Page 1

This document is stored and maintained electronically by Service. All printed copies not bearing this statement in RED are deemed “uncontrolled”

RRhheeeem

m AAuussttrraalliiaa PPttyy LLttdd

AABBNN 2211 009988 882233 551111

SERVICE

INSTRUCTIONS

Rheem Water Star

TM039

Revision: A

Published: January 09

W8100401

Page 2

TM039 Rheem Water Star Service Instructions REV: A

Date of Issue: 02/09

This document is stored and maintained electronically by Service. All printed copies not bearing this statement in RED are deemed “uncontrolled”

2

Contents

Introduction .......................................................................................................................... 3

Safety Warning .................................................................................................................... 3

Heater Model Identification Number .................................................................................... 3

Specifications ....................................................................................................................... 4

Preventative Maintenance ................................................................................................... 4

Operation ............................................................................................................................. 5

Components and their Function ........................................................................................... 6

Wiring Diagram .................................................................................................................... 6

Common Faults ................................................................................................................... 7

Fault Finding Chart Index ..................................................................................................... 8

General Fault Finding Chart ................................................................................................. 9

Fault Finding Chart 1 ......................................................................................................... 10

Fault Finding Chart 1.1 ...................................................................................................... 11

Fault Finding Chart 2 ......................................................................................................... 14

Fault Finding Chart 3 ......................................................................................................... 15

Fault Finding Chart 4 ......................................................................................................... 16

Fault Finding Chart 5 ......................................................................................................... 17

Fault Finding Chart 6 ......................................................................................................... 18

Electrical Insulation Testing ............................................................................................... 18

Component Replacement Procedures ............................................................................... 19

Exploded View ................................................................................................................... 24

Replacement Parts List ...................................................................................................... 24

Rheem Electric Water Heater Warranty - (Australia Only) ................................................. 25

Document Revision History ................................................................................................ 26

Page 3

TM039 Rheem Water Star Service Instructions REV: A

Date of Issue: 02/09

This document is stored and maintained electronically by Service. All printed copies not bearing this statement in RED are deemed “uncontrolled”

3

Introduction

The information provided in these instructions is based on the water heater being installed

in accordance with the Installation Instructions provided with each water heater

Should you require further technical advice on a Rheem Water Star, contact your nearest

Rheem Australia Service Department where all genuine replacement parts are also

available.

Safety Warning

The purpose of this Service Manual is to provide sufficient information to allow a person

with the skills as required by the controlling Regulatory Authorities to carry out effective

repairs to a Rheem Water Star in the minimum of time.

Safety precautions or areas where extra care should be observed when conducting tests

outlined in this service manual are indicated by print in bold italics and/or a warning

symbol. Take care to observe the recommended procedure.

“Live” testing to be conducted. Personal Protective Clothing (PPE) shall

be worn and an RCD shall be installed between the power point and 3-pin

cord of the water heater to reduce the risk of electric shock.

Isolate power before conducting the indicated test

Hot surface or liquid. Personal Protective Clothing (PPE) shall be worn to

reduce the risk of scalding.

General warning symbol. Observe the instructions accompanying the

symbol.

If the supply cord is damaged, it must be replaced by the manufacturer or

its service agent or a similarly qualified person in order to avoid a hazard.

When handling pipe work attached to the Rheem Water Star, assume that

all pipes are carrying hot water. Personal Protective Equipment should be

worn to prevent scalds or burns.

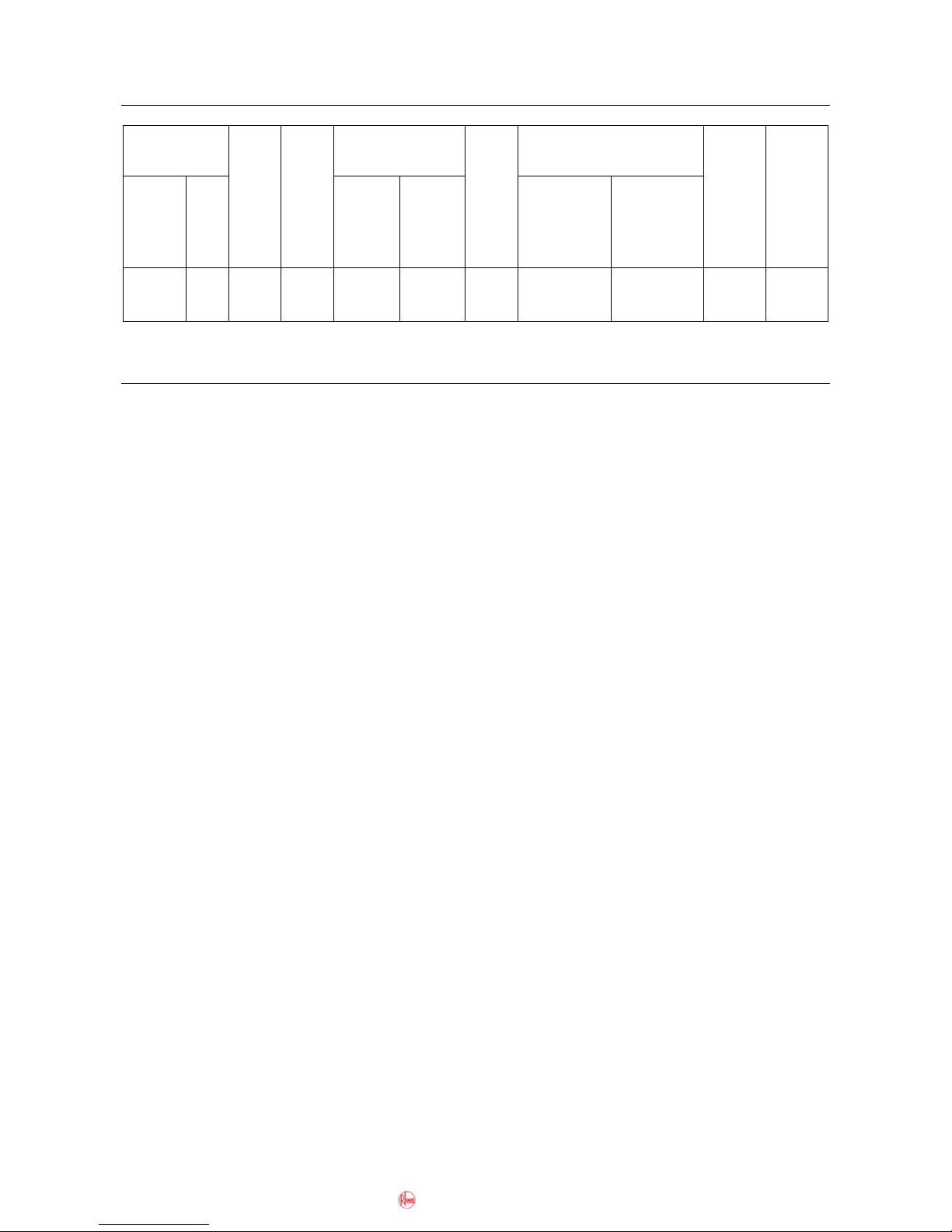

Heater Model Identification Number

The identification number is designed to convey detailed information about the water

heater to which it is attached. The model number consists of 8 digits.

W 8 1

004 0 1

W – Water Star

8 - 70°C temperature limited

1 – Single Heating Unit

Rated Capacity in Litres

0 – Not fitted

Top Element Rating

1 – 800 Watts

Bottom Element Rating

Note: Model number, serial number and date of manufacture should be quoted in all correspondence.

Page 4

TM039 Rheem Water Star Service Instructions REV: A

Date of Issue: 02/09

This document is stored and maintained electronically by Service. All printed copies not bearing this statement in RED are deemed “uncontrolled”

4

Specifications

Model

Rated Capacity

(Litres)

T & PR Valve

Rating (kPa)

Maximum Inlet

Pressure (kPa)

T/stat setting

(ºC)

Water Connections

T/stat Type

Element Rating

(w)

Series

Capacity

With ECV

Without

ECV

Inlet

Outlet

T&PR

W81

004

4

1000

680

800

70

RP¾/20

RP½/15

Fixed

800

Preventative Maintenance

It is suggested for peak performance that the water heater be serviced annually.

1. Check for discharge from the T&PR valve. When the element is operating a small

discharge of water may be evident. Direct access to the valve is via the circular plastic

cover at the top of the unit. Operate the valve-easing lever to ensure the valve opens

and resets properly. Always open and close the valve gently. The T&PR valve should

be replaced at 5-yearly intervals.

2. Check for leaks at all tank fittings.

3. Check for signs of excessive corrosion on the water heater jacket.

4. Isolate power to the water heater and check all electrical connections for signs of

overheating due to poor connection.

5. Conduct an insulation test on the water heater. (Refer to page 18)

Page 5

TM039 Rheem Water Star Service Instructions REV: A

Date of Issue: 02/09

This document is stored and maintained electronically by Service. All printed copies not bearing this statement in RED are deemed “uncontrolled”

5

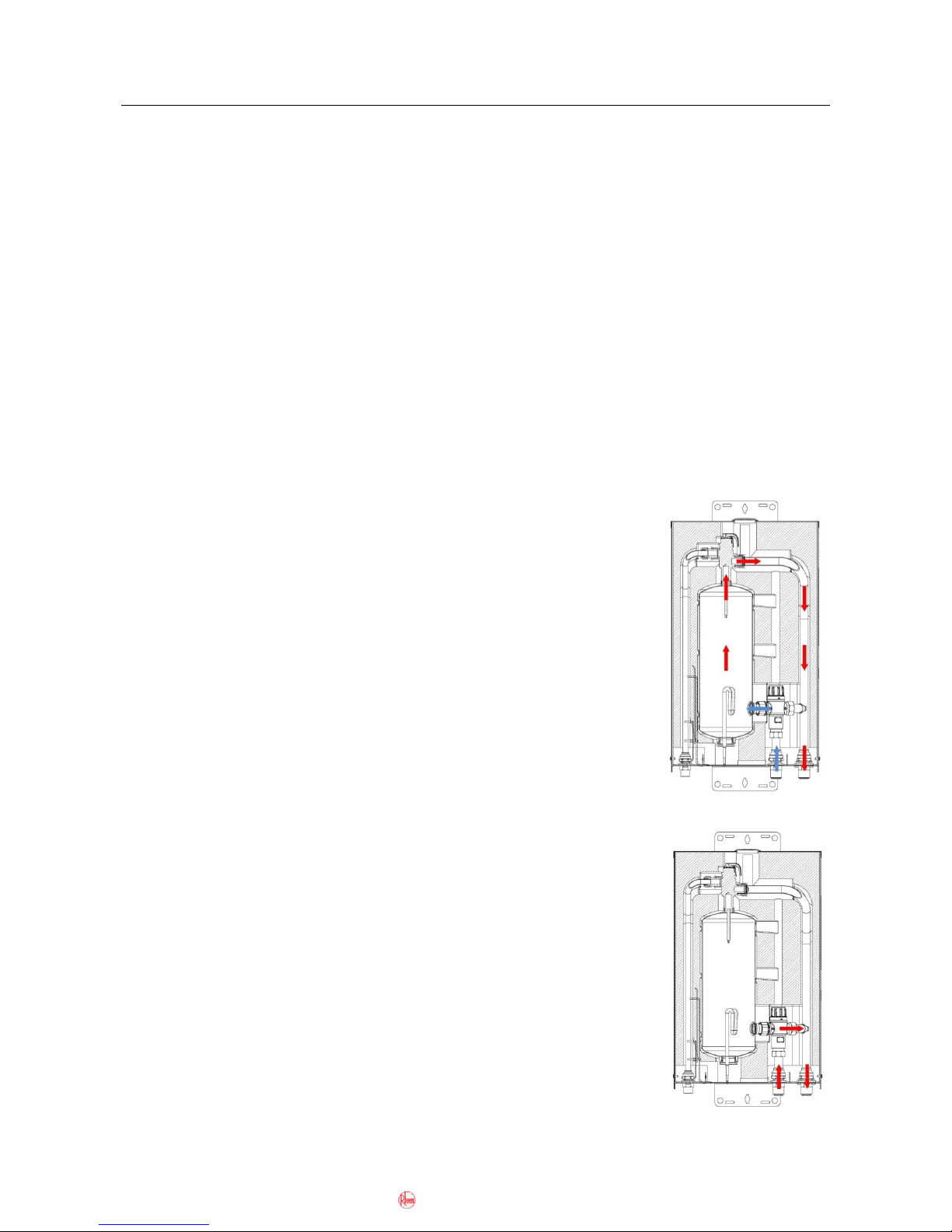

Operation

The Rheem Water Star is designed to work in conjunction (in series) with a continuous

flow gas water heater, e.g. Rheem Continuous Flow models. It works as a booster water

heater to ensure immediate availability of hot water. As such the inlet pipe to the Rheem

Water Star is referred to as an inlet pipe, NOT a cold water pipe, as water flowing through

this pipe could have a temperature as high as 60ºC.

The Rheem Water Star is designed for use with continuous flow water heaters that have

an outlet temperature of 60°C.

Continuous flow gas water heaters pass several litres of water before the temperature

reaches a useable temperature. The Rheem Water Star stores 4 litres of water at 70°C

which is delivered immediately to the household plumbing saving on water usage each

time a hot tap is opened.

The Rheem Water Star is available in a 70ºC model only. To meet the requirements of

AS/NZS 3500.4, this model may require an additional tempering valve set at a maximum

of 50°C (depending on the application), to be installed in pipe work to ablution areas.

When a hot tap is opened, water passes through the continuous

flow gas water heater, which commences operation, into the

Rheem Water Star via a transfer valve. The hot water stored in the

cylinder (4 litres @ 70ºC) is immediately supplied to the household

plumbing (refer to Figure 1).

When the outlet temperature of the continuous flow gas water

heater (inlet temperature to the Rheem Water Star) has risen to

between 52°C and 56°C the transfer valve shuts off the water flow

to the storage cylinder and transfers the flow of hot water to the

Rheem Water Star‟s outlet pipe, effectively bypassing the Rheem

Water Star (refer to figure 2).

The water temperature in the Rheem Water Star storage cylinder is

maintained via a thermostat switching the active conductor to an

electric immersion element.

When the water temperature within the cylinder falls sufficiently the

thermostat contacts close supplying power to the element. Once the

water temperature reaches the set point of the thermostat (70°C),

the contacts open cutting power to the element.

A double pole „manual reset‟ over temperature cut out is

incorporated into the thermostat to provide additional protection in

the event the controlling thermostat contacts fail. The ECO contacts

open at a water temperature of between 80ºC and 88ºC

Figure 1

Figure 2

Page 6

TM039 Rheem Water Star Service Instructions REV: A

Date of Issue: 02/09

This document is stored and maintained electronically by Service. All printed copies not bearing this statement in RED are deemed “uncontrolled”

6

Components and their Function

Temperature and Pressure Relief Valve: A T&PR valve is designed to provide automatic

relief to the water heater by discharging water in case of excessive temperature, pressure

or both.

Never fit a T&PR Valve with a pressure rating greater than that indicated on

the product-rating label.

Over Temperature Energy Cut Out (E.C.O.): An ECO is a temperature-sensing device in

combination with the thermostat that automatically cuts off the supply of electrical energy

to prevent excessive water temperature occurring. This device will not reset automatically

but may be manually reset once temperatures have fallen to a safe level.

Thermostat: A thermostat is a device, responsive to temperature, which controls the

supply of electrical energy to the element to maintain the stored water at the required

temperature.

Heating Unit (Element): An element is a tubular device containing an electric resistance

that converts electrical energy into heat. The maximum rating of the Rheem Water Star is

800 watts.

Transfer Valve: A 3 way valve, sensitive to temperature that simultaneously opens one

outlet and closes the other transferring the direction of water flow.

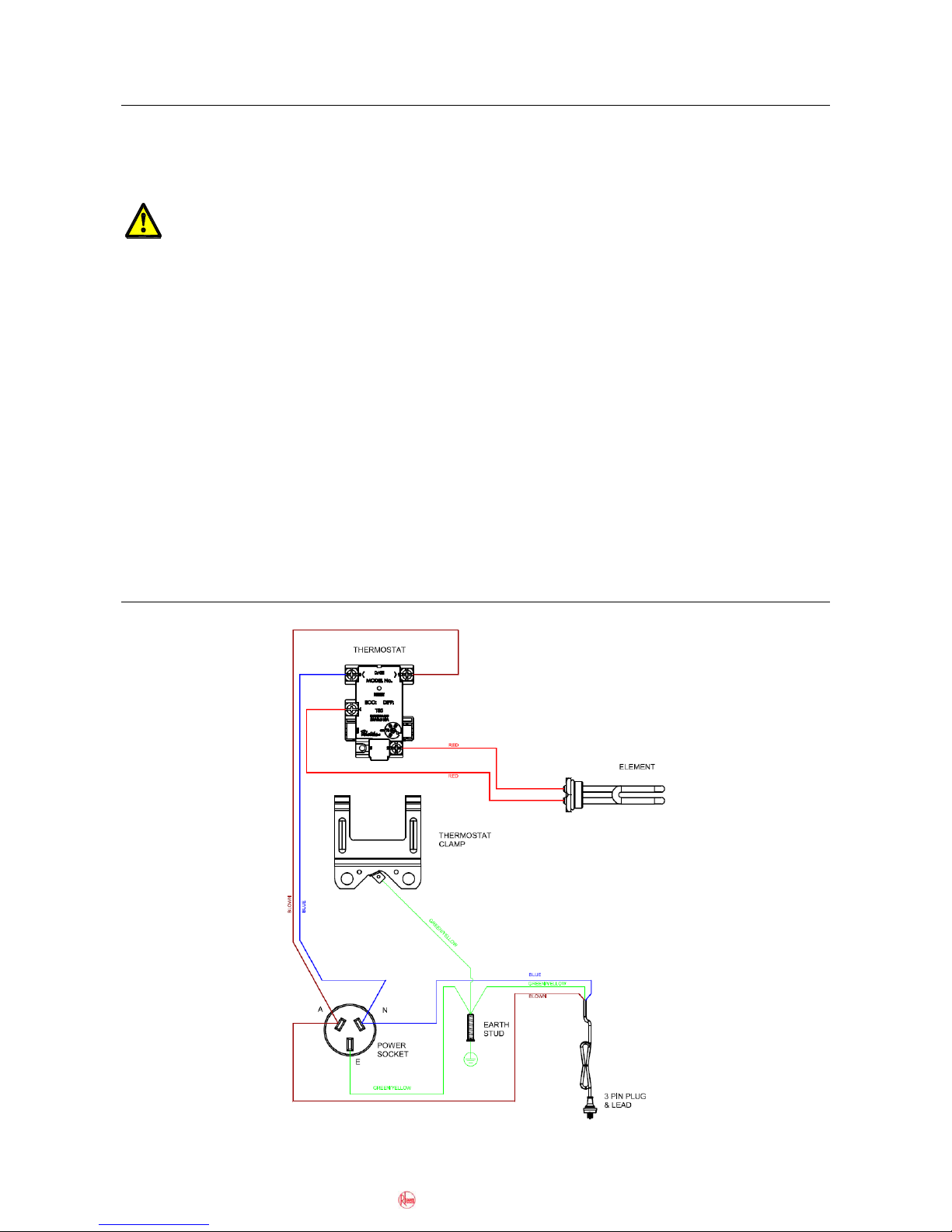

Wiring Diagram

Page 7

TM039 Rheem Water Star Service Instructions REV: A

Date of Issue: 02/09

This document is stored and maintained electronically by Service. All printed copies not bearing this statement in RED are deemed “uncontrolled”

7

Common Faults

When a complaint is lodged about the performance of a hot water system there are a

number of causes that should be checked and eliminated. In an attempt to pinpoint the

most likely cause it is important to discuss with the customer their reasons for the

complaint, the duration of the problem, any change in circumstances or usage and recent

weather conditions. This information in conjunction with the following listed common

complaints will assist you in locating the most likely cause. All procedures assume there is

water flowing through the water heater.

Excessive hot water usage

The complaints of insufficient hot water and no hot water can on many occasions be

attributed to hot water usage exceeding the capacity of the water heater to provide hot

water.

When first attending a call of this nature it is essential to establish the probable hot water

usage by querying the usage habits of the household and comparing this with the potential

delivery of the model water heater installed. It can then be established if the usage is

within or outside the capacity of the model. The areas to look at for excessive usage are:

1. Automatic washing machines.

2. Shower output rate exceeding 12 litres/minute for mixed water and being 5 minutes or

more, in duration.

3. Two or more showers operating at the same time.

4. Change of occupancy or number of persons increased.

5. High water pressure area. (Excessive pressure relief valve discharge).

6. Plumbing leaks.

7. Thermostat temperature setting.

8. Crossed connection.

Mixing or crossed connections

If an automatic dishwasher, washing machine, flick mixer tap, tempering valve or

thermostatic mixing valve is installed there is always the possibility that the cold water

could mix with the hot water through a faulty or incorrectly installed valve. This is referred

to as a cross connection. The complaints of insufficient hot water, water too cold or

excessive discharge from the pressure relief valve may be attributed to a cross

connection. The method of checking for a cross connection is:

1. Turn off the stopcock on the cold water supply to the water heater.

2. Open a hot tap. If water flow is persistent and cold a cross connection exists.

Water hammer

A water heater will not cause water hammer, however valves associated with the water

heater may be the source of the problem i.e. cold-water stopcock, non-return valve or relief

valve.

Most water hammer problems are associated with plumbing, hot and cold or appliances

i.e. solenoid valves, ballcocks, loose pipes, sharp angles in pipe work, faulty or worn valve

parts, loose tap washers or neighbouring equipment.

High water pressure areas will have more complaints of this nature and the use of a

pressure-limiting valve (PLV) to reduce the household cold-water pressure will usually

solve most problems.

Page 8

TM039 Rheem Water Star Service Instructions REV: A

Date of Issue: 02/09

This document is stored and maintained electronically by Service. All printed copies not bearing this statement in RED are deemed “uncontrolled”

8

Hot water plumbing leaks

If hot water has not been used for a period of time, feeling the temperature of the hot water

line may give an indication of water flow if the pipe is warm. The method of checking for

plumbing leaks is:

1. Turn off the stopcock on the cold water supply to the water heater.

2. Open a hot tap to ensure the flow of water stops. This will confirm the stopcock is

operating correctly.

3. Turn off the hot tap.

4. Turn on the stopcock to make up the water pressure in the water heater, and then turn

the stopcock off again.

5. Wait approximately 5 minutes then do either of the following:

a. With your ear close to the stopcock turn it on slightly and listen for any water

passing. If there are any leaks, the sound of water flowing would be audible.

b. Open a hot tap while listening for any pressure release. If there is a pressure

release there will be no leaks in the plumbing system.

Discoloured water

This may be the result of discoloured water entering from the cold water mains. Check if

the cold water is also discoloured.

Fault Finding Chart Index

Fault

Chart number

Page

No hot water

1, 1.1

10, 11

High energy bill / Insufficient hot water

2

14

Leaking water heater

3

15

Water too hot

4

16

Noisy water heater

5

17

Electrical insulation test

6

18

Page 9

TM039 Rheem Water Star Service Instructions REV: A

Date of Issue: 02/09

This document is stored and maintained electronically by Service. All printed copies not bearing this statement in RED are deemed “uncontrolled”

9

General Fault Finding Chart

Fault Diagnosis

Is the complaint for

no hot water?

Is the complaint for a

high energy bill or

insufficient hot water?

Is the complaint for a

leaking water heater?

Is the complaint for

water too hot?

NO

NO

NO

YES

YES

YES

1.

2.

3.

4.

5.

YES

Noisy Water Heater

Page 10

TM039 Rheem Water Star Service Instructions REV: A

Date of Issue: 02/09

This document is stored and maintained electronically by Service. All printed copies not bearing this statement in RED are deemed “uncontrolled”

10

Fault Finding Chart 1

1.

Is 240 volts present at the

terminal block?

Is the isolating switch

turned off?

Is the fuse blown at the

switchboard?

Is the reading below 1

Megaohm?

Restore power and advise

customer

Possible fault in household

electrical wiring. Continue with

diagnosis to confirm water heater

is operational.

Isolate power and continue

with diagnosis procedure

Conduct an electrical

insulation test (refer to section

on insulation testing)

No hot water

Warning: Terminals may be live.

Personal Protective Equipment

must be worn.

YES

YES

NO

YES

YES

NO

Test 1

Tests 2, 3 & 4

NO

1.1 6

NO

Page 11

TM039 Rheem Water Star Service Instructions REV: A

Date of Issue: 02/09

This document is stored and maintained electronically by Service. All printed copies not bearing this statement in RED are deemed “uncontrolled”

11

Fault Finding Chart 1.1

No hot water

Replace thermostat

Replace thermostat

Replace thermostat

Replace element

Locate wiring failure

and repair

Are the

thermostat ECO

contacts closed?

Are the

thermostat

contacts closed?

Is the overall

resistance of the

water heater

correct?

Does the element

have the correct

resistance?

Did the thermostat

contacts close?

Is the water in the tank at

least 6 degrees lower

than the thermostat

setting?

NO

NO

YES

NO YES

Water heater electrically OK.

Slide the thermostat out from

under the retaining clamp and

allow base to cool.

YES

Test 5

Test 6

Test 7

Test 8

NO

Test 6

NO

YES

YES

2.

YES

1.1

NO

Page 12

TM039 Rheem Water Star Service Instructions REV: A

Date of Issue: 02/09

This document is stored and maintained electronically by Service. All printed copies not bearing this statement in RED are deemed “uncontrolled”

12

Component Tests 1, 5, & 6

Test 1

With the water heater plugged in and

switched on, use a multimeter on the AC

volts scale and measure between active

and neutral on the terminal block.

Normal voltage is 240 volts

Test 5

Using a multimeter on the x1 resistance

scale, measure between terminals 3 and

4 on the thermostat.

The reading should be less than 1Ω.

Test 6

Using a multimeter on the x1 resistance

scale, measure between terminals 1 and

2 on the thermostat.

The reading should be less than 1Ω.

Page 13

TM039 Rheem Water Star Service Instructions REV: A

Date of Issue: 02/09

This document is stored and maintained electronically by Service. All printed copies not bearing this statement in RED are deemed “uncontrolled”

13

Component Tests 7 & 8

Test 7

Using a multimeter on the x1 resistance

scale, measure the resistance of the

element across the wires that connect to

terminals 2 and 4 of the thermostat.

Normal resistance for the element is 6879 ohms.

Test 8

Using a multimeter on the x1 resistance

scale, measure between active and

neutral on the terminal block.

Normal resistance when the thermostat

contacts are closed is 68 - 79 ohms

Page 14

TM039 Rheem Water Star Service Instructions REV: A

Date of Issue: 02/09

This document is stored and maintained electronically by Service. All printed copies not bearing this statement in RED are deemed “uncontrolled”

14

Fault Finding Chart 2

2

High energy bill/ Insufficient hot water

NO

Refer to Rheem sizing guide

Recommend a water heater

of sufficient capacity to meet

the customer‟s needs.

Fit pressure limiting valve

(PLV), if not already installed.

Replace faulty PLV. Replace

faulty T&PR valve.

Recommend a hot water

usage pattern that will suit

the water heater and the

customer‟s needs.

Check for cross water

connection. Replace the

T&PR valve (if required.).

Repair any leaks. Isolate

cross connections.

Replace the thermostat

Is the heater of

sufficient size for the

customer‟s ongoing

needs?

Has the usage

pattern changed

recently, ie.additional

appliances or people

using hot water?

Is the T&PR

valve continuously

discharging

water?

Does the cylinder

water temperature

correspond with the

thermostat setting?

Are there any plumbing

leaks,

crossed connections

or dripping taps?

Is the correct T&PR valve

fitted?

Is the water supply

pressure more than 80%

of the T&PR

valve rating?

YES NO

YES

NO

NO

NO

NO

YES

YES

Is a tempering valve

installed?

NO

YES

YES YES

Replace T&PR valve with one

with the correct pressure

rating. Do not use

reconditioned T&PR valves.

Measure the water temperature at the T&PR

valve drain by gently lifting the easing lever

Water Star OK. Possible fault

with continuous flow gas water

heater. (Refer to relevant

service instructions).

Has there been a recent

large draw off of hot

water

NO NO

Allow heater time to recoverYES

Possible fault with tempering

valve

YES

AS/NZS 3500 Part 4 only requires

fixtures used for ablution purposes to

be tempered. If practical a 2-zone

plumbing solution may be offered.

Replace the transfer valve

Is the transfer valve

allowing water to pass in

both directions?

NO

YES

Page 15

TM039 Rheem Water Star Service Instructions REV: A

Date of Issue: 02/09

This document is stored and maintained electronically by Service. All printed copies not bearing this statement in RED are deemed “uncontrolled”

15

2 Zone Plumbing Option

Fault Finding Chart 3

3.

Leaking Water Heater

Replace the

cylinder

Remove pipe and

replace contite

olives

Remove element

and replace

gasket

Replace the

cylinder

Remove the T&PR

valve and reseal with

thread tape

Is the

leak from or near

the top?

Is the

leak from the

element barrel

weld?

Is the

leak from the

element

gasket?

Is the

leak from the

T&PR valve?

Is the

leak from the

T&PR valve fitting

weld?

Is the

leak from the

outlet pipe?

Is the

leak from the inlet

tee weld?

YES

NO

Is the

leak from the

drain pipe?

YES

NO

NO

YES

NO

YES

YES

NO

YES

YES

NO

YES

Page 16

TM039 Rheem Water Star Service Instructions REV: A

Date of Issue: 02/09

This document is stored and maintained electronically by Service. All printed copies not bearing this statement in RED are deemed “uncontrolled”

16

Fault Finding Chart 4

4

Water too hot

Is the outlet water

temperature approx. 70

degrees?

Water heater operating

normally

YES

Is the thermostat in good

contact with the cylinder?

NO

Remove the thermostat, retension the bracket and refit

the thermostat

Allow the water heater to

recover and re-check the

water temperature

Is the water temperature

in the cylinder > 80°C?

NO

Replace the thermostat

YESYES

NO

An external tempering valve

should be considered if concerns

surround children or elderly

occupants

Water temperature can be

measured at the T&PR

valve drain by gently lifting

the easing lever

Has the correct

continuous flow gas water

heater been installed?

Is the water temperature

in the cylinder < 80°C?

NO

Fault rectified

The continuous flow gas water heater

connected to a Rheem Water Star MUST have

a maximum outlet temperature of 60 degrees

Reset the outlet

temperature of the

continuous flow water

heater or replace with a

suitable model

NO

Possible fault with

continuous flow gas water

heater. Refer to service

instructions on relevant

model for fault finding

YES

YES

Page 17

TM039 Rheem Water Star Service Instructions REV: A

Date of Issue: 02/09

This document is stored and maintained electronically by Service. All printed copies not bearing this statement in RED are deemed “uncontrolled”

17

Fault Finding Chart 5

5.

Noisy Water Heater

Check for:

(A) Mineral build-up on the element.

(B) Mineral or sludge build-up inm the

cylinder

(C) Normal noises associated with heating

water.

Check for faulty stop cock, non-return

valve or T&PR valve.

Refer to water hammer causes, under

Common Faults

Check all other appliances that can

generate noise, eg. washing machine,

dishwasher, etc.

Cylinder contracting due to pressure

release when hot tap is opened. This can

be accompanied by a creaking or cracking

sound from the insulation. This noise is

normal operation.

Is the

noise only evident

during the heating

cycle?

Is the

noise water hammer?

Is the

noise only evident

when water is flowing

through the water

heater?

Is the

noise a metallic

popping sound?

Is the

water pressure more

than 80% of the

T&PR valve rating?

YES

NO

NO

YES

NO

YES

NO

Check for restrictionsin pipe work, faulty

valves, loose plumbing or other

appliances, eg. Washing machine or

dishwasher. Fit a 600kPa PLV if pressure

is excessive.

YES

YES

NO

Page 18

TM039 Rheem Water Star Service Instructions REV: A

Date of Issue: 02/09

This document is stored and maintained electronically by Service. All printed copies not bearing this statement in RED are deemed “uncontrolled”

18

Fault Finding Chart 6

Electrical Insulation Testing

There are three basic test procedures that should be carried out when the operation and

function of a water heater‟s electrical system is in doubt.

Test 2 - To check insulation resistance of the water heater Neutral Circuit (reading

not to be below 1 MΩ).

1. Switch off power at GPO and unplug power cord from GPO (unplug continuous

flow water heater).

2. Connect megger leads to the neutral of the water heater wiring and earth.

3. Operate megger. A reading above 1 MΩ should be obtained.

4. If a reading below 1 MΩ is indicated, all component parts will need to be individually

tested to locate the fault. Refer to flow diagram chart 6, above.

Test 3 - To check insulation resistance of the water heater Active Circuit (reading

not to be below 1 MΩ).

1. Connect megger leads to the active of the water heater wiring and earth.

2. Operate megger. A reading above 1 MΩ should be obtained.

3. If a reading below 1 MΩ is indicated, all component parts will need to be individually

tested to locate the fault. Refer to flow diagram chart 6, above.

Test 4 - To check “Continuity” of water heater electrical circuit.

1. Set megger to resistance scale or multimeter to x1 resistance scale.

2. Measure between the active and the neutral of the water heater. If a reading between

68-79 ohms is not indicated, all electrical component parts will need to be individually

tested to locate the fault.

3. Reconnect the power cord. Note: If continuing with diagnostic procedure flow

chart 1.1 do not reconnect the power cord.

6

Disconnect the remaining wires

from the thermostat and megger

between each thermostat terminal

and earth.

Check for:

Faulty 3 pin outlet socket

Pinched or damaged wiring

touching the heater chassis

Replace thermostat

Is the reading below 1

Megaohm?

Is the reading below 1

Megaohm?

YES

Disconnect the wires to the

element from the thermostat and

megger between each element

wire and earth.

Replace elementYES

NO

NO

Rewire fuse or reset circuit

breaker, if necessary

Rewire fuse or reset circuit

breaker, if necessary

Electrical Insulation Test

NOTE: Unplug continuous flow water heater

prior to commencing insulation testing

Page 19

TM039 Rheem Water Star Service Instructions REV: A

Date of Issue: 02/09

This document is stored and maintained electronically by Service. All printed copies not bearing this statement in RED are deemed “uncontrolled”

19

Component Replacement Procedures

Draining the Water Heater (Procedure 1)

1. Switch off power at GPO, unplug power cord from GPO and isolate the water

supply to the water heater

2. Relieve pressure from the water heater by easing the T&PR valve or through a

hot tap.

3. Disconnect the inlet water supply pipe

4. Fit a drain hose to the inlet water connection and run the other end to a drain or safe

location.

5. Open the temperature and pressure relief valve to allow air into the system.

NOTE: A small amount of water will be left in the cylinder.

Transfer Valve (Procedure 2)

1. Drain the water heater (refer to procedure 1 above)

2. Remove the outer jacket screws.

3. Remove the outer jacket and front polystyrene insulation to expose the water heater.

4. Disconnect the inlet pipe from the transfer valve by undoing the ¾” brass nut.

5. Disconnect the outlet pipe from the transfer valve by undoing the ¾” brass nut.

Remove the old transfer valve.

6. Fit the replacement transfer valve and assemble in reverse order.

7. Restore the water supply and check for leaks.

8. Purge air from the system through hot taps.

9. Refit the front polystyrene insulation and outer jacket.

10. Restore the power supply to the water heater.

Temperature and Pressure Relief Valve (Procedure 3)

Never fit a T&PR valve with a rating higher than that indicated on the water

heater rating plate. Do not use reconditioned T&PR valves.

1. Partially drain the water heater (refer to procedure 1 on page 19).

2. Remove the outer jacket screws.

3. Remove the outer jacket and front polystyrene insulation to expose the water heater.

4. Disconnect the outlet pipe from the T&PR valve by undoing the ¾” brass nut.

5. Disconnect the drain line fitting from the T&PR valve

6. Unscrew the T&PR valve from the top of the cylinder.

7. Confirm the replacement T&PR valve is the correct rating and refit using thread tape.

8. Reassemble in the reverse order of above

9. Restore the water supply.

10. Check the T&PR valve thread and connections for leaks.

11. Operate the T&PR valve lever to reset relief drain.

Page 20

TM039 Rheem Water Star Service Instructions REV: A

Date of Issue: 02/09

This document is stored and maintained electronically by Service. All printed copies not bearing this statement in RED are deemed “uncontrolled”

20

12. Purge air from the system through hot taps.

13. Refit the front polystyrene insulation and outer jacket.

14. Restore the power supply to the water heater.

Thermostat (Procedure 4)

1. Switch off power at GPO and unplug power cord from GPO.

2. Remove the outer jacket screws.

3. Remove the outer jacket and front polystyrene insulation to expose the water heater.

4. Confirm the wiring is as per the wiring diagram on page 6.

5. Disconnect the wiring to the thermostat.

6. Slide the thermostat out from under the retaining clamp.

7. Slide the replacement thermostat under the clamp ensuring the thermostat is held firmly

against the cylinder.

8. Reconnect the wiring as per the wiring diagram on page 6.

9. Check water heater internal wiring insulation for cracking.

10. Refit the front polystyrene insulation and outer jacket.

11. Conduct an electrical insulation test. Refer to page 18.

12. Restore power to the water heater.

Inlet Water Connector (Procedure 5)

1. Drain the water heater (refer to procedure 1 on page 19).

2. Remove the outer jacket screws.

3. Remove the outer jacket and front polystyrene insulation to expose the water heater.

4. Undo the brass nuts retaining the inlet pipe to the inlet fitting and the transfer valve.

5. Loosen the remaining two brass nuts retaining the transfer valve.

6. Remove the two (2) screws retaining the inlet fitting to the bottom chassis.

7. Rotate the bottom of the transfer valve towards the front of the water heater so the inlet

water pipe could be manoeuvred free.

8. Fit the replacement inlet connector into place.

9. Reassemble in reverse order of above.

10. Restore the water supply.

11. Purge air from the system through hot taps and check for leaks.

12. Refit front polystyrene insulation and outer jacket.

13. Restore the power supply to the water heater.

Page 21

TM039 Rheem Water Star Service Instructions REV: A

Date of Issue: 02/09

This document is stored and maintained electronically by Service. All printed copies not bearing this statement in RED are deemed “uncontrolled”

21

Outlet Water Connector (Procedure 6)

1. Drain the water heater (refer to procedure 1 on page 19).

2. Remove the outer jacket screws.

3. Remove the outer jacket and front polystyrene insulation to expose the water heater.

4. Disconnect the outlet water pipe from the T&PR valve, transfer valve and outlet water

connector by undoing the ¾” brass nuts.

5. Remove the outlet pipe.

6. Remove the two (2) screws retaining the outlet water connector fitting to the bottom

chassis.

7. Fit the replacement outlet water connector

8. Reassemble in reverse order.

9. Restore the water supply.

10. Purge air from the system through hot taps and check for leaks.

11. Refit front polystyrene insulation and outer jacket.

12. Restore the power supply to the water heater.

T&PR Valve Drain Connector (Procedure 6)

1. Drain the water heater (refer to procedure 1 on page 19).

2. Remove the outer jacket screws.

3. Remove the outer jacket and front polystyrene insulation to expose the water heater.

4. Disconnect the T&PR drain pipe from the T&PR valve and drain connector by undoing

the brass nuts.

5. Remove the drain pipe.

6. Remove the two (2) screws retaining the connector to the water heater chassis.

7. Fit the replacement drain connector

8. Reassemble in reverse order of above.

9. Restore the water supply.

10. Purge air from the system through hot taps and check for leaks.

11. Refit front polystyrene insulation and outer jacket.

12. Restore the power supply to the water heater.

Page 22

TM039 Rheem Water Star Service Instructions REV: A

Date of Issue: 02/09

This document is stored and maintained electronically by Service. All printed copies not bearing this statement in RED are deemed “uncontrolled”

22

Element (Procedure 9)

1. Drain the water heater (refer to procedure 1 on page 19).

2. Remove the outer jacket screws.

3. Remove the outer jacket and front polystyrene insulation to expose the water heater.

4. Slide the thermostat out of the retaining clamp

5. Disconnect the T&PR valve drain line and outlet water pipe from the T&PR valve.

6. Disconnect the transfer valve from the cylinder by undoing the ¾” brass nut.

7. Remove the cylinder from the water heater and invert it.

8. Unscrew the element using a 42mm spanner or tube socket.

9. Withdraw the element. Care must be taken to ensure the loop of the element does not

catch in the cylinder opening and open out inside the cylinder.

NOTE: Do not “cut off” the element and leave a portion inside the cylinder

10. Clean around the cylinder fitting. Ensure that the replacement element is of the correct

rating and carefully insert and screw into the cylinder.

11. Reassemble in reverse order of above.

12. Restore the water supply.

13. Purge air from the system through hot taps and check for leaks.

14. Refit front polystyrene insulation and outer jacket.

15. Conduct an electrical insulation test (refer to page 18).

16. Restore the power supply to the water heater.

Cylinder Replacement (Procedure 10)

1. Drain the water heater (refer to Procedure 1 on page 19).

2. Remove the T&PR valve (follow steps 2-6 of Procedure 3 on page 19).

3. Remove the element (follow steps 2-9 of Procedure 9 on page 22).

4. Refit the element & T&PR valve to the replacement cylinder. NOTE: Depending on the

age of the water heater consideration should be given to fitting a new T&PR valve.

5. Fit the replacement cylinder into the rear polystyrene housing. Note: The cylinder will

need to be supported until the T&PR valve drain line and outlet pipe are

connected.

6. Reassemble in reverse order of above.

7. Restore the water supply.

8. Operate the T&PR valve lever to reset relief drain.

9. Purge air from the system through hot taps and check the entire water heater for leaks.

10. Refit front polystyrene insulation and outer jacket.

11. Conduct an electrical insulation test. (Refer to page 18).

12. Restore the power supply to the water heater.

Page 23

TM039 Rheem Water Star Service Instructions REV: A

Date of Issue: 02/09

This document is stored and maintained electronically by Service. All printed copies not bearing this statement in RED are deemed “uncontrolled”

23

3 Pin Outlet Socket

1. Switch off power at GPO and unplug power cord from GPO.

2. Unplug the continuous flow water heater 3 pin plug from the socket.

3. Remove the outer jacket screws.

4. Remove the outer jacket and front polystyrene insulation to expose the water heater.

5. Confirm the wiring is as per the wiring diagram on page 6.

6. Disconnect the wiring from the active, neutral and earth connectors.

7. Remove the screw from the centre of the 3 pin socket outlet and remove the bottom

half of the 3 pin outlet socket.

8. Remove the upper half of the 3 pin outlet socket from the water heater.

9. Reassemble in reverse order of above. NOTE: When fitting the replacement 3 pin

outlet socket ensure the bottom half is orientated correctly so the earth pin entry aligns

with the earth socket in the top half of the plug.

10. Refit front polystyrene insulation and outer jacket.

11. Conduct an electrical insulation test. (Refer to page 18).

12. Restore the power supply to the water heater.

Page 24

TM039 Rheem Water Star Service Instructions REV: A

Date of Issue: 02/09

This document is stored and maintained electronically by Service. All printed copies not bearing this statement in RED are deemed “uncontrolled”

24

Exploded View

Replacement Parts List

Item

Description

Part Nº

Item

Description

Part Nº

1

Base – cabinet

140003

16

Name band-Rheem Water Star

125996

2

Insulation - rear

090160

17

Front cover – cabinet

140001

3

T&PR valve

220350

18

Cover – T&PR valve

221720-1

4

Valve connection kit

220371

19

Insulation - front

090159

5

T&PR valve drain pipe ½”

220366

20

Pipe – Outlet ¾”

220373

6

Nut – M4

080406

21

Transfer valve

220370

7

Wiring ass earth (GPO socket)

080402

22

Pipe – Inlet ¾”

220372

8

Wiring loom & cord set

080403

23

Nut – ¾” contite

220357

9

Wiring loom – thermostat

080400

24

Cone fitting ¾”

220358

10

Washer – flat

080405

25

Cylinder assembly unit

050032

11

Nut – ½” contite

220359

26

Thermostat R/S – ST1203133

052075

12

Washer – tooth lock

080404

27

Clamp – thermostat assy.

102501

13

Cone fitting ½”

220360

28

Heating unit – 800 watt

050022

14

T&PR valve drain fitting

220362

29

GPO socket

080410

15

Inlet/Outlet fitting

220361

Page 25

TM039 Rheem Water Star Service Instructions REV: A

Date of Issue: 02/09

This document is stored and maintained electronically by Service. All printed copies not bearing this statement in RED are deemed “uncontrolled”

25

Rheem Electric Water Heater Warranty - (Australia Only)

WARRANTY CONDITIONS

1. This warranty is applicable only to water heaters

manufactured from 1st June 2008.

2. The water heater must be installed in accordance with

the Rheem water heater installation instructions,

supplied with the water heater, and in accordance

with all relevant statutory and local requirements of

the State in which the water heater is to be installed.

3. Where a failed component or water heater is replaced

under warranty, the balance of the original warranty

period will remain effective. The replaced part or

water heater does not carry a new warranty.

4. Where the water heater is installed outside the

boundaries of a metropolitan area as defined by

Rheem or further than 25 km from a regional Rheem

branch office, or an Accredited Service Agent, the

cost of transport, insurance and travelling costs

between the nearest Rheem Accredited Service

Agent‟s premises and the installed site shall be the

owner‟s responsibility.

5. Where the water heater is installed in a position that

does not allow safe, ready access, the cost of

accessing the site safely, including the cost of

additional materials handling and / or safety

equipment, shall be the owner‟s responsibility.

6. The warranty only applies to the water heater and

original or genuine (company) component

replacement parts and therefore does not cover any

plumbing or electrical parts supplied by the installer

and not an integral part of the water heater, e.g.

pressure limiting valve; isolation valves; non-return

valves; electrical switches; pumps or fuse.

7. The water heater must be sized to supply the hot

water demand in accordance with the guidelines in

Rheem water heater literature.

WARRANTY EXCLUSIONS

A). REPAIR AND REPLACEMENT WORK WILL BE CARRIED OUT AS SET OUT IN THE RHEEM WATER

HEATER WARRANTY , HOWEVER THE FOLLOWING EXCLUSIONS MAY CAUSE THE WATER

HEATER WARRANTY TO BECOME VOID AND MAY INCUR A SERVICE CHARGE AND / OR COST

OF PARTS.

1. Accidental damage to the water heater or any

component, including: Acts of God; failure due to

misuse; incorrect installation; attempts to repair the

water heater other than by a Rheem Accredited

Service Agent or the Rheem Service Department.

2. Where it is found there is nothing wrong with the

water heater; where the complaint is related to

excessive discharge from the temperature and / or

pressure relief valve due to high water pressure;

where there is no flow of hot water due to faulty

plumbing; where water leaks are related to plumbing

and not the water heater or water heater

components; where there is a failure of gas,

electricity or water supplies; where the supply of

gas, electricity or water does not comply with

relevant codes or acts.

3. Where the water heater or water heater component

has failed directly or indirectly as a result of:

excessive water pressure, excessive temperature

and / or thermal input; blocked overflow / vent drain;

corrosive atmosphere; ice formation in the pipe work

to or from the water heater.

4. Where the water heater is located in a position that

does not comply with the Rheem water heater

installation instructions or relevant statutory

requirements, causing the need for major

dismantling or removal of cupboards, doors or walls,

or use of special equipment to bring the water

heater to floor or ground level or to a serviceable

position.

5. Repair and / or replacement to the water heater due

to scale formation in the waterways or the effects of

either corrosive water or water with a high chloride

or low pH level when the water heater has been

connected to a scaling or corrosive water supply or

a water supply with a high chloride or low pH level

as outlined in the Owner‟s Guide and Installation

Instructions booklet.

B) SUBJECT TO ANY STATUTORY PROVISIONS TO THE CONTRARY, THIS WARRANTY EXCLUDES

ANY AND ALL CLAIMS FOR DAMAGE TO FURNITURE, WALLS, FOUNDATIONS OR ANY OTHER

CONSEQUENTIAL LOSS EITHER DIRECTLY OR INDIRECTLY DUE TO LEAKAGE FROM THE

WATER HEATER OR DUE TO LEAKAGE FROM FITTINGS AND / OR PIPE WORK OF METAL,

PLASTIC OR OTHER MATERIALS CAUSED BY WATER TEMPERATURE, WORKMANSHIP OR

OTHER MODES OF FAILURE.

In addition to this warranty, the Trade Practices Act 1974 and similar laws in each state and territory provide the owner under certain

circumstances with certain minimum statutory rights in relation to your Rheem water heater. This warranty must be read subject to that

legislation and nothing in this warranty has the effect of excluding or restricting those rights.

RHEEM WATER HEATERS AUSTRALIA

RHEEM AUSTRALIA PTY. LTD.

A.B.N 21 098 823 511

FOR SERVICE TELEPHONE

131 031 AUSTRALIA

or refer local Yellow Pages

NOTE: Every care has been taken to ensure accuracy in preparation of this publication. No liability can be accepted for any

consequences, which may arise as a result of its application.

Page 26

TM039 Rheem Water Star Service Instructions REV: A

Date of Issue: 02/09

This document is stored and maintained electronically by Service. All printed copies not bearing this statement in RED are deemed “uncontrolled”

26

Document Revision History

Title:

Service Instructions - Rheem Water Star

Document Nº:

TM039

Revision

Details of change

D.O.I.

A

Service Instructions issued for Rheem Water Star

2/09

Loading...

Loading...