Page 1

INSTALLATION INSTRUCTIONS

. FOR

AUXILIARY ELECTRIC HEATER KITS

A. Recognizethissymbolas an indicationofImportantSafetyInformationl

IMPORTANT: TO ENSUREPROPBRINSTALLAnON ANDOPBRATION,PLBASEREADALL INSTRUCTIONSPRIORTO

ASSBMBLY,INSTALLATION,OPERATION,MAINTENANCBORREPAIROFnus PRODUCT. AFTERUNPACKING11IB

HEATERKIT, INSPECTALL PARTSFORDAMAGBPRIORTOINSTALLATIONANDSTARTUP. .

INTRODUCfION

The information contained in these instructions has been prepared

to assist in the proper installation and operation of the auxiliary

electric heaters. Improper installation can result in unsatisfactory

opezation or dangerous conditions not covered I>ythe unit wammty

and may invalidate the Underwriters Laboratories recognition.

\

CHECKING PRODUCT RECEIVED

Upon receiving the heater kit, inspect it for any shipping damage.

Claims for damage should be tiled immediately with the shipping

company.

IChcclcheater kit model number to determine that it is the correct

series for the unit, as shown on the unit rating plate. and is of the

desired voltage and KW size.

APPLICATION

"'.

These-auxiliary-e1ectrie-resistance heater kits ar.e desi

insbiIIation in the discharge air compartment of the indoor blower.

Improper usage can cause results which may be dangecous. Do not

use heater kits other than those referenced on the unit rating plate.

Clearance to combustible material for the unit and fIrStthree (3)

feet of duct is "0" inches.

OPERATION

The heater elements are wired through controllers operated by the

24 volt thermostat circuit To insure blower operation, the blower

is also controlled by the heater controllers. The heater controllers

will turn the blower and first stage heater "on" first and will turn

the beater and blower "off" last when the thermostat is satisfied.

INDOORBLOWER SPEED

Refer to the blower airflow tables in the unit installation

instructionstoset the proper blower speed for your airflow and

static pressure requirements. .

A WARNING

DISCONN~CT ALL POWER BEFORE STARTING

REATER KIT INSTAL~ TION. FAILURETO DOSO CAN

RESULTIN SEVER ELECTRICAL SHOCK OR DEATIL

ELECTRICAL WIRING

Field wiring must comply with the National Electrical Code (CBC

in Canada) and any local ordinances that may apply.

POWER WIRING

e unit has been in operation without an elec::tricheater kit

installed, it may be necessary to change the field installed

power wiring. The added current of the electric heater kit may

require larger gauge wiring than that required for the unit

alone. Refer to the unit rating plate or instaUation instructions

for the required supply circuit sim and overcurrent protection.

A wire sizing table follows for reference

2. It is important that proper electrical power is available at the

heater kit terminals. Voltage should Dotvary more than 10%

from that marked on the unit rating plate. Phase voltages must

bebalancedwithin3%. .

3. A properlysized disconnectswitch shall be located within

sight of the unit or as required by local codes. .

.

TOOLS NEEDED

The following tools can be helpful in installing the kits:

1. Slottedscrewdriversand5/16" nutdriver.

2. Some kits will require the use of alien wrenches.

3. Needle-nose pliers.

4. Wire cutters and strippers.

4. Power wiring must be run in grounded, rain-tight conduit.

5. Refertothe unit installationinstructionsfor power entry

location.Thehighvoltagefieldinstalledpowersupplycircuit

shouldbe connectedto the line side of the tenninal block

located on the heater kit. Consult the heater kit wiring

diagram.

Page 2

.ror 1I1::1U WSUUlauUU Ul 11I1 C:JCC\OC nc:aacr au" LUI1UW we

instructions below:

a.

Removing screws as required, open heater access door

and detach adjacent power entry panel.

b.

Remove wires to unit contactor (Ill, 11.2,lL3) ftom the

unit terminal block on the left side of the electric heat

compartment Remove and discard the terminal block

. and the adjacent ground l';1g.

c.

Remove the heater kit block-off panel and installthe

heaterkit in itspla~ using9ofthe 12screwspreviously

removed.

d.

Connect the unit contactor wires (Ill, IL2, IL3) to the

compressor fuse block on the heater kit

e.

Re-install the power entty panel & ~n con(Juit and the

proper size field w.iringthrough the opening in the panel.

f.

ColUlectfield wiring to the power tenninal block located

\

on the electric heater kit Connect ground wire to the

adjacent ground lug.

g. Connect heaterkit controlplug to the receptacleon the

controlwiringharness.

h. Check all electrical connections including factory wiring

within the unit and make sure all connections are tigh

and properly located.

i. -- Close heater access door and secure. With tbe screws

previously removed.

t AffiHeatel'-kit-wiring4iagmm-m-inside-()k6ntro1--1filtcr

accessdoor.

I. AU lOWvOltage wanng mUStoe roUted mto the lOWvOltage

connection area and not into the power wiring or heater conCroI

area.

2. For thermostat low voltage connections, see unit installation

Instructions.

3. Thennostat heat anticipator should be adjustable for a

minimumrangeof .10- 1.20. Typicalsettingsare as follows:

THERMOSTAT HEATANTICIPATORSETTlNG*

NUMBER OF STAGES

I Z

SE'ITlNG .7 .7&."

*NOTES

I. Nonnally.1hc firststage heathas a fixed$CUing.

2. Some chcrmostaIs have DOll!iustable second stage heat antidpator

setting indicator. Follow the instnlctions in these spc:cific

lhennostaU 10 get proper operation.

3. RqJlace the control box cover and control compartmentacccss panel

after all wiring is complctccl.

4. Chcclcunit for properopcwlon.

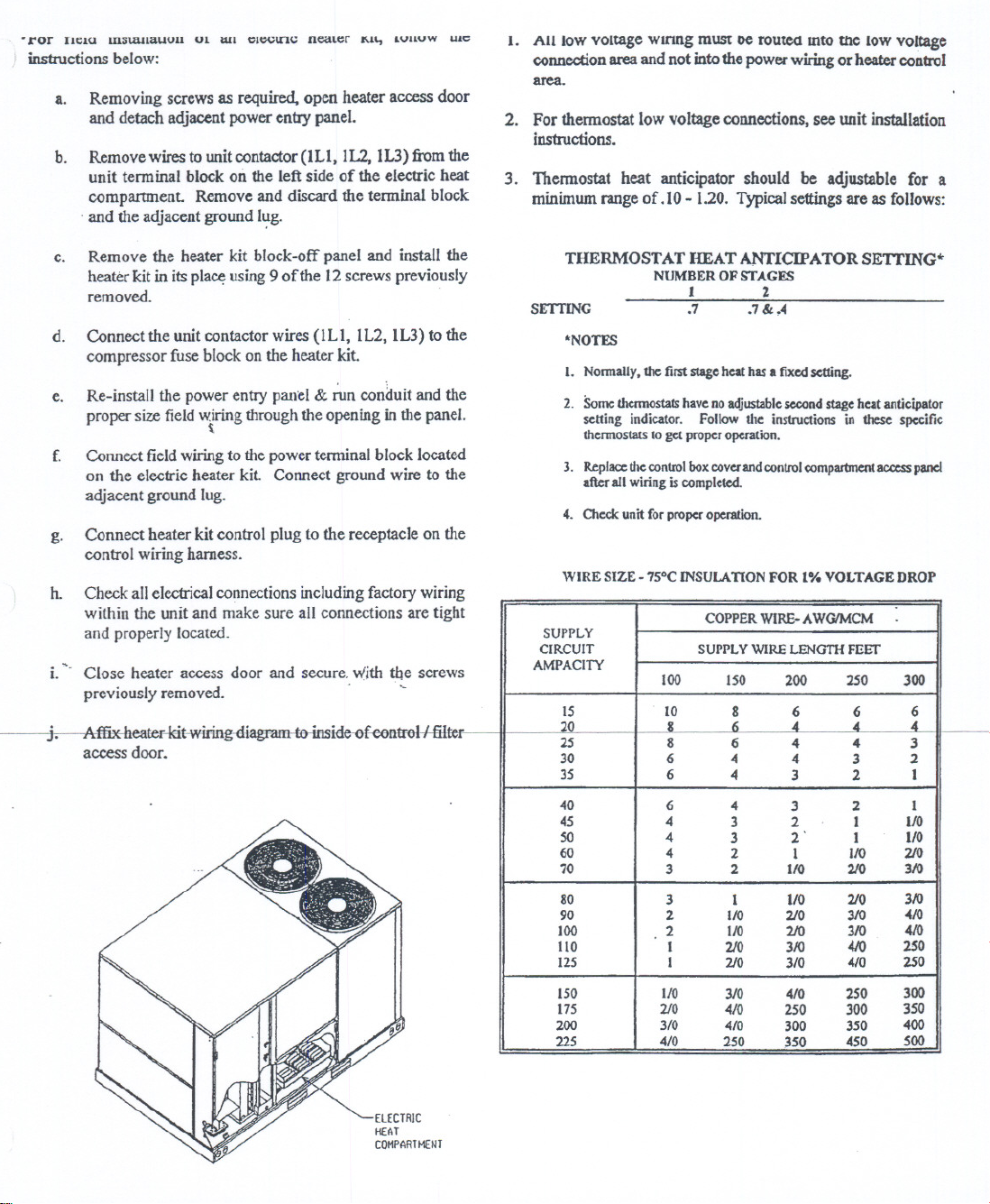

WIRE SIZE -7SOCINSULA110N FOR 1% VOLTAGE DROP

.

SUPPLY

CIRCUIT

AMPACITY

15

:20

25

30 6

35 6

40 6 4 3 2 I

45 4

SO 4

60 4

70

80 3

90 2 110 210

100 2 I/O 210

110

12S I 210 3/0 ...,0 250

150 110

175

200

225 'I/O

COPPERWIRE-AWG'MCM

SUPPLYWIRELENG1HFEET

100 ISO

10

I

8 6

3 2 110

I 210 310 <C/O

2/0

3/0 410

4 4

4

3 2 I

3

2

310 410 250

410

250

200 250 300

8 6 6 6

" ..

.. 4

3 2

2'

I

1 110 210

250

300

350

300 350

350

450

..

3 2

I

I/O 210

210 310

3/0 .c/O

3/0 .uo

..

3

I

VO

I/O

3/0

250

300

400

500

Loading...

Loading...