Page 1

INSTALLATION INSTRUCTIONS

LOW AMBIENT CONTROL KIT

(-)KNL/LNL-G090 THRU G300 MODELS

RXRZ-A06

!

Recognize this symbol as an indication of Important Safety Information!

!

WARNING

THESE INSTRUCTIONS ARE INTENDED AS AN AID TO QUALIFIED SERVICE PERSONNEL FOR PROPER INSTALLATION,

ADJUSTMENT, AND OPERATION OF THIS KIT. READ THESE INSTRUCTIONS THOROUGHLY BEFORE ATTEMPTING INSTALLATION, ADJUSTMENT, OR OPERATION. FAILURE TO FOLLOW THESE INSTRUCTIONS CAN RESULT IN IMPROPER INSTALLATION, ADJUSTMENT, SERVICE OR MAINTENANCE, POSSIBLY RESULTING IN FIRE, ELECTRICAL SHOCK, PROPERTY DAMAGE,

PERSONAL INJURY, OR DEATH.

PARTS LIST

DESCRIPTION PART NUMBER QUANTITY

Low Ambient Control AS-103034-01 2

Accessory Relay 42-102234-01 1

Relay Mounting Screws 63-22153-04 2

Relay Coil Wire (blue) AS-50204-29-AJ 1

Relay Coil Wire (brown) AS-50207-29-AJ 1

Relay Wire (black) AS-50230-27-DD 2

Wire Tie 64-17606-01 2

AR - Label 92-19438-43 1

!

WARNING

BEFORE BEGINNING ANY MODIFICATION, BE SURE MAIN

DISCONNECT SWITCH IS IN THE “OFF” POSITION. FAILURE TO DO SO CAN CAUSE ELECTRICAL SHOCK

RESULTING IN PROPERTY DAMAGE, PERSONAL INJURY

OR DEATH. TAG DISCONNECT WITH A SUITABLE WARNING LABEL

TOOLS/SUPPLIES REQUIRED

A. 1/4” flat blade screwdriver (to open control box door).

B. 1/8” flat blade screwdriver (to connect wires on Outdoor Fan

Motor Controller terminal block).

C. 1/4” nut driver.

D. 5/16” nut driver.

E. 7/16” open end wrench.

F. 9/16” open end wrench.

G. Box Cutter (to open packaging).

LOW AMBIENT SWITCH INSTALLATION

A. Shut off power to unit (see warning above).

B. Open blower access door. Refer to Figure 2.

C. Remove brass cap from Schrader valve located in the refrig-

erant liquid line near the TXV. Refer to Figure 2.

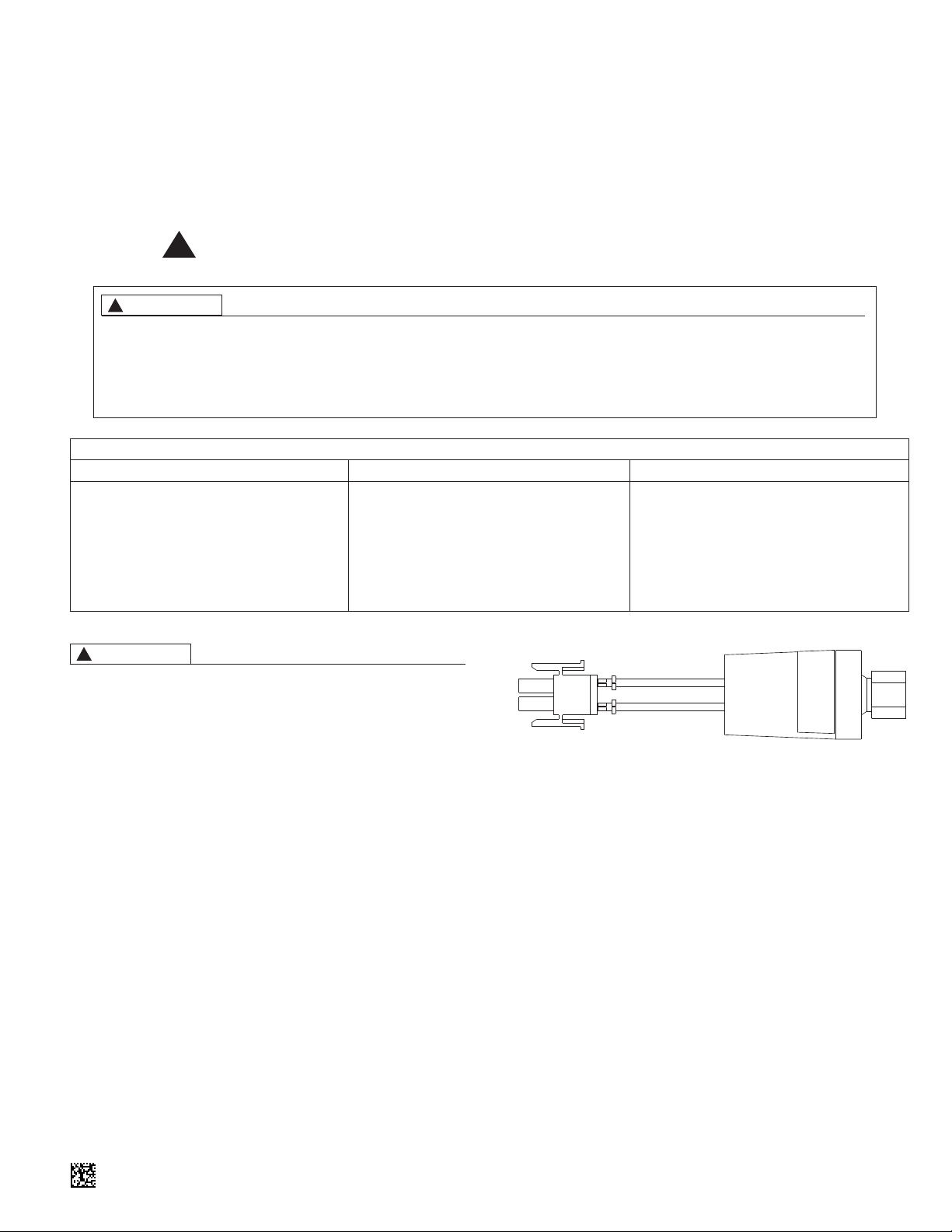

FIGURE 1. LOW AMBIENT CONTROL

D. Quickly screw Low Ambient Control (see Figure 1) onto

Schrader valve. Use 9/16” open end wrench on Low

Ambient Control and torque to 8-10 ft/lbs with 7/16” open

end backup wrench on the Schrader valve. CAUTION: If a

backup wrench is not used serious damage to the

equipment or personal injury may occur. Do not over

tighten connection.

E. Repeat C. through D. for second system.

F. Check all connections for refrigerant leaks and repair as

necessary.

G. Remove factory installed low ambient jumper wires located

inside the blower compartment. Connect female 2-wire connectors from unit to male 2-wire connectors on low ambient

controls. Note: Use the unit wiring diagram to verify the

low ambient control for refrigerant circuit #1 is connected to the electrical control circuit for compressor #1. A

low ambient control is required for each compressor.

H. Close blower access door.

92-105317-01-00

Page 2

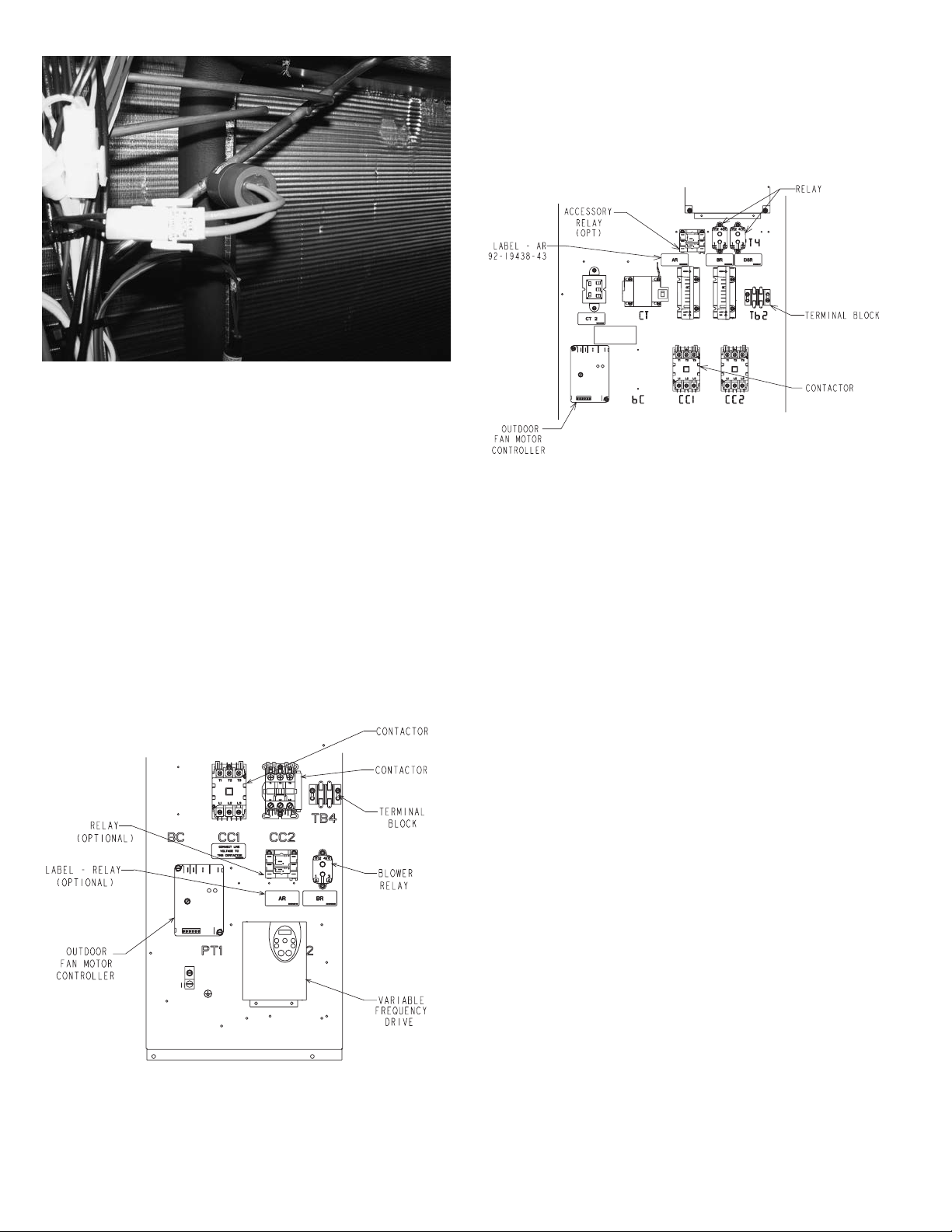

FIGURE 2. LOW AMBIENT CONTROL INSTALLATION.

ST-A1229-01-00

ST-A1229-02-00

TORQUE CONTROL 8-10 FT. LBS. DO NOT OVER TORQUE

OR DAMAGE TO CONTROL WILL RESULT.

E. For KNL/LNL-G180/240/300 models (Figure 4):

a. Attach one black wire (AS-50230-27-DD) to Accessory

Relay terminal AR(3) and Outdoor Fan Motor Controller

terminal OFMC (LINE 2).

b. Attach one black wire (AS-50230-27-DD) to AR(1) and

compressor contactor CC1 (T1).

LOW AMBIENT SWITCH INSTALLATION

A. Open control section door.

B. Remove control panel cover.

C. Mount Accessory Relay (AR) to control panel to the left of

the Blower Relay with 2 screws provided. Apply AR Label

(92-19438-43) to control panel (See Figure 3 or Figure 4).

D. For KNL/LNL-G090/120/151 models (Figure 3):

a. Attach one black wire (AS-50230-27-DD) to Accessory

Relay terminal AR(1) and Outdoor Fan Motor Controller

(OFMC) terminal (LINE 2).

b. Attach one black wire (AS-50230-27-DD) to AR(3) and

Terminal Block TB4 (1).

ST-A1229-01-00

FIGURE 3. CONTROL PANEL

ST-A1229-02-00

FIGURE 4. CONTROL PANEL

F. Attach Blue wire (AS-50204-29-AJ) to AR coil (left terminal)

and Outdoor Fan Motor Controller (OFMC) terminal block

(REHEAT).

G. Attach Brown wire (AS-50207-29-AJ) to Outdoor Fan Motor

Controller (OFMC) terminal block (COMMON) and AR coil

(right terminal).

H. Use unit wiring diagram to verify proper connections.

I. Secure loose wires with wire ties.

J. Replace control panel cover and close control section door.

UNIT OPERATIONAL CHECK

A. Restore power and check unit for proper operation.

B. Outdoor fan cycles off when liquid pressure drops below

250, ± 10 PSIG.

C. Outdoor fan cycles on when liquid pressure rises above

450, ± 10 PSIG.

D. In reheat mode with the low ambient control option, the

relay bypasses the function of the low ambient control on

refrigerant circuit #1 so that the refrigerant liquid line tem-

perature is controlled by the outdoor fan motor controller

(OFMC) instead of the low ambient control.

This accessory is used when unit operation is required during

low ambient conditions. Installation of this control provides a

means of de-energizing the condenser fan motor. This permits

the suction (low side) to remain above the point which can cause

icing of evaporator (inside coil).

NOTE: Liquid line pressure for multiple compressors must all

drop below 250 before fans will cycle off and above 450 before

fans will cycle on.

Page 3

FIGURE 5. TYPICAL WIRING DIAGRAM

ST-A1229-03-00

ST-A1229-03-00

Page 4

CM 0814

Loading...

Loading...