Page 1

Page 2

Page 3

1

CONTENTS

Section Page

Safety Symbol Description ..................................................................................................... i

Table of Contents ..............................................................................................................1

Introduction ....................................................................................................................2

Post Driver Safety ..............................................................................................................3

Rhino

®

Multi-Pro™ Operating Instructions ......................................................................................6

Starting the Engine .............................................................................................................6

Hot Restart ....................................................................................................................7

Driving a Post ..................................................................................................................8

Installing a Chuck Adapter .......................................................................................................9

Installing an Alternative Chuck ...................................................................................................9

Multi-Pro™ Maintenance ........................................................................................................10

Rhino

®

Multi-Pro™ Service Instructions .......................................................................................11

Servicing Cranksha and Piston .................................................................................................12

Service of the Hammer and Anvil ................................................................................................13

Regular Service Period .........................................................................................................18

Rhino

®

Multi-Pro™ Parts & Accessories List ...................................................................................20

Limited Warranty and Registration ............................................................................................28

Troubleshooting ..............................................................................................................29

Page 4

2

© 2016 Rhino Tool Company Inc., - All Rights Reserved

INTRODUCTION

Congratulations on your selection of the Rhino® Multi-Pro™ post

driver. We are certain that you will be pleased with your purchase. This post driver was built with the Honda GX35 engine.

Honda supplies its own owner’s manual that covers all the

operator and service procedures associated with the Honda

engine. Please read this manual as closely as you do the Rhino

manual. The success that you experience with this tool is dependent upon your knowledge and understanding of how to properly

operate and care for the Honda engine installed on your new post

driver.

As you read this manual, you will nd information preceded by a

NOTICE symbol. That information is intended to help you avoid

damage to your post driver, other property, or the environment.

We suggest you read the warranty information fully and understand its coverage and your responsibilities of ownership. Fill

out the warranty registration card or online registration to receive

Rhino® Limited Lifetime Impact Warranty. (See Page 28) Please

read and understand the Honda warranty policy. The Honda warranty is separate from the Rhino® warranty and is subject to its

own coverage conditions and responsibility requirements. The

warranty is a separate document and is included with the Honda

owner’s manual.

When your Rhino® post driver needs scheduled maintenance, the

technical service sta here at Rhino Tool Company is standing by

to assist you.. Our fully trained sta can ensure that you receive

the correct service kit or direct you to the nearest Rhino

Servicing Dealer.

The engine requires scheduled maintenance, keep in mind that

your Honda service dealer is fully equipped and specially trained

in servicing the Honda engine. Your Honda servicing dealer is

dedicated to your satisfaction, and will be pleased to answer your

questions and concerns.

Kindest Regards,

The Rhino Tool Company Team

Page 5

3

The Rhino® Multi-Pro™ gas powered

driver is designed to drive fence post,

ground rod, delineator post, vineyard post,

form pin, tent stake and other like items

into the ground.

Uses, other than those

intended, can result

in injury to the operator as well as those

around the operator. Damage to the driver

and to the surrounding area may result

as well. This post driver is intended for

use by professional installers. Never allow

children to operate this tool.

Most accidents can be prevented if you

follow all instructions in this manual and

on the post driver. The most common hazards are discussed below, along with the

best method to protect yourself and others.

UNDERGROUND

UTILITIES: Driving

a post into an underground utility can be

EXTREMELY DANGEROUS, exposing

the operator and those around to potentially life threatening danger. Damage to

surrounding property can also occur as a

result of a post being driven into an underground utility. Be absolutely certain that

you are aware of all underground utilities

in the area in which you intend to drive

posts. Ensure that a certied locating service has identied all underground utilities

prior to beginning your project. Failure to

do so can be catastrophic. Underground

utilities include but are not limited to:

Electric, Gas, Telephone, Water, Sewer,

TV Cable, Lawn Sprinklers, etc.

GASOLINE: Gasoline

is HIGHLY

FLAMMABLE and EXPLOSIVE. You

can be burned or seriously injured when

handling fuel.

EXHAUST: The ex-

haust from the engine

contains poisonous carbon monoxide gas

that can build up to dangerous levels in

closed areas. Breathing carbon monoxide

can cause unconsciousness or death. Never

run the engine in a closed or even partly

closed area where people may be present.

The engine exhaust

from this product contains chemicals

known to the State of California to cause

cancer, birth defects or other reproductive

harm.

ENGINE

MAINTENANCE:

Improperly maintaining the engine on this

power tool, or failure to correct a problem

before operation, can cause a malfunction in which you can be seriously hurt

or killed. In accordance with the engine

owner’s manual, always perform a preoperation inspection of the engine before

each use and correct any problem.

DRIVER

MAINTENANCE:

Improperly maintaining the driving

mechanism on this power tool, or failure

to correct a problem before operation, can

cause a malfunction in which you can be

seriously hurt or killed.

In accordance with this manual, always

perform a pre-operation inspection of the

driving mechanism before each use and

correct any problem.

IMPORTANT SAFETY INFORMATION

POST DRIVER SAFETY

!

WARNING

!

WARNING

!

WARNING

!

WARNING

!

WARNING

!

WARNING

!

WARNING

!

DANGER

!

CAUTION

Page 6

4

Do not lend or rent

your post driver without the instruction manuals. Be sure that

anyone using it understands the information contained in these manuals.

Do not use this post

driver for any purpose

other than driving posts into the ground.

Misuse may result in personal injury or

property damage, including damage to the

machine

Minors should never

be allowed to use this

power tool. Bystanders, especially children, and animals should not be allowed in

the area where it is in use.

NEVER let your

power tool run unat-

tended. When it is not in use, shut it o

and make sure that unauthorized persons

do not use it.

Do not operate this

post driver unless the

operator is wearing safety glasses, safety

shoes, hearing protection, gloves or any

other safety equipment advised by, ANSI,

NIOSH, OSHA, or any other safety regulatory agency, the employer or the owner

of this post driver.

Hearing protection is required as the

post driver emits noise at 100 dB level.

Bystanders should, at a minimum, wear

safety glasses and hearing protection while

in the presence of this power tool during

operation. If not wearing protective gear,

bystanders should keep a distance of 20

feet (6 m) from the post driver while in

operation.

Prolonged use of a

power tool (or other

machines) exposing the operator to vibra-

tions may produce white nger disease

(Raynaud’s phenomenon) or carpal tunnel

syndrome. These conditions reduce the

hand’s ability to feel and regulate temperature, produce numbness and burning

sensations and may cause nerve and circulation damage and tissue necrosis.

Not all factors contributing to white nger

disease are known, but cold weather,

smoking and diseases or physical condi-

tions that aect blood vessels and blood

transport, as well as high vibration levels

and long periods of exposure to vibration

are mentioned as factors in the develop-

ment of white nger disease.

In order to reduce the risk of white nger

disease and carpal tunnel syndrome, please

note the following:

• The Multi-Pro™ has been designed with

Rhino® CIS™ anti-vibration handles to

reduce the transmission of vibrations

created by the machine to the operator’s hands. An anti-vibration system is

recommended for those persons using

power tools on a regular or sustained

basis.

• The handle opposite the throttle handle

has been tted with an EPDM foam grip

further dampening vibrations.

• Wear gloves and keep your hands warm.

• Ensure that the EPDM foam and the

spring dampening system are in good

working condition.

IMPORTANT SAFETY INFORMATION

POST DRIVER SAFETY... continued

!

WARNING

!

WARNING

!

WARNING

!

WARNING

!

WARNING

!

WARNING

Page 7

• Ensure the post driver has no loose components. Loose components lead to high

vibration levels.

• Maintain a rm grip at all times, but do

not squeeze the handles with constant,

excessive pressure. Take frequent

breaks.

All of the above mentioned precautions

do not guarantee that you will not sustain

white nger disease or carpal tunnel syndrome. Therefore, continual and regular

users should closely monitor the condi-

tion of their hands and ngers. If any of

the above symptoms appear, seek medical

advice immediately.

DO NOT modify this

power tool in any way.

DO NOT put anything

other than a post into

the chuck on the driver.

DO NOT operate your

post driver unless it

is on a post to be driven. Operation of the

driver without it driving on a post could

damage the power tool.

SURROUNDINGS:

This power tool emits

noise at 100 Db, which may be disturbing

to animals and livestock. Ensure prior to

operation, that any livestock are cleared

from the operational area to prevent a situation in which startled livestock become a

safety hazard.

WARNING LABELS

If your post driver’s warning label is

marred or destroyed, replace it immediately. Simply call Rhino Tool Company

and we will send you a new warning label

at no expense to you.

End of Life Cycle

When your Rhino® gas powered driver is

coming to the end of its life cycle, destruction of the unit should to be conducted

according to international and local environmental regulations.

The gas powered post driver contains:

• Fuel

• Oil

• Rhino® Pro Series Lubricant

• Electric components

• Plastic-steel and aluminum components.

POST DRIVER SAFETY... continued

IMPORTANT SAFETY INFORMATION

!

WARNING

!

WARNING

!

DANGER

!

CAUTION

!

WARNING

!

DANGER

!

CAUTION

!

WARNING

!

DANGER

!

CAUTION

Rhino® Multi-Pro™

Specications imperial (metric)

Overall

Dimensions

10.75 x 17 x 26 in.

(273 x 432 x 660 mm)

Weight 44 lb (19.9 kg)

Engine

Conguration

4-stroke, 35.8 cc

Performance 1720 bpm

Fuel Unleaded Gas, US 86 Octane

(>Euro 91)

Fuel Capacity 0.67 US qt. (0.63 ltr)

Engine Oil SAE 10W-30

Lubricant Rhino

®

Pro Series Lubricant

Noise ≤ 100 Db

Vibration TBC

5

Page 8

6

Multi-Pro™ Operating Instructions

Your Rhino® Multi-Pro™ Gas Powered

Post Driver is an ecient and eective

power tool designed and developed to

tackle a dicult and time consuming task,

driving posts.

It is very important to understand that your

post driver is a very powerful machine.

With proper care and maintenance, your

Rhino® Multi-Pro™ will give you many

years of trouble free service.

You must read and understand your post

driver operating instructions before using

the post driver. It is also very important

that you make sure all operators are

trained to operate your post driver safely.

If you or any operator doesn’t understand

any of the instructions in this manual, call

Rhino Tool Company at 866-707-1808 or

309-853-5555 and we will assist you with

any questions you may have.

AVOID SERIOUS

INJURY OR DEATH

READ THIS MANUAL BEFORE

USING YOUR POST DRIVER.

Visually inspect your Multi-Pro™ Post

Driver before use. The interior of the

chuck tube should be checked for obstructions, damage or wear to the chuck tube

and anvil inside. The outer surfaces of the

driver should also be inspected for any

defects. Do not use the Multi-Pro™ if there

is any damage or wear until the damage or

wear is corrected and repaired.

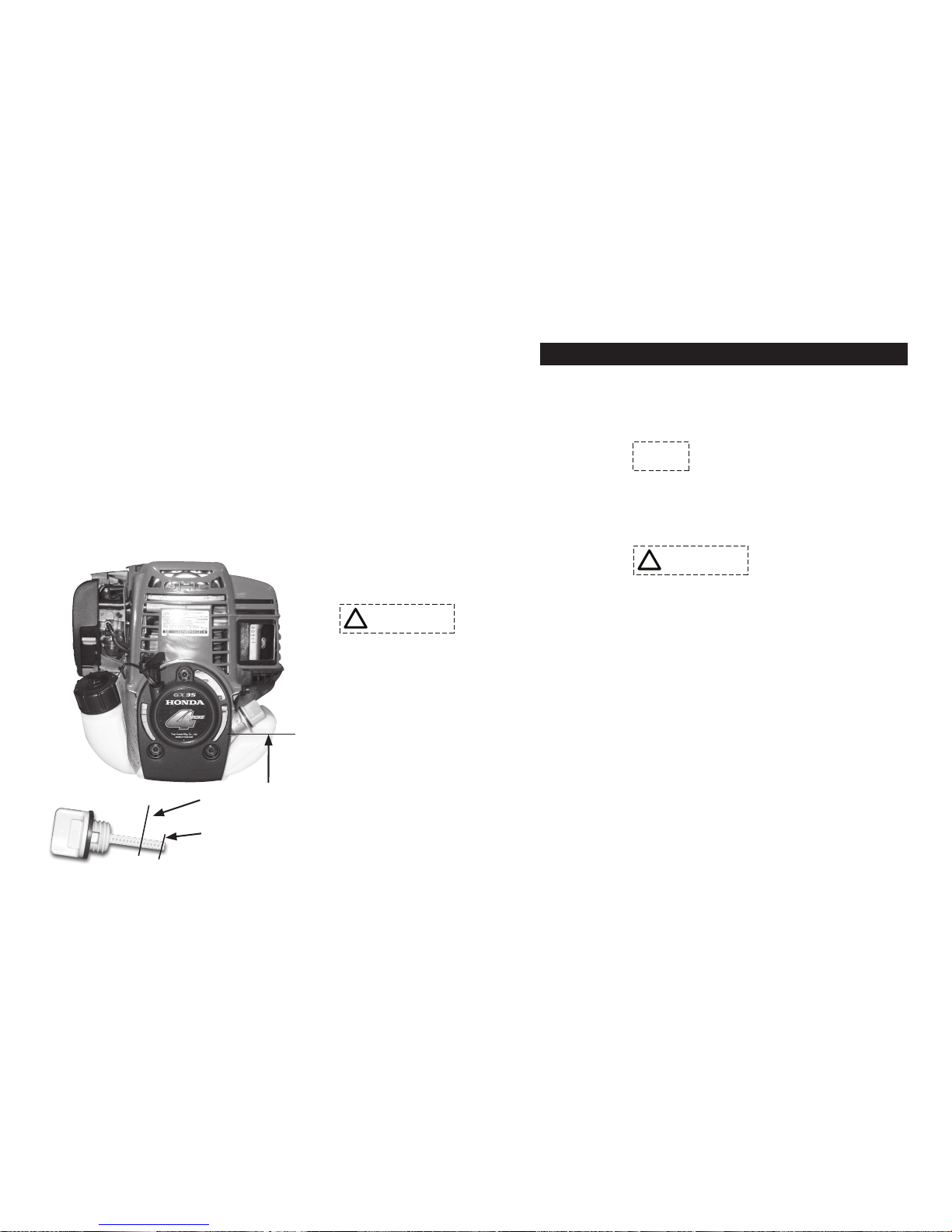

Check all uid levels, i.e. engine oil and

fuel and ll as needed as per manufacturer’s specications. (Fig. 1)

Proper oil level is essential

to the operation of the post

driver. Overlling of the oil will result in

loss of power and may cause permanent damage to the engine.

USE ALL RECOMMENDED

SAFETY EQUIPMENT.

Rest the driver on a solid surface, i.e.

tailgate, bench, or debris free solid ground

and posture your body in a safe position.

DO NOT start the driver anywhere but

an open, well-ventilated area. It is recommended that the Multi-Pro™ only be used

outdoors and never inside an enclosed

building.

Starting the Engine:

To start a COLD engine, move the choke

lever to the CLOSED position (Fig. 3).

Lock the throttle into high idle position.

(Fig. 2) This is done by depressing the

!

WARNING

!

DANGER

!

CAUTION

IMPORTANT

NOTE

!

WARNING

!

WARNING

Fig. 1

Upper limit of

engine oil.

Lower limit of

engine oil is end

of dipstick.

Page 9

7

trigger and the high idle lock simultaneously. The throttle is now in the high idle

position.

To start a WARM engine, leave the choke

lever in the OPEN position and do not

lock the throttle into the high idle position.

Press the priming bulb repeatedly (Fig. 4)

until fuel can be seen in the clear-plastic

fuel return tube.

Slide thumb switch on throttle handle

down or into the ON position.

Grasp the starter grip lightly until you

feel resistance, then pull briskly in the

direction of the arrow as shown in Fig. 5.

Return the starter grip gently.

Do not extend the

starter rope to its full

length as it can cause damage the recoil

mechanism.

An operator should

never wrap the starter

rope around their hand. This will cause

serious injury.

Do not allow the starter grip

to snap back against the

engine. Return it gently to prevent

damage to the starter.

If the choke lever was moved to the

CLOSED position to start the engine,

gradually move it to the open position

as the engine warms up. As the engine

warms up also release the high idle lock

by slightly depressing the trigger and then

immediately releasing it. Use caution as

to not engage the clutch. Dry-Firing will

shorten the life of the post driver and

could cause damage.

Hot Restart If the engine is operated at

higher ambient temperatures, then turned

!

WARNING

!

DANGER

!

CAUTION

!

WARNING

!

DANGER

!

CAUTION

IMPORTANT

NOTE

Multi-Pro™ Operating Instructions... continued

Choke Closed

Choke Open

Fig. 3

Priming Bulb

Fuel Return

Line (clear

plastic tube)

Fig. 4

Starter Grip

Fig. 5

!

WARNING

!

DANGER

!

CAUTION

Thumb Switch

High Idle Lock

Trigger

Fig. 2

Page 10

8

o and allowed to sit for a short time, it

may not restart on the rst pull. If neces-

sary, use the following procedure:

IMPORTANT

SAFETY

PRECAUTION

Failure to follow instructions can result in

personal injury

Turn the engine switch to the OFF

position before performing the following

procedure. This will prevent the engine

from starting and running at maximum

speed when the throttle is in the MAX.

speed position. If the engine starts with

the throttle in the MAX. speed position,

the post driver will operate at maximum

power. This may result in personal injury

and damage to the post driver.

1. Turn the engine switch on the post

driver to the OFF position.

2. Move the choke lever to the OPEN

position.

3. Hold the throttle in the MAX speed

position.

4. Pull the starter grip 3 to 5 times.

Follow the STARTING THE ENGINE

procedure on the previous page and start

the engine with the choke lever in the

OPEN position.

Driving a Post

Holding the post driver with your left

hand on the foam grip and your right hand

on the throttle will position the driver to

direct the engine exhaust away from the

operator (Fig 6). (See Exhaust Warning)

Insert a post into the Multi-Pro™ making

sure the end of the post to be driven is in

the correct location on the ground. (Fig. 7)

Position the driver aligned and centered to

the post. If not aligned properly, damage

could be caused to the driver or the post.

Apply steady downward pressure to the

handles and apply enough throttle to engage the clutch and hammer.

Once you are condent that the post is

driving straight, apply full throttle to the

driver until the post is driven to the desired

depth.

Release the trigger dropping the engine

RPM back to idle before removing from

the post. When the engine has returned to

Multi-Pro™ Operating Instructions... continued

!

WARNING

Fig. 6

Fig. 7

Post Driver

Post

Right Wrong

Page 11

9

idle, proceed to the next post repeating the

previous method of driving a post.

Installing a Chuck Adapter

CHUCK SIZE: A

chuck or chuck adapter

that is too large for the post being driven

may damage the driver and may damage

the end of the post. Using a the appropriate chuck or chuck with adapter will align

the post to optimum striking position and

prevent damage to the driver. See the chart

below to specify the appropriate adapter

for your application. Chucks and chuck

adapters wear out and should be replaced

as needed. Inspect your driver’s chuck and

chuck adapters frequently.

The Multi-Pro™ is equipped with the

Rhino® Chuck-Lok™ Adapter System. It is

comprised of the master chuck, the locking nut and two-piece adapters.

ALWAYS HAVE

THE LOCKING

NUT IN PLACE WHEN DRIVING

POSTS: The Chuck-Lok

™

locking nut

should always be tightened onto the

master chuck to protect the chuck threads,

even when not using an adapter. Failure

to do so exposes the chuck to possible

damage.

The two-piece adapter design is a solution for the occasional flared post. Should

a post flare and lodge inside the chuck

when using the adapter, in most cases the

operator can loosen the locking nut letting

it slide down the post, then lift the driver

off the post. The operator can quickly

re-insert the adapter, secure them with the

locking nut and resume driving posts. See

Fig. 8 for steps for installing Chuck-Lok™

adapters.

Installing an Alternative Chuck

The Multi-Pro™ quick change design

allows the operator to quickly remove

the standard master chuck and install an

alternative chuck configuration for your

post driving application.

Multi-Pro™ Operating Instructions... continued

!

WARNING

!

WARNING

Type or Size of Post to be Driven (mm) Chuck/Accessory Required

Fiberglass T-Post 1¾" (44.45) Adapter

T-Post 1¾" (44.45) Adapter

5/8" (15.87) to 3/4" (19) Ground Rod 1" (25.4) Adapter

Tent Stake Tent Stake Chuck

Concrete Form Pin 1" Adapter

1" (25.4) to 1-5/8" (41.27) Post 1¾" (44.45) Adapter

1-7/8" Post 2" (50.8) Adapter

2"(50.8) to 2-3/8" (60.32) Post Master Chuck

1-1/2” (38.1) to 2-1/2” (63.5) Square Post and Square Post Sign Anchor Short Chuck and Drive Cap

1.2 - 4 lb Channel Post and Channel Post Sign Anchor Channel Chuck and Long Anvil

Note: Custom chucks may be available for your specic application contact Rhino Tool Company.

Page 12

10

Multi-Pro™ Operating Instructions... continued

Turn off the engine and allow it to cool.

Position the post driver on a work bench

or level surface. Using a 1/4" hex bit

socket wrench loosen and remove the 4

chuck bolts (p/n 300717-4) and lock washers (p/n 300750-4). Replace lock washers

if they are worn. Remove the chuck and

set it aside in a convenient place to store

until needed.

Align the alternate chuck to the bolt holes

on the lower body, taking into account the

position of slots or internal configuration

for the post to insert according to the operator side of the post driver. Insert bolts

through the lock washers and into the bolt

holes. Hand tighten bolts. Using a torque

wrench set to 132 lb/in (14.9 Nm) for

stainless bolts or 251 lb/in (28.4 Nm) for

black oxide bolts, tighten them in a cross-

ing pattern to the correct torque.

If alternative anvil parts are needed please

follow the instructions provided with alternative chuck kit.

If you do not see a chuck option for a

specific post, contact your Rhino Tool

Company representative to inquire if there

is an option available.

Maintenance of the Multi-Pro

™

NEVER REFUEL

WITH THE ENGINE

HOT OR RUNNING: Never refuel your

Multi-Pro™ with the engine hot or run-

ning as there is a possibility the ammable

fumes from the gasoline

can ignite, causing severe

injury and/or damage

to you/your Multi-Pro™

and the surrounding area.

Follow engine manufacturer’s instructions

for the refueling of the

engine.

DO NOT OPEN

CRANKCASE COV-

ER WHILE ENGINE IS RUNNING.

With each use check the engine oil level,

air lter, and all fasteners. If necessary,

add oil, clean or replace the air lter and

tighten any loose nuts, bolts, or any other

fastener. (See page 6 for engine oil level)

Change engine oil as per engine manu-

facturer’s specications. Dispose of used

oil in accordance with any local, state, or

federal regulations.

To help insure years of operation, wipe

down the Multi-Pro

™

with a clean cloth

after each days use.

Refer to the Service Instructions for

more detail regarding maintenance of

the Post Driver.

!

WARNING

!

WARNING

Fig. 8 - Hand tighten ONLY. No Tools.

Page 13

11

Multi-Pro™ Service Instructions

Following the service requirements for

the Multi-Pro™ will insure years of trouble

free operation. Always refer to the Honda

GX35 manual for maintenance and service

on the engine. The following instructions

are for the Rhino® Multi-Pro™ specically

with general instructions for the Honda

GX35. Before any service is preformed,

remove the spark plug wire from the spark

plug and ground it to the engine body

to prevent any accidental start-up of the

engine.

Each Use:

1. Check engine oil level. Use SAE 10W-

30 to top oil level o, if necessary.

Correct ll level shown on page 6.

2. Check condition of the engine air

cleaner. The air cleaner can be cleaned

or replaced. Consult your Honda engine manual for instructions.

3. Check crankcase lubrication by removing the Crankcase Cover. Instructions

for service are on page 12.

4. Check all engine and post driver fasten-

ers. Retighten to proper specications if

necessary. (See Bolt Torque Specica-

tions on page 27)

5. Check overall condition of post

driver before use. Any loose, broken

or worn parts should be replaced before

using post driver.

Every10hoursorrstmonthuseofa

new or rebuilt Multi-Pro

™

1. Change engine oil following the

requirement for the Honda GX35. Dispose of used oil according to all local,

state, and federal regulations.

2. Check all engine and post driver fasten-

ers. Retighten to proper specications if

necessary.

3. Check crankshaft and piston lubrication. (See page 12 for instructions.)

Every 3 months or 25 hours of use

1. Change engine oil following the

requirement for the Honda GX35. Dispose of used oil according to all local,

state, and federal regulations.

2. Replace air cleaner elements. This

should be performed more often if operated in dusty areas.

3. Check crankshaft and piston lubrication. (See page 12 for instructions.)

4. Check all engine and post driver fasteners. Retighten to proper torque specications if necessary. (See page 27)

Every 6 months or 50 hours of use

1. Change engine oil following the

requirement for the Honda GX35. Dispose of used oil according to all local,

state, and federal regulations.

2. Replace air cleaner elements. This

should be performed more often if operated in dusty areas.

3. Check crankshaft and piston lubrication. (See page 12 for instructions.)

4. Check all engine and post driver fasteners. Retighten to proper torque specications if necessary. (See page 27)

Every 12 months or 100 hours of use

1. Change engine oil following the

Page 14

12

requirement for the Honda GX35. Dispose of used oil according to all local,

state, and federal regulations.

2. Replace air cleaner elements. This

should be performed more often if operated in dusty areas.

3. Check crankshaft and piston lubrication. (See page 12 for instructions.)

4. Remove and service the hammer and

anvil. (See page 13 for instructions.)

5. Check all engine and post driver fasteners. Retighten to proper torque specications if necessary. (See page 27)

Servicing Crankshaft and Piston

Lubrication

(Fig. 9) The crankcase cover (p/n 300132)

is designed for easy, “no tool” inspection

and maintenance. To remove the cover,

grip it tightly with your hand and twist it

left (counter-clockwise.) Use caution not

to lose or damage the O-ring Seal (p/n

301617).

DO NOT OPEN

CRANKCASE COV-

ER WHILE ENGINE IS RUNNING

DO NOT USE A

HAMMER OR

WRENCH TO

LOOSEN THE COVER AS IT MAY

CAUSE DAMAGE TO THE DRIVER.

Visually inspect the color and amount

of Rhino

®

Pro Series Lubricant inside

the crankcase. There should be a ring of

Rhino® Pro Series Lubricant collected to

the wall inside the crankcase. Should the

depth of the ring from the wall inward

measure 1/8" (3mm) or less (Fig. 10) this

indicates the Rhino

®

Pro Series Lubricant

is low. The maximum level should not be

more than 1/4" (6mm). If the amount of

Rhino® Pro Series Lubricant appears to be

low, add a small amount of Rhino® Pro Series Lubricant. Use only Rhino approved

Rhino® Pro Series Lubricant (p/n 300500.)

DO NOT OVER-

FILL RHINO® PRO

SERIES LUBRICANT AS IT CAN

DAMAGE THE DRIVER AND THE

HONDA ENGINE.

Multi-Pro™ Service Instructions... continued

Fig. 9 - Crankcase Cover

!

WARNING

!

DANGER

!

CAUTION

!

WARNING

!

DANGER

!

CAUTION

Fig. 10 - If ridge of Rhino

®

Pro Series

Lubricant measures 1/8″ or less, add a

small amount. At maximum level it should

measure 1/4".

!

WARNING

!

DANGER

!

CAUTION

Page 15

13

If the Rhino® Pro Series Lubricant appears

burnt or has an odor of burnt lubricant it

should be removed and the post driver

needs further maintenance. This is detailed

in the section titled “Service of the Hammer and Anvil.”

In the event of complete removal of old

Rhino® Pro Series Lubricant and adding

fresh Rhino® Pro Series Lubricant (Fig.

11) rotate the crankshaft with connecting

rod and crank pin until the crank pin is in

the 12:00 position, then add Rhino® Pro

Series Rhino Pro Series Lubricant

(p/n 300500). The level of Rhino® Pro

Series Lubricant should be to the bottom

of the crank pin. When the required service has been performed in the crankcase,

inspect the o-ring seal and replace it on the

crankcase cover. Position the crankcase

cover on the Multi-Pro™ body carefully

to start the threads and once in the thread

groove, with your hand twist to the right

(clock-wise) until it is securely in contact

with the post driver body.

HAND TIGHTEN

ONLY. DO NOT

OVERTIGHTEN. Do not use tools, such

as a hammer or wrench, to tighten the crankcase cover as it will damage the driver.

Service of the Hammer and Anvil

The tools required for servicing the hammer and anvil are, a 9/64″ hex wrench, a

1/4″ hex wrench, a 7/8″ deep well socket

with handle, a torque wrench that reads

in inch/pounds, and Loctite primer and

threadlocker.

Remove the crankcase cover (see crankcase

cover CAUTION on page 12) and clean

out any old Rhino

®

Pro Series Lubricant

from inside the crankcase.

Remove the four (4) chuck bolts (p/n

300717-4) and disconnect the chuck.

Remove the four (4) lower bolts (p/n

300701-4) from the lower driver body and

the four (4) bolts (p/n 300715-4) from the

upper handle bracket. Use caution as the

handle tubes have four (4) anti-vibration

springs (p/n 610010-4) installed and under

tension. Grasping the upper handle bracket

pull it directionally away from the driver

body to create a separation between them.

While separated, lift and remove the upper

driver body assembly (p/n 301016) from

the post driver assembly and set aside.

Multi-Pro™ Service Instructions... continued

Fig. 12 - View of the Lower Driver Body

Assembly when removed from the post

driver. 301115

!

WARNING

!

DANGER

!

CAUTION

Fig. 11 - After completely cleaning out old

lubricant, add new Rhino

®

Pro Series Lubricant till level with the bottom edge of the

crank pin head.

Rotate

Crankshaft

until crank pin

is in 12:00

position.

Page 16

14

Observe the lower driver body, it should

appear as shown in Fig. 12. The anvil oring retainer (p/n 301115) will sometimes

be removed with the lower driver body or

remain in place at the base of the cylinder

of the upper driver body.

Remove the anvil o-ring cup (p/n 301095)

and the anvil (p/n 301165). This can be accomplished by pushing a hammer handle

into the chuck tube from the opposite side.

When the parts are removed, note the order and disassemble for inspection. Check

the anvil for damage. The anvil o-ring (p/n

301615) should be replaced at this time.

Clean the anvil and carefully replace the

anvil o-ring. (Fig 13) shows an anvil with

the o-ring in place.

Inspect inside the sleeve in the lower body

for damage. If the ledge that supports the

anvil o-ring cup is damaged, replace with

new sleeve (p/n 301038.)

Remove the large retainer o-ring seals

(p/n 301614-2) and the large retainer (p/n

301105) from the anvil o-ring cup. Inspect

the large retainer. The large retainer oring seals should be replaced at this time.

Replace the large retainer if there are any

signs of damage or excessive wear.

The anvil o-ring retainer (p/n 301115) can

be removed from the end of the cylinder in

the post driver body by hand. Use caution

as it can become sharp with use of the

driver. Remove the hammer (p/n 301085),

piston and connecting rod assembly

(p/n 301075) by removing the crank pin

(p/n 300050). Access to the crank pin is

achieved by removing the crankcase cover

(p/n 300132), which is described in the

section titled “Servicing Crankshaft and

Piston Lubrication.” Remove the crank pin

using the 7/8″ deep well socket.

The crank pin has

LEFT-HAND

THREADS. Use caution stabilizing

the connecting rod and crankshaft (p/n

300040) to avoid damaging them. Use a

small wood or plastic block to keep the

crankshaft from rotating. When the crank

pin is removed, the piston, connecting rod,

and hammer can be removed by pushing

the connecting rod down into the cylinder

until it can be removed from the bottom

of the post driver body. Note position of

the hammer. The small end of the hammer

is toward the anvil as shown in (Fig. 14.)

Clean and inspect the hammer for damage.

The hammer o-ring seal (p/n 301610-2)

should be replaced at this time.

Multi-Pro™ Service Instructions... continued

Fig. 14 - Small end of Hammer is toward

the anvil.

Fig. 13 - Anvil with O-ring in place.

!

WARNING

!

DANGER

!

CAUTION

Page 17

Clean and inspect the piston and connecting rod. Insert the crank pin into the

bearing on the connecting rod. If there

is excessive play between the two, the

connecting rod and possibly the crank pin

should be replaced. Check the movement

in the bearing in the piston side. If there is

excessive play the piston assembly should

be replaced. The piston o-ring seal (p/n

301610-2) should be replaced at this time.

(See Fig. 15.)

Clean and inspect the cylinder and

crankcase for any damage or wear.

Replace any damaged parts. Lubricate the

cylinder, piston, and connecting rod with

Rhino

®

Pro Series Lubricant (p/n 300500.)

Insert the connecting rod, of piston

assembly, into the cylinder. Push the

piston up the cylinder until the bearing in

the connection rod aligns with the threaded hole for the crank pin. Apply Loctite

Primer N 7649 to the threads in the

crankshaft and crank pin. Let the Primer

dry completely. Apply a line of Loctite

243 Threadlocker to the threads on the

crankshaft. Insert the crank pin through

the bearing and start the threads into the

crankshaft by hand. Use caution holding

the connecting rod and crankshaft (p/n

300040). The connecting rod and crankshaft can be damaged. Use a small wood

or plastic block to keep the crankshaft

from rotating.

!

WARNING

!

DANGER

!

CAUTION

These are LEFTHAND THREADS.

Tighten the crank pin using the 7/8″ deep

well socket. Torque to 360 inch/pounds

(40.6 Nm). Add Rhino® Pro Series

Lubricant (p/n 300500) to the crankcase to

the level shown in Fig. 11. (See Caution:

DonotoverllRhinoProSeriesLubricant on page 12)

If Lubricant has been completely removed,

add 2.75 oz or 81.32 ml of Rhino

®

Pro

Series Lubricant or until level with the

bottom of the crankpin head. Close the

crankcase by placing the crankcase cover

o-ring seal onto the crankcase cover. Place

the crankcase cover onto the post driver

body, start the thread, and twist to the right

(clockwise) with your hand until it is

secure against the post driver body. (See

Caution: Do Not Overtighten on page

13)

Lubricate the hammer with Rhino® Pro

Series Rhino Pro Series Lubricant. Insert

the hammer into the cylinder, taking note

of the small end toward the anvil as shown

in Fig. 14. Push the hammer into the

cylinder making room to insert the anvil

o-ring retainer. Apply Rhino® Pro Series

Lubricant to the anvil o-ring retainer and

place the small end into the cylinder. The

Rhino® Pro Series Lubricant should hold it

in place. Lubricate with Rhino® Pro Series

Lubricant and assemble the large retainer

and the two (2) large retainer o-ring seals

in the order shown in (Fig. 16 on next

page) and assemble into the anvil o-ring

cup.

15

Multi-Pro™ Service Instructions... continued

Fig. 15 - Piston with Connecting Rod and

O-ring Seal in place.

Page 18

16

Multi-Pro™ Service Instructions... continued

THE LARGE RADI-

US OF THE LARGE

RETAINER MUST BE POSITIONED

UPWARD FACING THE HAMMER

OR IT WILL CAUSE DAMAGE TO

THE DRIVER.

Clean and inspect the lower driver body

(p/n 301032) for any damage or excessive wear. Replace if necessary. Lubricate

inside of the sleeve of the lower body with

Rhino

®

Pro Series Lubricant. Lubricate the

anvil with Rhino® Pro Series Lubricant.

Insert the anvil with new anvil o-ring into

lower body, making certain that the anvil

is seated into the lower body. Insert the anvil o-ring cup into the lower body. Discard

the used O-ring cup, O-ring (p/n 301618)

and Gasket. Replace with new O-ring cup

and Gasket. The O-ring is obsolete and no

longer needed. The assembly should look

like Fig. 12, but without the o-ring.

All threads on the bolts and in the body

and lower body need to be clean and free

of any dried threadlocker or debris. Apply

Loctite Primer N 7649 to the external and

internal threads. The primer must be dry

before assembly. Apply the gasket to the

lower body assembly by removing the

paper backing and exposing the adhesive

on one side. With the adhesive on one

side. With the facing the lower body, press

gasket into place making sure the bolt

holes are lined up. Apply threadlocker

to the threaded holes on the body. The

threadlocker needs to be applied starting

at the bottom of the threaded hole and

apply a bead of threadlocker up to the top

of the thread. With the gasket in place on

the lower body, remove the paper backing

on the other side of the gasket. Grasp the

Upper Handle Bracket and pull toward

the Upper Handle, depressing the upper

Springs. Seat the Lower Body onto the

upper Body making sure the bolt holes

are aligned. Gently let the upper handle

bracket slide back into place. Place the

lock washers onto the lower body bolts.

The lock washers are a two (2) piece design. Do not separate the parts of the lock

washer. Insert and start by hand the four

(4) lower body bolts through the lower

body and into the body. Use a 1/4" hex

wrench to tighten the bolts in a crossing

pattern. Check for any misalignment or

binding when joining the parts. Do not use

excessive force. Using a torque wrench

set to 132 lb/in (14.9 Nm) for stainless

bolts or 251 lb/in (28.4 Nm) for black

O-ring

O-ring

Anvil

O-ring

Cup

Anvil

with

O-ring

Large Retainer

Large Radius (up)

Fig. 16 - Insert O-ring into Anvil O-ring

Cup, then insert Large Retainer (with large

radius up), then insert other O-ring.

!

WARNING

!

DANGER

!

CAUTION

Page 19

17

Multi-Pro™ Service Instructions... continued

oxide bolts, tighten to the correct torque.

Hand thread the four (4) upper handle

bolts through the handle bracket and into

the body. Do not use lock washers on the

upper handle bolts. Use a 1/4" hex wrench

to tighten the bolts in a crossing pattern.

Using a torque wrench set to 132 lb/in

(14.9 Nm) for stainless bolts or 251 lb/in

(28.4 Nm) for black oxide bolts, tighten

to the correct torque.

Apply Loctite Primer N 7649 to the

threaded holdes in the lower body and to

the chuck bolts. Let the primer dry before

assembly. Apply the threadlocker to the

threaded holes in the lower body. The

threadlocker needs to be applied starting at

the bottom of the threaded hotes and apply

a bead of threadlocker up to the top of the

thread. Insert the chuck bolts into the lock

washers. The lock washers are two (2)

piece design. Do not separate the parts of

the lock washer. Insert and start the four

(4) chuck bolts through the chuck and into

the lower body. Use a 1/4" hex wrench to

tighten the bolts in a crossing pattern. Using a torque wrench set to 132 lb/in (14.9

Nm) for stainless bolts or 251 lb/in (28.4

Nm) for black oxide bolts tighten to the

correct torque.

To clean and lubricate the anti-vibration

handle springs loosen the two bolts

located in the recesses of the top handle

assembly (p/n 301222) until the upper

handle and handle collars are free from

the upper handle bracket. Slide the lower

handle downward to expose the lower

springs. Clean the springs, upper handle

bracket cups, and upper and lower handle

collars with acetone or cleaning solvent.

Apply Rhino lubricant to springs, right

and left collars of the lower handle, top

cups of the upper handle bracket, and upper handle collars. Slide the lower handle

assembly back up into position. Apply

Loctite Primer N 7649 to the handle bolts

and the threaded holes in the handles. Let

the primer dry. The threadlocker needs

to be applied starting at the bottom of

the internal thread and apply a bead of

threadlocker up to the top of the thread.

Insert the springs into the upper handle

bracket cups. Then insert the upper handle

with collars on top of the springs depressing them into the handle bracket cups and

tighten the bolts to secure the handle into

place. Using a torque wrench set to 132 lb/

in (14.91 Nm) for stainless bolts or 251 lb/

in (28.4 Nm) for black oxide bolts, tighten

to the correct torque.

Perform a visual check of the post driver.

Reconnect the spark plug wire to the spark

plug. Check that the engine has the proper

amount of oil. Start the engine using the

proper procedure and test the post driver.

Page 20

18

Regular Service Period

Item

Each Use

First Month Or

10 Hours

Every 3 Months

Or 25 Hours

Every 6 Months

Or 50 Hours

Every 12 Months

Or 100 Hours

Refer to

Page

Engine Oil

Check Level

X

Page 6

Engine Oil

Change

X X

Page 6

Air Cleaner

Check

X

See Honda

Engine Manual

Air Cleaner

Clean

X (1)

See Honda

Engine Manual

Air Cleaner

Replace

X

See Honda

Engine Manual

Crankcase

Lubrication Check

X

Page 12

Check Engine and

Post Diver

Fasteners

X

Page 23

Remove, Service,

Piston Hammer and

Anvil

X

Page 13

Other Honda Engine

Maintenance Schedule

See Honda

Engine Manual

(1) Service more frequently when used in dusty areas.

Multi-Pro™ Service Instructions... continued

Page 21

19

NOTES

Page 22

20

Rhino® Multi-Pro™ Parts and Accessories List

4

4

4

56

10

11

3

5

6

8

9

7

2

13

12

141516

17

18

19

21

22

20

20

23

4

24

25

26

26

28

293031

1

27

4

6

6

Multi-Pro™ Standard Conguration

*Please refer to page 24 for Multi-Pro XA parts and accessories

Page 23

21

Rhino® Multi-Pro™ Parts and Accessories List

No. P/N Description

1 300712 Ground Bolt

2 301016 Body Assembly with Cylinder and Bearings

3 301222 Top Handle Assembly

4 300715-4 Pro Series Handle Bolt (qty. of 4)

5 301221-2 Handle Collar Set (qty. of 2)

6 610010-4 Handle Springs (qty. of 4)

7 300214 Top Handle Bracket

8 301075 Piston and Connecting Rod Assembly

9 301610-2 Piston and Hammer O-ring Seal Set (qty. of 2)

10 301085 Multi-Pro™ Hammer

11 301115 Multi-Pro™ Anvil O-ring Retainer

12 301614-2 Large Retainer O-ring Seal Set (qty. of 2)

13 301105 Multi-Pro™ Large Retainer

14 301095 Multi-Pro™ Anvil O-ring Cup

15 301165 Anvil (See page 27 for Extended Anvil.)

16 301615 Multi-Pro™ Anvil O-ring Seal

17 301710 Multi-Pro™ Body Gasket

18 301038 Multi-Pro™ Sleeve for Lower Body

19 301032 Multi-Pro™ Lower Body

20 300750-4 Multi-Pro™ Lock Washers (qty. of 4)

21 300701-4 Lower Body Bolt Set (qty. of 4)

No. P/N Description

22 301158 Multi-Pro™ Master Chuck

23 300717-4 Multi-Pro™ Chuck Bolt Set (qty. of 4)

24 301920 Chuck-Lok

™

Locking Nut (1 per driver)

25 300221 8.5" (216mm) EPDM Foam Grip (1 per driver)

26 301232 Pro-Series Side Handle Assembly

27 300250 Throttle Control Assembly

28 301233 Lower Handle Assembly

29 300900 Chuck-Lok

™

System 1" (25.4 mm) Adapter

30 300895 Chuck-Lok

™

System 1¾" (44.45 mm) Adapter

31 300902 Chuck-Lok

™

System 2" (50.8 mm) Adapter

Page 24

Rhino® Multi-Pro™ Parts and Accessories List

2

41

38

38

39

40

42

43

44

45

46

47

2

48

47

22

!

WARNING

!

DANGER

!

CAUTION

IMPORTANT

NOTE

Disassembly of the Crankcase will break the tamper

evident seal, thereby voiding the warranty on the driver

Page 25

Rhino® Multi-Pro™ Parts and Accessories List

No. P/N Description

2 301016 Body Assembly with Cylinder and Bearings

38 300782-4 Retaining Ring Set for Crankshaft & Clutch Drum with Pinion Gear

(qty. of 4)

39 300200 Gear

40 300730 Machine Key

41 300700-4 Clutch Housing Bolt Set (qty. of 4)

42 300025 Clutch Housing with Bearings

43 300120 Clutch Drum with Pinion Gear

44 300132 Pro-Series

™

Crankcase Cover - Threaded

45 301617 O-ring Seal for Pro-Series

™

Crankcase Cover - Threaded

46 300050 Crank Pin (Left Hand Threads)

47 300704-6 Crankcase Bolt Set (qty. of 6)

48 300040 Crankshaft

23

Page 26

Rhino® Multi-Pro™ Parts and Accessories List

13143216

17

19

18

21 20

34

2023

24

293031

Multi-Pro™ XA Lower Body Conguration*

12

*Please refer to the Multi-Pro Standard Conguration for parts information on the upper portion of the Multi-Pro XA.

24

Page 27

No. P/N Description

Multi-Pro XA™ ONLY

11 301115 Multi-Pro™ Anvil O-ring Retainer

12 301614-2 Large Retainer O-ring Seal Set (qty. of 2)

13 301105 Multi-Pro™ Large Retainer

14 301095 Multi-Pro™ Anvil O-ring Cup

16 301615 Multi-Pro™ Anvil O-ring Seal

17 301710 Gasket

18 301038 Multi-Pro™ Sleeve for Lower Body

19 301032 Multi-Pro™ Lower Body

20 300750-4 Multi-Pro™ Lock Washers (qty. of 4)

21 300701-4 Lower Body Bolt Set (qty. of 4)

23 300717-4 Multi-Pro™ Chuck Bolt Set (qty. of 4)

24 301920 Chuck-Lok

™

Locking Nut (1 per driver)

29 300900 Chuck-Lok

™

System 1" (25.4 mm) Adapter

30 300895 Chuck-Lok

™

System 1¾" (44.45 mm) Adapter

31 300902 Chuck-Lok

™

System 2" (50.8 mm) Adapter

32 301169 Multi-Pro Extended Anvil

34 301420 Multi-Pro

™

Extended Master Chuck

Rhino® Multi-Pro™ Parts and Accessories List

25

Page 28

No. P/N Description

49 300180 Shroud

50 300181-2 Grommet (qty. of 2)

51 300190-2 Shroud Spacer (qty. of 2)

52 300706-2 Shroud Bolt (qty. of 2)

53 300705-2 Lower Shroud Bolt (qty. of 2)

300240 Honda GX35 Engine

Honda Engine Parts are Available from Your Local Honda Dealer

300805 Safety Label and Tag Set

301801 Multi-Pro

™

Operating, Safety, and Parts Manual

49

51

51

53

50

50

Rhino® Multi-Pro™ Parts and Accessories List

52

26

Page 29

Rhino® Multi-Pro™ Parts and Accessories List

No. P/N Description

Accessories

31 300902 Chuck-Lok

™

System 2" (50.8mm) Adapter

30 300895 Chuck-Lok

™

System 1¾" (44.4mm) Adapter

29 300900 Chuck-Lok

™

System 1" (25.4mm) Adapter

24 301920 Chuck-Lok

™

Locking Nut (1 required)

301159 Multi-Pro

™

Slotted Chuck

301169 Multi-Pro

™

Extended Anvil

301175 Multi-Pro™ U-Channel Drive Kit (includes 301159, 301169)

301155 Multi-Pro

™

Tent Stake Chuck

301400 Large Chuck Adapter (required for all large chucks) Plate*

301171 Multi-Pro

™

Square Tube Chuck

300932 Drive cap for 1¾" (44.4mm) Square Tube**

300933 Drive cap for 2" (50.8mm) Square Tube**

300934 Drive cap for 2¼" (57.15mm) Square Tube**

300935 Drive cap for 2½" (63.5mm) Square Tube**

301403 Multi-Pro

™

3½" Round Chuck Assembly***

301405 Multi-Pro

™

4" Round Chuck Assembly***

301415 Multi-Pro

™

3" Square Chuck Assembly***

301414 Multi-Pro

™

3" Round Chuck Assembly***

34 301420 Multi-Pro

™

Extended Master Chuck

No. P/N Description

301422 Multi-Pro

™

XA Square Tube Chuck

301000 ¼" Long Arm Hex Key

300500 Rhino

®

Pro Series Lubricant

300506 Rhino

®

Pro Series Lubricant - 12-pack

301509 Multi-Pro

™

Service Kit

Bolt Torque Specications

4 300715-4 Pro Series Handle Bolts (qty. of 4) - 132 lb/in (14.91 Nm)

21 300701-4 Lower Body Bolts (qty. of 4) - 251 lb/in (28.3 Nm)

23 300717-4 Multi-Pro™ Chuck Bolt Set (qty. of 4) - 251 lb/in (28.3 Nm)

41 300700-4 Clutch Housing Bolt (qty. of 4) - 95.0 in/lbs (10.73 Nm)

46 300050 Crank Pin (Left Hand Threads) - 360.0 in/lbs (40.6 Nm)

47 300704-6 Crankcase Bolt (qty. of 6) - 75.0 in/lbs (8.5 Nm)

52 300706-2 Shroud Bolt (qty. of 2) - 56.4 in/lbs (6.37 Nm)

53 300705-2 Shroud Bolt - Self Tapping (qty. of 2) - 56.4 in/lbs (6.37 Nm)

*Requires 301169 Multi-Pro

™

Extended Anvil

**Requires 301171 Square Tube Chuck of 301422 XA Square Tube Chuck

***Requires 301400 Large Chuck Adapter Plate

27

Page 30

Warranty: Rhino Tool Company, Inc. (“Rhino”) warrants

to the original purchaser, purchasing the Equipment in new

condition, in original packaging from an authorized dealer

that its Gasoline Powered

Post Driver will be free from

defects in workmanship and

materials (the “Limited Warranty”). The Limited Warranty

shall survive for the lifetime

of the product with respect to the Hammer and Anvil components

and for twelve (12) months with regard to all other components,

excluding the Honda GX35 engine for which Rhino provides no

warranty and for which the warranty provided by American Honda

Motor Co., Inc. shall be the sole warranty applicable thereto. This

Limited Warranty is non-transferable.

For Warranty Claims contact your dealer or distributor. Proof of

purchase date and serial number is required. In the event of a

warranty repair, the post driver should be returned to a Registered

and Warranty Authorized Rhino Servicing Dealer. Rhino’s obligation under this Limited Warranty is expressly limited to the repair

or replacement, at Rhino’s election, of such defective Gasoline

Powered Post Driver, which is proved to be defective upon inspection by a Rhino-certied/authorized technician.

This Limited Warranty does not extend to a Gasoline Powered

Post Driver which has been subject to misuse, neglect, or accident, nor does it extend to any Gasoline Powered Post Driver

which has been repaired, altered, or serviced by unauthorized

persons. This Limited Warranty does not cover any damage or

adjustments required to any Gasoline Powered Post Driver if such

damage or adjustment is caused by the use of supplies, parts, or

attachments not sold or approved by Rhino

EXCEPT AS OTHERWISE PROVIDED HEREIN, RHINO DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING, BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. UNDER NO CIRCUMSTANCES SHALL RHINO BE LIABLE FOR ANY LOSS OF BUSINESS, REVENUES,

OR PROFIT OR OTHER INDIRECT, INCIDENTAL, SPECIAL OR

CONSEQUENTIAL DAMAGES OR LOSS ARISING OUT OF ANY

DEFECTS IN OR PERFORMANCE OF THE GASOLINE POWERED POST DRIVER, HOWSOEVER CAUSED.

To register your product:

Fill out and mail in registration card supplied with post driver

Or online visit:

http://rhinotool.com/contact-support/warranty-information/

Rhino® Limited Lifetime Impact Warranty

Gasoline Powered Post Drivers

W

A

R

R

A

N

T

Y

L

I

F

E

T

I

M

E

28

Page 31

Page 32

Loading...

Loading...