Page 1

Rheem Prestige®Series

Variable Speed Heat Pumps

FORM NO. P11-811 REV. 3

Air

Heat Pumps

RP20 Series

“Proper sizing and installation of equipment is critical to achieve optimal

performance. Split system air conditioners and heat pumps must be

matched with appropriate coil components to meet Energy Star.

Ask your Contractor for details or visit www.energystar.gov.”

RP20 Series

Efficiencies up to 20 SEER/14.5 EER/11 HSPF

Nominal Sizes 2, 3, 4 & 5 Ton

[7.03, 10.6, 14.06 & 17.6 kW]

Cooling Capacities 17.3 to 60.5 kBTU

[5.7 to 17.7 kW]

• PlusOne®Energy Efficiency offers a minimum of 20 SEER

and 11 HSPF system performance across all capacities. The

RP20 achieves these performance measurements with

RHMV variable speed air handlers, R802V two-stage,

variable-speed 80% furnaces, R96V two-stage, variablespeed 96% furnaces and R97V modulating furnaces.

• PlusOne

®

Expanded Valve Space – 3"-4"-5" service valve

space – provides a minimum working area of 27-square

inches for easier access

• PlusOne

®

Triple Service Access – 15" wide, industry leading

corner service access – makes repairs easier and faster. The

three fastener removable corner allows optimal access to

internal unit components. Individual louver panels come out

once fastener is removed, for faster coil cleaning and easier

cabinet reassembly

• EcoNet

®

Enabled product. The EcoNet Smart Home System

provides advanced air & water control for maximum energy

savings and ideal comfort.

• New composite base pan – dampens sound, captures louver

panels, eliminates corrosion and reduces number of fasteners

needed

• Powder coat paint system – for a long lasting professional finish

• The Copeland Scroll™ Variable Speed Compressor has a

modulating technology which provides more precise temperature control, lower humidity and greater efficiency. The overdrive feature provides cooling load up to 107°F and heating

load down to 7°F.

• Modern cabinet aesthetics – increased curb appeal with visually appealing design

• Equipped with electronic expansion valve to precisely control

variable refrigerant flow.

• Improved tubing design – reduces vibration and stress, making unit quieter and reducing opportunity for leaks

• Optimized defrost characteristics - decrease defrosting and

provide better home comfort

• Optimized reversing valve sizing – improves shifting performance for quieter unit operation and increased life of the

system

• Enhanced mufflers – help to dissipate vibration energy for

quieter unit operation

• Integrated heat pump lift receptacle – allows standard CPVC

stands to be inserted into the base

• Curved louver panels – provide ultimate coil protection,

enhance cabinet strength, and increased cabinet rigidity

• Optimized fan orifice – optimizes airflow and reduces unit

sound

• Rust resistant screws – confirmed through 1500-hour salt

spray testing

• Diagnostic service window with two-fastener opening –

provides access to the high and low pressure.

• External gauge port access – allows easy connection of

“low-loss” gauge ports

• Single-row condenser coil (up thru 4 tons) – makes unit lighter

and allows thorough coil cleaning to maintain “out of the box”

performance

• 35% fewer cabinet fasteners and fastener-free base – allow

for faster access to internal components and hassle-free

panel removal

• Service trays – hold fasteners or caps during service calls

• QR code – provides technical information on demand for

faster service calls

• Fan motor harness with extra long wires allows unit top to be

removed without disconnecting fan wire.

• High and low pressure standard on all models.

Seasonal Energy Efficiency Ratio - SEER

THIS MODEL

10.0

USES LESS ENERGY

17.00

17.0

Page 2

Air

Table of Contents

RP20 Series

2

TABLE OF CONTENTS

Standard Feature......................................................................................................3

Available SKUs ........................................................................................................3

Features & Benefits ..............................................................................................4-8

Model Number Identification ..............................................................................9-10

General Data/Electrical Data ..................................................................................11

Accessories ..........................................................................................................12

Weighted Sound Power..........................................................................................12

Smart Home Systems ......................................................................................13-14

Unit Dimensions......................................................................................................15

Clearances..............................................................................................................16

Wiring Diagrams ....................................................................................................17

Refrigerant Line Size Information ......................................................................18-19

Performance Data ............................................................................................20-23

Guide Specifications ..............................................................................................24

Limited Warranty ....................................................................................................25

Page 3

Air

Standard Feature/Available SKUs

RP20 Series

3

STANDARD FEATURES

Feature 24 36 48 60

R-410A Refrigerant

√ √ √ √

Maximum SEER 20 20 20 20

Maximum EER 14.5 14 13 13

EcoNet Enabled

√ √ √ √

Copeland Scroll™ Variable Speed Compressor

√ √ √ √

Compressor Sound Blanket

√ √ √ √

Variable speed outdoor fan motor

√ √ √ √

Swept wing fan blade

√ √ √ √

Field Installed Filter Drier

√ √ √ √

Front Seating Service Valves

√ √ √ √

Internal Pressure Relief Valve

√ √ √ √

Internal Thermal Overload

√ √ √ √

Low Ambient capability

√ √ √ √

3-4-5 Expanded Valve Space

√ √ √ √

Composite Basepan

√ √ √ √

1" Screw Control Box Access

√ √ √ √

15" Access to Internal Components

√ √ √ √

Quick release louver panel design

√ √ √ √

No fasteners to remove along bottom

√ √ √ √

Optimized Venturi Airflow

√ √ √ √

Single row condenser coil

√ √ √

2 Row

Powder coated paint

√ √ √ √

Rust resistant screws

√ √ √ √

QR code

√ √ √ √

External gauge ports

√ √ √ √

Service trays

√ √ √ √

√ = Standard

Standard Feature Table

Available SKUs

Available Models Description

RP2024AJVCA 2 ton EcoNet®Enabled inverter driven Rheem

Prestige

®

Series Variable Speed Heat Pump-208/230/1/60

RP2036AJVCA 3 ton EcoNet®Enabled inverter driven Rheem

Prestige

®

Series Variable Speed Heat Pump-208/230/1/60

RP2048AJVCA 4 ton EcoNet®Enabled inverter driven Rheem

Prestige

®

Series Variable Speed Heat Pump-208/230/1/60

RP2060AJVCA 5 ton EcoNet®Enabled inverter driven Rheem

Prestige

®

Series Variable Speed Heat Pump-208/230/1/60

Page 4

Air

Features & Benefits

RP20 Series

4

Introduction to RP20 Heat Pump

4

The RP20 is our EcoNet®Enabled, Inverter Driven Prestige

®

Series Variable Speed Heat Pump and is part of the Rheem Heat

Pump product line that extends from 13 to 20 SEER. This highly

featured and reliable heat pump is designed for years of reliable,

efficient operation when matched with Rheem indoor aluminum

evaporator coils and furnaces or air handler units with aluminum

evaporators.

The EcoNet Smart Home System is an integrated system for a

home’s Heating, Cooling and Water Heating equipment – allowing homeowners to manage the products that consume up to

65% of the their home’s energy. EcoNet sets Rheem, and our

distributor and contractor customers, apart in the industry with a

unique, advanced and efficient technology solution.

The RP20 Prestige

®

Series inverter driven Variable Speed Heat

Pump is exclusively designed to operate with the EcoNet

®

Smart

Home System. Developed by Rheem, The EcoNet Smart Home

System allows homeowners to manage select high-efficiency,

EcoNet Enabled air conditioners, heat pumps, gas furnaces, air

handlers and water heaters from anywhere. EcoNet Enabled

products in a home are connected through standard HVAC

wiring; then contractors have the option of adding an EcoNet

WiFi Kit

()

so the homeowner can access everything remotely

through a free mobile app or mobile-friendly website. The

Control Center

()

acts as both a thermostat for the heating

and cooling system, and a remote control for connected

water heaters.

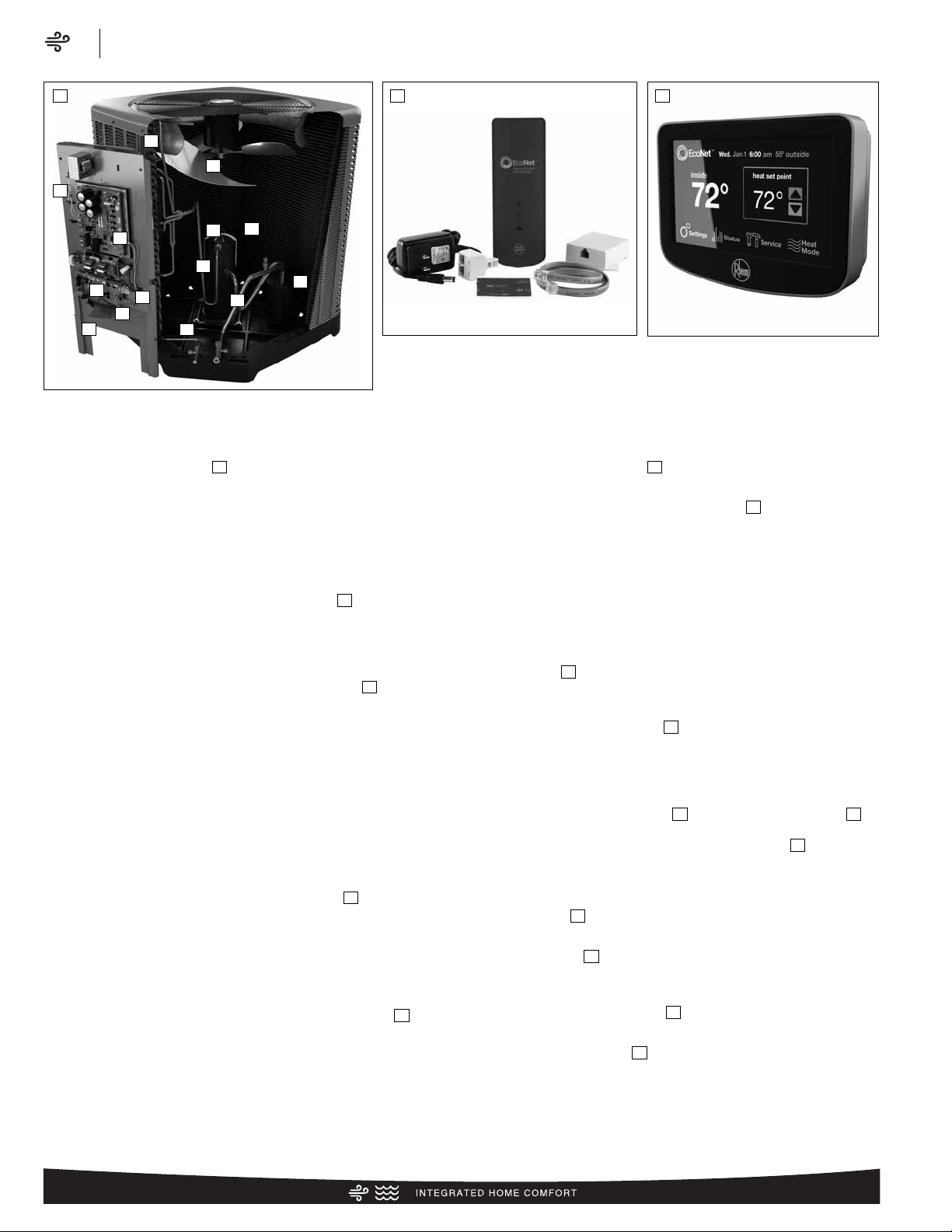

Along with the EcoNet Smart Home System the RP20 is

matched with the RHMV Constant CFM Variable Speed EcoNet

Enabled Air Handler

()

or can be applied in a Furnace application with the EcoNet Enabled Two-Stage Variable Speed R802V

or R96V Gas Furnaces or the fully modulating R97V and RCF

Aluminum Cased Furnace Coils with EEV ( ). See individual

specification documents for more details of the indoor products.

3

4

1

2

1

2

3

Page 5

Air

Features & Benefits

RP20 Series

5

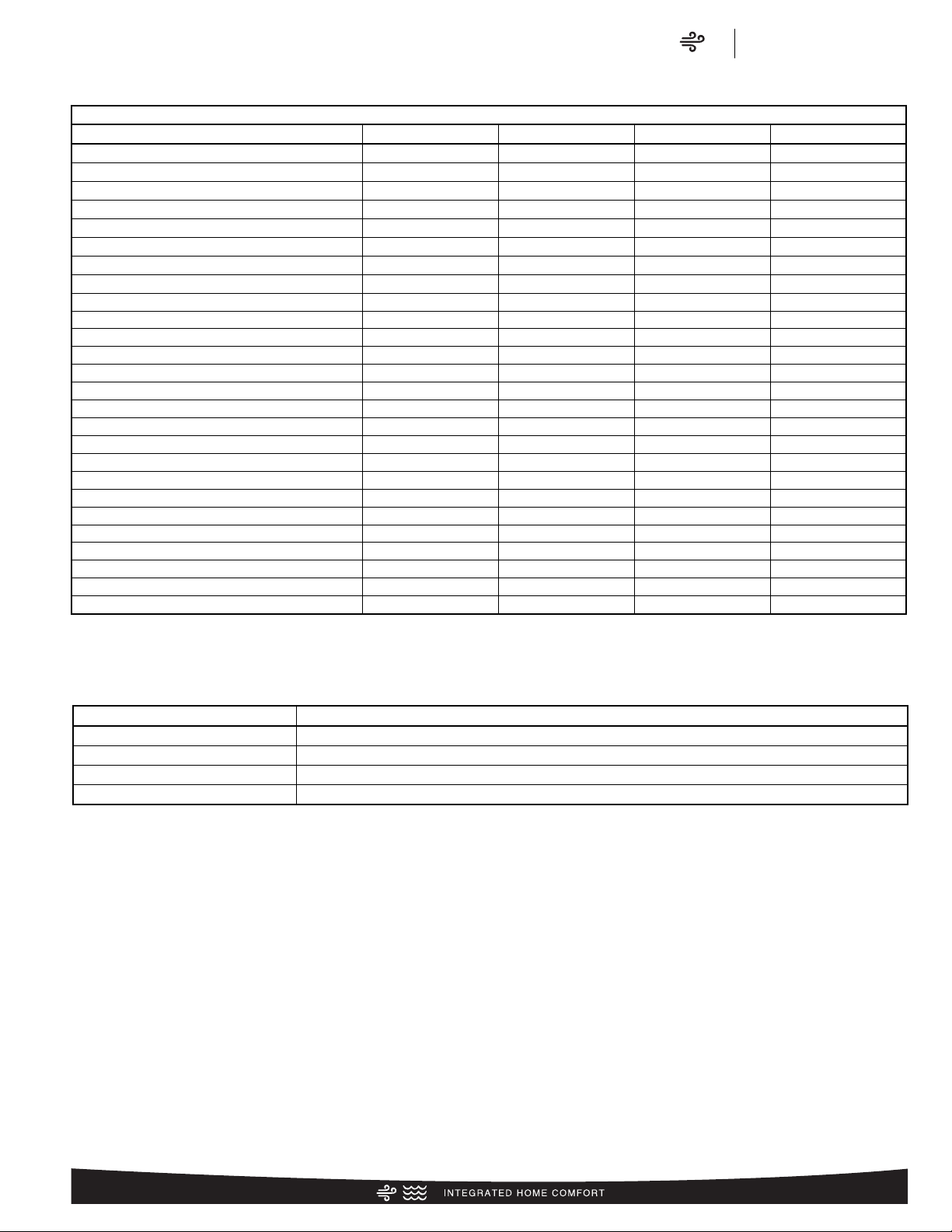

The EcoNet®Enabled, Inverter Driven Rheem®Prestige®Series

Variable Speed Heat Pump’s

()

variable speed outdoor unit

control (VSODU)

()

continuously monitors the EcoNet control

temperature and humidity set point, suction pressure

()

,

suction temperature

()

, outdoor coil temperature

()

and

outdoor temperature

()

and feeds this information to the

Copeland Inverter Control Motor Drive

()

. The Copeland

Inverter Control Motor Drive converts AC to DC power, sends

it to the Copeland Scroll™ variable speed compressor

()

Brushless Permanent Magnet motor (BPM), dynamically adjusting its speed. Simultaneously the VSODU provides input to the

ECM outdoor fan motor

()

which is equipped with the latest

swept wing fan technology

()

and the Electronic Expansion

Valve (EEV)

()

which syncs up with the compressor speed to

deliver the exact capacity the home needs to meet its comfort

requirements. The result of this advanced technology is significantly improved energy efficiency and comfort. Energy

efficiency is improved by precise load matching, less cycling on

and off and low amp gradual compressor, outdoor and indoor

motor operation. Comfort is improved by precise temperature

control, precise humidity control and extra capacity during

extreme summer and cold weather conditions.

5

6

7

8 9

10

11

12

13

14

15

How It Works

13

9

17

11

16

10

6

18

15

20

8

12

19

7

14

5

Page 6

Air

Features & Benefits

RP20 Series

6

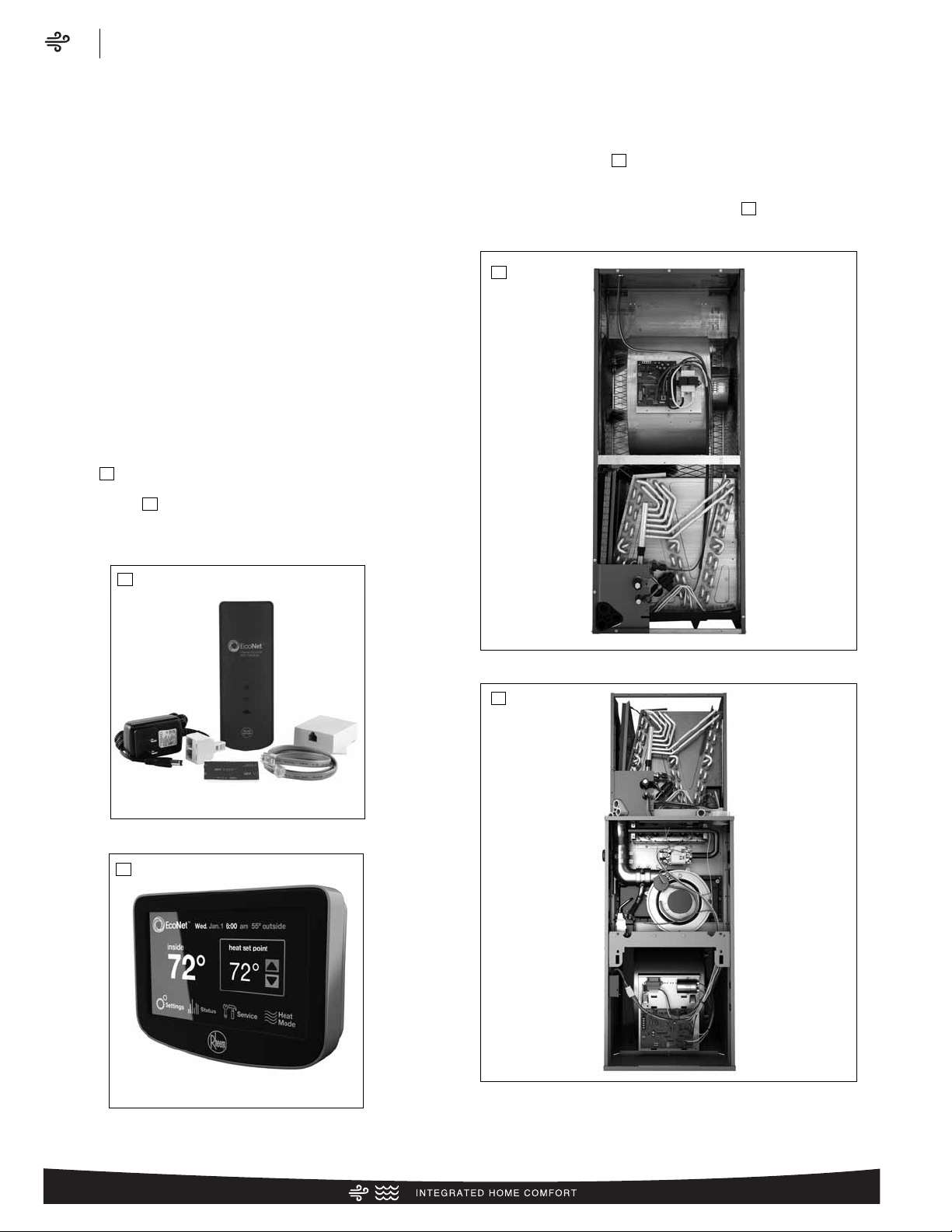

EcoNet Control Center –

()

: The EcoNet Control Center

serves as the hub of communication for a home’s Heating, Cooling and Water Heating systems and is required to operate an

EcoNet Enabled Heating and Cooling system in a fully communicating mode. The EcoNet Control center displays detail diagnostic from outdoor and indoor connected units. See individual

specification documents for more details of the EcoNet Control

Center.

EcoNet Cooling and Heating WiFi Module –

()

is required

to remotely operate an EcoNet Enabled Heating and Cooling

system from the EcoNet web portal and mobile apps. See individual specification documents for more details of the EcoNet

Control Center.

Variable Speed Outdoor Unit Control (VSODU) –

()

is where

control wiring is hooked to the RP20. The VSODU control takes

input from the EcoNet Control Center, outdoor suction temperature and pressure sensors, outdoor air and coil temperatures and

communicates to the Copeland Inverter Control Motor Drive,

EEV, reversing valve, outdoor fan and indoor blower to precisely

control system capacity output of the heat pump in heating and

cooling modes. It also is equipped with Dual Seven-Segment

Display for technician interface, operation status and fault code

communication. Two momentary buttons allow technician to

initiate various operating modes. Various LED’s communicate

active EcoNet communication, microprocessor activity and EEV

operation. See I&O for more details.

The Copeland Inverter Control Motor Drive –

()

converts

incoming single-phase AC power to 3 phase DC simulated sine

wave power. Once power is converted the Copeland Inverter

Control Motor Drive varies frequency of the power to the compressor varying the compressor speed. The Copeland Inverter

Control Motor Drive has active protection algorithms that keep

the compressor safely inside its operating envelope.

The Copeland Scroll™ Variable Speed compressor –

()

utilizes a Brushless Permanent Magnet Motor (BPM) that varies

the Scroll speed, thus, varying the refrigerant flow. The robust

scroll design has proven reliability over competing compressor

technologies.

Swept Wing Fan Blade –

()

is the latest technology in out-

door fans that increase efficiency and reduces air noise.

The Electronic Expansion Valve (EEV) –

()

is an electronically driven refrigerant control valve. A small stepper motor is

used to open and close valve to precisely control refrigerant

flow. It is controlled by the VSODU, which receives input from

the pressure transducer and suction line temperature sensor to

control the RP20 in the heating mode. The VSODU drives it fully

open in the cooling mode. The EEV is superior to a TXV (thermostatic expansion valve) because the EEV controls superheat

at the evaporator coil under varying load and refrigerant flow

conditions, more precisely than traditional TXV’s.

The Filter –

()

is an electrical device that “cleans” the AC

power component. This low pass filter only permits the passage

of 60-Hertz signal to the inverter drive.

The Pressure Transducer –

()

is used to measure suction

pressure in the outdoor heat pump. The VSODU takes this input

to operate the EEV and make decisions on system operation

such as low ambient cooling.

Various temperature sensors – are located on the Heat Pump.

There is an outdoor air sensor

()

, an outdoor coil sensor

()

,

a discharge line temperature sensor (not shown, located on

discharge line), a suction line temperature sensor

()

and a

compressor sump temperature sensor (not shown, located bottom of compressor). The VSODU uses these temperature measurements to operate the system.

The Choke –

()

is provided to absorb power spikes that might

occur on the DC line.

Ferrite Rings –

()

are iron cores through which AC power is

looped keeping any electrical noise contained. They also reduce

the induction of electrical transient into the DC drive.

The Suction Accumulator –

()

prevents liquid refrigerant from

entering the compressor.

The Reversing Valve –

()

reverses the flow of refrigerant in

cooling versus heating.

1

2

6

11

12

14

15

16

7

910

8

17

18

19

20

System Component Descriptions

9

17

11

16

10

6

18

15

20

8

12

19

7

14

5

1

2

Page 7

Air

Features & Benefits

RP20 Series

7

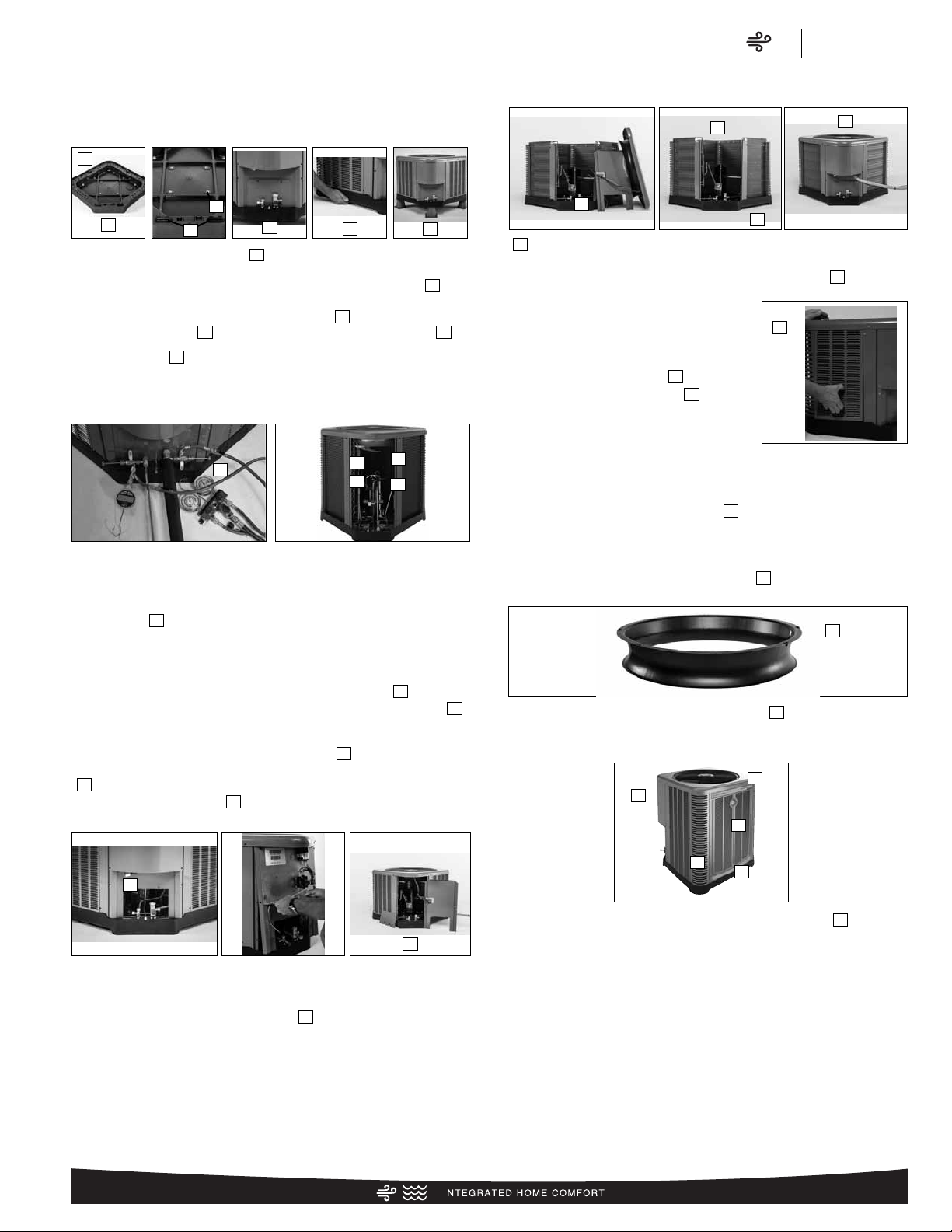

In addition all RP20 Prestige Series Inverter Driven Variable

Speed Heat Pumps have the following features:

Our unique composite base

()

reduces sound emission, eliminates rattles, significantly reduces fasteners, eliminates corrosion

and has integrated brass compressor attachment inserts

()

.

Furthermore it has incorporated into the design, water manage ment features, means for hand placement

()

for unit maneu -

vering, screw trays ( ) and inserts for lifting off unit pad. ( )

Service Valves

()

are rigidly mounted in the composite base

with 3" between suction and discharge valves, 4" clearance

below service valves and a minimum of 5" above the service

valves, creating industry leading ease of installation. The minimum

27 square-inches around the service valves allows ample room

to remove service valve schrader prior to brazing, plenty of clearance for easy brazing of the suction and discharge lines to service valve outlets, easy access and hookup of low loss refrigerant gauges

()

, and access to the service valve caps for

opening.

Controls are accessed from the corner of the unit by removing

only one fastener from the control access cover, revealing the

industry’s largest 15" wide and 22" tall control area

()

. With all

this room in the control area the high voltage electrical whip ( )

can easily be inserted through the right size opening in the

bottom of the control area. Routing it leads directly to lugs for

connection. The low voltage control wires

()

are easily con-

nected to the units VSODU terminal strip. The service window

()

can be removed by removing two screws, to access the EEV

and view interior of unit. ( ) (High and low pressure is standard

on RP20 models).

If in the rare event, greater access is needed to internal components, such as the compressor, the entire corner of the unit can

be removed along with the top cover assembly to have unprecedented access to interior of the unit

()

. Extra wire length is

incorporated into each outdoor fan and compressor so top

cover and control panel can be positioned next to the unit. Or

with minimal effort the plug can be removed from the compressor and the outdoor fan wires can be removed from the VSODU

to allow even more uncluttered access to the interior of the unit

()

. Outdoor coil heights range from as short as 35" to 48".

Disassembly to this degree and complete reassembly only takes

a first time service technician less than 10 minutes. ( )

All units utilize formed louver panels

which provide industry leading coil

protection. Louver removal for coil

cleaning is accomplished by removing

one screw and lifting the panel out of

the composite base pan.

()

All RP20

units utilize single row coils ( )

making cleaning easy and complete,

restoring the performance of the air

conditioner back to out of the box

performance levels year after year.

The outdoor fan motor has sleeve bearings and is inherently

protected. The motor is totally enclosed for maximum protection

from weather, dust and corrosion. ( ) Access to the outdoor fan

is made by removing four fasteners from the fan grille. The outdoor fan can be removed from the fan grille by removing 4 fasteners in the rare case outdoor fan motor fails.

Each cabinet has optimized composite ( ) fan orifice assuring

efficient and quiet airflow.

The entire cabinet has post powder paint ( ) achieving 1000

hour salt spray rating, allowing the cabinet to retain its aesthetics

throughout its life.

The Copeland Scroll

™

Variable Speed compressors ( ) with

standard internal pressure relief and internal thermal overload

are used on all capacities assuring longevity of high efficient and

quiet operation for the life of the product. All RP20 Heat Pump

come standard with high and low pressure switches reinforced

vinyl compressor sound covers containing a 1

1

/2 inch thick batt

of fiber glass insulation and open edges are sealed with a 1 inch

wide hook and loop fastening tape for superior sound quality.

4

5

76

8

10

11

12

14

15

16

3

17

17

19

18

20

21

22

28

9

19

22

26

25

24

23

21

Features

3

6

6

5 7

4

8

10

13

11

12

9

15

14

18

16

20

17

Page 8

Air

Features & Benefits

RP20 Series

8

Each unit is shipped with filter drier for field installation and will

trap any moisture or dirt that could contaminate the refrigerant

system.

All cabinets have industry leading structural strength due to the

composite base pan

()

, interlocking corner post ( ),formed

curved louver panels ( ) and drawn top cover ( ) making it

the most durable cabinet on the market today.

Each RP20 capacity has undergone rigorous psychometric testing to assure performance ratings of capacity, SEER and

EER per AHRI Standard 210/240 rating conditions. Also

each unit bears the UL mark and each unit is certified to

UL 1995 safety standards.

Each unit has undergone specific strain and modal testing to

assure tubing

()

is outside the units natural frequency and that

the suction and discharge lines connected to the compressor

withstand any starting, steady state operation, or shut down

forces imposed by the compressor.

All units have been sound tested in sound chamber to AHRI 270

rating conditions, and A-weighted Sound Power Level tables

produced, assuring units have acceptable noise qualities (see

page 12). Each unit has been ran in cooling operation at 95°F and

sound ratings for the RP20 range from as low as 56 dBA at low

speed and as high as 76 dBA at 95°F rated conditions.

All units have been ship tested to assure units meet stringent

“over the road” shipping conditions.

As manufactured, all units in the RP20 family have cooling capability to 40°F. Addition of low ambient control will allow the unit

to operate down to 0°F. Factory testing is performed on each

unit. All component parts meet well defined specification and

continually go through receiving inspections. Each component

installed on a unit is scanned, assuring correct component utilization for a given unit capacity and voltage. All condenser coils

are leak tested with pressurization test to 550#’s and once

installed and assembled, each units’ complete refrigerant

system is helium leak tested. All units are fully charged from the

factory for up to 15 feet of piping. All units are factory run tested.

The RP20 has a 10-year conditional unit replacement warranty

(registration required) and a 10 year limited parts warranty.

Optional Accessories

(Refer to accessory chart for model #)

3"/6"/12"

• Gray high density polyethylene feet are available to raise unit

off of mounting surface away from moisture

Accessories

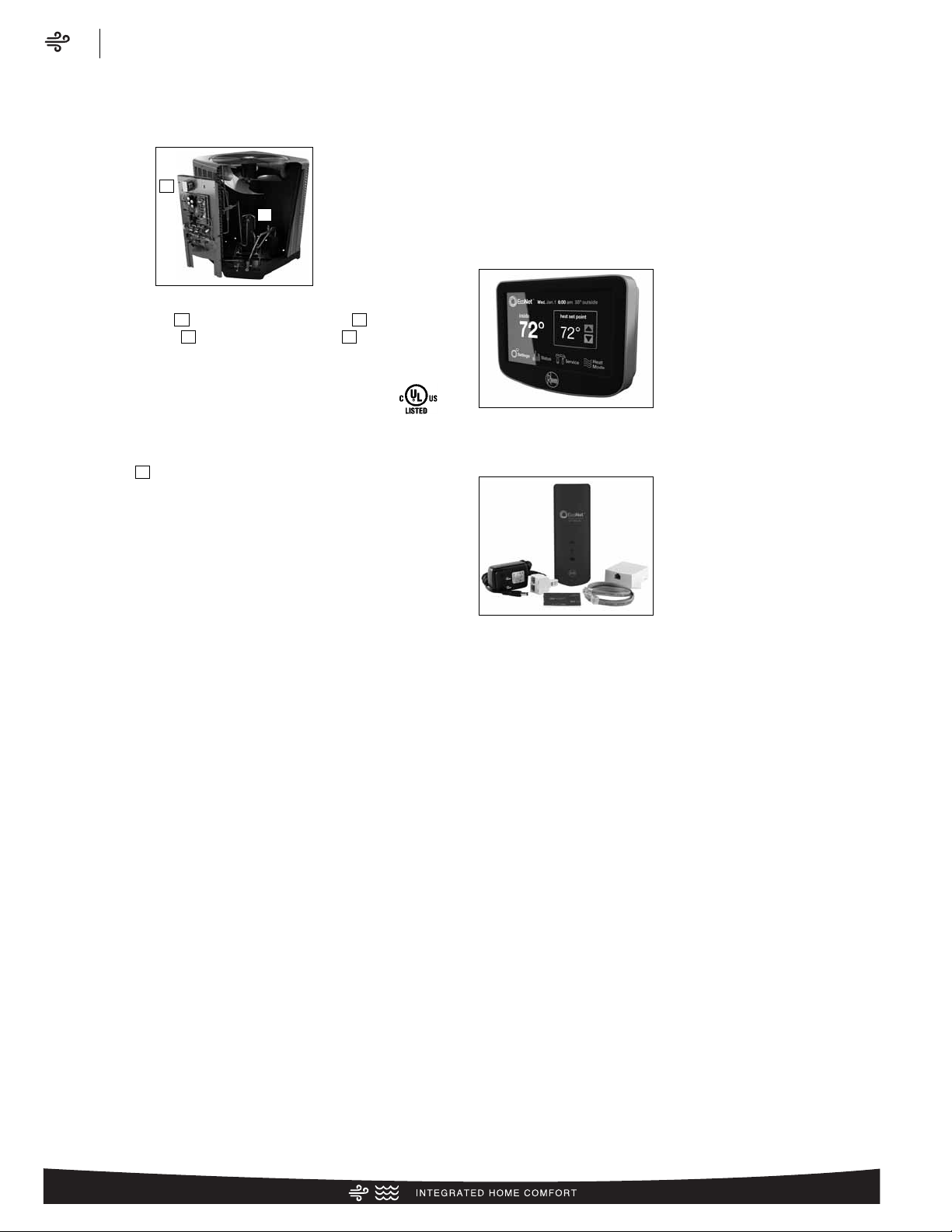

EcoNet Control Center

The EcoNet Control Center serves

as the hub of communication for a

home’s Heating, Cooling and

Water Heating systems, and is

required to operate an EcoNet

Enabled Heating & Cooling

system in a fully communicating

mode.

WiFi Kit for Heating and Cooling Systems

The WiFi kit is required to remotely

operate EcoNet Enabled Heating

and Cooling Systems from the

EcoNet Web portal and mobile

apps.

Thermistor Kit - RXHT-A02

2423

2625

27

Features (con’t.)

27

RETST601SYS

REWRA630SYS

28

Page 9

Air

Model Number Identification

RP20 Series

9

R

A 20 24 A

J

V C B *

Brand Product

Category

SEER Capacity†

BTU/HR

Major Series* Voltage Type Controls Minor Series** Option

Code

13 - 13 SEER

14 - 14 SEER

16 - 16 SEER

17 - 17 SEER

20 - 20 SEER

18 - 18,000 [5.28 kW]

24 - 24,000 [7.03 kW]

30 - 30,000 [8.79 kW]

36 - 36,000 [10.55 kW]

42 - 42,000 [12.31 kW]

48 - 48,000 [14.07 kW]

60 - 60,000 [17.58 kW]

A - 1st Design

B - 2nd Design

J - 1ph, 208-230/60

C - 3ph, 208-230/60

1 - Single-stage

2 - Two-stage

V - Inverter

C - Communicating

N - Non-Communicating

B - High

and low

pressure

control

N/A

R

P 20 24 A

J

V C A *

Brand Product

Category

SEER Capacity†

BTU/HR

Major Series* Voltage Type Controls Minor Series** Option

Code

Rheem P - Heat Pump

13 - 13 SEER

14 - 14 SEER

15 - 15 SEER

17 - 17 SEER

20 - 20 SEER

18 - 18,000 [5.28 kW]

24 - 24,000 [7.03 kW]

30 - 30,000 [8.79 kW]

36 - 36,000 [10.55 kW]

42 - 42,000 [12.31 kW]

48 - 48,000 [14.07 kW]

60 - 60,000 [17.58 kW]

A - 1st Design

J - 1ph, 208-230/60

C - 3ph, 208-230/60

D - 3ph, 460/60

1 - Single-stage

2 - Two-stage

V - Inverter

P - Piston

C - Communicating

N - Non-Communicating

A - 1st Design N/A

R

C F 24 17

S

E A M C A *

Brand Product

Category

Type Capacity

BTU/HR

Width Efficiency Metering

Device

Major

Series*

Orientation Casing Minor Series** Option

Code

Rheem

C - Evap Coil F - Furn Coil

H - Air-Handler

Coil

24 - 24,000 [7.03 kW]

36 - 36,000 [10.55 kW]

48 - 48,000 [14.07 kW]

60 - 60,000 [17.58 kW]

14 - 14"

17 - 17.5"

21 - 21"

24 - 24.5"

S- Standard Eff.

M- Mid Eff.

H- High Eff.

T-TXV

E-EEV

P-Piston

A - 1st Design M - Multipoise

V - Vertical only/

convertible

H - Ded.

Horizontal only

C - Cased

U - Uncased

A - 1st Design N/A

Heat Pumps (For Reference)**

Furnace Coils (For Reference)**

Air Conditioners*

*See page 3 for available SKU’s.

†Two-stage and inverter available in whole capacities only.

NOTE: The above Model Number ID’s are for reference only. Available SKU’s are listed on the standard features/available SKU page of model spec sheet.

[ ] Designates Metric Conversions

*See page 3 for available SKU’s.

†Two-stage and inverter available in whole capacities only.

Page 10

Air

Model Number Identification

RP20 Series

10

R

96 V A

70

2 3 17 M S A

Brand Series Motor Major Rev Input

BTU/HR

Stages Air Flow Cabinet

Width

Configuration Nox Minor Rev

Rheem

90 - 90 AFUE

92 - 92 AFUE

95 - 95 AFUE

96 - 96 AFUE

97 - 97 AFUE

V - Variable speed

T - Constant

Torque

(X-13)

P - PSC

A - 1st Design

040 - 42,000 [12.31 kW]

060 - 56,000 [16.41 kW]

070 - 70,000 [20.51 kW]

085 - 84,000 [24.62 kW]

100 - 98,000 [28.72 kW]

115 - 112,000 [32.82 kW]

1 - Single-stage

2 - Two-stage

M - Modulating

3 - up to 3 ton

5 - 3 1/2 up to 5 ton

14 - 14"

17 - 17.5"

21 - 21"

24 - 24.5"

M - Multi X - Low Nox

S - Standard

A - 1st Design

R

80 2 V A

075

3 17 M S A

Brand Series Stages Motor Major Rev Input

BTU/HR

Air Flow Cabinet

Width

Configuration Nox Minor Rev

Rheem

80 - 80+ AFUE 1 - Single-stage

2 - Two-stage

V - Variable speed

T - Constant Torque (X-13)

P - PSC premium

S - PSC standard

A - 1st Design

050 - 50,000 [15 kW]

075 - 75,000 [22 kW]

100 - 100,000 [29 kW]

125 - 125,000 [37 kW]

150 - 150,000 [44 kW]

3 - up to 3 ton

4 - 2 1/2 to 4 ton

5 - 3 1/2 up to 5 ton

14 - 14"

17 - 17.5"

21 - 21"

24 - 24.5"

M - Multi

D - Down

Z - Down &

zero clearance

down flow

X - Low Nox

S - Standard

A - 1st Design

R

H M V 36

17

S E A C J A 000 *

Brand Product

Category

Stages of

Airflow

Motor Type Capacity

BTU/HR

Width Coil Size Metering

Device

Major

Series*

Controls Voltage Minor

Series**

Factory Heat

Cap

Option

Code

Rheem

H - Air

Handler

1 - Single-Stage

2 - Two-Stage

M - Modulating

V - Variable

Speed

T - Constant

Torque

P - PSC

24 - 24,000 [7.03 kW]

36 - 36,000 [10.55 kW]

48 - 48,000 [14.07 kW]

60 - 60,000 [17.58 kW]

14 - 14"

17 - 17.5"

21 - 21"

24 - 24.5"

S - Standard

Eff.

M -Mid Eff.

H - High Eff.

T - TEV

E - EEV

P - Piston

A - 1st Design C -Communicating

N -Non-comm

J - 1ph, 208-240/60 A - 1st Design 00 - no

factory heat

with option

code

*TBD

90%+ AFUE Gas Furnaces (For Reference)**

80% AFUE Gas Furnaces (For Reference)**

Air Handlers (For Reference)**

NOTE: The above Model Number ID’s are for reference only. Available SKU’s are listed on the standard features/available SKU page of model spec sheet.

[ ] Designates Metric Conversions

Page 11

Air

General Data/Electrical Data

RP20 Series

11

¹Refrigerant charge sufficient for 15 ft. length of refrigerant lines. For longer line set requirements see the installation instructions for information about set length and additional

refrigerant charge required.

²HACR type circuit breaker of fuse.

³Refer to National Electrical Code manual to determine wire, fuse and disconnect size requirements.

Physical Data

Model No. RP2024A RP2036A RP2048A RP2060A

Nominal Tonnage 2.0 3.0 4.0 5.0

Valve Connections

Liquid Line O.D. – in. 3/8 3/8 3/8 3/8

Suction Line O.D. – in. 3/4 3/4 7/8 7/8

Refrigerant (R-410A) furnished oz.¹ 135.2 169 215.2 321

Compressor Type Scroll

Outdoor Coil

Net face area – Outer Coil 21.5 28.3 32.5 32.5

Net face area – Inner Coil – – – 29.0

Tube diameter – in. 0.375 0.375 0.375 0.375

Number of rows 1 1 1 2

Fins per inch 20 20 20 20

Outdoor Fan

Diameter – in. 26 26 26 26

Number of blades 3 3 3 3

Motor hp 1/5 1/2 1/2 1/2

CFM 4375 4250 4995 6240

RPM 731 784 842 1118

watts 95 290 108 290

Shipping weight – lbs. 231 280 301 362

Operating weight – lbs. 223 273 293 355

Electrical Data

Line Voltage Data (Volts-Phase-Hz) 208/230-1-60 208/230-1-60 208/230-1-60 208/230-1-60

Maximum overcurrent protection (amps)² 45 50 70 70

Minimum overcurrent protection 35 40 60 60

Minimum circuit ampacity³ 28 33 46 45

Compressor

Rated load amps 20.7 21.9 32.2 31.7

Locked rotor amps 35 35 50 50

Condenser Fan Motor

Full load amps 1.4 5.3 5.3 5.3

Locked rotor amps N/A N/A N/A N/A

Page 12

Air

Accessories/Weighted Sound Power

RP20 Series

12

Accessories

Model No. RP2024 RP2036 RP2048 RP2060

EcoNet Control Center RETST601SYS RETST601SYS RETST601SYS RETST601SYS

WiFi Kit for Heating & Cooling REWRA630SYS REWRA630SYS REWRA630SYS REWRA630SYS

Compressor sound cover STD STD STD STD

Heat pump Riser 6 in. 686020 686020 686020 686020

Supply Return Sensor RXHT-A02 RXHT-A02 RXHT-A02 RXHT-A02

Rheem Show Unit Shell RXHD-CU4 RXHD-CU4 RXHD-CU4 RXHD-CU4

Weighted Sound Power Level (dBA)

RP20 Sound Power Level

Model

Sound Power

Level [dB(A)]

Low Speed/

High Speed

Full Octave Linear Sound Power Level dB - Center Frequency - Hz

Sound Power

Level [dB(A)]

with Sound

Blanket

125 250 500 1000 2000 4000 6300 8000

RP2024

59 38.6 35.9 42.2 43.3 39.2 44.8 55.1 40.4

Sound

Blankets -

Standard

69 44.8 52.5 60.1 58.7 57.5 49 49.9 44.2

RP2036

64 33.7 45.1 51.6 53.5 51.8 45.4 48.4 42.4

70 50.3 53.3 58.9 58 55.9 49.5 49.2 45.4

RP2048

59 29.9 38.3 43.1 49.4 42.7 46.4 40.9 38.9

72 41.1 47.9 61.2 59.4 57.4 50.6 48.9 45.8

RP2060

59 41.1 40.8 45.6 48.6 43.4 41 40.2 38.9

71 45 54.1 61.1 57.5 55.9 50.1 48 47.3

NOTE: Tested in accordance with AHRI Standard 270-08 (not listed in AHRI)

Page 13

Air

Smart Home Systems

RP20 Series

13

Easy to Setup, Easy to Use, Easy to Save

• Built with our 360°+1 design philosophy, it

is optimized for Installability™, Performance,

Integration & Serviceability

• Controls 65%

†

or more of a typical home’s

energy use from a single device

• Can reduce energy costs by up to 30%

††

Features

• Added support for new EEV (Electronic

Expansion Valve) Air Handlers, Air Conditioners and Heat Pumps*

• Rapid installation with standard 4-wire

configuration

• Automatically configures communicating

equipment with optimal settings

• Adapts to home décor through

interchangeable faceplates and adjustable

background coloring

• Full-color, 4.7" LCD touchscreen display

with easy-to-read icons and text

• Convenient date, time and indoor/outdoor

temperature indications

• 5 operating modes with short-cycle protec-

tion (Heat, Cool, Auto, Emergency Heat,

Fan Only)

• 7-Day programmable schedule with

Smooth Arrival & Whole Home Vacation

options

• Detailed operating status, alarm history,

and audible alerts

• Supports humidifier accessories or overcool based dehumidification

• One-touch access to Water Heater

Management

†††

• Easily manage from anywhere in the world

with the compatible WiFi Module & EcoNet

app for smart phones and tablets

†††

Source – Department of Energy

†††

When compared to non-programmable thermostats.

Source: ENERGY STAR

®

for Programmable

Thermostats

†††

Requires wired connection to EcoNet Enabled Electric

or Hybrid Water Heaters

Integrated Controls

EcoNet is smart, new technology developed exclusively by Rheem that allows Heating, Cooling,

and Water Heating products to communicate with each other on one integrated network.

EcoNet®Control Center

Home control with intuitive LCD

touchscreen navigation

RETST601SYS

EcoNet Control Center Compatibility

OFFERINGS HEATING & COOLING

WiFi Kit for HVAC

REWRA630SYS

WATER HEATING

Product

Categories

Gas Furnaces Air Handlers Air Conditioners Heat Pumps

Electric Tank

Models

Ending in

EC2

Hybrid

Tank

HB50

Models

Gas

Powered

Damper

Tank Models

Models R97V R96V R802V RHMV*

RH2T

(EEV**)

RA20* RA17 RP20* RP17*

RETST601SYS √ √ √ √ √ √ √ √ √ √ √ √

*Available in 2016

**Electronic Expansion Valve (EEV) Models

Page 14

Air

Smart Home Systems

RP20 Series

14

Features

• Enables remote operation from:

- The EcoNet App on Apple

®

mobile devices

(iPhone

®

, iPad

®

, & iPod

®

Touch) using iOS

version 7.0 or later

- The EcoNet App on Android™ based smart

phones and tablets using Android™ version

4.4 or later

- Recent versions of popular web browsers

such as Internet Explorer, Chrome, Safari,

etc.

• Designed for use with EcoNet communi-

cating HVAC Systems

• Compatible with 802.11 b/g/n WiFi networks

• WPA-2 Security using AES/CCMP

• Status LEDs:

- Power & Equipment

Connection Status

- Home Network WiFi Status

- Internet Connection Status

• “WLAN SETUP" factory reset button

WiFi Kit Components

• EcoNet WiFi Module

• Installation Instructions

• V Power Adapter

• Junction Box

• 24" Port-to-Port Connection Cable

• 1" x 2" Double Adhesive Mounting Tape

• RJ12 Y Splitter (for use with

communicating electric water heaters)

Compatibility

• Works with any HVAC System

which includes an EcoNet Enabled

furnace or air handler and an EcoNet

control center.

Warranty

• 1 Year from installation date

The EcoNet

®

WiFi Kit for Heating & Cooling Systems

(REWRA630SYS) provides remote control of EcoNet

Enabled air and water products from smart phones,

tablets, and personal computers using the home’s

internet connection.

EcoNet WiFi Kit for Heating

& Cooling Systems

REWRA630SYS

HVAC Connection Illustration

Page 15

Air

Unit Dimensions

RP20 Series

15

Unit Dimensions

MODEL

NO.

OPERATING SHIPPING

H (Height) L (Length) W (Width) H (Height) L (Length) W (Width)

INCHES mm INCHES mm INCHES mm INCHES mm INCHES mm INCHES mm

RP2024 35 990 35.75 908 35.75 908 37.56 1055 39.37 999 39.64 1006

RP2036 39 990 35.75 908 35.75 908 41.56 1056 39.37 999 39.64 1006

RP2048 51 1295 35.75 908 35.75 908 53.56 1360 39.37 999 39.64 1006

RP2060 51 1295 35.75 908 35.75 908 53.56 1360 39.37 999 39.64 1006

[ ] Designates Metric Conversions

ST-A1226-02-00

Page 16

Air

Clearances

RP20 Series

16

6⬙

(152.4)

24⬙

(609.6)

Service

12⬙

(304.8)

6⬙

(152.4)

24⬙

(609.6)

Service

24⬙

(609.6)

24⬙ recommended

6⬙ minimum

12⬙

(304.8)

12⬙

(304.8)

6⬙

(152.4)

24⬙

(609.6)

Service

24⬙

(609.6)

Service

24⬙

(609.6)

Service

18⬙

(457.2)

WALL

WALL

WALL

WALL

NOTE: NUMBERS IN () = mm

CLEARANCES

IMPORTANT: When installing multiple units in an alcove, roof well or partially enclosed area, ensure there is adequate ventillation to prevent re-circulation of discharge air.

ST-A1225-01-00

24⬙

(609.6)

24⬙ recommended

6⬙ minimum

Page 17

Air

Wiring Diagram/Application Guidelines

RP20 Series

17

Indoor Unit

E1

E2

C

R

WIRING INFORMATION

Line Voltage

–Field Installed - - - - - –Factory Standard

E1

E2

R

C

E1

E2

R

C

Communicating Thermostat

Outdoor Unit

FIGURE 2

TYPICAL ECONET COMMUNICATING SYSTEM™ WIRING DIAGRAM

Application Guidelines

1. Intended for outdoor installation with free air inlet and outlet. Outdoor fan external static pressure available is less than 0.01 -in. wc.

2. Minimum outdoor operation air temperature for cooling mode without low-ambient operation accessory is 55°F (12.8°C).

3. Maximum outdoor operating air temperature is 125°F (51.7°C).

4. For reliable operation, unit should be level in all horizontal planes.

5. Use only copper wire for electric connections at unit. Aluminum and clad aluminum are not acceptable for the type of connector

provided.

6. Do not apply capillary tube indoor coils to these units.

7. Factory – supplied filter drier must be installed.

Control Wiring

Page 18

Air

Refrigerant Line Size Information

RP20 Series

18

R-410A System

Capacity Model

Liquid Line Size

Connection Size

(Inch I.D.) [mm]

Liquid Line Size

(Inch O.D.) [mm]

Liquid Line Selection Chart

Elevation (Above or Below) Indoor Coil

Tot al Equivalent Length - Feet [m]

25 [7.62] 50 [15.24] 75 [22.86] 100 [30.48] 125 [45.72] 150 [45.72] 175 [53.34] 200 [60.96] 225 [68.58] 250 [76.20] 275 [83.82] 300 [91.44]

Maximum Vertical Separation – Feet [m]

RP2024A 3/8" [9.53]

1/4 [6.35] 25 [7.62] 50 [15.24] 25 [7.62]

N/R N/R N/R N/R N/R N/R N/R N/R N/R

5/16 [7.94] 25 [7.62] 50 [15.24] 75 [22.86] 75 [22.86] 70 [21.34] 65 [19.81] 60 [18.29] 50 [15.24] 45 [13.72] 40 [12.19] 30 [9.14] 25 [7.62]

3/8 [9.53] 25 [7.62] 50 [15.24] 75 [22.86] 95 [28.96] 90 [27.43] 90 [27.43] 85 [25.91] 85 [25.91] 85 [25.91] 80 [24.38] 80 [24.38] 75 [22.86]

7/16 [11.12] 25 [7.62] 50 [15.24] 75 [22.86] 100 [30.48] 100 [30.48] 95 [28.96] 95 [28.96] 95 [28.96] 95 [28.96] 95 [28.96] 95 [28.96] 90 [27.43]

1/2 [12.71] 25 [7.62] 50 [15.24] 75 [22.86] 100 [30.48] 100 [30.48] 100 [30.48] 100 [30.48] 100 [30.48] 100 [30.48] 100 [30.48] 100 [30.48] 100 [30.48]

RP2036A 3/8" [9.53]

1/4 [6.35] 25 [7.62]

N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

5/16 [7.94] 25 [7.62] 50 [15.24] 50 [15.24] 40 [12.19] 30 [9.14] 15 [4.57] N/R

N/R N/R N/R N/R N/R

3/8 [9.53] 25 [7.62] 50 [15.24] 75 [22.86] 70 [21.34] 65 [19.81] 65 [19.81] 60 [18.29] 55 [16.76] 50 [15.24] 45 [13.72] 45 [13.72] 40 [12.19]

7/16 [11.12] 25 [7.62] 50 [15.24] 75 [22.86] 80 [24.38] 80 [24.38] 80 [24.38] 75 [22.86] 75 [22.86] 70 [21.34] 70 [21.34] 70 [21.34] 65 [19.81]

1/2 [12.71] 25 [7.62] 50 [15.24] 75 [22.86] 85 [25.91] 85 [25.91] 85 [25.91] 80 [24.38] 80 [24.38] 80 [24.38] 80 [24.38] 80 [24.38] 80 [24.38]

RP2048A 3/8" [9.53]

1/4 [6.35] 10 [3.05]

N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

5/16 [7.94] 25 [7.62] 50 [15.24] 30 [9.14] 10 [3.05]

N/R N/R N/R N/R N/R N/R N/R N/R

3/8 [9.53] 25 [7.62] 50 [15.24] 70 [21.34] 65 [19.81] 55 [16.76] 50 [15.24] 45 [13.72] 35 [10.67] 30 [9.14] 25 [7.62] 15 [4.57] 10 [3.05]

7/16 [11.12] 25 [7.62] 50 [15.24] 75 [22.86] 80 [24.38] 75 [22.86] 75 [22.86] 70 [21.34] 65 [19.81] 65 [19.81] 60 [18.29] 60 [18.29] 55 [16.76]

1/2 [12.71] 25 [7.62] 50 [15.24] 75 [22.86] 85 [25.91] 85 [25.91] 80 [24.38] 80 [24.38] 80 [24.38] 80 [24.38] 75 [22.86] 75 [22.86] 75 [22.86]

RP2060A 3/8" [9.53]

1/4 [6.35]

N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

5/16 [7.94] 25 [7.62] 35 [10.67] 10 [3.05]

N/R N/R N/R N/R N/R N/R N/R N/R N/R

3/8 [9.53] 25 [7.62] 50 [15.24] 60 [18.29] 50 [15.24] 40 [12.19] 30 [9.14] 25 [7.62] 15 [4.57] 5 [1.52]

N/R N/R N/R

7/16 [11.12] 25 [7.62] 50 [15.24] 75 [22.86] 70 [21.34] 65 [19.81] 65 [19.81] 60 [18.29] 55 [16.76] 50 [15.24] 50 [15.24] 45 [13.72] 40 [12.19]

1/2 [12.71] 25 [7.62] 50 [15.24] 75 [22.86] 80 [24.38] 75 [22.86] 75 [22.86] 75 [22.86] 70 [21.34] 70 [21.34] 65 [19.81] 65 [19.81] 65 [19.81]

Refrigerant Line Size Information

NOTES: [ ] Designates Metric Conversions

N/R = Application not recommended.

Grey =This application is acceptable, but the long line guidelines must be followed. Reference Long Line Set section in the I&O

Page 19

Air

Refrigerant Line Size Information

RP20 Series

19

R-410A System

Capacity Model

Vapor Line

Connection Size

(Inch I.D.) [mm]

Vapor Line Size

(Inch O.D.) [mm]

Vapor Line Selection Chart

Capacity Multiplier Table

Tot al Equivalent Length - Feet [m]

25 [7.62] 50 [15.24] 75 [22.86] 100 [30.48] 125 [45.72] 150 [45.72] 175 [53.34] 200 [60.96] 225 [68.58] 250 [76.20] 275 [83.82] 300 [91.44]

RP2024A

3/4" [19.06]

5/8 [15.88]

0.99 0.99 0.97 0.96 0.95 0.94 0.93 0.92 0.91 0.91 0.89 0.89

3/4 [19.05]

1.00 1.00 0.99 0.99 0.99 0.98 0.97 0.97 0.96 0.96 0.96 0.95

7/8 [22.23]

N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

1 [25.4]

N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

1-1/8 [28.58]

N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

RP2036A

3/4" [19.06]

5/8 [15.88]

0.98 0.97 0.95 0.93 0.92 0.9 0.89 0.87 0.86 0.85 0.84 0.84

3/4 [19.05]

1.00 0.99 0.98 0.98 0.97 0.97 0.96 0.95 0.95 0.94 0.93 0.93

7/8 [22.23]

1.00 1.01 1.01 0.99 0.99 0.99 0.98 0.98 0.98 0.98 0.97 0.97

1 [25.4]

N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

1-1/8 [28.58]

N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

RP2048A 7/8" [22.23]

5/8 [15.88]

0.99 0.97 0.97 0.96 0.95 0.93 0.93 0.92 0.91 0.9 0.89 0.88

3/4 [19.05]

0.96 0.94 0.91 0.89 0.86 0.84 0.82 0.82 0.81 0.81 0.8 0.81

7/8 [22.23]

1.00 0.99 0.98 0.97 0.97 0.97 0.96 0.96 0.95 0.95 0.95 0.94

1 [25.4]

N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

1-1/8 [28.58]

N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

RP2060A 7/8" [22.23]

5/8 [15.88]

0.99 0.98 0.96 0.95 0.94 0.92 0.91 0.9 0.89

N/R N/R N/R

3/4 [19.05]

0.97 0.93 0.9 0.86 0.84 0.82 0.81 0.8 0.8

N/R N/R N/R

7/8 [22.23]

1.00 0.99 0.99 0.98 0.97 0.97 0.96 0.95 0.95

N/R N/R N/R

1 [25.4]

N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

1-1/8 [28.58]

N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

Refrigerant Line Size Information (con’t.)

NOTES: [ ] Designates Metric Conversions

N/R = Application not recommended.

All calculations assume a 3/8" liquid line

Page 20

Air

Performance Data

RP20 Series

20

Performance Data @ AHRI Standard Conditions – Heat Pump

High Sales Volume Tested Combination (HSVTC)

Outdoor Unit Air Handler

Total Capacity

BTU/H [kW]

Net Sensible

BTU/H [kW]

Net Latent

BTU/H [kW]

SEER EER

Indoor CFM

[L/s]

47 Degree

Heating Capacity

BTU/H [kW]

47 Degree

COP

17 Degree

Heating Capacity

BTU/H [kW]

17 Degree

COP

Region IV

HSPF

AHRI#

RP2024AJV RHMV2421HEAC 24000 [7.0] 18500 [5.4] 5500 [1.6] 20.5 14.5 850 [401.2] 19500 [5.7] 4.60 12000 [3.5] 2.40 11.0 8950569

RP2036AJV RHMV6021SEAC 35400 [10.4] 27200 [8.0] 8200 [2.4] 20.0 14.5 1175 [554.5] 29400 [8.6] 4.56 18350 [5.4] 2.46 10.5 9047392

RP2048AJV RHMV6021SEAC 46500 [13.6] 36200 [10.6] 10300 [3.0] 20.0 12.5 1650 [778.7] 35600 [10.4] 4.50 21800 [6.4] 2.40 11.0 8950570

RP2060AJV RHMV6024MEAC 55500 [16.3] 40100 [11.8] 15400 [4.5] 20.5 13.0 1750 [825.9] 41000 [12.0] 4.30 25400 [7.5] 2.26 10.5 9047406

R802V: Prestige 2-Stage 80% ECM Furnace Ratings

Outdoor Unit Furnace Indoor Coil

Total Capacity

BTU/H [kW]

Net Sensible

BTU/H [kW]

Net Latent

BTU/H [kW]

SEER EER

Indoor CFM

[L/s]

47 Degree

Heating Capacity

BTU/H [kW]

47 Degree

COP

17 Degree

Heating Capacity

BTU/H [kW]

17 Degree

COP

Region IV

HSPF

AHRI#

RP2024AJV R802VA050317M RCF3621MEA 24600 [7.2] 18900 [5.5] 5700 [1.7] 20.0 14.5 850 [401.2] 19700 [5.8] 4.50 12000 [3.5] 2.34 11.0 9047375

RP2024AJV R802VA075317M RCF3621MEA 24800 [7.3] 19100 [5.6] 5700 [1.7] 20.0 14.5 850 [401.2] 19600 [5.7] 4.60 12000 [3.5] 2.40 11.0 9047376

RP2024AJV R802VA075421Z RCF3621MEA 24800 [7.3] 19100 [5.6] 5700 [1.7] 20.0 14.5 850 [401.2] 19600 [5.7] 4.60 12000 [3.5] 2.40 11.0 9135320

RP2024AJV R802VA100521M RCF3621MEA 24800 [7.3] 19100 [5.6] 5700 [1.7] 20.0 14.5 850 [401.2] 19500 [5.7] 4.66 12000 [3.5] 2.40 11.0 9047377

RP2024AJV R802VA100521Z RCF3621MEA 24800 [7.3] 19100 [5.6] 5700 [1.7] 20.0 14.5 850 [401.2] 19600 [5.7] 4.66 12000 [3.5] 2.40 11.0 9135321

RP2036AJV R802VA050317M RCF6021SEA 34800 [10.2] 26500 [7.8] 8300 [2.4] 19.5 13.5 1150 [542.7] 30000 [8.8] 4.34 18350 [5.4] 2.40 10.5 9047382

RP2036AJV R802VA075317M RCF6021SEA 35200 [10.3] 26900 [7.9] 8300 [2.4] 20.0 14.5 1150 [542.7] 29600 [8.7] 4.56 18350 [5.4] 2.46 10.5 9047383

RP2036AJV R802VA075421Z RCF6021SEA 35200 [10.3] 26900 [7.9] 8300 [2.4] 19.5 14.5 1150 [542.7] 29600 [8.7] 4.56 18350 [5.4] 2.46 10.5 9135322

RP2036AJV R802VA100521M RCF6021SEA 35400 [10.4] 27100 [7.9] 8300 [2.4] 20.0 14.5 1150 [542.7] 29200 [8.6] 4.76 18350 [5.4] 2.46 10.5 9047384

RP2036AJV R802VA100521Z RCF6021SEA 35200 [10.3] 26900 [7.9] 8300 [2.4] 19.5 14.5 1150 [542.7] 29600 [8.7] 4.60 18350 [5.4] 2.46 10.5 9135323

RP2036AJV R802VA125524M RCF6021SEA 35400 [10.4] 27100 [7.9] 8300 [2.4] 19.5 14.5 1150 [542.7] 29200 [8.6] 4.76 18350 [5.4] 2.46 10.5 9047385

RP2048AJV R802VA075421M RCF6021SEA 46000 [13.5] 35700 [10.5] 10300 [3.0] 20.0 12.0 1675 [790.5] 36000 [10.6] 4.40 21800 [6.4] 2.40 11.0 9047393

RP2048AJV R802VA075421Z RCF6021SEA 46000 [13.5] 35700 [10.5] 10300 [3.0] 20.0 12.0 1675 [790.5] 36000 [10.6] 4.40 21800 [6.4] 2.40 11.0 9135324

RP2048AJV R802VA100521M RCF6021SEA 46500 [13.6] 36200 [10.6] 10300 [3.0] 20.0 12.5 1675 [790.5] 35200 [10.3] 4.76 21800 [6.4] 2.46 11.0 9047394

RP2048AJV R802VA100521Z RCF6021SEA 46000 [13.5] 35700 [10.5] 10300 [3.0] 20.0 12.5 1675 [790.5] 35800 [10.5] 4.50 21800 [6.4] 2.40 11.0 9135325

RP2048AJV R802VA125524M RCF6021SEA 46500 [13.6] 36200 [10.6] 10300 [3.0] 20.0 12.5 1675 [790.5] 35200 [10.3] 4.76 21800 [6.4] 2.46 11.0 9047395

RP2060AJV R802VA100521M RCF6024MEA 55000 [16.1] 39500 [11.6] 15500 [4.5] 20.0 12.5 1725 [814.1] 41000 [12.0] 4.30 25400 [7.5] 2.26 10.5 9047402

RP2060AJV R802VA125524M RCF6024MEA 55000 [16.1] 39500 [11.6] 15500 [4.5] 20.0 13.0 1725 [814.1] 41000 [12.0] 4.34 25400 [7.5] 2.26 10.5 9047403

RP2060AJV R802VA125524Z RCF6024MEA 54500 [16.0] 39000 [11.4] 15500 [4.5] 19.5 12.5 1725 [814.1] 41000 [12.0] 4.16 25400 [7.5] 2.26 10.5 9135326

[ ] Designates Metric Conversions

Page 21

21

Air

Performance Data

RP20 Series

Performance Data @ AHRI Standard Conditions – Heat Pump (con’t.)

R96V: 96% AFUE 2-stage Variable Speed Multipoise Gas Furnace Ratings

Outdoor Unit Furnace Indoor Coil

Total Capacity

BTU/H [kW]

Net Sensible

BTU/H [kW]

Net Latent

BTU/H [kW]

SEER EER

Indoor CFM

[L/s]

47 Degree Heating

Capacity BTU/H

[kW]

47 Degree

COP

17 Degree Heating

Capacity BTU/H

[kW]

17 Degree

COP

Region IV

HSPF

AHRI#

RP2024AJV R96VA0402317M RCF3621MEA 24800 [7.3] 19100 [5.6] 5700 [1.7] 20.0 14.5 850 [401.2] 19600 [5.7] 4.56 12000 [3.5] 2.34 11.0 9047378

RP2024AJV R96VA0602317M RCF3621MEA 24800 [7.3] 19100 [5.6] 5700 [1.7] 20.0 14.5 850 [401.2] 19700 [5.8] 4.50 12000 [3.5] 2.34 11.0 9047379

RP2036AJV R96VA0852521M RCF6021SEA 35200 [10.3] 26900 [7.9] 8300 [2.4] 19.5 14.5 1150 [542.7] 29600 [8.7] 4.56 18350 [5.4] 2.46 10.5 9047386

RP2036AJV R96VA1002521M RCF6021SEA 35200 [10.3] 26900 [7.9] 8300 [2.4] 20.0 14.5 1150 [542.7] 29600 [8.7] 4.56 18350 [5.4] 2.46 10.5 9047387

RP2036AJV R96VA1152524M RCF6021SEA 35200 [10.3] 26900 [7.9] 8300 [2.4] 19.5 14.5 1150 [542.7] 29600 [8.7] 4.56 18350 [5.4] 2.46 10.5 9047388

RP2048AJV R96VA0852521M RCF6021SEA 46000 [13.5] 35700 [10.5] 10300 [3.0] 19.5 12.0 1675 [790.5] 36000 [10.6] 4.40 21800 [6.4] 2.40 11.0 9047396

RP2048AJV R96VA1002521M RCF6021SEA 46000 [13.5] 35700 [10.5] 10300 [3.0] 20.0 12.0 1675 [790.5] 36000 [10.6] 4.40 21800 [6.4] 2.40 11.0 9047397

RP2048AJV R96VA1152524M RCF6021SEA 46000 [13.5] 35700 [10.5] 10300 [3.0] 19.5 12.0 1675 [790.5] 35800 [10.5] 4.44 21800 [6.4] 2.40 11.0 9047398

RP2060AJV R96VA1152524M RCF6024MEA 54500 [16.0] 39000 [11.4] 15500 [4.5] 20.0 12.0 1725 [814.1] 41000 [12.0] 4.10 25400 [7.5] 2.20 10.5 9047404

R97V: 97% AFUE 2-stage Variable Speed Multipoise Gas Furnace Ratings

Outdoor Unit Furnace Indoor Coil

Total Capacity

BTU/H [kW]

Net Sensible

BTU/H [kW]

Net Latent

BTU/H [kW]

SEER EER

Indoor CFM

[L/s]

47 Degree Heating

Capacity BTU/H

[kW]

47 Degree

COP

17 Degree Heating

Capacity BTU/H

[kW]

17 Degree

COP

Region IV

HSPF

AHRI#

RP2024AJV R97VA060M317U RCF3621MEA 24800 [7.3] 19100 [5.6] 5700 [1.7] 20.0 14.5 850 [401.2] 19700 [5.8] 4.50 12000 [3.5] 2.34 11.0 9047380

RP2024AJV R97VA070M317U RCF3621MEA 24600 [7.2] 18900 [5.5] 5700 [1.7] 20.0 14.5 850 [401.2] 19700 [5.8] 4.50 12000 [3.5] 2.34 11.0 9047381

RP2036AJV R97VA085M521U RCF6021SEA 35200 [10.3] 26900 [7.9] 8300 [2.4] 19.5 14.5 1150 [542.7] 29600 [8.7] 4.56 18350 [5.4] 2.46 10.5 9047389

RP2036AJV R97VA100M521U RCF6021SEA 35200 [10.3] 26900 [7.9] 8300 [2.4] 20.0 14.5 1150 [542.7] 29600 [8.7] 4.56 18350 [5.4] 2.46 10.5 9047390

RP2036AJV R97VA115M524U RCF6021SEA 35200 [10.3] 26900 [7.9] 8300 [2.4] 19.5 14.5 1150 [542.7] 29600 [8.7] 4.56 18350 [5.4] 2.46 10.5 9047391

RP2048AJV R97VA085M521U RCF6021SEA 46000 [13.5] 35700 [10.5] 10300 [3.0] 19.5 12.0 1675 [790.5] 36000 [10.6] 4.40 21800 [6.4] 2.40 11.0 9047399

RP2048AJV R97VA100M521U RCF6021SEA 46000 [13.5] 35700 [10.5] 10300 [3.0] 20.0 12.0 1675 [790.5] 36000 [10.6] 4.40 21800 [6.4] 2.40 11.0 9047400

RP2048AJV R97VA115M524U RCF6021SEA 46000 [13.5] 35700 [10.5] 10300 [3.0] 19.5 12.0 1675 [790.5] 35800 [10.5] 4.44 21800 [6.4] 2.40 11.0 9047401

RP2060AJV R97VA115M524U RCF6024MEA 54500 [16.0] 39000 [11.4] 15500 [4.5] 20.0 12.0 1725 [814.1] 41000 [12.0] 4.10 25400 [7.5] 2.20 10.5 9047405

[ ] Designates Metric Conversions

Page 22

Air

Performance Data

RP20 Series

22

Performance Data @ OD Unit Overdrive (Max. Speed) Conditions – Heat Pump

High Sales Volume Tested Combination (HSVTC)

Outdoor Unit Air Handler

Total Capacity

BTU/H [kW]

Net Sensible

BTU/H [kW]

Net Latent

BTU/H [kW]

Indoor CFM

[L/s]

47 Degree

Heating Capacity

BTU/H [kW]

17 Degree

Heating Capacity

BTU/H [kW]

RP2024AJV RHMV2421HEAC 24000 [7.0] 18500 [5.4] 5500 [1.6]

850 [401.2] 19500 [5.7] 28000 [8.2]

RP2036AJV RHMV6021SEAC 35400 [10.4] 27200 [8.0] 8200 [2.4]

1175 [554.5] 29400 [8.6] 43500 [12.7]

RP2048AJV RHMV6021SEAC 46500 [13.6] 36200 [10.6] 10300 [3.0]

1650 [778.7] 35600 [10.4] 45500 [13.3]

RP2060AJV RHMV6024MEAC 55500 [16.3] 40100 [11.8] 15400 [4.5]

1750 [825.9] 41500 [12.2] 45000 [13.2]

R802V: Prestige 2-Stage 80% ECM Furnace Ratings

Outdoor

Unit

Furnace Indoor Coil

Total Capacity

BTU/H [kW]

Net Sensible

BTU/H [kW]

Net Latent

BTU/H [kW]

Indoor CFM

[L/s]

47 Degree

Heating Capacity

BTU/H [kW]

17 Degree

Heating Capacity

BTU/H [kW]

RP2024AJV R802VA050317M RCF3621MEA 24600 [7.2] 18900 [5.5] 5700 [1.7] 850 [401.2] 19700 [5.8] 28200 [8.3]

RP2024AJV R802VA075317M RCF3621MEA 24800 [7.3] 19100 [5.6] 5700 [1.7] 850 [401.2] 19600 [5.7] 28000 [8.2]

RP2024AJV R802VA100521M RCF3621MEA 24800 [7.3] 19100 [5.6] 5700 [1.7] 850 [401.2] 19500 [5.7] 28000 [8.2]

RP2036AJV R802VA050317M RCF6021SEA 34800 [10.2] 26500 [7.8] 8300 [2.4] 1150 [542.7] 30000 [8.8] 44000 [12.9]

RP2036AJV R802VA075317M RCF6021SEA 35200 [10.3] 26900 [7.9] 8300 [2.4] 1150 [542.7] 29600 [8.7] 43500 [12.7]

RP2036AJV R802VA100521M RCF6021SEA 35400 [10.4] 27100 [7.9] 8300 [2.4] 1150 [542.7] 29200 [8.6] 43500 [12.7]

RP2036AJV R802VA125524M RCF6021SEA 35400 [10.4] 27100 [7.9] 8300 [2.4] 1150 [542.7] 29200 [8.6] 43500 [12.7]

RP2048AJV R802VA075421M RCF6021SEA 46000 [13.5] 35700 [10.5] 10300 [3.0] 1675 [790.5] 36000 [10.6] 46000 [13.5]

RP2048AJV R802VA100521M RCF6021SEA 46500 [13.6] 36200 [10.6] 10300 [3.0] 1675 [790.5] 35200 [10.3] 45500 [13.3]

RP2048AJV R802VA125524M RCF6021SEA 46500 [13.6] 36200 [10.6] 10300 [3.0] 1675 [790.5] 35200 [10.3] 45500 [13.3]

RP2060AJV R802VA100521M RCF6024MEA 55000 [16.1] 39500 [11.6] 15500 [4.5] 1725 [814.1] 41500 [12.2] 45000 [13.2]

RP2060AJV R802VA125524M RCF6024MEA 55000 [16.1] 39500 [11.6] 15500 [4.5] 1725 [814.1] 41500 [12.2] 45000 [13.2]

[ ] Designates Metric Conversions

Page 23

Air

Performance Data

RP20 Series

23

Performance Data @ OD Unit Overdrive (Max. Speed) Conditions – Heat Pump (con’t.)

R96V: 96% AFUE 2-stage Variable Speed Multipoise Gas Furnace Ratings

Outdoor

Unit

Furnace Indoor Coil

Total Capacity

BTU/H [kW]

Net Sensible

BTU/H [kW]

Net Latent

BTU/H [kW]

Indoor CFM

[L/s]

47 Degree

Heating Capacity

BTU/H [kW]

17 Degree

Heating Capacity

BTU/H [kW]

RP2024AJV R96VA0402317M RCF3621MEA 24800 [7.3] 19100 [5.6] 5700 [1.7] 850 [401.2] 19600 [5.7] 28200 [8.3]

RP2024AJV R96VA0602317M RCF3621MEA 24800 [7.3] 19100 [5.6] 5700 [1.7] 850 [401.2] 19700 [5.8] 28200 [8.3]

RP2036AJV R96VA0852521M RCF6021SEA 35200 [10.3] 26900 [7.9] 8300 [2.4] 1150 [542.7] 29600 [8.7] 43500 [12.7]

RP2036AJV R96VA1002521M RCF6021SEA 35200 [10.3] 26900 [7.9] 8300 [2.4] 1150 [542.7] 29600 [8.7] 43500 [12.7]

RP2036AJV R96VA1152524M RCF6021SEA 35200 [10.3] 26900 [7.9] 8300 [2.4] 1150 [542.7] 29600 [8.7] 43500 [12.7]

RP2048AJV R96VA0852521M RCF6021SEA 46000 [13.5] 35700 [10.5] 10300 [3.0] 1675 [790.5] 36000 [10.6] 46000 [13.5]

RP2048AJV R96VA1002521M RCF6021SEA 46000 [13.5] 35700 [10.5] 10300 [3.0] 1675 [790.5] 36000 [10.6] 46000 [13.5]

RP2048AJV R96VA1152524M RCF6021SEA 46000 [13.5] 35700 [10.5] 10300 [3.0] 1675 [790.5] 35800 [10.5] 46000 [13.5]

RP2060AJV R96VA1152524M RCF6024MEA 54500 [16.0] 39000 [11.4] 15500 [4.5] 1725 [814.1] 42500 [12.5] 45500 [13.3]

R97V: 97% AFUE 2-stage Variable Speed Multipoise Gas Furnace Ratings

Outdoor

Unit

Furnace Indoor Coil

Total Capacity

BTU/H [kW]

Net Sensible

BTU/H [kW]

Net Latent

BTU/H [kW]

Indoor CFM

[L/s]

47 Degree

Heating Capacity

BTU/H [kW]

17 Degree

Heating Capacity

BTU/H [kW]

RP2024AJV R97VA060M317U RCF3621MEA 24800 [7.3] 19100 [5.6] 5700 [1.7] 850 [401.2] 19700 [5.8] 28200 [8.3]

RP2024AJV R97VA070M317U RCF3621MEA 24600 [7.2] 18900 [5.5] 5700 [1.7] 850 [401.2] 19700 [5.8] 28200 [8.3]

RP2036AJV R97VA085M521U RCF6021SEA 35200 [10.3] 26900 [7.9] 8300 [2.4] 1150 [542.7] 29600 [8.7] 43500 [12.7]

RP2036AJV R97VA100M521U RCF6021SEA 35200 [10.3] 26900 [7.9] 8300 [2.4] 1150 [542.7] 29600 [8.7] 43500 [12.7]

RP2036AJV R97VA115M524U RCF6021SEA 35200 [10.3] 26900 [7.9] 8300 [2.4] 1150 [542.7] 29600 [8.7] 43500 [12.7]

RP2048AJV R97VA085M521U RCF6021SEA 46000 [13.5] 35700 [10.5] 10300 [3.0] 1675 [790.5] 36000 [10.6] 46000 [13.5]

RP2048AJV R97VA100M521U RCF6021SEA 46000 [13.5] 35700 [10.5] 10300 [3.0] 1675 [790.5] 36000 [10.6] 46000 [13.5]

RP2048AJV R97VA115M524U RCF6021SEA 46000 [13.5] 35700 [10.5] 10300 [3.0] 1675 [790.5] 35800 [10.5] 46000 [13.5]

RP2060AJV R97VA115M524U RCF6024MEA 54500 [16.0] 39000 [11.4] 15500 [4.5] 1725 [814.1] 42500 [12.5] 45500 [13.3]

[ ] Designates Metric Conversions

Page 24

Air

Guide Specifications

RP20 Series

24

GUIDE SPECIFICATIONS

General

System Description

Outdoor-mounted, air-cooled, split-system heat pump unit suitable for ground or rooftop installation. Unit consists of a hermetic

compressor, composite basepan, an air-cooled coil, propellertype condenser fan, suction and liquid line service valve, and a

control box. Unit will discharge supply air upward as shown on

contract drawings. Unit will be used in a refrigeration circuit to

match up to a coil unit.

Quality Assurance

— Unit will be rated in accordance with the latest edition of AHRI

Standard 210.

— Unit will be certified for capacity and efficiency, and listed in

the latest AHRI directory.

— Unit construction will comply with latest edition of ANSI/

ASHRAE and with NEC.

— Unit will be constructed in accordance with UL standards and

will carry the UL label of approval. Unit will have c-UL-us

approval.

— Unit cabinet will be capable of withstanding ASTM B117 1000-

hr salt spray test.

— Air-cooled condenser coils will be leak tested at 150 psig and

pressure tested at 550 psig.

— Unit constructed in ISO9001 approved facility.

Delivery, Storage, and Handling

— Unit will be shipped as single package only and is stored and

handled per unit manufacturer’s recommendations.

Warranty (for inclusion by specifying engineer) — U.S. and

Canada only.

Products

Equipment

Factory assembled, single piece, air-cooled heat pump unit. Contained within the unit enclosure is all factory wiring, piping, controls, compressor, refrigerant charge R-410A, and special features required prior to field start-up.

Unit Cabinet

— Unit cabinet will be constructed of galvanized steel, bonder-

ized, and coated with a powder coat paint.

— All units constructed with louver coil protection and corner post.

Louver can be removed by removing one fastener per louver

panel.

AIR-COOLED, SPLIT-SYSTEM HEAT PUMP

RP20

1-1/2 TO 5 NOMINAL TONS

Fans

— Condenser fan will be direct-drive propeller type, discharging

air upward.

— Condenser fan motors will be totally enclosed, 1-phase type

with class B insulation and permanently lubricated bearings.

Shafts will be corrosion resistant.

— Fan blades will be statically and dynamically balanced.

— Condenser fan openings will be equipped with coated steel

wire safety guards.

Compressor

— Compressor will be hermetically sealed.

— Compressor will be mounted on rubber vibration isolators.

— Compressor will be Copeland fully variable speed.

Condenser Coil

— Condenser coil will be air cooled.

— Coil will be constructed of aluminum fins mechanically bonded

to copper tubes.

Refrigeration Components

— Refrigeration circuit components will include liquid-line shutoff

valve with sweat connections, vapor-line shutoff valve with

sweat connections, system charge of R-410A refrigerant, and

compressor oil.

— Unit will be equipped with filter drier for R-410A refrigerant for

field installation.

Operating Characteristics

— The capacity of the unit will meet or exceed _____ Btuh at a

suction temperature of _____ °F/°C. The power consumption

at full load will not exceed _____ kW.

— Combination of the unit and the evaporator or fan coil unit will

have a total net cooling capacity of _____ Btuh or greater at

conditions of _____ CFM entering air temperature at the evap-

orator at _____ °F/°C wet bulb and _____ °F/°C dry bulb, and

air entering the unit at _____ °F/°C.

— The system will have a SEER of _____ Btuh/watt or greater at

DOE conditions.

Electrical Requirements

— Nominal unit electrical characteristics will be _____ v, single

phase, 60 hz. The unit will be capable of satisfactory operation

within voltage limits of _____ v to _____ v.

— Nominal unit electrical characteristics will be _____ v, three

phase, 60 hz. The unit will be capable of satisfactory operation

within voltage limits of _____ v to _____ v.

— Unit electrical power will be single point connection.

— Control circuit will be 24v.

Special Features

— Refer to section of this literature identifying accessories and

descriptions for specific features and available enhancements.

Page 25

Air

Limited Warranty

RP20 Series

25

GENERAL TERMS OF LIMITED WARRANTY*

Rheem will furnish a replacement for any part of this product

which fails in normal use and service within the applicable

period stated, in accordance with the terms of the limited

warranty.

*For complete details of the Limited and Conditional Warranties, including

applicable terms and conditions, contact your local contractor or the

Manufacturer for a copy of the product warranty certificate.

Conditional Unit Replacement

(Registration Required) ...............................Ten (10) Years

Parts............................................................Ten (10) Years

Page 26

Air

Notes

RA20 Series

26

Page 27

Air

Notes

RA20 Series

27

Page 28

The new degree of comfort.

™

Rheem Heating, Cooling & Water Heating • P.O. Box 17010

Fort Smith, Arkansas 72917 • www.rheem.com

In keeping with its policy of continuous progress and product improvement, Rheem reserves the right to make changes without notice.

PRINTED IN U.S.A. 2/17 QG FORM NO. P11-811 REV. 3

Rheem Canada Ltd./Ltée • 125 Edgeware Road, Unit 1

Brampton, Ontario • L6Y 0P5

Loading...

Loading...