Rheem RKNL-B090CL22E, RKNL-B073CM15E, RKNL-B090CM22E, RKNL-B090CM15E, RKNL-B090CN22E User Manual

...Page 1

FORM NO. R11-855 REV. 1

Air

Package Gas Electric

RKNL-B Series

RKNL-B Series

Rheem Commercial Classic®Series

Package Gas Electric Unit

Nominal Sizes 6-12.5 Tons [21.1-44.0 kW]

ASHRAE 90.1-2010 Compliant Models

Page 2

Air

Table of Contents

RKNL-B Series

2

TABLE OF CONTENTS

Unit Features & Benefits ..............................................................................3-7

Model Number Identification ............................................................................8

Options..........................................................................................................9

Selection Procedure ......................................................................................10

General Data

RKNL- Series........................................................................................11-23

General Data Notes ......................................................................................24

Gross Systems Performance Data

RKNL- Series........................................................................................25-27

Indoor Airflow Performance

RKNL- Series........................................................................................28-32

Electrical Data

RKNL- Series........................................................................................33-36

Dimensional Data ....................................................................................37-40

Accessories ............................................................................................41-62

Mechanical Specifications ........................................................................63-69

Wiring Diagrams ......................................................................................70-77

Limited Warranty ..........................................................................................78

Page 3

Air

Unit Features & Benefits

RKNL-B Series

3

• R-410A HFC refrigerant.

• Complete factory charged, wired and run tested.

• Scroll compressors with internal line break overload and

high-pressure protection.

• Single stage compressor on B073 model.

• Dual stage compressor on B090 – B151 models.

• Convertible airflow.

• TXV refrigerant metering system on each circuit (except on

B073).

• High Pressure and Low Pressure/Loss of charge protection

standard on all models.

• Solid Core liquid line filter drier on each circuit.

• Single slab, single pass designed evaporator and condenser

coils facilitate easy cleaning for maintained high efficiencies.

• Cooling operation up to 125 degree F ambient.

• Foil faced insulation encapsulated throughout entire unit

minimizes airborne fibers from the air stream.

• Hinged major access door with heavy-duty gasketing, 1/4

turn latches and door retainers.

• Slide Out Indoor fan assembly for added service convenience.

• Powder Paint Finish meets ASTMB117 steel coated on each

side for maximum protection. G90 galvanized.

• One piece top cover and one piece base pan with drawn

supply and return opening for superior water management.

• Forkable base rails for easy handling and lifting.

• Single point electrical and gas connections.

• Internally sloped slide out condensate pan conforms to

ASHRAE 62 standards.

• High performance belt drive motor with variable pitch pulleys

and quick adjust belt system.

• Permanently lubricated evaporator, condenser and gas heat

inducer motors.

• Condenser motors are internally protected, totally enclosed

with shaft down design.

• 2 inch filter standard with slide out design.

• Two stage gas valve, direct spark ignition, and induced draft

for efficiency and reliability.

• Tubular heat exchange for long life and induced draft for

efficiency and reliability.

• Solid state furnace control with on board diagnostics.

• 24 volt control system with resettable circuit breakers.

• Colored and labeled wiring.

• Copper tube/Aluminum Fin coils (12

1

/2 uses MicroChannel

condenser).

• Molded compressor plug.

RKNL-B STANDARD FEATURES INCLUDE:

Page 4

Air

Unit Features & Benefits

RKNL-B Series

4

Rheem Package equipment is designed from the ground up with

the latest features and benefits required to compete in today’s

market. The clean design stands alone in the industry and is a

testament to the quality, reliability, ease of installation and ser vice ability that goes into each unit. Outwardly, the large Rheem

Commercial Series™ label ( ) identifies the brand to the customer.

The sheet-metal cabinet ( ) uses nothing less than 18-gauge

material for structural components with an underlying coat of

G90. To ensure the leak-proof integrity of these units, the design

utilizes a one-piece top with a 1/8" drip lip ( ), gasket-protected

panels and screws. The Rheem hail guard ( ) (optional) is its

trademark, and sets the standard for coil protection in the industry. Every Rheem package unit uses the toughest finish in the

industry, using electro deposition baked-on enamel tested to

withstand a rigorous 1000-hour salt spray test, per ASTM B117.

Anything built to last must start with the right foundation. In this

case, the foundation is 14-gauge, commercial-grade, full-perime ter base rails ( ), which integrate fork slots and rigging holes to

save set-up time on the job site. The base pan is stamped, which

forms a 1-1/8" flange around the supply and return opening and

has eliminated the worry of water entering the conditioned space

( ). The drainpan ( ) is made of material that resists the

growth of harmful bacteria and is sloped for the latest IAQ benefits. Furthermore, the drain pan slides out for easy cleaning. The

insulation has been placed on the underside of the basepan,

removing areas that would allow for potential moisture accumulation, which can facilitate growth of harmful bacteria. All insulation

is secured with both adhesive and mechanical fasteners, and all

edges are hidden.

During development, each unit was tested to U.L. 1995, ANSI

21.47, AHRI 340-370 and other Rheem-required reliability tests.

Rheem adheres to stringent IS0 9002 quality procedures, and

each unit bears the U.L. and AHRI certification labels located on

the unit nameplate ( ). Contractors can rest assured that when

a Rheem package unit arrives at the job, it is ready to go with a

factory charge and quality checks. Each unit also proudly dis plays the “Made in the USA” designation.

Access is granted with 1/4 turn fasteners and hinged access

panels. Access to all major compartments is from the front of the

unit, including the filter and electrical compartment, blower compartment, furnace section, and outdoor section. Each panel is

permanently embossed with the compartment name (control/filter

access, blower access and furnace access).

Electrical and filter compartment access is through a large

hinged-access panel. The unit charging chart is located on the

inside of the electrical and filter compartment door. Electrical

wiring diagrams are found on the control box cover, which allows

contractors to move them to more readable locations. To the right

of the control box the model and serial number can be found.

Having this information on the

inside will assure model identification for the life of the

product. The production line

quality test assurance label is

also placed in this location

( ). The two-inch throwaway

filters ( ) are easily removed

on a tracked system for easy

replacement.

1

7

6

5

2

4

3

8

9

10

6

6

9

10

2

8

1

4

3

5

7

Page 5

Air

Unit Features & Benefits

RKNL-B Series

5

Inside the control box ( ), each electrical component is clearly identified

with a label that matches the component to the wire diagram for ease of

trouble shooting. All wiring is numbered on each end of the termination

and color-coded to match the wiring

diagram. The integrated furnace control, used to control furnace operation,

incorporates a flashing LED trouble shooting device. Flash codes are

clearly outlined on the unit wiring diagram. The control transformer has a

low voltage circuit breaker that trips if a

low voltage electrical short occurs.

There is a blower contactor and compressor contactor for each compressor.

For added convenience in the field, a factory-installed convenience outlet and disconnect ( ) are available. Low and High

voltage can enter either from the side or through the base.

Low-voltage connections are made

through the low-voltage terminal strip.

For ease of access, the U.L.-required

low voltage barrier can be temporarily

removed for low-voltage termination

and then reinstalled. The high-voltage

connection is terminated at the number

1 compressor contactor. The

suggested mounting for the fieldinstalled disconnect is on the exterior

side of the electrical control box.

To the right of the electrical and filter

compartment are the externally

mounted gauge ports, which are permanently identified by embossed

wording that clearly identifies the compressor circuit, high pressure connection and low pressure connection ( ).

With the gauge ports mounted externally, an accurate diagnostic of system

operation can be performed quickly and easily. Brass caps on

the shraeder fitting assure that the gauge parts are leak proof.

The blower compartment is to the right of the gauge ports and

can be accessed by 1/4 turn fastener. To allow easy maintenance

of the blower assembly, the entire assembly easily slides out by

removing two 3/8" screws from the blower retention bracket. The

adjustable motor pulley ( ) can easily be adjusted by loosening

the bolts on either side of the motor mount. Removing the bolts

allows for easy removal of the blower pulley by pushing the

blower assembly up to loosen the belt. Once the belt is removed,

the motor sheave can be adjusted to the desired number of

turns, ranging from 0 to 6 turns open. Where the demands for

the job require high static, Rheem has high-static drives available

that deliver nominal airflow up to 2" of static. By referring to the

airflow performance tables listed in the installation instructions,

proper static pressure and CFM requirements can be dialed in.

The scroll housing ( ) and blower scroll provide quiet and efficient airflow. The blower sheave is secured by an “H” bushing

which firmly

secures the pulley

to the blower

shaft for years of

trouble-free operation. The “H”

bushing allows

for easy removal

of the blower

pulley from the

shaft, as opposed

to the use of a set

screw, which can

score the shaft,

creating burrs that

make blowerpulley removal difficult.

15

14

13

12

11

10

7

13

11

12

14

15

Page 6

Air

Unit Features & Benefits

RKNL-B Series

6

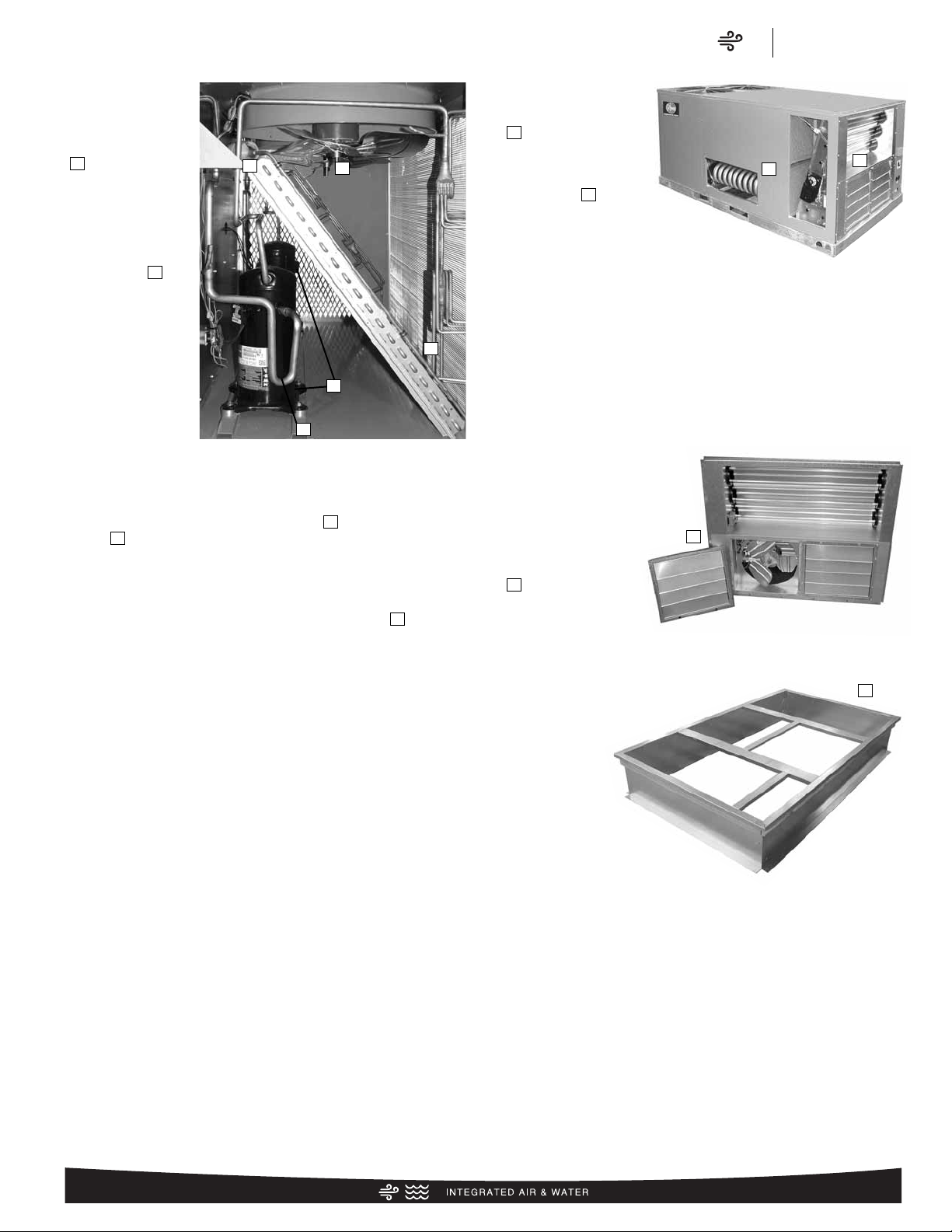

Also inside the blower compartment is the low-ambient control

( ), low-pressure switch ( ),

high-pressure switch ( ) and

freeze stat refrigerant safety

device ( ). The low-ambient

control allows for operation of the

compressor down to 0 degrees

ambient temperature by cycling

the outdoor fans on high pressure. The high-pressure switch

will shut off the compressors if

pressures in excess of 610 PSIG

are detected, this may occur if

the outdoor fan motor fails. The

low-pressure switch shuts off the

compressors if low pressure is

detected due to loss of charge.

The freeze stat protects the compressor if the evapora tor coil gets

too cold (below freezing) due to

low airflow. Each factory-installed option is brazed into the

appropriate high or low side and wired appropriately. Use of polarized plugs and sharder fittings allow for easy field installation.

Inside the blower compartment the interlaced evaporator can

also be viewed. The evaporator uses enhanced fin technology

for maximum heat transfer. The TXV metering device assures

even distribution of refrigerant throughout the evaporator. (Note:

the single stage 6 utilizes orifices).

Wiring throughout the unit is neatly bundled and routed. Where

wire harnesses go through the condenser bulkhead or blower

deck, a molded wire harness assembly ( ) provides an air-tight

and water-tight seal, and provides strain relief. Care is also taken

to tuck raw edges of insulation behind sheet metal to improve

indoor air quality.

The furnace compartment contains the latest furnace technology

on the market. The draft inducers ( ) draw the flame from the

Rheem exclusive in-shot burners ( ) into the aluminized tubular

heat exchanger ( ) for clean, efficient gas heat. Stainless steel

heat exchangers can be factory installed for those applications

that have high fresh-air requirements, or applications in corrosive

environments. Each furnace is equipment with a two-stage gas

valve ( ), which provides two stages of gas heat input. The first

stage operates at 50% of the second stage (full fire). 81% steady

state efficiency is maintained on both first and second stage by

staging the multiple inducers to optimize the combustion airflow

and maintain a near stioceometric burn at each stage.

The direct spark igniter ( ) assures reliable ignition in the most

adverse conditions. This is coupled with remote flame sense ( )

to assure that the flame has carried across the entire length of the

burner assembly. Gas supply can be routed from the side or up

through the base.

Each furnace has the following safety devices to assure consistent and reliable operation after ignition:

• Pressures switches ( ) to assure adequate combustion airflow

before ignition.

• Rollout switches ( ) to assure no obstruction or cracks in the

heat exchanger.

• A limit device that protects the furnace from over-temperature

problems.

16

17

18

19

20

21

22

23

24

25

26

27

28

18

16

24

21

21

26

27

27

25

28

28

22

23

22

17

20

Page 7

Air

Unit Features & Benefits

RKNL-B Series

7

The compressor

compartment

houses the heartbeat of the unit. The

scroll compressor

( ) is known for its

long life, and for

reliable, quiet, and

efficient operation.

The suction and

discharge lines are

designed with

shock loops ( ) to

absorb the strain

and stress that the

starting torque,

steady state operation, and shut down

cycle impose on the

refrigerant tubing.

Each compressor

and circuit is independent for built-in

redundancy, and

each circuit is clearly marked throughout the system. Each unit

has two stages of efficient cooling operation, first stage is

approximately 50% of second stage. (073 single stage)

Each unit comes standard with filter dryer . The condenser fan

motor ( ) can easily be accessed and maintained through the

blower compartment. The polarized plug connection allows the

motor to be changed quickly and eliminates the need to snake

wires through the unit.

The outdoor coil uses the latest enhanced fin design ( ) for the

most effective method of heat transfer. The outdoor coil is protected by optional* louvered panels, which allow unobstructed

airflow while protecting the unit from both Mother Nature and

vandalism.

Each unit is designed

for both downflow or

horizontal applications

( ) for job configuration flexibility. The

return air compartment

can also contain an

economizer ( ). Two

models exits, one for

downflow applications, and one

for horizontal applications. Each unit is

pre-wired for the economizer to allow quick

plug-in installation. The economizer is also available

as a factory-installed option. Power Exhaust is easily fieldinstalled. The economizer, which provides free cooling when

outdoor conditions are suitable and also provides fresh air to

meet local requirements, comes standard with single enthalpy

controls. The controls can be upgraded to dual enthalpy easily in

the field. The direct drive actuator combined with gear drive

dampers has eliminated the need for linkage adjustment in the

field. The economizer control has a minimum position setpoint,

an outdoor-air setpoint, a mix-air setpoint, and a CO

2

setpoint.

Barometric relief is standard on all economizers. The power

exhaust is housed in the

barometric relief opening

and is easily slipped in with

a plug-in assembly. The wire

harness to the economizer

also has accommodations

for a smoke detector.

The Rheem roofcurb

( ) is made for

toolless assembly at

the jobsite by engaging a pin into the

hinged corners of adjacent

curb sides, which makes the assembly process quick and easy.

31

36

35

34

33

32

30

29

29

32

33

36

35

35

34

30

31

Page 8

Air

Model Number Identification

RKNL-B Series

8

R K N L — B 090 C L 15 E X X X

Economizer Option (See Next Page)

Factory Installed Options

(See Next Page)

Ignition System

E = Electric

Heating Capacity (MBH)

15 = 150,000 [44.0]

22 = 225,000 [65.9]

25 = 252,000 [73.9]

Drive Package

L = Belt Drive

M= Belt Drive—High Static

N = Belt Drive—High Static

B090 Only

Electrical Designation

C = 208-230 V, 3 PH, 60 Hz

D = 460 V, 3 PH, 60 Hz

Y = 575 V, 3 PH, 60 Hz

Cooling Capacity (BTUH) [kW]

073 = 72,000 [21.10]

090 = 90,000 [26.38]

102 = 102,000 [29.89]

120 = 120,000 [35.17]

151 = 150,000 [43.96]

Future Technical Variations

Design Series

L = R410A

Efficiency Designation

N = EnergyStar Compliant

Product Classification

K = Rooftop—Commercial

Tradebrand

R = Rheem Packaged Gas/Electric

[ ] Designates Metric Conversions

Page 9

Air

Options

RKNL-B Series

9

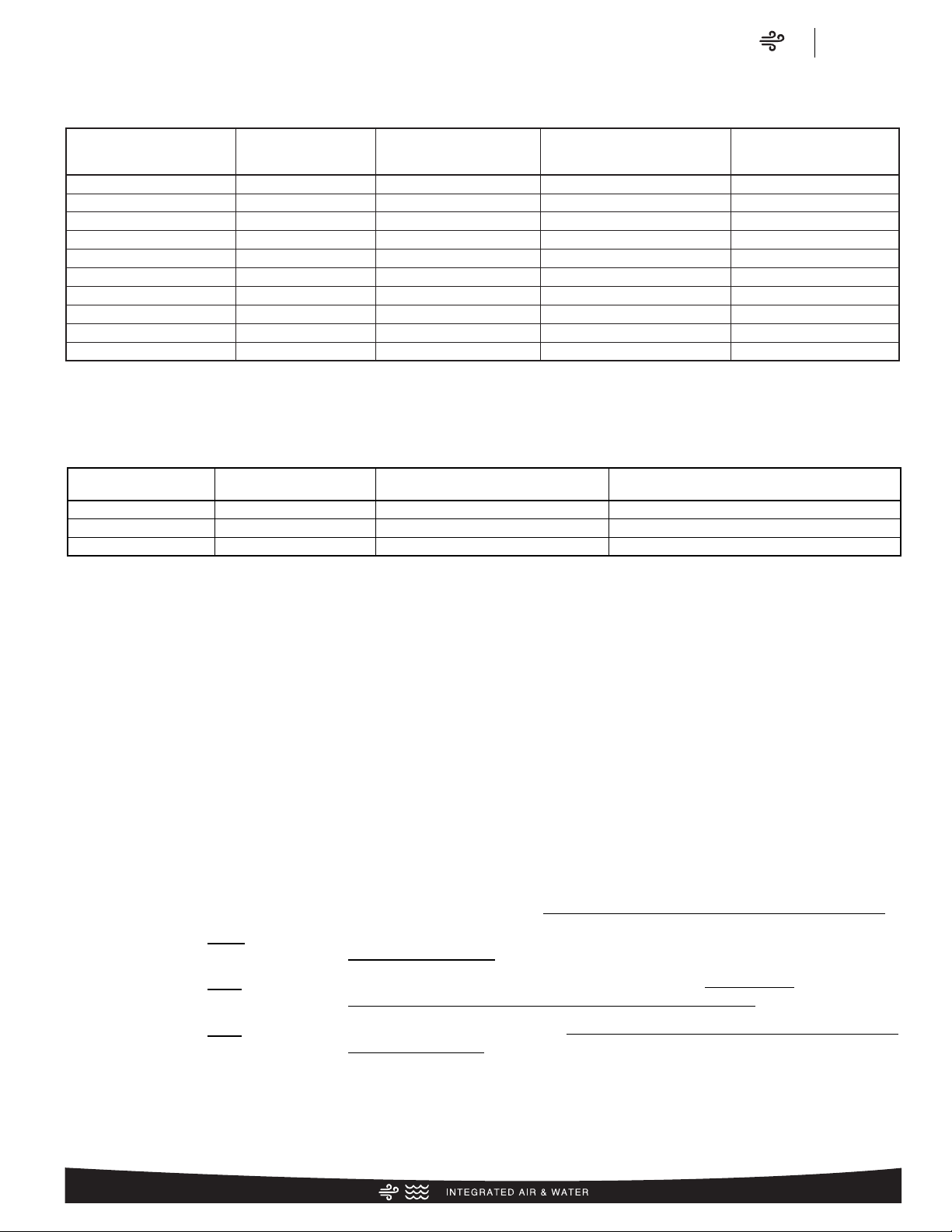

FACTORY INSTALLED OPTION CODES FOR KNL

(6 TO 12.5 TON) [21.1 TO 44.0 kW]

Option Code No Economizer

Single Enthalpy Economizer

w/Barometric Relief and Smoke Detector

A x

F

Single Enthalpy Economizer

w/Barometric Relief

x

G x

ECONOMIZER SELECTION FOR KNL

(6 TO 12.5 TON) [21.1 TO 44.0 kW]

“x” indicates factory installed option.

Instructions for Factory Installed Option(s) Selection

Note: Three characters following the model number will be utilized to designate a factory-installed option or

combination of options. If no factory option(s) is required, nothing follows the model number.

Step 1. After a basic rooftop model is selected, choose a two-character option code from the FACTORY

INSTALLED OPTION SELECTION TABLE.

Proceed to Step 2.

Step 2. The last option code character is utilized for factory-installed economizers. Choose a character from

the FACTORY INSTALLED ECONOMIZER SELECTION TABLE.

Examples:

RKNL-B120CL22E ............................this unit has no factory installed options.

RKNL-B120CL22EBGA......................this unit is equipped with hail guard and stainless steel heat exchanger.

RKNL-B120CL22EAHA......................this unit is equipped with a non-powered convenience outlet and

service disconnect.

RKNL-B120CL22EAHF ......................this unit is equipped as above and includes an Economizer

with single enthalpy sensor and with barometric relief.

RKNL-B120CL22EAAF ......................this unit is equipped with an Economizer with single enthalpy sensor and

Barometric Relief.

[ ] Designates Metric Conversions

Option Code

AD x

AJ

AH x

AP x

BF x x

BG x

BY x x

CR x x

DN x x x

Hail

Guard

Stainless

Steel

Heat Exchanger

x

x

xJB x

x

x

Non-Powered Convenience

Outlet/Unfused

Service Disconnect

Low Ambient/

Freeze

Stat

Page 10

Air

Selection Procedure

RKNL-B Series

10

To select an RKNL-B Cooling and Heating unit to meet a job

requirement, follow this procedure, with example, using data

supplied in this specification sheet.

1. DETERMINE COOLING AND HEATING REQUIREMENTS

AND SPECIFIC OPERATING CONDITIONS FROM PLANS

AND SPECS.

Example:

Voltage — 208/230V — 3 Phase — 60 Hz

Total Cooling Capacity — 106,000 BTUH [31.0 kW]

Sensible Cooling Capacity — 082,000 BTUH [24.0 kW]

Heating Capacity — 150,000 BTUH [43.9 kW]

*Condenser Entering Air — 95°F [35.0 °C] DB

*Evaporator Mixed Air Entering —65°F [18.3 °C] WB

78°F [25.6 °C] DB

*Indoor Air Flow (vertical) — 3600 CFM [1699 L/s]

*External Static Pressure — 0.40 in. WG [.10 kPa]

2. SELECT UNIT TO MEET COOLING REQUIREMENTS.

Since total cooling is within the range of a nominal 10 ton

[35.1 kW] unit, enter cooling performance table at 95°F

[35.0 °C] DB condenser inlet air. Interpolate between 63°F

[17.2 °C] WB and 67°F [19.4 °C] WB to determine total and

sensi ble capacity and power input for 65°F [18.3 °C] WB

evaporator inlet air at 3750 CFM [1770 L/s] indoor air flow

(table basis):

Total Cooling Capacity = 118,900 BTUH [34.82 kW]

Sensible Cooling Capacity = 99,950 BTUH [29.27 kW]

Power Input (Compressor and Cond. Fans) = 8,950 watts

Use formula in note to determine sensible capacity at 78°F

[25.6 °C] DB evaporator entering air:

99,950 + (1.10 x 3,600 x (1 - 0.03) x (78 - 80))

Sensible Cooling Capacity = 92,268 BTUH [27.02 kW]

3. CORRECT CAPACITIES OF STEP 2 FOR

ACTUAL AIR FLOW.

Select factors from airflow correction table at 3600 CFM

[1699 L/s] and apply to data obtained in step 2 to obtain

gross capacity:

Total Capacity = 118,900 x 0.98 = 116,522 BTUH [34.12 kW]

Sensible Capacity = 92,268 x 0.95 = 87,655 BTUH [25.67 kW]

Power Input = 8,950 x 0.99 = 8,861 Watts

These are Gross Capacities, not corrected for blower motor

heat or power.

4. DETERMINE BLOWER SPEED AND WATTS TO MEET

SYSTEM DESIGN.

Enter Indoor Blower performance table at 3600 CFM [1699

L/s]. Total ESP (external static pressure) per the spec of 0.40 in.

WG [.10 kPa] includes the system duct and grilles. Add from

the table ‘Component Air Resistance’, 0.076 in. WG [.02 kPa]

for wet coil, 0 in. WG [.00 kPa] for downflow air flow, for a

total selection static pressure of 0.476 (0.5) in. WG [.12 kPa],

and determine:

RPM = 769

WATTS = 1,576

DRIVE = L (standard 2 H.P. motor)

5. CALCULATE INDOOR BLOWER BTUH HEAT EFFECT

FROM MOTOR WATTS, STEP 4.

1,576 x 3.412 = 5,377 BTUH [1.57 kW]

6. CALCULATE NET COOLING CAPACITIES, EQUAL TO

GROSS CAPACITY, STEP 3, MINUS INDOOR BLOWER

MOTOR HEAT.

Net Total Capacity = 116,522-5,377 =

111,145 BTUH [32.54 kW]

Net Sensible Capacity = 87,655 - 5,377 =

82,278 BTUH [24.09 kW]

7. CALCULATE UNIT INPUT AND JOB EER.

Total Power Input = 8,861 (step 3) + 1,576

(step 4) = 10,437 Watts

EER =

Net Total BTUH [kW] (step 6) =111,145

= 10.65

Power Input, Watts (above) 10,437

8. SELECT UNIT HEATING CAPACITY.

From Physical Data Table read that gas heating output (input

rating x efficiency) is:

Heating Capacity = 182,250 BTUH [53.4 kW]

9. CHOOSE MODEL RKNL-B120CL22E

*NOTE: These operating conditions are typical of a commercial

application in a 95°F/79°F [35°C/26°C] design area with

indoor design of 76°F [24°C] DB and 50% RH and 10%

ventilation air, with the unit roof mounted and centered on

the zone it conditions by ducts.

[ ] Designates Metric Conversions

Page 11

Air

General Data

RKNL-B Series

11

NOM. SIZES 6-12.5 TONS [21.1-44.0 kW] ASHRAE 90.1-2007 COMPLIANT MODELS

Model RKNL- Series

B073CL15E B073CM15E B073DL15E B073DM15E

Cooling Performance

1

CONTINUED

Gross Cooling Capacity Btu [kW]

75,000 [21.97] 75,000 [21.97] 75,000 [21.97] 75,000 [21.97]

EER/SEER

2

11.2/NA 11.2/NA 11.2/NA 11.2/NA

Nominal CFM/AHRI Rated CFM [L/s]

2400/2325 [1133/1097] 2400/2325 [1133/1097] 2400/2325 [1133/1097] 2400/2325 [1133/1097]

AHRI Net Cooling Capacity Btu [kW]

72,000 [21.1] 72,000 [21.1] 72,000 [21.1] 72,000 [21.1]

Net Sensible Capacity Btu [kW]

52,800 [15.47] 52,800 [15.47] 52,800 [15.47] 52,800 [15.47]

Net Latent Capacity Btu [kW]

19,200 [5.63] 19,200 [5.63] 19,200 [5.63] 19,200 [5.63]

IEER

3

11.8 11.8 11.8 11.8

Net System Power kW

6.42 6.42 6.42 6.42

Heating Performance (Gas)

4

Heating Input Btu [kW] (1st Stage / 2nd Stage)

75,000/150,000 [21.97/43.95] 75,000/150,000 [21.97/43.95] 75,000/150,000 [21.97/43.95] 75,000/150,000 [21.97/43.95]

Heating Output Btu [kW] (1st Stage / 2nd Stage)

60,750/121,500 [17.8/35.6] 60,750/121,500 [17.8/35.6] 60,750/121,500 [17.8/35.6] 60,750/121,500 [17.8/35.6]

Temperature Rise Range ˚F [˚C]

(1st Stage / 2nd Stage)

30-60 [16.7-33.3] /

30-60 [16.7-33.3]

30-60 [16.7-33.3] /

30-60 [16.7-33.3]

30-60 [16.7-33.3] /

30-60 [16.7-33.3]

30-60 [16.7-33.3] /

30-60 [16.7-33.3]

Steady State Efficiency (%) 81 81 81 81

No. Burners

6 6 6 6

No. Stages 2 2 2 2

Gas Connection Pipe Size in. [mm] 0.5 [12.7] 0.5 [12.7] 0.5 [12.7] 0.5 [12.7]

Compressor

No./Type 1/Scroll 1/Scroll 1/Scroll 1/Scroll

Outdoor Sound Rating (dB)

5

88 88 88 88

Outdoor Coil—Fin Type

Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] OD

0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m]

13.5 [1.25] 13.5 [1.25] 13.5 [1.25] 13.5 [1.25]

Rows / FPI [FPcm] 1 / 22 [9] 1 / 22 [9] 1 / 22 [9] 1 / 22 [9]

Indoor Coil—Fin Type

Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 13.5 [1.25] 13.5 [1.25] 13.5 [1.25] 13.5 [1.25]

Rows / FPI [FPcm] 2 / 18 [7] 2 / 18 [7] 2 / 18 [7] 2 / 18 [7]

Refrigerant Control TX Valves TX Valves TX Valves TX Valves

Drain Connection No./Size in. [mm] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4]

Outdoor Fan—Type

Propeller Propeller Propeller Propeller

No. Used/Diameter in. [mm] 2/24 [609.6] 2/24 [609.6] 2/24 [609.6] 2/24 [609.6]

Drive Type/No. Speeds Direct/1 Direct/1 Direct/1 Direct/1

CFM [L/s] 8000 [3775] 8000 [3775] 8000 [3775] 8000 [3775]

No. Motors/HP 2 at 1/3 HP 2 at 1/3 HP 2 at 1/3 HP 2 at 1/3 HP

Motor RPM 1075 1075 1075 1075

Indoor Fan—Type

FC Centrifugal FC Centrifugal FC Centrifugal FC Centrifugal

No. Used/Diameter in. [mm] 1/11x12 [279x305] 1/11x12 [279x305] 1/11x12 [279x305] 1/11x12 [279x305]

Drive Type/No. Speeds Belt/Variable Belt/Variable Belt/Variable Belt/Variable

No. Motors 1 1 1 1

Motor HP 1 1/2 1 1/2 1 1/2 1 1/2

Motor RPM 1725 1725 1725 1725

Motor Frame Size 56 56 56 56

Filter—Type

Disposable Disposable Disposable Disposable

Furnished Yes Yes Yes Ye s

(NO.) Size Recommended in. [mm x mm x mm] (6)2x18x18 [51x457x457] (6)2x18x18 [51x457x457] (6)2x18x18 [51x457x457] (6)2x18x18 [51x457x457]

Refrigerant Charge Oz. [g]

125 [3544] 125 [3544] 125 [3544] 125 [3544]

Weights

Net Weight lbs. [kg] 901 [409] 901 [409] 901 [409] 901 [409]

Ship Weight lbs. [kg] 938 [425] 938 [425] 938 [425] 938 [425]

See Page 24 for Notes.

[ ] Designates Metric Conversions

Page 12

Air

General Data

RKNL-B Series

12

Model RKNL- Series B073YL15E B073YM15E B090CL15E B090CL22E

Cooling Performance

1

Gross Cooling Capacity Btu [kW]

75,000 [21.97] 75,000 [21.97] 93,000 [27.25] 93,000 [27.25]

EER/SEER

2

11.2/NA 11.2/NA 11.2/NA 11.2/NA

Nominal CFM/AHRI Rated CFM [L/s]

2400/2325 [1133/1097] 2400/2325 [1133/1097] 3000/2775 [1416/1310] 3000/2775 [1416/1310]

AHRI Net Cooling Capacity Btu [kW]

72,000 [21.1] 72,000 [21.1] 90,000 [26.37] 90,000 [26.37]

Net Sensible Capacity Btu [kW]

52,800 [15.47] 52,800 [15.47] 63,100 [18.49] 63,100 [18.49]

Net Latent Capacity Btu [kW]

19,200 [5.63] 19,200 [5.63] 26,900 [7.88] 26,900 [7.88]

IEER

3

11.8 11.8 11.9 11.9

Net System Power kW

6.42 6.42 7.99 7.99

Heating Performance (Gas)

4

Heating Input Btu [kW] (1st Stage / 2nd Stage)

75,000/150,000 [21.97/43.95] 75,000/150,000 [21.97/43.95] 75,000/150,000 [21.97/43.95] 112,500/225,000 [32.96/65.92]

Heating Output Btu [kW] (1st Stage / 2nd Stage)

60,750/121,500 [17.8/35.6] 60,750/121,500 [17.8/35.6] 60,750/121,500 [17.8/35.6] 91,125/182,250 [26.7/53.4]

Temperature Rise Range ˚F [˚C]

(1st Stage / 2nd Stage)

30-60 [16.7-33.3] /

30-60 [16.7-33.3]

30-60 [16.7-33.3] /

30-60 [16.7-33.3]

25-55 [13.9/30.6] /

25-55 [13.9/30.6]

40-70 [22.2/38.9] /

40-70 [22.2/38.9]

Steady State Efficiency (%) 81 81 81 81

No. Burners

6 6 6 9

No. Stages 2 2 2 2

Gas Connection Pipe Size in. [mm] 0.5 [12.7] 0.5 [12.7] 0.5 [12.7] 0.75 [19]

Compressor

No./Type 1/Scroll 1/Scroll 2/Scroll 2/Scroll

Outdoor Sound Rating (dB)

5

88 88 88 88

Outdoor Coil—Fin Type

Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] OD

0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m]

13.5 [1.25] 13.5 [1.25] 27 [2.51] 27 [2.51]

Rows / FPI [FPcm] 1 / 22 [9] 1 / 22 [9] 1 / 22 [9] 1 / 22 [9]

Indoor Coil—Fin Type

Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 13.5 [1.25] 13.5 [1.25] 13.5 [1.25] 13.5 [1.25]

Rows / FPI [FPcm] 2 / 18 [7] 2 / 18 [7] 2 / 18 [7] 2 / 18 [7]

Refrigerant Control TX Valves TX Valves TX Valves TX Valves

Drain Connection No./Size in. [mm] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4]

Outdoor Fan—Type

Propeller Propeller Propeller Propeller

No. Used/Diameter in. [mm] 2/24 [609.6] 2/24 [609.6] 2/24 [609.6] 2/24 [609.6]

Drive Type/No. Speeds Direct/1 Direct/1 Direct/1 Direct/1

CFM [L/s] 8000 [3775] 8000 [3775] 8000 [3775] 8000 [3775]

No. Motors/HP 2 at 1/3 HP 2 at 1/3 HP 2 at 1/3 HP 2 at 1/3 HP

Motor RPM 1075 1075 1075 1075

Indoor Fan—Type

FC Centrifugal FC Centrifugal FC Centrifugal FC Centrifugal

No. Used/Diameter in. [mm] 1/11x12 [279x305] 1/11x12 [279x305] 1/15x15 [381x381] 1/15x15 [381x381]

Drive Type/No. Speeds Belt/Variable Belt/Variable Belt/Variable Belt/Variable

No. Motors 1 1 1 1

Motor HP 1 1/2 1 1/2 2 2

Motor RPM 1725 1725 1725 1725

Motor Frame Size 56 56 56 56

Filter—Type

Disposable Disposable Disposable Disposable

Furnished Yes Yes Yes Yes

(NO.) Size Recommended in. [mm x mm x mm] (6)2x18x18 [51x457x457] (6)2x18x18 [51x457x457] (6)2x18x18 [51x457x457] (6)2x18x18 [51x457x457]

Refrigerant Charge Oz. [g]

125 [3544] 125 [3544] 107.5/110.7 [3048/3138] 107.5/110.7 [3048/3138]

Weights

Net Weight lbs. [kg] 901 [409] 901 [409] 1017 [461] 1053 [478]

Ship Weight lbs. [kg] 938 [425] 938 [425] 1054 [478] 1090 [494]

CONTINUED

NOM. SIZES 6-12.5 TONS [21.1-44.0 kW] ASHRAE 90.1-2007 COMPLIANT MODELS

See Page 24 for Notes.

[ ] Designates Metric Conversions

Page 13

Air

General Data

RKNL-B Series

13

Model RKNL- Series B090CM15E B090CM22E B090CN15E B090CN22E

Cooling Performance

1

Gross Cooling Capacity Btu [kW] 93,000 [27.25] 93,000 [27.25] 93,000 [27.25] 93,000 [27.25]

EER/SEER

2

11.2/NA 11.2/NA 11.2/NA 11.2/NA

Nominal CFM/AHRI Rated CFM [L/s] 3000/2775 [1416/1310] 3000/2775 [1416/1310] 3000/2775 [1416/1310] 3000/2775 [1416/1310]

AHRI Net Cooling Capacity Btu [kW] 90,000 [26.37] 90,000 [26.37] 90,000 [26.37] 90,000 [26.37]

Net Sensible Capacity Btu [kW] 63,100 [18.49] 63,100 [18.49] 63,100 [18.49] 63,100 [18.49]

Net System Power kW 7.99 7.99 7.99 7.99

Heating Performance (Gas)

4

Heating Input Btu [kW] (1st Stage / 2nd Stage) 75,000/150,000 [21.97/43.95] 112,500/225,000 [32.96/65.92] 75,000/150,000 [21.97/43.95] 112,500/225,000 [32.96/65.92]

Heating Output Btu [kW] (1st Stage / 2nd Stage) 60,750/121,500 [17.8/35.6] 91,125/182,250 [26.7/53.4] 60,750/121,500 [17.8/35.6] 91,125/182,250 [26.7/53.4]

Temperature Rise Range ˚F [˚C] 25-55 [13.9/30.6] 40-70 [22.2/38.9] 25-55 [13.9/30.6] 40-70 [22.2/38.9]

Net Weight lbs. [kg] 1017 [461] 1053 [478] 1025 [465] 1061 [481]

Steady State Efficiency (%) 81 81 81 81

IEER

3

11.9 11.9 11.9 11.9

No. Burners 6 9 6 9

No. Stages 2 2 2 2

Gas Connection Pipe Size in. [mm] 0.5 [12.7] 0.75 [19] 0.5 [12.7] 0.75 [19]

Compressor

No./Type 2/Scroll 2/Scroll 2/Scroll 2/Scroll

Outdoor Sound Rating (dB)

5

88 88 88 88

Outdoor Coil—Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] OD 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 27 [2.51] 27 [2.51] 27 [2.51] 27 [2.51]

Rows / FPI [FPcm] 1 / 22 [9] 1 / 22 [9] 1 / 22 [9] 1 / 22 [9]

Net Latent Capacity Btu [kW] 26,900 [7.88] 26,900 [7.88] 26,900 [7.88] 26,900 [7.88]

Indoor Coil—Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 13.5 [1.25] 13.5 [1.25] 13.5 [1.25] 13.5 [1.25]

Rows / FPI [FPcm] 2 / 18 [7] 2 / 18 [7] 2 / 18 [7] 2 / 18 [7]

Refrigerant Control TX Valves TX Valves TX Valves TX Valves

Drain Connection No./Size in. [mm] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4]

Outdoor Fan—Type Propeller Propeller Propeller Propeller

No. Used/Diameter in. [mm] 2/24 [609.6] 2/24 [609.6] 2/24 [609.6] 2/24 [609.6]

Drive Type/No. Speeds Direct/1 Direct/1 Direct/1 Direct/1

CFM [L/s] 8000 [3775] 8000 [3775] 8000 [3775] 8000 [3775]

No. Motors/HP 2 at 1/3 HP 2 at 1/3 HP 2 at 1/3 HP 2 at 1/3 HP

Motor RPM 1075 1075 1075 1075

Indoor Fan—Type FC Centrifugal FC Centrifugal FC Centrifugal FC Centrifugal

No. Used/Diameter in. [mm] 1/15x15 [381x381] 1/15x15 [381x381] 1/15x15 [381x381] 1/15x15 [381x381]

Drive Type/No. Speeds Belt/Variable Belt/Variable Belt/Variable Belt/Variable

No. Motors 1 1 1 1

Motor HP 2 2 3 3

Motor RPM 1725 1725 1725 1725

Motor Frame Size 56 56 56 56

Filter—Type Disposable Disposable Disposable Disposable

Furnished Yes Yes Yes Yes

(No.) Size Recommended in. [mm] (6)2x18x18 [51x457x457] (6)2x18x18 [51x457x457] (6)2x18x18 [51x457x457] (6)2x18x18 [51x457x457]

Refrigerant Charge Oz. [g] 107.5/110.7 [3048/3138] 107.5/110.7 [3048/3138] 107.5/110.7 [3048/3138] 107.5/110.7 [3048/3138]

Weights

Ship Weight lbs. [kg] 1054 [478] 1090 [494] 1062 [482] 1098 [498]

CONTINUED

NOM. SIZES 6-12.5 TONS [21.1-44.0 kW] ASHRAE 90.1-2007 COMPLIANT MODELS

See Page 24 for Notes.

[ ] Designates Metric Conversions

Page 14

Air

General Data

RKNL-B Series

14

See Page 24 for Notes.

[ ] Designates Metric Conversions

Model RKNL- Series B090DL15E B090DL22E B090DM15E B090DM22E

Cooling Performance

1

Gross Cooling Capacity Btu [kW] 93,000 [27.25] 93,000 [27.25] 93,000 [27.25] 93,000 [27.25]

EER/SEER

2

11.2/NA 11.2/NA 11.2/NA 11.2/NA

Nominal CFM/AHRI Rated CFM [L/s] 3000/2775 [1416/1310] 3000/2775 [1416/1310] 3000/2775 [1416/1310] 3000/2775 [1416/1310]

AHRI Net Cooling Capacity Btu [kW] 90,000 [26.37] 90,000 [26.37] 90,000 [26.37] 90,000 [26.37]

Net Sensible Capacity Btu [kW] 63,100 [18.49] 63,100 [18.49] 63,100 [18.49] 63,100 [18.49]

Net System Power kW 7.99 7.99 7.99 7.99

Heating Performance (Gas)

4

Heating Input Btu [kW] (1st Stage / 2nd Stage) 75,000/150,000 [21.97/43.95] 112,500/225,000 [32.96/65.92] 75,000/150,000 [21.97/43.95] 112,500/225,000 [32.96/65.92]

Heating Output Btu [kW] (1st Stage / 2nd Stage) 60,750/121,500 [17.8/35.6] 91,125/182,250 [26.7/53.4] 60,750/121,500 [17.8/35.6] 91,125/182,250 [26.7/53.4]

Temperature Rise Range ˚F [˚C] 25-55 [13.9/30.6] 40-70 [22.2/38.9] 25-55 [13.9/30.6] 40-70 [22.2/38.9]

Net Weight lbs. [kg] 1025 [465] 1053 [478] 1017 [461] 1053 [478]

Steady State Efficiency (%) 81 81 81 81

IEER

3

11.9 11.9 11.9 11.9

No. Burners 6 9 6 9

No. Stages 2 2 2 2

Gas Connection Pipe Size in. [mm] 0.5 [12.7] 0.75 [19] 0.5 [12.7] 0.75 [19]

Compressor

No./Type 2/Scroll 2/Scroll 2/Scroll 2/Scroll

Outdoor Sound Rating (dB)

5

88 88 88 88

Outdoor Coil—Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] OD 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 27 [2.51] 27 [2.51] 27 [2.51] 27 [2.51]

Rows / FPI [FPcm] 1 / 22 [9] 1 / 22 [9] 1 / 22 [9] 1 / 22 [9]

Net Latent Capacity Btu [kW] 26,900 [7.88] 26,900 [7.88] 26,900 [7.88] 26,900 [7.88]

Indoor Coil—Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 13.5 [1.25] 13.5 [1.25] 13.5 [1.25] 13.5 [1.25]

Rows / FPI [FPcm] 2 / 18 [7] 2 / 18 [7] 2 / 18 [7] 2 / 18 [7]

Refrigerant Control TX Valves TX Valves TX Valves TX Valves

Drain Connection No./Size in. [mm] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4]

Outdoor Fan—Type Propeller Propeller Propeller Propeller

No. Used/Diameter in. [mm] 2/24 [609.6] 2/24 [609.6] 2/24 [609.6] 2/24 [609.6]

Drive Type/No. Speeds Direct/1 Direct/1 Direct/1 Direct/1

CFM [L/s] 8000 [3775] 8000 [3775] 8000 [3775] 8000 [3775]

No. Motors/HP 2 at 1/3 HP 2 at 1/3 HP 2 at 1/3 HP 2 at 1/3 HP

Motor RPM 1075 1075 1075 1075

Indoor Fan—Type FC Centrifugal FC Centrifugal FC Centrifugal FC Centrifugal

No. Used/Diameter in. [mm] 1/15x15 [381x381] 1/15x15 [381x381] 1/15x15 [381x381] 1/15x15 [381x381]

Drive Type/No. Speeds Belt/Variable Belt/Variable Belt/Variable Belt/Variable

No. Motors 1 1 1 1

Motor HP 2 2 2 2

Motor RPM 1725 1725 1725 1725

Motor Frame Size 56 56 56 56

Filter—Type Disposable Disposable Disposable Disposable

Furnished Yes Yes Yes Yes

(No.) Size Recommended in. [mm] (6)2x18x18 [51x457x457] (6)2x18x18 [51x457x457] (6)2x18x18 [51x457x457] (6)2x18x18 [51x457x457]

Refrigerant Charge Oz. [g] 107.5/110.7 [3048/3138] 107.5/110.7 [3048/3138] 107.5/110.7 [3048/3138] 107.5/110.7 [3048/3138]

Weights

Ship Weight lbs. [kg] 1062 [482] 1090 [494] 1054 [478] 1090 [494]

CONTINUED

NOM. SIZES 6-12.5 TONS [21.1-44.0 kW] ASHRAE 90.1-2007 COMPLIANT MODELS

Page 15

Air

General Data

RKNL-B Series

15

See Page 24 for Notes.

[ ] Designates Metric Conversions

Model RKNL- Series B090DN15E B090DN22E B090YL22E B090YM22E

Cooling Performance

1

Gross Cooling Capacity Btu [kW] 93,000 [27.25] 93,000 [27.25] 93,000 [27.25] 93,000 [27.25]

EER/SEER

2

11.2/NA 11.2/NA 11.2/NA 11.2/NA

Nominal CFM/AHRI Rated CFM [L/s] 3000/2775 [1416/1310] 3000/2775 [1416/1310] 3000/2775 [1416/1310] 3000/2775 [1416/1310]

AHRI Net Cooling Capacity Btu [kW] 90,000 [26.37] 90,000 [26.37] 90,000 [26.37] 90,000 [26.37]

Net Sensible Capacity Btu [kW] 63,100 [18.49] 63,100 [18.49] 63,100 [18.49] 63,100 [18.49]

Net System Power kW 7.99 7.99 7.99 7.99

Heating Performance (Gas)

4

Heating Input Btu [kW] (1st Stage / 2nd Stage) 75,000/150,000 [21.97/43.95] 112,500/225,000 [32.96/65.92] 112,500/225,000 [32.96/65.92] 112,500/225,000 [32.96/65.92]

Heating Output Btu [kW] (1st Stage / 2nd Stage) 60,750/121,500 [17.8/35.6] 91,125/182,250 [26.7/53.4] 91,125/182,250 [26.7/53.4] 91,125/182,250 [26.7/53.4]

Temperature Rise Range ˚F [˚C] 25-55 [13.9/30.6] 40-70 [22.2/38.9] 40-70 [22.2/38.9] 40-70 [22.2/38.9]

Net Weight lbs. [kg] 1025 [465] 1061 [481] 1053 [478] 1053 [478]

Steady State Efficiency (%) 81 81 81 81

IEER

3

11.9 11.9 11.9 11.9

No. Burners 6 9 9 9

No. Stages 2 2 2 2

Gas Connection Pipe Size in. [mm] 0.5 [12.7] 0.75 [19] 0.75 [19] 0.75 [19]

Compressor

No./Type 2/Scroll 2/Scroll 2/Scroll 2/Scroll

Outdoor Sound Rating (dB)

5

88 88 88 88

Outdoor Coil—Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] OD 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 27 [2.51] 27 [2.51] 27 [2.51] 27 [2.51]

Rows / FPI [FPcm] 1 / 22 [9] 1 / 22 [9] 1 / 22 [9] 1 / 22 [9]

Net Latent Capacity Btu [kW] 26,900 [7.88] 26,900 [7.88] 26,900 [7.88] 26,900 [7.88]

Indoor Coil—Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 13.5 [1.25] 13.5 [1.25] 13.5 [1.25] 13.5 [1.25]

Rows / FPI [FPcm] 2 / 18 [7] 2 / 18 [7] 2 / 18 [7] 2 / 18 [7]

Refrigerant Control TX Valves TX Valves TX Valves TX Valves

Drain Connection No./Size in. [mm] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4]

Outdoor Fan—Type Propeller Propeller Propeller Propeller

No. Used/Diameter in. [mm] 2/24 [609.6] 2/24 [609.6] 2/24 [609.6] 2/24 [609.6]

Drive Type/No. Speeds Direct/1 Direct/1 Direct/1 Direct/1

CFM [L/s] 8000 [3775] 8000 [3775] 8000 [3775] 8000 [3775]

No. Motors/HP 2 at 1/3 HP 2 at 1/3 HP 2 at 1/3 HP 2 at 1/3 HP

Motor RPM 1075 1075 1075 1075

Indoor Fan—Type FC Centrifugal FC Centrifugal FC Centrifugal FC Centrifugal

No. Used/Diameter in. [mm] 1/15x15 [381x381] 1/15x15 [381x381] 1/15x15 [381x381] 1/15x15 [381x381]

Drive Type/No. Speeds Belt/Variable Belt/Variable Belt/Variable Belt/Variable

No. Motors 1 1 1 1

Motor HP 3 3 2 2

Motor RPM 1725 1725 1725 1725

Motor Frame Size 56 56 56 56

Filter—Type Disposable Disposable Disposable Disposable

Furnished Yes Yes Yes Yes

(No.) Size Recommended in. [mm] (6)2x18x18 [51x457x457] (6)2x18x18 [51x457x457] (6)2x18x18 [51x457x457] (6)2x18x18 [51x457x457]

Refrigerant Charge Oz. [g] 107.5/110.7 [3048/3138] 107.5/110.7 [3048/3138] 107.5/110.7 [3048/3138] 107.5/110.7 [3048/3138]

Weights

Ship Weight lbs. [kg] 1062 [482] 1098 [498] 1090 [494] 1090 [494]

CONTINUED

NOM. SIZES 6-12.5 TONS [21.1-44.0 kW] ASHRAE 90.1-2007 COMPLIANT MODELS

Page 16

Air

General Data

RKNL-B Series

16

See Page 24 for Notes.

[ ] Designates Metric Conversions

Model RKNL- Series B090YN22E B102CL15E B102CL22E B102CM15E

Cooling Performance

1

Gross Cooling Capacity Btu [kW] 93,000 [27.25] 101,000 [29.59] 101,000 [29.59] 101,000 [29.59]

EER/SEER

2

11.2/NA 11.2/NA 11.2/NA 11.2/NA

Nominal CFM/AHRI Rated CFM [L/s] 3000/2775 [1416/1310] 3200/3200 [1510/1510] 3200/3200 [1510/1510] 3200/3200 [1510/1510]

AHRI Net Cooling Capacity Btu [kW] 90,000 [26.37] 97,000 [28.42] 97,000 [28.42] 97,000 [28.42]

Net Sensible Capacity Btu [kW] 63,100 [18.49] 74,000 [21.68] 74,000 [21.68] 74,000 [21.68]

Net System Power kW 7.99 8.59 8.59 8.59

Heating Performance (Gas)

4

Heating Input Btu [kW] (1st Stage / 2nd Stage) 112,500/225,000 [32.96/65.92] 75,000/150,000 [21.97/43.95] 112,500/225,000 [32.96/65.92] 75,000/150,000 [21.97/43.95]

Heating Output Btu [kW] (1st Stage / 2nd Stage) 9,113/182,250 [2.67/53.4] 60,750/121,500 [17.8/35.6] 91,125/182,250 [26.7/53.4] 60,750/121,500 [17.8/35.6]

Temperature Rise Range ˚F [˚C] 40-70 [22.2/38.9] 25-55 [13.9/30.6] 40-70 [22.2/38.9] 25-55 [13.9/30.6]

Net Weight lbs. [kg] 1061 [481] 1059 [480] 1095 [497] 1067 [484]

Steady State Efficiency (%) 81 81 81 81

IEER

3

11.9 12 12 12

No. Burners 9 6 9 6

No. Stages 2 2 2 2

Gas Connection Pipe Size in. [mm] 0.75 [19] 0.5 [12.7] 0.75 [19] 0.5 [12.7]

Compressor

No./Type 2/Scroll 2/Scroll 2/Scroll 2/Scroll

Outdoor Sound Rating (dB)

5

88 88 88 88

Outdoor Coil—Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] OD 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 27 [2.51] 27 [2.51] 27 [2.51] 27 [2.51]

Rows / FPI [FPcm] 1 / 22 [9] 2 / 18 [7] 2 / 18 [7] 2 / 18 [7]

Net Latent Capacity Btu [kW] 26,900 [7.88] 23,000 [6.74] 23,000 [6.74] 23,000 [6.74]

Indoor Coil—Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 13.5 [1.25] 13.5 [1.25] 13.5 [1.25] 13.5 [1.25]

Rows / FPI [FPcm] 2 / 18 [7] 2 / 18 [7] 2 / 18 [7] 2 / 18 [7]

Refrigerant Control TX Valves TX Valves TX Valves TX Valves

Drain Connection No./Size in. [mm] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4]

Outdoor Fan—Type Propeller Propeller Propeller Propeller

No. Used/Diameter in. [mm] 2/24 [609.6] 2/24 [609.6] 2/24 [609.6] 2/24 [609.6]

Drive Type/No. Speeds Direct/1 Direct/1 Direct/1 Direct/1

CFM [L/s] 8000 [3775] 8000 [3775] 8000 [3775] 8000 [3775]

No. Motors/HP 2 at 1/3 HP 2 at 1/3 HP 2 at 1/3 HP 2 at 1/3 HP

Motor RPM 1075 1075 1075 1075

Indoor Fan—Type FC Centrifugal FC Centrifugal FC Centrifugal FC Centrifugal

No. Used/Diameter in. [mm] 1/15x15 [381x381] 1/15x15 [381x381] 1/15x15 [381x381] 1/15x15 [381x381]

Drive Type/No. Speeds Belt/Variable Belt/Variable Belt/Variable Belt/Variable

No. Motors 1 1 1 1

Motor HP 3 2 2 3

Motor RPM 1725 1725 1725 1725

Motor Frame Size 56 56 56 56

Filter—Type Disposable Disposable Disposable Disposable

Furnished Yes Yes Yes Yes

(No.) Size Recommended in. [mm] (6)2x18x18 [51x457x457] (6)2x18x18 [51x457x457] (6)2x18x18 [51x457x457] (6)2x18x18 [51x457x457]

Refrigerant Charge Oz. (Sys. 1/Sys. 2) [g] 107.5/110.7 [3048/3138] 154.4/166.6 [4377/4723] 154.4/166.6 [4377/4723] 154.4/166.6 [4377/4723]

Weights

Ship Weight lbs. [kg] 1098 [498] 1096 [497] 1132 [513] 1104 [501]

CONTINUED

NOM. SIZES 6-12.5 TONS [21.1-44.0 kW] ASHRAE 90.1-2007 COMPLIANT MODELS

Page 17

Air

General Data

RKNL-B Series

17

See Page 24 for Notes.

[ ] Designates Metric Conversions

Model RKNL- Series B102CM22E B102DL15E B102DL22E B102DM15E

Cooling Performance

1

Gross Cooling Capacity Btu [kW] 101,000 [29.59] 101,000 [29.59] 101,000 [29.59] 101,000 [29.59]

EER/SEER

2

11.2/NA 11.2/NA 11.2/NA 11.2/NA

Nominal CFM/AHRI Rated CFM [L/s] 3200/3200 [1510/1510] 3200/3200 [1510/1510] 3200/3200 [1510/1510] 3200/3200 [1510/1510]

AHRI Net Cooling Capacity Btu [kW] 97,000 [28.42] 97,000 [28.42] 97,000 [28.42] 97,000 [28.42]

Net Sensible Capacity Btu [kW] 74,000 [21.68] 74,000 [21.68] 74,000 [21.68] 74,000 [21.68]

Net System Power kW 8.59 8.59 8.59 8.59

Heating Performance (Gas)

4

Heating Input Btu [kW] (1st Stage / 2nd Stage) 112,500/225,000 [32.96/65.92] 75,000/150,000 [21.97/43.95] 112,500/225,000 [32.96/65.92] 75,000/150,000 [21.97/43.95]

Heating Output Btu [kW] (1st Stage / 2nd Stage) 91,125/182,250 [26.7/53.4] 60,750/121,500 [17.8/35.6] 91,125/182,250 [26.7/53.4] 60,750/121,500 [17.8/35.6]

Temperature Rise Range ˚F [˚C] 40-70 [22.2/38.9] 25-55 [13.9/30.6] 40-70 [22.2/38.9] 25-55 [13.9/30.6]

Net Weight lbs. [kg] 1103 [500] 1059 [480] 1095 [497] 1067 [484]

Steady State Efficiency (%) 81 81 81 81

IEER

3

12 12 12 12

No. Burners 9 6 9 6

No. Stages 2 2 2 2

Gas Connection Pipe Size in. [mm] 0.75 [19] 0.5 [12.7] 0.75 [19] 0.5 [12.7]

Compressor

No./Type 2/Scroll 2/Scroll 2/Scroll 2/Scroll

Outdoor Sound Rating (dB)

5

88 88 88 88

Outdoor Coil—Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] OD 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 27 [2.51] 27 [2.51] 27 [2.51] 27 [2.51]

Rows / FPI [FPcm] 2 / 18 [7] 2 / 18 [7] 2 / 18 [7] 2 / 18 [7]

Net Latent Capacity Btu [kW] 23,000 [6.74] 23,000 [6.74] 23,000 [6.74] 23,000 [6.74]

Indoor Coil—Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 13.5 [1.25] 13.5 [1.25] 13.5 [1.25] 13.5 [1.25]

Rows / FPI [FPcm] 2 / 18 [7] 2 / 18 [7] 2 / 18 [7] 2 / 18 [7]

Refrigerant Control TX Valves TX Valves TX Valves TX Valves

Drain Connection No./Size in. [mm] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4]

Outdoor Fan—Type Propeller Propeller Propeller Propeller

No. Used/Diameter in. [mm] 2/24 [609.6] 2/24 [609.6] 2/24 [609.6] 2/24 [609.6]

Drive Type/No. Speeds Direct/1 Direct/1 Direct/1 Direct/1

CFM [L/s] 8000 [3775] 8000 [3775] 8000 [3775] 8000 [3775]

No. Motors/HP 2 at 1/3 HP 2 at 1/3 HP 2 at 1/3 HP 2 at 1/3 HP

Motor RPM 1075 1075 1075 1075

Indoor Fan—Type FC Centrifugal FC Centrifugal FC Centrifugal FC Centrifugal

No. Used/Diameter in. [mm] 1/15x15 [381x381] 1/15x15 [381x381] 1/15x15 [381x381] 1/15x15 [381x381]

Drive Type/No. Speeds Belt/Variable Belt/Variable Belt/Variable Belt/Variable

No. Motors 1 1 1 1

Motor HP 3 2 2 3

Motor RPM 1725 1725 1725 1725

Motor Frame Size 56 56 56 56

Filter—Type Disposable Disposable Disposable Disposable

Furnished Yes Yes Yes Yes

(No.) Size Recommended in. [mm] (6)2x18x18 [51x457x457] (6)2x18x18 [51x457x457] (6)2x18x18 [51x457x457] (6)2x18x18 [51x457x457]

Refrigerant Charge Oz. (Sys. 1/Sys. 2) [g] 154.4/166.6 [4377/4723] 154.4/166.6 [4377/4723] 154.4/166.6 [4377/4723] 154.4/166.6 [4377/4723]

Weights

Ship Weight lbs. [kg] 1140 [517] 1096 [497] 1132 [513] 1104 [501]

CONTINUED

NOM. SIZES 6-12.5 TONS [21.1-44.0 kW] ASHRAE 90.1-2007 COMPLIANT MODELS

Page 18

Air

General Data

RKNL-B Series

18

See Page 24 for Notes.

[ ] Designates Metric Conversions

Model RKNL- Series B102DM22E B102YL22E B102YM22E B120CL15E

Cooling Performance

1

Gross Cooling Capacity Btu [kW] 101,000 [29.59] 101,000 [29.59] 101,000 [29.59] 123,000 [36.04]

EER/SEER

2

11.2/NA 11.2/NA 11.2/NA 11.2/NA

Nominal CFM/AHRI Rated CFM [L/s] 3200/3200 [1510/1510] 3200/3200 [1510/1510] 3200/3200 [1510/1510] 4000/3750 [1888/1770]

AHRI Net Cooling Capacity Btu [kW] 97,000 [28.42] 97,000 [28.42] 97,000 [28.42] 118,000 [34.57]

Net Sensible Capacity Btu [kW] 74,000 [21.68] 74,000 [21.68] 74,000 [21.68] 88,800 [26.02]

Net System Power kW 8.59 8.59 8.59 10.49

Heating Performance (Gas)

4

Heating Input Btu [kW] (1st Stage / 2nd Stage) 112,500/225,000 [32.96/65.92] 112,500/22,500 [32.96/6.59] 112,500/225,000 [32.96/65.92] 75,000/150,000 [21.97/43.95]

Heating Output Btu [kW] (1st Stage / 2nd Stage) 91,125/182,250 [26.7/53.4] 911,250/182,250 [266.99/53.4] 91,125/182,250 [26.7/53.4] 60,750/121,500 [17.8/35.6]

Temperature Rise Range ˚F [˚C] 40-70 [22.2/38.9] 40-70 [22.2/38.9] 40-70 [22.2/38.9] 15-45 [8.3/25]

Net Weight lbs. [kg] 1103 [500] 1095 [497] 1103 [500] 1112 [504]

Steady State Efficiency (%) 81 81 81 81

IEER

3

12 12 12 12

No. Burners 9 9 9 6

No. Stages 2 2 2 2

Gas Connection Pipe Size in. [mm] 0.75 [19] 0.75 [19] 0.75 [19] 0.5 [12.7]

Compressor

No./Type 2/Scroll 2/Scroll 2/Scroll 2/Scroll

Outdoor Sound Rating (dB)

5

88 88 88 88

Outdoor Coil—Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] OD 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 27 [2.51] 27 [2.51] 27 [2.51] 27 [2.51]

Rows / FPI [FPcm] 2 / 18 [7] 2 / 18 [7] 2 / 18 [7] 2 / 22 [9]

Net Latent Capacity Btu [kW] 23,000 [6.74] 23,000 [6.74] 23,000 [6.74] 29,200 [8.56]

Indoor Coil—Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 13.5 [1.25] 13.5 [1.25] 13.5 [1.25] 13.5 [1.25]

Rows / FPI [FPcm] 2 / 18 [7] 2 / 18 [7] 2 / 18 [7] 3 / 18 [7]

Refrigerant Control TX Valves TX Valves TX Valves TX Valves

Drain Connection No./Size in. [mm] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4]

Outdoor Fan—Type Propeller Propeller Propeller Propeller

No. Used/Diameter in. [mm] 2/24 [609.6] 2/24 [609.6] 2/24 [609.6] 2/24 [609.6]

Drive Type/No. Speeds Direct/1 Direct/1 Direct/1 Direct/1

CFM [L/s] 8000 [3775] 8000 [3775] 8000 [3775] 8000 [3775]

No. Motors/HP 2 at 1/3 HP 2 at 1/3 HP 2 at 1/3 HP 2 at 1/3 HP

Motor RPM 1075 1075 1075 1075

Indoor Fan—Type FC Centrifugal FC Centrifugal FC Centrifugal FC Centrifugal

No. Used/Diameter in. [mm] 1/15x15 [381x381] 1/15x15 [381x381] 1/15x15 [381x381] 1/15x15 [381x381]

Drive Type/No. Speeds Belt/Variable Belt/Variable Belt/Variable Belt/Variable

No. Motors 1 1 1 1

Motor HP 3 2 3 2

Motor RPM 1725 1725 1725 1725

Motor Frame Size 56 56 56 56

Filter—Type Disposable Disposable Disposable Disposable

Furnished Yes Yes Yes Yes

(No.) Size Recommended in. [mm] (6)2x18x18 [51x457x457] (6)2x18x18 [51x457x457] (6)2x18x18 [51x457x457] (6)2x18x18 [51x457x457]

Refrigerant Charge Oz. (Sys. 1/Sys. 2) [g] 154.4/166.6 [4377/4723] 154.4/166.6 [4377/4723] 154.4/166.6 [4377/4723] 172.8/180.8 [4899/5126]

Weights

Ship Weight lbs. [kg] 1140 [517] 1132 [513] 1140 [517] 1149 [521]

CONTINUED

NOM. SIZES 6-12.5 TONS [21.1-44.0 kW] ASHRAE 90.1-2007 COMPLIANT MODELS

Page 19

Air

General Data

RKNL-B Series

19

See Page 24 for Notes.

[ ] Designates Metric Conversions

Model RKNL- Series B120CL22E B120CM15E B120CM22E B120DL15E

Cooling Performance

1

Gross Cooling Capacity Btu [kW] 123,000 [36.04] 123,000 [36.04] 123,000 [36.04] 123,000 [36.04]

EER/SEER

2

11.2/NA 11.2/NA 11.2/NA 11.2/NA

Nominal CFM/AHRI Rated CFM [L/s] 4000/3750 [1888/1770] 4000/3750 [1888/1770] 4000/3750 [1888/1770] 4000/3750 [1888/1770]

AHRI Net Cooling Capacity Btu [kW] 118,000 [34.57] 118,000 [34.57] 118,000 [34.57] 118,000 [34.57]

Net Sensible Capacity Btu [kW] 88,800 [26.02] 88,800 [26.02] 88,800 [26.02] 88,800 [26.02]

Net System Power kW 10.49 10.49 10.49 10.49

Heating Performance (Gas)

4

Heating Input Btu [kW] (1st Stage / 2nd Stage) 112,500/225,000 [32.96/65.92] 75,000/150,000 [21.97/43.95] 112,500/225,000 [32.96/65.92] 75,000/150,000 [21.97/43.95]

Heating Output Btu [kW] (1st Stage / 2nd Stage) 91,125/182,250 [26.7/53.4] 60,750/121,500 [17.8/35.6] 91,125/182,250 [26.7/53.4] 60,750/121,500 [17.8/35.6]

Temperature Rise Range ˚F [˚C] 25-55 [13.9/30.6] 15-45 [8.3/25] 25-55 [13.9/30.6] 15-45 [8.3/25]

Net Weight lbs. [kg] 1148 [521] 1120 [508] 1156 [524] 1112 [504]

Steady State Efficiency (%) 81 81 81 81

IEER

3

12 11.9 11.9 11.9

No. Burners 9 6 9 6

No. Stages 2 2 2 2

Gas Connection Pipe Size in. [mm] 0.75 [19] 0.5 [12.7] 0.75 [19] 0.5 [12.7]

Compressor

No./Type 2/Scroll 2/Scroll 2/Scroll 2/Scroll

Outdoor Sound Rating (dB)

5

88 88 88 88

Outdoor Coil—Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] OD 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 27 [2.51] 27 [2.51] 27 [2.51] 27 [2.51]

Rows / FPI [FPcm] 2 / 22 [9] 2 / 22 [9] 2 / 22 [9] 2 / 22 [9]

Net Latent Capacity Btu [kW] 29,200 [8.56] 29,200 [8.56] 29,200 [8.56] 29,200 [8.56]

Indoor Coil—Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 13.5 [1.25] 13.5 [1.25] 13.5 [1.25] 13.5 [1.25]

Rows / FPI [FPcm] 3 / 18 [7] 3 / 18 [7] 3 / 18 [7] 3 / 18 [7]

Refrigerant Control TX Valves TX Valves TX Valves TX Valves

Drain Connection No./Size in. [mm] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4]

Outdoor Fan—Type Propeller Propeller Propeller Propeller

No. Used/Diameter in. [mm] 2/24 [609.6] 2/24 [609.6] 2/24 [609.6] 2/24 [609.6]

Drive Type/No. Speeds Direct/1 Direct/1 Direct/1 Direct/1

CFM [L/s] 8000 [3775] 8000 [3775] 8000 [3775] 8000 [3775]

No. Motors/HP 2 at 1/3 HP 2 at 1/3 HP 2 at 1/3 HP 2 at 1/3 HP

Motor RPM 1075 1075 1075 1075

Indoor Fan—Type FC Centrifugal FC Centrifugal FC Centrifugal FC Centrifugal

No. Used/Diameter in. [mm] 1/15x15 [381x381] 1/15x15 [381x381] 1/15x15 [381x381] 1/15x15 [381x381]

Drive Type/No. Speeds Belt/Variable Belt/Variable Belt/Variable Belt/Variable

No. Motors 1 1 1 1

Motor HP 2 3 3 2

Motor RPM 1725 1725 1725 1725

Motor Frame Size 56 56 56 56

Filter—Type Disposable Disposable Disposable Disposable

Furnished Yes Yes Yes Yes

(No.) Size Recommended in. [mm] (6)2x18x18 [51x457x457] (6)2x18x18 [51x457x457] (6)2x18x18 [51x457x457] (6)2x18x18 [51x457x457]

Refrigerant Charge Oz. (Sys. 1/Sys. 2) [g] 172.8/180.8 [4899/5126] 172.8/180.8 [4899/5126] 172.8/180.8 [4899/5126] 172.8/180.8 [4899/5126]

Weights

Ship Weight lbs. [kg] 1185 [538] 1157 [525] 1193 [541] 1149 [521]

CONTINUED

NOM. SIZES 6-12.5 TONS [21.1-44.0 kW] ASHRAE 90.1-2007 COMPLIANT MODELS

Page 20

Air

General Data

RKNL-B Series

20

See Page 24 for Notes.

[ ] Designates Metric Conversions

Model RKNL- Series B120DL22E B120DM15E B120DM22E B120YL22E

Cooling Performance

1

Gross Cooling Capacity Btu [kW] 123,000 [36.04] 123,000 [36.04] 123,000 [36.04] 123,000 [36.04]

EER/SEER

2

11.2/NA 11.2/NA 11.2/NA 11.2/NA

Nominal CFM/AHRI Rated CFM [L/s] 4000/3750 [1888/1770] 4000/3750 [1888/1770] 4000/3750 [1888/1770] 4000/3750 [1888/1770]

AHRI Net Cooling Capacity Btu [kW] 118,000 [34.57] 118,000 [34.57] 118,000 [34.57] 118,000 [34.57]

Net Sensible Capacity Btu [kW] 88,800 [26.02] 88,800 [26.02] 88,800 [26.02] 88,800 [26.02]

Net System Power kW 10.49 10.49 10.49 10.49

Heating Performance (Gas)

4

Heating Input Btu [kW] (1st Stage / 2nd Stage) 112,500/225,000 [32.96/65.92] 75,000/150,000 [21.97/43.95] 112,500/225,000 [32.96/65.92] 112,500/225,000 [32.96/65.92]

Heating Output Btu [kW] (1st Stage / 2nd Stage) 91,125/182,250 [26.7/53.4] 60,750/121,500 [17.8/35.6] 91,125/182,250 [26.7/53.4] 91,125/182,250 [26.7/53.4]

Temperature Rise Range ˚F [˚C] 25-55 [13.9/30.6] 15-45 [8.3/25] 25-55 [13.9/30.6] 25-55 [13.9/30.6]

Net Weight lbs. [kg] 1148 [521] 1120 [508] 1156 [524] 1148 [521]

Steady State Efficiency (%) 81 81 81 81

IEER

3

11.9 11.9 11.9 11.9

No. Burners 9 6 9 9

No. Stages 2 2 2 2

Gas Connection Pipe Size in. [mm] 0.75 [19] 0.5 [12.7] 0.75 [19] 0.75 [19]

Compressor

No./Type 2/Scroll 2/Scroll 2/Scroll 2/Scroll

Outdoor Sound Rating (dB)

5

88 88 88 88

Outdoor Coil—Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] OD 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 27 [2.51] 27 [2.51] 27 [2.51] 27 [2.51]

Rows / FPI [FPcm] 2 / 22 [9] 2 / 22 [9] 2 / 22 [9] 2 / 22 [9]

Net Latent Capacity Btu [kW] 29,200 [8.56] 29,200 [8.56] 29,200 [8.56] 29,200 [8.56]

Indoor Coil—Fin Type Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 13.5 [1.25] 13.5 [1.25] 13.5 [1.25] 13.5 [1.25]

Rows / FPI [FPcm] 3 / 18 [7] 3 / 18 [7] 3 / 18 [7] 3 / 18 [7]

Refrigerant Control TX Valves TX Valves TX Valves TX Valves

Drain Connection No./Size in. [mm] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4]

Outdoor Fan—Type Propeller Propeller Propeller Propeller

No. Used/Diameter in. [mm] 2/24 [609.6] 2/24 [609.6] 2/24 [609.6] 2/24 [609.6]

Drive Type/No. Speeds Direct/1 Direct/1 Direct/1 Direct/1

CFM [L/s] 8000 [3775] 8000 [3775] 8000 [3775] 8000 [3775]

No. Motors/HP 2 at 1/3 HP 2 at 1/3 HP 2 at 1/3 HP 2 at 1/3 HP

Motor RPM 1075 1075 1075 1075

Indoor Fan—Type FC Centrifugal FC Centrifugal FC Centrifugal FC Centrifugal

No. Used/Diameter in. [mm] 1/15x15 [381x381] 1/15x15 [381x381] 1/15x15 [381x381] 1/15x15 [381x381]

Drive Type/No. Speeds Belt/Variable Belt/Variable Belt/Variable Belt/Variable

No. Motors 1 1 1 1

Motor HP 2 3 3 2

Motor RPM 1725 1725 1725 1725

Motor Frame Size 56 56 56 56

Filter—Type Disposable Disposable Disposable Disposable

Furnished Yes Yes Yes Yes

(No.) Size Recommended in. [mm] (6)2x18x18 [51x457x457] (6)2x18x18 [51x457x457] (6)2x18x18 [51x457x457] (6)2x18x18 [51x457x457]

Refrigerant Charge Oz. (Sys. 1/Sys. 2) [g] 172.8/180.8 [4899/5126] 172.8/180.8 [4899/5126] 172.8/180.8 [4899/5126] 172.8/180.8 [4899/5126]

Weights

Ship Weight lbs. [kg] 1185 [538] 1157 [525] 1193 [541] 1185 [538]

CONTINUED

NOM. SIZES 6-12.5 TONS [21.1-44.0 kW] ASHRAE 90.1-2007 COMPLIANT MODELS

Page 21

Air

General Data

RKNL-B Series

21

See Page 24 for Notes.

[ ] Designates Metric Conversions

Model RKNL- Series

B120YM22E B151CL15E B151CL25E B151CM15E

Cooling Performance

1

CONTINUED

Gross Cooling Capacity Btu [kW]

123,000 [36.04] 146,000 [42.78] 146,000 [42.78] 146,000 [42.78]

EER/SEER

2

11.2/NA 10.8/NA 10.8/NA 10.8/NA

Nominal CFM/AHRI Rated CFM [L/s]

4000/3750 [1888/1770] 5000/4225 [2360/1994] 5000/4225 [2360/1994] 5000/4225 [2360/1994]

AHRI Net Cooling Capacity Btu [kW]

118,000 [34.57] 140,000 [41.02] 140,000 [41.02] 140,000 [41.02]

Net Sensible Capacity Btu [kW]

88,800 [26.02] 99,500 [29.15] 99,500 [29.15] 99,500 [29.15]

Net Latent Capacity Btu [kW]

29,200 [8.56] 40,500 [11.87] 40,500 [11.87] 40,500 [11.87]

IEER

3

11.9 10.8 10.8 10.8

Net System Power kW

10.49 12.73 12.73 12.73

Heating Performance (Gas)

4

Heating Input Btu [kW] (1st Stage / 2nd Stage)

112,500/225,000 [32.96/65.92] 75,000/150,000 [21.97/43.95] 126,000/252,000 [36.92/73.84] 75,000/150,000 [21.97/43.95]

Heating Output Btu [kW] (1st Stage / 2nd Stage)

91,125/182,250 [26.7/53.4] 60,750/121,500 [17.8/35.6] 102,000/204,000 [29.89/59.77] 60,750/121,500 [17.8/35.6]

Temperature Rise Range ˚F [˚C]

(1st Stage / 2nd Stage)

25-55

[13.9/30.6]

15-45 [8.3-25] /

15-45 [8.3-25]

25-55 [13.9-30.6] /

25-55 [13.9-30.6]

15-45 [8.3-25] /

15-45 [8.3-25]

Steady State Efficiency (%) 81 81 81 81

No. Burners

9 6 9 6

No. Stages 2 2 2 2

Gas Connection Pipe Size in. [mm] 0.75 [19] 0.5 [12.7] 0.75 [19] 0.5 [12.7]

Compressor

No./Type 2/Scroll 2/Scroll 2/Scroll 2/Scroll

Outdoor Sound Rating (dB)

5

88 88 88 88

Outdoor Coil—Fin Type

Louvered Louvered Louvered Louvered

Tube Type Rifled MicroChannel MicroChannel MicroChannel

Tube Size in. [mm] OD

0.375 [9.5] 1 [25.4] 1 [25.4] 1 [25.4]

Face Area sq. ft. [sq. m]

27 [2.51] 27 [2.51] 27 [2.51] 27 [2.51]

Rows / FPI [FPcm] 2 / 22 [9] 2 / 23 [9] 2 / 23 [9] 2 / 23 [9]

Indoor Coil—Fin Type

Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 13.5 [1.25] 13.5 [1.25] 13.5 [1.25] 13.5 [1.25]

Rows / FPI [FPcm] 3 / 18 [7] 4 / 15 [6] 4 / 15 [6] 4 / 15 [6]

Refrigerant Control TX Valves TX Valves TX Valves TX Valves

Drain Connection No./Size in. [mm] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4]

Outdoor Fan—Type

Propeller Propeller Propeller Propeller

No. Used/Diameter in. [mm] 2/24 [609.6] 2/24 [609.6] 2/24 [609.6] 2/24 [609.6]

Drive Type/No. Speeds Direct/1 Direct/1 Direct/1 Direct/1

CFM [L/s] 8000 [3775] 8000 [3775] 8000 [3775] 8000 [3775]

No. Motors/HP 2 at 1/3 HP 2 at 1/2 HP 2 at 1/2 HP 2 at 1/2 HP

Motor RPM 1075 1075 1075 1075

Indoor Fan—Type

FC Centrifugal FC Centrifugal FC Centrifugal FC Centrifugal

No. Used/Diameter in. [mm] 1/15x15 [381x381] 1/15x15 [381x381] 1/15x15 [381x381] 1/15x15 [381x381]

Drive Type/No. Speeds Belt/Variable Belt (Adjustable)/Single Belt (Adjustable)/Single Belt (Adjustable)/Single

No. Motors 1 1 1 1

Motor HP 3 3 3 5

Motor RPM 1725 1725 1725 1725

Motor Frame Size 56 56 56 184

Filter—Type

Disposable Disposable Disposable Disposable

Furnished Yes Yes Yes Yes

(NO.) Size Recommended in. [mm x mm x mm] (6)2x18x18 [51x457x457] (6)2x18x18 [51x457x457] (6)2x18x18 [51x457x457] (6)2x18x18 [51x457x457]

Refrigerant Charge Oz. [g]

172.8/180.8 [4899/5126] 147.2/152 [4173/4309] 147.2/152 [4173/4309] 147.2/152 [4173/4309]

Weights

Net Weight lbs. [kg] 1156 [524] 1266 [574] 1266 [574] 1238 [562]

Ship Weight lbs. [kg] 1193 [541] 1303 [591] 1267 [575] 1267 [575]

NOM. SIZES 6-12.5 TONS [21.1-44.0 kW] ASHRAE 90.1-2007 COMPLIANT MODELS

Page 22

Air

General Data

RKNL-B Series

22

Model RKNL- Series

B151CM25E B151DL15E B151DL25E B151DM15E

Cooling Performance

1

CONTINUED

Gross Cooling Capacity Btu [kW]

146,000 [42.78] 146,000 [42.78] 146,000 [42.78] 146,000 [42.78]

EER/SEER

2

10.8/NA 10.8/NA 10.8/NA 10.8/NA

Nominal CFM/AHRI Rated CFM [L/s]

5000/4225 [2360/1994] 5000/4225 [2360/1994] 5000/4225 [2360/1994] 5000/4225 [2360/1994]

AHRI Net Cooling Capacity Btu [kW]

140,000 [41.02] 140,000 [41.02] 140,000 [41.02] 140,000 [41.02]

Net Sensible Capacity Btu [kW]

99,500 [29.15] 99,500 [29.15] 99,500 [29.15] 99,500 [29.15]

Net Latent Capacity Btu [kW]

40,500 [11.87] 40,500 [11.87] 40,500 [11.87] 40,500 [11.87]

IEER

3

10.8 10.8 10.8 10.8

Net System Power kW

12.73 12.73 12.73 12.73

Heating Performance (Gas)

4

Heating Input Btu [kW] (1st Stage / 2nd Stage)

126,000/252,000 [36.92/73.84] 75,000/150,000 [21.97/43.95] 126,000/252,000 [36.92/73.84] 75,000/150,000 [21.97/43.95]

Heating Output Btu [kW] (1st Stage / 2nd Stage)

102,000/204,000 [29.89/59.77] 60,750/121,500 [17.8/35.6] 102,000/204,000 [29.89/59.77] 60,750/121,500 [17.8/35.6]

Temperature Rise Range ˚F [˚C]

(1st Stage / 2nd Stage)

25-55 [13.9-30.6] /

25-55 [13.9-30.6]

15-45 [8.3-25] /

15-45 [8.3-25]

25-55 [13.9-30.6] /

25-55 [13.9-30.6]

15-45 [8.3-25] /

15-45 [8.3-25]

Steady State Efficiency (%) 81 81 81 81

No. Burners

9 6 9 6

No. Stages 2 2 2 2

Gas Connection Pipe Size in. [mm] 0.75 [19] 0.5 [12.7] 0.75 [19] 0.5 [12.7]

Compressor

No./Type 2/Scroll 2/Scroll 2/Scroll 2/Scroll

Outdoor Sound Rating (dB)

5

88 88 88 88

Outdoor Coil—Fin Type

Louvered Louvered Louvered Louvered

Tube Type MicroChannel MicroChannel MicroChannel MicroChannel

Tube Size in. [mm] OD

1 [25.4] 1 [25.4] 1 [25.4] 1 [25.4]

Face Area sq. ft. [sq. m]

27 [2.51] 27 [2.51] 27 [2.51] 27 [2.51]

Rows / FPI [FPcm] 2 / 23 [9] 2 / 23 [9] 2 / 23 [9] 2 / 23 [9]

Indoor Coil—Fin Type

Louvered Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled Rifled

Tube Size in. [mm] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 13.5 [1.25] 13.5 [1.25] 13.5 [1.25] 13.5 [1.25]

Rows / FPI [FPcm] 4 / 15 [6] 4 / 15 [6] 4 / 15 [6] 4 / 15 [6]

Refrigerant Control TX Valves TX Valves TX Valves TX Valves

Drain Connection No./Size in. [mm] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4]

Outdoor Fan—Type

Propeller Propeller Propeller Propeller

No. Used/Diameter in. [mm] 2/24 [609.6] 2/24 [609.6] 2/24 [609.6] 2/24 [609.6]

Drive Type/No. Speeds Direct/1 Direct/1 Direct/1 Direct/1

CFM [L/s] 8000 [3775] 8000 [3775] 8000 [3775] 8000 [3775]

No. Motors/HP 2 at 1/2 HP 2 at 1/2 HP 2 at 1/2 HP 2 at 1/2 HP

Motor RPM 1075 1075 1075 1075

Indoor Fan—Type

FC Centrifugal FC Centrifugal FC Centrifugal FC Centrifugal

No. Used/Diameter in. [mm] 1/15x15 [381x381] 1/15x15 [381x381] 1/15x15 [381x381] 1/15x15 [381x381]

Drive Type/No. Speeds Belt (Adjustable)/Single Belt (Adjustable)/Single Belt (Adjustable)/Single Belt (Adjustable)/Single

No. Motors 1 1 1 1

Motor HP 5 3 3 5

Motor RPM 1725 1725 1725 1725

Motor Frame Size 184 56 56 184

Filter—Type

Disposable Disposable Disposable Disposable

Furnished Yes Yes Yes Ye s

(NO.) Size Recommended in. [mm x mm x mm] (6)2x18x18 [51x457x457] (6)2x18x18 [51x457x457] (6)2x18x18 [51x457x457] (6)2x18x18 [51x457x457]

Refrigerant Charge Oz. [g]

147.2/152 [4173/4309] 147.2/152 [4173/4309] 147.2/152 [4173/4309] 147.2/152 [4173/4309]

Weights

Net Weight lbs. [kg] 1265 [574] 1230 [558] 1266 [574] 1238 [562]

Ship Weight lbs. [kg] 1267 [575] 1267 [575] 1267 [575] 1267 [575]

NOM. SIZES 6-12.5 TONS [21.1-44.0 kW] ASHRAE 90.1-2007 COMPLIANT MODELS

See Page 24 for Notes.

[ ] Designates Metric Conversions

Page 23

Air

General Data

RKNL-B Series

23

Model RKNL- Series

B151DM25E B151YL25E B151YM25E

Cooling Performance

1

Gross Cooling Capacity Btu [kW]

146,000 [42.78] 146,000 [42.78] 146,000 [42.78]

EER/SEER

2

10.8/NA 10.8/NA 10.8/NA

Nominal CFM/AHRI Rated CFM [L/s]

5000/4225 [2360/1994] 5000/4225 [2360/1994] 5000/4225 [2360/1994]

AHRI Net Cooling Capacity Btu [kW]

140,000 [41.02] 140,000 [41.02] 140,000 [41.02]

Net Sensible Capacity Btu [kW]

99,500 [29.15] 99,500 [29.15] 99,500 [29.15]

Net Latent Capacity Btu [kW]

40,500 [11.87] 40,500 [11.87] 40,500 [11.87]

IEER

3

10.8 10.8 10.8

Net System Power kW

12.73 12.73 12.73

Heating Performance (Gas)

4

Heating Input Btu [kW] (1st Stage / 2nd Stage)

126,000/252,000 [36.92/73.84] 126,000/252,000 [36.92/73.84] 126,000/252,000 [36.92/73.84]

Heating Output Btu [kW] (1st Stage / 2nd Stage)

102,000/204,000 [29.89/59.77] 102,000/204,000 [29.89/59.77] 102,000/204,000 [29.89/59.77]

Temperature Rise Range ˚F [˚C]

(1st Stage / 2nd Stage)

25-55 [13.9-30.6] /

25-55 [13.9-30.6]

25-55 [13.9-30.6] /

25-55 [13.9-30.6]

25-55 [13.9-30.6] /

25-55 [13.9-30.6]

Steady State Efficiency (%) 81 81 81

No. Burners

9 9 9

No. Stages 2 2 2

Gas Connection Pipe Size in. [mm] 0.75 [19] 0.75 [19] 0.75 [19]

Compressor

No./Type 2/Scroll 2/Scroll 2/Scroll

Outdoor Sound Rating (dB)

5

88 88 88

Outdoor Coil—Fin Type

Louvered Louvered Louvered

Tube Type MicroChannel MicroChannel MicroChannel

Tube Size in. [mm] OD

1 [25.4] 1 [25.4] 1 [25.4]

Face Area sq. ft. [sq. m]

27 [2.51] 27 [2.51] 27 [2.51]

Rows / FPI [FPcm] 2 / 23 [9] 2 / 23 [9] 2 / 23 [9]

Indoor Coil—Fin Type

Louvered Louvered Louvered

Tube Type Rifled Rifled Rifled

Tube Size in. [mm] 0.375 [9.5] 0.375 [9.5] 0.375 [9.5]

Face Area sq. ft. [sq. m] 13.5 [1.25] 13.5 [1.25] 13.5 [1.25]

Rows / FPI [FPcm] 4 / 15 [6] 4 / 15 [6] 4 / 15 [6]

Refrigerant Control TX Valves TX Valves TX Valves

Drain Connection No./Size in. [mm] 1/1 [25.4] 1/1 [25.4] 1/1 [25.4]

Outdoor Fan—Type

Propeller Propeller Propeller

No. Used/Diameter in. [mm] 2/24 [609.6] 2/24 [609.6] 2/24 [609.6]

Drive Type/No. Speeds Direct/1 Direct/1 Direct/1

CFM [L/s] 8000 [3775] 8000 [3775] 8000 [3775]

No. Motors/HP 2 at 1/2 HP 2 at 1/2 HP 2 at 1/2 HP

Motor RPM 1075 1075 1075

Indoor Fan—Type

FC Centrifugal FC Centrifugal FC Centrifugal

No. Used/Diameter in. [mm] 1/15x15 [381x381] 1/15x15 [381x381] 1/15x15 [381x381]

Drive Type/No. Speeds Belt (Adjustable)/Single Belt (Adjustable)/Single Belt (Adjustable)/Single

No. Motors 1 1 1

Motor HP 5 3 5

Motor RPM 1725 1725 1725

Motor Frame Size 184 56 184

Filter—Type

Disposable Disposable Disposable

Furnished Yes Yes Yes

(NO.) Size Recommended in. [mm x mm x mm] (6)2x18x18 [51x457x457] (6)2x18x18 [51x457x457] (6)2x18x18 [51x457x457]

Refrigerant Charge Oz. [g]

147.2/152 [4173/4309] 147.2/152 [4173/4309] 147.2/152 [4173/4309]

Weights

Net Weight lbs. [kg] 1265 [574] 1266 [574] 1265 [574]

Ship Weight lbs. [kg] 1267 [575] 1267 [575] 1267 [575]

NOM. SIZES 6-12.5 TONS [21.1-44.0 kW] ASHRAE 90.1-2007 COMPLIANT MODELS

See Page 24 for Notes.

[ ] Designates Metric Conversions

Page 24

Air

General Data Notes

RKNL-B Series

24

NOTES:

1. Cooling Performance is rated at 95° F ambient, 80° F entering dry bulb, 67° F entering wet bulb. Gross capacity does

not include the effect of fan motor heat. AHRI capacity is net and includes the effect of fan motor heat. Units are

suitable for operation to ⫾20% of nominal cfm. Units are certified in accordance with the Unitary Air Conditioner

Equipment certification program, which is based on AHRI Standard 340/360.

2. EER and/or SEER are rated at AHRI conditions and in accordance with DOE test procedures.

3. IEER is rated in accordance with AHRI Standard 340/360.

4. Heating Performance limit settings and rating data were established and approved under laboratory test conditions

using American National Standard Institute standards. Ratings shown are for elevations up to 2000 feet. For elevations

above 2000 feet, ratings should be reduced at the rate of 4% for each 1000 feet above sea level.

5. Outdoor Sound Rating shown is tested in accordance with AHRI Standard 270.

Page 25

Air

Gross Systems Performance Data

RKNL-B Series

25

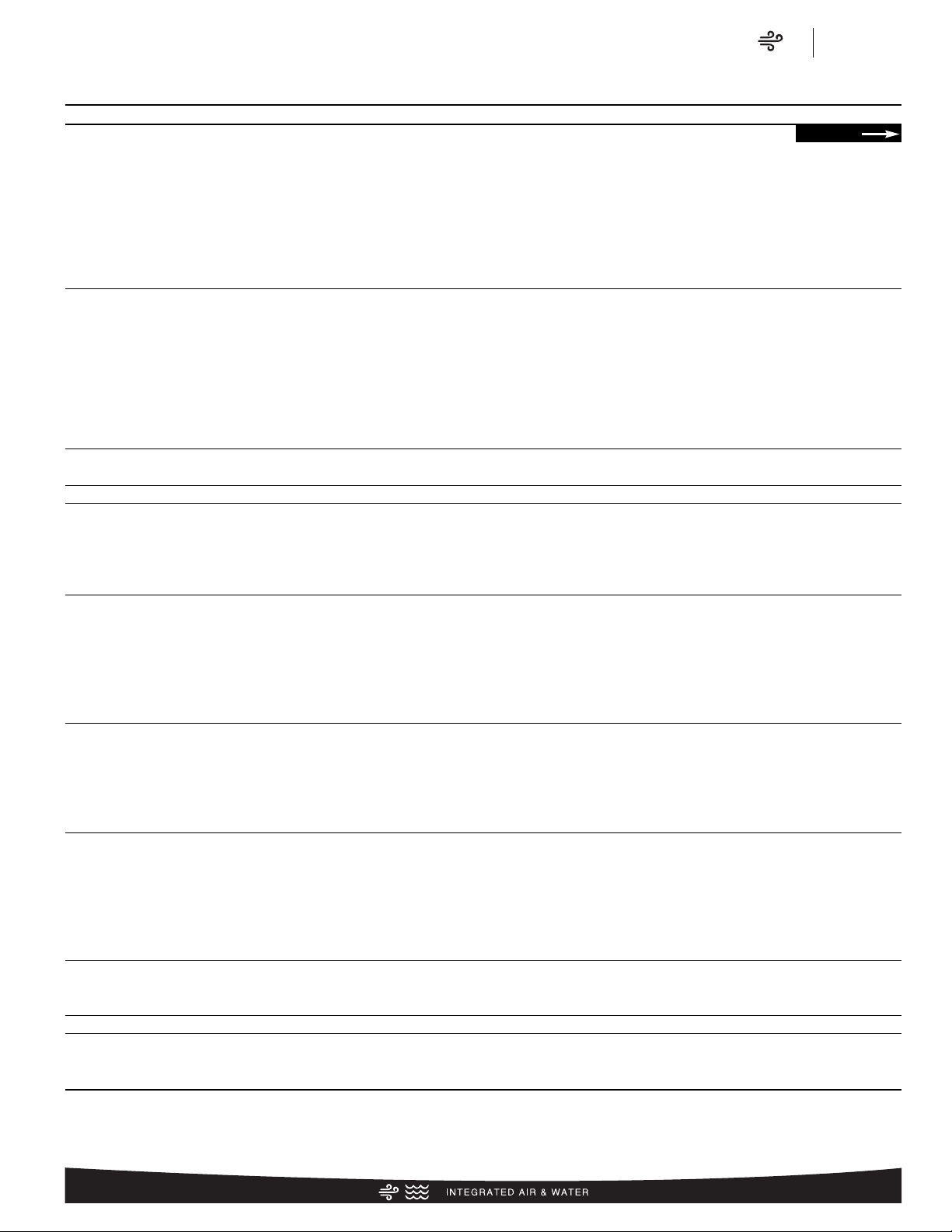

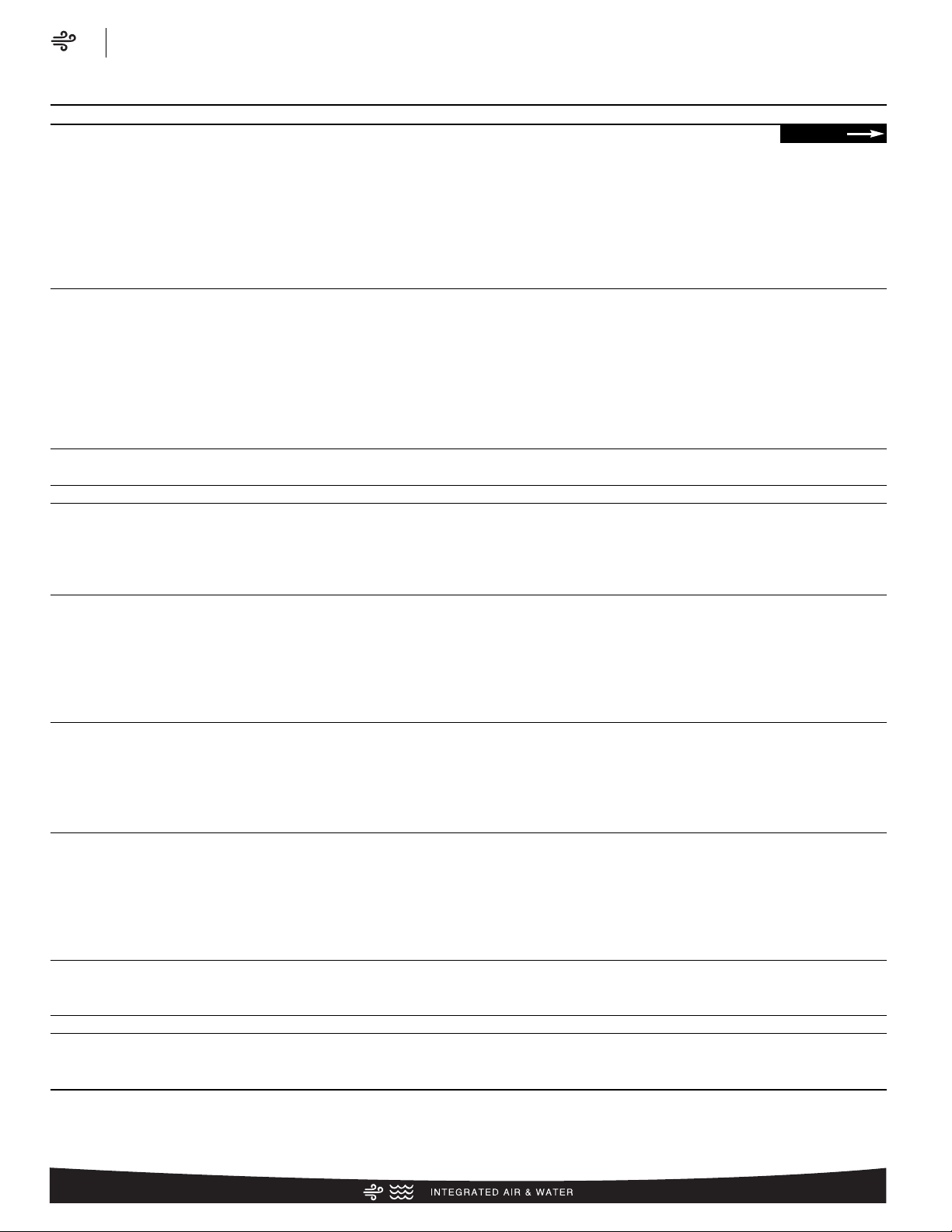

ENTERING INDOOR AIR @ 80°F [26.7°C] dbE ➀

wbE 71°F [21.7°C] 67°F [19.4°C] 63°F [17.2°C]

CFM [L/s] 2790 [1317] 2325 [1097] 1860 [878] 2790 [1317] 2325 [1097] 1860 [878] 2790 [1317] 2325 [1097] 1860 [878]

DR ➀

.06 .01 .15 .06 .01 .15 .06 .01 .15

O

U

T

D

O

O

R

D

R

Y

B

U

L

B

T

E

M

P

E

R

A

T

U

R

E

°F

[°C]

75

[23.9]

Total BTUH [kW]

Sens BTUH [kW]

Power

92.8 [27.2]

58.8 [17.2]

4.7

89.5 [26.2]

50.5 [14.8]

4.6

86.3 [25.3]

42.9 [12.6]

4.5

86.4 [25.3]

67.9 [19.9]

4.6

83.4 [24.4]

59.1 [17.3]

4.5

80.3 [23.5]

50.8 [14.9]

4.5

81.8 [24.0]

75.4 [22.1]

4.6

78.9 [23.1]

66.1 [19.4]

4.5

76.1 [22.3]