Rheem RH-EVR Series, Rheem S-SS Series Installation, Operation And Maintenance Manual

Page: 1 / 8

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

Commercial Electric Water Heater

Model : Rheem RH-EVR/S-SS Series

Installation and service must be

performed by

Qualified Service Personnel Only.

CHECKING EQUIPMENT

This manual supplies information for the

installation, operation and servicing of the

appliance. It is strongly recommended that this

manual be reviewed completely before

proceeding with an installation. Upon receiving

equipment, check for signs of shipping damage.

Pay particular attention to parts accompanying

the water heater, which may show signs of being

hit or otherwise being mishandled. Verify total

number of pieces shown on packing slip with

those actually received. In case there is damage

or a shortage, immediately notify carrier.

INSTALLATION PROCEDURE

LOCATION OF UNIT

1. Locate the appliance so that if water

connections should leak, water damage

will not occur. When such locations

cannot be avoided, it is recommended that

a suitable drain pan, adequately drained,

be installed under the unit. Under no

circumstances is the manufacturer to be

held responsible for water damage in

connection with this unit, or any of its

components.

2. Insure that the appliance is located near

an acceptable drain so that the vessel can

be properly drained when performing

service or maintenance. The drain must

also provide adequate drainage in the

event of leakage the tank or related

piping. The drain must prevent water

damage to the adjacent area and lower

floors of the structure.

3. The appliance must be installed so that

the electrical components are protected

from water (dripping, spraying, etc.)

during appliance operation and service

(replacing of fuses, elements, etc.)

4. The appliance must be installed on a level

floor. Shim the base as necessary if

leveling is required.

5. The floor on which the appliance is

installed must be capable of supporting

the total weight of the water heater when

completely filled with water.

Combustible floor locations may be used.

Maintain required clearances from

combustible surfaces.

6. The appliance must not be installed on

carpet.

7. The appliance must be installed indoors

where it is protected from exposure to

wind, rain and weather.

8. Locate the appliance as close as possible

to the point of major hot water usage, the

water piping and branch electrical circuit

wiring.

9. Insulate water piping to control heat loss

and possible condensation.

10. The appliance must be located in an area

that is not subject to freezing. The

ambient temperature of the space where

the appliance is installed must not go

below 32° F (0° C) or above 104° F (40° C).

11. The water heater is not intended for space

heating applications.

Page: 2 / 8

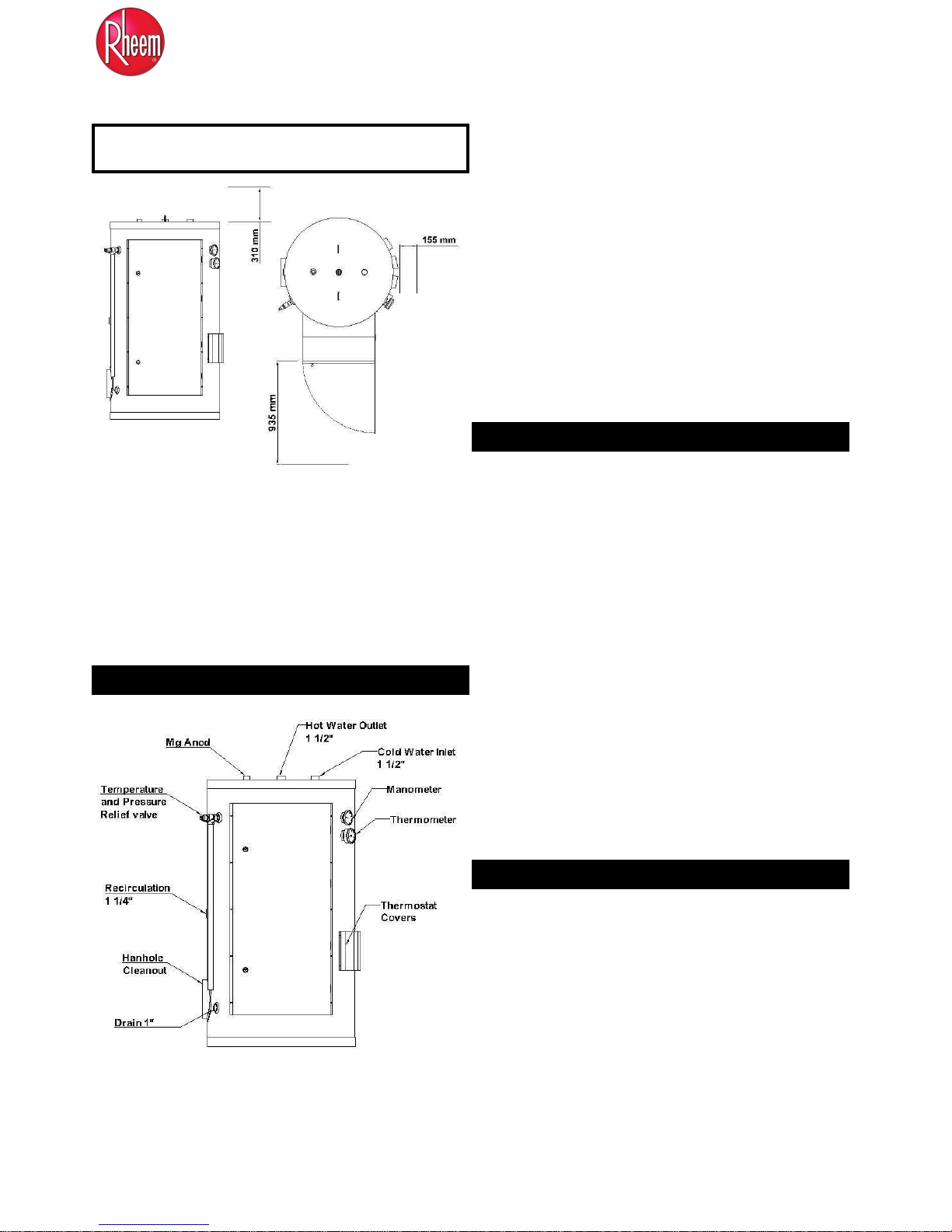

Minimum Clearences Between Water Heater

and Surrounding Surfaces

Maintain minimum specified clearances for

adequate operation. All installations must allow

sufficient space for servicing the electrical

components, water pipe connections, piping and

other auxiliary equipment, as well as the

appliance.

WATER CONNECTIONS

Inlet and Outlet Connections

For ease of service, install unions on the cold

water inlet and hot water outlet of the water

heater. The cold water inlet connection is located

on the lower right side of the water heater. A

manual shutoff valve should be installed

upstream on the cold water source as an isolation

device. The hot water outlet connection is located

on the top center of the water heater. A manual

shutoff valve should be installed downstream on

the hot water outlet source as an isolation device

in case the water heater must be disconnected

from the system.

STORAGE TANK

This appliance uses AISI 304L quality stainless

steel tank to store the heated water for use. The

storage tank is constructed in accordance with the

ASME Boiler and Pressure Vessel Code

requirements. The volume capacity of storage

tank is approximately 1000 liters (265 gal).

Please refer to the attached mechanical general

arrangement dimensional drawing of storage tank.

The tank is furnished with threaded connections

for cold water inlet, hot water outlet, recirculation,

a relief valve and a drain connection.

The storage tank has a hand hole for ease of

inspection, cleanout and service. An optional

manhole may be specified for greater ease of

inspection.

A magnesium anode(s) is standard to help prevent

dissipation of the tank material by electrolytic

action.

JACKET ASSEMBLY

Outer Jacket – The outer jacket assembly is

constructed from steel, galvanized on both sides.

The galvanized surface is specially prepared and

phosphate coated to allow application of

electrostatic paint process. This coating

process insures a long life from the jacket

assembly. The storage tank is insulated by rock

wool material covered by outer jacket.

Page: 3 / 8

RELIEF VALVE

This water heater is supplied with a temperature

and pressure relief valve(s) sized in accordance

with ASME Boiler and Pressure Vessel Code,

Section IV. The relief valve(s) is installed in the

horizontal position and mounted in the tapping

provided in the storage tank. No valve is to be

placed between the relief valve and the water

heater. To prevent water damage, the discharge

from the relief valve must be piped to a suitable

floor drain for disposal when relief occurs. No

reducing couplings or other restrictions shall be

installed in the discharge line. The discharge line

shall allow complete drainage of the valve and

line. Relief valves should be manually operated at

least once a year. A relief valve that fails to

completely reseat and continues to discharge

water must be immediately replaced with a new,

properly sized, temperature and pressure relief

valve.

CAUTION: Avoid contact with hot

discharge water. Insure that no one is in

front of or around the relief valve discharge

line. Make sure that the extremely hot

water manually discharged from the relief

valve will not cause bodily injury or

property damage.

CAUTION:L EXPANSION OF WATER

THERMAL EXPANSION OF WATER

A relief valve that discharges periodically may be

due to thermal expansion in a closed system. A

water heater installed in a closed system, such as

one with a backflow preventer or check valve

installed in the cold water supply, shall be

provided with means to control expansion.

Contact the water supplier or local plumbing

inspector on how to correct this situation.

DO NOT plug or cap the relief valve.

ELECTRICAL CONNECTIONS

All installation procedures involving electric

power connection should only be performed by a

trained, certified electrician.

WARNING: WATER HEATER IS EQUIPPED

FOR OPERATION ON ONE VOLTAGE

ONLY. Check the rating plate on the front of the

control panel access for the correct voltage and

phase. DO NOT use this water heater with any

other voltage other than the voltage specified on

the rating plate. Failure to use the correct voltage

can cause problems that can result in death,

serious bodily injury or property damage.

CAUTION: THE SUPPLY VOLTAGE OF THE

WATER HEATER IS 415VAC, 3 PHASE,

60 HZ.

DO NOT CONNECT THE WATER HEATER

TO AN IMPROPER SOURCE OF

ELECTRICITY!

1. Use copper conductors only. All wiring

between the appliance and field installed

devices shall be made with copper wire

suitable for at least 75° C (167° F)

temperature rating.

2. The factory internal wiring is attached to a

terminal block inside the unit. The branch

circuit is connected to the terminal block

through an opening provided on the side of the

water heater electrical access panel.

3. Line voltage wire exterior to the appliance

must be enclosed in approved conduit or

approved metal clad cable.

4. To avoid serious damage, DO NOT energize

the appliance until the system is full of

water. Ensure that all air is removed from the

storage tank and piping before beginning

initial operation. Operation of a water heater

without a completely filled tank may result in

serious damage to the appliance and heating

element burn out.

5. The water heater should be connected with a

separate grounded branch circuit with over

current protection and disconnect switch. The

water heater should be grounded in

accordance with national and local codes. A

ground terminal is provided for ground

connection only.

Page: 4 / 8

6. Provide the appliance with proper overload

protection in the branch circuit. It is suggested

that the electrician size the branch circuit at

125 percent of the heater ampere rating and

further increase wire size as necessary to

compensate for voltage drop in long runs.

Branch circuit voltage drop should not exceed

3% at the heater.

7. Voltage applied to the heater should not vary

more than +5% to -10% of the model and

rating plate marking for satisfactory operation.

8. A wiring diagram is provided with the water

heater for the electrician’s use.

LOW WATER CUTOFF

This water heater is equipped with an electronic

low water cut-off installed at the factory. This low

water cut-off device uses a water level sensing

probe located above the heating element installed

in the highest point in the storage tank. If the

internal water level drops below this point, the

low water cut-off will shut down operation of the

heating elements. The electronic low water cut-off

has an LED located on its casing. This LED will

be illuminated and the control circuit will be

completed between the common and normally

open contacts on the relay unit when the sensing

probe is below the water level in the storage tank.

The operation of a low water cutoff should be

inspected every six months. For details refer to

electrical control circuit drawing attached to this

manuel.

STANDARD EQUIPMENT

Your commercial electric water heater is

equipped with the following as standard

equipment.

Low watt density immersion heating

elements with an stainless steel sheath.

Each heating element has 18 KW power

and two elements are grouped so the group

power is 36 KW. There are 4 groups of

elements making the total input power

144 KW.

Internal fusing of all elements in a

maximum of 48 amp increments provides

additional safety.

Electrostatic paint coated galvanized steel

outer jacket and electrical control panel are

provided.

Electrical control panel is provided with a

hinged door and key lock.

An AISI 304L stainless steel tank

constructed to ASME specifications and

provided with magnesium anode(s).

ASME rated temperature and pressure

relief valve provided by factory to ensure

safe heater operation.

Terminal block connections are installed

by the factory for safe easy wiring

connection.

Manual reset high water temperature limit

control.

Surface mounted mechanical thermostats

for each heater group. Max temperature

setting 162°F (72 °C)

3 year limited warranty provides

protection against failure of tanks due to

defects in material and workmanship in

commercial application.

Four groups of heating elements are

controlled by four regulating thermostats

as one thermostat for each group.

Time relays are provided to turn on the

heater groups in sequence with a user

defined time delay between each group.

Manual on-off switches for each heater

group with pilot lights.

Page: 5 / 8

MECHANICAL THERMOSTATS

Temperature regulating thermostat

High Limit thermostat with manual reset

This water heater uses mechanical surface

mounted thermostats to activate magnetic

contactors allowing current to flow to the

immersion heating elements. The standard control

system uses one immersion thermostat for each

36kW of electric heating power in a water heater.

TEMPERATURE REGULATING

THERMOSTATS

This water heater has an adjustable thermostat to

control water temperature. The thermostat is

factory pre-set at approximately 125° F (51.7° C)

or less. Households with small children or

invalids may require a 120° F (48.9° C) or lower

temperature setting to reduce risk of scald injury.

Remember, no water heating system will provide

exact temperatures at all times. Allow a few days

of operation at the setting to determine the correct

temperature setting consistent with your needs.

WATER TEMPERATURE SETTINGS

1. Turn “OFF” the electrical power to the

water heater.

2. Open the thermostat cover on the tank.

3. Adjust each thermostat to the

desired temperature setting by turning the

adjusting knob from hot to very hot

position to increase the temperature.

When the knob is at very hot position the

adjusted temperature is max. 72 ° C. Each

thermostat will be factory pre-set to

approximately 125° F (51.7° C) or less as

shipped.

4. Close the thermostat cover.

5. Turn “ON” the electrical power to the

water heater.

WARNING:

HAZARD OF ELECTRICAL SHOCK –

Before opening the electrical access panel

to adjust the thermostat make sure the

electrical supply to the water heater is

turned “OFF”.

HIGH WATER TEMPERATURE

LIMIT CONTROL

The unit is equipped with a fixed setting, manual

reset high water temperature limit control. The

water heater temperature limit control has a fixed

limit setting of 180° F (82 ° C). If water

temperature exceeds the limit set point, the limit

will break the control circuit and shut down the

unit. The limit control can only be reset after the

water temperature has cooled below the set point

of the limit. The high water temperature limit

control is mounted on the surface of the tank,

above the heating element installed at the highest

point in the tank. The high limit control is reset

by pushing the red reset button on the control.

Operation of the limit control usually indicates a

major problem with the thermostat, contactors or

heating elements. Do not continue to push the

reset multiple times. The source of the problem

Loading...

Loading...