Page 1

INSTALLATION INSTRUCTIONS

DO NOT DESTROY THIS MANUAL. PLEASE READ CAREFULLY AND KEEP

IN A SAFE PLACE FOR FUTURE REFERENCE BY QUALIFIED SERVICE PERSONNEL.

ISO 9001:2008

HYDRONIC AIR HANDLER

RWIT-

SUPERSEDES 92-24161-150-00

92-24161-150-01

Page 2

SAFETY INFORMATION

WARNING

!

WHEN AN AIR HANDLER IS

INSTALLED SO THAT SUPPLY

DUCTS CARRY AIR CIRCULATED

BY THE AIR HANDLER TO AREAS

OUTSIDE THE SPACE

CONTAINING THE AIR HANDLER,

THE RETURN AIR SHALL ALSO

BE HANDLED BY DUCT(S)

SEALED TO THE AIR HANDLER

CASING AND TERMINATING

OUTSIDE THE SPACE

CONTAINING THE AIR HANDLER.

WARNING

!

INSTALLATION MUST COMPLY

WITH ALL INSTALLATION

INSTRUCTIONS INCLUDING:

• AIR HANDLER OPERATING

UNDER THERMOSTATIC

CONTROL;

• RETURN AIR DUCT SEALED TO

THE AIR HANDLER;

• AIR FILTERS IN PLACE;

• RETURN AIR TEMPERATURE

MAINTAINED BETWEEN 55°F

(13°C) AND 80°F (27°C); AND

• CLEAN AIR HANDLER, DUCT

WORK AND COMPONENTS

UPON SUBSTANTIAL

COMPLETION OF THE

CONSTRUCTION PROCESS,

AND VERIFY AIR HANDLER

OPERATING CONDITIONS

INCLUDING FLOW RATE AND

TEMPERATURE RISE,

ACCORDING TO THE

INSTRUCTIONS.

NOTICE

IMPROPER INSTALLATION, OR

INSTALLATION NOT MADE IN

ACCORDANCE WITH THE

UNDERWRITERS LABORATORY

(UL) CERTIFICATION OR THESE

INSTRUCTIONS, CAN RESULT IN

UNSATISFACTORY OPERATION

AND/OR DANGEROUS CONDITIONS AND ARE NOT COVERED

BY THE UNIT WARRANTY.

WARNING

!

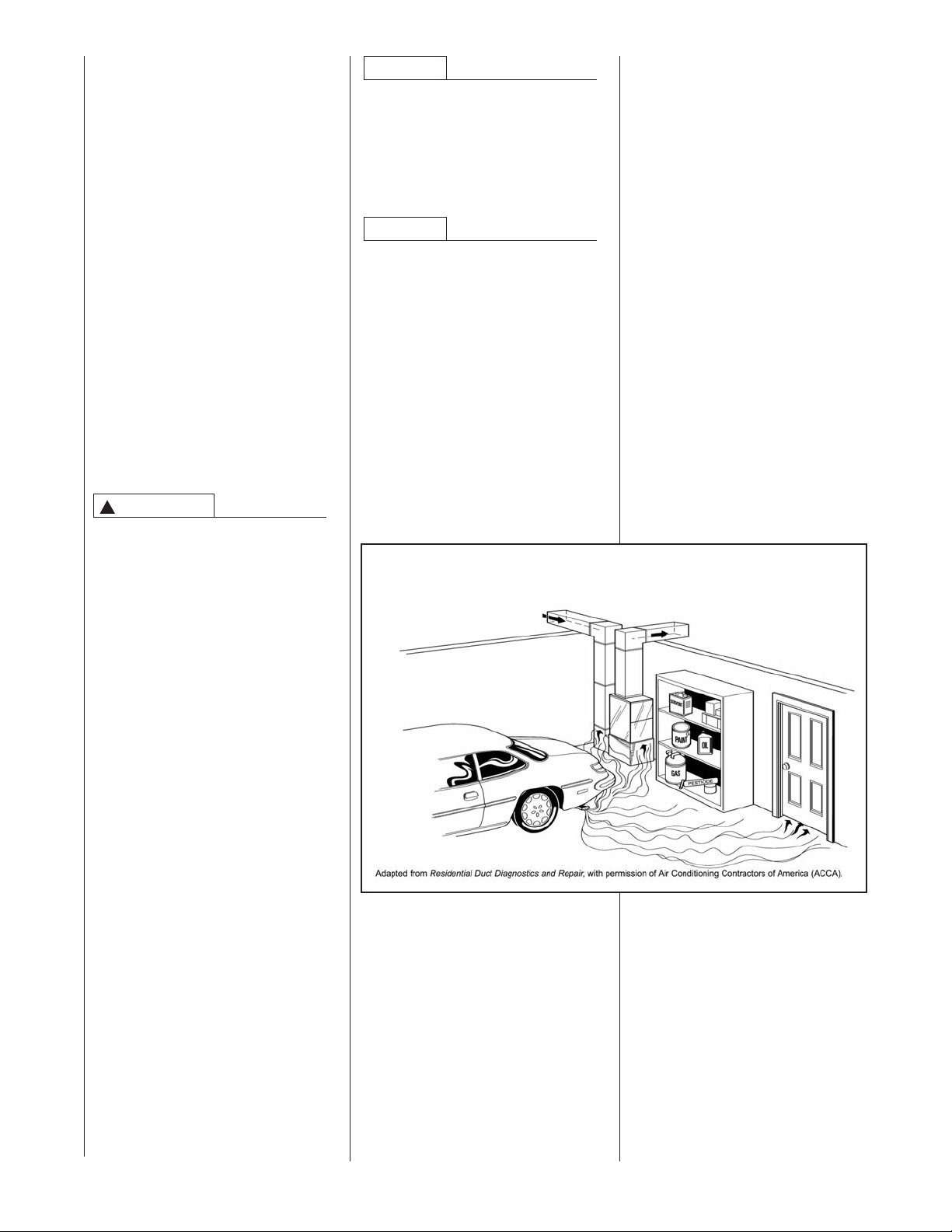

DUCT LEAKS CAN CREATE AN

UNBALANCED SYSTEM AND

DRAW POLLUTANTS SUCH AS

DIRT, DUST, FUMES AND ODORS

INTO THE HOME CAUSING

PROPERTY DAMAGE. FUMES

AND ODORS FROM TOXIC,

VOLATILE OR FLAMMABLE

CHEM I CALS, AS WELL AS AUTOMOBILE EXHAUST AND CARBON

MONOXIDE (CO), CAN BE DRAWN

INTO THE LIVING SPACE

THROUGH LEAKING DUCTS AND

UNBALANCED DUCT SYSTEMS

CAUSING PERSONAL INJURY OR

DEATH (SEE FIGURE 2).

• IF AIR-MOVING EQUIPMENT OR

DUCTWORK IS LOCATED IN

GARAGES OR OFF-GARAGE

STORAGE AREAS - ALL JOINTS,

SEAMS, AND OPENINGS IN THE

EQUIPMENT AND DUCT MUST

BE SEALED TO LIMIT THE

MIGRATION OF TOXIC FUMES

AND ODORS INCLUDING CAR BON MONOXIDE FROM

MIGRATING INTO THE LIVING

SPACE.

• IF AIR-MOVING EQUIPMENT OR

DUCTWORK IS LOCATED IN

SPACES CONTAINING FUEL

BURNING APPLIANCES SUCH

AS WATER HEATERS OR

BOILERS - ALL JOINTS, SEAMS,

AND OPENINGS IN THE EQUIP MENT AND DUCT MUST ALSO

BE SEALED TO PREVENT

DEPRESSURIZATION OF THE

SPACE AND POSSIBLE

MIGRATION OF COMBUSTION

BYPRODUCTS INCLUDING

CARBON MONOXIDE INTO THE

LIVING SPACE.

NOTICE

APPLICATION OF THIS HYDRONIC

AIR HANDLER SHOULD BE

INDOORS. SPECIAL ATTENTION

SHOULD BE GIVEN TO UNIT

SIZING AND PIPING, FILLING, AND

PURGING.

CAUTION

FAILURE TO FOLLOW THIS

CAUTION MAY RESULT IN

PERSONAL INJURY. SHEET

METAL PARTS MAY HAVE

SHARP EDGES OR BURRS. USE

CARE AND WEAR APPROPRIATE

PROTECTIVE CLOTHING.

CAUTION

!

WHEN USED IN COOLING

APPLICATIONS, EXCESSIVE

SWEATING MAY OCCUR WHEN

UNIT IS INSTALLED IN AN

UNCONDITIONED SPACE. THIS

CAN RESULT IN PROPERTY

DAMAGE.

NOTICE

IN COMPLIANCE WITH

RECOGNIZED CODES, IT IS

RECOMMENDED THAT AN

AUXILIARY DRAIN PAN BE

INSTALLED UNDER ALL

EVAPORATOR COILS AND UNITS

CONTAINING EVAPORATOR

COILS AND AIR HANDLERS USED

WITH EVAPORATOR COILS THAT

ARE LOCATED IN ANY AREA OF A

STRUCTURE WHERE DAMAGE TO

THE BUILDING OR BUILDING

CONTENTS MAY OCCUR AS A

RESULT OF AN OVERFLOW OF

THE COIL DRAIN PAN, A

STOPPAGE IN THE PRIMARY

CONDENSATE DRAIN PIPING OR

ANY WATER LEAK POTENTIAL

FROM THE AIR HANDLER.

WARNING

!

DO NOT OPERATE THE SYSTEM

WITHOUT FILTERS. A PORTION

OF THE DUST ENTRAINED IN THE

AIR MAY TEMPORARILY LODGE

IN THE DUCT RUNS AND AT THE

SUPPLY REGISTERS. THIS

RESIDUE COULD SOIL CEILINGS,

WALLS, DRAPES, CARPETS AND

OTHER ARTICLES IN THE HOUSE.

SOOT DAMAGE MAY OCCUR

WITH FILTERS IN PLACE, WHEN

CERTAIN TYPES OF CANDLES,

OIL LAMPS OR STANDING PILOTS

ARE BURNED.

CAUTION

!

HORIZONTAL UNITS MUST BE

CONFIGURED FOR RIGHT HAND

AIR SUPPLY OR LEFT HAND AIR

SUPPLY. HORIZONTAL DRAIN

PAN MUST BE LOCATED UNDER

INDOOR COIL. FAILURE TO USE

THE DRAIN PAN CAN RESULT IN

PROPERTY DAMAGE.

NOTICE

!

CODES AND STANDARDS:

IT IS THE RESPONSIBILITY OF

THE INSTALLER TO FOLLOW ALL

NATIONAL CODES, STANDARDS

AND LOCAL ORDINANCES, IN

ADDITION TO INSTRUCTIONS

LAID OUT IN THIS MANUAL. THE

INSTALLATION MUST COMPLY

WITH REGULATIONS OF THE

LOCAL BUILDING, HEATING,

PLUMBING, AND OTHER CODES.

WHERE LOCAL CODES ARE NOT

APPLICABLE, THE INSTALLATION

MUST COMPLY WITH THE

NATIONAL CODES AND ANY AND

ALL AUTHORITIES HAVING

JURISDICTION.

2

Page 3

WARNING

!

IMPORTANT: All manufacturer

products meet current Federal OSHA

Guidelines for safety. California

Proposition 65 warnings are required

for certain products, which are not

covered by the OSHA standards.

California's Proposition 65 requires

warnings for products sold in California

that contain, or produce, any of over

600 listed chemicals known to the State

of California to cause cancer or birth

defects such as fiberglass insulation,

lead in brass, and combustion products

from natural gas.

All “new equipment” shipped for sale in

California will have labels stating that

the product contains and/or produces

Proposition 65 chemicals. Although we

have not changed our processes,

having the same label on all our

products facilitates manufacturing and

shipping. We cannot always know

“when, or if” products will be sold in the

California market.

You may receive inquiries from

customers about chemicals found in, or

produced by, some of our heating and

air-conditioning equipment, or found in

natural gas used with some of our

products. Listed below are those

chemicals and substances commonly

associated with similar equipment in

our industry and other manufacturers.

• Glass Wool (Fiberglass) Insulation

• Carbon Monoxide (CO)

• Formaldehyde

• Benzene

More details are available at the

Websites for OSHA (Occupational

Safety and Health Administration), at

www.osha.gov

California's OEHHA (Office of

Environmental Health Hazard

Assessment), at www.oehha.org.

Consumer education is important since

the chemicals and substances on the

list are found in our daily lives. Most

consumers are aware that products

present safety and health risks, when

improperly used, handled and

maintained.

and the State of

CONTENTS

Safety Precautions...................................................................................................1

Safety Information....................................................................................................2

General Information..................................................................................................4

Location Requirements and Considerations............................................................6

Selection Procedure.................................................................................................8

Ducting...................................................................................................................10

Installation..............................................................................................................12

Plumbing.................................................................................................................13

Electrical Wiring......................................................................................................16

Accessories............................................................................................................16

Sequence of Operation..........................................................................................20

Maintenance...........................................................................................................22

Troubleshooting......................................................................................................24

Wiring Diagrams................................................................................................25-26

PROHIBITED APPLICATIONS

RWI(-) HYDRONIC AIR HANDLERS ARE EQUIPPED STANDARD WITH

STAINLESS STEEL PUMPS AND COMPLY WITH CALIFORNIA PER AB1953

AND VERMONT PER SB152 FOR USE IN AIR HANDLER AND IN AN OPEN

SYSTEM WITH POTABLE WATER.

IMPORTANT: TO ENSURE PROPER INSTALLATION AND OPERATION OF

THIS PRODUCT, COMPLETELY READ ALL INSTRUCTIONS PRIOR TO

ATTEMPTING TO ASSEMBLE, INSTALL, OPERATE, MAINTAIN OR REPAIR

THIS PRODUCT. UPON UNPACKING OF THE AIR HANDLER, INSPECT ALL

PARTS FOR DAMAGE PRIOR TO INSTALLATION AND START-UP.

3

Page 4

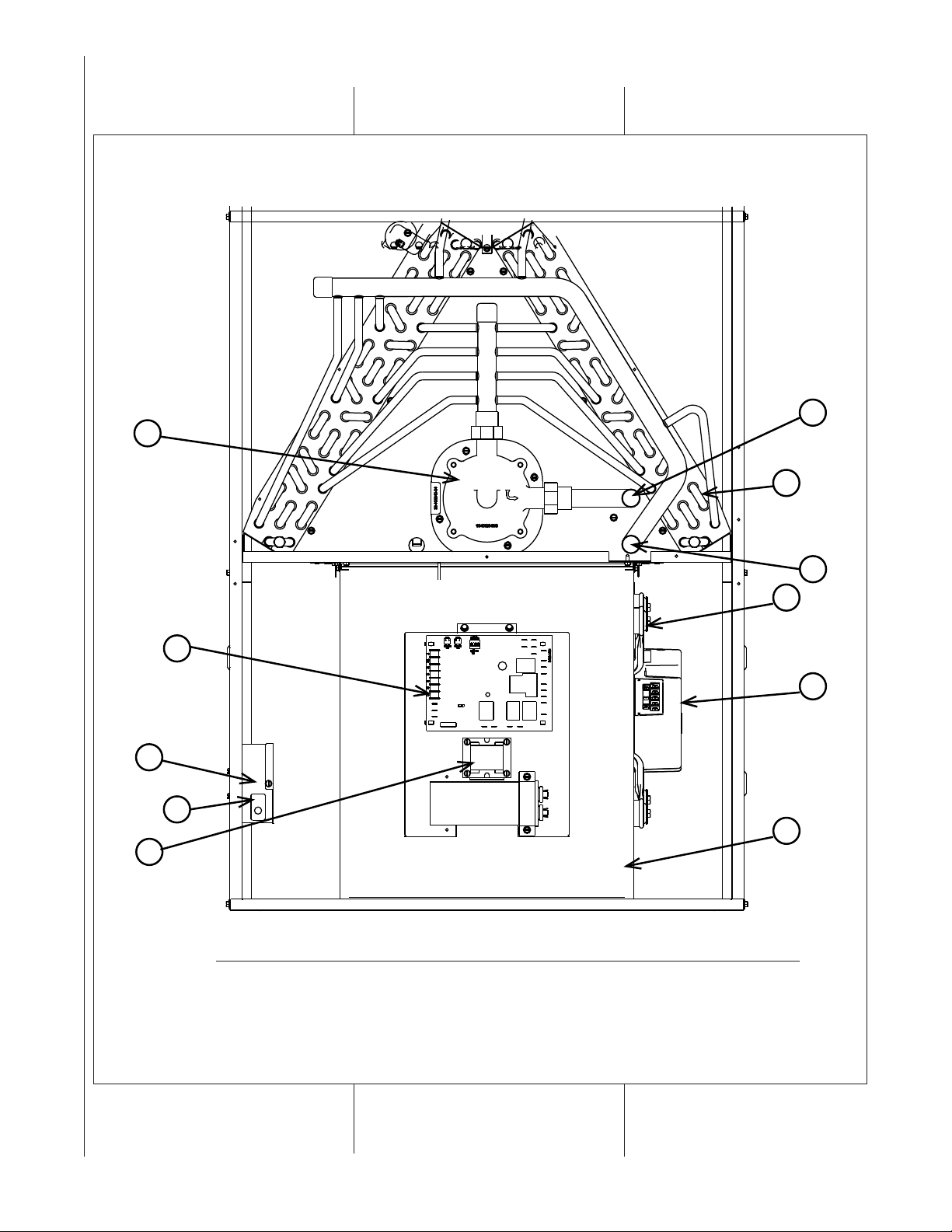

GENERAL INFORMATION

11

8

9

10

6

4

7

5

1

2

3

FIGURE 1

THE RWI(-) SERIES HYDRONIC AIR HANDLERS ARE DESIGN-CERTIFIED BY UL

ITEM ITEM

NO. PART NAME NO. PART NAME

1 DOOR SWITCH 7 PUMP

2 JUNCTION BOX 8 WATER INLET (OUTLET FOR 14” HAH)

3 TRANSFORMERS 9 WATER OUTLET (INLET FOR 14” HAH)

4 CAPACITORS 10 BLOWER MOTOR

5 LOW VOLTAGE (THERMOSTAT) TERMINAL 11 HYDRONIC COIL ASSEMBLY

6 BLOWER

ST-A1242-01-X0

4

Page 5

IMPORTANT

INFORMATION ABOUT

EFFICIENCY AND INDOOR

AIR QUALITY

Central cooling and heating

equipment is only as efficient as the

duct system that carries the cooled or

heated air. To maintain efficiency,

comfort and good indoor air quality, it

is important to have the proper

balance between the air being

supplied to each room and the air

returning to the cooling and heating

equipment.

Proper balance and sealing of the

duct system improves the efficiency

of the heating and air conditioning

system and improves the indoor air

quality of the home by reducing the

amount of airborne pollutants that

enter homes from spaces where the

ductwork and/or equipment is

located. The manufacturer and the

U.S. Environmental Protection

Agency’s ENERGY STAR Program

recommend that central duct systems

be checked by a qualified contractor

for proper balance and sealing.

WARNING

!

DUCT LEAKS CAN CREATE AN

UNBALANCED SYSTEM AND

DRAW POLLUTANTS SUCH AS

DIRT, DUST, FUMES AND ODORS

INTO THE HOME CAUSING

PROPERTY DAMAGE. FUMES

AND ODORS FROM TOXIC,

VOLATILE OR FLAMMABLE

CHEMICALS, AS WELL AS

AUTOMOBILE EXHAUST AND

CARBON MONOXIDE (CO), CAN

BE DRAWN INTO THE LIVING

SPACE THROUGH LEAKING

DUCTS AND UNBALANCED DUCT

SYSTEMS CAUSING PERSONAL

INJURY OR DEATH (SEE FIGURE

2).

• IF AIR-MOVING EQUIPMENT OR

DUCTWORK IS LOCATED IN

GARAGES OR OFF-GARAGE

STORAGE AREAS - ALL JOINTS,

SEAMS, AND OPENINGS IN THE

EQUIPMENT AND DUCT MUST

BE SEALED TO LIMIT THE

MIGRATION OF TOXIC FUMES

AND ODORS INCLUDING

CARBON MONOXIDE FROM

MIGRATING INTO THE LIVING

SPACE.

• IF AIR-MOVING EQUIPMENT OR

DUCTWORK IS LOCATED IN

SPACES CONTAINING FUEL

BURNING APPLIANCES SUCH

AS WATER HEATERS OR

BOILERS - ALL JOINTS, SEAMS,

AND OPENINGS IN THE

EQUIPMENT AND DUCT MUST

ALSO BE SEALED TO PREVENT

DEPRESSURIZATION OF THE

SPACE AND POSSIBLE

MIGRATION OF COMBUSTION

BYPRODUCTS INCLUDING

CARBON MONOXIDE INTO THE

LIVING SPACE.

NOTICE

IMPROPER INSTALLATION, OR

INSTALLATION NOT MADE IN

ACCORDANCE WITH THE UL

CERTIFICATION OR THESE

INSTRUCTIONS, CAN RESULT IN

UNSATISFACTORY OPERATION

AND/OR DANGEROUS CONDITIONS AND ARE NOT COVERED BY

THE UNIT WARRANTY.

NOTICE

IN COMPLIANCE WITH

RECOGNIZED CODES, IT IS

RECOMMENDED THAT AN

AUXILIARY DRAIN PAN BE

INSTALLED UNDER ALL

EVAPORATOR COILS OR UNITS

CONTAINING EVAPORATOR COILS

OR AIR HANDLERS USED WITH

EVAPORATOR COILS THAT ARE

LOCATED IN ANY AREA OF A

STRUCTURE DAMAGE TO THE

BUILDING OR BUILDING CONTENTS

MAY OCCUR AS A RESULT OF AN

OVERFLOW OF THE COIL DRAIN

PAN OR A STOPPAGE IN THE

PRIMARY CONDENSATE DRAIN

PIPING.

FIGURE 2

MIGRATION OF DANGEROUS SUBSTANCES, FUMES, AND ODORS INTO LIVING SPACES

RECEIVING

Immediately upon receipt, all cartons

and contents should be inspected for

transit damage. Units with damaged

cartons should be opened

immediately. If damage is found, it

should be noted on the delivery

papers, and a damage claim filed

with the last carrier.

• After unit has been delivered to job

site, remove carton, taking care

not to damage unit.

• Check the unit rating plate for unit

size, voltage, phase, etc. to be

sure equipment matches what is

required for the job specification.

• Read the entire instructions before

starting the installation.

• Some building codes require extra

cabinet insulation and gasketing

when unit is installed in attic

applications.

• If installed in an unconditioned

space, apply caulking around the

power wires, control wires,

refrigerant tubing and condensate

line where they enter the cabinet.

Seal the power wires on the inside

where they exit conduit opening.

Caulking is required to prevent air

leakage into and condensate from

forming inside the unit, control box,

and on electrical controls.

• Install the unit in such a way as to

allow necessary access to the

coil/pump and blower/control

compartment.

• Install the unit in a level position to

ensure proper condensate

drainage. Make sure unit is level in

both directions within 1/8”.

• Install the unit in accordance with

any local code which may apply

and the national codes. Latest

editions are available from:

“National Fire Protection

Association, Inc., Batterymarch

Park, Quincy, MA 02269.” These

publications are:

• ANSI/NFPA No. 70-(Latest Edition)

National Electrical Code.

• NFPA90A Installation of Air

Conditioning and Ventilating

Systems.

• NFPA90B Installation of Warm Air

Heating and Air Conditioning

Systems.

• The equipment has been

evaluated in accordance with the

Code of Federal Regulations,

Chapter XX, Part 3280.

5

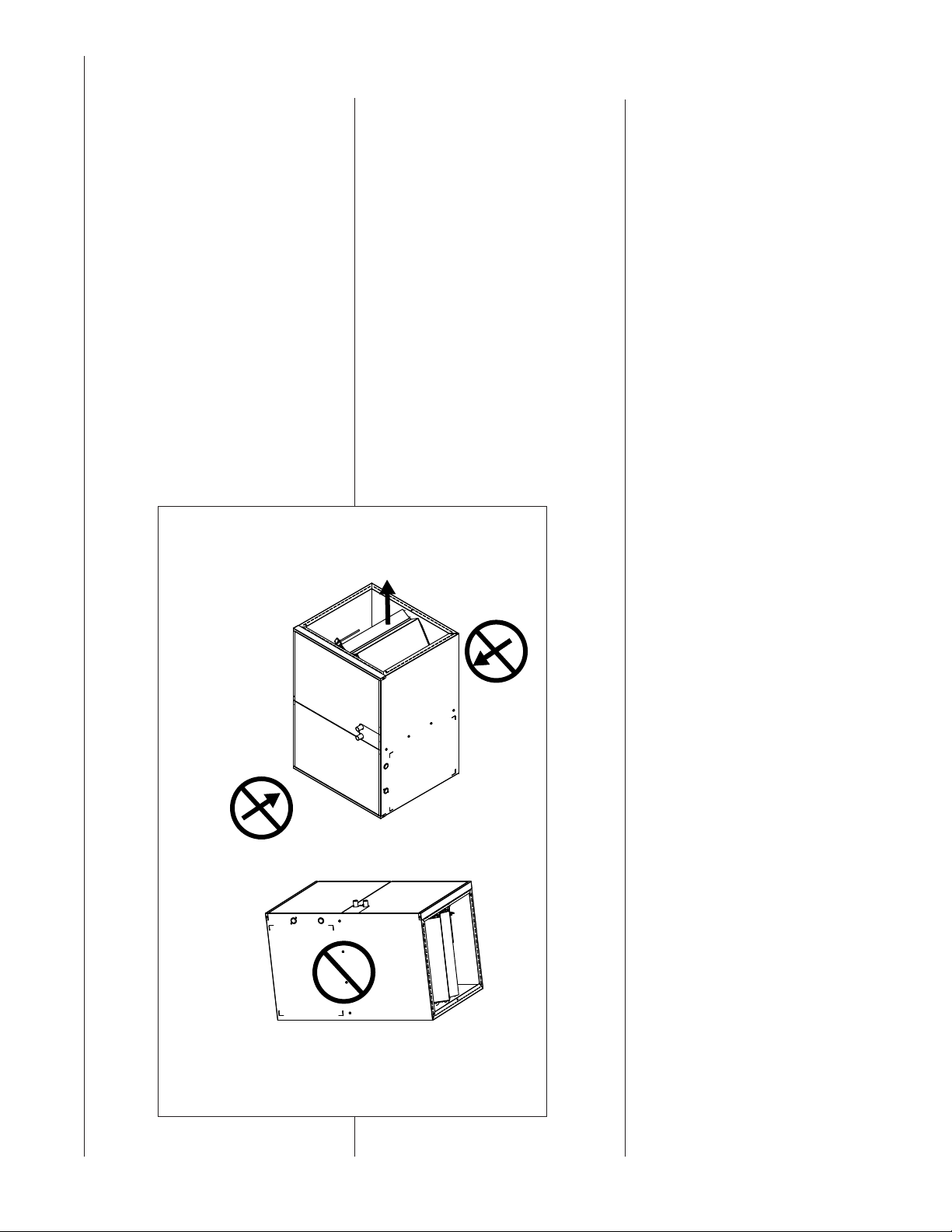

Page 6

LOCATION REQUIREMENTS AND CONSIDERATIONS

FRONT

BACK

THE AIR INLET IS NOT ALLOWED TO BE AT THE FRONT

OR BACK OF THE AIR HANDLER.

DO NOT POSITION THE AIR HANDLER ON ITS BACK OR

WITH IT FACE DOWN. DO NOT CUT SIDES OF

HORIZONTAL APPLICATION.

PROHIBITED INSTALLATIONS

NOTE: MULTIPLE AIR

HANDLERS CONFIGURED

FOR INSTALLATION WITH A

SINGLE TANKLESS WATER IS

PROHIBITED.

ST-A1242-02-X0

GENERAL INFORMATION

1. IMPORTANT: If installing the unit

over a finished ceiling or living

area, be certain to install an

auxiliary condensate drain pan

under the entire unit. This

auxiliary drain pan should extend

under any evaporator coil

installed with the air handler and

the open portion of the

condensate drain assembly.

2. IMPORTANT: If using a cooling

evaporator coil with this air

handler:

Be sure the air passes over the

coil/pump before passing over

the cooling coil.

FIGURE 3

IMPORTANT: Support this unit

when installed. Since this air

handler is suitable for attic or

crawl space installations, it may

be installed on combustible wood

flooring or by using support

brackets. See Figure 5.

5. IMPORTANT: If installing in a

utility room, be sure the door

is wide enough to:

a. allow the largest part of the air

handler to pass; or

b. allow any other appliance

(such as a water heater)

to pass.

6. IMPORTANT: This air handler is

not approved or recommended

for installation on its back, with

access doors facing upwards

(see Figure 3).

CLEARANCE ACCESSIBILITY

The design of air handlers with input

ratings as listed in the tables under

Figure 4 are certified by UL for the

clearances to combustible materials

shown in inches.

See name/rating plate and clearance

label for specific model number and

clearance information.

Service clearance of at least 24” is

recommended in front of

all air handlers.

NOTE: Use recommended 24”

clearance if accessibility clearances

are greater than fire protection

clearances.

Air handlers are shipped with a

bottom closure panel installed.

When bottom return air is used,

remove the panel by removing the

two screws attaching the panel to

the front base angle.

SITE SELECTION

1. Select a site in the building near

the center of the proposed, or

existing, duct system.

2. Locate the air handler to maintain

proper clearance to combustibles

as shown in the following tables.

6

ST-A1242-02-X0

Page 7

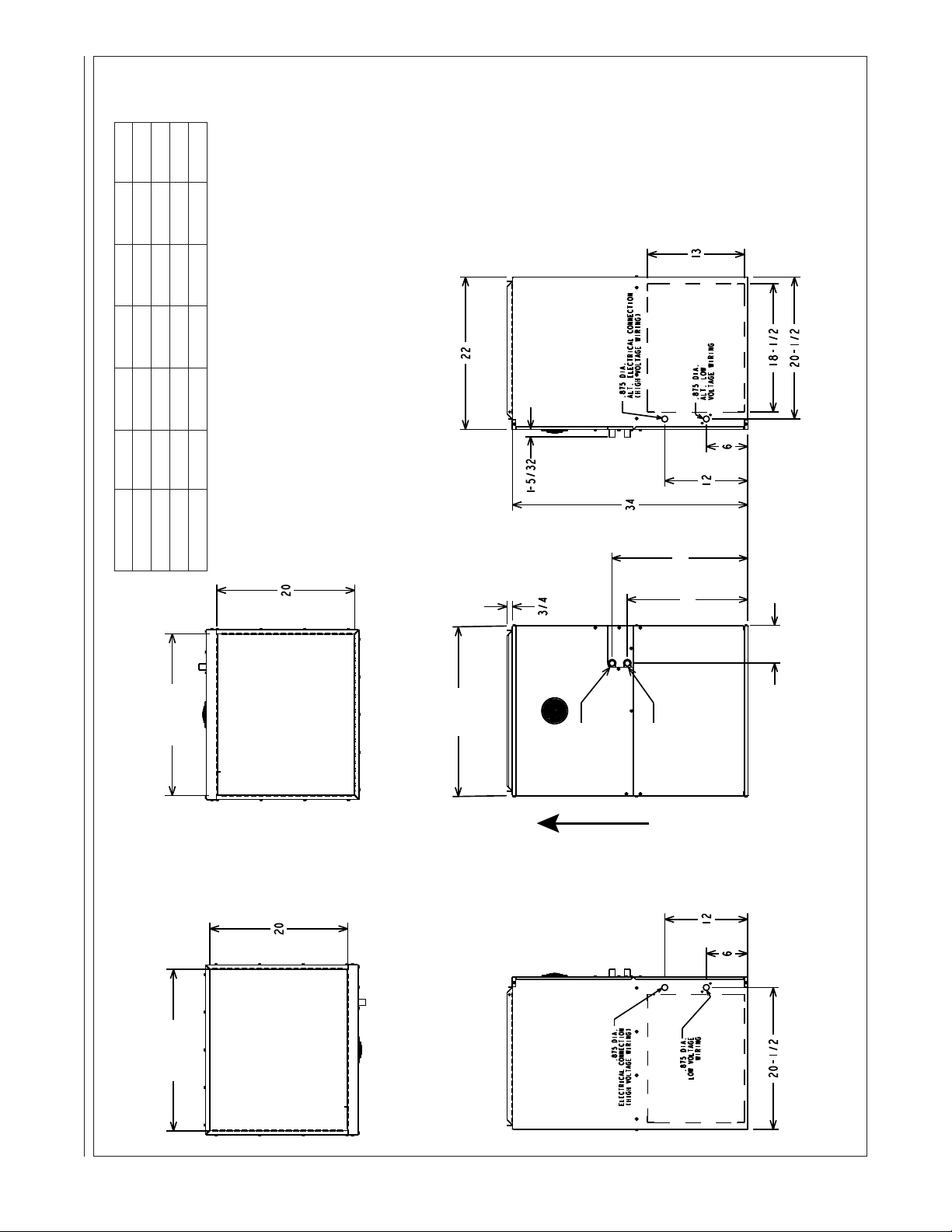

FIGURE 4

RETURN AIRSUPPLY AIR

TOP

BOTTOM

LEFT

RIGHT

FRONT

OPTIONAL RETURN AIR CUTOUT

(EITHER SIDE)

OPTIONAL RETURN AIR CUTOUT

(EITHER SIDE)

A

I

R

F

L

O

W

A

B

C

REF

D

E

F

G

H

CLEARANCE TO COMBUSTIBLES, UPFLOW, HORIZONTAL LEFT OR RIGHT, DOWNFLOW

⁄8

⁄8

⁄16

3

⁄16 19 3

13

⁄16

5

7

7

⁄8 5

5

⁄16 19 4

⁄16 19 4

⁄16 19

7

13

13

⁄2 16

⁄2 17

1

1

⁄2 16

⁄2 23

1

1

⁄2 16

⁄2 23

1

1

ST-A1242-03-X0

Model A B C D E F

RW1T06A3617 17

RW1T08A4821 21 20 20 16

RW1T04A2414 14 13 13 16

RW1T10A6024 24

Note: Service clearance of 24” is recommended in front of air handler.

7

Page 8

SELECTION PROCEDURE

2

Model Number Nomenclature

(WITH EXAMPLE)

I. Define hot water load for the total

required domestic hot water

usage.

As an example, let’s assume that the

selected Tankless Water Heater for your

whole house solution is the RTG-74 and

your calculated heat gain and heat loss

values are as stated in section II.

II. Determine cooling and heating

requirements at design conditions:

The ACCA’s Manual J Residential Load

Calculation method is the established

trade standard, approved by ANSI, for

the correct siziing and selection of

Heating, Ventilation, Air-Conditioning

and Refrigeration (HVACR) equipment in

residential homes. The most recent

revision is the eight edition, an allinclusive new approach to ensuring that

Indoor Air Quality (IAQ) systems are as

efficient, safe, and healthy as possible.

Refer to the Air Conditioning Contractors

of America website at:

http://www.acca.org/tech/manualj/

qualified HVACR contractor for further

assistance.

or a

Assumptions:

Required Cooling Capacity . 48,000 BTU/HR

(Total Capacity)

Required Heating Capacity . 60,000 BTU/HR

Evaporator Air Quantity. . . . . . . . . 1600 CFM

External Static Pressure . . . . . . . 0.2 in. W.C.

Electrical Characteristics . . . . . . . . . 115-1-60

III. Determine total external static

pressure (ESP) at design

conditions:

Before using the Airflow Performance

Table calculate the total static pressure

required. From the given example, note

the Wet Coil Pressure Drop (selected

from the field supplied Evaporative

Cased Coil Installation Instructions), and

the Filter Pressure Drop. Determine both

static pressures at 1600 CFM:

Wet Coil Pressure Drop . . . .0.3 in. W.C.

(From Coil Manufacturer’s Installation Instructions)

External Static Pressure . . . 0.2 in. W.C.

(Ductwork, etc.)

Filter Pressure Drop . . . .08 in. W.C.

(.08 inches if the included filter is used; refer to

the filter’s manufacturer’s instructions if another

filter is used.)

Total Static Pressure. . . 0.58 in. W.C.

IV. Select unit based on required

cooling capacity airflow:

For an initial selection, choose a unit

size that will provide the required

airflow. Refer to Airflow Performance

Table. Note that at 0.6 ESP (external

static pressure) the

RW1T06A3617NAA unit will deliver

1560 CFM when configured for HIGH

speed.

V. Select heating capacity of unit

to provide the requisite design

condition:

From the Hydronic Air Handler/

Tankless Water Heater, note that the

unit RW1T06A3617NAA, (as selected

above) when matched with the RTG95 Tankless Water Heater, will

provide 59.2 MBH (59,200 BTU/HR)

at an input water temperature (to Air

Handler) of 150°F.

TRADE BRAND

R = RHEEM

PRODUCT CATEGORY

W = HYDRONIC AIR HANDLER

STAGE OF AIR FLOW

1 = SINGLE

2 = TWO STAGE

M = MODULATING

MOTOR TYPE

T = CONSTANT TORQUE

V = VARIABLE SPEED

P = PSC

NOMINAL CAPACITY

04 = 40,000 BTU/H

06 = 60,000 BTU/H

08 = 80,000 BTU/H

10 = 100,000 BTU/H

MAJOR SERIES

A = FIRST

8

RW 1 T 04 A 24 14 NAA***

CONTROLS

C = COMMUNICATING

N = NON-COMMUNICATING

WIDTH

14 = 14”

17 = 17.5”

21 = 21”

24 = 24.5”

MAX COOLING AIRFLOW TONNAGE

24 = UP TO 2 TON

36 = UP TO 3 TON

48 = 2.5 TO 4 TON

60 = 3 TO 5 TON

OPTION CODE (SEE ADS-3803)

BLANK = NONE

MINOR SERIES

A = FIRST

VOLTAGE

A = 115/1/60

Page 9

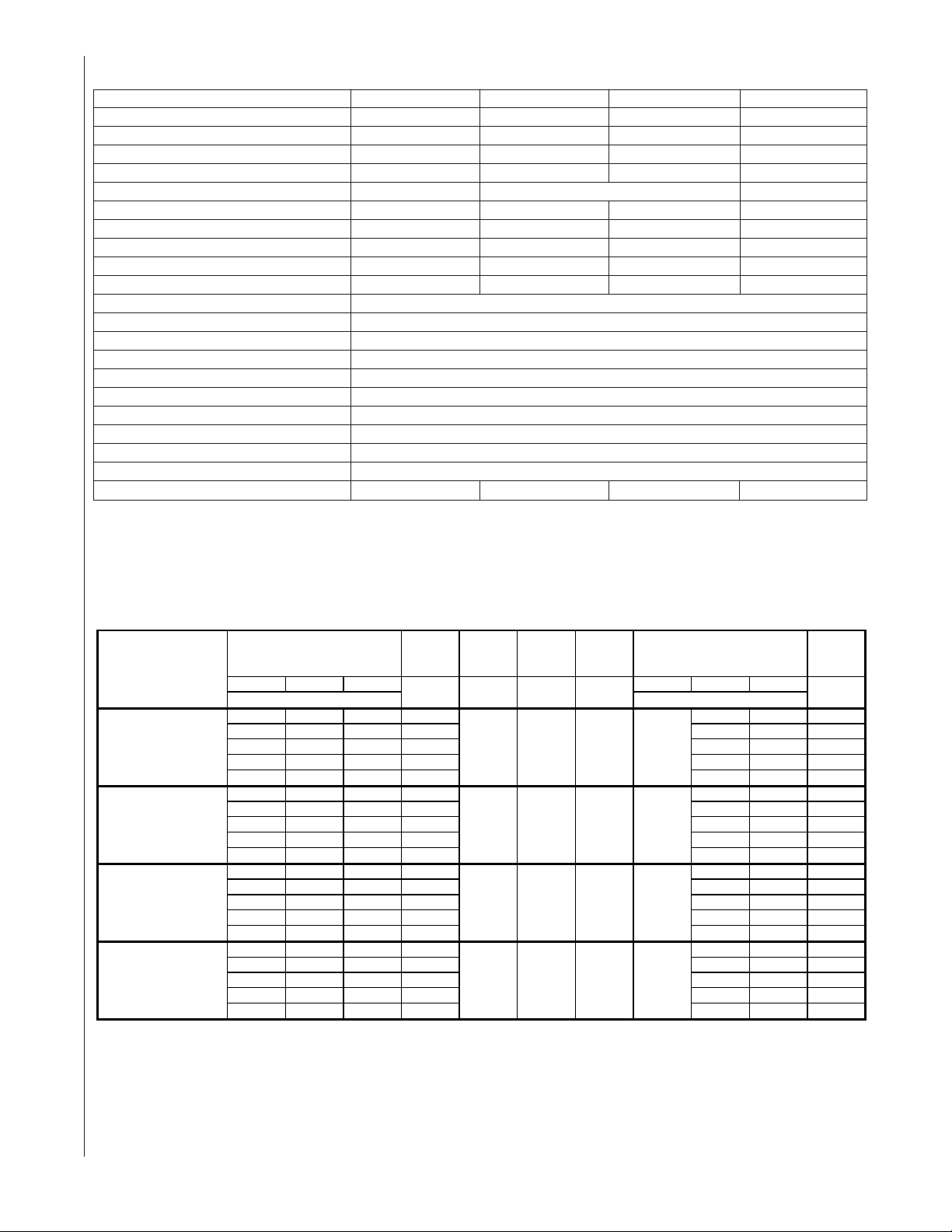

HYDRONIC AIR HANDLER ELECTRICAL PHYSICAL SPECIFICATIONS - ECO-TECH™ MODELS

!"#$% &

'()*&%"#$

+()*$%&

,-$$.

/0#$%1"(&

2#"#34&

-%$225%$

63%&'()*

7$"#&

8"-"43#9

:1($# ;5#($# <$(#" :1($# ;5#($# <$(#"

!"# !#$ !!

%&# !#" '! "()$!*

!'# !!( !*

*&( !#+ '( '!)*++

!*# !"" !+

*&# !!' *! '%)("+

!%# !"$ "!

'&+ !!$ *, *#)%$'

!(# !'" "+

'&' !"# %' *%)*%*

!"# $( "*

*&# !#* '(

*,)#*#

!'# !#! "$

'&+ !!# *"

%*)'##

!*# !#% '%

'&' !!" **

%,)%$+

!%# !!% '%

'&* !!* *(

%$)'*+

!(# !"! '$ '&' !!+ %# (*)'$+

!"# !## "#

*&+ $% ",

*,),((

!'# !#' ",

*&" !## '"

%%),#'

!*# !#% '%

'&( !#* '(

(")'*!

!%# !#+ *"

'&% !!# *"

,*)!*,

!(# !#( %* '&# !!* *( +#)$$,

!"# $' ",

*&( !## '"

(")'#+

!'# $+ '"

*&" !#' '%

(,)('%

!*# !#! '$

'&( !#* '(

($)$'(

!%# !#' *,

'&( !!! *'

+*)!'#

!(# !#! %$ '&' !!+ %# $,)%!*

63%&7"1.($%&=).$(

>?@=A

>%-BA

>31C&*C4CA

>8D=A

-.!/#*0

-.!/#(0

-.!/#+0

-.!/!#0

1234

#&%

!+##

(+&##

!"#$% &E$B-$%"#5%$

63%&E$B-$%"#5%$

>FDA

>FDA

(+&##

1234

#&%$

!"##

(+&##

!("%

#&%

1234

>+#5GH%A

(+&##

1234

#&%*

+##

Model Numbers

RW1T04A2414NAA RW1T06A3617NAA RW1T08A4821NAA RW1T10A6024NAA

Nominal Heating Capacity BTU/hr [kw] 40000 [11.7] 60000 [17.6] 80000 [23.4] 100000 [29.3]

Air Side Temperature Rise* °F [°C] 32-53 [17.6-29.2] 24-43 [13.2-23.7] 25-49 [13.8-27.0] 25-46 [13.8-25.3]

Rated Heating CFM [L/s] 800 [378] 1200 [566] 1625 [767] 1800 [850]

Cooling Range CFM [L/s] 600-800 [283-556] 800-1200 [283-612] 1000-1625 [472-775] 1200-1800 [612-804]

Power Supply (V - HZ - PH) 115 - 60 - 1

Minimum Circuit Ampacity - Amps 8 10 12.9 12.9

Max Rating of Over Current Protective Device - Amps 11.7 18 23.2 23.2

Maximum Fuse or Circuit Breaker Size - Amps 10 15 20 20

Motor HP [W] 1/3 [248] 1/2 [373] 3/4 [559] 3/4 [559]

Blower (D x W) in [mm] 10 x 6 [254 x 152] 10 x 8 [254 x 203] 10 x 10 [254 x 254] 11 x 11 [279 x 279]

Blower Motor Type EcoTech / ECM Type

Pump Type Wet Rotor

Pump Power Supply (V - HZ - PH) 115 - 60 - 1

Pump Motor RLA/LRA - Amps 1.8

Pump HP [W] 1/8 [.86]

Pump Maximum Working Pressure psi [kPa] 125 [861]

Max Working Temperature °F [°C] 160 [71]

Water Connection Type Copper Studs

Inlet Water Connection Diameter in [mm] 3/4 [19]

Out Water Connection Diameter in [mm] 3/4 [19]

Shipping Weight LBS [kg] 91 [41] 100 [45] 122 [55] 129 [58]

HYDRONIC AIR HANDLER HEATING PERFORMANCE

9

Page 10

DUCTING

CUT OUT USING

EMBOSSED ANGLES

AS A GUIDE FOR THE

PROPER SIZE.

JACKET

Proper air flow is required for the

correct operation of this air handler.

Too little air flow can cause erratic

operation and can damage the heat

exchanger. The duct system must

carry the correct amount of air for

heating and cooling if summer air

conditioning is used.

Size the ducts according to

acceptable industry standards and

methods. The total static pressure

drop of the air distribution system

should not exceed 0.8" w.c.

NOTE: Return air grilles and warm air

registers must not be obstructed

IMPORTANT: Some high efficiency

filters have a greater than normal

resistance to air flow. This can

adversely affect air handler operation.

BE SURE TO CHECK AIR FLOW.

IMPORTANT: When using outside

air, design and adjust the system to

maintain a return air temperature

ABOVE 50° F during the heating

season.

UPFLOW UNITS

1. Position the unit to minimize long

runs of duct or runs of duct with

many turns and elbows.

2. Open the return air compartment.

a. Cut an opening in the side.

The opening should

be cut the full width of the

knockouts on the unit. See

Figure 5.

FIGURE 5

CUTOUT AND DRILL INFORMATION

UPFLOW ONLY

NOTE: Where the maximum air flow

is 1800 CFM or more, both sides or

the bottom must be used for return

air.

3. Connect the return duct or return

air cabinet to the unit. Make the

connection air tight to prevent

entraining combustion gases

from an adjacent fuel-burning

appliance.

4. Be sure to have adequate

space for the unit filter.

NOTE: DO NOT take return air

from bathrooms, kitchens, air

handler rooms, garages, utility or

laundry rooms, or cold areas.

NOTE: DO NOT use a rear air

return.

5. If summer air conditioning (heat

pump) is desired, position the

indoor coil on the top of the unit.

Insure that no air can bypass this

coil.

6. Connect the supply air plenum to

the air handler plenum opening.

HORIZONTAL UNIT

1. Position the unit to minimize long

runs or runs with many turns and

elbows.

2. If summer air conditioning or heat

pump is desired, position the

indoor coil on the supply air end

of the unit. Insure that no air can

bypass this coil.

3. Connect the air handler to the

supply air plenum.

4. Connect the return air ducting to

the return air opening of the unit.

Make the connection air tight to

prevent pulling combustion gases

from an adjacent fuel-burning

appliance.

5. Be sure to have adequate

space for the unit filter.

NOTE: DO NOT take return air

from bathrooms, kitchens, air

handler rooms, garages, utility or

laundry rooms, or cold areas.

DOWNFLOW UNITS

1. Position the unit to minimize long

runs of duct or runs of duct with

many turns and elbows.

2. If summer air conditioning is

desired, position the indoor coil

on the supply air side of the unit.

Insure that no air can bypass this

coil.

3. Connect the furnace to the

supply air plenum.

4. Connect the return air ducting to

the return air opening at the top

of the unit. Make the connection

air tight to prevent entraining

combustion gases from an

adjacent fuel-burning appliance.

5. Be sure to have adequate space

for the unit filter.

NOTE: DO NOT take return air

from bathrooms, kitchens,

furnace rooms, garages, utility or

laundry rooms, or cold areas.

*Solid metal bottom required if side duct penetration is used.

10

ST-A1242-04-X0

Page 11

FIGURE 6

POSITION ORIENTATION

ST-A1242-05-X0

11

Page 12

INSTALLATION

Refer to the specification section of this

d

DOOR

ASSEMBLY

8” MIN FOR

DOOR REMOVAL

(2) HEX NUTS, (2) WASHERS & (2)

LOCK WASHERS REQ. PER ROD

USE 1” SQUARE, 1-1/4 x 1-1/4 x 1/4

ANGLE IRON OR EQUIVALENT

SECURE ANGLE

IRON TO BOTTOM

OF AIR HANDLER

WITH 3 #8 x 3/4”

SCREWS TYPCIAL

FOR 2 SUPPORTS

1/4” THREADED ROD

(4 REQUIRED)

F

DOORS

1 INCH x 22 GAUGE

GALVANIZED STRAPS

TYPICAL FOR 4 STRAPS

RETURN AIR

OPENING

SUPPLYAIR OPENING

BACK

SUSPENDED CABINET

INSTALLATION

If the cabinet cannot be supported on a

frame or supported from the wall, it may

be suspended.

Use metal strapping or threaded rod with

angle iron supports under cabinet for

support. These supports MUST run

parallel with the length of the cabinet.

Ensure that there is adequate room to

remove service and access panels after

installing supporting brackets.

If an auxiliary drain pan is required, the

support is to be placed under a drain

pan.

FIGURE 7

HORIZONTAL UNIT SUSPENSION

WARNING

!

IT IS THE INSTALLER’S

RESPONSIBILITY TO USE AN

APPROPRIATE HANGING METHOD

CAPABLE OF SUPPORTING THE

UNIT’S WEIGHT. REFER TO THE

SPECIFICATION SECTION OF THIS

DOCUMENT FOR THE RESPECTIVE

UNIT’S INSTALLED WEIGHTS.

NOTICE

FOR SEISMIC HANGING

REQUIREMENTS, REFER TO LOCAL

CODES.

Attachment Methods Using Straps

Method 1

Use (4) #8 x 3/4 sheet metal screws

for each strap. The straps should be

vertical against the air handler sides

and not pull away from the air handler

sides.

Method 2

Fold all straps under the air handler

and secure with (4) #8 x 3/4 sheet

metal screws (2 screws at the side

and 2 screws at the bottom. (Care

must be taken not to drive the screw

through the coil.)

FIGURE 8

HORIZONTAL UNIT SUSPENSION WITH STRAPS

12

Page 13

PLUMBING

Codes:

The RW1T air handler is used in potable

water systems. Therefore, it is important

to observe all local sanitary codes when

installing water lines. The water supply

mating connection to the Hydronic Air

Handler is made via the two 3/4 in. dia.

copper stubs labeled “WATER IN” and

“WATER OUT” (see Figure 1).

All associated hydronic piping MUST

comply with ICC, UPC and any other

local codes or ordinances having

jurisdiction. USE POTABLE GRADE

COPPER PIPING AND BRASS

APPURTENANCES ONLY.

Soldering Copper Tubing:

The common method of joining copper

tubing in hydronic heating systems is

soft soldering. Plumbing codes do not

allow solders containing lead to be used

for domestic water service. USE ONLY

95/5 tin/antimony solder for all piping

systems that incorporate a domestic

water supply.

NOTE: Precautions must be taken

during soldering to avoid debris or

solder from lodging in piping system.

Water Storage Tank:

When connecting directly to a water

storage tank it is necessary to ensure

the water flow rate does not become

excessive. Excessive water flow can

result in increased system noise and

potential system damage. In order to

regulate the flow it is required that an

adjustable valve be placed between the

air handler outlet and the storage tank.

Furthermore, two pressure taps will

need to be installed, the first located

between the air handler outlet and the

adjustable valve as near as possible to

the outlet, and the second on the inlet

water attached as near as possible to

the inlet. While the water pump is

engaged the adjustable valve will be

closed until the pressure difference

between the outlet and the inlet is

greater than 13.5 PSID.

Tubing Insulation:

Any tube-conveying fluid at a

temperature greater than that of the

surrounding air releases heat.

Insulate all accessible hot water lines

and associated valves with material,

such as expanded neoprene or

polyurethane 3/8-in. to 1⁄2-in. thick.

Match the pipe sleeve’s inside diameter

to the pipe’s outside diameter for a snug

fit. Place the pipe sleeve so the seam

will be face down on the pipe. Tape,

wire, or clamp insulation every foot or

two to secure it to the pipe. If taping is

desired, use acrylic tape instead of duct

tape.

Copper Tubing Support:

Copper tubing must be properly

supported to prevent sagging or

buckling. On horizontal runs with hard

temper tubing, the following maximum

support spacing is suggested:

• 1/2 in. to 3/4 in. tube: 5 feet maximum

spacing

• 1 in. to 1-1/4 in. tube: 6 feet maximum

spacing

The above suggested spacing does not

account for extra weight of piping

components such as an expansion tank,

etc. When such components are

present, the piping should be supported

immediately adjacent to the component.

On vertical runs, copper tubing should

be supported at each floor level or at a

maximum of every 10 feet.

Thermal Expansion of Piping:

In all hydronic systems, piping

undergoes temperature swings as the

system operates. This causes changes

in the length of the piping due to thermal

expansion.

If the piping is rigidly mounted, this

expansion can cause annoying popping

or squeaking sounds and, in extreme

cases, the piping can even buckle.

To counter expansion movement,

design piping circuits with sufficient

elbows, tees or expansion loops (only

used in large systems) or piping

supports that allow the tubing to expand

and contract freely.

Another alternative is to install an

expansion compensator fitting capable

of absorbing the movement.

Hydronic Resistance of

Fittings, Valves, and Other

Devices:

Before the total hydronic resistance

of a piping circuit can be found, the

individual hydronic resistances of all

fittings, valves, or other such

components must be determined.

One approach is to consider each

fitting, valve, or other device as an

equivalent length of copper tube of

the same pipe size (see Table 1).

By using the equivalent length of

piping for all components in the

circuit, the circuit can be treated as if

it were a single piece of pipe having

a length equal to the sum of the

actual pipe length, the total

equivalent lengths of all fittings,

valves, or other devices. Refer to

Figure 9 and the calculation of

equivalent lengths.

Pipe Sizing Considerations:

When selecting a pipe size for a

given flow rate, the resulting average

flow velocity should be between 2

and 4 feet per second.

At water flow velocities of

approximately 2 feet per second,

flowing water will carry air bubbles

along a vertical pipe. Average flow

velocities of 2 feet per second or

higher can draw along air bubbles in

a downward flow. At the above

stated velocities air bubbles shall be

routed to an air separator where they

can be collected and discharged from

the system. Use Taco 4900 series air

separator, Model 49-075, or

equivalent (field supplied).

Average flow velocities higher than 4

feet per second could cause flow

noise and should be avoided.

Expansion Tank:

All liquids used in hydronic heating

systems expand when heated. For

all practical purposes, liquids are

incompressible. Any container

completely filled with a liquid and

sealed from the atmosphere will

experience a rapid increase in

pressure as the liquid is heated.

To prevent this from occurring, all

closed-loop hydronic systems MUST

be equipped with an expansion tank.

Refer to expansion tank man u fac turer’s instructions for proper sizing

and installation.

Water circulation:

The hydronic air handler has a strict

in press cycle which will circulate the

water in the coil for 6 minutes per day

to prevent water stagnation.

13

Page 14

PROCEDURE FOR

COLDHOT

T

3

T1

1-1/2 FT

BV

1

1 FT

T4

EV2

COLD

WATER

SUPPLY

T

2

T5

EL7

2 FT

1-1/2 FT

TEMPERED

WATER

AS

EL

5

1 FT

EL

6

2 FT

1 FT

4 FT

EL

4

4 FT

3 FT

EL

3

IN

1/2 FT

EL

2

EL1

1 FT

OUT

AIR

HANDLER

CALCULATING THE TOTAL

EQUIVALENT LENGTH OF PIPE

Given piping assembly as shown in

Figure 9 below, what is the total

equivalent length of the system?

First determine the total straight pipe

lengths; next refer to Table 1 to

determine the equivalent straight pipe

length for each fitting shown. Add

together the equivalent lengths of piping

and fittings.

(3/4”) Tubing 24 ft.

7 (3/4”) 90 deg. Elbows 7 (1.9) = 13.3 ft.

5 (3/4”) Side Port Tees 5 (3.8) = 19.0 ft.

1 (3/4”) Taco air separator = .3 ft.

2 (3/4”) Ball Valve 2 (.2) = .4 ft.

Total Equivalent Length . . . . . = 57 ft.

FIGURE 9

EQUIVALENT LENGTH CALCULATION

NOTICE

WHERE POSSIBLE THE LENGTH OF

PIPE SHOULD NOT EXCEED 100

FEET TOTAL EQUIVALENT LENGTH.

ANY PIPING RUNNING THROUGH

UNCONDITIONED SPACE MUST BE

INSULATED TO PREVENT HEAT

LOSS, AND POSSIBLE FREEZING OF

THE LINE.

STICKERS INDICATING DIRECTION

OF FLOW (WATER IN AND WATER

OUT) ARE LABELED ON THE

OUTSIDE OF THE CABINET. DO NOT

REVERSE THESE LINES, AS THIS

WILL CAUSE THE UNIT TO

MALFUNCTION.

Piping Configuration

When employing a Tankless Water

Heater in a hydronic system, the

system is considered an open-loop

system when configured to

simultaneously deliver both domestic

hot water and space heating. By

definition, if the circuit is sealed off

from the atmosphere at all locations

(as is true for most modern hydronic

systems), it is called a closed-loop

system. If the circuit is open to the

atmosphere at any point, it is called

an open-loop system.

Rheem Tankless

Water Heater

COLD

WATER

SUPPLY

AIR

HANDLER

TEMPERED

WATER

Globe Valve 14.1 18.8 28.1 37.5 46.9 56.3

Angle Valve 6.3 8.3 12.5 16.7 20.8 25.0

Gate Valve 0.5 0.7 1.1 1.4 1.8 2.1

Table 1 – Equivalent Length of Straight Pipe for Valves and Fittings (ft)

0.375 0.5 0.75 1 1.25 1.5

Ball Valve (BV) 0.1 0.1 0.2 0.3 0.3 0.4

90 Degree Standard Elbow 0.9 1.3 1.9 2.5 3.1 3.8

45 Degree Standard Elbow 0.5 0.7 1.0 1.3 1.7 2.0

Diameter (in.)

Standard Tee with flow through run 0.6 0.8 1.3 1.7 2.1 2.5

Standard Tee with flow through branch 1.9 2.5 3.8 5.0 6.3 7.5

14

Page 15

Open-Loop System

All piping to be 3/4 inch.

(BV)

(DV)

Evaporator Coil

Air Separator

If piping is done in accordance with the

recommended schematic diagram

shown in Figure 10, the following purge

and priming procedure applies.

PURGING AND PRIMING THE

SYSTEM:

The following procedure describes how

the system may be piped to eliminate

the need for a “purge cart” to fill the

system and remove entrapped air

bubbles.

STEP 1: CLOSE the air separator

venting valve.

STEP 2: CLOSE ball valve 3 (BV

FIGURE 10

TYPICAL PIPING ARRANGEMENT FOR DIRECT SPACE HEATING AND DOMESTIC WATER SUPPLY WITH TANKLESS

3);

STEP 3: OPEN drain valve 3 (DV

which a hose MUST be connected and

draining to a sink, drain or outdoors.

STEP 4: CLOSE drain valves 1 & 2

1 and DV2) and OPEN ball valve 2

(DV

(BV

2).

STEP 5: OPEN cold water supply main

valve (ball valve 1 - BV

1). The system

will begin the prime/purge process using

the street pressure. Entrapped air

bubbles being pushed out of the system

will be evident by a slight vibration of the

discharge hose connected to drain valve

3 (DV

3). The hose will stop vibrating

when laminar flow is achieved.

3) to

STEP 6: CLOSE drain valve 3 (DV

STEP 7: OPEN ball valve 3 (BV

The system is now purged, primed

and ready to go.

STEP 8: OPEN the air separator

venting valve.

NOTE: For an open-loop system, use

expansion tank approved for potable

water use only.

3);

3).

15

Page 16

ELECTRICAL WIRING

WARNING

!

TURN OFF ELECTRIC POWER AT

FUSE BOX OR SERVICE PANEL

BEFORE MAKING ANY

ELECTRICAL CONNECTIONS.

FAILURE TO DO SO CAN CAUSE

ELECTRICAL SHOCK RESULTING

IN PERSONAL INJURY OR DEATH.

WARNING

!

THE CABINET MUST HAVE AN

UNINTERRUPTED GROUND

ACCORDING TO THE LATEST

EDITION OF THE NATIONAL

ELECTRICAL CODE (NEC), ANSI/

NFPA70- OR IN CANADA, THE

CANADIAN ELECTRICAL CODE,

CSA-C221 OR LOCAL CODES

THAT APPLY. DO NOT USE GAS

PIPING AS AN ELECTRICAL

GROUND. A GROUND SCREW IS

PROVIDED IN THE JUNCTION

BOX. FAILURE TO DO SO CAN

CAUSE ELECTRICAL SHOCK,

RESULTING IN PERSONAL

INJURY OR DEATH.

WARNING

!

THIS AIR HANDLER IS EQUIPPED

WITH A BLOWER DOOR SAFETY

SWITCH. DO NOT DISABLE THIS

SWITCH. FAILURE TO FOLLOW

THIS WARNING CAN RESULT IN

ELECTRICAL SHOCK, PERSONAL

INJURY OR DEATH.

IMPORTANT: The air handler must

be installed so that the electrical

components are protected from water

(condensate).

Before proceeding with the electrical

connections, be certain that the

voltage, frequency and phase

corresponds to that specified on the

air handler rating plate. For single air

handler application, maximum overcurrent protection is 15 amperes.

CAUTION

!

IF A DISCONNECT SWITCH IS TO

BE MOUNTED ON THE UNIT,

SELECT A LOCATION WHERE A

DRILL OR FASTENER WILL NOT

CONTACT ELECTRICAL OR

HYDRONIC COMPONENTS.

ELECTRICAL SHOCK CAN CAUSE

PERSONAL INJURY OR DEATH.

NOTE: Prior to making any electrical

connections, ensure that supply

voltage, frequency, and phase are as

specified on unit rating plate.

Check to ensure that the existing

electrical service is adequate to

handle the additional load imposed by

the Hydronic Air Handler. Refer to

unit wiring diagram for proper

electrical connections.

All electrical connections MUST

comply with NEC and any other local

codes or ordinances having

jurisdiction. USE COPPER WIRE

ONLY. Provide separate branch electric

circuit with field supplied disconnect

switch.

Location of disconnect switch to be in

clear site, accessible and in close

proximity to the unit.

Correct polarity MUST be maintained for

115 V wiring. If polarity is incorrect, unit

will NOT operate.

Use a separate fused branch electrical

circuit containing a properly sized fuse

or circuit breaker. Run this circuit directly

from the main switch box to an electrical

disconnect that is readily accessible and

located near the air handler. Connect

from the electrical disconnect to the

junction box on the left side of the air

handler, inside the blower compartment.

For the proper connection, refer to the

appropriate wiring diagram located on

the inside cover of the air handler

control box and in these instructions.

The electrical junction box may be

moved to the right side if necessary. A

knockout is provided. Seal the opposite

hole with plug provided.

Make all electrical connections in

accordance with the latest edition of the

National Electrical Code, ANSI/NFPA70

and local codes having jurisdiction.

These may be obtained from:

National Fire Protection

Association, Inc.

Batterymarch Park

Quincy, MA 02269

CSA - International

178 Rexdale Blvd.

Etobicoke (Toronto), Ontario

Canada M9W, 1R3

THERMOSTAT

The room thermostat must be compatible with the integrated air handler

control on the air handler. Generally,

all thermostats that are not of the

“current robbing” type are compatible

with the integrated air handler control.

The low voltage wiring should be

sized as shown (see Figures 12 and

13).

NOTE: Do not use 24 volt control

wiring smaller than No. 18 AWG.

Install the room thermostat in

accordance with the instruction sheet

packed in the box with the thermostat.

Run the thermostat lead wires inside

the blower compartment and connect

to low voltage terminals as shown on

the wiring diagram. Never install the

thermostat on an outside wall or

where it will be influenced by drafts,

concealed hot or cold water pipes or

ducts, lighting fixtures, radiation from

fireplace, sun rays, lamps, televisions,

radios or air streams from registers.

Refer to instructions packed with the

thermostat for “heater” selection or

adjustment.

ACCESSORIES

FIELD-INSTALLED

OPTION ACCESSORIES

ELECTRONIC AIR CLEANER

Line voltage power can be supplied

from the screw terminal “EAC” and a

line voltage neutral screw terminal on

the control board. This will power the

electronic air cleaner whenever the

circulating air blower is in operation.

Expansion Tank:

Expansion tank for closed systems

air separator – TACO Model 49-075.

16

Page 17

FIGURE 11

W

G

R C

Y1

Y1

Y2

W

G

B

R

C

P3

FS

BLK

WHT

AIR HANDLER

Flow Sensor

(Packaged with Unit)

5 Wire

3 Wire Heating Only

Single Stage

Thermostat

24Volt FS / WH Connector

24 VoltTerminal Block

Control Box

PCB

Condensing Unit

Field115, 208 / 230Volt Wiring

Field 24 Volt Wiring

Factory 24 Volt Wiring

Factory115Volt Wiring

Junction Box

L1

L2

FIRST STAGE HEAT/COOL

AUX HEATING

FAN

24VAC HOT

24 VAC COMMON

SINGLE STAGE

AIR-HA NDLER

SINGLE SPEED

CONDENSING

UNIT

HEAT/COOL & COOL ONLY

THERMOSTATS

Y1

W

G

R

C

Y1

Y2

W

G

B

R

C

Y1

C

FIRST STAGE HEAT/COOL

AUX HEATING

FAN

RVS HEATING

24VAC HOT

24 VAC COMMON

HEAT PUMP THERMOSTATS

SINGLE STAGE

AIR-HANDLER

SINGLE STAGE

HEAT PUMP

Y1

W

G

B

R

C

Y1

W

G

B

R

C

Y1

B

R

C

Y2

FIELD WIRING DIAGRAM

FIGURE 12

THERMOSTAT WIRING DIAGRAMS

SINGLE STAGE AIR HANDLER W/SINGLE STAGE A/C

FIGURE 13

THERMOSTAT WIRING DIAGRAMS

SINGLE STAGE AIR HANDLER W/SINGLE STAGE HEAT PUMP*

*Requires Fossil Fuel Kit

Refer to Kit for further wiring instructions.

17

Page 18

System Low Voltage Wiring

Diagrams

NOTE: Local codes may require

thermostat wiring to be routed through

conduit or raceways. In such instances

splices can be made inside the Hydronic

Air Handler. All wiring must be NEC Class

I and must be separated from incoming

power leads.

Provide field-supplied disconnect for

maximum fuse or circuit breaker sizes, as

required by code.

Transformer is factory wired for 115V

operation.

The secondary circuit of the transformer

is protected by a 3-amp fuse mounted on

the printed circuit board.

FIGURE 14

HYDRONIC AIR-HANDLER CONTROL BOARD

Dip Switch Options:

Refer to the appropriate diagram for the

proper dip switch setting to be used with

the designed application (Figure 17).

THERMOSTAT INSTALLATION:

Thermostat should be mounted:

• approximately 5 ft. (1.5 m) from floor

TABLE 2

Wire Gauge Maximum Distance (feet)

18 gauge 60

16 gauge 100

14 gauge 160

12 gauge 250

• close to or in a frequently used

room, preferably on an inside,

partitioning wall

• on a section of wall without pipes

or duct work.

Thermostat should NOT be mounted:

• close to a window, on an outside

wall, or next to a door leading to

the outside.

NOTES:

1. For proper operation of an open loop system (refer to Figures 11 and 17), the jumper (shunt) position on PCB point “P7” should be in

the FS position.

2. When changing shunt position ensure that unit power is turned off.

18

Page 19

30 SECONDS OFF

DELAY (DEFAULT)

60 SECONDS OFF

DELAY

1

O

N

2 3 41

O

N

2 3 4

90 SECONDS OFF

DELAY

120 SECONDS OFF

DELAY

1

O

N

2 3 41

O

N

2 3 4

1

O

N

Key:

Switch is in the ON position.

Switch does not affect this setting.

1

O

N

Switch is in the OFF position.

TWO-STAGEA/C

CONFIGURATION

TWO

-STAGEHP

CONFIGURATION

1

O

N

2 3 41

O

N

2 3 4

• exposed to direct light and heat from

a lamp, sun, fireplace, or other heatradiating object which may cause a

false reading.

• close to or in direct airflow from

supply registers and return-air grilles

• In areas with poor air circulation,

such as behind a door or in an alcove

Refer to thermostat wiring diagram and

thermostat installation instructions for

further details.

FIGURE 15

DIP SWITCH POSITIONS

START-UP PROCEDURE

(HEATING ONLY):

The following conditions must be met

prior to unit start-up.

Debris from soldering and/or other

installation activities can cause

equipment failure. Ensure that all

associated lines and appurtenances

are free of debris.

Check to ensure that unit is secure.

Check that blower wheel rotates freely

within the scroll housing.

Check all wiring to ensure that

connections are tight.

Check all ductwork and pipe

connections to ensure proper seal.

Check to ensure that all packaging

wraps are removed from equipment.

Ensure that front access doors are

properly installed.

Check to ensure proper connection(s)

to the appropriate blower speed tap

(Heat /Cool – High and Low). Refer to

Dry Air Delivery Table and/or the

appropriate wiring diagram(s) in this

manual.

Perform all safety and start-up checks

for Tankless Water Heater as per

manufacturer’s instructions.

Having verified all preceding checks,

the Air Handler’s Start-Up Procedure is

as follows:

STEP 1: Purge and fill system; follow

appropriate purging procedure as laid

out in this manual in section titled

“Purging and Priming the System”.

STEP 2: Turn on power supply to air

handler. Caution: blower and/or

circulator may start to operate if

thermostat is on and a call is present.

STEP 3: Turn thermostat ON and

switch system to the heating mode.

The thermostat shall be set higher than

the actual room temperature; this will

cause the circulator to energize and

initiate the heating cycle. (If the pump

does not start, or the Air Handler is not

producing heat, refer to the

Troubleshooting Section, in this

manual).

STEP 4: Program room thermostat as

desired by homeowner.

START-UP PROCEDURE

(COOLING SYSTEM)

Refer to field-supplied evaporator coil

and outdoor unit manufacturer’s

Installation Instructions for system

hook-up, start-up instructions and

refrigerant-charging method details.

TROUBLESHOOTING BLOWER

AND/OR PUMP MOTOR AND

CONTROLS

If blower and/or pump motor does

not run:

Turn OFF power and check the

following:

1. Check that door switch is in the

CLOSED position.

2. Check 3 amp fuse on Printed

Circuit Board (PCB).

3. Check for 24 VAC between COM

and 24 VAC on IAC. If no voltage

is present, check transformer.

4. Check all connections for kinks

which could cause loose

connections. Ensure connections

are secure.

5. Verify that approximately 120

VAC is present across L1 and L2.

19

Page 20

SEQUENCE OF OPERATION

COOLING

Single Stage Cooling

• When the thermostat calls for cooling

(Y), there is a 1 second delay then

the control energizes the high blower

tap (COOL_HI).

• When the thermostat ends the call for

cooling (Y), there is a 30 second

cooling off delay then the control deenergizes the high blower tap

(COOL_HI).

• A call for cooling has priority over

continuous fan.

HEATING (HYDRONIC)

• On a call for heating the pump will

start.

• After a sixty second delay the control

will look at the FS jumper if this is

jumpered the control will go into

water heating mode and ignore the

temperature sensors.

• If the air supply temperature is

greater than 85°F the control will

energize the indoor blower. If the air

temperature is less than 85°F the

control will turn off the pump and go

into a 5 minute delay.

• If the supply temperature is adequate

the main blower will then be

energized and run for 30 seconds.

• After the 30 second delay the control

will monitor the supply temperature. If

this drops the control will turn off the

pump and go into a 5 minute delay. If

the temperature is greater than the

shut off temperature the control shall

remain in heating mode.

• There must be a minimum delta of

10°F to remain in the heating mode.

• When the W call ends the pump shall

de-energize the blower shall turn off

after a blower off delay.

The FS input shall be used to allow a

way to bypass the system to allow it to

run. If this is jumpered the control will

ignore the temperature and go into a

heating cycle.

HEATING (Heat pump is the

primary source of heat)

Single Stage Heating

• The thermostat calls for heating (Y,

R, and B), there is a 1 second delay

then the control energizes the high

blower tap (COOL_HI).

• When the thermostat ends the call for

cooling (Y), there is a 30 second

cooling off delay then the control deenergizes the high blower tap

(COOL_HI).

• When the thermostat calls for

emergency heat (W), the hydronic

heating mode is activated.

BLOWER TIME DELAY (HEATING

OR COOLING)

All models are equipped with a blower

time delay (BTD) in lieu of a blower relay

(BR) (see Figure 19). The blower will run

for 30 seconds after the blower time

delay (BTD) is de-energized.

DEFROST (DEFROST HEAT

CONTROL)

• For sequence of operation of defrost

controls, see outdoor heat pump

installation instructions.

• Supplemental heat during defrost can

be provided by connecting the purple

(PU) pigtail in the outdoor unit to the

W on the thermostat. This will

complete the circuit between R and W

through a set of contacts in the defrost

relay (DR) when the outdoor heat

pump is in defrost. This circuit, if

connected, will help prevent cold air

from being discharged from the indoor

unit during defrost.

• For most economical operation, if cold

air is not of concern during defrost, the

purple wire can be left disconnected.

Supplemental heat will then come on

only when called for by second stage

room thermostat.

EMERGENCY HEAT (HEATING

HEAT PUMP)

• If selector switch on thermostat is set

to the emergency heat positioin, the

heat pump will be locked out of the

heating circuit, and all heating will be

hydronic heat. Jumper should be

placed between W and E on the

thermostat sub-base so that the

electric heat control will transfer to the

first stage heat on the thermostat. This

will allow the indoor blower to cycle on

and off with the electric heat when the

fan switch is in the auto position.

ROOM THERMOSTAT

(ANTICIPATOR SETTING)

See instructions with outdoor section,

condensing unit or heat pump for

recommended room thermostats.

• The thermostat should be mounted

4 to 5 feet above the floor on an

inside wall of the living room or a

hallway that has a good air

circulation from the other rooms

being controlled by the thermostat.

It is essential that there be free air

circulation at the location of the

same average temperature as other

rooms being controlled. Movement

of air should not be obstructed by

furniture, doors, draperies, etc. The

thermostat should not be mounted

where it will be affected by drafts,

hot or cold water pipes or air ducts

in walls, radiant heat from

fireplaces, lamps, the sun, T.V. or

an outside wall. See instructions

sheet packaged with thermostat for

mounting and installation

instructions.

20

Page 21

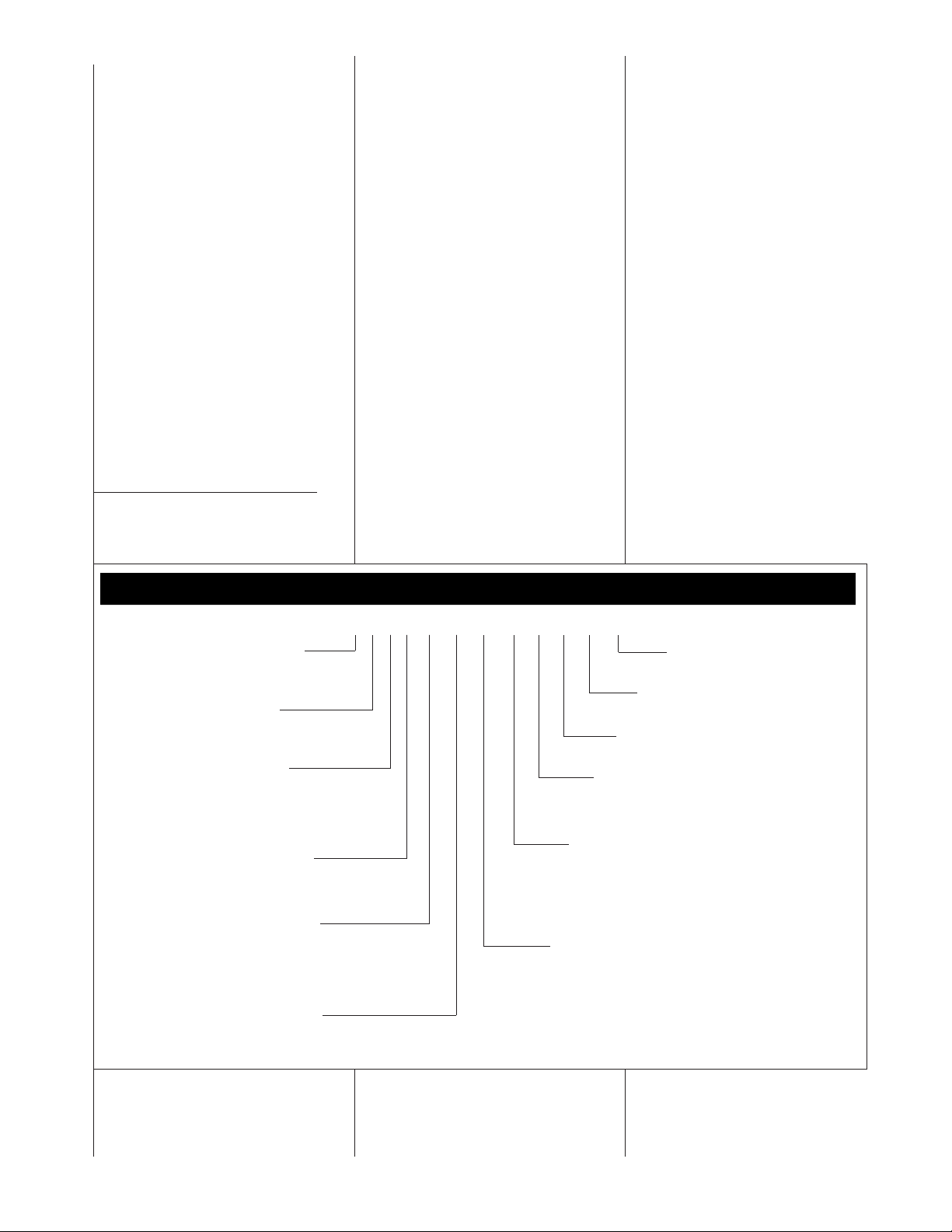

!"# $"!%& !" % $"!'& !"( $"!)& !"* $"#!& !"' $"#%& !"+ $"#'& !") $"#)& !", $"#-& !"- $"%%

./0 +,+ $(%*& +(* $%--& ',% $%)'& '(! $%'!&

12345/0 )%( $(*#& +,, $(%'& +#) $%-#& '+) $%+,& '#% $%*%& *'- $%#)&

123 )*, $('(& +-) $(%-& +*, $(!+& '-) $%,%& '*, $%'-& *-# $%(%& **' $%#!&

12346786 -%% $*('& ,,' $*#,& ,*- $*!#& ,## $(,(& ))' $(++& )(( $(*+& +-' $(%,& +** $(!*& +*' $(!*&

9786 -*! $***& -#) $*((& ,)' $*#(& ,(, $(-'& )-- $())& )+! $('-& )#+ $((,& +)( $(#,& +%, $%-+&

./0 +*+ $(!'& ',% $%)'& '#) $%**& *(+ $%!+&

12345/0 -,* $*+*& -() $**%& ,-* $*%%& ,*+ $(--& )-, $())& )') $(')& )#! $(('&

123 #!() $*,-& --' $*)!& -'( $*'!& -#! $*%-& ,+, $*#!& ,%# $(,)& ),# $(+-& )() $(*,&

12346786 ##+# $'*,& #!%! $*,#& #!), $'!-& #!*! $*-#& --- $*)#& -+( $*'*& -%! $*(*& ,)( $*#%& )'( $(''&

9786 #(-) $+'-& #('* $+(-& #(%# $+%(& #%)- $+!*& #%(, $',*& ##-( $'+(& ##') $'*+& #!+, $'!*& -'+ $*'#&

./0 ,#' $(,'& )+' $(+#& )#' $(()& ++' $(#*& +#* $%-!& '', $%+(& '#* $%*(&

12345/0 #%,* $+!+& #%(( $',%& ##), $''+& ##%- $'((& #!)! $'!'& --- $*)#& -%) $*()& ,)+ $*#(& ,%( $(,,&

123 #*#- $+)!& #()( $+*,& #(%( $+%*& #%,% $+!'& #%%, $',!& ##,! $'')& ##%- $'((& #!'* $*-)& -,# $*+(&

12346786 #*,' $)!#& #*'% $+,'& #*#, $++-& #(,+ $+'*& #(*+ $+('& #(#( $+%!& #%)% $+!!& #%%% $'))& ##-' $'+*&

9786 #)*' $,%*& #)%% $,#(& #+-% $)--& #++* $),'& #+(! $)+-& #'-- $)''& #'++ $)(-& #'!* $)#!& #('+ $+*!&

./0 #!** $*-(& -'( $*'!& ,+) $*!-& )+) $(+%& ++) $(#'& ')- $%)(& '!# $%(+&

12345/0 #!#! $*))& -)! $*',& -(+ $**%& -!% $*%+& ,+) $*!-& ,(% $(-(& )-, $())& )++ $(+%& )%' $(*%&

123 #%*) $',-& ##,( $'',& ##%# $'%-& #!+* $'!%& --- $*)#& -(( $**!& ,+* $*!,& )-) $()+& )(' $(*)&

12346786 #,(* $,++& #)+, $,(*& #+-) $,!#& #+(- $))*& #',' $)*,& #'(- $)%+& #*), $+-,& #*%) $+)(& #()! $+*)&

9786 %!!, $-*,& #-'+ $-%(& #-!' $,--& #,** $,)!& #,!% $,'!& #)'! $,%+& #+-, $,!#& #+'' $),#& #+!* $)')&

:5/02;<=2;>/;?@A2<B2@CD;23<07E6/DE<>75E2;<7?<=5@A2

4

4

4

FG#H#!I+!%*JII

##<K<##<<<<<<<<<<<<

$%)-<K<%)-&

(L*<<$''-&

4

4

FG#H!,I*,%#JII

#!<K<#!<<<<<<<<<<<<<

$%'*<K<%'*&

(L*<<$''-&

4

4

FG#H!+I(+#)JII

#!<K<,<<<<<<<<<<

$%'*<K<%!(&

#L%<<$()(&

444

4

4

444

4

4

4

4

4

FG#H!*I%*#*JII

#!<K<+<<<<<<<<<<<<

$%'*<K<#'%&

#L(<$%*,&

4

4

!"#$%&'()*'$)!*&#+,$)*'$)-+%.)/,$-%$0*&(,)1),(!%)2,(!)0%#,+3

1/325

:5/02;<M7N2<7?<<

$BB&

1/E/;<9O<<

$G@EE&

:5/02;<M=223

(-0)4+567)*89)#:;8<:9=)),>?:9@A;)3?A?8B)/9:66C9:)'@BD:6).A?:9)(E;CF@)4G/A7

TABLE 3

DIRECT DRIVE

INSTRUCTIONS FOR

CHANGING BLOWER

SPEED

WARNING

!

DISCONNECT THE ELECTRICAL

SUPPLY TO THE AIR HANDLER

BEFORE ATTEMPTING TO

CHANGE THE BLOWER SPEED.

FAILURE TO DO SO CAN CAUSE

ELECTRICAL SHOCK RESULTING

IN PERSONAL INJURY OR DEATH.

The blower motor must be wired for

blower speeds required for normal

operation.

If additional blower speed taps are

available (leads connected to “M1” and

“M2” on the electronic control), speeds

may be changed if necessary to fit

requirements of the particular

installation. Reconnect the unused

motor leads to “M1” or “M2.” Check

motor lead color for speed designation.

Heating speeds should not be

reduced where it could cause the air

handler air temperature rise to

exceed the maximum outlet air

temperature specified for the unit.

IMPORTANT: Always check air

temperature rise after changing the

heating speed for any reason.

21

Page 22

MAINTENANCE

JACKET ASSEMBLY

SOLID BOTTOM

SCREWS (2) REQ’D

REMOVE FROM

SHIPPED LOCATION

RELOCATE FOR SIDE

RETURN

WARNING

!

THESE INSTRUCTIONS ARE

INTENDED AS AN AID TO

QUALIFIED SERVICE

PERSONNEL FOR PROPER

INSTALLATION, ADJUSTMENT

AND OPERATION OF THIS UNIT.

READ THESE INSTRUCTIONS

THOROUGHLY BEFORE

ATTEMPTING INSTALLATION

OR OPERATION. FAILURE TO

FOLLOW THESE INSTRUCTIONS

MAY RESULT IN IMPROPER

INSTALLATION, ADJUSTMENT,

SERVICE OR MAINTENANCE,

POSSIBLY RESULTING IN FIRE,

ELECTRICAL SHOCK, CARBON

MONOXIDE POISONING,

EXPLOSION, PROPERTY

DAMAGE, PERSONAL INJURY

OR DEATH.

DISCONNECT MAIN ELECTRICAL

POWER TO THE UNIT BEFORE

ATTEMPTING ANY MAINTENANCE. FAILURE TO DO SO CAN

CAUSE ELECTRICAL SHOCK

RESULTING IN PERSONAL

INJURY OR DEATH.

CAUTION

!

DO NOT OPERATE THE SYSTEM

FOR EXTENDED PERIODS

WITHOUT FILTERS.

A PORTION OF THE DUST

ENTRAINED IN THE AIR MAY

TEMPORARILY LODGE IN THE AIR

DUCT RUNS AND AT THE SUPPLY

REGISTERS. THIS RESIDUE CAN

SOIL CEILINGS, WALLS, DRAPES,

CARPETS AND OTHER

HOUSEHOLD ARTICLES.

FIGURE 16

22

NOTE: DISCARD BLOCK OFF PLATE

IF SIDE RETURN IS NOT REQUIRED.

ST-A1242-06-X0

Page 23

FIGURE 17

CUT OUT USING

EMBOSSED ANGLES

AS A GUIDE FOR THE

PROPER SIZE.

JACKET

FILTER LOCATIONS

LUBRICATION

IMPORTANT: DO NOT attempt to

lubricate the bearings on the blower

motor or the induced draft blower

motor. Addition of lubricants can

reduce the motor life and void the

warranty.

The blower motor and induced draft

blower motor are permanently

lubricated by the manufacturer and do

not require further attention.

The blower motor and induced draft

blower motor must be cleaned

periodically by a qualified installer,

service agency, or the gas supplier to

prevent the possibility of overheating

due to an accumulation of dust and

dirt on the windings or on the motor

exterior. And, as suggested

elsewhere in these instructions, the

air filters should be kept clean. Dirty

filters can restrict airflow. The motor

depends upon sufficient air flowing

across and through it to keep from

overheating.

SYSTEM OPERATION

INFORMATION

Advise The Customer

1. Keep the air filters clean. The

heating system will operate

better, more efficiently and more

economically.

ST-A1242-04-X0

2. Arrange the furniture and drapes

so that the supply air registers

and the return air grilles are

unobstructed.

3. Close doors and windows. This

will reduce the heating load on

the system.

4. Avoid excessive use of kitchen

exhaust fans.

5. Do not permit the heat generated

by television, lamps or radios to

influence the thermostat

operation.

6. Except for the mounting platform,

keep all combustible articles 3

feet from the air handler and vent

system.

7. IMPORTANT: Replace all blower

doors and compartment covers

after servicing the air handler. Do

not operate the unit without all

panels and doors securely in

place.

8. Explain proper operation of the

system with constant air

circulation.

ANNUAL INSPECTION

• The air handler should operate for

many years without excessive scale

build-up in the flue passageways.

However, it is recommended that a

qualified installer, service agency, or

the gas supplier annually inspect

ST-A1242-07-X0

the flue passageways, the vent

system and the main burners for

continued safe operation. Pay

particular attention to deterioration

from corrosion or other sources.

• IMPORTANT: It is recommended

that at the beginning and at

approximately half way through the

heating season, a visual inspection

be made of the main burner flames

for the desired flame appearance by

a qualified installer, service agency

or the gas supplier. If the flames are

distorted and/or there is evidence of

back pressure, check the vent and

inlet air system for blockage. If there

is carbon and scale in the heat

exchanger tubes, the heat

exchanger assembly should be

replaced.

REPLACEMENT PARTS

See sheet enclosed with air handler

for replacement part information.

TROUBLESHOOTING

Refer to Figure 18 for determining

cause of unit problems.

WIRING DIAGRAMS

Figure 19 are complete wiring

diagrams for the air handler and

power sources.

23

Page 24

FIGURE 18

ydemeResuaC elbissoPmotpmyS

lortnoc ta egatlov tcerroc rof kcehCnoitcennoc lacirtcele ensool ro ffo rewoP

lortnoc ta egatlov tcerroc rof kcehChgih oot tes - noitarbilac fo tuo tatsomrehT

Call for domesc hot water - air handler disabled unl call ends. Unit

is operang as designed.

Unit is operang as designed

rekaerb teser / sesuf ecalpeRrekaerb deppirt / sesuf nwolB

remrofsnart ecalperg–niriw kcehCevitcefed remrofsnarT

daol etaluclaceRretaeh retaw ro reldnah ria dezis ylreporpmI

gnittes pat deeps rotom kcehCwolf ria roodni reporpmI

Call for domesc hot water–air handler disabled unl call ends. Unit

is operang as designed.

Unit is operang as designed

Check line voltage at pump

Check wires and connectors

Check pump capacitor

Call for domesc hot water - air handler disabled unl call ends. Unit

is operang as designed.

Unit is operang as designed

Check line voltage at blower motor

Check wires and connectors

Check blower motor capacitor

General Trouble Shoong Chart

Power off or loosen electrical connecon

Pump does not run

Power off or loosen electrical connecon

Blower does not run

Warning: Disconnect all power to unit before servicing. Failure to shut off power can cause electrical shock resulng in personal injury or death.

Unit will not run

Insufficient heang

Water does not flow

Water lines are air locked

Purge air from lines

GENERAL TROUBLESHOOTING CHART

General Troubleshooting Chart

24

Page 25

FIGURE 19

NOTES

COMPONENT CODES

WIRE COLOR CODE

BK......BLACK

BR......BROWN

BL.......BLUE

G........GREEN

GY......GRAY

O........ORANGE

PR......PURPLE

R........RED

W.......WHITE

Y........YELLOW

WIRING INFORMATION

WARNING

-CABINET MUST BE PERMANENTLY GROUNDED

AND CONFORM TO I.E.C., N.E.C., C.E.C.,

NATIONAL WIRING REGULATIONS, AND LOCAL

CODES AS APPLICABLE.

REPLACEMENT WIRE

-MUST BE THE SAME SIZE AND TYPE

OF INSULATION AS ORIGINAL (105C. MIN.)

-FIELD INSTALLED

-FACTORY STANDARD

LOW VOLTAGE

-FIELD INSTALLED

-FACTORY OPTION

-FACTORY STANDARD

LINE VOLTAGE

ORIGINAL RELEASE

NO.:

ELECTRICAL WIRING DIAGRAM

MODELED

BY:

CHECKED:APPROVED:

REV:PART NO.:

DATE:

90-103346-05

6-26-15

H-1025S012

JHB

00

ELECTRICAL WIRING DIAGRAM – ECO TECH™ MODELS

25

Page 26

262728

Page 27

Page 28

CM 0915

Loading...

Loading...