Page 1

INSTALLATION INSTRUCTIONS

MODEL RXGY-G01 (SP20286)

DIRECT VENT – SIDE WALL VENT KIT

FOR USE WITH (-)GRA, (-)GRJ, (-)GTA, (-)GTJ, (-)GFD, (-)GGD, (-)GRK,

(-)GTK, (-)GRS, (-)GTS, (-)GFE, (-)GGE, (-)GFG, (-)GJF, (-)GRL,

(-)GRM, (-)GTM, (-)GTC, (-)GRC & (-)GRB FURNACES

FOR USE WITH CONDENSING TANKLESS WATER HEATERS PER

MANUFACTURE INSTRUCTION

KIT CONTENTS:

• Vent Cap

• Vent Plate

• Mounting Hardware

NOTE: Field-supplied pipe and fittings are

required to complete the installation.

!

WARNING

THIS VENT KIT MUST BE INSTALLED BY A QUALIFIED SERVICE TECHNICIAN. CODES AND LOCAL UTILITY

REQUIREMENTS GOVERNING THE INSTALLATION OF GAS FIRED EQUIPMENT, WIRING, PLUMBING, AND FLUE

CONNECTIONS MUST BE ADHERED TO. IN THE ABSENCE OF LOCAL CODES, THE INSTALLATION MUST CONFORM

WITH THE NATIONAL FUEL GAS CODE ANSI Z223.1 “LATEST EDITION,” OR CAN/CGA B149 INSTALLATION CODES.

THE LATEST CODE MAY BE OBTAINED FROM THE INTERNATIONAL APPROVAL SERVICES, 8501 E. PLEASANT

VALLEY RD., CLEVELAND, OHIO 44131, OR 55 SCARSDALE RD., TORONTO, ONTARIO, CANADA, M3B 2R3.

This manual covers the installation of the RXGY-G01

Direct Vent Furnace – Side Wall Vent Kit. The

RXGY-G01 Vent Kit can be used for all above listed

furnace models or gas fired Direct Vent Condensing

Tankless Water Heaters, excluding models featuring

alternate terminations. See vent application charts in

applicable furnace installation instructions.

IMPORTANT:

!

WARNING

DO NOT OPERATE THE FURNACE OR TANKLESS WATER HEATER WITHOUT THE SIDE WALL CAP IN PLACE AS

RECIRCULATION OF COMBUSTION PRODUCTS MAY OCCUR. WATER MAY ALSO COLLECT INSIDE THE COMBUSTION AIR PIPE AND FLOW TO THE BURNER ENCLOSURE. FAILURE TO FOLLOW THIS WARNING COULD RESULT IN

PRODUCT DAMAGE OR IMPROPER OPERATION, PERSONAL INJURY OR DEATH.

!

WARNING

THESE INSTRUCTIONS ARE INTENDED AS AN AID TO QUALIFIED SERVICE PERSONNEL FOR PROPER INSTALLATION, ADJUSTMENT AND OPERATION OF THIS UNIT. READ THESE INSTRUCTIONS THOROUGHLY BEFORE

ATTEMPTING INSTALLATION OR OPERATION. FAILURE TO FOLLOW THESE INSTRUCTIONS MAY RESULT IN

IMPROPER INSTALLATION, ADJUSTMENT, SERVICE OR MAINTENANCE, POSSIBLY RESULTING IN FIRE, CARBON

MONOXIDE POISONING, EXPLOSION, PROPERTY DAMAGE, PERSONAL INJURY OR DEATH.

DO NOT DESTROY THIS MANUAL. PLEASE READ CAREFULLY AND KEEP

IN A SAFE PLACE FOR FUTURE REFERENCE BY A SERVICEMAN.

SUPERSEDES 92-102005-01-00

92-102005-01-01

Page 2

INSTALLATION - Side Wall Vent Kit

IMPORTANT: Refer to Furnace or Condensing Tankless Water Heater Installation Instructions for complete information on installation

of Side Vent Kit. (See Figures 1-3.) All applicable codes should be followed when determining vent location.

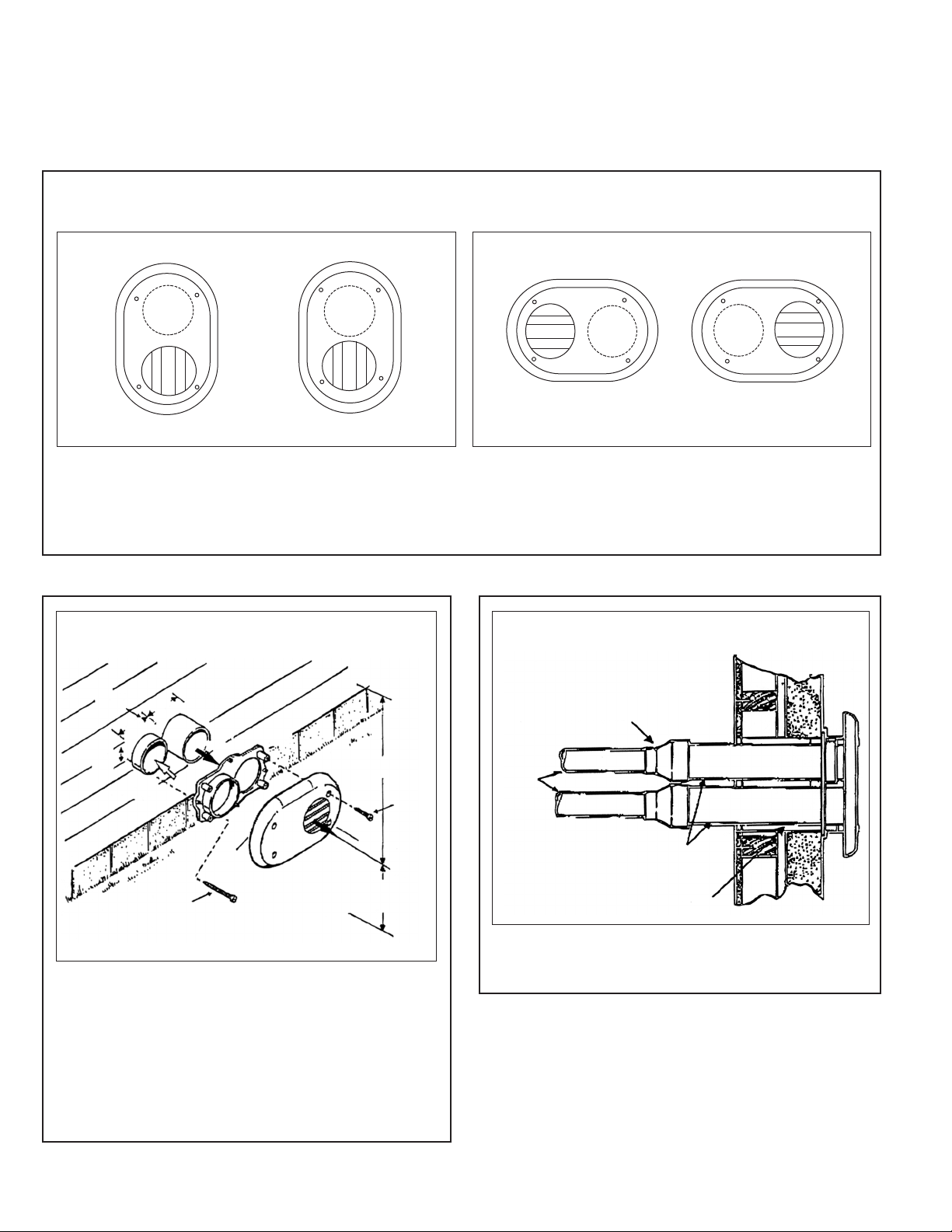

FIGURE 1

ENT KIT INSTALLATION OPTIONS

V

OPTION A

TYPICAL VERTICAL INSTALLATION

OPTION B

TYPICAL HORIZONTAL INSTALLATION

NOTE: Install the vent and air intake piping into the vent plate openings. Seal all gaps between the pipes and wall. Use silicon

sealant to seal the vent pipe to the vent cap to permit field disassembly for cleaning. Also seal all pipe penetrations in wall. To prevent possibility of condensate freeze-up, do not install vent kits one above the other.

FIGURE 2

TYPICAL SIDE WALL APPLICATION

ANCHORS

(4 req.)

2.53"

COMBUSTION

"

.53

4

"

.53

4

VENT

AIR

VENT

PLATE

12" MINIMUM

TO OVERHANG

1" SCREWS

(4 req.)

FIGURE 3

TOP VIEW – TYPICAL INSTALLATION

REDUCING

COUPLING,

FIELD SUPPLIED

IF NEEDED

2", 2-1/2"

or 3" PIPING

VENT

2" SCREWS

(4 req.)

VENT

CAP

MAINTAIN12" (18" FORCANADA) MINIMUM

CLEARANCE ABOVE HIGHEST ANTICIPATED

SNOW LEVEL OR GRADE WHICHEVER IS GREATER

Use the vent plate as a template to locate the vent and air

intakes holes and four mounting holes. Cut two 3-7/8 inch

diameter holes for the vent and air intake openings. Drill four

3/16ⴖ diameter holes for inserting the plastic anchors into the

wall. Attach the vent plate to the wall with four screws (#8

pan, 2ⴖ long, SMS Type A18-8 stainless steel).

Assemble the vent cap to the vent plate. Insert the four (#8

pan, 1ⴖ long, SMS Type A18-8 stainless steel) screws into

the vent cap screw hole openings and securely attach the

vent cap to the vent plate.

2

3" PIPING

SEAL ALL

WALL CAVITIES

NOTE: Reducing couplings are required, but not supplied,

for pipe reduction.

CM 0111

Loading...

Loading...