Page 1

Cased/Uncased Coils For

Gas And Oil Furnaces

FORM NO. C11-224 REV. 2

RCF- Series

featuring Industry Standard R-410A

Refrigerant

Airflow Capacity

600-1,900 CFM [283-897 L/s]

• Rheem

®

Indoor Furnace cased coils and replacement

uncased coils are designed for use with Rheem outdoor

units and are available for vertical upflow or downflow, and

horizontal left or horizontal right airflow. When matched

with Rheem outdoor units, the coils provide a nominal

capacity range from 18,000 BTU/HR [5.24 kW] to 60,000

BTU/HR [17.6 kW].

• Constructed of aluminum fins bonded to internally grooved

aluminum tubing.

• Coils are tested at the factory with an extensive refrigerant

leak check.

• Coils have copper sweat refrigerant connections.

• Feature two sets of

3

/4" [14.1 mm] N.P.T. Condensate drain

connections for ease of connection.

• Chatleff metering device connections, at inlet and outlet of

TXV and equalizer connections.

• Approved for system application with variety of Rheem

outdoor units.

• Condensate drain pan is constructed of high grade, heat

resistant, corrosion free thermal-set material.

• Compatible with Germicidal Light System (UV resistant)

• Bi-Directional airflow eliminates the need to switch any

internal components from horizontal left to right.

• Unique drain pan design maximizes application flexibility

and condensate removal.

• N-Coil design maximizes performance and minimizes height

required at installation.

• Coils are AHRI certified for system application with a variety

of Rheem outdoor units.

Air

Indoor Coils

RCF Series

Page 2

2

Air

Table of Contents

RCF Series

TABLE OF CONTENTS

Model Number Identification ............................................................................3

Coil Specifications ......................................................................................4-5

Coil Dimensions and Weights........................................................................6-7

Accessories ................................................................................................8-9

Limited Warranty ..........................................................................................10

Page 3

3

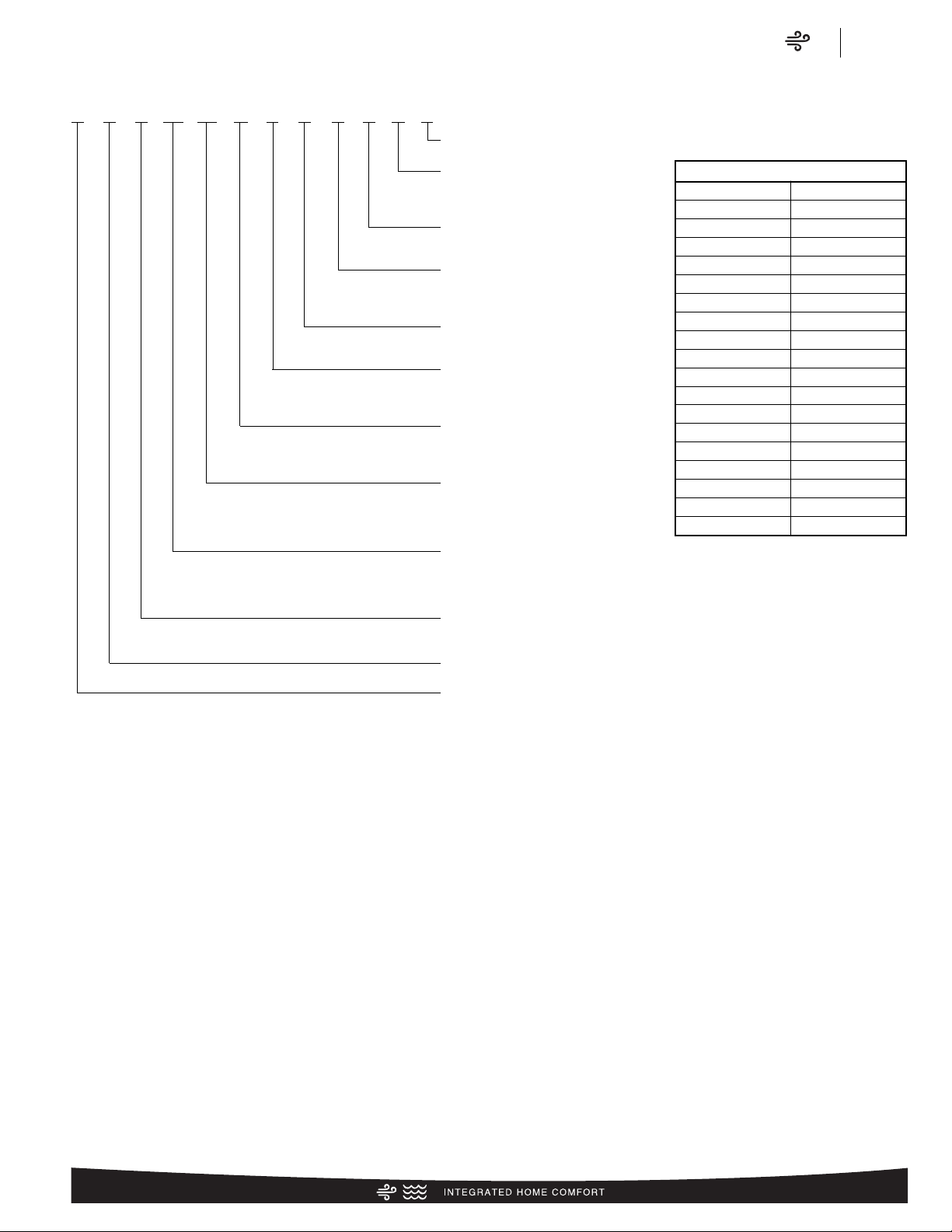

RCF2417S TA MUA*

Option Code

*TBD

Minor Series**

Component Change

Cost Reduction

Non-performance Changes

Casing

U = Uncased

C = Cased

Orientation

M = Multipoise

V = Vertical only/convertible

H = Ded. Horizontal Only

Major Series*

Feature Set Change

Performance Change

Metering Device

T = TEV

E = EEV

P = Piston

Efficiency

S = Standard Efficiency

M = Mid. Efficiency

H = High Efficiency

Width

14 = 14" [356 mm]

17 = 17.5" [431.8 mm]

21 = 21" [533.4 mm]

24 = 24.5" [609.6 mm]

Capacity

24 – 2 Ton

36 – 3 Ton

48 – 4 Ton

60 – 5 Ton

Type

F = Furnace Coil

H = Air Handler Coil

Product Category

C = Evaporator Coil

Rheem

[ ] Designates Metric Conversions

Model Number Identification

MODELS AVAILABLE

RCF2414STAMCA RCF4821STSVUA

RCF2417STAMCA RCF4824STSVUA

RCF2417MTAMCA RCF6024STAVUA

RCF2421MTAMCA RCF2417HTAMCA

RCF3617STAMCA RCF2421HTAMCA

RCF3621STAMCA RCF3624HTAMCA

RCF3621MTAMCA RCF4824HTAMCA

RCF3624MTAMCA RCF6024HTAMCA

RCF4821STAMCA RCF2417HTAVUA

RCF4824STAMCA RCF2421HTAVUA

RCF6024STAMCA RCF3624HTAVUA

RCF2414STAVUA RCF4824HTAVUA

RCF2417STAVUA RCF6024HTAVUA

RCF2417MTAVUA RCF2417SPAVUA

RCF2421MTAVUA RCF3617SPAVUA

RCF3617STAVUA RCF3621SPAVUA

RCF3621STAVUA RCF4821SPAVUA

RCF3621MTAVUA RCF4824SPAVUA

RCF3624MTAVUA

Air

Model I.D.

RCF Series

Page 4

Air

Coil Specifications

RCF Series

4

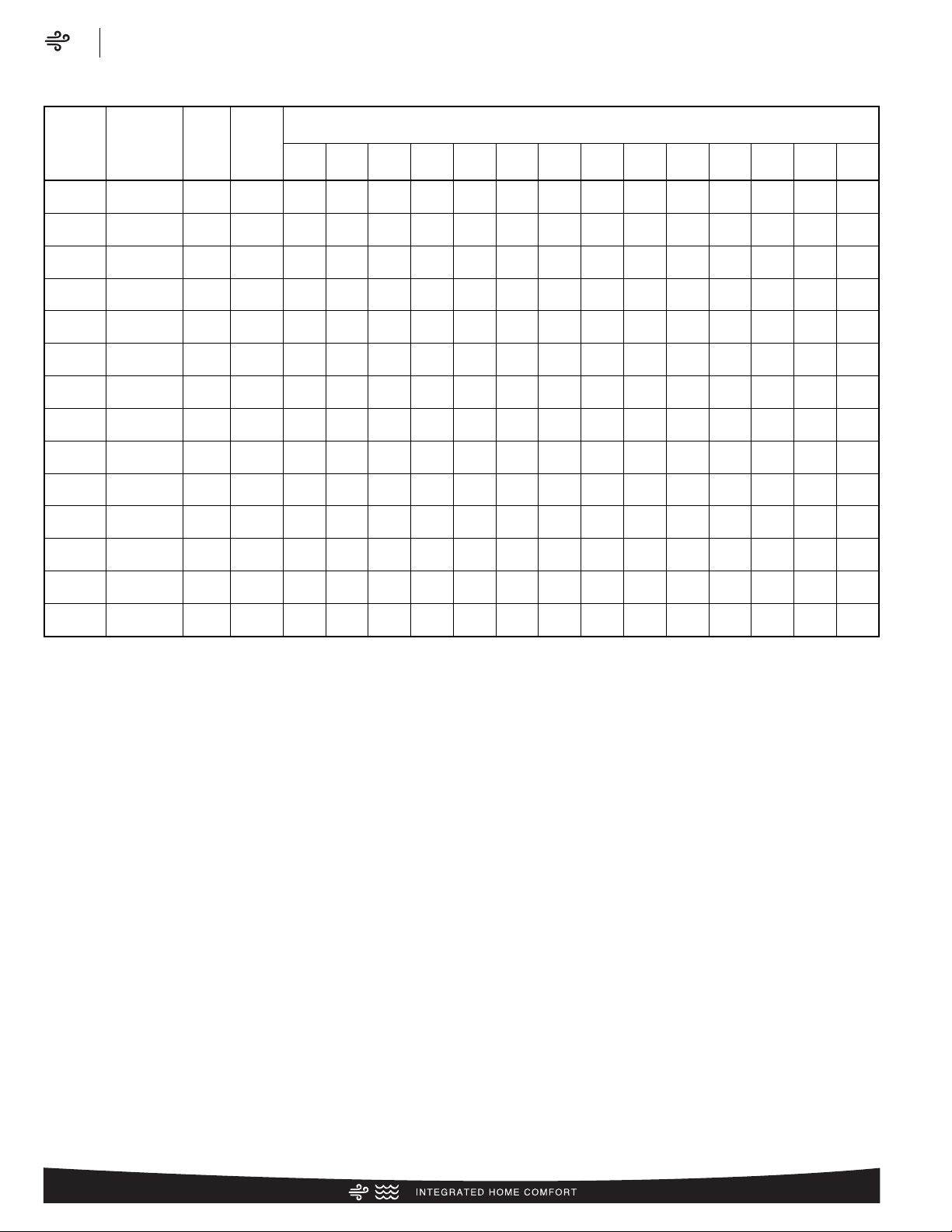

Table 1: Coil Specifications/Airflow Pressure Drop

Coil

Model

(-)CF

Approx.

Design Cooling

Air Flow

Range CFM

[L/s]

Face

Area

Sq. Ft.

[m

2

]

Fins-in./

Rows

Deep

Wet Coil Static Pressure Drop (Inches W.C.) [kPa] @ CFM [L/s] – (Coil-Only)

600

[283]

700

[330]

800

[378]

900

[425]

1000

[472]

1100

[519]

1200

[566]

1300

[614]

1400

[661]

1500

[708]

1600

[755]

1700

[802]

1800

[850]

1900

[897]

2414S

600/900

[283/425]

4.56

[.42]

16 / 2 0.17 0.22 0.28 0.34 — — — — — — — — — —

2417S

600/900

[283/425]

4.56

[.42]

16 / 2 0.13 0.16 0.21 0.25 — — — — — — — — — —

2417M

600/900

[283/425]

4.56

[.42]

16 / 2 0.11 0.15 0.18 0.22 — — — — — — — — — —

2421M

600/900

[283/425]

5.70

[.52]

16 / 2 0.11 0.15 0.18 0.22 — — — — — — — — — —

2421H

600/900

[283/425]

5.70

[.52]

16 / 2 0.11 0.15 0.18 0.22 — — — — — — — — — —

3617S

700/1300

[330/614]

5.70

[.52]

16 / 2 0.11 0.15 0.18 0.22 0.27 0.31 0.37 0.42 — — — — — —

3621S

700/1300

[330/614]

5.70

[.52]

16 / 2 0.11 0.15 0.18 0.22 0.27 0.31 0.37 0.42 — — — — — —

3621M

700/1400

[330/661]

8.55

[.79]

16 / 2 0.06 0.09 0.11 0.14 0.17 0.20 0.24 0.27 0.31 — — — — —

3624H

700/1400

[330/661]

9.98

[.93]

14 / 3 0.03 0.05 0.07 0.09 0.11 0.14 0.17 0.20 0.23 — — — — —

4821S

1100/1800

[519/850]

8.55

[.79]

16 / 2 0.06 0.09 0.11 0.14 0.17 0.20 0.24 0.27 0.31 0.35 0.39 0.43 0.48 —

4824S

1100/1800

[519/850]

8.55

[.79]

16 / 2 0.06 0.09 0.11 0.14 0.17 0.20 0.24 0.27 0.31 0.35 0.39 0.43 0.48 —

4824H

1100/1800

[519/850]

9.98

[.93]

14 / 3 0.03 0.05 0.07 0.09 0.11 0.14 0.17 0.20 0.23 0.26 0.30 0.33 0.37 —

6024S

1400/1900

[661/897]

9.98

[.93]

14 / 3 0.03 0.05 0.07 0.09 0.11 0.14 0.17 0.20 0.23 0.26 0.30 0.33 0.37 0.41

6024H

1400/1900

[661/897]

9.98

[.93]

14 / 3 0.03 0.05 0.07 0.09 0.11 0.14 0.17 0.20 0.23 0.26 0.30 0.33 0.37 0.41

Important Note: Gas furnace heating CFM can exceed the design cooling CFM. Ductwork and coil selection must accommodate the higher of the cooling or gas heating CFM to prevent furnace limit tripping,

excessive noise, and coil freeze-up.

[ ] Designates Metric Conversions

Page 5

Air

Coil Specifications

RCF Series

5

Table 1: Coil Specifications/Airflow Pressure Drop (con’t.)

Coil

Model

(-)CF

Approx.

Design Cooling

Air Flow

Range CFM

[L/s]

Face

Area

Sq. Ft.

[m

2

]

Fins-in./

Rows

Deep

Dry Coil Static Pressure Drop (Inches W.C.) [kPa] @ CFM [L/s] – (Coil-Only)

600

[283]

700

[330]

800

[378]

900

[425]

1000

[472]

1100

[519]

1200

[566]

1300

[614]

1400

[661]

1500

[708]

1600

[755]

1700

[802]

1800

[850]

1900

[897]

2414S

600/900

[283/425]

4.56

[.42]

16 / 2 0.12 0.16 0.21 0.26 0.31 0.37 0.44 — — — — — — —

2417S

600/900

[283/425]

4.56

[.42]

16 / 2 0.10 0.13 0.17 0.21 0.25 0.30 0.35 0.41 0.47 0.53 0.60 — — —

2417M

600/900

[283/425]

4.56

[.42]

16 / 2 0.10 0.13 0.16 0.20 0.24 0.28 0.32 0.37 0.43 0.48 0.54 — — —

2421M

600/900

[283/425]

5.70

[.52]

16 / 2 0.10 0.13 0.16 0.20 0.24 0.28 0.32 0.37 0.43 0.48 0.54 0.61 0.67 —

2421H

600/900

[283/425]

5.70

[.52]

16 / 2 0.10 0.13 0.16 0.20 0.24 0.28 0.32 0.37 0.43 0.48 0.54 0.61 0.67 —

3617S

700/1300

[330/614]

5.70

[.52]

16 / 2 0.10 0.13 0.16 0.20 0.24 0.28 0.32 0.37 0.43 0.48 0.54 — — —

3621S

700/1300

[330/614]

5.70

[.52]

16 / 2 0.10 0.13 0.16 0.20 0.24 0.28 0.32 0.37 0.43 0.48 0.54 0.61 0.67 —

3621M

700/1400

[330/661]

8.55

[.79]

16 / 2 0.04 0.06 0.07 0.10 0.12 0.14 0.17 0.19 0.22 0.25 0.28 0.32 0.35 —

3624H

700/1400

[330/661]

9.98

[.93]

14 / 3 0.02 0.04 0.06 0.07 0.10 0.12 0.14 0.17 0.20 0.23 0.26 0.30 0.34 0.38

4821S

1100/1800

[519/850]

8.55

[.79]

16 / 2 0.04 0.06 0.07 0.10 0.12 0.14 0.17 0.19 0.22 0.25 0.28 0.32 0.35 0.39

4824S

1100/1800

[519/850]

8.55

[.79]

16 / 2 0.04 0.06 0.07 0.10 0.12 0.14 0.17 0.19 0.22 0.25 0.28 0.32 0.35 0.39

4824H

1100/1800

[519/850]

9.98

[.93]

14 / 3 0.02 0.04 0.06 0.07 0.10 0.12 0.14 0.17 0.20 0.23 0.26 0.30 0.34 0.38

6024S

1400/1900

[661/897]

9.98

[.93]

14 / 3 0.02 0.04 0.06 0.07 0.10 0.12 0.14 0.17 0.20 0.23 0.26 0.30 0.34 0.38

6024H

1400/1900

[661/897]

9.98

[.93]

14 / 3 0.02 0.04 0.06 0.07 0.10 0.12 0.14 0.17 0.20 0.23 0.26 0.30 0.34 0.38

Important Note: Gas furnace heating CFM can exceed the design cooling CFM. Ductwork and coil selection must accommodate the higher of the cooling or gas heating CFM to prevent furnace limit tripping,

excessive noise, and coil freeze-up.

[ ] Designates Metric Conversions

Page 6

Air

Coil Dimensions and Weights

RCF Series

6

FRONT VIEW

SIDE VIEW

FIGURE 1: DIMENSIONS UNCASED

[ ] Designates Metric Conversions

Table 2: Coil Dimensions and Weights

Coil

Model

RCF

Connections

Uncased Coil Dimensions

(in) [mm]

Weight

Sweat (in.) [mm]

Liquid Suction

AB

Coil Weight

(lbs.) [Kg.]

Shipping Weight

(lbs.) [Kg.]

I.D. I.D.

2414ST

3

/8[9.53]

3

/4[19.05] 213/

4 88

[552] 127/8[327] 43 [19]

47 [21]

2417SP/2417ST

3

/8[9.53]

3

/4[19.05] 153/

8 88

[390] 163/8[416] 43 [19] 48 [22]

2417MT/2417HT/3617ST/3617SP

3

/8[9.53]

3

/4[19.05] 183/

4 88

[476] 163/8[416] 49 [22] 54 [24]

2421MT/2421HT/3621ST/3621SP

3

/8[9.53]

3

/4[19.05] 183/

4 88

[476] 197/8[505] 51 [23] 60 [27]

3621MT/4821ST/4821SP

3

/8[9.53]

3

/4[19.05] 265/

8 88

[676] 197/8[505] 71 [32] 78 [35]

3624MT/4824ST/4824ST

3

/8[9.53]

3

/4[19.05] 2611/16[678] 233/8[594] 83 [37] 93 [42]

3624HT/4824HT/6024ST/6024HT

3

/8[9.53]

3

/4[19.05] 3015/16[786] 233/8[594] 100 [45]

108 [48]

*The 14 inch, 2 ton RCF coil (2414) is part of the “N-Coil” design series, even though the coil shape resembles an “A” coil design.

Page 7

7

53/8

[136.5 mm]

SUCTION LINE

LIQUID LINE

1

13

/16 [46 mm]

2

1

/4 [57.1 mm]

1

1

/4

[31.7 mm]

7

/16

[11.1 mm]

5

15

/16

[150.8 mm]

4

1

/8

[104.7 mm]

17/16

[36.5 mm]

21

11

/16

[550.8 mm]

PRIMARY DRAIN

3

/4 N.P.T. (VERTICAL)

PRIMARY DRAIN

3

/4 N.P.T.

(VERTICAL &

HORIZONTAL)

SECONDARY DRAIN

3

/4 N.P.T. (VERTICAL)

NOTE:

FLANGES ARE

PROVIDED

FOR FIELD

INSTALLATION

1

/2 [12.7 mm]

FRONT VIEW

SIDE VIEW

FIGURE 1: DIMENSIONS CASED

➀ Casing top and bottom openings are the same dimensions.

[ ] Designates Metric Conversions

PLENUM WIDTH

Air

Coil Dimensions and Weights

RCF Series

Table 2: Coil Dimensions and Weights

Coil

Model

RCF

Connections

Cased Coil Dimensions

(in) [mm]

Weight

Sweat (in.) [mm]

Liquid Suction

ABC

Coil Weight

(lbs.) [Kg.]

Shipping Weight

(lbs.) [Kg.]

I.D. I.D.

2414ST

3

/8[9.53]

3

/4[19.05] 14 1/2[356] 21 1/2[533] 233/16[584] 43 [19]

47 [21]

2417SP/2417ST

3

/8[9.53]

3

/4[19.05] 171/2[445] 141/2[368] 201/2[508] 43 [19] 48 [22]

2417MT/2417HT/3617ST/3617SP

3

/8[9.53]

3

/4[19.05] 171/2[445] 177/8[454] 201/2[508] 49 [22] 54 [24]

2421MT/2421HT/3621ST/3621SP

3

/8[9.53]

3

/4[19.05] 21 1/2[533] 171/2[445] 201/2[508] 51 [23] 60 [27]

3621MT/4821ST/4821SP

3

/8[9.53]

3

/4[19.05] 21 1/2[533] 257/8[657] 287/8[711] 71 [32] 78 [35]

3624MT/4824ST/4824ST

3

/8[9.53]

3

/4[19.05] 241/2[622] 253/8[645] 321/2[812] 83 [37] 93 [42]

3624HT/4824HT/6024ST/6024HT

3

/8[9.53]

3

/4[19.05] 241/2[622] 301/4[768] 321/2[812] 100 [45]

108 [48]

*The 14 inch, 2 ton RCF coil (2414) is part of the “N-Coil” design series, even though the coil shape resembles an “A” coil design.

197/8

A MINUS ONE INCH ➀

[505 mm]

Page 8

Air

Accessories

RCF Series

8

2414ST

RXHH-A01

2417MT/2421MT/3617ST/

3621ST/2421HT

RXHH-A03

3621MT/3624MT/

4821ST/4824ST

RXHH-A04

Coil Model Horizontal Adapter Kit Model No.

2417ST

RXHH-A02

3624HT/4824HT/

6024ST/6024HT

RXHH-A05

Table 4: Horizontal Adapter Kit Model No.

Accessories

• PLENUM ADAPTER ACCESSORY

RXBA-AE

This plenum adapter accessory is for use with the 24

1

/2" wide

cased indoor cooling and heat pump coils. This allows a 24

1

/2"

wide cased coil to be installed on a 28" wide oil furnace. This is a

field-installed accessory only.

• RXBA-AC (Upflow/Horizontal)

These plenum adapter accessories are for use when a cooling

coil is matched with a gas furnace of one smaller size.

• HORIZONTAL ADAPTER KIT RXHH (See Figure 2)

This horizontal adapter kit is used to convert a upflow or downflow

coil for a horizontal application. See Table 4 to order the proper

horizontal adapter kit.

Table 3: Coil Application

Coils can be matched to heating products as listed in table below.

Coil Model

RCF

Oil Gas

2414ST

2417ST

2417HT/2417MT

3617ST

— 14 [356]

2417ST

2417MT/2417HT/2417SP

3617ST/3617SP

171/2[431]

171/2[444]

14 [356]

21 [533]

171/2[444]

Furnace Width

(In.) (mm)

241/2[622]

21 [533]

21 [533]

2421MT/2421HT

3621ST/3621SP

3621MT/4821ST/4821SP

241/2[622]

3624MT/3624HT

4824ST/4824HT/4824SP

6024ST/6024HT

AIR FLOW

HORIZONTAL-DUAL

DIRECTION

FIGURE 2: HORIZONTAL ADAPTER KIT ILLUSTRATION

RXBC—D14I

INSULATION

I = Insulated

Blank = Uninsulated

CABINET WIDTH

14 = 14" [356 mm]

17 = 17.5" [444 mm]

21 = 21" [533 mm]

24 = 24.5" [622 mm]

DESIGN SERIES

COIL CASING

BLOWER UNIT

ACCESSORY

RHEEM

Table 5: Unit Dimensions and Weights- RXBC Indoor Coil Casings

• INDOOR COIL CASING- RXBC (See Table 5)

HORIZONTAL ADAPTER KIT (RXHH-)

B14x20 131/8[333]

B17x20

165/8[422]

Uncased Coil Adapter

Model Number RXBA

A

Width (in.) [mm]

B21x20 201/8[511]

-HUxx14

-HUxx17

Uncased Coil

Model RCFP

-HUxx21

B24x20 235/8[599] -HUxx24

Table 6: Uncased Coil Adapter Kit

[ ] Designates Metric Conversions

Model

Number

RXBC-D14AI 14 [356] 233/16[589]

RXBC-D17AI 171/2[445] 20 [508] 18 [8] 161/2[419]

RXBC-D21AI 21 [533] 20 [508] 20 [9] 20 [508]

RXBC-D21BI 21 [533] 28 [711] 27 [12] 20 [508]

RXBC-D24AI 241/2[622] 321/2[826]

Width

(in.) [mm]

(in.) [mm]

Height

Depth

(in.)

[mm]

215/

[549]

Unit Weight

Weight

(lbs.) [Kg.]

19 [9] 13 [330]

8

34 [16]

Ship. Wt.

(lbs.) [Kg.]

23 [10]

23 [10]

26 [12]

36 [17]

44 [20]

Supply Air/Return

Air Openings

Depth

Width

(in.) [mm]

231/2[597]

(in.)

[mm]

1931/

[508]

32

Page 9

Air

Accessories

RCF Series

9

FIGURE 4: UNCASED COIL ADAPTER KIT ASSEMBLED

Note: Sliding the coil into the coil rail before attaching coil rack front.

FIGURE 3: UNCASED COIL ADAPTER KIT ILLUSTRATION

• UNCASED COIL ADAPTER KIT

RXBA- (See Figure 3 & 4)

This uncased coil adapter kit is used to adapt the coil to a furnace or ductwork. See Table 6 to order the proper adapter kit.

Each kit contains a quantity of 20 adapters.

Accessories (cont.)

[ ] Designates Metric Conversions

FURNACE COIL CROSS REFERENCE CHART

ORIGINAL COIL RECOMMENDED ALUMINUM TUBE REPLACEMENT COIL R-22 TXV CONVERSION KIT MODEL NO.

RCFA-**2414 RCF2414STAT RXCT-HBA

RCFA-**2417 RCF2417STA RXCT-HBA

RCFA-**3617 RCF3617STA, RCF2417MTA, or RCF2417HTA RXCT-HBB

RCFA-**3621 RCF3621STA, RCF2417MTA, or RCF2421HTA RXCT-HBB

RCFA-**4821 RCF4821STA or RCF3621MTA RXCT-HBC

RCFA-**4824 RCF4824STA or RCF3624MTA RXCT-HBC

RCFA-**6024 RCF6024STA, RCF6024HTA, RCF4824HTA, or RCF3624HTA RXCT-HBD

**= AU, HM, or HU

R-22 TXV Conversion Kits

To be used to convert R410-A coil to operate with R-22

11

/16

7

[196 mm]

11/2

[41 mm]

A

5

20

/16

[516 mm]

Page 10

Air

Limited Warranty

RCF Series

10

GENERAL TERMS OF LIMITED WARRANTY*

Rheem will furnish a replacement for any part of this product

which fails in normal use and service within the applicable

periods stated, in accordance with the terms of the limited

warranty.

*For complete details of the Limited and Conditional Warranties, including

applicable terms and conditions, contact your local contractor or the

Manufacturer for a copy of the product warranty certificate.

Parts.......................................................................Five (5) Years

Page 11

Air

Notes

RCF Series

11

Page 12

The new degree of comfort.

™

Rheem Heating, Cooling & Water Heating • P.O. Box 17010

Fort Smith, Arkansas 72917 • www.rheem.com

In keeping with its policy of continuous progress and product improvement, Rheem reserves the right to make changes without notice.

PRINTED IN U.S.A. 12/14 QG FORM NO. C11-224 REV. 2

Rheem Canada Ltd./Ltée • 125 Edgeware Road, Unit 1

Brampton, Ontario • L6Y 0P5

Loading...

Loading...