Page 1

FORM NO. P11-759 REV. 2

Supersedes Form No. P11-759 Rev. 1

RPPB- SERIES

Seven Models

14 SEER with efficiencies

ranging up to 14.40 SEER in

certain matched systems.

Nominal Sizes 1

1

/2 to 5 Tons

[5.28 kW] to [17.58 kW]

The Rheem®RPPB- Classic Series®Heat Pump Outdoor

units can provide year-round heating and cooling comfort

for residential, multi-family and light commercial applications. They are designed to operate with Rheem indoor

units with cooling and heating capacities certified under

the ARI Certification program.

The Rheem RBHK- Air Handler equipped with auxiliary

heating elements for supplementary heat was designed

especially for use with the RPPB- Heat Pump. Together

they provide systems capable of delivering a maximum

HSPF (Heating Seasonal Performance Factor) of 8.90 in the

heating mode or a maximum standard S.E.E.R. (Seasonal

Energy Efficiency Ratio) of 14.40 in the cooling mode.

The following additional features, plus its energy-saving

characteristics, make the RPPB- Heat Pump outdoor unit

an excellent choice for new construction or upgrading your

present system.

■ Attractive, louvered wrap around jacket protects coil from

weather extremes and yard hazards. Top grille is steel

reinforced for extra strength. Cabinet is powder painted

for all weather protection.

■ Four sided outdoor coil design allows compressor opera-

tion with access panel removed.

■ Air is discharged upward away from bushes and shrubs.

The discharge pattern of the top grille provides minimum

air restriction, resulting in quiet fan operation.

■ Exclusive Combination Grille/Motor Mount secures the

fan motor to the underside of the discharge grille. The

grille protects the motor windings and bearings from rain

and snow.

■ All controls are accessible by removing one service

panel. Removable top grille provides access to the outdoor fan motor and outdoor coil.

■ Compressor compartment offers additional protection

from the elements and reduces operating noise.

■ Single speed, 8-pole fan motor is designed for low

speed, quieter, energy-saving operation.

■ Non-cycling reversing valve.

■ All models meet or exceed a 1000-hour salt spray test

per ASTM B117 Standard Practice for Operating Salt

Spray Testing Apparatus.

HEAT PUMPS

*“CERTIFIED UNDER THE

A.R.I. CERTIFICATION

PROGRAM—A.R.I. STANDARD 240-81”

ENER UIDE

Seasonal Energy Efficiency Ratio - SEER

THIS MODEL

14.00

10.0

USES LESS ENERGY

17.0

Page 2

2 Rheem Manufacturing Company

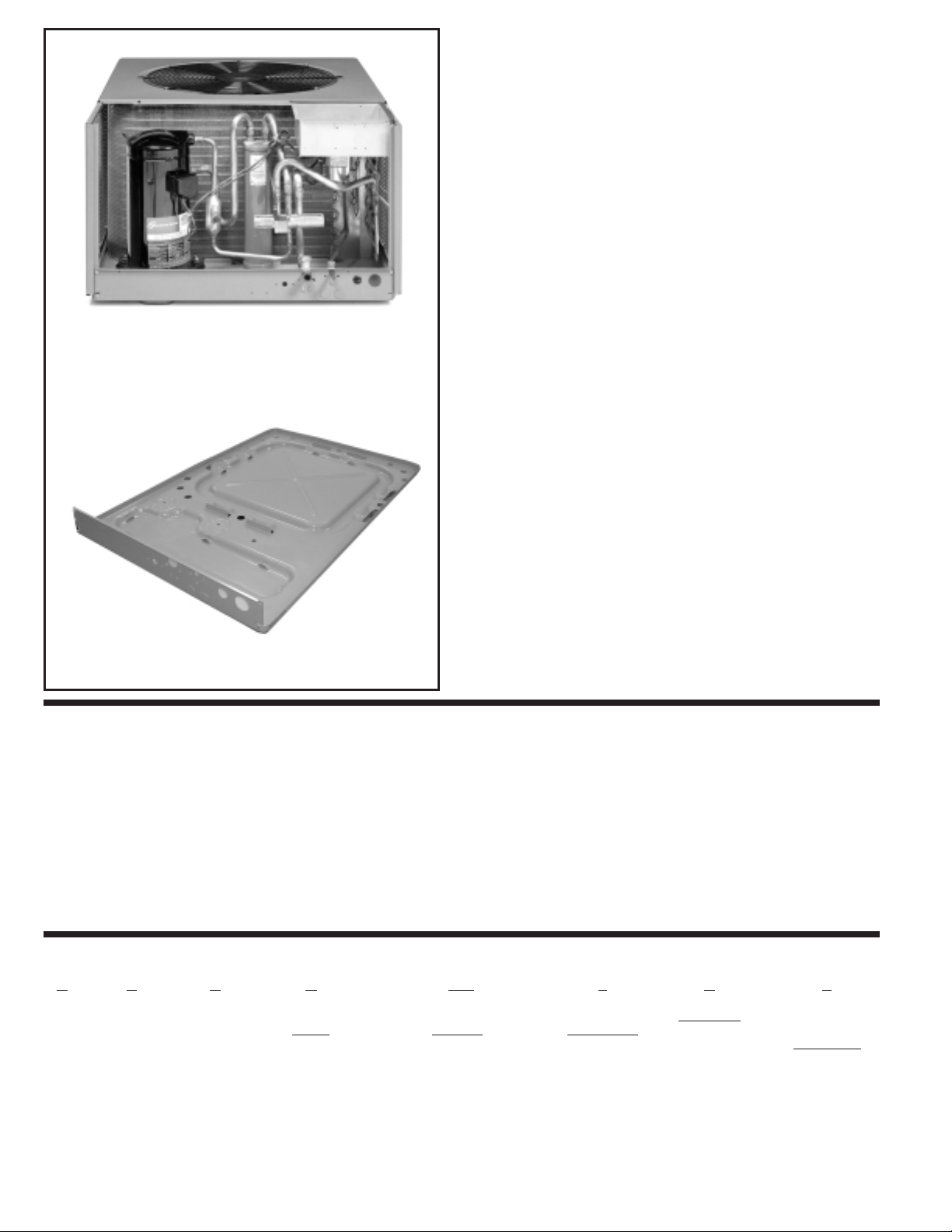

Drawn Painted Base Pan.

Accessories

■

Low Ambient Control—Allows low temperature operation in the

cooling cycle down to 0°F [-17.8°C] outdoor temperature. It is

recommended that this control be installed in units to be operated

for cooling at outdoor ambient temperatures under 65°F [18°C].

(Model No. RXPZ-C01)

■

Outdoor Thermostats—

RXPT-A01—One outdoor thermostat in box.

RXPT-A02—One outdoor thermostat for mounting in box for use

with RXPT-A01 or A03.

RXPT-A03—One outdoor thermostat with emergency Heat Relay

wired and mounted in box.

RXPT-A04—Tne outdoor thermostats with emergency Heat Relay

wired and mounted in box.

■

Heat Pump Monitor—Indicates inefficient operation or malfunction of

heat pump. (Model No. RXPM-B01)

■

Thermostats and Subbases—Available through the PROSTOCK

®

Department.

■

Compressor Time Delay Control—Compressor will remain off for

five minutes after power or thermostat interruption, allowing system

pressures to equalize. Starting during high pressure conditions can

result in shortened compressor life. (Model No. RXMD-B01)

■

Blower Time Delay Control—RXMD-C02.

■

Fossil Fuel Kits—RXPF-01

RXPF-02

Engineering Features

RPPB- Series Heat Pump Outdoor Unit

1. Scroll compressor is hermetically sealed and incorporates internal

high temperature motor overload protection, and durable insulation

on the motor windings. It is externally mounted on rubber grommets

to reduce vibration and noise.

2. Copper Tube/Aluminum Fin Coils—Both indoor and outdoor coils.

3. Strong, Attractive Cabinet—Constructed of powder painted steel.

Louvered design protects the coil from damage.

4. Internal Check Valve—Provides for more quiet refrigerant metering.

5. Manual Reset High Pressure Control—Deactivates system if

abnormally high pressure occurs.

6. Drawn, Painted Base Pan—For extra corrosion resistance and

sound reduction.

7. Hard Start Components—Offer additional starting torque to cover a

wide range of voltage and pressure variations.

8. Non-Cycling Reversing Valve—Eliminates discharge noises on

each heating cycle.

9. Hot Gas Muffler—Reduces noise in heating cycle.

10. Suction Line Accumulator—Provides protection for the

compressor.

11. Bi-Directional Filter Drier—Provided on all models.

12. Se rvice valves are standard on all models.

13. Refrigerant Metering—TX valves accurately meter refrigerant into

indoor and outdoor coils.

14. Demand Defrost—Provides complete defrost when defrost is

required.

Convenience Features

■

The scroll compressor models, additionally have a

10 year compressor warranty as standard.

■

All refrigerant connections are on the exterior of the unit, located

close to the ground for neat appearing installations.

■

Coil design permits compressor operation with the access panel

removed.

■

Control box is fully accessible in the upper part of the cabinet, just

under the access panel.

■

Power and control wiring are kept separate.

■

Every unit is factory charged and tested.

Model Number Identification

R P P B —024

COOLING

CAPACITY

018 = 18,000 BTU/HR [5.28 kW]

024 = 24,000 BTU/HR [7.03 kW]

030 = 30,000 BTU/HR [8.79 kW]

036 = 36,000 BTU/HR [10.55 kW]

042 = 42,000 BTU/HR [12.31 kW]

048 = 48,000 BTU/HR [14.07 kW]

049 = 48,000 BTU/HR [14.07 kW]

060 = 60,000 BTU/HR [17.58 kW]

061 = 60,000 BTU/HR [17.58 kW]

J A Z

RHEEM REMOTE

HEAT PUMP

HIGH

EFFICIENCY

(STANDARD)

DESIGN

SERIES

B = SECOND DESIGN

ELECTRICAL

DESIGNATION

J = 208/230V-1-60

VARIATIONS

A = STANDARD

COOLING

CONNECTION

FITTING

Z = SWEAT W/SCROLL

All controls and compressor are accessible

for servicing by removal of the service panel.

[ ] Designates Metric Conversions

Page 3

Rheem Manufacturing Company 3

COPELAND®SCROLL

®

COMPRESSOR

The Copeland scroll compressor is the key to efficiency for this

Rheem model. It’s the latest in high-efficiency compressor technology.

The advanced scroll compressor offers low noise and vibration

characteristics and features tolerance to liquid refrigerant and system

contamination. The Copeland Scroll also has low start torque,

eliminating start problems in the field. And its unique design enables

the RPPB- heat pump to perform efficiently, quietly and reliably.

For all season home comfort, performance and energy conservation, choose a Rheem RPPB- Series Heat Pump and RBHK- Series

Air Handler.

More than a reverse cycle air conditioner, it’s a specially designed combination Winter/Summer comfort system using a single indoor coil

for heating and cooling.

To choose an RBHK- Air Handler designed for use with the RPPB- Heat Pump, refer to the Performance Data Tables and/or the air

handler specification sheet.

Rheem Heat Pump System

Page 4

4 Rheem Manufacturing Company

Performance Data ARI Standard Conditions—Single Phase (Scroll Compressor)

Note: Only these combinations of indoor/outdoor units are approved and any other combinations should not be used.

➀ Highest sales volume tested combination required by DOE test procedures.

[ ] Designates Metric Conversions

ARI Cooling Performance ARI Heating Performance (70°F [21°C] Indoor)

95°F [35°C] DB Outdoor Air

Net

Sens.

BTU/H

[kW]

12,750

[3.7]

12,600

[3.7]

13,150

[3.9]

13,450

[3.9]

13,450

[3.9]

13,500

[4.0]

13,100

[3.8]

13,100

[3.8]

13,450

[3.9]

13,500

[4.0]

16,100

[4.7]

15,700

[4.6]

16,700

[4.9]

16,900

[5.0]

16,950

[5.0]

17,000

[5.0]

16,950

[5.0]

16,400

[4.8]

16,400

[4.8]

16,800

[4.9]

17,000

[5.0]

21,250

[6.2]

19,600

[5.7]

22,050

[6.5]

21,700

[6.4]

21,800

[6.4]

21,850

[6.4]

21,800

[6.4]

21,200

[6.2]

Net

Latent

BTU/H

[kW]

5,750

[1.7]

5,700

[1.7]

5,750

[1.7]

5,950

[1.7]

5,950

[1.7]

5,900

[1.7]

5,700

[1.7]

5,700

[1.7]

5,850

[1.7]

5,900

[1.7]

6,700

[2.0]

6,500

[1.9]

6,700

[2.0]

6,700

[2.0]

6,850

[2.0]

6,800

[2.0]

6,850

[2.0]

6,600

[1.9]

6,600

[1.9]

6,800

[2.0]

6,800

[2.0]

6,950

[2.0]

7,000

[2.1]

6,950

[2.0]

6,900

[2.0]

6,800

[2.0]

6,950

[2.0]

7,000

[2.1]

6,800

[2.0]

EER

SEER

10.65 12.10

10.65 12.20

12.15 14.00

12.45 14.10

12.50 14.10

12.65 14.10

12.10 13.90

12.10 13.95

12.15 14.00

12.25 14.10

10.75 12.40

10.75 12.50

12.10 14.15

12.00 14.00

12.10 14.15

12.25 14.35

12.15 14.25

12.30 14.35

12.30 14.35

12.15 14.20

12.30 14.35

10.80 12.00

10.80 12.10

12.10 14.00

11.60 13.65

11.85 14.00

11.95 14.00

11.90 14.00

12.05 13.90

Indoor

CFM

[L/s]

600

[283]

600

[283]

600

[283]

600

[283]

600

[283]

600

[283]

600

[283]

600

[283]

600

[283]

600

[283]

800

[378]

800

[378]

800

[378]

800

[378]

800

[378]

800

[378]

800

[378]

800

[378]

800

[378]

800

[378]

800

[378]

975

[460]

995

[470]

1,000

[472]

1,000

[472]

1,000

[472]

1,000

[472]

1,025

[484]

1,000

[472]

Outdoor Air

47°F [8.5°C] DB/

43°F [6°C] WB

DOE High Temp.

BTU/H

[kW]

18,700

[5.5]

18,700

[5.5]

18,100

[5.3]

18,100

[5.3]

18,100

[5.3]

18,100

[5.3]

18,200

[5.3]

18,200

[5.3]

18,100

[5.3]

18,100

[5.3]

23,200

[6.8]

23,200

[6.8]

22,600

[6.6]

22,600

[6.6]

22,600

[6.6]

22,600

[6.6]

22,600

[6.6]

22,400

[6.6]

22,400

[6.6]

22,600

[6.6]

22,400

[6.6]

28,400

[8.3]

28,400

[8.3]

27,800

[8.1]

28,000

[8.2]

28,000

[8.2]

28,000

[8.2]

28,000

[8.2]

28,000

[8.2]

COP

3.20

3.20

3.44

3.46

3.47

3.49

3.44

3.44

3.44

3.46

3.24

3.24

3.46

3.40

3.42

3.45

3.43

3.48

3.48

3.46

3.48

3.30

3.30

3.46

3.42

3.45

3.47

3.46

3.46

Outdoor Air

17°F [–8.5°C] DB/

15°F [–9.5°C] WB

DOE Low Temp.

BTU/H

[kW]

12,100

[3.5]

12,100

[3.5]

11,500

[3.4]

11,400

[3.3]

11,400

[3.3]

11,300

[3.3]

11,500

[3.4]

11,500

[3.4]

11,500

[3.4]

11,500

[3.4]

14,600

[4.3]

14,600

[4.3]

14,000

[4.1]

14,100

[4.1]

14,100

[4.1]

14,000

[4.1]

14,000

[4.1]

13,900

[4.1]

13,900

[4.1]

14,000

[4.1]

13,900

[4.1]

17,600

[5.2]

17,600

[5.2]

17,300

[5.1]

17,600

[5.2]

17,500

[5.1]

17,400

[5.1]

17,400

[5.1]

17,400

[5.1]

COP

2.30 8.10

2.30 8.20

2.46 8.55

2.44 8.55

2.44 8.55

2.45 8.55

2.44 8.55

2.44 8.55

2.46 8.55

2.46 8.55

2.18 7.55

2.18 7.65

2.32 7.90

2.33 8.00

2.34 8.00

2.36 8.00

2.35 8.00

2.32 7.95

2.32 7.95

2.32 7.95

2.34 7.95

2.26 8.10

2.26 8.40

2.36 8.50

2.32 8.10

2.34 8.40

2.36 8.50

2.35 8.50

2.36 8.50

Outdoor

Unit

RPPB-

018JAZ

024JAZ

030JAZ

Model Numbers

Indoor

Coil and/or

Air Handler

RCHJ-24A1

RCHJ-24A1+RXMD-C02

RCHJ-24A1 (RBHK-17) ➀

RCHJ-24A1 (RGFD-06?MCK?)

RCHJ-24A1 (RGFD-07?MCK?)

RCHJ-24A1 (RGGD-06?MCK?)

RCHJ-24A1 (RGLL-05?BMK?)

RCHJ-24A1 (RGLL-07?BRK?)

RCHJ-24A1 (RGPL-05?BMK?)

RCHJ-24A1 (RGPL-07?BRK?)

RCHJ-24A2

RCHJ-24A2+RXMD-C02

RCHJ-24A2 (RBHK-17) ➀

RCHJ-24A2 (RGFD-06?MCK?)

RCHJ-24A2 (RGFD-07?MCK?)

RCHJ-24A2 (RGGD-06?MCK?)

RCHJ-24A2 (RGGD-07?MCK?)

RCHJ-24A2 (RGLL-05?BMK?)

RCHJ-24A2 (RGLL-07?BRK?)

RCHJ-24A2 (RGPL-05?BMK?)

RCHJ-24A2 (RGPL-07?BRK?)

RCHJ-36A1

RCHJ-36A1+RXMD-C02

RCHJ-36A1 (RBHK-21) ➀

RCHJ-36A1 (RGFD-06?MCK?)

RCHJ-36A1 (RGFD-07?MCK?)

RCHJ-36A1 (RGGD-06?MCK?)

RCHJ-36A1 (RGGD-07?MCK?)

RCHJ-36A1 (RGLL-05?BMK?)

Capacity

80°F [26.5°C] DB/67°F [19.5°C] WB Indoor Air

Total

BTU/H

[kW]

18,300

[5.4]

18,300

[5.4]

18,800

[5.5]

18,800

[5.5]

18,800

[5.5]

18,800

[5.5]

18,800

[5.5]

18,800

[5.5]

18,800

[5.5]

18,800

[5.5]

22,200

[6.5]

22,200

[6.5]

23,000

[6.7]

23,000

[6.7]

23,200

[6.8]

23,200

[6.8]

23,200

[6.8]

23,000

[6.7]

23,000

[6.7]

23,000

[6.7]

23,000

[6.7]

26,600

[7.8]

26,600

[7.8]

28,000

[8.2]

28,000

[8.2]

28,000

[8.2]

28,000

[8.2]

28,000

[8.2]

28,000

[8.2]

DOE

Region

IV

HSPF

Page 5

Rheem Manufacturing Company 5

Performance Data ARI Standard Conditions—Single Phase (Scroll Compressor) (cont.)

Note: Only these combinations of indoor/outdoor units are approved and any other combinations should not be used.

➀ Highest sales volume tested combination required by DOE test procedures.

[ ] Designates Metric Conversions

ARI Cooling Performance

95°F [35°C] DB Outdoor Air

Net

Sens.

BTU/H

[kW]

21,200

[6.2]

20,800

[6.1]

21,800

[6.4]

21,900

[6.4]

22,050

[6.5]

24,600

[7.2]

23,800

[7.0]

25,200

[7.4]

24,850

[7.3]

24,800

[7.3]

25,050

[7.3]

25,200

[7.4]

25,250

[7.4]

24,900

[7.3]

24,850

[7.3]

25,250

[7.4]

25,250

[7.4]

25,300

[7.4]

24,600

[7.2]

24,600

[7.2]

24,200

[7.1]

24,600

[7.2]

24,600

[7.2]

24,900

[7.3]

25,100

[7.4]

25,350

[7.4]

25,250

[7.4]

25,450

[7.5]

Outdoor

Unit

RPPB-

030JAZ

036JAZ

Model Numbers

Indoor

Coil and/or

Air Handler

RCHJ-36A1 (RGLL-07?BRK?)

RCHJ-36A1 (RGLL-07?BRQ?)

RCHJ-36A1 (RGPL-05?BMK?)

RCHJ-36A1 (RGPL-07?BRK?)

RCHJ-36A1 (RGPL-07?BRQ?)

RCHJ-36A2

RCHJ-36A2+RXMD-C02

RCHJ-36A2 (RBHK-21) ➀

RCHJ-36A2 (RGFD-06?MCK?)

RCHJ-36A2 (RGFD-07?MCK?)

RCHJ-36A2 (RGFD-09?ZCM?)

RCHJ-36A2 (RGFD-10?ZCM?)

RCHJ-36A2 (RGFD-12?ZCM?)

RCHJ-36A2 (RGGD-06?MCK?)

RCHJ-36A2 (RGGD-07?MCK?)

RCHJ-36A2 (RGGD-09?ZCM?)

RCHJ-36A2 (RGGD-10?ZCM?)

RCHJ-36A2 (RGGD-12?RCM?)

RCHJ-36A2 (RGLL-05?BMK?)

RCHJ-36A2 (RGLL-07?BRK?)

RCHJ-36A2 (RGLL-07?BRQ?)

RCHJ-36A2 (RGLL-10?BRM?)

RCHJ-36A2 (RGLL-12?ARM?)

RCHJ-36A2 (RGPL-05?BMK?)

RCHJ-36A2 (RGPL-07?BRK?)

RCHJ-36A2 (RGPL-07?BRQ?)

RCHJ-36A2 (RGPL-10?BRM?)

RCHJ-36A2 (RGPL-12?ARM?)

Total

Capacity

BTU/H

[kW]

28,000

[8.2]

27,600

[8.1]

27,800

[8.1]

28,000

[8.2]

27,800

[8.1]

33,800

[9.9]

33,800

[9.9]

34,600

[10.1]

34,800

[10.2]

34,600

[10.1]

35,000

[10.3]

35,200

[10.3]

35,200

[10.3]

34,800

[10.2]

34,800

[10.2]

35,200

[10.3]

35,200

[10.3]

35,400

[10.4]

34,400

[10.1]

34,400

[10.1]

34,000

[10.0]

34,400

[10.1]

34,400

[10.1]

34,400

[10.1]

34,600

[10.1]

34,200

[10.0]

34,400

[10.1]

34,600

[10.1]

80°F [26.5°C] DB/67°F [19.5°C] WB Indoor Air

Net

Latent

BTU/H

[kW]

6,800

[2.0]

6,800

[2.0]

6,800

[2.0]

6,900

[2.0]

6,950

[2.0]

10,000

[2.9]

10,000

[2.9]

10,000

[2.9]

9,950

[2.9]

9,800

[2.9]

9,950

[2.9]

10,000

[2.9]

9,950

[2.9]

9,900

[2.9]

9,950

[2.9]

9,950

[2.9]

9,950

[2.9]

10,100

[3.0]

9,800

[2.9]

9,800

[2.9]

9,800

[2.9]

9,800

[2.9]

9,800

[2.9]

9,900

[2.9]

9,900

[2.9]

10,050

[2.9]

9,950

[2.9]

10,150

[3.0]

EER

SEER

12.10 13.95

11.55 13.25

11.90 14.00

12.10 14.10

11.90 14.40

10.90 12.00

10.90 12.10

12.00 14.00

11.20

13.00

11.15 12.95

12.00 14.00

11.90 13.90

12.00 14.00

11.35 13.20

11.25 13.05

12.05 14.10

12.05 14.10

12.15 14.20

11.90 13.95

11.90 13.95

11.30 13.15

11.90 13.90

11.80 13.75

11.30 13.10

11.75 13.70

11.65 14.00

11.70 14.00

12.05 14.10

Indoor

CFM

[L/s]

1,000

[472]

1,000

[472]

1,000

[472]

1,000

[472]

1,000

[472]

1,200

[566]

1,200

[566]

1,200

[566]

1,175

[554]

1,200

[566]

1,150

[543]

1,175

[554]

1,225

[578]

1,225

[578]

1,225

[578]

1,175

[554]

1,175

[554]

1,225

[578]

1,200

[566]

1,200

[566]

1,200

[566]

1,200

[566]

1,200

[566]

1,200

[566]

1,200

[566]

1,200

[566]

1,200

[566]

1,200

[566]

ARI Heating Performance (70°F [21°C] Indoor)

Outdoor Air

47°F [8.5°C] DB/

43°F [6°C] WB

DOE High Temp.

BTU/H

[kW]

28,000

[8.2]

28,200

[8.3]

28,000

[8.2]

28,000

[8.2]

28,000

[8.2]

35,400

[10.4]

35,400

[10.4]

35,800

[10.5]

36,000

[10.5]

36,000

[10.5]

36,000

[10.5]

36,000

[10.5]

36,000

[10.5]

36,000

[10.5]

36,000

[10.5]

36,000

[10.5]

36,000

[10.5]

36,000

[10.5]

35,800

[10.5]

35,800

[10.5]

36,400

[10.7]

36,000

[10.5]

36,000

[10.5]

36,000

[10.5]

35,800

[10.5]

36,000

[10.5]

36,000

[10.5]

35,800

[10.5]

COP

3.46

3.38

3.42

3.46

3.44

3.40

3.40

3.58

3.47

3.46

3.62

3.59

3.60

3.50

3.48

3.61

3.61

3.63

3.58

3.58

3.48

3.58

3.56

3.48

3.56

3.54

3.54

3.60

Outdoor Air

17°F [–8.5°C] DB/

15°F [–9.5°C] WB

DOE Low Temp.

BTU/H

[kW]

17,300

[5.1]

17,600

[5.2]

17,500

[5.1]

17,300

[5.1]

17,400

[5.1]

22,200

[6.5]

22,200

[6.5]

22,200

[6.5]

22,800

[6.7]

22,800

[6.7]

22,200

[6.5]

22,200

[6.5]

22,200

[6.5]

22,600

[6.6]

22,600

[6.6]

22,200

[6.5]

22,200

[6.5]

22,200

[6.5]

22,200

[6.5]

22,200

[6.5]

22,600

[6.6]

22,200

[6.5]

22,400

[6.6]

22,400

[6.6]

22,200

[6.5]

22,400

[6.6]

22,400

[6.6]

22,200

[6.5]

COP

2.36 8.50

2.32 8.35

2.34 8.45

2.36 8.50

2.34 8.50

2.40 8.40

2.40 8.50

2.46 8.90

2.39

2.38 8.95

2.48 9.30

2.46 9.20

2.47 9.25

2.40 9.00

2.39 8.95

2.48 9.00

2.48 9.00

2.49 9.00

2.46 8.85

2.46 8.85

2.40 8.65

2.46 8.85

2.44 8.80

2.39 8.80

2.44 8.90

2.44 8.90

2.44 8.90

2.48 8.90

DOE

Region

IV

HSPF

8.95

Page 6

6 Rheem Manufacturing Company

Performance Data ARI Standard Conditions—Single Phase (Scroll Compressor) (cont.)

Note: Only these combinations of indoor/outdoor units are approved and any other combinations should not be used.

➀ Highest sales volume tested combination required by DOE test procedures.

[ ] Designates Metric Conversions

ARI Cooling Performance

80°F [26.5°C] DB/67°F [19.5°C] WB Indoor Air

95°F [35°C] DB Outdoor Air

Net

Sens.

BTU/H

[kW]

29,850

[8.7]

27,900

[8.2]

30,000

[8.8]

29,900

[8.8]

29,800

[8.7]

30,350

[8.9]

30,150

[8.8]

30,150

[8.8]

30,450

[8.9]

28,700

[8.4]

29,200

[8.6]

29,200

[8.6]

30,300

[8.9]

30,200

[8.8]

30,300

[8.9]

34,600

[10.1]

34,600

[10.1]

35,200

[10.3]

34,100

[10.0]

35,200

[10.3]

34,700

[10.2]

34,700

[10.2]

34,700

[10.2]

35,200

[10.3]

Outdoor

Unit

RPPB-

042JAZ

048JAZ

Model Numbers

Indoor

Coil and/or

Air Handler

RCHJ-48A1

RCHJ-48A1+RXMD-C02

RCHJ-48A1 (RBHK-24) ➀

RCHJ-48A1 (RGFD-09?ZCM?)

RCHJ-48A1 (RGFD-10?ZCM?)

RCHJ-48A1 (RGFD-12?ZCM?)

RCHJ-48A1 (RGGD-09?ZCM?)

RCHJ-48A1 (RGGD-10?ZCM?)

RCHJ-48A1 (RGGD-12?RCM?)

RCHJ-48A1 (RGLL-07?BRQ?)

RCHJ-48A1 (RGLL-10?BRM?)

RCHJ-48A1 (RGLL-12?ARM?)

RCHJ-48A1 (RGPL-07?BRQ?)

RCHJ-48A1 (RGPL-10?BRM?)

RCHJ-48A1 (RGPL-12?ARM?)

RCHJ-51A1

RCHJ-51A1+RXMD-C02

RCHJ-51A1 (RBHK-24) ➀

RCHJ-51A1 (RGLL-07?BRQ?)

RCHJ-51A1 (RGLL-10?BRM?)

RCHJ-51A1 (RGLL-12?ARM?)

RCHJ-51A1 (RGPL-07?BRQ?)

RCHJ-51A1 (RGPL-10?BRM?)

RCHJ-51A1 (RGPL-12?ARM?)

Total

Capacity

BTU/H

[kW]

39,000

[11.4]

39,000

[11.4]

40,500

[11.9]

40,500

[11.9]

40,500

[11.9]

41,000

[12.0]

40,500

[11.9]

40,500

[11.9]

41,000

[12.0]

39,500

[11.6]

40,000

[11.7]

40,000

[11.7]

40,000

[11.7]

40,000

[11.7]

40,000

[11.7]

46,000

[13.5]

46,000

[13.5]

46,500

[13.6]

45,500

[13.3]

46,500

[13.6]

46,000

[13.5]

46,000

[13.5]

46,000

[13.5]

46,500

[13.6]

Net

Latent

BTU/H

[kW]

11,150

[3.3]

11,100

[3.3]

11,000

[3.2]

11,100

[3.3]

11,200

[3.3]

11,150

[3.3]

10,850

[3.2]

10,850

[3.2]

11,050

[3.2]

10,800

[3.2]

10,800

[3.2]

10,800

[3.2]

11,200

[3.3]

11,300

[3.3]

11,200

[3.3]

11,400

[3.3]

11,400

[3.3]

11,300

[3.3]

11,400

[3.3]

11,300

[3.3]

11,300

[3.3]

11,300

[3.3]

11,300

[3.3]

11,300

[3.3]

EER

SEER

10.90 12.00

10.90 12.10

12.10 14.00

11.70 13.25

11.55 13.20

11.75 13.25

11.75 13.25

11.75 13.25

12.00

13.60

11.20 12.85

11.80 13.60

11.85 13.65

11.50 13.20

11.60 13.35

11.90 13.70

11.45 12.00

11.45 12.10

12.25 14.10

10.80 12.35

12.00 13.75

11.55 13.20

11.45 13.10

11.65 13.35

12.00 13.80

Indoor

CFM

[L/s]

1,400

[661]

1,400

[661]

1,400

[661]

1,325

[625]

1,325

[625]

1,475

[696]

1,425

[672]

1,425

[672]

1,450

[684]

1,400

[661]

1,400

[661]

1,400

[661]

1,400

[661]

1,400

[661]

1,400

[661]

1,600

[755]

1,600

[755]

1,600

[755]

1,600

[755]

1,600

[755]

1,600

[755]

1,600

[755]

1,600

[755]

1,600

[755]

ARI Heating Performance (70°F [21°C] Indoor)

Outdoor Air

47°F [8.5°C] DB/

43°F [6°C] WB

DOE High Temp.

BTU/H

[kW]

42,500

[12.5]

42,500

[12.5]

41,500

[12.2]

42,000

[12.3]

42,000

[12.3]

42,000

[12.3]

42,000

[12.3]

42,000

[12.3]

42,000

[12.3]

42,500

[12.5]

42,000

[12.3]

42,000

[12.3]

42,000

[12.3]

42,000

[12.3]

42,000

[12.3]

47,000

[13.8]

47,000

[13.8]

47,000

[13.8]

48,500

[14.2]

47,000

[13.8]

47,500

[13.9]

47,500

[13.9]

47,500

[13.9]

47,000

[13.8]

COP

3.40

3.40

3.52

3.52

3.49

3.48

3.50

3.50

3.52

3.38

3.48

3.48

3.42

3.44

3.50

3.44

3.44

3.64

3.38

3.60

3.52

3.50

3.54

3.60

Outdoor Air

17°F [–8.5°C] DB/

15°F [–9.5°C] WB

DOE Low Temp.

BTU/H

[kW]

27,200

[8.0]

27,200

[8.0]

26,200

[7.7]

26,600

[7.8]

26,800

[7.9]

26,800

[7.9]

26,800

[7.9]

26,800

[7.9]

26,600

[7.8]

27,000

[7.9]

26,600

[7.8]

26,400

[7.7]

26,800

[7.9]

26,600

[7.8]

26,400

[7.7]

28,400

[8.3]

28,400

[8.3]

29,000

[8.5]

30,400

[8.9]

29,200

[8.6]

29,600

[8.7]

29,800

[8.7]

29,600

[8.7]

29,200

[8.6]

COP

2.28 8.30

2.28 8.40

2.28 8.30

2.29 8.35

2.28 8.25

2.27 8.20

2.28 8.25

2.28 8.25

2.29

2.20 8.25

2.24 8.25

2.26 8.25

2.22 8.35

2.24 8.35

2.26 8.25

2.22 8.10

2.22 8.50

2.38 8.60

2.26 8.20

2.36 8.50

2.32 8.40

2.32 8.35

2.32 8.40

2.36 8.55

DOE

Region

IV

HSPF

8.30

Page 7

Rheem Manufacturing Company 7

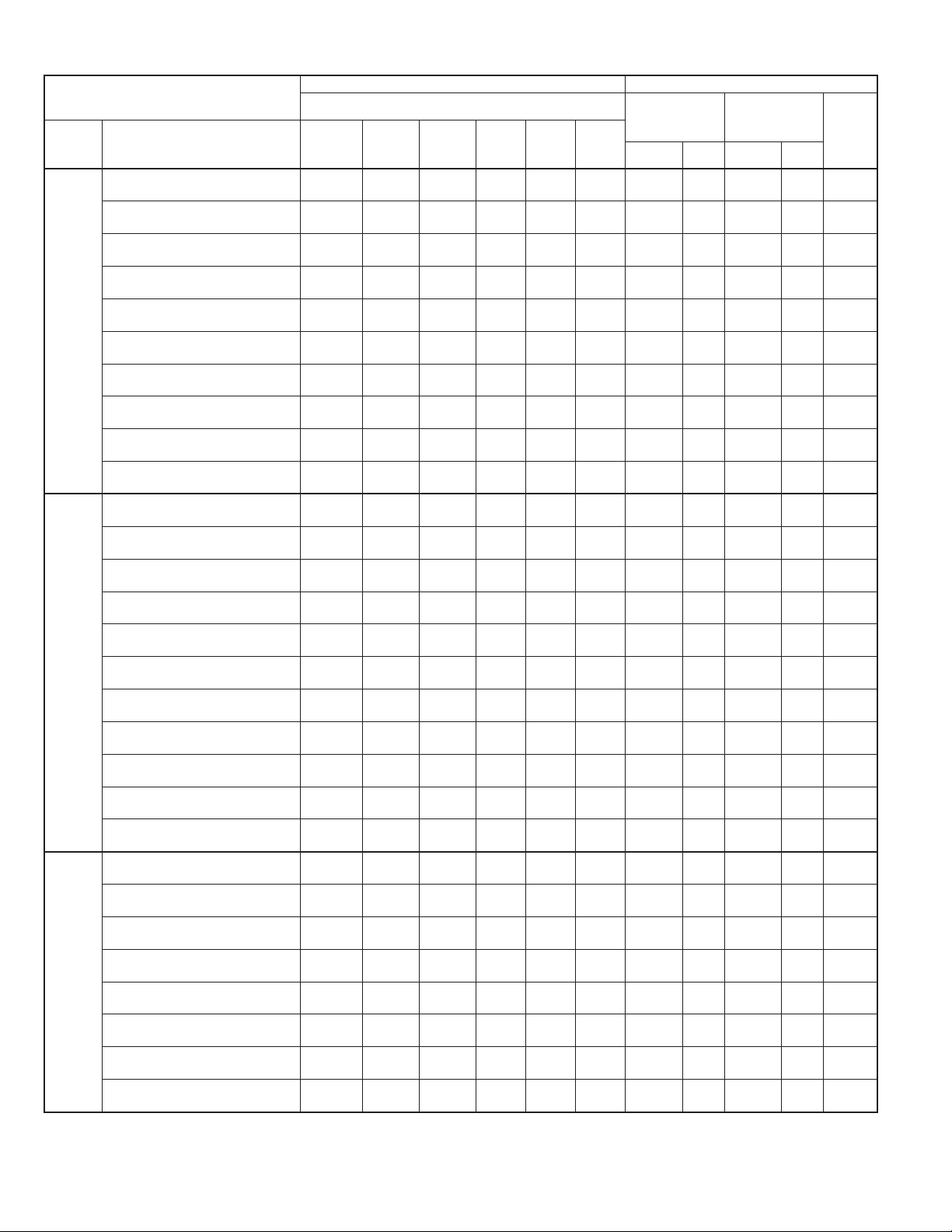

Electrical and Physical Data

[ ] Designates Metric Conversions

Performance Data ARI Standard Conditions—Single Phase (Scroll Compressor) (cont.)

Note: Only these combinations of indoor/outdoor units are approved and any other combinations should not be used.

➀ Highest sales volume tested combination required by DOE test procedures.

ARI Cooling Performance

80°F [26.5°C] DB/67°F [19.5°C] WB Indoor Air

95°F [35°C] DB Outdoor Air

Net

Sens.

BTU/H

[kW]

36,150

[10.6]

36,650

[10.7]

36,300

[10.6]

36,400

[10.7]

36,250

[10.6]

36,250

[10.6]

40,400

[11.8]

40,400

[11.8]

42,100

[12.3]

41,100

[12.0]

40,050

[11.7]

40,550

[11.9]

Outdoor

Unit

RPPB-

049JAZ

060JAZ

061JAZ

Model Numbers

Indoor

Coil and/or

Air Handler

RCQC-4824A

RCQC-4824A (RBHL-25) ➀

RCQC-4824A (RGFD-12?ZCM?)

RCQC-4824A (RGPL-07?BRQ?)

RCQC-4824A (RGPL-10?BRM?)

RCQC-4824A (RGPL-12?ARM?)

RCHJ-61A1

RCHJ-61A1+RXMD-C02

RCHJ-61A1 (RBHK-25) ➀

RCHJ-61A1 (RGPL-12?ARM?)

RCQC-6024A

RCQC-6024A (RBHL-26) ➀

Total

Capacity

BTU/H

[kW]

47,500

[13.9]

48,000

[14.1]

47,500

[13.9]

47,500

[13.9]

47,500

[13.9]

47,500

[13.9]

52,500

[15.4]

52,500

[15.4]

54,000

[15.8]

53,000

[15.5]

52,000

[15.2]

52,500

[15.4]

Net

Latent

BTU/H

[kW]

11,350

[3.3]

11,350

[3.3]

11,200

[3.3]

11,100

[3.3]

11,250

[3.3]

11,250

[3.3]

12,100

[3.5]

12,100

[3.5]

11,900

[3.5]

11,900

[3.5]

11,950

[3.5]

11,950

[3.5]

EER

SEER

11.50 13.55

12.20 14.25

11.75 13.65

11.95 13.90

11.70 13.60

11.95 13.95

11.30 12.00

11.30

12.10

11.65 13.50

10.65 12.20

10.90 12.85

11.65 13.60

Indoor

CFM

[L/s]

1,625

[767]

1,625

[767]

1,650

[779]

1,625

[767]

1,625

[767]

1,575

[743]

1,950

[920]

1,950

[920]

1,950

[920]

1,950

[920]

1,875

[885]

1,875

[885]

ARI Heating Performance (70°F [21°C] Indoor)

Outdoor Air

47°F [8.5°C] DB/

43°F [6°C] WB

DOE High Temp.

BTU/H

[kW]

49,000

[14.4]

48,000

[14.1]

49,000

[14.4]

48,500

[14.2]

49,000

[14.4]

48,500

[14.2]

53,500

[15.7]

53,500

[15.7]

53,500

[15.7]

54,500

[16]

55,500

[16.3]

53,500

[15.7]

COP

3.60

3.71

3.65

3.69

3.65

3.71

3.54

3.54

3.60

3.42

3.51

3.65

Outdoor Air

17°F [–8.5°C] DB/

15°F [–9.5°C] WB

DOE Low Temp.

BTU/H

[kW]

31,200

[9.1]

30,000

[8.8]

30,800

[9.0]

30,600

[9.0]

31,000

[9.1]

30,600

[9.0]

32,400

[9.5]

32,400

[9.5]

33,000

[9.7]

34,000

[10.0]

34,800

[10.2]

33,400

[9.8]

COP

2.46 9.30

2.55 9.30

2.49 9.45

2.52 9.50

2.49 9.40

2.53 9.55

2.34 8.40

2.34

2.36 8.70

2.26 8.10

2.50 9.10

2.60 9.25

DOE

Region

IV

HSPF

8.50

ELECTRICAL PHYSICAL

Model

Number

RPPB-

Phase

Frequency (Hz)

Voltage (Volts)

Compressor

Rated Load

Amperes

(RLA)

Locked Rotor

Amperes

(LRA)

Fan Motor

Full Load

Amperes

(FLA)

Minimum

Circuit

Ampacity

Amperes

018JA 1-60-208-230 9.6/9.6 45 .75 13/13 20/20 20/20 11.0 [1.02] 1 2100 [991] 84 [2381] 160 [72.6] 170 [77.1]

024JA 1-60-208-230 10.9/10.9 54 .75 15/15 20/20 25/25 17.3 [1.60] 1 2200 [1038] 118 [3345] 195 [88.5] 205 [93.0]

030JA 1-60-208-230 12.2/12.2 67 .75 16/16 20/20 25/25 17.3 [1.60] 1 2200 [1038] 124 [3515] 200 [90.7] 210 [95.3]

036JA 1-60-208-230 16.0/16.0 88 1.0 22/22 25/25 35/35 16.8 [1.56] 2 2600 [1227] 195 [5528] 230 [104.3] 240 [108.9]

042JA 1-60-208-230 17.9/17.9 104 1.5 24/24 30/30 40/40 22.4 [2.08] 2 3100 [1463] 234 [6634] 295 [133.8] 305 [138.3]

048JA 1-60-208-230 18.3/18.3 109 1.5 25/25 30/30 40/40 22.4 [2.08] 2 3100 [1463] 281 [7966] 300 [1361] 310 [140.6]

049JA 1-60-208-230 20.0/20.0 109 1.5 27/27 35/35 45/45 22.4 [2.08] 2 3100 [1463] 288 [8165] 300 [136.1] 310 [140.6]

060JA 1-60-208-230 19.9/19.9 137 1.5 27/27 35/35 45/45 22.4 [2.08] 2 3100 [1463] 267 [7569] 305 [138.3] 315 [142.9]

061JA 1-60-208-230 20.2/20.2 137 1.5 27/27 35/35 45/45 22.4 [2.08] 2 3100 [1463] 288 [8165] 305 [138.3] 315 [142.9]

Fuse or HACR

Circuit Breaker

Minimum

Amperes

Maximum

Amperes

Face Area

Sq. Ft. [m

Outdoor Coil

No.

2

Rows

]

CFM [L/s]

R22

Oz. [g]

Net

Lbs. [kg]

Weight

Shipping

Lbs. [kg]

Page 8

8 Rheem Manufacturing Company

Unit Dimensions

[ ] Designates Metric Conversions

Rheem will furnish a replacement for any part of this product

which fails in normal use and service within the applicable

period stated, in accordance with the terms of the limited

warranty.

For Complete Details of the Limited Warranty, Including Applicable Terms

and Conditions, See Your Local Installer or Contact the Manufacturer for

a Copy.

Condenser Coil leaks caused by

factory defects..........................................Five (5) Years

Compressor ..............................................Ten (10) Years

*Any Other Part ..........................................Five (5) Years

*This five year limited warranty is applicable only to single-phase products

installed in residential applications on or after January 1, 2001.

BEFORE PURCHASING THIS APPLIANCE, READ IMPORTANT ENERGY COST AND EFFICIENCY

INFORMATION AVAILABLE FROM YOUR RETAILER.

GENERAL TERMS OF LIMITED WARRANTY

AIR DISCHARGE

ALLOW 600 [1524 mm] CLEARANCE

W

H

AIR INLETS

(LOUVERS)

ALLOW 120 [305 mm]

MIN. CLEARANCE

3 SIDES

Model Number

RPPB-

Height “H”

(Inches) [mm]

018 19 [482.6]

024/030/036 25 [635.0]

Length “L”

(Inches) [mm]

401/2 [1028.7] 275/8 [701.2]

443/8 [1127.1] 311/2 [800.1]

L

1

0

0

0

0

-

A

Width “W”

(Inches) [mm]

042/048/049/060/061 33 [838.2] 443/8 [1127.1] 311/2 [800.1]

ACCESS

PANEL

ALLOW 240 [610 mm]

ACCESS CLEARANCE

SERVICE

FITTINGS

LOW VOLTAGE

CONNECTION

7

/80 [22 mm]

HIGH VOLTAGE

CONNECTION

11

/320 [34 mm]

1

LIQUID LINE

CONNECTION

VAPOR LINE

A-00003

HIGH PRESSURE

CONTROL

MANUAL RESET

(FIELD INSTALLED

ACCESSORY)

CONNECTION

7

/80 [73 mm] DIA.

2

ACCESSORY

KNOCKOUTS

SERVICE ACCESS

TO ELECTRICAL &

VALVES ALLOW

240 [610 mm]

CLEARANCE

ONE SIDE

Page 9

Rheem Manufacturing Company 9

Heat Pump Refrigerant Line Size Information

NOTES: Capacity Multiplier x Rated Capacity = Actual Capacity.

Additional compressor oil is n

ot required for runs up to 150 feet [45.72 m].

Oil traps in vertical runs are n

ot required for any height up to 125 feet [38.10 m]. See Liquid Line chart for Vertical Separation Requirements and Limitations.

*Adapter to 1

1

/8" [28.58 mm] factory supplied.

[ ] Designates Metric Conversions

System

Capacity

Model

018

024

Line

Size

(Inch O.D.)

[mm]

25 [7.62] 50 [15.24] 75 [22.86] 100 [30.48] 125 [38.10] 150 [45.72] 25 [7.62] 50 [15.24] 75 [22.86] 100 [30.48] 125 [38.10] 150 [45.72]

1/4* [6.35] 25 [7.62] 50 [15.24] 70 [21.34] 25 [7.62] 23 [7.01] 8 [2.44]

5/16 [7.94] 36 [10.97] 42 [12.80] 48 [14.63] 54 [16.46] 0 0 0 0

1/4* [6.35] 25 [7.62] 50 [15.24] 25 [7.62] 23 [7.01]

5/16 [7.94] 24 [7.32] 34 [10.36] 44 [13.41] 54 [16.46] 64 [19.51] 0 0 0 0 0

1/4* [6.35] 25 [7.62] 50 [15.24] 25 [7.62] 23 [7.01]

030

5/16 [7.94] 19 [5.79] 33 [10.06] 47 [14.33] 61 [18.59] 0 0 0 0

3/8 [9.53] 11 [3.35] 15 [4.57]

5/16* [7.94] 25 [7.62] 50 [15.24] 70 [21.34] 25 [7.62] 23 [7.01] 9 [2.74]

036

042

048/049

060/061

*Standard line size

NOTES:

➀ This chart is applicable for heat pumps.

➁ If the separation height exceeds the table values, increase the outdoor flow-check piston two sizes plus

one size for each additional 10 feet [3.05 m].

Example 1: A 5 ton [17.58 kW] heat pump with a total line length of 100 feet [30.48 m] with a vertical

separation of 93 feet [28.35 m] utilizing a

vertical separation for 100 feet [30.48 m] run. Separation exceeds table by (93-72) = 21 feet [6.40 m].

Therefore, reduce the indoor coil flow-check piston 2 + 2 = 4 sizes (For example, a #89 piston would reduce

to a #85 piston). Increase the outdoor flow-check piston 2 + 2 = 4 sizes (For example, a #56 would increase

to a #60).

➂ Do not exceed 120 feet [36.58 m] maximum vertical separation.

➃ No changes are required for expansion valve coils.

➄ Do not exceed table values for capillary tube coils.

➅ Always use the smallest liquid line possible to minimize system charge.

➆ For heat pumps with vertical separation: • Route liquid line outside building • Do not insulate liquid line.

➇ Chart may be used to size horizontal runs.

3/8 [9.53] 34 [10.36] 40 [12.19] 46 [14.02] 52 [15.85] 0 0 0 0

5/16* [7.94] 25 [7.62] 50 [15.24] 75 [22.86] 25 [7.62] 23 [7.01] 9 [2.74]

3/8 [9.53] 32 [9.75] 39 [11.89] 46 [14.02] 53 [16.15] 0 0 0 0

3/8* [9.53] 25 [7.62] 44 [13.41] 53 [16.15] 61 [18.59] 70 [21.34] 25 [7.62] 28 [8.53] 19 [5.79] 11 [3.35] 3 [.91]

1/2 [12.7] 37 [11.28] 39 [11.89] 0 0

3/8* [9.53] 25 [7.62] 48 [14.63] 61 [18.59] 72 [21.95]

1/2 [12.7] 35 [10.67] 38 [11.58] 41 [12.50] 0 0 0

3

/8" [9.53 mm] liquid line: Table = 72 feet [21.95 m] maximum

Liquid Line Size

Outdoor Unit Above Indoor Coil

Total Length—Feet [m] Total Length—Feet [m]

Vertical Separation—Feet [m]

Liquid Line Size

Outdoor Unit Below Indoor Coil

Vertical Separation—Feet [m]

25 [7.62] 23 [7.01] 11 [3.35] 3 [.91]

NOTES:

➀ This chart is applicable for heat pumps. Heat pumps with any vertical

separation require the use of standard line sizes only, due to the possibility

of charge imbalance between heating and cooling modes.

Example 1: A 3 ton [10.55 kW] heat pump with a total line length of 50 feet

[15.24 m] can have a maximum vertical separation of 19 feet [5.79 m].

Do not increase line size to

➁ This chart may also be used to size horizontal runs.

Example 2: A 1.5 ton [5.28 kW] heat pump can have a total horizontal line

length of 150 feet [45.72 m] when using the

No vertical separation allowed.

➂ Do not exceed vertical separation as indicated on the chart.

➃ Always use the smallest liquid line possible to minimize system charge.

➄ No changes required for flow-check pistons or expansion valve coils.

3

/8" [9.53 mm].

5

/16" [7.94 mm] liquid line size.

0

Unit Vapor Line Connection Size

Vapor Line Run—Feet [m]

Optional

25' [7.62]

Standard

Optional

Optional

50' [15.24]

Standard

Optional

Optional

100' [30.48]

Standard

Optional

Optional

150' [45.72]

Standard

Optional

Vapor Line Length/Size versus Capacity Multiplier

3

/4" [19.05 mm] I.D. Sweat

5

/8" [15.88 mm] O.D. Optional

3

/4" [19.05 mm] O.D. Standard

7

/

8" [22.23 mm] O.D. Optional

.98

1.00

1.01

0.96

0.99

1.00

0.93

0.99

1.00

—

0.98

1.00

0.98

1.00

1.01

.96

0.99

1.00

0.93

0.98

0.99

—

0.97

0.98

—

1.00

1.01

—

0.99

1.00

—

0.97

0.99

—

0.95

0.97

7

/8" [22.23 mm] I.D. Sweat

3

/4" [19.05 mm] O.D. Optional

7

/8" [22.23 mm] O.D. Standard

1

1

/

8" [28.58 mm] O.D. Optional

.99

1.00

1.01

.97

0.99

1.01

.93

0.98

1.00

—

0.97

0.99

—

1.00

1.01

—

0.99

1.01

—

0.98

1.00

—

0.96

0.99

060/061048/049042036030024RPPB- 018

1

/8" [28.58 mm] I.D. Sweat*

1

7

/8" [22.23 mm] O.D. Optional

1

1

/8" [28.58 mm] O.D. Standard

3

1

/

8" [34.93 mm] O.D. Optional

0.99

1.00

1.01

0.97

1.00

1.01

0.96

0.99

1.00

0.93

0.99

1.00

0.99

1.00

1.01

0.97

0.99

1.01

0.95

0.99

1.00

0.93

0.98

0.99

Page 10

10 Rheem Manufacturing Company

Notes

Page 11

Rheem Manufacturing Company 11

Notes

Page 12

Before proceeding with installation, refer

to installation instructions packaged

with each model, as well as complying

with all Federal, State, Provincial, and

Local codes, regulations, and practices.

RHEEM

AIR CONDITIONING

DIVISION

5600 Old Greenwood Road, Fort Smith, Arkansas 72908

“In keeping with its policy of continuous progress and product improvement, Rheem reserves the right to make changes without notice.”

PRINTED IN U.S.A. 10-05 DC FORM NO. P11-759 REV. 2

Supersedes Form No. P11-759 Rev. 1

Loading...

Loading...