Rheem RXGJ-FP33 Installation Manual

90 PLUS GAS FURNACE

INSTALLATION INSTRUCTIONS

HONEYWELL VALVE

ELECTRIC IGNITION RXGJ-FP33

BEFORE INSTALLING THIS KIT, CHECK CONVERSION KIT INDEX TO BE

SURE YOU HAVE THE RIGHT KIT FOR THE FURNACE MODEL YOU ARE CONVERTING.

PARTS LIST

DESCRIPTION PART NUMBER FP33

Installation Instructions 92-104443-01 1

Conversion Label 92-18153-05 1

Conversion Kit #396221-2 (Honeywell) 60-22513-03 1

Orifice - Burner (1.10 mm) 62-22175-90 8

!

WARNING

THESE INSTRUCTIONS ARE INTENDED AS AN AID TO QUALIFIED, LICENSED SERVICE PERSONNEL FOR

PROPER INSTALLATION, ADJUSTMENT AND OPERATION OF THIS UNIT. READ THESE INSTRUCTIONS THOR OUGHLY BEFORE ATTEMPTING ANY MAINTENANCE OR OPERATION. FAILURE TO FOLLOW THESE

INSTRUCTIONS CAN RESULT IN IMPROPER INSTALLATION, ADJUSTMENT, SERVICE OR MAINTENANCE

RESULTING IN FIRE, ELECTRICAL SHOCK, CARBON MONOXIDE POISONING, EXPLOSION, PROPERTY DAMAGE,

PERSONAL INJURY OR DEATH.

FOR CANADIAN INSTALLATIONS, THE CONVERSION SHALL BE CARRIED OUT BY A MANUFACTURER’S

AUTHORIZED REPRESENTATIVE, IN ACCORDANCE WITH REQUIREMENTS OF THE MANUFACTURER, PROVINCIAL OR TERRITORIAL AUTHORITIES HAVING JURISDICTION AND IN ACCORDANCE WITH THE REQUIREMENTS

OF THE CAN/CGA-B149.1 OR CAN/CGA-B149.2 INSTALLATION CODES.

IMPORTANT: DAMAGE TO THE PRODUCT RESULTING

FROM FAILURE TO FOLLOW INSTRUCTIONS OR USE OF

UNAUTHORIZED PARTS MAY BE EXCLUDED FROM THE

MANUFACTURER’S PRODUCT WARRANTY COVERAGE.

IMPORTANT NOTE FOR ALTITUDES ABOVE 2,000 FEET:

The main burner orifices in this kit are sized for nameplate

input and intended for installations at elevations up to 2,000

feet only. For elevations above 2,000 feet, the burner orifices

must be sized as shown in Chart 5 in Conversion Kit Index 9221519-69.

In USA: All gas piping must comply with the latest NFPA 54

National Fuel Gas Code and all state and local codes. All electrical wiring must comply with the latest NFPA 70, National

Electrical Code and all state and local codes.

In Canada: All gas piping must comply with the latest CAN1B149-1 & 2 installation codes for gas burning appliances and all

provincial and local codes, Part 1– CSA Standard C22.1 and all

provincial and local codes.

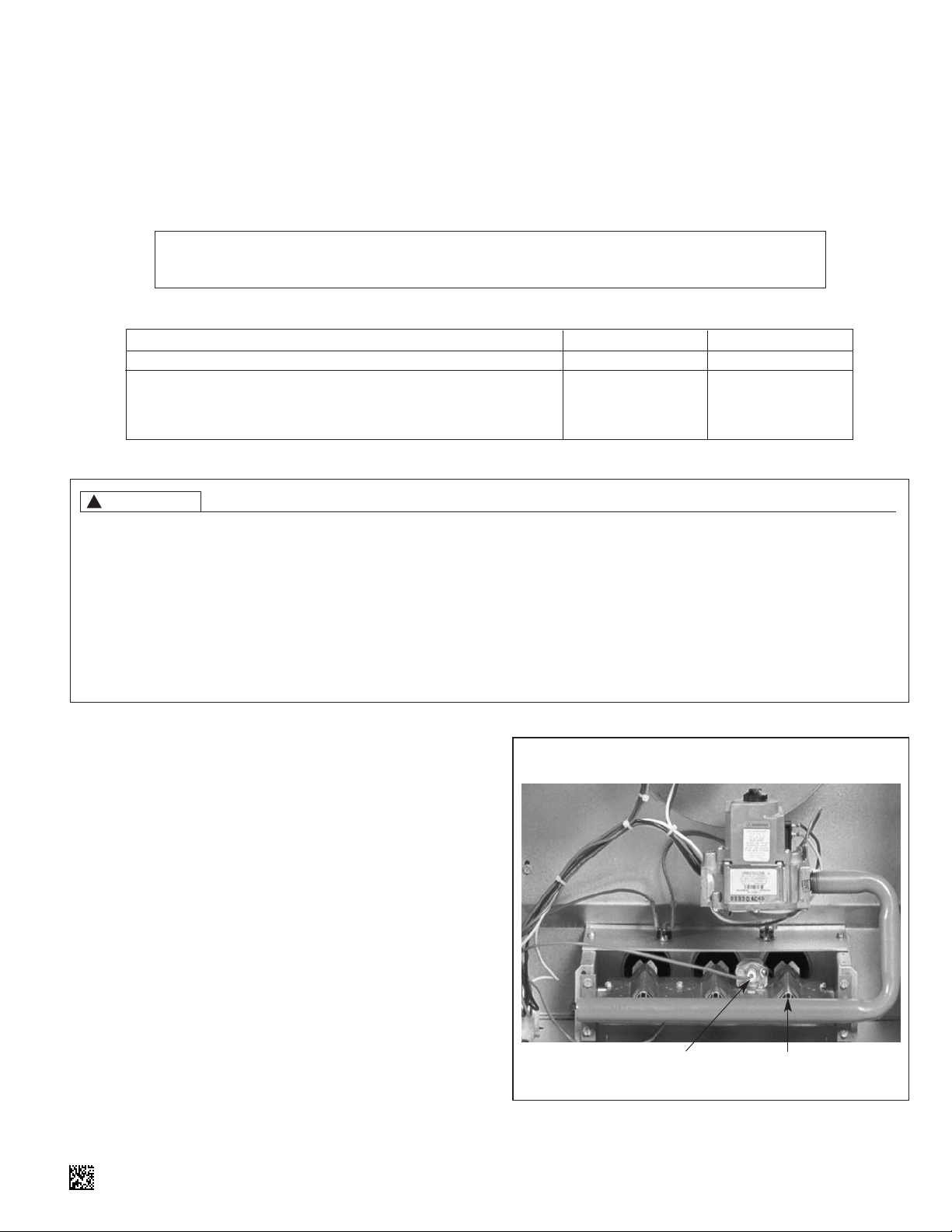

FIGURE 1

DIRECT SPARK IGNITION LOCATION

DIRECT

SPARK

IGNITOR

MAIN

BURNER

ORIFICE

SUPERSEDES 92-104443-01-00

92-104443-01-01

KIT INSTALLATION (SEE ILLUSTRATION)

1. Disconnect the gas line at the union ahead of the combination gas valve.

2. Remove burners from assembly.

A. To Change Burner Orifice

Remove each burner orifice from the manifold. See

Figure 1. Refer to Table 1 and verify the correct burner

orifice size required. Open the burner orifice envelope

marked with the orifice drill size required and install in the

burner when the unit is converted to LP gas.

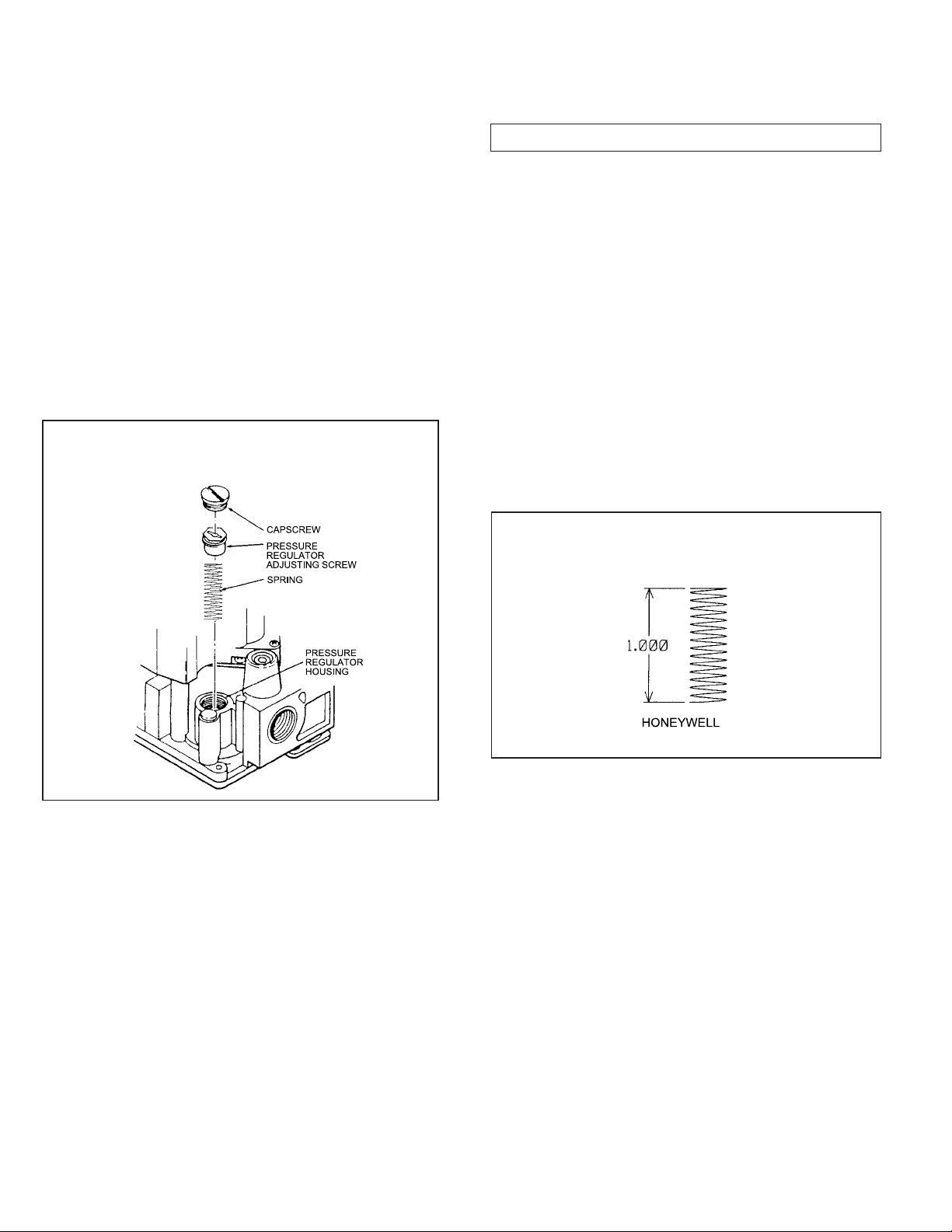

B. Convert Gas Valve to LP Gas (See Figure 2)

See Honeywell envelope kit #396221-2 for proper LP regulator spring and instructions. If unsure of which spring is

correct for the valve you are converting refer to Figure 3.

Manifold gas pressure must be adjusted to 10ⴖ W.C. after

valve conversion to LP gas with furnace in operation and

proper gas supply pressure (see rating plate). The gas

supply line pressure should be between 11ⴖ and 14ⴖ W.C.

at the appliance.

FIGURE 2

CONVERTING HONEYWELL VR8215 CONTROLS FROM NATURAL GAS

TO L.P. GAS OPERATION

NOTE: Use a pipe compound resistant to the action of the lique-

fied petroleum gases at all threaded pipe connections.

3. Place the conversion label adjacent to the rating plate.

4. Turn on gas supply and electrical supply.

DO NOT REMOVE OR DEFACE ORIGINAL RATING PLATE.

5. Check unit thoroughly for gas leaks — with soap and water —

not with a flame.

6. Follow lighting instructions to put furnace into operation.

7. Operate thermostat to check unit operation for ignition and

extinction characteristics.

COMPLETING CONVERSION

1. Using a ballpoint indelible pen, record the following informa tion on label 92-18153-05 provided in this kit.

a. Date of conversion.

b. Installer’s name, address and telephone number.

c. Burner orifice size.

2. Place completed conversion label next to the rating plate.

3. Install the burner compartment access door.

FIGURE 3

HONEYWELL REGULATOR SPRINGS (ACTUAL SIZE)

2 CM 0313

Loading...

Loading...