Rheem RGRK SERIES, RGRL SERIES, RGTK SERIES Installation Instructions Manual

INSTALLATION INSTRUCTIONS

ISO 9001:2008

FOR UPFLOW AND DOWNFLOW/HORIZONTAL

HIGH EFFICIENCY CONDENSING TWO-STAGE

GAS FURNACES

RGRK, RGRL, AND RGTK SERIES

U.L. recognized fuel gas and CO (carbon monoxide) detectors are recommended in all

applications, and their installation should be in accordance with the manufacturer’s

recommendations and/or local laws, rules, regulations, or customs.

92-24161-36-22

SUPERSEDES 92-24161-36-21

INSTALLATION CHECK LIST

REFER TO INSTALLATION INSTRUCTIONS

TERMINATIONS – DIRECT VENT

AS SUPPLY

G

______ Adequate pipe size

_____ Correct supply pressure (during furnace operation)

_

______ Manifold pressure

______ No gas leaks

_____ L.P. Kit Number (if applicable)

_

ELECTRICAL

______ 115 V.A.C. supply (Single Circuit)

______ Polarity observed

______ Furnace properly grounded

______ Adequate wire size

FURNACE INSTALLATION

______ Adequate clearance to combustibles

______ Adequate clearance for service (at front)

VERTICAL

______ Intake – 12" min. above roof/snow level

______ Correct relationship – exhaust to intake

HORIZONTAL/VERTICAL – CONCENTRIC ((-)XGY-E03A)

______ Intake – 12" min. above roof/snow level

______ Intake “Y” rotated above center

______ Exhaust sloped toward furnace

HORIZONTAL – STANDARD ((-)XGY-D02, -D03) – US

((-)XGY-D02A, (-)XGY-D03A) – CANADA

______ Correct relationship – exhaust to intake

______ 12" min. above grade/snow level

HORIZONTAL – ALTERNATE

((-)XGY-D02, -D03 OR -D04) – US

((-)XGY-D02A, -D03A, -D04A) – CANADA

DUCT STATIC PRESSURE

______ in. w.c. on heating speed

______ in. w.c. on cooling speed

______ Air temperature rise

CONDENSATE LINE

______ Trap filled with water

______ Vented

______ Sloped toward drain

______ Condensate drain line hoses connected

and clamped

______ Freeze protection (if necessary)

VENTING – DIRECT VENT

______ in. diameter – intake pipe

______ in. diameter – exhaust pipe

______ ft. of pipe – intake air

______ Correct relationship – exhaust to intake

______ Above anticipated snow level

VENTING – NON-DIRECT VENT

______ in. diameter – exhaust pipe

______ ft. of pipe – exhaust

______ no. of elbows

TERMINATION – NON-DIRECT VENT

VERTICAL

______ 12" min. above roof/snow level

HORIZONTAL – STANDARD

______ 12" min. above grade/snow level

HORIZONTAL – ALTERNATE

______ Above anticipated snow level

______ no. of elbows – intake air

______ ft. of pipe – exhaust pipe

______ no. of elbows – exhaust pipe

______ Exhaust Vent Temperature

2

_____________________________ Model Number

_____________________________ Serial Number

_____________________________ Date of Installation

IMPORTANT: All manufacturer

products meet current Federal OSHA

Guidelines for safety. California

Proposition 65 warnings are required

for certain products, which are not

covered by the OSHA standards.

California's Proposition 65 requires

arnings for products sold in California

w

that contain, or produce, any of over

600 listed chemicals known to the State

f California to cause cancer or birth

o

defects such as fiberglass insulation,

lead in brass, and combustion products

rom natural gas.

f

All “new equipment” shipped for sale in

California will have labels stating that

the product contains and/or produces

Proposition 65 chemicals. Although we

have not changed our processes,

having the same label on all our

products facilitates manufacturing and

shipping. We cannot always know

“when, or if” products will be sold in the

California market.

You may receive inquiries from

customers about chemicals found in, or

produced by, some of our heating and

air-conditioning equipment, or found in

natural gas used with some of our

products. Listed below are those

chemicals and substances commonly

associated with similar equipment in

our industry and other manufacturers.

• Glass Wool (Fiberglass) Insulation

• Carbon Monoxide (CO)

• Formaldehyde

• Benzene

More details are available at the

Websites for OSHA (Occupational

Safety and Health Administration), at

www.osha.gov

California's OEHHA (Office of

Environmental Health Hazard

Assessment), at www.oehha.org.

Consumer education is important since

the chemicals and substances on the

list are found in our daily lives. Most

consumers are aware that products

present safety and health risks, when

improperly used, handled and

maintained.

and the State of

CONTENTS

afety Precautions ...................................................................................................1

S

nstallation Check List ..............................................................................................2

I

eneral Information..................................................................................................4

G

afety Information ....................................................................................................6

S

ocation Requirements and Considerations ............................................................8

L

ucting ...................................................................................................................13

D

enting and Combustion Air Piping .......................................................................15

V

ombustion and Ventilation Air ..............................................................................17

C

ent Pipe Installation..............................................................................................20

V

Condensate Drain/Neutralizer................................................................................33

Gas Supply and Piping...........................................................................................37

Electrical Wiring......................................................................................................42

Accessories............................................................................................................43

Furnace Twinning...................................................................................................44

High Altitude Installations.......................................................................................48

Start-Up Procedures...............................................................................................51

Air Flow...................................................................................................................54

Maintenance...........................................................................................................57

Troubleshooting......................................................................................................59

Wiring Diagram.......................................................................................................62

3

GENERAL INFORMATION

NOTE: A load calculation must be

performed to properly determine the

required furnace BTU size for the

structure. Also, the duct must be properly

designed and installed for proper airflow.

Existing ductwork must be inspected for

proper size and sealed system. Proper

airflow is necessary for both user comfort

and equipment performance.

Before opening the furnace carton and

installation of the furnace, verify the data

tags on the carton and inside the

furnace, match and is what was ordered

from the local distributor. Also, check for

any damage to the furnace before

installation.

IMPORTANT: Proper application,

installation and maintenance of this

furnace and system is a must if

consumers are to receive the full benefits

for which they have paid.

The (-)GRK-, (-)GRL-, (-)GTK- series

furnaces are design-certified by CSA for

use with natural and propane gases as

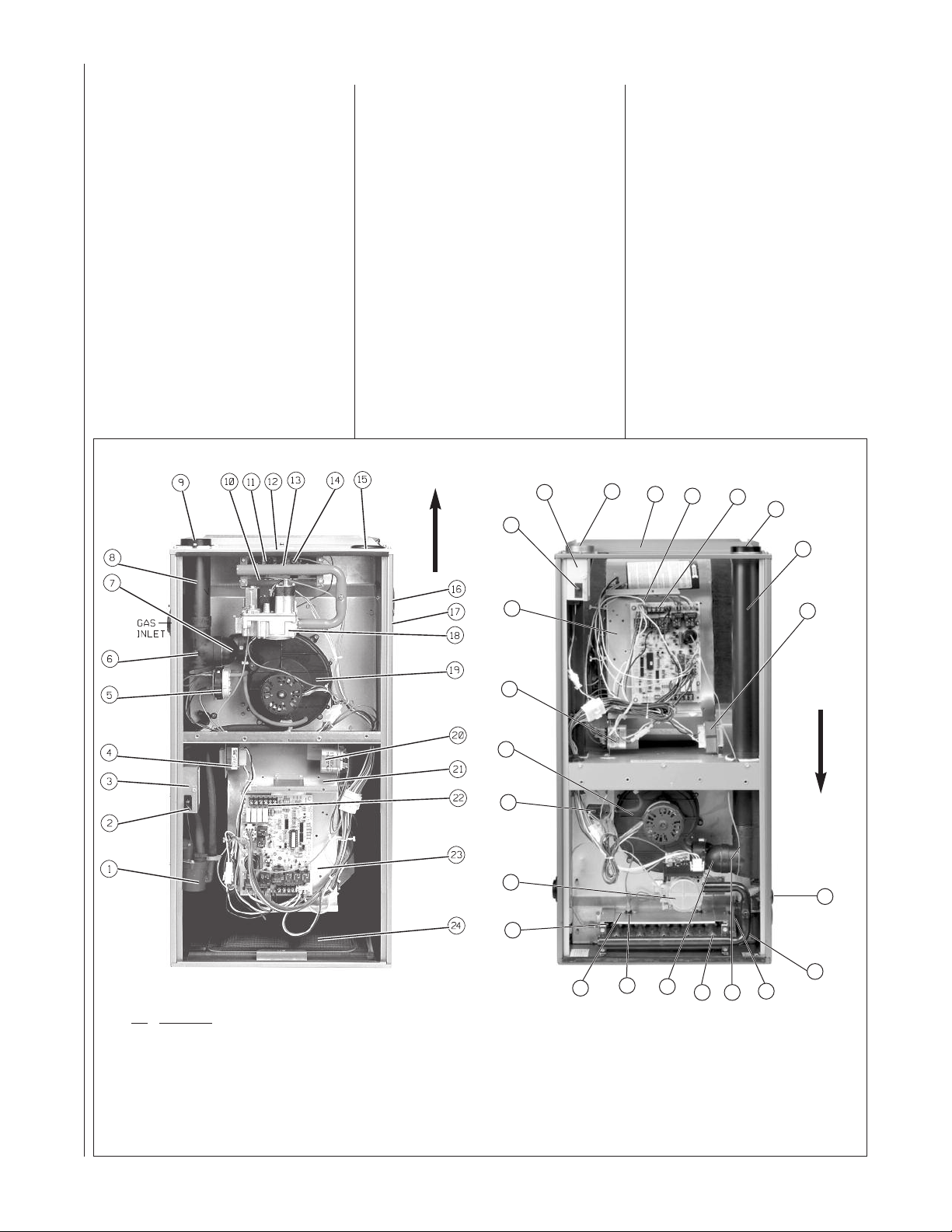

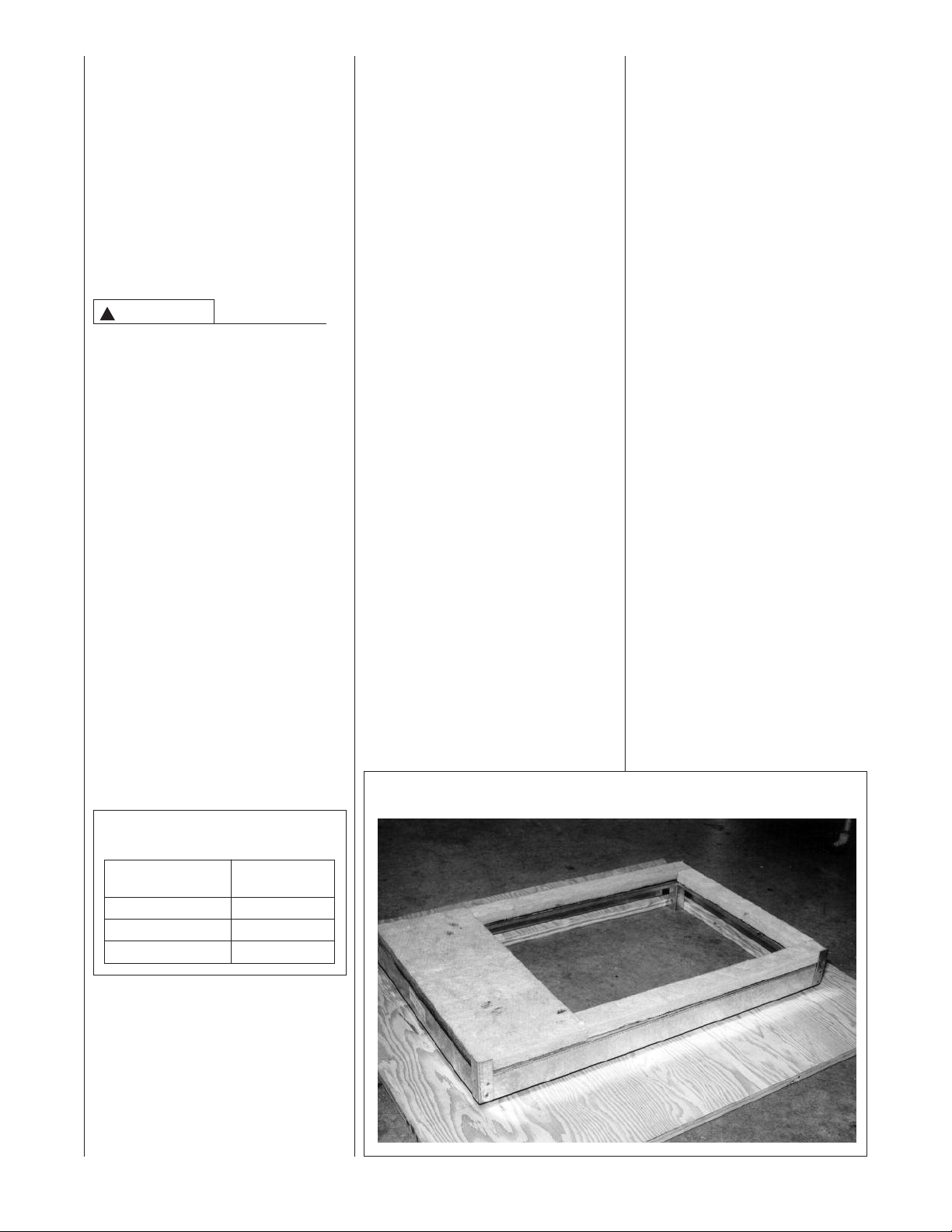

FIGURE 1

UPFLOW FURNACE COMPONENTS

follows:

1. As non-direct vent central forced air

furnaces taking combustion air from

the installation area or using air

ducted from the outside.

2. As direct vent central forced air

furnaces with all combustion air

supplied directly to the furnace

burners through a special air intake

system outlined in these

instructions.Install this furnace in

accordance with the American

National Standard Z223.1 – latest

edition entitled “National Fuel Gas

Code” (NFPA54) and requirements

or codes of the local utilities or

other authorities having jurisdiction.

This is available from the following:

National Fire Protection

Association, Inc.

Batterymarch Park

Quincy, MA 02269

OWNFLOW/HORIZONTAL FURNACE COMPONENTS

D

AIRFLOW

3

2

CSA-INTERNATIONAL

8501 East Pleasant Valley Road

Cleveland, Ohio 44131-5575

Install units in Canada in accordance

with CSA-B149, local installation

codes and authorities having

jurisdiction. CSA-B149 is available

from:

CSA-INTERNATIONAL

178 Rexdale Blvd.

Toronto, Ontario

Canada M9W, 1R3

NOTE: It is our recommendation that

any HVAC equipment which were

subject to flooding be replaced to

avoid any risk of property damage,

personal injury or death. Also, our

position that the immersion by flood

waters compromises any HVAC

products thus voiding this warranty.

15

12

23

22

9

8

ITEM

NO. PART NAME

1 CONDENSATE TRAP

2 DOOR SWITCH

3 JUNCTION BOX

4 TRANSFORMER

5 PRESSURE SWITCHES

6 EXHAUST TRANSITION

7 CONNECTOR

8 OUTLET AIR PIPE

NOTE: A PARTS BAG IS INCLUDED WITH THE FURNACE. IF A NEW

PARTS BAG NEEDS TO BE ORDERED, USE THE FOLLOWING PART

NUMBERS: AS-100717-01 FOR (-)GRL-45, (-)GRL-60, (-)GRK-75, (-)GRL90 AND (-)GRK-105 AS-100717-02 FOR (-)GRK-120

9 SHIPPING PLUG (TO BE REMOVED)

10 FLAME SENSOR

11 OVERTEMPERATURE SWITCH

12 TOP PLATE

13 BURNER

14 IGNITER

15 COMBUSTION AIR INLET

16 OPTIONAL AIR INLET (UPFLOW UNITS ONLY)

17 OPTIONAL GAS INLET

18 GAS VALVE

21

20

19

5

18

10

11

25

19 INDUCED DRAFT BLOWER

20 CAPACITORS

21 BLOWER

22 LOW VOLTAGE TERMINAL

23 CONTROL MOUNTING PLATE

24 FILTER / SOLID METAL BASEPLATE (UPFLOW

UNITS ONLY)

25 BURNER COVER PLATE

NOTE: A PARTS BAG IS INCLUDED WITH THE FURNACE. IF A NEW

PARTS BAG NEEDS TO BE ORDERED, USE THE FOLLOWING PART

NUMBERS: AS-100717-03 FOR (-)GTK-60, (-)GTK-75, (-)GTK-90, (-)GTK105 AND (-)GTK-120

7

(DOWNFLOW/HORIZONTAL UNITS ONLY)

6

13

4

AIRFLOW

17

1

14

4

IMPORTANT INFORMATION

ABOUT EFFICIENCY AND

INDOOR AIR QUALITY

Central cooling and heating equipment

is only as efficient as the duct system

that carries the cooled or heated air. To

maintain efficiency, comfort and good

indoor air quality, it is important to have

he proper balance between the air

t

being supplied to each room and the air

returning to the cooling and heating

equipment.

Proper balance and sealing of the duct

system improves the efficiency of the

heating and air conditioning system

and improves the indoor air quality of

the home by reducing the amount of

airborne pollutants that enter homes

from spaces where the ductwork and /

or equipment is located. The

manufacturer and the U.S.

Environmental Protection Agency’s

Energy Star Program recommend that

central duct systems be checked by a

qualified contractor for proper balance

and sealing.

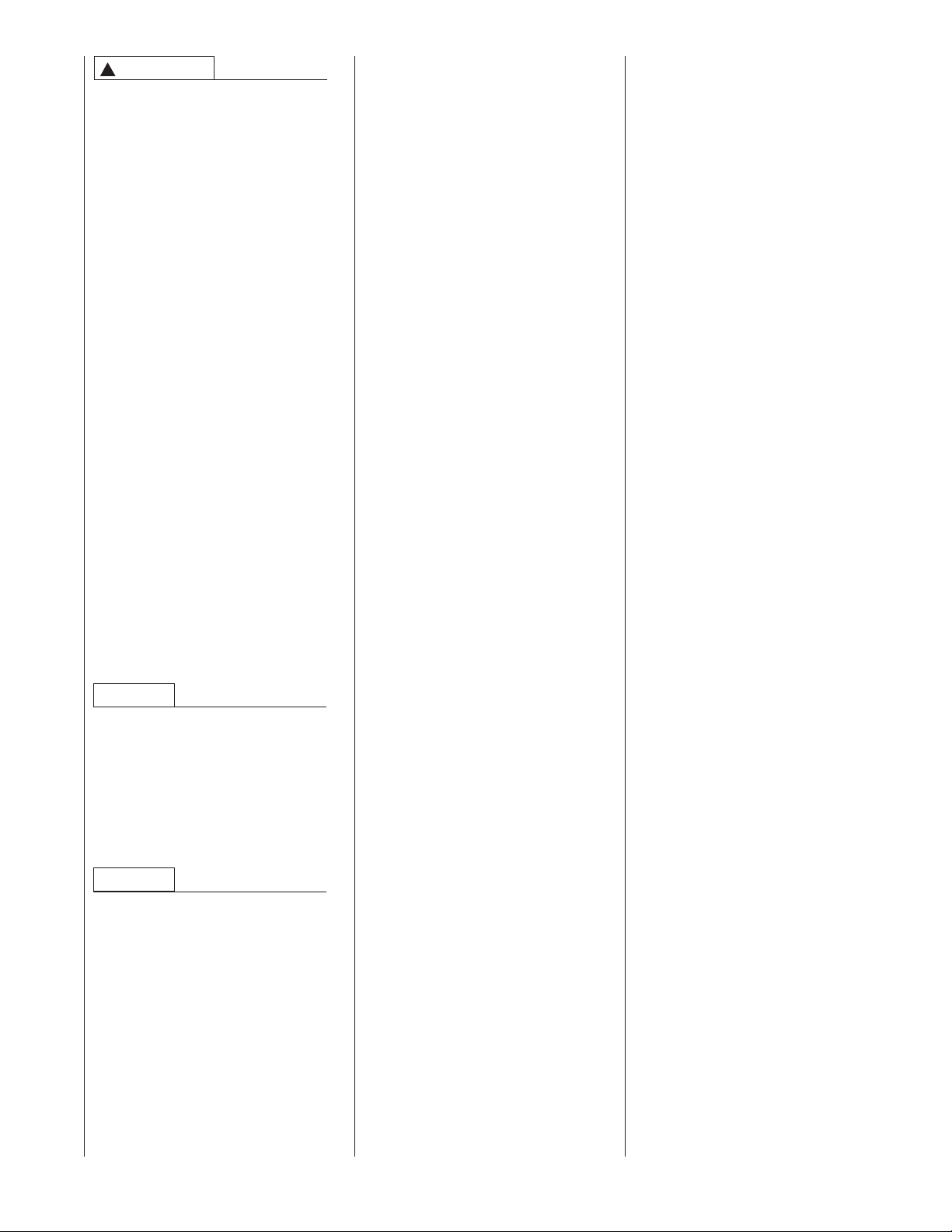

WARNING

!

DUCT LEAKS CAN CREATE AN

UNBALANCED SYSTEM AND DRAW

POLLUTANTS SUCH AS DIRT, DUST,

FUMES AND ODORS INTO THE

HOME CAUSING PROPERTY

DAMAGE. FUMES AND ODORS

FROM TOXIC, VOLATILE OR

FLAMMABLE CHEMICALS, AS WELL

AS AUTOMOBILE EXHAUST AND

CARBON MONOXIDE (CO), CAN BE

DRAWN INTO THE LIVING SPACE

THROUGH LEAKING DUCTS AND

UNBALANCED DUCT SYSTEMS

CAUSING PERSONAL INJURY OR

DEATH (SEE FIGURE 2).

• IF AIR-MOVING EQUIPMENT OR

DUCTWORK IS LOCATED IN

GARAGES OR OFF-GARAGE

STORAGE AREAS - ALL JOINTS,

SEAMS, AND OPENINGS IN THE

EQUIPMENT AND DUCT MUST BE

SEALED TO LIMIT THE MIGRATION

OF TOXIC FUMES AND ODORS

INCLUDING CARBON MONOXIDE

FROM MIGRATING INTO THE

LIVING SPACE.

• IF AIR-MOVING EQUIPMENT OR

DUCTWORK IS LOCATED IN

SPACES CONTAINING FUEL

BURNING APPLIANCES SUCH AS

WATER HEATERS OR BOILERS ALL JOINTS, SEAMS, AND

OPENINGS IN THE EQUIPMENT

AND DUCT MUST ALSO BE

SEALED TO PREVENT

DEPRESSURIZATION OF THE

SPACE AND POSSIBLE

MIGRATION OF COMBUSTION

BYPRODUCTS INCLUDING

CARBON MONOXIDE INTO THE

LIVING SPACE.

FIGURE 2

MIGRATION OF DANGEROUS SUBSTANCES, FUMES, AND ODORS INTO LIVING SPACES

NOTICE

IMPROPER INSTALLATION, OR

INSTALLATION NOT MADE IN

ACCORDANCE WITH THE CSA

INTERNATIONAL (CSA)

CERTIFICATION OR THESE

INSTRUCTIONS, CAN RESULT IN

UNSATISFACTORY OPERATION

AND/OR DANGEROUS CONDI-TIONS

AND ARE NOT COVERED BY THE

UNIT WARRANTY.

NOTICE

IN COMPLIANCE WITH

RECOGNIZED CODES, IT IS

RECOMMENDED THAT AN

AUXILIARY DRAIN PAN BE

INSTALLED UNDER ALL

EVAPORATOR COILS OR UNITS

CONTAINING EVAPORATOR COILS

THAT ARE LOCATED IN ANY AREA

OF A STRUCTURE WHERE DAMAGE

TO THE BUILDING OR BUILDING

CONTENTS MAY OCCUR AS A

RESULT OF AN OVERFLOW OF THE

COIL DRAIN PAN OR A STOPPAGE

IN THE PRIMARY CONDENSATE

DRAIN PIPING. SEE ACCESSORIES

SECTION OF THESE INSTRUCTIONS

FOR AUXILIARY HORIZONTAL

OVERFLOW PAN INFORMATION

(MODEL (-)XBM).

RECEIVING

Immediately upon receipt, all cartons

and contents should be inspected for

transit damage. Units with damaged

cartons should be opened immediately.

If damage is found, it should be noted

on the delivery papers, and a damage

claim filed with the last carrier.

• After unit has been delivered to job

site, remove carton taking care not to

damage unit.

• Check the unit rating plate for unit

size, electric heat, coil, voltage,

phase, etc. to be sure equipment

matches what is required for the

job specification.

• Read the entire instructions before

starting the installation.

• Some building codes require extra

cabinet insulation and gasketing

when unit is installed in attic

applications.

• If installed in an unconditioned

space, apply caulking around the

power wires, control wires,

refrigerant tubing and condensate

line where they enter the cabinet.

Seal the power wires on the inside

where they exit conduit opening.

Caulking is required to prevent air

leakage into and condensate from

forming inside the unit, control box,

and on electrical controls.

• Install the unit in such a way as to

allow necessary access to the

coil/filter rack and blower/control

compartment.

• Install the unit in a level position to

ensure proper condensate

drainage. Make sure unit is level in

both directions within 1/8”.

• Install the unit in accordance with

any local code which may apply

and the national codes. Latest

editions are available from:

“National Fire Protection

Association, Inc., Batterymarch

Park, Quincy, MA 02269.” These

publications are:

• ANSI/NFPA No. 70-(Latest Edition)

National Electrical Code.

• NFPA90A Installation of Air

Conditioning and Ventilating

Systems.

• NFPA90B Installation of warm air

heating and air conditioning

systems.

• The equipment has been

evaluated in accordance with the

Code of Federal Regulations,

Chapter XX, Part 3280.

5

SAFETY INFORMATION

WARNING

!

USE ONLY WITH TYPE OF GAS

APPROVED FOR THIS FURNACE.

REFER TO THE FURNACE RATING

PLATE.

WARNING

!

INSTALL THIS FURNACE ONLY IN

A LOCATION AND POSITION AS

SPECIFIED IN THE LOCATION

REQUIREMENTS AND

CONSIDERATIONS SECTION OF

THESE INSTRUCTIONS. PROVIDE

ADEQUATE COMBUSTION AND

VENTILATION AIR TO THE

FURNACE SPACE AS SPECIFIED

IN THE VENTING SECTION OF

THESE INSTRUCTIONS.

WARNING

!

PROVIDE ADEQUATE

COMBUSTION AND VENTILATION

AIR TO THE FURNACE SPACE AS

SPECIFIED IN THE COMBUSTION

AND VENTILATION AIR SECTION

OF THESE INSTRUCTIONS.

WARNING

!

COMBUSTION PRODUCTS MUST

BE DISCHARGED OUTDOORS.

CONNECT THIS FURNACE TO AN

APPROVED VENT SYSTEM ONLY,

AS SPECIFIED IN VENT PIPE

INSTALLATION SECTION OF

THESE INSTRUCTIONS.

WARNING

!

DO NOT OPERATE THE SYSTEM

WITHOUT FILTERS. A PORTION

OF THE DUST ENTRAINED IN THE

AIR MAY TEMPORARILY LODGE IN

THE AIR DUCT RUNS AND AT THE

SUPPLY REGISTERS. ANY

CIRCULATED DUST PARTICLES

WILL BE HEATED AND CHARRED

BY CONTACT WITH THE FURNACE

HEAT EXCHANGER. THIS SOOTY

RESIDUE WILL SOIL CEILINGS,

WALLS, DRAPES, CARPETS AND

OTHER HOUSEHOLD ARTICLES.

SOOT DAMAGE MAY ALSO

RESULT WITH, OR WITHOUT,

FILTERS IN PLACE, WHEN

CERTAIN TYPES OF CANDLES

ARE BURNED, OR CANDLEWICKS

ARE LEFT UNTRIMMED.

WARNING

!

NEVER TEST FOR GAS LEAKS

WITH AN OPEN FLAME. USE A

COMMERCIALLY AVAILABLE

OAP SOLUTION MADE

S

SPECIFICALLY FOR THE

DETECTION OF LEAKS TO CHECK

ALL CONNECTIONS, AS

SPECIFIED IN GAS SUPPLY AND

PIPING SECTION OF THESE

INSTRUCTIONS.

WARNING

!

ALWAYS INSTALL FURNACE TO

OPERATE WITHIN THE

FURNACE'S INTENDED

TEMPERATURE-RISE RANGE

WITH A DUCT SYSTEM WHICH

HAS AN EXTERNAL STATIC

PRESSURE WITHIN THE

ALLOWABLE RANGE, AS

SPECIFIED IN DUCTING SECTION

OF THESE INSTRUCTIONS. SEE

ALSO FURNACE RATING PLATE.

WARNING

!

WHEN A FURNACE IS INSTALLED

SO THAT SUPPLY DUCTS CARRY

AIR CIRCULATED BY THE

FURNACE TO AREAS OUTSIDE

THE SPACE CONTAINING THE

FURNACE, THE RETURN AIR

SHALL ALSO BE HANDLED BY

DUCT(S) SEALED TO THE

FURNACE CASING AND

TERMINATING OUTSIDE THE

SPACE CONTAINING THE

FURNACE.

WARNING

!

DO NOT INSTALL THIS FURNACE

IN A MOBILE HOME!! THIS

FURNACE IS NOT APPROVED FOR

INSTALLATION IN A MOBILE

HOME. DOING SO COULD CAUSE

FIRE, PROPERTY DAMAGE,

PERSONAL INJURY OR DEATH.

WARNING

!

HEN THIS FURNACE IS

W

INSTALLED IN A RESIDENTIAL

GARAGE, IT MUST BE INSTALLED

SO THE BURNERS AND IGNITION

SOURCE ARE LOCATED NO LESS

THAN 18 INCHES ABOVE THE

FLOOR. THIS IS TO REDUCE THE

RISK OF IGNITING FLAMMABLE

VAPORS WHICH MAY

E PRESENT IN A GARAGE.

B

ALSO, THE FURNACE MUST BE

LOCATED OR PROTECTED TO

AVOID PHYSICAL DAMAGE BY

VEHICLES. FAILURE TO FOLLOW

THESE WARNINGS CAN CAUSE A

FIRE OR EXPLOSION, RESULTING

IN PROPERTY DAMAGE,

PERSONAL INJURY OR DEATH.

WARNING

!

THE FURNACE MAY BE USED FOR

HEATING OF BUILDINGS OR

STRUCTURES UNDER

CONSTRUCTION.

INSTALLATION MUST COMPLY

WITH ALL INSTALLATION

INSTRUCTIONS INCLUDING:

• PROPER VENT INSTALLATION;

• FURNACE OPERATING UNDER

THERMOSTATIC CONTROL;

• RETURN AIR DUCT SEALED TO

THE FURNACE;

• AIR FILTERS IN PLACE;

• SET FURNACE INPUT RATE

AND TEMPERATURE RISE PER

RATING PLATE MARKING;

• MEANS FOR PROVIDING

OUTDOOR AIR REQUIRED FOR

COMBUSTION;

• RETURN AIR TEMPERATURE

MAINTAINED BETWEEN 55°F

(13°C) AND 80°F (27°C); AND

• CLEAN FURNACE, DUCT WORK

AND COMPONENTS UPON

SUBSTANTIAL COMPLETION OF

THE CONSTRUCTION

PROCESS, AND VERIFY

FURNACE OPERATING

CONDITIONS INCLUDING

IGNITION, INPUT RATE,

TEMPERATURE RISE AND

VENTING, ACCORDING TO THE

INSTRUCTIONS AND CODES.

6

WARNING

!

DUCT LEAKS CAN CREATE AN

UNBALANCED SYSTEM AND DRAW

POLLUTANTS SUCH AS DIRT, DUST,

FUMES AND ODORS INTO THE

HOME CAUSING PROPERTY

DAMAGE. FUMES AND ODORS

FROM TOXIC, VOLATILE OR

FLAMMABLE CHEMICALS, AS WELL

AS AUTOMOBILE EXHAUST AND

CARBON MONOXIDE (CO), CAN BE

DRAWN INTO THE LIVING SPACE

THROUGH LEAKING DUCTS AND

UNBALANCED DUCT SYSTEMS

CAUSING PERSONAL INJURY OR

DEATH (SEE FIGURE 2).

• IF AIR-MOVING EQUIPMENT OR

DUCTWORK IS LOCATED IN

GARAGES OR OFF-GARAGE

STORAGE AREAS - ALL JOINTS,

SEAMS, AND OPENINGS IN THE

EQUIPMENT AND DUCT MUST BE

SEALED TO LIMIT THE MIGRATION

OF TOXIC FUMES AND ODORS

INCLUDING CARBON MONOXIDE

FROM MIGRATING INTO THE

LIVING SPACE.

• IF AIR-MOVING EQUIPMENT OR

DUCTWORK IS LOCATED IN

SPACES CONTAINING FUEL

BURNING APPLIANCES SUCH AS

WATER HEATERS OR BOILERS ALL JOINTS, SEAMS, AND

OPENINGS IN THE EQUIPMENT

AND DUCT MUST ALSO BE

SEALED TO PREVENT

DEPRESSURIZATION OF THE

SPACE AND POSSIBLE

MIGRATION OF COMBUSTION

BYPRODUCTS INCLUDING

CARBON MONOXIDE INTO THE

LIVING SPACE.

NOTICE

IMPROPER INSTALLATION, OR

INSTALLATION NOT MADE IN

ACCORDANCE WITH THE CSA

INTERNATIONAL (CSA)

CERTIFICATION OR THESE

INSTRUCTIONS, CAN RESULT IN

UNSATISFACTORY OPERATION

AND/OR DANGEROUS CONDI-TIONS

AND ARE NOT COVERED BY THE

UNIT WARRANTY.

NOTICE

IN COMPLIANCE WITH RECOGNIZED

CODES, IT IS RECOMMENDED THAT

AN AUXILIARY DRAIN PAN BE

INSTALLED UNDER ALL

EVAPORATOR COILS OR UNITS

CONTAINING EVAPORATOR COILS

THAT ARE LOCATED IN ANY AREA

OF A STRUCTURE WHERE DAMAGE

TO THE BUILDING OR BUILDING

CONTENTS MAY OCCUR AS A

RESULT OF AN OVERFLOW OF THE

COIL DRAIN PAN OR A STOPPAGE IN

THE PRIMARY CONDENSATE DRAIN

PIPING. SEE ACCESSORIES

SECTION OF THESE INSTRUCTIONS

FOR AUXILIARY HORIZONTAL

OVERFLOW PAN INFORMATION

(MODEL (-)XBM).

IMPORTANT!

THE COMMONWEALTH OF

MASSACHUSETTS REQUIRES

COMPLIANCE WITH REGULATION

248 CMR 4.00 AND 5.00 FOR

INSTALLATION OF THROUGH-THEWALL VENTED GAS APPLIANCES AS

FOLLOWS:

(a) For all side wall horizontally vented

gas fueled equipment installed in every

dwelling, building or structure used in

whole or in part for residential purposes,

including those owned or operated by

the Commonwealth and where the side

wall exhaust vent termination is less than

seven (7) feet above finished grade in

the area of the venting, including but not

limited to decks and porches, the

following requirements shall be satisfied:

1. INSTALLATION OF CARBON

MONOXIDE DETECTORS. At the time

of installation of the side wall horizontal

vented gas fueled equipment, the

installing plumber or gasfitter shall

observe that a hard wired carbon

monoxide detector with an alarm and

battery back-up is installed on the floor

level where the gas equipment is to be

installed. In addition, the installing

plumber or gasfitter shall observe that a

battery operated or hard wired carbon

monoxide detector with an alarm is

installed on each additional level of the

dwelling, building or structure served by

the side wall horizontal vented gas

fueled equipment. It shall be the

responsibility of the property owner to

secure the services of qualified licensed

professionals for the installation of hard

wired carbon monoxide detectors.

a. In the event that the side wall

horizontally vented gas fueled equipment

is installed in a crawl space or an attic,

the hard wired carbon monoxide detector

with alarm and battery back-up may be

installed on the next adjacent floor level.

b. In the event that the requirements of

this subdivision can not be met at the

time of completion of installation, the

owner shall have a period of thirty (30)

days to comply with the above

requirements; provided, however, that

during said thirty (30) day period, a

battery operated carbon monoxide

detector with an alarm shall be installed.

2. APPROVED CARBON MONOXIDE

DETECTORS. Each carbon monoxide

detector as required in accordance with

the above provisions shall comply with

NFPA 720 and be ANSI/UL 2034 listed

and IAS certified.

3. SIGNAGE. A metal or plastic

identification plate shall be permanently

mounted to the exterior of the building at

a minimum height of eight (8) feet above

grade directly in line with the exhaust

vent terminal for the horizontally vented

gas fueled heating appliance or

equipment. The sign shall read, in print

size no less than one-half (1/2) inch in

size, “GAS VENT DIRECTLY BELOW.

KEEP CLEAR OF ALL

OBSTRUCTIONS”.

4. INSPECTION. The state or local

gas inspector of the side wall

horizontally vented gas fueled

equipment shall not approve the

installation unless, upon inspection,

the inspector observes carbon

monoxide detectors and signage

installed in accordance with the

provisions of 248 CMR 5.08(2)(a) 1

through 4.

(b) EXEMPTIONS: The following

equipment is exempt from 248 CMR

5.08(2)(a)1 through 4:

1. The equipment listed in Chapter 10

entitled “Equipment Not Required To

Be Vented” in the most current edition

of NFPA 54 as adopted by the Board;

and

2. Product Approved side wall

horizontally vented gas fueled

equipment installed in a room or

structure separate from the dwelling,

building or structure used in whole or

in part for residential purposes.

(c) MANUFACTURER

REQUIREMENTS – GAS

EQUIPMENT VENTING SYSTEM

PROVIDED. When the manufacturer

of Product Approved side wall

horizontally vented gas equipment

provides a venting system design or

venting system components with the

equipment, the instructions provided

by the manufacturer for installation of

the equipment and the venting

system shall include:

1. Detailed instructions for the

installation of the venting system

design or the venting system

components; and

2. A complete parts list for the venting

system design or venting system.

(d) MANUFACTURER

REQUIREMENTS – GAS

EQUIPMENT VENTING SYSTEM

NOT PROVIDED. When the

manufacturer of a Product Approved

side wall horizontally vented gas

fueled equipment does not provide

the parts for venting the flue gases,

but identifies “special venting

systems”, the following requirements

shall be satisfied by the manufacturer:

1. The referenced “special venting

system” instructions shall be included

with the appliance or equipment

installation instructions; and

2. The “special venting systems” shall

be Product Approved by the Board,

and the instructions for that system

shall include a parts list and detailed

installation instructions.

(e) A copy of all installation

instructions for all Product Approved

side wall horizontally vented gas

fueled equipment, all venting

instructions, all parts lists for venting

instructions, and/or all venting design

instructions shall remain with the

appliance or equipment at the

completion of the installation.

7

LOCATION REQUIREMENTS AND CONSIDERATIONS

GENERAL INFORMATION

. install a parallel duct system

WARNING

!

DO NOT INSTALL THIS FURNACE

IN A MOBILE HOME!! This furnace is

not approved for installation in a

mobile home. Doing so could cause

IRE, PROPERTY DAMAGE,

F

PERSONAL INJURY OR DEATH.

WARNING

!

WHEN THIS FURNACE IS

INSTALLED IN A RESIDENTIAL

GARAGE, IT MUST BE INSTALLED

SO THE BURNERS AND IGNITION

SOURCE ARE LOCATED NO LESS

THAN 18 INCHES ABOVE THE

FLOOR. THIS IS TO PREVENT

THE RISK OF IGNITING

FLAMMABLE VAPORS WHICH MAY

BE PRESENT IN A GARAGE.

ALSO, THE FURNACE MUST BE

LOCATED OR PROTECTED TO

AVOID PHYSICAL DAMAGE BY

VEHICLES. FAILURE TO FOLLOW

THESE WARNINGS CAN CAUSE A

FIRE OR EXPLOSION, RESULTING

IN PROPERTY DAMAGE,

PERSONAL INJURY OR DEATH.

1. IMPORTANT: If installing the unit

over a finished ceiling or living

area, be certain to install an

auxiliary condensate drain pan

under the entire unit. This

auxiliary drain pan should extend

under any evaporator coil

installed with the furnace and the

open portion of the condensate

drain assembly. See

“Condensate Drain/Neutralizer”

section for more details.

2. IMPORTANT: If using a cooling

evaporator coil with this furnace:

a. be sure the air passes over

the heat exchanger before

passing over the cooling

coil. The cooled air passing

over the warm ambient air

inside the heat exchanger

tubes can cause

condensation inside the tubes

resulting in corrosion and

eventual failure.

b

to divert all the air from the

furnace allowing it to pass

over the cooling coil only. Use

dampers or other means to

prevent chilled air from

passing over the heat

exchanger.

If these are manual dampers, they

must be equipped to prevent heating

or cooling operation unless the

damper is in the full heat or cool

position.

3. IMPORTANT: Install the furnace

level. If it is not level, condensate

cannot drain properly, possibly

causing furnace shut down.

NOTE: These furnaces are approved

for installation in attics, as well as

alcoves, utility rooms, closets and

crawlspaces. Provisions must be

made to prevent freezing of

condensate.

4. IMPORTANT: If this furnace is

installed in a garage, attic and/or

any unconditioned space, install a

self-regulating heat tape around

the condensate trap and along the

entire length of the condensate

drain in the unconditioned space.

When the condensing horizontal

gas furnace is installed in an

unconditioned space where the

temperature would be capable of

reaching close to or below 32°F

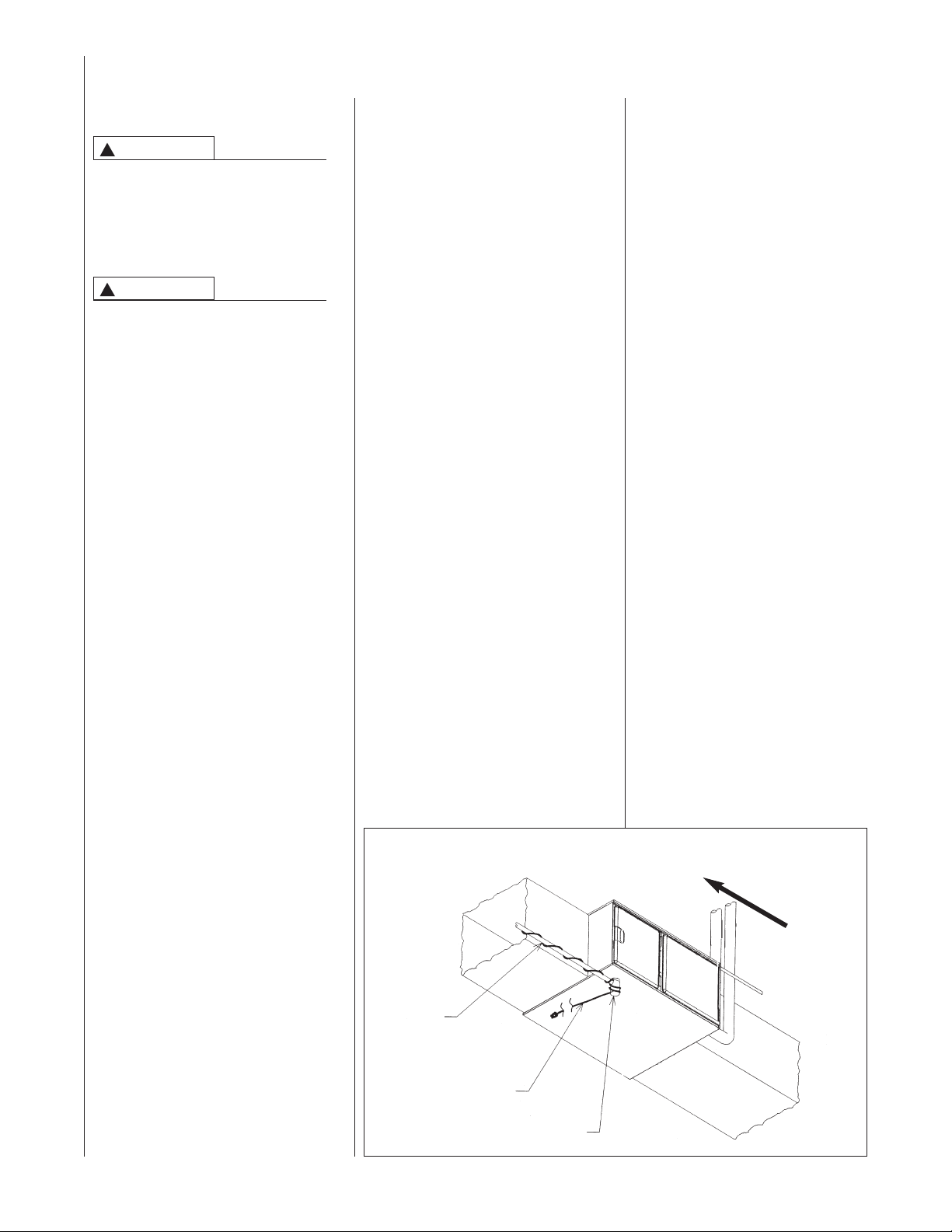

FIGURE 3

HORIZONTAL FURNACE W/HEAT TAPE ON CONDENSATE TRAP

DRAIN

PIPE

5. IMPORTANT: If installing in a

0°C), a self-regulating heat tape

(

is required on the condensate

drain, along with an insulation

wrap. The heat tape should meet

the following requirements:

a. The heat tape must be UL

listed.

b. The heat tape must be

installed per the

manufacturer’s instructions for

the entire length of drain pipe

in the unconditioned space.

c. The heat tape should be rated

at 5 or 6 watts per foot at

120V

IMPORTANT: Support this unit

when installed. Since this furnace

is suitable for attic or crawl space

installation, it may be installed on

combustible wood flooring or by

using support brackets.

utility room, be sure the door is

wide enough to:

a. allow the largest part of the

furnace to pass; or

b. allow any other appliance

(such as a water heater)

to pass.

c. allow service clearance

AIRF

LOW

HEAT

TAPE

TRAP

8

I526

CAUTION

!

THIS FURNACE IS NOT

APPROVED OR RECOMMENDED

FOR INSTALLATION ON ITS BACK,

WITH ACCESS DOORS FACING

UPWARDS OR IN ANY

ORIZONTAL CONFIGURATION.

H

SITE SELECTION

1. Select a site in the building near

he center of the proposed, or

t

existing, duct system.

2. Give consideration to the vent

system piping when selecting the

furnace location. Be sure the

venting system can get from the

furnace to the termination with

minimal length and elbows.

3. Locate the furnace near the

existing gas piping. Or, if running

a new gas line, locate the

furnace to minimize the length

and elbows in the gas piping.

4. Locate the furnace to maintain

proper clearance to combustibles

as shown in the following tables.

WARNING

!

DO NOT LIFT THE UNIT BY THE

HEAT EXCHANGER TUBES. DOING

SO CAN DAMAGE THE HEAT

EXCHANGER ASSEMBLY.

CLEARANCE ACCESSIBILITY

The design of forced air furnaces with

input ratings as listed in the table

under Figure 5 are certified by CSAInternational for the clearances to

combustible materials shown in

inches.

See name/rating plate and clearance

label for specific model number and

learance information.

c

Service clearance of at least 24

inches is recommended in front of

all furnaces.

NOTE: Use recommended 24”

clearance if accessibility clearances

are greater than fire protection

clearances.

WARNING

!

UPFLOW FURNACES ARE DESIGNCERTIFIED FOR INSTALLATION

ON COMBUSTIBLE FLOORS.

NOTE, HOWEVER, THAT

FURNACES MUST NOT BE

INSTALLED DIRECTLY ON

CARPETING, TILE OR OTHER

COMBUSTIBLE MATERIAL OTHER

THAN WOOD FLOORING.

INSTALLATION ON A

COMBUSTIBLE MATERIAL CAN

RESULT IN FIRE, CAUSING

PROPERTY DAMAGE, PERSONAL

INJURY OR DEATH.

Upflow furnaces are shipped with a

bottom closure panel installed. When

bottom return air is used, remove the

panel by removing the two screws

attaching the panel to the front base

angle. See filter section for details.

WARNING

!

COMBUSTIBLE MATERIAL MUST

NOT BE PLACED ON OR AGAINST

THE FURNACE JACKET. THE AREA

AROUND THE FURNACE MUST BE

KEPT CLEAR AND FREE OF ALL

COMBUSTIBLE MATERIALS

INCLUDING GASOLINE AND

OTHER FLAMMABLE VAPORS AND

LIQUIDS. PLACEMENT OF

COMBUSTIBLE MATERIALS ON,

AGAINST OR AROUND THE

FURNACE JACKET CAN CAUSE AN

EXPLOSION OR FIRE RESULTING

IN PROPERTY DAMAGE,

PERSONAL INJURY OR DEATH.

THE HOMEOWNER SHOULD BE

CAUTIONED THAT THE FURNACE

AREA MUST NOT BE USED AS A

BROOM CLOSET OR FOR ANY

OTHER STORAGE PURPOSES.

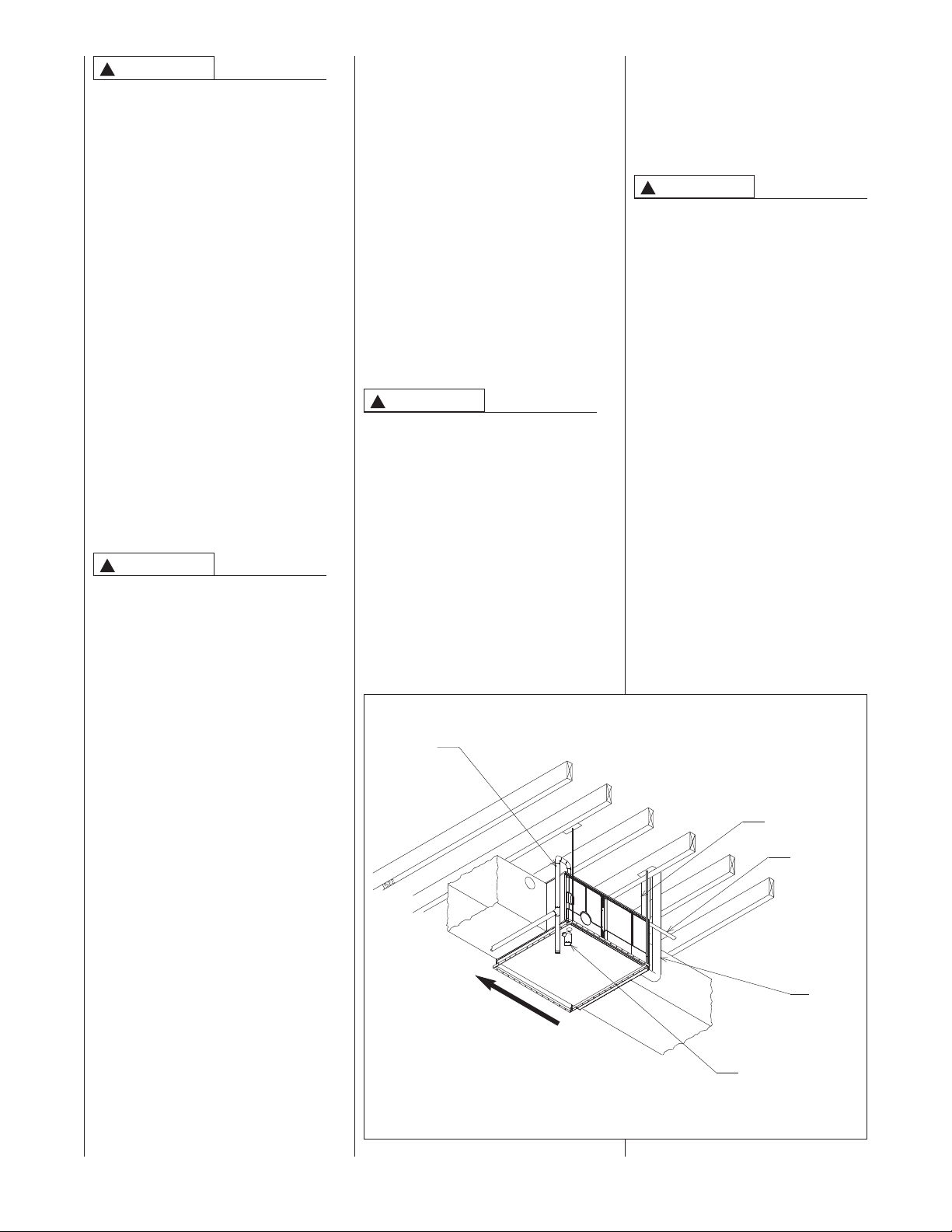

FIGURE 4

HORIZONTAL FURNACE INSTALLED W/SUPPORT BRACKETS

GAS

PIPE

INTAKE

VENT

ELECTRICAL

CONDUIT

AIRF

LOW

TRAP

NOTE: Do not block furnace access with support rods. Maintain clearances recommended in Figure

7. Allow enough space for proper service maintenance or replacement of the heat exchanger and

blower assembly.

EXHAUST

FAN

I522

9

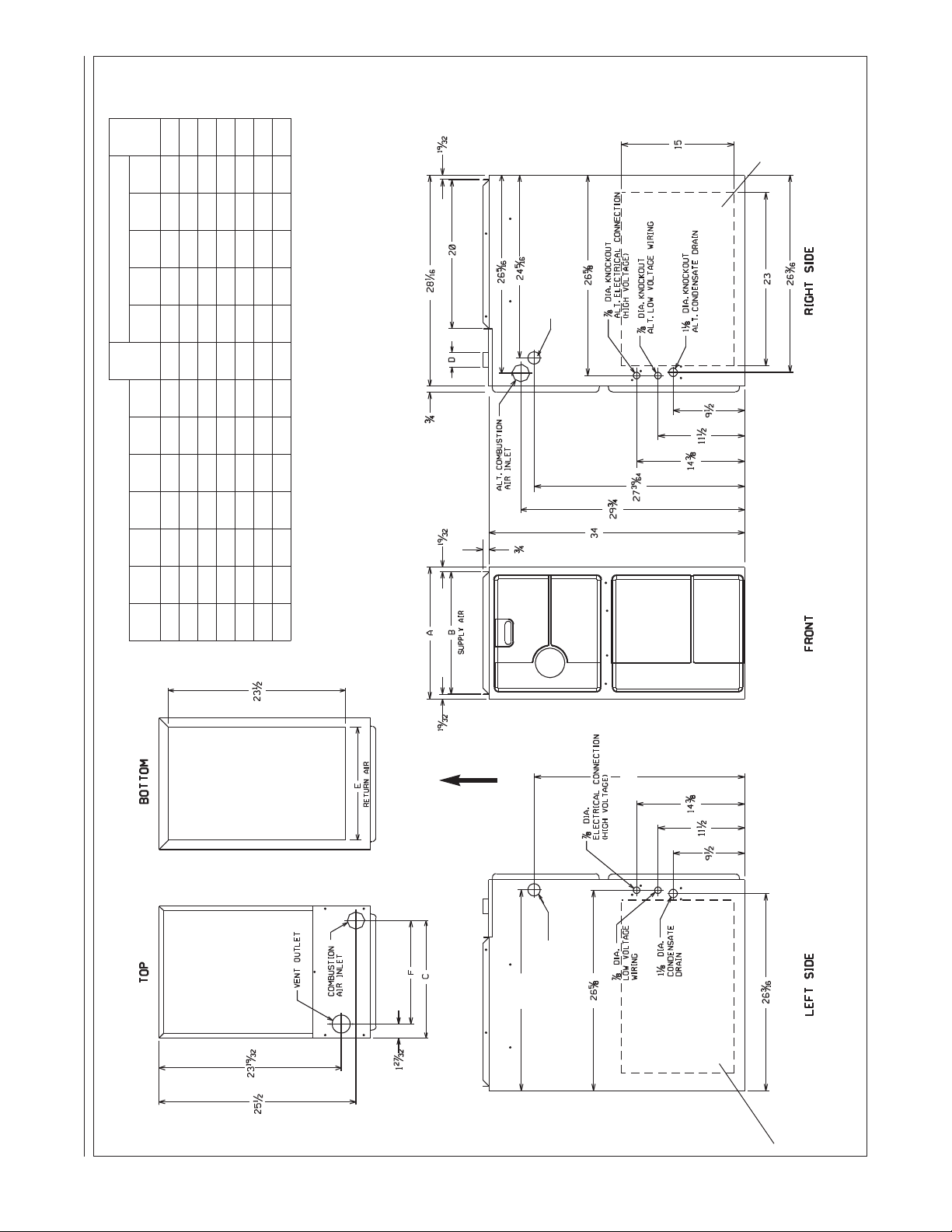

IGURE 5

F

CLEARANCE TO COMBUSTIBLES, UPFLOW UNITS

WGTS

OPTIONAL

RETURN

AIR CUTOUT

(EITHER SIDE)*

I392.DGN

BACK TOP FRONT VENT

2 DIA. KNOCKOUT

ALT. GAS CONNECTION

SIDE SIDE

LEFT RIGHT SHIP

/32 0 0 0 1 2* 0 111

/32 0 0 0 1 2* 0 117

/32 0 0 0 1 2* 0 123

/32 0 0 0 1 2* 0 145

25

/8 2 15 13

5

UPFLOW MODELS MINIMUM CLEARANCE (IN.)

/32 15

11

/2 16

1

9

25

25

/2 17

1

/8 2 15 13

/8 2 15 13

/8 2 18

5

5

1

/32 15

/32 15

/32 19

11

11

27

/2 16

/2 16

1

1

/32 0 0 0 1 2* 0 160

/32 0 0 0 1 2* 0 148

/32 0 0 0 1 2* 0 152

9

9

25

/2 17

/2 17

1

1

/8 2 18

/8 2 18

/8 2 22 20

1

1

5

/32 19

/32 19

/32 22

27

27

11

/2 23

1

04 17

06 17

MODEL A B C D E F

09 21 19

10 21 19

07A 17

07B 21 19

RETURN

12 24

*A service clearance of at least 24 inches is recommended in front of all furnaces.

⁄8

5

AIR

27

AIRFLOW

*BOTH SIDES FOR 1800 CFM

GAS CONNECTION

AIR

SUPPLY

2 DIA.

⁄16

7

26

10

I392

CUTOUT (EITHER SIDE)*

OPTIONAL RETURN AIR

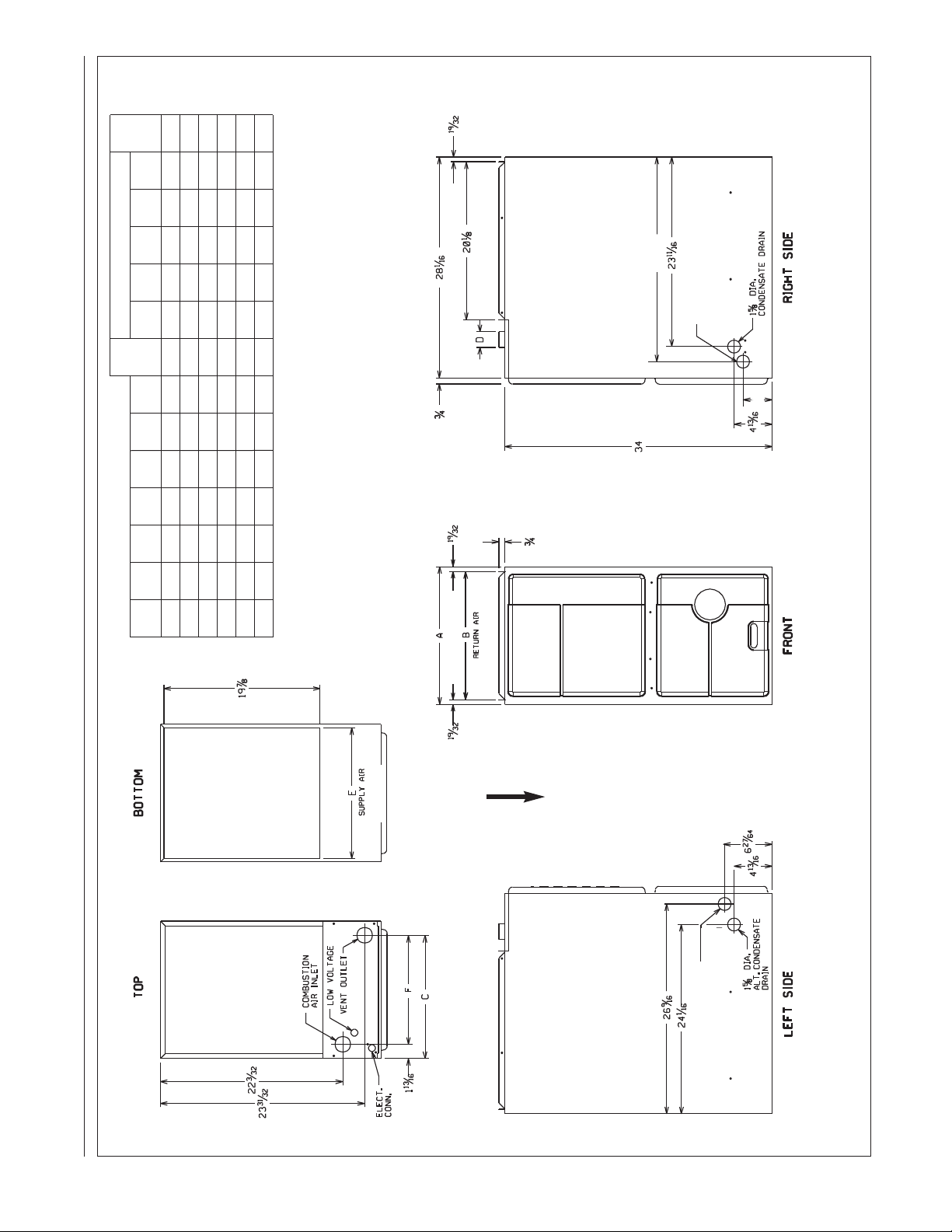

IGURE 6

F

CLEARANCE TO COMBUSTIBLES, DOWNFLOW UNITS

WGTS

BACK TOP FRONT VENT

SIDE SIDE

LEFT RIGHT SHIP

⁄8 0 0 0 1 2* 0 117

⁄8 0 0 0 1 2* 0 123

⁄8 0 0 0 1 2* 0 148

⁄8 0 0 0 1 2* 0 152

/32 0 0 0 1 2* 0 123

7

7

9

⁄8 13

⁄8 13

/2 17

5

5

1

⁄8 2 16

⁄8 2 16

/16 2 18

5

5

3

⁄8 0 0 0 1 2* 0 160

3

3

7

⁄8 17

⁄8 17

⁄8 20

1

1

5

⁄8 2 23

⁄16 2 20

⁄16 2 20

5

3

3

A103501.DGN

⁄16

13

25

2 DIA.

ALT. GAS CONNECTION

⁄8

3

4

⁄32 15

⁄32 15

⁄32 19

⁄32 19

/32 19

11

11

DOWNFLOW MODELS MINIMUM CLEARANCE (IN.)

MODEL A B C D E F

27

⁄2 16

⁄2 16

1

1

06 17

07A 17

07B 21 19

⁄32 22

27

27

11

⁄2 23

1

09 21 19

10 21 19

12 24

*A service clearance of at least 24 inches is recommended in front of all furnaces.

AIR

SUPPLY

AIRFLOW

GAS

CONNECTION

2 DIA.

AIR

RETURN

I393

NOTE: IN DOWNFLOW CONFIGURATION, RETURN AIR CUTOUT IS NOT PERMITTED.

11

IGURE 7

F

CLEARANCE TO COMBUSTIBLES, HORIZONTAL UNITS

WGTS

A103601.DGN

BACK TOP FRONT VENT

SIDE SIDE

LEFT RIGHT SHIP

⁄8 0 0 0 1 2* 0 117

⁄8 0 0 0 1 2* 0 123

⁄8 0 0 0 1 2* 0 123

⁄8 0 0 0 1 2* 0 148

⁄8 0 0 0 1 2* 0 152

7

7

3

⁄8 0 0 0 1 2* 0 160

3

3

7

RETURN AIR

⁄8 13

⁄8 13

⁄8 17

⁄8 17

⁄8 17

5

5

1

⁄8 2 16

⁄8 2 16

⁄16 2 20

5

5

3

⁄32 15

⁄32 15

⁄32 19

11

11

HORIZONTAL MODELS MINIMUM CLEARANCE (IN.)

27

⁄2 16

⁄2 16

1

1

⁄8 20

1

1

5

NOTE: In horizontal configuration, return air cutout is not permitted.

Horizontal left-hand airflow only.

IMPORTANT: This furnace is not approved or recommended for

⁄8 2 23

⁄16 2 20

⁄16 2 20

5

3

3

⁄32 19

⁄32 19

⁄32 22

27

27

11

⁄2 23

1

installation on its back, with access doors facing upwards.

06 17

MODEL A B C D E F

09 21 19

10 21 19

07A 17

07B 21 19

12 24

*A service clearance of at least 24 inches is recommended in front of all furnaces.

AIRFLOW

⁄16

13

25

GAS

CONNECTION

2 DIA.

2 DIA.

ALT. GAS

DRAIN TRAP LOCATION

⁄8

3

4

CONNECTION

12

AIR

SUPPLY

I520

JACKET

DRILL (2)

3/16" DIA.

HOLES

8.000

4.875

1.531

DUCTING

Proper air flow is required for the

correct operation of this furnace.

Too little air flow can cause erratic

operation and can damage the heat

exchanger. The duct system must

carry the correct amount of air for

heating and cooling if summer air

conditioning is used.

Size the ducts according to

acceptable industry standards and

methods. The total static pressure

drop of the air distribution system

should not exceed 0.5" w.c.

WARNING

!

NEVER ALLOW THE PRODUCTS

OF COMBUSTION FROM THE FLUE

TO ENTER THE RETURN AIR

DUCTWORK OR THE CIRCULATED

AIR SUPPLY. ALL RETURN

DUCTWORK MUST BE

ADEQUATELY SEALED AND

SECURED TO THE FURNACE WITH

SHEET METAL SCREWS; AND

JOINTS, TAPED. ALL OTHER DUCT

JOINTS MUST BE SECURED WITH

APPROVED CONNECTIONS AND

SEALED AIRTIGHT. WHEN AN

UPFLOW FURNACE IS MOUNTED

ON A PLATFORM WITH RETURN

THROUGH THE BOTTOM, IT MUST

BE SEALED AIRTIGHT BETWEEN

THE FURNACE AND THE RETURN

AIR PLENUM. THE FLOOR OR

PLATFORM MUST PROVIDE

SOUND PHYSICAL SUPPORT OF

THE FURNACE WITHOUT

SAGGING, CRACKS, OR GAPS,

AROUND THE BASE, PROVIDING A

SEAL BETWEEN THE SUPPORT

AND THE BASE.

FAILURE TO PREVENT PRODUCTS

OF COMBUSTION FROM BEING

CIRCULATED INTO THE LIVING

SPACE CAN CREATE

POTENTIALLY HAZARDOUS

CONDITIONS, INCLUDING

CARBON MONOXIDE POISONING

THAT COULD RESULT IN

PERSONAL INJURY OR DEATH.

DO NOT, UNDER ANY

CIRCUMSTANCES, CONNECT

RETURN OR SUPPLY DUCTWORK

TO OR FROM ANY OTHER HEAT

PRODUCING DEVICE SUCH AS A

FIREPLACE INSERT, STOVE, ETC.

DOING SO MAY RESULT IN FIRE,

CARBON MONOXIDE POISONING,

EXPLOSION, PERSONAL INJURY

OR PROPERTY DAMAGE.

IMPORTANT: Some high efficiency

filters have a greater than normal

resistance to air flow. This can

adversely affect furnace operation.

BE SURE TO CHECK AIR FLOW.

IMPORTANT: When using outside air,

design and adjust the system to maintain

a return air temperature ABOVE 55° F

during the heating season.

NOTE: Return air grilles and warm air

registers must not be obstructed or

closed.

UPFLOW UNITS

. Position the unit to minimize long

1

runs of duct or runs of duct with

many turns and elbows.

2. Open the return air compartment.

WARNING

!

UPFLOW FURNACE: A SOLID METAL

BASE PLATE MUST REMAIN IN THE

FURNACE BOTTOM WHEN USING

SIDE AIR RETURN. FAILURE TO

INSTALL A BASE PLATE COULD

CAUSE THE PRODUCTS OF

COMBUSTION TO CIRCULATE INTO

THE LIVING SPACE AND CREATE

POTENTIALLY HAZARDOUS

CONDITIONS, INCLUDING CARBON

MONOXIDE POISONING OR DEATH.

FOR BOTTOM RETURN, REMOVE

SOLID METAL BASE PLATE.

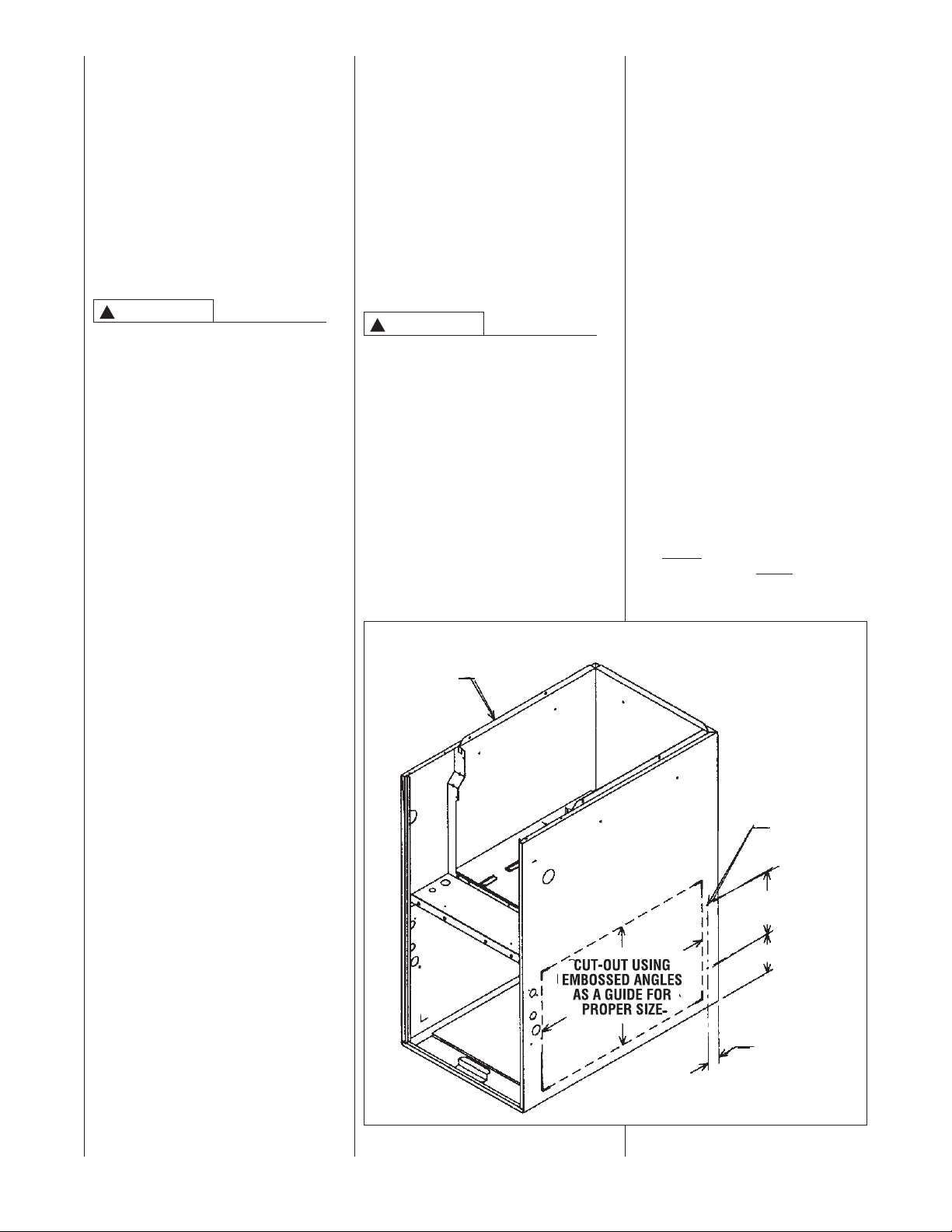

a. Cut an opening in the side. The

opening should be cut the full

width and height of the knockouts

on the unit. See Figure 8.

FIGURE 8

UPFLOW CUTOUT AND DRILL INFORMATION

NOTE: Where the maximum air flow

is 1800 CFM or more, both sides or 1

side and the bottom must be used for

return air.

3. Connect the return duct or return

air cabinet to the unit. Make the

onnection air tight to prevent

c

entraining combustion gases

from an adjacent fuel-burning

appliance.

4. Be sure to have adequate space

or the unit filter.

f

NOTE: DO NOT take return air

from bathrooms, kitchens,

furnace rooms, garages, utility or

laundry rooms, or cold areas.

NOTE: DO NOT use a rear air

return.

5. If summer air conditioning is

desired, position the indoor coil

on the supply-air side of the unit.

Insure that no air can bypass this

coil.

6. Connect the supply air plenum to

the furnace plenum opening.

IMPORTANT: If a flexible duct

connector must be used, it

MUST

be rated for a minimum

temperature of 250°F

continuous.

.

1313

OWNFLOW UNITS

D

1. Position the unit to minimize long

runs of duct or runs of duct with

many turns and elbows.

2. If summer air conditioning is

desired, position the indoor coil

on the supply-air side of the unit.

Insure that no air can bypass this

coil.

3. If installing on a combustible floor

and not using an air conditioning

plenum, install the special non-

combustible floor base. See

Table 1 and Figure 9.

WARNING

!

THE DOWNFLOW FURNACE

DESIGN IS CERTIFIED FOR

INSTALLATION ON A NONCOMBUSTIBLE FLOOR. USE THE

SPECIAL BASE SPECIFIED ON THE

FURNACE CLEARANCE LABEL.

FAILURE TO INSTALL THE

SPECIAL BASE MAY RESULT IN

FIRE, PROPERTY DAMAGE,

PERSONAL INJURY OR DEATH.

THIS SPECIAL BASE IS SHIPPED

FROM THE FACTORY AS AN

ACCESSORY.

4. Connect the furnace to the

supply air plenum.

5. Connect the return air ducting to

the return air opening at the top

of the unit. Make the connection

air tight to prevent entraining

combustion gases from an

adjacent fuel-burning appliance.

NOTE: In downflow

configuration, return air cut out is

not permitted.

6. Be sure to have adequate space

for the unit filter.

NOTE: DO NOT take return air

from bathrooms, kitchens, furnace

rooms, garages, utility or laundry

rooms, or cold areas.

HORIZONTAL UNIT

IMPORTANT: THIS FURNACE MAY

ONLY BE INSTALLED SO AS WHEN

ACING THE FRONT OF THE

F

FURNACE, SUPPLY AIR IS

DISCHARGED ON THE LEFT HAND

SIDE.

1. Position the unit to minimize long

uns of duct or runs of duct with

r

many turns and elbows.

2. If summer air conditioning is

desired, position the indoor coil on

the supply air side of the unit.

Insure that no air can bypass this

coil.

3. Connect the furnace to the supply

air plenum.

4. Connect the return air ducting to

the return air opening at the right

end of the unit. Make the

connection air tight to prevent

pulling combustion gases from an

adjacent fuel-burning appliance.

NOTE: In horizontal configuration,

return air cut out is not permitted.

5. Be sure to have adequate space

for the unit filter.

NOTE: DO NOT take return air

from bathrooms, kitchens, furnace

rooms, garages, utility or laundry

rooms, or cold areas.

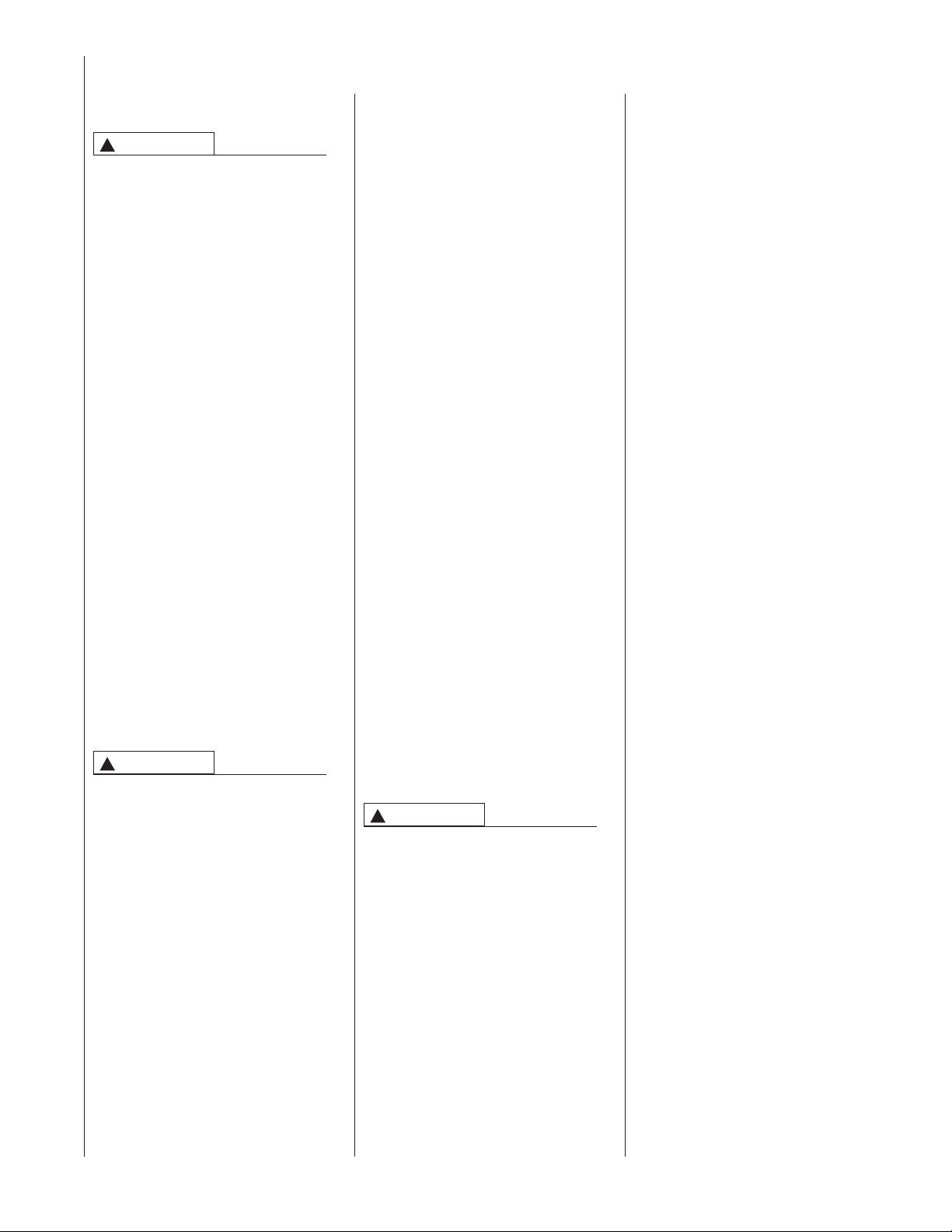

TABLE 1

NON-COMBUSTIBLE FLOOR BASES

Floor Base Size

No. Cabinet

(-)XGC-B17 17

(-)XGC-B21 21

(-)XGC-B24 24

14

FIGURE 9

NON-COMBUSTIBLE FLOOR BASE

VENTING AND COMBUSTION AIR PIPING

EQUIREMENT THAT VENT

GENERAL INFORMATION

WARNING

!

READ AND FOLLOW ALL

INSTRUCTIONS IN THIS SECTION.

FAILURE TO PROPERLY VENT

THIS FURNACE CAN CAUSE

CARBON MONOXIDE POISONING

R AN EXPLOSION OR FIRE,

O

RESULTING IN PROPERTY

DAMAGE, PERSONAL INJURY

OR DEATH.

This furnace removes both sensible

and latent heat from the combustion

flue gases. Removal of latent heat

results in condensation of flue gas

water vapor. This condensed water

vapor drains from the secondary heat

exchanger and out of the unit into a

drain trap.

When installed as a non-direct vent

furnace, only exhaust piping is

required and inside combustion air

may be used. Refer to section on

COMBUSTION & VENTILATION AIR

“

FOR FURNACE INSTALLATIONS.”

Direct vent installations require a

dedicated combustion air and venting

system. All air for combustion is taken

from the outside atmosphere and all

combustion products are discharged

to the outdoors.

The combustion air and vent pipe

fittings must conform to American

National Standards Institute (ANSI)

and American Society for Testing

Materials (ASTM) standards

D1785 (Schedule 40 PVC), D2665

(PVC-DWV), D2241 (SDR-21 and

SDR26-26 PVC), D2661 (ABS-DWV)

or F628 (Schedule 40 ABS-DWV).

WARNING

!

IN CANADA, PRODUCTS

CERTIFIED FOR INSTALLATION

AND INTENDED TO BE VENTED

WITH PLASTIC VENT SYSTEMS

(PVC, CPVC) MUST USE VENT

SYSTEMS THAT ARE CERTIFIED

TO THE STANDARD FOR TYPE BH

GAS VENTING SYSTEMS, ULC

S636.

THE COMPONENTS OF THE

CERTIFIED MATERIAL MUST NOT

BE INTERCHANGED WITH OTHER

VENT SYSTEMS OR UNLISTED

PIPE/FITTINGS.

PLASTIC COMPONENTS AND

SPECIFIED PRIMERS AND GLUES

OF THE CERTIFIED SYSTEM MUST

BE FROM A SINGLE SYSTEM

MANUFACTURER AND NOT

INTERMIXED WITH OTHER

SYSTEM MANUFACTURER’S

PARTS.

NOTE: INLET AIR PIPING IS NOT

CONSIDERED TO BE A PART OF

THE “VENTING SYSTEM”. THE

R

ATERIAL BE CERTIFIED TO ULC

M

636 DOES NOT APPLY TO INLET

S

IR PIPING. VENT TERMINATIONS

A

ND CONCENTRIC TERMINATIONS

A

UST BE APPROVED BY THE

M

ANUFACTURER AND CERTIFIED

M

LC-636.

U

MPORTANT: The plastic combustion

I

air and venting components are of

Schedule 40 PVC. If using ABS

piping, ensure that the solvent

cement is compatible for joining PVC

to ABS components or use a

mechanical connection that can

withstand the vent temperatures and

are corrosion resistant.

NOTE: Schedule 40 ABS-DWV pipe

and fittings may be used as an

alternate to PVC pipe for the

combustion air inlet and vent pipes.

NOTE: Cellular core PVC is also

approved for use. It must be schedule

40PVC-DWV cellular pipe for nonpressure applications and

manufactured under ASTM F-891.

NOTE: With the furnace correctly

vented, the inducer will move

approximately 25 cfm per 100,000

Btu’s.

IMPORTANT: No part of the

combustion air and vent pipes may

run under ground.

OVERTEMPERATURE

SAFETY SWITCHES

Furnaces are equipped with safety

switches in the control compartment

to protect against overtemperature

conditions caused by inadequate

combustion air supply. The switches

are located in the burner

compartment. If a switch is tripped it

must be manually reset.

WARNING

!

DO NOT JUMPER THESE

DEVICES! IF ONE OF THESE

SWITCHES SHOULD TRIP, A

QUALIFIED INSTALLER, SERVICE

AGENCY OR THE GAS SUPPLIER

MUST BE CALLED TO CHECK

AND/OR CORRECT FOR

ADEQUATE COMBUSTION AIR

SUPPLY. DO NOT RESET THE

SWITCHES WITHOUT TAKING

CORRECTIVE ACTION TO ASSURE

THAT AN ADEQUATE SUPPLY OF

COMBUSTION AIR IS MAINTAINED

UNDER ALL CONDITIONS OF

OPERATION. FAILURE TO DO SO

CAN RESULT IN CARBON

MONOXIDE POISONING OR

DEATH. IF THIS UNIT IS MOUNTED

IN A CLOSET, THE DOOR MUST BE

CLOSED WHEN MAKING THIS

CHECK.

REPLACE THESE SWITCHES

ONLY WITH THE IDENTICAL

REPLACEMENT PART.

EXISTING VENT SYSTEMS

When the installation of this furnace

replaces an existing furnace that is

removed from a vent system serving

ther appliances, the vent system is

o

likely to be too large to properly vent

the remaining attached appliances.

he following steps should be

T

followed with each appliance

remaining connected to the original

common vent system. Place the

appliance to be tested in operation,

while the other appliances remaining

connected to the common vent

system are not in operation. Test the

operation of each appliance

individually by the following method.

1. Permanently seal any unused

openings in the common venting

system.

2. Visually inspect the venting

system for proper size and

horizontal pitch and determine

that there is no blockage,

restriction, leakage, corrosion or

other deficiencies which could

cause an unsafe condition.

3. If practical, close all building

doors, windows and all doors

between the space where the

appliances remaining connected

to the common venting system

are located.

Turn on clothes dryers and any

appliance not connected to the

common venting system. Turn on

any exhaust fans, such as range

hoods and bathroom exhausts,

so they will operate at maximum

speed. Do not operate a summer

exhaust fan. Close fireplace

dampers.

4. Follow the lighting instructions.

Place the appliance being

inspected into operation. Adjust

the thermostat so the appliance

will operate continuously.

5. Test for spillage at the draft hood

relief opening after 5 minutes of

main burner operation. Use the

flame of a match or candle, or

smoke from a cigarette, cigar

or pipe.

15

6. After it has been determined that

each appliance that remains

connected to the common

venting system properly vents

(when tested as outlined above),

return doors, windows, exhaust

fans, fireplace dampers and any

other gas-burning appliance to

their previous conditions of use.

7. If improper venting is observed

during any of the above tests, the

common venting system must be

resized.

When the furnace is installed in the

same space with other gas

appliances such as a water heater, be

sure there is an adequate supply of

ombustion and ventilation air for the

c

other appliances. Do not delete or

reduce the combustion air supply

required by the other gas appliances

in this space. See Z223.1, National

Fuel Gas Code (NFPA54) for

determining the combustion air

requirements for gas appliances. An

unconfined space must have at least

50 cubic feet (volume) for each

1,000 BTUH of the total input of all

appliances in the space. If the open

space containing the appliances is in

a building with tight construction

(contemporary construction), outside

air may still be required for the

appliances to burn and vent properly.

Outside air openings should be sized

the same as for a confined space.

IMPORTANT: Only the current vent

instructions apply. All 90 Plus Gas

Furnaces cannot be common vented.

JOINING PIPE AND

FITTINGS

WARNING

!

PVC SOLVENT CEMENTS AND

PRIMERS ARE HIGHLY

FLAMMABLE. PROVIDE

ADEQUATE VENTILATION AND DO

NOT ASSEMBLE NEAR HEAT

OURCE OR AN OPEN FLAME. DO

S

NOT SMOKE. AVOID SKIN OR EYE

CONTACT. OBSERVE ALL

CAUTIONS AND WARNINGS

PRINTED ON MATERIAL

CONTAINERS. FAILURE TO

FOLLOW THESE GUIDELINES MAY

RESULT IN FIRE, EXPLOSION OR

ASPHYXIATION CAUSING

PERSONAL INJURY OR DEATH.

All pipe, fittings, solvent cement,

primers and procedures must

conform to American National

Standard Institute and American

Society for Testing and Materials

(ANSI/ASTM) standards as shown

below:

CEMENTING JOINTS

Properly seal all joints in the PVC

vent using the following materials and

procedures.

PVC CLEANER-PRIMER AND

PVC MEDIUM-BODY SOLVENT

CEMENT

IMPORTANT: After cutting pipe,

remove all ragged edges and burrs.

This is important to prevent reduction

in pressure drop throughout the

system.

1. Cut pipe end square. Chamfer

edge of pipe. Clean fitting socket

and pipe joint area of all dirt,

grease and moisture.

2. After checking pipe and socket

or proper fit, wipe socket and

f

pipe with cleaner-primer. Apply

a liberal coat of primer to inside

surface of socket and outside of

pipe. Read instructions included

with the primer for proper

application.

3. Apply a thin coat of cement

evenly in the socket. Quickly

apply a heavy coat of cement to

the pipe end and insert pipe into

fitting with a slight twisting

ovement until it bottoms out.

m

NOTE: Cement must be fluid; if

not, recoat.

4. Hold the pipe in the fitting for 30

seconds to prevent the tapered

socket from pushing the pipe out

of the fitting.

5. Wipe all excess cement from the

joint with a rag. Allow 15 minutes

before handling. Cure time varies

according to fit, temperature and

humidity.

NOTE: Stir the solvent cement

frequently while using. Use a natural

bristle brush or the dauber supplied

with the can. The proper brush size is

one inch.

IMPORTANT: For Proper Installation

DO NOT use solvent cement that

has become curdled, lumpy or

thickened.

DO NOT thin. Observe shelf

precautions printed on containers.

For application below 32°F, use only

low-temperature-type solvent

cement.

16

PIPE & FITTING MATERIAL

Schedule 40 PVC (Pipe) D1785

Schedule 40 PVC (Cellular Core Pipe) F891

Schedule 40 PVC (Fittings) D2466

SDR-21PVC (Pipe) D2241

SDR-26 PVC (Pipe) D2241

Schedule 40 ABS Cellular Core DWV (Pipe) F628

Schedule 40 ABS (Pipe) D1527

Schedule 40 ABS (Fittings) D2468

ABS-DWV (Drain Waste & Vent)

(Pipe & Fittings)

PVC-DWV (Drain Waste & Vent)

(Pipe & Fittings)

ASTM

SPECIFICATION

D2661

D2665

COMBUSTION AND VENTILATION AIR

NON-DIRECT

erchloroethylene)

FURNACE INSTALLATIONS

WARNING

!

THE FURNACE AND ANY OTHER

UEL-BURNING APPLIANCE MUST

F

BE PROVIDED WITH ENOUGH

FRESH AIR FOR PROPER

COMBUSTION AND VENTILATION

OF THE FLUE GASES. MOST

HOMES WILL REQUIRE THAT

OUTSIDE AIR BE SUPPLIED INTO

THE FURNACE AREA. FAILURE TO

DO SO CAN CAUSE PERSONAL

INJURY OR DEATH FROM

CARBON MONOXIDE POISONING.

Adequate facilities for providing air for

combustion and ventilation must be

provided in accordance with section

5.3, “Air for Combustion and

Ventilation” of the National Fuel Gas

Code, ANSI Z223.1 (latest edition) or

applicable provisions for the local

building codes, and not obstructed so

as to prevent the flow of air to the

furnace.

IMPORTANT: Air for combustion and

ventilation must not come from a

corrosive atmosphere. Any failure

due to corrosive elements in the

atmosphere is excluded from

warranty coverage.

The following types of installation

(but not limited to the following) will

require OUTDOOR AIR for

combustion, due to chemical

exposures:

• Commercial buildings

• Buildings with indoor pools

• Furnaces installed in laundry rooms

• Furnaces in hobby or craft rooms

• Furnaces installed near chemical

storage areas.

Exposure to the following substances

in the combustion air supply (but not

limited to the following) will also

require OUTDOOR AIR for

combustion:

• Permanent wave solutions

• Chlorinated waxes and cleaners

• Chlorine-based swimming pool

chemicals

• Water softening chemicals

• De-icing salts or chemicals

• Carbon tetrachloride

• Halogen type refrigerants

• Cleaning solvents (such as

p

• Printing inks, paint removers,

varnishes, etc.

• Hydrochloric acid

• Cements and glues

• Antistatic fabric softeners for

lothes dryers

c

• Masonry curing and acid washing

materials

Combustion air must be free of acidforming chemicals such as sulphur,

fluorine and chlorine. These elements

are found in aerosol sprays,

detergents, bleaches, cleaning

solvents, air fresheners, paint and

varnish removers, refrigerants and

many other commercial and

household products. When burned in

a gas flame, vapors from these

products form acid compounds. The

acid compounds increase the dew

point temperature of the flue products

and are highly corrosive after they

condense.

WARNING

!

ALL FURNACE INSTALLATIONS

MUST COMPLY WITH THE

NATIONAL FUEL GAS CODE AND

LOCAL CODES TO PROVIDE

ADEQUATE COMBUSTION AND

VENTILATION AIR FOR THE

FURNACE. FAILURE TO DO SO

CAN RESULT IN EXPLOSION, FIRE,

PROPERTY DAMAGE, CARBON

MONOXIDE POISONING,

PERSONAL INJURY OR DEATH.

Combustion air requirements are

determined by whether the furnace is

in an open (unconfined) area or in a

confined space such as a closet or

small room.

EXAMPLE 1:

FURNACE LOCATED IN AN

UNCONFINED SPACE

Using indoor air for combustion.

An unconfined space must have at

least 50 cubic feet for each 1,000

BTUH of the total input for all

appliances in the space. Here are a

few examples of the room sizes

required for different inputs. The sizes

are based on 8-foot ceilings.

BTUH Minimum Sq. Feet Typical Room Size

Input With 8' Ceiling With 8' Ceiling

5,000 281 14' x 20' OR 16' x 18'

4

0,000 375 15' x 25' OR 19' x 20'

6

5,000 469 15' x 31' OR 20' x 24'

7

0,000 563 20’ x 28’ OR 24’ x 24’

9

105,000 657 20' x 33' OR 26' x 25'

120,000 750 25' x 30' OR 24' x 32'

If the open space containing the

furnace is in a building with tight

construction, outside air may still be

required for the furnace to operate

and vent properly. Outside air

openings should be sized the same

as for a confined space.

EXAMPLE 2:

FURNACE LOCATED IN A

CONFINED SPACE

A confined space (any space smaller

than shown above as “unconfined”)

must have openings into the space

which are located in accordance with

the requirements set forth in the

following subsections A and B. Size

the openings by how they are

connected to the heated area or to

the outside,

and by the input of all appliances in

the space.

If confined space is within a building

with tight construction, combustion air

must be taken from outdoors or area

freely communicating with the

outdoors.

A. USING INDOOR AIR FOR

COMBUSTION

IMPORTANT: Air should not be

taken from a heated space with a

fireplace, exhaust fan or other

device that may produce a

negative pressure.

If combustion air is taken from the

heated area, the openings must

each have at least 100 square

inches of free area. Each opening

must have at least one square inch

of free area for each 1,000 BTUH

of total input in the space. Here

are some examples of typical

openings required.

BTUH Free Area

17

nput Each Opening

I

5,000 100 square inches

4

0,000 100 square inches

6

5,000 100 square inches

7

90,000 100 square inches

105,000 105 square inches

120,000 120 square inches

IGURE 10

F

AIR FROM HEATED SPACE

B. USING OUTDOOR AIR FOR

COMBUSTION

MPORTANT: Do not take air from

I

an attic space that is equipped

with power ventilation.

The confined space must

communicate with the outdoors in

accordance with Methods 1 or 2.

The minimum dimension of air

openings shall not be less than 3

inches. Where ducts are used,

they shall be of the same crosssectional area as the free area of

the openings to which they

connect.

Method 1

Two permanent openings, one

located within 12 inches of the top

and one located within 12 inches

of the bottom of the enclosure,

shall be provided. The openings

shall communicate directly, or by

ducts, with the outdoors or spaces

(crawl or attic) that freely

communicate with the outdoors.

a. Where directly communicating

with the outdoors or where

communicating to the outdoors

AS

G

WATER

HEATER

through vertical ducts as shown in

Figure 11, each opening shall

have a minimum free area of 1

square inch for each 4,000 BTUH

of total appliance input rating in the

enclosure.

BTUH Free Area Round Pipe

Input Each Opening Size

45,000 11.25 square inches 4"

60,000 15.00 square inches 5"

75,000 18.75 square inches 5"

90,000 22.50 square inches 6"

105,000 26.25 square inches 6"

120,000 30.00 square inches 6"

b. Where communicating with

URNACE

F

NOTE:

ACH OPENING SHALL

E

HAVE A FREE AREA OF

NOT LESS THAN ONE

QUARE INCH PER 1,000

S

BTU PER H0UR OF THE

TOTAL INPUT RATING OF

LL EQUIPMENT IN THE

A

ENCLOSURE, BUT NOT

LESS THAN 100 SQUARE

NCHES.

I

outdoors through horizontal ducts,

each opening shall have a

minimum free area of 1 square

inch for each 2,000 BTUH of total

input rating of all equipment in the

enclosure (see Figure 12).

Here are some typical sizes:

BTUH Free Area Round Pipe

Input Each Opening Size

45,000 22.50 square inches 6"

60,000 30.00 square inches 6"

75,000 37.50 square inches 7"

90,000 45.00 square inches 8"

105,000 52.50 square inches 8"

120,000 60.00 square inches 9"

Method 2 (not shown)

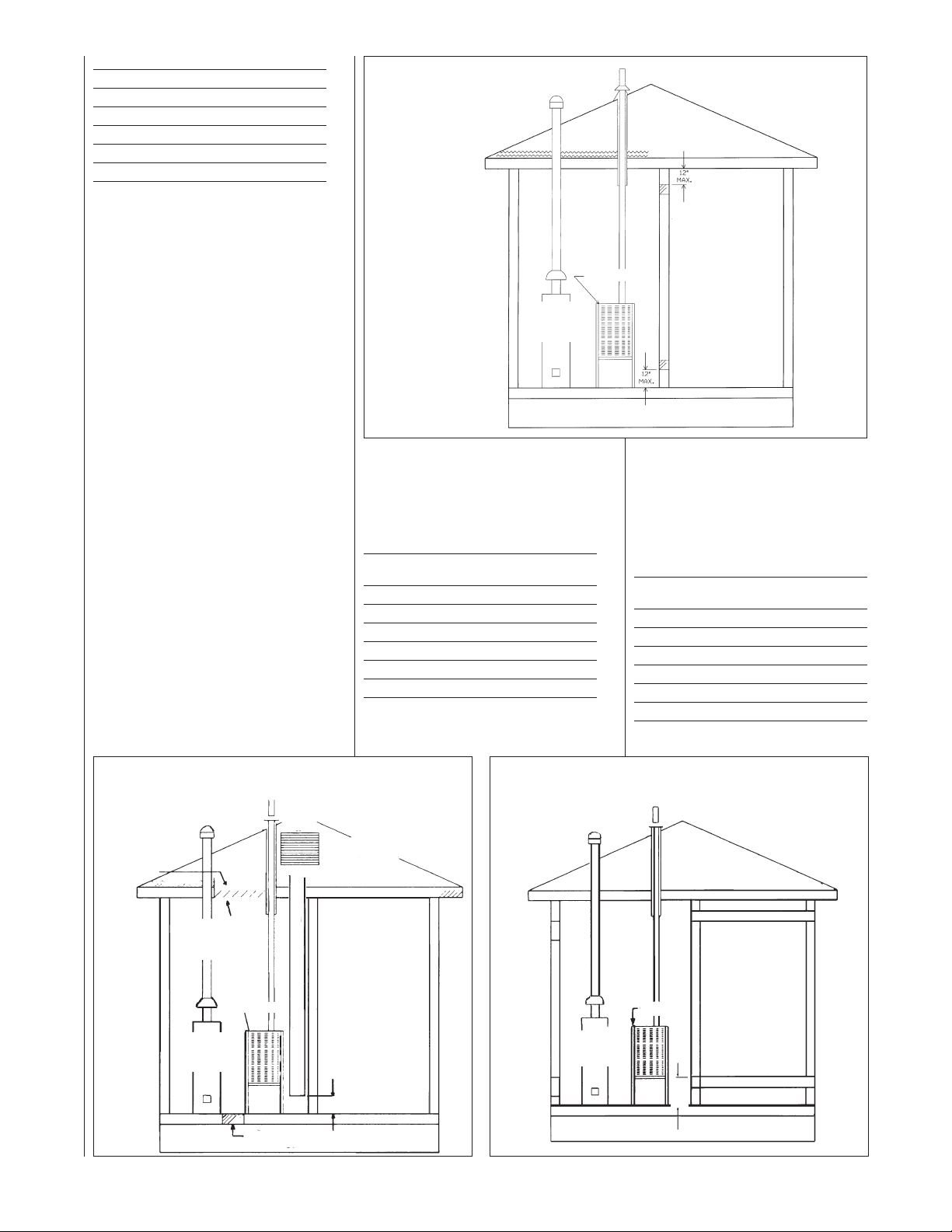

FIGURE 11

AIR FROM ATTIC/CRAWL SPACE

OUTLET AIR

IN ATTIC

MUST BE

ABOVE

INSULATION

1 SQ. INCH PER

4000 BTUH

OUTLET AIR

GAS

WATER

HEATER

18

GABLE

VENT

FURNACE

OPTIONAL1 SQ. INCH PER 4000 BTUH INLET AIR

1 SQ. INCH PER

4000 BTUH INLET AIR

VENTILATED

ATTIC GABLE OR

SOFFIT VENTS

12" MAX.

FIGURE 12

OUTSIDE AIR USING A HORIZONTAL DUCT

OUTLET AIR 1 SQ. INCH

FURNACE

GAS

WATER

HEATER

INLET AIR 1 SQ. INCH

12"

MAX.

PER 2000 BTUH

PER 2000 BTUH

One permanent opening, located

within 12 inches of the top of the

enclosure, shall be permitted

where the equipment has

clearances of at least 1 inch from

the sides and back and 6 inches

from the front of the appliance.

The opening shall directly

communicate with the outdoors or

communicate through a vertical or

orizontal duct to the outdoors or

h

spaces (crawl or attic) that freely

communicate with the outdoors,

and shall have a minimum free

area of:

. 1 square inch for each 3,000

a

BTUH of the total input rating of all

equipment located in the enclosure

and

FIGURE 13

COMBUSTION AIR FITTING

TUH Free Area Round Pipe

B

nput Each Opening Size

I

5,000 15.00 square inches 4"

4

0,000 16.67 square inches 5"

6

5,000 25.00 square inches 6"

7

90,000 30.00 square inches 6"

105,000 35.00 square inches 7"

120,000 40.00 square inches 7"

b. Not less than the sum of the

areas of all vent connectors in the

confined space.

If unit is installed where there is an

exhaust fan, sufficient ventilation

must be provided to prevent the

exhaust fan from creating a negative

pressure.

Combustion air openings must not be

restricted in any manner.

CONSULT LOCAL CODES FOR

SPECIAL REQUIREMENTS.

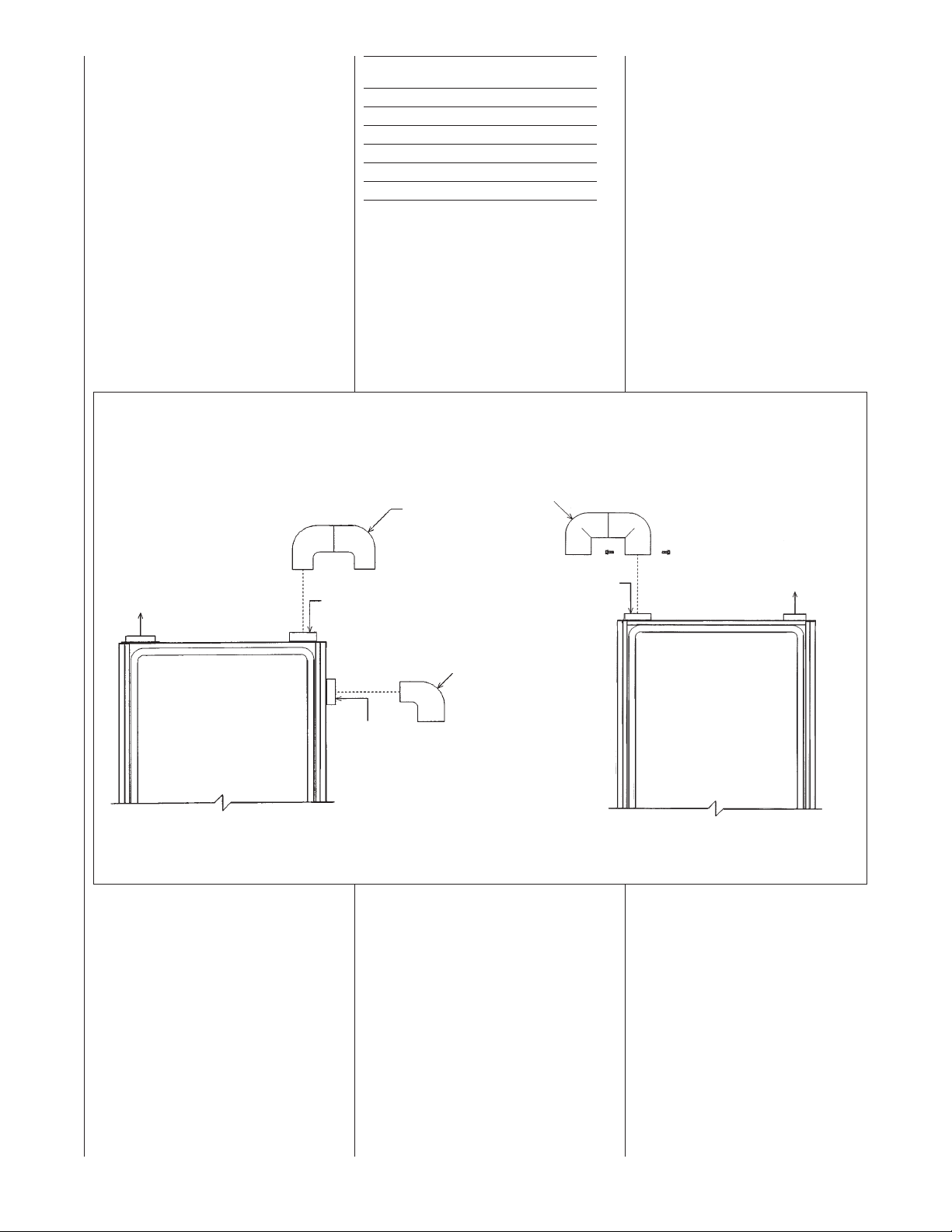

CONNECTION TO

FURNACE

IMPORTANT: When indoor

combustion air is used, the inlet air

pening at the furnace must be

o

protected from accidental blockage.

(See Figure 13).

UPFLOW

TTACH DOUBLE ELBOW TO TOP INLET

A

IR OPENING OR 90° ELBOW TO SIDE

A

NLET AIR OPENING TO PREVENT

I

CCIDENTALBLOCKAGE OF INTAKE

A

PENING. PLUG OPENING NOT USED.

O

XHAUST

E

OP

T

OPTION

I337

SIDE

OPTION

2" PVC

OUBLE

D

ELBOW

2" PVC ELBOW

" PVC

DOWNFLOW/HORIZONTAL

2

DOUBLE

ELBOW*

COMBUSTION AIR

*NOTE: WHEN FURNACE IS INSTALLED IN A HORIZONTAL POSITION

ONLY ONE 90° ELBOW IS REQUIRED. INSTALLTHE ELBOW SO THE

OPEN END IS POINTED DOWNWARD.

TTACH DOUBLE ELBOW TO INTAKE AIR

A

OLLAR AND SECURE WITH TWO SHEET

C

ETAL SCREWS TO PREVENT ACCIDENTAL

M

LOCKAGE OF INTAKE AIR OPENING.

B

REDRILL FOR SCREWS.

P

EXHAUST

I336

19

VENT PIPE INSTALLATION

NON-DIRECT VENT

INSTALLATION

GUIDELINES

IMPORTANT: Failure to correctly follow

all venting guidelines may result in

rratic furnace operation, freeze-up of

e

combustion air or exhaust air piping or

sooting of the furnace.

ll exhaust piping must be installed in

A

compliance with Part 7, “Venting of

Equipment,” of the latest edition of the

National Fuel Gas Code NPFA54/ ANSI

Z223.1-, local codes or ordinances and

these instructions.

1. Vertical piping is preferred.

2. All horizontal piping must slope

upward a minimum of

foot of run so that condensate drains

toward the furnace.

3. All horizontal runs must be

supported at least every 4 feet. No

sags or dips are permitted.

4. IMPORTANT: Do not common vent

with any other appliance. Do not

install in the same chase or chimney

with a metal or high temperature

plastic pipe from another gas or fuelburning appliance unless the

required minimum clearances to

combustibles are maintained

between the pvc pipe and other

pipes.

5. All vent runs through unconditioned

spaces where below-freezing

temperatures are expected should

be insulated with 1-in. thick,

medium-density, foil-faced

fiberglass. An equivalent “arm-aflex” or “rub-a-tex” insulation may

also be used as long as there is no

heat tape applied to the vent pipe.

For horizontal runs where water may

collect, wrap the vent pipe with selfregulating 3 or 5 watt heat tape. The

heat tape must be U.L. listed and

installed per the manufacturer’s

instructions.

6. The minimum vent pipe length is

5 feet.

7. Extend the exhaust pipe a minimum

of 18” from the cabinet before turning

vent.

8. Vent cannot be ran underground.

FIGURE 14

TEE TERMINAL – FOR STANDARD

HORIZONTAL NON-DIRECT

INSTALLATION

VENT

1

/4 inch per

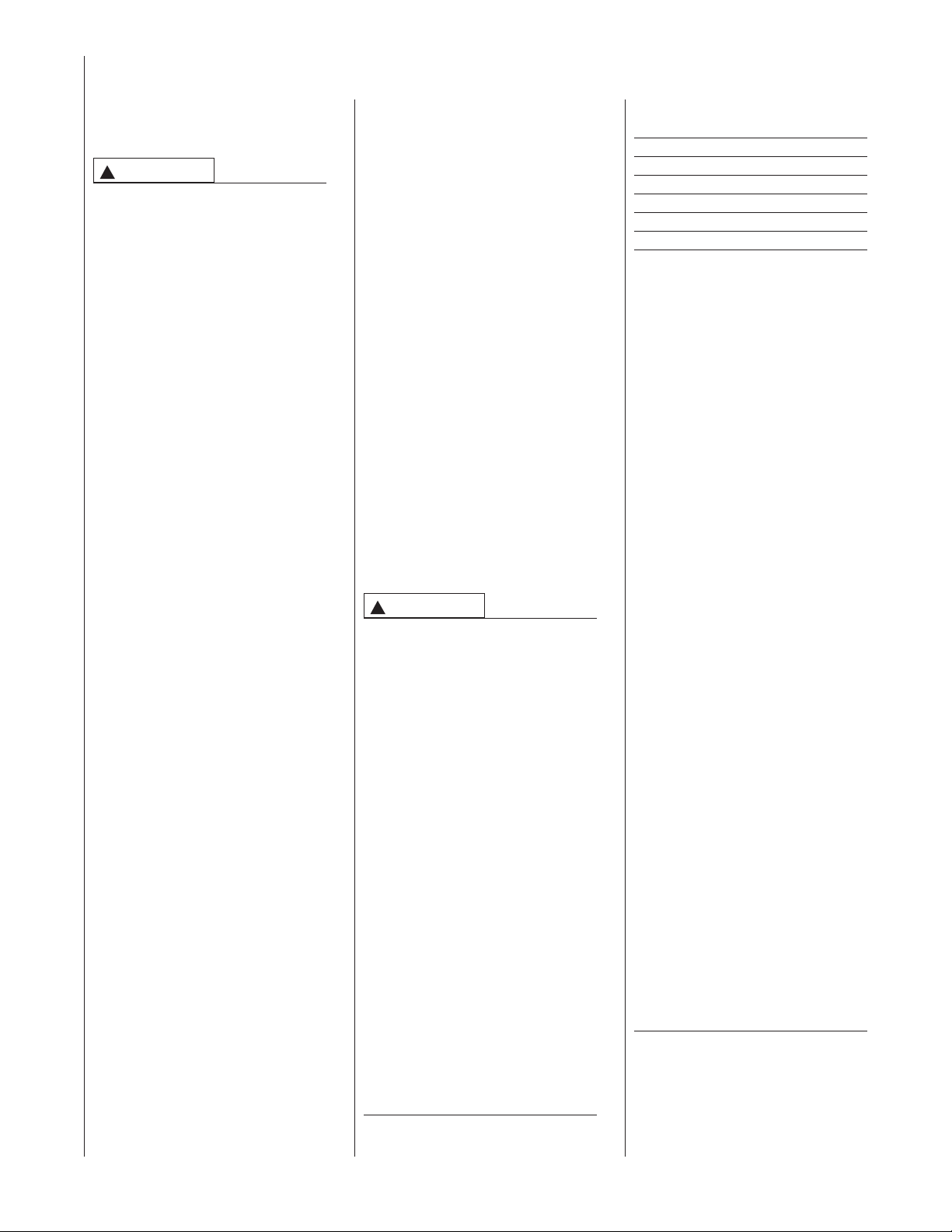

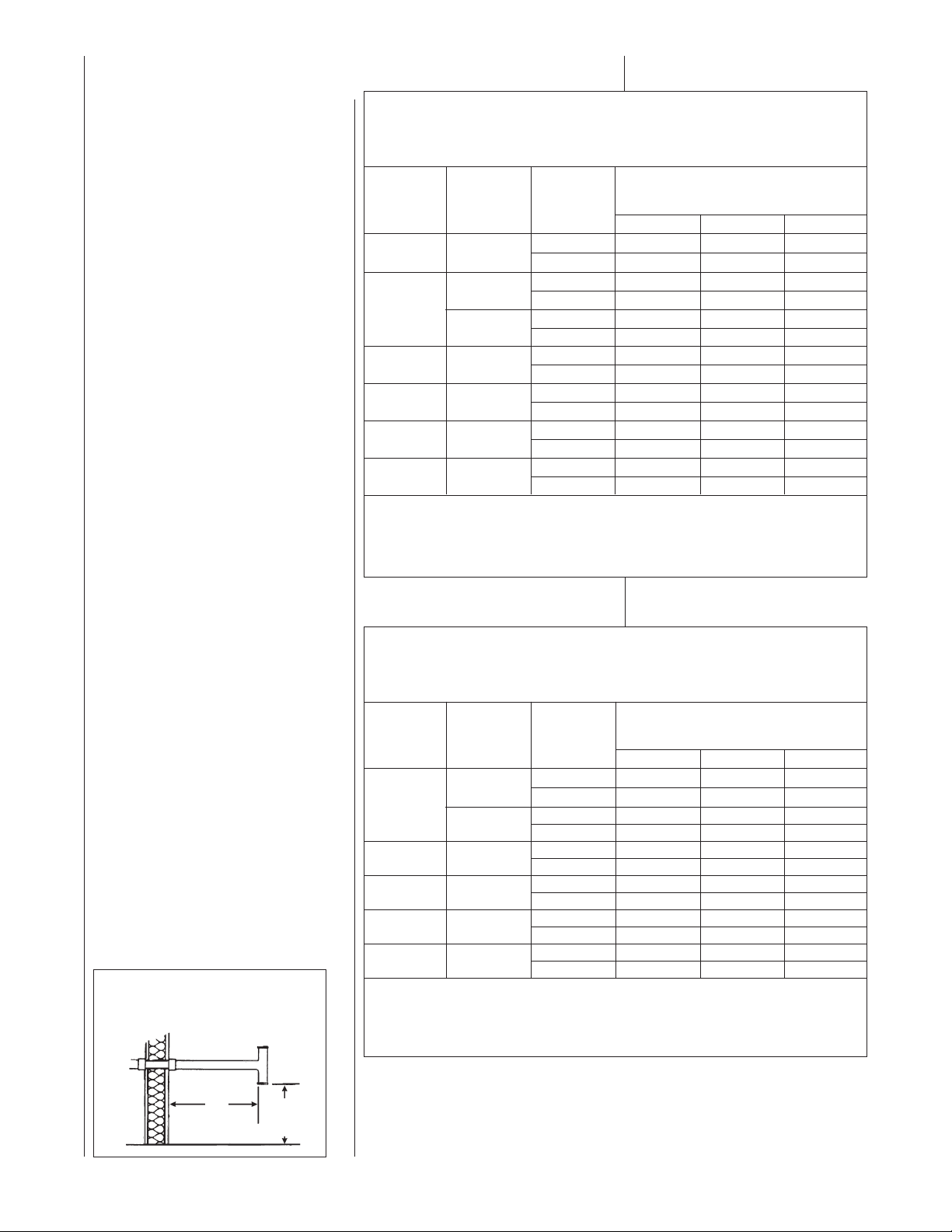

TABLE 2

UPFLOW UNITS

FOR NON-DIRECT VENT APPLICATIONS - AIR FOR COMBUSTION

PROVIDED FROM INDOORS

MAXIMUM ALLOWABLE LENGTH IN FEET OF EACH EXHAUST PIPE AND INTAKE PIPE

NUMBERS OF ELBOWS

FURNACE

INPUT

45,000

0,000

6

75,000

90,000

05,000 3”

1

120,000 3”

NOTES:

1. *N.A. - NOT APPLICABLE.

2. MAXIMUM OF 6 ELBOWS MAY BE USED. DO NOT COUNT ELBOWS REQUIRED FOR

ALTERNATE TERMINATION. USE ONLY MEDIUM OR LONG SWEEP ELBOWS.

3. A 45 OR 22.5 DEGREE ELBOW IS CONSIDERED ONE ELBOW.

4. NO SCREENS MAY BE USED TO COVER EXHAUST.

*A = 17-1/2” CABINET WIDTH B = 21) CABINET WIDTH

PIPE

SIZE

2”

2

3

3

3”

ERMINATION

T

1-2 3-4 5-6

Standard 60 55 50

Alternate 55 50 45

”

”

”

Standard 30 25 20

Alternate 25 20 15

tandard 120 120 115

S

lternate 120 120 110

A

tandard 45 40 NA

S

Alternate 45 45 NA

Standard 90 85 75

Alternate 60 50 45

Standard 45 40 NA

lternate NA NA NA

A

tandard 70 65 55

S

lternate 40 30 25

A

45° OR 90°

edium / Long Radius ONLY

M

TABLE 3

DOWNFLOW/HORIZONTAL UNITS

FOR NON-DIRECT VENT APPLICATIONS - AIR FOR COMBUSTION

PROVIDED FROM INDOORS

MAXIMUM ALLOWABLE LENGTH IN FEET OF EACH EXHAUST PIPE AND INTAKE PIPE

NUMBERS OF ELBOWS

FURNACE

INPUT

60,000

75,000

90,000 3”

105,000 3”

120,000 3”

NOTES:

1. *N.R. - NOT RECOMMENDED.

2. MAXIMUM OF 6 - 90 DEGREE ELBOWS MAY BE USED. DO NOT COUNT ELBOWS REQUIRED FOR

ALTERNATE TERMINATION. USE ONLY MEDIUM OR LONG SWEEP ELBOWS.

3. A 45 OR 22.5 DEGREE ELBOW IS CONSIDERED ONE ELBOW.

4. NO SCREENS MAY BE USED TO COVER EXHAUST.

*A = 17-1/2” CABINET WIDTH B = 21” CABINET WIDTH

PIPE

SIZE

2”

3”

3”

TERMINATION

1-2 3-4 5-6

Standard 40 35 30

Alternate 30 25 20

Standard 120 120 120

Alternate 110 105 100

Standard 120 120 120

Alternate 100 95 85

Standard 110 105 95

Alternate 50 40 35

Standard 65 60 55

Alternate 50 40 35

Standard 40 35 30

Alternate 40 35 30

45° OR 90°

Medium / Long Radius ONLY

20

12"

12" MIN. ABOVE

GRADE OR

SNOW LEVEL

ELEVATED SINGLE PIPE ALTERNATE TEE TERMINATION

See Figure 15. The tee termination may be elevated up to 24 inches above the

wall penetration if required for anticipated snow levels. Use 2 long-sweep, 2-in.

PVC elbows and 2-in. PVC pipe, attaching the tee so it is 12 inches from the wall.

Loading...

Loading...