (64MB

recommended, required for NT4, 2000, XP), and

at least 40MB of available hard disk space for

installation.

2. With both indicator and PC powered off,

connec

t the PC serial port to the RS-232 pins on

the indicator EDP port.

3. Power up the PC and the indi cator. Use th e setup

switc

h to place the indicator in setup mode.

4. Start the

Revolution III program.

Figure 3-1 shows an example of one of the Revolution

configuration displays.

Revolution III provides online help for each of its

configuration displays. Parameter descriptions

provided in this manual for front panel configuration

can also be used when configuring the indicator using

Revolution: the interface is different, but the

parameters set are the same.

Figure 3-1. Sample Revolution Configuration Display

Revolution III

downloading of indicator configuration data. This

capability allows configuration data to be retrieved

from one indicator, edited, then downloaded to

another.

supports both uploading and

Configuration 7

Page 12

3.1.2 EDP Command Configuration

Note

When editing numeric values, press to allow numeric mode

change entry, then press or to change the digit selected.

Press or to increment or decrement the value of the flashing

selected digit.

Press to save the value entered and return to the level above.

The EDP command set can be used to configure the 120 indicator using a personal computer, terminal, or remote

keyboard. Like Revolution, EDP command configuration sends commands to the indicator EDP port; unlike

Revolution, EDP commands can be sent using any external device capable of sending ASCII characters over a

serial connection.

EDP commands duplicate the functions available usin

g the indicator front panel and provide some functions not

otherwise available. EDP commands can be used to simulate pressing front panel keys, to configure the indicator,

or to dump lists of parameter settings. See Section 5.0 on page 23 for more information about using the EDP

command set.

3.1.3 Front Panel Configuration

The 120 indicator can be configured using a series of menus accessed through the indicator front panel when the

indicator is in setup mode. Table 3-1 summarizes the functions of each of the main menus.

Menu Menu Function

CONFIG Configuration Configure load cell sensitivity, grads, zero tracking

rate, and digital filtering parameters.

FORMAT Format Set format of primary and secondary units, display rate.

CALIBR Calibration Calibrate indicator. See Section 4.0 on page 21 for calibration procedures.

SERIAL Serial Configure EDP and printer serial ports.

PROGRM Program Set power-up mode, regulatory mode,

P FORMT Print Format Set print format used for gross and net tickets. See Section 5.0 for more information.

TIME Time Display and set time

DATE Date Display and set date

VERSION Version Display installed software version number.

and consecutive number values.

, zero range, motion band, overload, sample

Table 3-1. 120 Menu Summary

Four front panel keys are used as directional keys to navigate through the menus in setup mode. The UNITS ( )

PRINT ( ) keys scroll left and right (horizontally) on the same menu level; ZERO ( ) and GROSS/NET ( )

and

move up and down (vertically) to

parameter values within the menus. A label

different menu levels. The TARE key ( ) serves as an Enter key for selecting

under each of these keys identifies the direction prov ided by the key

when navigating through the setup menus.

T o select a parameter , press

press

to move down to the submenu or parameter you want. When moving through the menu parameters, the

or to scroll left or right until the desired menu group appears on the display, then

default or previously selected value appears first on the display.

To change a parameter value, scroll left or right to view the

appears on the display, press

You must press to save the selected value. The 120 does not automatically save the last-displayed value.

to select the value and move back up one level.

values for that parameter. When the desired value

To edit numerical values, press (rightmost digit will

flash), then use the navigation keys to select the digit

to increment or decrement the value (see

and

Figure 3.2). When done, press

again to save the

edited value.

8 120 Installation Manual

Figure 3-2. Editing Procedure for Numeric Values

Page 13

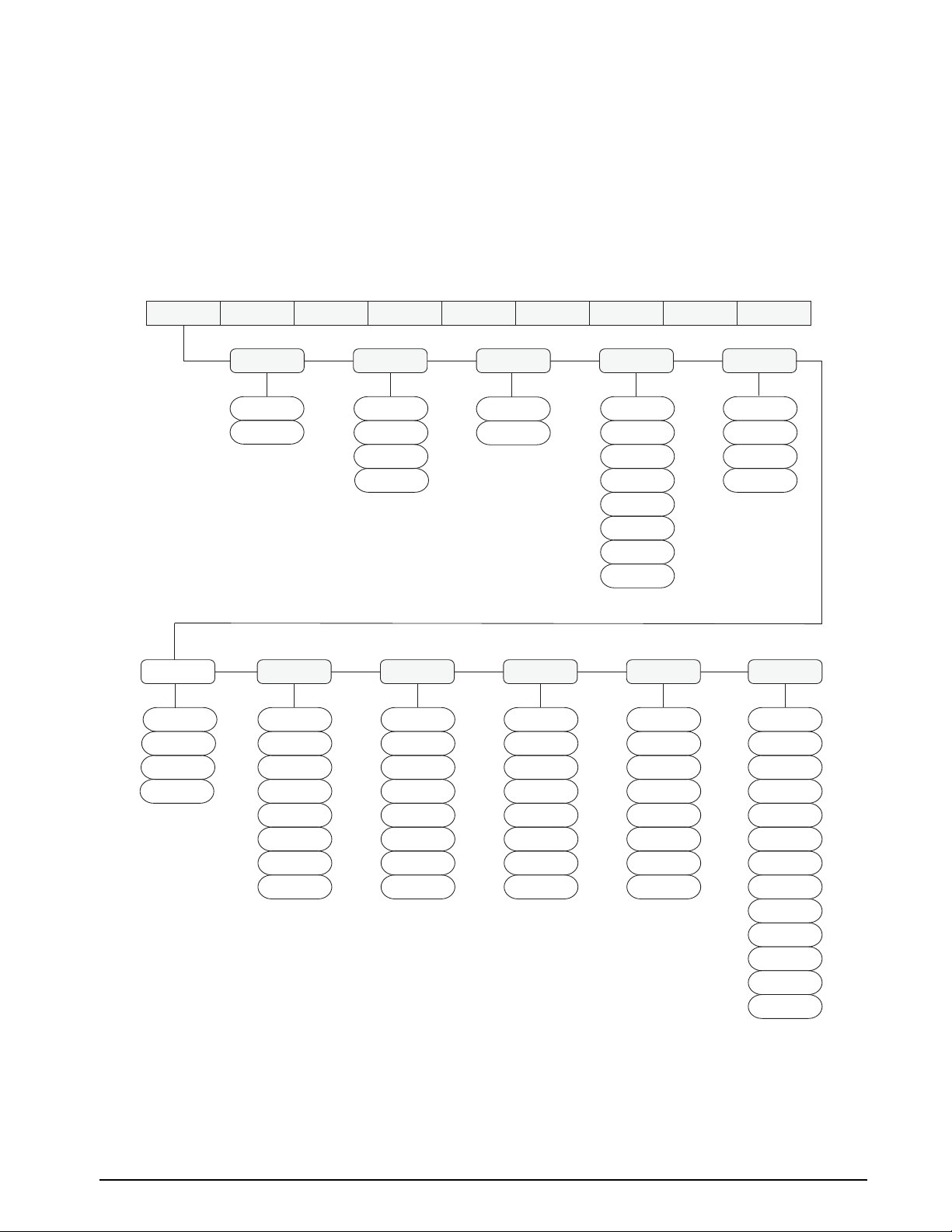

3.2 Menu Structures and Parameter Descriptions

GRADS

10000

OFF

1D

0.5D

3D

ZTRKBN ZRANGE

1.9%

100%

50D

2D

1D

3D

MOTBAN

10D

5D

20D

FS+2%

FS+9D

FS+1D

FS

OVRLOA

8

4

DIGFL1

64

32

number

DIGFL2 DIGFL3

8OUT

32OUT

16OUT

64OUT

DFSENS DFTHRH

1OUT

128OUT

2OUT

2DD

NONE

5DD

20DD

10DD

50DD

200DD

100DD

250DD

30HZ

7.5HZ

15HZ

3.75HZ

SMPRA

T

OFF

1

2

4OUT

16

8

4

64

32

1

2

16

128

128

VERS DA TE TIME

PFORMT

SERIAL CALIBR CONFIG FORMA T

PROGRM

8

4

64

32

1

2

16

128

0.1DD

0.2DD

1DD

0.5DD

The following sections provide graphic representations of the 120 menu structures. In the actual menu structure,

the settings you choose under each parameter are arranged horizontally. To save page space, menu choices are

shown in vertical columns. The factory default setting appears at the top of each column.

Most menu diagrams are accompanied by a table that describes all parameters and parameter values

with that menu. Default parameter values are shown in bold type.

3.2.1 Configuration Menu

associated

Figure 3-3. Configuration Menu

Configuration 9

Page 14

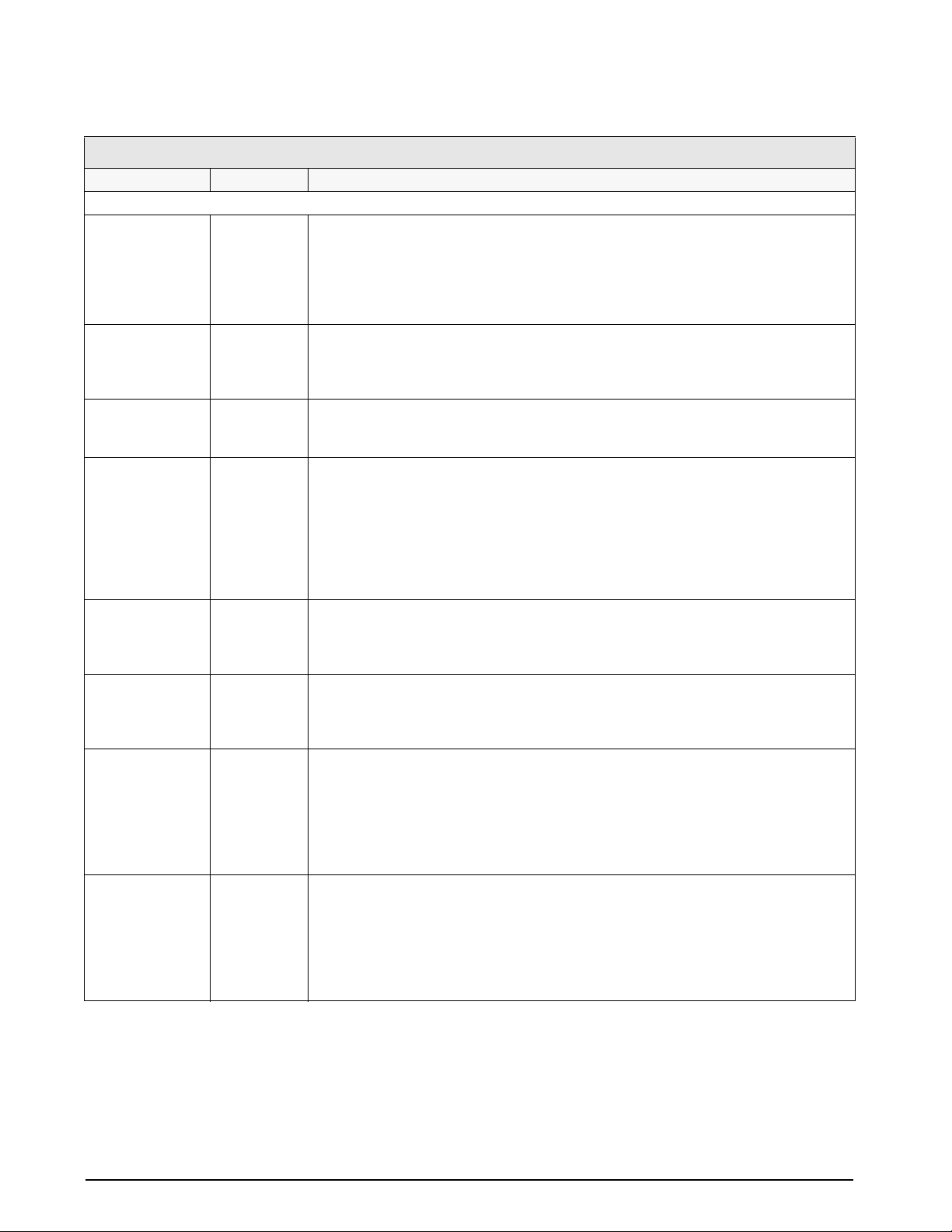

CONFIG Menu

Parameter Choices Description

Level 2 submenus

GRADS 10000

number

ZTRKBN OFF

0.5D

1D

3D

ZRANGE 1.9%

100%

MOTBAN 1D

2D

3D

5D

10D

20D

50D

OFF

OVRLOA FS+2%

FS+1D

FS+9D

FS

SMPRAT 15HZ

7.5HZ

3.75HZ

30HZ

DIGFL1

DIGFL2

DIGFL3

DFSENS 8OUT

2

4

8

16

32

64

1

16OUT

32OUT

64OUT

128OUT

2OUT

4OUT

Graduations. Specifies the number of full scale graduations. The value entered must be in

the range 1–100 000 and should be consistent with legal requirements and environmental

limits on system resolution.

To calculate GRADS, use the formula, GRADS = Capacity / Display Divisions.

Display divisions for primary and secondary units are specified on the FORMAT menu.

Zero track band. Automatically zeroes the scale when within the range specified, as long

as the input is within the configured zero range (ZRANGE parameter). Selections are ±

display divisions. Maximum legal value varies depending on local regulations.

Zero range. Selects the range within which the scale can be zeroed. The 1.9% selection is

± 1.9% around the calibrated zero point, for a total range of 3.8%. Indicator must be at

standstill to zero the scale. Use 1.9% for legal-for-trade applications.

Motion band. Sets the level, in display divisions, at which scale motion is detected. If

motion is not detected for 1 second or more, the standstill symbol lights. Some

operations, including print, tare, and zero, require the scale to be at standstill. Maximum

legal value varies depending on local regulations.

If OFF is selected, ZTRKBN should also be set to OFF.

Overload. Determines the point at which the display blanks and an out-of-range error

message is displayed. Maximum legal value varies depending on local regulations.

Sample rate. Selects measurement rate, in samples per second, of the analog-to-digital

converter. Lower sample rate values provide greater signal noise immunity.

Digital filtering. Selects the digital filtering rate used to reduce the effects of mechanical

vibration from the immediate area of the scale.

Choices indicate the number of A/D conversions that are averaged to obtain the

displayed reading. A higher number gives a more accurate display by minimizing the

effect of a few noisy readings, but slows down the settling rate of the indicator. See

Section 7.6 on page 34 for more information on digital filtering.

Digital filter cutout sensitivity. Specifies the number of consecutive readings that must fall

outside the filter threshold (DFTHRH parameter) before digital filtering is suspended. If

NONE is selected, the filter is always enabled.

10 120 Installation Manual

Table 3-2. Configuration Menu Parameters

Page 15

CONFIG Menu

Parameter Choices Description

DFTHRH NONE

0.1DD

0.2DD

0.5DD

1DD

2DD

5DD

10DD

20DD

50DD

100DD

200DD

250DD

Digital filter cutout threshold. Specifies the filter threshold, in display divisions. When a

specified number of consecutive scale readings (DFSENS parameter) fall outside of this

threshold, digital filtering is suspended. If NONE is selected, the filter is always enabled.

Table 3-2. Configuration Menu Parameters (Continued)

Configuration 11

Page 16

3.2.2 Format Menu

DSPDIV MULTUNITSDECPNT

0.45359

1D

5D

2D

number

PRIMAR SECNDR

6SEC

4SEC

3SEC

2500MS

2SEC

1500MS

750MS

500MS

250MS

8SEC

DSPRAT

DSPDIV UNITSDECPNT

T

KG

1D

5D

2D

LB

8.88888

888888

88888.8

8888.88

888.888

88.8888

OZ

TN

NONE

G

KG

LB

MULEXP

1SEC

8.88888

888888

88888.8

8888.88

888.888

88.8888

dec_position

VERSDATETIME

PFORMT

SERIALCALIBRCONFIG FORMAT

PROGRM

20D

10D

50D

20D

10D

50D

T

OZ

TN

NONE

G

Figure 3-4. Format Menu

FORMAT Menu

Parameter Choices Description

Level 2 submenus

PRIMAR DECPNT

DSPDIV

UNITS

SECNDR DECPNT

DSPDIV

UNITS

MULT

MULEXP

DSPRAT 250MS

500MS

750MS

1SEC

1500MS

2SEC

2500MS

3SEC

4SEC

6SEC

8SEC

12 120 Installation Manual

Specifies the decimal position, display divisions, a

nd units used for the primary units. See

Level 3 submenu parameter descriptions.

Specifies the decimal position, display divisions, units,

and conversion multiplier used for

the secondary units. See Level 3 submenu parameter descriptions.

Display rate. Sets the update rate for displ

ayed values. Values are in milliseconds (MS) or

seconds (SEC).

Table 3-3. Format Menu Parameters

Page 17

FORMAT Menu

Parameter Choices Description

Level 3 submenus

Primary Units (PRIMAR Parameter)

DECPNT 888888

8.88888

88.8888

888.888

8888.88

88888.8

DSPDIV 1D

2D

5D

10D

20D

50D

UNITS LB

KG

OZ

TN

T

G

NONE

Secondary Units (SECNDR Parameter)

DECPNT 88888.8

888888

8.88888

88.8888

888.888

8888.88

DSPDIV 5D

10D

20D

50D

1D

2D

UNITS KG

OZ

TN

T

G

LB

NONE

MULT 0.45359

number

MULEXP dec_position Multiplier decimal shift. Specifies a divisor used to shift the decimal position in the

Decimal point location. Specifies the location of the decimal point or dummy zeroes in the

primary unit display. Value should be consistent with local legal requirements.

Display divisions. Selects the minimum division size for the primary units displayed weight.

Specifies primary units for displayed and printed weight. Values are: LB=pound;

KG=kilogram; OZ=ounce; TN=short ton; T=metric ton; G=gram.

Decimal point location. Determines the location of the decimal point or dummy zeros in

the secondary unit display.

Display divisions. Selects the value of minimum division size of the displayed weight.

Specifies secondary units for displayed and printed weight. Values are: KG=kilogram;

OZ=ounce; TN=short ton; T=metric ton; G=gram; LB=pound.

Multiplier. Specifies the conversion factor by which the primary units are multiplied to

obtain the secondary units. The default is 0.45359, which is the conversion factor for

changing pounds to kilograms. Use the MULEXP parameter to shift the decimal position

of the multiplier. See

To toggle between primary and secondary units, press the UNITS key.

secondary units multiplier value. Use the left and right arrow keys to shift the decimal point

within the displayed MULT value.

Section 7.5 on page 33 for a list of multipliers.

Table 3-3. Format Menu Parameters (Continued)

Configuration 13

Page 18

3.2.3 Calibration Menu

WZERO

*CAL*

Display and edit

zero calibration

A/D count value

Display and edit

test weight value

WVAL

*CAL*

Display and edit

span calibration

A/D count value

WSPA N

*

CAL*

Press Enter to

remove offset from

zero and span

calibrations

REZERO

VERSDATETIME

PFORMT

SERIALCALIBRCONFIG FORMAT

PROGRM

10000

See Section 4.0 on page 21 for calibration procedures.

Figure 3-5. Calibration Menu

CALIBR Menu

Parameter Choices Description

Level 2 submenus

WZERO — Display and edit the zero calibration A/D count value.

DO NOT adjust this value after WSPAN has been set!

WVAL 10000

test_weight

WSPAN — Display and edit the span calibration A/D count value.

REZERO — Press Enter to remove an offset value from the zero and span calibrations.

Display and edit the test weight value.

Use this parameter only after WZERO and WSP

AN have been set. See Section 4.1 on

page 21 for more information about using this parameter.

Table 3-4. Calibration Menu Parameters

14 120 Installation Manual

Page 19

3.2.4 Serial Menu

EDP PRINT

PRN

EDP

PRNDES

BITS TERMBAUD

CR

9600

7SPACE

7ODD

8NONE

CR/LF

1200

38400

19200

EDP

OFF

STREAM

PRN

VERSDATETIME

PFORMT

SERIALCALIBRCONFIG FORMAT

DISABLE

ENABLE

PROTCT

2SEC

1SEC

STMDLY

4SEC

4800

2400

7EVEN

BITS TERMBAUD

CR

9600

7SPACE

7ODD

8NONE

CR/LF

1200

4800

2400

7EVEN

PROGRM

15SEC

8SEC

NONE

250MS

500MS

ECHO

OFF

ON

See Section 7.2 on page 29 for information about the 120 serial data format.

Figure 3-6. Serial Menu

SERIAL Menu

Parameter Choices Description

Level 2 submenus

EDP BAUD

BITS

Specifies settings for baud rate, data bits, termi

the EDP port.

TERM

PRINT BAUD

BITS

Specifies settings for baud rate, data bits, termi

the printer port.

TERM

STREAM OFF

EDP

PRN

Selects the serial port used for continuous transmission. See Section 7.2 on page 29 for

information about the

Table 3-5. Serial Menu Parameters

nation characters, and end-of-line delay used by

nation characters, and end-of-line delay used by

120 continuous data format.

Configuration 15

Page 20

SERIAL Menu

Parameter Choices Description

STMDLY 250MS

500MS

1SEC

2SEC

4SEC

8SEC

15SEC

NONE

PRNDES EDP

PRN

PROTCT ENABLE

DISABL

Level 3 Submenus EDP Port

BAUD 9600

19200

38400

1200

2400

4800

BITS 8NONE

7ODD

7EVEN

7SPACE

TERM CR/LF

CR

ECHO ON

OFF

Level 3 Submenus Printer Port

BAUD 9600

1200

2400

4800

BITS 8NONE

7ODD

7EVEN

7SPACE

TERM CR/LF

CR

Stream delay. Specifies the delay, seconds (SEC) or milliseconds (MS), inserted between stream

frames.

Print destination. Selects the port for data transmission when the PRINT key is pressed or the

KPRINT EDP command is sent.

EDP port protection. Select ENABLE to secure the EDP port from configuration changes.

Baud rate. Selects the transmission speed for the EDP port.

Selects number of data bits and parity of data transmitted from the EDP port.

Termination character. Selects termination character for data sent from the EDP port.

Echo. Specify whether serial commands sent to the indicator are echoed.

Baud rate. Selects the transmission speed for the printer port.

Selects number of data bits and parity of data transmitted from the printer port.

Termination character. Selects termination character for data sent from the printer port.

16 120 Installation Manual

Table 3-5. Serial Menu Parameters (Continued)

Page 21

3.2.5 Program Menu

PFORMT

CONSTU

0

number

PWRUPM

GO NTEP

DELAY

REGULA

OIML

CANADA

NONE

SERIALCALIBRCONFIG FORMAT

CONSNU

PROGRM

0

number

Figure 3-7. Program Menu

PROGRM Menu

Parameter Choices Description

Level 2 submenus

PWRUPM GO

DELAY

REGULA NTEP

OIML

CANADA

NONE

CONSNU 0

number

CONSTU 0

number

Power up mode. In GO mode, the indicator goes into ope

up display test.

In DELAY mode, the indica

tor performs a power up display test, then enters a 30-second

warm up period. If no motion is detected during the warm up period, the indicator becomes

operational when the warm up period ends; if motion is detected, the delay timer is reset and

the warm up period repeated.

Regulatory mode. Specifies the regulatory agency having

• OIML, NTEP, and CANADA modes allow a tare to be acquir

zero. NONE allows tares to be acquired at any weight value.

• OIML, NTEP, and CANADA modes allow a tare to be

no load. NONE allows tares to be cleared at any weight value.

• NTEP and OIML modes allow a new tare to be acquir

In CANADA mode, the previous tare must be cleared before a new tare can be acquired.

• NONE, NTEP and CANADA modes allow the scale t

mode as long as the current weight is within the specified ZRANGE. In OIML mode, the

scale must be in gross mode before it can be zeroed; pressing the ZERO key in net mode

clears the tare.

Consecutive numbering. Allows sequential number

number value is incremented following each print operation.

The initial value of this parameter is set to the

parameter. Changing either CONSTU or CONSNU immediately resets the consecutive number

used for printing.

Consecutive number start up value

. Specifies the initial consecutive number (CONSNU) value

used when the indicator is powered on.

VERSDATETIME

ration immediately after a brief power

jurisdiction over the scale site.

ed at any weight greater than

cleared only if the gross weight is at

ed even if a tare is already present.

o be zeroed in either gross or net

ing for print operations. The consecutive

start up value specified on the CONSTU

Table 3-6. Program Menu Parameters

Configuration 17

Page 22

3.2.6 Print Format Menu

See Section 6.0 on page 27 for information about custom print formatting.

EDIT

00_@40

01_N4E

Position

Character

ASCII

Value

SERIALCALIBRCONFIG FORMAT

PROGRM

INSERT DELETE

00

PFORMT

xx__00

Figure 3-8. Print Format Menu

VERSDATETIME

18 120 Installation Manual

Page 23

3.2.7 Time Menu

Time can also be set by the operator in panel mode. See Section 1.4.2 on page 4.

PFORMT

SECOND

00–59

SHOW

00.00.00

display time

SERIALCALIBRCONFIG FORMAT

HOUR MINUTE

00 00 00

00–23

PROGRM

00–59

Figure 3-9. Time Menu

TIME Menu

Parameter Choices Description

Level 2 submenus

SHOW HH.MM.SS Displays current time in HH.MM.SS format

HOUR hour (HH) Set hour using 24-hour format

MINUTE minute (MM) Set minute

SECOND second (SS) Set second

Table 3-7. Time Menu Parameters

3.2.8 Date Menu

Date can also be set by the operator in panel mode. See Section 1.4.2 on page 4.

VERSDATETIME

PFORMT

DAY

01-31

SHOW

03.01.01

display date

SERIALCALIBRCONFIG FORMAT

YEAR MONTH

03 01 01

PROGRM

01–1200–99

Figure 3-10. Date Menu

DATE Menu

Parameter Choices Description

Level 2 submenus

SHOW YY.MM.DD Displays current date in YY.MM.DD format

YEAR year (YY) Set year (two digits, 00–99)

MONTH month (MM) Set month

DAY day (DD) Set day

Table 3-8. Date Menu Parameters

VERSDATETIME

Configuration 19

Page 24

3.2.9 Version Menu

The VERS menu is used to check the software version installed in the indicator. There are no parameters

associated with the Version menu: when selected, the indicator displays the installed software version number.

and the indicator model

SERIALCALIBRCONFIG FORMAT

PROGRM

Figure 3-11. Version Menu

PFORMT

VERSDATETIME

Software

version

20 120 Installation Manual

Page 25

4.0 Calibration

WZERO

*CAL*

Display and edit

zero calibration

A/D count value

Display and edit

test weight value

WVAL

*CAL*

Display and edit

span calibration

A/D count value

WSPA N

*

CAL*

Press Enter to

remove offset from

zero and span

calibrations

REZERO

VERSDATETIME

PFORMT

SERIALCALIBRCONFIG FORMAT

PROGRM

10000

Note

The 120 can be calibrated using the front panel, EDP commands, or the Revolution® configuration utility. Each

method consists of the following steps:

• Zero calibration

• E ntering the test weight value

• Span calibration

• Optional rezero calibration for test weights using hooks or chains.

The following sections describe the

calibration procedure for each of the calibration methods.

Figure 4-1. Calibration (CALIBR) Menu

4.1 Front Panel Calibration

To calibrate the indicator using the front panel, do the

following:

1. Place the indicator in configuration mode

(display reads

from the scale platform. If your test weights

require hooks or chains, place the hooks or

chains on the scale for zero calibration.

2. Press

Figure 4-1). Press to go to zero calibration

(

WZERO).

3. With

WZERO displayed, press to calibrate

zero. The indicator displays

calibration is in progress then the display goes

WVAL).

to (

4. With

WVAL displayed, place test weights on

the scale and press to show the test weight

value. Use the procedure shown in Figure 4-2

to enter the actual test weight, then press

save the value and go to span calibration

(

WSPAN).

5. With

WSPAN displayed, press to calibrate

span. The indicator displays

calibration is in progress, then the display

goes to (

6. The

REZERO function is used to remove a

calibration offset when hooks or chains are

used to hang the test weights.

CONFIG) and remove all weight

until the display reads CALIBR (see

*CAL* while

to

*CAL* while

REZERO).

If no other apparatus was used to hang the

test weights during calibration, remove the

test wei

ghts and go to Step 7.

• If hooks or chains were used during

calibration, remove these and the test

weights from the scale. With all weight

removed, press

to rezero the scale. This

function adjusts the zero and span

calibration values. The indicator displays

*CAL* while the zero and span calibrations

are adjusted.

7. Press

press

When editing numeric values, press to allow numeric mode

change entry, then press or to change the digit selected.

Press or to increment or decrement the value of the flashing

selected digit.

Press to save the value entered and return to the level above.

Figure 4-2. Editing Procedure for Numeric Values

until the display reads EXIT Y, then

to exit configuration mode.

Calibration 21

Page 26

4.2 EDP Command Calibration

Note

To calibrate the indicator using EDP commands, the

indicator EDP port must be connected to a terminal or

personal computer. See Section 2.2.1 on page 5 for

EDP port pin assignments; see Section 5.0 on page 23

for more information about using EDP commands.

Once the indicator is connecte

do the following:

1. Place the indicator in configuration mode

(display reads

CONFIG) and remove all weight

from the scale platform. If your test weights

require hooks or chains, place the hooks or

chains on the scale for zero calibration.

2. Send the WZERO EDP command to calibrate

ro. The indicator displays

ze

calibration is in progress.

During EDP command calibration, the *CAL*

message remains on the display. The OK

ponse is returned when calibration is

res

complete.

d to the sending device,

*CAL* while

3. Place test weights on the scale and use the

WVAL command to enter the test weight

value in the following format:

WVAL=nnnnnn<CR>

4. Send the WSPAN EDP command to calibrate

span. The indicator displays

*CAL* while

calibration is in progress.

5. To remove an offset value, clear all weight

from the sca

le, including hooks or chains used

to hang test weights, then send the REZERO

EDP command. The indicator displays

*CAL*

while the zero and span calibrations are

adjusted.

6. Send the KUPARROW EDP command to exit

con

figuration mode.

22 120 Installation Manual

Page 27

5.0 EDP Commands

Note

The 120 indicator can be controlled by a personal

computer or remote keyboard connected to the

indicator EDP port. Control is provided by a set of

EDP commands that can simulate front panel key

press functions, display and change setup parameters,

and perform reporting functions. The EDP port

provides the capability to print configuration data or

to save that data to an attached personal computer.

This section describes the EDP command set and

procedures for saving and transferring data using the

EDP port.

5.1 The EDP Command Set

The EDP command set includes key press commands,

mode commands, reporting commands, the RS special

function command, and parameter setting commands.

The indicator responds to

sending the message

OK. The OK response verifies that

the command was received and has been executed.

(Pressing

ENTER after processing a valid EDP

command repeats the previous command.) If the

command is unrecognized or cannot be executed, the

indicator responds with

The following sections list the commands and

command syntax use

5.1.1 Key Press Commands

d for each of these groups.

Key press EDP commands (see Table 5-1) simulate

pressing the front panel indicator keys. These

commands can be used in both configuration and

ing mode.

weigh

Command Function

KZERO In weighing mode, press the ZERO key

KGROSSNET In weighing mode, press the GROSS/

NET key

KTARE In weighing mode, press the TARE key

KUNITS In weighing mode, press the UNITS key

KPRINT In weighing mode, press the PRINT key

Table 5-1. Key Press EDP Commands

most EDP commands by

??.

5.1.2 Reporting Commands

Reporting commands (Table 5-2) send specific

information to the EDP port. These commands can be

sed in both configuration mode and normal mode.

u

Command Function

DUMPALL List all parameter values

VERSION

P Write current displayed weight with units

RS Reset software

Table 5-2. EDP Reporting Commands

5.1.3 The RS Command

120 software version

Write

identifier

The RS (reset configuration) command can be used to

restore all configuration parameters to their default

values. Before issuing this command, the indicator

must be placed in test mode (press and hold setup

switch for approximately three seconds to enter test

mode).

This command is equivalent to using the DEFLT

ction on the TEST menu. See Section 7.7 on

fun

page 35 for more information about test mode and

using the TEST menu.

All load cell calibration settings are lost when

the RS command is run.

5.1.4Parameter Setting Commands

Parameter setting commands allow you to display or

change the current value for a particular configuration

parameter (Tables 5-3 through 5-8).

Current configuration parameter sett

ings can be

displayed in either configuration mode or normal

mode using the following syntax:

command<ENTER>

Most parameter values can be changed in

configuration mode only. Use the following command

syntax when changing parameter values:

command=value<ENTER>

where value is a number or a parameter value. Use no

spaces before or after the equal (=) sign. If you type an

incorrect command or value, the display reads

??.

Changes to the parameters are saved as they are

entered but typically do not take effect until you exit

configuration mode.

For example, to set the motion band par

ameter to 5,

type the following:

MOTBAND=5D<ENTER>

EDP Commands 23

Page 28

Command Description Values

GRADS Graduations 1–100 000

ZTRKBND Zero track band OFF, 0.5D, 1D, 3D

ZRANGE Zero range 1.9%, 100%

MOTBAND Motion band 1D, 2D, 3D, 5D, 10D, 20D, 50D, OFF

OVRLOAD Overload FS+2%, FS+1D, FS+9D, FS

SMPRAT Sample rate 15HZ, 7.5HZ, 3.75HZ, 30HZ

DIGFLTR1

DIGFLTR2

DIGFLTR3

DFSENS Digital filter cutout sensitivity 2OUT, 4OUT, 8OUT, 16OUT, 32OUT, 64OUT, 128OUT

DFTHRH Digital filter cutout threshold NONE, 0.1DD, 0.2DD, 0.5DD, 1D

Digital filtering 1, 2, 4, 8, 16, 32, 64, 128

D, 2DD, 5DD, 10DD, 20DD,

50DD, 100DD, 200DD, 250DD

Table 5-3. CONFIG EDP Commands

Command Description Values

PRI.DECPNT Primary units decimal position 8.88888, 88.8888, 888.888, 8888.88, 88888.8, 888888

PRI.DSPDIV Primary units display divisions 1D, 2D, 5D, 10D, 20D, 50D

PRI.UNITS Primary units LB, KG, OZ, TN, T, G, NONE

SEC.DECPNT Secondary units decimal position 8.88888, 88.8888, 888.888, 8888.88, 88888.8, 888888

SEC.DSPDIV Secondary units display divisions 1D, 2D, 5D, 10D, 20D, 50D

SEC.UNITS Secondary units LB, KG, OZ, TN, T, G, NONE

SEC.MULT Secondary units multiplier 0.00000–9999.99

DSPRATE Display rate 250MS, 500MS, 750MS, 1SEC, 1500MS, 2SEC, 2500MS, 3SEC,

, 6SEC, 8SEC

4SEC

Table 5-4. FORMAT EDP Commands

Command Description Values

WZERO Zero calibration —

WVAL Test weight value test_weight_value

WSPAN Span calibration —

REZERO Rezero —

LC.CD Set deadload coefficient value

LC.CW Set span coefficient value

Table 5-5. CALIBR EDP Commands

24 120 Installation Manual

Page 29

Command Description Values

EDP.BAUD EDP port baud rate 1200, 2400, 4800, 9600, 19200, 38400

EDP.BITS EDP port data bits/parity 8NONE, 7ODD, 7SPACE, 7EVEN

EDP.TERM EDP port termination character CR/LF, CR

EDP.ECHO EDP port echo ON, OFF

PRN.BAUD Printer port baud rate 1200, 2400, 4800, 9600

PRN.BITS Printer port data bits/parity 8NONE, 7ODD, 7SPACE, 7EVEN

PRN.TERM Printer port termination character CR/LF, CR

STREAM Streaming port OFF, EDP, PRN

STMDLY Stream delay NONE, 250MS, 500MS, 1SEC, 2SEC, 4SEC, 8SEC, 15SEC

PRNDEST Print destination EDP, PRN

PROTCT EDP port protection ENABLE, DISABLE

Table 5-6. SERIAL EDP Commands

Command Description Values

PWRUPMD Power up mode GO, DELAY

REGULAT Regulatory compliance NTEP, OIML, CANADA, NONE

CONSNUM Consecutive number 0–999 999

CONSTUP Consecutive number start-up value 0–999 999

Table 5-7. PROGRM EDP Commands

Command Description Values

WWPF Print characters of format string See Section 6.0 on page 27 for detailed information

WPF Print hex values of format string

Table 5-8. PFORMT EDP Commands

EDP Commands 25

Page 30

5.2 Saving and Transferring Data

Note

Connecting a personal computer to the 120 EDP port allows you to save indicator configuration data to the PC or

to download configuration data from the PC to an indicator. The following sections describe the procedures for

these save and transfer operations.

5.2.1 Saving Indicator Data to a Personal Computer

Configuration data can be saved to a pers onal computer connected to the ED P port. The PC must be running a

communications program such as PROCOMMPLUS

communications wiring and EDP port pin assignments.

When configuring the indicator, ensure that the values

menu match the baud rate, bits, and parity settings configured for the serial port on the PC. Set the PRNDES

parameter to EDP.

To save all configuration data, place the indicator in configuration mo

command to the indicator. The 120 responds by sending all configuration parameters to the PC as

ASCII-formatted text.

5.2.2 Downloading Configuration Data from PC to Indicator

Configuration data saved on a PC or floppy disk can be downloaded from the PC to an indicator. This procedure

is useful when a number of indicators with similar configurations are set up or when an indicator is replaced.

T o download configuration data, connect the

in configuration mode and use the PC

PC to the EDP port as described in Section 5.2.1. Place the indicator

communications software to send the saved configuration data to the

indicator. When transfer is complete, calibrate the indicator as described in Section 4.0 on page 21.

®

. See Section 2.2.1 on page 5 for information about serial

set for the BAUD and BITS parameters on the SERIAL

de and send the DUMPALL EDP

• Calibration settings are included in the configuration data downloaded to the indicator. If the receiving

indicator is a direct replacement for another 120 and the attached scale is not changed, recalibration is

not required.

• When downloading configurations that include changed

serial communications settings, edit the data file

to place the serial communications changes at the end of the file. Communication between the PC and

indicator will be lost once the indicator receives settings for baud rate (BAUD parameter) or data bits

and parity (BITS parameter) that do not match those configured for the PC.

26 120 Installation Manual

Page 31

6.0 Print Formatting

Note

Note

Note

The 120 print format can be edited to specify the

format of the printed output when the

PRINT key is

pressed or when a KPRINT EDP command is

received.

Each print format can be customized to include

up to

300 characters of information, such as company name

and address, on printed tickets. You can use the

indicator front panel (PFORMT menu), EDP

commands, or the Revolution® configuration utility

to customize the print format.

6.1 Print Formatting Commands

Table 6-1 lists commands you can use to format the

print format. Text included in the format string must

be enclosed in quotation marks (hex 22). T

characters can include any ASCII character that can

be printed by the output device.

Command Description

@G Gross weight in displayed units

@N Net weight in displayed units

@T Tare weight in displayed units

@C Consecutive number

@M Conditional net and tare weights.

Use the @M command in pairs to enclose the

and @T commands. If no tare is in the

@N

system, net and tare weights are not printed.

@t Time

@d Date

@Lnn New line (nn =

[CR/LF or CR] )

@Snn

Gross, net, and tare weights are 9 digits in length, including

sign (10 digits with decimal point), followed by a space and a

two-digit units identifier. Total field length with units identifier

is 12 (or 13) characters.

ID and consecutive number (CN) fields are 1–6 characters in

length, as required.

Space (nn = number of spaces)*

number of termination characters

ext

6.2 Customizing Print Formats

The following sections describe procedures for

customizing the print format using the EDP port or the

front panel (PFORMT menu).

6.2.1 Using the EDP Port

With a personal computer, terminal, or remote

keyboard attached to the 120 EDP port, you can use

the EDP command set to customize the print format

string.

To view the current setting of the print format, type

WWPF (to

values) then press

sending the current configuration for the print format:

Use the WWPF or WPF EDP command followed by

an equals sign (=) and ze

string.

The following example shows the commands used to

define

printer.

WWPF=0

N

A0,0,0,3,1,2,N,”Blue Hills T

A8,50,0,5,1,1,N,”@G”

@M A8,120,0,5,1,1,N,”@T”

A8,190,0,5,1,1,

B8,260,0,3,3,7,100,B,”@G”

P1

enter ASCII text) or WPF (to enter hex

ENTER. The indicator responds by

ro (0) to edit the print format

a print format string for an Eltron LP-2742

The N, AxxxxxxN, Bx, and P1 commands used

in the example are all Eltron printer-specific

comma

After entering the WWPF=0 or WPF=0

command, you must begin entering the print

form

times out, resulting in a blank format.

nds.

ransfer Co. @d @t @C”

N,”@N”@M

at. If no data is entered, the command

Table 6-1. Print Format Commands

The 300-character limit of the print format

string includes the output field length of the

print formatting co

command length. For example, if the indicator is

configured to show a decimal point, the @G command

generates an output field of 13 characters: the

10-character weight value (including decimal point), one

space, and a two-digit units identifier.

mmands, not the

Print Formatting 27

Page 32

6.2.2 Using the Front Panel

Note

If you have no access to equipment for communication through the EDP port or are working at a site where such

equipment cannot be used, you can use the PFORMT menu (see Figure 6-1) to customize the print format. Using

the PFORMT menu, you can edit the print format

string by changing the hex values of the ASCII characters in

the format string.

To edit a print format, do the following:

1. In setup mode, use the navigation keys to go to the PFORMT menu. Press

2. Press

again to show the print format string. Use the and keys to scroll through the format. The

number position of each character is shown in the two digits at the left

3. To ed

4. If done, press

5. To inser

it a character, press while the characte r is displayed. The rightmost digit flashes, indicating that

it can be changed. Use the

to the next digit. Press

and keys to increment or decrement the value, or use the key to move

to save any changes and advance to the next character in the string.

to return to the EDIT submenu.

t one or more characters, display the character position after which characters are to be inserted.

Press

to return to the EDIT submenu, then press to show the INSERT parameter. Press to insert

one character; repeat presses to add more characters. Each press of the

location last shown under EDIT submenu and shifts all subs

equent characters to the right. Inserted

to show the EDIT submenu.

of the display, hex 00–BF.

key adds a character at the

characters are assigned hex value 00 (null).

To edit inserted characters, return to the EDIT

6. To delete

one or more characters, display the character to be deleted. Press to return to the EDIT

submenu and make changes as described under step 3.

submenu, then press twice to show the DELETE parameter. Press to delete one character; repeat

presses to delete more characters. Each press of the

key deletes a character, starting at the location last

shown under EDIT submenu, then moving left to preceding characters. Each deletion shifts all

subsequent characters to the left.

Some characters cannot be displayed on the 120 front panel (see the ASCII character chart on page 31) and

are shown as blanks. The

the particular ASCII character set implemented for the receiving device.

120 can send or receive any ASCII character; the character printed depends on

SERIALCALIBRCONFIG FORMAT

EDIT

00_@40

01_N4E

Position

Character

ASCII

Value

Figure 6-1. PFORMT Menu, Showing Alphanumeric Character Entry Procedure

PROGRM

INSERT DELETE

00

xx__00

PFORMT

VERSDATETIME

28 120 Installation Manual

Page 33

7.0 Appendix

<STX> <POL> <wwwwwww> <UNIT> <G/N> <S> <EXTEND> <TERM>

ASCII 02

(decimal)

Polarity:

<Space> = Positive

<–> = Negative

Weight data: 7 digits, right-justified, with

decimal point, leading zero suppression.

Error =

- - - - - -

L = pounds

K = kilogram

T = ton

G = grams

O = ounces

<space> = none

G = Gross

N = Net

Status:

<space> = valid

I = Invalid

M = In motion

<CR> <LF>

or <CR>

ASCII 13, 10

(decimal)

<SPACE> <TIME> < / > <DATE> <SPACE> <RAW_COUNT>

ASCII 32

(decimal)

ASCII 32

(decimal)

ASCII 47

(decimal)

Time: 8 digits, hh:mm:ss

hh: 00–24

mm: 00–59

ss: 00–59

Date: 2 digits, dd

dd: 01–31

Raw count: 8 digits

00000000–16777216

7.1 Error Messages

Error Message Description Solution

_ _ _ _ _ _

(bottom LED segments lit)

_ _ _ _ _ _

(middle LED segments lit)

_ _ _ _ _ _

(top LED segments lit)

7.2 Continuous Output (Stream) Format

Figure 7-1 shows the continuous output format sent to the 120 EDP or printer port when the STREAM parameter

(SERIAL menu) is set to either EDP or PRN.

Display overflow (negative) Negative weight value too large to be

displayed (<

–99999)

Overload Weight value exceeds scale capacity

Display overflow (positive) Positive weight value too large to be

displayed (> 999999)

Table 7-1. 120 Error Messages

Figure 7-1. Continuous Output Data Format

Appendix 29

Page 34

7.3 Front Panel Display Characters

!

"

#

$

%

&

'

(

)

*

+

,

-

.

/

0

1

2

3

4

5

6

7

8

9

:

;

<

Figure 7-2 shows the 7-segment LED character set used to display alphanumeric characters on the 120 front

panel.

Figure 7-2. 120 Display Characters

30 120 Installation Manual

Page 35

7.4 ASCII Character Chart

Use the decimal values for ASCII characters listed in

Tables 7-2 and 7-3 when specifying print format

strings on the 12

0 PFORMT menu. The actual

character printed depends on the character mapping

used by the output device.

Control ASCII Dec Hex ASCII Dec Hex ASCII Dec Hex ASCII Dec Hex

Ctrl-@ NUL 00 00 space 32 20 @ 64 40 ` 96 60

Ctrl-A SOH 01 01 ! 33 21 A 65 41 a 97 61

Ctrl-B STX 02 02 “ 34 22 B 66 42 b 98 62

Ctrl-C ETX 03 03 # 35 23 C 67 43 c 99 63

Ctrl-D EOT 04 04 $ 36 24 D 68 44 d 100 64

Ctrl-E ENQ 05 05 % 37 25 E 69 45 e 101 65

Ctrl-F ACK 06 06 & 38 26 F 70 46 f 102 66

Ctrl-G BEL 07 07 ’ 39 27 G 71 47 g 103 67

Ctrl-H BS 08 08 ( 40 28 H 72 48 h 104 68

Ctrl-I HT 09 09 ) 41 29 I 73 49 i 105 69

Ctrl-J LF 10

Ctrl-K VT 11 0B + 43 2B K 75 4B k 107 6B

Ctrl-L FF 12 0C , 44 2C L 76 4C l 108 6C

Ctrl-M CR 13 0D - 45 2D M 77 4D m 109 6D

Ctrl-N SO 14 0E . 46 2E N 78 4E n 110 6E

Ctrl-O SI 15 0F / 47 2F O 79 4F o 111 6F

Ctrl-P DLE 16 10 0 48 30 P 80 50 p 112 70

Ctrl-Q DC1 17 11 1 49 31 Q 81 51 q 113 71

Ctrl-R DC2 18 12 2 50 32 R 82 52 r 114 72

Ctrl-S DC3 19 13 3 51 33 S 83 53 s 115 73

Ctrl-T DC4 20 14 4 52 34

Ctrl-U NAK 21 15 5 53 35 U 85 55 u 117 75

Ctrl-V SYN 22 16 6 54 36 V 86 56 v 118 76

Ctrl-W ETB 23 17 7 55 37 W 87 57 w 119 77

Ctrl-X CAN 24 18 8 56 38 X 88 58 x 120 78

Ctrl-Y EM 25 19 9 57 39 Y 89 59 y 121 79

Ctrl-Z SUB 26 1A : 58 3A Z 90 5A z 122 7A

Ctrl-[ ESC 27 1B ; 59 3B [ 91 5B { 123 7B

Ctrl-\ FS 28 1C < 60 3C \ 92 5C | 124 7C

Ctrl-] GS 29 1D = 61 3D ] 93 5D } 125 7D

Ctrl-^ RS 30 1E > 62 3E ^ 94 5E ~

Ctrl-_ US 31 1F ? 63 3F _ 95 5F DEL 127 7F

0A * 42 2A J 74 4A j 106 6A

Table 7-2. ASCII Character Chart (Part 1)

The 12

0 can send or receive any ASCII character

value (decimal 0–255), but the indicator display is

limited to numbers, upper-case, unaccented letters,

and a few special characters.

T 84 54 t 116 74

126 7E

Appendix 31

Page 36

ASCII Dec Hex ASCII Dec Hex ASCII Dec Hex ASCII Dec Hex

Ç 128 80 á 160 A0 192 C0 224 E0

ü 129 81 í 161 A1 193 C1 225 E1

é 130 82 ó 162 A2 194 C2 226 E2

â 131 83 ú 163 A3 195 C3 227 E3

ä 132 84 ñ 164 A4 196 C4 228 E4

à 133 85 Ñ 165 A5 197 C5 229 E5

å 134 86 ª 166 A6 198 C6 230 E6

ç 135 87 º 167 A7 199 C7 231 E7

ê 136 88 ¿ 168 A8 200 C8 232 E8

ë 137 89 169 A9 201 C9 233 E9

è 138 8A ¬ 170 AA 202 CA 234 EA

ï 139 8B 1/2 171 AB 203 CB 235 EB

î 140

8C 1/4 172 AC 204 CC 236 EC

ì 141 8D ¡ 173 AD 205 CD 237 ED

Ä 142 8E « 174 AE 206 CE 238 EE

Å 143 8F » 175 AF 207 CF 239 EF

É 144 90 176 B0 208 D0 240 F0

æ 145 91 177 B1 209 D1 241 F1

Æ 146 92 178 B2 210 D2 242 F2

ô 147 93 179 B3 211 D3 243 F3

ö 148 94 180 B4 212 D4 244 F4

ò 149 95 181 B5 213 D5 245 F5

û 150 96 182 B6 214 D6 246 F6

ù 151 97 183 B7 215 D7 247 F7

ÿ 152 98 184 B8 216 D8 248 F8

Ö 153

99 185 B9 217 D9 249 F9

Ü 154 9A 186 BA 218 DA 250 FA

¢ 155 9B 187 BB 219 DB 251 FB

£ 156 9C 188 BC 220 DC 252 FC

¥ 157 9D 189 BD 221 DD

253 FD

Pts 158 9E 190 BE 222 DE 254 FE

ƒ 159 9F 191 BF 223 DF 255 FF

Table 7-3. ASCII Character Chart (Part 2)

32 120 Installation Manual

Page 37

7.5 Conversion Factors for Secondary Units

Note

The 120 has the capability to mathematically convert

a weight into many different types of units and

instantly display those results with a press of the

UNITS key.

Secondary units can be specified on the FORMAT

u using the SECNDR parameter, or by using EDP

men

commands.

• To configure secondary units using the front

nel menus, use the Table 7-4 to find the

pa

conversion multiplier for the MULT parameter.

For example, if

the secondary unit is short tons, set the MULT

parameter to 000050.

Next, use the MULEXP parameter to set the

decimal point position. In the example above,

e conversion factor for pounds to short tons is

th

actually 0.0005 (2000 lb x 0.0005 = 1 tn). Use

and keys to shift the decimal point to

the

show a value of 0.00050.

Another example: If the primary unit is ounces

and the

secondary unit is grams, the conversion

factor is 28.3495. To enter this value using the

menus, first enter 283495 for the MULT

parameter, then use the MULEXP parameter to

adjust the decimal point to 28.3495.

• To configure secondary units using EDP

comma

nds, use the Ta bl e 7-4 to find the

conversion value for the SEC.MULT and

and. For example, if the primary unit is

comm

pounds and the secondary unit is short tons, send

the following EDP command to set the

multiplier for the secondary units.

SEC.MULT= 0.00050<CR>

• Units of weight other than those listed in

Table 7-4 cannot be directly specified as primary

or secondary units on the 12