Rheem RIWH09AVFJ, RIWH15AVFJ, RIWH07AVFJ, RIWH24AVFJ, ROMH45AFXZJ Design & Technical Manual

...Page 1

AIR CONDITIONER

REFRIGERANT R410A

INVERTER

Multi: 5 rooms type

DESIGN & TECHNICAL MANUAL

INDOOR

OUTDOOR

RIWH07AVFJ

RIWH09AVFJ

RIWH12AVFJ

RIWH15AVFJ

ROMH45AFXZJ

RIWH18AVFJ

RIWH24AVFJ

DR_MU015EM_01

2017.02.10

Page 2

Notices:

• Product specifications and design are subject to change without notice for future improvement.

• For further details, please check with our authorized dealer.

Page 3

CONTENTS

Part 1. INDOOR UNIT....................................................................... 1

1. Model lineup ..............................................................................................2

1-1. Indoor unit connection patterns................................................................................... 3

2. Specifications............................................................................................6

2-1. Wall mounted type ...................................................................................................... 6

3. Dimensions................................................................................................8

3-1. Wall mounted type ...................................................................................................... 8

4. Wiring diagrams ......................................................................................12

4-1. Wall mounted type .................................................................................................... 12

5. Air velocity and temperature distributions ........................................... 14

5-1. Wall mounted type .................................................................................................... 14

6. Airflow......................................................................................................20

6-1. Wall mounted type .................................................................................................... 20

7. Noise level curve.....................................................................................22

7-1. Wall mounted type .................................................................................................... 22

7-2. Sound level check point............................................................................................ 25

8. Electrical characteristics ........................................................................26

9. Safety devices ......................................................................................... 27

10. External input and output....................................................................... 28

10-1.External input........................................................................................................... 28

10-2.External output......................................................................................................... 30

11. Remote controller ...................................................................................33

11-1.Wireless remote controller (AR-RAH2U).................................................................. 33

11-2.Wireless remote controller (AR-REG1U).................................................................. 35

11-3.Wired remote controller (RXRNNUM: Optional part)................................................ 37

11-4.Simple remote controller (RXRSNUM: Optional part) .............................................. 42

12. Function settings .................................................................................... 47

12-1.Indoor unit (setting by wireless remote controller).................................................... 47

12-2.Indoor unit (setting by wired remote controller) ........................................................ 60

12-3.Indoor unit (setting by simple remote controller) ...................................................... 63

12-4.Function details........................................................................................................ 67

12-5.Wired remote controller............................................................................................ 71

12-6.Simple remote controller.......................................................................................... 73

13. Accessories .............................................................................................74

13-1.Wall mounted type ................................................................................................... 74

14. Optional parts..........................................................................................76

14-1.Controllers ............................................................................................................... 76

14-2.Others...................................................................................................................... 77

15. Indoor unit installation precautions ...................................................... 78

Page 4

CONTENTS (continued)

15-1.Place where prohibited for use................................................................................. 78

15-2.Points to remember when installing ......................................................................... 79

Page 5

CONTENTS (continued)

Part 2. OUTDOOR UNIT................................................................. 81

1. Specifications..........................................................................................82

1-1. Model: ROMH45AFXZJ ............................................................................................ 82

2. Dimensions..............................................................................................83

2-1. Model: ROMH45AFXZJ ............................................................................................ 83

3. Installation space ....................................................................................84

3-1. Model: ROMH45AFXZJ ............................................................................................ 84

4. Refrigerant circuit ................................................................................... 87

4-1. Model: ROMH45AFXZJ ............................................................................................ 87

5. Wiring diagram ........................................................................................88

5-1. Model: ROMH45AFXZJ ............................................................................................ 88

6. Capacity table..........................................................................................89

6-1. Combinations............................................................................................................ 89

6-2. Cooling capacity........................................................................................................ 93

6-3. Heating capacity ..................................................................................................... 105

7. Capacity compensation rate for pipe length and height difference..115

7-1. Model: ROMH45AFXZJ .......................................................................................... 115

8. Additional charge calculation .............................................................. 119

8-1. Model: ROMH45AFXZJ .......................................................................................... 119

9. Airflow....................................................................................................120

9-1. Model: ROMH45AFXZJ .......................................................................................... 120

10. Operation noise (sound pressure)....................................................... 121

10-1.Noise level curve.................................................................................................... 121

10-2.Sound level check point......................................................................................... 121

11. Electrical characteristics ......................................................................122

12. Safety devices ....................................................................................... 123

13. Function settings .................................................................................. 124

13-1.Setting methods..................................................................................................... 124

13-2.Outdoor unit low noise operation function (option)................................................. 127

14. Check and test....................................................................................... 128

14-1.Check run .............................................................................................................. 128

14-2.Test run.................................................................................................................. 134

14-3.Error code .............................................................................................................. 136

14-4.Pump down............................................................................................................ 139

15. Accessories ...........................................................................................141

16. Outdoor unit installation precautions ................................................. 142

16-1.Place where prohibited for use............................................................................... 142

16-2.Points to remember when installing ....................................................................... 142

Page 6

Page 7

Part 1. INDOOR UNIT

WALL MOUNTED TYPE:

RIWH07AVFJ

RIWH09AVFJ

RIWH12AVFJ

RIWH15AVFJ

RIWH18AVFJ

RIWH24AVFJ

Page 8

1. Model lineup

MULTI TYPE

5 rooms type

Indoor unit

RIWH07AVFJ

RIWH09AVFJ

RIWH12AVFJ

RIWH15AVFJ

Outdoor unit

ROMH45AFXZJ

RIWH18AVFJ

RIWH24AVFJ

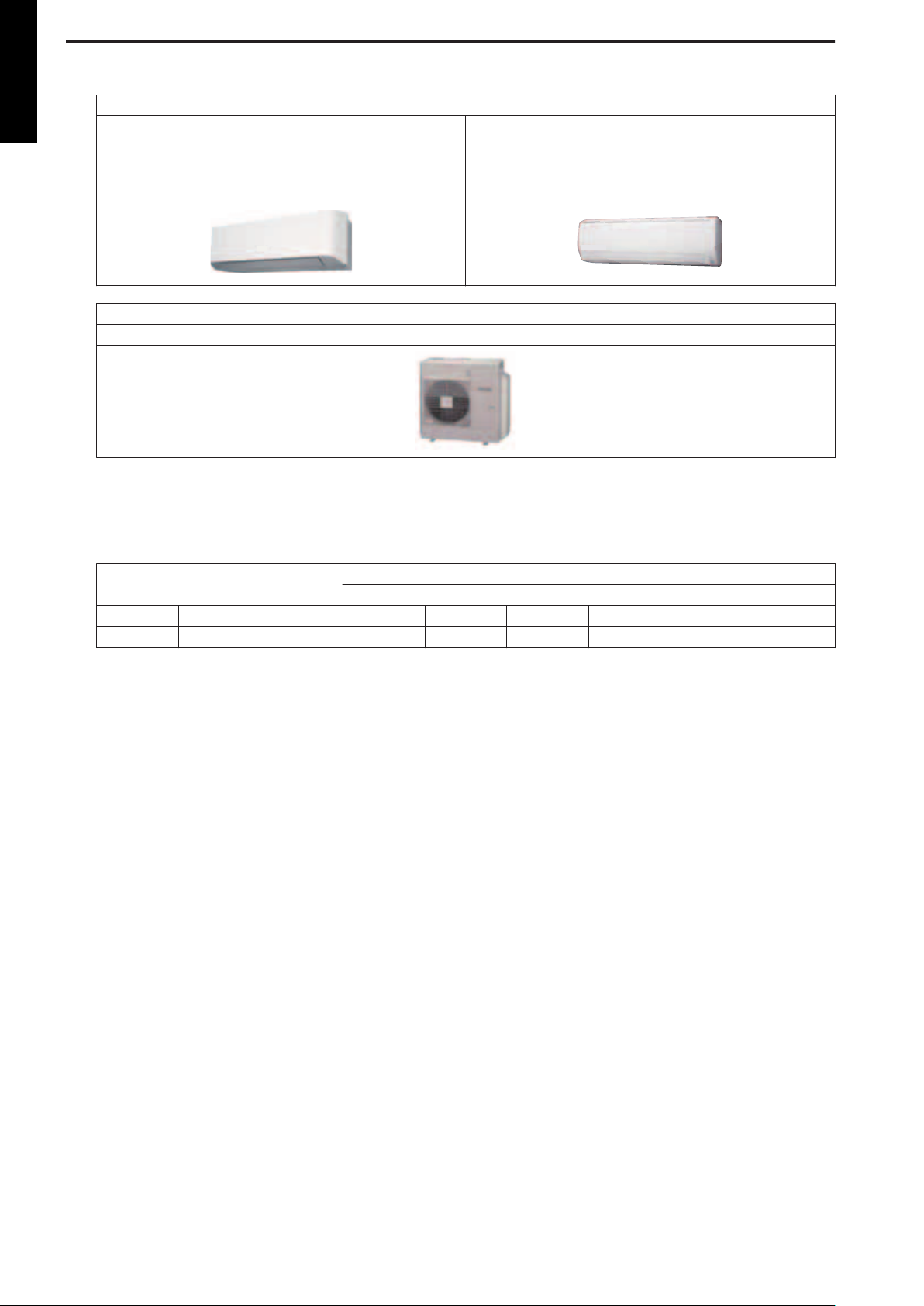

Indoor units that can be connected to each outdoor unit

●: Connectable / -: Not connectable

Outdoor unit

kBtu Class 07 09 12 15 18 24

5 Rooms ROMH45AFXZJ ● ● ● ● ● ●

Wall mounted

RIWH07—24AVFJ

- 2 -

Page 9

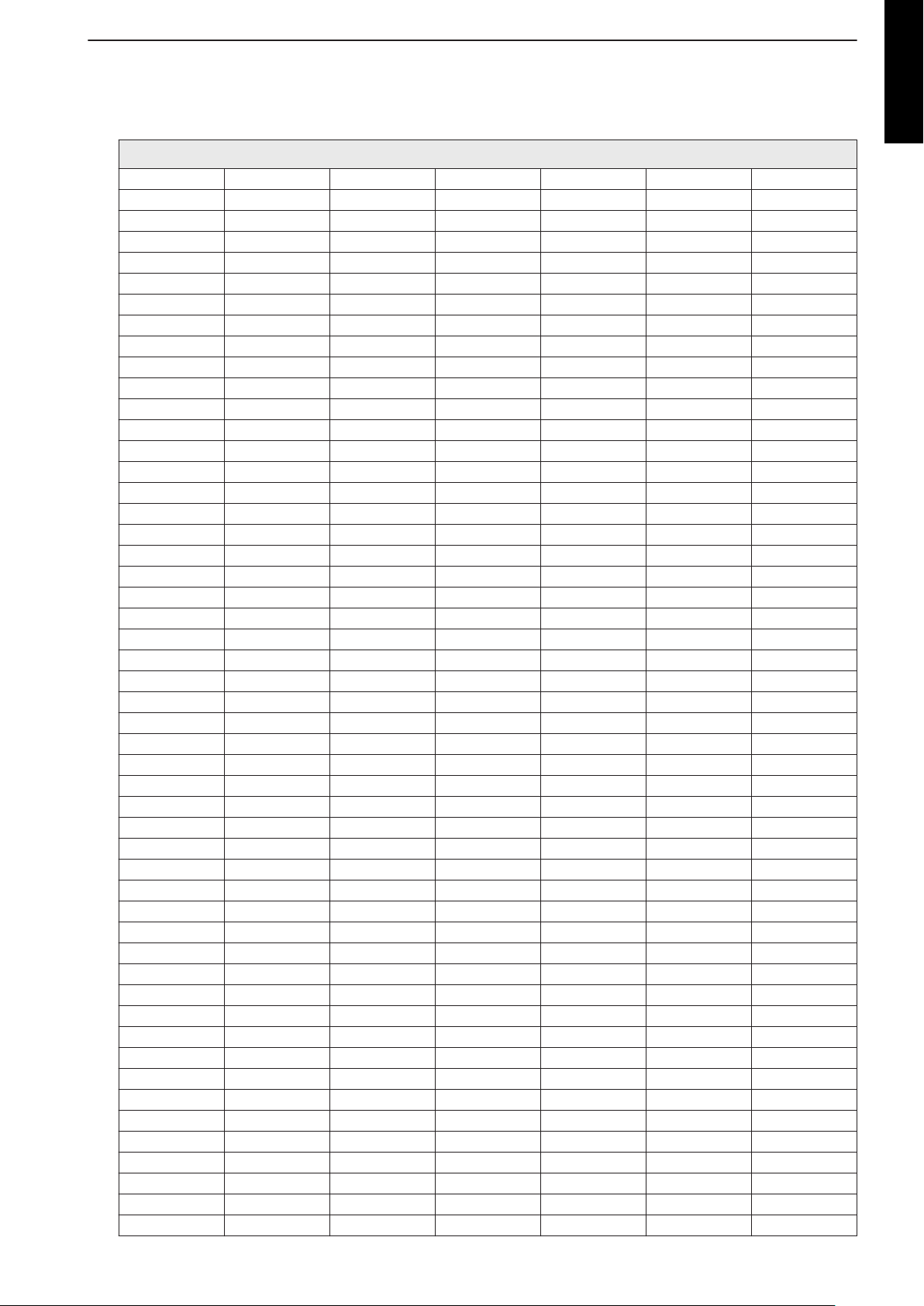

1-1. Indoor unit connection patterns

5 rooms

ROMH45AFXZJ

No. room 1 room 2 room 3 room 4 room 5 total

1 18 18 — — — 36

2 12 24 — — — 36

3 15 24 — — — 39

4 18 24 — — — 42

5 24 24 — — — 48

6 7 7 24 — — 38

7 7 9 18 — — 34

8 7 9 24 — — 40

9 7 12 18 — — 37

10 7 12 24 — — 43

11 7 15 15 — — 37

12 7 15 18 — — 40

13 7 15 24 — — 46

14 7 18 18 — — 43

15 7 18 24 — — 49

16 9 9 18 — — 36

17 9 9 24 — — 42

18 9 12 15 — — 36

19 9 12 18 — — 39

20 9 12 24 — — 45

21 9 15 15 — — 39

22 9 15 18 — — 42

23 9 15 24 — — 48

24 9 18 18 — — 45

25 9 18 24 — — 51

26 12 12 12 — — 36

27 12 12 15 — — 39

28 12 12 18 — — 42

29 12 12 24 — — 48

30 12 15 15 — — 42

31 12 15 18 — — 45

32 12 15 24 — — 51

33 12 18 18 — — 48

34 12 18 24 — — 54

35 15 15 15 — — 45

36 15 15 18 — — 48

37 15 15 24 — — 54

38 15 18 18 — — 51

39 18 18 18 — — 54

40 7 7 7 15 — 36

41 7 7 7 18 — 39

42 7 7 7 24 — 45

43 7 7 9 12 — 35

44 7 7 9 15 — 38

45 7 7 9 18 — 41

46 7 7 9 24 — 47

47 7 7 12 12 — 38

48 7 7 12 15 — 41

49 7 7 12 18 — 44

50 7 7 12 24 — 50

MULTI TYPE

5 rooms type

- 3 -

Page 10

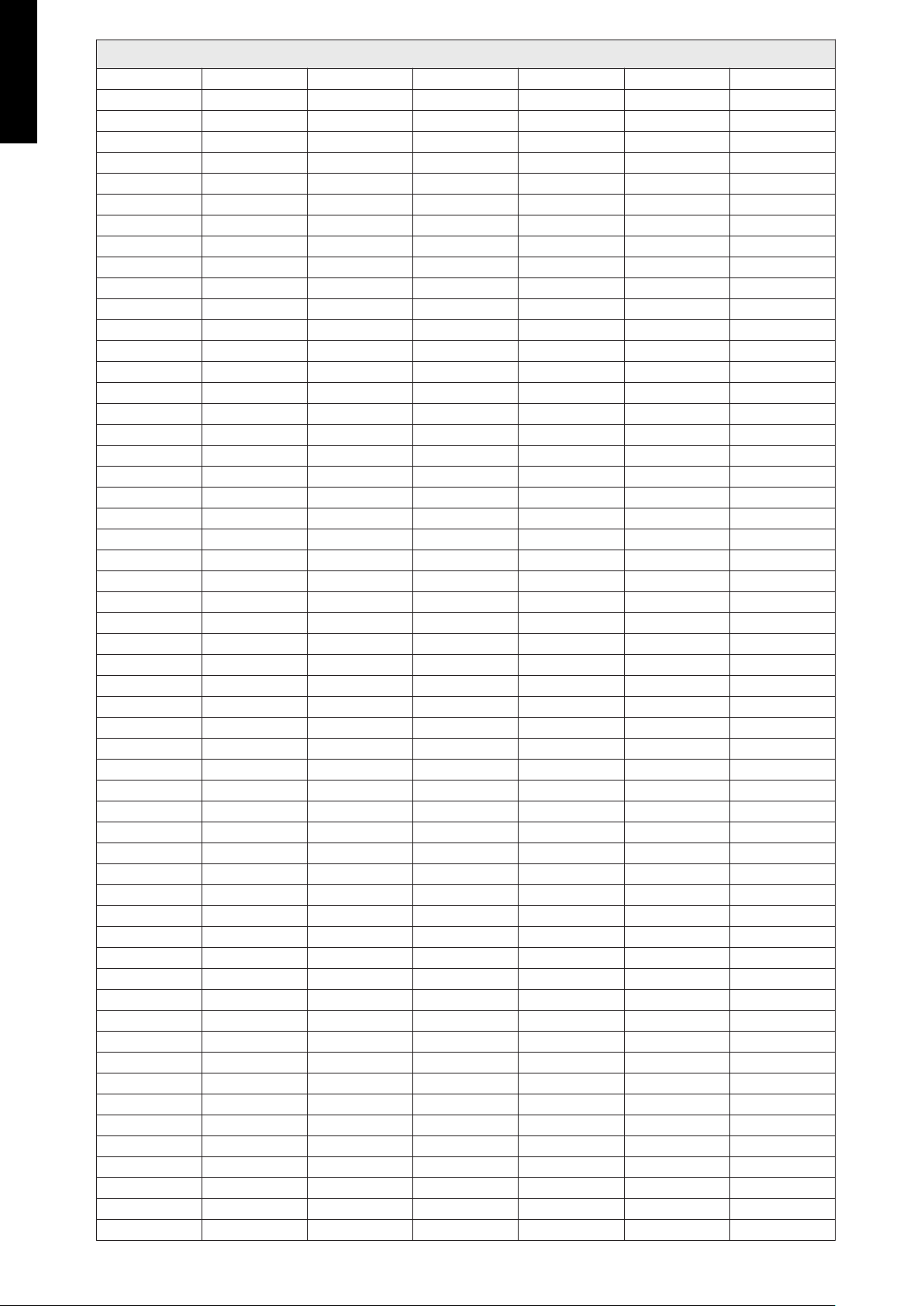

MULTI TYPE

5 rooms type

ROMH45AFXZJ

51 7 7 15 15 — 44

52 7 7 15 18 — 47

53 7 7 15 24 — 53

54 7 7 18 18 — 50

55 7 9 9 9 — 34

56 7 9 9 12 — 37

57 7 9 9 15 — 40

58 7 9 9 18 — 43

59 7 9 9 24 — 49

60 7 9 12 12 — 40

61 7 9 12 15 — 43

62 7 9 12 18 — 46

63 7 9 12 24 — 52

64 7 9 15 15 — 46

65 7 9 15 18 — 49

66 7 9 18 18 — 52

67 7 12 12 12 — 43

68 7 12 12 15 — 46

69 7 12 12 18 — 49

70 7 12 15 15 — 49

71 7 12 15 18 — 52

72 7 15 15 15 — 52

73 9 9 9 9 — 36

74 9 9 9 12 — 39

75 9 9 9 15 — 42

76 9 9 9 18 — 45

77 9 9 9 24 — 51

78 9 9 12 12 — 42

79 9 9 12 15 — 45

80 9 9 12 18 — 48

81 9 9 12 24 — 54

82 9 9 15 15 — 48

83 9 9 15 18 — 51

84 9 9 18 18 — 54

85 9 12 12 12 — 45

86 9 12 12 15 — 48

87 9 12 12 18 — 51

88 9 12 15 15 — 51

89 9 12 15 18 — 54

90 12 12 12 12 — 48

91 12 12 12 15 — 51

92 12 12 12 18 — 54

93 12 12 12 18 — 54

94 12 12 15 15 — 54

95 7 7 7 7 7 35

96 7 7 7 7 9 37

97 7 7 7 7 12 40

98 7 7 7 7 15 43

99 7 7 7 7 18 46

100 7 7 7 7 24 52

101 7 7 7 9 9 39

102 7 7 7 9 12 42

103 7 7 7 9 15 45

104 7 7 7 9 18 48

105 7 7 7 9 24 54

106 7 7 7 12 12 45

- 4 -

Page 11

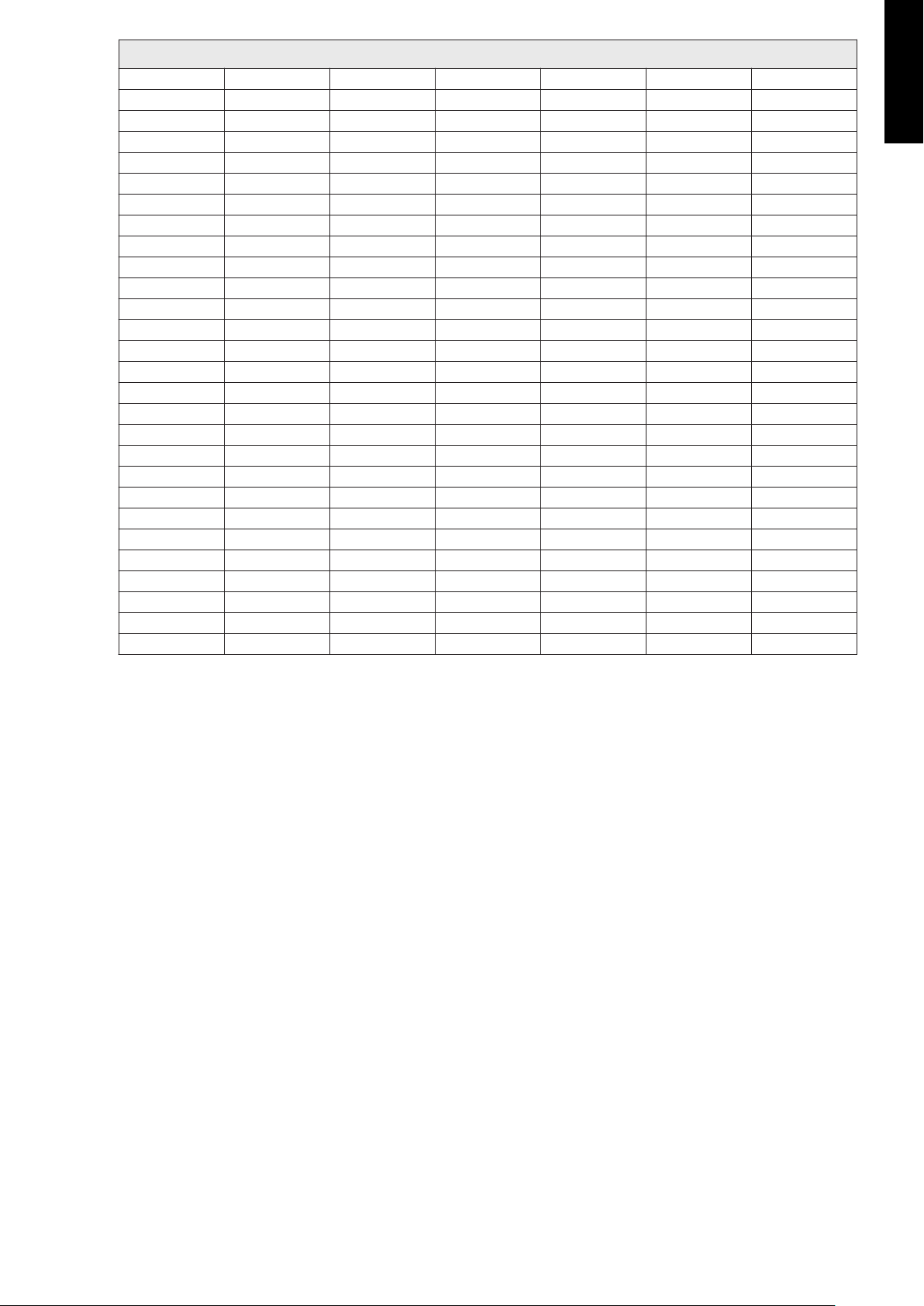

ROMH45AFXZJ

107 7 7 7 12 15 48

108 7 7 7 12 18 51

109 7 7 7 15 15 51

110 7 7 7 15 18 54

111 7 7 9 9 9 41

112 7 7 9 9 12 44

113 7 7 9 9 15 47

114 7 7 9 9 18 50

115 7 7 9 12 12 47

116 7 7 9 12 15 50

117 7 7 9 12 18 53

118 7 7 9 15 15 53

119 7 7 12 12 12 50

120 7 7 12 12 15 53

121 7 9 9 9 9 43

122 7 9 9 9 12 46

123 7 9 9 9 15 49

124 7 9 9 9 18 52

125 7 9 9 12 12 49

126 7 9 9 12 15 52

127 7 9 12 12 12 52

128 9 9 9 9 9 45

129 9 9 9 9 12 48

130 9 9 9 9 15 51

131 9 9 9 9 18 54

132 9 9 9 12 12 51

133 9 9 9 12 15 54

134 9 9 12 12 12 54

MULTI TYPE

5 rooms type

7: 7,000Btu/h, 9: 9,000Btu/h, 12: 12,000Btu/h, 15: 14,000Btu/h, 18: 18,000Btu/h,

24: 24,000Btu/h

- 5 -

Page 12

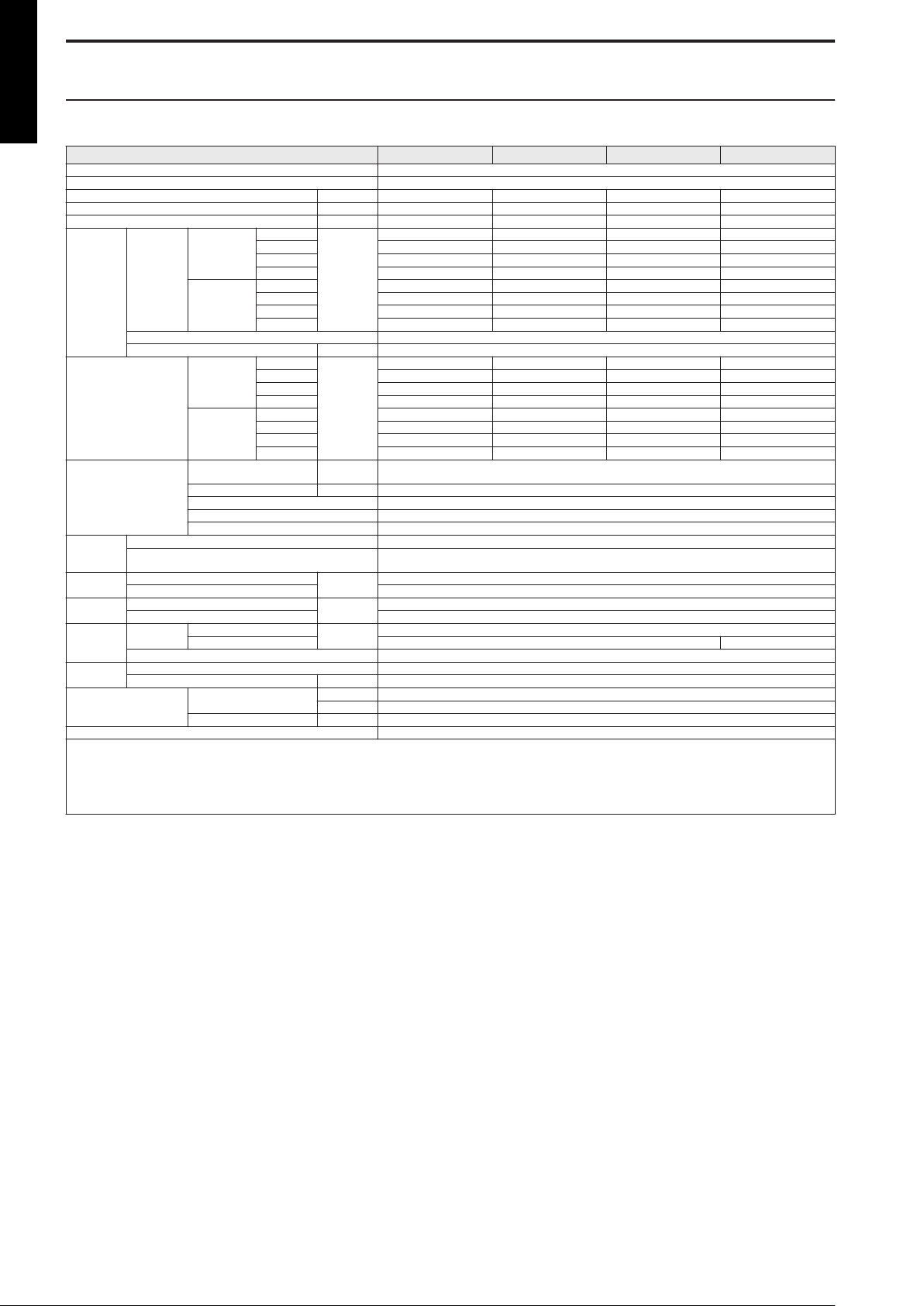

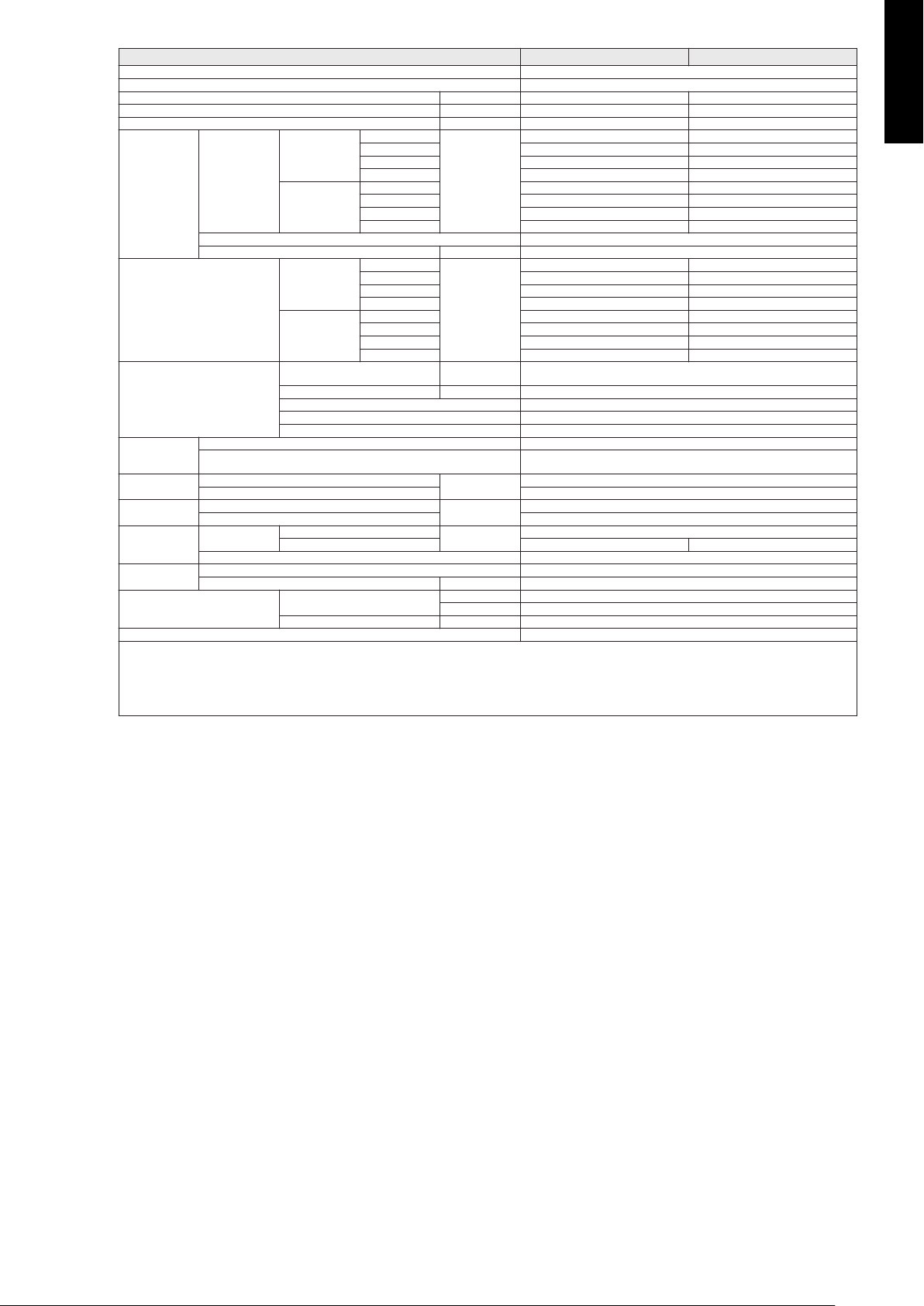

2. Specifications

MULTI TYPE

2-1. Wall mounted type

5 rooms type

Model name RIWH07AVFJ RIWH09AVFJ RIWH12AVFJ RIWH15AVFJ

Power supply 208/230 V ~ 60 Hz

Available voltage range 187—264 V

Capacity Btu/h class 7,000 9,000 12,000 14,000

Input power W 15 17 22 28

Running current A 0.13 0.15 0.19 0.25

Fan

Sound pressure level *

Heat exchanger type

Enclosure

Dimensions

(H × W × D)

Weight

Connection

pipe

Drain hose

Operation range

Remote controller type Wireless (Wired [option])

NOTES:

HIGH

Cooling

Airflow rate

Heating

Type × Q'ty Cross flow fan × 1

Motor output W 30

Cooling

Heating

Dimensions (H × W × D) in (mm)

Fin pitch FPI Main: 23, Sub: 18

Rows × Stages Main: 2 × 20, Sub: 1 × 4

Pipe type Copper tube

Material Polystyrene

Color

Net

Gross 10-5/8 × 36-7/16 × 13-1/4 (270 × 925 × 336)

Net

Gross 24 (11)

Size

Method Flare

Material PP + LLDPE

Size in (mm) Ø 9/16(I.D.), Ø 5/8 to Ø 11/16(O.D.) [Ø 13.8(I.D.), Ø 15.8 to Ø 16.7(O.D.)]

• The protective function might work when using it outside the operation range.

• *Sound pressure level:

– Measured values in manufacturer’s anechoic chamber.

– Because of the surrounding sound environment, the sound levels measured in actual installation conditions might be higher than the specified values here.

Fin type Aluminum

Liquid

Gas Ø3/8 (Ø9.52) Ø1/2 (Ø12.70)

Cooling

Heating °F (°C) 60 to 88 (16 to 30)

MED 294 (500) 306 (520) 330 (560) 353 (600)

LOW 253 (430) 253 (430) 265 (450) 312 (530)

QUIET 182 (310) 182 (310) 182 (310) 212 (360)

HIGH 330 (560) 353 (600) 388 (660) 430 (730)

MED 294 (500) 306 (520) 330 (560) 362 (615)

LOW 253 (430) 253 (430) 277 (470) 330 (560)

QUIET 194 (330) 194 (330) 194 (330) 221 (375)

HIGH

MED 32 33 36 38

LOW 29 29 30 33

QUIET 21 21 21 25

HIGH 36 37 40 42

MED 32 33 36 38

LOW 29 29 31 35

QUIET 22 22 22 27

CFM (m3/h)

dB (A)

in (mm)

lb (kg)

in (mm)

°F (°C) 64 to 90 (18 to 32)

%RH 80 or less

330 (560) 353 (600) 388 (660) 430 (730)

36 37 40 42

Main: 12-5/8 × 24-13/16 × 13/16 (320 × 630 × 20)

Sub: 3-5/16 × 24-13/16 × 1/2 (84 × 630 × 13.3)

(Approximate color of MUNSELL N9.25 /)

10-5/8 × 34-1/4 × 8-1/16 (270 × 870 × 204)

White

19 (8.5)

Ø1/4 (Ø6.35)

- 6 -

Page 13

Model name RIWH18AVFJ RIWH24AVFJ

Power supply 208/230 V ~ 60 Hz

Available voltage range 187—264 V

Capacity Btu/h class 18,000 24,000

Input power W 41 69

Running current A 0.32 0.53

Cooling

Fan

Sound pressure level *

Heat exchanger type

Enclosure

Dimensions

(H × W × D)

Weight

Connection pipe

Drain hose

Operation range

Remote controller type Wireless (Wired [option])

NOTES:

• The protective function might work when using it outside the operation range.

• *Sound pressure level:

– Measured values in manufacturer’s anechoic chamber.

– Because of the surrounding sound environment, the sound levels measured in actual installation conditions might be higher than the specified values here.

Airflow rate

Heating

Type × Q'ty Cross flow fan ×1

Motor output W 42

Cooling

Heating

Dimensions (H × W × D) in (mm)

Fin pitch FPI Main: 21, Sub: 18

Rows × Stages Main: 2 × 18, Sub: 1 × 4

Pipe type Copper tube

Material Polystyrene

Color

Net

Gross 12-15/16 × 42-15/16 × 16-9/16 (329 × 1,090 × 420)

Net

Gross 40 (18)

Size

Method Flare

Material PVC

Size in (mm) Ø 1/2(I.D.), Ø 5/8(O.D.) [Ø 12(I.D.), Ø 16(O.D.)]

Fin type Aluminum

Liquid

Gas Ø1/2 (Ø12.70) Ø5/8 (Ø15.88)

Cooling

Heating °F (°C) 60 to 88 (16 to 30)

HIGH

MED 436 (740) 530 (900)

LOW 365 (620) 436 (740)

QUIET 324 (550) 365 (620)

HIGH 542 (920) 647 (1,100)

MED 436 (740) 530 (900)

LOW 365 (620) 436 (740)

QUIET 324 (550) 365 (620)

HIGH

MED 37 42

LOW 33 37

QUIET 31 33

HIGH 44 48

MED 37 42

LOW 33 37

QUIET 31 33

CFM (m3/h)

dB (A)

in (mm)

lb (kg)

mm (in)

°F (°C) 64 to 90 (18 to 32)

%RH 80 or less

542 (920) 659 (1,120)

43 49

Main: 15-7/8 × 33-3/4 × 1-1/16 (378 × 832 × 26.6)

Sub: 3-5/16 × 33-3/4 × 1/2 (84 × 832 × 13.3)

(Approximate color of MUNSELL N9.25 /)

12-5/8 × 39-5/16 × 9-3/8 (320 × 998 × 238)

White

31 (14)

Ø1/4 (Ø6.35)

MULTI TYPE

5 rooms type

- 7 -

Page 14

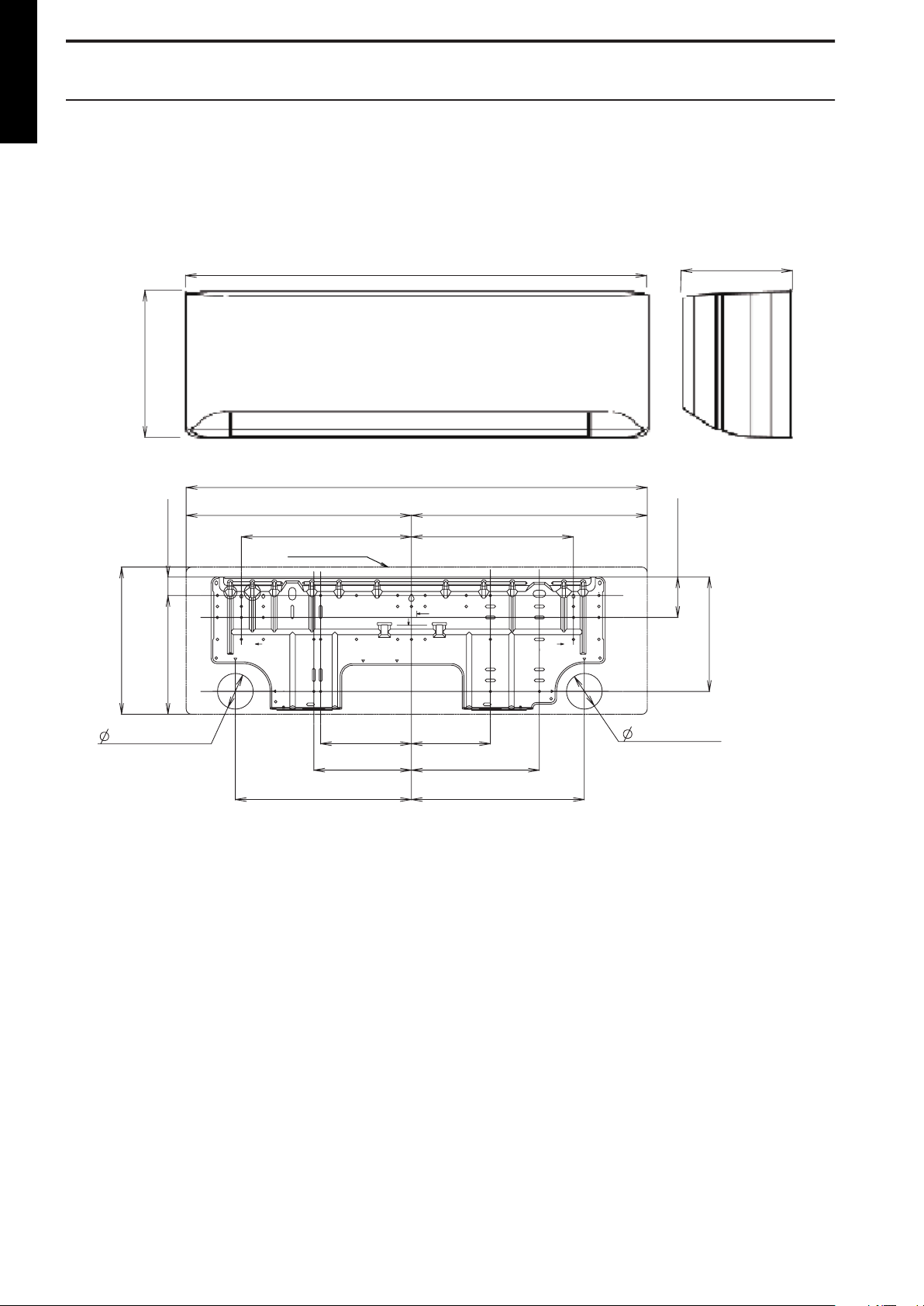

3. Dimensions

10-5/8 (270)

34-1/4 (870)

8-1/16 (204)

Outline of unit

Unit: in (mm)

[10-5/8 (270)]

1-5/16 (34)

8-9/16 (217)

8-1/4 (209)

2-15/16(74)

[34-1/4 (870)]

16-3/4 (426)

12-3/16 (310)

17-1/2 (444)

6-1/2 (165) 5-11/16 (144)

7 (178) 9-3/16 (233)

12-5/8 (321) 12-3/8 (315)

11-5/8 (295)

2-9/16 (65)

for pipe inlet

2-9/16 (65)

for pipe inlet

MULTI TYPE

3-1. Wall mounted type

5 rooms type

¢ Models: RIWH07AVFJ, RIWH09AVFJ, RIWH12AVFJ, and RI-

WH15AVFJ

- 8 -

Page 15

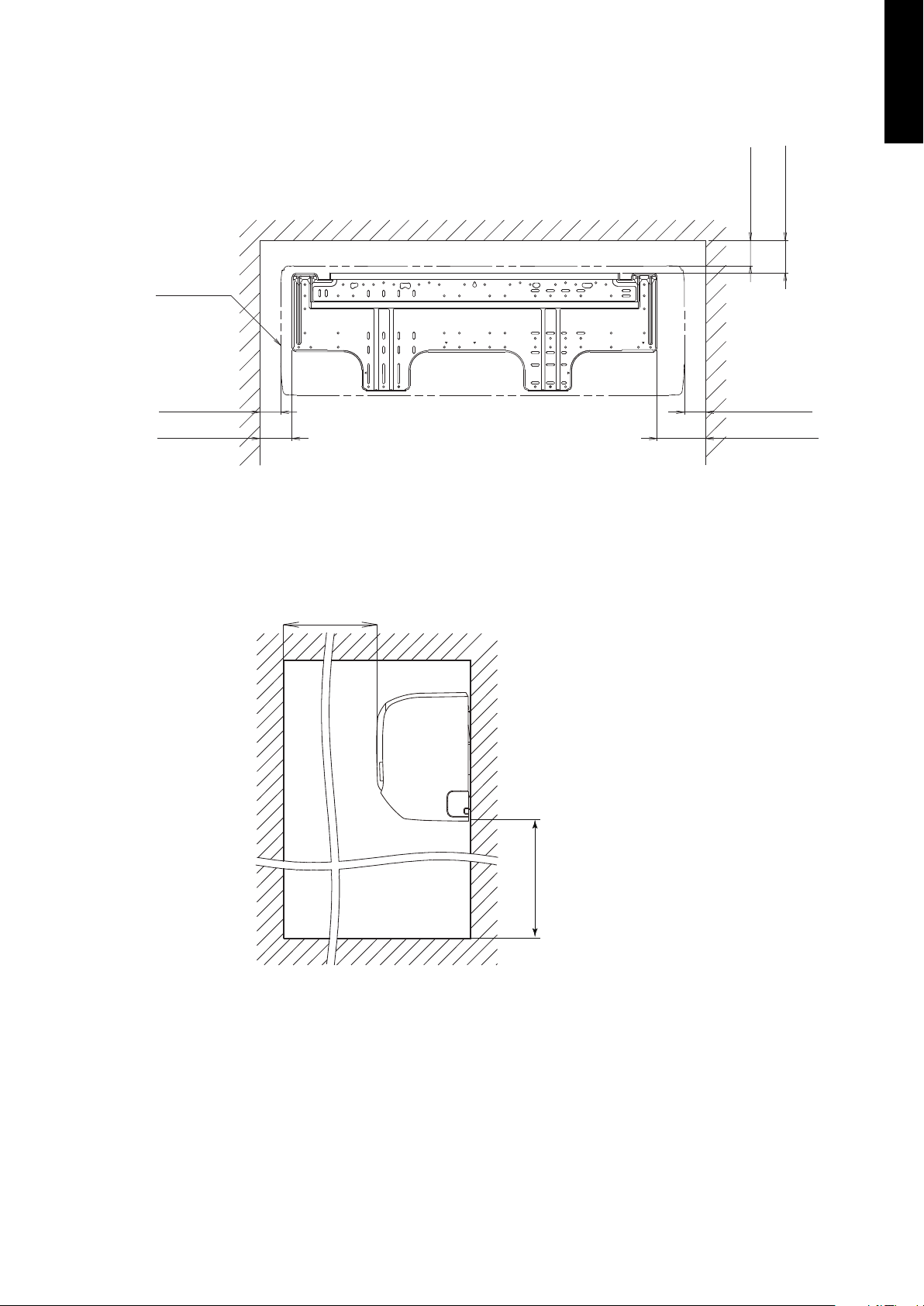

Installation space requirement

Unit: in (mm

)

2 (45) or more

71 (1,800)

or more

3 (63) or more

Outline of unit

1 (25) or more

3 (52) or more

6 (144) or more

60 (1,500) or more

4 (86) or more

Provide sufficient installation space for product safety.

MULTI TYPE

5 rooms type

- 9 -

Page 16

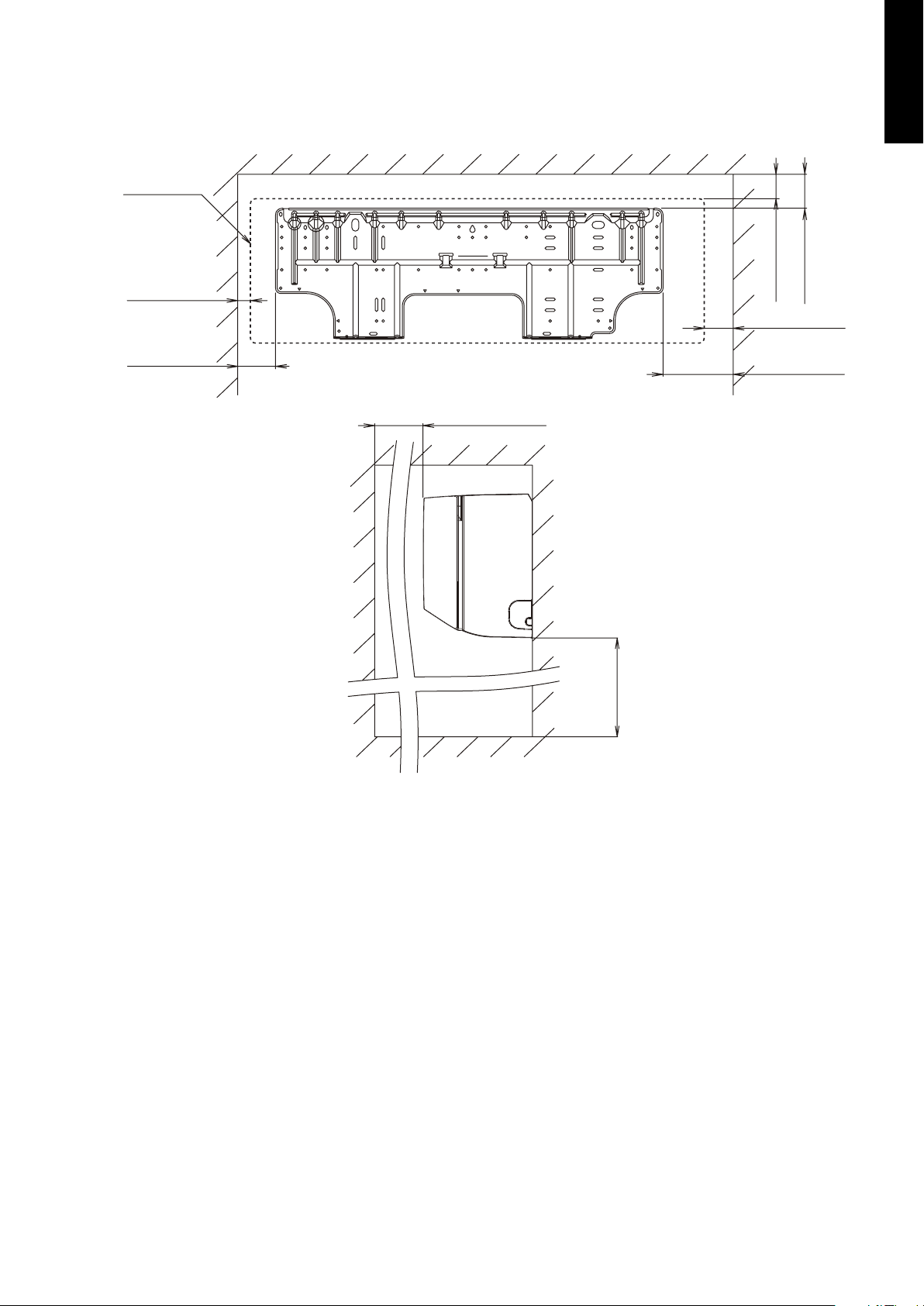

39-5/16 (998)

9 (238)

12-5/8 (320)

39-5/16 (998)

Outline of unit

18-9/16 (471)

2-5/8 (67)

1-1/8 (28)

1-13/16 (46)

17-1/4 (438)2-3/8 (61) 4 (102)15-5/8 (397)

17 (432)

2-3/16 (56)

2-3/16 (56)

3/8 (10)

12-5/8 (320)

11/16 (17)

Ø 3-1/8 (80) hole

Piping inlet

Ø 3-1/8 (80) hole

Piping inlet

Unit: in (mm)

MULTI TYPE

5 rooms type

Models: RIWH18AVFJ and RIWH24AVFJ

¢

- 10 -

Page 17

Installation space requirement

Unit: in (mm)

3 (63) or more

4 (80) or more

3 (52) or more 3 (53) or more

4 (80) or more

Outline of unit

5 (120) or more

60 (1,500) or more

71 (1,800) or more

Provide sufficient installation space for product safety.

MULTI TYPE

5 rooms type

- 11 -

Page 18

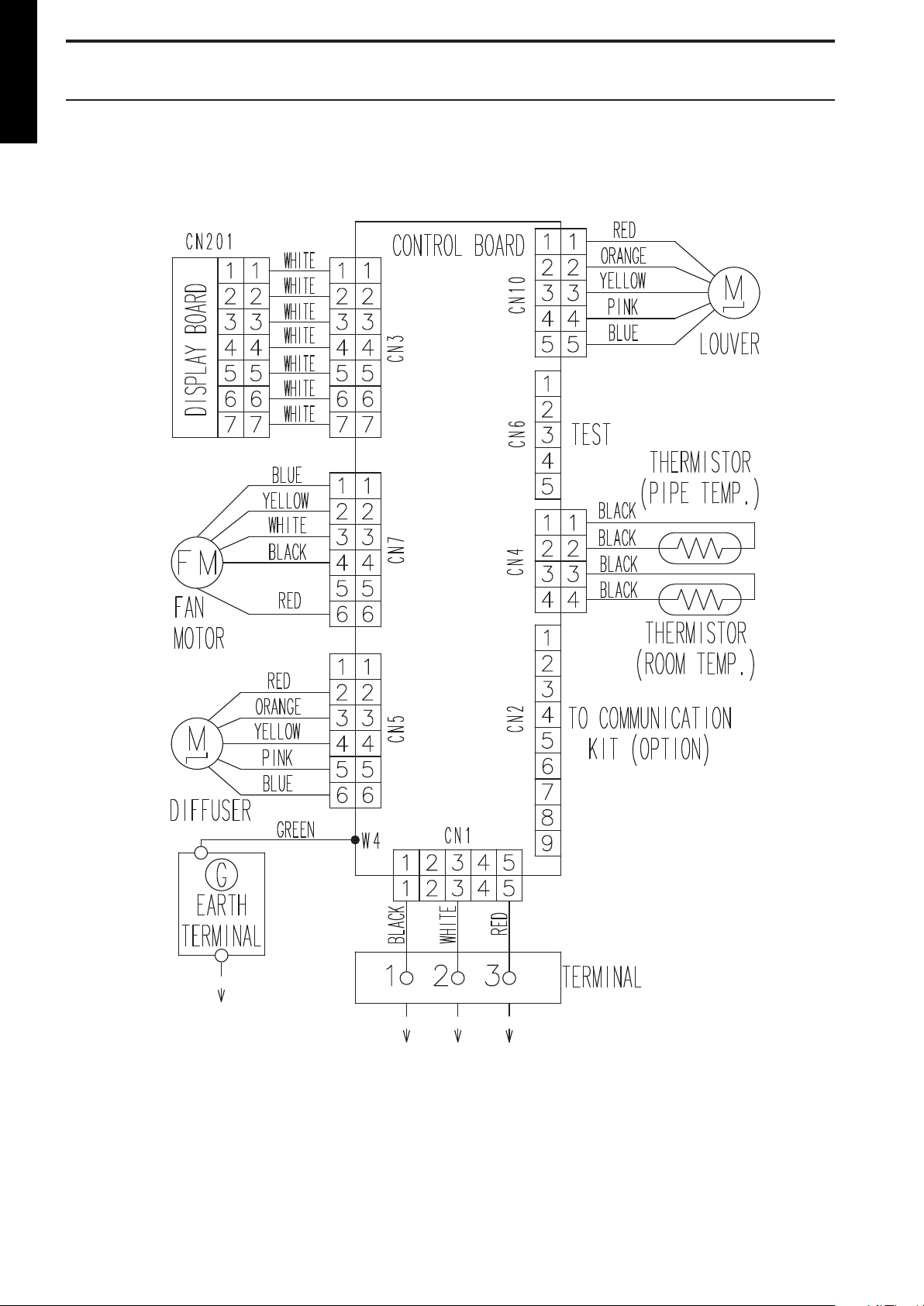

4. Wiring diagrams

MULTI TYPE

4-1. Wall mounted type

5 rooms type

¢ Models: RIWH07AVFJ, RIWH09AVFJ, RIWH12AVFJ, and RI-

WH15AVFJ

- 12 -

Page 19

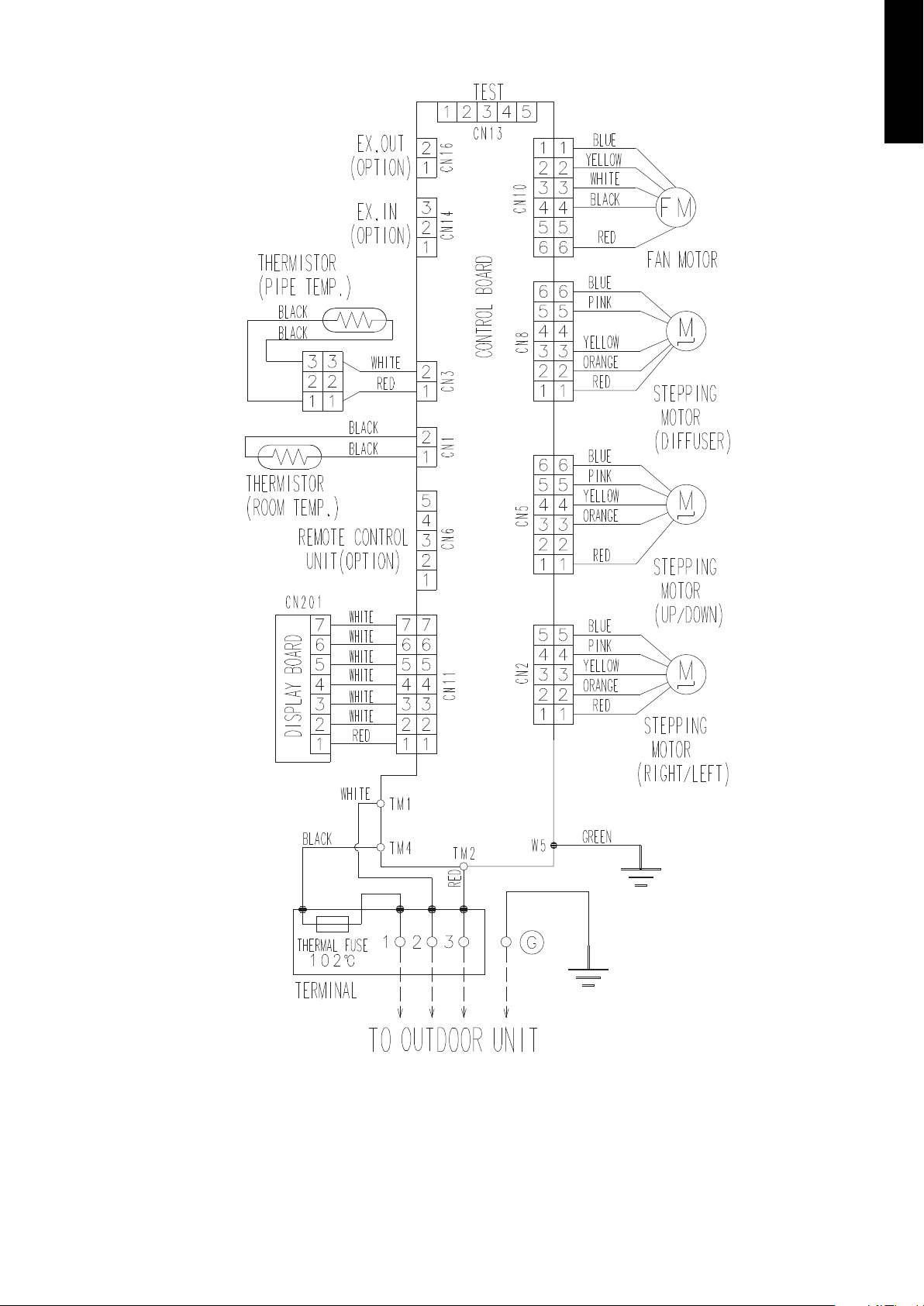

Models: RIWH18AVFJ and RIWH24AVFJ

¢

MULTI TYPE

5 rooms type

- 13 -

Page 20

5. Air velocity and temperature distributions

7 (2.0)

3 (1.0) 2 (0.5)

2

1

0

1

2

Unit: ft/s (m/s)

(m)

(m)

01234567

8

7

3

0

3

7

(ft)

(ft)

0 3 7 10 13 16 20 23

26

9

29

7 (2.0)

7 (2.0)

2 (0.5)

2 (0.5)

3 (1.0)

3 (1.0)

10

7

3

0

3

7

10

(ft)

(ft)

0 3 7 10 13 16 20 23

26

3

2

1

0

1

2

3

Unit: ft/s (m/s)

(m)

(m)

01234567

8

9

29

7 (2.0)

2 (0.5)

3 (1.0)

3

2

1

0

Unit: ft/s (m/s)

(m)

(m)

012345678

10

7

3

0

(ft)

(ft)

0 3 7 10 13 16 20 23 26

9

29

2 (0.5)

7 (2.0)

3 (1.0)

3

2

1

0

Unit: ft/s (m/s)

(m)

(m)

012345678

10

7

3

0

(ft)

(ft)

0 3 7 10 13 16 20 23 26

9

29

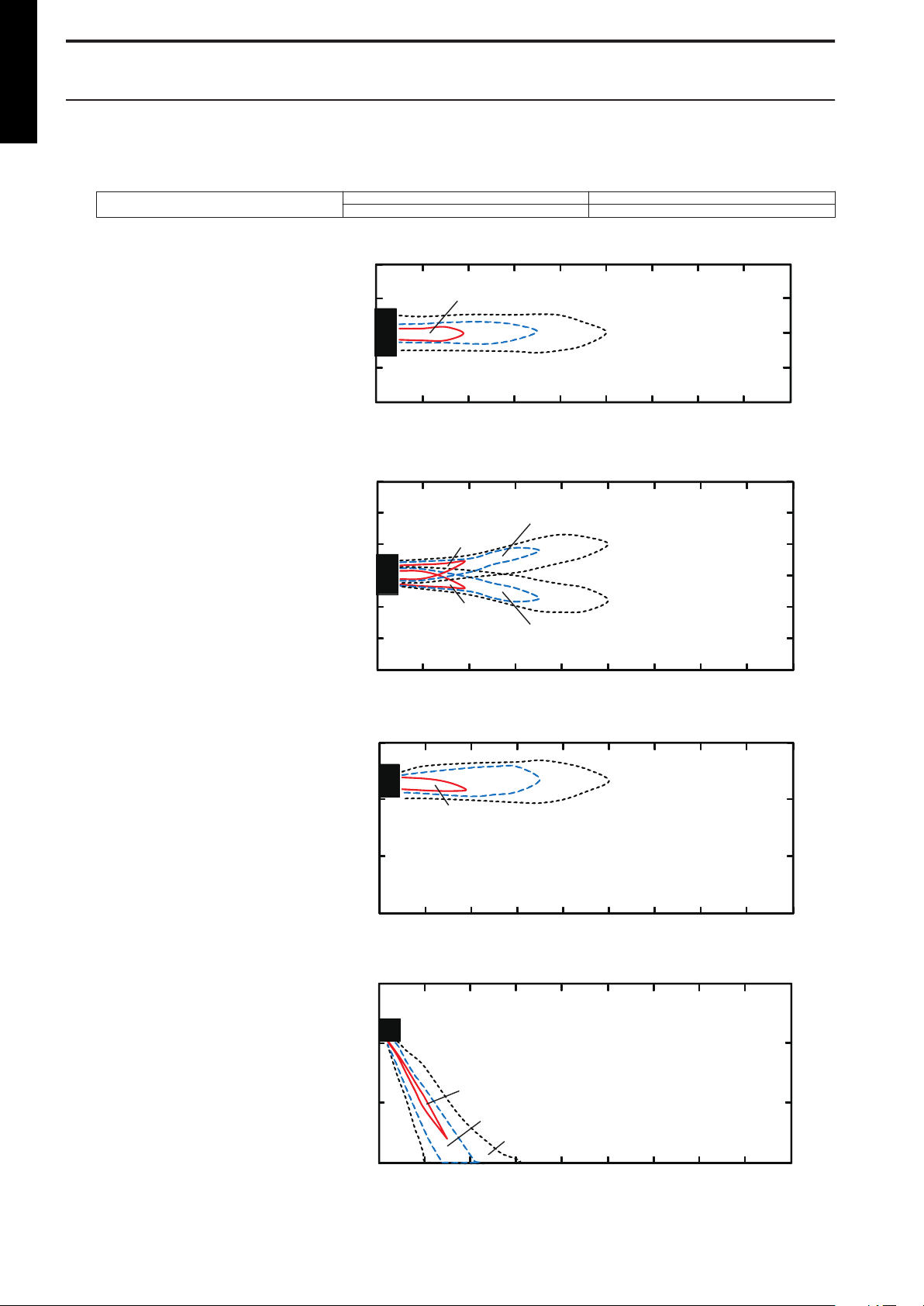

MULTI TYPE

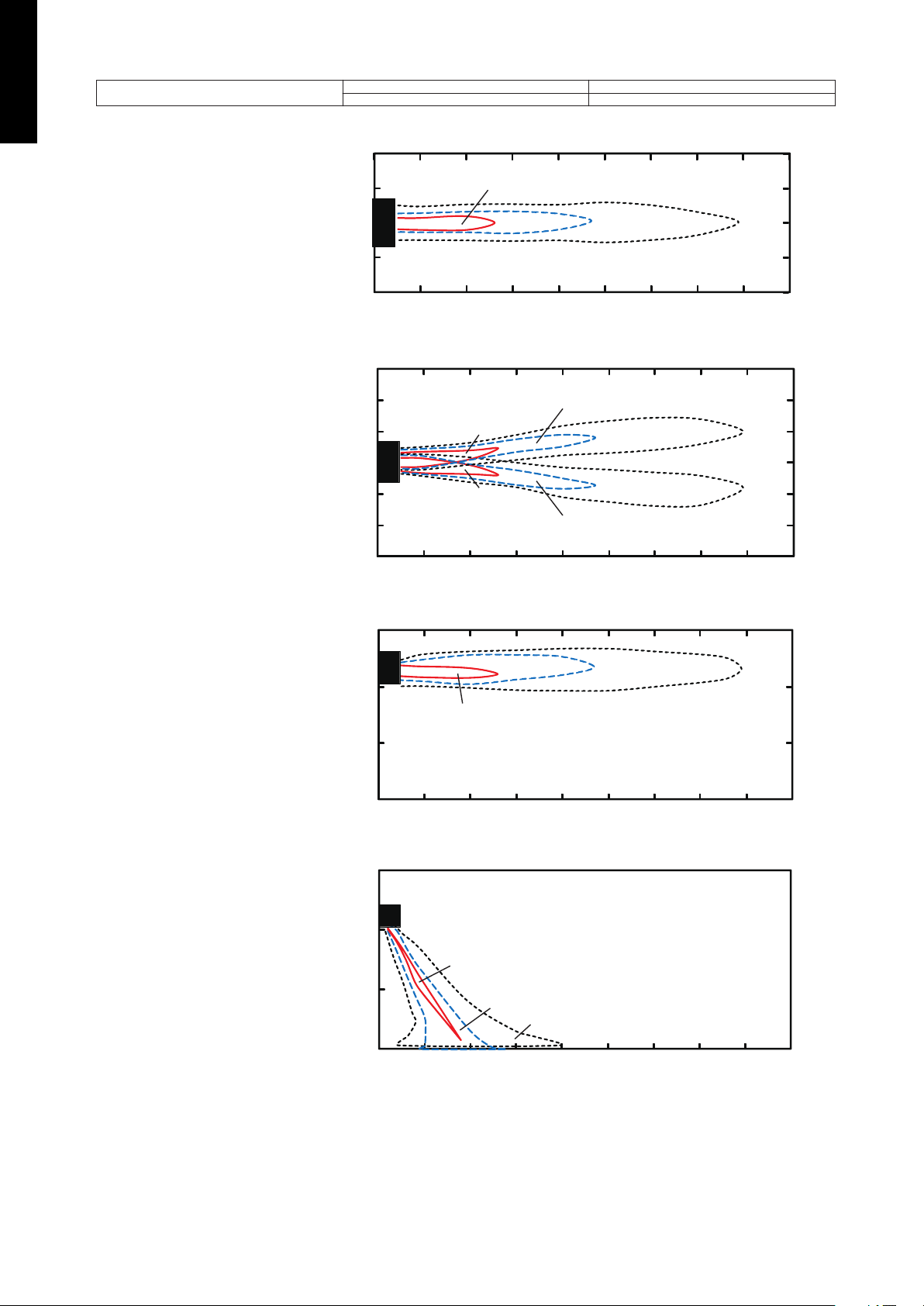

5-1. Wall mounted type

5 rooms type

Model: RIWH07AVFJ

¢

Measuring conditions

Top view

Vertical airflow direction louver: Up

Horizontal airflow direction louver: Center

Top view

Vertical airflow direction louver: Up

Horizontal airflow direction louver: Left & Right

Fan speed Operation mode

HIGH FAN

Side view

Vertical airflow direction louver: Up

Horizontal airflow direction louver: Center

Side view

Vertical airflow direction louver: Down

Horizontal airflow direction louver: Center

- 14 -

Page 21

Model: RIWH09AVFJ

7 (2.0)

3 (1.0) 2 (0.5)

2

1

0

1

2

Unit: ft/s (m/s)

(m)

(m)

01234567

8

7

3

0

3

7

(ft)

(ft)

0 3 7 10 13 16 20 23

26

9

29

7 (2.0)

7 (2.0)

2 (0.5)

2 (0.5)

3 (1.0)

3 (1.0)

10

7

3

0

3

7

10

(ft)

(ft)

0 3 7 10 13 16 20 23

26

3

2

1

0

1

2

3

Unit: ft/s (m/s)

(m)

(m)

01234567

8

9

29

3 (1.0) 2 (0.5)

7 (2.0)

3

2

1

0

Unit: ft/s (m/s)

(m)

(m)

012345678

10

7

3

0

(ft)

(ft)

0 3 7 10 13 16 20 23 26

9

29

3 (1.0)

2 (0.5)

7 (2.0)

3

2

1

0

Unit: ft/s (m/s)

(m)

(m)

012345678

10

7

3

0

(ft)

(ft)

0 3 7 10 13 16 20 23 26

9

29

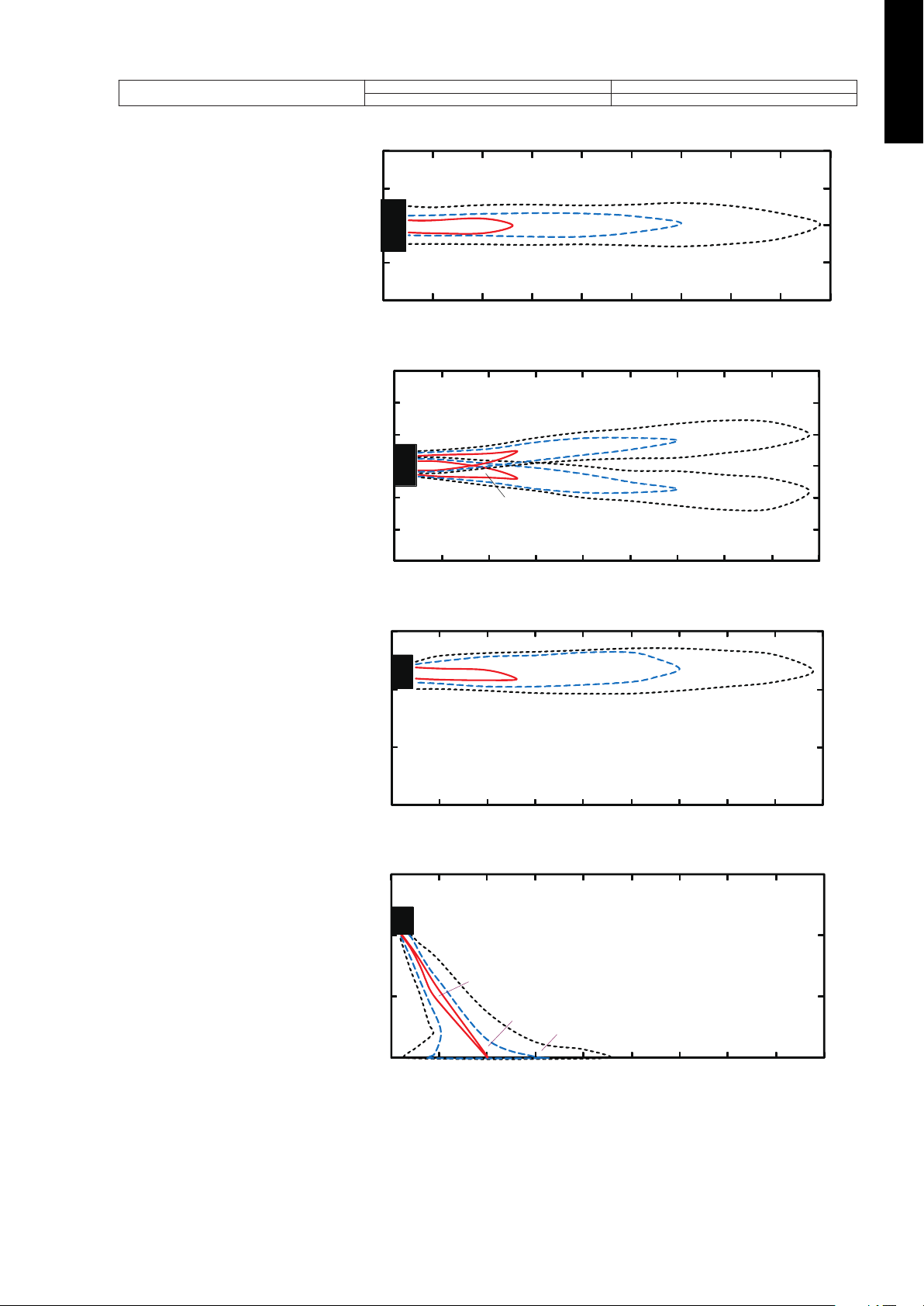

¢

Measuring conditions

Top view

Vertical airflow direction louver: Up

Horizontal airflow direction louver: Center

Top view

Vertical airflow direction louver: Up

Horizontal airflow direction louver: Left & Right

Fan speed Operation mode

HIGH FAN

MULTI TYPE

5 rooms type

Side view

Vertical airflow direction louver: Up

Horizontal airflow direction louver: Center

Side view

Vertical airflow direction louver: Down

Horizontal airflow direction louver: Center

- 15 -

Page 22

Model: RIWH12AVFJ

3 (1.0) 2 (0.5)

7 (2.0)

2

1

0

1

2

Unit: ft/s (m/s)

(m)

(m)

01234567

8

7

3

0

3

7

(ft)

(ft)

0 3 7 10 13 16 20 23

26

9

29

7 (2.0)

7 (2.0)

2 (0.5)

2 (0.5)

3 (1.0)

3 (1.0)

10

7

3

0

3

7

10

(ft)

(ft)

0 3 7 10 13 16 20 23

26

3

2

1

0

1

2

3

Unit: ft/s (m/s)

(m)

(m)

01234567

8

9

29

3 (1.0)

2 (0.5)

7 (2.0)

3

2

1

0

Unit: ft/s (m/s)

(m)

(m)

012345678

10

7

3

0

(ft)

(ft)

0 3 7 10 13 16 20 23 26

9

29

7 (2.0)

3 (1.0)

2 (0.5)

3

2

1

0

Unit: ft/s (m/s)

(m)

(m)

012345678

10

7

3

0

(ft)

(ft)

0 3 7 10 13 16 20 23 26

9

29

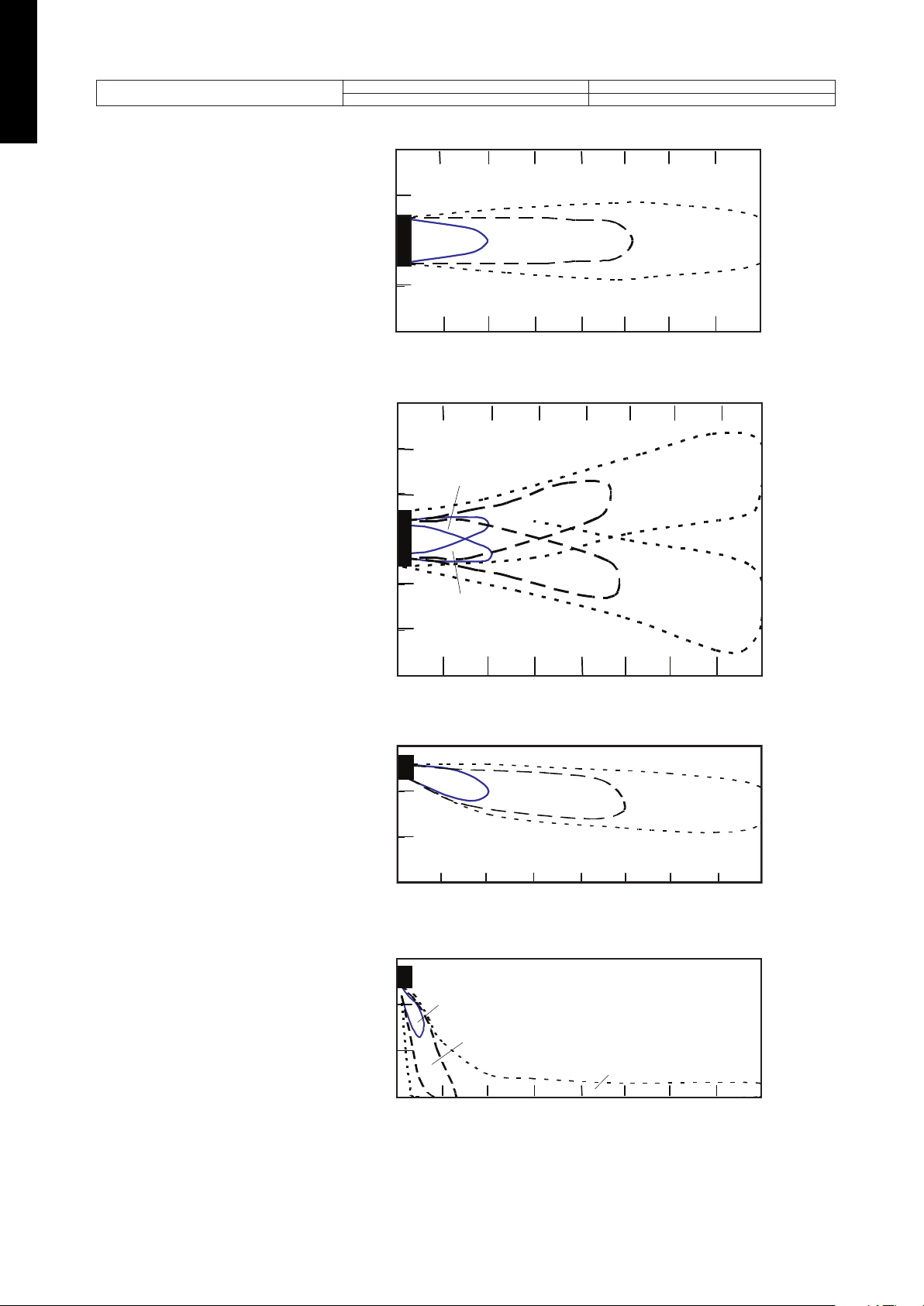

¢

MULTI TYPE

5 rooms type

Measuring conditions

Top view

Vertical airflow direction louver: Up

Horizontal airflow direction louver: Center

Top view

Vertical airflow direction louver: Up

Horizontal airflow direction louver: Left & Right

Fan speed Operation mode

HIGH FAN

Side view

Vertical airflow direction louver: Up

Horizontal airflow direction louver: Center

Side view

Vertical airflow direction louver: Down

Horizontal airflow direction louver: Center

- 16 -

Page 23

Model: RIWH15AVFJ

7 (2.0)

3 (1.0)

2 (0.5)

2

1

0

1

2

Unit: ft/s (m/s)

(m)

(m)

0123456

78

7

3

0

3

7

(ft)

(ft)

03710131620

23

26

9

29

3 (1.0)

3 (1.0)

2 (0.5)

2 (0.5)

7 (2.0)

7 (2.0)

10

7

3

0

3

7

10

(ft)

(ft)

03

710 13162023

26

3

2

1

0

1

2

3

Unit: ft/s (m/s)(m)

(m)

01

23 4567

8

9

29

7 (2.0)

3 (1.0)

2 (0.5)

3

2

1

0

Unit: ft/s (m/s)

(m)

(m)

012345678

10

7

3

0

(ft)

(ft)

037101316202326

9

29

7 (2.0)

3 (1.0)

2 (0.5)

3

2

1

0

Unit: ft/s (m/s)

(m)

(m)

012 34 5 67 8

10

7

3

0

(ft)

(ft)

0 3 7 10 13 16 20 23 26

9

29

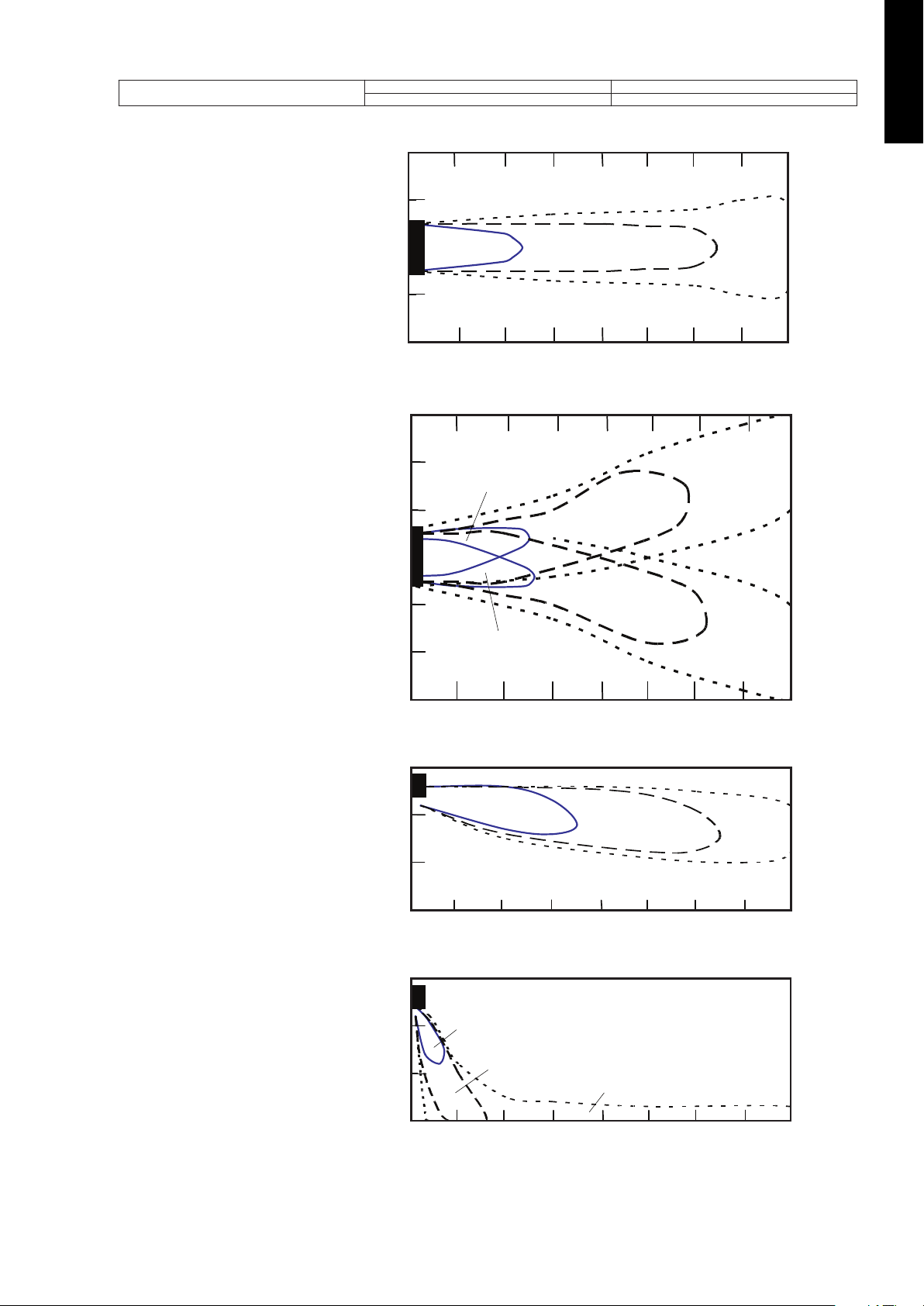

¢

Measuring conditions

Top view

Vertical airflow direction louver: Up

Horizontal airflow direction louver: Center

Top view

Vertical airflow direction louver: Up

Horizontal airflow direction louver: Left & Right

Fan speed Operation mode

HIGH FAN

MULTI TYPE

5 rooms type

Side view

Vertical airflow direction louver: Up

Horizontal airflow direction louver: Center

Side view

Vertical airflow direction louver: Down

Horizontal airflow direction louver: Center

- 17 -

Page 24

Model: RIWH18AVFJ

Unit: ft/s (m/s)

(m)(ft)

0

0

3

3

7

7

1

1

2

2

(m)

(ft)

0

0

1

3 7 10 13 16 20 23 26

2345678

7 (2.0)

3 (1.0)

2 (0.5)

7 (2.0)

7 (2.0)

3 (1.0)

3 (1.0)

2 (0.5)

2 (0.5)

Unit: ft/s (m/s)

(m)

(ft)

0

0

1

3 7 10 13 16 20 23 26

2345678

(m)(ft)

00

3

3

7

7

1

1

2

2

3310

10

3

2

1

0

Unit: ft/s (m/s)

(m)

(m)

012345678

10

7

3

0

(ft)

(ft)

0 3 7 101316202326

7 (2.0)

3 (1.0)

2 (0.5)

7 (2.0)

3 (1.0)

2 (0.5)

3

2

1

0

Unit: ft/s (m/s)

(m)

(m)

012345678

10

7

3

0

(ft)

(ft)

0 3 7 101316202326

¢

MULTI TYPE

5 rooms type

Measuring conditions

Top view

Vertical airflow direction louver: Up

Horizontal airflow direction louver: Center

Top view

Vertical airflow direction louver: Up

Horizontal airflow direction louver: Left & Right

Fan speed Operation mode

HIGH FAN

Side view

Vertical airflow direction louver: Up

Horizontal airflow direction louver: Center

Side view

Vertical airflow direction louver: Down

Horizontal airflow direction louver: Center

- 18 -

Page 25

Model: RIWH24AVFJ

7 (2.0)

3 (1.0)

2 (0.5)

(m)(ft)

0

0

3

3

7

7

1

1

2

2

(m)

(ft)

0

0

1

3 7 10 13 16 20 23 26

2345678

Unit: ft/s (m/s)

7 (2.0)

7 (2.0)

3 (1.0)

3 (1.0)

2 (0.5)

2 (0.5)

Unit: ft/s (m/s)

(m)

(ft)

0

0

1

3 7 10 13 16 20 23 26

2345678

(m)(ft)

00

3

3

7

7

1

1

2

2

3310

10

7 (2.0)

3 (1.0)

2 (0.5)

Unit: ft/s (m/s)

(m)

(ft)

0

0

1

3 7 10 13 16 20 23 26

2345678

(m)(ft)

0

0

3

7

10

1

2

3

7 (2.0)

3 (1.0)

2 (0.5)

Unit: ft/s (m/s)

(m)

(ft)

0

0

1

3 7 10 13 16 20 23 26

2345678

(m)(ft)

0

0

3

7

10

1

2

3

¢

Measuring conditions

Top view

Vertical airflow direction louver: Up

Horizontal airflow direction louver: Center

Fan speed Operation mode

HIGH FAN

MULTI TYPE

5 rooms type

Top view

Vertical airflow direction louver: Up

Horizontal airflow direction louver: Left & Right

Side view

Vertical airflow direction louver: Up

Horizontal airflow direction louver: Center

Side view

Vertical airflow direction louver: Down

Horizontal airflow direction louver: Center

- 19 -

Page 26

6. Airflow

MULTI TYPE

5 rooms type

6-1. Wall mounted type

Conversion factor:

• 1 m3/h = 0.2778 l/s = 0.5886 CFM

• 3.6 m3/h = 1 l/s

• 1.699 m3/h = 1 CFM

Model

RIWH07AVFJ

RIWH09AVFJ

RIWH12AVFJ

RIWH15AVFJ

RIWH18AVFJ

Operation

mode

Cooling

Heating

Cooling

Heating

Cooling

Heating

Cooling

Heating

Cooling

Heating

Airflow

Fan speed

m3/h

High 560 156 330

Med 500 139 294

Low 430 119 253

Quiet 310 86 182

High 560 156 330

Med 500 139 294

Low 430 119 253

Quiet 330 92 194

High 600 167 353

Med 520 144 306

Low 430 119 253

Quiet 310 86 182

High 600 167 353

Med 520 144 306

Low 430 119 253

Quiet 330 92 194

High 660 183 388

Med 560 156 330

Low 450 125 265

Quiet 310 86 182

High 660 183 388

Med 560 156 330

Low 470 131 277

Quiet 330 92 194

High 730 203 430

Med 600 167 353

Low 530 147 312

Quiet 360 100 212

High 730 203 430

Med 615 171 362

Low 560 156 330

Quiet 375 104 221

High 920 256 542

Med 740 206 436

Low 620 172 365

Quiet 550 153 324

High 920 256 542

Med 740 206 436

Low 620 172 365

Quiet 550 153 324

l/s CFM

- 20 -

Page 27

Model

RIWH24AVFJ

Operation

mode

Cooling

Heating

Airflow

Fan speed

m3/h

l/s CFM

High 1,120 311 659

Med 900 250 530

Low 740 206 436

Quiet 620 172 365

High 1,100 306 647

Med 900 250 530

Low 740 206 436

Quiet 620 172 365

MULTI TYPE

5 rooms type

- 21 -

Page 28

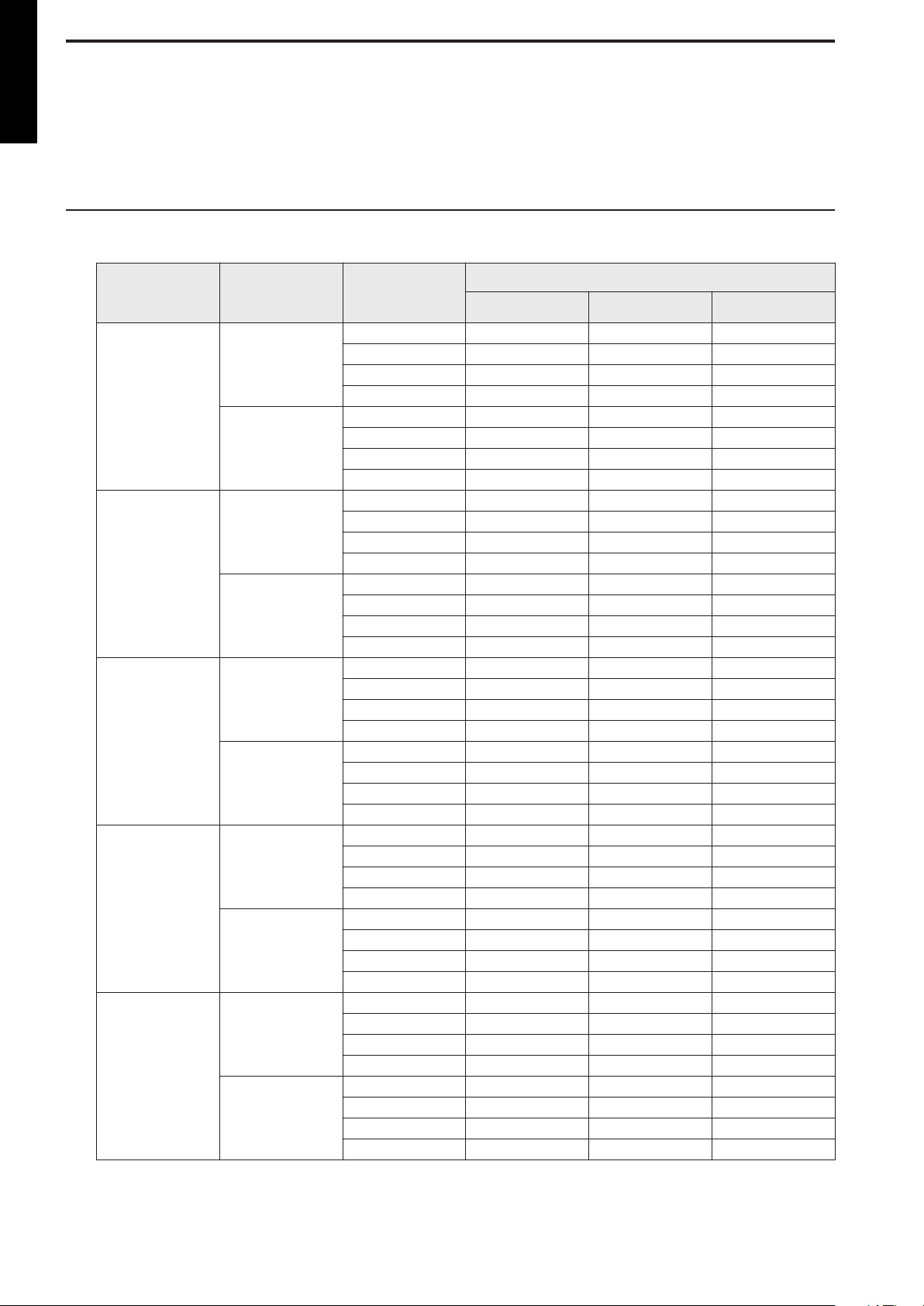

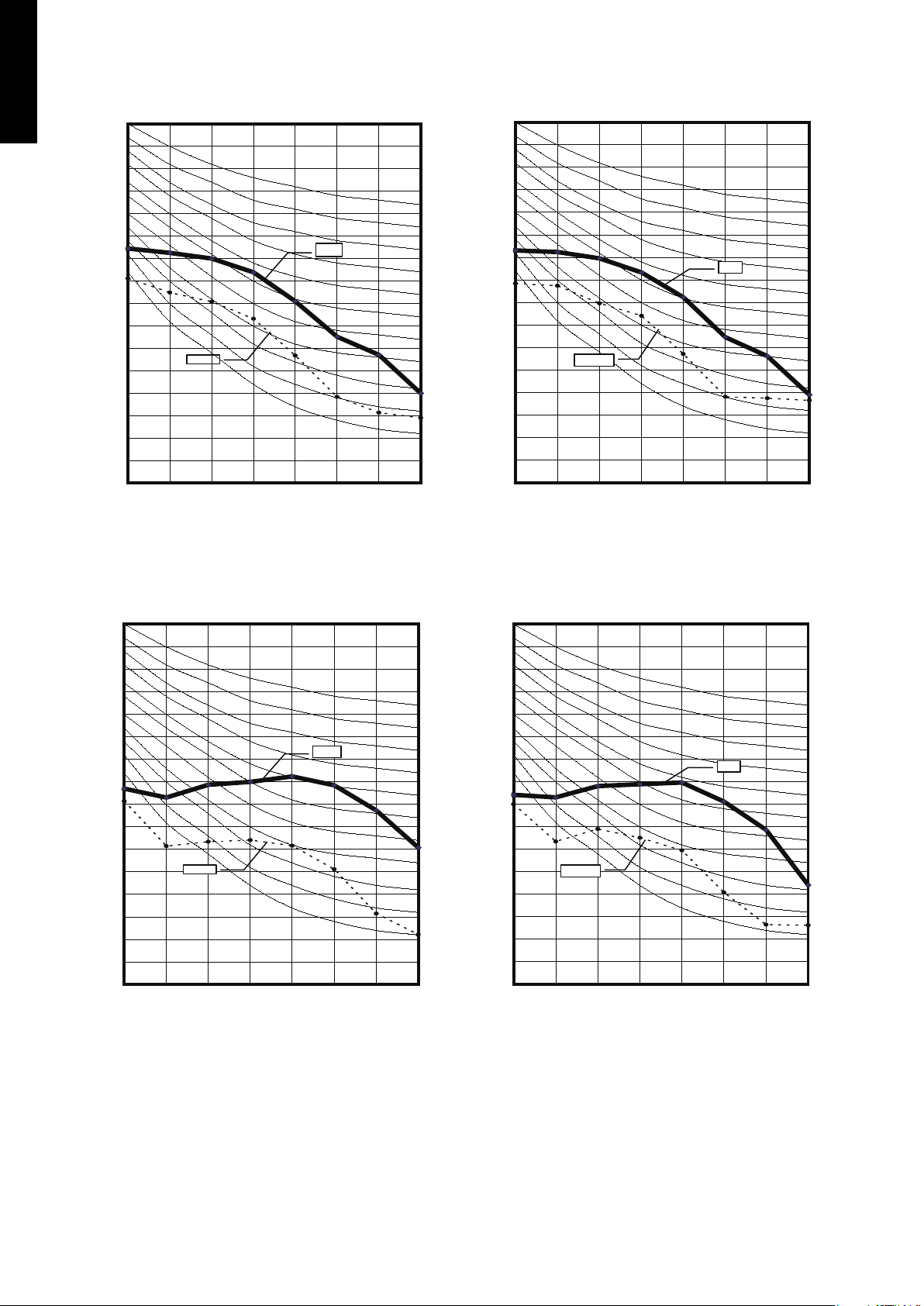

7. Noise level curve

0

10

20

30

40

50

60

70

80

63 125 250 500 1,000 2,000 4,000 8,000

Octave band sound pressure level, dB: (0 dB=0.00020 μbar)

Octave band center frequency, Hz

NC-65

NC-60

NC-55

NC-50

NC-45

NC-40

NC-35

NC-30

NC-25

NC-20

NC-15

High

Quiet

0

10

20

30

40

50

60

70

80

63 125 250 500 1,000 2,000 4,000 8,000

Octave band sound pressure level, dB: (0 dB=0.00020 μbar)

Octave band center frequency, Hz

NC-65

NC-60

NC-55

NC-50

NC-45

NC-40

NC-35

NC-30

NC-25

NC-20

NC-15

High

Quiet

0

10

20

30

40

50

60

70

80

63 125 250 500 1,000 2,000 4,000 8,000

Octave band sound pressure level, dB: (0 dB=0.00020 μbar)

Octave band center frequency, Hz

NC-65

NC-60

NC-55

NC-50

NC-45

NC-40

NC-35

NC-30

NC-25

NC-20

NC-15

High

Quiet

0

10

20

30

40

50

60

70

80

63 125 250 500 1,000 2,000 4,000 8,000

Octave band sound pressure level, dB: (0 dB=0.00020 μbar)

Octave band center frequency, Hz

NC-65

NC-60

NC-55

NC-50

NC-45

NC-40

NC-35

NC-30

NC-25

NC-20

NC-15

-

High

Quiet

MULTI TYPE

7-1. Wall mounted type

5 rooms type

Model: RIWH07AVFJ

¢

Cooling

Heating

Model: RIWH09AVFJ

¢

Cooling

Heating

- 22 -

Page 29

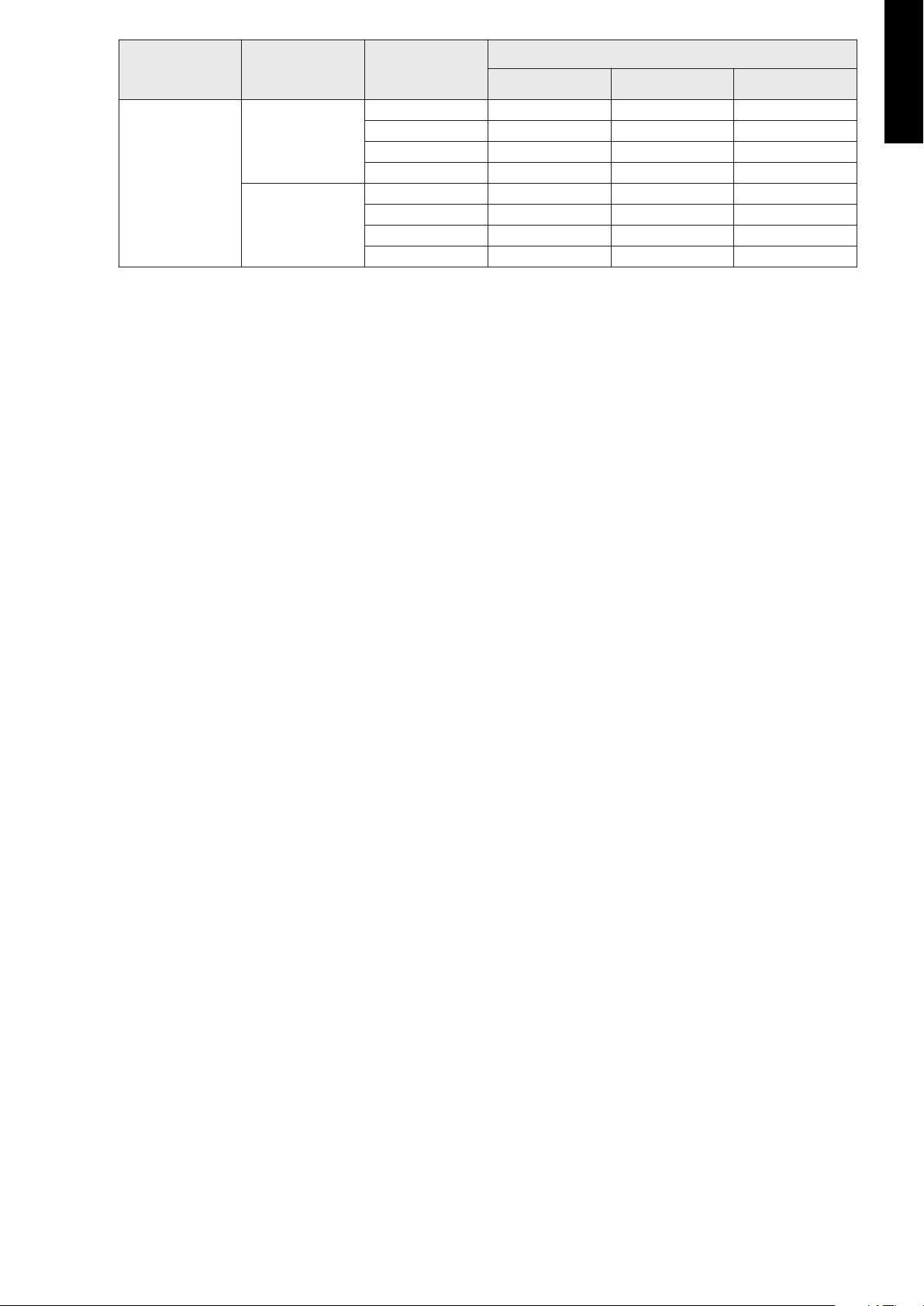

Model: RIWH12AVFJ

0

10

20

30

40

50

60

70

80

63 125 250 500 1,000 2,000 4,000 8,000

Octave band sound pressure level, dB: (0 dB=0.00020 μbar)

Octave band center frequency, Hz

NC-65

NC-60

NC-55

NC-50

NC-45

NC-40

NC-35

NC-30

NC-25

NC-20

NC-15

High

Quiet

0

10

20

30

40

50

60

70

80

63 125 250 500 1,000 2,000 4,000 8,000

Octave band sound pressure level, dB: (0 dB=0.00020 μbar)

Octave band center frequency, Hz

NC-65

NC-60

NC-55

NC-50

NC-45

NC-40

NC-35

NC-30

NC-25

NC-20

NC-15

High

Quiet

HIGH

㻽㼁㻵㻱㼀

0

10

20

30

40

50

60

70

80

63 125 250 500 1,000 2,000 4,000 8,000

Octave band sound pressure level, dB: (0 dB=0.00020 μbar)

Octave band center frequency, Hz

NC-65

NC-60

NC-55

NC-50

NC-45

NC-40

NC-35

NC-30

NC-25

NC-20

NC-15

HIGH

㻽㼁㻵㻱㼀

0

10

20

30

40

50

60

70

80

63 125 250 500 1,000 2,000 4,000 8,000

Octave band sound pressure level, dB: (0 dB=0.00020 μbar)

Octave band center frequency, Hz

NC-65

NC-60

NC-55

NC-50

NC-45

NC-40

NC-35

NC-30

NC-25

NC-20

NC-15

¢

Cooling

Heating

MULTI TYPE

5 rooms type

Model: RIWH15AVFJ

¢

Cooling

Heating

- 23 -

Page 30

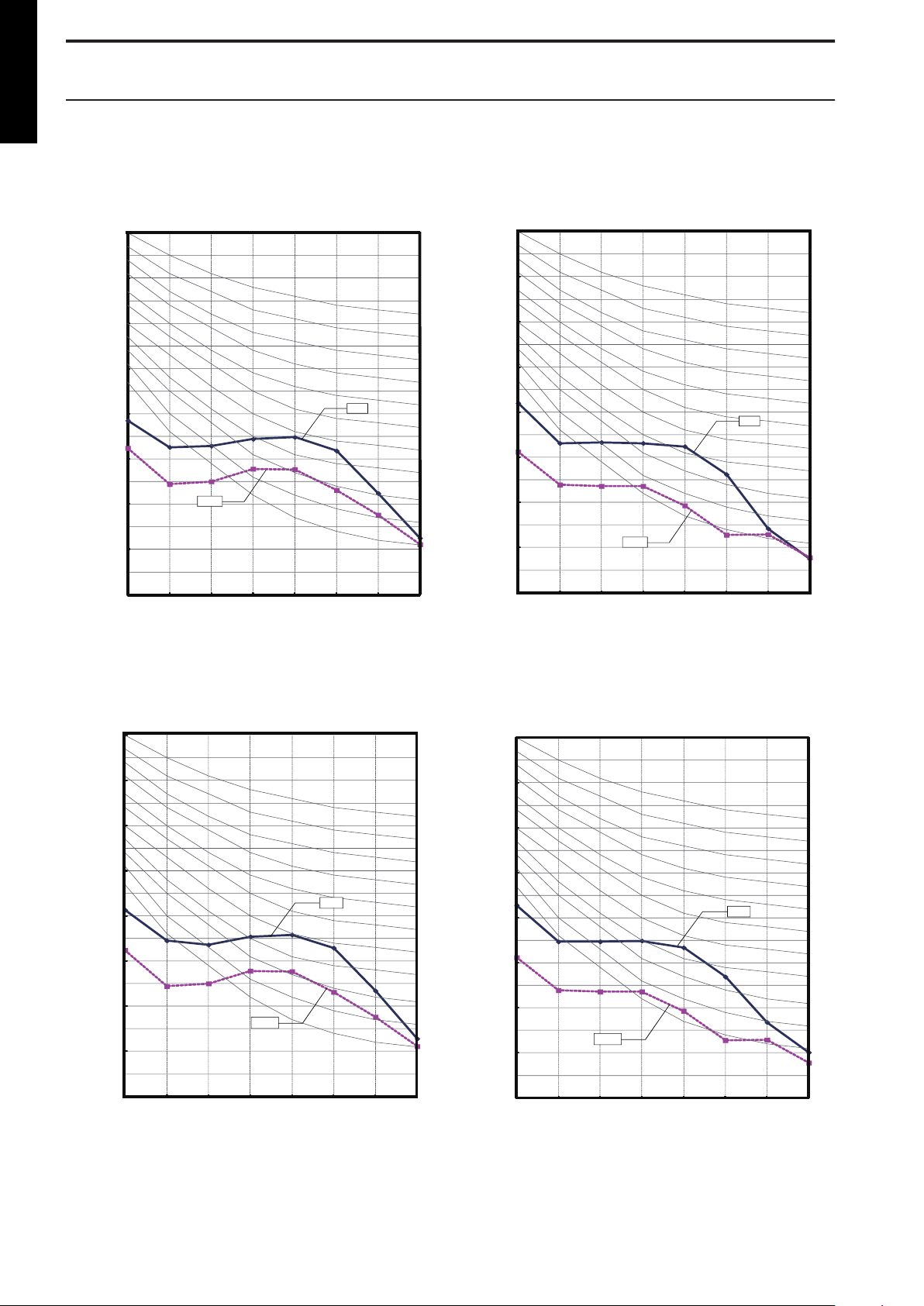

Model: RIWH18AVFJ

0

10

20

30

40

50

60

70

80

63 125 250 500 1,000 2,000 4,000 8,000

Octave band sound pressure level, dB: (0 dB=0.00020 μbar)

Octave band center frequency, Hz

NC-65

NC-60

NC-55

NC-50

NC-45

NC-40

NC-35

NC-30

NC-25

NC-20

NC-15

Quiet

H igh

0

10

20

30

40

50

60

70

80

63 125 250 500 1,000 2,000 4,000 8,000

Octave band sound pressure level, dB: (0 dB=0.00020 μbar)

Octave band center frequency, Hz

NC-65

NC-60

NC-55

NC-50

NC-45

NC-40

NC-35

NC-30

NC-25

NC-20

NC-15

H igh

Quiet

0

10

20

30

40

50

60

70

80

63 125 250 500 1,000 2,000 4,000 8,000

Octave band sound pressure level, dB: (0 dB=0.00020 μbar)

Octave band center frequency, Hz

NC-65

NC-60

NC-55

NC-50

NC-45

NC-40

NC-35

NC-30

NC-25

NC-20

NC-15

H igh

Quiet

0

10

20

30

40

50

60

70

80

63 125 250 500 1,000 2,000 4,000 8,000

Octave band sound pressure level, dB: (0 dB=0.00020 μbar)

Octave band center frequency, Hz

NC-65

NC-60

NC-55

NC-50

NC-45

NC-40

NC-35

NC-30

NC-25

NC-20

NC-15

H igh

Quiet

¢

MULTI TYPE

5 rooms type

Cooling

Heating

Model: RIWH24AVFJ

¢

Cooling

Heating

- 24 -

Page 31

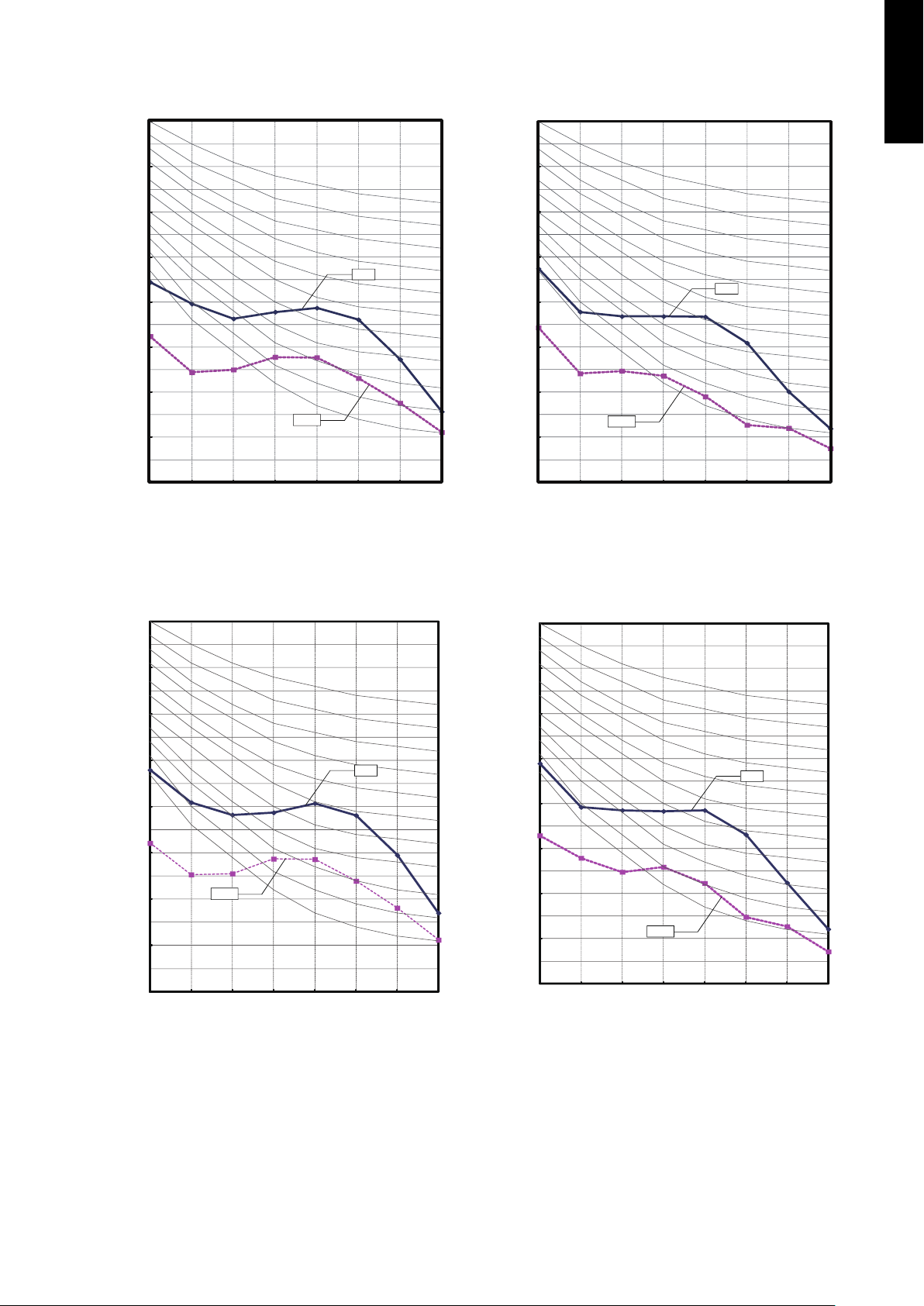

7-2. Sound level check point

2 ft 7

-5/8

in (0.8 m)

3 ft 3

-3/8

in (1 m)

Microphone Microphone

Wall mounted type

¢

NOTE: Detailed shape of the actual indoor unit might be slightly different from the one illustrated

above.

MULTI TYPE

5 rooms type

- 25 -

Page 32

8. Electrical characteristics

MULTI TYPE

5 rooms type

Type Model name Hz

RIWH07AVFJ

RIWH09AVFJ 0.20 / 0.19 17 / 17 0.16 / 0.15

Wall mounted

RIWH12AVFJ 0.25 / 0.24 22 / 22 0.20 / 0.19

RIWH15AVFJ 0.34 / 0.31 28 / 28 0.27 / 0.25

RIWH18AVFJ 0.42 / 0.40 40 / 41 0.34 / 0.32

RIWH24AVFJ 0.71 / 0.66 68 / 69 0.57 / 0.53

Power supply Indoor rated

Voltage

(V)

60 208 / 230

MCA

(A)

0.18 / 0.16 15 / 15 0.14 / 0.13

Input power

(W)

FLA

(A)

Wiring spec.

(Indoor unit to outdoor unit)

Connection cable AWG 14

Limited wiring length ft (m) 85 (26)

MCA: Minimum Circuit Ampacity = Maximum operating current (Full load)

FLA: Full Load Amperes (Fan motor)

- 26 -

Page 33

9. Safety devices

Indoor unit

type

Wall mounted

Model name PCB* fuse

RIWH07AVFJ

RIWH09AVFJ

RIWH12AVFJ

RIWH15AVFJ

RIWH18AVFJ

RIWH24AVFJ

*: Printed Circuit Board

250 V, 3.15 A

Fan motor thermal

protector

Activate: 221 ±18 °F

(105 ±10 °C)

Fan motor stop

Reset: 194 ±18 °F

(90 ±10 °C)

Fan motor restart

Activate: 302 ±27 °F

(150 ±15 °C)

Fan motor stop

Reset: 248 ±27 °F

(120 ±15 °C)

Fan motor restart

Terminal thermal

fuse

― ―

Activate: 216 °F

(102 °C)

Float

switch

―

MULTI TYPE

5 rooms type

- 27 -

Page 34

10. External input and output

Indoor unit

control PCB*1

Example: Switch

Locally purchased

Connected unit

1

3

Signal

Connector

33 ft. (10 m)*2

MULTI TYPE

5 rooms type

10-1. External input

Indoor unit type

Wall mounted ● ●

External input External output

Control input Operation status output Error status output

●

(RIWH07/09/12/15AVFJ)

With using external input function, some functions on this product can be controlled from an external device.

• “Operation/Stop” mode or "Forced stop" mode can be selected with function setting of indoor

unit.

• A twisted pair cable (22AWG) should be used. Maximum length of cable is 492 ft (150 m).

• The wire connection should be separate from the power cable line.

Control input (Operation/Stop or Forced stop)

¢

Indoor unit type Connector

Wall mounted

RIWH07AVFJ, RIWH09AVFJ, RIWH12AVFJ,

RIWH15AVFJ

RIWH18AVFJ, RIWH24AVFJ CN14

CNA01

The air conditioner can be remotely operated by means of the following on-site work.

Operation is started at the following contents by adding the contact input of a commercial on/off

switch to a connector on the external control PCB and turning it on.

Unit operation Initial setting after power is on

Operation mode Auto changeover Mode at previous operation

Set temperature 76 °F (24 °C) Temperature at previous operation

Airflow mode AUTO Mode at previous operation

Air direction (swing) Standard air direction (swing: off) Air direction at previous operation

Starting mode other than initial

setting

Circuit diagram example

• Contact capacity: DC 24 V or more, 10 mA or more.

• *1: PCB of Communication kit is used for wall mounted (RIWH07AVFJ, RIWH09AVFJ, RIWH12AVFJ,

and RIWH15AVFJ) type.

• *2: Make the distance from the PCB to the connected unit within 33 ft (10 m).

• Use non-polar relays and switches.

Wall mounted

Indoor unit type

RIWH07AVFJ, RIWH09AVFJ, RIWH12AVFJ,

RIWH15AVFJ, RIWH18AVFJ, RIWH24AVFJ

- 28 -

1-pin 3-pin

(Polarity) (Polarity)

- +

Page 35

• When function setting is "Operation/Stop" mode

Operation

Stop

On

Off

Input signal

Indoor unit

Remote controller

On On On

Input signal

Indoor unit

Command

Remote control

operation invalidity

On

Off

Operation

Stop

Forced stop

Normal

• When function setting is "Forced stop" mode

MULTI TYPE

5 rooms type

Optional part

Indoor unit type Part name Model name

Wall mounted

Wall mounted

RIWH07AVFJ, RIWH09AVFJ, RIWH12AVFJ,

RIWH15AVFJ

RIWH18AVFJ, RIWH24AVFJ RXXWZX

Indoor unit type Part name Model name

RIWH07AVFJ, RIWH09AVFJ, RIWH12AVFJ,

RIWH15AVFJ

RIWH18AVFJ, RIWH24AVFJ — —

External connect

kit

Communication kit RXXCBXZ2

*For operating the external input function, the wall mounted (RIWH07AVFJ, RIWH09AVFJ,

RIWH12AVFJ, and RIWH15AVFJ) type requires optional communication kit (RXXCBXZ2) in

addition to the wire (RXXWZXZ5).

RXXWZXZ5

- 29 -

Page 36

10-2. External output

Locally purchased

Indoor unit

control PCB

*1

Connected unit

Example: Display

Example: Relay unit

Relay

power supply

DC 24 V

1

2

Signal

V

Connector

33 ft

(10 m)*2

On

Off

Operation

Stop

Indoor unit

Output signal

MULTI TYPE

5 rooms type

Use an external output cable with appropriate external dimension, depending on the number of

cables to be installed.

Operation status output

¢

Indoor unit type Connector

Wall mounted

RIWH07AVFJ, RIWH09AVFJ, RIWH12AVFJ,

RIWH15AVFJ

CNB01

RIWH18AVFJ, RIWH24AVFJ CN16

Air conditioner operation status signal can be output.

Circuit diagram example

• *1: PCB of Communication kit is used for wall mounted (RIWH07AVFJ, RIWH09AVFJ, RIWH12AVFJ, and RIWH15AVFJ) type.

• *2: Make the distance from the PCB to the connected unit within 33 ft (10 m).

• Relay spec: Max. DC 24 V, 10 mA to less than 500 mA.

- 30 -

Page 37

Optional part

Indoor unit type Part name Model name

RIWH07AVFJ, RIWH09AVFJ, RIWH12AVFJ,

Wall mounted

RIWH18AVFJ, RIWH24AVFJ RXXWZX

Indoor unit type Part name Model name

RIWH07AVFJ, RIWH09AVFJ, RIWH12AVFJ,

Wall mounted

RIWH18AVFJ, RIWH24AVFJ — —

RIWH15AVFJ

RIWH15AVFJ

*For operating the external output function, the wall mounted type (RIWH07AVFJ, RIWH09AVFJ, RIWH12AVFJ, and RIWH15AVFJ) requires optional Communication kit

(RXXCBXZ2) in addition to the wire (RXXWZXZ5).

External connect

kit

Communication kit RXXCBXZ2

RXXWZXZ5

MULTI TYPE

5 rooms type

- 31 -

Page 38

Locally purchased

Example: Display

Indoor unit

control PCB *1

Connected unit

Example:

Relay unit

1

2

Signal

Relay

power

supply

V

Connector

33 ft

(10 m) *2

DC 24 V

On

Off

Error

Normal

Error status

Output signal

MULTI TYPE

5 rooms type

Error status output

¢

Indoor unit type Connector

RIWH07AVFJ, RIWH09AVFJ, RIWH12AVFJ,

Wall mounted

RIWH18AVFJ, RIWH24AVFJ —

Air conditioner error status signal can be output.

Circuit diagram example

RIWH15AVFJ

CNB02

• *1: PCB of Communication kit is used for wall mounted (RIWH07AVFJ, RIWH09AVFJ, RIWH12AVFJ, and RIWH15AVFJ) type.

• *2: Make the distance from the PCB to the connected unit within 33 ft (10 m).

• Relay spec.: Max. DC 24 V, 10 mA to less than 500 mA.

Optional part

Indoor unit type Part name Model name

Wall mounted

RIWH07AVFJ, RIWH09AVFJ,

RIWH12AVFJ, RIWH15AVFJ

RIWH18AVFJ, RIWH24AVFJ — —

External connect kit RXXWZXZ5

Indoor unit type Part name Model name

RIWH07AVFJ, RIWH09AVFJ,

Wall mounted

*For operating the external input function, the wall mounted (RIWH07AVFJ, RIWH09AVFJ,

RIWH12AVFJ, and RIWH15AVFJ) type requires Communication kit (RXXCBXZ2) in addition

to the wire (RXXWZXZ5).

RIWH12AVFJ, RIWH15AVFJ

RIWH18AVFJ, RIWH24AVFJ — —

- 32 -

Communication kit RXXCBXZ2

Page 39

11. Remote controller

o

p

j

k

l

n

m

b

d

e

a

f

i

g

h

c

q

r

s

t

u

v

w

x

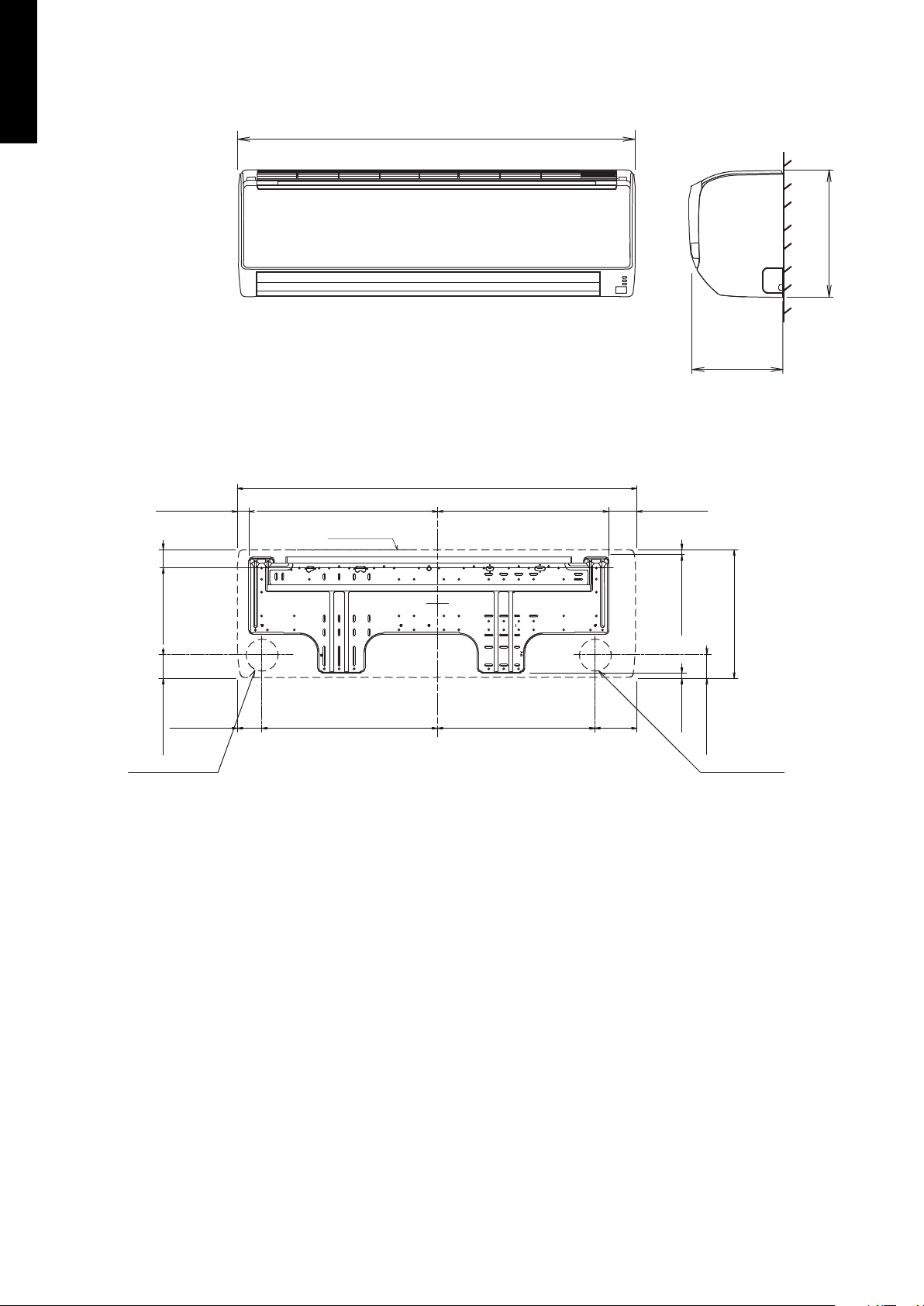

11-1. Wireless remote controller (AR-RAH2U)

Overview

¢

a

FAN button

Selects the fan speed (AUTO, HIGH, MED, LOW, and

QUIET).

b START/STOP button

Starts and stops operation.

c SET button (vertical)

Adjusts the vertical airflow direction.

d SET button (horizontal)

Adjusts the horizontal airflow direction.

e SWING button

Sets the automatic swing operation and selects swing

mode (Up/down, Left/right, Up/down/left/right, and Stop

swing).

f RESET button

Used when replacing batteries.

g Timer set (- / +) button

Sets the current time and on-off time.

h TEST RUN button

Only used for the initial test in the unit installation.

i CLOCK ADJUST button

Used for adjusting the clock.

j TIMER MODE button

Selects the timer mode (off timer, on timer, program

timer, and timer reset).

k SLEEP button

Pressed to select sleep timer.

Display panel

l ECONOMY button

m MIN. HEAT button

MULTI TYPE

5 rooms type

NOTE:

Functions may differ by type of the indoor

unit. For details, refer to the operation manual.

n

SET TEMP. (temperature) (

• Sets desired temperature.

• Sets remote controller custom code.

/ ) button

o MODE button

• Switches operation mode (AUTO, COOL, DRY, FAN,

and HEAT).

• Starts/ends the remote controller custom code (max.

4 types) change.

Signal transmitter

p

q Signal transmit indicator

r Fan speed indicator

s Swing indicator

t Timer mode indicator

u Clock indicator

v Sleep indicator

w Operating mode indicator

x Temperature indicator

- 33 -

Page 40

Front view Side view Rear view

6-11/16 (170)

3/4 (19)

2-3/16 (56)

Top view

Front view Side view Bottom view

2-3/8 (60.4)

1-3/16 (30.2)

Ø1/8 (3.5)

1/8 x 1/4 (3.5 x 6.5)

(hole)

(hole)

1-1/16

1

3-3/4 (95)

6-1/16 (154.7)

(25.5)

(26.2)

MULTI TYPE

5 rooms type

Specifications

¢

Controller

Unit: in (mm)

Size (H × W × D) in (mm) 6-11/16 × 2-3/16 × 3/4 (170 × 56 × 19)

Weight oz (g) 3 (85) (without batteries)

NOTE: Actual number of buttons might be different from the figure above.

Holder

Unit: in (mm)

Size (H × W × D) in (mm) 6-1/16 × 2-3/8 × 1-1/16 (154.7 × 60.4 × 26.2)

Weight oz (g) 10 (28)

- 34 -

Page 41

11-2. Wireless remote controller (AR-REG1U)

REG1U

REG1U

Signal

transmitter

MIN. HEAT

button

TEMP.

button

POWERFUL

button

Start/Stop

button

MODE button

FAN button

ECONOMY button

SWING button

SET button

ON TIMER button

OFF TIMER button

TIMER SELECT button

SLEEP TIMER button

TIMER CANCEL button

RESET button

°C / °F switching button

CLOCK ADJUST button

Mode indicator

Clock and Timer indicator

SEND indicator

Transmit indicator

Temperature indicator

Fan speed indicator

Swing indicator

Overview

¢

AR-REG1U

MULTI TYPE

5 rooms type

NOTE: Functions may differ by type of the indoor unit. For details, refer to the operation manual.

Display panel

To facilitate explanation, the accompanying illustration has been drawn to show all possible indicators; in actual operation, however, the display will only show those indicators appropriate to the current operation.

- 35 -

Page 42

Top view

Front view Side view

8-1/16 (205)

11/16

(17)

2-3/8

(61)

1-15/16 (48.5)

3/16 (5.5)

1-1/16

(26.2)

2-3/4 (69.3)

1/4 (6.5)

Front View Side View

Bottom View

Ø 1/8

(Ø3.5)

(Hole)

5-7/8 (150)

4-3/16 (106.8)

Hole

(1/83.5)

2-R

MULTI TYPE

5 rooms type

Specifications

¢

Controller

Unit: in (mm)

Size (H × W × D) in (mm) 8-1/16 × 2-3/8 × 11/16 (205 × 61 × 17)

Weight oz (g) 4.3 (122) (without batteries)

Holder

Unit: in (mm)

Size (H × W × D) in (mm) 5-7/8 × 2-3/4 × 1-1/16 (150 × 69.3 × 26.2)

Weight oz (g) 1 (27)

- 36 -

Page 43

b

f

g

h

i

j

k

a

c

d

e

l

m

n

o

pqrst

u

11-3. Wired remote controller (RXRNNUM: Optional part)

Overview

¢

a START/STOP button

Starts and stops operation.

b SET TEMP. button

Selects the setting temperature.

c MODE button

, HEAT ,FAN

Display panel

NOTE:

Functions may differ by type of the indoor unit. For details, refer to the operation manual.

Selects the operating mode (AUTO

, COOL , and DRY ).

d FAN button

Selects the fan speed AUTO ,QUIET , LOW ,

MED , and HIGH ).

e ECONOMY (THERMO SENSOR) button

Turns the economy-efficient mode on and off.

f TIMER MODE (CLOCK ADJUST) button

Selects the timer mode (off timer, on timer, and

weekly timer). Sets the current time.

g DAY (DAY OFF) button

Temporarily cancels one day timer.

h SET BACK button

Selects the set back timer.

i Set time button

Pressed to set time.

j TIMER DELETE button

Deletes the weekly timer schedule.

k TIMER SET button

Sets the date, hour, minute, and on-off time.

l Vertical airflow direction and swing button

Push for 2 seconds to change the swing mode.

m Horizontal airflow direction and swing but-

ton

Push for 2 seconds to change the swing mode.

n FILTER RESET button

o Operation lamp

Lights during operation and when the timer is on.

p Timer and clock indicator

q Operation mode indicator

r Fan speed indicator

s Operation lock indicator

t Temperature indicator

u Function indicators

Defrost indicator

Thermo sensor indicator

Economy indicator

Vertical swing indicator

Horizontal swing indicator

Filter indicator

MULTI TYPE

5 rooms type

- 37 -

Page 44

System diagram

A

Indoor unit

Remote controller

Primary

Secondary

BC

Indoor unit

Remote controllers

Remote controller

1 (Red): 12 V

2 (White): Signal

3 (Black): COM

Indoor unit

Remote

controller

123

123

Remote controllers

1 (Red): 12 V

2 (White): Signal

3 (Black): COM

Primary Secondary

Indoor unit

123

123 123

Remote

controller

¢

MULTI TYPE

5 rooms type

1 remote controller:

Electrical wiring

¢

1 remote controller:

2 remote controllers:

A, B, C: Remote controller cable

A ≤ 1,640 ft (500 m);B + C ≤ 1,640 ft (500

m)

2 remote controllers:

- 38 -

Page 45

Specifications

4-3/4 (120)

4-3/4 (120)

4-3/4 (120)

11/16 (18)

Side viewFront view

¢

Dimensions and other specifications on the wired remote controller are as follows.

Unit: in (mm)

Size (H × W × D) in (mm) 4-3/4 × 4-3/4 × 11/16 (120 × 120 × 18)

Weight oz (g) 5.6 (160)

Cable length (accessory) ft (m) 33 (10)

Power V 12

MULTI TYPE

5 rooms type

Wiring specifications

Use Cable size Wire type Remarks

Remote controller cable

22 AWG (0.33 mm2)

Polar 3-core Use sheathed PVC cable.

- 39 -

Page 46

13/16 in.

(20 mm)

Remote controller cable

Connecting

cable

White

Red

White

Red

Black

Insulated

connection

Black

Remote controller cable

Connecting cable Terminal

(*1)

Terminal

(*2)

Communication kit

Indoor unit PCB

MULTI TYPE

5 rooms type

Installation

¢

Connection pattern

NOTE: Connection pattern is different according to type of Indoor unit.

Indoor unit types Connection pattern

Wall mounted type

Pattern A

1. Modify the remote controller cable as follows:

• Use a tool to cut off the terminal on the end of the remote controller cable and then

remove the insulation from the cut end of the cable as shown in following figure.

• Connect the remote controller cable and connecting cable as shown in following figure.

• Be sure to insulate the connection between the cables.

RIWH07AVFJ, RIWH09AVFJ,

RIWH12AVFJ, and RIWH15AVFJ

RIWH18AVFJ and RIWH24AVFJ Pattern B

Pattern A

2. Connect the remote controller cable.

• Connect the cable made in step 1. to the terminal (*1) of optional communication kit.

• Connect the cable from the terminal (*2) of communication kit to the indoor unit PCB.

*1: CNC01 (for RIWH07—15AVFJ: RXXCBXZ2)

*2: CND01 (for RIWH07—15AVFJ: RXXCBXZ2)

- 40 -

Page 47

Pattern B

13/16 in.

(20 mm)

Remote controller cable

Connecting

cable

White

Red

White

Red

Black

Insulated

connection

Black

Remote controller cable

Connecting cable

Indoor unit PCB

1. Modify the remote controller cable as follows:

• Use a tool to cut off the terminal on the end of the remote controller cable and then

remove the insulation from the cut end of the cable as shown in following figure.

• Connect the remote controller cable and connecting cable as shown in following figure.

• Be sure to insulate the connection between the cables.

2. Connect the remote controller cable.

• Connect the cable made in step 1. to the indoor unit PCB.

MULTI TYPE

5 rooms type

¢ Optional parts

Wall mounted Model name

RIWH07—15AVFJ RXXCBXZ2

The communication kit is needed for connecting the wired remote controller to the wall mounted type.

- 41 -

Page 48

11-4. Simple remote controller (RXRSNUM: Optional part)

a

b

c

d

e

f

g

h

i

j

k

l

m

MULTI TYPE

5 rooms type

Overview

¢

a START/STOP button

Starts and stops operation.

b Display backlight button

Lights during operation.

c Operation lamp

Lights during operation.

d FAN button

Selects the fan speed (AUTO

LOW , and QUIET ).

,HIGH , MED ,

Display panel

e SET TEMP. button

Selects the setting temperature.

f MODE button

Selects the operating mode (AUTO

FAN , HEAT ).

, COOL , DRY ,

g Standby indicator

Indicates during the oil recovery and defrosting operation.

h Power source indicator

Indicates the main power is on.

i Central control indicator

Indicates when function is locked.

j Fan speed indicator

Deletes the weekly timer schedule.

k Set temperature

• Indicates error history number in error code history

display mode.

• Indicates indoor unit address in address display

mode.

l Operating mode indicator

m Indicator

• Upper:

– Indicates the error code in error code history dis-

play mode and in self diagnosis mode.

– Indicates the refrigerant system address in address

display mode.

• Lower: Indicates the remote controller address in error code history display mode, address display mode,

and self diagnosis mode.

- 42 -

Page 49

System diagram

A

Indoor unit

Remote controller

Primary

Secondary

BC

Indoor unit

Remote controllers

Remote controller

1 (Red): 12 V

2 (White): Signal

3 (Black): COM

Indoor unit

Remote

controller

123

123

Remote controllers

1 (Red): 12 V

2 (White): Signal

3 (Black): COM

Primary Secondary

Indoor unit

123

123 123

Remote

controller

¢

1 remote controller:

Electrical wiring

¢

1 remote controller:

2 remote controllers:

2 remote controllers:

A, B, C: Remote controller cable

A ≤ 1,640 ft (500 m);B + C ≤ 1,640 ft (500

m)

MULTI TYPE

5 rooms type

- 43 -

Page 50

Specifications

4-3/4 (120)

2-15/16 (75)

1-15/16 (49)

1-9/16 (39)

15/16 (23.5)

9/16 (14)

3/16 (4)

7/16 (11)

3/16 (4.5)

1/2 (12.5)

hole x 2

hole x 2

5/16 (8)

2-3/8 (60)

1/4 (6)

11/16 (18)

3/8 (9)

1-7/8 (47.5)

3-5/16 (83.5)

Front View Side View Rear View

¢

Dimensions and other specifications on the wired remote controller are as follows.

MULTI TYPE

5 rooms type

Unit: in (mm)

Size (H × W × D) in (mm) 4-3/4 × 2-15/16 × 9/16 (120 × 75 × 14)

Weight oz (g) 3.2 (90)

Cable length (accessory) ft (m) 33 (10)

Power V 12

¢

Wiring specifications

Use Size Wire type Remarks

Remote controller cable

22 AWG (0.33 mm2)

Polar 3 core Use sheathed PVC cable.

- 44 -

Page 51

Installation

13/16 in.

(20 mm)

Remote controller cable

Connecting

cable

White

Red

White

Red

Black

Insulated

connection

Black

Remote controller cable

Connecting cable Terminal

(*1)

Terminal

(*2)

Communication kit

Indoor unit PCB

¢

Connection pattern

NOTE: Connection pattern is different according to type of Indoor unit.

Indoor unit types Connection pattern

Wall mounted type

Pattern A

1. Modify the remote controller cable as follows:

• Use a tool to cut off the terminal on the end of the remote controller cable and then

remove the insulation from the cut end of the cable as shown in following figure.

• Connect the remote controller cable and connecting cable as shown in following figure.

• Be sure to insulate the connection between the cables.

RIWH07AVFJ, RIWH09AVFJ,

RIWH12AVFJ, and RIWH15AVFJ

RIWH18AVFJ and RIWH24AVFJ Pattern B

Pattern A

MULTI TYPE

5 rooms type

2. Connect the remote controller cable.

• Connect the cable made in step 1. to the terminal (*1) of optional communication kit.

• Connect the cable from the terminal (*2) of communication kit to the indoor unit PCB.

*1: CNC01 (for RIWH07—15AVFJ: RXXCBXZ2)

*2: CND01 (for RIWH07—15AVFJ: RXXCBXZ2)

- 45 -

Page 52

13/16 in.

(20 mm)

Remote controller cable

Connecting

cable

White

Red

White

Red

Black

Insulated

connection

Black

Remote controller cable

Connecting cable

Indoor unit PCB

MULTI TYPE

5 rooms type

Pattern B

1. Modify the remote controller cable as follows:

• Use a tool to cut off the terminal on the end of the remote controller cable and then

remove the insulation from the cut end of the cable as shown in following figure.

• Connect the remote controller cable and connecting cable as shown in following figure.

• Be sure to insulate the connection between the cables.

2. Connect the remote controller cable.

• Connect the cable made in step 1. to the indoor unit PCB.

¢ Optional parts

Wall mounted Model name

RIWH07—15AVFJ RXXCBXZ2

The communication kit is needed for connecting the wired remote controller to the wall mounted type.

- 46 -

Page 53

12. Function settings

Breaker on

Outdoor unit

Indoor units

To adjust the functions of this product according to the installation environment, various types of

function settings are available.

NOTE:

Incorrect settings can cause a product malfunction.

12-1. Indoor unit (setting by wireless remote controller)

• The function settings of the control of the indoor unit can be changed by this procedure according to the installation conditions. Incorrect settings can cause the indoor unit malfunction.

• After the power is turned on, perform the “Function setting” according to the installation conditions using the remote controller.

• The settings may be selected between the following two: Function number or Setting number.

• Settings will not be changed if invalid numbers or setting numbers are selected.

¢ Preparation

Before connecting the power supply of the indoor unit, reconfirm following items:

• Piping air tight test and vacuuming have been performed firmly.

• There is no wiring mistake. Then, connect the power supply of the indoor unit.

MULTI TYPE

5 rooms type

- 47 -

Page 54

AR-RAH2U

MODE button

START/STOP button

TIMER MODE button

SET TEMP. " " and " " button

FAN button

Setting number

Function number

Refer to Function details.

Refer to Function details.

Switches bet ween the setting number (bottom line)

and function number (top line)

Increases and decreases the displayed number

- Starts the function setting mode

- Changes the display digits

Transmits function setting

Transmits function mode

SET TEMP. ( )

RESET

FAN

Function setting

mode display

Custom code

(

--

-

)

The initial setting is " "

¢

Button name and function

MULTI TYPE

5 rooms type

During address setting mode, indoor unit reject the any operation command from remote controller.

NOTE:

Function setting procedure

1. Connect the power supply of the outdoor unit.

2. To enter the function setting mode, while holding down the FAN and the SET TEMP.

tons, press the RESET button.

3. Press the SET TEMP. or buttons to select the custom code that matches the setting

with the indoor unit. By selecting the appropriate custom code, the communication between

the indoor unit and the wireless remote controller become possible.

Actual number of buttons might be different from the figures in following instructions.

but-

- 48 -

Page 55

4. For confirming the custom code, press the TIMER MODE button to send the code to the in-

2 short beeps

Change digit

Change digit

door unit.

5. Press the MODE button to enter the function setting mode.

6. Select the function number by pressing the or the button.

Each time the MODE button is pressed, it switches between the left digit and the right digit.

MULTI TYPE

5 rooms type

7. Proceed to number setting by pressing the FAN button.

To return to the function number selection, press the FAN button again.

8. Select the setting number by pressing the or the button.

Each time the MODE button is pressed, it switches between the left digit and the right digit.

- 49 -

Page 56

2 short beeps

2 short beeps

RESET

MULTI TYPE

5 rooms type

9. Send the function mode information by pressing the TIMER MODE button once.

10. Send the function setting information by pressing the START/STOP button once.

2 short beeps will be emitted from the indoor unit when the signal is received correctly. If

wrong code is set, no beep sound will be emitted.

NOTE: Press START/STOP button within 30 seconds after pressing TIMER MODE button.

Function details: Refer to Chapter 12-4. "Function details" on page 67.

11. Exit the function setting mode by pressing the RESET button.

To set custom code , , or , perform same procedures for each code.

Setting up each indoor unit

Repeat step from 1. to 11. to set up each indoor unit. If the custom code is other than " ", steps

from 1. to 4. and 11. need to be performed.

- 50 -

Page 57

Resetting the power after setting up function of all indoor units

NOTES:

• If the reset is not performed, function can not be read correctly.

• After all the functions have been set, the circuit breaker needs to be switched off for at least 2

minutes.

– After the 2 minutes has passed, power can be restored.

– The set function is stored in the PCB and will remain in memory even when the power of

indoor unit is turned off.

However setting function is effective after disconnecting the power supply and then reconnecting it.

• Record the latest configuration of the indoor unit function setting on a label, and put the label

on the unit so it can be used for after-sales service operations.

Once the RESET button is pressed on the remote controller, the operation mode will be set to the

AUTO MODE.

Adjust the operation mode to either cooling or heating before starting the operation of the air conditioner.

MULTI TYPE

5 rooms type

NOTE:

If custom code other than " " is set, the remote control must be set accordingly to the

indoor unit setting.

- 51 -

Page 58

MULTI TYPE

5 rooms type

Remote controller custom code setting

Custom code setting of wireless remote controller needs to be same as the setting of the indoor

unit. When you change the custom code setting of the wireless remote controller, do as follows:

1. Press the START/STOP button until only the clock is displayed on the remote controller display.

2. Press the MODE button for at least 5 seconds to display the current custom code (initially

set to A).

3. Press the SET TEMP. or the button to change the custom code between → → →

.

- 52 -

Page 59

4. Press the MODE button again to return to the clock display. The custom code will be

changed.

• If no buttons are pressed within 30 seconds after the custom code is displayed, the system returns to the original clock display. In this case, start again from step 1.

• The air conditioner custom code is set to A prior to shipment.

• The remote controller resets to custom code A when the batteries in the remote controller are

replaced. If you use a custom code other than custom code A, reset the custom code after replacing the batteries. If you do not know the air conditioner custom code setting, try each of the

custom codes (

→ → → ) until you find the code which operates the air conditioner.

MULTI TYPE

5 rooms type

- 53 -

Page 60

AR-REG1U

MIN HEAT button

Setting number

Function number

Refer to Function details

Refer to Function details

Switches bet ween the settin g number

(bottom line) and functi on number (top

line)

The displayed numb er Increases and

decreases

Changes the display digits

Transmits function set ting

Transmits function mode

POWERFUL button

SET TEMP. (

/ ) button

START/STOP ( ) button

RESET button

MODE button

POWERFUL

SET TEMP. (

)

RESET

Function setting

mode display

¢

Button name and function

MULTI TYPE

5 rooms type

During address setting mode, indoor unit reject the any operation command from remote controller.

1. Connect the power supply of the outdoor unit.

2. To enter the function setting mode, while holding down the POWERFUL and SET TEMP.

Function setting procedure

buttons, press the RESET button.

- 54 -

Page 61

3. Select the function number by pressing the or the buttons. Each time the 10°C HEAT

Change digitChange digit

Change digit

button is pressed, it switches between the right digit and the left digit.

4. Proceed to the setting number by pressing the POWERFUL button. (To return to the function

number selection, press the POWERFUL button again.)

MULTI TYPE

5 rooms type

5. Select the function number by pressing the or the button. Each time the 10°C HEAT

button is pressed, it switches between the right digit and the left digit.

6. Press the MODE button once to transmit the function mode information.

- 55 -

Page 62

/

2 short

beeps

/

RESET

MULTI TYPE

5 rooms type

7. Press the

button once to transmit the function setting information. 2 short beeps will be

emitted from the indoor unit when the signal is received correctly. If wrong code is set, no

beep sound will be emitted.

NOTE:

Press

button within 30 seconds after pressing MODE button.

For the function details, refer to Chapter 12-4. "Function details" on page 67.

8. Exit the function setting mode by pressing the RESET button.

- 56 -

Page 63

Setting up each indoor unit

Repeat step from 1. to 8. to set up each indoor unit. If the custom code is other than " ", steps

from 1. to 2. and 8. need to be performed.

Resetting the power after setting up function of all indoor units

NOTES:

• If the reset is not performed, function can not be read correctly.

• After all the functions have been set, the circuit breaker needs to be switched off for at least 2

minutes.

– After the 2 minutes has passed, power can be restored.

– The set function is stored in the PCB and will remain in memory even when the power of

indoor unit is turned off.

However setting function is effective after disconnecting the power supply and then reconnecting it.

• Record the latest configuration of the indoor unit function setting on a label, and put the label

on the unit so it can be used for after-sales service operations.

MULTI TYPE

5 rooms type

Once the RESET button is pressed on the remote controller, the operation mode will be set to the

AUTO MODE.

Adjust the operation mode to either cooling or heating before starting the operation of the air conditioner.

NOTE:

If custom code other than " " is set, the remote control must be set accordingly to the

indoor unit setting.

- 57 -

Page 64

MULTI TYPE

5 rooms type

Remote controller custom code setting

Custom code setting of wireless remote controller needs to be same as the setting of the indoor

unit. When you change the custom code setting of the wireless remote controller, do as follows:

1. Press the START/STOP button until only the clock is displayed on the display.

2. Press the MODE button for at least 5 seconds to display the current custom code (initially

set to A).

3. Press the SET TEMP. “ ” or the “ ” button to change the custom code between →

→ → .

4. Press the MODE button again to return to the clock display. The custom code will be

changed.

• If no buttons are pressed within 30 seconds after the custom code is displayed, the system re-

turns to the original clock display. In this case, start again from step 1.

• The air conditioner custom code is set to A prior to shipment.

• If you do not know the air conditioner custom code setting, try each of the custom codes ( →

→ → ) until you find the code which operates the air conditioner.

- 58 -

Page 65

Remote controller temperature unit

To change the displayed temperature unit, press the "°C/°F" switching button to select the preferred temperature unit. (Factory setting is set to “°F”.):

MULTI TYPE

5 rooms type

- 59 -

Page 66

12-2. Indoor unit (setting by wired remote controller)

Breaker on

Outdoor unit

Indoor units

MULTI TYPE

5 rooms type

• The function settings of the control of the indoor unit can be changed by this procedure accord-

ing to the installation conditions. Incorrect settings can cause the indoor unit malfunction.

• After the power is turned on, perform the “Function setting” according to the installation condi-

tions using the remote controller.

• The settings may be selected between the following two: Function number or Setting number.

• Settings will not be changed if invalid numbers or setting numbers are selected.

• This function cannot be used on the secondary units.

¢ Preparation

Before connecting the power supply of the indoor unit, reconfirm following items:

• Piping air tight test and vacuuming have been performed firmly.

• There is no wiring mistake. Then, connect the power supply of the indoor unit.

- 60 -

Page 67

RXRNNUM

Function number

Refer to Function details

Remote controller address

SET TIME “<” and “>” button

Switches the function number.

Setting number

Refer to Function details

SET TEMP. “V” and “Λ” button

Switches the setting number.

TIMER SET button

Transmits function setting

¢

Button name and function

During address setting mode, indoor unit reject the any operation command from remote controller.

Function setting procedure

1. Connect the power supply of the outdoor unit.

2. Switch to the function setting mode.

To enter the function setting mode, hold down the 3 buttons of SET TEMP. , SET TEMP.

, and FAN at the same time for 5 seconds or longer.

MULTI TYPE

5 rooms type

3. Select the function number by pressing the SET TIME < or the SET TIME > button.