RHINO PSH-24-480, PSH-48-480 Installation Instructions

RHINO PSH-xx-480 Power Supplies

Installation Instructions

READ INSTRUCTIONS BEFORE INSTALLING OR OPERATING

THIS DEVICE. KEEP FOR FUTURE REFERENCE.

Safety Instructions and Warnings

• Do not open the device!

• Before any installation or maintenance, ensure that the main

switch is switched off and prevented from being switched on

again.

• The device must be installed and put into service by qualified

personnel only.

• Never work on the device if power is applied.

• Risk of electric arcs and electrical shock, which can cause death,

severe personal injury or substantial property damage.

• The unit must be connected to the mains supply in compliance

with national regulations (e.g., VDE0100 and EN50178). All wire

strands must be fastened in the terminal blocks. (Potential danger

of contact with the case.)

• All input and output wires must be properly rated for the power

supply and must be connected with the correct polarity (Fig. 3).

• The Power Supply wiring must be sufficiently fused.

• Sufficient cooling must be ensured (Fig. 2).

• Do not introduce any objects into the device.

• The output voltage adjustment potentiometer may only be

actuated using an insulated screwdriver.

• Keep away from fire and water.

• The internal fuse is not accessible. If this internal fuse has blown,

the power supply has an internal defect and, for safety reasons,

must be replaced.

• This device is designed for use in a clean, dry environment.

• The device must be mounted in an enclosure in the end

application and must not be accessible in operation.

Installation Instructions

• The device can be mounted onto 35mm DIN rails, compliant with

the specifications of DIN EN 50022. Observe the requirements for

ventilation space above and below the device (Fig. 2).

• The standard mounting orientation is with input terminals at the

bottom.

• Alternative side-mounting for flat panels: The case offers the

potentially useful feature to fix the DIN-rail clip to the side wall to

mount inside flat panels.

Recycling

• The device contains elements that are suitable for recycling,

and components that need special disposal. You are therefore

requested to make sure that the device will be recycled at the

end of its service life.

Notes for Technical Specifications Table:

1. Output voltage can be adjusted as indicated. However, output power has to be maintained at nominal value. This

means the output nominal current has to be reduced in accordance with the increase of output voltage.

2. In case of an internal error, a second voltage regulation loop keeps the output voltage at a safe level, and the power

supply turns off and restarts after 10 seconds.

3. When external voltage is supplied above set output voltage and below OVP threshold, the power supply will function

normally without switch off or destruction, even if external voltage is applied continuously.

4. In case of overload or short circuit, the unit switches the output voltage off after 4 seconds and tries to restart every

10 seconds.

1st Edition Rev. B, 05/08/2020

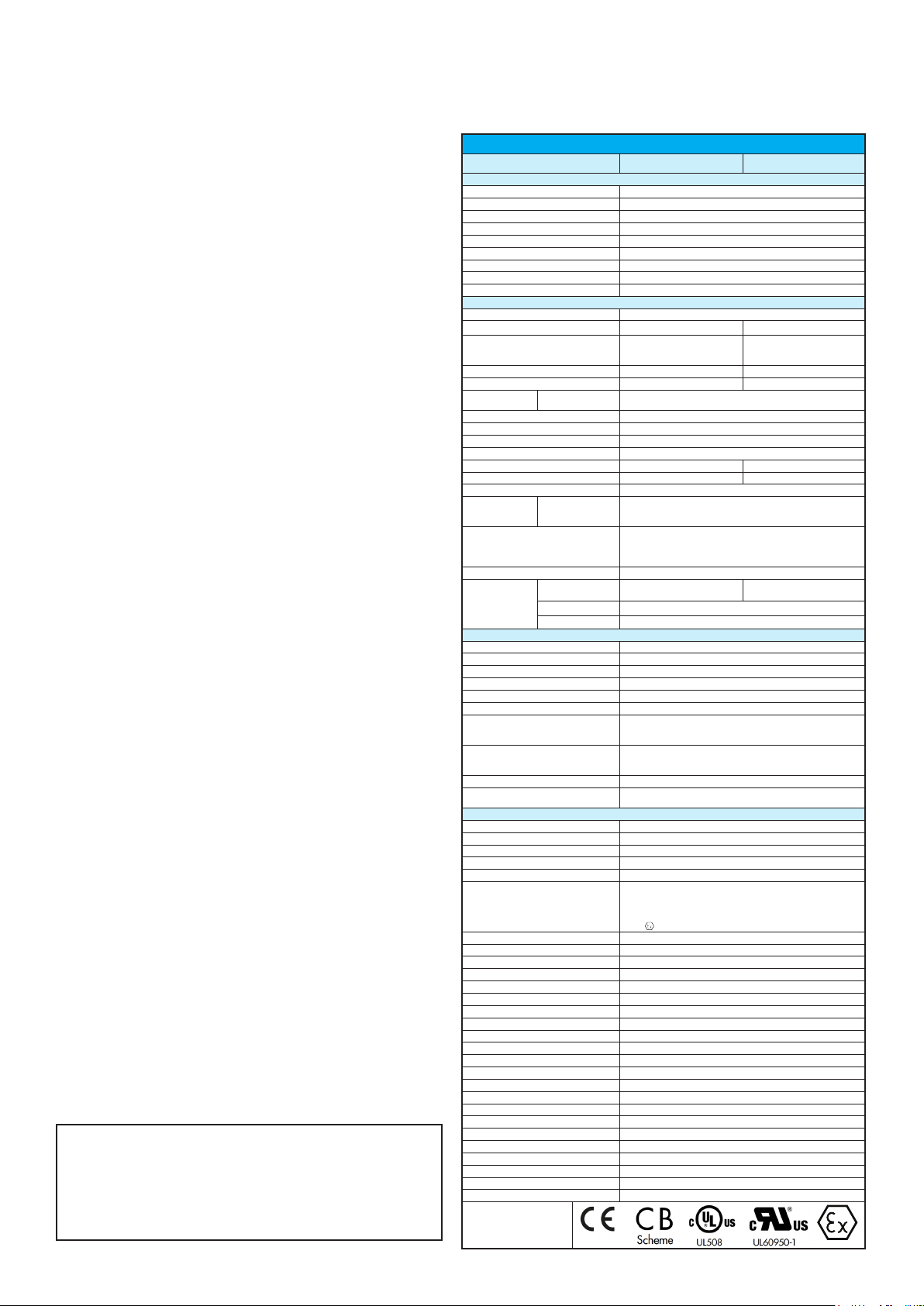

Technical Specifications

Input (AC)

Nominal Input Voltage 100–240 VAC

Nominal Input Current 5.8–2.5 A

Operational Input Voltage Range 85–264 VAC

Input Voltage Frequency Range 45–65 Hz

Inrush Current (115/230 VAC) 15/30 A

Standby Power Consumption 4.8/3.8 W (115/230 VAC)

Active Power Factor Correction (PFC) 0.99/0.97 (115/230 VAC)

Harmonic limits – acc. EN 61000-3-2 Class A, D

Circuit Breaker Rating / Characteristic 6-16 A /B, C (IEC); 20 A /B, C (USA)

Output (DC)

Max. Output Power 480W

Output Voltage 24V 48V

Max. Output Current / Max. Output Current 4s

("Boost power" which facilitates the activation of

stepper motors, solenoids or actuators)

Output Voltage Adjustment Range 23.5–28 V 47.5–56 V

Typical Efficiency (230 VAC) 95% 95%

Regulation

Output Power Derating - Temperature 2%/K above 60°C, refer to Fig. 5

Output Power Derating - Input Voltage 3%/V below 90 VAC, refer to Fig. 4

Hold-up time 20 ms min.

Start-up time 2s max.

Ripple and Noise (20MHz bandwidth) (Note 1) 100 mVp-p max. 200 mVp-p max.

Output Overvoltage Protection (OVP) (Note 2) 32–35V 56–60V

Power Back Immunity (Note 3) < OVP level

Operation

Duty Cycle (for peak and cc mode) (Note 4)

Threshold

CC or Peak Operation Timer

Normal Operation / Off Period

Short Circuit Protection Switch off after 4s delay, automatic restart (Note 4)

DC OK Signal

General Data

Weight 1018g [35.91 oz]

Leakage Current (max.) 2.3 mA

Network Configuration TN-S, TN-C, TT, IT

Enclosure Material (Chassis/Cover) Aluminum / Stainless Steel

Cooling Convection cooling, no internal fan

Over Temperature Protection Switch off at over temperature

Isolation Voltage

Creepage Clearance

Remote On/Off The unit can be controlled by external relay contact or open collector signal.

Contact Rating

Safety / Environmental

Surrounding Ambient Temperature Range -40°C to +70°C [-40°F to +158°F]

Temperature Coefficient 0.02 %/K

Humidity 5–95%, non-condensing

Storage Temperature -40°C to +85°C [-40°F to +185°F]

Maximum Altitude 2000m

Safety Standards

MTBF (acc. to IEC 61709 at 25°C) > 1,000,000 hrs

Protection Class Class I

Degree of Protection IP20

Electromagnetic compatibility (EMC)

Emissions EN 61000-6-3, EN 61204-3

Conducted RI Suppression On Input EN 55032, EN 55011 class B,

Radiated RI Suppression EN 55032, EN 55011 class B,

Immunity EN 61000-6-2, EN 61204-3

Railway Applications Signaling Apparatus EN 50121-4

Railway Applications Rolling Stock Apparatus

Electrostatic Discharge (ESD) IEC/EN 61000-4-2 4 kV/8 kV , criteria A

Radiated RF Field Immunity IEC/EN 61000-4-3 10 V/m , criteria A

Electrical Fast Transient / Burst Immunity IEC/EN 61000-4-4 2 kV , criteria B

Surge Immunity IEC/EN 61000-4-5 1 kV/2 kV , criteria B

Immunity To Conducted RF Disturbances IEC/EN 61000-4-6 10 V , criteria A

Power Frequency Field Immunity IEC/EN 61000-4-8 30 A/m , criteria A

Mains Voltage Dips And Interruptions IEC/EN 61000-4-11 criteria B/C

Voltage Sag Immunity SEMI F47 230VAC, criteria B/C

Environment

Railway Applications Shock and Vibration According EN 61373

Vibration Acc. IEC 60068-2-6-3 3 axis, 2 g sine sweep, 10–55 Hz, 11 oct/min

Shock Acc. IEC 60068-2-27 3 axis, 25 g half sine, 11ms

Approvals

Input Variation

Load Variation

Nominal Operation

Peak Power Operation

Constant Current (CC)

Threshold for Vout

DC ON Relay contact closed, max. 1A, < 100mOhm, also indicated by green LED

DC OFF Relay contact open, max 30V

PSH-24-480 PSH-48-480

20A 10A

0.1 % max.

(10–90 %) 0.5 % max.

100% of Iout nominal

105–150% of Iout nominal

155% of Iout nominal

> 105 %

4s max. (switch off)

< 10s typ (automatic restart after switch off or peak and cc operation timer reset)

ON: > 22.5 V typ.

OFF: < 21.5 V typ.

Input/Output 4250VDC

Input/Chassis 1500VDC

Output/Chassis 750VDC

Input/Output 8mm

Input/Chassis 4mm

Output/Chassis 1.5 mm

Open: 15V; leakage current max 100μA

Close: 0.3 V; max drop at 15mA

Information technology equipment IEC/EN 60950-1, UL 60950-1

CSA 22.2 No 60950-1-03, File E198298

Safety low voltage switchgear and controlgear UL 508, File E197592

Process Control Equipment Haz Loc, File E502478

ATEX II 3 G Ex ec nC IIC T4 Gcw

EN 50121-3-2

ON: > 45V typ.

OFF: < 43V typ.

-40 -35 55 60 65 70 75

4 seconds

Continuous

60

70

80

90

100

110

120

130

140

150

160

T

(amb)

[°C]

P

(O/P)

- T

(amb)

P/Pmax

[%]

Fig. 5

PSH-48-480

P/Pmax

Fig. 4P

- V

V

[VAC]

260

264

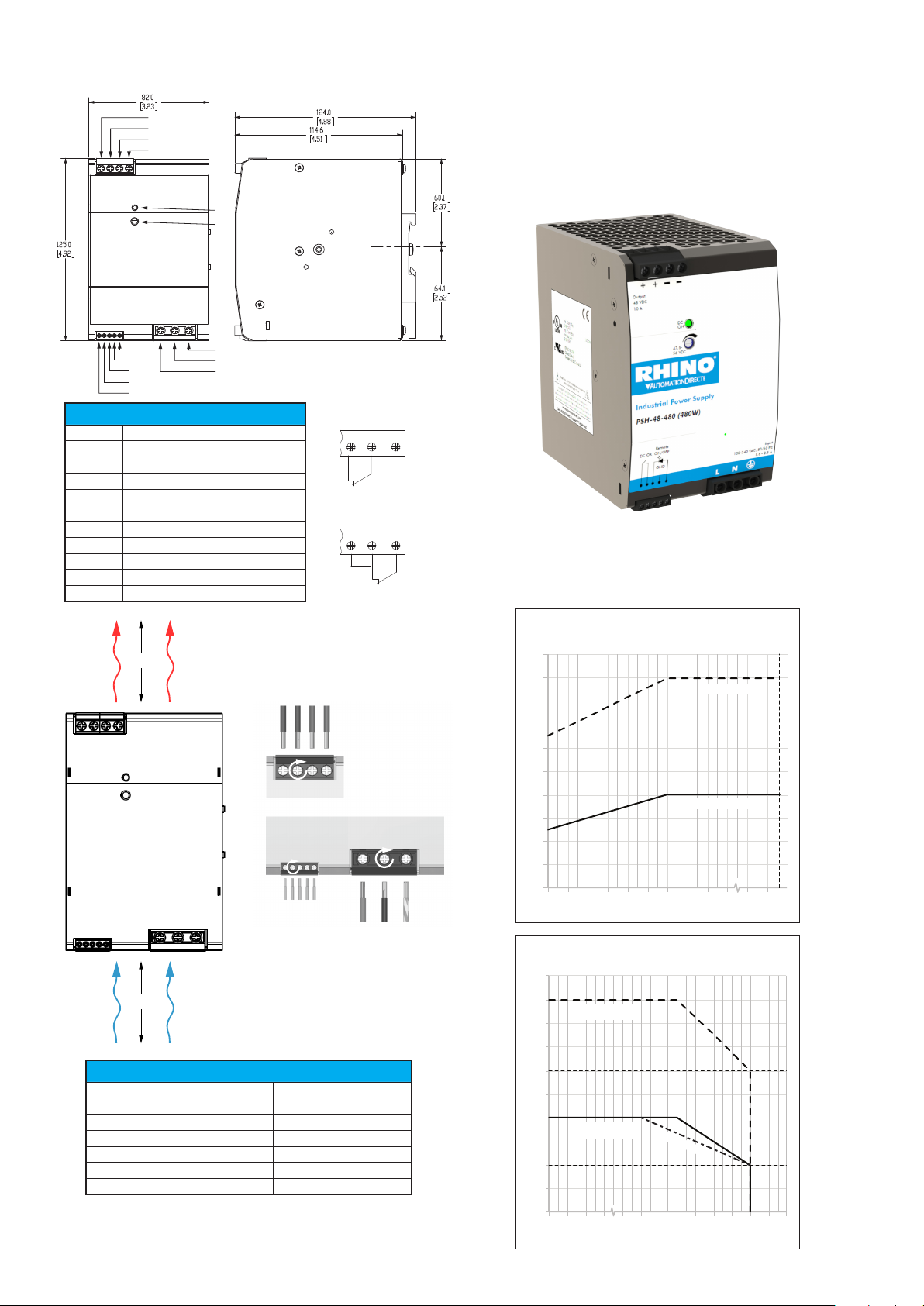

Fig. 1

14

13

12

11

5

4

RHINO PSH-xx-480

Power Supplies

10

9

8

7

6

3

2

1

Identification of Features (Fig.1)

1

Input Terminal L

2

Input Terminal N

3

Input Terminal GND

4 Output Voltage adjustment potentiometer

5 DC ON LED

6/7 DC OK Contact

8–10 Remote On/Off

11

Output Connection Terminal –

12

Output Connection Terminal –

13

Output Connection Terminal +

14

Output Connection Terminal +

50mm

A

D

SIGNALS INPUT

Units: mm [in]

Remote On/Off

Normal operation

8

10

9

ON = open

OFF = closed

Reversed operation

8

10

9

ON = closed

OFF = open

(O/P)

(I/P)

[%]

Fig. 3Fig. 2

OUTPUT

F

G

E

C

F

D

B

160

150

140

130

120

110

100

4 seconds

90

80

70

60

85

90 95 100 105

(I/P)

Continuous

50mm

Wiring Specifications (see Fig. 3)

A Wire Size, Output 12–10 AWG

B Wire Size, Input 18–10 AWG

C Wire Size, Signal 30–16 AWG

D Strip Length, Input/Output 10mm [0.39 in]

E Strip Length, Signal 5mm [0.20 in]

F Tightening Torque, Input/Output 0.7 N·m [6.2 lb·in]

G Tightening Torque, Signal 0.2 N·m [1.8 lb·in]

FOR TECHNICAL ASSISTANCE CALL 770-844-4200

1st Edition Rev. B, 05/08/2020

Loading...

Loading...