Rheem RHBL, RHAL Installation Manual

WARNING

ISO 9001:2008

INSTALLATION INSTRUCTIONS

FRONT RETURN AIR HANDLERS

EARTH-FRIENDLY R-410A REFRIGERANT:

RHBL High Efficiency

RHAL Standard Efficiency

!

▲WARNING

These instructions are intended as an aid to qualified licensed

service personnel for proper installation, adjustment and

operation of this unit. Read these instructions thoroughly before

attempting installation or operation. Failure to follow these

instructions may result in improper installation, adjustment,

service or maintenance possibly resulting in fire, electrical

shock, property damage, personal injury or death.

SUPERSEDES 92-20521-56-08

92-20521-56-09

TABLE OF CONTENTS

1.0 SAFETY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.0 GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 Important Information About Efficiency and Indoor Air Quality. . . . . . . . . . . . 5

2.2 Receiving. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3 Clearances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.4 Model Number Explanation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4A Available Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

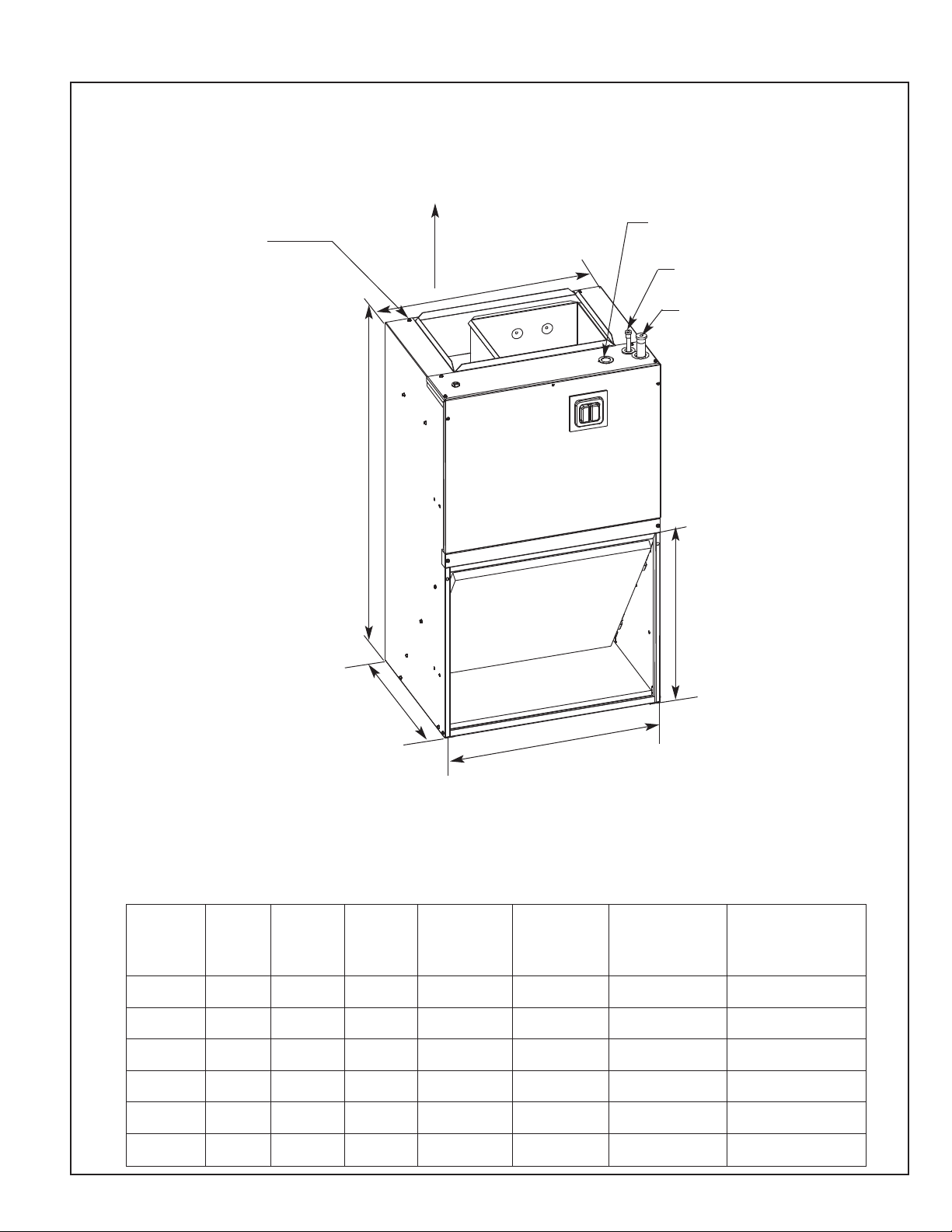

2.5 Dimensions and Weights. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.0 APPLICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.1 Vertical Upflow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.0 AIR HANDLER MOUNTING OPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.1 Wall Mount. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.2 Frame Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.0 ELECTRICAL WIRING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.1 Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.2 Control Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.3 Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.4 Electrical Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.5 Blower Motor Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.5A Blower Motor Electrical Data: RHAL . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.5B Blower Motor Electrical Data: RHBL . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.6 Electric Heat Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.6A Electric Heat Electrical Data: RHAL. . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.6B Heater Kit Supplemental Information. . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.0 AIRFLOW PERFORMANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.1 Airflow Operating Limits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.2 240V Airflow Performance Data RHAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

6.3 208/240V Airflow Performance Data RHBL. . . . . . . . . . . . . . . . . . . . . . . . . 18

7.0 DUCTWORK. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

8.0 REFRIGERANT CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

8.1 Condensate Drain Tubing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

9.0 AIR FILTER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

10.0 SYSTEM CHARGING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

10.1 Orifice Size. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

10.2 Charging Charts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

11.0 SEQUENCE OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

11.1 Cooling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

11.2 Heating (electric heat only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

11.3 Heating (heat pump) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

11.4 Blower Time Delay. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

11.5 Defrost . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

11.6 Emergency Heat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

11.7 Room Thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

12.0 CALCULATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

12.1 Calculating Temperature Rise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

12.2 Calculating BTUH Heating Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

12.3 Calculating Airflow CFM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

12.4 Calculating Correction Factor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

13.0 PRE-START CHECKLIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

14.0 MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

14.1 Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

14.2 Indoor Coil/Drain Pan/Drain Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

14.3 Blower Motor & Wheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

14.4 Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

14.5 Blower Assembly Removal & Replacement. . . . . . . . . . . . . . . . . . . . . . . . . 28

14.6 Blower Motor Removal Procedure

(RHAL-FR30, RHAL-FR36, RHBL-FR36) . . . . . . . . . . . . . . . . . . . . . . . . . 29

14.7 Small Cabinet Blower Assembly Removal Procedure

(RHAL-FR18, RHAL-FR24, RHBL-FR24) . . . . . . . . . . . . . . . . . . . . . . . . . 31

14.8 Large Cabinet Assembly Removal Procedure

(RHAL-FR30, RHAL-FR36, RHBL-FR36) . . . . . . . . . . . . . . . . . . . . . . . . . 32

15.0 REPLACEMENT PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

16.0 ACCESSORIES - KITS - PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2

(SEE SECTION 4.0:

WARNING

!

Disconnect all power to unit

before installing or servicing.

More than one disconnect switch

may be required to de-energize

the equipment. Hazardous voltage

can cause severe personal injury

or death.

WARNING

!

If removal of the blower assembly is

required, all disconnect switches

supplying power to the equipment

must be de-energized and locked (if

not in sight of unit) so the field

power wires can be safely removed

from the blower assembly. Failure to

do so can cause electrical shock

resulting in personal injury or

death.

WARNING

!

Because of possible damage to

equipment or personal injury,

installation, service, and maintenance should be performed by a

trained, qualified service personnel. Consumer service is recommended only for filter cleaning/

replacement. Never operate the

unit with the access panels

removed.

ELECTRICAL WIRING)

(SEE SECTION 12.5: BLOWER

ASSEMBLY REMOVAL &

REPLACEMENT)

1.0 SAFETY INFORMATION

WARNING

!

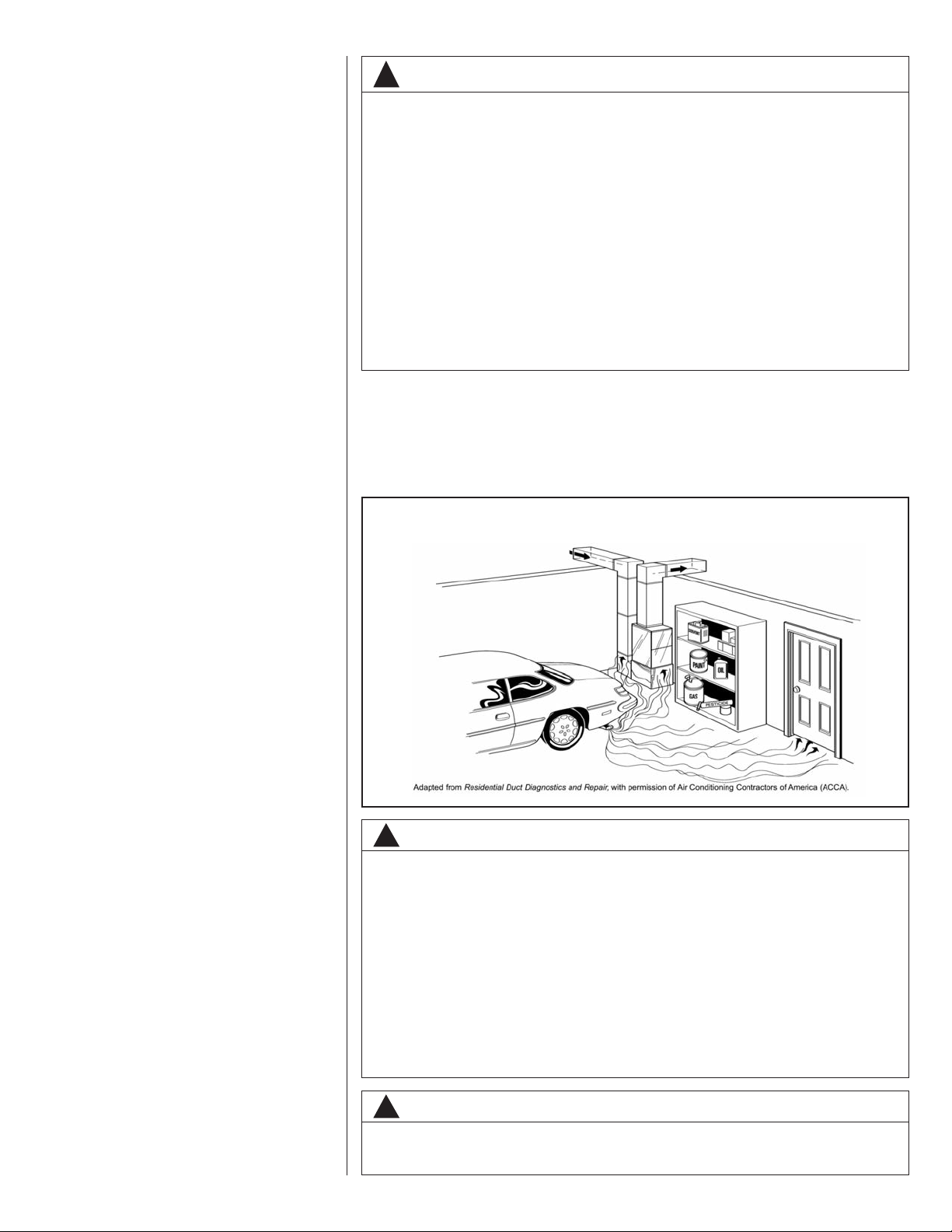

Duct leaks can create an unbalanced system and draw pollutants such as dirt,

dust, fumes and odors into the home causing property damage. Fumes and

odors from toxic, volatile or flammable chemicals, as well as automobile

exhaust and carbon monoxide (CO), can be drawn into the living space

through leaking ducts and unbalanced duct systems causing personal injury

or death (see Figure 1).

• If air-moving equipment or ductwork is located in garages or off-garage storage areas - all joints, seams, and openings in the equipment and duct must

be sealed to limit the migration of toxic fumes and odors including carbon

monoxide from migrating into the living space.

• If air-moving equipment or ductwork is located in spaces containing fuel

burning appliances such as water heaters or boilers - all joints, seams, and

openings in the equipment and duct must also be sealed to prevent depressurization of the space and possible migration of combustion byproducts

including carbon monoxide into the living space.

WARNING

!

These instructions are intended as an aid to qualified, licensed service personnel for proper installation, adjustment and operation of this unit. Read these

instructions thoroughly before attempting installation or operation. Failure to

follow these instructions may result in improper installation, adjustment, service or maintenance possibly resulting in fire, electrical shock, property damage, personal injury or death.

WARNING (SEE WARNINGS IN REGARD TO DUCTWORK)

!

Do not install this unit in manufactured (mobile) homes. Improper installation is

more likely in manufactured housing due to ductwork material, size, location, and

arrangement. Installations in manufactured housing can cause a fire resulting in

property damage, personal injury or death.

EXCEPTION

tation by a recognized inspection authority that the installation has been made in

compliance with the instructions and all warnings have been observed.

: Manufactured housing installations are approved only with documen-

WARNING (SEE SECTION 4.3: GROUNDING)

!

The unit must be permanently grounded. Failure to do so can result in electrical shock causing personal injury or death.

WARNING (SEE SECTION 12.0: MAINTENANCE)

!

Units with circuit breaker(s) meet requirements as a service disconnect switch,

however, if access is required to the line side (covered) of the circuit breaker,

this side of the breaker(s) will be energized with the breaker(s) de-energized.

Contact with the line side can cause electrical shock resulting in personal

injury or death.

!

WARNING (SEE SECTION 5.0: DUCTWORK)

Do not, under any circumstances, connect return ductwork to any other heat

producing device such as fireplace insert, stove, etc. Unauthorized use of

such devices may result in fire, carbon monoxide poisoning, explosion, personal injury or property damage.

Continued on next page ➜

3

WARNING

!

PROPOSITION 65: This appliance contains fiberglass insulation.

Respirable particles of fiberglass

are known to the State of California

to cause cancer.

All manufacturer products meet current Federal OSHA Guidelines for

safety. California Proposition 65

warnings are required for certain

products, which are not covered by

the OSHA standards.

California's Proposition 65 requires

warnings for products sold in

California that contain or produce

any of over 600 listed chemicals

known to the State of California to

cause cancer or birth defects such

as fiberglass insulation, lead in

brass, and combustion products

from natural gas.

All “new equipment” shipped for

sale in California will have labels

stating that the product contains

and/or produces Proposition 65

chemicals. Although we have not

changed our processes, having the

same label on all our products facilitates manufacturing and shipping.

We cannot always know “when, or

if” products will be sold in the

California market.

You may receive inquiries from customers about chemicals found in, or

produced by, some of our heating

and air-conditioning equipment, or

found in natural gas used with some

of our products. Listed below are

those chemicals and substances

commonly associated with similar

equipment in our industry and other

manufacturers.

• Glass Wool (Fiberglass) Insulation

• Carbon Monoxide (CO).

• Formaldehyde

• Benzene

More details are available at the

websites for OSHA (Occupational

Safety and Health Administration),

at www.osha.gov

California’s OEHHA (Office of

Environmental Health Hazard

Assessment), at www.oehha.org

Consumer education is important

since the chemicals and substances

on the list are found in our daily

lives. Most consumers are aware

that products present safety and

health risks, when improperly used,

handled and maintained.

and the State of

.

WARNING (SEE SECTION 12.6: MOTOR REPLACEMENT)

!

To avoid electrical shock which can result in personal injury or death, use only

the screws furnished in the motor shell mounting holds. Screws are #8-18 x .25

in. long blunt nose thread forming. Screws longer than 1/4 in. may contact the

motor winding.

WARNING (SEE SECTION 7.0: AIR FILTER)

!

Do not operate the system without filters. A portion of the dust entrained in the

air may temporarily lodge in the duct runs and at the supply registers. Any circulated dust particles could be heated and charred by contact with the air handler elements. This residue could soil ceilings, walls, drapes, carpets and other

articles in the house.

Soot damage may occur with filters in place, when certain types of candles, oil

lamps or standing pilots are burned.

WARNING

!

The first 36 inches of supply air plenum and ductwork must be constructed of

sheet metal as required by NFPA 90B. The supply air plenum or duct must have

a solid sheet metal bottom directly under the unit with no openings, registers

or flexible air ducts located in it. If flexible supply air ducts are used they may

be located only in the vertical walls of a rectangular plenum, a minimum of 6

inches from the solid bottom. Metal plenum or duct may be connected to the

combustible floor base, if not, it must be connected to the unit supply duct

flanges such that combustible floor or other combustible material is not

exposed to the supply air opening from the downflow unit. Exposing combustible (non-metal) material to the supply opening of a downflow unit can

cause a fire resulting in property damage, personal injury or death.

CAUTION (SEE SECTION 2.1: RECEIVING)

!

In compliance with recognized codes, it is recommended that an auxiliary

drain pan be installed under all evaporator coils or units containing evaporator

coils that are located in any area of a structure where damage to the building

or building contents may occur as a result of an overflow of the coil drain pan

or a stoppage in the primary condensate drain piping.

CAUTION

!

When used in cooling applications, excessive sweating may occur when unit is

installed in an unconditioned space. This can result in property damage.

NOTICE

!

Improper installation, or installation not made in accordance with the Underwriters

Laboratory (UL) certification or these instructions, can result in unsatisfactory

operation and/or dangerous conditions and are not covered by the unit warranty.

4

NOTICE

!

Use of this air-handler during construction is not recommended. If operation during construction is absolutely required, the following temporary

installation requirements must be followed:

Installation must comply with all Installation Instructions in this manual

including the following items:

• Properly sized power supply and circuit breaker/fuse

• Air-handler operating under thermostatic control;

• Return air duct sealed to the air-handler;

• Air filters must be in place;

• Correct air-flow setting for application

• Removing the coil and storing it in a clean safe place is highly recommended until construction is completed and the outdoor unit is installed.

• Clean air-handler, duct work, and components including coil upon completion of the construction process and verify proper air-handler operating conditions according as stated in this instruction manual.

• NOTE: Electric strip heater elements tend to emit a burning odor for a few

days if dust has accumulated during construction. Heater elements are

easily damaged. Take great care when cleaning them. Low pressure compressed air is recommended for cleaning elements.

2.0 GENERAL INFORMATION

2.1 IMPORTANT INFORMATION ABOUT EFFICIENCY AND INDOOR

2.1 AIR QUALITY

Central cooling and heating equipment is only as efficient as the duct system that carries

the cooled or heated air. To maintain efficiency, comfort and good indoor air quality, it is

FIGURE 1

MIGRATION OF DANGEROUS SUBSTANCES, FUMES, AND ODORS INTO LIVING SPACES

WARNING

!

Duct leaks can create an unbalanced system and draw pollutants such as dirt,

dust, fumes and odors into the home causing property damage. Fumes and

odors from toxic, volatile or flammable chemicals, as well as automobile

exhaust and carbon monoxide (CO), can be drawn into the living space

through leaking ducts and unbalanced duct systems causing personal injury

or death (see Figure 1).

• If air-moving equipment or ductwork is located in garages or off-garage storage areas - all joints, seams, and openings in the equipment and duct must

be sealed to limit the migration of toxic fumes and odors including carbon

monoxide from migrating into the living space.

• If air-moving equipment or ductwork is located in spaces containing fuel

burning appliances such as water heaters or boilers - all joints, seams, and

openings in the equipment and duct must also be sealed to prevent depressurization of the space and possible migration of combustion byproducts

including carbon monoxide into the living space.

NOTICE

!

Improper installation, or installation not made in accordance with the Underwriters

Laboratory (UL) certification or these instructions, can result in unsatisfactory

operation and/or dangerous conditions and are not covered by the unit warranty.

5

important to have the proper balance between the air being supplied to each room and

the air returning to the cooling and heating equipment.

Proper balance and sealing of the duct system improves the efficiency of the heating

and air conditioning system and improves the indoor air quality of the home by reducing

the amount of airborne pollutants that enter homes from spaces where the ductwork

and/or equipment is located. The manufacturer and the U.S. Environmental Protection

Agency’s Energy Star Program recommend that central duct systems be checked by a

qualified contractor for proper balance and sealing.

NOTICE

!

In compliance with recognized codes, it is recommended that an auxiliary

drain pan be installed under all evaporator coils or units containing evaporator coils that are located in any area of a structure where damage to the

building or building contents may occur as a result of an overflow of the

coil drain pan or a stoppage in the primary condensate drain piping.

2.2 RECEIVING

Immediately upon receipt, all cartons and contents should be inspected for transit damage. Units with damaged cartons should be opened immediately. If damage is found, it

should be noted on the delivery papers, and a damage claim filed with the last carrier.

• After unit has been delivered to job site, remove carton taking care not to damage

unit.

• Check the unit rating plate for unit size, electric heat, coil, voltage, phase, etc. to be

sure equipment matches what is required for the job specification.

• Read the entire instructions before starting the installation.

• Some building codes require extra cabinet insulation and gasketing when unit is

installed in attic applications.

• If installed in an unconditioned space, apply caulking around the power wires, control

wires, refrigerant tubing and condensate line where they enter the cabinet. Seal the

power wires on the inside where they exit conduit opening. Caulking is required to

pre-vent air leakage into and condensate from forming inside the unit, control box,

and on electrical controls.

• Install the unit in such a way as to allow necessary access to the coil/filter rack and

blower/control compartment.

• Install the unit in a level position to ensure proper condensate drainage. Make sure

unit is level in both directions within 1/8”.

• Install the unit in accordance with any local code which may apply and the national

codes. Latest editions are available from: “National Fire Protection Association, Inc.,

Batterymarch Park, Quincy, MA 02269.” These publications are:

• ANSI/NFPA No. 70-(Latest Edition) National Electrical Code.

• NFPA90A Installation of Air Conditioning and Ventilating Systems.

• NFPA90B Installation of warm air heating and air conditioning systems.

• The equipment has been evaluated in accordance with the Code of Federal

Regulations, Chapter XX, Part 3280.

2.3 CLEARANCES

• All units are designed for “0” inches clearance to combustible material on all cabinet

surfaces.

• Units with electric heat require a one inch clearance to combustible material for the

first three feet of supply plenum and ductwork.

• All units require 24 inches minimum access to the front of the unit for service.

• These units may be installed in either ventilated or non-ventilated spaces.

6

2.4 MODEL NUMBER EXPLANATION

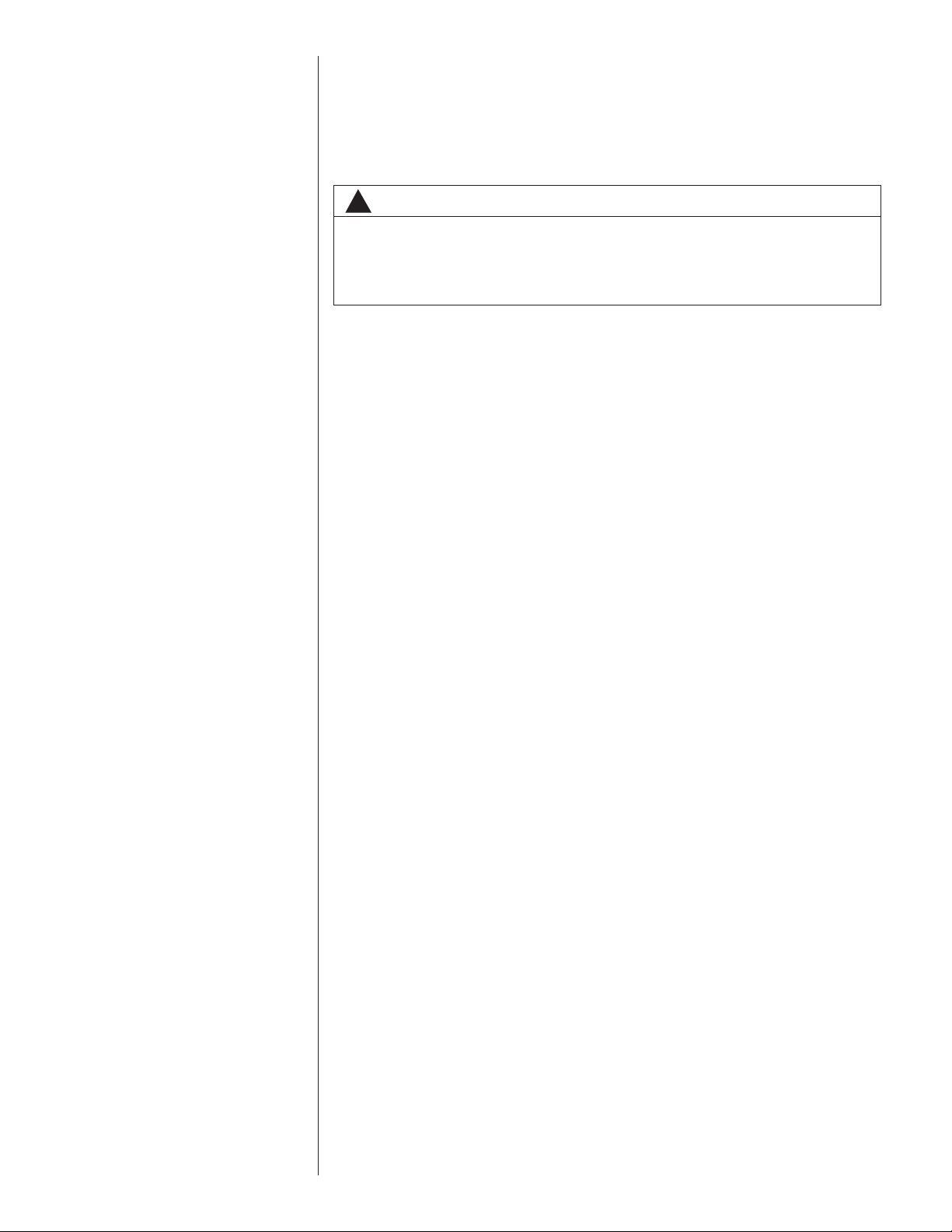

FIGURE 2

MODEL NUMBER EXPLANATION

R H A L — FR 24 P J N 00 A

DESIGN VARIATION

ELECTRIC HEAT

00 = NO HEAT

05 = 5 kW

08 = 8 kW

10 = 10 kW

DISCONNECT CONFIGURATION

N = NONE

B = BREAKER

VOLTAGE

J = 208/240V/1/60

METERING

P = PISTON

T = TXV

CAPACITY

18 = 18,000 BTU/H

24 = 24,000 BTU/H

30 = 30,000 BTU/H

36 = 36,000 BTU/H

FR = FRONT RETURN

REFRIGERANT

L = 410A

FRONT RETURN/WALL MOUNT

A = PSC MOTOR - STANDARD EFFICIENCY

CLASSIFICATION

H = AIR HANDLER

TRADE BRAND

R H B L — FR 24 T J N 00 A

CAPACITY

24 = 18,000/24,000 BTU/H

36 = 30,000/36,000 BTU/H

FR = FRONT RETURN

REFRIGERANT

L = 410A

DESIGN VARIATION

ELECTRIC HEAT

00 = NO HEAT

05 = 5 kW

08 = 8 kW

10 = 10 kW

DISCONNECT CONFIGURATION

N = NONE

B = BREAKER

VOLTAGE

J = 208/240V/1/60

METERING

T = TXV

FRONT RETURN/WALL MOUNT

B = CONSTANT TORQUE MOTOR - HIGH EFFICIENCY

CLASSIFICATION

H = AIR HANDLER

TRADE BRAND

7

2.4A AVAILABLE MODELS

AVAILABLE MODELS AT J VOLTAGE

RHAL-FR18PJ

RHAL-FR24PJ

RHAL-FR30PJ

RHAL-FR36PJ

Notes:

• Supply circuit protective devices may be fuses or “HACR” type circuit breakers.

• Largest motor load is included in single circuit and multiple circuit 1.

• If non-standard fuse size is specified, use next size larger fuse size.

• J Voltage (208/240V) single phase air handler is designed to be used with single or

three phase 208/240V power. In the case of connecting 3-phase power to the air handler terminal block, bring only two leads to the terminal block. Cap, insulate and fully

secure the third lead.

• The air handlers are shipped from the factory with the proper indoor coil installed, and

cannot be ordered without a coil.

RHAL-FR36TJ

RHBL-FR24TJ

RHBL-FR36TJ

8

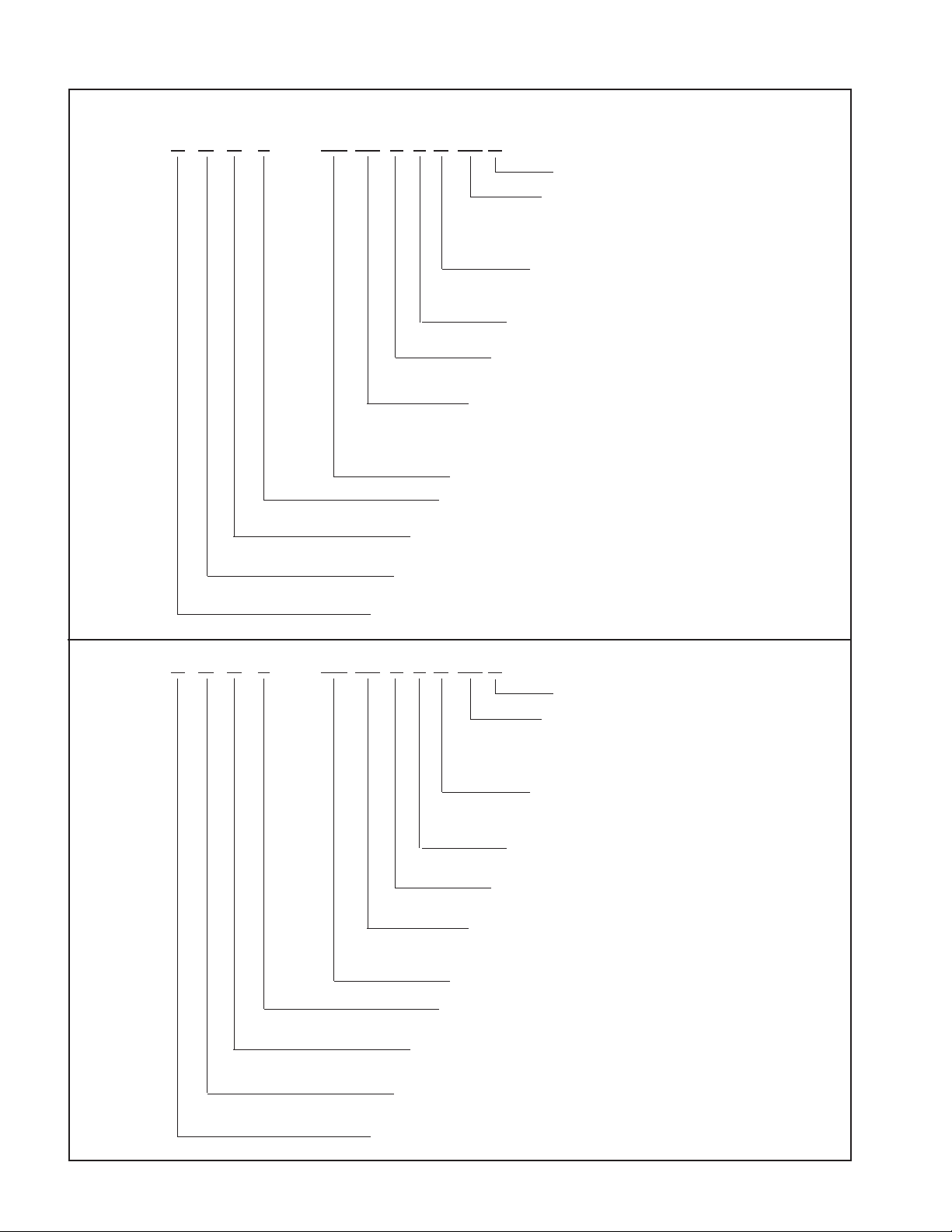

2.5 DIMENSIONS & WEIGHTS

FIGURE 3

DIMENSIONS AND WEIGHTS

FLANGES FOR FIELD

INSTALLED DUCTWORK

NOTE: 24" CLEARANCE REQUIRED

IN FRONT OF UNIT FOR FILTER

AND COIL MAINTENANCE.

HIGH VOLTAGE CONNECTION,

1-3/8” AND 7/8” KNOCKOUTS

SUPPLY AIR

A

LIQUID LINE CONNECTION

COPPER (SWEAT)

VAPOR LINE CONNECTION

COPPER (SWEAT)

B

DIMENSIONAL DATA

(A)

MODEL

RHAL-18

RHAL-24

RHAL-30

RHAL-36

RHBL-24

RHBL-36

UNIT

WIDTH

IN. [mm]

21-1/2

[546.1]

21-1/2

[546.1]

24

[609.6]

24

[609.6]

21-1/2

[546.1]

24

[609.6]

(B)

UNIT

HEIGHT

IN. [mm]

36

[914.4]

36

[914.4]

36

[914.4]

36

[914.4]

36

[914.4]

36

[914.4]

RETURN AIR

C

ALL UNITS ARE CONFIGURED FOR

VERTICAL UPFLOW. UNITS CANNOT

BE INSTALLED IN ANY OTHER CONFIGURATION.

(C)

UNIT

DEPTH

IN. [mm]

17

[431.8]

17

[431.8]

21

[533.4]

21

[533.4]

17

[431.8]

21

[533.4]

(D) RETURN

AIR OPENING

WIDTH IN.

[mm]

20

[508]

20

[508]

23

[584.2]

23

[584.2]

20

[508]

23

[584.2]

OPENING

(E)

RETURN AIR

OPENING

HEIGHT IN.

[mm]

17-7/16

[442.9]

17-7/16

[442.9]

21-3/8

[542.9]

21-3/8

[542.9]

17-7/16

[442.9]

21-3/8

[542.9]

E

D

FRONT RETURN SHOWN.

UNITS MAY ALSO BE INSTALLED

AS BOTTOM RETURN.

SEE THE APPLICATIONS SECTION

FOR MORE DETAIL.

AIRFLOW

COIL / [L/s]

600

[283]

800

[378]

1000

[472]

1200

[566]

600/800

[283/378]

1000/1200

[472/566]

UNIT WEIGHT /

SHIPPING WEIGHT

LBS. / [kg]

80/90

[36]/[41]

80/90

[36]/[41]

95/105

[43]/[48]

95/105

[43]/[48]

80/90

[36]/[41]

95/105

[43]/[48]

9

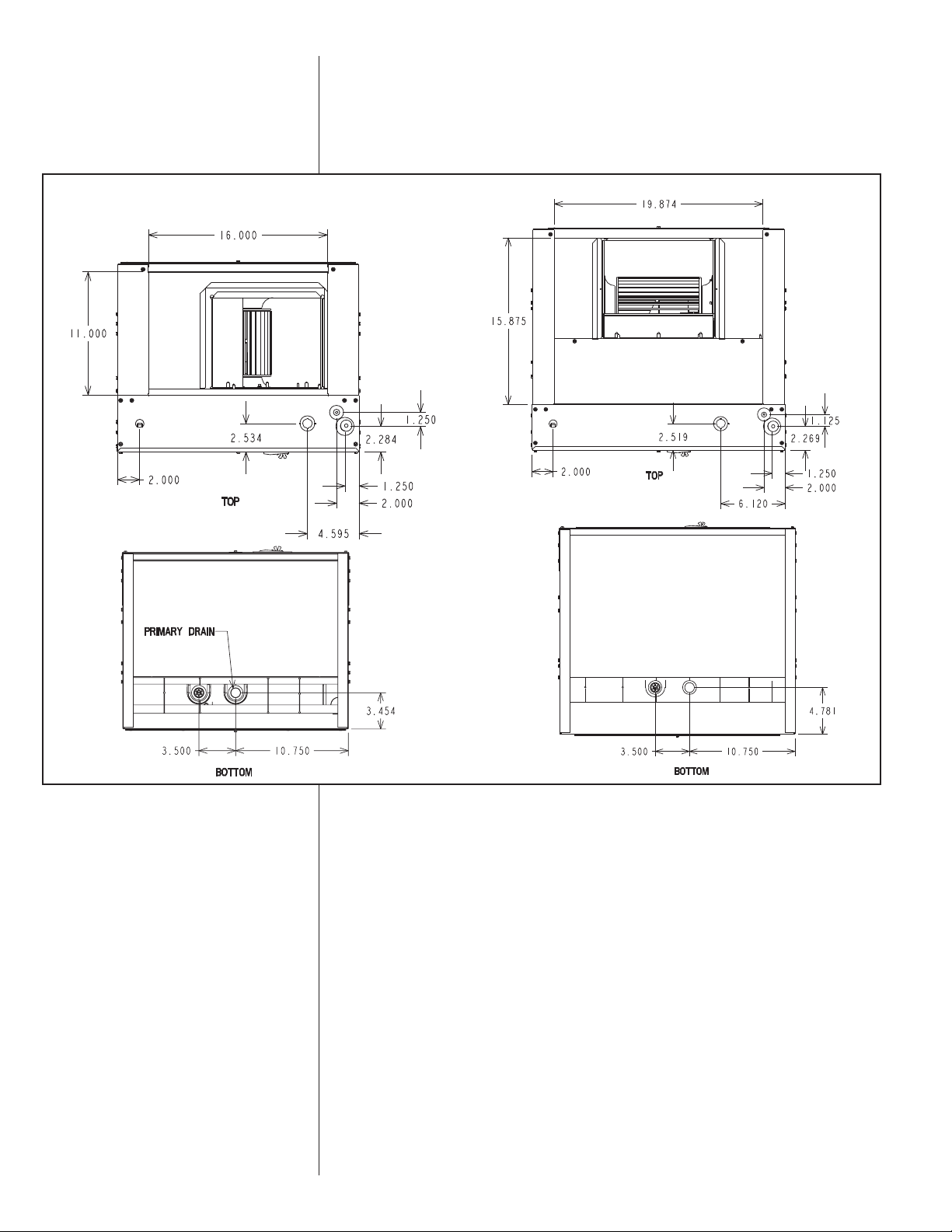

FIGURE 4

DIMENSIONS FOR DUCTWORK & DRAINS

3.0 APPLICATIONS

3.1 VERTICAL UPFLOW

• Vertical Upflow is the factory configuration for all models (see Figure 3).

• If return air is to be ducted, install duct flush with floor. Use fireproof resilient gasket 1/8

to 1/4 in. thick between duct, unit and floor. Set unit on floor over opening.

10

4.0 AIR HANDLER MOUNTING OPTIONS

The air handler comes standard with two different options for mounting, wall mount or

frame mount. Both mounting options require the unit to be level from side to side and

from front to back in order to allow condensate to properly drain from the unit. Failure to

do this will result in condensate to leak out from the unit potentially causing structural

damage to the surrounding support structures, dry wall, carpet, etc. around the unit.

Also, both mounting structures require the ability to accommodate a minimum of 150 lb.

load. Failure to do this will cause damage to the support structure and potentially damage the unit.

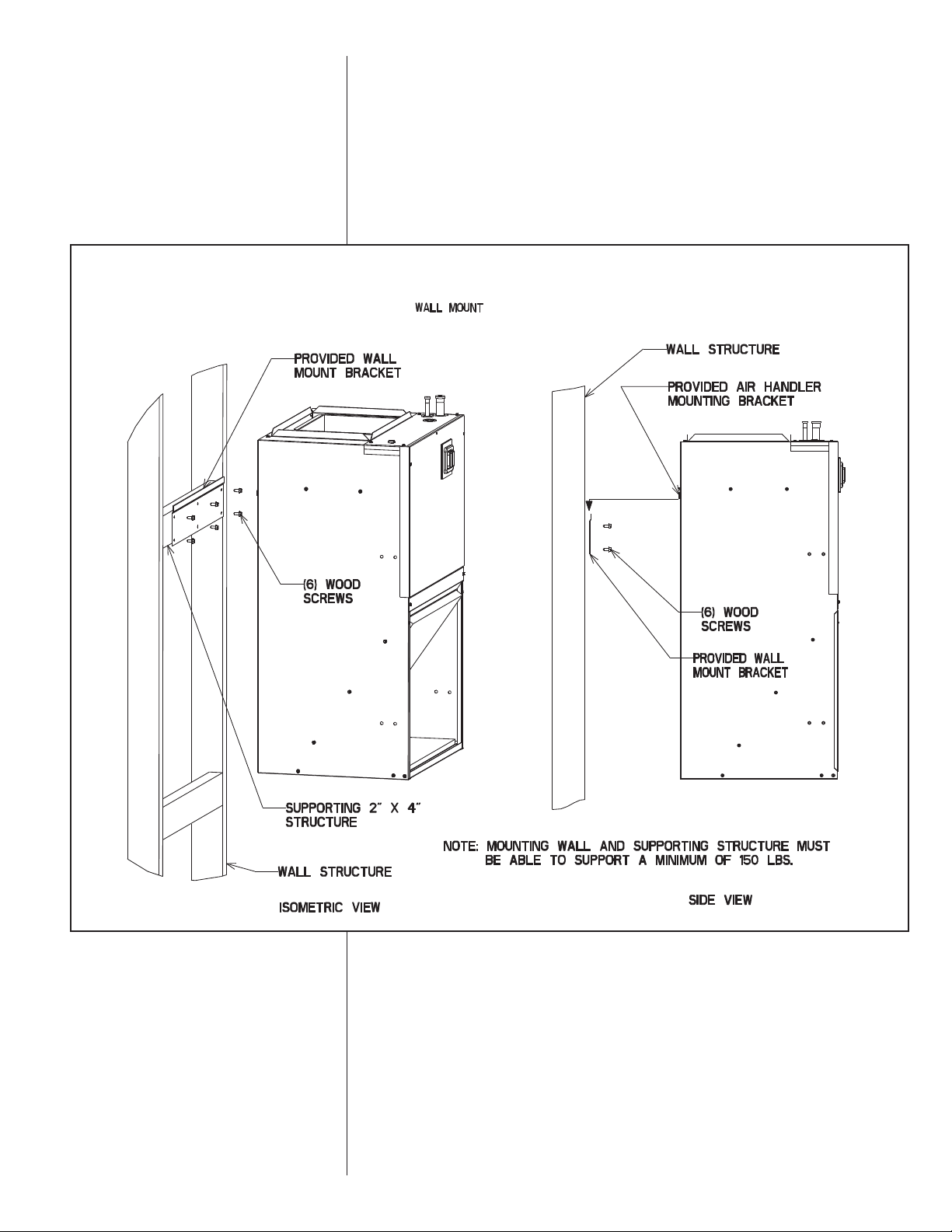

4.1 WALL MOUNT

The air handler comes standard with a wall mounting bracket and air handler mounting

bracket. Reference figure 5 for more detail.

1. Remove the wall mounting bracket from the back of the unit by removing one screw

which attaches the bracket to the air handler. Note: Discard the screw after you have

removed the wall mounting bracket.

2. Install bracket one the wall by using 6 wood screws (not provided). Make sure the

bracket is level in order to provided proper drainage from the unit. Note: Do not attach

the wall mounting bracket into unsupported dry wall. Make sure that the wood screws

are going into a structure that can support a minimum of 150 lb load.

FIGURE 5

WALL MOUNT

3. Lift the air handler above the wall mounting bracket and attached the unit to the

installed bracket. Reference figure 5.

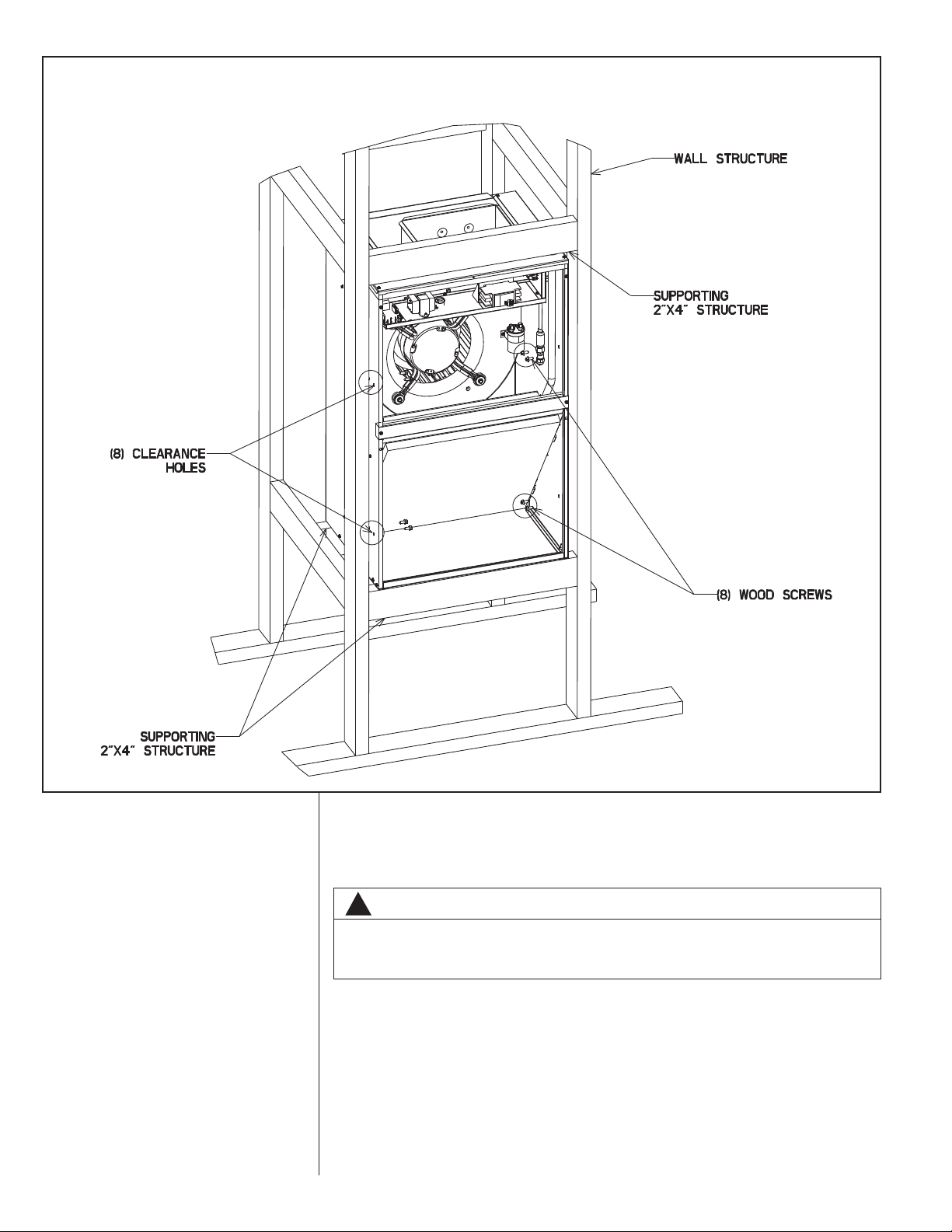

4.2 FRAME MOUNT

The air handler comes with 8 clearance holes 4 on each side. These holes are used to

mount the air handler inside of a frame structure (see figure 6). When mounting in this

fashion, make sure that the wood screws are mounted from within the air handler and

not outside of the unit. Installing the screws from the outside could cause damage to the

coil.

11

FIGURE 6

FRAME MOUNT

12

5.0 ELECTRICAL WIRING

Field wiring must comply with the National Electric Code (C.E.C. in Canada) and any

applicable local ordinance.

WARNING

!

Disconnect all power to unit before installing or servicing. More than one disconnect switch may be required to de-energize the equipment. Hazardous voltage can cause severe personal injury or death.

5.1 POWER WIRING

It is important that proper electrical power is available for connection to the unit model

being installed. See the unit nameplate, wiring diagram and electrical data in the installation instructions.

• If required, install a branch circuit disconnect of adequate size, located within sight of,

and readily accessible to the unit.

• IMPORTANT: After the Electric Heater is installed, units may be equipped with a circuit breaker. This circuit breaker protects the internal wiring in the event of a short circuit and serves as a disconnect. Circuit breakers installed within the unit do not pro-

Loading...

Loading...