Rheem RP1336AD1NA, RP1360AC1NA, RP1348AC1NA, RP1342AC1NA, RP1342AD1NA Installation Instructions Manual

...Page 1

WARNING:

RECOGNIZE THIS SYMBOL

AS AN INDICATION OF

IMPORTANT SAFETY

INFORMATION

WARNING

THESE INSTRUCTIONS

ARE INTENDED AS AN AID

TO QUALIFIED, LICENSED

SERVICE PERSONNEL FOR

PROPER INSTALLATION,

ADJUSTMENT, AND

OPERATION OF THIS UNIT.

READ THESE INSTRUCTIONS

THOROUGHLY BEFORE

ATTEMPTING INSTALLATION

OR OPERATION. FAILURE

TO FOLLO W THESE

INSTRUCTIONS MAY RESULT

IN IMPROPER INSTALLATION,

ADJUSTMENT, SERVICE,

OR MAINTENANCE

POSSIBLY RESULTING IN

FIRE, ELECTRICAL SHOCK,

PROPERTY DAMAGE,

PERSONAL INJURY, OR

DEATH.

R-410A HEAT PUMP

OUTDOOR UNITS

INSTALLATION INSTRUCTIONS

RP13 (13 SEER)

RP14 (14 SEER) AND RP15 (15 SEER)

Do not destroy this manual.

Please read carefully and

keep in a safe place for future

reference by a serviceman.

[ ] indicates metric conversions.

92-105074-04-01 (1/15)

Printed in USA

Page 2

CONTENTS

Important

Safety Information ��������������������������������������������� 3

General Information ����������������������������������������4-7

Checking Product Received ����������������������������������������4

Application �������������������������������������������������������������������4

Electrical and Physical Data ������������������������������������� 5-6

Specifications ���������������������������������������������������������������7

Contents

Proper Installation ��������������������������������������������������������7

Installation ���������������������������������������������������� 8-19

Choosing a Location �������������������������������������� 8-10

Operational Issues��������������������������������������������������������8

Corrosive Environment �������������������������������������������������8

For Units With

Space Limitations ���������������������������������������������������������9

Customer Satisfaction Issues ��������������������������������������9

Unit Mounting ���������������������������������������������������������������9

Factory-Preferred

Tie-Down Method���������������������������������������������������������9

Snow Depth Table ������������������������������������������������������ 10

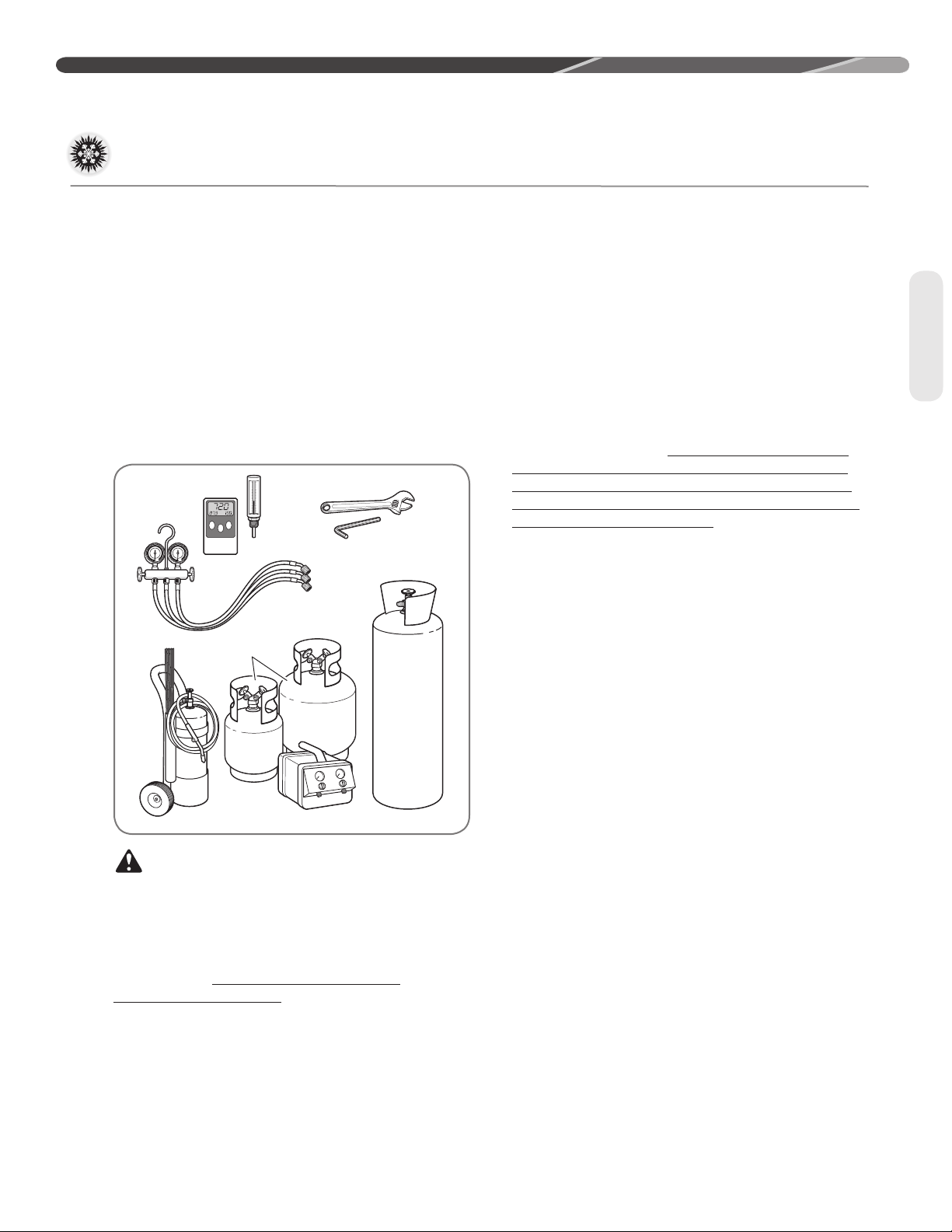

Tools and Refrigerant ���������������������������������������11

Tools Required for Installing and

Servicing R-410A Models ������������������������������������������11

Specifications of R-410A �������������������������������������������11

Quick-Reference

Guide for R-410A �������������������������������������������������������11

Replacement Units �������������������������������������������12

Indoor Coil ��������������������������������������������������������12

Location ����������������������������������������������������������������������12

Interconnecting Tubing �������������������������������� 12-26

Refrigerant Level Adjustment �������������������������������������12

Maximum Length of Lines ������������������������������������������12

Outdoor Unit Installed

Above or Below Indoor Coil ��������������������������������� 13-26

Tubing Installation ������������������������������������������������������24

Tubing Connections ���������������������������������������������������25

Leak Testing ���������������������������������������������������������������26

Wiring ���������������������������������������������������������27-28

Control Wiring ������������������������������������������������������������27

Conventional 24 VAC

Thermostat Control Wiring �����������������������������������������27

Typical Thermostat Wiring Diagrams �������������������������27

Power Wiring �������������������������������������������������������������� 28

Grounding ������������������������������������������������������������������� 28

Start-Up

Start-Up ����������������������������������������������������������������������29

Checking Airflow ��������������������������������������������������������29

Evacuation Procedure ����������������������������������������������� 30

Final Leak Testing ���������������������������� ���������������������������30

Checking

Refrigerant Charge �������������������������������������� 31-33

Charging Units

With R-410A Refrigerant ��������������������������������������������31

Confirm ID Airflow

and Coils Are Clean ���������������������������������������������������31

Measurement Device Setup ���������������������������������������31

Charging by Weight ����������������������������������������������������31

Gross Charging by Pressures ������������������������������������32

Final Charge by Subcooling ���������������������������������������32

Finishing Up Installation ��������������������������������������������� 33

Components and Controls ������������������������������� 34

Compressor

Crankcase Heat (CCH) ��������������������������������������34

Hard-Start Components ������������������������������������34

High- and Low-Pressure

Controls (HPC and LPC) ������������������������������������34

Demand Defrost ��������������������������������������������������� 35-36

Accessories ����������������������������������������������������� 37

Remote Outdoor

Temperature Model ����������������������������������������������������37

Low Ambient Control (LAC) �������������������������������������� 37

Diagnostics ������������������������������������������������ 38-40

Cooling Mechanical

Checks Flowchart ����������������������������������������������������� 38

Heating Mechanical

Checks Flowchart ����������������������������������������������������� 39

Defrost Mechanical

Checks Flowchart ����������������������������������������������������� 40

General Troubleshooting Chart ������ ���������������������������41

Service Analyzer Charts ��������������������������������������� 42-46

Cooling/Heating Tips �������������������������������������������������������������47

Wiring Diagrams ���������������������������������������� 48-50

������������������������������������������������������29-33

2

Page 3

IMPORTANT SAFETY INFORMATION

WARNINGS:

• These instructions are intended as an aid to

qualified, licensed service personnel for proper

installation, adjustment, and operation of this

unit� Read these instructions thoroughly before

attempting installation or operation� Failure to

follow these instructions may result in improper

installation, adjustment, service, or maintenance

possibly resulting in fire, electrical shock,

property damage, personal injury, or death.

• The unit must be permanently grounded. Failure

to do so can cause electrical shock resulting in

severe personal injury or death.

• Turn off electric power at the fuse box or service

panel before making any electrical connections.

• Complete the ground connection before making

line voltage connections. Failure to do so can

result in electrical shock, severe personal injury,

or death.

• Disconnect all power to unit before starting

maintenance. Failure to do so can cause

electrical shock resulting in severe personal

injury or death.

• Never assume the unit is properly wired and/or

grounded. Always test the unit cabinet with a

noncontact voltage detector available at most

electrical supply houses or home centers before

removing access panels or coming into contact

with the unit cabinet.

• Do not use oxygen to purge lines or pressurize

system for leak test. Oxygen reacts violently with

oil, which can cause an explosion resulting in

severe personal injury or death.

• The top of the scroll compressor shell is hot�

Touching the compressor top may result in serious

personal injury�

• The manufacturer’s warranty does not cover

any damage or defect to the unit caused by the

attachment or use of any components, accessories,

or devices (other than those authorized by the

manufacturer) into, onto, or in conjunction with

the heat pump� You should be aware that the

use of unauthorized components, accessories,

or devices may adversely affect the operation

of the heat pump and may also endanger life

and property. The manufacturer disclaims any

responsibility for such loss or injury resulting

from the use of such unauthorized components,

accessories, or devices�

CAUTIONS:

• R-410A systems operate at approximately 60%

higher pressures (1�6 times) than R-22 systems� Do

not use R-22 service equipment or components on

R-410A equipment� Use appropriate care when using

this refrigerant� Failure to exercise care may result in

equipment damage or personal injury�

• Only match this outdoor unit with a matched indoor

coil or air handler approved for use with this outdoor

unit per the unit manufacturer’s specification sheet�

The use of unmatched coils or air handler will likely

result in a charge imbalance between the cooling

and heating modes which can cause unsatisfactory

operation including a high-pressure switch lockout

condition�

• Only use indoor coils approved for use on R-410A

systems� An R-22 coil will have a TXV or fixed

restrictor device that is not designed to operate

properly in an R-410A system and will result in

serious operational issues� The R-22 coil could also

contain mineral oil which is incompatible with the

POE oil used in R-410A systems and could result in

reliability issues with the compressor and TXVs�

• When coil is installed over a finished ceiling and/or

living area, it is required that a secondary sheet metal

condensate pan be constructed and installed under

the entire unit� Failure to do so can result in property

damage�

• The compressor has an internal overload protector�

Under some conditions, it can take up to 2 hours for

this overload to reset� Make sure overload has had

time to reset before condemning the compressor�

• UNIT MAY START SUDDENLY AND WITHOUT

WARNING� A flashing red light on the heat pump/

defrost control indicates a call for unit operation is

present at the heat pump/defrost control� The heat

pump/defrost control will attempt to start unit after

the anti-short cycle time expires, when a high or low

pressure control automatically resets, or when the

heat pump/defrost control exits the lockout mode as

the temperature rises above 5°F�

Safety

3

Page 4

GENERAL INFORMATION

WARNING:

Improper installation, or installation not made in

accordance with these instructions, can result

in unsatisfactory operation and/or dangerous

conditions and can cause the related warranty

not to apply.

The RP series of heat pumps are designed to

operate with standard 24 VAC thermostats and air

handlers or gas furnaces�

This installation instruction manual contains

complete instructions for installation and setup

using conventional 24 VAC controls� Please refer

to the manufacturer’s specification sheets for

complete performance data, thermostat, and

accessory listings�

The information contained in this manual has

been prepared to assist in the proper installation,

operation, and maintenance of the air conditioning

system�

General Information

Read this manual and any instructions packaged

with separate equipment required to make up the

system prior to installation� Homeowner should

retain this manual for future reference�

To achieve optimum efficiency and capacity,

the matching indoor cooling coils listed in the

manufacturer’s specification sheet must be used

for this model heat pump�

Checking Product Received

Upon receiving unit, inspect it for any shipping

damage� Claims for damage, either apparent or

concealed, should be filed immediately with the

shipping company� Check model number, electrical

characteristics, and accessories to determine if they

are correct� Check system components (indoor coil,

outdoor unit, air handler/furnace, etc�) to make sure

they are properly matched�

Application

Before specifying any heat pump equipment,

a survey of the structure and a heat loss and

heat gain calculation must be made� A heat loss

calculation involves identifying all surfaces and

openings that lose heat to the surrounding air

and quantifying that heat loss� A cooling heat

gain calculation makes similar measurements

and determines the amount of heat needed

to be removed� A heat gain calculation also

calculates the extra heat load caused by sunlight

and by humidity removal� These factors must

be considered before selecting a heat pump

system to provide year-round comfort� The Air

Conditioning Contractors of America (ACCA)

J Manual method of load calculation is one

recognized procedure for determining the heating

and cooling load�

After the proper equipment combination has

been selected, satisfying both sensible and

latent requirements, the system must be properly

installed� Only then can the unit provide the

comfort it was designed to provide�

There are several factors that installers must

consider�

• Outdoor unit location

• Indoor unit blower speed and airflow

• Proper equipment evacuation

• Supply and return air duct design and sizing

• Refrigerant charge

• System air balancing

• Diffuser and return air grille location and sizing

4

Page 5

GENERAL INFORMATION

Model

Number

Voltage

Phase

Freq

Rated Load

Amperes

(RLA)

Locked Rotor

Amperes

(LRA)

Fan

Motor

Full

Load

Amperes

(FLA)

Minimum

Circuit

Ampacity

Amperes

Minimum

Amperes

Maximum

Amperes

Face

Area

Sq. Ft .

[m

2

]

No.

Rows

CFM

[L/s]

Refrig .

Per

Circuit

(oz.)

[g]

Net

Lbs.

[kg]

Shipping

Lbs. [kg]

Fuse or HACR

Circuit Breaker

Outdoor Coil WeightCompressor

ELECTRICAL PHYSICAL

RP1418AJ1NA 208-230 1 60 9/9 48.0 0.70 12/12 20/20 15/15 9.06 [0.84] 1 2411 [1137] 97 [2750] 149 [67.6] 156 [70.8]

RP1424AJ1NA 208-230 1 60 12.8/12.8 58.3 0.70 17/17 25/25 20/20 9.06 [0.84] 1 2411 [1137] 89 [2523] 144 [65.3] 151 [68.5]

RP1430AJ1NA 208-230 1 60 14.1/14.1 73.0 0.70 19/19 30/30 25/25 11.14 [1.03] 1 2535 [1196] 106 [3005] 155 [70.3] 162 [73.5]

RP1436AJ1NA 208-230 1 60 15.4/15.4 83.9 0.60 20/20 35/35 25/25 14.82 [1.38] 1 3333 [1573] 111 [3146] 171 [77.6] 178 [80.7]

RP1442AJ1NA 208-230 1 60 17.9/17.9 112.0 0.90 24/24 40/40 30/30 14.82 [1.38] 1 2943 [1389] 155 [4394] 201 [91.2] 208 [94.3]

RP1448AJ1NA 208-230 1 60 19.6/19.6 130.0 1.20 26/26 45/45 35/35 19.76 [1.82] 1 4055 [1913] 143 [4054] 227 [103.0] 234 [106.1]

RP1460AJ1NA 208/230 1 60 23.7/23.7 152.5 1.00 31/31 50/50 40/40 24.23 [2.25] 1 4780 [2255] 232 [6577] 262 [118.8] 269 [122.0]

RP1436AC1NA 208-230 3 60 10.4 73.0 0.80 14 24.3 16.5 14.82 [1.38] 1 3333 [1573] 111 [3146] 171 [77.6] 178 [80.7]

RP1442AC1NA 208-230 3 60 13.5 88.0 1.00 18 31.4 21.3 14.82 [1.38] 1 2943 [1389] 155 [4394] 201 [91.2] 208 [94.3]

RP1448AC1NA 208-230 3 60 13.7 83.1 1.20 19 32.1 21.8 19.76 [1.84] 1 4055 [1913] 143 [4054] 227 [103.0] 234 [106.1]

RP1460AC1NA 208-230 3 60 15.9 110.0 1.00 21 36.8 24.8 24.23 [2.25] 1 4780 [2255] 232 [6577] 262 [118.8] 269 [122.0]

RP1436AD1NA 460 3 60 5.8 38.0 0.50 8 13.5 9.2 14.82 [1.38] 1 3333 [1573] 111 [3146] 171 [77.6] 178 [80.7]

RP1442AD1NA 460 3 60 6.0 44.0 0.50 8 13.9 9.4 14.82 [1.38] 1 2943 [1389] 155 [4394] 201 [91.2] 208 [94.3]

RP1448AD1NA 460 3 60 6.2 41.0 0.60 9 14.6 9.9 19.76 [1.84] 1 4055 [1913] 143 [4054] 227 [103.0] 234 [106.1]

RP1460AD1NA 460 3 60 7.1 52.0 0.50 10 16.4 11.1 24.23 [2.25] 1 4780 [2255] 232 [6577] 262 [118.8] 269 [122.0]

Model

Number

Voltage

Phase

Freq

Rated Load

Amperes

(RLA)

Locked Rotor

Amperes

(LRA)

Fan

Motor

Full

Load

Amperes

(FLA)

Minimu m

Circuit

Ampacity

Amperes

Minimu m

Amperes

Maximum

Amperes

Face

Area

Sq. Ft .

[m

2

]

No.

Rows

CFM

[L/s]

Refrig .

Per

Circuit

(oz.)

[g]

Net

Lbs.

[kg]

Shipping

Lbs. [kg]

Fuse or HACR

Circuit Breaker

Outdoor Coil We ightCompressor

ELECTRICAL PHYSICAL

RP1518AJ1NA 208-230 1 60 9/ 9 48.0 0.70 12/12 20/20 15/15 9.06 [0.84] 1 2411 [1137] 97 [2750] 123 [55.8] 130 [59.0]

RP1524AJ1NA 208-230 1 60 12.8/12.8 58.3 0.70 17/17 25/25 20/20 11.14 [1.03] 1 2411 [1137] 88 [2495] 131 [59.4] 138 [62.6]

RP1530AJ1NA 208-230 1 60 14.1/14.1 73.0 1.00 19/19 30/30 25/25 17.29 [1.61] 1 3840 [1812] 122 [3459] 160 [72.6] 167 [75.7]

15.4/15.4

83.9 2.80

22/22

35/35

30/30 19.76 [1.84]

3889 [1835] 118 [3345]

172 [78.0]

179 [81.2]

RP1542AJ1NA

208-230 1 60

17.9/17.9

112.0 1.00

23/23

40/40 30/30

19.76 [1.84]

1

3773 [1781] 139 [3941]

180 [81.6] 187 [84.8]

RP1548AJ1NA

18.5/18.5

124.0 2.80

26/26 40/40 35/35 24.23 [2.25]

5180 [2445] 188 [5330]

208 [94.3]

215 [97.5]

RP1560AJ1NA

208-230 1 60

23.7/23.7

152.5

1.00

31/31

50/50

40/40 28.26 [2.62]

1

3654 [1724] 212 [6010]

236 [107.0] 243 [110.2]

RP1536AJ1NA

208-230 1 60

208-230 1 60

1

1

RP1536AC1NA 208-230 3 60 1

10.4

73.0 2.80

16/16

20/20

25/25

19.76 [1.84]

3121 [1472] 124 [3515] 172 [78.0]

179 [81.2]

208-230 3 60 1 RP1542AC1NA

13.5

88.0

1.00 18/18

25/25 30/30 19.76 [1.84] 3815 [1800]

145 [4110]

180 [81.6] 187 [84.8]

RP1548AC1NA

208-230 3 60

13.8

83.11 2.80

21/21

25/25 30/30 24.23 [2.25]

4379 [2066] 194 [5500]

208 [94.3] 215 [97.5]

RP1560AC1NA

208-230 3 60

15.9

110.0

1 1.00 21/21

25/25 35/35

28.26 [2.62]

3654 [1724] 223 [6321]

236 [107.0] 243 [110.2]

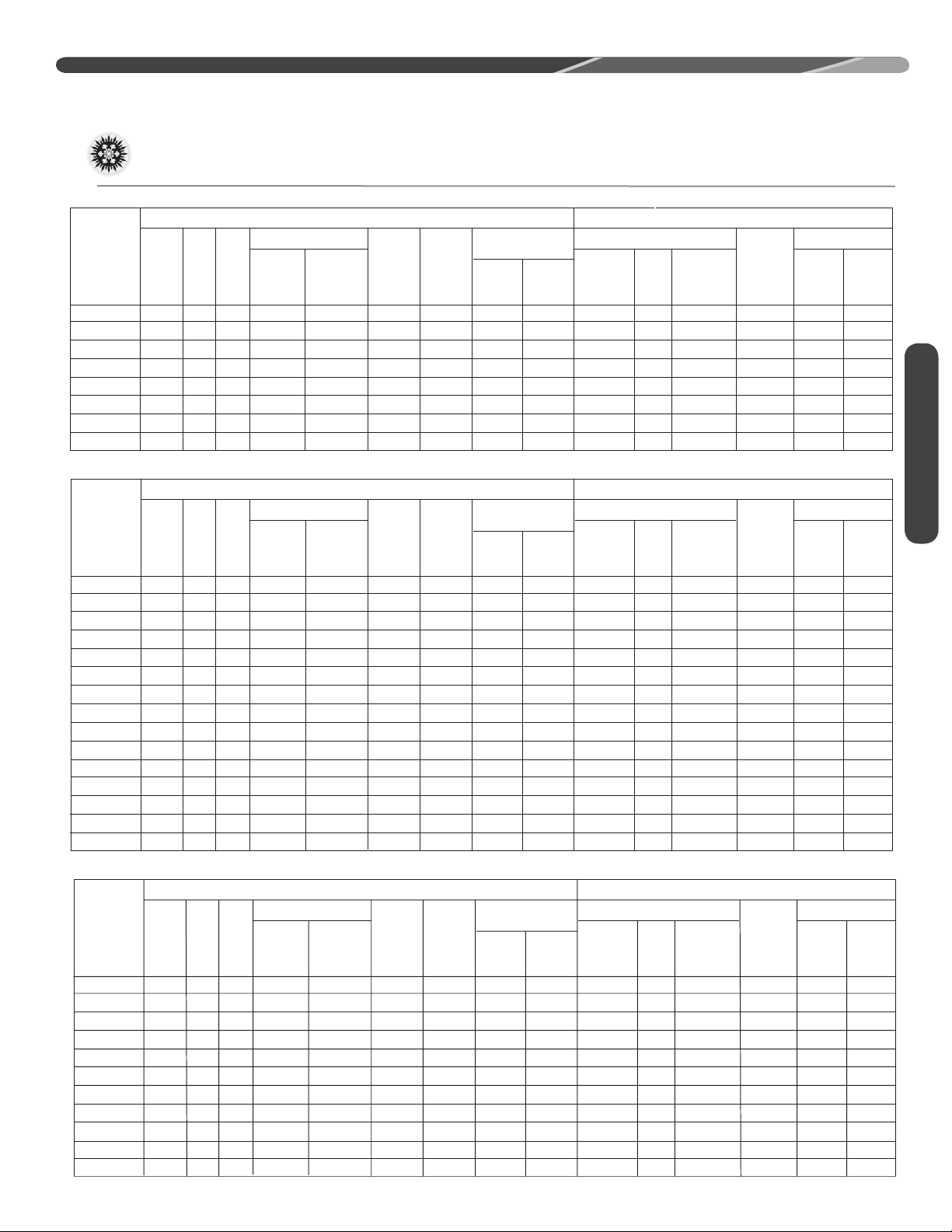

Electrical and Physical Data

RP13

ELECTRICAL PHYSICAL

Fan

Model

Number

RP1336AC1NA 208-230 3 60 10.4 73.0 0.80 14 24.3 16.5 14.82 [1.38] 1 3333 [1573] 111 [3146] 171 [77.6] 178 [80.7]

RP1342AC1NA 208-230 3 60 13.5 88.0 1.00 18 31.4 21.3 14.82 [1.38] 1 2943 [1389] 201 [91.2] 208 [94.3]

RP1348AC1NA 208-230 3 60 13.7 83.1 1.20 19 32.1 21.8 19.76 [1.84] 1 4055 [1913]

RP1360AC1NA 208-230 3 60 15.9 110.0 1.00 21 36.8 24.8 24.23 [2.25] 1 4780 [2255]

RP1336AD1NA 460 3 60 5.8 38.0 0.50 8 13.5 9.2 14.82 [1.38] 1 3333 [1573]

RP1342AD1NA 460

RP1348AD1NA 460

RP1360AD1NA 460

Voltage

Phase

3 60 6.0 44.0

3 60

3 60

Rated Load

Freq

Amperes

6.2 41.0 0.60

7.1 52.0 0.50

(RLA)

Locked Rotor

Amperes

(LRA)

Amperes

0.50

Motor

Full

Load

(FLA)

Minimum

Circuit

Ampacity

Amperes

8

9

10

Fuse or HACR

Circuit Breaker

Minimum

Amperes

13.9

14.6

16.4

Maximum

Amperes

9.4

9.9

11.1

14.82 [1.38]

19.76 [1.84]

24.23 [2.25]

RP14

Face

Area

Sq. Ft .

[m

Outdoor Coil We ightCompressor

No.

Rows

2

]

CFM

[L/s]

1

2943 [1389]

1

4055 [1913]

1

4780 [2255]

Refrig .

Per

Circuit

(oz.)

[g]

155 [4394]

143 [4054]

232 [6577]

111 [3146]

155 [4394]

143 [4054]

232 [65717]

227 [103.0] 234 [106.1]

262 [118.8] 269 [122.0]

171 [77.6] 178 [80.7]

Net

Lbs.

[kg]

201 [91.2]

227 [103.0]

262 [118.8]

Shipping

Lbs. [kg]

208 [94.3]

234 [106.1]

269 [122.0]

General Information

RP15

5

Page 6

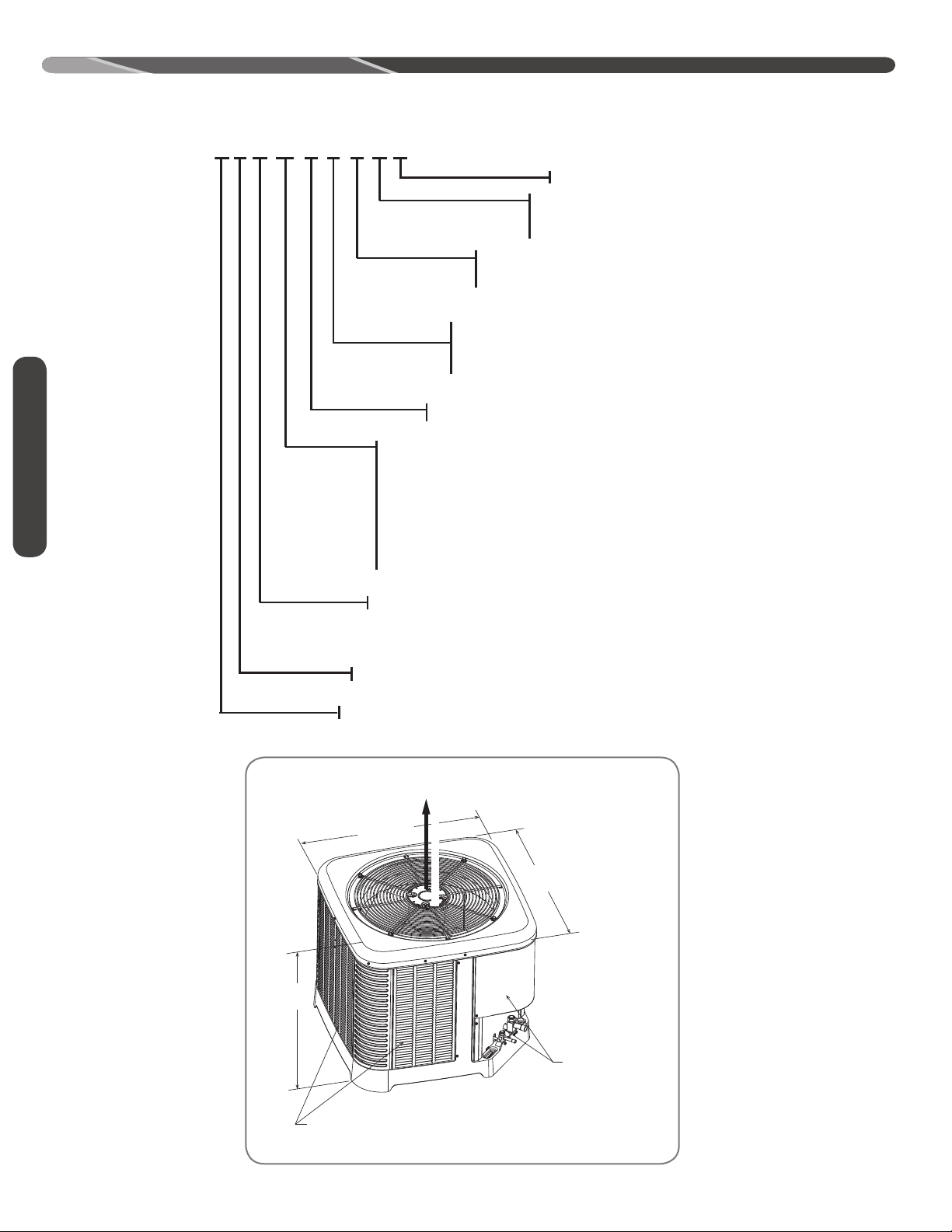

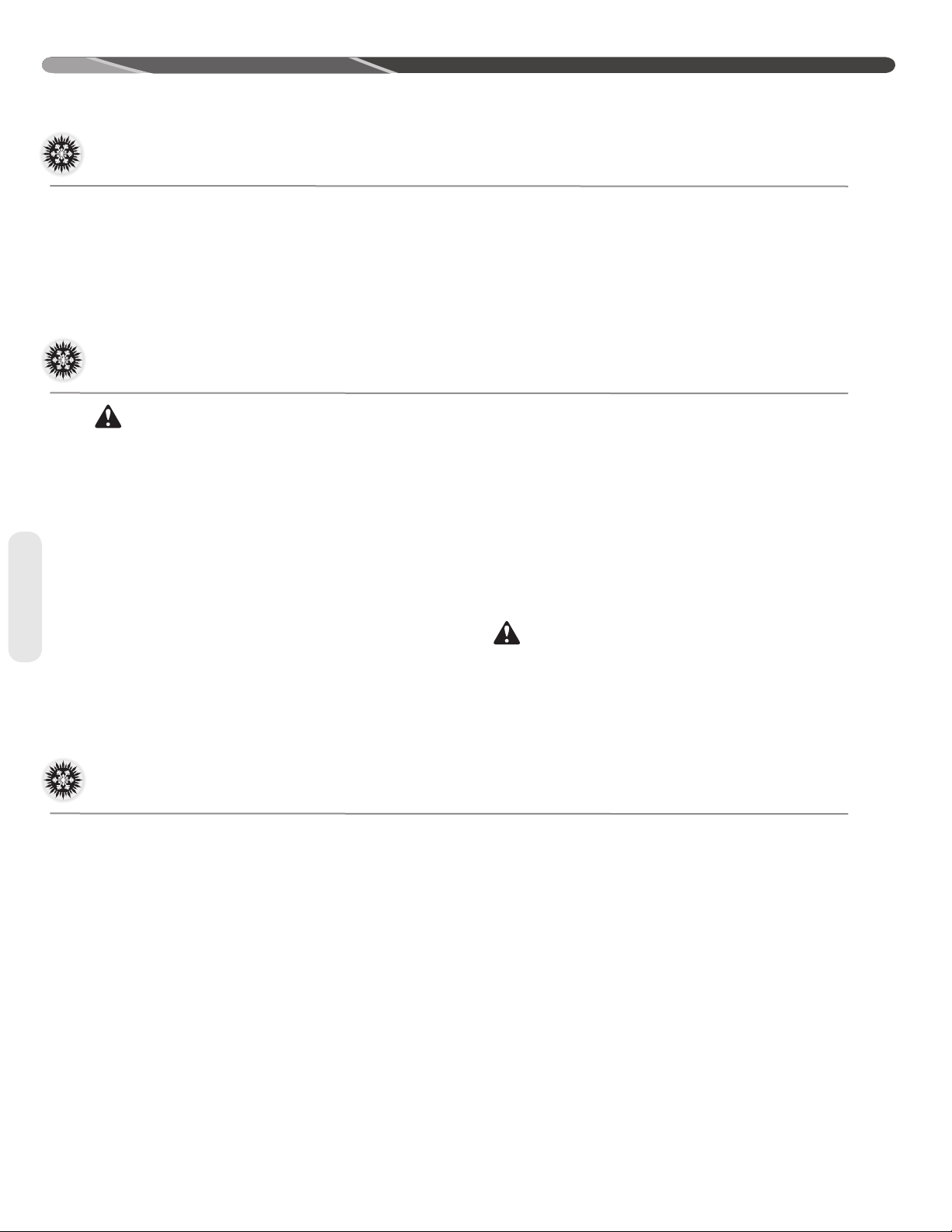

“ L”

“W”

“H”

A

I

R

D

I

S

C

H

A

R

G

E

ALLOW 60” [1524mm]

OF CLEARANCE

AIR INLET LOUVERS ALLOW

6” [152mm] Min. OF CLEARANCE ALL SIDES

12” [305mm] RECCOMMENDED

SERVICE PANELS/

INLET CONNECTIONS / HIGH & LOW

VOLTAGE ACCESS

ALLOW 24” [ 610 mm] OF CLEARANCE

ST-A1226-02-00

R P 14 24 A J 1 N A

MINOR SERIES

Z

TYPE

1 - SINGLE STAGE P - PISTON

VOLTAGE

J = 1 PH, 208-230/60

C = 3 PH, 208-230/60

D = 3 PH, 460/60

MAJOR SERIES

CAPACITY

18 = 18000 BTU/HR [5.28 kW]

24 = 24000 BTU/HR [7.03 kW]

30 = 30000 BTU/HR [8.79 kW]

36 = 36000 BTU/HR [10.55 kW]

42 = 42000 BTU/HR [12.31 kW]

48 = 48000 BTU/HR [14.07 kW]

60 = 60000 BTU/HR [17.58 kW]

13 SEER

14 SEER

15 SEER

HEAT PUMP

BRAND

CONTROLS

C - COMMUNICATING

N - NON-COMMUNICATING

GENERAL INFORMATION

General Information

6

ALLOW 60" [1524mm] OF

CLEARANCE

AIR INLET LOUVERS ALLOW

6" [152 mm] OF CLEARANCE ALL SIDES

12" [305 mm] RECOMMENDED

SERVICE PANELS/

INLET CONNECTIONS /

HIGH & LOW VOLTAGE

ACCESS ALLOW

24" [610 mm] OF

CLEARANCE

Page 7

Specifications

GENERAL INFORMATION

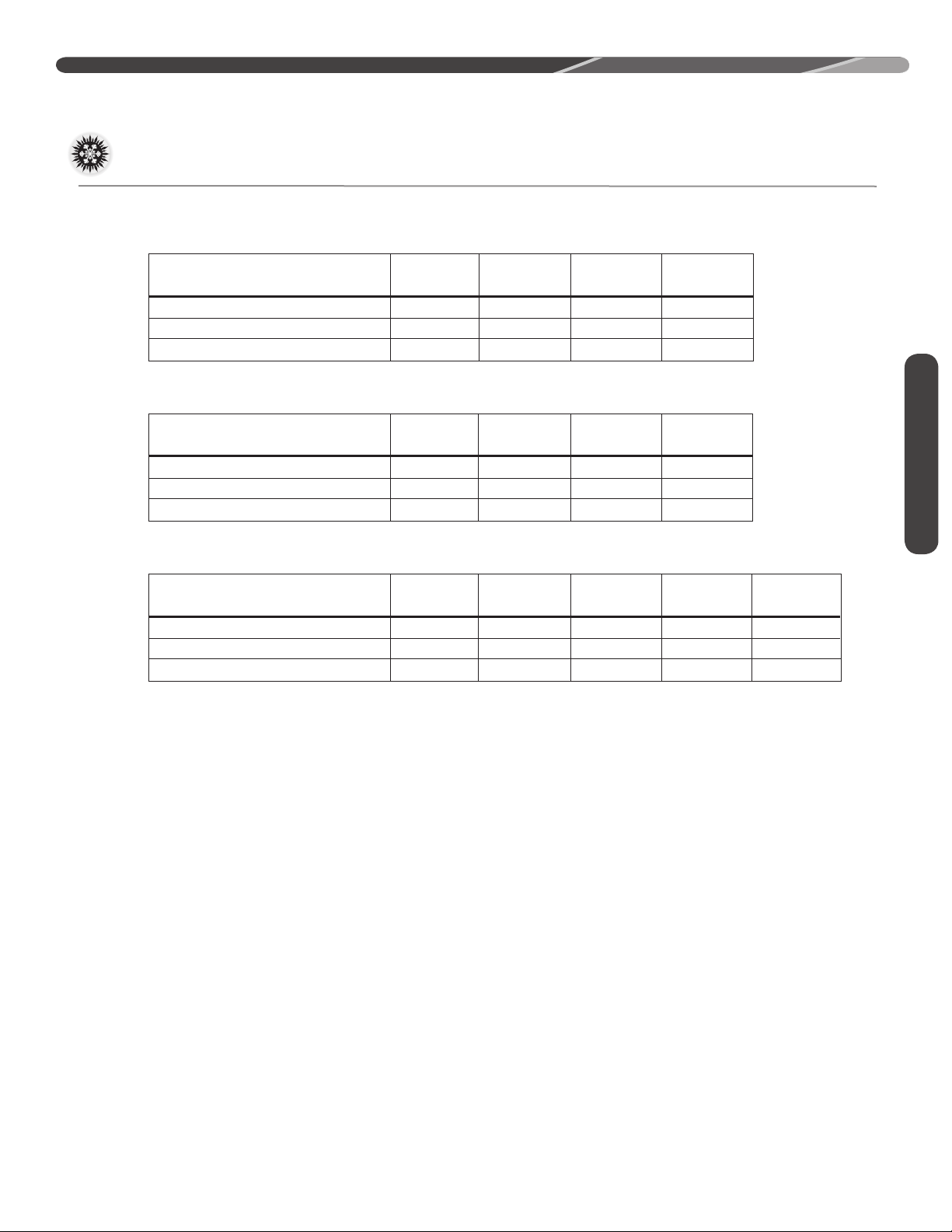

DIMENSIONAL DATA

Height “H” inches (mm)

Length “L” inches (mm)

Width “W” inches (mm)

Height “H” inches (mm)

Length “L” inches (mm)

Width “W” inches (mm)

Height “H” inches (mm)

Length “L” inches (mm)

Width “W” inches (mm)

RP13

RP14

RP15

18, 24, 30

25 (635)27 (686)39 (991)35 (889)

29.75 (756)33.75 (857) 35.75 (908)33.75 (857)

29.75 (756)

18, 24, 30

25 (635) 27 (686)39 (991)35 (889)

29.75 (756)33.75 (857) 35.75 (908)33.75 (857)

29.75 (756)

18, 24 30 36, 42 48 60

25 (635) 27 (686) 27 (686) 31 (787) 35 (889)

29.75 (756) 29.75 (756) 33.75 (857) 33.75 (857) 35.75 (908)

29.75 (756) 29.75 (756) 33.75 (857) 33.75 (857) 35.75 (908)

36, 42 6048

33.75 (857)

36, 42 6048

33.75 (857)

35.75 (908)33.75 (857)

35.75 (908)33.75 (857)

General Information

Proper Installation

Proper sizing and installation of this equipment is

critical to achieve optimal performance� Use the

information in this Installation Instruction Manual

and reference the applicable manufacturer’s

specification sheet when installing this product�

IMPORTANT: This product has been

designed and manufactured to meet ENERGY

STAR criteria for energy efficiency when matched

with appropriate indoor components� However,

proper refrigerant charge and proper airflow are

critical to achieve rated capacity and efficiency�

Installation of this product should follow the

manufacturer’s refrigerant charging and airflow

instructions� Failure to confirm proper charge

and airflow may reduce energy efficiency and

shorten equipment life�

MATCH ALL COMPONENTS:

• OUTDOOR UNIT

• INDOOR COIL

• INDOOR AIR HANDLER/FURNACE

• REFRIGERANT LINES

• INDOOR THERMOSTAT

7

Page 8

INSTALLATION

Choosing a Location

Location

IMPORTANT:

national building codes and ordinances for special

installation requirements� Following location

information will provide longer life and simplified

servicing of the outdoor heat pump�

Consult local and

NOTICE: These units must be installed

outdoors� No ductwork can be attached, or

other modifications made, to the discharge grille�

Modifications will affect performance or operation�

Operational Issues

IMPORTANT: Locate the unit

in a manner that will not prevent, impair, or

compromise the performance of other equipment

installed in proximity to the unit� Maintain all

required minimum distances to gas and electric

meters, dryer vents, and exhaust and inlet

openings� In the absence of national codes or

manufacturers’ recommendations, local code

recommendations and requirements will take

precedence�

• Refrigerant piping and wiring should be properly

sized and kept as short as possible to avoid

capacity losses and increased operating costs�

• Locate the unit where water runoff will not create

a problem with the equipment� Position the unit

away from the drip edge of the roof whenever

possible� Units are weatherized, but can be

affected by the following:

• Water pouring into the unit from the junction

of rooflines, without protective guttering�

Large volumes of water entering the heat

pump while in operation can impact fan blade

or motor life, and coil damage may occur to a

heat pump if moisture cannot drain from the

unit under freezing conditions�

• Freezing moisture or sleeting conditions can

cause the cabinet to ice-over prematurely

and prevent heat pump operation, requiring

backup heat, which generally results in less

economical operation�

• Closely follow the clearance recommendations

on page 8�

• 24" [61.0 cm] to the service panel access

• 60" [152.4 cm] above heat pump fan

discharge (unit top) to prevent recirculation

• 6" [15.2 cm] to heat pump coil grille air inlets

with 12" [30.5 cm] minimum recommended

Corrosive Environment

The metal parts of this unit may be subject to

rust or deterioration if exposed to a corrosive

environment� This oxidation could shorten the

equipment’s useful life�

Corrosive elements include, but are not limited to,

salt spray, fog or mist in seacoast areas, sulphur or

chlorine from lawn watering systems, and various

chemical contaminants from industries such as

paper mills and petroleum refineries�

If the unit is to be installed in an area where

contaminants are likely to be a problem, special

attention should be given to the equipment

location and exposure�

• Avoid having lawn sprinkler heads spray directly

on the unit cabinet�

• In coastal areas, locate the unit on the side of

the building away from the waterfront�

• Shielding provided by a fence or shrubs may

give some protection, but cannot violate

minimum airflow and service access clearances�

• Elevating the unit off its slab or base enough to

allow air circulation will help avoid holding water

against the base pan�

WARNING: Disconnect all power

to unit before starting maintenance� Failure to do

so can cause electrical shock resulting in severe

personal injury or death�

Regular maintenance will reduce the buildup of

contaminants and help to protect the unit’s finish�

• Frequent washing of the cabinet, fan blade, and

coil with fresh water will remove most of the salt

or other contaminants that build up on the unit�

• Regular cleaning and waxing of the cabinet with

a good automobile polish will provide some

protection�

• A good liquid cleaner may be used several times

a year to remove matter that will not wash off

with water�

8

Page 9

INSTALLATION

SERVICE PANELS/

INLET CONNECTIONS

/ HIGH & LOW

VOLTAGE ACCESS

ALLOW 24” [610 mm] OF

CLEARANCE

ALLOW 60” [1524 mm]

OF CLEARANCE

AIR INLET LOUVERS ALLOW

6” [152 mm] Min. OF

CLEARANCE ALL SIDES

12” [305 mm] RECOMMENDED

ST-A1226-04-00

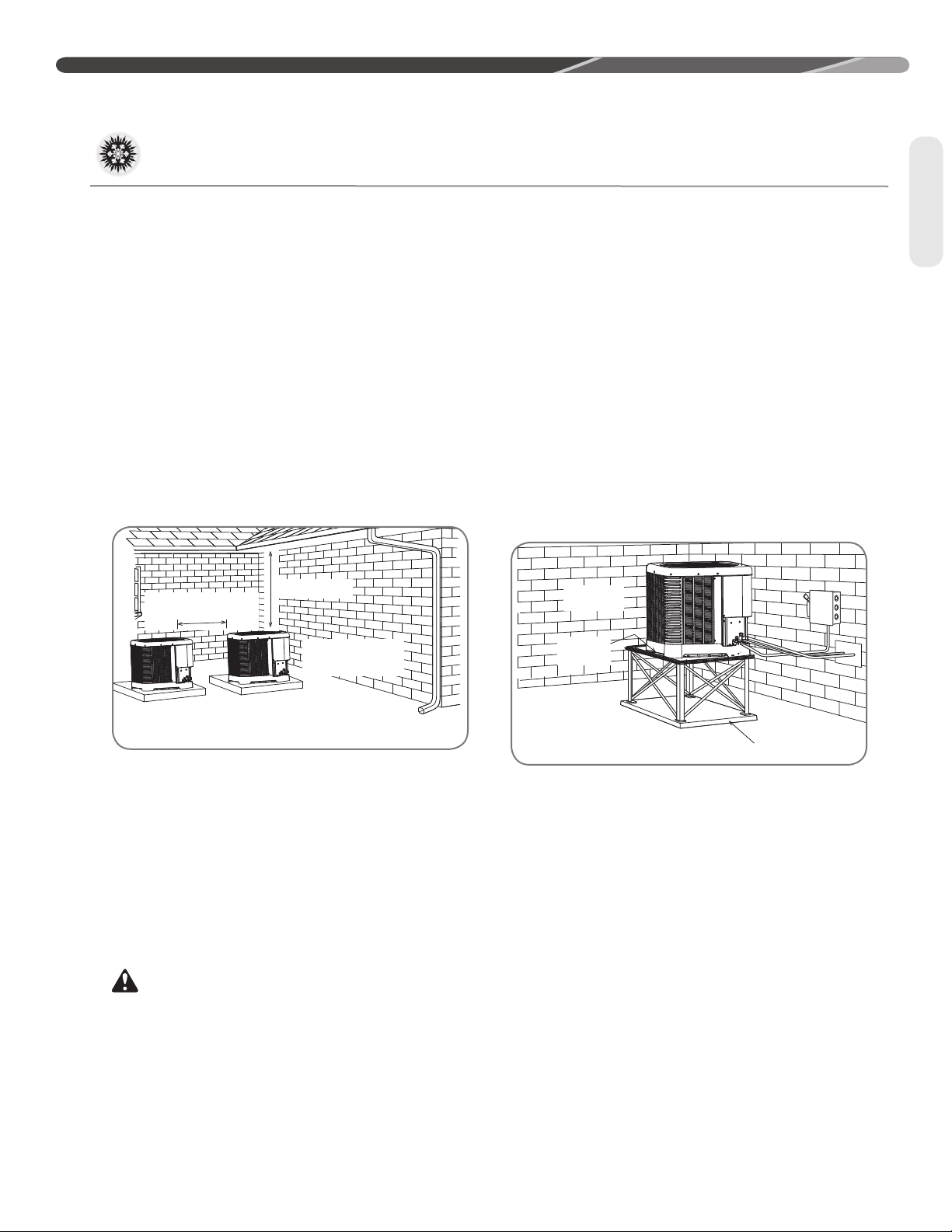

6" MIN. (152 mm) FOR 1.5 & 2 TON

9" MIN. (229 mm) FOR 2.5-5 TON

24" MIN. (610 mm)

ST-A1226-03-00

ELEVATE ABOVE

ANTICIPATE HIGH

SNOW FALL

DO NOT BLOCK

OPENINGS

IN BASE PAN

BASE PAD

(CONCRETE OR OTHER SUITABLE

MATERIAL)

Choosing a Location (cont�)

For Units With Space

Limitations

In the event that a space limitation exists, we will

permit the following clearances:

Single-Unit Applications: Clearances below 6"

[15.2 cm] will reduce unit capacity and efficiency.

Do not reduce the 60" [152.4 cm] discharge or the

24" [61.0 cm] service clearances.

Multiple-Unit Applications: When multiple

condenser grille sides are aligned, a 6" [15.2

cm] clearance is recommended for 1.5 and 2

ton models and 9" [22.9 cm] for 2.5 ton to 5 ton

models� Two combined clearances below the

minimum will reduce capacity and efficiency� Do

not reduce the 60" [152.4 cm] discharge or 24"

[61.0 cm] service clearances.

Location

• If elevating a unit on a flat roof, use 4" x 4"

[10.2 cm x 10.2 cm] or equivalent stringers

positioned to distribute unit weight evenly and

prevent noise and vibration�

• Where snowfall is anticipated, raise the unit

above the base pad to prevent ice buildup and

coil damage� Mount the unit high enough to be

above the average accumulated area snowfall�

See “Ground Snow Depth” chart on page 9 for

representative snow depths�

NOTICE: Do not block drain openings on

bottom of unit�

• If unit must be elevated because of anticipated

snowfall, secure unit and elevating stand such

that unit and/or stand will not tip over or fall off�

Keep in mind that someone may try to climb on

unit�

Customer Satisfaction Issues

• The heat pump should be located away from the

living, sleeping, and recreational spaces of the

owner and those spaces on adjoining property�

• To prevent noise transmission, the mounting pad

for the outdoor unit should not be connected to

the structure and should be located a sufficient

distance above grade to prevent ground water

from entering the unit�

Unit Mounting

WARNING: Secure an elevated unit

and its elevating stand in order to prevent tipping�

Failure to do so may result in severe personal

injury or death�

Elevation of Unit

If elevating the heat pump, either on a flat roof or

on a slab, observe the following guidelines�

Factory-Preferred Tie-Down

Method for High Wind or

Seismic Loads

IMPORTANT: The manufacturer-

approved/recommended method is a guide to

securing equipment for wind and seismic loads�

Other methods might provide the same result, but

the manufacturer method is the only one endorsed

by the manufacturer for securing equipment where

wind or earthquake damage can occur� Additional

information is available in the PTS (Product

Technical Support) section of the manufacturer’s

Web sites Rheemote�net, MyRheem�com, or

MyRuud�com and can be found as a listing under

each outdoor model� If you do not have access to

this site, your distributor can offer assistance�

9

Page 10

INSTALLATION

Choosing a Location (cont�)

Location

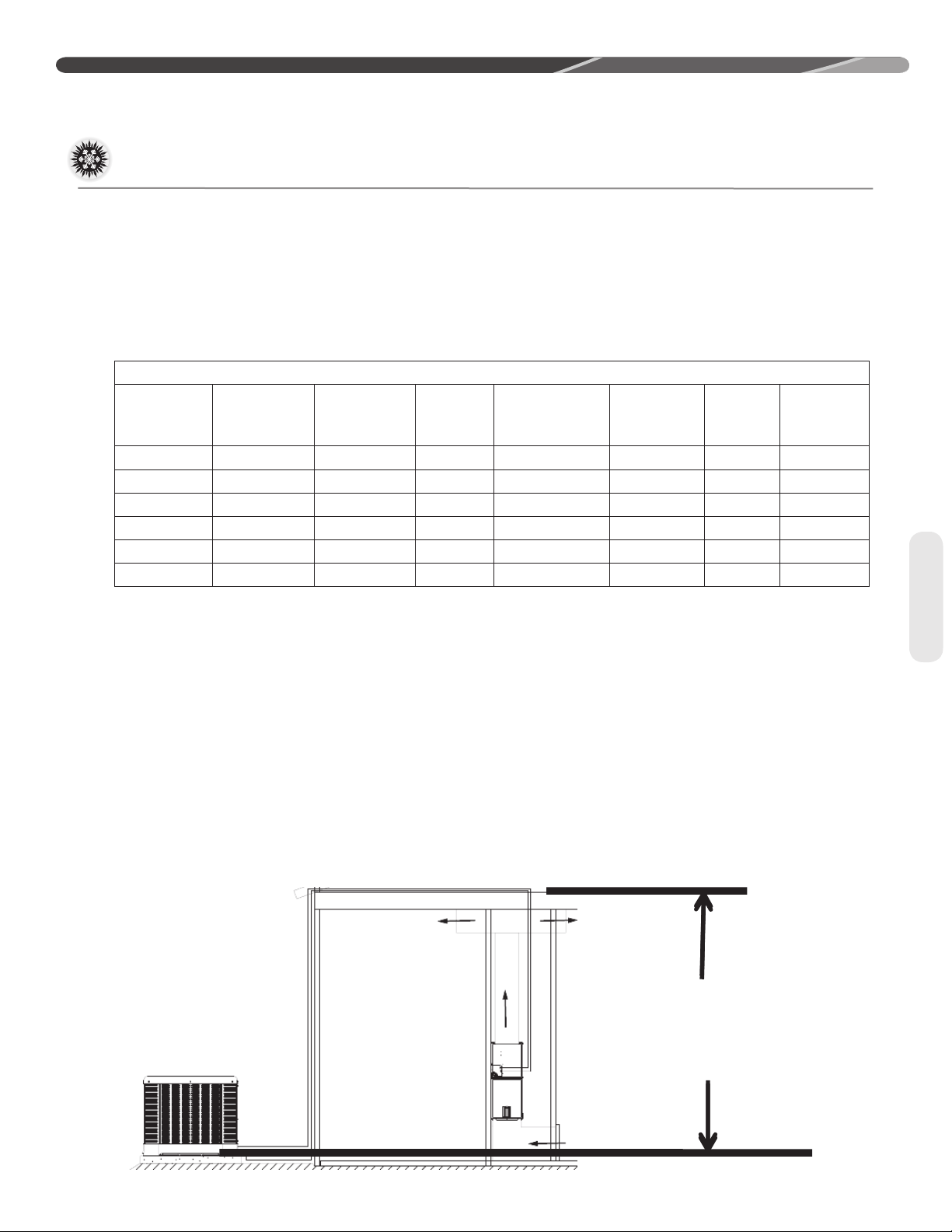

ALABAMA INDIANA MINNESOTA NEW MEXICO PENNSYLVANIA VIRGINIA

Huntsville 7 Evansville 12 Duluth 64 Albuquerque 4 Allentown 23 Dulles Airport 19

ARIZONA

Flagstaff 48 Indianapolis 21

Prescott 3 South Bend 44 Rochester 50

Winslow 7

ARKANSAS

Ft. Smith 5 Des Moines 22 Jackson 3 Buffalo 42 Williamsport 20

Little Rock 6 Dubuque 38 MISSOURI

CALIFORNIA

Blue Canyon 25 Waterloo 36 Kansas City 18 Rochester 38

Mt. Shasta 69

COLORADO

Alamosa 15 Dodge City 12

Colorado Springs 14 Goodland 14 Billings 17 Cape Hattaras 5 Aberdeen 42

Denver 15 Topeka 19 Glasgow 17 Charlotte 10 Huron 43 Beckley 51

Grand Junction 16 Wichita 11 Great Falls 16 Greensboro 11 Rapid City 14 Charleston 20

Pueblo 7

CONNECTICUT

Bridgeport 23 Lexington 12 Kalispell 53 Winston-Salem 17 Bristol 8

Hartford 29 Louisville 11 Missoula 23

New Haven 15

DELAWARE

Wilmington 13 Portland 62 Lincoln 20 Williston 25 Nashville 8 Milwaukee 32

GEORGIA MARYLAND

Athens 5 Baltimore 17 North Platte 15 Akron-Canton 15 Abilene 6 Casper 10

Macon 8

IDAHO

Boise 6 Nantucket 18 Valentine 22 Dayton 11 El Paso 5 Sheridan 25

Lewiston 9 Worcester 35

0 Pocatello 7

ILLINOIS

Chicago O’Hare 18 Detroit City 9 Reno 11

Chicago 22 Detroit Airport 17 Winnemucca 6 Oklahoma City 5 Wichita Falls 5

Moline 17

Peoria 16 Flint 28 Concord 66

Rockford 25 Grand Rapids 37

Springfield 23 Houghton Lake 56 Atlantic City 11 Eugene 17 Wendover 3

NOTICE:

Local records and experience must be considered when establishing the unit installation height� There is a 2% probability that

Fort Wayne 17 International Falls 43 Clayton 10 Erie 19 Lynchburg 16

IOWA

Burlington 17

Sioux City 33 Columbia 21

KANSAS

Concordia 23 Springfield 14

KENTUCKY

Covington 12 Helena 18 Wilmington 9

MAINE NEBRASKA

Caribou 100 Grand Island 30 Fargo 34 Memphis 5 Madison 32

MASSACHUSETTS

Boston 30 Scottsbluff 11 Columbus 10 Dallas 3 Lander 20

MICHIGAN

Alpena 53 Ely 9 Youngstown 12 Midland 2

Detroit – Willow Run

Lansing 42 Newark 15 Medford 8

Marquette 53 Pendleton 11 Burlington 37

Muskegon 43 Portland 10

Sault Ste. Marie 80 Salem 7

the ground snow depth shown in this table will be exceeded annually� Drifts have not been considered� This data represents 184

10

National Weather Service locations at which measurements are made and assumes a nationwide snow density of 12 lb�/ft�

GROUND SNOW DEPTH – INCHES

Minneapolis/St. Paul

St. Cloud 53 Albany 25 Pittsburgh 22 Richmond 12

MISSISSIPPI

St. Louis 16 Syracuse 35 Columbia 12 Spokane 41

MONTANA

Havre 24 Raleigh-Durham 10 Sioux Falls 38 Elkins 21

Norfolk 29

Omaha 20 Cleveland 16 Amarillo 10 Cheyenne 15

NEVADA

Elko 20 Toledo Express 8 Lubbock 10

NEW HAMPSHIRE

21

NEW JERSEY

50 Roswell 8 Harrisburg 23 National Airport 18

NEW YORK

Binghamton 35 Scranton 16 Roanoke 17

NYC – Kennedy Airport 18

NYC – LaGuardia Airport 18

NORTH CAROLINA

Asheville 12

NORTH DAKOTA

Bismarck 25 Knoxville 8 La Crosse 32

OHIO TEXAS WYOMING

Mansfield 17 Fort Worth 6

OKLAHOMA

Tulsa 8

OREGON

Burns City 24 Salt Lake City 8

Philadelphia 16 Norfolk 9

WASHINGTON

RHODE ISLAND

Providence 21 Quillayute 24

SOUTH CAROLINA

Greenville 4 Stampede Pass 51

SOUTH DAKOTA

TENNESSEE

Chattanooga 6 Green Bay 36

San Antonio 3

UTAH

Milford 16

VERMONT

Olympia 24

Seattle-Tacoma 14

Yakima 25

WEST VIRGINIA

Huntington 15

WISCONSIN

3

Page 11

Tools and Refrigerant

Ambient and Tube

Thermometers

Manifold

Gauge

Set

Brazing

Rods

Torch Nitrogen

Reclaimer

Recovery

Cylinders

Allen Wrench

Crescent Wrench

INSTALLATION

Tools Required for Installing

and Servicing R-410A Models

Manifold Sets:

– Up to 800 PSIG High-Side

– Up to 250 PSIG Low-Side

– 550 PSIG Low-Side Retard

Manifold Hoses:

– Service Pressure Rating of 800 PSIG

Recovery Cylinders:

– 400 PSIG Pressure Rating

– Dept� of Transportation 4BA400 or BW400

CAUTION: R-410A systems operate

at higher pressures than R-22 systems� Do not

use R-22 service equipment or components on

R-410A equipment�

Specifications of R-410A

Application: R-410A is not a drop-in

replacement for R-22� Equipment designs must

accommodate its higher pressures� It cannot be

retrofitted into R-22 heat pumps�

Physical Properties: R-410A has an atmospheric

boiling point of -62.9°F [-52.7°C] and its saturation

pressure at 77°F [25°C] is 224.5 psig.

Composition: R-410A is a near-azeotropic

mixture of 50% by weight difluoromethane (HFC-

32) and 50% by weight pentafluoroethane (HFC-

125)�

Pressure: The pressure of R-410A is

approximately 60% (1�6 times) greater than

R-22� Recovery and recycle equipment, pumps,

hoses, and the like must have design pressure

ratings appropriate for R-410A� Manifold sets

need to range up to 800 psig high-side and 250

psig low-side with a 550 psig low-side retard.

Hoses need to have a service pressure rating of

800 psig. Recovery cylinders need to have a 400

psig service pressure rating, DOT 4BA400 or DOT

BW400.

Combustibility: At pressures above 1

atmosphere, a mixture of R-410A and air can

become combustible� R-410A and air should

never be mixed in tanks or supply lines or

be allowed to accumulate in storage tanks�

Leak checking should never be done with a

mixture of R-410A and air� Leak-checking can

be performed safely with nitrogen or a mixture of

R-410A and nitrogen�

Quick-Reference Guide For

R-410A

• R-410A refrigerant operates at approximately

60% higher pressure (1�6 times) than R-22�

Ensure that servicing equipment is designed to

operate with R-410A�

• R-410A refrigerant cylinders are light rose in

color�

• R-410A, as with other HFCs, is only compatible

with POE oils�

• Vacuum pumps will not remove moisture from

POE oil used in R-410A systems�

• R-410A systems are to be charged with liquid

refrigerants� Prior to March 1999, R-410A

refrigerant cylinders had a dip tube� These

cylinders should be kept upright for equipment

charging� Post-March 1999 cylinders do not

have a dip tube and should be inverted to ensure

liquid charging of the equipment�

• Do not install a suction line filter drier in the

liquid line�

• A factory-approved biflow liquid line filter drier

is shipped with every unit and must be installed

in the liquid line at the time of installation� Only

manufacturer-approved liquid line filter driers can

be used� These are Sporlan (CW083S) and Alco

(80K083S) driers� These filter driers are rated for

minimum working pressure of 600 psig� The filter

drier will only have adequate moisture-holding

capacity if the system is properly evacuated�

• Desiccant (drying agent) must be compatible for

POE oils and R-410A refrigerant�

Tools

11

Page 12

INSTALLATION

Replacement Units

Tubing

To prevent failure of a new unit, the existing line set

must be correctly sized and cleaned or replaced�

Care must be exercised that the expansion device

is not plugged� For new and replacement units, a

liquid line filter drier must be installed and refrigerant

tubing must be properly sized� Test the oil for acid� If

positive, a suction line filter drier is mandatory�

Indoor Coil

CAUTION: Only use evaporators

approved for use on R-410A systems that are

specifically matched with the outdoor unit per

the manufacturer’s specification sheets� Use

of existing R-22 evaporators can introduce

mineral oil to the R-410A refrigerant, forming two

different liquids and decreasing oil return to the

compressor� This can result in compressor failure�

REFER TO INDOOR COIL MANUFACTURER’S

INSTALLATION INSTRUCTIONS.

IMPORTANT: The manufacturer is not

responsible for the performance and operation of

a mismatched system or for a match listed with

another manufacturer’s coil�

NOTICE: All outdoor units must be

installed with a matched TXV indoor coil� Refer to

manufacturer’s outdoor unit specification sheet for

approved indoor coils�

IMPORTANT: When replacing an

R-22 unit with an R-410A unit, either replace

the line set or ensure that residual mineral oil is

drained from existing lines including oil trapped in

low spots�

The thermostatic expansion valve in the

matching coil is specifically designed to operate

with R-410A� DO NOT use an R-22 TXV or

evaporator� The existing evaporator must

be replaced with the factory-specified TXV

evaporator specifically designed for R-410A�

Location

Do not install the indoor coil in the return duct

system of a gas or oil furnace� Provide a service

inlet to the coil for inspection and cleaning� Keep

the coil pitched toward the drain connection�

CAUTION: When coil is installed

over a finished ceiling and/or living area, it is

required that a secondary condensate pan be

installed under entire unit� Failure to do so can

result in property damage�

12

Interconnecting Tubing

The purpose of this section is to specify the

best construction/sizing practices for installing

interconnection tubing between the indoor and

outdoor unit�

Refrigerant Level Adjustment

All units are factory-charged with R-410A

refrigerant to cover 15 feet of standard size

interconnecting liquid and vapor lines with a

required field installed filter drier� Adjustment of

charge may be necessary even if the application

has exactly 15 feet of line set due to other

installation variables such as pressure drop,

vertical lift, and indoor coil size� For different

lengths, adjust the charge as indicated below�

• 1/4" ± .3 oz./foot [6.4 mm ± 8.5 g/.30 m]

• 5/16" ± .4 oz./foot [7.9 mm ± 11.3 g/.30 m]

• 3/8" ± .6 oz./foot [9.5 mm ± 17.0 g/.30 m]

• 1/2" ± 1.2 oz./foot [12.7 mm ± 34.0 g/.30 m]

• 6 oz. required factory supplied field-installed

• filter drier�

Charge Adjustment = (Line Set (oz./ft.) x Total

Length) – Factory Charge for Line Set

Example: A three ton heat pump unit with factory

installed 3/8” liquid service valve requires 75 ft. of

line set with a liquid line diameter of 1/2”.

Factory Charge for Line Set = 15 ft. x .6 oz. = 9 oz.

Charge Adjustment = (1.2 oz. x 75 ft.) – 9 oz. =

+ 81 oz.

Page 13

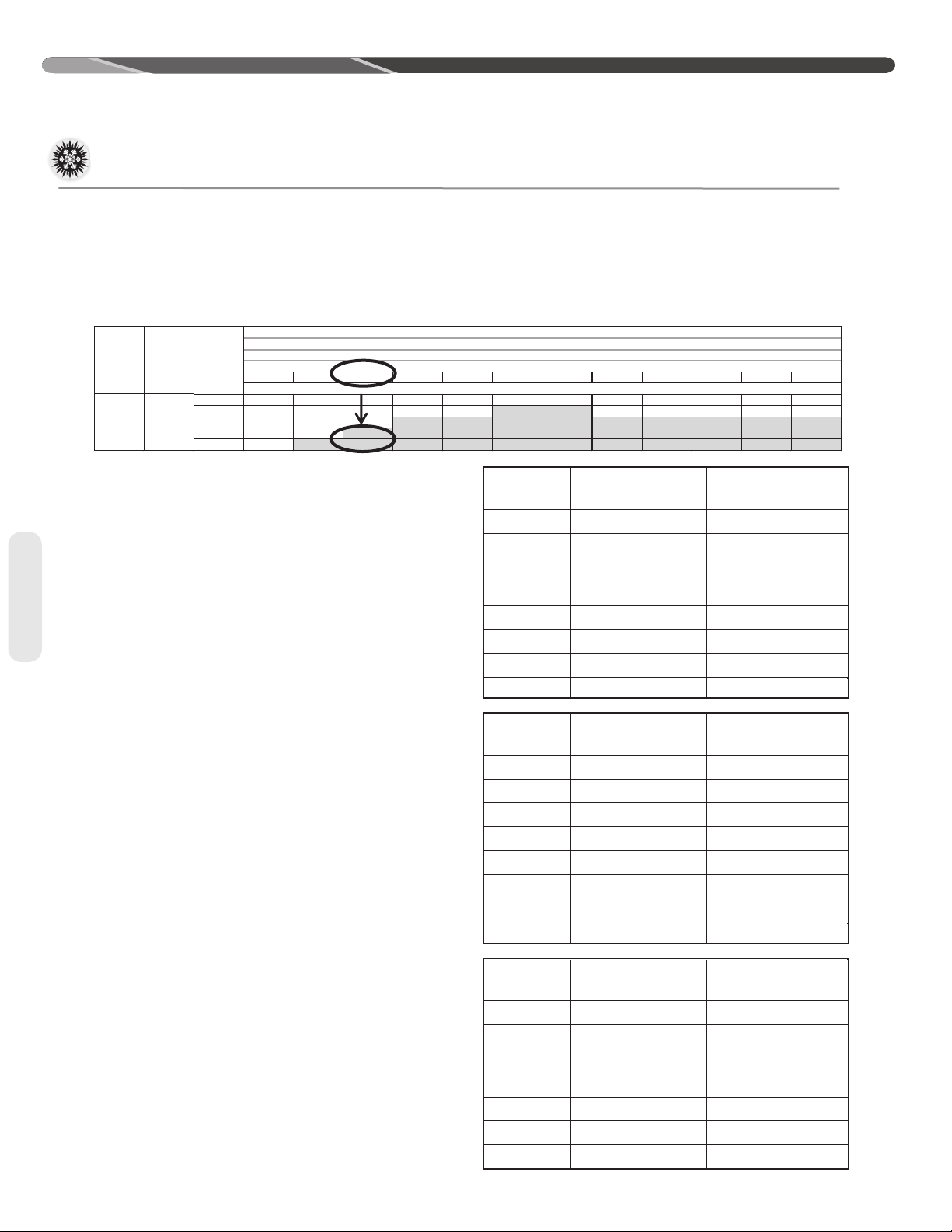

Interconnecting Tubing (cont�)

INSTALLATION

Interconnecting Tubing and

Fitting Losses

Refrigerant tubing is measured in terms of actual

length and equivalent length� Actual length is used

for refrigerant charge applications� Equivalent

length takes into account pressure losses from

Table 1

Equivalent Length for Fings ()

90° Short

Line Size

(in)

3/8 1.3 0.8 0.3 6 4 0.4 6

1/2 1.4 0.9 0.4 9 5 0.6 6

5/8 1.5 1 0.5 12 6 0.8 6

3/4 1.9 1.3 0.6 14 7 0.9 6

7/8 2.3 1.5 0.7 15 8 1 6

1-1/8 2.7 1.8 0.9 22 12 1.5 6

Radius

Elbow

90° Long

Radius

Elbow

45°

Elbow

Liquid Line Selection

The purpose of the liquid line is to transport warm

sub-cooled liquid refrigerant from the outdoor unit

to the indoor unit� It is important not to allow the

refrigerant to ash any superheated vapor prior

to the expansion device of the indoor coil� The

ashing of refrigerant can occur for the following

reasons:

• Low refrigerant charge

• Improperly selected liquid line size

• Absorption of heat prior to expansion device

• Excessive vertical rise between the condenser

and evaporator

Table 2 lists the equivalent length per 25’ of liquid

line at various diameters up to 300’� The total pres-

tubing length, ttings, vertical separation, accessories, and lter dryers. The table below references

dierent commonly used equivalent lengths.

Solenoid

Valve

sure drop allowed for the liquid line is 50 PSI� The

procedure for selecting the proper liquid line is as

follows:

• Measure the total amount of vertical rise

• Measure the total amount of liquid line needed

• Add all of the equivalent lengths associated with

any ttings or accessories using the table above.

• Add the total length and tting pressure drop.

This will equal your total equivalent length�

• Round-down the total equivalent length to the

closest value in Table 2�

• Reference Table 2 to verify the rounded-down

value of the calculated equivalent length is compatible with the required vertical rise and diameter of liquid line�

Check

Valve

Site

Glass

Filter

Dryer

Tubing

Note: Elevaon is defined as the

highest point of the line set to the

lowest

13

Page 14

INSTALLATION

OD Model

Compressor

Name Plate Oil

Charge (oz)

RP1336AC

ZP31K5E-TF5-13R 42

RP1342AC

ZP36K5E-TF5-13R 42

RP1348AC

ZP42K5E-TF5-13R 42

RP1360AC

ZP49K6E-TF5-130 42

RP1336AD

ZP31K5E-TFD-13R 42

RP1342AD

ZP36K5E-TFD-13R 42

RP1348AD

ZP42K5E-TFD-13R 42

RP1360AD

42ZP49K6E-TFD-130

Interconnecting Tubing (cont�)

Example: A 3-Ton heat pump unit is installed 50’

below the ID unit, requires a 75’ of 1/2” diameter

liquid line, and 4 90° LR elbows�

• Fitting Equivalent Length (ft.) = 4 x .9 = 3.6’

• Total Equivalent Length (ft.) = 75’ + 3.6’ = 78.6’

• Rounded-down value (ft.) = 75’

Liquid Line

R-410A

System

Capacity

Model

37 3/8" [9.53]

(Exerpt from Table 2, page 17)

Size

Connection

Size (Inch

I.D.) [mm]

Liquid Line

Size (Inch

O.D.) [mm]

1/4 [6.35] 25 [7.62]

5/16 [7.94] 25 [7.62] 50 [15.24] 60 [18.29] 45 [13.72] 35 [10.67] 20 [6.1] 5 [1.52]

3/8 [9.53] 25 [7.62] 50 [15.24] 75 [22.86] 80 [24.38] 80 [24.38] 75 [22.86] 70 [21.34] 65 [19.81] 60 [18.29] 55 [16.76] 50 [15.24] 45 [13.72]

7/16 [11.12] 25 [7.62] 50 [15.24] 75 [22.86] 95 [28.96] 90 [27.43] 90 [27.43] 85 [25.91] 85 [25.91] 85 [25.91] 80 [24.38] 80 [24.38] 80 [24.38]

1/2 [12.71] 25 [7.62] 50 [15.24] 75 [22.86] 95 [28.96] 95 [28.96] 95 [28.96] 95 [28.96] 95 [28.96] 95 [28.96] 90 [27.43] 90 [27.43] 90 [27.43]

25 [7.62] 50 [15.24] 75 [22.86] 100 [30.48] 125 [45.72] 150 [45.72] 175 [53.34] 200 [60.96] 225 [68.58] 250 [76.20] 275 [83.82] 300 [91.44]

N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

Long Line Set Applications

Long line set applications are dened as applications that require accessories or alternate construction methods� The following are special considerations that need to be addressed when installing a

long line set application:

• Additional refrigerant charge

Tubing

• Fitting losses and maximum equivalent length

considerations

• Refrigerant migration during the o cycle

• Oil return to the compressor

• Capacity losses

• System oil level adjustment

This application is acceptable because the 50’

vertical rise is less than the maximum rise of 75’ for

this application� The application is also considered

to have a long line set� Reference the long line set

section of the I&O for detail�

Liquid Line Size

Elevation (Above or Below) Indoor Coil

Total

Maximum

Length - Feet [m]

Equivalent

Vertical Separation - Feet [m]

N/R N/R N/R N/R N/R

14

Table 2 is used to determine if the application is

considered to have a long line set� The region of

the chart that is shaded grey is considered to be

a long line set application.

Oil Level Adjustments for Long

Line Set Applications

Additional oil will need to be added for long line set

applications� (Ref� Table 2)� Below is the equation for

the oil level adjustment and the compressor name

plate oil charge for the dierent od units.

Oil to be Added = [(Charge Adjustment + OD

Unit Name Plate Charge (oz.)) x (0.022) – [(0.10) x

(Compressor Name Plate Oil Charge (oz.))]

Example: An application requires 125ft of line set

with a liquid line diameter of 3/8”, Charge Adjust-

ment = 52.4 oz., Name Plate Charge = 107 oz.,

Name Plate Oil Charge = 25 oz., Oil to be Added =

((52.4 oz. +107 oz.) x .022) – (.10 x 25 oz.) = 1.0 oz.

OD Model

RP1436AC

RP1442AC

RP1448AC

RP1460AC

RP1436AD

RP1442AD

RP1448AD

RP1460AD

OD Model

RP1418AJ

RP1442AJ

RP1430AJ

RP1436AJ

RP1442AJ

RP1448AJ

RP1460AJ

Compressor

Name Plate Oil

Charge (oz)

ZP31K5E-TF5-13R 42

ZP36K5E-TF5-13R 42

ZP42K5E-TF5-13R 42

ZP49K6E-TF5-130 42

ZP31K5E-TFD-13R 42

ZP36K5E-TFD-13R 42

ZP42K5E-TFD-13R 42

42ZP49K6E-TFD-130

Compressor

Name Plate Oil

Charge (oz)

ZP16K5E-PFV-13R 21

ZP21K6E-PFV-130 21

ZP25K5E-PFV-13R 25

ZP31K5E-PFV-13R 21

ZP36K5E-PFV-13R 42

ZP42K5E-PFV-13R 42

ZP49K6E-PFV-130 42

Page 15

Interconnecting Tubing (cont�)

INSTALLATION

OD Model

RP1518AJ

RP1524AJ

RP1530AJ

RP1536AJ

RP1542AJ

RP1548AJ

RP1560AJ

RP1536AC

RP1542AC

RP1548AC

RP1560AC

Compressor

ZP16K5E-PFV-13R 21

ZP21K5E-PFV-13R 21

ZP25K5E-PFV-13R 25

ZP31K6E-PFV-130 21

ZP36K5E-PFV-13R 42

ZP40K6E-PFV-130 42

ZP49K6E-PFV-130

ZP31K6E-TF5-130

ZP36K5E-TF5-13R

ZP40K6E-TF5-130

ZP49K6E-TF5-130

Name Plate Oil

Charge (oz)

42

21

42

42

42

Suction Line Selection

Purpose of the suction line is to return superheated

vapor to the condensing unit from the evaporator�

Proper suction line sizing is important because it

plays an important role in returning oil to the compressor to prevent potential damage to the bearings, valves, and scroll sets� Also, an improperly

sized suction line can dramatically reduce capacity

and performance of the system� The procedure for

selecting the proper suction line is as follows:

• The total amount of suction line needed

• Add all of the equivalent lengths associated with

any ttings or accessories using the table on

previous page�

• Add the total length and tting pressure drop.

This will equal your total equivalent length�

• Reference Table 2 to verify that the calculated

equivalent length falls within the compatibility

region of the chart�

• Verify Table 3 to verify the capacity dierence is

compatible with the application�

Refrigerant Migration During

Off Cycle

Long line set applications can require a considerable amount of additional refrigerant� This additional refrigerant needs to be managed throughout the

entire ambient operating envelope that the system

will go through during its life cycle. O-Cycle migration is where excess refrigerant condenses and

migrates to the lowest part of the system� Excessive build-up of refrigerant at the compressor will

result in poor reliability and noisy operation during

startup� This section demonstrates the required

accessories and unit conguration for dierent applications�

Tubing

OUTDOOR UNIT LEVEL OR NEAR LEVEL TO INDOOR SECTION LINE SET

REFERENCE TABLE 2 FOR

MAXIMUM LENGTH LIMITATIONS

IDEALLY, LINE SET SLOPES AWAY

FROM OUTDOOR. VERIFY

SUB-COOLING PRIOR TO

THROTTLEING DEVICE, INSULATED

LIQUID LINE.

ST-A1219-01-01

15

Page 16

INSTALLATION

Interconnecting Tubing (cont�)

Tubing

For applications that are considered to have a long

line set with the outdoor unit and indoor unit on the

same level the following is required:

• TXV or EEV on the indoor unit

• Start components may be required depending

upon quality of voltage

• Crankcase heater

• Insulated liquid and suction line

OUTDOOR UNIT BELOW INDOOR SECTION LINE SET

INSULATE LIQUID

AND SUCTION

LINE

• Vapor line should slope toward the indoor unit

• Follow the proper line sizing, equivalent length,

charging requirements, and oil level adjustments

spelled out in this document and the outdoor

units I&O

• Verify at least 5°F sub-cooling at the ID unit prior

to throttling device

INVERT TRAP

EVEN WITH TOP

OF THE COIL

REFERENCE TABLE 2 FOR

MAXIMUM LENGTH LIMITATIONS

For applications that are considered to have a long

line set with the outdoor unit below the indoor unit

the following is required:

• TXV or EEV at the IDunit

• Crankcase heater

• Start components may be required depending

upon quality of voltage

• Inverted vapor-line trap (Reference Figure 3)

• Insulated liquid and suction line

16

ST-A1219-02-01

Figure 4

• Follow the proper line sizing, equivalent length,

charging requirements, and oil level adjustments

spelled out in this document and the outdoor

units I&O

• Measure pressure at the liquid line service valve

and prior to expansion device� Verify that it is

not greater than 50 PSI

• For elevations greater that 25’ can expect a

lower sub-cooling

Page 17

Interconnecting Tubing (cont�)

p

g

Outdoor Unit Above Indoor Unit

INSTALLATION

Verify sub-cooling prior

to throlin

device

Insulated liquid and

sucon line

TXV or EEV at indoor

eva

Figure 5

Reference Table 2

for elevaon

limitaons

Tubing

orator

For applications that are considered to have a long

line set with the outdoor unit above the indoor unit

the following is required:

• TXV at the indoor unit

• Crankcase heater

• Start components maybe required depending

upon quality of voltage

• Insulated liquid and suction line

• Follow the proper line sizing, equivalent length,

charging requirements, and oil level adjustments

spelled out in this document and the outdoor

units I&O

• Verify at least 5°F sub-cooling at the ID unit prior

to throttling device

17

Page 18

N/R N/R N/R N/R N/R N/R N/R N/R

1/4 [6.35] 25 [7.62] N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

1/4 [6.35] N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

Grey=Thisapplicationisacceptable,butthelonglineguidelinesmustbefollowed.ReferenceLongLineSetsectionintheI&O

Liquid Line Size

Liquid Line Size

INSTALLATION

Interconnecting Tubing

NOTES:

N/R = Application not recommended.

RP1360 3/8" [9.53]

RP1348 3/8" [9.53]

RP1336

3/8" [9.53]

RP1324 3/8" [9.53]

R-410A System

Capacity Model

Size (Inch I.D.)

Connection

[mm]

Tubing

7/16 [11.12] 25 [7.62] 50 [15.24] 60 [18.29] 55 [16.76] 50 [15.24] 45 [13.72] 40 [12.19] 40 [12.19] 35 [10.67] 30 [9.14] 25 [7.62] 20 [6.1]

1/2 [12.71] 25 [7.62] 50 [15.24] 65 [19.81] 65 [19.81] 60 [18.29] 60 [18.29] 60 [18.29] 55 [16.76] 55 [16.76] 50 [15.24] 50 [15.24] 50 [15.24]

3/8 [9.53] 25 [7.62] 50 [15.24] 40 [12.19] 30 [9.14] 20 [6.1] 10 [3.05] N/R N/R N/R N/R N/R N/R

5/16 [7.94] 25 [7.62] 10 [3.05] N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

1/2 [12.71] 25 [7.62] 50 [15.24] 75 [22.86] 70 [21.34] 70 [21.34] 70 [21.34] 65 [19.81] 65 [19.81] 65 [19.81] 65 [19.81] 60 [18.29] 60 [18.29]

1/4 [6.35] N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

7/16 [11.12] 25 [7.62] 50 [15.24] 70 [21.34] 65 [19.81] 60 [18.29] 60 [18.29] 55 [16.76] 50 [15.24] 50 [15.24] 45 [13.72] 45 [13.72] 40 [12.19]

5/16 [7.94] 25 [7.62] 35 [10.67] 10 [3.05] N/R N/R N/R N/R N/R N/R N/R N/R N/R

3/8 [9.53] 25 [7.62] 50 [15.24] 55 [16.76] 45 [13.72] 40 [12.19] 30 [9.14] 25 [7.62] 15 [4.57] 10 [3.05] N/R N/R N/R

7/16 [11.12] 25 [7.62] 50 [15.24] 75 [22.86] 85 [25.91] 85 [25.91] 85 [25.91] 80 [24.38] 80 [24.38] 80 [24.38] 75 [22.86] 75 [22.86] 70 [21.34]

1/2 [12.71] 25 [7.62] 50 [15.24] 75 [22.86] 90 [27.43] 90 [27.43] 90 [27.43] 90 [27.43] 85 [25.91] 85 [25.91] 85 [25.91] 85 [25.91] 85 [25.91]

3/8 [9.53] 25 [7.62] 50 [15.24] 75 [22.86] 75 [22.86] 70 [21.34] 70 [21.34] 65 [19.81] 60 [18.29] 55 [16.76] 50 [15.24] 45 [13.72] 40 [12.19]

5/16 [7.94] 25 [7.62] 50 [15.24] 55 [16.76] 45 [13.72] 30 [9.14] 20 [6.1] N/R N/R N/R N/R N/R N/R

7/16 [11.12] 25 [7.62] 50 [15.24] 75 [22.86] 100 [30.48] 100 [30.48] 100 [30.48] 100 [30.48] 100 [30.48] 100 [30.48] 95 [28.96] 95 [28.96] 95 [28.96]

1/2 [12.71] 25 [7.62] 50 [15.24] 75 [22.86] 100 [30.48] 100 [30.48] 100 [30.48] 100 [30.48] 100 [30.48] 100 [30.48] 100 [30.48] 100 [30.48] 100 [30.48]

3/8 [9.53] 25 [7.62] 50 [15.24] 75 [22.86] 95 [28.96] 95 [28.96] 95 [28.96] 90 [27.43] 90 [27.43] 85 [25.91] 85 [25.91] 80 [24.38] 80 [24.38]

5/16 [7.94] 25 [7.62] 50 [15.24] 75 [22.86] 80 [24.38] 75 [22.86] 70 [21.34] 60 [18.29] 55 [16.76] 50 [15.24] 45 [13.72] 35 [10.67] 30 [9.14]

(Inch O.D.)

1/4 [6.35] 25 [7.62] 50 [15.24] 30 [9.14] 10 [3.05]

[mm]

25 [7.62] 50 [15.24] 75 [22.86] 100 [30.48] 125 [45.72] 150 [45.72] 175 [53.34] 200 [60.96] 225 [68.58] 250 [76.20] 275 [83.82] 300 [91.44]

Maximum Vertical Separation - Feet [m]

Total Equivalent Length - Feet [m]

Elevation (Above or Below) Indoor Coil

Liquid Line Selection Chart

18

Page 19

1/4 [6.35] 25 [7.62] 50 [15.24] 60 [18.29] 50 [15.24] 35 [10.67] 20 [6.1] N/R N/R N/R N/R N/R N/R

1/4 [6.35] 25 [7.62] 50 [15.24] 30 [9.14] 10 [3.05] N/R N/R N/R N/R N/R N/R N/R N/R

1/4 [6.35] 25 [7.62] 30 [9.14] N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

1/4 [6.35] 25 [7.62] N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

1/4 [6.35] 5 [1.52] N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

1/4 [6.35] N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

Grey=Thisapplicationisacceptable,butthelonglineguidelinesmustbefollowed.ReferenceLongLineSetsectionintheI&O

R-410A System

Liquid Line Size

Liquid Line Size

INSTALLATION

Interconnecting Tubing

NOTES:

N/R = Application not recommended.

RP1460

3/8" [9.53]

RP1448

3/8" [9.53]

RP1442

3/8" [9.53]

RP1436

3/8" [9.53]

RP1430

3/8" [9.53]

RP1424

3/8" [9.53]

RP1418

3/8" [9.53]

Capacity Model

Size (Inch I.D.)

Connection

[mm]

7/16 [11.12] 25 [7.62] 50 [15.24] 60 [18.29] 55 [16.76] 50 [15.24] 45 [13.72] 40 [12.19] 40 [12.19] 35 [10.67] 30 [9.14] 25 [7.62] 20 [6.1]

1/2 [12.71] 25 [7.62] 50 [15.24] 65 [19.81] 65 [19.81] 60 [18.29] 60 [18.29] 60 [18.29] 55 [16.76] 55 [16.76] 50 [15.24] 50 [15.24] 50 [15.24]

3/8 [9.53] 25 [7.62] 50 [15.24] 40 [12.19] 30 [9.14] 20 [6.1] 10 [3.05] N/R N/R N/R N/R N/R N/R

5/16 [7.94] 25 [7.62] 10 [3.05] N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

7/16 [11.12] 25 [7.62] 50 [15.24] 70 [21.34] 65 [19.81] 60 [18.29] 60 [18.29] 55 [16.76] 50 [15.24] 50 [15.24] 45 [13.72] 45 [13.72] 40 [12.19]

1/2 [12.71] 25 [7.62] 50 [15.24] 75 [22.86] 70 [21.34] 70 [21.34] 70 [21.34] 65 [19.81] 65 [19.81] 65 [19.81] 65 [19.81] 60 [18.29] 60 [18.29]

3/8 [9.53] 25 [7.62] 50 [15.24] 55 [16.76] 45 [13.72] 40 [12.19] 30 [9.14] 25 [7.62] 15 [4.57] 10 [3.05] N/R N/R N/R

5/16 [7.94] 25 [7.62] 35 [10.67] 10 [3.05] N/R N/R N/R N/R N/R N/R N/R N/R N/R

1/4 [6.35]

7/16 [11.12] 25 [7.62] 50 [15.24] 70 [21.34] 65 [19.81] 65 [19.81] 60 [18.29] 60 [18.29] 55 [16.76] 55 [16.76] 50 [15.24] 50 [15.24] 45 [13.72]

1/2 [12.71] 25 [7.62] 50 [15.24] 70 [21.34] 70 [21.34] 70 [21.34] 70 [21.34] 65 [19.81] 65 [19.81] 65 [19.81] 65 [19.81] 60 [18.29] 60 [18.29]

3/8 [9.53] 25 [7.62] 50 [15.24] 60 [18.29] 50 [15.24] 45 [13.72] 40 [12.19] 35 [10.67] 30 [9.14] 20 [6.1] 15 [4.57] 10 [3.05] N/R

5/16 [7.94] 25 [7.62] 40 [12.19] 25 [7.62] 5 [1.52] N/R N/R N/R N/R N/R N/R N/R N/R

7/16 [11.12] 25 [7.62] 50 [15.24] 75 [22.86] 85 [25.91] 85 [25.91] 85 [25.91] 80 [24.38] 80 [24.38] 80 [24.38] 75 [22.86] 75 [22.86] 70 [21.34]

1/2 [12.71] 25 [7.62] 50 [15.24] 75 [22.86] 90 [27.43] 90 [27.43] 90 [27.43] 90 [27.43] 85 [25.91] 85 [25.91] 85 [25.91] 85 [25.91] 85 [25.91]

3/8 [9.53] 25 [7.62] 50 [15.24] 75 [22.86] 75 [22.86] 70 [21.34] 70 [21.34] 65 [19.81] 60 [18.29] 55 [16.76] 50 [15.24] 45 [13.72] 40 [12.19]

5/16 [7.94] 25 [7.62] 50 [15.24] 55 [16.76] 45 [13.72] 30 [9.14] 20 [6.1] N/R N/R N/R N/R N/R N/R

7/16 [11.12] 25 [7.62] 50 [15.24] 75 [22.86] 95 [28.96] 95 [28.96] 90 [27.43] 90 [27.43] 90 [27.43] 90 [27.43] 85 [25.91] 85 [25.91] 85 [25.91]

1/2 [12.71] 25 [7.62] 50 [15.24] 75 [22.86] 95 [28.96] 95 [28.96] 95 [28.96] 95 [28.96] 95 [28.96] 95 [28.96] 95 [28.96] 95 [28.96] 90 [27.43]

3/8 [9.53] 25 [7.62] 50 [15.24] 75 [22.86] 90 [27.43] 85 [25.91] 80 [24.38] 80 [24.38] 75 [22.86] 75 [22.86] 70 [21.34] 65 [19.81] 65 [19.81]

5/16 [7.94] 25 [7.62] 50 [15.24] 75 [22.86] 65 [19.81] 55 [16.76] 50 [15.24] 40 [12.19] 30 [9.14] 25 [7.62] 15 [4.57] 5 [1.52] N/R

7/16 [11.12] 25 [7.62] 50 [15.24] 75 [22.86] 100 [30.48] 100 [30.48] 100 [30.48] 100 [30.48] 100 [30.48] 100 [30.48] 95 [28.96] 95 [28.96] 95 [28.96]

1/2 [12.71] 25 [7.62] 50 [15.24] 75 [22.86] 100 [30.48] 100 [30.48] 100 [30.48] 100 [30.48] 100 [30.48] 100 [30.48] 100 [30.48] 100 [30.48] 100 [30.48]

3/8 [9.53] 25 [7.62] 50 [15.24] 75 [22.86] 95 [28.96] 95 [28.96] 95 [28.96] 90 [27.43] 90 [27.43] 85 [25.91] 85 [25.91] 80 [24.38] 80 [24.38]

5/16 [7.94] 25 [7.62] 50 [15.24] 75 [22.86] 80 [24.38] 75 [22.86] 70 [21.34] 60 [18.29] 55 [16.76] 50 [15.24] 45 [13.72] 35 [10.67] 30 [9.14]

7/16 [11.12] 25 [7.62] 50 [15.24] 75 [22.86] 100 [30.48] 105 [32] 100 [30.48] 100 [30.48] 100 [30.48] 100 [30.48] 100 [30.48] 100 [30.48] 100 [30.48]

1/2 [12.71] 25 [7.62] 50 [15.24] 75 [22.86] 100 [30.48] 105 [32] 105 [32] 105 [32] 105 [32] 105 [32] 105 [32] 100 [30.48] 100 [30.48]

3/8 [9.53] 25 [7.62] 50 [15.24] 75 [22.86] 100 [30.48] 100 [30.48] 100 [30.48] 95 [28.96] 95 [28.96] 95 [28.96] 90 [27.43] 90 [27.43] 90 [27.43]

5/16 [7.94] 25 [7.62] 50 [15.24] 75 [22.86] 90 [27.43] 85 [25.91] 85 [25.91] 80 [24.38] 75 [22.86] 70 [21.34] 70 [21.34] 65 [19.81] 60 [18.29]

(Inch O.D.)

[mm]

25 [7.62] 50 [15.24] 75 [22.86] 100 [30.48] 125 [45.72] 150 [45.72] 175 [53.34] 200 [60.96] 225 [68.58] 250 [76.20] 275 [83.82] 300 [91.44]

Maximum Vertical Separation - Feet [m]

Total Equivalent Length - Feet [m]

Tubing

Elevation (Above or Below) Indoor Coil

Liquid Line Selection Chart

19

Page 20

N/R N/R N/R N/R N/R N/R

1/4 [6.35] 25 [7.62] 50 [15.24] 30 [9.14] N/R N/R N/R N/R N/R N/R N/R N/R N/R

N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

1/4 [6.35] 25 [7.62] N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

1/4 [6.35] 25 [7.62] N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

1/4 [6.35] N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

Grey=Thisapplicationisacceptable,butthelonglineguidelinesmustbefollowed.ReferenceLongLineSetsectionintheI&O.

Liquid Line Size

Liquid Line Size

INSTALLATION

Interconnecting Tubing

NOTES:

N/R = Application not recommended.

3/8" [9.53]

3/8" [9.53]

3/8" [9.53]

3/8" [9.53]

3/8" [9.53]

3/8" [9.53]

3/8" [9.53]

R-410A System

Capacity Model

Size (Inch I.D.)

Connection

[mm]

7/16 [11.12] 25 [7.62] 50 [15.24] 55 [16.76] 50 [15.24] 50 [15.24] 45 [13.72] 40 [12.19] 35 [10.67] 30 [9.14] 25 [7.62] 25 [7.62] 20 [6.1]

1/2 [12.71] 25 [7.62] 50 [15.24] 60 [18.29] 60 [18.29] 60 [18.29] 55 [16.76] 55 [16.76] 50 [15.24] 50 [15.24] 50 [15.24] 45 [13.72] 45 [13.72]

3/8 [9.53] 25 [7.62] 50 [15.24] 40 [12.19] 30 [9.14] 20 [6.1] 10 [3.05] N/R N/R N/R N/R N/R N/R

5/16 [7.94] 25 [7.62] 10 [3.05] N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

7/16 [11.12] 25 [7.62] 50 [15.24] 75 [22.86] 80 [24.38] 75 [22.86] 75 [22.86] 70 [21.34] 70 [21.34] 65 [19.81] 60 [18.29] 60 [18.29] 55 [16.76]

1/2 [12.71] 25 [7.62] 50 [15.24] 75 [22.86] 85 [25.91] 85 [25.91] 80 [24.38] 80 [24.38] 80 [24.38] 80 [24.38] 75 [22.86] 75 [22.86] 75 [22.86]

3/8 [9.53] 25 [7.62] 50 [15.24] 70 [21.34] 65 [19.81] 55 [16.76] 50 [15.24] 40 [12.19] 35 [10.67] 30 [9.14] 20 [6.1] 15 [4.57] 10 [3.05]

5/16 [7.94] 25 [7.62] 50 [15.24] 30 [9.14] 10 [3.05] N/R N/R N/R N/R N/R N/R N/R N/R

1/2 [12.71] 25 [7.62] 50 [15.24] 75 [22.86] 90 [27.43] 90 [27.43] 90 [27.43] 90 [27.43] 85 [25.91] 85 [25.91] 85 [25.91] 85 [25.91] 80 [24.38]

1/4 [6.35] 10 [3.05] N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

7/16 [11.12] 25 [7.62] 50 [15.24] 75 [22.86] 85 [25.91] 85 [25.91] 80 [24.38] 80 [24.38] 75 [22.86] 75 [22.86] 70 [21.34] 70 [21.34] 65 [19.81]

5/16 [7.94] 25 [7.62] 50 [15.24] 45 [13.72] 30 [9.14] 10 [3.05] N/R N/R N/R N/R N/R N/R N/R

3/8 [9.53] 25 [7.62] 50 [15.24] 75 [22.86] 75 [22.86] 65 [19.81] 60 [18.29] 55 [16.76] 50 [15.24] 45 [13.72] 40 [12.19] 30 [9.14] 25 [7.62]

7/16 [11.12] 25 [7.62] 50 [15.24] 75 [22.86] 95 [28.96] 95 [28.96] 90 [27.43] 90 [27.43] 85 [25.91] 85 [25.91] 85 [25.91] 80 [24.38] 80 [24.38]

1/2 [12.71] 25 [7.62] 50 [15.24] 75 [22.86] 100 [30.48] 95 [28.96] 95 [28.96] 95 [28.96] 95 [28.96] 95 [28.96] 95 [28.96] 90 [27.43] 90 [27.43]

3/8 [9.53] 25 [7.62] 50 [15.24] 75 [22.86] 85 [25.91] 80 [24.38] 75 [22.86] 70 [21.34] 65 [19.81] 65 [19.81] 60 [18.29] 55 [16.76] 50 [15.24]

5/16 [7.94] 25 [7.62] 50 [15.24] 65 [19.81] 50 [15.24] 40 [12.19] 25 [7.62] 15 [4.57] N/R N/R N/R N/R N/R

7/16 [11.12] 25 [7.62] 50 [15.24] 75 [22.86] 90 [27.43] 90 [27.43] 90 [27.43] 85 [25.91] 85 [25.91] 85 [25.91] 85 [25.91] 80 [24.38] 80 [24.38]

1/2 [12.71] 25 [7.62] 50 [15.24] 75 [22.86] 95 [28.96] 95 [28.96] 90 [27.43] 90 [27.43] 90 [27.43] 90 [27.43] 90 [27.43] 90 [27.43] 90 [27.43]

3/8 [9.53] 25 [7.62] 50 [15.24] 75 [22.86] 85 [25.91] 80 [24.38] 80 [24.38] 75 [22.86] 70 [21.34] 70 [21.34] 65 [19.81] 65 [19.81] 60 [18.29]

5/16 [7.94] 25 [7.62] 50 [15.24] 70 [21.34] 60 [18.29] 55 [16.76] 45 [13.72] 35 [10.67] 30 [9.14] 20 [6.1] 10 [3.05] N/R N/R

1/4 [6.35] 25 [7.62] 30 [9.14]

7/16 [11.12] 25 [7.62] 50 [15.24] 75 [22.86] 100 [30.48] 100 [30.48] 95 [28.96] 95 [28.96] 95 [28.96] 95 [28.96] 95 [28.96] 95 [28.96] 90 [27.43]

1/2 [12.71] 25 [7.62] 50 [15.24] 75 [22.86] 100 [30.48] 100 [30.48] 100 [30.48] 100 [30.48] 100 [30.48] 100 [30.48] 100 [30.48] 95 [28.96] 95 [28.96]

3/8 [9.53] 25 [7.62] 50 [15.24] 75 [22.86] 95 [28.96] 90 [27.43] 90 [27.43] 90 [27.43] 85 [25.91] 85 [25.91] 80 [24.38] 80 [24.38] 75 [22.86]

5/16 [7.94] 25 [7.62] 50 [15.24] 75 [22.86] 80 [24.38] 70 [21.34] 65 [19.81] 60 [18.29] 50 [15.24] 45 [13.72] 40 [12.19] 35 [10.67] 25 [7.62]

7/16 [11.12] 25 [7.62] 50 [15.24] 75 [22.86] 100 [30.48] 105 [32] 100 [30.48] 100 [30.48] 100 [30.48] 100 [30.48] 100 [30.48] 100 [30.48] 100 [30.48]

1/2 [12.71] 25 [7.62] 50 [15.24] 75 [22.86] 100 [30.48] 105 [32] 105 [32] 105 [32] 105 [32] 105 [32] 105 [32] 100 [30.48] 100 [30.48]

3/8 [9.53] 25 [7.62] 50 [15.24] 75 [22.86] 100 [30.48] 100 [30.48] 100 [30.48] 95 [28.96] 95 [28.96] 95 [28.96] 90 [27.43] 90 [27.43] 90 [27.43]

5/16 [7.94] 25 [7.62] 50 [15.24] 75 [22.86] 90 [27.43] 85 [25.91] 85 [25.91] 80 [24.38] 75 [22.86] 70 [21.34] 70 [21.34] 65 [19.81] 60 [18.29]

(Inch O.D.)

1/4 [6.35] 25 [7.62] 50 [15.24] 60 [18.29] 50 [15.24] 35 [10.67] 20 [6.1]

[mm]

25 [7.62] 50 [15.24] 75 [22.86] 100 [30.48] 125 [45.72] 150 [45.72] 175 [53.34] 200 [60.96] 225 [68.58] 250 [76.20] 275 [83.82] 300 [91.44]

Maximum Vertical Separation - Feet [m]

Total Equivalent Length - Feet [m]

Elevation Above or Below Indoor Coil

Liquid Line Size

20

Page 21

5/8 [15.88] 0.99 0.99 0.98 0.98 0.97 0.97 0.96 0.96 0.96 0.95 0.95 0.94

5/8 [15.88] 0.97 0.95 0.94 0.92 0.89 0.88 0.86 0.86 0.84 N/R N/R N/R

5/8 [15.88] 0.98 0.94 0.92 0.9 0.88 0.85 N/R N/R N/R N/R N/R N/R

NOTES:

INSTALLATION

Vapor Line Size

N/R = Application not recommended.

RP1360 3/8" [9.53]

RP1348 3/8" [9.53]

RP1336

3/8" [9.53]

RP1324 3/8" [9.53]

R-410A System

Capacity Model

Liquid Line Size

Size (Inch I.D.)

Connection

[mm]

Interconnecting Tubing (cont.)

1-1/8 [28.58] N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

1 [25.4] 1.01 1.00 1.01 1.01 1.00 1.00 N/R N/R N/R N/R N/R N/R

7/8 [22.23] 1.00 1.00 1.00 0.99 0.99 0.98 N/R N/R N/R N/R N/R N/R

3/4 [19.05] 1.00 0.99 0.98 0.96 0.95 0.94 N/R N/R N/R N/R N/R N/R

1-1/8 [28.58] N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

1 [25.4] 1.00 1.00 1.00 0.99 0.99 1.00 0.99 1.00 0.99 N/R N/R N/R

7/8 [22.23] 1.00 0.99 0.99 0.99 0.98 0.98 0.98 0.97 0.97 N/R N/R N/R

3/4 [19.05] 0.99 0.99 0.98 0.97 0.96 0.96 0.95 0.94 0.93 N/R N/R N/R

1-1/8 [28.58] N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

1 [25.4] 1.01 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00

7/8 [22.23] 1.00 1.00 1.00 1.00 0.99 0.99 0.99 0.99 0.99 0.98 0.98 0.98

3/4 [19.05] 1.00 0.99 0.98 0.98 0.97 0.97 0.97 0.96 0.96 0.95 0.94 0.94

5/8 [15.88] 0.99 0.97 0.95 0.93 0.92 0.91 0.9 0.9 0.9 0.87 0.87 0.86

1-1/8 [28.58] N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

1 [25.4] N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

7/8 [22.23] 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.01 1.01 1.01 1.01 1.01

3/4 [19.05] 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 0.99 0.99 0.99 0.99

(Inch O.D.)

[mm]

25 [7.62] 50 [15.24] 75 [22.86] 100 [30.48] 125 [45.72] 150 [45.72] 175 [53.34] 200 [60.96] 225 [68.58] 250 [76.20] 275 [83.82] 300 [91.44]

Total Equivalent Length - Feet [m]

Capacity Multiplier Table

Suction Line Selection Chart

21

Page 22

5/8 [15.88] 0.99 0.99 0.98 0.98 0.97 0.97 0.96 0.96 0.96 0.95 0.95 0.94

5/8 [15.88] 0.99 0.98 0.97 0.96 0.96 0.94 0.93 0.93 0.93 0.91 0.91 0.9

5/8 [15.88] 0.99 0.97 0.95 0.93 0.92 0.91 0.9 0.9 0.9 0.87 0.87 0.86

5/8 [15.88] 0.97 0.95 0.94 0.92 0.89 0.88 0.86 0.86 0.84 N/R N/R N/R

5/8 [15.88] 0.98 0.94 0.92 0.9 0.88 0.85 N/R N/R N/R N/R N/R N/R

NOTES:

INSTALLATION

Interconnecting Tubing (cont.)

Liquid Line Size

Vapor Line Size

N/R = Application not recommended.

3/8" [9.53]

3/8" [9.53]

3/8" [9.53]

3/8" [9.53]

3/8" [9.53]

3/8" [9.53]

3/8" [9.53]

R-410A System

Capacity Model

Size (Inch I.D.)

Connection

[mm]

1-1/8 [28.58] N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

1 [25.4] 1.01 1.00 1.01 1.01 1.00 1.00 N/R N/R N/R N/R N/R N/R

7/8 [22.23] 1.00 1.00 1.00 0.99 0.99 0.98 N/R N/R N/R N/R N/R N/R

3/4 [19.05] 1.00 0.99 0.98 0.96 0.95 0.94 N/R N/R N/R N/R N/R N/R

1-1/8 [28.58] N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

1 [25.4] 1.00 1.00 1.00 0.99 0.99 1.00 0.99 1.00 0.99 N/R N/R N/R

7/8 [22.23] 1.00 0.99 0.99 0.99 0.98 0.98 0.98 0.97 0.97 N/R N/R N/R

3/4 [19.05] 0.99 0.99 0.98 0.97 0.96 0.96 0.95 0.94 0.93 N/R N/R N/R

1-1/8 [28.58] 1.01 1.01 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.01 1.01 N/R

1 [25.4] 1.01 1.00 1.00 1.00 1.00 1.00 1.00 1.00 0.99 0.99 1.00 N/R

7/8 [22.23] 1.00 1.00 1.00 0.99 1.00 0.99 0.99 0.99 0.98 0.98 0.98 N/R

3/4 [19.05] 0.99 0.98 0.98 0.98 0.97 0.97 0.96 0.96 0.95 0.95 0.94 N/R

5/8 [15.88] 0.98 0.97 0.95 0.94 0.92 0.91 0.89 0.88 0.87 0.86 0.85 N/R

1-1/8 [28.58] N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

1 [25.4] 1.01 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00

7/8 [22.23] 1.00 1.00 1.00 1.00 0.99 0.99 0.99 0.99 0.99 0.98 0.98 0.98

3/4 [19.05] 1.00 0.99 0.98 0.98 0.97 0.97 0.97 0.96 0.96 0.95 0.94 0.94

1-1/8 [28.58] N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

1 [25.4] 1.00 1.01 1.01 1.01 1.01 1.01 1.01 1.01 1.01 1.01 1.01 1.00

7/8 [22.23] 1.00 1.01 1.01 1.00 1.00 1.01 1.01 1.00 1.00 1.00 1.00 0.99

3/4 [19.05] 1.00 1.00 1.00 0.99 0.98 0.98 0.98 0.98 0.98 0.97 0.96 0.96

1-1/8 [28.58] N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

1 [25.4] N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

7/8 [22.23] 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.01 1.01 1.01 1.01 1.01

3/4 [19.05] 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 0.99 0.99 0.99 0.99

1-1/8 [28.58] N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

1 [25.4] N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

7/8 [22.23] N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

3/4 [19.05] 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00

5/8 [15.88] 1.00 0.99 0.99 0.99 0.99 0.98 0.98 0.98 0.97 0.97 0.97 0.97

(Inch O.D.)

[mm]

25 [7.62] 50 [15.24] 75 [22.86] 100 [30.48] 125 [45.72] 150 [45.72] 175 [53.34] 200 [60.96] 225 [68.58] 250 [76.20] 275 [83.82] 300 [91.44]

Total Equivalent Length - Feet [m]

Capacity Multiplier Table

Suction Line Selection Chart

22

Page 23

5/8 [15.88] 1.00 1.00 1.00 0.99 0.99 0.98 0.98 0.98 0.97 0.97 0.97 0.97

5/8 [15.88] 1.00 0.99 0.98 0.98 0.97 0.97 0.96 0.96 0.95 0.95 0.94 0.93

5/8 [15.88] 0.99 0.98 0.97 0.95 0.94 0.94 0.93 0.92 0.91 0.91 0.9 0.88

5/8 [15.88] 0.99 0.96 0.94 0.92 0.91 0.89 0.87 0.86 0.84 0.83 0.82 0.8

5/8 [15.88] 0.79 0.99 0.95 0.93 0.91 0.89 N/R N/R N/R N/R N/R N/R

Allcalculationsassumea3/8"liquidline

INSTALLATION

R-410A System

Vapor Line Size

NOTES:

N/R = Application not recommended.

3/4" [19.06]

3/4" [19.06]

3/4" [19.06]

3/4" [19.06]

3/4" [19.06]

3/4" [19.06]

3/4" [19.06]

Capacity Model

Connection Size

(Inch I.D.) [mm]

Vapor Line

Interconnecting Tubing (cont.)

1-1/8 [28.58] N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

1 [25.4] 1.00 1.02 1.01 1.01 1.01 1.01 N/R N/R N/R N/R N/R N/R

7/8 [22.23] 1.00 1.01 1.01 1.01 1.00 1.00 N/R N/R N/R N/R N/R N/R

3/4 [19.05] 0.9 1.01 1.00 0.99 0.97 0.96 N/R N/R N/R N/R N/R N/R

1-1/8 [28.58] N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

1 [25.4] N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

7/8 [22.23] 1.00 1.01 1.01 1.00 1.00 0.99 0.99 0.99 0.98 0.98 0.97 0.97

3/4 [19.05] 1.01 1.00 0.99 0.97 0.97 0.96 0.95 0.94 0.94 0.93 0.92 0.92

1-1/8 [28.58] 1.03 1.03 1.02 1.02 1.02 1.02 1.02 1.02 1.02 1.02 1.01 1.01

1 [25.4] 1.03 1.02 1.02 1.02 1.02 1.01 1.01 1.01 1.01 1.01 1.01 1.01

7/8 [22.23] 1.00 1.01 1.01 1.01 1.01 1.01 1.01 1.00 0.99 1.00 1.00 0.99

3/4 [19.05] 1.01 1.01 1.00 0.99 0.99 0.98 0.97 0.97 0.96 0.95 0.95 0.94

5/8 [15.88] 1.00 0.98 0.96 0.95 0.94 0.92 0.91 0.89 0.88 0.87 0.86 0.85

1-1/8 [28.58] N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

1 [25.4] 1.01 1.01 1.01 1.01 1.01 1.01 1.01 1.00 1.00 1.00 1.00 1.01

7/8 [22.23] 1.01 1.01 1.01 1.00 1.00 1.00 1.00 1.00 1.00 0.99 0.98 0.98

3/4 [19.05] 1.00 1.00 0.99 0.98 0.99 0.99 0.98 0.97 0.97 0.96 0.96 0.95

5/8 [15.88] 1.00 0.97 0.97 0.95 0.94 0.93 0.91 0.92 0.91 0.88 0.87 0.86

1-1/8 [28.58] N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

1 [25.4] 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 0.99 0.99

7/8 [22.23] 1.00 1.00 1.00 1.00 1.00 0.99 0.99 0.98 0.98 0.98 0.98 0.98

3/4 [19.05] 1.00 1.00 0.99 0.98 0.98 0.98 0.97 0.97 0.97 0.96 0.96 0.95

1-1/8 [28.58] N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

1 [25.4] N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

7/8 [22.23] 1.00 1.00 1.00 1.00 0.99 1.00 1.00 1.00 1.00 1.00 1.01 1.01

3/4 [19.05] 1.00 1.00 1.00 0.99 1.00 0.99 0.99 1.00 0.99 0.99 0.99 0.99

1-1/8 [28.58] N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

1 [25.4] N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

7/8 [22.23] N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R N/R

3/4 [19.05] 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00

(Inch O.D.)

[mm]

25 [7.62] 50 [15.24] 75 [22.86] 100 [30.48] 125 [45.72] 150 [45.72] 175 [53.34] 200 [60.96] 225 [68.58] 250 [76.20] 275 [83.82] 300 [91.44]

Total Equivalent Length - Feet [m]

Capacity Multiplier Table