Rheem RH1V3617STANJA, RH1V4824STANJA, RH1V4821STANJA, RH1V6024STANJA, RH2V2421HTACJA Installation Instructions Manual

...Page 1

INSTALLATION INSTRUCTIONS

WARNING

ISO 9001:2008

AIR HANDLERS

FEATURING INDUSTRY STANDARD R-410A REFRIGERANT:

(-)H1V Premium Efficiency Single Stage with Aluminum Coil

2

(-)H2V Premium Efficiency Two Stage Comfort Control

(-)H2V with Aluminum Coil

System™

!

▲WARNING

These instructions are intended as an aid to qualified licensed

service personnel for proper installation, adjustment and

operation of this unit. Read these instructions thoroughly before

attempting installation or operation. Failure to follow these

instructions may result in improper installation, adjustment,

service or maintenance possibly resulting in fire, electrical

shock, property damage, personal injury or death.

92-20521-65-00

Page 2

CONTENTS

1.0 SAFETY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.0 GENERAL INFORMATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 Important Information About Efficiency and Indoor Air Quality . . . . . . . . . . . . . . 5

2.2 Model Number Explanation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3 Dimensions and Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4 Receiving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.5 Clearances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.0 APPLICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.1 Zoning Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.2 Vertical Upflow & Horizontal Left . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.3 Vertical Downflow & Horizontal Right. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.4 Installation in an Unconditioned Space . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3.5 Installation in Mobile/Manufactured Homes . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.0 ELECTRICAL WIRING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.1 Power Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.2 Copper Wire Size. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.3 Control Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.4 Typical Thermostat Wiring Diagrams (-)H1V, (-)H2V. . . . . . . . . . . . . . . . . . . . . 15

4.5 Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.6 Blower Motor Electrical Data (-)H1V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.7 Blower Motor Electrical Data (-)H2V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

4.8 Conventional 24VAC Thermostat Control Wiring (-)H2V . . . . . . . . . . . . . . . . . . 19

4.9 Electric Heat Electrical Data (-)H1V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

4.10 Electric Heat Electrical Data (-)H2V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.11 Heater Kit Supplemental Information (-)H1V & (-)H2V. . . . . . . . . . . . . . . . . . . . 23

5.0 ECM MOTOR INTERFACE CONTROL BOARD . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.1 ECM Motor Interface Control & Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.2 Using the On-board LED to Determine Blower CFM . . . . . . . . . . . . . . . . . . . . . 25

5.3 Cooling Airflow Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.4 Cooling Airflow Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.5 Electric Heat Airflow Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.6 Cooling Delay Profiles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.7 Cooling Mode Dehumidification - Passive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.8 Cooling Mode Dehumidification - Active . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.9 On Demand Dehumidification Airflow Adjustment - Active . . . . . . . . . . . . . . . . 29

5.10 Airflow Performance (-)H1V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5.11 Airflow Performance Data (-)H1V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.0 AIRFLOW PERFORMANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.1 Airflow Performance Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.2 Copper Wire Size - Awg. (3% Voltage Drop) . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.3 Blower Motor Electrical Data (-)H2v. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.4 Electric Heat Electrical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.5 Cooling Airflow Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.6 Cooling Airflow Adjustment (-)H2V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.7 Electric Heat Airflow (-)H2V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.8 Cooling Mode Dehumidification (-)H2V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.9 Cooling Delay Profiles (-)H2V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.10 Using the On-Board LED to determine Blower CFM (-)H2V . . . . . . . . . . . . . . . 36

6.11 Cooling Airflow Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.12 Cooling Airflow Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.13 Airflow Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.14 Electric Heat Airflow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.15 Cooling Mode Dehumidification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.16 Cooling Delay Profiles (-)H2V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.17 Airflow Performance Data (-)H2V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.18 Air Handler Diagnostic Codes (-)H2V . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.0 DUCTWORK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

8.0 REFRIGERANT CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8.1 TEV Sensing Bulb . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8.2 Condensate Drain Tubing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

8.3 Duct Flanges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

9.0 AIR FILTER (Not Factory Installed) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

10.0 SEQUENCE OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

10.1 Cooling (cooling only & heat pump) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

10.2 Heating (electric heat only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

10.3 Heating (heat pump) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

10.4 Defrost . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

10.5 Emergency Heat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

10.6 Room Thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

11.0 CALCULATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

11.1 Calculating Temperature Rise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

11.2 Calculating BTUH Heating Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

11.3 Calculating Airflow CFM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

11.4 Calculating Correction Factor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

12.0 PRE-START CHECKLIST. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

13.0 MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

13.1 Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

13.2 Indoor Coil/Drain Pan/Drain Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

13.3 The Comfort Control2System™ Control Board . . . . . . . . . . . . . . . . . . . . . . . . . 47

13.4 Blower Motor & Wheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

13.5 Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

13.6 Blower Assembly Removal and Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . 48

13.7 Motor Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

13.8 ECM Control Module Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

13.9 Blower Wheel Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

14.0 REPLACEMENT PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

15.0 ACCESSORIES - KITS - PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

2

Page 3

1.0 SAFETY INFORMATION

WARNING

!

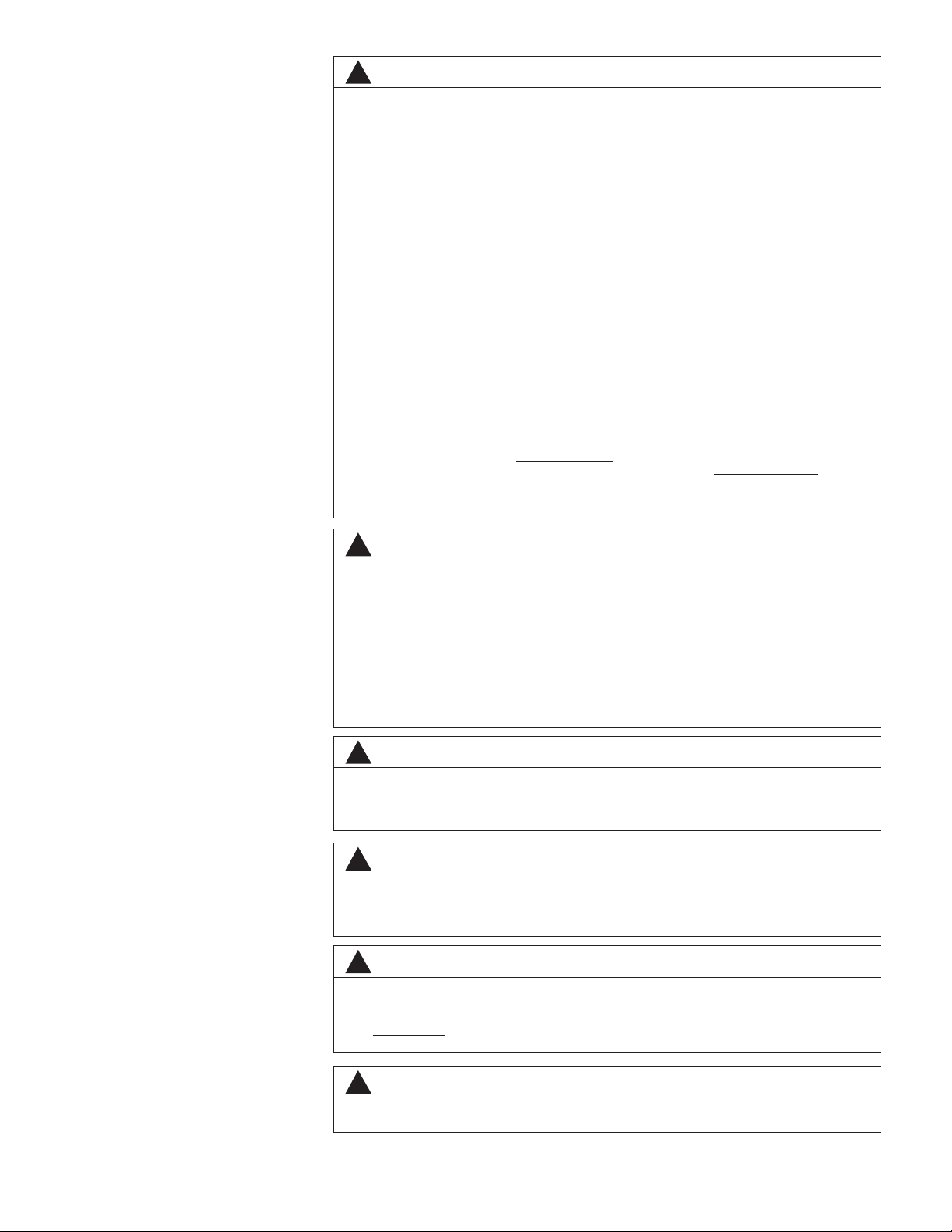

Duct leaks can create an unbalanced system and draw pollutants such as dirt,

dust, fumes and odors into the home causing property damage. Fumes and odors

from toxic, volatile or flammable chemicals, as well as automobile exhaust and

carbon monoxide (CO), can be drawn into the living space through leaking ducts

and unbalanced duct systems causing personal injury or death (see Figure 1).

• If air-moving equipment or ductwork is located in garages or off-garage storage

areas - all joints, seams, and openings in the equipment and duct must be

sealed to limit the migration of toxic fumes and odors including carbon monoxide from migrating into the living space.

• If air-moving equipment or ductwork is located in spaces containing fuel burning appliances such as water heaters or boilers - all joints, seams, and openings

in the equipment and duct must also be sealed to prevent depressurization of

the space and possible migration of combustion byproducts including carbon

monoxide into the living space.

!

WARNING (SEE SECTION 3.2: VERTICAL UPFLOW & HORIZONTAL LEFT)

If unit is to be installed without an indoor coil, return air duct, or plenum, it must

not be in stalled directly over combustible material. If installed without an indoor

coil with a return duct or plenum, the air plenum or duct must have a solid sheet

metal bottom with no return air openings, registers or flexible air ducts located

directly under the unit. Exposing combustible material to the return opening of an

upflow unit without an indoor coil can cause a fire resulting in property damage,

personal injury or death.

!

WARNING (SEE SECTION 14.7: ECM CONTROL MODULE REPLACEMENT)

Always have 240 volt power turned off to the furnace before attempting any

replacement of the motor or control module. Failure to do so may result in serious equipment damage, personal injury or death.

WARNING (SEE SECTION 4.0: ELECTRICAL WIRING)

!

Disconnect all power to unit before installing or servicing. More than one disconnect switch may be required to de-energize the equipment. Hazardous voltage can cause severe personal injury or death.

!

WARNING (SEE SECTION 4.3: GROUNDING)

The unit must be permanently grounded. Failure to do so can result in electrical

shock causing personal injury or death.

!

WARNING (SEE SECTION 14.0: MAINTENANCE)

Units with circuit breaker(s) meet requirements as a service disconnect switch,

however, if access is required to the line side (covered) of the circuit breaker,

this side of the breaker(s) will be energized with the breaker(s) de-energized.

Contact with the line side can cause electrical shock resulting in personal

injury or death.

!

WARNING (SEE SECTION 14.5: BLOWER ASSEMBLY REMOVAL & REPLACEMENT)

If removal of the blower assembly is required, all disconnect switches supplying

power to the airhandler must be de-energized and locked (if not in sight of unit)

so the field power wires can be safely removed from the blower assembly. Failure

to do so can cause electrical shock resulting in personal injury or death.

Continued on next page ➜

3

Page 4

WARNING

!

PROPOSITION 65: This appliance contains fiberglass insulation. Respirable

particles of fiberglass are known to the State of California to cause cancer.

All manufacturer products meet current Federal OSHA Guidelines for safety.

California Proposition 65 warnings are required for certain products, which are

not covered by the OSHA standards.

California's Proposition 65 requires warnings for products sold in California

that contain or produce any of over 600 listed chemicals known to the State of

California to cause cancer or birth defects such as fiberglass insulation, lead in

brass, and combustion products from natural gas.

All “new equipment” shipped for sale in California will have labels stating that

the product contains and/or produces Proposition 65 chemicals. Although we

have not changed our processes, having the same label on all our products

facilitates manufacturing and shipping. We cannot always know “when, or if”

products will be sold in the California market.

You may receive inquiries from customers about chemicals found in, or produced by, some of our heating and air-conditioning equipment, or found in natural gas used with some of our products. Listed below are those chemicals and

substances commonly associated with similar equipment in our industry and

other manufacturers.

• Glass Wool (Fiberglass) Insulation

• Carbon Monoxide (CO).

• Formaldehyde

• Benzene

More details are available at the websites for OSHA (Occupational Safety and

Health Administration), at www.osha.gov

(Office of Environmental Health Hazard Assessment), at www.oehha.org

Consumer education is important since the chemicals and substances on the

list are found in our daily lives. Most consumers are aware that products present safety and health risks, when improperly used, handled and maintained.

and the State of California’s OEHHA

.

!

WARNING

The first 36 inches of supply air plenum and ductwork must be constructed of

sheet metal as required by NFPA 90B. The supply air plenum or duct must have a

solid sheet metal bottom directly under the unit with no openings, registers or

flexible air ducts located in it. If flexible supply air ducts are used they may be

located only in the vertical walls of a rectangular plenum, a minimum of 6 inches

from the solid bottom. Metal plenum or duct may be connected to the combustible

floor base, if not, it must be connected to the unit supply duct flanges such that

combustible floor or other combustible material is not exposed to the supply air

opening from the downflow unit. Exposing combustible (non-metal) material to the

supply openings of a downflow unit can cause a fire resulting in property damage,

personal injury or death.

!

WARNING (SEE SECTION 8.0: DUCTWORK)

Do not, under any circumstances, connect return ductwork to any other heat producing device such as fireplace insert, stove, etc. Unauthorized use of such

devices may result in fire, carbon monoxide poisoning, explosion, personal injury

or property damage.

!

WARNING

Because of possible damage to equipment or personal injury, installation, service, and maintenance should be performed by trained, qualified service personnel. Consumer service is recommended only for filter cleaning/ replacement. Never operate the unit with the access panels removed.

WARNING (SEE SECTION 3.3: VERTICAL DOWNFLOW & HORIZONTAL RIGHT)

!

The RXHB-17, RXHB-21, or RXHB-24 combustible floor base is required when

certain units are applied downflow on combustible flooring. Failure to use the

base can cause a fire resulting in property damage, personal injury or death.

See clearances

section in this manual for combustible floor base RXHB-.

for units requiring a combustible floor base. See the accessory

!

CAUTION (SEE SECTION 14.7: ECM CONTROL MODULE REPLACEMENT)

Reversing the 5-pin connector on the ECM motor causes immediate failure of

the control module.

Continued on next page ➜

4

Page 5

CAUTION (SEE SECTION 3.2: VERTICAL UPFLOW & HORIZONTAL LEFT)

Horizontal units must be configured for right hand air supply. Horizontal drain

pan must be located under indoor coil. Failure to use the drain pan can result in

property damage.

CAUTION (SEE SECTION 14.2: INDOOR COIL - DRAIN PAN - DRAIN LINE)

In compliance with recognized codes, it is recommended that an auxiliary

drain pan be installed under all evaporator coils or units containing evaporator

coils that are located in any area of a structure where damage to the building

or building contents may occur as a result of an overflow of the coil drain pan

or a stoppage in the primary condensate drain piping. See accessory section

in this manual for secondary horizontal drain pan RXBM-.

NOTICE

!

When used on cooling applications, excessive sweating may occur when unit

is installed in an unconditioned space. This can result in property damage.

NOTICE

!

Improper installation, or installation not made in accordance with the

Underwriters Laboratory (UL) certification or these instructions, can result

in unsatisfactory operation and/or dangerous conditions and are not covered by the unit warranty.

NOTICE

!

In compliance with recognized codes, it is recommended that an auxiliary

drain pan be installed under all evaporator coils or units containing evaporator coils that are located in any area of a structure where damage to the

building or building contents may occur as a result of an overflow of the

coil drain pan or a stoppage in the primary condensate drain piping. See

accessories section of these instructions for auxiliary horizontal overflow

pan information (model RXBM).

NOTICE

!

Use of this air-handler during construction is not recommended. If operation during construction is absolutely required, the following temporary

installation requirements must be followed:

Installation must comply with all Installation Instructions in this manual

including the following items:

• Properly sized power supply and circuit breaker/fuse

• Air-handler operating under thermostatic control;

• Return air duct sealed to the air-handler;

• Air filters must be in place;

• Correct air-flow setting for application

• Removing the coil and storing it in a clean safe place is highly recommended until construction is completed and the outdoor unit is installed.

• Clean air-handler, duct work, and components including coil upon completion of the construction process and verify proper air-handler operating conditions according as stated in this instruction manual.

• NOTE: Electric strip heater elements tend to emit a burning odor for a few

days if dust has accumulated during construction. Heater elements are

easily damaged. Take great care when cleaning them. Low pressure compressed air is recommended for cleaning elements.

2.0 GENERAL INFORMATION

2.1 IMPORTANT INFORMATION ABOUT EFFICIENCY AND INDOOR

2.1 AIR QUALITY

Central cooling and heating equipment is only as efficient as the duct system that car ries

the cooled or heated air. To maintain efficiency, comfort and good indoor air quality, it is

important to have the proper balance between the air being supplied to each room and

the air returning to the cooling and heating equipment.

Proper balance and sealing of the duct system improves the efficiency of the heating

and air conditioning system and improves the indoor air quality of the home by reducing

the amount of airborne pollutants that enter homes from spaces where the ductwork and

/ or equipment is located. The manufacturer and the U.S. Environmental Protection

Agency’s Energy Star Program recommend that central duct systems be checked by a

qualified contractor for proper balance and sealing.

5

Page 6

FIGURE 1

MIGRATION OF DANGEROUS SUBSTANCES, FUMES, AND ODORS INTO LIVING SPACES

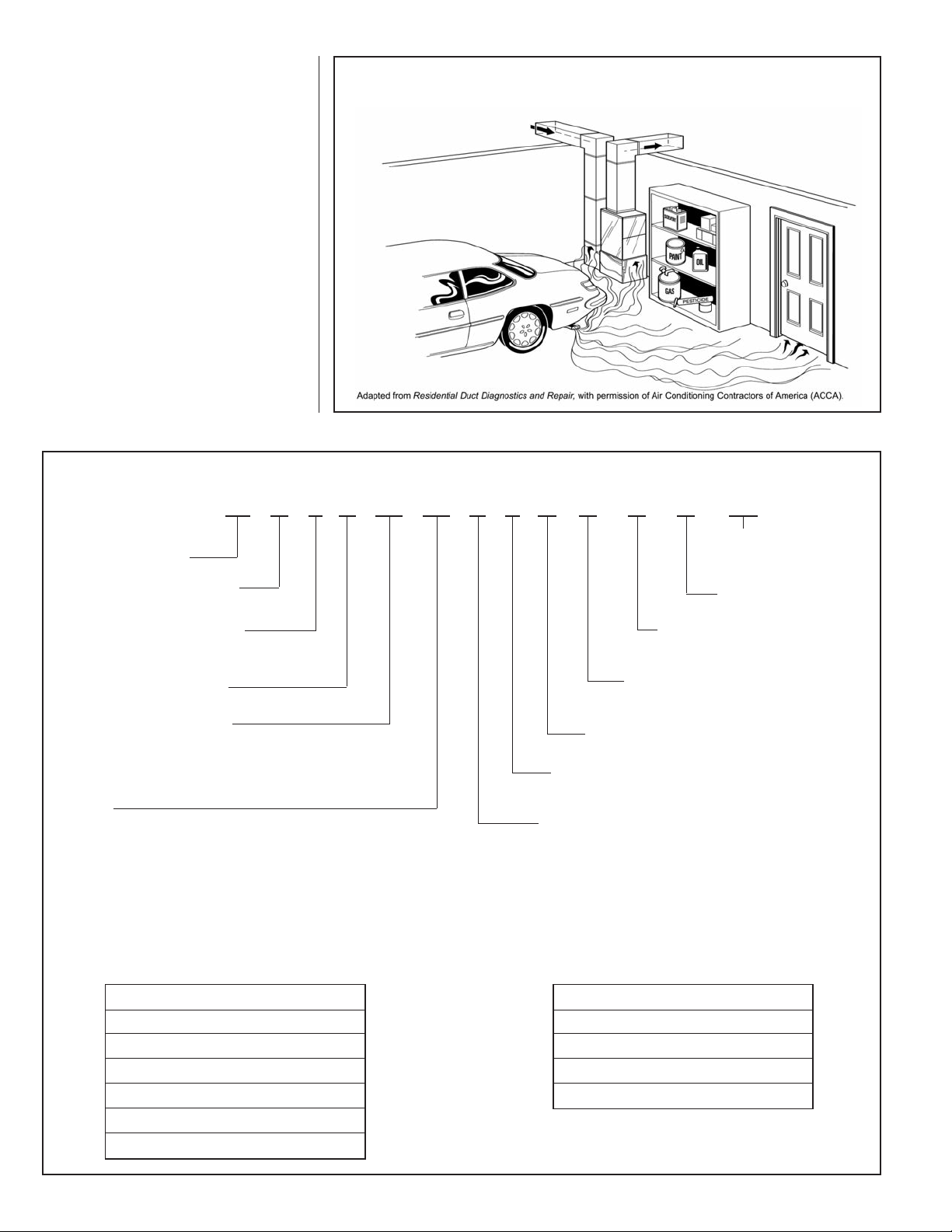

2.2 MODEL NUMBER EXPLANATION (SEE FIGURE 2)

FIGURE 2

MODEL NUMBER EXPLANATION

(-) H 1 V 24 17 S T A N A A ***

OPTION CODE

BRAND

PRODUCT CATEGORY

H = AIR HANDLER

STAGES OF AIR FLOW

1 = SINGLE

2 = TWO STAGE

MOTOR TYPE

V = ECM

NOMINAL CAPACITY

24 = 18,000-24,000 BTU/H

36 = 30,000-36,000 BTU/H

48 = 42,000-48,000 BTU/H

60 = 60,000 BTU/H

WIDTH

17 = 17.5” (600-1200 CFM) 24 = 24.5 (1400-1800 CFM)

21 = 21” (800-1600 CFM)

NOTES:

1) J Voltage (230V) single phase air handler is designed to be used with single or three phase 230 volt power. In the case

of connecting 3-phase power to the air handler terminal block, bring only two leads to the terminal block. Cap, insulate

and fully secure the third lead.

2) The air handlers are shipped from the factory with the proper indoor coil installed, and cannot be ordered without a coil.

3) Electric heat elements are field-installed items.

4) The air handlers do not have an internal filter rack. An external filter rack or other means of filtration is required.

MAJOR SERIES

A = FIRST

METERING DEVICE

T = TEV P = PISTON

E = EEV

COIL EFFICIENCY

S = STANDARD H = HIGH

M = MEDIUM

VOLTAGE

A = 115/1/60 J = 208/240/1/50

D = 480/3/60 T = 220/240/1/50

CONTROLS

C = COMMUNICATING

N = NON-COMMUNICATING

(SEE ADS-3803)

BLANK = NONE

MINOR SERIES

A = FIRST

AVAILABLE MODELS

RH1V2417STANJA

RH1V3617STANJA

RH1V3621MTANJA

RH1V4821STANJA

AVAILABLE MODELS

RH2V2421HTACJA

RH2V3624HTACJA

RH2V4824HTACJA

RH2V6024HTACJA

RH1V4824STANJA

RH1V6024STANJA

6

Page 7

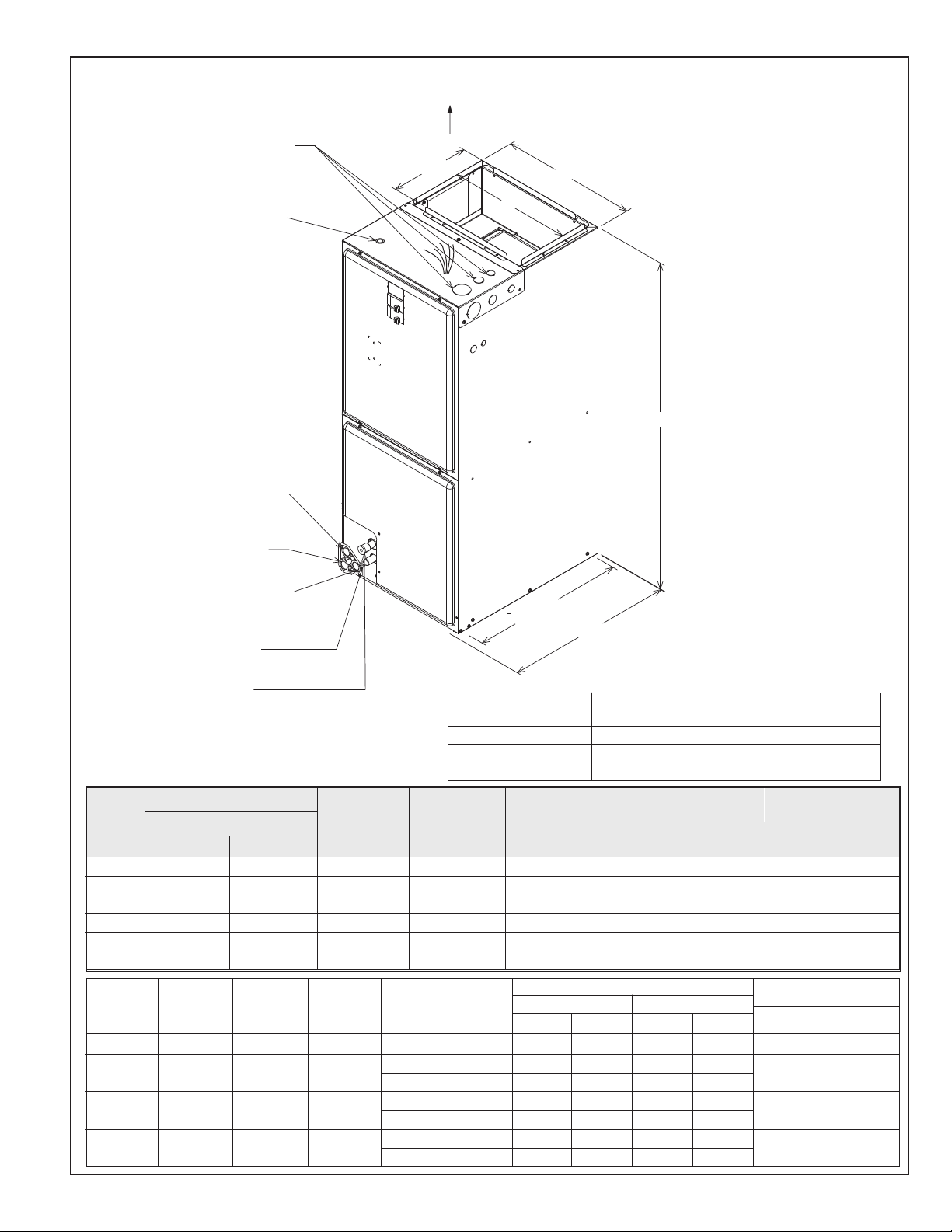

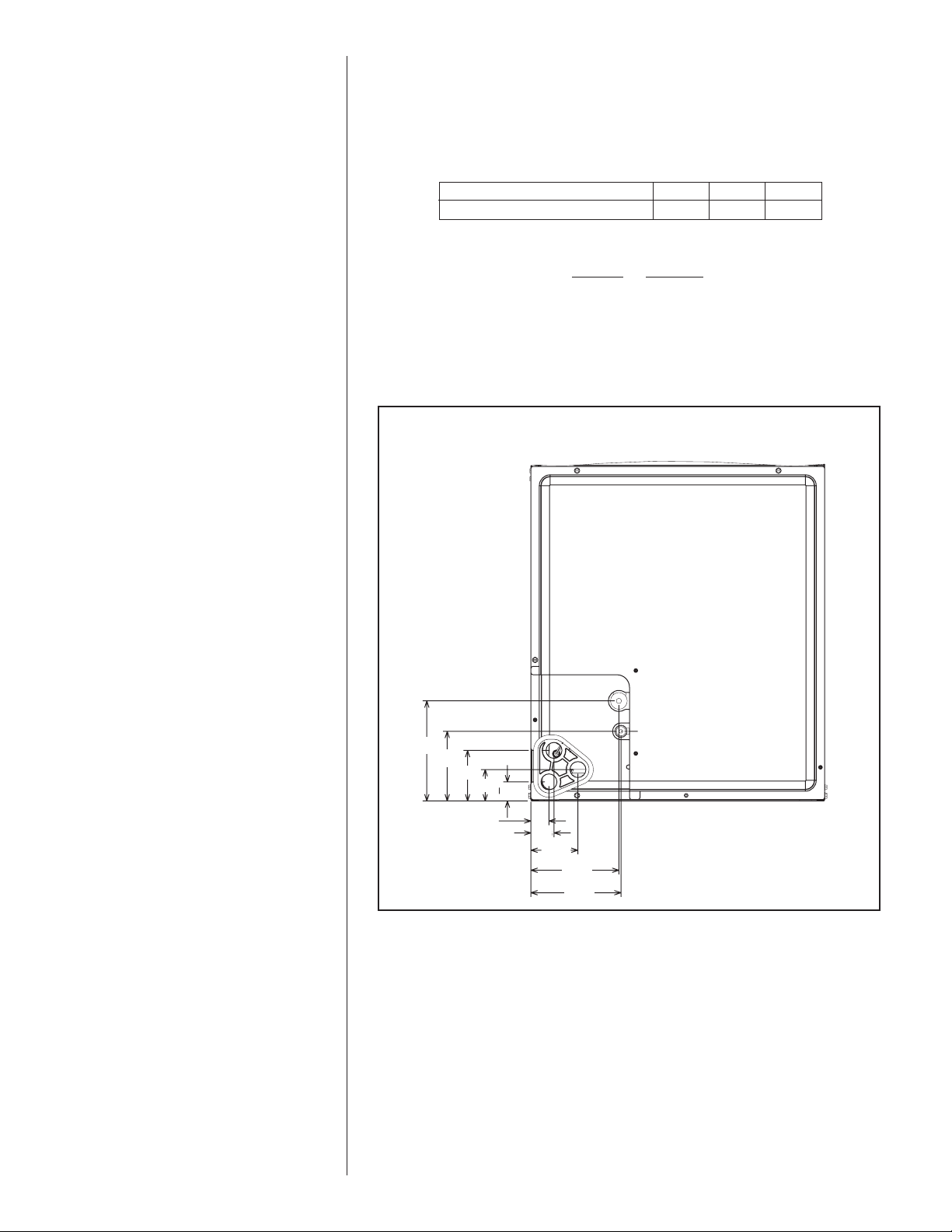

2.3 DIMENSIONS & WEIGHTS (SEE FIGURE 3)

FIGURE 3

DIMENSIONS AND WEIGHTS -- SINGLE COIL UNITS

HIGH VOLTAGE CONNECTION 7/8".

1 3/32", 1 31/32" DIA. KNOCK OUTS.

SUPPLY AIR

105/16

ELECTRICAL CONNECTIONS

MAY EXIT TOP OR EITHER SIDE

W

NOTE: 24" CLEARANCE REQUIRED

IN FRONT OF UNIT FOR FILTER

AND COIL MAINTENANCE.

LOW VOLTAGE CONNECTION

5/8" AND 7/8" KNOCK OUT

(OUTSIDE OF CABINET)

A

H

AUXILIARY DRAIN CONNECTION

3/4" FEMALE PIPE THREAD (NPT)

HORIZONTAL APPLICATION ONLY

PRIMARY DRAIN CONNECTION

3/4" FEMALE PIPE THREAD (NPT)

AUXILIARY DRAIN CONNECTION

3/4" FEMALE PIPE THREAD (NPT)

UPFLOW/DOWNFLOW APPLICATION

ONLY

LIQUID LINE CONNECTION

COPPER (SWEAT)

VAPOR LINE CONNECTION

COPPER (SWEAT)

UPFLOW UNIT SHOWN;

UNIT MAY BE INSTALLED UPFLOW, DOWNFLOW.

HORIZONTAL RIGHT, OR LEFT AIR SUPPLY.

DIMENSIONAL DATA

MODEL

(-)H1V

2417ST3/8" [9.53]

3617ST3/8" [9.53]

3621MT3/8" [9.53]

4821ST3/8" [9.53]

4824ST3/8" [9.53]

6024ST3/8" [9.53]

REFRIGERANT CONNECTIONS

SIZE

MODEL

SIZE

(-)H2V

SWEAT (IN.) [mm] ID

LIQUID

UNIT WIDTH

“W” IN. [mm]

UNIT HEIGHT

“H” IN. [mm]

RETURN AIR OPENING DIMENSIONS

UNIT

WIDTH

“W” IN

VAPOR

3

/4" [19.05] 171/2" [445] 421/2" [1080] 16" [409] 600 [283] 800 [378] 82/96 [37/44]

3

/4" [19.05] 171/2" [445] 421/2" [1080] 16" [409] 1000 [472] 1200 [566] 90/104 [41/47]

7

/8" [22.23] 21" [533] 501/2" [1282] 191/2" [495] 1000 [472] 1200 [566] 126/142 [57/64]

7

/8" [22.23] 21" [533] 501/2" [1282] 191/2" [495] 1400 [661] 1600 [755] 130/146 [59/66]

7

/8" [22.23] 241/2" [622] 501/2" [1282] 23" [585] 1600 [755] — 142/160 [64/72]

7

/8" [22.23] 241/2" [622] 551/2" [1410] 23" [585] — 1800 [850] 162/179 [73/81]

[mm]

SUPPLY

DUCT

“A” IN. [mm]

UNIT

HEIGHT

“H” IN

[mm]

MATCHED

TO

OUTDOOR UNIT

191/2

RETURN AIR

OPENING

2111/16

A-1038-01

Model Return Air Opening Return Air Opening

Cabinet Size Width (Inches) Depth/Length (Inches)

17 15

7

⁄8 193⁄4

21 193⁄8 193⁄4

24 227⁄8 193⁄4

SUPPLY

DUCT

“A” IN.

[mm]

NOMINAL COIL AIRFLOW [L/s]

ST

STAGE 2

1

1

ODD*

AIR FLOW

COIL (NOM) [L/s]

LO HI

ND

STAGE

ODD*Normal Normal

UNIT WEIGHT / SHIPPING

WEIGHT (LBS.) [kg]

UNIT WITH

COIL (MAX. kW.)

UNIT WEIGHT / SHIPPING

WEIGHT (LBS.) [kg]

UNIT WITH COIL

(MAX. kW.)

2421HT 21 [533] 421/2 [1080] 191/2 [495] (-)ARL/(-)ASL-024JEC 500 [236] 600 [283] 650 [307] 775 [366] 99/117 [45/51]

3624HT 241/2 [622] 551/2 [1410] 23 [584]

4824HT 241/2 [622] 551/2 [1410] 23 [584]

6024HT 241/2 [622] 551/2 [1410] 23 [584]

(-)ASL-039JEC 725 [342] 825 [389] 975 [460] 1175 [555]

(-)ARL/(-)ASL-0935JEC 825 [389] 950 [448] 1000 [472] 1175 [555]

(-)ASL-048JEC 825 [389] 1000 [472] 1300 [614] 1600 [755]

(-)ARL-048JEC 1000 [472] 1200 [566] 1350 [637] 1600 [755]

(-)ASL-060JEC 925 [437] 1050 [496] 1325 [625] 1700 [802]

(-)ARL-060JEC 1025 [484] 1275 [602] 1400 [661] 1700 [802]

129/146 [59/66]

143/160 [65/72]

159/176 [72/80]

7

Page 8

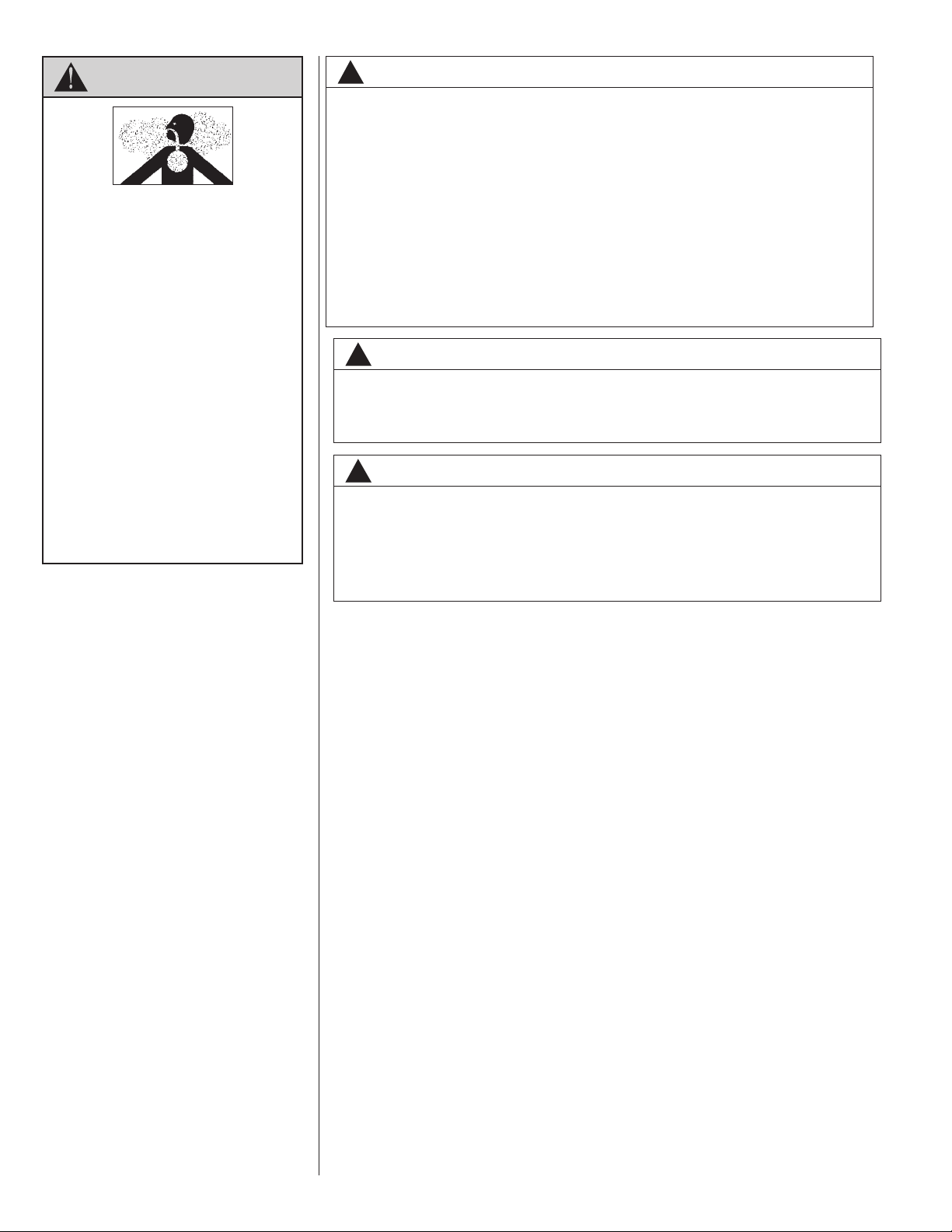

▲WARNING

Carbon Monoxide (CO) Poisoning

Can Cause Severe Injury or Death.

Carbon Monoxide from the exhaust of motor

vehicles and other fuel burning devices can be

drawn into the living space by the operation of the

central heating and air conditioning system.

Exhaust from motor vehicles, generators, garden

tractors, mowers, portable heaters, charcoal and gas

grills, gasoline powered tools, and outdoor camping

equipment contains carbon monoxide, a poisonous

gas that can kill you. You cannot see it, smell it, or

taste it.

• Do NOT operate an automobile or any engine in a

garage for more than the few seconds it takes to

enter or exist the garage.

• Do NOT operate any fuel-burning device in an

enclosed or partly enclosed space, or near building windows, doors or air intakes.

The U.S. Consumer Product Safety Commission (CPSC)

and Health Canada recommend the installation of UL or

CSA certified Carbon Monoxide Alarm(s) in every home.

!

Duct leaks can create an unbalanced system and draw pollutants such as

dirt, dust, fumes and odors into the home causing property damage.

Fumes and odors from toxic, volatile or flammable chemicals, as well as

automobile exhaust and carbon monoxide (CO), can be drawn into the living space through leaking ducts and unbalanced duct systems causing

personal injury or death (see Figure 1).

• If air-moving equipment or ductwork is located in garages or off-garage

storage areas - all joints, seams, and openings in the equipment and

duct must be sealed to limit the migration of toxic fumes and odors

including carbon monoxide from migrating into the living space.

• If air-moving equipment or ductwork is located in spaces containing fuel

burning appliances such as water heaters or boilers - all joints, seams,

and openings in the equipment and duct must also be sealed to prevent

depressurization of the space and possible migration of combustion

byproducts including carbon monoxide into the living space.

Improper installation, or installation not made in accordance with the

Underwriters Laboratory (UL) certification or these instructions, can result

in unsatisfactory operation and/or dangerous conditions and are not covered by the unit warranty.

In compliance with recognized codes, it is recommended that an auxiliary

drain pan be installed under all evaporator coils or units containing evaporator coils that are located in any area of a structure where damage to the

building or building contents may occur as a result of an overflow of the

coil drain pan or a stoppage in the primary condensate drain piping. See

accessories section of these instructions for auxiliary horizontal overflow

pan information (model RXBM).

WARNING

NOTICE

!

NOTICE

!

2.4 RECEIVING

Immediately upon receipt, all cartons and contents should be inspected for transit damage. Units with damaged cartons should be opened immediately. If damage is found, it

should be noted on the delivery papers, and a damage claim filed with the last carrier.

• After unit has been delivered to job site, remove carton taking care not to damage

unit.

• Check the unit rating plate for unit size, electric heat, coil, voltage, phase, etc. to be

sure equipment matches what is required for the job specification.

• Read the entire instructions before starting the installation.

• Some building codes require extra cabinet insulation and gasketing when unit is

installed in attic applications.

• If installed in an unconditioned space, apply caulking around the power wires, control

wires, refrigerant tubing and condensate line where they enter the cabinet. Seal the

power wires on the inside where they exit conduit opening. Caulking is required to

pre-vent air leakage into and condensate from forming inside the unit, control box,

and on electrical controls.

• Install the unit in such a way as to allow necessary access to the coil/filter rack and

blower/control compartment.

• Install the unit in a level position to ensure proper condensate drainage. Make sure

unit is level in both directions within 1/8”.

• Install the unit in accordance with any local code which may apply and the national

codes. Latest editions are available from: “National Fire Protection Association, Inc.,

Batterymarch Park, Quincy, MA 02269.” These publications are:

• ANSI/NFPA No. 70-(Latest Edition) National Electrical Code.

• NFPA90A Installation of Air Conditioning and Ventilating Systems.

• NFPA90B Installation of warm air heating and air conditioning systems.

• The equipment has been evaluated in accordance with the Code of Federal

Regulations, Chapter XX, Part 3280.

8

Page 9

2.5 CLEARANCES

41/8

31/16

13/16

11/8

11/16

13/8

213/16

51/4

53/8

515/16

• All units are designed for “0” inches clearance to combustible material on all cabinet

surfaces.

• Units with electric heat require a one inch clearance to combustible material for the

first three feet of supply plenum and ductwork.

• Some units require a combustible floor base depending on the heating kW. The following table should be used to determine these requirements.

Model Cabinet Size 17 21 24

Model Designation kW 15 18 20

Additionally, if these units are installed down-flow, a combustible floor base is

required. See Accessories for Combustible Floor Base RXHB-XX.

Units with electric heating kW equal to

not require a combustible floor base.

• Vertical units require clearance on at least one side of the unit for electrical connections. Horizontal units require clearance on either top or bottom for electrical connections. Refrigerant and condensate drain connections are made on the front of the unit.

(See Figure 4.)

• All units require 24 inches maximum access to the front of the unit for service.

• These units may be installed in either ventilated or nonventilated spaces.

FIGURE 4

DIMENSIONS FOR FRONT CONNECT COIL

or less than the values listed in the table do

3.0 APPLICATIONS

3.1 ZONING SYSTEMS

The manufacturer does not currently provide or support zoning. However, zoning systems

can be installed with a variable speed air-handler as long as the zoning equipment manufacturers specifications and installation instructions are met and followed.

The preferred zoning method is to use a “bypass” system which is properly installed for

maximum efficiency. In these systems, excess air is routed back through the system to

be used again – this is opposed to a “dump” system in which excess air is routed to a

zone where it is expected that the extra heat or cooling would be least noticed.

If installed as a “bypass” system, the installation must have an optional freeze stat

installed to prevent the coil from icing with excess bypass cooling. Also, if the zoning

equipment manufacturer provides a limit switch (usually provided by the zoning manufacturer), this limit must be installed in the system to prevent the furnace from overheating.

9

Page 10

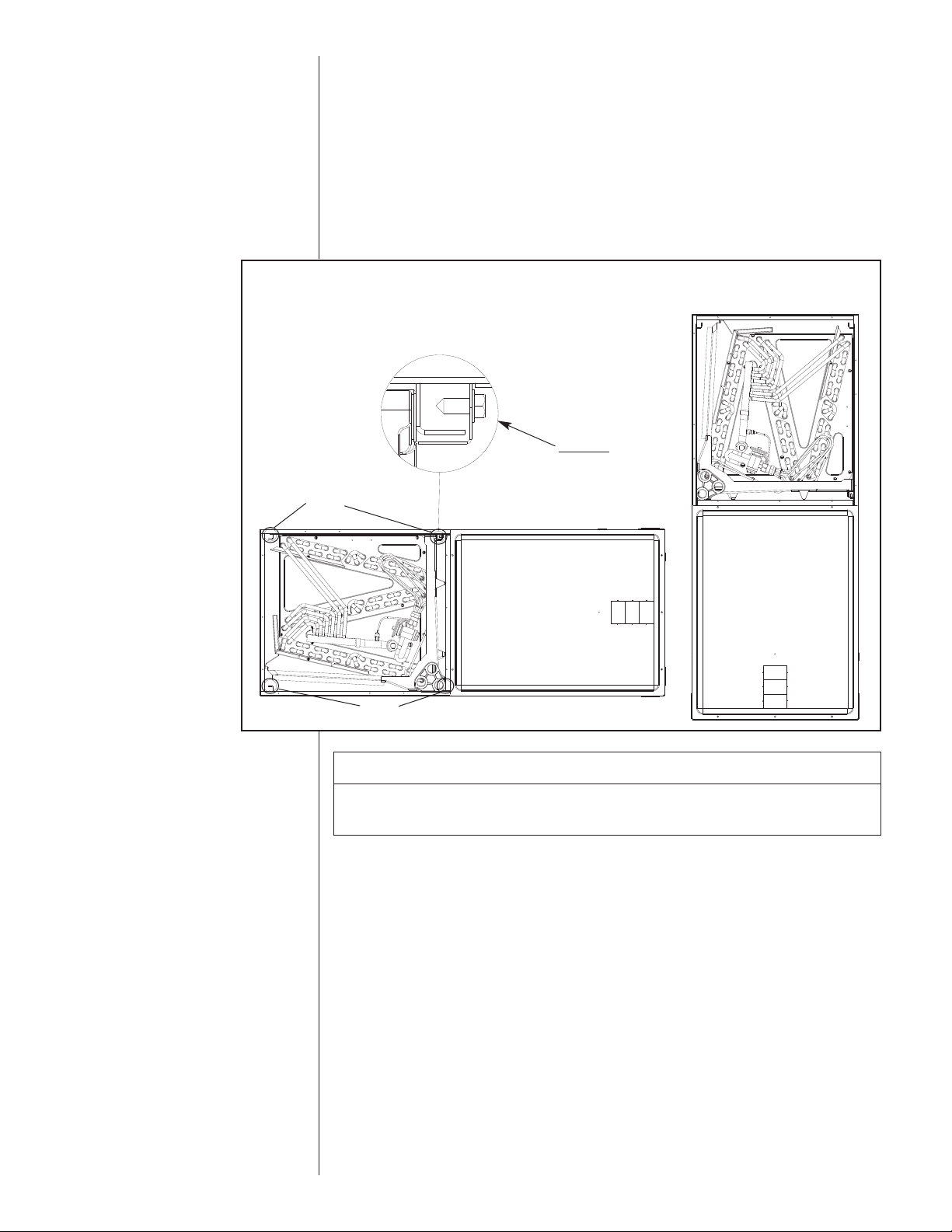

3.2 VERTICAL UPFLOW AND HORIZONTAL LEFT

The air handler unit is factory shipped for vertical upflow and horizontal left application.

• If return air is to be ducted, install duct flush with floor. Use fireproof resilient gasket 1/8

to 1/4 in. thick between duct, unit and floor. Set unit on floor over opening.

• Support along the length of the unit, on all units installed horizontally. Do not support

or suspend unit from both ends without support in the center of the cabinet. If unit is

to be supported or suspended from corners, run two reinforcing rails length of unit

and support or suspend from reinforcing rails.

• Secondary drain pan kits RXBM- are required when the unit is configured for the horizontal left position over a finished ceiling and/or living space. (See Section 16.0:

Accessories - Kits - Parts.)

FIGURE 5

VERTICAL DOWNFLOW & HORIZONTAL RIGHT APPLICATIONS

DETAIL A

ENSURE THE RETAIN-

ING CHANNEL IS FULLY

ENGAGED WITH THE

RAILS

COIL RAIL.

RAILS

CAUTION

Horizontal units must be configured for right hand air supply. Horizontal drain

pan must be located under indoor coil. Failure to use the drain pan can result

in property damage.

3.3 VERTICAL DOWNFLOW AND HORIZONTAL RIGHT

Conversion to Vertical Downflow/Horizontal Right: A vertical upflow unit may be converted to vertical downflow/horizontal right. (See Figure 5.) Remove the door and indoor

coil.

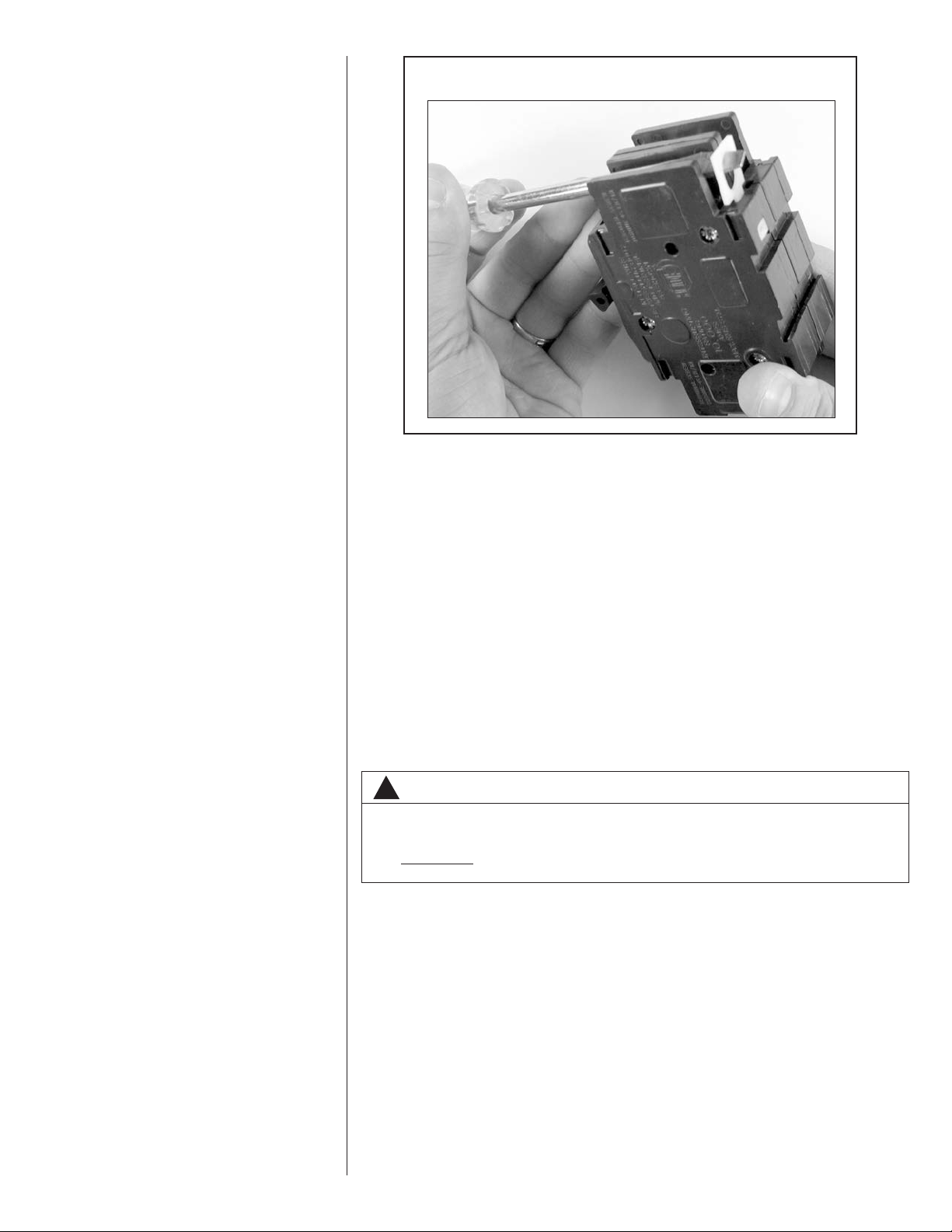

IMPORTANT: To comply with certification agencies and the National Electric Code for

horizontal right application, the circuit breaker(s) on field-installed electric heater kits

must be re-installed per procedure below so that the breaker switch “on” position and

marking is up and, “off” position and marking is down.

- To turn breaker(s): Rotate one breaker pair (circuit) at a time starting with the one on the

right. Loosen both lugs on the load side of the breaker. Wires are bundles with wire ties,

one bundle going to the right lug and one bundle going to the left lug.

- Using a screwdriver or pencil, lift white plastic tab with hole away from breaker until

breaker releases from mounting opening (see Figure 6).

- With breaker held in hand, rotate breaker so that “on” position is up, “off” position is down

with unit in planned vertical mounting position. Insert right wire bundle into top right

breaker lug, ensuring all strands of all wires are inserted fully into lug, and no wire insulation is in lug.

10

Page 11

FIGURE 6

ROTATING CIRCUIT BREAKER

- Tighten lug as tight as possible while holding circuit breaker. Check wires and make sure

each wire is secure and none are loose. Repeat for left wire bundle in left top circuit

breaker lug.

- Replace breaker by inserting breaker mounting tab opposite white pull tab in opening,

hook mounting tab over edge in opening.

- With screwdriver or pencil, pull white tab with hole away from breaker while setting that

side of breaker into opening. When breaker is in place, release tab, locking circuit breaker into location in opening.

- Repeat above operation for remaining breaker(s) (if more than one is provided).

- Replace single point wiring jumper bar, if it is used, on line side of breaker and tighten

securely.

- Double check wires and lugs to make sure all are secure and tight. Check to make sure

unit wiring to circuit breaker load lugs match that shown on the unit wiring diagram.

DRIP LOOP: When installing the unit in down-flow or horizontal-right positions, make sure

that the wires coming from the motor form a proper drip loop. This allows water to cascade

off the lowest point of the wiring before it enters the motor head. This may require cutting

the wire tie and installing a new wire tie to form this loop.

!

WARNING

The RXHB-17, RXHB-21, or RXHB-24 combustible floor base is required when

certain units are applied downflow on combustible flooring. Failure to use the

base can cause a fire resulting in property damage, personal injury or death.

See clearances for units requiring a combustible floor base. See the accessory

section in this manual for combustible floor base RXHB-.

• Rotate unit into the downflow position, with the coil compartment on top and the blower compartment on bottom.

• The set of coil rails must be moved for vertical down-flow and horizontal right application. Remove the coil rail from the factory configuration (6 screws in all). Fastener clearance holes will need to be drilled in the cabinet sides (proper hole locations are marked

with “dimples” for this purpose). Note that the shorter (no notch) coil rail must be mounted on the left-hand side to provide clearance for the drain pan condensate connection

boss.

• Reinstall the indoor coil 180° from original position. Ensure the retaining channel is fully

engaged with the coil rail. (See Figure 5, Detail A.)

• Secondary drain pan kits RXBM- are required when the unit is configured for the horizontal right position over a finished ceiling and/or living space. (See Section 16.0:

Accessories - Kits - Parts.)

IMPORTANT: Units cannot be installed horizontally laying on or suspended from the

back of the unit.

11

Page 12

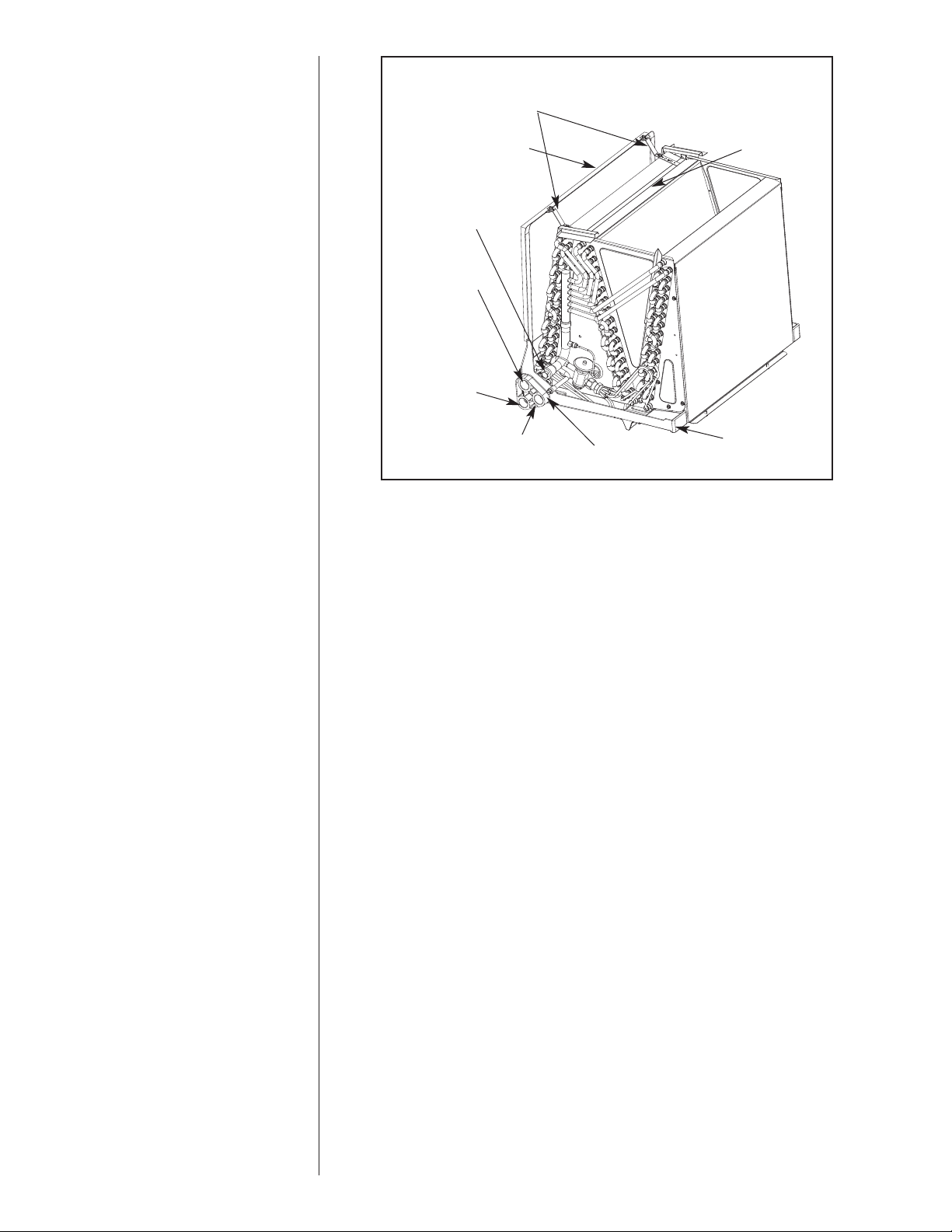

FIGURE 7

INDOOR COIL AND DRAIN PAN SET-UP

STRAPS

HORIZONTAL ADAPTER

VAPOR LINE

CONNECTION

AUXILIARY

HORIZONTAL

DRAIN

CONNECTION

PRIMARY

DRAIN

CONNECTION

UPFLOW/DOWNFLOW

DRAIN CONNECTION

KIT

AUXILIARY

LIQUID LINE

CONNECTION

TOP AIR STOP

VERTICAL

DRAIN PAN

ST-A1213-01

3.4 INSTALLATION IN AN UNCONDITIONED SPACE

The exterior cabinet of an air handler has a greater risk of sweating when installed in an

unconditioned space than when it is installed in the conditioned space. This is primarily

due to the temperature of the conditioned air moving through the air handler and the air

circulating around the unit where it is installed. For this reason, we recommend the following for all air handler applications, but special attention should be paid to those

installed in unconditioned spaces:

• Duct sizing and airflow are critical and based on the equipment selected

• Supply and return duct attachment: If other than the factory flanges are used, the

attachment of ducting must be insulated and tight to prevent sweating.

• No perimeter supply flanges are provided. If a full perimeter supply duct is used, it is

the responsibility of the installer to provide duct flanges as needed, to secure and seal

the supply duct to prevent air leakage and the sweating that will result.

• All wire penetrations should be sealed. Take care not to damage, remove or compress insulation in those cases.

• In some cases, the entire air handler can be wrapped with insulation. This can be

done as long as the unit is completely enclosed in insulation, sealed and service

access is provided to prevent accumulation of moisture inside the insulation.

• As required, use a secondary pan that will protect the structure from excessive sweating or a restricted coil drain line.

• If a heater kit is installed, be sure the breaker or disconnect cover is sealed tightly to

the door panel.

12

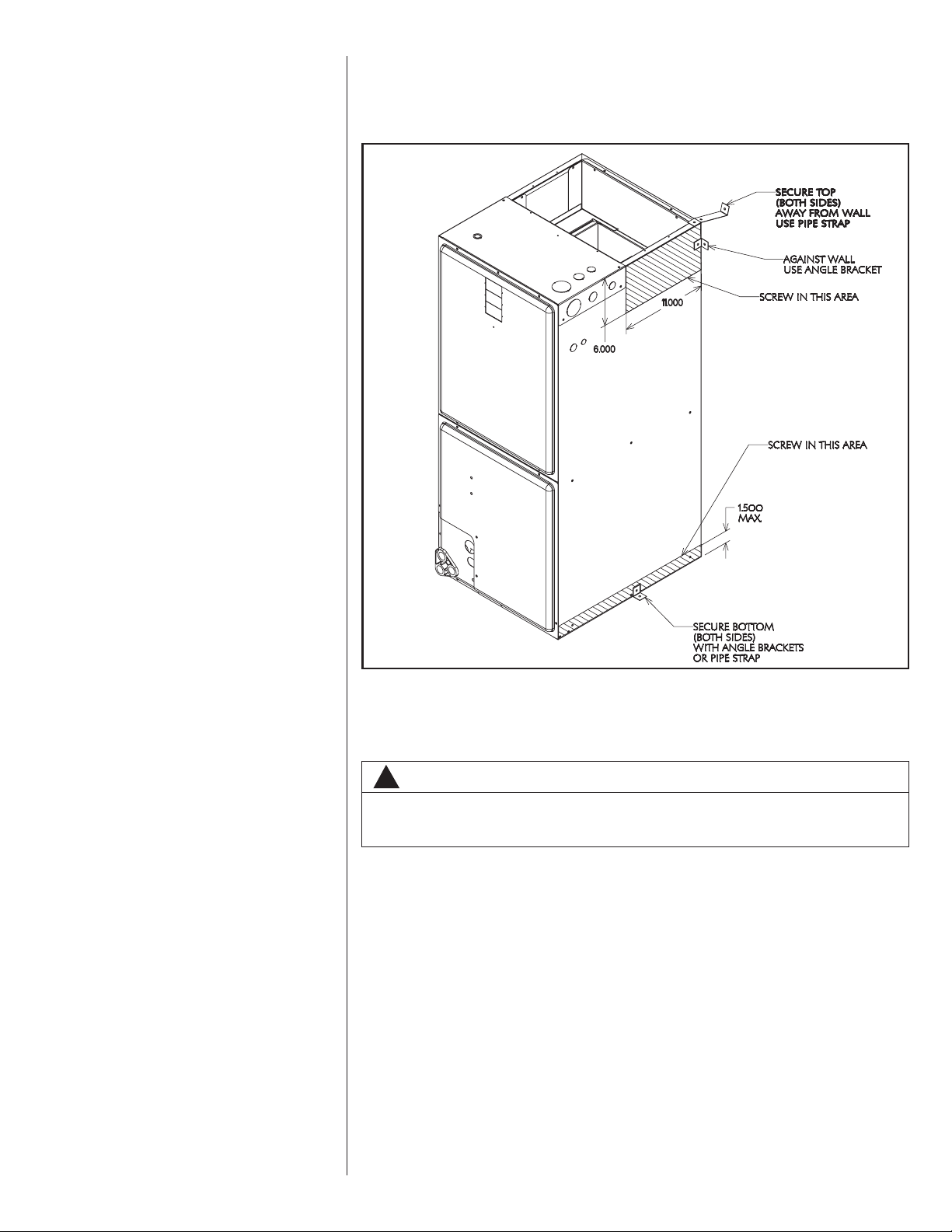

3.5 INSTALLATION IN MOBILE/MANUFACTURED HOMES

1. Air handler must be secured to the structure using “L” brackets or pipe strap.

2. Allow a minimum of 24 inches (610 mm) front clearance required to access doors.

3. Recommended method for securing air handler:

A. If air handler is against the wall, secure top of air handler to wall stud using two

16ga thick angle brackets one on each side. Attach brackets with No. 10 self-tap-

1

⁄2 long screws to air handler and use 5⁄16 lag screws 11⁄2 long to wall stud.

ping

Secure bottom of unit with two 16ga “L” brackets with No. 10 self-tapping

screws to air handler and use

5

⁄16 lag screws 11⁄2 long to floor.

1

⁄2 long

Page 13

B. If air handler is away from wall attach pipe strap to top of air handler using No. 10

1

⁄2 long self-tapping screws on both sides. Angle strap down and away from back

of air handler, remove all slack, and fasten to wall stud of structure using

screws 1

self-tapping screws to air handler and use

FIGURE 8

1

⁄2 long. Secure bottom of unit with two 16ga “L” brackets with No. 10

5

⁄16 lag screws 11⁄2 long to floor.

5

⁄16 lag

ST-A-1193-01

4.0 ELECTRICAL WIRING

Field wiring must comply with the National Electric Code (C.E.C. in Canada) and any

applicable local ordinance.

!

WARNING

Disconnect all power to unit before installing or servicing. More than one disconnect switch may be required to de-energize the equipment. Hazardous voltage can cause severe personal injury or death.

4.1 POWER WIRING

It is important that proper electrical power is available for connection to the unit model

being installed. See the unit nameplate, wiring diagram and electrical data in the installation instructions.

• If required, install a branch circuit disconnect of adequate size, located within sight of,

and readily accessible to the unit.

• IMPORTANT: After the Electric Heater is installed, units may be equipped with one,

two, or three 60 amp. circuit breakers. These breaker(s) protect the internal wiring in

the event of a short circuit and serve as a disconnect. Circuit breakers installed within

the unit do not provide over-current protection of the supply wiring and therefore may

be sized larger than the branch circuit protection.

• Supply circuit power wiring must be 75°C minimum copper conductors only. See

Electrical Data in this section for ampacity, wire size and circuit protector requirement.

Supply circuit protective devices may be either fuses or “HACR” type circuit breakers.

7

• Power wiring may be connected to either the right, left side or top. Three

31

/32” dia. concentric knockouts are provided for connection of power wiring to unit.

1

• Power wiring is connected to the power terminal block(s) in unit control compartment.

/8”, 13/32”,

13

Page 14

4.2 COPPER WIRE SIZE - AWG. (3% VOLTAGE DROP)

S

L

U

P

P

L

Y

W

I

R

E

200 [61]

E

150 [46]

N

100 [30]

G

50 [15]

T

H

F

E

E

T

12

12

14

14

15

10

10

12

12

20

8

8

8

6

10

10

10

10

25

8

10

8

10

8

30

35

NOTE: WIRE BASED ON COPPER CONDUCTORS 75°C MINIMUM RATING.

FOR MORE THAN 3 CONDUCTORS IN A RACEWAY OR CABLE, SEE

N.E.C. FOR DERATING THE AMPACITY OF EACH CONDUCTOR.

6

8

6

8

8

8

8

40

45

SUPPLY CIRCUIT AMPACITY

4.3 CONTROL WIRING

IMPORTANT: Class 2 low voltage control wire should not be run in conduit with power

wiring and must be separated from power wiring, unless Class 1 wire of proper voltage

rating is used.

• Low voltage control wiring should be 18 AWG color-coded (105°C minimum). For

lengths longer than 100 ft., 16 AWG wire should be used.

• Low voltage control connections are made by extending wires from top of air handler

using wire nuts.

• See wiring diagrams attached to indoor and outdoor sections to be connected

• Do not leave excess field control wiring inside unit, pull excess control wire to outside

of unit and provide strain relief for field control wiring on inside of cabinet at point

wiring penetrates cabinet.

• Make sure, after installation, separation of control wiring and power wiring has been

maintained.

50

6

4

4

3

3

2

2

1

0

6

6

4

4

3

3

2

6

6

4

4

3

6

6

4

70

4

80

60

90

3

3

3

100

2

2

110

1

1

1

125

0

0

0

150

00

00

00

00

175

FIELD WIRE SIZE FOR 24 VOLT THERMOSTAT CIRCUITS

SOLID COPPER WIRE - AWG.

3.0

2.5

2.0

Thermostat Load - Amps

(1) Wire length equals twice the run distance.

NOTE: Do not use control wiring smaller than No. 18 AWG between thermostat and outdoor unit.

16

16

18

50

14

14

16

100

12

12

14

150

200

Length of Run - Feet (1)

10

12

12

10

10

12

250

300

10

10

10

14

Page 15

w

W2

G

W1

B

ODD

C

R

Air Handler

G

Y

C

R

Single-Stage A/C The rmos tat

A/C Outdoor Unit

Y

C

Y2

Y

Field Installed

Line Voltage

-

WIRING INFORMATIO N

Factory Standard

-

W/BL

G/BK

Y

W/BK

BL

G/Y

BR

R

Y/BL

W2

G

Y

W1

B

ODD

C

R

Air Handler

G

Y

C

R

Single-Stage A/C The rmostat

A/C Outdoor Unit

Y

C

Humidistat

Y2

Field Installed

Line Voltage

-

WIRING INFORMATIO N

Factory Standard

-

W

W/BL

G/BK

Y

W/BK

BL

G/Y

BR

R

Y/BL

W2

G

Y

W1

B

ODD

C

R

Air Handler

C

R

Two-Stage A/C Thermostat

A/C Outdoor Unit

Y

C

W

G

W2

Y

Y2

Y2

D

Field Installed

Line Voltage

-

WIRING INFORMATION

Factory Standard

-

W/BL

G/BK

Y

W/BK

BL

G/Y

BR

R

Y/BL

*

B

W2

G

Y

W1

B

ODD

C

R

Air Handler

Y

G

W2

E

Heat Pump Thermostat

Heat Pump

Outdoor Unit

Y

B

C

R

R

D

C

Y

Field Installed

Line Voltage

-

WIRING INFORMATION

Factory Standard

-

W/BL

G/BK

Y

W/BK

G/Y

BR

BL

R

Y/BL

*

B

W2

G

Y

W1

B

ODD

C

R

Air Handler

Y

G

W2

E

Heat Pump Thermostat

Heat Pump

Outdoor Unit

Y

B

Humidistat

C

R

R

D

C

Y2

Field Installed

Line Voltage

-

WIRING INFORMATION

Factory Standard

-

W/BL

G/BK

Y

W/BK

BL

G/Y

BR

R

Y/BL

*

B

W2

G

Y

W1

B

ODD

C

R

Air Handler

Y2

G

W

W2

Two-Stage Heat Pump Thermostat

Heat Pump

Outdoor Unit

Y

B

C

R

R

D

C

Y1

Y2

Field Installed

Line Voltage

-

WIRING INFORMATION

Factory Standard

-

W/BL

G/BK

Y

W/BK

BL

G/Y

BR

R

Y/BL

*

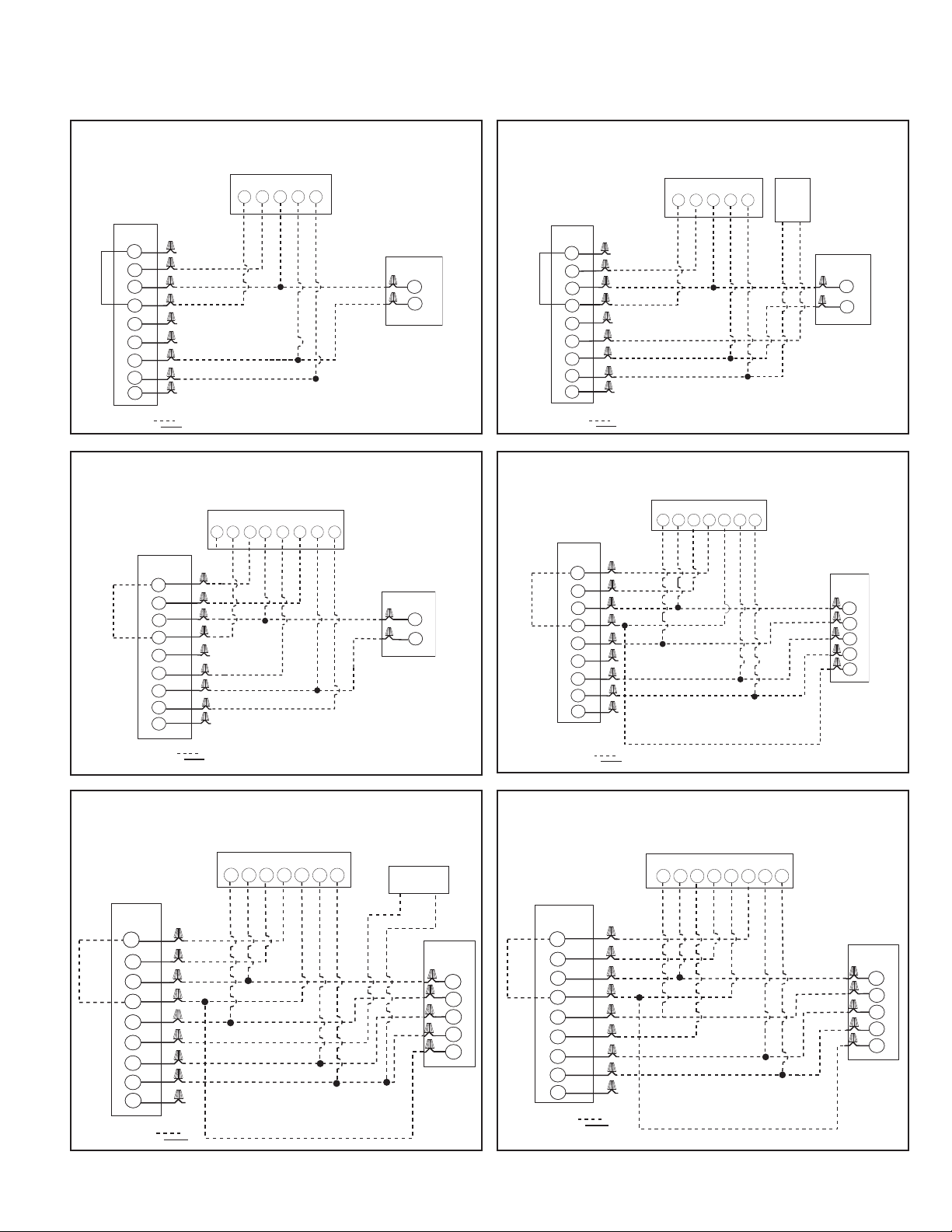

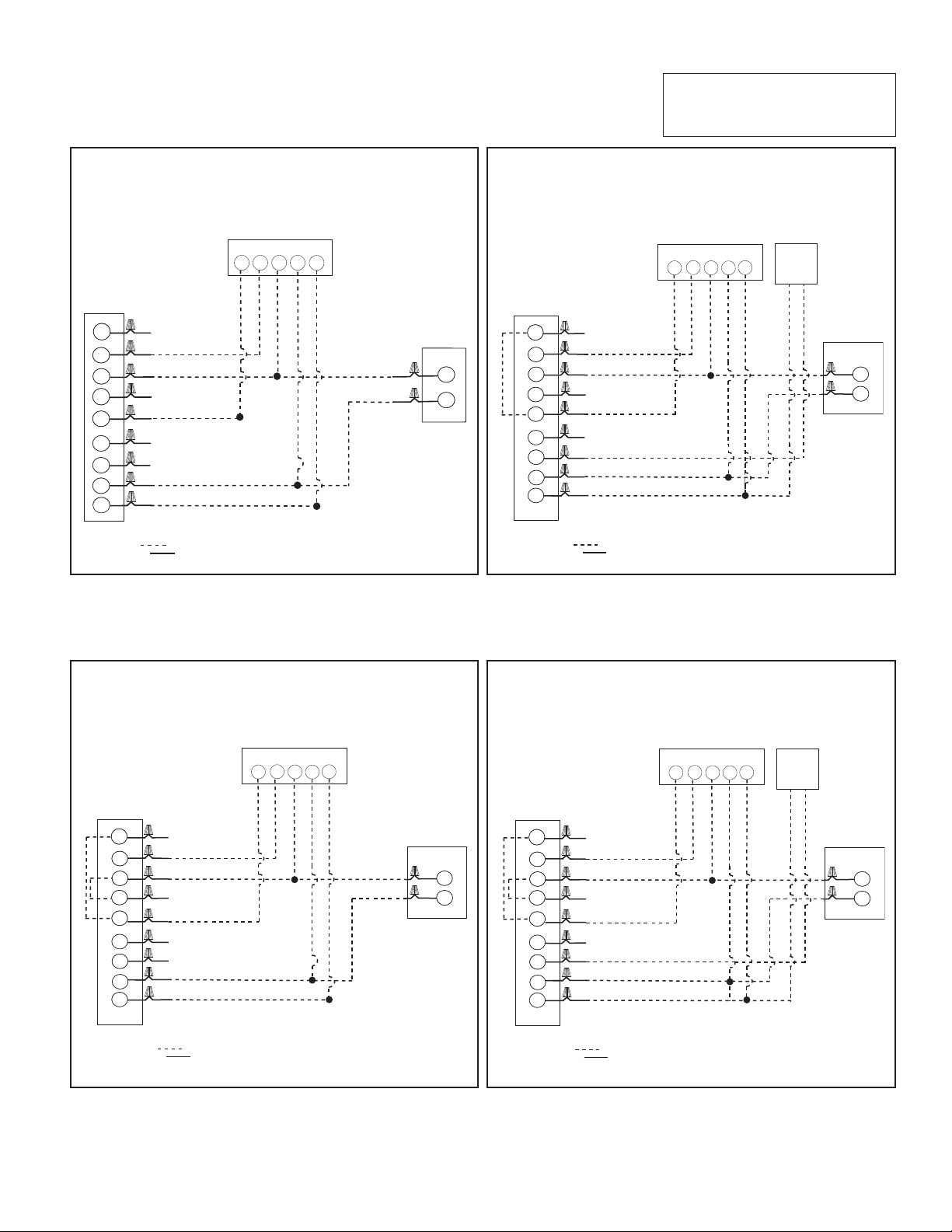

4.4 Typical Thermostat Wiring Diagrams (-)H1V

NOTE: These low voltage application diagrams are generic. Your indoor/ outdoor

units may not have all the characteristics shown or may not wire exactly as shown.

Refer to the diagrams and information sent with your indoor/outdoor sections.

BK – BLACK G – GREEN PR – PURPLE Y – YELLOW

BR – BROWN GY – GRAY R – RED

BL – BLUE O – ORANGE W – WHITE

WIRE COLOR CODE

FIGURE 9

TYPICAL THERMOSTAT: STRAIGHT COOLING WITH ELECTRIC

HEAT

FIGURE 11

TYPICAL THERMOSTAT: STRAIGHT COOLING WITH ELECTRIC

HEAT USING A TWO-STAGE FOR DEHUMIDIFYING THERMOSTAT

FIGURE 10

TYPICAL THERMOSTAT: STRAIGHT COOLING WITH ELECTRIC

HEAT AND USING A HUMIDISTAT FOR DEHUMIDIFICATION

FIGURE 12

TYPICAL THERMOSTAT: HEAT PUMP WITH ELECTRIC HEAT

*When using 13kW and higher, it is recommitted to jump

W1 and W2 together for maximum temperature rise.

FIGURE 13

TYPICAL THERMOSTAT: HEAT PUMP WITH ELECTRIC HEAT

AND USING A HUMIDISTAT FOR DEHUMIDIFICATION

*When using 13kW and higher, it is recommitted to jump W1 and W2 together for maximum temperature rise.

*When using 13kW and higher, it is recommitted to jump W1 and

W2 together for maximum temperature rise.

FIGURE 14

TYPICAL THERMOSTAT: HEAT PUMP WITH ELECTRIC HEAT

USING A TWO-STAGE THERMOSTAT FOR DEHUMIDIFICATION

*When using 13kW and higher, it is recommitted to jump W1 and W2 together for

maximum temperature rise.

15

Page 16

W2

W1

C

G

Y1

Typical Two-Stage Thermostat

(-)ARL/(-)ASL

Condensing

Unit

Y2

C

R

Y2

Field Installed

Line Voltage

-

WIRING INFORMATION

Factory Standard

-

ODD

R

Y1

Y2

G

W2

R

Y1

C

L

Y

Y/BL

R

BR

W/R

W1

*

W2

W1

C

G

Y1

Typical Two-Stage Thermostat

(-)ARL/(-)ASL

Condensing

Unit

Y2

C

R

Y2

Field Installed

Line Voltage

-

WIRING INFORMATION

Factory Standard

-

ODD

R

Y1

Y2

G

W2

R

Y1

C

L

Y

Y/BL

R

BR

W/R

Humidistat

W1

*

W2

W1

C

G

Y1

Typical Two-Stage Thermostat

(-)ARL/(-)ASL

Condensing

Unit

Y2

C

R

Y2

Field Installed

Line Voltage

-

WIRING INFORMATION

Factory Standard

-

ODD

R

Y1

Y2

G

W2

R

Y1

C

L

Y

Y/BL

R

BR

W/R

DHM

W1

*

W2

W1

C

G

Y1

Typical Two-Stage Thermostat

(-)ARL/(-)ASL

Condensing

Unit

Y2

C

R

Y2

Field Installed

Line Voltage

-

WIRING INFORMATION

Factory Standard

-

ODD

R

Y1

Y2

G

W2

R

Y1

C

L

Y

Y/BL

R

BR

W/R

DHM

L

W1

*

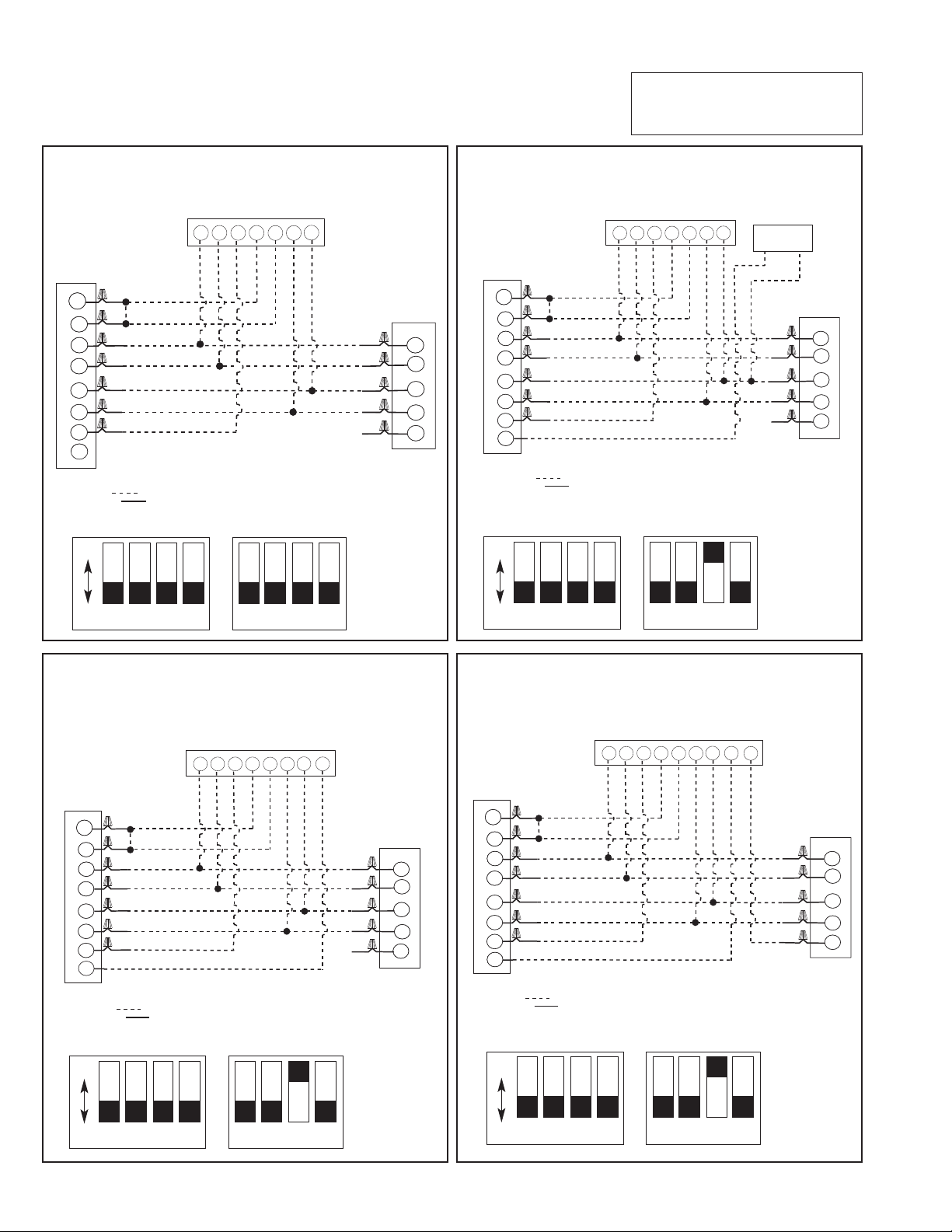

4.4 Typical Thermostat Wiring Diagrams (-)H2V

BK – BLACK G – GREEN PR – PURPLE Y – YELLOW

WIRE COLOR CODE

BR – BROWN GY – GRAY R – RED

BL – BLUE O – ORANGE W – WHITE

FIGURE 15

TYPICAL 2-STAGE THERMOSTAT: 2-STAGE CONDENSING UNIT

WITH ELECTRIC HEAT

*When using 13Kw and higher, it is recommitted to jump

W1 and W2 together for maximum temperature rise.

DIP SWITCH POSITIONS

ON

OFF

S1

S2

S3

S4

S5

S6

S7

S8

FIGURE 16

TYPICAL TWO-STAGE THERMOSTAT: 2-STAGE CONDENSING

UNIT WITH ELECTRIC HEAT USING A HUMIDISTAT FOR

DEHUMIDIFICATION*.

*When using 13Kw and higher, it is recommitted to jump

W1 and W2 together for maximum temperature rise.

*See Section 5.15 for proper DIP switch selection.

DIP SWITCH POSITIONS

ON

OFF

S1

S2

S3

S4

S5

S6

S7

S8

FIGURE 17

TYPICAL TWO-STAGE THERMOSTAT: 2-STAGE CONDENSING UNIT

WITH ELECTRIC HEAT USING A TWO-STAGE THERMOSTAT WITH

DEHUMIDIFICATION*

16

DIP SWITCH POSITIONS

ON

OFF

S1

S2

S3

*When using 13Kw and higher, it is recommitted to jump

W1 and W2 together for maximum temperature rise.

S4

S5

S6

S7

S8

*See Section 5.15 for proper DIP switch selection.

FIGURE 18

2-STAGE CONDENSING UNIT WITH ELECTRIC HEAT USING A TWOSTAGE THERMOSTAT WITH DEHUMIDIFICATION* AND A MALFUNCTION LIGHT

*When using 13Kw and higher, it is recommitted to jump

W1 and W2 together for maximum temperature rise.

*See Section 5.15 for proper DIP switch selection.

DIP SWITCH POSITIONS

ON

OFF

S1

S2

S3

S4

S5

S6

S7

S8

Page 17

W2

C

R

Single-Stage A/C Thermostat

C

-Field Installed

Line Voltage

WIRING INFORMATION

-Factory Standard

ODD

B

Y1

G

R

Y

C

W1

G

W

Y

W/BL

G/BK

Y

W/BK

BL

G/Y

BR

R

Y2

Y/BL

G

W2

C

R

Single-Stage A/C Thermostat

A/C Outdoor Unit

C

Y

Field Installed

Line Voltage

-

WIRING INFORMATION

Factory Standard

-

ODD

B

Y1

W

Y

R

C

Y

W/BL

Humidistat

G

W1

G/BK

W/BK

BL

G/Y

BR

R

Y2

Y/BL

G

W2

C

R

Single-Stage A/C Thermostat

A/C Outdoor Unit

C

Y

Field Installed

Line Voltage

-

WIRING INFORMATION

Factory Standard

-

ODD

B

Y1

W

Y

R

C

Y

W/BL

G

W1

G/BK

W/BK

BL

G/Y

BR

R

Y2

Y/BL

G

W2

C

R

Single-Stage A/C Thermostat

A/C Outdoor Unit

C

Y

Field Installed

Line Voltage

-

WIRING INFORMATION

Factory Standard

-

ODD

B

Y1

W

Y

R

C

Y

W/BL

Humidistat

G

W1

G/BK

W/BK

BL

G/Y

BR

R

Y2

Y/BL

4.4 Typical Thermostat Wiring Diagrams (-)H2V - continued

WIRE COLOR CODE

BK – BLACK G – GREEN PR – PURPLE Y – YELLOW

BR – BROWN GY – GRAY R – RED

BL – BLUE O – ORANGE W – WHITE

FIGURE 19

TYPICAL SINGLE-STAGE THERMOSTAT: SINGLE STAGE STRAIGHT

COOLING WITH ELECTRIC HEAT

1STSTAGE AIR FLOW

FIGURE 20

TYPICAL SINGLE-STAGE THERMOSTAT: SINGLE STAGE STRAIGHT

COOLING WITH ELECTRIC HEAT AND USING A HUMIDISTAT FOR

DEHUMIDIFICATION

1STSTAGE AIR FLOW

FIGURE 21

TYPICAL SINGLE-STAGE THERMOSTAT: SINGLE STAGE STRAIGHT

COOLING WITH ELECTRIC HEAT

2ND STAGE AIR FLOW

FIGURE 22

SINGLE STAGE STRAIGHT COOLING WITH ELECTRIC HEAT AND

USING A HUMIDISTAT FOR DEHUMIDIFICATION

2ND STAGE AIR FLOW

17

Page 18

4.5 GROUNDING

!

WARNING

The unit must be permanently grounded. Failure to do so can result in electrical shock causing personal injury or death.

• Grounding may be accomplished by grounding metal conduit when installed in accordance with electrical codes to the unit cabinet.

• Grounding may also be accomplished by attaching ground wire(s) to ground lug(s)

provided in the unit wiring compartment.

• Ground lug(s) are located close to wire entrance on left side of unit (upflow). Lug(s)

may be moved to marked locations near wire entrance on right side of unit (upflow), if

alternate location is more convenient.

• Use of multiple supply circuits require grounding of each circuit to lug(s) provided in

unit.

4.6 BLOWER MOTOR ELECTRICAL DATA (-)H1V

MODEL

SIZE

(-)H1V

2417ST 208/240 1 60 1/3 300-1100 2 2.2 3 15

3617ST 208/240 1 60 1/2 300-1100 2 3.1 4.0 15

3621MT/4821ST 208/240 1 60 3/4 300-1100 2 4.0 5.0 15

6024ST 208/240 1 60 3/4 300-1100 2 4.4 6 15

VOLTAGE

SPEEDSRPMHPHERTZPHASE

CIRCUIT

AMPS

MINIMUM

CIRCUIT

AMPACITY

MAXIMUM

CIRCUIT

PROTECTOR

4.7 BLOWER MOTOR ELECTRICAL DATA (-)H2V

(-)H2V HP Voltage Phase Hertz RPM

2421HT 1/3 208/230 1 60 300-1100 1.7 4.0 15

3624HT 3/4 208/230 1 60 300-1100 4.9 9.0 15

4824HT 3/4 208/230 1 60 300-1100 4.9 9.0 15

6024HT 3/4 208/230 1 60 300-1100 4.9 9.0 15

Circuit

AMPS

Minimum

Circuit

Ampacity

Max. Circuit

Protector

18

Page 19

4.8 CONVENTIONAL 24VAC THERMOSTAT CONTROL WIRING (-)H2V

The (-)ARL/(-)ASL-series of condensing units allow the installer to use conventional

24VAC control wiring and a conventional thermostat for proper unit operation.

IMPORTANT: The preferred method of unit installation and operation is by the Comfort

2

Control

tic information is not available when the (-)ARL/(-)ASL unit is using a conventional thermostat. Reference section 7.1 Comfort Control

Thermostat control wiring requires a minimum of seven (7) wires for proper unit operation:

Optional wiring:

NOTE: W1 and W2 may be jumpered together to energize all the electric heat when a

call for electric heat is received if warmer supply air is desired.

NOTE: When using 24VAC thermostat control wiring, the serial communicating control

will ignore any inputs to Data wire 1 and Data wire 2.

IMPORTANT: Class 2 low voltage control wire should not be run in conduit with power

wiring and must be separated from power wiring, unless Class 1 wire of proper voltage

rating is used.

Low voltage control wiring should be 18 AWG color-coded (105°C minimum). For

lengths longer than 100 ft., 16 AWG wire should be used.

Low voltage control connections are made by extending wires from top of air handler

using wire nuts.

See wiring diagrams attached to indoor and outdoor sections to be connected

Do not leave excess field control wiring inside unit, pull excess control wire to outside of

unit and provide strain relief for field wiring on inside of cabinet where wiring penetrates

cabinet.

Make sure, after installation, separation of control wiring and power wiring has been

maintained.

System™, which allows access to the fault history of the system. This diagnos-

2

System™ Control Wiring.

R – 24VAC

C – 24VAC common

G – Constant Fan

W1 – First stage electric heat

W2 – Second stage electric heat

Y1 – First stage operation

Y2 – Second stage operation

ODD – On demand humidification

19

Page 20

4.9 ELECTRIC HEAT ELECTRICAL DATA (-)H1V

Installation of the UL Listed original equipment manufacturer provided heater kits listed in the following table is recommended for all auxiliary heating requirements.

HIGH KW ELECTRIC HEAT ELECTRICAL DATA: (-)H1V

AIR-HANDLER

MODEL

(-)H1V

2417ST 9.4/12.5 1/60 3-4.17 SINGLE 45.1/52.1 2.2 60/68 60/70

3617ST 10.8/14.4 1/60 3-4.8 SINGLE 51.9/60.0 3.1 69/79 70/80

3621MT

4821ST 7.2/9.6 1/60 2-4.8 MULTIPLE CKT 2 34.6/40.0 0.0 44/50 45/50

HEATER

MODEL

NO.

RXBH-1724?03J 2.25/3.0 1/60 1-3.0 SINGLE 10.8/12.5 2.2 17/19 20/20

RXBH-1724?05J 3.6/4.8 1/60 1-4.8 SINGLE 17.3/20.0 2.2 25/28 25/30

RXBH-1724?07J 5.4/7.2 1/60 2-3.6 SINGLE 26.0/30.0 2.2 36/41 40/45

RXBH-1724?10J 7.2/9.6 1/60 2-4.8 SINGLE 34.6/40.0 2.2 46/53 50/60

RXBH-1724A13J 3.1/4.2 1/60 1-4.17 MULTIPLE CKT 1 15.0/17.4 2.2 22/25 25/25

RXBH-1724A07C 5.4/7.2 3/60 3-2.4 SINGLE 15.0/17.3 2.2 22/25 25/25

RXBH-1724A10C 7.2/9.6 3/60 3-3.2 SINGLE 20.0/23.1 2.2 28/32 30/35

RXBH-1724A13C 9.4/12.5 3/60 3-4.17 SINGLE 26.1/30.1 2.2 36/41 40/45

RXBH-1724?03J 2.25/3.0 1/60 1-3.0 SINGLE 10.8/12.5 3.1 18/20 20/20

RXBH-1724?05J 3.6/4.8 1/60 1-4.8 SINGLE 17.3/20.0 3.1 26/29 30/30

RXBH-1724?07J 5.4/7.2 1/60 2-3.6 SINGLE 26.0/30.0 3.1 37/42 40/45

RXBH-1724?10J 7.2/9.6 1/60 2-4.8 SINGLE 34.6/40.0 3.1 48/54 50/60

RXBH-1724A13J 3.1/4.2 1/60 1-4.17 MULTIPLE CKT 1 15.0/17.4 3.1 23/26 25/30

RXBH-1724A15J 3.6/4.8 1/60 1-4.8 MULTIPLE CKT 1 17.3/20.0 3.1 26/29 30/30

RXBH-1724A18J 4.3/5.7 1/60 1-5.68 MULTIPLE CKT 1 20.5/23.6 3.1 30/34 30/35

RXBH-1724A07C 5.4/7.2 3/60 3-2.4 SINGLE 15.0/17.3 3.1 23/26 25/30

RXBH-1724A10C 7.2/9.6 3/60 3-3.2 SINGLE 20.0/23.1 3.1 29/33 30/35

RXBH-1724A13C 9.4/12.5 3/60 3-4.17 SINGLE 26.1/30.1 3.1 37/42 40/45

RXBH-1724A15C 10.8/14.4 3/60 3-4.8 SINGLE 30.0/34.6 3.1 42/48 45/50

RXBH-1724A18C 12.8/17.0 3/60 3-5.68 SINGLE 35.5/41.0 3.1 49/56 50/60

RXBH-1724?05J 3.6/4.8 1/60 1-4.8 SINGLE 17.3/20.0 4.0 27/30 30/30

RXBH-1724?07J 5.4/7.2 1/60 2-3.6 SINGLE 26.0/30.0 4.0 38/43 40/45

RXBH-1724?10J 7.2/9.6 1/60 2-4.8 SINGLE 34.6/40.0 4.0 49/55 50/60

RXBH-1724A15J 3.6/4.8 1/60 1-4.8 MULTIPLE CKT 1 17.3/20.0 4.0 27/30 30/30

RXBH-1724A18J 6.4/8.5 1/60 2-4.26 MULTIPLE CKT 1 30.8/35.4 4.0 44/50 45/50

RXBH-24A20J

(31⁄2, 4-ton only)

RXBH-24A25J 6.0/8.0 1/60 2-4.0 MULTIPLE CKT 1 28.8/33.3 4.0 42/47 45/50

(4-ton only) 6.0/8.0 1/60 2-4.0 MULTIPLE CKT 2 28.8/33.3 0.0 36/42 40/45

RXBH-1724A07C 5.4/7.2 3/60 3-2.4 SINGLE 15.0/17.3 4.0 24/27 25/30

RXBH-1724A10C 7.2/9.6 3/60 3-3.2 SINGLE 20.0/23.1 4.0 30/34 30/35

RXBH-1724A15C 10.8/14.4 3/60 3-4.8 SINGLE 30.0/34.6 4.0 43/49 45/50

RXBH-1724A18C 12.8/17.0 3/60 3-2.84 SINGLE 35.6/41.0 4.0 50/57 50/60

RXBH-24A20C*

(31⁄2, 4-ton only)

RXBH-24A25C*

(4-ton only)

HEATER

KW

208/240V

6.3/8.3 1/60 2-4.17 MULTIPLE CKT 2 30.1/34.7 0 38/44 40/45

9.4/12.5 1/60 3-4.17 SINGLE 45.1/52.1 3.1 61/69 70/70

6.3/8.3 1/60 2-4.17 MULTIPLE CKT 2 30.1/34.7 0 38/44 40/45

7.2/9.6 1/60 2-4.8 MULTIPLE CKT 2 34.6/40.0 0 44/50 45/50

12.8/17.0 1/60 3-5.68 SINGLE 61.6/70.8 3.1 81/93 90/100

8.5/11.3 1/60 2-5.68 MULTIPLE CKT 2 41.1/47.2 0 52/59 60/60

10.8/14.4 1/60 3-4.8 SINGLE 51.9/60.0 4.0 70/80 70/80

7.2/9.6 1/60 2-4.8 MULTIPLE CKT 2 34.6/40.0 0.0 44/50 45/50

12.8/17.0 1/60 4-4.26 SINGLE 61.6/70.8 4.0 82/94 90/100

6.4/8.5 1/60 2-4.26 MULTIPLE CKT 2 30.8/35.4 0.0 39/45 40/45

14.4/19.2 1/60 4-48 SINGLE 69.2/80 4.0 92/105 100/110

7.2/9.6 1/60 2-4.8 MULTIPLE CKT 1 34.6/40.0 4.0 49/55 50/60

18.0/24.0 1/60 6-4.0 SINGLE 86.4/99.9 4.0 113/130 125/150

6.0/8.0 1/60 2-4.0 MULTIPLE CKT 3 28.8/33.3 0.0 36/42 40/45

14.4/19.2 3/60 3-3.2 SINGLE 40.0/46.2 4.0 55/63 60/70

7.2/9.6 3/60 3-3.2 MULTIPLE CKT 1 20.0/23.1 4.0 30/34 30/35

7.2/9.6 3/60 3-3.2 MULTIPLE CKT 2 20.0/23.1 0.0 25/29 25/30

18.0/24.0 3/60 6-4.0 SINGLE 50.0/57.8 4.0 68/78 70/80

9.0/12.0 3/60 3-4.0 MULTIPLE CKT 1 25.0/28.9 4.0 37/42 40/45

9.0/12.0 3/60 3-4.0 MULTIPLE CKT 2 25.0/28.9 0.0 32/37 35/40

PH/HZ

NO.

ELEMENTS

- KW PER

TYPE SUPPLY

CIRCUIT

SINGLE CIRCUIT

MULTIPLE CIRCUIT

CIRCUIT

AMPS.

MOTOR

AMPACITY

MINIMUM

CIRCUIT

AMPACITY

MAXIMUM

CIRCUIT

PROTECTION

20

Page 21

4.9 ELECTRIC HEAT ELECTRICAL DATA: (-)H1V - continued

AIR-HANDLER

MODEL

(-)H1V

4824ST 6.0/8.0 1/60 2-4.0 MULTIPLE CKT 3 28.8/33.3 0 36/42 40/45

6024ST RXBH-24A30J 21.6/28.8 1/60 6-4.8 SINGLE 103.8/120. 4.4 136/156 150/175

HEATER

MODEL

NO.

RXBH-1724?05J 3.6/4.8 1/60 1-4.8 SINGLE 17.3/20.0 4.4 28/31 30/35

RXBH-1724?07J 5.4/7.2 1/60 2-3.6 SINGLE 26.0/30.0 4.4 38/43 40/45

RXBH-1724?10J 7.2/9.6 1/60 2-4.8 SINGLE 34.6/40.0 4.4 49/56 50/60

RXBH-1724A15J 10.8/14.4 1/60 3-4.8 SINGLE 51.9/60.0 4.4 71/81 80/90

RXBH-1724A15J

RXBH-1724A18J 12.8/17 1/60 4-4.26 SINGLE 61.6/70.8 4.4 83/94 90/100

RXBH-1724A18J

RXBH-24A20J 14.4/19.2 1/60 4-4.8 SINGLE 69.2/80 4.4 93/106 100/110

RXBH-24A20J

RXBH-24A25J 18.0/24.0 1/60 6-4.0 SINGLE 86.4/99.9 4.4 114/131 125/150

RXBH-24A25J 6.0/8.0 1/60 2-4.0 MULTIPLE CKT 2 28.8/33.3 0 36/42 40/45

(1800 CFM only)

RXBH-24A30J

(5-ton only) 7.2/9.6 1/60 2-4.8 MULTIPLE CKT 2 34.6/40.0 0 44/50 45/50

(1800 CFM only)

RXBH-1724A07C 5.4/7.2 3/60 3-2.4 SINGLE 15.0/17.3 4.4 25/28 25/30

RXBH-1724A10C 7.2/9.6 3/60 3-3.2 SINGLE 20.0/23.1 4.4 31/35 35/35

RXBH-1724A15C 10.8/14.4 3/60 3-4.8 SINGLE 30.0/34.6 4.4 43/49 45/50

RXBH-1724A18C 12.8/17.0 3/60 3-2.84 SINGLE 35.6/41.0 4.4 50/57 50/60

RXBH-24A20C* 7.2/9.6 3/60 3-3.2 MULTIPLE CKT 1 20.0/23.1 4.4 31/35 35/35

RXBH-24A25C* 18.0/24.0 3/60 6-4.0 SINGLE 50.0/57.8 4.4 68/78 70/80

RXBH-24A25C

RXBH-24A30C*

(1800 CFM only)

RXBH-24A30C

(5-ton only)

(1800 CFM only)

HEATER

KW

208/240V

3.6/4.8 1/60 1-4.8 MULTIPLE CKT1 17.3/20.0 4.4 28/31 30/35

7.2/9.6 1/60 2-4.8 MULTIPLE CKT 2 34.6/40.0 0 44/50 45/50

6.4/8.5 1/60 2-4.26 MULTIPLE CKT 1 30.8/35.4 4.4 44/50 45/50

6.4/8.5 1/60 2-4.26 MULTIPLE CKT 2 30.8/35.4 0 39/45 40/45

7.2/9.6 1/60 2-4.8 MULTIPLE CKT 1 34.6/40.0 4.4 49/56 50/60

7.2/9.6 1/60 2-4.8 MULTIPLE CKT 2 34.6/40.0 0 44/50 45/50

6.0/8.0 1/60 2-4.0 MULTIPLE CKT 1 28.8/33.3 4.4 42/48 45/50

7.2/9.6 1/60 2-4.8 MULTIPLE CKT 1 34.6/40.0 4.4 49/56 50/60

7.2/9.6 1/60 2-4.8 MULTIPLE CKT 3 34.6/40.0 0 44/50 45/50

14.4/19.2 3/60 3-3.2 SINGLE 40.0/46.2 4.4 56/64 60/70

7.2/9.6 3/60 3-3.2 MULTIPLE CKT 2 20.0/23.1 0 25/29 25/30

9.0/12.0 3/60 3-4.0 MULTIPLE CKT 1 25.0/28.9 4.4 37/42 40/45

9.0/12.0 3/60 3-4.0 MULTIPLE CKT 2 25.0/28.9 0 32/37 35/40

21.6/28.8 3/60 6-4.8 SINGLE 60.0/69.4 4.4 81/93 90/100

10.8/14.4 3/60 3-4.8 MULTIPLE CKT 1 30.0/34.7 4.4 43/50 45/50

10.8/14.4 3/60 3-4.8 MULTIPLE CKT 2 30.0/34.7 0 38/44 40/45

PH/HZ

NO.

ELEMENTS

- KW PER

TYPE SUPPLY

CIRCUIT

SINGLE CIRCUIT

MULTIPLE CIRCUIT

CIRCUIT

AMPS.

MOTOR

AMPACITY

MINIMUM

CIRCUIT

AMPACITY

PROTECTION

MAXIMUM

CIRCUIT

NOTES:

* Values only. No single point kit available.

• Electric heater BTUH - (heater watts + motor watts) x 3.414 (see airflow table for motor watts.)

• Supply circuit protective devices may be fuses or “HACR” type circuit breakers.

• Largest motor load is included in single circuit and multiple circuit 1.

• If non-standard fuse size is specified, use next size larger fuse size.

• J Voltage (230V) single phase air handler is designed to be used with single or three phase 230 volt electric heaters. In the case

of connecting 3-phase power to the air handler terminal block without the heater, bring only two leads to the terminal block. Cap,

insulate and fully secure the third lead.

• If the kit is listed under both single and multiple circuits, the kit is shipped from factory as multiple circuits. For single phase application, Jumper bar kit RXBJ-A21 and RXBJ-A31 can be used to convert multiple circuits to a single supply circuit. Refer to

Accessory Section for details.

• The airflow for continuous fan is set 50% of the cooling airflow.

• ?Heater kits connection type. A=Breaker B=Terminal Block C=Disconnect Pull Out

21

Page 22

4.10 ELECTRIC HEAT ELECTRICAL DATA (-)H2V

Installation of the UL Listed original equipment manufacturer provided heater kits listed in the table below is

recommended for all auxiliary heating requirements.

Model Size

(-)H2V

2421HT RXBH-1724?07J Single 208/240 1/60 5.4/7.2 26.0/30.0 1.7 35/40 35/40

3624HT RXBH-1724A15J MULTI. CKT 1 208/240 1/60 3.6/4.8 17.3/20.0 4.9 30/35 28/32

4824HT RXBH-1724A18J MULTI. CKT 1 208/240 1/60 6.4/8.5 30.8/35.4 4.9 45/60 45/51

6024HT RXBH-24A20J MULTI. CKT 1 208/240 1/60 7.2/9.6 34.6/40.0 4.9 50/60 50/57

Manufacturer

Model Number

RXBH-1724?05J Single 208/240 1/60 3.6/4.8 17.3/20.0 1.7 25/30 24/28

RXBH-1724?10J Single 208/240 1/60 7.2/9.6 34.6/40.0 1.7 50/60 46/53

RXBH-1724?05J Single 208/240 1/60 3.6/4.8 17.3/20.0 4.9 30/35 28/32

RXBH-1724?07J Single 208/240 1/60 5.4/7.2 26.0/30.0 4.9 40/45 39/44

RXBH-1724?10J Single 208/240 1/60 7.2/9.6 34.6/40.0 4.9 50/60 50/57

RXBH-1724A18J MULTI. CKT 1 208/240 1/60 6.4/8.5 30.8/35.4 4.9 45/60 45/51

RXBH-1724?05J Single 208/240 1/60 3.6/4.8 17.3/20.0 4.9 30/35 28/32

RXBH-1724?07J Single 208/240 1/60 5.4/7.2 26.0/30.0 4.9 40/45 39/44

RXBH-1724?10J Single 208/240 1/60 7.2/9.6 34.6/40.0 4.9 50/60 50/57

RXBH-1724A15J MULTI. CKT 1 208/240 1/60 3.6/4.8 17.3/20.0 4.9 30/35 28/32

RXBH-24A20J MULTI. CKT 1 208/240 1/60 7.2/9.6 34.6/40.0 4.9 50/60 50/57

RXBH-24A25J MULTI. CKT 1 208/240 1/60 6.0/8.0 29.0/33.3 4.9 45/50 43/48

(4-ton only) MULTI. CKT 2 208/240 1/60 6.0/8.0 29.0/33.3 0 40/45 37/42

RXBH-1724?07J Single 208/240 1/60 5.4/7.3 26.0/30.0 4.9 40/45 39/44

RXBH-1724?10J Single 208/240 1/60 5.4/7.2 26.0/30.0 4.9 40/45 39/44

RXBH-1724A15J MULTI. CKT 1 208/240 1/60 3.6/4.8 17.3/20.0 4.9 30/35 28/32

RXBH-1724A18J MULTI. CKT 1 208/240 1/60 6.4/8.5 30.8/35.4 4.9 45/60 45/51

RXBH-24A25J MULTI. CKT 2 208/240 1/60 6.0/8.0 29.0/33.3 0 40/45 37/42

RXBH-24A30J Single 208/240 1/60 21.6/28.8 103.8/120.0 4.9 136/156 150/175

RXBH-24A30J MULTI. CKT 2 208/240 1/60 2-4.8 34.6/40.0 0 44/50 45/50

Type Supply

Circuit

Single 208/240 1/60 10.8/14.4 51.9/60.0 4.9 80/90 72/82

MULTI. CKT 2 208/240 1/60 7.2/9.6 34.6/40.0 0 45/50 44/50

Single 208/240 1/60 12.8/17 61.6/70.8 4.9 90/100 84/95

MULTI. CKT 2 208/240 1/60 6.4/8.5 30.8/35.4 0 40/45 39/45

Single 208/240 1/60 10.8/14.4 51.9/60.0 4.9 80/90 72/82

MULTI. CKT 2 208/240 1/60 7.2/9.6 34.6/40.0 0 45/50 44/50

Single 208/240 1/60 12.8/17 61.6/70.8 4.9 90/100 84/95

MULTI. CKT 2 208/240 1/60 6.4/8.5 30.8/35.4 0 40/45 39/45

Single 208/240 1/60 14.4/19.2 69.2/80.0 4.9 100/110 93/107

MULTI. CKT 2 208/240 1/60 7.2/9.6 34.6/40.0 0 45/50 44/50

Single 208/240 1/60 18.0/24.0 87.0/99.9 4.9 125/150 115/132

MULTI. CKT 3 208/240 1/60 6.0/8.0 29.0/33.3 0 40/45 37/42

Single 208/240 1/60 10.8/14.4 51.9/60.0 4.9 80/90 72/82

MULTI. CKT 2 208/240 1/60 7.2/9.6 34.6/40.0 0 45/50 44/50

Single 208/240 1/60 12.8/17 61.6/70.8 4.9 90/100 84/95

MULTI. CKT 2 208/240 1/60 6.4/8.5 30.8/35.4 0 40/45 39/45

Single 208/240 1/60 14.4/19.2 69.2/80.0 4.9 100/110 93/107

MULTI. CKT 2 208/240 1/60 7.2/9.6 34.6/40.0 0 45/50 44/50

Single 208/240 1/60 18.0/24.0 87.0/99.9 4.9 125/150 115/132

MULTI. CKT 1 208/240 1/60 6.0/8.0 29.0/33.3 4.9 45/50 43/48

MULTI. CKT 3 208/240 1/60 6.0/8.0 29.0/33.3 0 40/45 37/42

MULTI. CKT 1 208/240 1/60 7.2/9.6 34.6/40.0 4.9 49/56 50/60

MULTI. CKT 3 208/240 1/60 7.2/9.6 34.6/40.0 0 44/50 45/50

Voltage PH/HZ

HeaterkWHeater

AMPS

Motor

Ampacity

Maximum

Circuit

Protection

Minimum

Circuit

Ampacity

NOTES:

• Supply circuit protective devices may be fuses or “HACR” type circuit breakers.

• Largest motor load is included in single circuit and multiple circuit 1.

• If non-standard fuse size is specified, use next size larger fuse size.

• J Voltage (230V) signal phase air handler is designed to be used with single or three phase 230 volt electric heaters. In the case of connecting

3-phase power to the air handler terminal block without the heater, bring only two leads to the terminal block. Cap, insulate and fully secure the

third lead.

• ?Heater Kit Connection Type A=Breaker B=Terminal Block C=Pullout Disconnect

22

Page 23

4.11 HEATER KIT SUPPLEMENTAL INFORMATION (-)H1V & (-)H2V

AIR CONDITIONING DIVISION

(-)HLA-HM4821JA

MARK HEATER INSTALLED/

L’APPAREIL DE CHAUFFAGE DE MARQUE A INSTALLE

If a heater

kit is listed

both

Single

and Multicircuit, the

kit is

shipped

as a Multicircuit and

will

require a

single

Only listed kits can be applied

point kit

Contractor

should “mark

or check” the

left column for

the kit installed

These are the

required maximum and minimum circuit

breaker sizes

for overcurrent

protection and

should not be

confused with

the size of the

breakers

installed in the

heater kit.

Heater Kit Supplemental Information: What allows the manufacturer to use standard Circuit Breakers

up to 60 amps inside the air handler, when using an approved Heater Kit?

National Electric Code (Section 424-22b) and our UL requirements allow us to subdivide heating element

circuits, of less than 48 amps, using breakers of not more than 60 amps and, additionally by, NEC 424-3b, a

rating not less than 125 percent of the load and NEC 424-22c, which describes the supplementary overcurrent protection required to be factory-installed within, or on the heater. The breakers in the heater kit are not,

and have never been, by NEC, intended to protect power wiring leading to the air handler unit. The breakers

in the heating kit are for short circuit protection. All internal unit wiring, where the breakers apply, has been

UL approved for short circuit protection.

Ampacity, (not breaker size), determines supply circuit wire size. The ampacity listed on the unit rating plate

and the Maximum and Minimum circuit breaker size (noted above) or in the units specification sheet or

installation instructions provides the information to properly select wire and circuit breaker/protector size. The