1

Rhino

Rhino Tool Co. Inc.

®

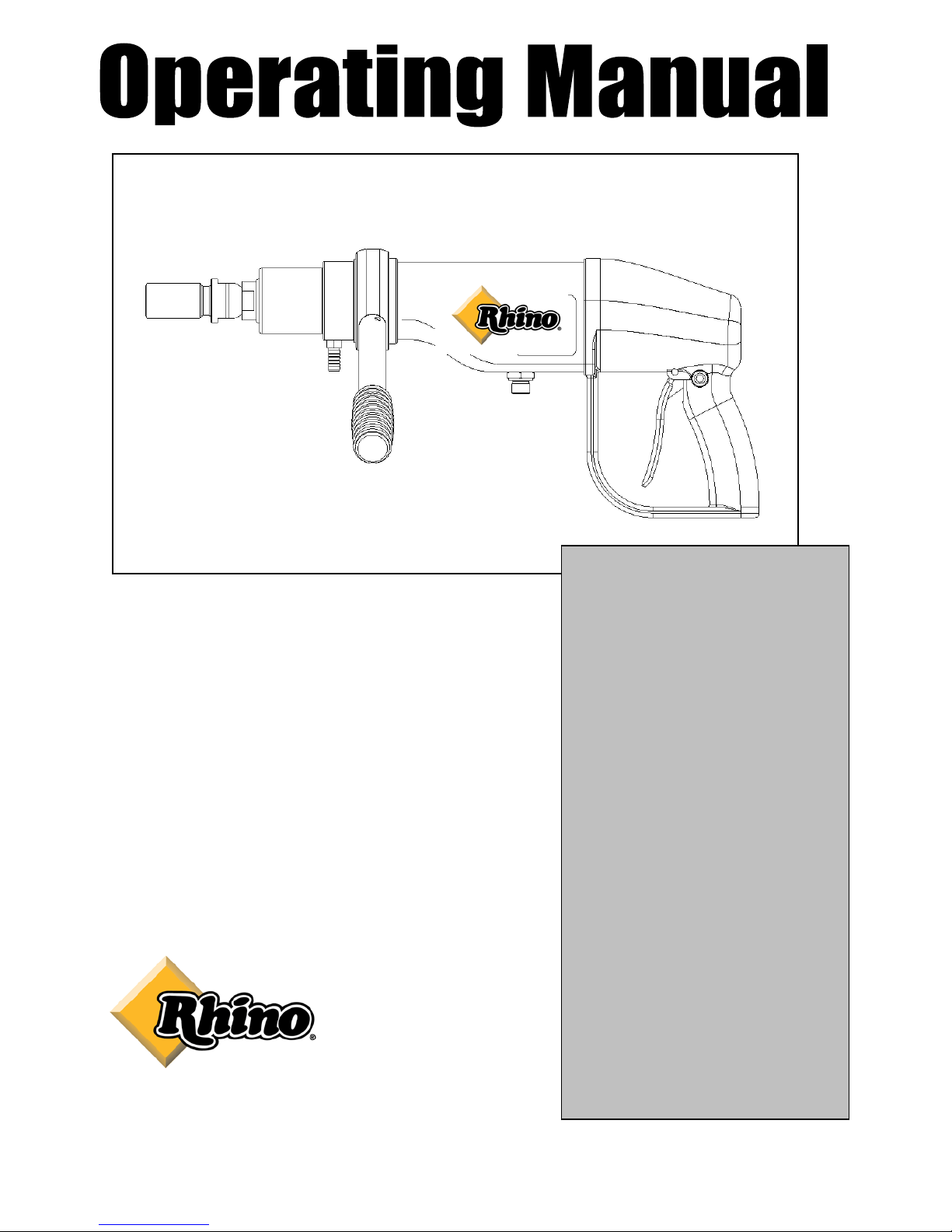

Hydraulic Core Drill

HCD 1-4

HCD 2-14

Revised 6.14.2016

000386.08.25.16

620 Andrews Ave.

Kewanee, IL 61443

Tel: 309.853.5555

Tel: 866.707.1808

Fax: 309.856.5905

info@rhino.com

www.rhinotool.com

Prior to Operation

We thank you for choosing a

Rhino® core drill.

To ensure smooth operation

and long-lasting performance of

your new core drill, we recommend you to study this

operating manual carefully and

pay special attention to the

chapters about

Safety and Service

Precautions

We are confident you will be

satisfied with your new Rhino®

core drill.

Best regards

Rhino® Tool Company

2

Contents

Page

Safety Precautions .............................................................................................. 2

Oil Flow and Pressure .......................................................................................... 4

Useful information regardi ng the use of core drill .................................................. 4

Starting Instructions ............................................................................................ 6

Technical Data .................................................................................................... 7

Performance Chart .............................................................................................. 8

Dimensions ......................................................................................................... 9

Connection to Hydraulic Power Sources .............................................................. 10

Service and Maintenance ................................................................................... 11

Oil Types .......................................................................................................... 11

Warranty Terms ............................................................................................... 13

000386.08.25.16

3

Safety Precautions

• Read the core drill and power source operating manuals pri or to use.

• Only use the core drill in accor da nc e with the local working regulations on

allowed working time

• Check the oil supply to the core drill. The oil supply may not exceed 5 g.p.m. (20 l.p.m.)

/max. 2500 psi (170 bar). Please refer to page 4.

• Make sure that the core bit is firmly fastened in the drill

• For handheld drilling, always use core bits approved for this purpose.

• The Rhino® core drill is supplied with a trigger lock. This may only be used when drilling in a

rig.

• The core drill has an automatic integ r ated clutch that makes the core drill stop if the core bit

jams. However, in case of jamming, always loosen the core bit from the material, before you

start drilling again. The integrated clutch is set from the factory and may not be disturbed.

• Start the core drill just before you start drilling, and stop it once the drilling is done. Do not

let the core drill run freely in the air.

• In case of horizontal drilling or drilling above the head, always be aware of falling debris.

• A fine jet of oil at high pressure can penetrate th e sk i n . It is therefore i mportant never t o

use your fingers to check for oil leaks and never to hold your face close to suspected leaks –

use a piece of cardboard instead. If oil has penetrated the skin, you should get medical

treatment immediately.

• Never leave the core drill unattached when connected to the powerpack.

• Always use approved hoses. Contact your dealer, if necessary. Mount the hoses correctly so

that the core drill rotates in the correct (clockwise) direction.

• The operator must pay extra attentio n and sho w caution when working in difficult wo r ki ng

areas, such as slopes and o ther dangerous environment. Do not reach too far with the core

drill, but always maintain a good footing and keep your balance.

• The operator must be properly trained in using the core drill or under supervision of a

qualified instructor.

• The operator must always use protective goggles, earplugs, hard hat and protective

footwear when operating the core drill.

000386.08.25.16

4

• Never use the core drill close to utilities, electric, gas, telephone, water, cable, ect. Prior to

operation, check whether there are hidden or buried cables.

• Never wear loose clothing as it may get entangled in the moving parts of the core drill or

other hazards in the work area.

• Inspection or cleaning of the core drill, change of core bit or disconnection of hoses may

never be done while the core drill is connected to the powerpack and under pressure as

unintentional activation of the core drill can cause severe damage.

• Always connect hoses to the core drill before starting the powerpack. Be sure that all

couplings are tight.

• The core drill may not be operated if the oil temperature is above 160 F° (70 C°). Operation

at higher temperatures may result in the core drill getting warmer than normal and the

operator risks getting a thermal burn.

• To avoid all personal injury and damage to the core drill, all repair, maintenance a nd service

work must be carried out by authorized or properly trained persons only.

IMPORTANT

• A core drill, when not in use should always be kept in a secured and dry place.

• Always make sure that the core drill l abels and warning signs are legible.

• Always use hoses, couplings and spares as such recommend by Rhino®.

• Repairs may only be carried out by experienced personnel.

• Make sure that all couplings are cleaned before connection.

• Always disconnect the hydraulic circ ui t before connecting or disco nnecting the core drill. If

this is not done, there is a risk of damage to the quick release

couplings or the hydraulic system getting overheated.

000386.08.25.16